Mercury 45 Jet 50-55, Marathon-Seapro 60-60, Marathon-Seapro 60 Bigfoot Service Manual

Cleanliness and Care of

Service Manual Outline

Outboard Motor

A marine power product is a combination of many machined, honed, polished and lapped surfaces with tolerances that are measured in the ten thousands of an

inch./mm When any product component is serviced, care

and cleanliness are important. Throughout this manual, it

should be understood that proper cleaning, and protection

of machined surfaces and friction areas is a part of the repair procedure. This is considered standard shop practice

even if not specifically stated.

Whenever components are removed for service, they

should be retained in order. At the time of installation, they

should be installed in the same locations and with the same

mating surfaces as when removed.

Before raising or removing and outboard engine from a

boat, the following precautions should be adhered to:

(1) Check that flywheel is secured to end of crankshaft with

a locknut and lifting eye is threaded into flywheel a minimum of 5 turns.

(2) Connect a hoist of suitable strength to the lifting eye.

In addition, personnel should not work on or under an out-

board which is suspended. Outboards should be attached

to work stands, or lowered to ground as soon as possible.

We reserve the right to make changes to this manual without prior notification.

Refer to dealer service bulletins for other pertinent information concerning the products described in this manual.

Section 1 - General Information & Specifications

Section 2 - Electrical & Ignition

Part A - Ignition System

Part B - Battery, Charging System &

Starting System

Part C - T iming/Synchronizing &

Adjusting

Part D - Wiring Diagrams

Section 3 - Fuel Systems

Part A - Carburetion

Part B - Fuel Pump

Part C - Fuel Enrichment

Part D - Oil Injection

Section 4 - Powerhead

Section 5 - Mid-Section

Part A - Clamp/Swivel Brackets and

Driveshaft Housing

Part B - Power Trim (Design I)

Part C - Power Trim (Design II)

Part D - Power Trim (Design III)

Part E - Power Trim (Design IV)

Part F - Manual Tilt (Design I, II, III)

Part G - Manual Tilt (Design IV)

Section 6 - Lower Unit

Part A - Standard Gear Housing

Part B - 60 Big Foot, 60 SeaPro &

Marathon Gear Housing

Part C - Jet Drive

Section 7 - Outboard Installation/

Attachments

Part A - Ride-Guide Steering -

Throttle/Shift Cables &

Electrical Connections

Part B - Tiller Handle and Co-Pilot

Part C - Rewind Starter

ii

90-817643R1 DECEMBER 1996

Notice

Throughout this publication, “Dangers”, “Warnings” and

“Cautions” (accompanied by the International HAZARD

Symbol ) are used to alert the mechanic to special instructions concerning a particular service or operation that

may be hazardous if performed incorrectly or carelessly.

OBSERVE THEM CAREFULLY!

These “Safety Alerts” alone cannot eliminate the hazards

that they signal. Strict compliance to these special instructions when performing the service, plus “Common Sense”

operation, are major accident prevention measures.

! DANGER

DANGER - Immediate hazards which WILL result in severe personal injury or death.

! WARNING

WARNING - Hazards or unsafe practices which COULD

result in severe personal injury or death.

!

Hazards or unsafe practices which could result in minor personal injury or product or property damage.

!

CAUTION

We could not possibly know of and advise the service trade

of all conceivable procedures by which a service might be

performed and of the possible hazards and/or results of

each method. We have not undertaken any such wide evaluation. Therefore, anyone who uses a service procedure

and/or tool, which is not recommended by the manufacturer, first must completely satisfy himself that neither his nor

the products safety will be endangered by the service procedure selected.

All information, illustrations and specifications contained in

this manual are based on the latest product information

available at the time of publication. As required, revisions

to this manual will be sent to all dealers contracted by us

to sell and/or service these products.

It should be kept in mind, while working on the product, that

the electrical system and ignition system are capable of violent and damaging short circuits or severe electrical

shocks. When performing any work where electrical terminals could possibly be grounded or touched by the mechanic, the battery cables should be disconnected at the

battery.

Any time the intake or exhaust openings are exposed during service they should be covered to protect against accidental entrance of foreign material which could enter the

cylinders and cause extensive internal damage when the

engine is started.

Notice to Users of This

Manual

This service manual has been written and published by the

Service Department of Mercury Marine to aid our dealers’

mechanics and company service personnel when servicing the products described herein.

It is assumed that these personnel are familiar with the

servicing procedures of these products, or like or similar

products manufactured and marketed by Mercury Marine,

that they have been trained in the recommended servicing

procedures of these products which includes the use of

mechanics’ common hand tools and the special Mercury

Marine or recommended tools from other suppliers.

It is important to note, during any maintenance procedure

replacement fasteners must have the same measurements and strength as those removed. Numbers on the

heads of the metric bolts and on the surfaces of metric nuts

indicate their strength. American bolts use radial lines for

this purpose, while most American nuts do not have

strength markings. Mismatched or incorrect fasteners can

result in damage or malfunction, or possibly personal injury. Therefore, fasteners removed should be saved for reuse in the same locations whenever possible. Where the

fasteners are not satisfactory for re-use, care should be

taken to select a replacement that matches the original.

90-817643R1 DECEMBER 1996

i

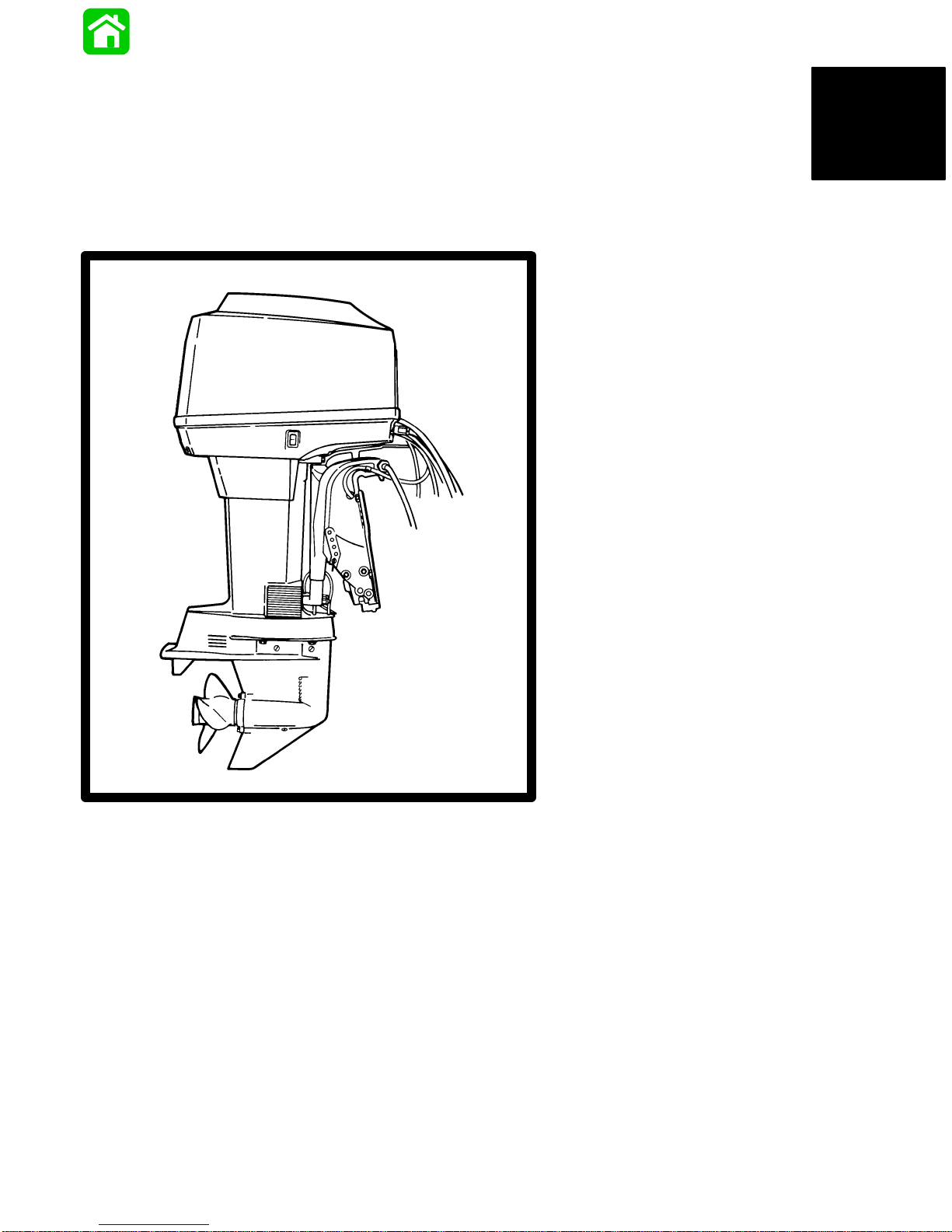

GENERAL INFORMATION

and SPECIFICATIONS

1

50557

Table of Contents

Propeller Information 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

How To Use This Manual 1-1. . . . . . . . . . . . . . . . . . . . . . . .

Page Numbering 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master Specifications 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Powerhead 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cowl Removal 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filling Oil Injection System 1-5. . . . . . . . . . . . . . . . . . . .

Propeller Selection 1-6. . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller Installation 1-6. . . . . . . . . . . . . . . . . . . . . . . . .

Trim “In” Angle Adjustment 1-7. . . . . . . . . . . . . . . . . . .

Propeller Information Chart 1-8. . . . . . . . . . . . . . . . . . .

50/55 models 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

60 models 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller Information Chart 1-9. . . . . . . . . . . . . . . . . . .

60 Big foot, 60 SeaPro/Marathon 1-9. . . . . . . . . . .

50-60 Models 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stainless Steel Race Propellers –

Available from Mercury Performance

Products 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information: 1-9. . . . . . . . . . . . . . . . . . . . . .

Power Trim System

(Models with Power Trim) 1-10. . . . . . . . . . . . . . . . . . .

General Information 1-10. . . . . . . . . . . . . . . . . . . . . .

Checking Trim System Fluid Level 1-11. . . . . . . . .

Trimming (Models with Power Trim) 1-11. . . . . . . . . . .

Trimming Outboard “Out” (“Up”) 1-11. . . . . . . . . . .

Trimming Outboard “In” (“Down”) 1-11. . . . . . . . . .

Trim Tab Adjustment 1-12. . . . . . . . . . . . . . . . . . . . . . . .

Boat Performance 1-12. . . . . . . . . . . . . . . . . . . . . . . . . .

Test Instructions 1-12. . . . . . . . . . . . . . . . . . . . . . . .

Page

Page

Lubrication Points 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ride Guide Steering Cable and Pivot

Point Lubrication 1-15. . . . . . . . . . . . . . . . . . . . . . .

Gear Housing Lubrication 1-16. . . . . . . . . . . . . . . . .

Salt Water Corrosion - Gear Housing

Bearing Carrier and Cover Nut 1-16. . . . . . . . . .

Periodic Inspection 1-17. . . . . . . . . . . . . . . . . . . . . . . . .

Flushing Outboard Cooling System 1-17. . . . . . . . . . .

Following Complete Submersion 1-18. . . . . . . . . . . . .

Salt Water Submersion (Special

Instructions) 1-18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Submerged While Running (Special

Instructions) 1-18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Submerged Engine (Fresh Water)

(Plus Special Instructions) 1-18. . . . . . . . . . . . . .

Out-of-Season Outboard Storage 1-19. . . . . . . . . . . . .

Out-of-Season Battery Storage 1-19. . . . . . . . . . . . . . .

How Weather Affects Engine Performance 1-20. . . . .

Conditions Affecting Operation 1-21. . . . . . . . . . . . . . .

Detonation: Causes and Prevention 1-21. . . . . . . . . .

Compression Check 1-21. . . . . . . . . . . . . . . . . . . . . . . .

Water Pressure Check 1-22. . . . . . . . . . . . . . . . . . . . . .

Serial Number Location 1-22. . . . . . . . . . . . . . . . . . . . .

Painting Procedures 1-23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Decal Application 1-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-0 - GENERAL INFORMA TION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

Propeller Information

For in-depth information on marine propellers and boat

performance – written by marine engineers – see your Authorized Dealer for the illustrated “What Y ou Should Know

About Quicksilver Propellers... and Boat Performance Information” (Part No. 90-86144).

How To Use This Manual

Section Section Heading

1 General Information and Specifications

2 Electrical & Ignition

3 Fuel Systems

4 Powerhead

5 Mid-Section

6 Lower Unit

7 Outboard Installation/Attachments

The manual is divided into SECTIONS (shown, right) which

represents major components and systems.

Some SECTIONS are further divided into PARTS. Each

P ART has a title page. A “T able of Contents” for the particular PART is printed on the back of the title page.

SECTIONS and P AR TS are listed on the “Service Manual

Outline” sheet which immediately follows the cover of this

book.

EXAMPLE:

EXAMPLE:

Page Numbering

Two number groups appear at the bottom of each page.

The example, below, is self-explanatory.

90-817643R2 DECEMBER 1996

Revision No. 2

Month of Printing

Year of Printing

LOWER UNIT - 6A-7

Section Description

Section Number

Part of Section Letter

Page Number

GENERAL INFORMATION and SPECIFICATIONS - 1-190-817643R1 DECEMBER 1996

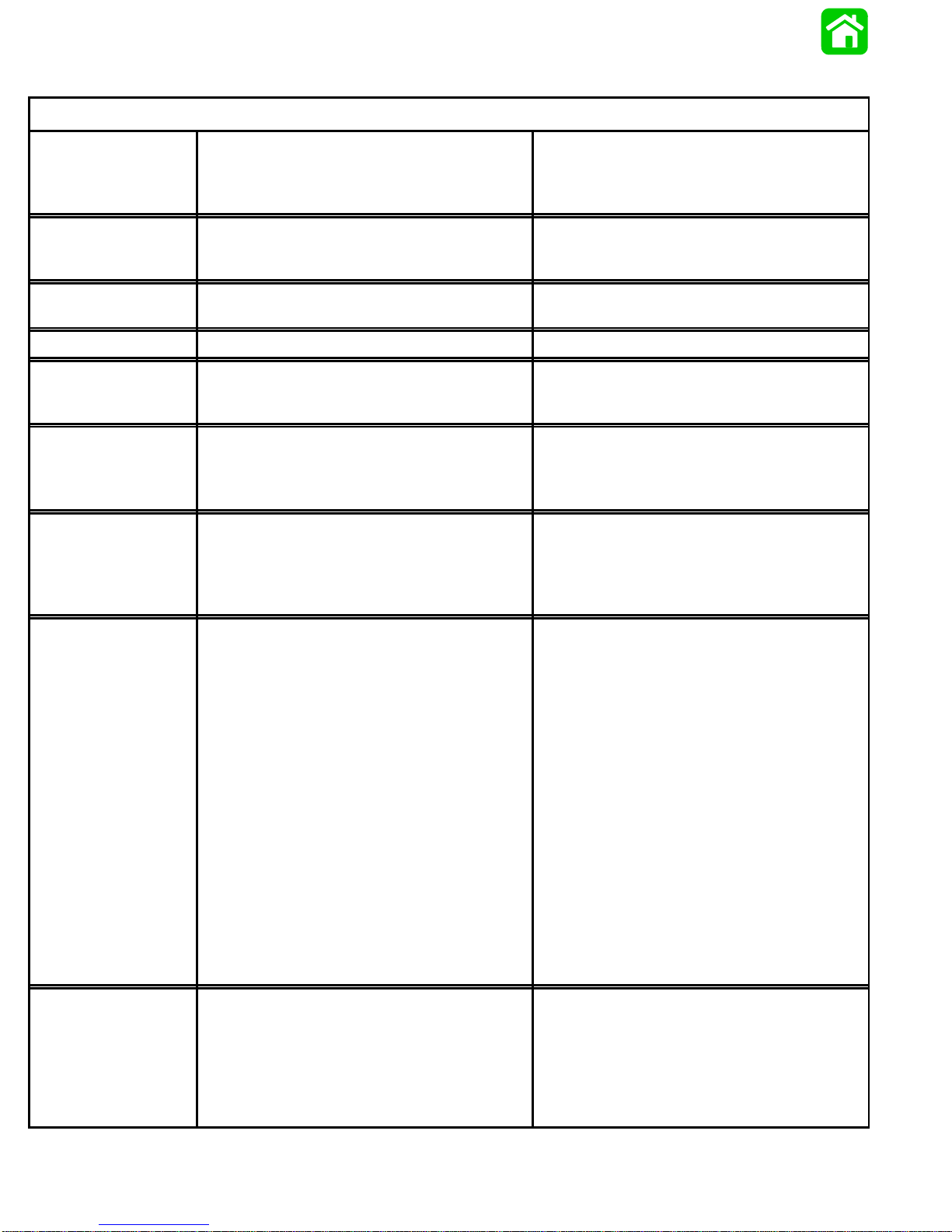

Master Specifications

Model 45 Jet/50/55 Marathon-Seapro/60/60 Marathon-Seapro/60 Bigfoot

HORSEPOWER

(KW)

OUTBOARD

WEIGHT

CYLINDER

BLOCK

STROKE Length 2.520 in. (64.008mm)

CYLINDER

BORE

PISTON Piston Type

REEDS Reed Stand 0pen (Max.)

