Page 1

A0309_50IVZ.fm

BAS 505 Precision

Originalbetriebsanleitung. . . . . . . . . . . . . . .3

Original operating instructions . . . . . . . . . .15

Instructions d’utilisation originales . . . . . . .27

Origineel gebruikaanwijzing. . . . . . . . . . . .39

115 174 5446 / 2711 - 5.0

Page 2

2

5

7

9

10

11

12

13

1

15

16

18

19

3

4

14

22

23

24

17

8

20

21

6

25

26

27

26

XA0046E5.fm Original operating instructions DEUTSCH

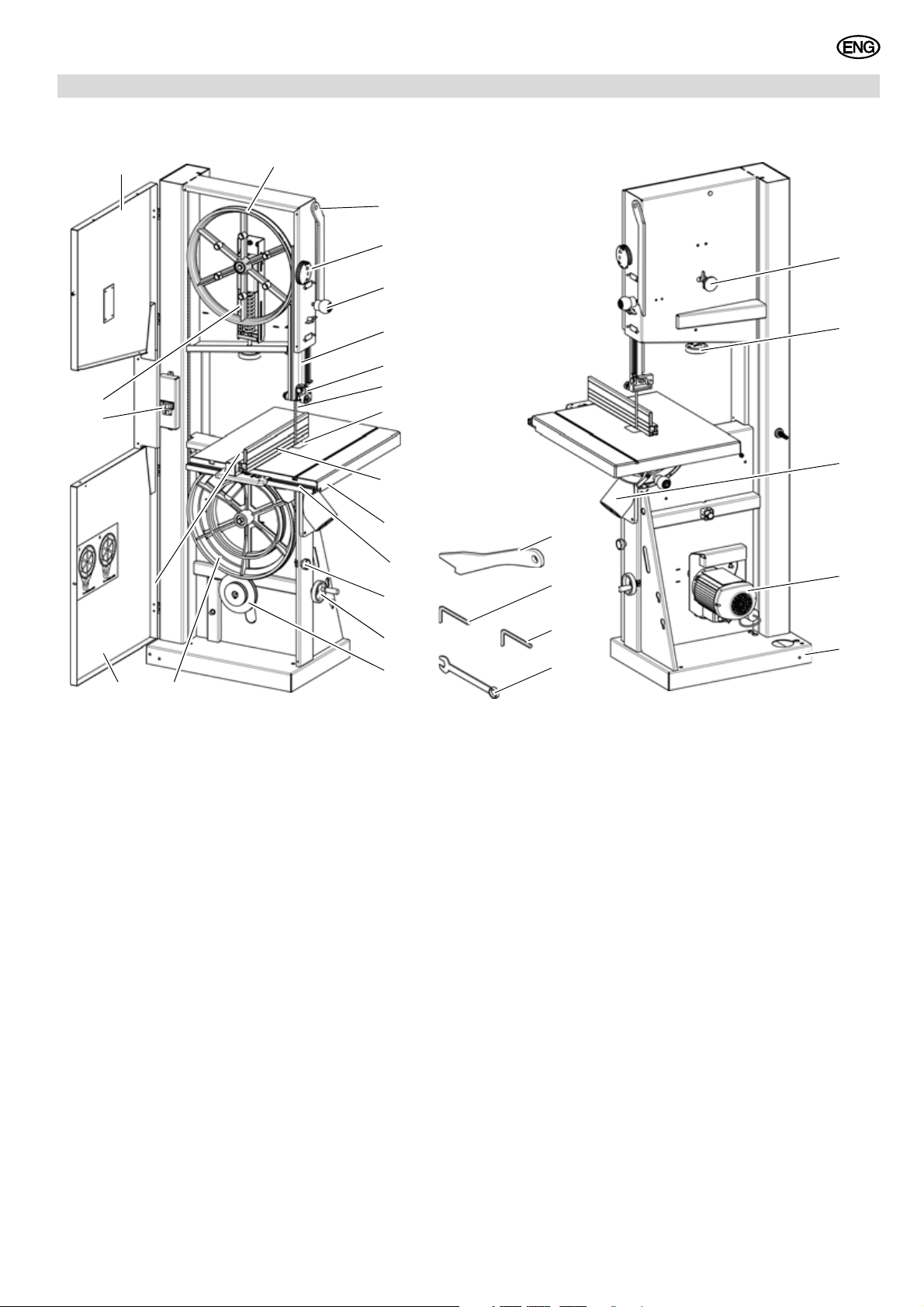

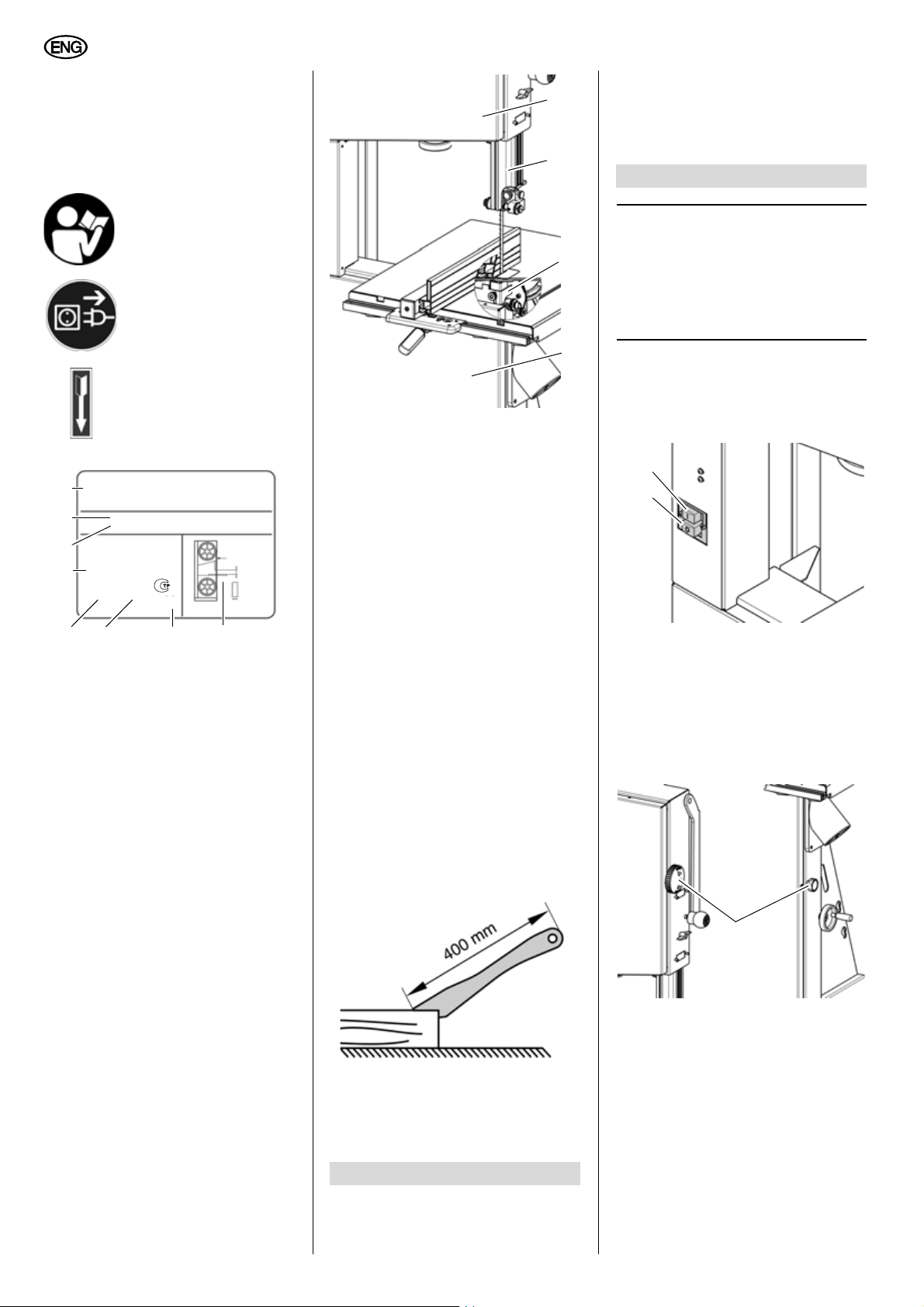

1. Parts Identification

ENGLISH

Front

1 Upper housing door

2 Upper band saw wheel

3 Push stick holder

4 Turn-lock fasterner, housing door

5 Twist handle for blade guard

6 Blade guard

7 Blade guide, upper

8 Band saw blade

9 Table insert

10 Rip fence

11 Saw table

12 Fence guide extrusion

13 Turn-lock fasterner, housing door

14 Twist handle for V-belt tension set-

ting

15 V-belt drive

16 Lower band saw wheel

17 Lower housing door

18 On/Off switch with emergency

stop

19 Blade tension indicator

Rear

20 Setting knob for blade tracking

adjustment

21 Setting knob for band saw

blade tension

22 Dust extraction port

23 Motor

24 Machine base

25 Wrench

26 Allen key

27 Push stick

15

Page 3

ENGLISH

Table of Contents

1. Parts Identification....................15

2. Please Read First!.....................16

3. Initial Operation.........................16

4. Safety .........................................16

4.1 Specified conditions of use .........16

4.2 General Safety Instructions.........16

4.3 Symbols on the machine.............18

4.4 Safety devices.............................18

5. Transport ...................................18

6. Machine details .........................18

6.1 Aligning the saw table .................19

6.2 Mounting .....................................20

6.3 Installing the Saw Table ..............20

6.4

Tensioning the Band Saw Blade

6.5 Fence guide extrusion

installation ...................................20

