Page 1

SXE 425 TurboTec

SXE 450 TurboTec

en Operating Instructions 4

fr Mode d'emploi 8

www.metabo.com Made in Germany

es Instrucciones de manejo 12

Page 2

1

2

2

3

4

5

6

7

8

9

10

12

11

12

11

3

4

5

6

7

8

10

13

14

12

10

15

2

16

SXE 450 TurboTec

SXE Partner Edition

SXE 425 TurboTec

344097790

(SXE 450 TurboTec)

344097820

(SXE 425 TurboTec)

(6.31980)

(6.25599)

o 35 mmo 35 mmo 35 mm

2

Page 3

SXE 450 TurboTec SXE 425 TurboTec

12.

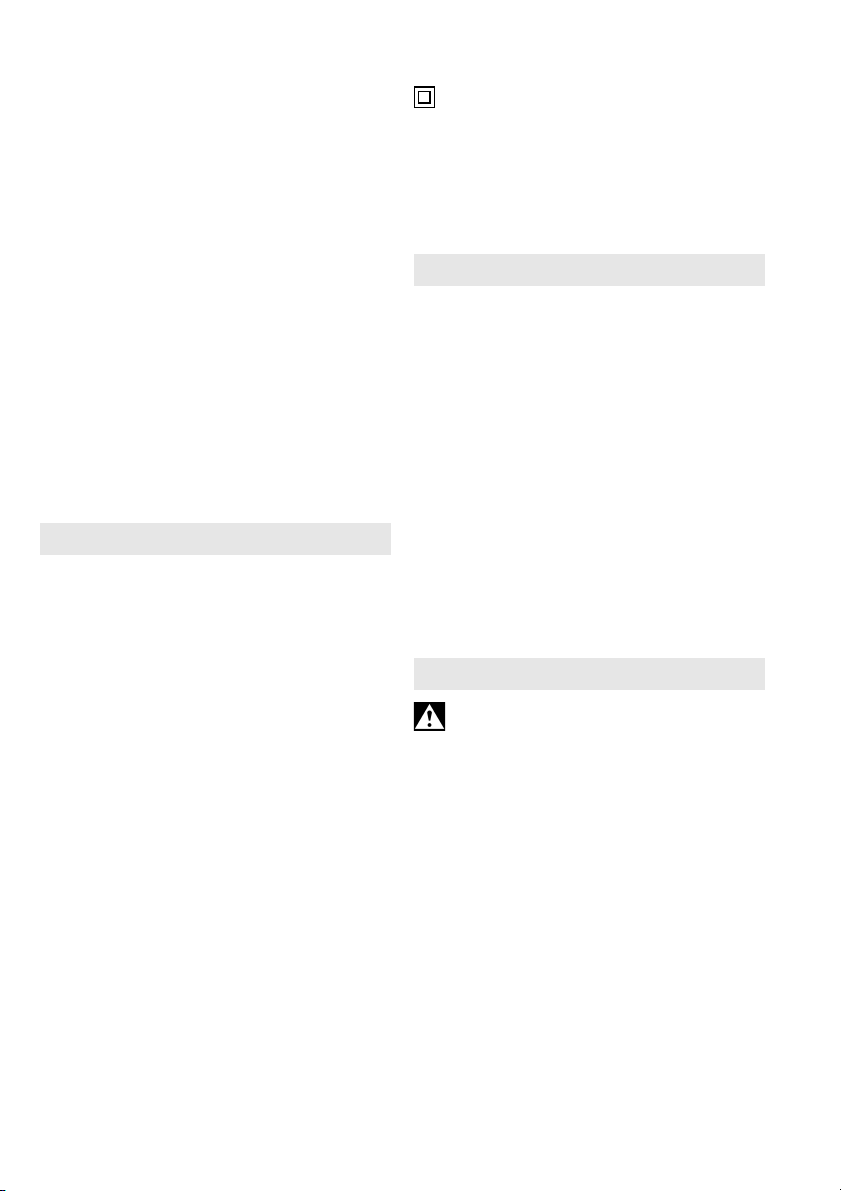

A mm (in)

P

1

P

2

n

n

s

s

n

0, TB

1, TB

s

0, TB

1, TB

min

0

min

min

min

0

min

min

S mm (in)

W 350 320

W 180 160

-1

(rpm)

-1

(rpm)

-1

(rpm)

-1

(opm)

-1

(opm)

-1

(opm)

2,8 / 6,2 (

29

150 (5

/32) 125 (4

4200-9200 4200-9200

11000 11000

8500 9000

8400-18400 8400-18400

22000 22000

17000 18000

1

/8 / 1/4)5 (

m kg (lbs) 2,2 (4.9) 2,0 (4.4)

15

/16)

3

/16)

Metabowerke GmbH

Postfach 1229

Metabo-Allee 1

D-72622 Nuertingen

Germany

3

Page 4

ENGLISHen

Operating Instructions

1. Specified Use

The disc sander is suitable for dry sanding of flat

and curved surfaches, wood, plastics, non-ferrous

metals, sheet steel and similar materials, spackled

and painted surfaces, and is also suitable for

polilshing.

The user bears sole responsibility for damage

caused by improper use.

Generally accepted accident prevention

regulations and the enclosed safety information

must be observed.

2. General Safety Instructions

WARNING – Reading the operating instructions

will reduce the risk of injury.

For your own protection and for the protection of your power tool pay attention to all

parts of the text that are marked with this

symbol!

General Power Tool Safety Warnings

WARNING

instructions.

instructions may result in electric shock, fire and/or

serious injury.

future reference!

ings refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

1) Work area safety

a)

Keep work area clean and well lit.

areas invite accidents.

Do not operate power tools in explosive

b)

atmospheres, such as in the presence of

flammable liquids, gases or dust.

create sparks which may ignite the dust or fumes.

Keep children and bystanders away while

c)

operating a power tool.

to lose control.

2) Electrical safety

a)

Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools.

Unmodified plugs and matching outlets will

reduce risk of electric shock.

Avoid body contact with earthed or grounded

b)

surfaces, such as pipes, radiators, ranges and

refrigerators.

shock if your body is earthed or grounded.

Do not expose power tools to rain or wet

c)

conditions.

the risk of electric shock.

Do not abuse the cord. Never use the cord for

d)

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

4

Read all safety warnings and all

Failure to follow the warnings and

Save all warnings and instructions for

The term "power tool" in the warn-

Cluttered or dark

Power tools

Distractions can cause you

There is an increased risk of electric

Water entering a power tool will increase

moving parts.

the risk of electric shock.

When operating a power tool outdoors, use an

e)

extension cord suitable for outdoor use.

cord suitable for outdoor use reduces the risk of

electric shock.

If operating a power tool in a damp location is

f)

unavoidable, use a residual current device (RCD)

protected supply.

electric shock.

3) Personal safety

a)

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication.

moment of inattention while operating power tools

may result in serious personal injury.

Use personal protective equipment. Always wear

b)

eye protection.

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

Prevent unintentional starting. Ensure the switch

c)

is in the off-position before connecting to power

source and/or battery pack, picking up or

carrying the tool.

finger on the switch or energising power tools that

have the switch on invites accidents.

Remove any adjusting key or wrench before

d)

turning the power tool on.

attached to a rotating part of the power tool may result

in personal injury.

Do not overreach. Keep proper footing and

e)

balance at all times.

the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or

f)

jewellery. Keep your hair, clothing and gloves

away from moving parts.

long hair can be caught in moving parts.

If devices are provided for the connection of dust

g)

extraction and collection facilities, ensure these

are connected and properly used.

collection can reduce dust-related hazards.

