Members Mark 9905tb Owner's Manual

P4770A

ASSEMBLY & OPERATING INSTRUCTIONS

REVISED:

TABLE OF CONTENTS

PAGE

MODEL

9905TB

LPG

SAFETY INSTRUCTIONS

PARTS LIST

ASSEMBLY INSTRUCTIONS

LIGHTING & OPERATING INSTRUCTIONS

CLEANING & MAINTENANCE INSTRUCTIONS

FREQUENTLY ASKED QUESTIONS

INTRODUCTION TO COOKING METHODS

BAKERS & CHEFS RECIPES

2

5

8

12

13

15

17

26

READ THE FOLLOWING INSTRUCTIONS CAREFULLY AND BE SURE YOUR

GRILL IS PROPERLY INSTALLED, ASSEMBLED AND MAINTAINED. FAILURE

TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN SERIOUS BODILY

INJURY AND/OR PROPERTY DAMAGE. IF YOU HAVE QUESTIONS

CONCERNING ASSEMBLY OR OPERATION, CALL OUR SERVICE CENTER

AT 1-800-770-9769, MONDAY THROUGH FRIDAY 8:00 AM - 4:30 PM, CST.

NOTE TO INSTALLER:

LEAVE THESE INSTRUCTIONS WITH THE CONSUMER AFTER INSTALLATION.

NOTE TO CONSUMER: RETAIN FOR FUTURE REFERENCE.

THIS OUTDOOR COOKING GAS APPLIANCE IS NOT INTENDED TO BE

INSTALLED IN OR ON RECREATIONAL VEHICLES AND/OR BOATS.

DATE: JUNE 24,1999

Safety Instructions

Read carefully before assembling and operating your Gas Grill.

ment hose.

INSTALLATION

This gas grill must be installed in accordance with the

local codes or, if in an area without local codes, with

the latest edition of the National Fuel Gas Code ANSI

Z223.1. In Canada, installation must conform to the

standard CAN/CGA 1-b149.1 and/or .2 (Installation

Code for Gas Burning Appliances and Equipment) and

any local codes.

NEVER light grill with lid closed or before checking

to insure burner tubes are fully seated over gas

valve orifices.

NEVER lean over cooking surface while lighting

grill. Use barbecue tools with long wooden

handles and good quality insulated oven mitts

when operating grill.

PAGE 2

THE LOCATION FOR YOUR GRILL

DO NOT use your gas grill in garages, porches,

breezeways, sheds or other enclosed areas. Your gas

grill is to be used OUTDOORS ONLY, at least 21" from

the back and side to any combustible surface. The

grill should not be placed under any surface that will

burn. Do not obstruct the flow of combustion and

ventilation air around the grill housing.

This outdoor cooking gas appliance is not intended to be

installed in or on recreational vehicles and/or boats.

FOR YOUR SAFETY

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. Open lid.

4. If odor continues, immediately call

your gas supplier or your fire

department.

FOR YOUR SAFETY

1.

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

An LP cylinder not connected for use

2.

shall not be stored in the vicinity of this

or any other appliance.

(a) Do not store (empty or full) spare gas

cylinders under or near this or any other

appliance.

(b) Never fill the cylinder beyond 80 percent

full.

If the information in "(a)" and "(b)" is not

followed exactly, a fire causing death or

serious injury may occur.

Keep the gas fuel hose away from hot grill

surfaces and dripping grease. Avoid unnecessary twisting of hose. Visually Inspect

hose prior to each use for cuts, cracks,

excessive wear or other damage.

If damaged - do not use the grill. Contact

your dealer for a factory authorized replace-

PROTECT YOUR CHILDREN: Keep them away

from a hot grill during and after cooking. Do not allow

children to play near or operate grill.

CHECKING FOR GAS LEAKS

NEVER TEST FOR LEAKS WITH A FLAME

Prior to first use and at the beginning of each new

season (or whenever LP gas cylinder is changed),

you must check for gas leaks. Follow these steps:

1.

Make soap solution by mixing one part liquid

detergent and one part water.

2.

Turn off heat control valve(s), then turn on gas at

source.

3.

Apply the soap solution to all gas connections.

Bubbles will appear in the soap solution if connections are not properly sealed. Tighten or repair

as necessary.

4.

If you have a gas leak that you cannot repair, turn

off the gas at the source, disconnect fuel line from

grill and immediately call your grill dealer or gas

supplier for professional assistance.

LP GAS CYLINDER SAFETY

Your gas grill is designed for use with a standard 20

lb. LP gas cylinder (not included). DO NOT CONNECT

YOUR GRILL TO AN LP GAS CYLINDER EXCEEDING

THIS CAPACITY. A tank of approximately 12 inches

in diameter by 18-1/2 inches high should be the

Maximum size tank used. We recommend buying an

"OPD" gas cylinder - which offers an Overfilling

Prevention Device. This safety feature prevents the

tank from being accidentally overfilled which can cause

malfunction with your cylinder, regulator and/or grill.

Also be sure that (1) the cylinder is provided with a

shutoff valve terminating in an LP gas supply cylinder

valve outlet compatible with a Type I cylinder connection device and a safety relief device having a

direct communication with the vapor space of the

cylinder; (2) the cylinder supply system must be

arranged for vapor withdrawal; and (3) the cylinder

used must include a collar to protect the cylinder valve.

The LP gas cylinder must be constructed and marked

in accordance with specifications of the U.S. Department of Transportation (DOT). In Canada, gas

cylinders must meet Canadian Transportation and

Communications(CTC) specifications.

Safety Instructions

PAGE 3

DANGER: If you smell or hear the hiss of

escaping gas from the LP gas cylinder:

Get away from the LP gas cylinder.

>

Do not attempt to correct the problem

>

yourself.

Call your fire department (Do not make the

>

call from near the LP gas cylinder - your

telephone is an electrical device).

Never connect an unregulated LP gas cylinder to

your grill. A gas regulator adjusted to have an outlet

pressure of 11" water column (W.C.) is supplied for

connection to the LP gas cylinder. The pressure

regulator and hose assembly supplied with the appliance must be used. Replacement pressure regulators

and hose assemblies must be those specified by the

appliance manufacturer.

Have the LP gas cylinder filled by a reputable LP gas

dealer, and visually inspected and re-qualified at each

filling.

Have your LP gas dealer check the release valve after

every filling to assure that it remains free of defects.

Always keep cylinder in an upright position. Always

close the cylinder valve when the grill is not in use.

Do not subject LP gas cylinder to excessive heat.

Never store your LP gas cylinder indoors. If you store

your grill indoors, ALWAYS disconnect LP gas

cylinder FIRST, and store LP gas cylinder safely

outside.

Check tank valve features to ensure it has proper

2.

external mating threads. (Type 1 connection per 1094 AGA Requirement)

Make sure all burner valves are in their off position.

3.

4.

Inspect valve connections port and regulator assembly. Look for any damage or debris. Remove any

debris. Inspect hose for damage. Never attempt to

use damaged or plugged equipment. See your local

LP gas dealer for repair.

When connecting regulator assembly to the tank

5.

valve, hand tighten nut clockwise to a positive stop. Do

Not use a wrench to tighten. Use of a wrench may

damage quick coupling nut and result in a hazardous

condition.