6.6 Rip fence installation...................20

6.7 Dust collector connection............20

6.8 Changing the Band Saw Blade ...20

6.9 Mains connection ........................21

7. Operation ...................................21

7.1 Adjusting the Upper

Blade Guide ................................22

7.2 Sawing ........................................22

8. Care and Maintenance..............22

8.1 Band saw blade alignment ..........23

8.2 Upper blade guide alignment ......23

8.3

Aligning the Lower Blade Guide

8.4 Replacing the Band Saw Tyre.....24

8.5 Replacing the Table Insert ..........24

8.6 Saw Cleaning..............................24

8.7 Saw storage ................................24

9. Tips and Tricks..........................24

10. Available Accessories ..............24

11. Repairs.......................................24

12. Environmetal Protection...........24

13. Trouble shooting.......................24

14. Technical specifications...........25

14.1 Available Band Saw Blades ........26

...20

....23

2. Please Read First!

These operating instructions have been

written to make it easier for you, the

user, to learn how to operate this

machine and to do so safely. These

instructions should be used as follows:

− Read instructions before use. Pay

special attention to the safety infor

mation.

− These instructions are intended for

persons with basic technical knowl

edge regarding the operation of a

device like the one described

herein. If you have no experience

whatsoever, you are strongly

-

-

advised to seek competent advise

and guidance from an experienced

person before operating this

machine.

− Keep all documents supplied with

this machine for future reference.

Retain your proof of purchase in

case of a future warranty claim.

− If you lend or sell this machine be

sure to have these instructions go

with it.

− The equipment manufacturer is not

liable for any damage resulting from

neglect of these operating instruc

tions.

