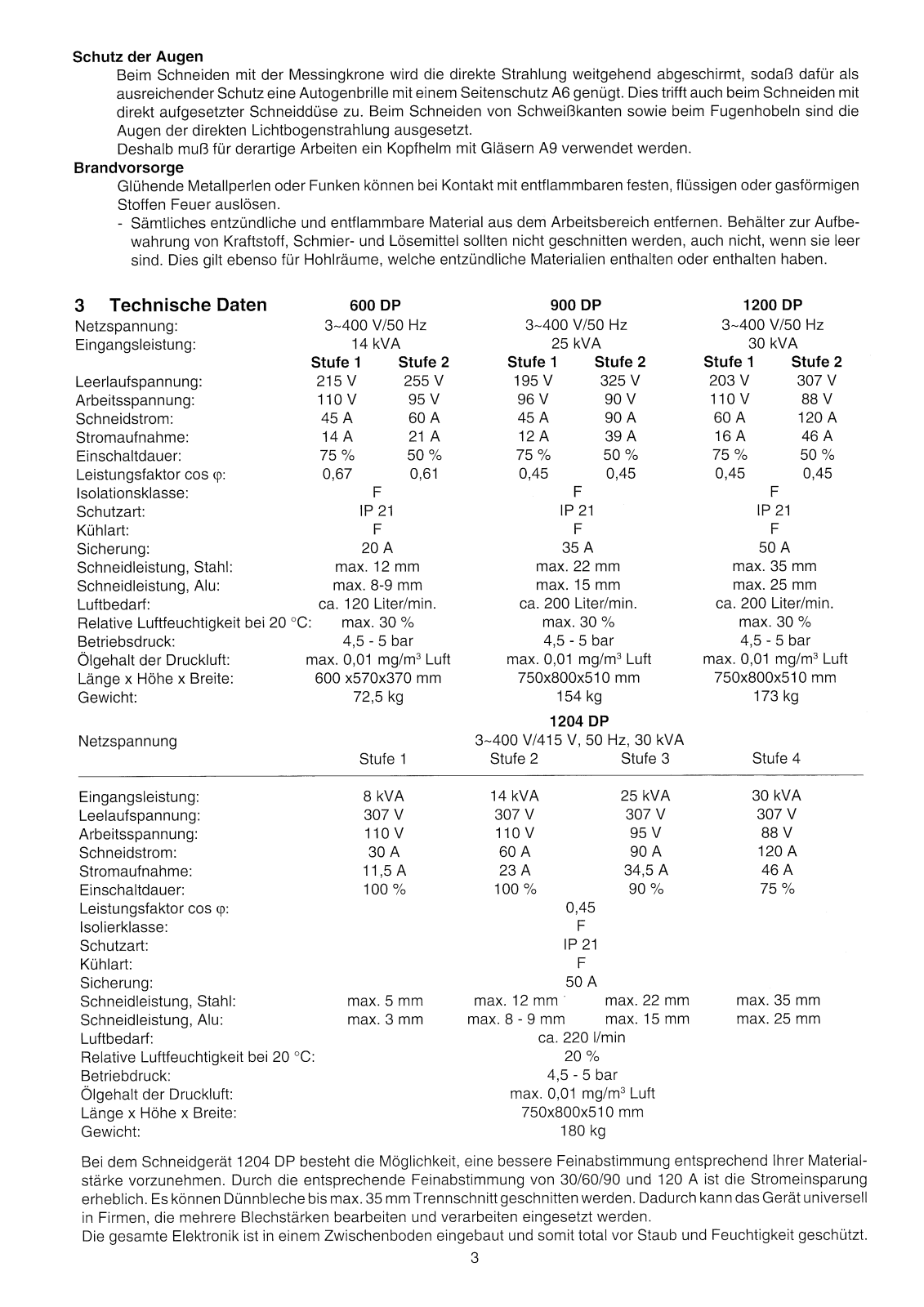

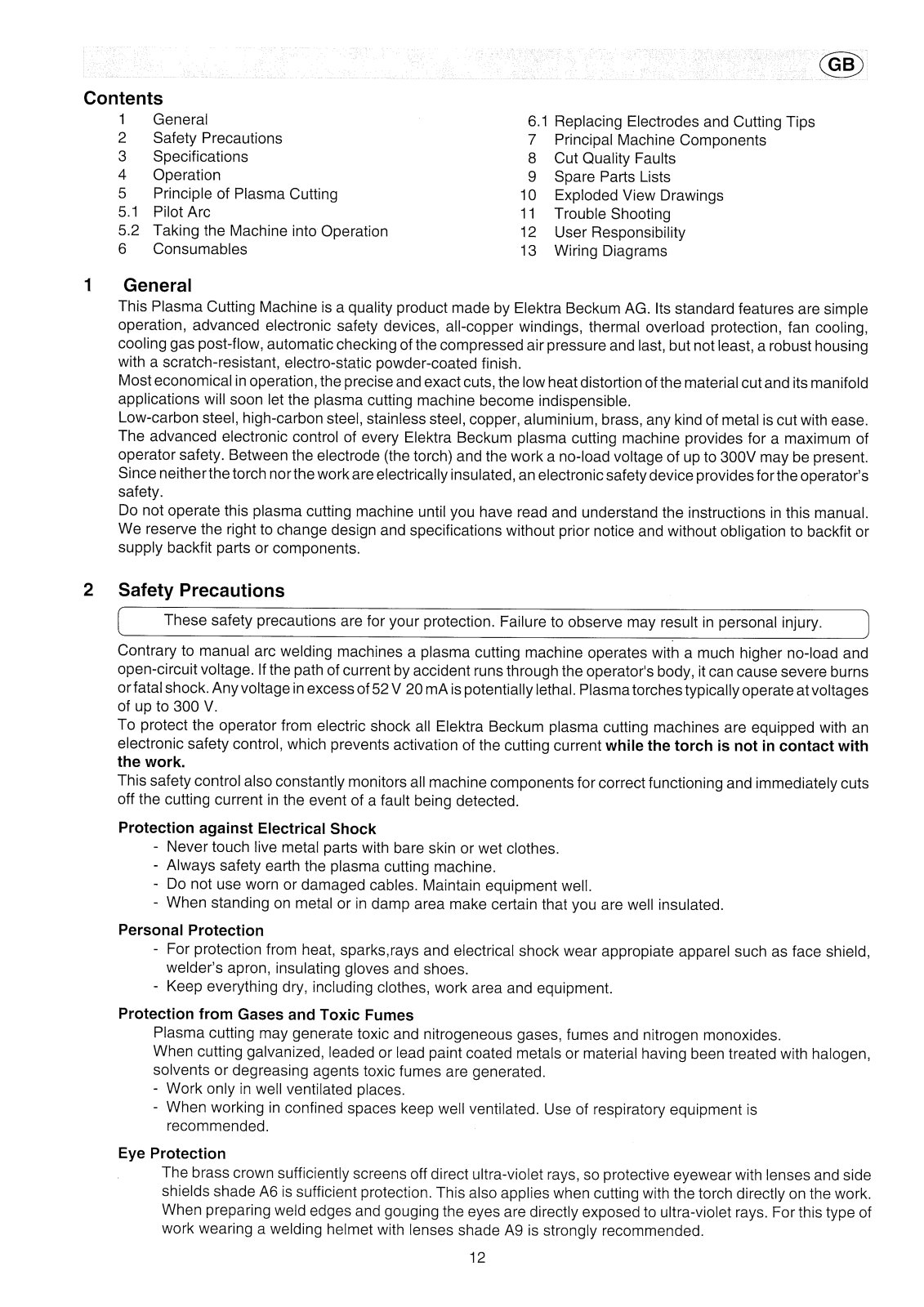

Specifications and Main Features

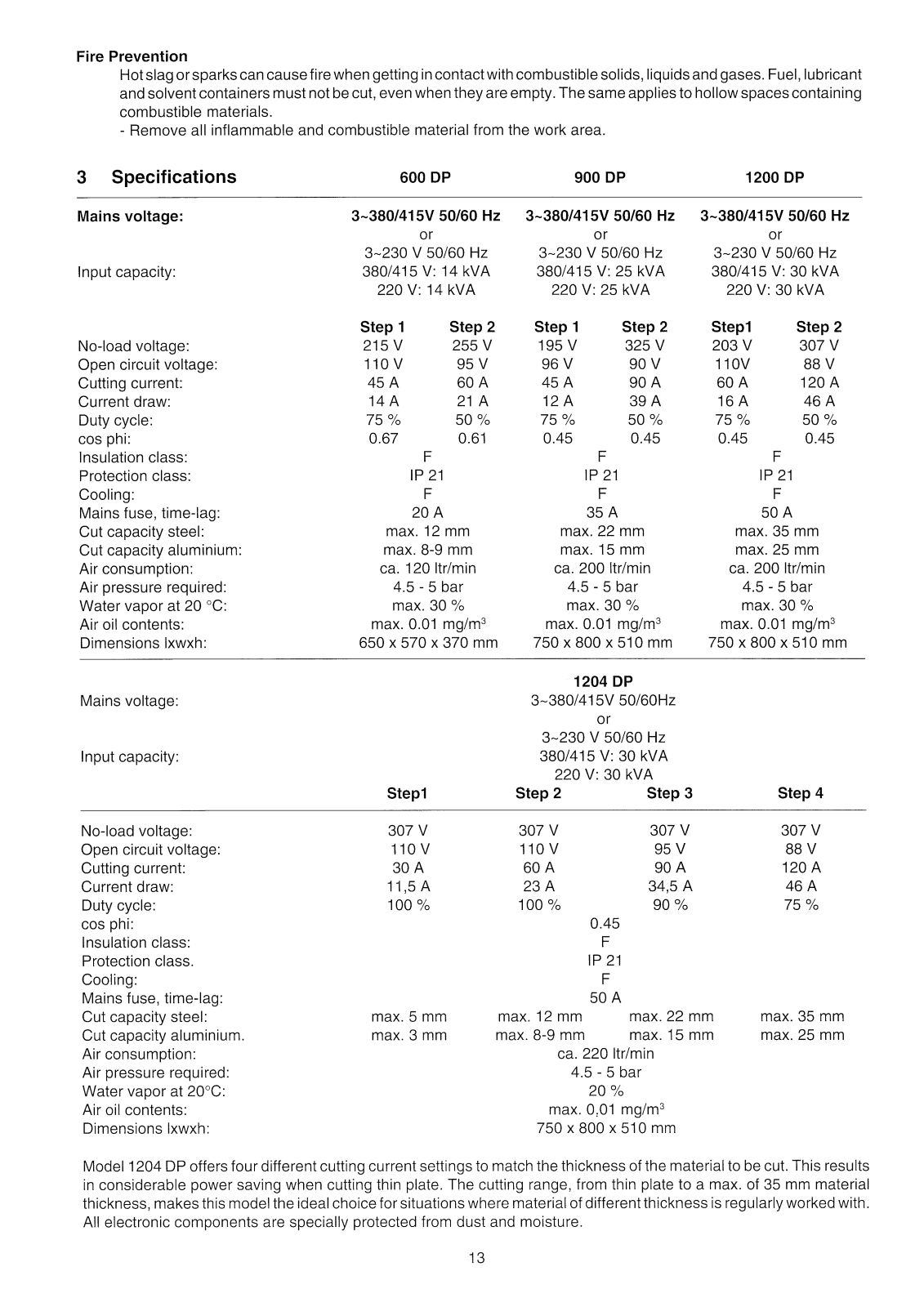

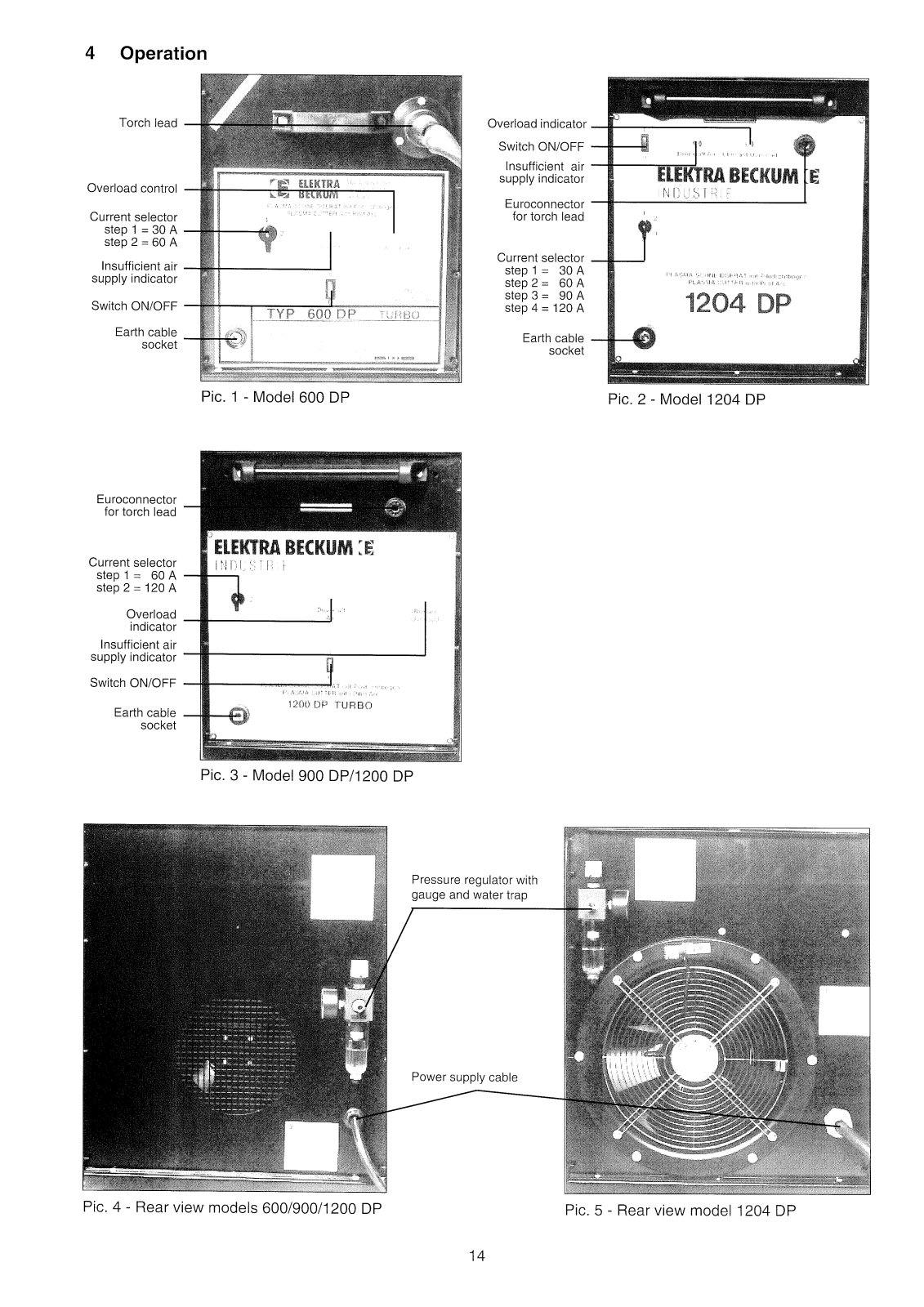

- Model Variants: These include 600 DP, 900 DP, 1200 DP, and 1204 DP.

- Input Voltage Specifications: Equivalent to 3~380/415 V for 1204 DP when alternated to a frequency of 50 Hz alongside a 3,230 V frequency for 600 DP and 900 DP sets.

- Power Requirements: The following list outlines the power requirements by type;

- 600 DP- 14 kVA

- 900 DP- 25 kVA

- 1200 DP- 30 kVA

- 1204 DP- 30 kVA

- Maximum No-load Voltage Supply:

- 600 DP-215V while 255V is used during stage 2

- 900 DP- 195 during stage 1 followed by 325 during stage 2

– 1200 DP- 203.0 at stage 1 and 307 – stage 2

- 1204 DP- 307 volts at all stages

- Working Voltage:

- 600 DP-110 volts during stage 1 and 95 during stage 2

- 900 DP- 96 with 90 to follow (stage 1 and 2 respectively)

- 1200 DP- 110 volts stage 1 and 88 during stage 2

- 1204 DP- stage 1, 110, stage 2, 110, and stage 3 – 95, stage 4 and so forth

- Cutting Current Ratings:

- 600 DP- stage 1 uses 45A while 60A is used in stage 2.

