Page 1

OPERATING MANUAL

CO2 incubators

INCO 108 INCO 108 med

INCO 153 INCO 153 med

INCO 246 INCO 246 med

Page 2

Manufacturer and customer service

MEMMERT GmbH + Co. KG

Postfach 17 20

D-91107 Schwabach

Äußere Rittersbacherstr. 38

D-91126 Schwabach

Germany

Fon: +49 (0) 09122 / 925-0

Fax: +49 (0) 09122 / 14585

E-Mail: sales@memmert.com

Internet: www.memmert.com

Customer service:

Fon: +49 (0) 09122/925-128

and: +49 (0) 09122/925-126

E-Mail: service@memmert.com

For service enquiries, please always specify the appliance number on the nameplate (see page

18 ).

© 2012 Memmert GmbH + Co. KG

Edition 1/2012

Subject to modifications

Page 3

About this manual

About this manual

Purpose and target group

This manual describes the setup, function, operation and maintenance of CO2 incubators

of the types INCO and INCOmed with a chamber volume of 108, 153 and 246 litres. In this

manual, the term INCO is used for INCO as well as INCOmed for the purpose of simplification.

Distinctions are explicitly pointed out.

This manual is intended for use by the trained staff of the operator in charge of operating

and/or maintaining the incubator. If you are asked to work on the incubator, you should read

this manual carefully before starting work on the unit. Familiarise yourself with the safety

regulations. Only perform the work that is described in this manual. If there is something you

don't understand, or certain information is missing, ask your superior or get in touch with the

manufacturer. Do not do anything without authorisation.

Contents

The INCO incubator is available with different fittings: as a basic model, and with six different

additional modules. The technical fittings and functional range of the basic model and the

individual additional modules are described from page 11 .

If specific equipment features or functions are available only with one of the additional modules, this is pointed out in the relevant sections in this manual.

Due to individual fittings, depictions in this manual may be different from the actual appearance.

Other documents that you must read:

► for service and repair work (see page 63 ) – a separate service manual

Storage and Forwarding

This instruction manual belongs with the incubator and should always be stored so that those

who work on the incubator have access to it. It is the responsibility of the operator to ensure

that persons who work on or who will work on the incubator are informed as to the whereabouts of this instruction manual. We recommend that it is always stored in a protected location close to the incubator. Make sure that the instruction manual is not damaged by heat or

damp. If the incubator is sold on or transported and then set up again at a different location,

this instruction manual must go with it.

3

Page 4

Content

Content

1. Safety regulations 6

1.1 Terms and icons used .......................................................................................................... 6

1.2 Product safety and dangers ................................................................................................ 7

1.3 Requirements of the operating personnel .......................................................................... 8

1.4 Responsibility of the owner ................................................................................................. 8

1.5 Changes and conversions ....................................................................................................8

1.6 Behaviour in case of malfunctions and irregularities .......................................................... 8

1.7 What to do in case of accidents .......................................................................................... 9

1.8 Switching off incubator in an emergency ........................................................................... 9

2. Design and Function 10

2.1 Design ................................................................................................................................ 10

2.2 Function .............................................................................................................................11

2.3 Optional extras .................................................................................................................. 11

2.4 Material.............................................................................................................................. 13

2.5 Electrical equipment .......................................................................................................... 13

2.6 Connections .......................................................................................................................13

2.7 Intended use ......................................................................................................................14

2.8 EC Declaration of Conformity............................................................................................16

2.9 Designation (nameplate) ................................................................................................... 18

2.10 Technical data .................................................................................................................... 18

2.11 Ambient conditions ........................................................................................................... 20

2.12 Accessories included ..........................................................................................................20

3. Delivery, Transport and Setting Up 21

3.1 Safety regulations ..............................................................................................................21

3.2 Transport ............................................................................................................................21

3.3 Delivery ..............................................................................................................................21

3.4 Setup.................................................................................................................................. 22

4. Putting into Operation 24

4.1 Checks ................................................................................................................................24

4.2 Connecting ........................................................................................................................ 24

4.3 Oxygen calibration............................................................................................................. 26

5. Operation and control 27

5.1 Operating personnel.......................................................................................................... 27

5.2 Opening the door ............................................................................................................ 27

5.3 Loading the incubator .......................................................................................................27

5.4 Inserting water tray(s) .......................................................................................................28

5.5 Connect gas supply ...........................................................................................................28

5.6 Switch on appliance ..........................................................................................................28

5.7 Basic operation ..................................................................................................................29

5.8 Setting parameters ............................................................................................................ 29

5.9 Operating modes ............................................................................................................... 30

5.10 Setting the operating mode .............................................................................................. 30

5.11 During operation ............................................................................................................... 36

5.12 Ending operation ...............................................................................................................39

6. Warning messages and malfunctions 40

6.1 Warning messages ............................................................................................................ 40

6.2 System/appliance errors ....................................................................................................41

6.3 Power failure ...................................................................................................................... 44

4

Page 5

Content

7. Advanced functions 45

7.1 Printer ............................................................................................................................... 45

7.2 Basic appliance settings (Setup) ........................................................................................45

7.3 Temperature monitoring ..................................................................................................47

7.4 Sterilisation chipcard .........................................................................................................51

7.5 User ID card (optionally available as an accessory) ...........................................................52

7.6 Calibration .........................................................................................................................53

7.7 Communication interfaces ................................................................................................58

7.8 Log memory ...................................................................................................................... 62

8. Maintenance and Servicing 63

8.1 Cleaning ............................................................................................................................. 63

8.2 Regular maintenance.........................................................................................................63

8.3 Adjusting door ...................................................................................................................64

8.4 Repairs and Service ............................................................................................................ 64

9. Storage and Disposal 65

9.1 Storage .............................................................................................................................. 65

9.2 Disposal .............................................................................................................................65

Index 66

5

Page 6

Safety regulations

1. Safety regulations

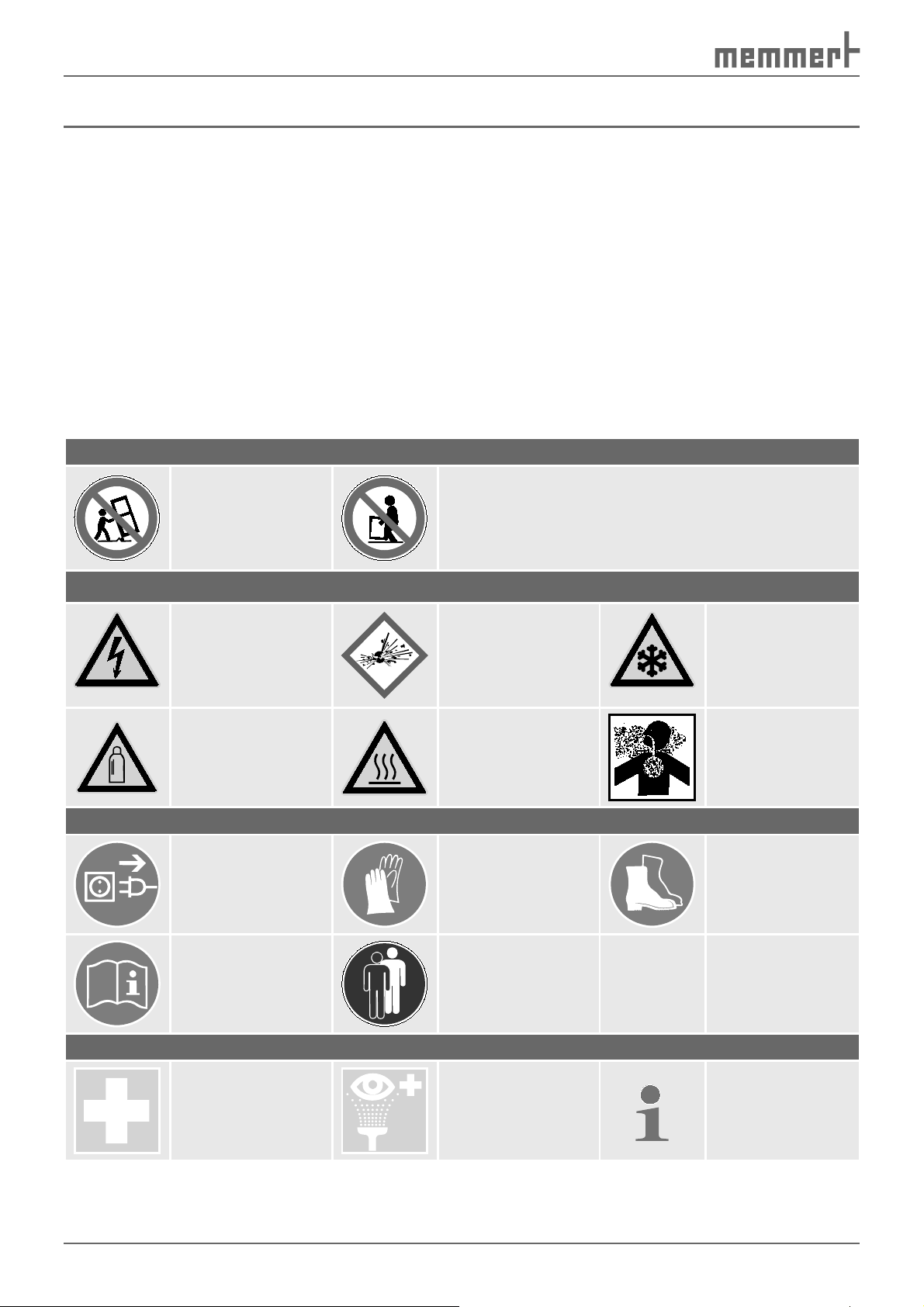

1.1 Terms and icons used

In this manual, certain common terms and icons are used to warn you of dangers or to give

you notes that are important in avoiding injury or damage. Observe and follow these notes

and regulations to avoid accidents and damage. These terms and icons are explained below.

1.1.1 Terms used

"Warning" is always used whenever you or somebody else could be injured if you do

not observe the accompanying safety regulation.

"Caution" is used for information that is important for avoiding damage.