6.

Open tank valve fully (counter-clockwise). Use a

soapy water solution to check all connections for

leaks before attempting to light grill. If a leak is found,

turn tank valve off and do not use grill untill repairs can

be made by a local LP gas dealer.

To disconnect LP gas cylinder:

a) Turn the burner valve off.

b) Turn the tank valve off fully.( Turn clockwise to stop.)

c) Detach the regulator assembly from tank valve by

turning the quick coupling nut counter-clockwise.

When the appliance is not in use, the gas must

be turned off at the supply cylinder.

Storage of an appliance indoors is permissible only

if the cylinder is disconnected and removed from the

appliance.

Cylinders must be stored outdoors in a well-ventilated

area out of the reach of children. Disconnected

cylinders must not be stored in a building, garage or

any other enclosed area.

HOSE ASSEMBLY SAFETY

The hose assembly must be inspected before each use of

the appliance. If it is evident there is excessive abrasion

or wear; or the hose is cut, it must be replaced prior to the

appliance being put into operation.

TO CONNECT THE LP GAS SUPPLY CYLINDER,

PLEASE FOLLOW THESE STEPS:

Make sure tank valve is in its full off position. (Turn

1.

clockwise to stop)

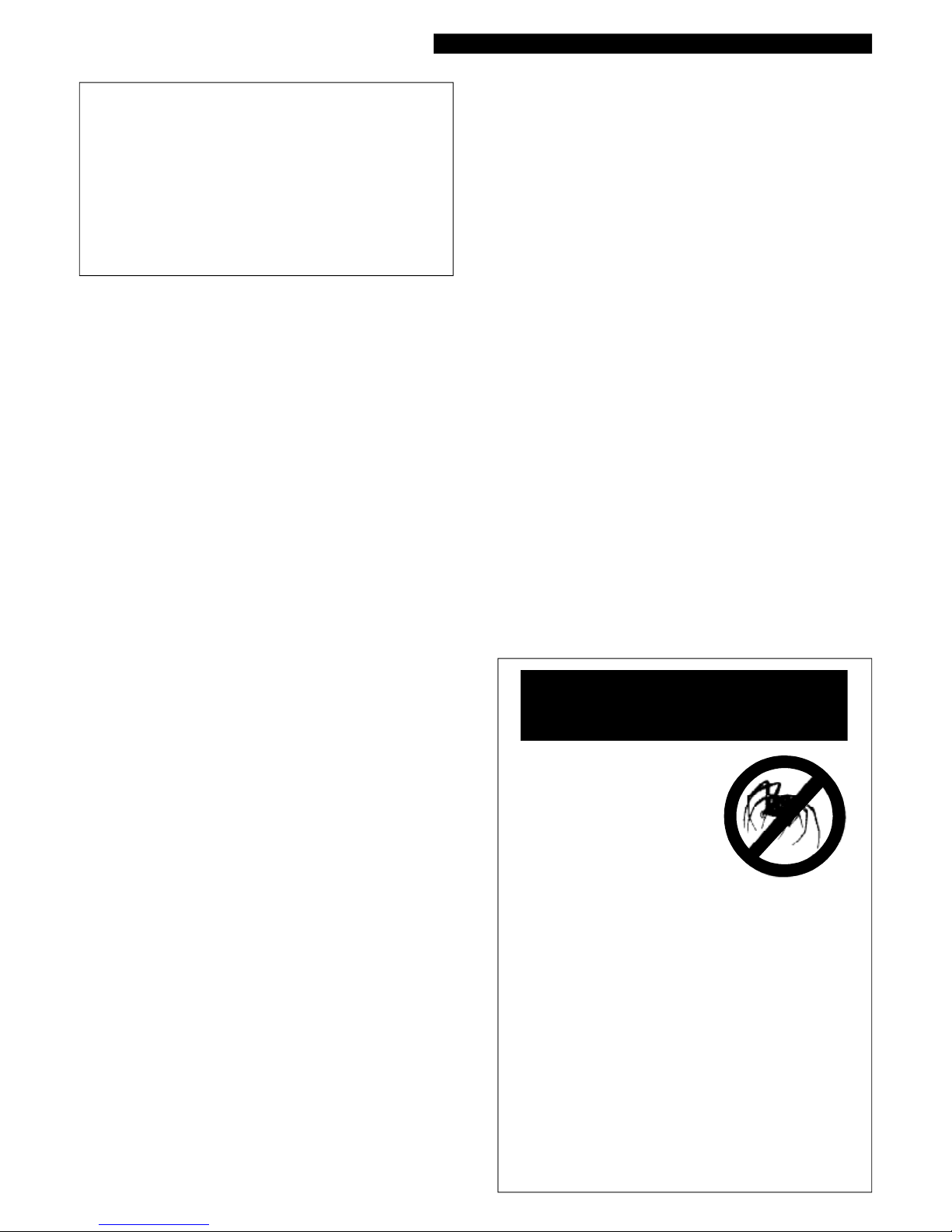

SAFETY !

BEWARE

OF

SPIDERS

CAUTION: BURNER TUBES MUST BE INSPECTED AND CLEANED BEFORE FIRST

USE

Spiders and small insects occasionally spin

webs or make nests in the burner tubes during

warehousing and transit. These webs can lead

to a gas flow obstruction which could result in

a fire in and around the burner tubes. This

type of fire is known as "FLASH-BACK" and

can cause serious damage to your grill and

create an unsafe operating condition for the

user. Although an obstructed burner tube is

not the only cause of "FLASH-BACK" it is the

most common cause and frequent inspection

and cleaning of the burner tubes is necessary.

Safety Instructions

SAFETY !

CARE AND MAINTENANCE

As with all appliances, proper care and maintenance

will keep them in top operating condition and prolong

their life. Your new gas grill is no exception. By

following these cleaning procedures on a timely basis,

your grill will be kept clean and working properly with

minimum effort.

FOLLOW THE BURNER AND BURNER TUBE

CLEANING PROCEDURE BEFORE ASSEMBLY OF

YOUR GRILL.

To reduce the chance of "Flash-back", the procedure

below should be followed at least once a month in

late summer or early fall when spiders are most active,

or when your grill has not been used for an extended

period of time.