4) Power tool use and care

a)

Do not force the power tool. Use the correct

power tool for your application.

tool will do the job better and safer at the rate for which

it was designed.

Do not use the power tool if the switch does not

b)

turn it on and off.

controlled with the switch is dangerous and must be

repaired.

Disconnect the plug from the power source and/

c)

or the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools.

ures reduce the risk of starting the power tool

accidentally.

Damaged or entangled cords increase

Use of a

Use of an RCD reduces the risk of

Protective equipment such as dust

Carrying power tools with your

A wrench or a key left

This enables better control of

Loose clothes, jewellery or

Use of dust

The correct power

Any power tool that cannot be

Such preventive safety mea

A

Page 5

d)

Store idle power tools out of the reach of

children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool.

hands of untrained users.

Maintain power tools. Check for misalignment or

e)

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool's operation. If damaged, have the power tool

repaired before use.

poorly maintained power tools.

Keep cutting tools sharp and clean.

f)

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc.

g)

in accordance with these instructions, taking

into account the working conditions and the

work to be performed.

operations different from those intended could result

in a hazardous situation.

5) Service

a)

Have your power tool serviced by a qualified

repair person using only identical replacement

parts.

This will ensure that the safety of the power tool

is maintained.

Power tools are dangerous in the

Many accidents are caused by

Properly

Use of the power tool for

3. Special Safety Instructions

Dust from material such as paint containing lead,

some wood species, minerals and metal may be

harmful. Contact with or inhalation of the dust may

cause allergic reactions and/or respiratory diseases

to the operator or bystanders.

Certain kinds of dust are classified as carcinogenic

such as oak and beech dust especially in

conjunction with additives for wood conditioning

(chromate, wood preservative). Material containing

asbestos must only be treated by specialists.

- Use a dust extractor or the dust collection box

where possible.

- To achieve a high level of dust collection, use a

suitable Metabo vacuum cleaner together with this

tool.

- The work place must be well ventilated.

- The use of a dust mask of filter class P2 is

recommended.

Follow national requirements for the materials you

want to work with.

Pull the plug out of the plug socket before any

adjustments or servicing are performed.

Wear ear protectors when working for long periods

of time. High noise levels over a prolonged period of

time may affect your hearing.

Materials that generate dusts or vapours that may

be harmful to health (e.g. asbestos) must not be

processed.

Secure the workpiece against slipping, e.g. with the

help of clamping devices.

ENGLISH en

SYMBOLS ON THE TOOL:

.......Class II Construction

V .......... volts

A.......... amperes

Hz........ hertz

~.......... alternating current

n

.........no load speed

0

../min ...revolutions per minute

rpm .....revolutions per minute

opm ....oscillations per minute

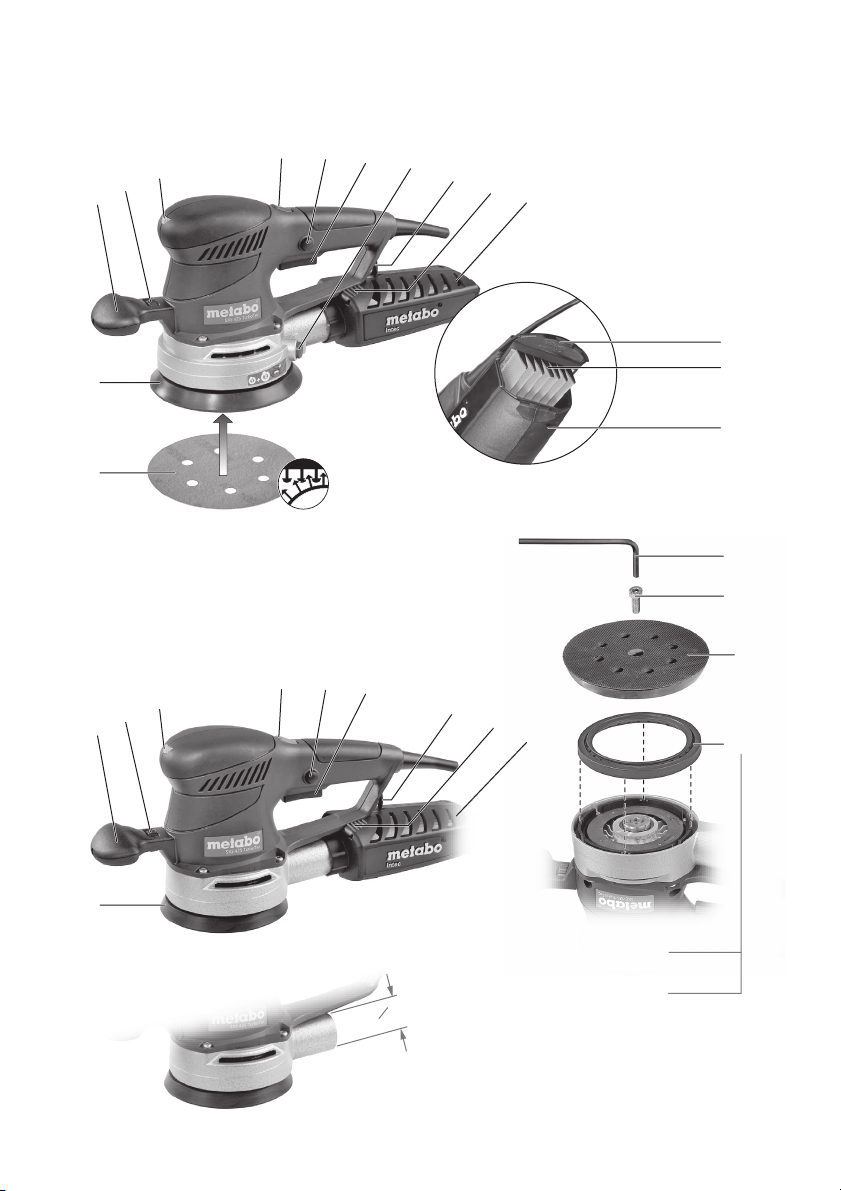

4. Overview

See page 2.

1 Sanding disc

2Support plate

3 Additional handle (removable)

4 Knurled screw

5 Setting wheel for selecting oscillating frequency

6 TurboBoost switch

7 Locking button for continuous activation

8Trigger switch

9 Locking button for

"Duo" oscillating circuit setting *

10 Hexagon spanner

11 Button for removing the

12 Dust collection box

13 Cleaning flap

14 Fluted filter

15 Locking screw for support plate

16 Braking ring of support plate brake

* depends on model

dust collection box

5. Commissioning

Before plugging in, check to see that the rated

mains voltage and mains frequency,

as stated on the rating label, match your power

supply.

5.1 Additional handle

The removable additional handle (3) can be

screwed onto the machine with the integrated

knurled screw (4).

If required, insert a Phillips screwdriver in the hole at

the end of the additional handle to release or tighten

the knurled screw (4).

5.2 Installation of sanding disc

Simple attachment and removal thanks to the

velcro-type fastening.

Simply press on the sanding disc such that the

holes in the sanding disc (1) are aligned with the

support plate (2).

5

Page 6

ENGLISHen

6. Use 7. Cleaning, Maintenance

6.1 Duo oscillating circuit setting (only with

SXE 450 TurboTec)

You can choose between two oscillating frequency

settings:

• Oscillating circuit high setting (6.2 mm): coarse

sanding with high material removal rate

• Oscillating circuit low setting (2.8 mm): fine

sanding, polishing

Changing oscillating circuit:

- Disconnect the mains plug!

- Press in the locking button (9) and hold in place.

- Rotate support plate (2) in a counter-clockwise

direction until you can hear it engage.