Model 50

Model 55

Model 60

Model 45 Jet

Electric Start (ELPTO)

(ELO)

Manual Start (ML)

Type

Displacement

Diameter (Std)

Taper/Out of Round Maximum

Bore Type

Standard

0.015 in. (0.381mm) Oversize

0.030 in. (0.762) Oversize

Reed Stop (Max.)

Reed Thickness

– 45 Jet/50/60

– 55

50 (37)

55 (41)

60 (45)

60 (45)

217.0 lbs. (98.4kg)

213.0 lbs. (96.6kg)

213.0 lbs. (96.6kg)

Two-Stoke Cycle – Loop Charged

51.8 cu. in. (849cc)

2.955 in. (75.057mm)

0.003 in. (0.076mm)

Cast Iron

Aluminum

2.950 in. (74.93 mm)

2.965 in. (75.31 mm)

2.980 in. (75.69 mm)

0.020 in. (0.50mm)

Not Adjustable

0.008 in. (0.203mm)

0.010 in. (0.254mm)

GEAR

HOUSING

FUEL

SYSTEM

50/55/60

Gear Ratio

Gearcase Capacity

Forward Gear - No. of Teeth

Pinion Gear - No. of Teeth

Pinion Height

Forward Gear Backlash

Water Pressure

– @ Idle

– @ WOT

60 SeaPro/Marathon, 60 Bigfoot

Gear Ratio

Gearcase Capacity

Forward Gear - No. of Teeth-Type

Pinion Gear - No. of Teeth-Type

Pinion Height

Forward Gear Backlash

Water Pressure @ RPM

Fuel

Recommended Gasoline

Recommended Oil

Gasoline/Oil Ratio

Fuel Pressure – @ Idle

– @ WOT

1.64:1

11.5 fl. oz. (340ml)

23

14

0.025 in. (0.64mm)

0.013 in. – 0.019 in.

(0.33mm – 0.48mm)

1 – 3 PSI

7 – 12 PSI

2.3:1

22.5 fl. oz. (655ml)

30

13

0.025 in. (0.64mm)

0.012 in. to 0.019 in. (0.30mm to 0.48mm)

10 to 15 PSI (69 to 103 kPa) @ 5250 RPM

Pre-Mixed Gasoline and Oil

Unleaded 87 Octane Minimum

Quicksilver TC-W II or TC-W3 2 Cycle

Outboard Oil

50:1 (25:1 Break-In)

3-1/2 PSI

6 PSI

1-2 - GENERAL INFORMA TION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

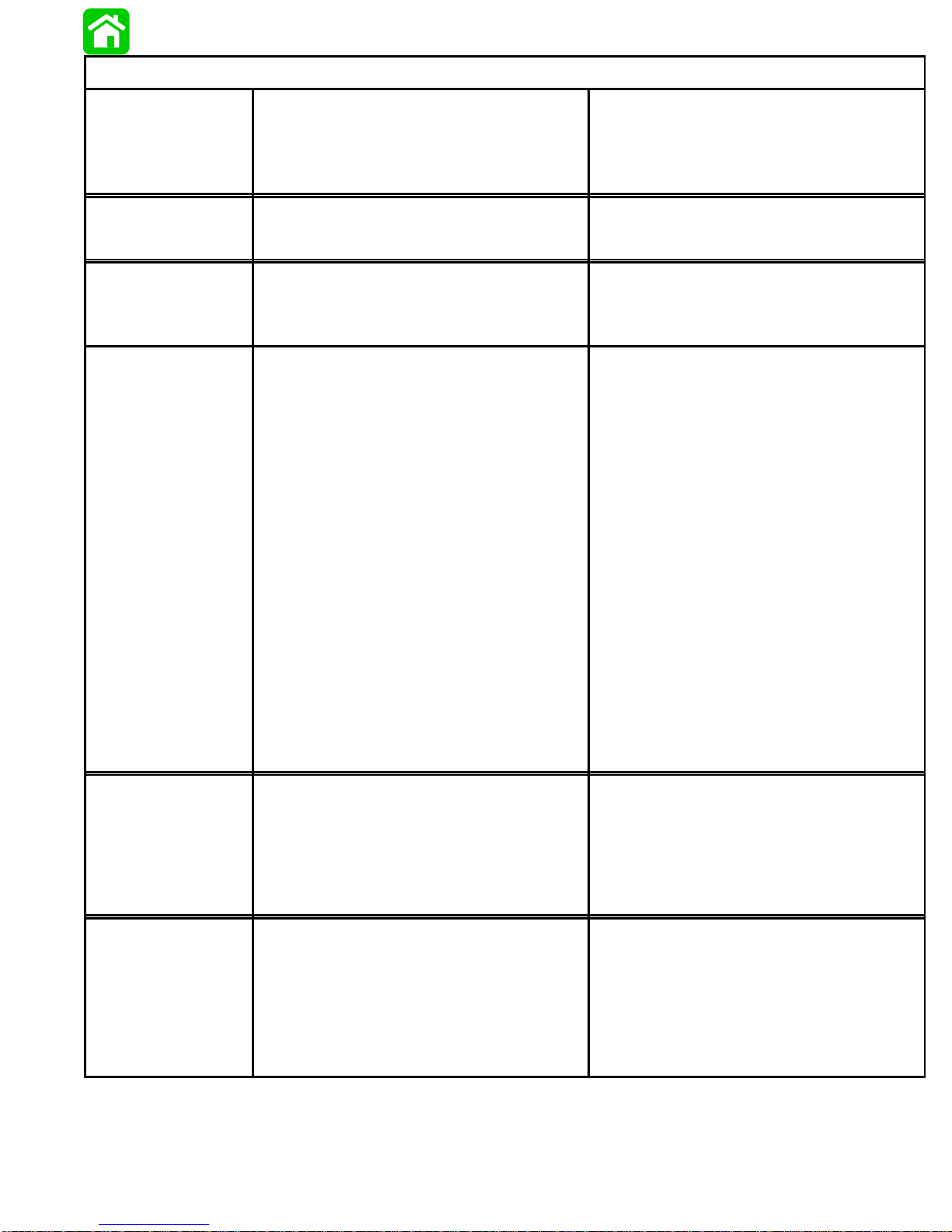

Model 45 Jet/50/55 Marathon-Seapro/60/60 Marathon-Seapro/60 Bigfoot

STARTING

SYSTEM

IGNITION

SYSTEM

CHARGING

SYSTEM

C

A

R

B

U

R

E

T

O

R

Manual Start – All Models

Electric Start – Optional – All Models

Starter Draw (Under Load)

Battery Rating

Type

Spark Plug Type

Spark Plug Gap

Alternator Output

Electric Models

Manual Models (Not Regulated)

Idle RPM

Wide Open Throttle (WOT) RPM

Idle Mixture Screw Adjustment

(Preset - Turns Out)

Model 50

All Other Models

Float Adjustment

Float Level

Recoil Starter

125 Amperes

Min. Reserve Cap. Rating of 100 Min. and

CCA of 350 Amperes

Capacitor Discharge

NGK BP8H-N-10

0.040 in. (1.0mm)

16 Amperes @ 3000 RPM

14 Amperes @ 300 RPM

9 Amperes @ 3000 RPM

675 ± 25

5000 – 5500

1-1/8 ± 1/4

1-1/2 ± 1/4

7/16 in. (11.2mm)

OIL

INJECTION

T

I

M

I

N

G

Main Jet

– Model 50 (WME – 43)

– Model 55/60 Seapro-Marathon

(WME – 44)

– Model 45 Jet/60 (WME – 45)

Vent Jet

– Model 50 (WME – 43)

– Model 55/60 Seapro-Marathon

(WME – 44)

– Model 45 Jet/60 (WME – 45)

Recommended Oil

Oil Tank Capacity/Approx. Time

Reserve Capacity/Approx. Time

Output @ 1500 RPM for 10 Minutes

with Pump @ Full Open

Idle

Maximum BTDC

@ Cranking Speed

– Model 50/60

– Model 55/60 Seapro-Marathon

@ 5000 RPM

– Model 50/60

– Model 55/60 Seapro-Marathon

.048 in.

.060 in.

.062 in.

.090 in.

None

.090 in.

Quicksilver TC-W II or TC-W 3

3.0 qts. (2.8L) 7 hrs.

14.5 fl. oz. (0.43L) 1/2 hr.

10.0cc ± 3cc

2° – 6° ATDC

24° BTDC

18° BTDC

22° BTDC

16° BTDC

GENERAL INFORMATION and SPECIFICATIONS - 1-390-817643R1 DECEMBER 1996

Powerhead

Specifications

Block

Type 3 Cylinder, 2 Cycle. . . . . . . . . . . . . . . . . . .

Displacement

50/55/60 Horsepower 51.8 cu in. (849 cc).

Reed Block

Reed Stop Opening (Max.) 0.020 in. . . . . . . .

(0.50 mm)

Crankshaft

Runout (Max.) 0.003 in. (0.08 mm). . . . . . . . . .

Taper (Max.) 0.003 in. (0.08 mm). . . . . . . . . . .

Firing Order 1-3-2. . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Bore

Dia. Standard 2.955 in. (75.057 mm). . . . . . . . . . .

Dia. .015 in. Oversize 2.970 in. (75.438 mm). . . .

Dia. .030 in. Oversize 2.985 in. (75.819 mm). . . .

Out of Round (Max.) 0.003 in. (0.076 mm). . . . .

Taper (Max.) 0.003 in. (0.076 mm). . . . . . . . . . . .

Piston

Dia. Standard 2.950 in. (74.93 mm). . . . . . . . . . .

Dia. .015 in. Oversize 2.965 in. (75.31 mm). . . .

Dia. .030 in. Oversize 2.980 in. (75.69 mm). . . .

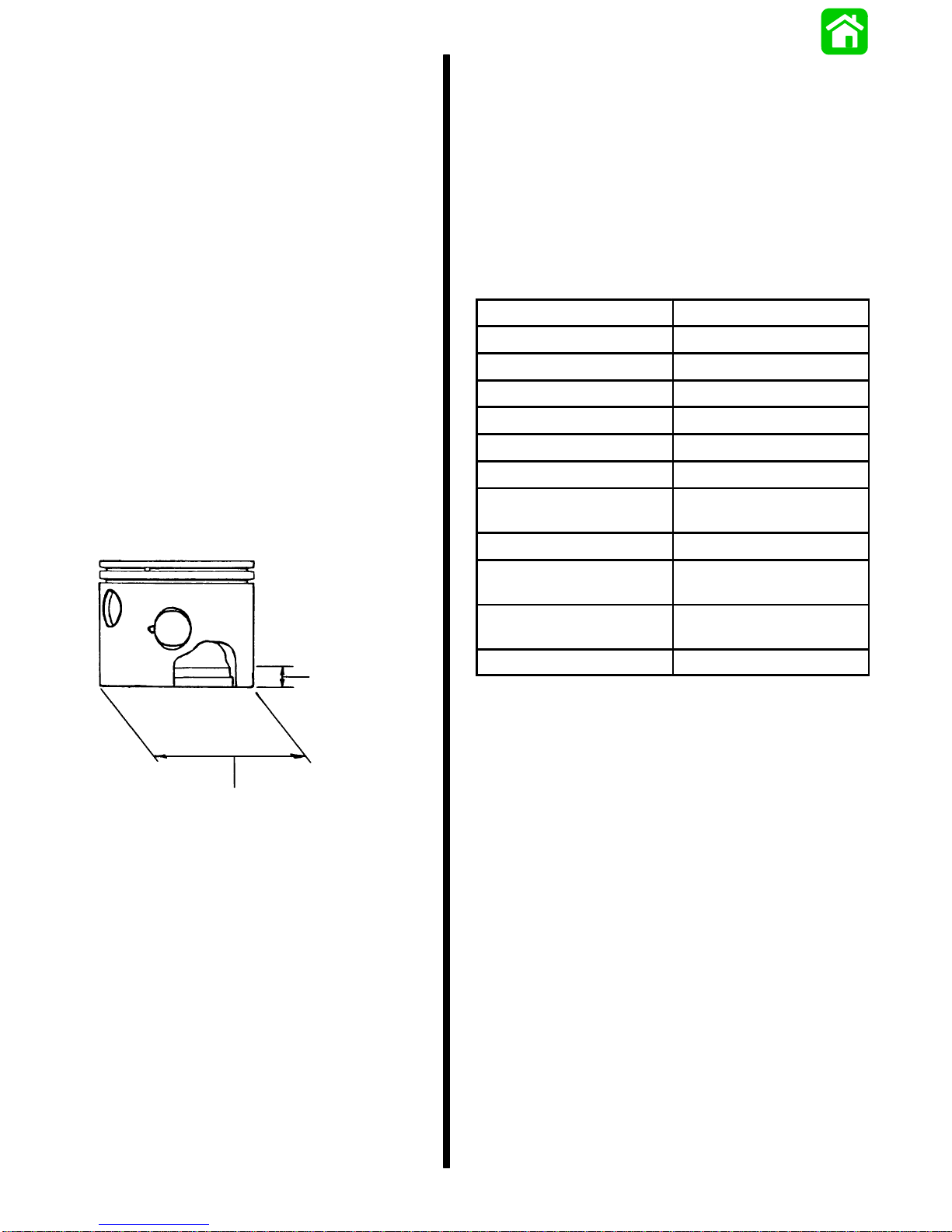

IMPORTANT: Measure piston skirt at right angle (90°)

to piston pin center line, 0.50 in. (12.7mm) up from bottom edge of skirt.

0.50 in.

(12.7mm)

Special Tools

Description Part Number

Flywheel Holder 91–52344

Protector Cap 91-24161

Flywheel Puller 91-73687A1

Lifting Eye 91-90455

Piston Ring Expander 91-24697

Piston Pin Tool 91-74607A2

Lock Ring Installation

Tool

Powerhead Stand 91-25821A1

*Torque Wrench (0–200

lb. ft.)

*Torque Wrench (0–150

lb. in.)

Compression Tester 91-29287

*May be Obtained Locally

91-77109A1

91-32610

91-66274

PISTON PISTON SKIRT CYLINDER BORE

SIZE DIAMETER FINISH HONE

Standard 2.950 in. 2.955 in.

Piston (74.93 mm) (75.057mm)

0.015 in. 2.965 in. 2.970 in.

(0.381 mm) (75.31 mm) (75.438 mm)

Oversize

0.030 in. 2.980 in. 2.985 in.