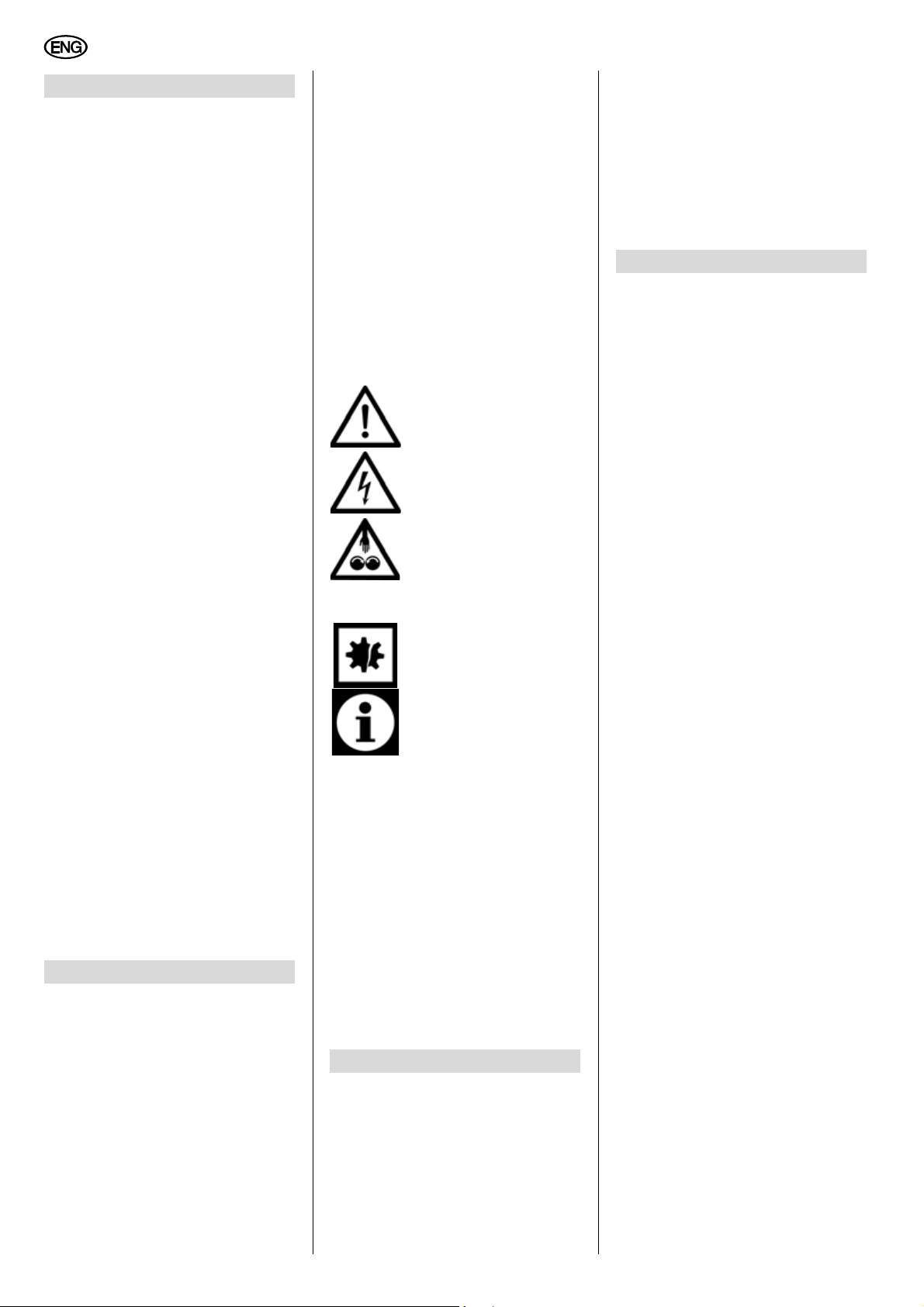

Information in this manual is denoted as

follows:

Danger!

Risk of personal injury or

environmental damage.

Risk of electric shock!

Risk of personal injury

by electric shock.

Drawing-in/trapping hazard!

Risk of personal injury

by body parts or clothing

being drawn into the

rotating saw blade.

Caution!

Risk of material damage.

Note:

Additional information.

− At times numbers are used in illustrations (1, 2, 3, ...). These numbers

− indicate component parts;

− are consecutively numbered;

− correspond with the number(s) in

brackets (1), (2), (3) ... in the

neighbouring text.

− Numbered steps must be carried out

in sequence.

− Instructions which can be carried

out in any sequence are marked

with a bullet (•).

− Listings are indicated by an En Dash

(–).

3. Initial Operation

A

Danger!

Start the saw only after the following

preparations have been completed:

− saw is mounted;

− saw table is installed and aligned;

− the V-belt tension checked;

− safety devices have been

checked.

− Connect the saw to the mains

supply only after all of the above

preparations are completed! Oth

erwise there is a risk of an unintentional starting of the saw,

which can cause severe personal

injury.

4. Safety

4.1 Specified conditions of

-

use

This machine is intended for indoor use

in dry rooms only. Any outdoor use is not

permitted!

The machine is suitable for cutting wood,

wood-derived materials and plastics.

Do not cut round stock transverse to its

longitudinal axis without suitable jigs or

fixtures. The rotating saw blade could

turn the work piece.

When sawing thin stock layed on edge,

a suitable guide must be used for firm

support.

Any other use is not as specified. The

manufacturer is not liable for any damage caused by unspecified use.

Modification of the machine or use of

parts not approved by the equipment

manufacturer can cause unforeseeable

damage!

4.2 General Safety Instructions

• When using this machine observe

the following safety instructions, to

minimize the risk of personal injury

or material damage.

• Please also observe the special

safety instructions in the respective

sections.

• Where applicable, follow the legal

directives or regulations for the pre

vention of accidents pertaining to

the use of band saws.

A

General hazards!

• Keep your work area tidy – a messy

work area invites accidents.

• Be alert. Know what you are doing.

Set out to work with reason. Do not

operate device while under the influ

ence of drugs, alcohol or medication.

• Consider environmental conditions.

keep work area well lighted.

• Prevent adverse body positions.

Ensure firm footing and keep your

balance at all times.

• Use suitable workpiece supports

when cutting long stock.

-

-

-

16

Page 4

ENGLISH

• Do not operate the machine near

inflammable liquids or gases.

• The machine shall only be started

and operated by persons familiar

with bandsaws and who are at any

time aware of the dangers associ

ated with the operation of such

machine.

Persons under 18 years of age shall

use this device only in the course of

their vocational training, under the

supervision of an instructor.

• Keep bystanders, particularly children, out of the danger zone. Do not

permit other persons to touch the

machine or power cable while it is

running.

• Do not overload device – use it only

within the performance range it was

designed for (see “Technical Speci

fications”).

B

• Do not expose machine to rain.

Do not operate the machine in damp

or wet environment.

Prevent body contact with earthed

objects such as radiators, pipes,

cooking stoves, refrigerators when

operating this device.

• Do not use the power cable for any

purpose it is not intended for.

A

• Do not operate the machine without

installed guards.

• Always keep sufficient distance to

the band saw blade. Use suitable

feeding aids if necessary. Keep suf

ficient distance to driven components when operating the electric

tool.

• Wait for the band saw blade to come

to a complete stop before removing

cutoffs, scrap, etc. from the work

area.

• Cut only stock of dimensions that

allow for safe and secure holding

while cutting.

• Do not attempt to stop the band saw

blade by pushing the workpiece

against its side.

• Ensure the tool is disconnected from

power before servicing.

• When turning ON the machine (e.g.

after servicing) ensure that no tools

or loose parts are left on or in the

machine.

• Unplug the tool when not in use.

Danger! Risk of electric shock!

Risk of injury by moving parts!

-

-

-

A

Cutting hazard, even with the

cutting tool at standstill!

• Wear gloves when changing cutting

tools.

• Store band saw blades in such manner that nobody will get hurt.

A

Risk of kickback (workpiece is

caught by the band saw blade and

thrown against the operator)!

• Do not jam workpieces.

• Cut thin or thin-walled work pieces

only with fine-toothed band saw

blades. Always use sharp band saw

blades.

• If in doubt, check workpiece for

inclusion of foreign matter (e.g. nails

or screws).

• Cut only stock of dimensions that

allow for safe and secure holding

while cutting.

• Never cut several workpieces at the

same time – and also no bundles

containing several individual pieces.