1.1.2 Icons used

Prohibited sign (forbidding an action)

Do not tilt

appliance

Warning icons (warning of a danger)

Danger of

electrical shock

Warning of gas

bottles

Regulation signs (stipulate an action)

Disconnect the

mains plug

Do not lift appliance

Explosive

atmosphere

heat/hot surfaces Gas

Wear gloves

Danger of frostbite/cold burns

Wear safety

shoes

Other icons

6

Observe

information in

separate manual

Information on

first aid

Two or more

persons required

First Aid:

Rinse eyes out

Important or

useful additional information

Page 7

Safety regulations

1.2 Product safety and dangers

Incubators of the INCO type are technically well-developed, manufactured using high-quality

materials and tested for many hours in the factory. They contain the latest technology and

comply with recognised technical safety regulations. But there are still dangers involved, even

when the appliance is used as intended. These dangers are described below.

Warning!

After removing covers, live parts may be exposed. You may receive

an electric shock if you touch these parts. Disconnect the mains plug

before removing any covers. Any work inside the unit may only be

performed by qualified electricians.

Warning!

When loading the chamber with an unsuitable load, poisonous or

explosive vapours or gases may be produced. This could cause the

chamber to explode, and people could be badly injured or poisoned.

The chamber may only be loaded with materials/test objects which

do not form any poisonous or explosive vapours when heated up

(see also Chapter 2.7 Intended use on page 14 ).

Warning!

Danger of suffocation. In high concentrations, CO

and N2 can have

2

a suffocating effect. In normal operation, the incubator gives off

small amounts of CO

and – if equipped with the O2 module – N2

2

to its environment. You should therefore ensure that the room in

which it is installed is properly ventilated. If a gas bottle is not connected, or is empty, always close the stop valve or pressure reducer

on the bottle.

Warning!

High concentrations of CO

contact with CO

gas to the eyes and skin.

2

can cause cold burns or frostbite. Avoid

2

Warning!

CO

gas bottles may burst or explode at high temperature. Do not

2

use naked flames in the vicinity of the gas bottles. Store gas bottles

at lower than 50 °C in a well-ventilated location. Prevent water from

penetrating, as well as backflow into the gas bottles. It is essential

that you read the safety notes and regulations of the gas suppliers.

CO

and N

2

are not dangerous substances in terms of the German Ordinance on Hazardous

2

Substances (GefStoffV). You should nevertheless familiarise yourself with the applicable safety

regulations prior to handling such gas bottles.

7

Page 8

Safety regulations

1.3 Requirements of the operating personnel

The incubator may only be operated and maintained by persons who are of legal age, and

who have received instructions for the incubator. Personnel who are to be trained, instructed

or who are undergoing general training may only be active on the incubator under the continuous supervision of an experienced person.

The incubator may only be transported by persons (fork-lift truck, manual pallet jack), who are

trained for this work and who know the corresponding safety regulations.

Repairs may only be performed by qualified electricians. In this case the regulations in the

separate service manual must be observed.

1.4 Responsibility of the owner

The owner of the incubator

► is responsible for the flawless condition of the incubator and for the incubator being oper-

ated in accordance with its intended use (see page 14 );

► is responsible for ensuring that persons who are to operate or service the incubator are

qualified to do this, have received instructions about the incubator and are familiar with

this operating manual;

► must know about the applicable regulations, requirements and work protection regula-

tions, and train staff acordingly;

► is responsible for ensuring that unauthorised persons have no access to the incubator;

► is responsible for ensuring that the maintenance plan is adhered to and that maintenance

and repair work is properly carried out (see page 63 );

► ensures, for example through corresponding instructions and inspections, that the incuba-

tor and its surroundings are kept clean and tidy;

► is responsible for ensuring that personal protective clothing is worn by operating person-

nel, e.g. work clothes, safety shoes, protective gloves.

1.5 Changes and conversions

No independent conversions or alterations may be made to the incubator. No parts may be

added or inserted which have not been approved by the manufacturer.

Independent conversions or alterations result in the EC declaration of conformity (see page

16 ) losing its validity, and the incubator may no longer be operated.

The manufaturer is not liable for any damage, danger or injuries that result from independent

conversions or alterations, or from non-observation of the regulations in this manual.

1.6 Behaviour in case of malfunctions and irregularities

The incubator may only be used when in a flawless condition. If you as the operator notice

irregularities, malfunctions or damage, immediately put the incubator out of service (see

Chapter 1.8 ) and inform your superiors.

You can find information on eliminating malfunctions from page 40 .

8

Page 9

Safety regulations

1.7 What to do in case of accidents

1. Keep calm. Act resolutely and with consideration. Pay attention to your own

safety.

2. Switch off the incubator and close the valves on the gas bottle.

3. Call a doctor.

4. Initiate first aid measures. If available: Call a trained first aid helper.

In case of contact with CO2 to the eyes and skin:

Rinse eyes out with water for at least 15 minutes. With cold burns, rinse with water

for at least 15 minutes. Cover over in a sterile manner. Call a doctor.

Inhaling CO2 or N2:

High concentrations can cause suffocation. Symptoms may include a loss of mobility and

consciousness. The victim is not aware of suffocating.

Low concentrations of CO

Anyone affected should breathe fresh air, using a breathing device independent of recircu-

lating air. Keep the person warm and calm. Call a doctor. In case of respiratory arrest, use

artificial respiration.

can cause accelerated breathing and headaches.

2

If gas is escaping:

Leave the room immediately, warn others and ventilate the room. If you re-enter the room,

use an autonomous breathing device (independent of ambient air) if it has not been established that the atmosphere is harmless.

1.8 Switching off incubator in an emergency

► Push main switch on front side of appliance

( Fig. 1 ).

► Close the valves on the gas bottle.

Fig. 1 Switch off incubator by

pressing the main switch

9

Page 10

Design and Function

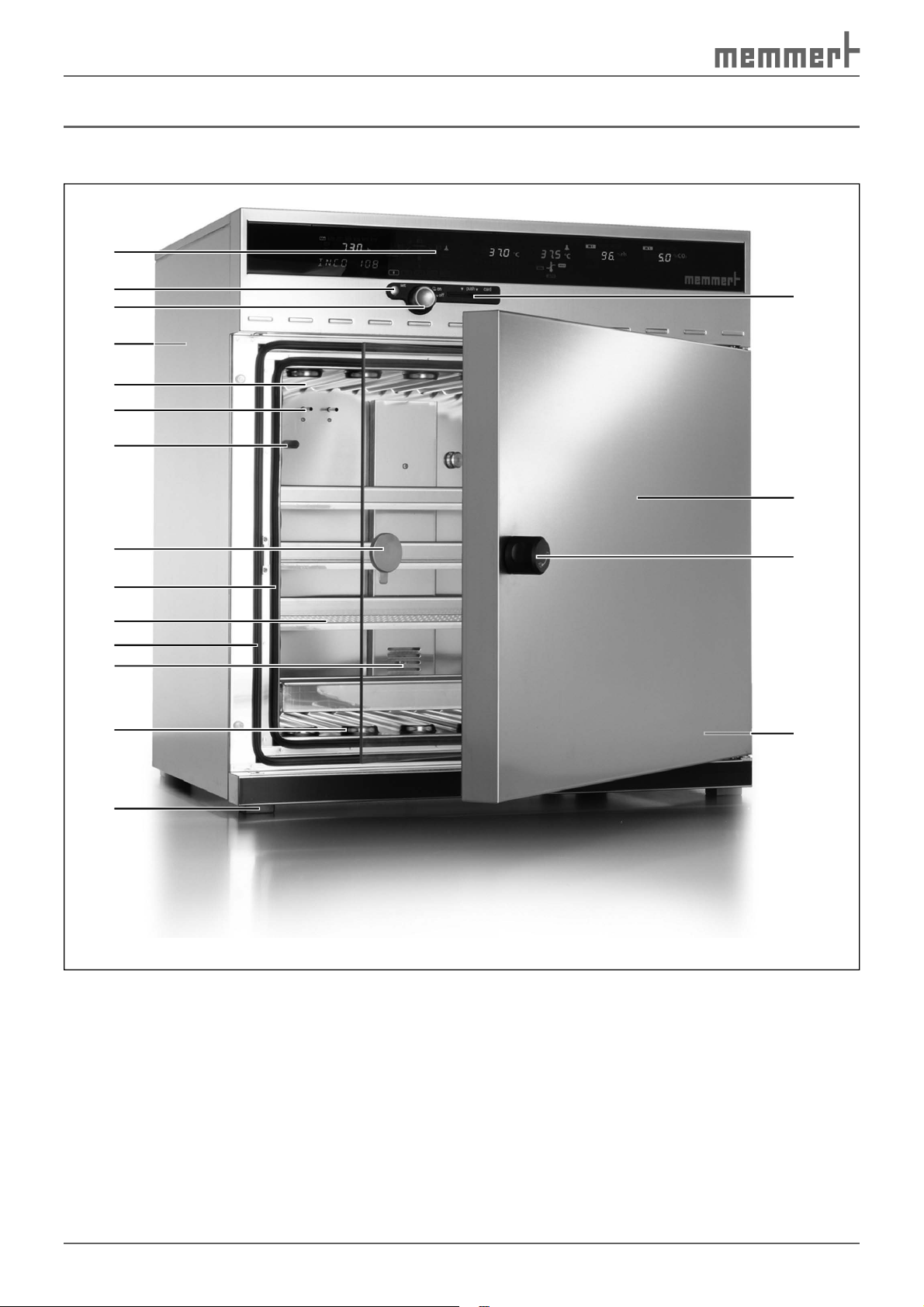

2. Design and Function

2.1 Design

1

10

11

12

13

2

3

18

4

5

6

7

17

8

16

9

15

14

Fig. 2 Design of INCO incubators

1 Controller/control panel (see page 29 )

2 Set key

3 Push/turn control

4 Connections on the rear of the oven

(see page 13 )