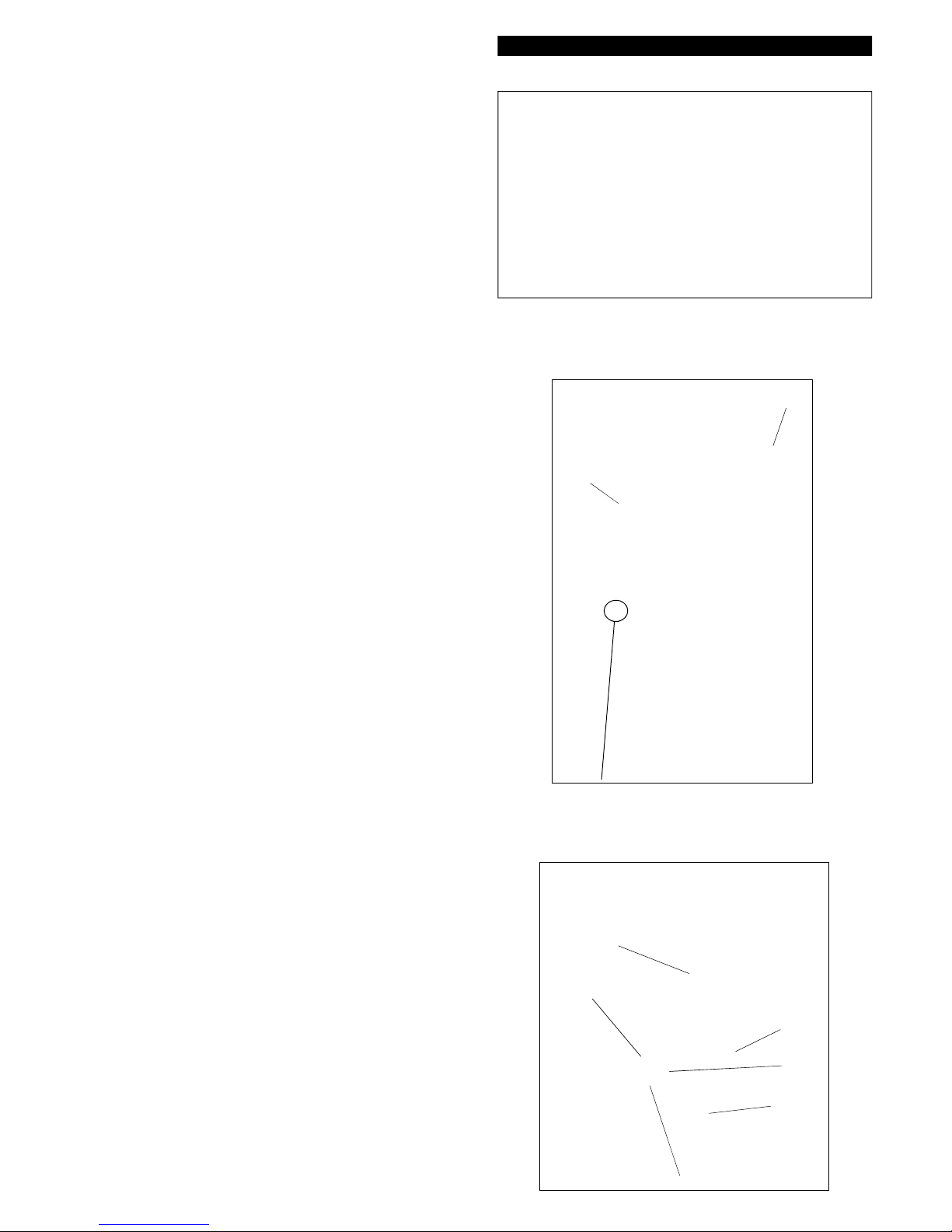

BURNER TUBE CLEANING

For cleaning the burner tubes. Follow the procedure

that is most convenient for you.

1.

Remove burner assembly from the grill bowl.

Bend a stiff wire, (a light weight coat hanger works

well) into a small hook as shown below,

PAGE 4

2.

Use a bottle brush with a flexible handle.

Run the brush up through each venturi tube and

into the burner several times.

BURNER CLEANING

Regardless of which venturi cleaning procedure you

used, we recommend that you complete the following

steps to help prolong burner life.

1.

Wire brush entire outer surface of burner to

remove loose corrosion.

2.

Clean any clogged holes with a stiff wire (for

example: an open paper clip).

Inspect the burner assembly for any opening

3.

caused by corrosion.

4.

If openings due to corrosion are found, order a

new burner.

Replace the burner and cotter pin as described

5.

in the assembly instructions.

Check the burner for proper location after replac-

6.

ing.

Check to assure the valve orifices are inside of

7.

the burner tubes.

Run the hook up through each venturi tube and

into the burner several times.

Should "Flash-back" occur, immediately turn the control knobs to "OFF" and carefully turn the gas supply

off at the gas source.

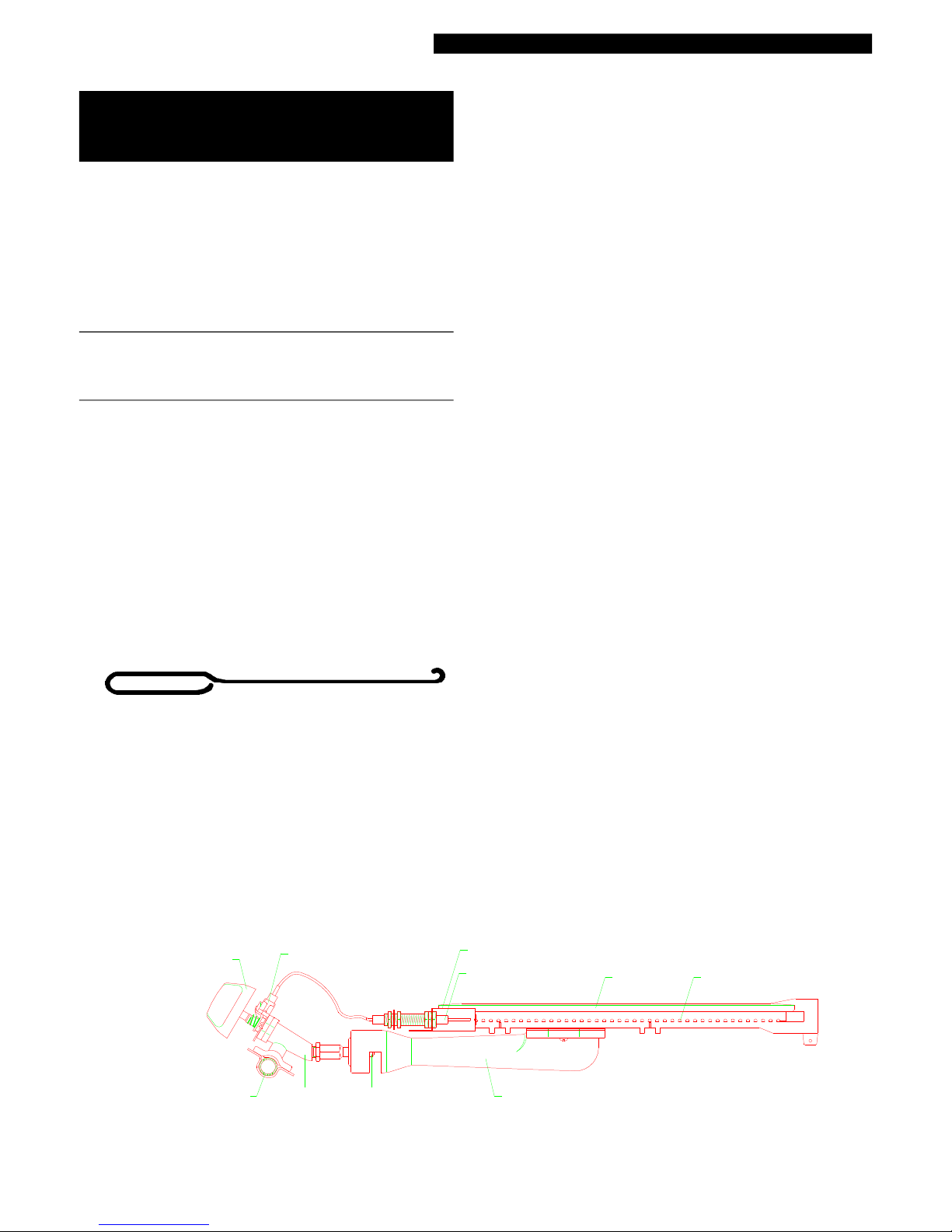

VERY IMPORTANT:

The location of burner with respect to orifice is vital for safe operation. Check to assure the valve

orifices are inside of the burner tubes before using your gas grill. See drawing below.