- 900 DP- comparable to its predecessor, 45A was stage one while 90A was stage two.

- 1200 DP- at 1 the rating applied was 60A while the rating for second stage to 120 Amps.

- Max Direct Current (DP): 30A(1st Stage), 60A(2nd Stage), 90A(3rd Stage), 120A(4th Stage).

- Power Consumption:

- DP 600: 14A/21A DP 900: 12A/39A DP 1200: 16A/46A DP 1204: 11.5A/23A/34.5A/46A

- Duty Cycle:

- DP 600: 75% at 1st Stage, 50% at 2nd Stage.

- DP 900: 75% at 1st Stage, 50% at 2nd Stage.

- DP 1200: 75% at 1st Stage, 50% at 2nd Stage.

- DP 1204: 100% at 1st, 2nd, 90% at 3rd and 75% at 4th stage.

- Power Factor:

- DP 600: 0.67 at 1st, 0.61 at 2nd stage, DP 900& 1200: 0.45 Both Stages

DP 1204: 0.45 at Stage 1.

- Insulation Rating:: F.

- Protection Rating: IP 21 which indicates devices that are protected against the ingress of fingers or similar objects and against vertically falling water drops.

- Type of cooling Fan.

- Marks on Mains:

DP 600: 20A;

DP 900: 35A;

DP 1200:50A;

DP 1204: 50A.

- Cutting Range:

DP 600: maximum 12 mm

DP 900: maximum 22 mm

DP 1200: maximum 35 mm

DP 1204: maximum

35 mm (differs by stage)

- Aluminum:

- 600 DP, max. 8-9 mm

- 900 DP, max. 15 mm

- 1200 DP, max. 25 mm

- 1204 DP, max. 25 mm (differs by stage)

- Air consumption:

- 600 DP : 120 Liters/min

- 900 DP : 200 Liters/min

- 1200 DP : 200 Liters/min

- 1204 DP : 220 Liters/min

- Operating pressure: 4.5 – 5 bar.

- Relative humidity: (at 20 degrees C): 30% maximum.

- Air oil content: 0.01 mg/m3 maximum.

- Dimensions:

- 600 DP : 600 x 570 x 370 mm

- 900 DP : 750 x 800 x 510 mm

- 1200 DP : 750 x 800 x 510 mm

- 1204 DP : 750 x 800 x 510 mm

- Weight:

- 600 DP : 72.5 kg

- 900 DP : 154 kg

- 1200 DP : 173 kg

- 1204 DP : 180 kg

Frequently Asked Questions

Q: What is the maximum cutting capacity for steel with the use of the 600 DP model?

A: Steel cutting capacity for this model is 12 mm maximum using the 600 DP model.

Q: How much current does the 1204 DP Model pulls when operating on stage one?

A: The 1204 DP draws 46A on its peak settings, and its first stage is 120A.

Q: What is the recommended air pressure for operation?

A: It is advised that the air pressure for the machine is set within the range of 4.5 to 5 bars.

Q: I can not start the machine what should I do?

A: Ensure that the compressed air supply has the appropriate pressure. You must also check to if all three phases of the power supply are operational.

Q: How often should the electrodes and cutting tips be checked for wear?

A: Electrodes and cutting tips are to be inspected on a frequent basis especially when the cutting quality is noticeably less than satisfactory

Q: Is it possible to use this plasma cutting machine to cut painted materials?

A: The machine in question uses a pilot arc which enables it to cut through painted materials without the need for prior cleaning of the surface.

Q: What safety features does the machine have?

A: The cutting current for the machine is only turned on when the torch makes contact with a workpiece thanks to the advanced electronic safety control inbuilt into the device.

Q: What is the weight of the 900 DP model?

A: For the model 900 DP the weight can be calculated to be around 154 kg.

User Manual

Loading...

Loading...