- Continue holding in the button.

- Continue turning the support plate half a

revolution to the next snap-in point.

- Release the locking button.

6.2 On/Off switch, continuous activation

To start the machine, press the trigger switch (8).

For continuous operation the trigger switch can be

locked using the lock button (7). To stop the

machine, press the trigger switch (8) again.

6.3 Setting oscillating frequency

When the TurboBoost switch (6) is switched off,

the oscillating speed can be set at the setting

wheel (5). This is also possible during operation.

Recommended oscillating frequency settings:

Plastic materials. . . . . . . . . . . . . . . . . . . . . 1-2

Metal, Plexiglas

Coarse and fine sanding, polishing, wood5

The best way to determine the ideal setting is

through a practical trial.

6.4 TurboBoost switch

Actuate the TurboBoost switch (6) during operation

to switch on additional power reserves for maximum

material removal rate.

6.5 Dust extraction

To optimise the dust extraction performance, fit the

sanding disc such that the holes on the sanding disc

(1) are aligned to the support plate (2).

Own extraction system:

Fit the dust collection box (12) onto the exhaust

nozzle until it engages. To remove, press the button

(11) and pull off the dust collection box (12) to the

rear.

To optimise the extraction performance, empty the

dust collection box (12) in good time and clean the

filter (14).

External extraction system:

Connect a suitable extraction device.

6

®

, old coats of paint. . . . . 3-4

Empty dust collection box (12).

- Open cleaning flap (13).

- Empty dust collection box (12).

- Remove fluted filter (14) and knock off dust stuck

to filter or remove with brush.

- When inserting, ensure that the fluted filter (14) is

inserted in the lateral guides.

The clean the machine regularly, frequently

and thoroughly. Vacuum clean the ventilation

slots on the motor or blow compressed air through

the ventilation slots. Hold the machine firmly at the

same time.

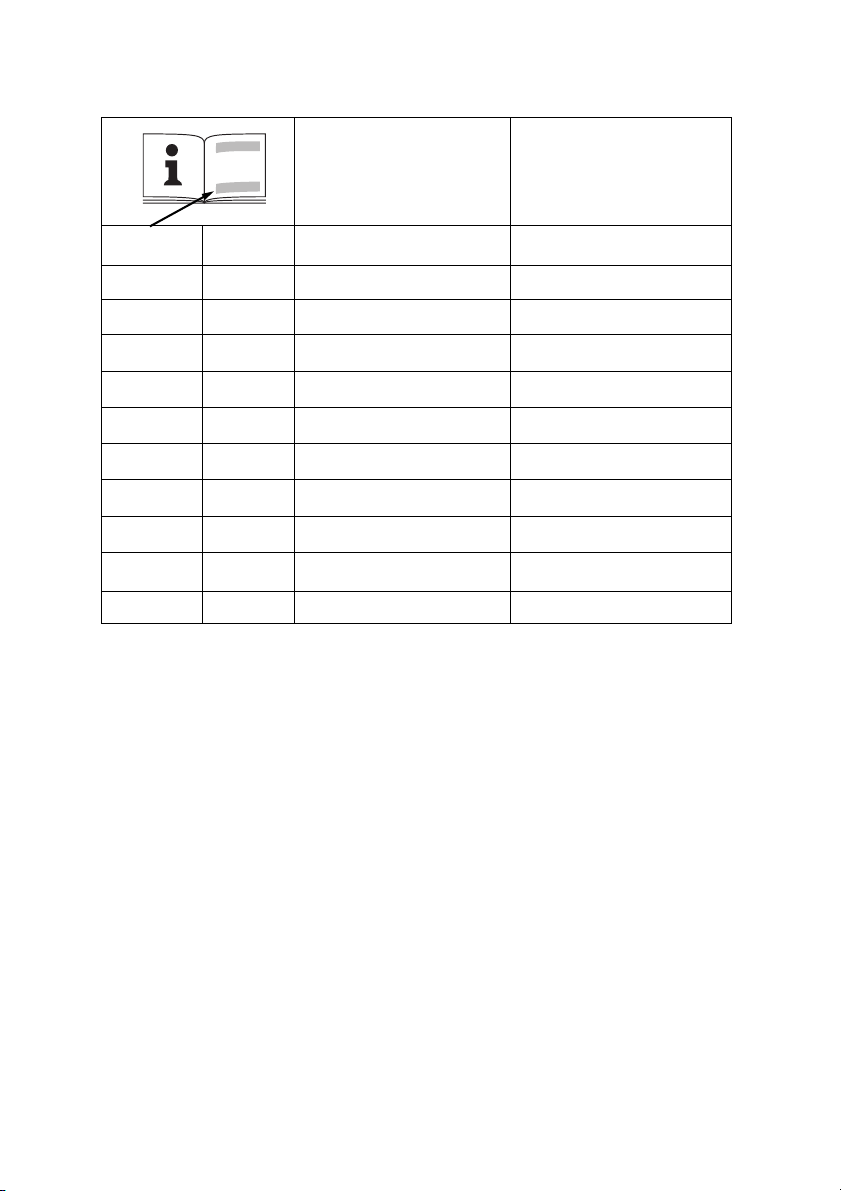

Replacing a worn support plate

Note:

If abrasive material (e.g. filled or painted

surfaces, etc.) is being sanded, the support plate

inevitably wears faster.

-Use the

- Remove support plate (2).

- For replacement support plates, refer to the

- Mount support plate (2) and rotate until it engages

- Insert locking screw (15) again and tighten.

Replacing support plate brake / braking ring

If the idling speed of the support plate increases in

course of time, the braking ring (16) is worn and

must be replaced.

Note:

surfaces, etc.) is being sanded, the braking ring

inevitably wears faster.

-Use the

- Remove support plate (2).

- Replace the old braking ring (16) with the new

- Mount support plate (2) and rotate until it engages

- Insert locking screw (15) again and tighten.

hexagon spanner

fixing screw (15) on the support plate.

Accessories chapter.

on carrier disc.

If abrasive material (e.g. filled or painted

hexagon spanner

fixing screw (15) on the support plate.

braking ring (see Chapter on Accessories),

ensuring that the new braking ring is in the same

position as the old braking ring. Ensure that the

position of the marking on the braking ring is

correct.

on carrier disc.

8. Tips and Tricks

Do not press the device too firmly against the

surface being sanded. This does not improve, but

rather impairs, the sanding performance.

To optimise the extraction performance, empty the

dust collection box (12) in good time and clean the

fluted filter (14).english

Use a suitable sanding disc to achieve the best

possible work results: Removal of old paint layers =

P 40

Pre-sanding of wood = P 60, P 80

Finishing of wood = P 100, P 120

Sanding of veneers, sealing primer, filler, paint = P

180, P 240, P 320, P 400

(10) to unscrew the

(10) to unscrew the

Page 7

9. Accessories

Use only genuine Metabo accessories.

For a complete range of accessories, see

www.metabo.com or the main catalogue.

10. Repairs

Repairs to electrical tools must be carried out by

qualified electricians ONLY!

If the mains connection cable of this machine is

damaged, it must be replaced by the manufacturer

or an authorized service centre to avoid hazard.

Contact your local Metabo representative if you

have Metabo power tools requiring repairs. For

addresses see www.metabo.com.

You can download a list of spare parts from

www.metabo.com.

11. Environmental Protection

Observe national regulations on environmentally

compatible disposal and on the recycling of disused

machines, packaging and accessories.

12. Technical Specifications

Explanatory notes on the specifications on page 3.

Changes due to technological progress reserved.