(0.752 mm) (75.69 mm) (75.819 mm)

Oversize

1-4 - GENERAL INFORMA TION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

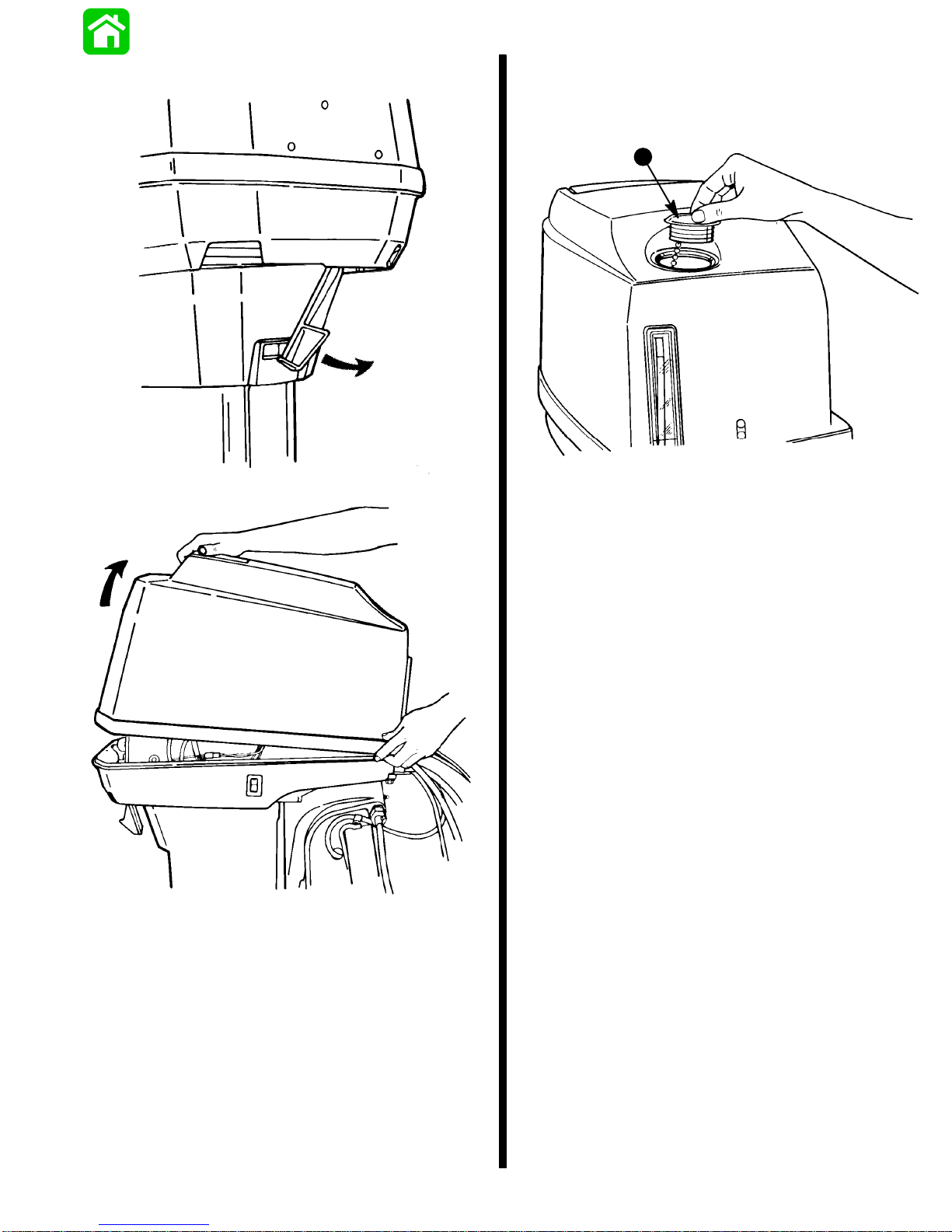

Cowl Removal

Filling Oil Injection System

Remove fill cap (a) from the oil tank and fill tank with oil. Retighten the fill cap.

a

50553

50554

50552

Use Quicksilver NMMA Certified TC-W3 or TC-WII 2-Cycle

Outboard Oil.

• Quicksilver Certified TC-W3 Outboard Oil is a higher

grade oil that provides increased lubrication and extra

resistance to carbon buildup when used with good or varying grades of gasoline.

• Quicksilver Certified TC-WII Outboard Oil is an industry

leading oil that provides superior outboard lubrication

and resistance to carbon buildup when used with good

grades of gasoline.

Periodically consult with your dealer to get the latest gasoline and oil recommendations. If Quicksilver 2-Cycle Outboard Oil is not available, substitute a 2-Cycle outboard

manufacturers oil that is NMMA Certified TC-W3 or TCWII, or another brand of 2-Cycle outboard oil that is NMMA

Certified TC-W3 or TC-WII. The use of an inferior 2-Cycle

outboard oil can reduce engine durability. Damage from

use of inferior oil may not be covered under the limited warranty .

GENERAL INFORMATION and SPECIFICATIONS - 1-590-817643R1 DECEMBER 1996

Propeller Selection

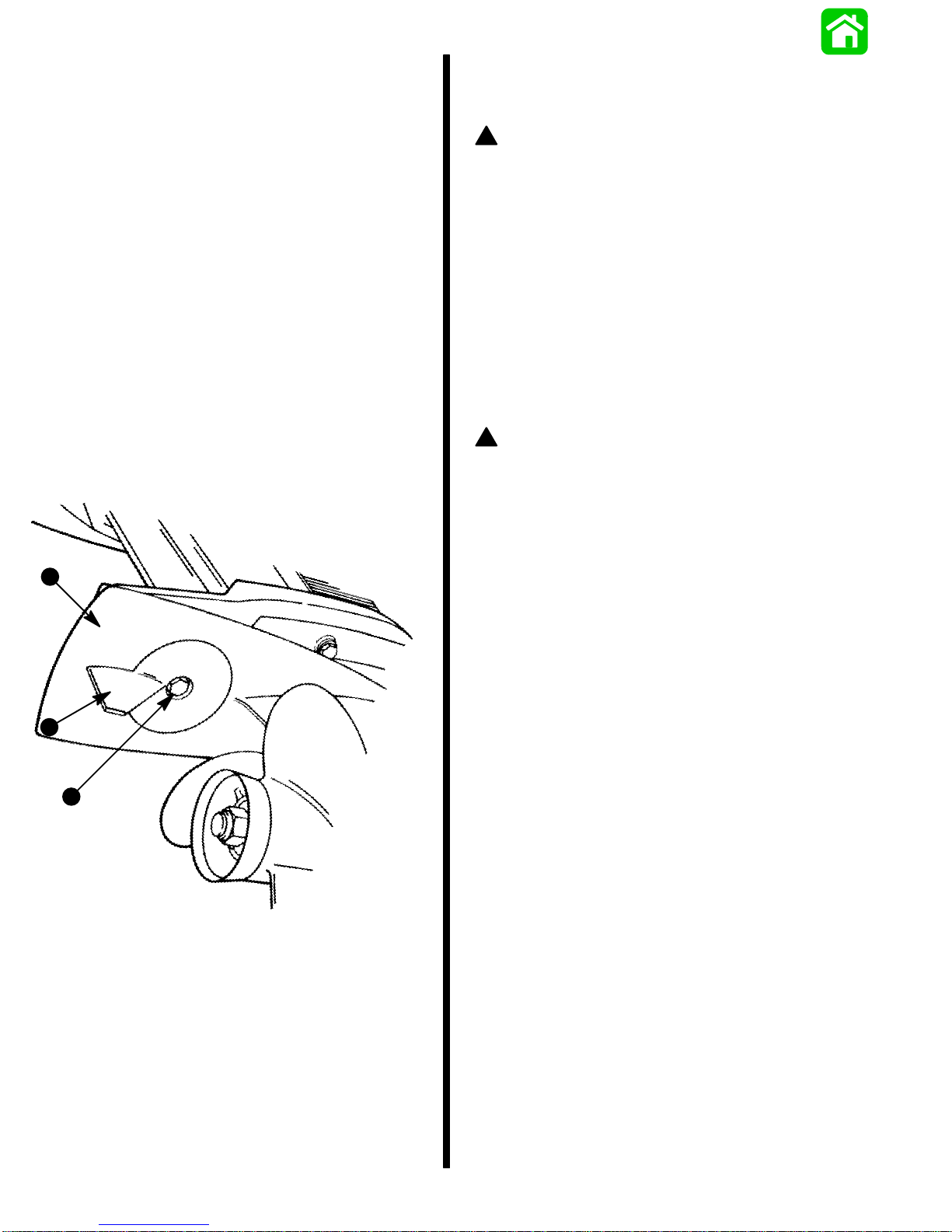

Propeller Installation

1. Select a propeller that will allow the engine to operate

at or near the top of the recommended full throttle RPM

range (listed in “Specifications,” preceding) with a normal load. Maximum engine speed (RPM) for propeller

selection exists when boat speed is maximum and trim

is minimum for that speed. (High RPM, caused by an

excessive trim angle, should not be used in determining correct propeller.) Normally, there is a 150-350

RPM change between propeller pitches.

2. If full throttle operation is below the recommended

range, the propeller MUST BE changed to one with a

lower pitch to prevent loss of performance and possible engine damage.

3. For better acceleration, such as is needed in water

skiing, changing to a different pitch to increase the

engine speed to 500 RPM above the recommended

range is advised. Continuous operation above the recommended maximum RPM, however, is not permissible.

4. After initial propeller installation, the following common

conditions may require that the propeller be changed

to a lower pitch:

a. Warmer weather and great humidity will cause an

RPM loss.

b. Operating in a higher elevation causes an RPM

loss.

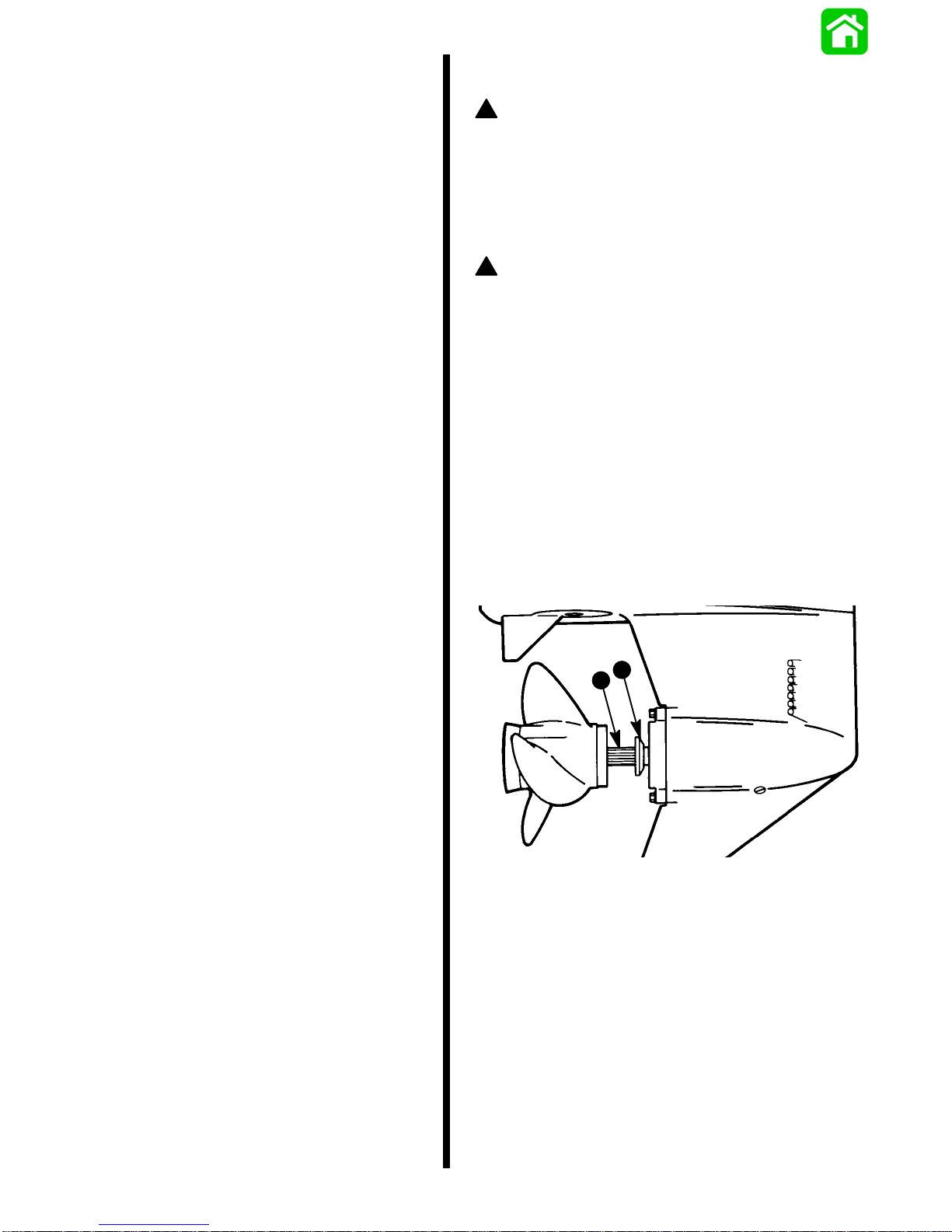

! WARNING

T o avoid accidental starting, which could result in personal injury, remove spark plug leads from spark

plugs before working near propeller. Place a block of

wood between the anti-ventilation plate and propeller

to protect hands from propeller blades while tightening propeller nut.

!

CAUTION

If the propeller moves forward-and-aft on the propeller

shaft (is loose), retighten the propeller nut. Operation

with a loose propeller could cause damage to the

thrust hub and gear housing during acceleration, deceleration or when shifting gears.

IMPORTANT: To assure that the propeller remains secure on the shaft during the season, periodically

check propeller shaft nut for tightness.

1. To aid in future removal of the propeller, liberally coat

the propeller shaft spline with one of the following

Quicksilver lubricants:

– Anti-Corrosion Grease

– 2-4-C Marine Lubricant

– Special Lubricant 101

2. Place forward thrust hub on propeller shaft.

c. Operating with a damaged propeller or a dirty boat

bottom or gear housing will cause an RPM loss.

d. Operation with an increased load (additional pas-

sengers, equipment, pulling skiers, etc.).