5 Heating ribs (see page 11 )

6 Pt100 temperature sensors

7 Humidity sensor

8 Glass door

9 Chamber seal

10 Sliding shelf

11 Door seal

12 Ventilator/inlet opening

13 Heating ribs

14 Adjustable feet

15 Nameplate (beneath door, see page 18 )

16 Door knob (see page 27 )

17 Door

18 Chip card reader

10

Page 11

Design and Function

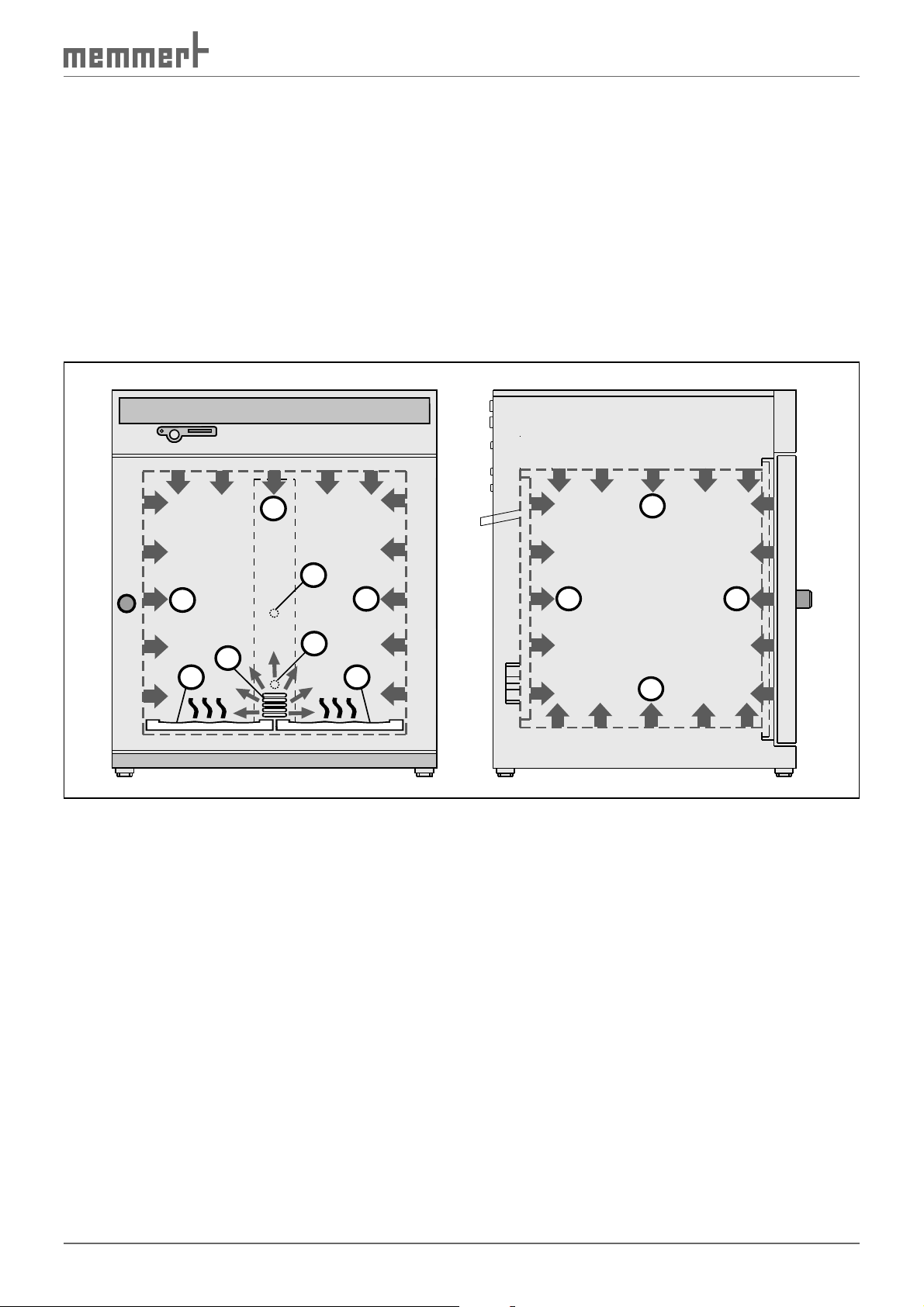

2.2 Function

The air in the incubator is heated up by an all-round heater with a large surface ( Fig. 3 , No. 1).

The CO

has a much higher specific weight than air, the gas is let into the working chamber above the

interior fan (2). The turbulence-free interior ventilation (3) ensures a uniform distribution of

the gases, creating a homogenous atmosphere.

In the basic version, humidification takes place by means of water trays (4). To avoid uncontrolled condensation, dosed fresh air is piped into the interior. If the appliance is equipped

with a humidity module, humidification takes place via a hot-air generator, which allows

water to evaporate at a set rate. The sterile hot air is let into the interior above the fan and is

mixed with the air current (5).

and/or N2 gas is introduced into the working chamber via a sterile filter. Because CO2

2

1

5

1

2

3

4

1

4

1

11

1

Fig. 3 How INCO incubators work

2.3 Optional extras

2.3.1 Basic equipment

► Electronic fuzzy-supported PID process controller with pulse width modulation and per-

manent performance adjustments and time-saving self-diagnosis system to quickly locate

errors (see page 41 )

► All-round heater with larger surface area, with additional thermal conduction layer (see

Fig. 3 )

► Capacitive humidity sensor

► Humidity control (fresh air via sterile filter) ensures that setpoint humidity is quickly

reached and guarantees short recovery times, while avoiding condensation formation

► Homogenous atmosphere and temperature distribution through encapsulated, turbu-

lence-free ventilation system

► STERICard for fully automatic sterilisation process control for hot air sterilisation of appli-

ance, including sensors and fan rotor (see page 51 )

11

Page 12

Design and Function

► Digitalised electronic CO

with self-diagnosis system and acoustic error display, air pressure compensation

control with automatic zero position, NDIR measuring system

2

► Language settings (see page 46 )

► Alphanumeric text display

► Integrated week time switch with grup function (e.g. each working day) (see page 33 )

► Retracting push-turn control for simple operation of appliance (see page 28 )

► Two separate Pt100 temperature sensors DIN Class A in a 4-wire circuit for control and

monitoring

► Digital monitoring control for overtemperature, undertemperature and automatic

setpoint following (ASF) (see page 50 )

► Mechanical temperature limiter (TB protection class 1, see page 47 )

► Monitoring relay to switch off heater in case of error

► Optical alarm display

► Acoustic signal messages if temperature or CO

if gas bottle is empty (see page 40 )

► Calibration of temperature, humidity, CO

rate PC (see from page 53 )

and O2 possible on the device without a sepa-

2

limits are crossed, when door is open and

2

2.3.2 Optionally available additional modules

Comfort module:

► Two gas connections with quick release connectors (see page 13 )

► Automatic switch-over of gas bottles

Hygiene module

► Electro-polished, seamless laser-welded chamber

Communication module

► Logging option of temperature, CO2 and relative humidity via computer/laptop

► Internal log memory with 1024 kB as ring memory for all setpoint and actual values, errors

and settings in real time and with date, logging approx. 3 months at 1 minute storage

interval (see page 62 )

► Parallel printer port (PCL3-compatible) for printing out log data (see page 13 and page 45 )

► optionally USB, Ethernet, RS-232 or RS-485 interface (see from page 58 )

CO2 module

► Extended adjustment range from 0 to 20 %

► 3-point calibration (5 %, 10 %, 15 % CO

O2 module

)

2

► Control of oxygen concentration through the introduction of nitrogen (N

range 1 % to 20 % O

(not in combination with Comfort or Premium module)

2

2

Premium module

► Includes comfort, hygiene, communication and CO

modules

2

Humidity module

► Active microprocessor humidification and dehumidification control (40-97 % rh)

12

); adjustment

Page 13

Design and Function

2.4 Material

For the outer housing, MEMMERT uses stainless steel (W.St.No. 1.4016), and for the interior,

stainless steel (W.St.No. 1.4301), which stands out through its high stability, optimal hygienic

properties and corrosion-resistance towards many (but not all!) chemical compounds (caution

for example with chlorine compounds). The chamber load for the appliance must be carefully

checked with respect to chemical compatibility with the materials mentioned.

A material resistance table can be requested from the manufacturer.

2.5 Electrical equipment

► Operating voltage: See nameplate (page 18 ), 50/60 Hz

► Current consumption: See nameplate (page 18 )

► Protection class 1, i.e. operating insulation with safety earth terminal in accordance with

EN 61010

► Protection type IP 20 acc. to EN 60 529

► Interference-suppressed acc. to EN 55011 class B

► Appliance fuse: Fusible link 250 V/15 A quick-blow

► The temperature controller is protected with a miniature fuse 100 mA (200 mA at 115 V)