If the burner tubes (venturi) do not fit over the valve orifices, lighting the burners may cause explosion

and/or fire.

Control Knob

section of Manifold

Ignitor

Gas Valve

Orifice

Gas Collector Box

Spark Electrode

Burner Tube

BurnerBurner Port

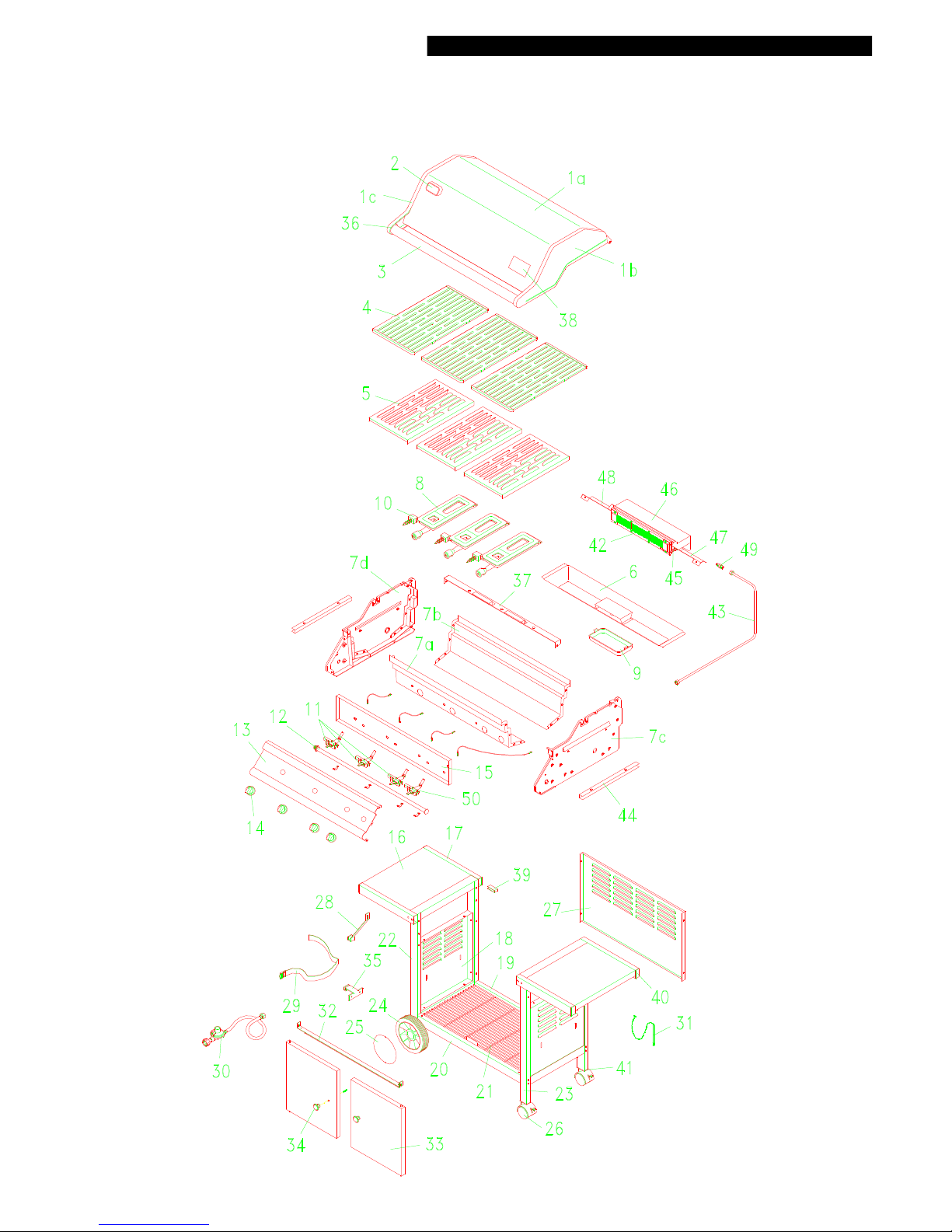

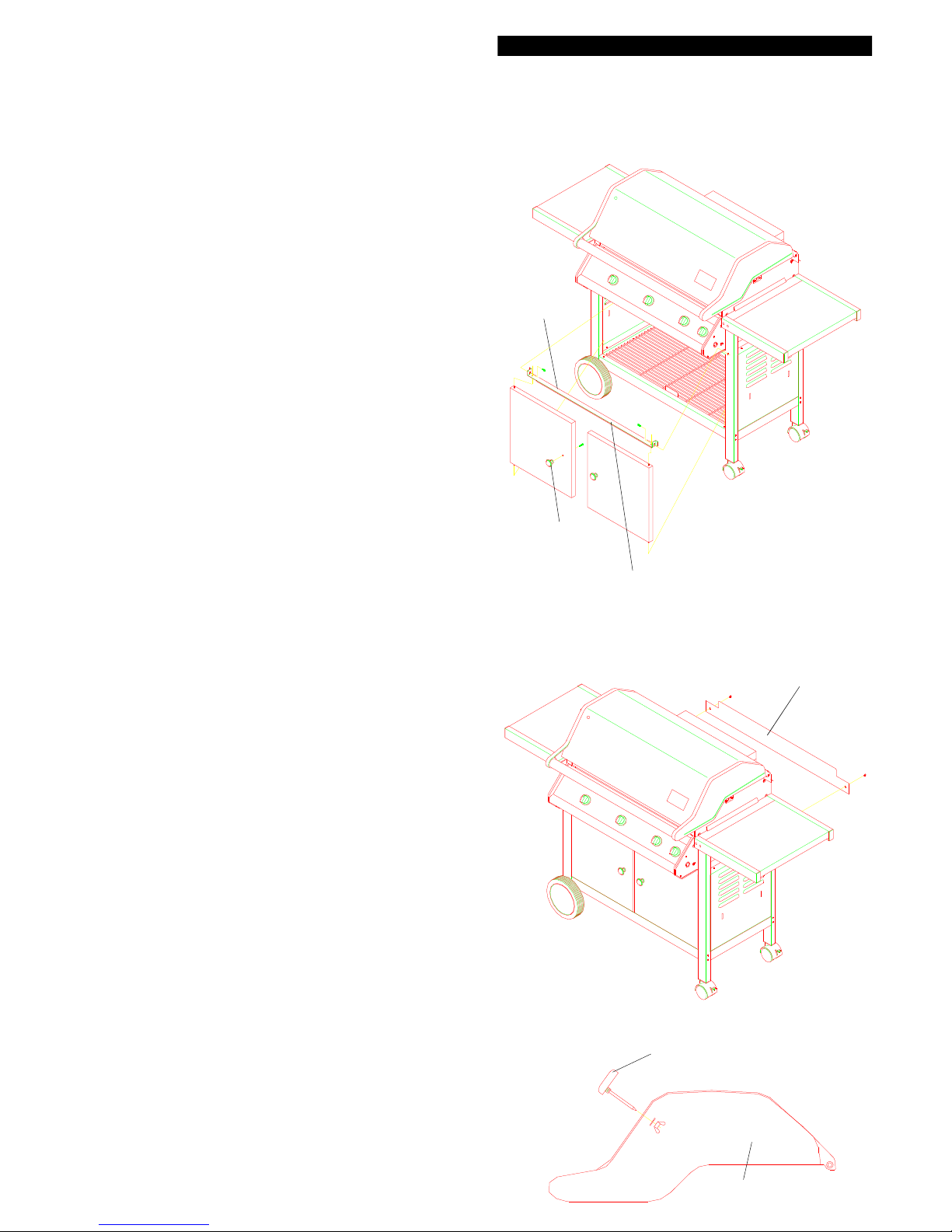

9905TB Parts List

PAGE 5

Remove all components from cartons and place within easy reach. Turn the largest carton

upside down and it will provide a comfortable height work surface for grill assembly.

9905TB Parts List

PAGE 6

1a.

LID PLATE-Stainless Steel

LID SIDE PANEL, RIGHT

1b.

LID SIDE PANEL, LEFT

1c.

HEAT INDICATOR

2.

ROUND LID HANDLE-Stainless Steel

3.

CAST IRON COOKING GRID

4.

STEEL FLAME TAMER

5.

GREASE DRAINING TRAY

6.

BOWL FRONT PANEL

7a.

BOWL REAR PANEL

7b.

BOWL SIDE PANEL, RIGHT

7c.

BOWL SIDE PANEL, LEFT

7d.

CAST IRON BURNER

8.

GREASE RECEPTACLE

9.

SPARK ELECTRODE W. WIRE

10.

GAS VALVE ASSEMBLY

11.

GAS MANIFOLD

12.

CONTROL PANEL-Stainless Steel

13.

CONTROL KNOB

14.

HEAT SHIELD FOR CONTROL PANEL

15.

SIDE SHELF-Stainless Steel

16.

SIDE SHELF BRACKET

17.

SIDE PANEL

18.

BOTTOM SHELF BRACKET-REAR

19.

BOTTOM SHELF BRACKET-FRONT

20.

BOTTOM SHELF

21.

CART LEGS-WHEEL SIDE

22.

CART LEGS-CASTER SIDE

23.

WHEEL

24.

WHEEL HUB

25.

CASTER

26.

REAR PANEL

27.

TANK HOOK

28.

TANK-HOLDING STRAP

29.

REGULATOR

30.

LIGHTING STICK

31.

DOOR BRACKET

32.

DOOR PANEL-Stainless Steel

33.

DOOR KNOB

34.

TANK HOLDER

35.

HEAT-INSULATING SPACER-Phenolic

36.

CROSS OVER CHANNEL

37.

NAME PLATE

38.

U-SHAPE INSERT