Risk of personal injury if individual

pieces are caught by the band saw

blade uncontrolled.

• When cutting round stock, use a

suitable jig to prevent the workpiece

from turning.

c

Drawing-in/trapping hazard!

• Ensure that no parts of the body or

clothing can be caught and drawn in

by rotating components (no neck

ties, no gloves, no loose-fitting

clothes; contain long hair with hair

net).

• Never saw workpieces containing

the following materials:

− ropes

− strings

− cords

− cables

− wires.

A

Danger due to insufficient per-

sonal protection equipment!

• Wear hearing protection.

• Wear safety goggles.

• Wear dust mask.

• Wear suitable work clothes.

• When working outdoors wearing of

non-slip shoes is recommended.

A

Risk of injury by inhaling wood

dust!

• Some types of wood dust (e.g. oak,

beech and ash) may cause cancer

when inhaled. Work only with a suit

able dust extractor attached to the

saw. The dust collector must comply

-

-

-

with the specifications stated in the

Technical Data.

• Make sure that as little as possible

wood dust can escape into the environment:

− remove wood dust deposit in the

work area (do not blow away!);

− fix any leakages on the dust col-

lector;

− keep your work area well venti-

lated at all times.

A

Hazard generated by modification of the machine or use of parts

not tested and approved by the manufacturer!

• Strictly follow these instructions

when assembling the device.

• Use only parts approved by the

manufacturer. This applies espe

cially for:

− band saw blades (see “Technical

Specifications” for stock nos.);

− safety devices (see "Spare parts

list" for stock numbers).

• Do not change any parts.

A

Hazard generated by tool

defects!

• Keep device and accessories in

good repair. Observe the mainte

nance instructions.

• Prior to any use check the machine

for possible damage: before operat

ing the machine all safety devices,

protective guards or slightly damaged parts need to be checked for

proper function as specified. Check

to see that all moving parts work

properly and do not jam. All parts

must be correctly installed and meet

all conditions necessary for a proper

operation of the device.

• Before switching on: Check if saw

blade coasts down for more than 10

seconds; if more than 10 seconds,

have motor replaced by a qualified

electrician.

• Damaged protection devices or

parts must be repaired or replaced

by a qualified specialist. Have dam

aged switches replaced by a service

centre. Do not operate tool if the

switch cannot be turned ON or OFF.

• Keep handles free of oil and grease.

A

Danger from blocking work-

pieces or workpiece parts!

If blockage occurs:

1. Switch machine OFF.

2. Unplug mains cable.

3. Wear gloves.

4. Clear blockage with suitable tool.

17

-

-

-

-

Page 5

ENGLISH

29

30

31

32 33 35

28

34

36

37

38

36

39

40

41

4.3 Symbols on the machine

A

Danger!

Disregard of the following warnings

could lead to serious personal injury

or material damage.

Read instructions.

Unplug mains cable.

Band saw blade running

direction.

Information on the nameplate:

Lower blade guard

The lower blade guard (38) protects

against inadvertent contact with the

band saw blade below the saw table.

The lower blade guard must be installed

during operation.

• Transport the saw with the help of a

second person.

• For transport use the original packing where possible.

6. Machine details

Note:

3

In this chapter the essential operating elements of the machine are introduced.

The proper use of the saw is detailed in

chapter “Operation”. Read this chapter

before using the saw for the first time.

ON/OFF switch

• To start = press green switch button

(39).

•

To stop = press red switch button

(40).

28 Manufacturer

29 Serial number

30 Machine designation

31 Motor specifications (see

also "Technical Specifications")

32 CE mark – This machine meets

the EC directives as per declara

tion of conformity

33 Waste disposal symbol – Device

can be disposed of by returning it

to the manufacturer

34 Date of manufacture

35 Dimensions of approved band saw

blades

4.4 Safety devices

Upper blade guard

The upper blade guard (37) protects

against unintentional contact with the

saw blade and from chips flying about.

In order for the upper blade guard to provide adequate protection against contact

with the band saw blade, it must always

be set as close as possible against the

workpiece (max. distance 3

18

mm).

Housing doors

The housing doors (36) protect against

contact with the rotating parts inside the

machine.

The housing doors are equipped with

interlocking contacts. These turn the

motor OFF when one housing door is

opened while the saw is running.

The housing doors must be closed while

the machine is in use.

Push stick

The push stick serves as an extension of

the hand and protects against accidental

-

contact with the saw blade.

The push stick must always be used if

the distance between band saw blade

and a rip fence is less than 120

Guide the push stick at an angle of

20° … 30° against the saw table's surface.

When the push stick is not used, it can

be stored on the push stick holder pro

vided at the band saw frame.

Replace the push stick if damaged.

mm.

In the event of a power failure an undervoltage relay will trip. This prevents the

starting of the machine when the power

is restored. To restart, the green switch

button must be pressed.

Turn-lock fastener, housing door

Open and close the housing door using

the turn-lock fastener (41).

Opening the housing door:

1. Rotate the upper turn-lock fastener

clockwise approx. one turn and the

lower turn-lock fastener anticlock

-

wise approx. one turn.

The housing door opens slightly.

This activates the door interlock

which switches the motor off.

-

5. Transport

• Set upper blade guide to its lowest

position.

• Remove projecting accessories.

Page 6

ENGLISH

42

43

44

+

–

45

46

47

48

49

50

A

Danger from exposed bandsaw

blades and wheels!

If after one turn the motor does not

switch off or the door immediately

opens wide, the door interlock or the

closure system is defective. Shut down

the saw and return it to the Service

Centre in your country for repair.

2. Rotate the turn-lock fastener further.

The housing door opens wide.

Closing the housing door:

• Press on the housing door and

rotate the upper turn-lock fastener

anticlockwise and the lower turnlock fastener clockwise all the way.

The housing door is completely contacting the housing.

Setting knob for band saw blade tension

With the setting knob (42) the band saw

blade tension is corrected, if necessary:

− Turning the setting knob clockwise

increases the blade tension.

−

Turning the setting knob counterclockwise reduces the blade tension.

Setting knob for drive belt tension

With the setting knob (44) the drive belt

tension is corrected, if necessary:

− Turning the adjustment knob anticlockwise decreases the blade tension.

− Turning the setting knob clockwise

increases the blade tension.

Saw table tilt

After loosening the locking screw (46)

the saw table (45) tilts steplessly through

20° against the blade.

Saw table lateral alignment

1. Loosen lock lever (48) and hexagon

nut (49).

A

Danger!

Risk of injury, even with the band saw

blade at standstill. To loosen and

tighten the fastening screws use a

tool that allows for keeping your hand

at a sufficient distance from the band

saw blade.