► For models with a humidity model the CO

fuse

controller is protected with a 6.3 A miniature

2

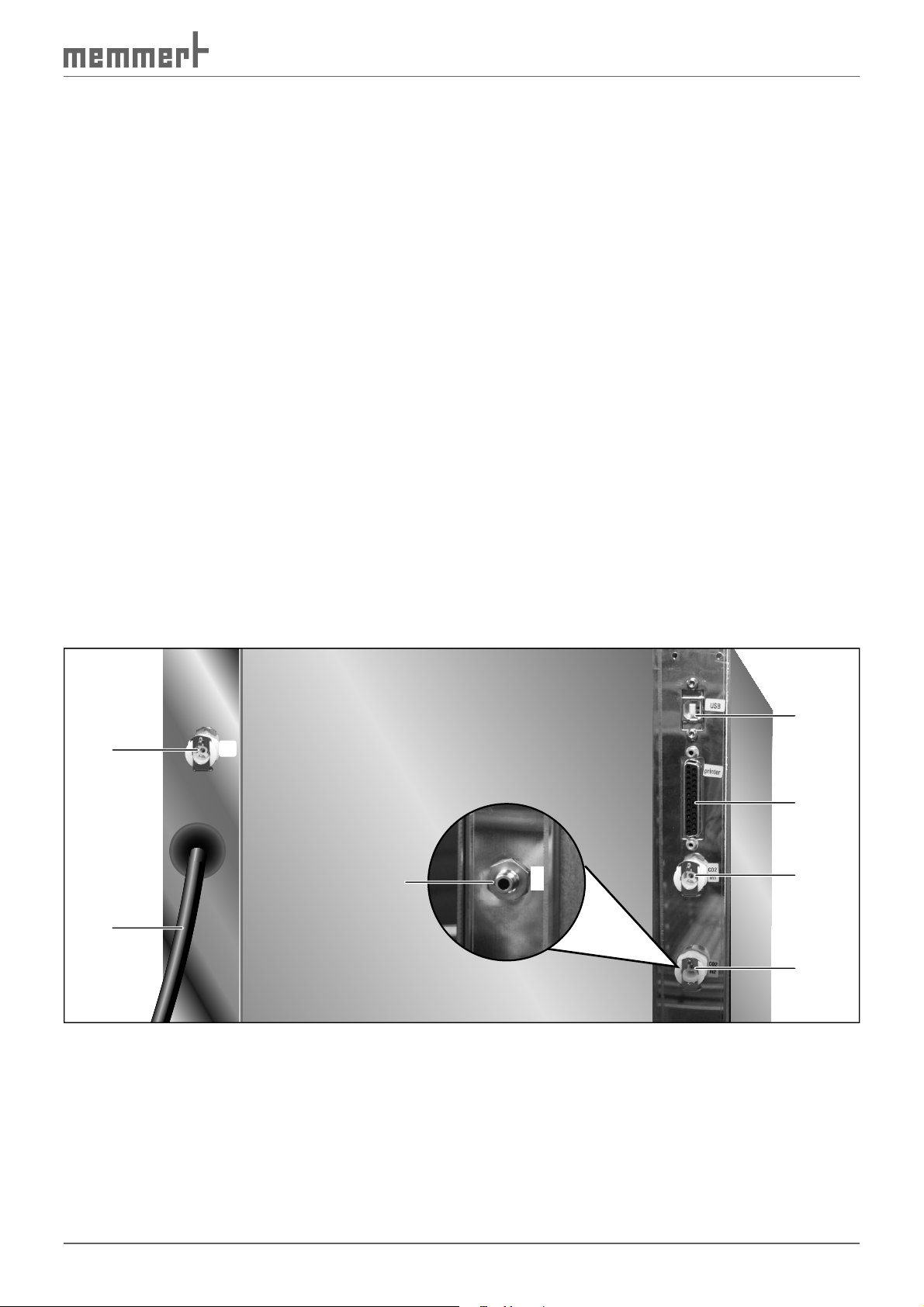

2.6 Connections

1

2

H2O

N2

7

In

3

4

5

6

Fig. 4 Connections on rear of appliance

1 Water connection (only for model with humidity module)

2 Mains lead

3 USB connection (only for models with communication or premium modules;

alternatively Ethernet, RS-232 or RS-485 connection) (details from page 58 )

4 Printer connection (only for models with communication or premium modules) (see page

45 )

5 CO

6 CO

connection to main gas bottle

2

connection to reserve gas bottle (only for models with CO2 or premium modules)

2

7 N2 connection (quick-release connector, only if equipped with O2 module)

13

Page 14

Design and Function

2.6.1 Electrical connection

Observe the country-specific regulations when making connections (e. g. in Germany DIN VDE

0100 with residual current device).

This appliance is intended for operation on an electrical power system with a system impedance Z

at the point of transfer (service line) of a maximum of 0.292 ohm. The operator must

max

ensure that the incubator is operated only on an electrical power system that meets these

requirements. If necessary, you can ask your local energy supply company what the system

impedance is.

2.6.2 Connection of external appliances

Only appliances may be connected externally (depending on the model, USB, RS 232, RS 485,

Ethernet, printer) whose interfaces comply with the requirements for safety extra-low voltage

(e.g. PC).

2.6.3 Gas connection

The oven can be connected with the supplied compressed air hose via a pressure regulator

with gas bottle monitor (DIN 8546) to a CO

gas supply.

compressed gas bottle or directly to a central CO2

2

For models with the CO

can be connected. If equipped with the O

of a second CO

gas bottle ( Fig. 4 ).

2

or premium modules, two gas bottles with quick release connectors

2

module, an N2 gas bottle can be connected instead

2

The pre-pressure must not exceed 1.2 bar. A value between 0.8 and 1 bar is considered to be

an ideal value.

2.6.4 Water connection

For models with a humidity module, the incubator can be connected with the supplied hose

to the also supplied water supply tank.

2.7 Intended use

INCO incubators may only be used for incubating cell cultures or similar. Any other use is

improper, and may result in hazards and damage.

The incubators are not explosion-proof (they do not comply with workplace health & safety

regulation VBG 24). The chambers may only be loaded with materials and substances which

cannot produce any toxic or explosive vapours at temperature ranges up to 50 ºC, and which

themselves cannot explode, burst or ignite.

The incubators may not be used for drying, vaporising and branding paints or similar materials, the solvents of which could form an explosive mixture when combined with air. If there is

any doubt as to the composition of materials, they must not be loaded into the incubator. Potentially explosive gas-air mixtures must not be produced, either in the interior of the chamber

or in the direct vicinity of the appliance.

The incubator may not be used for sterilisation purposes. It is not a steriliser with respect to

the Law on Medical Devices.

Only gas bottles with a pressure regulator may be connected to the gas connections of the

oven. Introducing other gases or materials than CO

14

or N2 is not permitted.

2

Page 15

Design and Function

2.7.1 Intended use of the INCOmed

For INCOmed incubators, which are subject to the 93/42/EEC guideline (Council Directive on

the approximation of the laws of the Member States relating to medical devices), the intended

use is defined as follows:

The CO2 incubator INCO med is intended for the creation and maintenance of constant environmental conditions for application in the field of in vitro fertilisation (IVF), especially for the

incubation of oocytes, spermatozoa and zygotes in special culture dishes for IVF application as

well as for gene expression and the biosynthesis of RNA and proteins.

15

Page 16

Design and Function

2.8 EC Declaration of Conformity

EC Declaration of Conformity

Manufacturer´s name and address: MEMMERT GmbH + Co. KG

Äußere Rittersbacher Straße 38

D-91126 Schwabach

Product: CO2 Incubator

Type: INCO 2

Sizes: 108 l / 153 l / 246 l

Nominal voltage: AC 230 V 50/60 Hz

The designated product is in conformity with the European EMC-Directive

2004/108/EEC

including amendments

Council Directive of 03 May 1989 on the approximation of the laws of the Member States relating to

electromagnetic compatibility.

Full compliance with the standards listed below proves the conformity of the designated product with the essential

protection requirements of the above-mentioned EC Directive:

DIN EN 61326-1:2006-10 EN 61326-1:2006

DIN EN 61000-3-11:2001-04 EN 61000-3-11 :2000

The designated product is in conformity with the European Low Voltage Directive

2006/95/EEC

Council Directive on the approximation of the laws of the Member States relating to Electrical

equipment for use within certain voltage limits.

Full compliance with the standards listed below proves the conformity of the designated product with the essential

protection requirements of the above-mentioned EC Directive:

DIN EN 61 010-1 (VDE 0411 part 1):2002-08 EN 61 010-1:2001

DIN EN 61 010-2-010 (VDE 0411 part 2-010):2004-06 EN 61 010-2-010:2003

Schwabach, 22.06.10

______________________________

(Legally binding signature of the issuer)

This declaration certifies compliance with the above mentioned directives but does not include a property assurance. The

safety note given in the product documentation which are part of the supply, must be observed.

including amendments

16

Modelljahr 2006 D10318 / 22.06.10

Page 17

Design and Function

Manufacturer's name and address:

MEMMERT GmbH + Co. KG

Äußere Rittersbacher Straße 38

91126 Schwabach, Germany

Product:

Incubators

Type:

INCO med

Sizes:

108 l / 153 l / 246 l

Rated voltage:

AC 230 V 50/60 Hz

EC Declaration of Conformity

This product complies with the provisions of the directive:

93/42/EEC

including annex and revisions

Council Directive on the approximation of the laws of the Member States relating to medical

devices of 14 June 1993 (Official Journal of the EC No. L 169, page 1 of 12 July 1993)

Schwabach, Germany, 01/11/2012

legally binding signature of the manufacturer)

(

This declaration states the compliance with the above Directives, however, does not provide any warranted properties.

The safety instructions in the supplied documents have to be observed.

D24002

17

Page 18

Design and Function

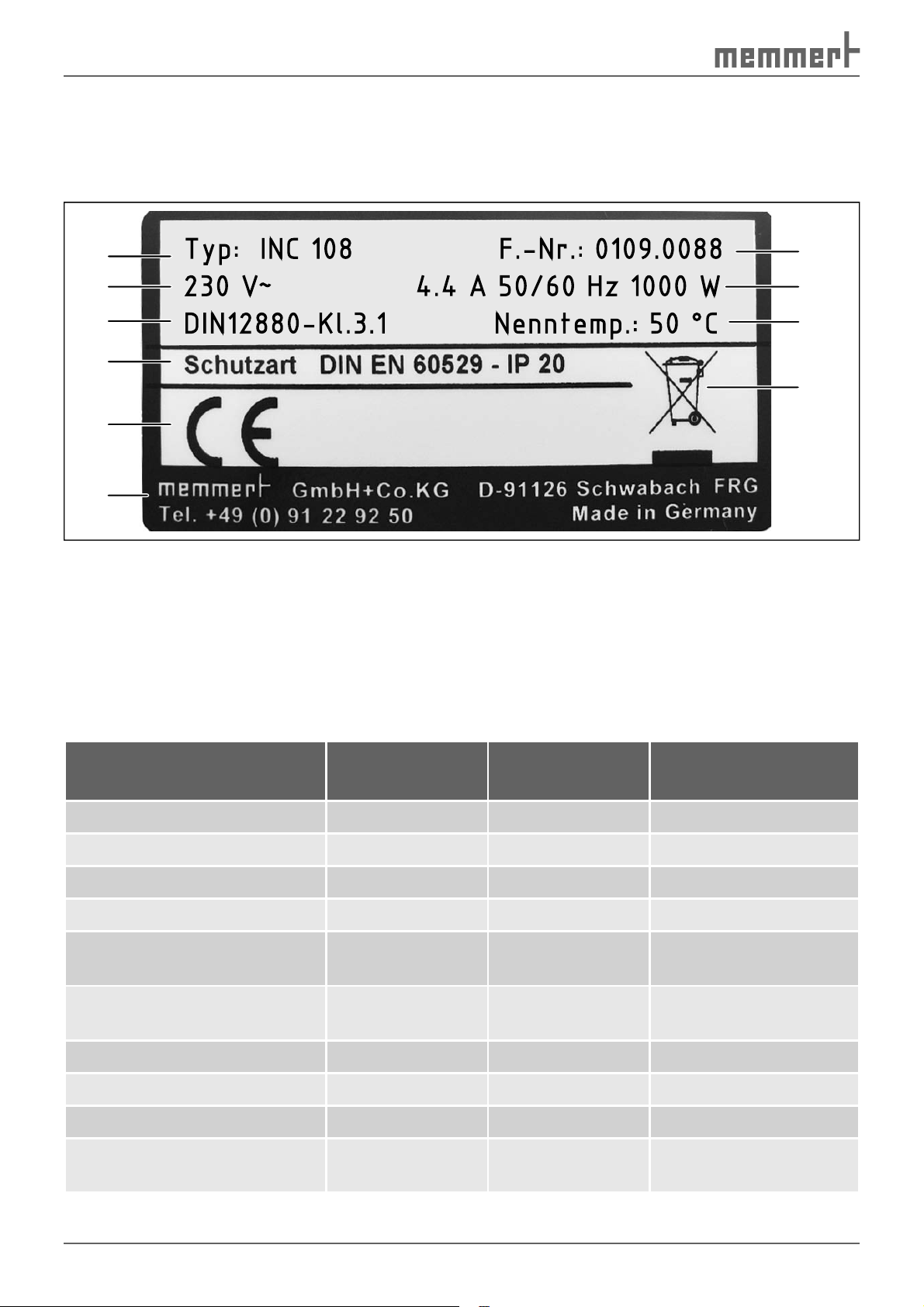

2.9 Designation (nameplate)

The nameplate ( Fig. 5 ) provides information about the appliance model, manufacturer and

technical data. It is attached to the front of the appliance, on the right beneath the door (see

page 10 ).