D = Diameter of support plate

P

= Nominal power input

1

= Power output

P

2

= Idle speed (setting wheel)

n

0

= Idle speed (TurboBoost switch)

n

0, TB

= Speed at rated load (TurboBoost

n

1, TB

s

0

s

0, TB

s

1, TB

S = Oscillating circuit diameter

m = Weight without mains cable

switch)

= Oscillating frequency at idle speed

(setting wheel)

= Oscillating frequency at idle speed

(TurboBoost switch)

= Oscillating frequency at rated load

(TurboBoost switch)

Wear ear protectors!

ENGLISH en

The technical specifications quoted are subject to

tolerances (in compliance with the relevant valid

standards).

7

Page 8

FRANÇAISfr

Mode d'emploi

1. Utilisation conforme à la

destination

Cette ponceuse excentrique sert à poncer à sec

des surfaces planes et bombées, du bois, des

plastiques, des métaux non-ferreux, de la tôle et

des surfaces mastiquées et peintes ainsi qu'à

lustrer.

L'utilisateur sera entièrement responsable de tous

dommages résultant d'une utilisation non conforme

à la destination de la machine.

Il est impératif de respecter les consignes

générales de protection contre les accidents ainsi

que les consignes de sécurité ci-jointes.

2. Consignes générales de

sécurité

AVERTISSEMENT – Lire la notice d'utilisation

afin d'éviter tout risque de blessure.

Dans l'intérêt de votre propre sécurité et afin

de protéger votre outil électrique, respectez

les passages de texte marqués de ce

symbole !

Avertissements de sécurité généraux pour l'outil

AVERTISSEMENT

ments de sécurité et toutes les instructions.

Ne pas suivre les avertissements et instructions peut

donner lieu à un choc électrique, un incendie et/ou une

blessure sérieuse.

ments et toutes les instructions pour pouvoir s'y

reporter ultérieurement!

avertissements fait référence à votre outil électrique

alimenté par le secteur (avec cordon d'alimentation)

ou votre outil fonctionnant sur batterie (sans cordon

d'alimentation).

1) Sécurité de la zone de travail

a)

Conserver la zone de travail propre et bien

éclairée.

propices aux accidents.

b)

en atmosphère explosive, par exemple en

présence de liquides inflammables, de gaz ou

de poussières.

des étincelles qui peuvent enflammer les poussières

ou les fumées.

c)

présentes à l'écart pendant l'utilisation de l'outil.

Les distractions peuvent vous faire perdre le contrôle

de l'outil.

2) Sécurité électrique

a)

adaptées au socle. Ne jamais modifier la fiche

de quelque façon que ce soit. Ne pas utiliser

d'adaptateurs avec des outils à branchement de

8

Les zones en désordre ou sombres sont

Ne pas faire fonctionner les outils électriques

Maintenir les enfants et les personnes

Il faut que les fiches de l'outil électrique soient

Lire tous les avertisse-

Conserver tous les avertisse-

Le terme "outil" dans les

Les outils électriques produisent

Des fiches non modifiées et des socles

terre.

adaptés réduiront le risque de choc électrique.

Eviter tout contact du corps avec des surfaces

b)

reliées à la terre telles que les tuyaux, les

radiateurs, les cuisinières et les réfrigérateurs.

existe un risque accru de choc électrique si votre

corps est relié à la terre.

Ne pas exposer les outils à la pluie ou à des

c)

conditions humides.

l'intérieur d'un outil augmentera le risque de choc

électrique.

Ne pas maltraiter le cordon. Ne jamais utiliser

d)

le cordon pour porter, tirer ou débrancher l'outil.

Maintenir le cordon à l'écart de la chaleur, du

lubrifiant, des arêtes ou des parties en

mouvement.

emmêlés augmentent le risque de choc électrique.

Lorsqu'on utilise un outil à l'extérieur, utiliser

e)

un prolongateur adapté à l'utilisation extérieure

L'utilisation d'un cordon adapté à l'utilisation

extérieure réduit le risque de choc électrique.

Si l'usage d'un outil dans un emplacement

f)

humide est inévitable, utiliser une alimentation

protégée par un dispositif à courant différentiel

résiduel (RCD)

de choc électrique.

3) Sécurité des personnes

Rester vigilant, regarder ce que vous êtes en

a)

train de faire et faire preuve de bon sens dans

votre utilisation de l'outil. Ne pas utiliser un outil

lorsque vous êtes fatigué ou sous l'emprise de

drogues, d'alcool ou de médicaments.

moment d'inattention en cours d'utilisation d'un outil

peut entraîner des blessures graves des personnes.

Utiliser un équipement de sécurité. Toujours

b)

porter une protection pour les yeux.

équipements de sécurité tels que les masques

contre les poussières, les chaussures de sécurité

antidérapantes, les casques ou les protections

acoustiques utilisés pour les conditions appropriées

réduiront les blessures de personnes.

Eviter tout démarrage intempestif. S'assurer

c)

que l'interrupteur est en position arrêt avant de

brancher l'outil au secteur et/ou au bloc de

batteries, de le ramasser ou de le porter.

les outils en ayant le doigt sur l'interrupteur ou

brancher des outils dont l'interrupteur est en position

marche est source d'accidents.

Retirer toute clé de réglage avant de mettre

d)

l'outil en marche.

partie tournante de l'outil peut donner lieu à des

blessures de personnes.

Ne pas se précipiter. Garder une position et un

e)

équilibre adaptés à tout moment.

meilleur contrôle de l'outil dans des situations

inattendues.

S'habiller de manière adaptée. Ne pas porter de

f)

vêtements amples ou de bijoux. Garder les

cheveux, les vêtements et les gants à distance

La pénétration d'eau à

Des cordons endommagés ou

. L'usage d'un RCD réduit le risque

Les

Une clé laissée fixée sur une

Cela permet un

Il

.

Un

Porter

Page 9

des parties en mouvement.

amples, des bijoux ou les cheveux longs peuvent

être pris dans desparties en mouvement.

Si des dispositifs sont fournis pour le

g)

raccordement d'équipements pour l'extraction

et la récupération des poussières, s'assurer

qu'ils sont connectés et correctement utilisés.

Utiliser des collecteurs de poussière peut réduire les

risques dus aux poussières.

4) Utilisation et entretien de l'outil

a)

Ne pas forcer l'outil. Utiliser l'outil adapté à

votre application.

travail et de manière plus sûre au régime pour lequel

il a été construit.

Ne pas utiliser l'outil si l'interrupteur ne permet

b)

pas de passer de l'état de marche à arrêt et vice

versa.

Tout outil qui ne peut pas être commandé par

l'interrupteur est dangereux et il faut le réparer.

Débrancher la fiche de la source

c)

d'alimentation en courant et/ou le bloc de

batteries de l'outil avant tout réglage,

changement d'accessoires ou avant de ranger

l'outil.

De telles mesures de sécurité préventives

réduisent le risque de démarrage accidentel de

l'outil.

Conserver les outils à l'arrêt hors de la portée

d)

des enfants et ne pas permettre à des

personnes ne connaissant pas l'outil ou les

présentes instructions de le faire fonctionner.

Les outils sont dangereux entre les mains

d'utilisateurs novices.

Observer la maintenance de l'outil. Vérifier

e)

qu'il n'y a pas de mauvais alignement ou de

blocage des parties mobiles, des pièces

cassées ou toute autre condition pouvant

affecter le fonctionnement de l'outil. En cas de

dommages, faire réparer l'outil avant de

l'utiliser.

outils mal entretenus.

f)

de couper.

correctement entretenus avec des pièces coupantes

tranchantes sont moins susceptibles de bloquer et

sont plus faciles

à contrôler.

g)

conformément à ces instructions, en tenant

compte des conditions de travail et du travail à

réaliser.

différentes de celles prévues pourrait donner lieu à

des situations dangereuses.