2. Loosen the four fastening screws

(50)

.

Setting knob for blade tracking

adjustment

With the setting knob

upper band saw wheel can be adjusted, if

necessary. This tracking adjustment is

required to have the blade run dead centre

on the rubber tyres of the band saw

wheels:

− turning clockwise = blade moves to

the rear

− Turning counter-clockwise = blade

moves to the front.

(43)

the tilt of the

Rip fence

The rip fence (47) is clamped to the

front. The rip fence can be used on both

sides of the blade.

6.1 Aligning the saw table

The saw table needs to be aligned in two

planes

− laterally, in order for the blade to run

dead centre through the table insert;

− at right angles to the band saw

blade.

3. Align saw table so that the blade

runs through the centre of the table

insert's slot.

4. Tighten the four fastening screws

(50) again.

5. Tighten hexagon nut (49) only so

much that the saw table can still

easily be tilted.

6. Tighten lock lever (48).

Aligning the saw table at right angles

to the band saw blade

1. Raise upper blade guide fully (see

“Operation”).

2. Check band saw blade tension (see

“Care and Maintenance”).

3. Loosen lock lever (48).

4. Using a try square, set the table at

right angles to the blade and tighten

the lock lever

5. Loosen locking nut (51) and adjust

limit stop screw (52) until it touches

the saw housing.

(48) again.

19

Page 7

ENGLISH

51

52

53

54

55

56

57

58

6. Tighten locking nut.

6.2 Mounting

For a firm stand the saw must be

mounted on a stable supporting floor:

1. Drill four holes in the supporting

floor.

2. Put fixing bolts through the base

plate and secure with nuts.

6.3 Installing the Saw Table

1. Fit limit stop screw (53) to the underside of the saw table.

2. Guide saw table over the band saw

blade and place it on the table trunnion.

3. Attach the saw table with four each

screws (54) and washers to the

table trunnion.

6.4 Tensioning the Band Saw

Blade

A

Danger!

Too much tension can cause the

band saw blade to break. Too little

tension can cause the driven band

saw wheel to slip and the band saw

blade to stop.

1. Raise upper blade guide fully (see

“Operation”).

2. Checking the blade tension:

− Check tension by pushing with a

finger, halfway between table and

upper blade guide, against the

side of the blade (the blade

should flex not more than 1-2

mm).

− Check adjustment at the blade

tension indicator. The scale indi

cates the correct adjustment in

dependence on the band saw

blade width.

3. Correct tension if necessary:

− turning the setting knob (55)

counter-clockwise increases the

blade tension.

− turning the setting knob (55)

counter-clockwise reduces the

blade tension.

-

6.5 Fence guide extrusion

installation

• Fasten the fence guide extrusion

(56) with four thumb screws and

washers to the saw table.

1. Place rip fence on rip fence guide.

2. Tighten lock lever (57) of rip fence.

6.7 Dust collector connection

A

Danger!

Some types of saw dust (e.g. of oak,

beech and ash wood) can cause can

cer when inhaled: always use a dust

collector when working indoors

(required air speed at the saw's suc

tion connector ≥ 20 m/s).

A

Caution!

Operation without a dust collector is

only possible:

− outdoors;

− for short-term operation

(up to 30 minutes maximum);

− with dust respirator.

− If no dust collector is used chips will

accumulate, which need to be

removed periodically.

Connect dust collector or industrial vacuum with a suitable adaptor to the dust

extraction port.

-

-

6.8 Changing the Band Saw

Blade

A

Danger!

Risk of injury, even with the band saw

blade at standstill. Wear gloves when

changing blades.

Use only suitable band saw blades

(see “Technical specifications”).

1. Loosen the four thumb screws and

remove the fence guide extrusion

(58) for the rip fence.

20

6.6 Rip fence installation

The rip fence can be used on both sides

of the blade.