1

2

3

4

5

6

Fig. 5 Nameplate

1 Type designation

2 Operating voltage

3 Applied standard

4 Protection type

5 CE conformity

Typ: INC 108 F.-Nr.: 0109.0088

230 V

DIN12880-Kl.3.1 Nenntemp.: 50 °C

~

4.4 A 50/60 Hz 1000 W

6 Address of manufacturer

7 Disposal note

8 Temperature range

9 Connection / performance values

10 Factory number

10

9

8

7

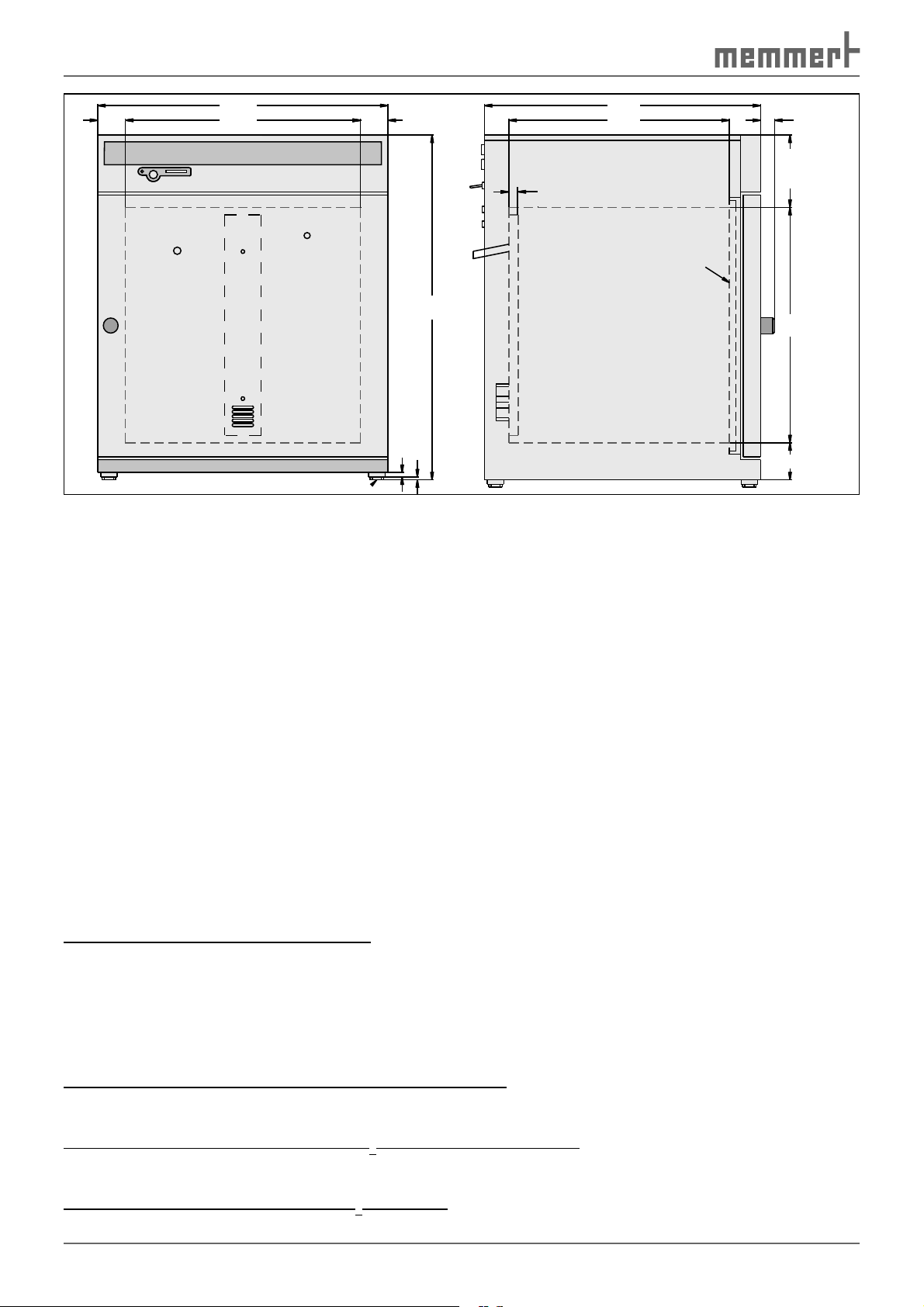

2.10 Technical data

Model

* See Fig. 6 on page 20 .

Chamber width A* [mm] 560 480 640

Chamber height B* [mm] 480 640 640

Chamber depth C* [mm] 400 500 600

Appliance width D* [mm] 710 630 790

Appliance height E* (varies

due to adjustable feet) [mm]

Appliance depth F* (includ-

ing door handle) [mm]

Chamber volume [litres] 108 153 246

Weight [kg] 70 90 110

Performance [W] 1000 1500 2000

Max. number of sliding

shelves half size / full size

108 153 246

778 920 938

590 690 790

-/4 -/6 2 x 6/6

18

Page 19

Design and Function

Model

* See Fig. 6 on page 20 .

Max. load per sliding shelf

[kg]

Max. load per appliance [kg] 40 40 60

Temperature Temperature recording by means of Pt100 in a 4-wire circuit

Adjustment range: Normal mode: 20 °C to 50 °C

Sterilisation mode: 160 °C (4 hours) via STERICard

Adjustment precision: 0.1 °C

Control range: from 8 °C above room temperature to 50 °C

Variation (time): max. ±0,1 °C at 37 °C

Variation (spatial): max. ±0.3 °C at 37 °C

Humidity The relative humidity in the chamber is measured by a capac-

itive humidity sensor and displayed digitally in percent.

The measurement precision of the humidity sensor is 1 % rh

108 153 246

15 15 15

► Adjustment range: 88 to 97 % rh (for models with

humidity module 40 to 97 % rh)

► Adjustment precision: 1 % rh

CO

2

(only if equipped with O2

O

2

module)

► Display range: 10 to 98 % rh

► Variation (time): max. ±1 % rh

The CO2 content is determined through an NDIR measuring system, controlled constantly by a microprocessor and

displayed digitally in percent

► Adjustment range: 0 to 10 % (for models with CO

premium modules 0 to 20 %)

or

2

► Adjustment precision: 0.1 %

► Variation (time): max. ±0.1 % rh

► Variation (spatial): max. ±0.3 %

The O2 content is determined with a long-lasting, maintenance-free zirconium dioxide sensor, constantly controlled by

a microprocessor and displayed digitally in percent

► Adjustment range: 1 to 20 %

► Adjustment precision: 0.1 %

► Variation (time): max. ±0.1 %

► Variation (spatial): max. ±0.3 %

19

Page 20

Design and Function

D

A75 75

12

Fig. 6 Dimensions of INCO incubators

2.11 Ambient conditions

F

C

38

E

8

38

202

B

76

► The incubator may only be used in enclosed rooms and under the following environmental

conditions:

Ambient temperature: 5 ºC to 35 ºC

Humidity: max. 80 % not condensing

Degree of pollution: 2

Altitude of installation max. 3,000 m above sea level

► The incubator may not be used in areas where there is a risk of explosions. The ambient air

must not contain any explosive dusts, gases, vapours or gas-air mixtures. The incubator is

not explosion-proof.

► Heavy dust production or aggressive vapours in the vicinity of the appliance could lead to

sedimentation in the chamber interior and as a consequence, could result in short circuits

or damage to electrical parts. For this reason, sufficient measures should be taken to

prevent large clouds of dust or aggressive vapours from developing.

2.12 Accessories included

For incubators with basic fittings:

► Two (INCO 108) or three (INCO 153 and 246) sliding shelves

► Gas pressure hose

► Water tray (one for INCO 108 and 153 incubators, two for INCO 246 incubators)

► Sterilisation chipcard

Additionally, for models with humidity module:

► Water supply tank and connection hose

Additionally, for models with CO2 or premium module:

► Second gas pressure hose with quick-release connector

Additionally, for models with O2 module:

► Second gas pressure hose with quick-release connector

20

Page 21

Delivery, Transport and Setting Up

3. Delivery, Transport and Setting Up

3.1 Safety regulations

Warning!

You may injure your hands or feet when transporting and

installing the incubator. You should wear protective gloves

and work shoes.

Warning!

Because of the weight of the incubator, you could injure yourself if

you try to lift it on your own.

If possible, only transport the incubator with a fork-lift truck or

manual pallet jack. The incubator may only be moved using a means

of transport by persons who have the required qualification for this

(e.g. fork-lift truck licence). This incubator may not be transported

with a crane.

If the incubator has to be carried, at least two people are required

for models 108 and 153, and at least four people for model 246.

Warning!

The incubator could fall over and seriously injure you. Never tilt the

incubator and transport it only in an upright position.

3.2 Transport

The incubator can be transported in three ways:

► with a fork-lift truck; move the forks of the truck entirely under the incubator

► on the manual pallet jack.