5) Maintenance et entretien

a)

qualifié utilisant uniquement des pièces de

rechange identiques.

de l'outil est maintenue.

De nombreux accidents sont dus à des

Garder affûtés et propres les outils permettant

Utiliser l'outil, les accessoires et les lames etc.,

L'utilisation de l'outil pour des opérations

Faire entretenir l'outil par un réparateur

L'outil adapté réalisera mieux le

Des outils destinés à couper

Des vêtements

Cela assurera que la sécurité

FRANÇAIS fr

3. Consignes de sécurité

particulières

Les poussières de matériaux tels que les peintures

au plomb, certains types de bois, de minéraux et de

métaux peuvent s'avérer nocives pour la santé.

Toucher ou inhaler ces poussières peut entraîner

des réactions allergiques et/ou des maladies

respiratoires chez l'utilisateur ou les personnes se

trouvant à proximité.

Certaines poussières provenant par exemple du

chêne ou du hêtre sont considérées comme

cancérigènes, particulièrement lorsqu'elle sont

associées à des adjuvants de traitement du bois

(chromate, produit de protection du bois). Seuls des

spécialistes sont habilités à traiter les matériaux

contenant de l'amiante.

- Utilisez autant que possible un système

d'aspiration des poussières ou la cassette

de réception des poussières.

- Pour obtenir un degré élevé d'aspiration, utiliser

un aspirateur Metabo approprié en association

avec cet outil électrique.

- Veiller à une bonne aération du site de travail.

- Il est recommandé de porter un masque

antipoussières avec filtre à particules de classe 2.

Respecter les directives nationales en vigueur

relatives aux matériaux à traiter.

Débrancher le cordon d'alimentation de la prise de

courant avant toute opération de réglage ou de

maintenance.

Pour des travaux de longue durée, une protection

acoustique est nécessaire. Des nuisances

acoustiques intenses et prolongées peuvent

provoquer une perte d'audition.

Le sciage de matériaux produisant des poussières

ou vapeurs nocives (p. ex. amiante) au moment de

la découpe est proscrit.

Bloquer la pièce pour éviter qu'elle ne glisse,

par ex. à l'aide de dispositifs de serrage.

SYMBOLES SUR L’OUTIL:

.......... Construction de classe II

V ............. volts

A............. ampères

Hz........... hertz

~ ............. courant alternatif

n

............ vitesse à vide

0

../min ...... révolutions par minute

rpm ........ révolutions par minute

opm

........ oscillation

s par minute

4. Vue d'ensemble

Voir page 2.

1 Feuille abrasive

2 Plateau à poncer

3 Poignée supplémentaire (amovible)

4Vis moletée

5 Molette pour la présélection de la vitesse

d'oscillation

6 Commutateur TurboBoost

7 Bouton de marche continue

9

Page 10

FRANÇAISfr

8Gâchette

9 Bouton d'arrêt pour le réglage du cercle

d'oscillation "Duo" *

10 Clé à six pans

11 Touche pour enlever la cassette de réception

des poussières

12 Cassette de réception des poussières

13 Clapet de nettoyage

14 Filtre à plis

15 Vis de fixation du plateau à poncer

16 Anneau de freinage pour le frein du plateau

à poncer

* en fonction du modèle

5. Mise en service

Avant la mise en service, comparer si tension

secteur et la fréquence secteur indiquées sur

la plaque signalétique correspondent aux

caractéristiques de votre réseau de courant.

5.1 Poignée supplémentaire

La poignée supplémentaire amovible (3) peut être

fixée sur la ponceuse au moyen de la vis moletée

(4) intégrée.

Le cas échéant, introduire un tournevis cruciforme

dans le logement à l'extrémité de la poignée

supplémentaire afin de desserrer ou de serrer

la vis moletée (4).

5.2 Mise en place de la feuille abrasive

Mise en place et retrait simples grâce à la bande

velcro.

Appuyer simplement la feuille abrasive de sorte que

les trous de la feuille abrasive (1) et du plateau à

poncer (2) coïncident.

6. Utilisation

6.1 Réglage du cercle d'oscillation duo

(uniquement pour SXE 450 TurboTec)

Vous avez le choix entre deux réglages du cercle

d'oscillation :

• Grand cercle d'oscillation (6,2 mm) : ponçage

grossier avec puissance d'enlèvement

importante

• Petit cercle d'oscillation (2,8 mm) : ponçage fin,

polissage

Modification du cercle d'oscillation :

- Débrancher la fiche secteur !

- Appuyer sur le bouton d'arrêt (9) et le maintenir

enfoncé.

- Faire tourner le plateau à poncer (2) dans le sens

antihoraire jusqu'à entendre son enclenchement.

- Continuer de maintenir le bouton enfoncé.

- Faire pivoter le plateau à poncer d'un demi-tour

supplémentaire jusqu'au point d'enclenchement

suivant.

10

- Relâcher le bouton d'arrêt.

6.2 Marche/arrêt, fonctionnement en continu

Pour mettre l'outil en route, appuyer sur la

gâchette (8).

Pour un fonctionnement en continu, il est possible

de bloquer la gâchette à l'aide du bouton de

blocage (7). Pour arrêter la machine, appuyer à

nouveau sur la gâchette (8).

6.3 Régler la vitesse d'oscillation

Quand le commutateur TurboBoost (6) est

désactivé, régler la vitesse d'oscillation à l'aide de la

molette (5). Ceci est également possible pendant la

marche.

Réglages de vitesse d'oscillation recommandés :

Matières plastiques . . . . . . . . . . . . . . . . . . 1-2

Métal, plexiglas

de peinture . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Ponçage grossier, ponçage fin,

polissage, bois . . . . . . . . . . . . . . . . . . . . . . 5

Pour savoir quel réglage sera optimal, le mieux est

de faire un essai pratique.

6.4 Commutateur TurboBoost

Actionner le commutateur TurboBoost (6) pour

activer des réserves supplémentaires de puissance

pour un pouvoir abrasif maximal pendant le travail.

6.5 Système d'aspiration des poussières

Pour obtenir la meilleure puissance d'aspiration,

placer simplement la feuille abrasive de sorte que

les trous de la feuille abrasive (1) et du plateau à

poncer (2) coïncident.

Auto-aspiration :

Positionner la cassette de réception des poussières

(12) jusqu'à enclenchement sur le raccord

d'aspiration. Pour la retirer, appuyer sur la touche

(11) et retirer la cassette de réception des

poussières (12) vers l'arrière.

Pour obtenir la meilleure puissance d'aspiration,

vider à temps la cassette de réception des

poussières (12) et nettoyer le filtre (14).

Aspiration externe :

Brancher un aspirateur adéquat.

®

, vieilles couches

7. Nettoyage, maintenance

Vider la cassette de réception des

poussières (12)

- Ouvrir le clapet de nettoyage (13).

- Vider la cassette de réception des

poussières (12).

- Retirer le filtre à plis (14) et secouer la poussière

de ponçage qui adhère ou l'enlever avec un

pinceau.

- Faire attention lors de la mise en place : insérer le

filtre à plis (14) dans les guidages latéraux.

Nettoyer la machine régulièrement,

fréquemment et soigneusement. Aspirer en

même temps les fentes d'aération du moteur à

l'aide d'un aspirateur ou souffler de l'air comprimé à

Page 11

travers les fentes d'aération. Veiller à bien maintenir

la machine pendant ce temps.