a - Thrust Hub

b - Propeller Shaft

a

b

50551

1-6 - GENERAL INFORMA TION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

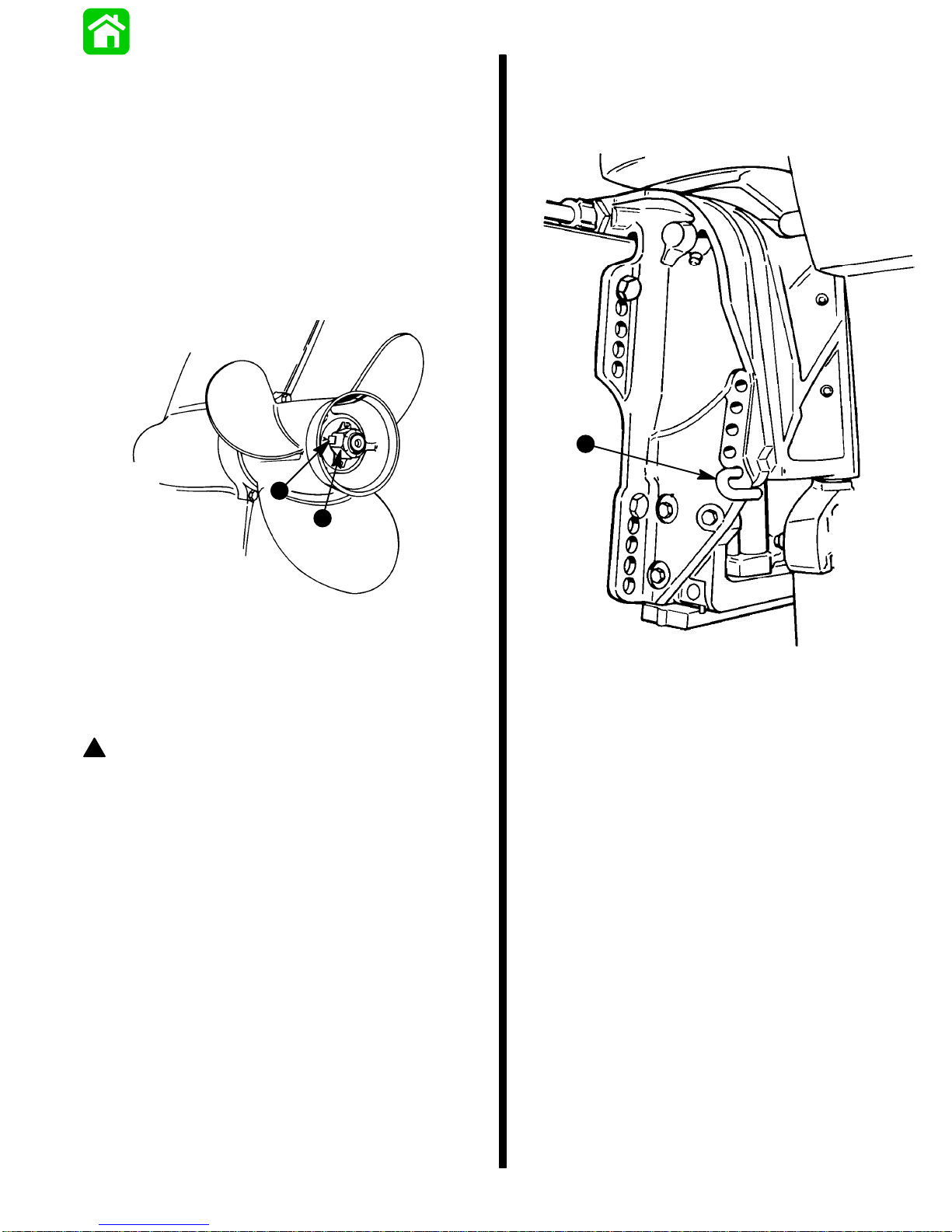

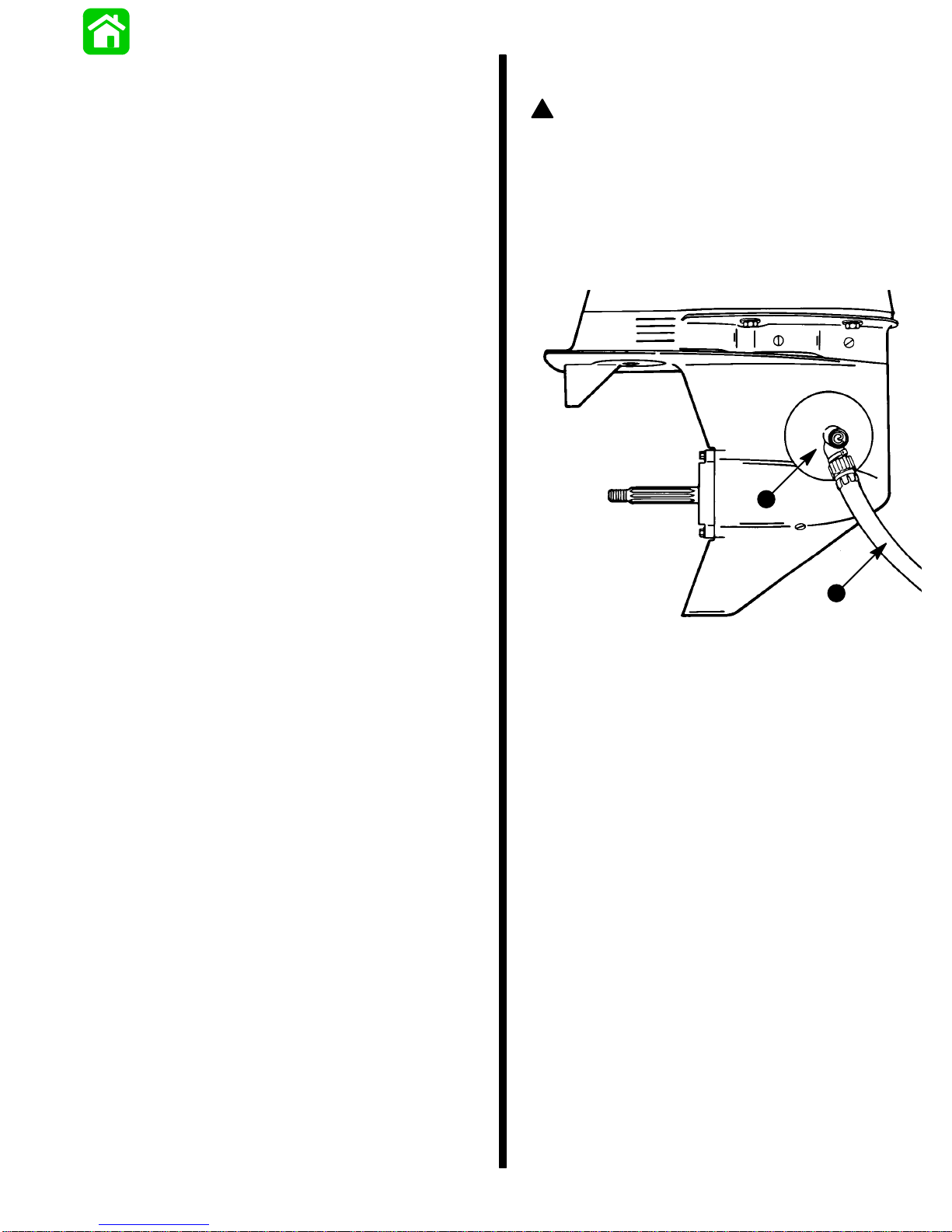

3. While aligning splines, place Quicksilver propeller and

tab washer on propeller shaft in this order.

4. T o prevent propeller from rotating, place a flat block of

wood between the anti-ventilation plate and the

propeller.

5. Thread propeller nut on propeller shaft, tighten securely with wrench [minimum of 55 lb. ft. (74.5 N·m) of

torque] and bend on tab washer to secure propeller

nut.

6. After first use, bend the tab straight, retighten propeller

nut [minimum of 55 lb. ft. (74.5 N⋅m) of torque] and

again bend tab washer to secure nut. Check propeller

periodically for tightness.

c

Water test the boat not using the trim adjustment pin. If undesirable and/or unsafe steering conditions are experienced (boat runs with nose down), install trim adjustment

pin in proper hole to prevent unsafe handling characteristics.

a

d

51119

c - Tab Washer

d - Propeller Nut

Installing and Removing Propeller

Trim “In” Angle Adjustment

! WARNING

Operating some boats with outboard trimmed to the

full “in” trim angle [not using trim adjustment bolt (a)]

at planing speed will cause undesirable and/or unsafe

steering conditions. Each boat must be water tested

for handling characteristics after outboard installation

and after any trim adjustments.

IMPORTANT: Some boat/outboard combinations, that

do not use the trim adjustment pin (a) and are trimmed

to the full “in” trim angle, will not experience any undesirable and/or unsafe steering conditions during planing speed. Thus, not using trim adjustment pin may be

desired. However, some boats with outboard trimmed

to the full “in” trim angle at planing speeds will cause

undesirable and/or unsafe steering conditions. If

these steering conditions are experienced, under no

circumstances should the outboard be operated without the trim adjustment pin and without the pin adjusted in the proper holes to prevent unsafe handling

characteristics.

50157

GENERAL INFORMATION and SPECIFICATIONS - 1-790-817643R1 DECEMBER 1996

Propeller Information Chart

50/55 MODELS

Wide Open Throttle RPM: 5000-5500

Recommended Transom Height: Short Shaft 16-1/2 in. (41.9 cm), Long Shaft 21 in. (53.3 cm)

Right Hand Rotation

Gear Reduction: 1.64:1

Thrust Hub: 73345A 1

Approx. Approx. Speed

No. of Gross Boat Boat Range Propeller

Diameter Pitch Blades Material Wgt. (Lbs.) Length (MPH) Part Number

10″ 19″ 3 Alum Up to 700 Up to 14′ 48-55 48-73146A400

10″ 17″ 3 Alum Up to 800 Up to 15′ 44-51 48-73144A400

10″ 16″ 3 Steel 700-900 Up to 15′ 41-48 48-91818A500

10″ 16″ 3 Alum 700-900 Up to 15′ 41-48 48-73142A400

10.13″ 15″ 3 Steel 800-1100 13′ to 15′ 38-45 48-76232A500

10.13″ 15″ 3 Alum 800-1100 13′ to 15′ 38-45 48-73140A400

10.38″ 14″ 3 Alum 900-1300 14′ to 16′ 35-41 48-816706A40

10-1/4″ 14″ 3 Steel 900-1300 14′ to 16′ 35-41 48-76230A500

10.38″ 13″ 3 Steel 1000-1500 14′ to 17′ 32-38 48-76228A500

10-1/2″ 13″ 3 Alum 1000-1500 14′ to 17′ 32-38 48-816704A40

10.63″ 12″ 3 Steel 1100-1700 15′ to 17′ 28-34 48-79792A500

10-3/4″ 12″ 3 Alum 1100-1700 15′ to 17′ 28-34 48-816702A40

10.88″ 11″ 3 Alum 1200-1900 16′ to 18′ 24-30 48-85632A400

12″ 10-1/2″ 3 Alum 1400-2100 16′ + 22-28 48-42740A100

11-1/4″ 10″ 3 Alum 1500-2300 17′ + 20-26 48-73132A400

12-1/4″ 9″ 3 Steel 1800 + 18′ + 14-22 48-97868A500

12-1/4″ 9″ 3 Alum 1800 + 18′ + 14-22 48-87818A100

12-1/2″ 8″ 3 Alum 2100 + 18′ + 01-18 48-42738A100

60 MODELS

Wide Open Throttle RPM: 5000-5500

Recommended Transom Height: Short Shaft 16-1/2 in. (41.9 cm), Long Shaft 20 in. (53.3 cm)

Right Hand Rotation

Gear Reduction: 1.64:1

Thrust Hub: 73345A 1

Approx. Approx. Speed

No. of Gross Boat Boat Range Propeller

Diameter Pitch Blades Material Wgt. (Lbs.) Length (MPH) Part Number

10″ 19″ 3 Alum Up to 8000 Up to 14′ 48-55 48-73146A400

10″ 17″ 3 Alum Up to 1000 Up to 15′ 44-51 48-73144A400

10″ 16″ 3 Steel 700-1100 Up to 15′ 41-48 48-91818A500

10″ 16″ 3 Alum 700-1100 Up to 15′ 41-48 48-73142A400

10.13″ 15″ 3 Steel 800-1200 13′ to 15′ 38-45 48-76232A500

10.13″ 15″ 3 Alum 800-1200 13′ to 15′ 38-45 48-73140A400

10.38″ 14″ 3 Alum 900-1500 14′ to 16′ 35-41 48-816706A40

10-1/4″ 14″ 3 Steel 900-1500 14′ to 16′ 35-41 48-76230A500

10.38″ 13″ 3 Steel 1200-1800 15′ to 17′ 32-38 48-76228A500

10-1/2″ 13″ 3 Alum 1200-1800 15′ to 17′ 32-38 48-816704A40

10.63″ 12″ 3 Steel 1500-2100 16′ to 18′ 28-34 48-79792A500

10-3/4″ 12″ 3 Alum 1500-2100 16′ to 18′ 28-34 48-816702A40

10.88″ 11″ 3 Alum 1800-2400 16′ to 18′ 24-30 48-85632A400

12″ 10-1/2″ 3 Alum 2000-2600 17′ + 22-28 48-42740A100

11-1/4″ 10″ 3 Alum 2100-2600 17′ + 20-26 48-73132A400

12-1/4″ 9″ 3 Steel 2400 + 18′ + 14-22 48-97868A500

12-1/4″ 9″ 3 Alum 2400 + 18′ + 14-22 48-87818A100

12-1/2″ 8″ 3 Alum 2800 + 19′ + 01-18 48-42738A100

1-8 - GENERAL INFORMA TION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

Propeller Information Chart

60 BIG FOOT, 60 SEAPRO/MARATHON MODELS

Wide Open Throttle RPM: 5000-5500

Recommended Transom Height: Short Shaft 16-1/2 in. (41.9 cm), Long Shaft 21 in. (53.3 cm),

Extra Long Shaft 23-1/2 in. (59.7cm)

Right Hand Rotation, 4-1/4 in. Gear Case Torpedo

Gear Reduction: 2.3:1

Thrust Hub : 13191A1

Approx. Approx. Speed

No. of Gross Boat Boat Range Propeller

Diameter Pitch Blades Material Wgt. (Lbs.) Length (MPH) Part Number

12-3/4″ 26″ 5 Steel Up to 800 Up to 15′ 48-55 48-815748A400

13-1/2″ 26″ 3 Steel Up to 800 Up to 15′ 48-54 48-16996A40 0

12-3/4″ 24″ 5 Steel Up to 1000 Up to 15′ 46-52 48-815746A400

13-1/2″ 24″ 3 Steel Up to 1000 Up to 15′ 46-52 48-16994A40 0

12-1/2″ 23″ 3 Alum 700-1100 Up to 15′ 45-51 48-77350A4000

12-3/4″ 22″ 5 Steel 700-1100 Up to 15′ 43-49 48-815744A400

13-1/2″ 22″ 3 Steel 700-1100 Up to 16′ 43-49 48-16992A40

12-3/4″ 21″ 3 Alum 800-1200 13′ to 16′ 40-47 48-77348A4000

12-3/4″ 20″ 5 Steel 800-1200 13′ to 16′ 38-45 48-816612A400

13-1/2″ 20″ 3 Steel 800-1200 13′ to 16′ 38-45 48-16990A40

13″ 19″ 3 Alum 1000-1500 14′ to 17′ 35-42 48-77346A40 0

13″ 18″ 3 Steel 1000-1500 14′ to 17′ 33-40 48-16988A 5

13-1/4″ 17″ 3 Alum 1300-1800 15′ to 18′ 31-38 48-77344A40 0

13-1/8″ 16″ 3 Steel 1300-1800 15′ to 18′ 29-36 48-16986A 5 0

13-3/4″ 15″ 3 Alum 1600-2200 16′ to 19′ 26-33 48-77342A40 0

13-3/8″ 14″ 3 Steel 1600-2200 16′ to 19′ 23-31 48-17314A 500

14″ 13″ 3 Alum 2000-2600 17′ + 20-28 48-77340A40 0

14″ 12″ 3 Steel 2000-2600 17′ + 17-26 48-17312A 5 0

14″ 11″ 3 Alum 2400 + 18′ + 1-22 48-77338A40 0

14″ 10″ 3 Steel 2800 + 19′ + 1-20 48-17310A 5

0

50-60 MODELS

Stainless Steel Race Propellers – Available from Mercury Performance Products

No. of Propeller

Diameter Pitch Blades Rotation Part Number

11″ 18″ 3 RH 48-66106

11″ 20″ 3 RH 48-66108

11″ 22″ 3 RH 48-66110

GENERAL INFORMA TION:

Propeller-Drive Hub: 43676

Diffuser Rings: Alum Propellers – 32201

GENERAL INFORMATION and SPECIFICATIONS - 1-990-817643R1 DECEMBER 1996

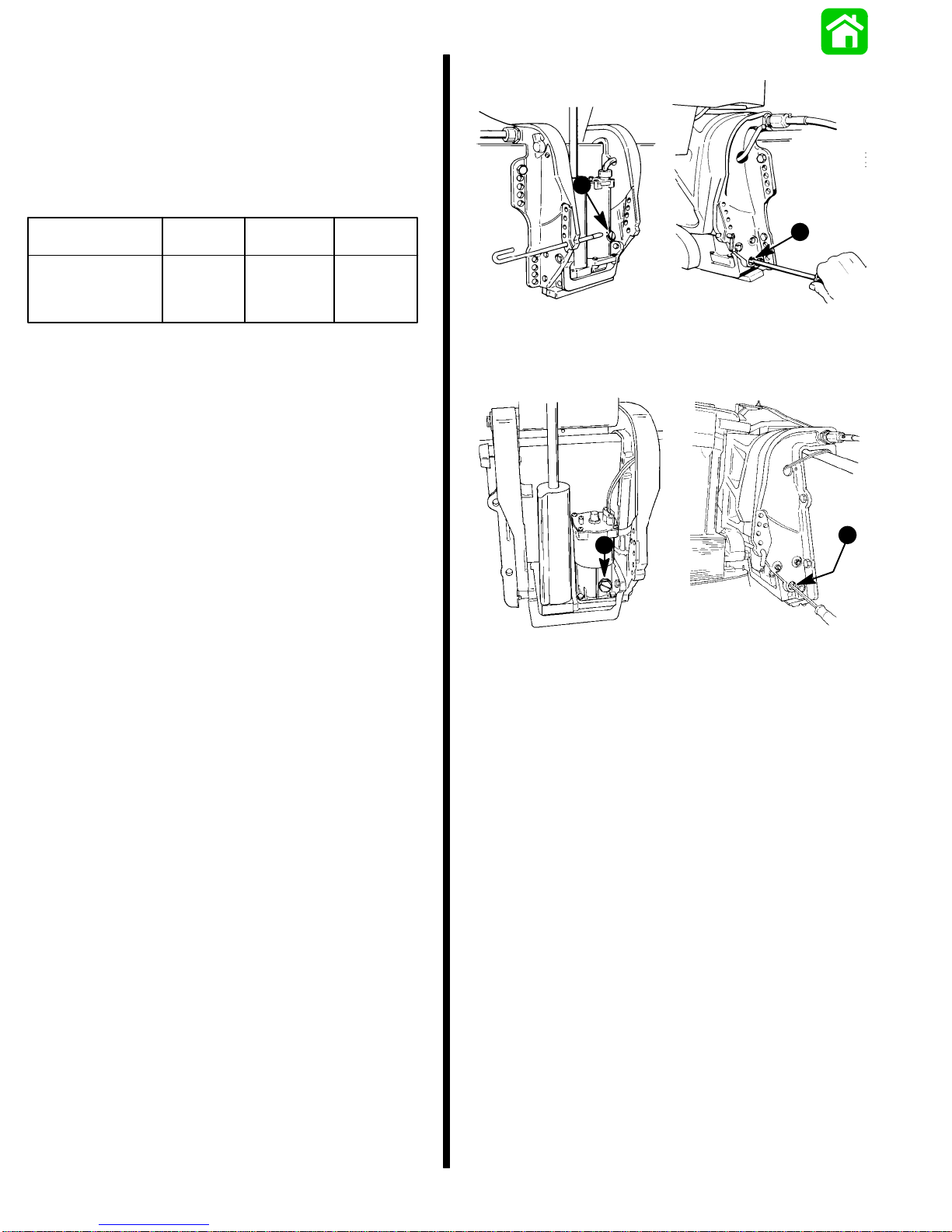

Power Trim System

(Models with Power Trim)

GENERAL INFORMATION

NOTE: 50/60 models are not equipped with Trim System

Design I. See chart below.