► by carrying; to do this, at least two people are required for models 108 and 153, and four

people for model 246. Read the weight information detailed on page 18 .

3.3 Delivery

The incubator is delivered in cardboard packaging on a cardboard pallet.

3.3.1 Unpacking

1. Remove cardboard packaging or cut open carefully along an edge.

2. Lift up incubator from pallet and put down on the appliance feet.

3.3.2 Checking for completeness and transport damage

► Check the delivery note to ensure that the delivery is complete.

► Check the inside and outside of the incubator for damage.

If you notice deviations from the delivery note, damage or irregularities, do not put the incubator into operation, but inform the haulage company and the manufacturer.

3.3.3 Disposing of packaging material

Dispose of the packaging material (cardboard) in accordance with the effective legal disposal

regulations for cardboard packaging in your country.

21

Page 22

Delivery, Transport and Setting Up

3.3.4 Storage after delivery

If the incubator is initially to be stored after delivery: Read the storage conditions from page

65 .

3.4 Setup

The incubator can be placed either on the ground or on a table (work surface). When doing

this, ensure that the appliance is positioned exactly horizontally. The installation site must be

level and able to reliably carry the weight of the incubator (see page 18 ). Do not place the appliance on an inflammable surface.

A power connection must be available at the installation site in accordance with the connection data on the nameplate (see page 18 ).

The distance between the wall and the rear of the chamber must be at least 15 cm. The clearance from the ceiling must not be less than 20 cm and the side clearance from the wall not

less than 8 cm ( Fig. 7 ). Sufficient air circulation in the vicinity of the chamber must be guaranteed at all times.

FP

FP

FP

Fig. 7 Minimum clearance from walls and ceiling

FP

22

Page 23

Delivery, Transport and Setting Up

3.4.1 Base (accessory)

The incubator can be placed on a base ( Fig. 8 ).

3.4.2 Stacking frame (accessory)

Two appliances of the same model size can be placed on top of one another. To do this, foot

alignment provisions must be attached to the lower oven ( Fig. 9 ):

1. Remove the housing cover from the lower oven.

2. Insert drilling template (supplied with the foot alignments) into the overturned lid.

3. Mark drilling points and drill with a 4.2 mm diameter drill bit.

4. Screw the foot alignment provisions to the top of the lid with the screws and nuts supplied.

5. Put the covers back on.

Fig. 8 Base

Fig. 9 Assembly of the foot alignment

provisions when two incubators are

placed on top of one another

23

Page 24

Putting into Operation

4. Putting into Operation

4.1 Checks

4.1.1 Checking the temperature sensor

Especially strong vibrations during transport could

result in the temperature sensors being moved

in their holders in the working chamber.

Check the temperature sensor for its correct

positioning and if necessary adjust its position

in the holder ( Fig. 10 ).

4.1.2 Check the door and adjust if

necessary

See page 64 .

4.2 Connecting

4.2.1 Power supply

Caution:

Observe the country-specific regulations when making connections (e. g. in Germany DIN VDE 0100 with residual current

device / RCD). Observe the connection and power ratings (see nameplate).

The incubator is intended for operation on an electrical power system with a system impedance Z

must ensure that the incubator is operated only on an electrical power system that meets

these requirements. If necessary, you can ask your local energy supply company what the

system impedance is.

Connect power cable (see Fig. 4 on page 13 ).

at the point of transfer (service line) of a maximum of 0.292 ohms. The operator

max

Fig. 10 Temperature sensor

4.2.2 External devices

(only for models with communication or premium modules)

Only appliances whose interfaces comply with the requirements for safety extra-low voltge

(e.g. PC, laptop, printer) may be connected to the connections on the rear of the incubator

(see Fig. 4 on page 13 ). Which devices may be connected depends on the chosen model /

module variant ( Communication interfaces described in detail from page 58 ).

4.2.3 Water connection

(only for models with humidity module)

Only use distilled water or DI water.

1. Fill up the supplied water supply tank (canister) with distilled water and place behind/

next to the incubator.

2. Attach the supplied hose the quick-release connections to the canister and the water supply "H

24

O“ on the rear of the appliance (see Fig. 4 on page 13 ).

2

Page 25

4.2.4 Gas connection

Warning!

Danger of suffocation: In high concentrations, CO

a suffocating effect. In normal operation, the incubator gives off

small amounts of CO

to its environment. You should therefore ensure that the room in

which it is installed is properly ventilated.

Warning!

High concentrations of CO

contact with CO

gas to the eyes and skin.

2

Warning!

CO

gas bottles may burst or explode at high temperature. Do not

2

use naked flames in the vicinity of the gas bottles. Store gas bottles

at lower than 50 °C in a well-ventilated location. Prevent water from

penetrating, as well as backflow into the gas bottles. It is essential

that you read the safety notes and regulations of the gas suppliers.

For incubators with basic fittings:

Putting into Operation

and N2 can have

2

and – if equipped with the O2 module – N2

2

can cause cold burns or frostbite. Avoid

2

Attach the supplied pressure hose to the

gas bottle (pressure regulator) and to the

"CO

" connection on the rear of the appli-

2

ance with two hose clamps ( Fig. 11 , see

also page 13 ).

Fig. 11

Gas connection for incubators with basic

fittings

For incubators with CO2 or premium module:

Two gas bottles can be connected by simply

pushing the supplied pressure hoses onto

the "CO

connections on the rear of the appliance

( Fig. 12 , see also page 13 ).

Connect the main gas bottle to "In1", a reserve gas bottle can be connected to "In2".

Attach the pressure hose to the gas bottles

(pressure regulator) with hose clamps.

In1" and "CO2 In2" quick-release

2

„CO2 In“

„CO2 In1“

In2“

„CO

2

CO

CO

2

CO

2

2

Fig. 12

Gas connection for incubators with CO

or Premium modules

2

25

Page 26

Putting into Operation

For incubators with O2 module:

► Attach the supplied CO

to the CO

gas bottle (pressure reducer)

2

pressure hose

2

and to the “CO2 In” connection on the

rear of the incubator with a hose clamp

( Fig. 13 , see also page 13 ).

► Attach (push on) the supplied N

sure hose to the N

reducer) and to the “N2 In” connection

on the rear of the incubator with a hose

clamp.

gas bottle (pressure

2

4.3 Oxygen calibration

(only for models with O2 module)

Perform an O

into operation (see page 57 ).

calibration before putting

2

pres-

2

„CO2 In“

„N

In“

2

CO

2

Fig. 13

Gas connection for incubators with O

ule

N

2

mod-

2

26

Page 27

Operation and control

5. Operation and control

5.1 Operating personnel

The incubator may only be operated by persons who are of legal age and have received instructions for the incubator. Personnel who are to be trained, instructed or who are undergoing general training may only be active on the incubator under the continuous supervision of

an experienced person.

5.2 Opening the door

► To open the door, turn handle to the right ( Fig. 14 ).

► To close, turn door handle to the left.

When the door is opened, the CO

cally interrupted. If the heated outer door is left open for

any length of time, condensation may form on the glass

door.

5.3 Loading the incubator

Warning!

When loading the chamber with an

unsuitable load, poisonous or explosive

vapours or gases may be produced. This

could cause the chamber to explode, and people could be badly injured or poisoned. The chamber may only be loaded with materials/

test objects which do not form any toxic or explosive vapours when

heated up, and which cannot ignite. If there is any doubt as to the

composition of materials, they must not be loaded into the incubator.

Caution:

Check the chamber load for chemical compatibility with the materials of the incubator

(see page 13 ), since considerable damage could otherwise occur to the chamber load,

the appliance or the surroundings.

supply is automati-

2

close

Fig. 14 Opening and

closing the door

open

The incubators are not explosion-proof (they do not comply with workplace health & safety

regulation VBG 24) and are therefore not suitable for drying, vaporising and branding paints

or similar materials, the solvents of which could form an explosive mixture when combined

with air. Potentially explosive gas-air mixtures must not be produced, either in the interior of

the chamber or in the direct vicinity of the appliance.

Heavy dust production or aggressive vapours in the chamber or in the vicinity of the appliance could lead to sedimentation in the chamber interior and as a consequence, could result

in short circuits or damage to electrical parts. For this reason, sufficient measures should be

taken to prevent large clouds of dust or aggressive vapours from developing.

The chamber must not be loaded too tightly, so that proper air circulation in the working

chamber is guaranteed. Do not place any of the chamber load on the floor, touching the side

walls or right below the ceiling (heating ribs) of the working chamber. To guarantee an optimal air circulation, push in the sliding shelves so that the gaps between the door, sliding shelf

and rear wall of the chamber are roughly the same size.

27

Page 28

Operation and control

5.4 Inserting water tray(s)

(for appliances with basic fittings)

Fill the water tray with distilled water and push into the lowest slot ( Fig. 15 ).

INCO

model

108 1 1.5 to 2.5 1 to 1.5

153

246 2

Fig. 15 Inserting water tray(s)

Number

of

water

trays

1 1.5 to 2.5 1 to 1.5

Filling

level in

cm for

each tray

approx.

1.5 to 2.5 1 to 1.5

each tray

Amount

of water

in ltr. for

approx.

5.5 Connect gas supply

1. Check that the gas bottle(s) is properly connected (see also page 13 ).

2. Open valve(s).

5.6 Switch on appliance

The incubator is switched on and off by pressing the main switch/ push-turn control on the

front of the appliance.

► Switching on: press the main switch so that it comes out of the appliance ( Fig. 16 ).

► Switching off: press the main switch so that it retracts back into the appliance ( Fig. 17 ).

Fig. 16 Switching on incubator

Fig. 17 Switching off incubator

28

Page 29

Operation and control

5.7 Basic operation

The desired parameters are entered on the operating panel of the controller on the front of

the appliance ( Fig. 18 ). Basic settings, as well as those for time and printing, can also be made

here. In addition, programmed and current parameters are displayed, as well as warning messages:

123465 7 8 109 11 12

Tu

Mo

We

on

off

Sa Su

Fr

Th

t1

t3

t2

PRINT

4

t4

3

loop

2

1

SETUP

Fig. 18 Operating panel

1 Time display

2 Display appliance locked with user-ID

card (see page 52 )

3 Display appliance is heating up

4 Sterilisation mode (see page 51 )

5 Temperature display

6 Alarm display

7 Monitoring temperature display

(see page 47 )

8 Horn

set

All operating functions are selected by turning the push-turn control to the

left or right...