Remplacer le plateau à poncer usagé

Remarque :

(par ex. surfaces mastiquées ou peintes, etc),

le plateau à poncer s'use forcément plus vite.

- Dévisser la vis de fixation (15) du plateau à poncer

avec la

- Retirer le plateau à poncer (2).

- Plateau à poncer (de rechange) voir chapitre

Accessoires

- Positionner le plateau à poncer (2) et le tourner

jusqu'à ce qu'il s'enclenche sur la plaque

d'entraînement.

- Revisser la vis de fixation (15) et la serrer.

si on ponce un matériau abrasif

clé à six pans

(10).

Remplacer le frein du plateau à poncer /

l'anneau de freinage

Si au bout d'un certain temps, la vitesse à vide du

plateau à poncer augmente, l'anneau de freinage

(16) est usé et doit être remplacé.

Remarque :

surfaces mastiquées ou peintes, etc), l'anneau de

si on ponce un matériau abrasif (par ex.

freinage s'use forcément plus vite.

- Dévisser la vis de fixation (15) du plateau à poncer

avec la

- Retirer le plateau à poncer (2).

clé à six pans

- Remplacer l'ancien anneau de freinage (16) par

le nouvel anneau de freinage (voir chapitre

Accessoires) et placer le nouvel anneau de

fr ei na ge da ns la mê me po sition que l'ancien. Tenir

compte de la position du marquage sur l'anneau

de freinage.

- Positionner le plateau à poncer (2) et le tourner

jusqu'à ce qu'il s'enclenche sur la plaque

d'entraînement.

- Revisser la vis de fixation (15) et la serrer.

(10).

8. Conseils et astuces

Ne pas appuyer trop fort l'appareil contre la surface

à poncer. La puissance de ponçage n'en sera pas

augmentée, au contraire elle sera plutôt inférieure.

Pour obtenir la meilleure puissance d'aspiration,

vider à temps la cassette de réception des

poussières (12) et nettoyer le filtre à plis. (14)

Pour obtenir un résultat optimal de ponçage, utiliser

la feuille abrasive appropriée :

Pour enlever d'anciennes couches de vernis = P 40

Pour poncer le bois = P 60, P 80

Pour le ponçage fin du bois = P 100, P 120

Pour poncer le bois de placage, le produit

d'encollage, l'enduit, le vernis = P 180, P 240, P

320, P 400

FRANÇAIS fr

En cas de détérioration du cordon d'alimentation de

cette machine, vous devez le faire remplacer par le

fabricant ou le service après-vente, afin d'éviter

toute situation dangereuse.

Pour toute réparation sur un outil Metabo, contacter

le représentant Metabo. Voir les adresses sur

www.metabo.com.

Les listes des pièces détachées peuvent être

téléchargées sur www.metabo.com.

11. Protection de l'environnement

Suivre les règlementations nationales concernant

l'élimination dans le respect de l'environnement et

le recyclage des machines, emballages et accessoires.

12. Caractéristiques techniques

Commentaires sur les indications de la page 3.

Sous réserve de modifications allant dans le sens

du progrès technique.

D = Diamètre du plateau à poncer

P

= Puissance absorbée

1

P

=Puissance débitée

2

n

= Vitesse à vide (molette)

0

n

=Vitesse à vide

0, TB

n

1, TB

s

0

s

0, TB

s

1, TB

S = Diamètre du cercle d'oscillation

m = Poids sans cordon d'alimentation

Les caractéristiques indiquées sont soumises à

tolérance (selon les normes en vigueur

correspondantes).

(commutateur TurboBoost)

= Vitesse en charge nominale

(commutateur TurboBoost)

= Vitesse d'oscillation à vide (molette)

= Vitesse d'oscillation à vide

(commutateur TurboBoost)

= Vitesse d'oscillation en charge

nominale (commutateur TurboBoost)

Porter un casque antibruit !

9. Accessoires

Utilisez uniquement du matériel Metabo.

Voir programme complet des accessoires sur

www.metabo.com ou dans le catalogue principal.

10. Réparations

Les travaux de réparation sur les outils électriques

ne peuvent être effectués que par un spécialiste !

11

Page 12

ESPAÑOLes

Instrucciones de manejo

1. Aplicación de acuerdo a la

finalidad

La lijadora excéntrica es adecuada para el

rectificado en seco de superficies planas y

curvadas, madera, plásticos, metales no férreos,

chapa de acero y superficies similares,

emplastecidas y pintadas así como para el pulido.

Los posibles daños derivados de un uso

inadecuado son responsabilidad exclusiva del

usuario.

Deben observarse las normas para prevención de

accidentes aceptadas generalmente y la

información sobre seguridad incluida.

2. Instrucciones generales de

seguridad

AV IS O: Par a r ed uci r e l r ies go de les io ne s, lea el

manual de instrucciones.

Para su propia protección y la de su herramienta eléctrica, observe las partes marcadas

con este símbolo.

Instrucciones generales de seguridad para

herramientas eléctricas

¡ATENCIÓN

ciones de seguridad.

instrucciones de seguridad siguientes puede dar lugar

a descargas eléctricas, incendios y/o lesiones graves.

Guarde estas instrucciones en un lugar seguro!

término "herramienta eléctrica" empleado en las siguientes instrucciones se refiere a su aparato eléctrico

portátil, ya sea con cable de red, o sin cable, en caso de

ser accionado por acumulador.

1)Puesto de trabajo

a)

Mantenga limipo y bien iluminado su puesto de

trabajo.

El desorden y una iluminación deficiente en

las áreas de trabajo pueden provocar accidentes.

No utilice la herramienta eléctrica en un entorno

b)

con peligro de explosión, en el que se

encuentren combustibles líquidos, gases o

material en polvo.

producen chispas que pueden llegar a inflamar los

materiales en polvo o vapores.

Mantenga alejados a los niños y otras personas

c)

de su puesto de trabajo al emplear la herramienta

eléctrica.

control sobre el aparato.

2)Seguridad eléctrica

a)

El enchufe de la herramienta eléctrica debe

corresponder a la toma de corriente utilizada. No

es admisible modificar el enchufe en forma

alguna. No emplee adaptadores con

herramientas eléctricas dotadas de una toma de

tierra.

12

Los enchufes sin modificar adecuados a las

Lea íntegramente estas instruc-

La no observación de las

Las herramientas eléctricas

Una distracción le puede hacer perder el

respectivas tomas de corriente reducen el riesgo de

una descarga eléctrica.

Evite que su cuerpo toque partes conectadas a

b)

tierra como tuberías, radiadores, cocinas y

refrigeradores.

sacudida eléctrica es mayor si su cuerpo tiene

contacto con tierra.

No exponga las herramientas eléctricas a la

c)

lluvia y evite que penetren líquidos en su interior.

Existe el peligro de recibir una descarga eléctrica si

penetran ciertos líquidos en la herramienta eléctrica.

No utilice el cable de red para transportar o

d)

colgar la herramienta eléctrica, ni tire de él para

sacar el enchufe de la toma de corriente.

Mantenga el cable de red alejado del calor,

aceite, esquinas cortantes o piezas móviles.

cables de red dañados o enredados pueden provocar

una descarga eléctrica.

Al trabajar con la herramienta eléctrica a la

e)

intemperie utilice solamente cables de

prolongación homologados para su uso en

exteriores.

prolongación adecuado para su uso en exteriores

reduce el riesgo de una descarga eléctrica.

Si fuera necesario utilizar la herramienta

f)

eléctrica en un entorno húmedo, utilice un

interruptor de protección diferencial.

utilización de un cable de prolongación adecuado

para su uso en exteriores reduce el riesgo de una

descarga eléctrica.