39.

CAP FOR SIDE SHELF BRACKET

40.

CASTER SEAT

41.

REAR WIND SHIELD

42.

P0129C

P0146A

P0147A

P0615C

P0234A

P1621C

P1721B

P2726A

P0733A

P0734A

P0729A

P0730A

P1925A

P2717A

P2623A

P3229T

P5029A

P2943A

P3409B

P2943B

P1133B

P1207A

P4318A

P1034D

P1034E

P1034F

P0929B

P0829C

P5106C

P5113A

P5109B

P4317B

P4023C

P4008E

P3632D

P5540A

P4407B

P4329A

P3419A

P4023B

P5573A

P2219A

P0435A

P5574A

P4517A

P4519A

P8089A

QTY.REF#PART#DESCRIPTION

1

1

1

1

1

3

3

1

1

1

1

1

3

1

3

3

1

1

4

1

2

4

2

1

1

1

1

1

2

2

2

1

1

1

1

1

1

2

2

1

2

1

1

4

4

2

1

HOW TO ORDER REPLACEMENT PARTS

AND ACCESSORIES:

Call our service center at 1-800-770-9769,

Monday through Friday 8:00 am - 4:30 pm,

CST.

To make sure you obtain the correct replacement part(s) for your Baker's & Chef Gas

Grill, please refer to the parts list on this

page. The following information is required

to assure getting the correct part:

1. Gas Grill Model Number (see AGA sticker

on grill)

2. Part Number

3. Description

4. Quantity of parts needed

Please allow sufficient time to process and

ship.

IMPORTANT: Keep this assembly and operating instruction manual for convenient

referral and for part replacement.

IMPORTANT: Use only factory authorized

parts. The use of any part that is not factory

authorized can be dangerous. This will also

void your warranty.

BACK BURNER

43.

GAS TUBE ASSEMBLY

44.

COVER FOR GAS TUBE

45.

SPARK ELECTRODE W. WIRE

46.

COVER FOR BACK BURNER

47.

WIND SHIELD, RIGHT

48.

WIND SHIELD, LEFT

49.

ORIFICE

50.

GAS VALVE ASSEMBLY FOR BACK

51.