2. Open housing door.

Page 8

ENGLISH

59

60

61

62

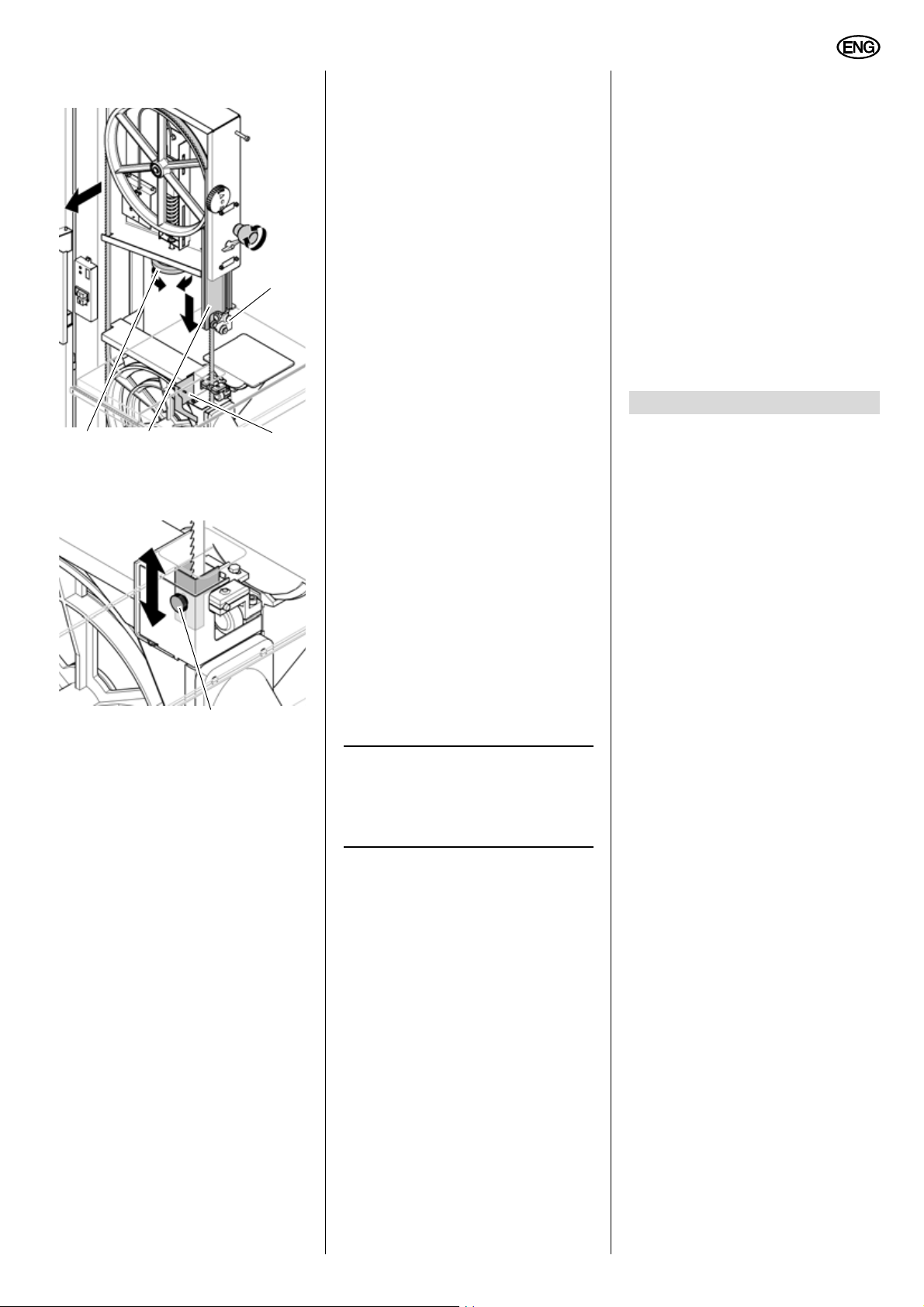

63

3. Adjust upper blade guide (59) to its

lowest position.

4. Loosen knurled nut (63) on the hand

guard and slide hand guard into its

lower position.

5. Open the lower blade guard (60).

6. Loosen setting knob (62) until the

band saw blade has slackened.

7. To remove the band saw blade,

guide it through

− the slot in the saw table,

− the blade guard on the upper

blade guide

− the lower blade guard (60) and

− the blade guides.

A

Danger!

Use a suitable transport device to

transport wide clamped saw blades.

8. Fit fresh band saw blade. Observe

correct position: the teeth point

towards the front (door) side of the

saw.

9. Center band saw blade on the rub-

ber tyres of the band saw wheels.

10. Tighten setting knob (62) until blade

does no longer slip off the band saw

wheels.

11. Clamp band saw blade (see section

"Clamping the band saw blade").

12. Close lower blade guard (60) and

slide hand guard into upper position

(61),

or against the table's edge, tighten

knurled nut

13. Close housing door.

14. Then:

− align band saw blade (see section "Aligning the band saw

blade");

− align blade guides (see “Care

and maintenance”);

− let saw test run for at least one

minute;

− stop saw, unplug and recheck

settings.

15. Fasten the fence guide extrusion

(58) to the saw table with the four

thumb screws and washers.

(63).

6.9 Mains connection

B

Danger! High voltage

• Operate saw in dry environment

only.

• Operate saw only on a power

source matching the following

requirements (see also 'Technical

Data'):

− mains voltage and system fre-

quency conform to the voltage

and frequency shown on the

device's name plate;

− fuse protection by a residual

current operated device (RCD)

of 30 mA sensitivity;

− outlets properly installed,

earthed, and tested;

− three-phase outlets with neu-

tral wire installed;

Note:

3

Check with your local Electricity

Board or electrician if in doubt whether

your house service connection meets

these requirements.

• Position power supply cable in a

way that it does not interfere with

the work and is not damaged.

• Protect power supply cable from

heat, aggressive liquids and

sharp edges.

• Use only rubber-insulated extension cables of sufficient lead

cross section (3

machines with 3-phase motor:

5 x 1.5 mm2).

• Do not pull on power supply

cable to unplug.

A

change of direction of rotation

(only for version with AC motor):

This can lead to the workpiece being

hurled away when attempting to make

a cut. The direction of rotation must

therefore be checked every time the

saw is connected to another outlet.

x 1.5 mm2, for

If the direction of rotation is incorrect,

the electrical connection must be

changed by a qualified electrician!

1. After the saw and all of its safety

devices have been assembled, con

nect it to the mains supply.

2. Start saw and switch OFF immediately.

3. Observe the correct rotational direction of the band saw blade: In the

cutting area the band saw blade

must run downwards.

4. If the band saw blade turns in the

wrong correction, unplug the power

supply cable at the saw.

5. Have the electric supply changed by

a qualified electrician!

-

7. Operation

A

Danger!

To reduce the risk of personal injury

as much as possible, the following

safety recommendations should be

observed when operating the saw.

• Use personal protection equipment:

− dust respirator;

− hearing protection;

− safety goggles.

• Cut only one work piece at a time.

• Always hold the work piece down

on the table.

• Do not jam the workpiece.

• Do not attempt to stop the band

saw blade by pushing the work

piece against its side.

• Sawing of bowed or irregular

work pieces: hold the workpiece

firmly against the table and feed

in at a uniform speed. Keep your

hands in the safe area.

• If the type of work requires, use

the following:

− push stick – if distance rip

fence – band saw blade less

≤120 mm;

than

− work support – for long stock,

which would otherwise fall off

the table on completion of the

cut;

− dust collector;

− a circle cutting device when

cutting circular pieces;

− a guide when cutting small

wedges;

− an appropriate jig when cutting

round stock, to keep it from

turning;

-

21

Page 9

ENGLISH

64

65

66

965 m/min408 m/min

− a suitable guide for firm support when cutting thin stock

layed on edge.

• Before starting work, check to

see that the following are in

proper working order:

− band saw blade;

− upper and lower blade guard.

• Replace damaged parts immedi-

ately.

• Assume correct work position

(the band saw blade's teeth must

point towards the operator).

• Never cut more than one workpiece at a time – and also no bundles containing several individual

pieces. Risk of personal injury if

individual pieces are caught by

the saw blade uncontrolled.

c

Drawing-in/trapping hazard!

• Do not wear loose clothing, jewellery, or gloves, which may get

caught and wound up by revolv

ing machine parts.

• Contain long hair with a hairnet.

• Never cut stock to which ropes,

cords, strings, cables and wires

are attached or which contain

such materials.

7.1 Adjusting the Upper

Blade Guide

The height of the upper blade guide (66)

needs to be adjusted:

− prior to every cutting operation, to

accommodate the height of the

workpiece (the upper blade guide

should be set approx. 3 mm above

the workpiece);

− after adjustments of band saw blade

or saw table (e.g. band saw blade

change, tensioning of the band saw

blade, saw table alignment).

A

Danger!

Turn the machine OFF and wait for

the band saw blade to stop before

adjusting the upper blade guide or

the saw table.

1. Loosen screw (65).

2. Set the upper blade guide (66) with

the twist handle (64) to the desired

height.

3. Re-tighten screw (65).

Cutting speed adjustment

1. Open the lower housing door.

2. Slacken the V-belt by turning the

tension crank handle anticlockwise.

3. Put V-belt on the required pulley of

the driving wheel (lower band saw

wheel) and the corresponding motor

pulley – note label inside the lower

housing door.