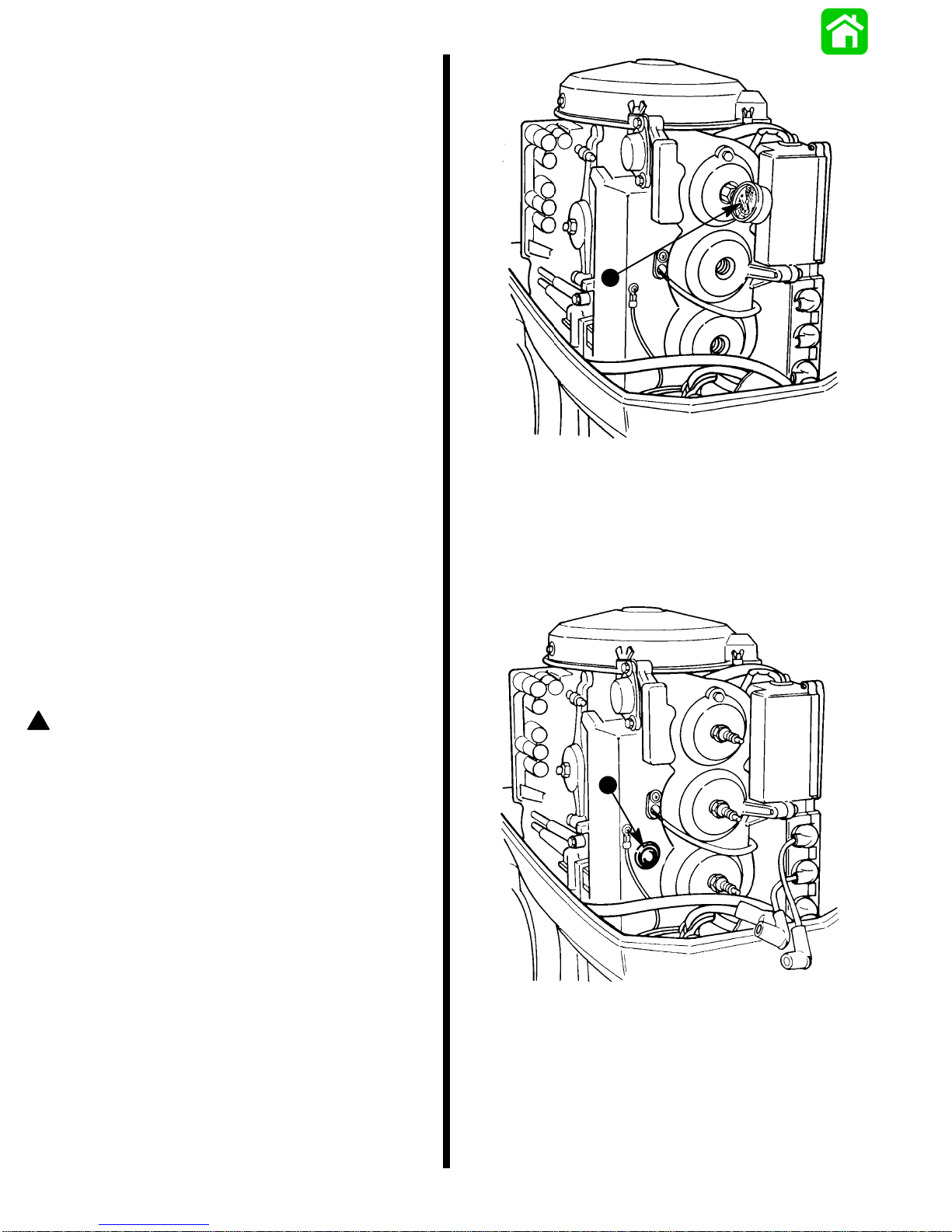

Trim System Design II

a

Design I Design II Design IIIModel

40 (4cyl)

50/60

XXX

XX

The power trim system is filled at the manufacturer and is

ready for use.

Trim outboard through entire trailering range several times

to remove any air from the system.

The trim system is pressurized and is not externally vented.

The outboard can be raised or lowered manually by loos-

ening the manual release valve 2 to 3 turns counterclockwise.

The trim “out” angle of this outboard is not adjustable. The

trim system has an internal valve which will automatically

stop the outward trim travel at 20° when engine RPM is approximately 2000 RPM or higher; outboard also has to be

in water and in gear.

The outboard can be operated beyond the 20° trim limit for

operating outboard in shallow water if engine RPM is kept

below approximately 2000 RPM.

b

50158 50146

Trim System Design III

a

52029

a - Fill Screw (System is Pressurized, DO NOT Open Unless Outboard

is Tilted to Full Up Position)

b - Manual Tilt Release Valve Location

a

52028

1-10 - GENERAL INFORMATION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

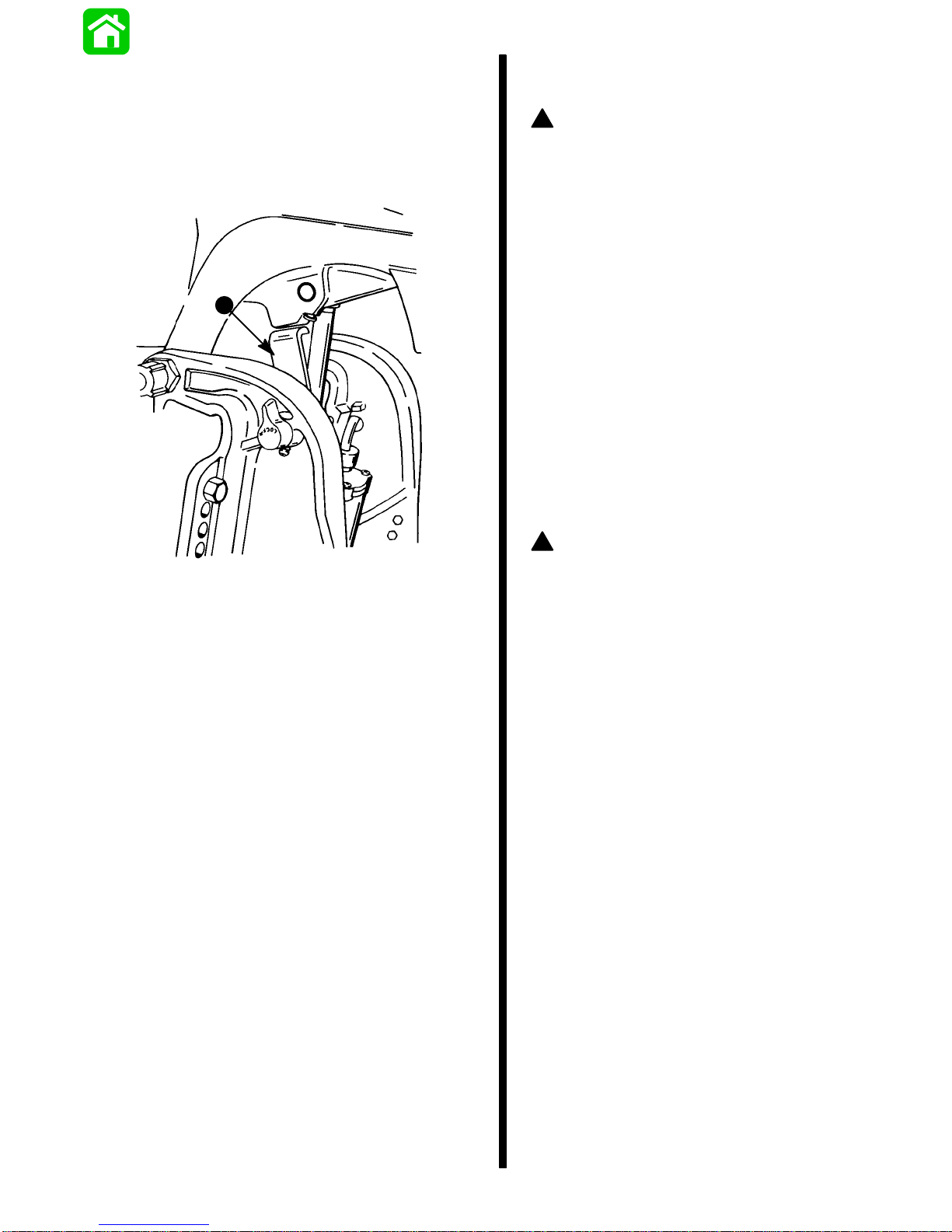

CHECKING TRIM SYSTEM FLUID LEVEL

IMPORT ANT : This trim system is pressurized. Remove

fill screw when outboard is trimmed to the full “up” position. Retighten fill screw securely.

1. Trim outboard to full “up” position. Engage tilt lock lever

(a). Trim system fluid can only be checked when outboard is in this position.

a

TRIMMING OUTBOARD “OUT” (“UP”) CHARACTERISTICS

! WARNING

Excessive trim “out” also may reduce the stability of

some high speed hulls. To correct instability at high

speed, reduce the power GRADUALLY and trim the

outboard “in” slightly before resuming high speed operation. (Rapid reduction in power will cause a sudden

change of steering torque and may cause additional

momentary boat instability.)

1. Will lift bow of boat, generally increasing top speed.

2. Transfers steering torque harder to left on standard or

slightly elevated transom installation (single outboard).

3. Increases clearance over submerged objects.

4. In excess, can cause porpoising and/or ventilation.

5. If trimmed out beyond the water pickup, reduced water

supply can cause serious overheating.

TRIMMING OUTBOARD “IN” (“DOWN”)

CHARACTERISTICS

50157

2. Remove fill screw and check fluid level. Fluid level

should be to bottom of threads in fill hole (b).

3. If necessary, add Quicksilver Power Trim & Steering

Fluid or; Automatic Transmission Fluid (ATF) Type F,

FA or Dexron II fluid to trim system.

4. Reinstall fill screw.

Trimming (Models with Power Trim)

NOTE: Because varying hull designs react differently in

various degrees of rough water, it is recommended to experiment with trim positions to determine whether trimming

up or down will improve the ride in rough water.

When trimming your outboard from a mid-trim position (trim

tab in neutral straight fore-and-aft position), you can expect

the following results:

! WARNING

Excessive speed at minimum trim “in” may cause undesirable and/or unsafe steering conditions. Each

boat should be tested for handling characteristics after any adjustment is made to the trim angle (trim adjustment pin relocation).

1. Will help planing off, particularly with a heavy load.

2. Usually improves ride in choppy water.

3. In excess, can cause boat to veer to the left or right

(bow steer).

4. Transfers steering torque harder to right (or less to the

left) on single outboard installations.

5. Improves planing speed acceleration.

GENERAL INFORMATION and SPECIFICATIONS - 1-1190-817643R1 DECEMBER 1996

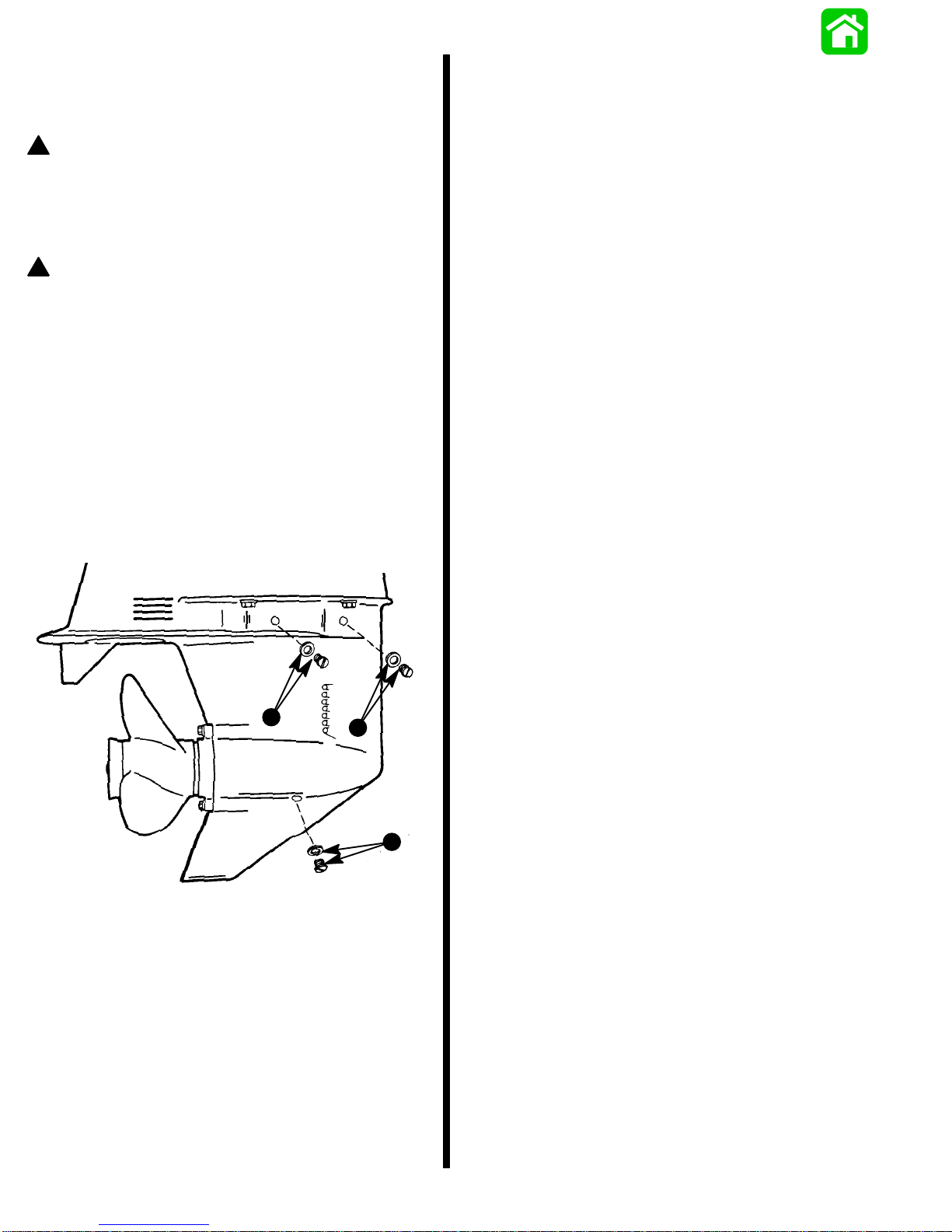

Trim Tab Adjustment

Boat Performance

1. Check trim tab position as follows:

a. Operate boat at the speed at which it would nor-

mally be operated.

b. If the boat pulls to the right (starboard), the trailing

edge of trim tab must be moved to the right. If the

boat pulls to the left (port), the trailing edge of trim

tab must be moved to the left.

2. If necessary, adjust trim tab as follows:

a. Shift outboard control into neutral and turn ignition

key to “Off” position.

b. Loosen bolt (c) and trim tab (b).

c. If boat pulls to the left, adjust trailing edge of trim

tab to the left. If boat pulls to the right, adjust trailing

edge of trim tab to the right.

d. Tighten trim tab bolt securely.

e. Operate boat per “Check trim tab position as

follows,” to check trim tab setting. If necessary

readjust trim tab.

a

TEST INSTRUCTIONS

! WARNING

A tight grip on the steering wheel/tiller handle is

always advisable and is required when accelerating,

decelerating or when trimming the boat. On models

with Power Trim, upon reaching cruising speed, the

outboard should be trimmed to obtain a balanced

steering condition. While trimming, steering loads will

vary and will pull in one direction until a balanced

condition has been attained. If the outboard is trimmed

past the balanced steering condition, the steering

wheel/tiller handle then will have a tendency to pull in

the opposite direction. Excessive trimming past the

balanced steering position will result in increased

steering loads and, in most boat applications, a

decrease in performance.

!

CAUTION

When trimming boat with dual outboards, both outboards should be at approximately the same tilt angle

and be tilted out (up) simultaneously (to prevent boat

from veering side-to-side) until desired boat attitude is

achieved. Outboards can then be trimmed individually

to precisely adjust boat trim angle and pitch.

1. With boat in water, trim the outboard(s) (trim button in

remote control handle) so that the decal on the side of

cowl is horizontal. This is a typical average setting that

should give reasonable acceleration and top speed.

b

c

a - Anti-Ventilation Plate

b - Adjustable Trim Tab

c - Bolt

50553

2. Go for a short familiarization ride at various throttle and

trim settings BEFORE starting testing.

NOTE: Instruments should be read with eye directly in front

to eliminate any error in reading the instruments.

3. When making either top speed or acceleration runs,

best accuracy will be obtained by running with or

against any wind. Side winds require driving in a constant turn to keep the boat moving straight-ahead. If

winds are 10 MPH (16 km/hr) or greater, it is suggested

that all acceleration runs be made downwind.

4. The top speed WOT (wide-open-throttle) test should

be done with the boat normally loaded (to duplicate

actual running conditions). Operate boat in gear at

WOT and check RPM. Engine RPM must be within the

recommended full throttle RPM range (listed in the

Operation and Maintenance Manual).