BURNER

P1934A

P3512A

P8084A

P2624A

P8085A

P8086A

P8086B

P5633A

P3229U

1

1

2

1

1

1

1

1

1

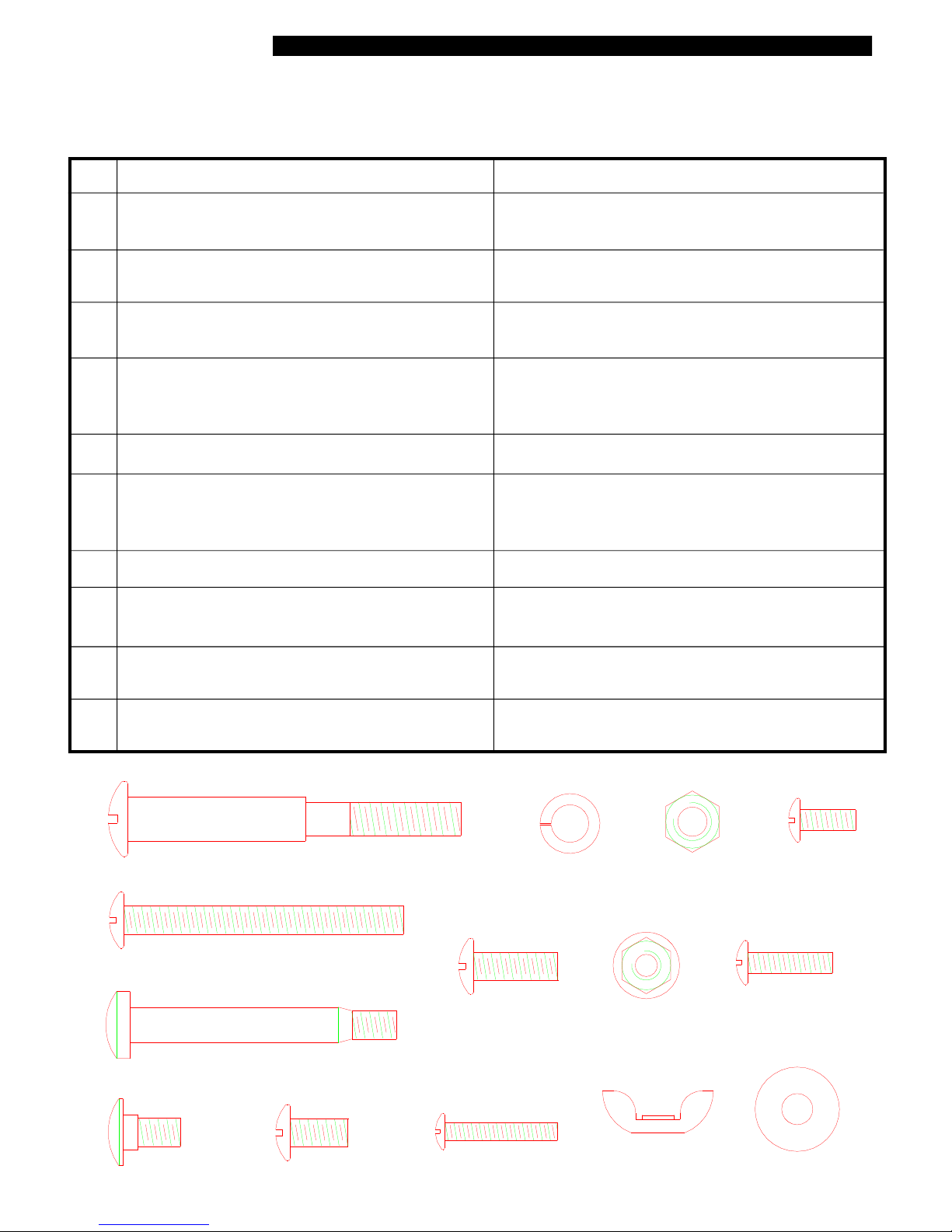

Parts List

COLLAR SCREW x 1

HEAD SCREW x 2

PHILLIPS HEAD SCREW x 2

PAGE 7

The following table illustrates a breakdown of the screwpack. It highlights what

components are used in the various stages of assembly.

REF.

B.

N.

L.

B.

L.

D.

I.

H.

G.

A.

J.

M.

E.

C.

L.

COMPONENTS USES

1/4" x 2 1/2" PHILLIPS HEAD SCREW

X8

1/4" x 3/4" PHILLIPS HEAD SCREW

X4

1/4" LOCK NUT

X4

1/4" x 2 1/2" PHILLIPS HEAD SCREW

X2

1/4" LOCK NUT

X2

X1

1/4" x 1/2" SQUARE COLLAR SCREW

X1

PLAIN WASHER

X1

WING NUT

X4

3/16" x 3/4" PHILLIPS HEAD SCREW

X2

5/16" WHEEL BOLT

X2

SPRING WASHER

X2

5/16" NUT

X2

1/4" x 1/2" PHILLIPS HEAD SCREW

X8

1/4" x 2 1/4" SQUARE BOLT

X8

1/4" LOCK NUT

ASSEMBLES 2 BOTTOM SHELF BRACKETS TO

THE CART LEGS

SECURES GRILL BOWL ONTO THE CART

ATTACHES TANK HOLDER TO THE CROSS BRACE

OF WHEEL-SIDE CART LEGS

SECURES TANK HOOK TO THE LEFT SIDE OF

GRILL BOWL

SECURES REAR PANEL TO THE CART

SECURES WHEELS ONTO THE CART LEGS WITH

AXLE HOLES

ATTACHES DOOR BRACKET TO THE CART

ATTACHES 2 SIDE SHELVES TO THE CART LEGS

F.

K.

X2

No.8-36 UNF x 1" PHILLIPS HEAD SCREW

(ALREADY SCREWED INTO DOOR KNOBS)

X2

3/16" x 1/2" PHILLIPS HEAD SCREW

Actual Sizes:

A. 5/16" WHEEL BOLT x 2

B. 1/4" x 2 1/2" PHILLIPS HEAD SCREW x 10

C. 1/4" x 2 1/4" SQUARE BOLT x 8

INSTALLS THE KNOBS ONTO THE DOOR PANELS

SECURES REAR WIND SHIELD TO THE BACK OF

GRILL CART.

J. SPRING

WASHER x 2

N. 1/4" x 3/4" PHILLIPS

HEAD SCREW x 4

M. 5/16" NUT

L. 1/4" LOCK

NUT x 14

K. 3/16" x 1/2"

x 2

G. 3/16" x 3/4" PHILLIPS

PHILLIPS HEAD

SCREW x 2

HEAD SCREW x 4

D. 1/4" x 1/2" SQUARE

E. 1/4" x 1/2" PHILLIPS

(found in door knobs)