-

A

Caution!

The V-belt must run either on both

front or both rear pulleys. Never have

the V-belt run diagonally!

− V-belt on front pulley

= low speed, high torque.

− V-belt on rear pulleys

= high speed, low torque.

4. Re-tighten the V-belt by rotating the

crank clockwise (the V-belt must be

able to be depressed in the middle

about 10

5. Close the lower housing door.

mm).

7.2 Sawing

1. Check the band saw blade tension

(see 'Tensioning the band saw

blade').

2. If necessary, adjust the table tilt.

3. Select rip fence and table tilt for the

type of cutting operation to be carried out.

A

Hazard generated by a jam-

ming workpiece!

When sawing with the rip fence and a

tilted saw table, the rip fence must be

installed on that side of the saw table

which is tilted downward.

4. Set upper blade guide 3 mm above

the workpiece.

Note:

3

Always make a trial cut in a piece

of scrap to verify settings; correct if necessary before cutting the workpiece.

5. Place workpiece on the saw table.

6. Start saw.

7. Cut workpiece in a single pass.

8. Switch off if no further cutting is to

be done immediately afterwards.

9. If no further cutting is to be done

immediately afterwards: decrease

the bandsaw blade tension and

attach a notice indicating that the

bandsaw blade tension must be

reset prior to the next cutting opera

tion to the machine (see 'Tensioning

the bandsaw blade').

8. Care and Maintenance

A

Danger!

Prior to all servicing:

1. switch machine OFF;

2. Wait for saw blade to stop

3. Unplug mains cable.

− Check that all safety devices are

operational again after each service.

− Replace damaged parts, especially

safety devices, with genuine

replacement parts only, since parts

not tested and approved by the

manufacturer can cause unforesee

able damage.

− Repair and maintenance work other

than described in this section should

only be carried out by qualified spe

cialists.

-

-

-

22

Page 10

ENGLISH

965 m/min408 m/min

67

68

69

70

71

73

72

74 75 76

77

78

79

8081

A

Danger!

If the table insert is damaged, small

objects may get caught between the

table insert and the kerf plate and

block the saw blade. Replace dam

aged table inserts immediately!

Speed adjustment

By shifting the drive belt the band saw

can be operated at two speeds (see

“Technical specifications”):

− 408 m/min for hard wood, plastics

and non-ferrous metals (with special

band saw blade);

− 965 m/min for all kinds of wood.

A

Caution!

The drive belt must not run in a diagonal position; this will damage the belt

-

8.1 Band saw blade alignment

If the band saw blade does not run in the

centre of the rubber tyres, the tracking

needs to be corrected by adjusting the

tilt of the upper band saw wheel:

1. Loosen lock nut (68).

2. Setting knob (67):

− Turn setting knob (67) clockwise

if the band saw blade runs

towards the front of the saw.

− Turn setting knob (67) counter-

clockwise if the band saw blade

runs towards the rear of the saw.

− a thrust bearing (supports the band

saw blade from the rear),

− two guide bearings (providing lateral

support).

All bearings need to be readjusted after

every band saw blade change or tracking.

Note:

3

Periodically check all bearings for

wear, if necessary replace both guide

bearings at the same time.

Adjusting the thrust bearing

1. If necessary, align and tighten the

band saw blade.

2. Loosen the thrust bearing's (69) lock

screw (70).

3. Adjust thrust bearing position (dis-

tance thrust bearing - band saw

blade = 0.5 mm – if the band saw

blade is turned by hand, it must not

touch the thrust bearing).

4. Tighten the thrust bearing lock

screw.

Adjusting the guide bearings

1. Loosen knurled nut (72).

2. Set guide bearings (73) with the

knurled thumb screws (71) against

the band saw blade.

8.3 Aligning the Lower Blade

Guide

The lower blade guide consists of:

− a thrust bearing (supports the band

saw blade from the rear),

− two guide bearings (providing lateral

support).

These parts need to be readjusted after

every band saw blade change or tracking adjustment:

Note:

3

Periodically check thrust bearings

and guide bearings for wear, if neces

sary replace both guide bearings at the

same time.

Basic alignment

1. Open the lower housing door.

2. Slide hand guard into lower position

and open lower blade guard

3. Loosen the screw (75) for the lower

blade guide.

4. Adjust position of lower blade guide

until band saw blade is centred

between the guide bearings (76).

5. Tighten screw (75).

Adjusting the thrust bearing

1. Loosen the thrust bearing's lock

(80).

screw

2. Adjust thrust bearing position (81)

(distance thrust bearing - band saw

blade = 0.5 mm – if the band saw

blade is turned by hand, it shall not

touch the thrust bearing).

3. Tighten the thrust bearing lock

(80).

screw

-

(74).

3. Tighten locking nut (68).

8.2 Upper blade guide alignment

The upper blade guide consists of:

3. Turn band saw wheel by hand in a

clockwise direction several times to

bring the guide bearings in correct

position – both guide bearings

should just touch the band saw

blade.

4. Retighten knurled nut (72) to lock

the knurled thumb screw (71).

Adjusting the guide bearings

1. Loosen the knurled nut (78).

23

Page 11

ENGLISH

82

2. Set guide bearings (77) with the

knurled thumb screws (79) against

the band saw blade.

3. Turn band saw wheel by hand clockwise a few times to ensure that the

guide bearings are in correct position – both guide bearings should be

lightly touching the band saw

blade.

4. Retighten knurled nut (78) to lock

the knurled thumb screw .

5. Close lower blade guard (74)

6. Close the lower housing door.

8.4 Replacing the Band Saw

Tyre

Periodically check band saw tyres for

wear. Replace only in pairs:

1. Remove band saw blade (see “Care

and maintenance”);

2. Lift band saw tyre with a small

screwdriver, then pull off the band

saw wheel.

in your hand when the saw is in operation!

Prior to all servicing:

1. Switch machine OFF.

2. Wait for saw blade to stop

3. Unplug power cable.

Saw Cleaning

1. Open housing door.

2. Remove chips and saw dust with

brush or vacuum cleaner.

3. Close housing door.

8.7 Saw storage

A

Danger!

Store saw so that

− it cannot be started by unauthorised persons and

− nobody can get hurt.

A

Caution!

Do not store saw unprotected outdoors or in damp environment.

H Dust collector

helps to protect your health and to

keep the shop clean.

I WAXILIT Sliding Compound

Improves workpiece sliding on the

saw table.

J Care and Maintenance Spray

For removing resin residue and preserving metal surfaces.