3)Seguridad de personas

a)

Esté atento a lo que hace y emplee la

El

herramienta eléctrica con prudencia. No utilice la

herramienta eléctrica si estuviese cansado, ni

tampoco después de haber consumido alcohol,

drogas o medicamentos.

el uso de una herramienta eléctrica puede provocarle

serias lesiones.

Utilice un equipo de protección y en todo caso

b)

unas gafas de protección.

se reduce considerablemente si, dependiendo del

tipo y la aplicación de la herramienta eléctrica

empleada, se utiliza un equipo de protección

adecuado como una mascarilla antipolvo, zapatos de

seguridad con suela antideslizante, casco, o

protectores auditivos.

Evite una puesta en marcha fortuita del aparato.

c)

Asegúrese de que la herramienta eléctrica está

apagada antes de conectarla a la toma de

corriente y/o la batería, de desconectarla o de

transportarla.

sujetándola por el interruptor de conexión/

desconexión, o si introduce el enchufe en la toma de

corriente con el aparato conectado, puede dar lugar a

un accidente.

Retire las herramientas de ajuste o llaves fijas

d)

antes de conectar la herramienta eléctrica.

herramienta o llave colocada en una pieza rotante

puede producir lesiones al ponerse a funcionar.

El riesgo a quedar expuesto a una

La utilización de un cable de

El no estar atento durante

El riesgo de lesionarse

Si transporta la herramienta eléctrica

Los

La

Una

Page 13

e)

Evite trabajar con posturas forzadas. Trabaje

sobre una base firme y mantenga el equilibrio en

todo momento.

herramienta eléctrica en caso de presentarse una

situación inesperada.

Lleve puesta una vestimenta de trabajo

f)

adecuada. No utilice vestimenta amplia ni joyas.

Mantenga su pelo, vestimenta y guantes alejados

de las piezas móviles.

joyas y el pelo largo se pueden enganchar con las

piezas en movimiento.

Siempre que sea posible utilizar equipos de

g)

aspiración o captación de polvo, asegúrese que

éstos estén montados y que sean utilizados

correctamente.

aspiración de polvo puede reducir los riesgos de

aspirar polvo nocivo para la salud.

4)Trato y uso cuidadoso de herramientas

eléctricas

a)

No sobrecargue el aparato. Use la herramienta

prevista para el trabajo a realizar.

herramienta adecuada podrá trabajar mejor y más

seguro dentro del margen de potencia indicado.

No utilice herramientas con un interruptor

b)

defectuoso.

conectar o desconectar son peligrosas y deben

hacerse reparar.

Saque el enchufe de la red y/o retire la batería

c)

antes de realizar un ajuste en la herramienta,

cambiar de accesorio o guardar el aparato.

medida preventiva reduce el riesgo de conectar

accidentalmente el aparato.

Guarde las herramientas eléctricas fuera del

d)

alcance de los niños. No permita que las utilcen

personas que no estén familiarizadas con ellas o

que no hayan leído estas instrucciones.

herramientas utilizadas por personas inexpertas son

peligrosas.

Cuide sus herramientas eléctricas con esmero.

e)

Controle si funcionan correctamente, sin

atascarse, las partes móviles de la herramienta y

si existen partes rotas o deterioradas que

pudieran afectar a su funcionamiento. Si la

herramienta eléctrica estuviese defectuosa,

hágala reparar antes de volver a utilizarla.

Muchos de los accidentes se deben a aparatos con

un mantenimiento deficiente.

Mantenga los útiles limpios y afilados.

f)

mantenidos correctamente se dejan guiar y controlar

mejor.

Utilice las herramientas eléctricas, los

g)

accesorios, las herramientas de inserción, etc.

de acuerdo con estas instrucciones. Considere

en ello las condiciones de trabajo y la tarea a

realizar.

trabajos diferentes de aquellos para los que han sido

concebidas puede resultar peligroso.

5) Servicio

a)

Únicamente haga reparar su herramienta

eléctrica por un profesional, empleando

exclusivamente piezas de repuesto originales.

Ello le permitirá controlar mejor la

La vestimenta suelta, las

La utilización de un equipo de

Con la

Las herramientas que no se puedan

Esta

Las

Los útiles

El uso de herramientas eléctricas para

ESPAÑOL es

Solamente así se mantiene la seguridad de la

herramienta eléctrica.

3. Instrucciones especiales de

seguridad

El polvo procedente de algunos materiales, como la

pintura con plomo o algunos tipos de madera,

minerales y metales, puede ser perjudicial para la

salud. Tocar o respirar el polvo puede causar

reacciones alérgicas y/o enfermedades

respiratorias al usuario o a las personas próximas a

él.

Algunas maderas, como la madera de roble o de

haya, producen un polvo que podría ser

cancerígeno, especialmente en combinación con

otros aditivos para el tratamiento de madera

(cromato, conservante para madera). Sólo

personal especializado debe trabajar el material

con contenido de asbesto.

- Utilice en la medida de lo posible un aspirador

de polvo o el casete colector de polvo.

- Para alcanzar un elevado grado de aspiración

de polvo, emplee un aspirador Metabo junto con

esta herramienta eléctrica.

- Ventile su lugar de trabajo.

- Se recomienda utilizar una máscara de

protección contra el polvo con clase de filtro P2.

Preste atención a la normativa vigente en su país

respecto al material que se va a trabajar.

Desenchufe el equipo antes de llevar a cabo

cualquier ajuste o mantenimiento.

Si los trabajos duran un período de tiempo

prolongado, usar protección para los oídos. La

exposición a niveles de ruido elevados durante

períodos prolongados puede causar daños en la

capacidad auditiva.

No pueden trabajarse materiales que produzcan

polvo o vapores perjudiciales para la salud

(p. ej. asbesto).

Asegurar la pieza de trabajo para inmovilizarla,

p. ej., con ayuda de dispositivos de sujeción.

SÍMBOLOS SOBRE LA HERRAMIENTA:

...... Classe II de construcción

V ......... voltios

A......... amperios

Hz....... hertzios

~......... corriente alterna

n

........ velocidad sin carga

0

../min .. revoluciones por minuto

rpm .... revoluciones por minuto

opm

.... oscilaciones

por minuto

4. Descripción general

Véase la página 2.

1 Hoja lijadora

2Placa de apoyo

3 Empuñadura complementaria (desmontable)

4 Tornillo de cabeza moleteada

5 Ruedecilla de ajuste para preselección del

número de oscilaciones

6 Interruptor de turboalimentación

13

Page 14

ESPAÑOLes

7 Botón de fijación para funcionamiento

continuado

8Interruptor

9 Botón de bloqueo para el ajuste del circuito

oscilante "Duo" *

10 Llave hexagonal

11 Tecla para la retirada del c

12 Colector de polvo

13 Chapaleta de limpieza

14 Filtro plegable

15 Tornillo de fijación de la placa de apoyo

16 Anillo de freno de la placa de apoyo

* en función del modelo

olector de polvo

5. Puesta en marcha

Antes de enchufar la herramienta, compruebe

que la tensión y la frecuencia de red que se

indican en la placa de identificación se

corresponden con las características de la red

eléctrica.

5.1 Empuñadura complementaria

La empuñadura complementaria desmontable (3)

puede fijarse a la herramienta (4) con el tornillo de

cabeza moleteada integrado.

En caso necesario, introducir un destornillador para

tornillos de estrella en el orificio del extremo de la

empuñadura complementaria para aflojar o apretar

el tornillo de cabeza moleteada (4).

5.2 Montaje de la hoja lijadora

Montaje y extracción sencillos gracias al cierre de

cardillo.