F. No.8-36 UNF x 1"

H. WING NUT x 1

I. PLAIN

WASHER x 1

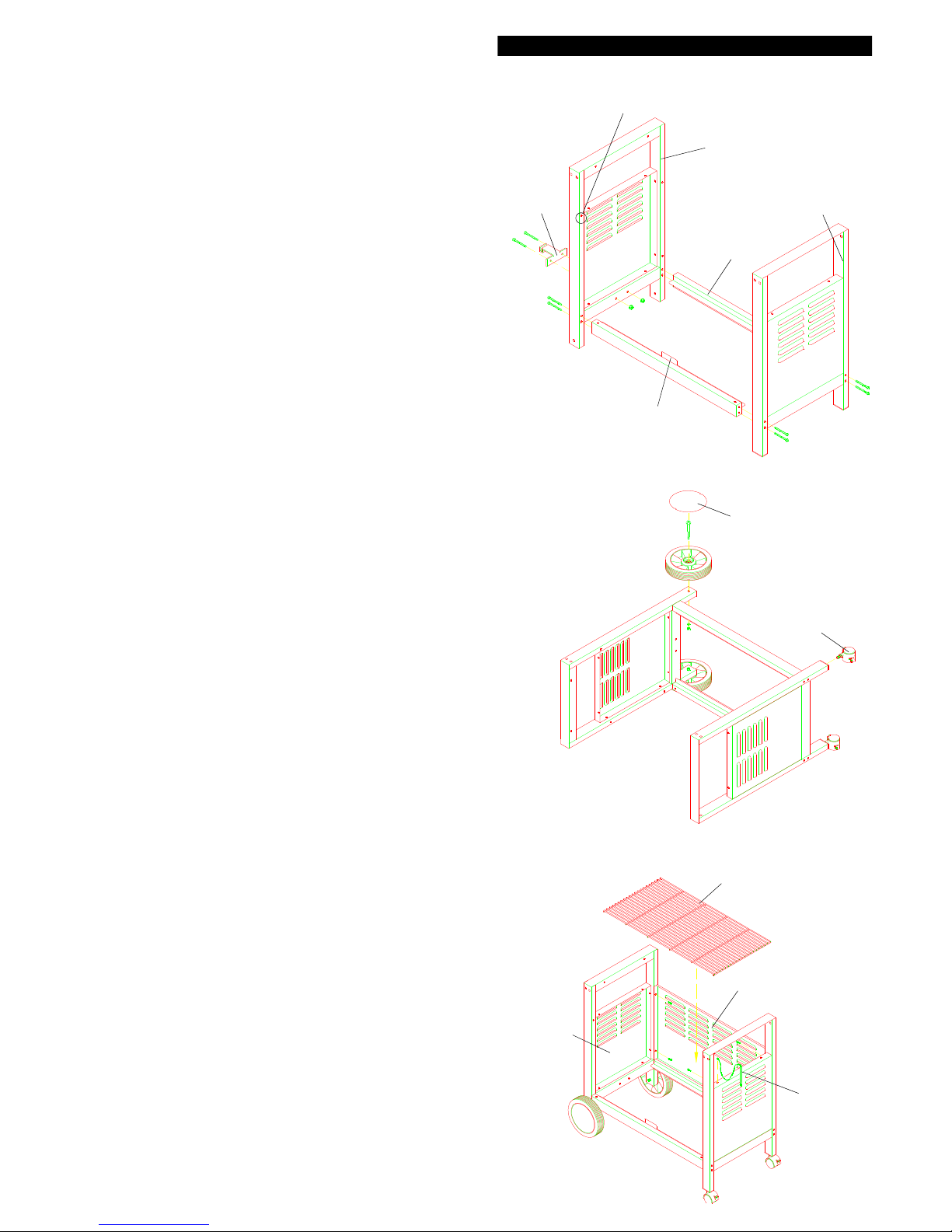

Assembly Instructions

PAGE 8

Before attempting to assemble your gas grill, check that

all the necessary parts have been included using the

parts lists on page 5, 6 and 7. Inspect grill and trolley

parts for damage as you proceed. Contact our service

center regarding replacement of any damaged parts. Do

not assemble or operate a barbecue grill that appears

damaged.

While it is possible for an individual to assemble this

gas grill, we recommend asking for the assistance of

another person when maneuvering some of the larger

or heavier pieces. You may need both Adjustable

Wrench and Phillips Screw Driver (not provided) for

securing the nuts and screws.

1.

Before installing the bottom shelf brackets, make

sure: A) the ledges of both bottom shelf brackets

face each other B) the bottom shelf bracket equipped

with door stop must be located in the front C) the

side of Cart Legs having a threaded hole for Door

Bracket must face inwards. Refer to ILL. 1.

2.

Install the bottom shelf brackets between cart legs.

Align the threaded holes on the ends of bottom shelf

bracket with the holes on cart legs. Screw loosely

using 8 of the "B" 1/4" x 2-1/2" phillips head screws.

HINT:

Insert the screw through the Cart Leg, then

match the screw end with the threaded hole on

the Bottom Shelf Bracket.

ILL. 1

TANK

HOLDER

ILL. 2

THREADED HOLE FOR

DOOR BRACKET

WHEEL-SIDE

CART LEG

CASTOR-SIDE

CART LEG

BOTTOM SHELF

BRACKET

DOOR

STOP

WHEEL HUB

Attach the Tank Holder to the cross brace between

3.

both Wheel-side Cart Legs as shown in ILL. 1. Align

the holes on Tank Holder with holes on the cross brace.

Fix firmly by using 2 of the "B" 1/4" x 2-1/2" phillips

head screws and 2 of the "L" lock nuts.

Install the Wheel to a Wheel-side Cart Leg by inserting

4.

one "A" wheel bolt through the Wheel and Cart Leg

as shown in ILL. 2. Then tighten securely using one

"J" spring washer and one "M" 5/16" nut provided.

Snap Wheel Hub in place and repeat steps for second

wheel.

5.

Secure the Caster to the bottom of the Castor-side

Cart Leg by turning the threaded caster stem

clockwise until full stop. Fasten firmly using a

wrench.

Attach the rear panel to the cart legs as shown in

6.

ILL. 3. Align the holes on panel with the holes on

cart legs. Fix firmly by using 4 of the "G" 3/16"

x 3/4" phillips head screws provided.

Tighten the loosely attached screws in step 2 for

fastening both Cart Legs and Bottom shelf brackets

together.

ILL. 3

SIDE

PANEL

CASTER

BOTTOM

SHELF

REAR

PANEL

Secure the Lighting Stick to the top of the right side

7.

panel. The tapping screw is already attached to the

lighting stick.

8.

Place the bottom shelf over the ledges of both bottom

shelf brackets.