K Sanding Belt

80 grit, 3380 x 25 (pack of 3)

L Sanding Belt

120 grit, 3380 x 25 (pack of 3)

M Band Saw Blade A6

For cutting NF-metals

N Band Saw Blade A4

For contour cutting and small radii.

O Band Saw Blade A6

For cutting wood, straight cuts.

P Band Saw Blade A6

For cutting wood, universal cuts.

Q Band Saw Blade A8

For cutting firewood.

11. Repairs

3. Mount new band saw tyres and reinstall the band saw blade.

8.5 Replacing the Table

Insert

The table insert needs replacement

when its slot has become enlarged or

damaged.

1. Remove table insert (82) from saw

table (push up from underneath).

2. Fit new table insert.

8.6 Saw Cleaning

A

Danger!

Never touch the band saw blade or

the band saw wheel with a brush held

A

Caution!

Fold bandsaw blades when not in use

and store dry.

9. Tips and Tricks

• Keep surfaces of the saw table

clean – in particular, remove resin

residue with a suitable cleaning and

maintenance spray (optional acces

sory).

• Afterwards, apply a light coat of sliding compound (e.g. Waxilit).

-

10. Available Accessories

For special tasks the following accessories are available at your specialised

dealer – see back cover for illustrations:

A Circle Cutting Attachment

For cutting circles of 120 to 260 mm

diameter. Optimal cutting results

when using a band saw blade for

contoured cutting and radii.

B Wheel Set

For easy transport.

C Rip Fence

For making accurate long cuts.

D Mitre Fence Steplessly adjustable

mitre angle from 90 ° to 45°.

E Precision Roller Guide

Provides optimal band saw blade

guiding and prolonged service life.

F Belt Sanding Attachment

For finishing cut edges.

G Dust collection adapter for Ø 100

mm port.

A

Danger!

Repairs to electric tools must only be

carried out by qualified electricians!

Electric tools in need of repair can be

sent to the Service Centre of your country. Refer to the spare parts list for the

address.

Please attach a description of the fault to

the electric tool.

12. Environmetal Protection

The machine's packing can be 100%

recycled.

Worn out power tools and accessories

contain considerable amounts of valuable raw and rubber materials, which are

recyclable.

These instructions are printed on paper

produced with elemental chlorine-free

bleaching process.

13. Trouble shooting

A

Danger!

Before carrying out any fault servicing, always do the following:

1. switch machine OFF;

2. Unplug mains cable.

3. Wait until the band saw blade has

come to a complete stop.

Check to see that all safety devices

are operational after each fault serv

ice.

-

24

Page 12

ENGLISH

Motor does not run

Undervoltage relay tripped by power failure:

− switch on again.

No mains voltage

− check cable, plug, outlet and mains

fuse.

Band saw blade wanders off the line

of cut or runs off the band saw

wheels

Band saw blade is not running properly

on the band saw wheels:

− Correct tracking (see “Care and

Maintenance”).

Band saw blade breaks

Incorrect tension:

− correct band saw blade tension (see

“Care and Maintenance”).

Load too high:

− reduce pressure against band saw

blade (reduced feed rate).

Incorrect band saw blade:

− replace band saw blade (see “Care

and Maintenance”):

Contour cuts =

narrow band saw blade,

Straight cuts =

wide band saw blade.

Band saw blade warped

Load too high:

− avoid lateral pressure on the band

saw blade.

Saw vibrates

Insufficient mounting:

− Fasten saw properly to a suitable

floor (see “Initial Operation”).

Saw table loose:

− Align and fasten saw table.

Motor mount loose:

− Check fastening screws, tighten if

necessary.

Dust extraction port blocked

No dust collector connected or suction

capacity insufficient:

− Connect a dust collector or increase

suction capacity (air speed ≥20 m/

sec at dust extraction port).

14. Technical specifications

WNB DNB

Voltage V 230 (1~ 50 Hz) 400 (3~ 50 Hz)

Nominal current A 6,7 3,9

Fuse protection A 10 (time-lag or K-Auto-

mat)

10 (time-lag or K-Auto-

mat)

Protection rating IP 54 IP 54

Protection class I I

Performance

Power input P1

effective shaft output P2

Rated no-load speed min

kW

kW

-1

1.50 kW S6 40%

1.10 kW S6 40%

1400 1400

1.90 kW S6 40%

1.50 kW S6 40%

Cutting speed m/min 408/965 408/965

Band saw blade length mm 3380 3380

Max. throat capacity mm 440 440

Max. capacity under guide mm 280 280

Max. band saw blade width mm 25 25

Max. band saw blade thickness mm 0,65 0,65

Dimensions

Machine in packing

− Length

− Width

− Height

mm

mm

mm

790

710

1970

790

710

1970

Machine ready for work (saw table horizontal)

− Length

− Width

− Height

mm

mm

mm

834

639

1860

834

639

1860

Saw table only

− Length

− Width

mm

mm

640

536

640

536

Weight

Machine ready for work (with accessories supplied) kg 133 133

Permissible ambient temperature for operation

Permissible temperature for transport and storage

° C

° C

0 to +40

0 to +40

0 to +40

0 to +40

Noise emission value (DIN EN 1870-1*) at idle

A-sound pressure level LpA

A-sound power level

LWA

Uncertainty K

dB (A)

dB (A)

dB (A)

75,0

84,6

4,0

75,0

84,6

4,0

25

Page 13

ENGLISH

WNB DNB

Noise emission value (DIN EN 1870-1*) during sawing

A-sound pressure level LpA

A-sound power level

Uncertainty K

* The values stated are emission values and as such do not necessarily constitute values which are safe for the workplace.

Although there is a correlation between emission levels and environmental impact levels, whether further precautions are neces

sary cannot be derived from this. Factors influencing the actually present environmental impact level in the workplace include the

characteristics of the work area and other noise sources, i.e. the number of machines and other neighbouring work processes. Also,

permissible workplace values may vary from country to country. This information is intended to assist the user in his estimate of

hazards and risks.

LWA

14.1 Available Band Saw

Blades

Application Dimensions mm Tooth spacing Stock number

NF-metals 3380 x15 x 0.5 A2 090 902 9210

Contour cutting 3380 x 6.0 x 0.5 A4 090 902 9180

Wood – straight cuts 3380 x 25 x 0.5 A6 090 900 0416

Wood – universal cuts 3380 x 15 x 0.5 A6 090 902 9171

dB (A)

dB (A)

dB (A)

82,2

89,9

4,0

82,2

89,9

4,0

-

Firewood 3380 x 25 x 0.5 A8 090 900 0424

26

Page 14

Metabowerke GmbH,

72622 Nürtingen, Germany

www.metabo.com

Loading...

Loading...