STERI DEFRO

IN 1

°C

MIN

°C

MAX

AUTO

OUT

IN 2

rh

%

mb

IN 1

OUT

IN 2

13141516

9 Warning water supply tank empty

10 Humidity display

11 Gas bottle 1 active

12 Gas bottle 2 active

13 CO

display

2

14 Display appliance is humidifying

15 Operating mode display (see page 30 )

16 Text display/O

display (O2 display only if

2

equipped with O2 module)

CO

mb

2

set

...and adjusted by turning this with the SET key held down.

5.8 Setting parameters

In general, all setting actions on the operating panel described on the following pages are

made in the same way:

set

set

set

Settings for other parameters are made in the same way.

1. You select the desired parameter with the push-turn control (menu item, e. g.

temperature); then all other parameters go dark and the selected one flashes.

2. With the SET key held down, set the desired value (e. g. 37.0 °C) with the

push-turn control.

3. Release the SET key, and the set value is saved. The display briefly shows the

set value, flashing. The current temperature is displayed and the incubator

begins to heat up to the set temperature.

29

Page 30

Operation and control

t

The control returns automatically to the main menu if the push-turn key or set key is

not operated for approx. 30 seconds.

Setting the temperature (Quick adjustment):

1. Hold down the SET key and set the desired temperature setpoint with the push-turn

control.

2. Release the SET key

The appliance flashes briefly, showing the temperature setpoint. Then the current temperature

appears on the display and the controller begins to move to the set temperature.

5.9 Operating modes

INCO incubators can be operated in three ways ( Fig. 19 ).

► Normal mode: The incubator runs in permanent operation at the temperature, humidity

and CO

31 .

► Week time switch: The incubator runs at the set values only at certain times. Operation in

this mode is described from page 33 .

values set on the operating panel. Operation in this mode is described from page

2

► Interface mode with PC/laptop (for models with communication or premium modules, see

from page 58 )

In addition, basic appliance settings can be made (SETUP, see page 45 ) and printouts can be

made if the appliance is equipped with the communication or premium module (PRINT, see

page 45 ).

SETUP

Basic appliance

settings

(see Page 45 )

Normal

operation

(see Page 31 )

Fig. 19 Operating modes

Week time

switch

(see Page 33 )

PRINT

Printer

(see Page 45 )

5.10 Setting the operating mode

se

1. Hold SET key down for approx. three seconds, the selected operating mode

then begins to flash.

set

set

30

2. Select the desired operating mode (normal mode, week time switch, programming mode, printer or basic appliance settings/setup by turning control

with SET key held down.

3. Release the SET key, and the selected operating mode is saved.

Page 31

Operation and control

5.10.1 Normal mode

The appliance runs in this operating mode in permanent operation. The desired setpoints for

operating the chamber can be selected. The settings have an immediate effect on the functions of the appliance.

1. Load incubator (see page 27 ).

2. Switch on appliance. To do this, press the push-turn control on the operating panel so that

it comes out of the appliance (see Fig. 16 on page 28 ).

3. Select the normal operating mode

with the push-turn control:

PRINT

SETUP

4. As described above, set the individual parameters with the push-turn control and the set

key:

Temperature setpoint

Adjustment range: 20°C to 50°C

°C

Temperature monitoring

Adjustment range:

MIN MAX AUTO

°C

(see also page 47 )

MIN

AUTO

MAX

Humidity setpoint

rh

Adjustment range:

%

► For incubators with basic

fittings: 88 to 97 %rh

► For models with humidity

module: 40 to 97 %rh

CO2 setpoint

Adjustment range: 0 bis 10 %

(or models with CO

modules 0 to 20 0 to 20 %)

O2 setpoint

(only for models with O

ule)

Adjustment range:

Off, 1 to 20 %

or premium

2

mod-

2

2

Sa Su

Mo

on

off

Tu

We

Th

CO

Fr

o2=3.4%

t2

t1

31

Page 32

Operation and control

5.10.2 Settings example normal mode

With a 5% CO2 content, a 3% oxygen content and a humidity of 96%, the appliance should

heat up to 37°C. The monitoring function should respond at 38.5 °C ( Fig. 20 ).

50

Monitoring temperature

40

30

20

10

Temperature in °C

Time Time Time

100

80

60

40

20

Humidity rh in %

Fig. 20 Example for normal mode

1. Setting the normal operating mode:

Hold SET key down for approx. 3 seconds, the current

operating mode then begins to flash.

Select the

operating mode with the push-turn control, while the SET key is held down. After you let go of

the SET key, the control is in the normal operating mode.

2. Setting the temperature setpoint:

Hold down the SET key and set the desired temperature

setpoint of 37.0 °C with the push-turn control.

25

20

in %

2

15

CO

10

5

25

20

in %

2

O

15

10

5

PRINT

Time

SETUP

°C

Release the SET key, the appliance will briefly flash, showing the temperature setpoint. Then the current temperature

appears on the display and the controller begins to move

to the set temperature of 37.0 °C.

► Heating up is indicated by the icon.

3. Setting the monitoring temperature:

Turn the push-turn control to the right until the monitor-

ing temperature and the MIN or MAX icon flashes. Hold

down the SET key and with the push-turn control, set

the overtemperature limit to 38.5 °C and the undertemperature limit to 36.0 °C. Turn the push-turn control to

the right until the monitoring temperature and the AUTO

icons flash. Hold down the SET key and set to on with the

push-turn control.

The tolerance band is set in the SETUP menu (see

page 46 ).

°C

MAX

MIN

AUTO

32

Page 33

4. Setting the humidity setpoint:

Turn the push-turn control to the right until the humid-

ity display flashes. Hold down the SET key and set the

desired humidity setpoint of 96.0 %rh with the push-turn

control. After releasing the SET key, the humidity setpoint

briefly flashes. The current humidity value appears on

the display and the controller begins to move to the set

value.

Operation and control

rh

%

The humidification process is indicated by the

icon

(only for models with humidity module).

5. Setting the CO2 setpoint

Turn the push-turn control to the right until the CO

2

display flashes. Hold down the SET key and set the desired

CO

setpoint of 5.0 % with the push-turn control. The

2

appliance flashes briefly, showing the CO

current CO

actual value appears on the display and the

2

controller begins to move to the set CO

setpoint. The

2

setpoint.

2

Depending on the bottle used, fumigation is displayed by the

IN 1

6. Adjust the O2 setpoint

(only for models with O

2

Turn the push-turn control to the left until the O

flashes. Hold down the set-key and set the desired O

IN 2

or

module)

icon.

display

2

2

Mo

on

off

Tu

We

setpoint of 3.0 % with the push-turn control. Release

the set-key. The appliance flashes briefly, showing the O

setpoint. Then, the current O2 actual value appears on

2

o2=3.0%

the display and the controller begins to move to the set

O

value.

2

The incubator is now running in permanent operation with the set values.

Th

CO

Fr

2

Sa Su

5.10.3 Week time switch

In this operating mode, the appliance switches on and

off automatically at the times programmed.

PRINT

During the OFF phase of the week time switch, the

appliance is in standby mode. The heating and cooling functions, along with the CO

humidity supply are switched off here and the controller display shows the time, dimmed.

The sequence of the week time switch repeats itself each week.

In total, a maximum of 9 time blocks can be programmed, consisting of the switching on and

switching off times.

and

2

SETUP

33

Page 34

Operation and control

Weekday

Adjustment range: Monday to Sunday

Day groups

Adjustment range: Working days Mo-Fr

Weekend Sat-Sun

No switch on time: ---Appliance not switched on on this day

Switch on time (on)

Adjustment range: 00:00 to 23:59 hours

Switch off time (off)

One minute beyond the switch on time up to

24:00

By turning further to the right, parameters (temperature, humidity setpoints etc.) can be

selected as in the normal operating mode.

Mo

Mo

Mo

on

off

on

off

on

off

Tu

Tu

Tu

We

We

We

Th

Th

Th

Fr

Fr

Fr

Sa

Sa

Sa

h

h

Su

Su

Su

If no settings (temperature setpoint etc.) are made for the ON phase, the controller takes

over the values from the normal operating mode.

For reasons of safety, you should always check that only one switch one time is programmed

in the desired time blocks and days. By turning further to the right, parameters (temperature

setpoint etc.) can be selected as in the normal operating mode.

If the controller is in standby mode or the week time switch is in the ON phase, the temperature setpoint can be directly accessed by briefly pressing the SET key. By turning the control to

the right, you are returned to temperature monitoring, humidity and CO

to the left, you come back to the settings for the individual time blocks.

setting. By turning

2

34

Page 35

Operation and control

5.10.4 Settings example week time switch

From Mo-Fr (workdays group), the appliance should switch on at 9.30 and switch off at

19.00. In addition it should work on Saturday from 10.00 to 14.00 ( Fig. 21 ).

24:00h

12:00h

01:00h

9:30h - 19:00h

Mo

9:30h - 19:00h

Tu

9:30h - 19:00h

We

9:30h - 19:00h

Th

Fig. 21 Operation with week time switch (example)

1. Setting the week time switch operating mode

Hold the SET key down for approx. 3 seconds, the current

operating mode then begins to flash. Select the week

time switch operating mode with the push-turn control,

while the SET key is held down.

Release the SET key, the control is now in the week time

switch operating mode.

2. Switch on Mo-Fr at 09:30

Turning the push-turn control to the left, select the

"Mo-Fr on" icons (group working days).

Hold down the SET key and set the desired switch-on

time with the push-turn switch to 9:30.

9:30h - 19:00h

10:0h -

14:00h

Fr

Mo

Sa

Tu

on

off

We

Su

Th

PRINT

Fr

SETUP

Sa Su

3. Switch off Mo-Fr at 19:00

Select "Mo-Fr off" (group working days) with the push-

turn control.

Hold down the SET key and set the desired switch-off

time with the push-turn switch to 19:00.

Mo

on

off

Tu

We

Th

Fr

Sa Su

35

Page 36

Operation and control

4. Switch on Sa at 10:00

With the push-turn control, select "Sat on".

Hold down the SET key and set the desired switch-on

Tu

on

off

We

Th

Sa

Su

Fr

h

Mo

time with the push-turn switch to 10:00.