NOTE: When performing an acceleration test, it is

recommended that a stop watch be used to improve testing

accuracy. A wrist watch with a second hand may also be

substituted.

1-12 - GENERAL INFORMATION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

BOAT TEST CHART (Example)

Propeller

Diameter

and

Pitch

101/8” x

15

1

10

/4” x

WOT

WOT

MPH

RPM

*

5450

57003534

Acceleration

in Seconds

*

Time

7

6

Propeller Break Loose Wind during Run

During

Acceleration

slight

no

During

Turns

no

no

*WOT is wide-open-throttle

5. An acceleration test can also be performed if desired.

Start the test with boat motionless in the water and outboard in neutral. A stop watch should be started as the

throttle is quickly pushed to WOT (wide-open-throttle).

Stop the watch as the speedometer needle sweeps

past 20 MPH (32 km/hr). Several runs should be made

to assure a good average.

6. Prop “break loose” (sudden higher RPM), if not excessive, in some cases can be beneficial during acceleration. If undesirable “break loose” occurs, it can be decreased by trimming the outboard further under. If it

remains excessive with all similar propellers, the outboard must be lowered.

Direction

Air

Temperature

(

°F)

73

73

Comments

MPH

5

5

Water

Condition

3”

chop

7. It is suggested that all applicable data be recorded on

a chart (such as that illustrated, above) and retained

for future reference.

8. After several propellers of different pitch and/or design

have been tried, select one that best serves the general purpose of the boat. The selected propeller should

enable the engine to operate within its recommended

full throttle RPM range, without excessive propeller

“break loose” during acceleration or turns. A second

propeller that would make both a suitable spare or a

special purpose alternate might also be desirable.

NOTE: A higher pitch often gives best top speed, but the

next lower pitch gives adequate top speed with much better

acceleration.

GENERAL INFORMATION and SPECIFICATIONS - 1-1390-817643R1 DECEMBER 1996

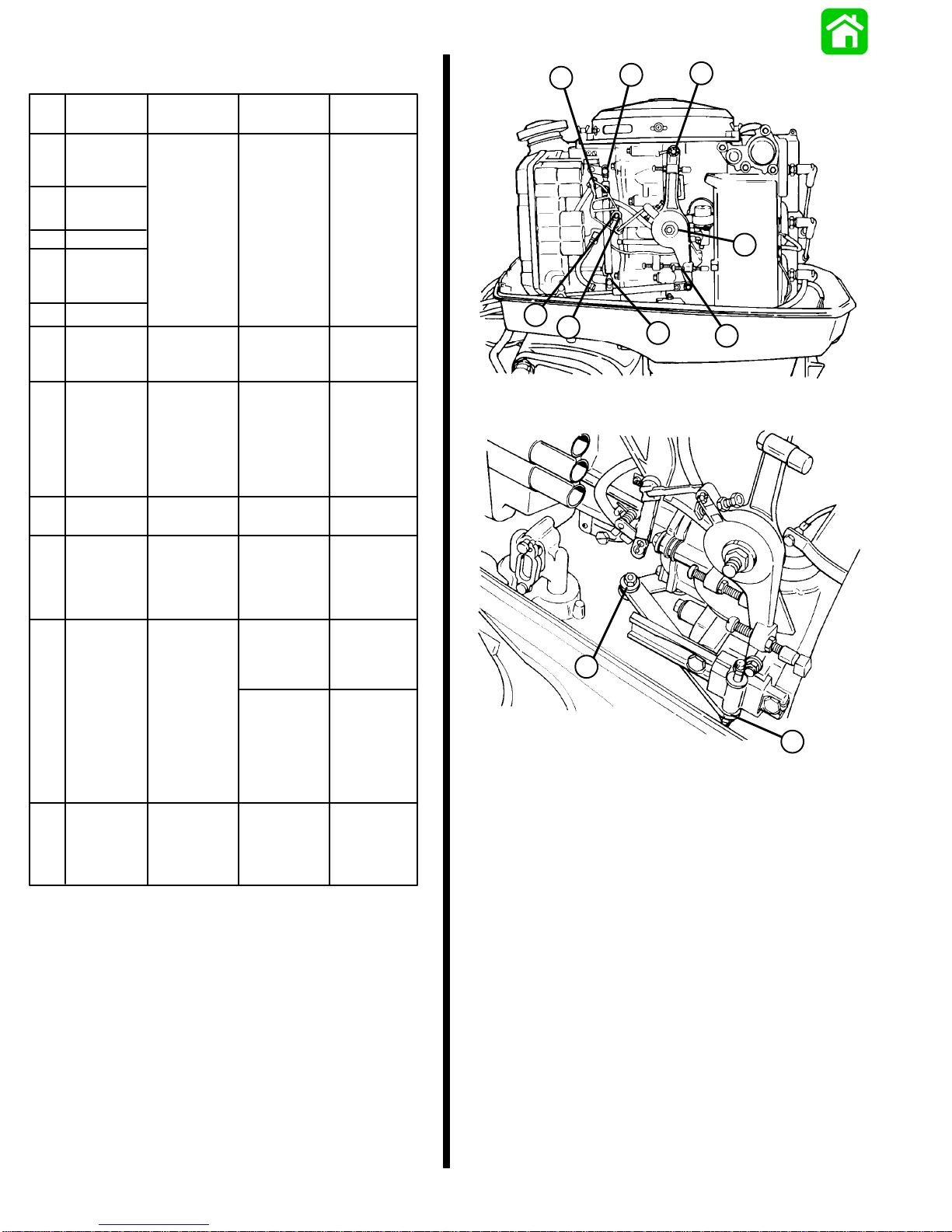

Lubrication Points

1

1

1

Item

No.

1

2

3

4

5

6

7

8

9

*

Description

Throttle/Shift

Linkage

Pivot Points

Upper

Shift

Shaft

Swivel Pin

Ride Guide

Steering

Cable

Tilt Tube

Steering

Link Rod

Pivot Points

Propeller

Shaft

Starter Motor

Pinion Gear

Gear

Housing

Bearing

Carrier

Type of

Lubricant

Quicksilver

2-4-C w/Te-

flon

Marine

Lubricant

SAE 30W

Motor Oil

Quicksilver

-Anti-Corrosion Grease

SAE 30W

Motor Oil

Quicksilver

2-4-C w/Te-

flon

Marine

Lubricant

Fresh Water

Frequency

Every

60 Days

Every

60 Days

Once in

Season

Once in

Season

Salt Water

Frequency

Every

30 Days

Every

30 Days

Every

60 Days

Every

60 Days

After first 20

Hours, then

once in

season

1

1

1 - Throttle/Shift Linkage Pivot Point Lubrication

1

1

1

50554

Check and fill

after first 10

days, then

every 30 days

10

Gear

Housing

◊

Engine

Crankshaft

Splines to

∆

Drive Shaft

Splines

* Refer to lubrication instructions outlined in “Salt Water Corrosion -

Gear Housing Bearing Carrier and Cover Nut” of this section (see

“Table of Contents”).

Quicksilver

Gear Lube

Quicksilver

2-4-C w/Te-

flon

Marine

Lubricant

Drain and re-

fill after 1st 25

hours, then

after every

100 hours, or

once a year

before storing

Once in

Season

Check and fill

after first 10

days, then

every 30 days

Drain and re-

fill after 1st 25

hours, then

after every

100 hours, or

once a year

before storing

Once in

Season

◊ Refer to “Gear Housing Lubrication” of this section (see “Table of

Contents”).

∆ Refer to “Gear Housing Removal and Installation” (Section 5).

2

2 - Upper Shift Shaft Lubrication

2

51122

1-14 - GENERAL INFORMATION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

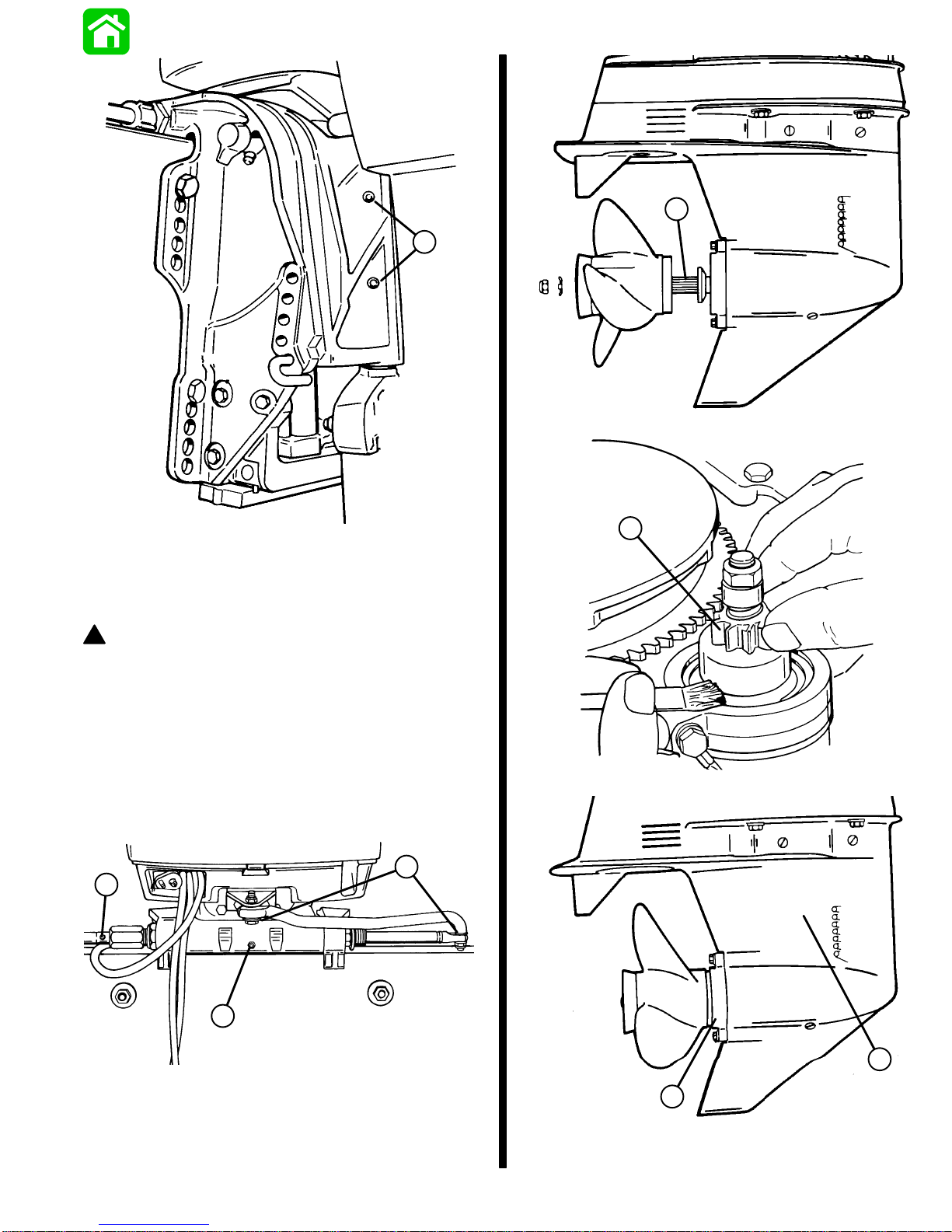

7

3

50551

7 - Propeller Shaft Lubrication (a)

50157

3 - Swivel Pin Grease Fittings

RIDE GUIDE STEERING CABLE and PIVOT POINTS

LUBRICATION

! WARNING

Core of steering cable (transom end) must be fully

retracted into cable housing before lubricating cable.

If cable is lubricated while extended, hydraulic lock of

cable could occur.

With core of Ride Guide Steering cable (transom end) fully

retracted, lubricate transom end of steering cable thru

grease fitting and exposed portion of cable end with Quicksilver 2-4-C Marine Lubricant. Lubricate all pivot points with

SAE 30W engine oil.

6

4

8

51118

8 - Rotate Starter Motor Pinion Gear To Expose Shaft and Lubricate

5

4 - Ride Guide Steering Grease Fitting

5 - Tilt Tube Grease Fitting

6 - Steering Link Rod Pivot Point Lubrication

50334

Gear Housing Lubrication

GENERAL INFORMATION and SPECIFICATIONS - 1-1590-817643R1 DECEMBER 1996

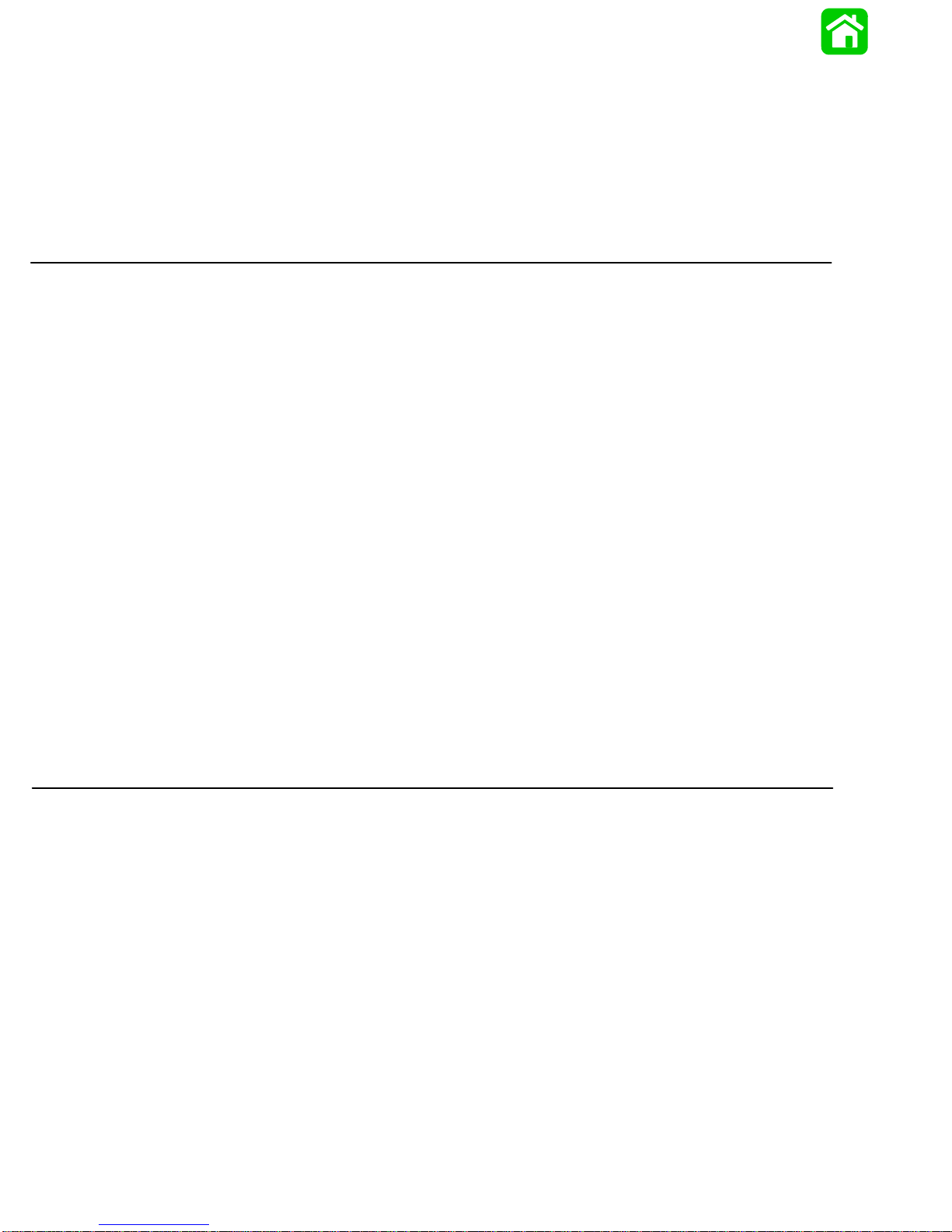

10

9

50558

GEAR HOUSING LUBRICATION

NOTE: Refer to “Specifications,” for gear housing lubricant

capacity .

! WARNING

If gear housing is installed on outboard, to avoid accidental starting, disconnect (and isolate) spark plug

leads from spark plugs before working near the propeller.

5. Note color of gear lubricant. White or cream color indicates presence of water in lubricant. Gear lubricant

which has been drained from a gear housing recently

in operation will have a yellowish color due to lubricant

agitation/aeration. This is normal and should not be

confused with the presence of water.

6. Presence of water in gear lubricant indicates the need

for disassembly and inspection of oil seals, seal surfaces, O-rings, water pump gaskets as well as gear

housing components for damage.

!

CAUTION

Do not use automotive grease in the gear housing. Use

only Quicksilver Gear Lube or Quicksilver Super-Duty

Lower Unit Lubricant.