LIGHTING

STICK

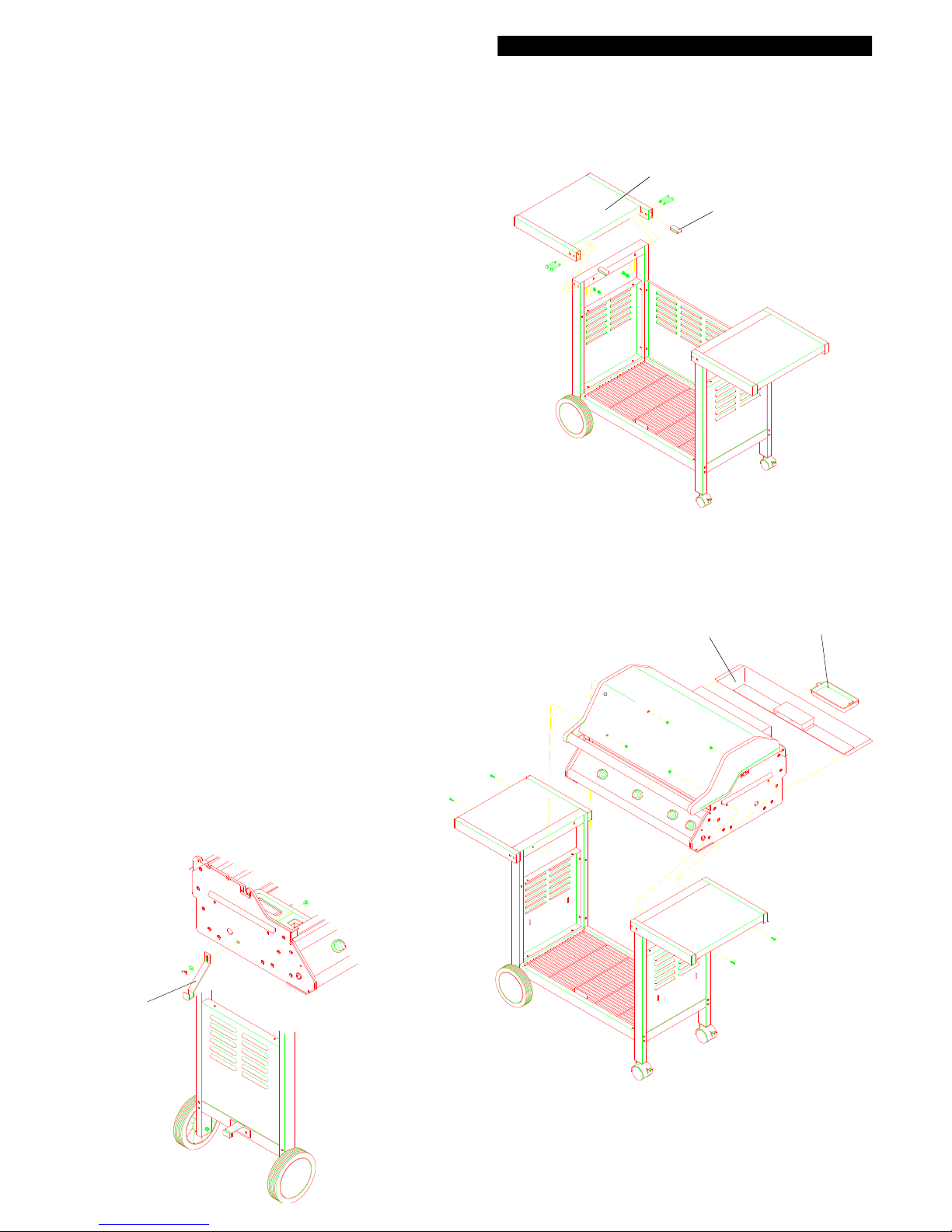

Assembly Instructions

PAGE 9

9.

Attach a (pre-assembled) stainless steel side shelf

to each side of grill as shown in ILL. 4. Align the

square holes of the side shelf with holes at upper

section of each cart leg. Screw loosely using 8

of the "C" square bolts and 8 of the "L" lock nuts.

Slide the U-shape Inserts into each Side Shelf

Bracket. The Inserts cover the square bolts inside

and add support. Fix firmly by tightening lock nuts.

10.

Place the Grill Bowl over the cart as shown in ILL.

5. Align the holes on both sides of Grill Bowl with

the two (2) holes at the bowl support bracket.

Tighten firmly using 4 of "N" 1/4" x 3/4" phillips

head screws and 4 of "L" lock nuts. You may

have to lift up the Grill Bowl slightly to align the

holes properly.

Attach the Tank Hook to the left side of Grill Bowl.

11.

as in ILL. 6. Align the hole on Tank Hook with

the hole on the grill Bowl and tighten securely using

1 "H" wing nut, one "D" 1/4" x 1/2" square collar

screw and one large "I" plain washer.

Slide the Grease Draining Tray in position over

12.

the ledges under Grill Bowl from the rear of Grill.

See ILL. 5.

ILL. 4

ILL. 5

STAINLESS STEEL SIDE SHELF,

PRE-ASSEMBLED WITH BRACKETS

U-SHAPE

INSERT

GREASE

DRAINING TRAY

GREASE

RECEPTACLE

Grease Receptacle should be positioned centrally

under Grease Draining Tray.

ILL. 6

TANK HOOK

Assembly Instructions

Please find the Door Bracket and Doors in the

13.

same box as Grill Head.

Attach the Door Bracket to cart legs (under

Control Panel). Be sure the folded strip of the

bracket is closest to the cart legs. Then align

the holes on both ends of the bracket with the

threaded holes on the cart legs. Fix the Door

Bracket by screwing 2 of the "E" 1/4" x 1/2"

phillips head screws loosely. Refer to ILL. 7.

Locate the hinge holes for the door on the Bottom

14.

Shelf Bracket. Insert the door hinges into these

holes and holes on Door Bracket. Push the Door

Bracket down to an even level and then tighten

it securely using a screw driver. See ILL. 7.

Install the door knobs onto the door plates with

15.

the 2 "F" No.8-36 UNF x 1" phillips head screws

(can be found with the door knobs).

PAGE 10

ILL. 7

DOOR

BRACKET

Install the Rear Wind Shield to the back of grill

16.

cart. Fix securely using 2 of the "K" 3/16" x

1/2" phillips head screws. See ILL. 8

Install the Heat Indicator by inserting it into the

17.

hole on upper left side of Grill Lid. Adjust it

to level position, then tighten securely using lock

washer and wing nut provided in the Heat

Indicator box. See ILL. 9.

BUILT-IN IGNITOR / ELECTRODE CHECK

Before placing the flame tamers or cooking grids,

1.

ensure that the gap between each spark electrode tip and the collector box is approximately

3/16". Adjust if necessary.

Push and turn the Control Knob to HIGH, a blue

2.

spark should be produced at the electrode tip.

If not, check ignition wire, the terminal of wire

to the ceramic electrode could become loose in

delivery. Push in the terminal for a tight

connection.

DOOR KNOB

FOLDED STRIP USED AS

DOOR STOP

ILL. 8

REAR WIND SHIELD

Push and turn the Control Knob to HIGH for blue

spark again.

ILL. 9

HEAT INDICATOR

GRILL LID

Assembly Instructions

PAGE 11

COOKING COMPONENT INSTALLATION

Place Steel Flame Tamers on the lower ledge of

1.

Grill Bowl. See ILL. 10.

2.

Place Cast Iron Cooking Grids on the ledge of

Grill Bowl above Flame Tamers.

IMPORTANT: The Grill is not designed for use with

lava rock or briquettes and the use of such items will

void the warranty.

CONNECTING TO GAS SOURCE

Insert the Tank-Holding Strap through the two (2)

1.

slots on Side Panel. See ILL. 11. Hang filled

gas tank on the Tank Hook attached to the Grill

Bowl. The ring foot of the gas tank will rest on

the Tank Holder. Fasten the gas tank using the

Tank-Holding Strap. Make sure tank valve is in

its full off position (Turn clockwise to stop).

Check tank valve features to ensure it has proper

2.

external mating threads. (Type 1 connection per

10-94 AGA Requirement)

WARNING :

Now your gas grill is ready to use. Before

first use and at the beginning of each

barbecue season and whenever LP gas

cylinder is changed.

1.

Please read safety, lighting and operating

instructions carefully.

2.

Check gas valve orifices, venturi tubes and

burner ports for any obstructions.

3.

Perform gas leak check (see page 2).

ILL. 10

CAST IRON

COOKING GRID

STEEL FLAME

TAMER

Make sure all burner valves are in their off position.

3.

Inspect valve connection ports and regulator as-

4.

sembly. Look for any damage or debris. Remove

any debris. Inspect hose for damage. Never

attempt to use damaged or plugged equipment.

See your local LP gas dealer for repair.

5.

When connecting regulator assembly to the tank

valve, hand tighten nut clockwise to a positive stop.

Do Not use a wrench to tighten. Use of a wrench

may damage quick coupling nut and result in a

hazardous condition.

Open tank valve fully (counter-clockwise). Use a

6.

soapy water solution to check all connections for

leaks before attempting to light grill. If a leak is

found, turn tank valve off and do not use grill until

repairs can be made by a local LP gas dealer.

CAUTION: When the appliance is not in use, the

gas must be turned off at the supply cylinder.

These holes are for rotisserie mounting bracket use.

ILL. 11

TANK HOOK

TANK-HOLDING

STRAP

SIDE PANEL

To disconnect LP gas cylinder:

a) Turn the burner valve off.

b) Turn the tank valve off fully.( Turn clockwise to stop.)

c) Detach the regulator assembly from tank valve by

turning the quick coupling nut counter-clockwise.

REGULATOR

TANK HOLDER

COUPLING NUT

Loading...

Loading...