5. Switch off Sa at 14:00

With the push-turn control, select "Sat off".

Hold down the SET key and set the desired switch-off

Tu

on

off

We

Th

Sa

Su

Fr

h

Mo

time with the push-turn switch to 14:00.

5.10.5 Operation with PC/ laptop (optional)

If equipped with the communication or premium module, the incubator can optionally be

used, controlled and programmed with a PC/laptop. It has corresponding communication

interfaces for this purpose (see page 13 and page 58 ).

Operation is described in a separate manual. It is delivered with the incubator for

the relevant models.

5.11 During operation

Regularly check the water level. If necessary, add distilled water.

Warning messages during operation: See Page 40 .

CO2 mode

In the heating up phase, the CO2 controller is initially deactivated. The CO2 intake is interrupted during this period. About 5 minutes after the setpoint temperature has been reached,

the CO

valve on the gas bottle must be open). To ensure a homogenous distribution of the CO

the interior, the gas is piped in above the chamber fan. The setpoint can be adjusted in 0.1 %

steps from 0 to 10% (for models with CO

Displays in CO2 mode:

control begins measuring and CO2 gas is let in to the chamber via a sterile filter (the

2

or premium modules 0 to 20 %)

2

After a sterilisation procedure, and in cycles every 24 hours, an automatic zero balance

adjustment is carried out. This automatic zero balance adjustment is completed after a

few minutes.

HEAT UP is shown during the heating up phase of

HEAT UP

the CO

sensor. In the CO2 display, CO2 is shown.

2

gas in

2

36

AUTOZERO - DO NOT OPEN DOOR is displayed during the

zero balance adjustment.

Page 37

Operation and control

IN 1

IN 2

OUT

CO

After the setpoint temperature has been reached,

the CO

on the setting.

is active.

2

Is displayed if the CO2 concentration exceeds the

defined setpoint by at least 1 % for more than 3

minutes. If the concentration is higher, the CO

display and the

In this case you should open the door for 30 sec.

and wait to see if the controller steadily adjusts

to the setpoint. If the error occurs again, contact

Customer Service.

CO2 empt is displayed if gas bottle 1 and/or 2 is/are

empty. In this case, you should connect new gas

bottles (see page 28 ).

concentration is displayed in %, depending

2

This monitoring function only starts to work

once the CO

IN 1

indicates that gas bottle 1

icon flash.

setpoint has been reached.

2

2

The pressure in the gas bottles is a constant

approx. 57 bar at 20 °C ambient temperature. It

is not possible to determine how full the bottle

is through the pressure, since the pressure only

drops immediately before the bottle is completely empty.

The CO2 supply is automatically interrupted when

the outer doors are opened. door open is indicated

in the text display.

on

off

empty

is displayed if the N2 supply is interrupted. In this

case, check if the N

and if the valve is open.

If that does not solve the problem, you should connect a new gas bottle (see page 25 ).

bottle is correctly connected

2

2

Automatic switch-over of CO2 gas bottles (only for models with comfort or premium

modules)

The automatic switch-over of gas bottles guarantees an uninterrupted supply with CO2 gas

when two independent supply systems are connected.

► Gas bottle 1 is always the main supply bottle.

► Gas bottle 2 is always the reserve bottle.

Operation is only possible with one bottle. In this case it must be connected to IN1 (see also

Fig. 4 on page 13 ).

37

Page 38

Operation and control

To be on the safe side, a freshly filled CO2 gas bottle should always be used. So if the gas in

bottle 1 is used up, you connect the opened bottle to IN1 and the newly filled bottle as a

reserve bottle to IN2.

The hose connection system used by Memmert shuts off automatically if a connection hose is

pulled off. You should still always close the stop valve on the gas bottle if a bottle is empty or

not connected.

lights up when gas bottle 1 is active. If gas bottle 1 is empty,

IN 1

IN 2

In the following cases, a switch-over is made from reserve bottle 2 back to the main supply

bottle 1:

there is an automatic switch-over to the reserve bottle.

lights up after the switch-over to gas bottle 2 (reserve bottle).

Switching over to the reserve bottle is marked by a short repeated acoustic signal (about 3 seconds long) (the default after

switching on is gas bottle 1).

► if the reserve bottle is empty

► each time after the appliance is switched on

► after every change of the CO

Humidity limit control

A humidity limit control prevents the formation of condensation water in the chamber and

at the same time ensures that the setpoint humidity is quickly reached, with short recovery

times.

The maximum achievable humidity can be adjusted in the standard model from 88 to 97% rh.

Active humidity control (only for models with humidity module)

The active humidity control guarantees that setpoint humidity is quickly reached, without the

use of water trays.

In the heating up phase, the humidity control is initially deactivated. Approx. 5 minutes after

the setpoint temperature is reached, the humidification and dehumidification control starts

working. The setpoint can be set from 40 to 97 % rh. The humidity setpoint can also be adjusted during the transient state. For humidification, water is let into the chamber via a dosing

pump. To avoid the formation of germs, the steam is first heated to approx. 140 °C. Dehumidifcation takes place through the supply of dry air via a sterile filter.

If no humidity is required in the chamber, the humidity control can be deactivated by

setting it to OFF.

setpoint

2

38

Page 39

5.12 Ending operation

1. Switch off appliance. To do this, press the

main switch on the operating panel so

that it clicks into place in the appliance

(see Fig. 22 ).

2. Close the valve(s) of the gas bottle(s).

3. Open the door (see page 27 ).

4. Remove the chamber load.

5. For appliances with the basic model:

Remove and empty the water trays. Fill

water trays and insert them only when

the appliance is next used.

For incubators with a humidity module,

empty the water tanks if the incubator is

not used for several days.

Operation and control

Fig. 22 Switching off incubator

39

Page 40

Warning messages and malfunctions

6. Warning messages and malfunctions

6.1 Warning messages

An intermittent tone is also set off by the warning messages. This can be temporarily

switched off by pressing the SET key.

DOOR OPEN if the door of

appliance is opened for

longer than 3 minutes.

Remedy: Close the door

Error in the temperature control system (see also Chapter “ Temperature monitoring ”

on page 47 ):

Tb active - temperature

limiter triggered if the

temperature limiter

responds

hi-alarm - overtemperature alarm limit max exceeded if overtemperature

protection responds

Remedy: Switch off the appliance

and leave to cool down. If the

error occurs again after switching the

appliance back on: Switch off

the appliance and Contact the

customer service

Remedy: Check the setting of

the MAX temperature monitoring (see Chapter “ Temperature

monitoring ” on page 47 .

lo-alarm - undertemperature alarm limit min

crossed if undertemperature

protection responds

asf alarm - temperature

outside tolerance band if

automatic monitoring

function responds

Remedy: Check the setting of

the MIN temperature monitoring (see Chapter “ Temperature

monitoring ” on page 47 .

Remedy: Check the setting of the

ASF temperature monitoring (see

Chapter “ Automatic temperature

monitor (ASF) ” on page 50 .

Error in humidity system (only for appliances with humidity module)

if the water supply is

defective

Remedy: Check that the water

supply hose is properly connected. Fill the water supply tank

with distilled water if it is empty.

40

Page 41

Warning messages and malfunctions

Mo

Tu

W

Th

Fr

Sa Su

Error in CO2 system:

If humidity exceeds the

preset setpoint for longer

than 30 minutes.

if the CO2 supply is defective

If the CO2 concentration exceeds the defined

setpoint by at least 1 % for

more than 3 minutes.

Remedy: Open door for 30 sec.

and wait to see if the controller

steadily adjusts to the setpoint.

If the error occurs again, Contact

the customer service.

Remedy: Set CO2 setpoint value

to 0, check stop valve of gas

bottle(s) and ensure that they

are properly connected; if gas

bottle(s) empty, change gas bottles, set CO

setpoint to desired

2

value

Remedy: Open door for 30 sec.

and wait to see if the controller

steadily adjusts to the setpoint.

If the error occurs again, Contact

the customer service.

Error in O2 system:

e

on

off

empty

2

if the N2 supply is defective Remedy: check if the N2 bottle

is correctly connected and if the

valve is open. If that does not

solve the problem, you should

connect a new gas bottle (see

page 25 ).

6.2 System/ appliance errors

Warning!

After removing covers, live parts may be exposed. You may receive

an electric shock if you touch these parts. Malfunctions requiring intervention inside the appliance may only be rectified by electricians.

You must read the separate service manual for the INCO incubator

for this.

Do not try and rectify the error yourself, but contact an authorised customer service point for

MEMMERT appliances or Contact the customer services department directly of the company

MEMMERT (see page 2 ).

In case of enquiries, please always specify the model and appliance number on the nameplate

(see page 18 ).

41

Page 42

Warning messages and malfunctions

Error Possible causes Remedy

Nothing shows on the

display although the

incubator is switched

on.

Appliance cannot be

operated

No CO

in the CO

display shown

2

module

2

icon flashes ...

Power supply

interrupted

Appliance fuse or

miniature fuse or

controller faulty

Appliance error

Mainboard faulty

Incubator locked with

user-ID card

Push/turn control

faulty

Switched mode power

supply SP 200 faulty

Temperature fuse

(TWW, ASF) has responded

Check power supply and fuse/safety

switch.

Contact the customer service and read

the service manual.

Unlock incubator with user-ID card (see

page 52 ).

Contact the customer service and read

the service manual.

Contact the customer service and read

the service manual.

► Increase temperature difference

between monitoring and working

temperature (see page 47 ).

► Replace Pt100 temperature sensor

of monitoring controller if necessary

(see Service manual)

... and rh empty

... and rh empty

... and co2 over

... and error Autozero

Error display (E...) in

display

Water supply tank

empty

Set humidity setpoint to OFF, fill up

distilled water, then reset humidity

setpoint back to desired value.

Humidity setpoint

exceeded

Open door for 30 sec. and wait to see if

subsequently the controller steadily adjusts to the setpoint. If the error occurs

again, Contact the customer service.

setpoint is ex-

CO

2

ceeded

Open door for 30 sec. and wait to see if

subsequently the controller steadily adjusts to the setpoint. If the error occurs

again, Contact the customer service.

► Autozero pump

faulty

► CO

controller

2

Contact the customer service and read

the service manual.

faulty

Appliance/system error Contact the customer service and read

the service manual.

42

Page 43

Warning messages and malfunctions