Basta con apretar la hoja lijadora hasta que los

orificios de la misma (1) encajen con los de la placa

de apoyo (2).

6. Manejo

6.1 Ajuste del circuito oscilante "Duo"

(solamente para SXE 450 TurboTec)

Existen dos ajustes posibles del circuito oscilante:

• Circuito oscilante grande (6,2 mm): lijado basto

con gran potencia de arranque de material

• Circuito oscilante pequeño (2,8 mm): rectificado

fino y pulido

Reajuste del circuito oscilante:

- ¡Desenchufar el equipo!

- Pulsar y mantener pulsado el botón de

bloqueo (9).

- Girar la placa de apoyo (2) en sentido contrario a

las agujas del reloj hasta que quede encajada de

forma audible.

- Mantener pulsado el botón.

- Girar la placa de apoyo media vuelta hasta que

encaje en el siguiente punto.

- Soltar el botón de bloqueo.

14

6.2 Conexión/desconexión, funcionamiento

continuado

Pulse el interruptor (8)de la herramienta para

ponerla en marcha.

Para un funcionamiento continuado puede

bloquearse el interruptor con el botón de

retención (7). Para parar la herramienta,

pulse el interruptor (8) de nuevo.

6.3 Ajuste del número de oscilaciones

Si el interruptor de turboalimentación (6) está

desconectado, se puede ajustar el número de

oscilaciones en la (5) ruedecilla de ajuste.

Dicho ajuste también se puede efectuar durante

el funcionamiento.

Ajuste del número de oscilaciones recomendado:

Plásticos . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Metal, plexiglás

Lijado basto, rectificado fino, pulido, madera5

El ajuste óptimo se puede determinar mediante la

práctica.

6.4 Interruptor de turboalimentación

Accione el interruptor de turboalimentación (6) para

ganar un extra de potencia y maximizar el arranque

de material durante el trabajo.

6.5 Aspiración de polvo

Para conseguir una potencia de aspiración óptima,

debe montarse la hoja lijadora de modo que los

orificios de la misma (1) encajen con los

de la placa de apoyo (2).

Aspiración independiente:

Insertar el colector de polvo (12) hasta que quede

encajado en el racor de aspiración. Para retirarlo,

pulsar la tecla (11) y retirar hacia atrás el colector de

polvo (12).

Para conseguir una potencia de aspiración óptima,

se debe vaciar convenientemente el colector de

polvo (12) y limpiar el filtro (14).

Aspiración externa:

Conectar un aspirador apropiado.

®

, pinturas desgastadas . 3-4

7. Limpieza, mantenimiento

Vaciar el colector de polvo (12)

- Abrir la (13) chapaleta de limpieza.

- Vaciar el colector de polvo (12).

- Retirar el filtro plegable (14)y sacudir el polvo de

lijar adherido o retirarlo con una brocha.

- Al insertar el filtro plegable (14)debe tenerse en

cuenta que encaje convenientemente en las guías

laterales.

Limpiar a fondo la máquina periódicamente.

Aspirar para ello las ranuras de ventilación del

motor con una aspirador o limpiar con aire a presión

las ranuras de ventilación. Para ello, fije bien la

herramienta.

Sustituir la placa de apoyo desgastada

Advertencia:

(p. ej., superficies emplastadas o pintadas, etc.),

acelera el desgaste de la placa de apoyo.

El afilado de material abrasivo

Page 15

- Utilizar la

tornillo de sujeción (15) de la placa de apoyo.

- Retirar la placa de apoyo (2).

- Placa de apoyo (recambio), véase capítulo

accesorios

- Colocar y girar la placa de apoyo (2) hasta que

encaje en el disco de arrastre.

- Atornillar de nuevo el tornillo de fijación (15) y

apretarlo.

llave hexagonal

(10) para desenroscar el

Sustituir el freno de la placa de apoyo / anillo

de freno

Si transcurrido cierto tiempo aumenta el número de

revoluciones en marcha en vacío de la placa de

apoyo, es síntoma de que el anillo de freno (16) está

desgastado y debe sustituirse.

Advertencia:

(p. ej., superficies emplastadas o pintadas, etc.),

acelera el desgaste del anillo de freno.

- Utilizar la

tornillo de sujeción (15) de la placa de apoyo.

- Retirar la placa de apoyo (2).

- Sustituir el anillo de freno antiguo (16) por el anillo

de freno nuevo (véase el capítulo Accesorios);

para ello colocar el nuevo anillo de freno en la

misma posición que el anillo de freno antiguo.

Asegúrese de la correcta posición de la marca en

el anillo de freno.

- Colocar y girar la placa de apoyo (2) hasta que

encaje en el disco de arrastre.

- Atornillar de nuevo el tornillo de fijación (15) y

apretarlo.

El afilado de material abrasivo

llave hexagonal

(10) para desenroscar el

8. Consejos y trucos

No apretar la herramienta con fuerza contra la

superficie de lijado. Una presión excesiva no

mejora la potencia de lijado, sino todo lo contrario.

Para conseguir una potencia de aspiración óptima,

se debe vaciar convenientemente el colector de

polvo (12) y limpiar el filtro plegable (14).

Para conseguir unos resultados óptimos, debe

utilizarse la hoja lijadora adecuada:

Lijado de capas de pintura = P 40

Lijado previo de madera = P 60, P 80

Lijado de acabado de madera = P 100, P 120

Lijado de contrachapados, imprimadores acrílicos,

masilla, pintura = P 180, P 240, P 320, P 400

9. Accesorios

Use solamente accesorios originales Metabo.

Programa completo de accesorios disponible en

www.metabo.com o en el catálogo principal.

ESPAÑOL es

En caso de tener herramientas eléctricas que

necesiten ser reparadas, diríjase, por favor, a su

representante de Metabo. En la página

www.metabo.com encontrará las direcciones

necesarias.

En la página web www.metabo.com puede

descargar listas de repuestos.

11. Protección ecológica

Cumpla lo estipulado por las normativas nacionales

relativas a la gestión ecológica de los residuos y al

reciclaje de herramientas, embalaje y accesorios

usados.

12. Especificaciones técnicas

Notas explicativas sobre la información de la

página 3.

Nos reservamos el derecho a efectuar

modificaciones conforme al avance técnico.

D = Diámetro de la placa de apoyo

P

= Potencia de entrada nominal

1

P

=Potencia suministrada

2

n

= Número de revoluciones con marcha

0

n

0, TB

n

1, TB

s

0

s

0, TB

s

1, TB

S = Diámetro del circuito oscilante

m = Peso sin cable a la red

Las especificaciones técnicas aquí indicadas se

entienden dentro de determinadas tolerancias

(conformes a las normas que rigen actualmente).

en vacío (ruedecilla de ajuste)

= Número de revoluciones con

marcha en vacío

(interruptor de turboalimentación)

= Número de revoluciones con

carga nominal

(interruptor de turboalimentación)

= Número de oscilaciones con marcha

en vacío (rueda de ajuste)

= Número de oscilaciones con marcha

en vacío (interruptor de

turboalimentación)

= Número de oscilaciones

con carga nominal

(interruptor de turboalimentación)

¡Utilice auriculares protectores!

10. Reparación

Las reparaciones de herramientas eléctricas SÓLO

deben efectuarlas técnicos electricistas

especializados.

Si resulta dañado el cable de alimentación de red

de esta máquina, deberá ser sustituido por el

fabricante o su servicio de atención al cliente para

evitar riesgos.

15

Page 16

Metabowerke GmbH,

72622 Nürtingen, Germany

www.metabo.com

170 26 8380 - 0712

Loading...

Loading...