1. Tilt outboard so that lubricant in gear housing will drain

toward front of housing, out fill hole and into clean container.

IMPORT ANT: Inspect FILL and VENT plug washers for

damage. Use new washer as needed.

2. Remove lubricant fill plug and washer. Note amount of

metal particles on magnetic fill plug.

3. Remove VENT plugs and washers (a and c) and allow

all lubricant to drain.

c

a

b

IMPORTANT: Never add lubricant to gear housing

without first removing VENT plugs, as trapped air will

prevent housing from being filled. Fill gear housing

only when outboard is in operating position.

7. With outboard in operating position, insert lubricant

tube into fill hole.

8. Fill gear housing until excess lubricant flows from forward VENT hole.

9. Install VENT plug and washer (a).

10. Continue to fill gear housing until lubricant flows from

VENT hole.

11. Install VENT plug and washer (c).

12. Clean magnet on FILL plug and install FILL plug and

washer (b).

SALT WATER CORROSION - GEAR HOUSING

BEARING CARRIER and COVER NUT

Salt water corrosion buildup can be sufficient to split a gear

housing and destroy an entire lower unit. T o protect against

such damage, therefore, it is recommended that the gear

housing bearing carrier be lubricated on a regular basis, as

follows:

Service first at the 20-hour inspection, then on an annual

basis. Remove the entire bearing carrier to adequately

clean corrosive deposits and dried-up lubricant from both

ends of the bearing carrier, as well as the gear housing.

Apply a liberal amount of 2-4-C w/Teflon Marine Lubricant

to the 2 ends of the bearing carrier, then reassemble and

torque to specifications. Refer to gear housing disassembly and reassembly (Section 6A).

50558

a - Lubricant VENT Plug/Washer

b - Lubricant Fill Plug/Washer

c - Lubricant VENT Plug/Washer

4. Inspect gear lubricant for metal particles (lubricant will

have a “metal flake” appearance). Presence of fine

metal particles (resembling powder) on the FILL plug

bar magnet indicates normal wear. The presence of

metal chips on the drain plug bar magnet indicates the

need for gear housing disassembly and components

inspection.

1-16 - GENERAL INFORMATION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

Periodic Inspection

Flushing Outboard Cooling System

Conduct a periodic, systematic inspection to uncover and

correct a failure before it can cause inconvenience or mechanical damage. Inspection interval is based on average

operating conditions in recreation service. Under severe

conditions, the inspection interval should be shortened. Inspection includes:

1. Clean entire unit thoroughly, including all accessible

powerhead parts.

2. Check entire unit for loose, damaged or missing parts.

Tighten or replace as required.

3. Lubricate gear housing.

4. Lubricate other points as indicated, previously.

5. Lubricate starter motor shaft with light film of SAE 10W

motor oil. Do not over-lubricate.

6. Service spark plugs. Inspect spark plug leads and

electrical leads for damage or deterioration, as explained in Section 2 “Electrical and Ignition”.

7. Inspect fuel lines for damage or deterioration and service fuel filters as indicated in Section 3 “Fuel System

and Carburetion.”

8. Remove propeller and inspect. Trim nicks and burrs

with a file, being careful not to remove more metal than

absolutely necessary. Inspect for cracks, damage or

bent condition. If condition is doubtful, refer to authorized Quicksilver Propeller Repair Station facilities.

Before reinstalling propeller, coat propeller shaft with

Quicksilver Special Lubricant 101, Anti-Corrosion

Grease or 2-4-C w/Teflon Marine Lubricant.

9. Inspect the outboard surface finish for damage or

corrosion. Thoroughly clean damaged or corroded

areas and apply matching paint (Quicksilver Spray

Paints).

10. Check trim tab and galvanic corrosion sacrificial anode

for damage or for deterioration from salt water

operation.

11. Check remote controls and steering. Be sure that all

connections and fittings are in good condition, properly

secured and correctly adjusted.

! WARNING

When flushing, be certain that area in vicinity of propeller is clear and that no person is standing nearby –

to avoid possible injury . It is recommended to remove

propeller as a precautionary measure.

1. Install Quicksilver Flushing Attachment (73971A2) [or

equivalent tool] on the gear housing from the FRONT

side, positioning the rubber cups over the water intake

openings.

b

a

50551

a - Water Hose (1/2 in. [13mm] I.D. or Larger)

b - Flushing Attachment (73971A2)

(Typical Gear Housing)

2. Connect hose (1/2 in. [13mm] I.D. or larger) between

flushing attachment and water tap.

IMPORTANT: To prevent water pump damage, do not

start or run engine unless cooling water is flowing.

3. With the outboard in normal operating position (vertical), partially open water tap (IT MA Y NOT BE NECESSARY to use full water pressure) and adjust water flow

so that there is a significant water loss around the rubber cups.

GENERAL INFORMATION and SPECIFICATIONS - 1-1790-817643R1 DECEMBER 1996

4. Start engine and idle in neutral. Then increase engine

speed, not to exceed 2500 RPM.

SUBMERGED ENGINE (FRESH WATER)

(PLUS SPECIAL INSTRUCTIONS)

5. Flush or service engine as required. Be sure adequate

cooling water is provided.

a. Water must be discharged thru “tell-tale outlet.”

IMPORT ANT : Prevent engine overheating. If water flow

is insufficient, stop engine and determine cause before continuing.

b. Flush until discharged water is clear. In saltwater

areas, run outboard 3 to 5 minutes.

c. Stop engine before turning off water.

6. Stop engine, turn water off and remove flushing attachment from gear housing.

IMPORTANT: While and after flushing, keep outboard

in upright position until all water has drained from

drive shaft housing to prevent water from entering the

powerhead via drive shaft housing and exhaust ports.

Following Complete Submersion

Submerged engine treatment is divided into 3 distinct

problem areas. The most critical is submersion in salt

water; the second is submersion while running.

SAL T WATER SUBMERSION (SPECIAL

INSTRUCTIONS)

Due to the corrosive effect of salt water on internal engine

components, complete disassembly is necessary before

any attempt is made to start the engine.

1. Recover engine as quickly as possible.

2. Remove cowling.

3. Flush exterior of outboard with fresh water to remove

mud, weeds, etc. DO NOT attempt to start engine if

sand has entered powerhead, as powerhead will be

severely damaged. Disassemble powerhead if necessary to clean components.

4. Remove spark plugs and get as much water as possible out of powerhead. Most water can be eliminated by

placing engine in a horizontal position (with spark plug

holes down) and rotating flywheel.

5. Pour alcohol into carburetor throat (alcohol will absorb

water). Again rotate flywheel.

6. Turn engine over and pour alcohol into spark plug

openings and again rotate flywheel.

7. Turn engine over (place spark plug openings down)

and pour engine oil into throats of carburetors while

rotating flywheel to distribute oil throughout crankcase.

8. Again turn engine over and pour approximately one

teaspoon of engine oil into each spark plug opening.

Again rotate flywheel to distribute oil in cylinders.

9. Remove and clean carburetors and fuel pump assembly .

10. Reinstall spark plugs, carburetors and fuel pump.

11. Attempt to start engine, using a fresh fuel source. If

engine starts, it should be run for at least one hour to

eliminate any water in engine.

SUBMERGED WHILE RUNNING (SPECIAL

INSTRUCTIONS)

When an engine is submerged while running, the possibility of internal engine damage is greatly increased. If, after

engine is recovered and with spark plugs removed, engine

fails to rotate freely when turning flywheel, the possibility of

internal damage (bent connecting rod and/or bent crankshaft) exists. If this is the case, the powerhead must be

disassembled.

12. If engine fails to start, determine cause (fuel, electrical

or mechanical). Engine should be run within 2 hours

after recovery of outboard from water, as serious internal damage may occur. If unable to start engine in this

period, disassemble engine and clean all parts and

apply oil as soon as possible.

1-18 - GENERAL INFORMATION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

Out-of-Season Outboard Storage

! WARNING

As a safety precaution, when boat is in storage,

remove positive (+) battery cable. This will eliminate

possibility of accidental starting of engine and resultant overheating and damage to engine from lack of

water.

In preparing an outboard for out-of-season storage, 2 precautions must be considered: 1) The engine must be protected from physical damage and 2) the engine must be

protected from rust, corrosion and dirt.

1. Remove cowling from engine.

2. Place outboard in water or install Quicksilver Flushing

Attachment over water intake by following instructions

outlined in “Flushing Cooling System” (see “Table of

Contents”).

3. Start engine and allow to warm up. Disconnect fuel

line. When engine starts to stall quickly spray Quicksilver Storage Seal into each carburetor throat. Continue

to spray until engine dies from lack of fuel.

4. Remove spark plugs and inject a 5 second spray of

Quicksilver Storage Seal around the inside of each cylinder. Manually turn engine over several times to distribute Storage Seal throughout cylinders. Reinstall

spark plugs.

5. If engine fuel filter appears to be contaminated, remove and replace. Refer to Section 3 “Fuel System

and Carburetion.”

6. Drain and refill lower unit with Quicksilver Gear Lube,

as explained in “Gear Housing Lubrication” (see “T able

of Contents”).

7. Clean outboard thoroughly, including all accessible

powerhead parts, and spray with Corrosion and Rust

Preventive.

8. Refer to lubrication chart in this section (see “Table of

Contents”) and lubricate all lubrication points.

9. Remove propeller. Apply Quicksilver Special Lubricant

101, Anti-Corrosion Grease or 2-4-C w/Teflon Marine

Lubricant to propeller shaft and reinstall propeller.

Refer to “Propeller Installation” (see “Table of

Contents”).

10. If the water pickup is clogged, the speedometer will be

inoperative. Clean the pickup with a piece of wire or

blow out with compressed air. Before blowing out with

air, disconnect the tubing from the speedometer.

11. To prevent freeze damage, drain the speedometer

system of water completely before storage. Remove

tubing from speedometer fitting and blow thru the

tubing to remove water.

12. Store battery as outlined in “Out-of-Season Battery

Storage,” following.

13. For out-of-season storage information on Autoblend

units, refer to Section 8 in this service manual.

IMPORT ANT: When storing outboard for the winter, be

sure that all water drain holes in gear housing are open

and free so that all water will drain out. If a speedometer is installed in the boat, disconnect the pickup tube

and allow it to drain. Reconnect the tube after draining.

Trapped water may freeze and expand, thus cracking

gear housing and/or water pump housing. Check and

refill gear housing with Quicksilver Gear Lube before

storage to protect against possible water leakage into

gear housing which is caused by loose lubricant vent

plug or loose grease fill plug. Inspect gaskets under

lubricant vent and fill plugs, replacing any damaged

gaskets, before reinstalling plugs.

Out-of-Season Battery Storage

1. Remove battery as soon as possible and remove all

grease, sulfate and dirt from top surface.

2. Cover PLA TES with distilled water, but not over 3/16 in.

(5mm) above perforated baffles.

3. Cover terminal bolts well with grease.

4. Store battery in a COOL, DRY place in a dry carton or

box.

5. Remove battery from storage every 60 days. Check

water level and place on charge for 5 to 6 hours at 6

amperes. DO NOT fast charge.

!

CAUTION

A discharged battery can be damaged by freezing.

GENERAL INFORMATION and SPECIFICATIONS - 1-1990-817643R1 DECEMBER 1996

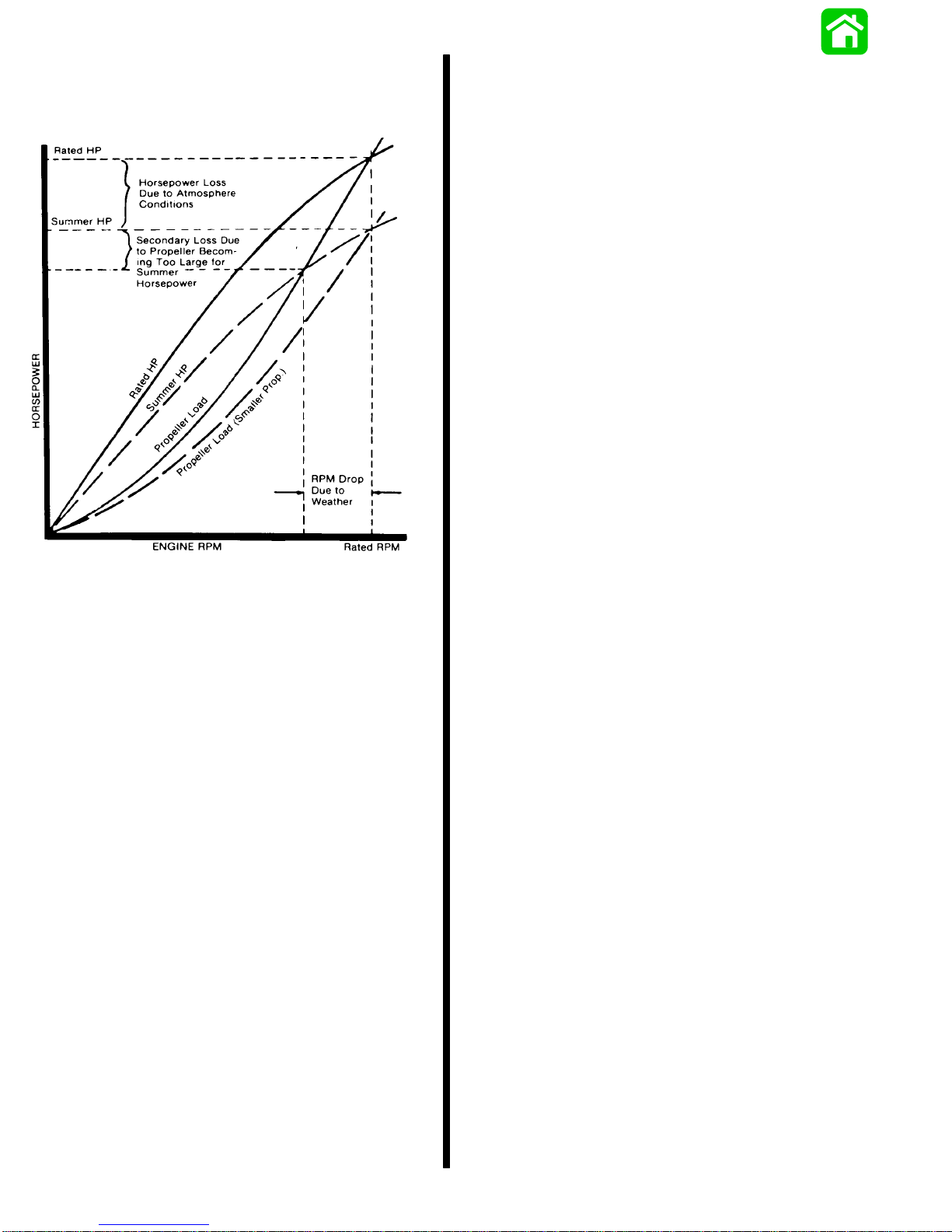

How Weather Affects Engine

Performance

Summer Conditions of high temperature, low barometric

pressure and high humidity all combine to reduce the

engine power. This, in turn, is reflected in decreased boat

speeds--as much as 2 or 3 miles-per-hour (3 or 5 Km

per-hour) in some cases. (Refer to previous chart.) Nothing

will regain this speed for the boater, but the coming of cool,

dry weather.

In pointing out the practical consequences of weather

effects, an engine--running on a hot, humid summer

day--may encounter a loss of as much as 14% of the

horsepower it would produce on a dry, brisk spring or fall

day . The horsepower , that any internal combustion engine

produces, depends upon the density of the air that it

consumes and, in turn, this density is dependent upon the

temperature of the air, its barometric pressure and water

vapor (or humidity) content.

Accompanying this weather-inspired loss of power is a

second but more subtle loss. At rigging time in early spring,

the engine was equipped with a propeller that allowed the

engine to turn within its recommended RPM range at full

throttle. With the coming of the summer weather and the

consequent drop in available horsepower, this propeller

will, in effect, become too large. Consequently , the engine

operates at less than its recommended RPM.

It is a known fact that weather conditions exert a profound

effect on power output of internal combustion engines.

Therefore, established horsepower ratings refer to the

power that the engine will produce at its rated RPM under

a specific combination of weather conditions.

Corporations internationally have settled on adoption of

I.S.O. (International Standards Organization) engine test

standards, as set forth in I.S.O. 3046 standardizing the

computation of horsepower from data obtained on the dynamometer, correcting all values to the power that the engine will produce at sea level, at 30% relative humidity at

77° F (25° C) temperature and a barometric pressure of

29.61 inches of mercury.

Due to the horsepower/RPM characteristics of an engine,

this will result in further loss of horsepower at the propeller

with another decrease in boat speed. This secondary loss,

however, can be regained by switching to a smaller pitch

propeller that allows the engine to again run at recommended RPM.

For boaters to realize optimum engine performance under

changing weather conditions, it is essential that the engine

have the proper propeller to allow it to operate at or near

the top end of the recommended maximum RPM range at

wide-open-throttle with a normal boat load.

Not only does this allow the engine to develop full power,

but equally important is the fact that the engine also will be

operating in an RPM range that discourages damaging

detonation. This, of course, enhances overall reliability and

durability of the engine.

1-20 - GENERAL INFORMATION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

Conditions Affecting Operation

1. Proper positioning of the weight inside the boat (persons and gear) has a significant effect on the boat’s

performance, for example:

a. Shifting weight to the rear (stern)

(1) Generally increases top speed.

(2) If in excess, can cause the boat to porpoise.

(3) Can make the bow bounce excessively in

choppy water.

(4) Will increase the danger of the following -

wave splashing into the boat when coming off

plane.

b. Shifting weight to the front (bow)

(1) Improves ease of planing off.

(2) Generally improves rough water ride.

(3) If excessive, can make the boat veer left and

right (bow steer).

2. Boat Bottom: For maximum speed, a boat bottom

should be nearly a flat plane where it contacts the

water and particularly straight and smooth in fore-andaft direction.

a. Hook: Exists when bottom is concave in fore-and-

aft direction when viewed from the side. When

boat is planing, “hook” causes more lift on bottom

near transom and allows bow to drop, thus greatly

increasing wetted surface and reducing boat

speed. “Hook” frequently is caused by supporting

boat too far ahead of transom while hauling on a

trailer or during storage.

Detonation generally is thought of as spontaneous ignition,

but it is best described as a noisy explosion in an unburned

portion of the fuel/air charge after the spark plug has fired.

Detonation creates severe, untimely, shock waves in the

engine, and these shock waves often find or create a weakness: The dome of a piston, piston rings or piston ring

lands, piston pin and roller bearings.

While there are many causes for detonation in a 2-cycle

engine, emphasis is placed on those causes which are

most common in marine 2-cycle application. A few, which

are not commonly understood, are:

1. Over-advanced ignition timing.

2. Use of low octane gasoline.

3. Propeller pitch too high (engine RPM below recommended maximum range).

4. Lean fuel mixture at or near wide-open-throttle.

5. Spark plugs (heat range too hot - incorrect reach

- cross-firing).

6. Inadequate engine cooling (deteriorated cooling

system).

7. Combustion chamber/piston deposits (result in

higher compression ratio).

Detonation usually can be prevented, provided that 1) the

engine is correctly set up and 2) diligent maintenance is

applied to combat the detonation causes, listed, preceding.

b. Rocker: The reverse of hook and much less com-

mon. “Rocker” exists if bottom is convex in foreand-aft direction when viewed from the side, and

boat has strong tendency to porpoise.

c. Surface Roughness: Moss, barnacles, etc., on

boat or corrosion of outboard’s gear housing increase skin friction and cause speed loss. Clean

surfaces when necessary.

3. Gear Housing: If unit is left in the water , marine vegetation may accumulate over a period of time in certain

types of water. This growth must be removed from unit

before operation, as it may clog the water inlet holes in

the gear housing and cause the engine to overheat.

Detonation: Causes and Prevention

Detonation in a 2-cycle engine somewhat resembles the

“pinging” heard in an automobile engine. It can be otherwise described as a tin-link “rattling” or “pinging” sound.

511 15

Damaged Piston Resulting from Detonation

Compression Check

1. Remove spark plugs.

2. Install compression gauge (a) in spark plug hole.

3. Hold throttle plates at W.O.T.

GENERAL INFORMATION and SPECIFICATIONS - 1-2190-817643R1 DECEMBER 1996

4. Crank engine thru at least 4 compression strokes to

obtain highest possible reading.

5. Check and record compression of each cylinder.

Variation of more than 15 psi. (103.5 kPa) between

cylinders indicates that lower compression cylinder is

in some way defective, such as worn or sticking piston

rings and/or scored piston and cylinder.

6. Compression check is important because an engine

with low or uneven compression cannot be tuned

successfully to give peak performance. It is essential,

therefore, that improper compression be corrected

before proceeding with an engine tuneup.

7. Cylinder scoring: If powerhead shows any indication of

overheating, such as discolored or scorched paint,

visually inspect cylinders for scoring or other damage

as outlined in Section 4 “Powerhead.”

Water Pressure Check

NOTE: T o perform these checks, a Water Pressure Gauge

Kit, P/N 91-79250A2 is recommended.

1. Water pressure at idle, in neutral, is 1-3 psi (7-21 kPa).

2. Water pressure should increase, then drop to 4-6 psi

(21-35 kPa) prior to 2500 RPM (due to poppet valve

opening.)

3. At 2500 RPM, water pressure should not exceed 12 psi

(83 kPa). Readings above 12 psi at 2500 RPM may indicate a stuck poppet valve.

a

51046

a - Compression Gauge (P/N 91-29287)

Serial Number Location

The engine serial number is located on the starboard side

of the swivel bracket (as on all Mariner/Mercury models)

and also on the cylinder head (a).

4. Static test (boat stationary - operate in forward gear

with a cut down “ smaller diameter” propeller) at 5000

RPM or above is 7-12 psi (48-83 kPa).

!

CAUTION

A MODIFIED PROPELLER OR LOW PITCH PROPELLER IS REQUIRED TO PERFORM THE ABOVE ST ATIC

TEST. STATIC TEST REQUIRES THE BOAT BE STATIONARY IN THE WATER SECURED TO A DOCK OR

TRAILER AND RUN IN FORW ARD GEAR. DO NOT USE

A FLUSHING DEVICE FOR THIS TEST.

a

51139

1-22 - GENERAL INFORMATION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

Painting Procedures

3. Sand blistered area with 3M 180 grit sandpaper

or P180 Gold Film Disc to remove paint blisters

only. Feather edge all broken paint edges.

Cleaning & Painting Aluminum

Propellers & Gear Housings

! WARNING

Avoid serious injury from flying debris. A void serious injury from airborne particles. Use eye and

breathing protection with proper ventilation.

PROPELLERS

1. Sand the entire area to be painted with 3M 120

Regalite Polycut or coarse Scotch-Brite, disc or

belts.

2. Feather edges of all broken paint edges. Try not

to sand through the primer.

3. Clean the surface to be painted using PPG

Industries DX330 Wax and Grease Remover or

equivalent (Xylene or M.E.K.).

4. If bare metal has been exposed, use Quicksilver’s Light Gray Primer.

5. Allow a minimum of 1 hour dry time and no more

than 1 week before applying the finish coat.

6. Apply the finish coat using Quicksilver’s EDP

Propeller Black.

GEAR HOUSINGS

The following procedures should be used in refinishing gear housings. This procedure will provide the

most durable paint system available in the field. The

materials recommended are of high quality and

approximate marine requirements. The following

procedure will provide a repaint job that compares

with a properly applied factory paint finish. It is recommended that the listed materials be purchased

from a local Ditzler Automotive Finish Supply Outlet.

The minimum package quantity of each material

shown following is sufficient to refinish several gear

housings.

Procedure:

4. Clean gear housing thoroughly with (DX-330)

wax and grease remover.

5. Spot repair surfaces where bare metal is exposed with (DX-503) alodine treatment.

IMPORTANT: Do not use any type of aerosol

spray paints as the paint will not properly adhere

to the surface nor will the coating be sufficiently

thick to resist future paint blistering.

6. Mix epoxy chromate primer (DP-40) with equal

part catalyst (DP-401) per manufacturers

instructions, allowing proper induction period for

permeation of the epoxy primer and catalyst.

7. Allow a minimum of one hour drying time and no

more than one week before top coating assemblies.

8. Use Ditzler Urethane DU9000 for Mercury Black,

DU34334 for Mariner Grey, and DU35466 for

Force Charcoal, and DU33414M for Sea Ray

White. Catalyze all three colors with Ditzler DU5

catalyst mixed 1:1 ratio. Reduce with solvents

per Ditzler label.

!

CAUTION

Be sure to comply with instructions on the label

for ventilation and respirators. Using a spray gun,

apply one half to one mil even film thickness. Let

dry, flash off for five minutes and apply another

even coat of one half to one mil film thickness.

This urethane paint will dry to the touch in a matter of hours, but will remain sensitive to scratches

and abrasions for a few days.

9. The type of spray gun used will determine the

proper reduction ratio of the paint.

IMPORT ANT: Do not paint sacrificial zinc trim tab

or zinc anode.

10. Cut out a cardboard “plug” for trim tab pocket to

keep paint off of mating surface to maintain good

continuity circuitry between trim tab and gear

housing.

1. Wash gear housing with a muriatic acid base

cleaner to remove any type of marine growth,

and rinse with water, if necessary.

2. Wash gear housing with soap and water, then

rinse.

GENERAL INFORMATION and SPECIFICATIONS - 1-2390-817643R1 DECEMBER 1996

Decal Application

Decal Removal

1. Mark decal location before removal to assure

proper alignment of new decal.

2. Carefully soften decal and decal adhesive with a

heat gun or heat blower while removing old decal.

3. Clean decal contact area with a 1:1 mixture of isopropyl alcohol and water.

4. Thoroughly dry decal contact area and check for

a completely cleaned surface.

DECAL APPLICATION

1

1. Mix

/2 ounce (16 ml) of dish washing liquid in one

gallon (4 l) of cool water to use as wetting solution.

NOTE: Leave protective masking, if present, on the face of

decal until final steps of decal installation. This will ensure

that the vinyl decal keeps it’s shape during installation.

2. Place the decal face down on a clean work surface and remove the paper backing from “adhesive side” of decal.

3. Using a spray bottle, flood the entire “adhesive

side” of the decal with the pre-mixed wetting solution.

4. Flood area where the decal will be positioned with

wetting solution.

Instructions for “Wet” Application

NOTE: The following decal installation instructions are pro-

vided for a “Wet” installation. All decals should be applied

wet.

TOOLS REQUIRED

1. Plastic Squeegee*

2. Stick Pin

3. Dish Washing Liquid/Detergent without am-

monia** “Joy” and “Drift” are known to be compatible for this process.

** Automotive Body Filler Squeegee

** Do not use a soap that contains petroleum based

solvents.

SERVICE TIP: Placement of decals using the

“Wet” application will allow time to position decal. Read entire installation instructions on this

technique before proceeding.

TEMPERATURE

5. Position pre-wetted decal on wetted surface and

slide into position.

6. Starting at the center of the decal, “lightly”

squeegee out the air bubbles and wetting solution

with overlapping strokes to the outer edge of the

decal. Continue going over the decal surface until

all wrinkles are gone and adhesive bonds to the

cowl surface.

7. Wipe decal surface with soft paper towel or cloth.

8. Wait 10 - 15 minutes.

9. Starting at one corner, “carefully and slowly” pull

the masking off the decal surface at a 180° angle.

NOTE: T o remove any remaining bubbles, pierce the decal

at one end of the bubble with stick pin and press out the entrapped air or wetting solution with your thumb (moving toward the puncture).

IMPORTANT: Installation of vinyl decals should

not be attempted while in direct sunlight. Air and

surface temperature should be between 60°F

(15°C) and 100°F (38°C) for best application.

SURFACE PREPARATION

IMPORT ANT: Do not use a soap or any petroleum

based solvents to clean application surface.

Clean entire application surface with mild dish washing liquid and water. Rinse surface thoroughly with

clean water.

1-24 - GENERAL INFORMATION and SPECIFICATIONS 90-817643R1 DECEMBER 1996

ELECTRICAL and IGNITION

2

A

IGNITION SYSTEM

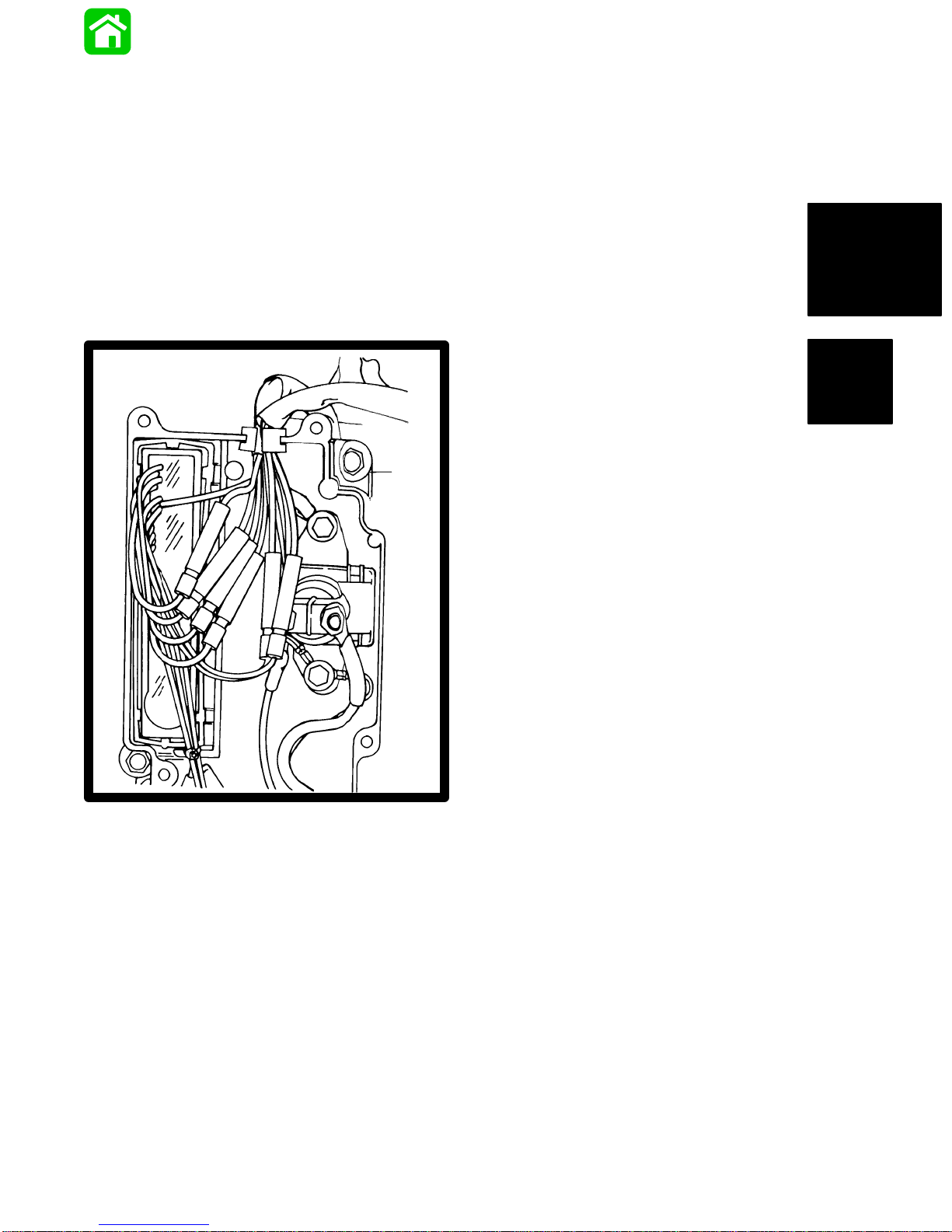

51123

Table of Contents

Description 2A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Procedures 2A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Direct Voltage Adapter (DVA) Tests 2A-1. . . . . . . . . . .

Test Sequence 2A-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition System Test Chart 2A-3. . . . . . . . . . . . . . . . . . .

Stator Test 2A-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Coil Test 2A-5. . . . . . . . . . . . . . . . . . . . . . . . .

Trigger Test 2A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADI Ignition using a RED Stator with an

Adapter Module 2A-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RED Stator with Adaptor and Ignition Coils 2A-6. . . . . . .

RED Stator DVA Test 2A-6. . . . . . . . . . . . . . . . . . . . . . .

Electric Start Engines 2A-6. . . . . . . . . . . . . . . . . . . . . . .

Manual Start Engines 2A-6. . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Procedures 2A-6. . . . . . . . . . . . . . . . .

Ignition (Key) Switch Test 2A-7. . . . . . . . . . . . . . . . . . . . . . .

Page

Page

Ignition Components

Removal and Installation 2A-7. . . . . . . . . . . . . . . . . . . . . . .

Flywheel 2A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 2A-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BLACK and RED Stator 2A-8. . . . . . . . . . . . . . . . . . . . .

Removal 2A-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BLACK Stator Installation 2A-9. . . . . . . . . . . . . . . . .

RED Stator Installation 2A-9. . . . . . . . . . . . . . . . . . .

Trigger 2A-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 2A-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2A-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Coils 2A-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Box 2A-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2A-0 - ELECTRICAL and IGNITION 90-817643R1 DECEMBER 1996

Loading...

Loading...