Page 1

Place this chapter in the Coffee Machine

section of the Equipment Manual.

®

Manufactured exclusively for McDonald’s

CAFINA Ltd.

Römerstrasse 2

5502 Hunzenschwil

Switzerland

represented by:

MelittaSystemService USA Inc.

665 Tollgate Road, Suite B

Elgin, IL 60123 (EE. UU.)

Phone: (847) 717 8900

Fax: (847) 717 8924

www.melitta-mss.com

Hotline: (866) 910 9105

by

EN

c5-12C FF

TABLE OF CONTENTS

WARRANTY 2

WARRANTY McD 4

INTRODUCTION 5

SAFETY 6

PARTS IDENTIFICATION / FUNCTIONS AND EXPLODED VIEW 10

EQUIPMENT SET-UP AND CLOSE PROCEDURES 12

SYSTEM SETUP / OPERATION 17

MAINTENANCE 26

TROUBLESHOOTING 29

ORDERING PARTS / SERVICE 33

NON-SCHEDULED MAINTENANCE 33

APPENDICES 33

© Cana Ltd. coffee machines

All Rights Reserved

created 06/13/2013

OM V3.0

Page 2

EN

WARRANTY

1. Scope of Warranty

MSS warrants the products as follows:

• All products (other than as specied in the following): 2 years parts and labor;

• Electronic circuit and/or control boards: 3 years parts only.

2. General Conditions of Warranty

The exchange of parts is limited to 3 per year. The warranty period runs from the earlier of (i) the date

of installation or (ii) 6 months after the shipment date from the place of manufacture in Switzerland

or Germany. The warranty covers defects in material or workmanship. Defective products must be

returned prepaid to MSS-USA, 665 Tollgate Road, Suite B, Elgin, IL 60118 or a dealer/repair station

authorized by MSS. A list of authorized dealers/repair stations may be obtained by writing to MSS at the

foregoing address or calling (847) 717-8924. MSS, in its sole discretion, shall determine the scope of

a repair and exchange of parts. Any repair or exchange of parts shall not extend the warranty period.

3. Prerequisites of Warranty

Not covered by this warranty are products that have:

(a) been altered or modied;

(b) been improperly installed by persons not authorized by MSS;

(c) failed due to abuse or inadequate or improper maintenance or care;

(d) been used in violation of the manual or other instructions for use or installation; or

(e) been damaged due to defects or malfunctioning or defects of equipment, parts or installtions

not provided by MSS.

Examples of the foregoing include:

• Defects or malfunctioning resulting from improper cleaning, human errors or mishandling

(such as blocked valves or mixer);

• Defects due to lime-scale build-up or other deposits resulting from the use of water softening

equipment (such as boilers or water pumps);

• Defects or malfunctioning due to electric overloads or power surges (such as burned electronic boards);

• Defects or malfunctioning due to deviations from the quality specications for milk, water and

coffee beans; or

• Defects of malfunctioning due to deviations from the quality settings recommend by MSS.

2

V3.0

OPERATING MANUAL

Page 3

4. Requirements for Water Quality

This Warranty is valid only if the following water quality requirements/ranges are complied with:

• 54 ppm - 125 ppm total dissolved solids

• 3.1 gpg – 7.3 gpg dissolved hardness minerals in water

• 6.8 -7.2 pH acidity/alkalinity

5. Requirements for Power and Plumbing

This Warranty is valid only if the requirements for Power and Plumbing as per Installation Guide

and drawing included in packaging are complied with.

6. Ordinary Wear and Tear Items Excluded From Warranty

Excluded from the warranty are items or parts that are subject to natural wear in the ordinary use

of the equipment, such as

• Seals

• Filters

• Piston sprays

• Piston plunger

• Paint coatings

EN

• Grinding burrs

• Foamer head

7. No Implied Warranties

THE WARRANTY PROVIDED HEREUNDER IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES, AND MSS DISCLAIMS ANY AND ALL OTHER EXPRESS WARRANTIES AND ALL

IMPLIED WARRANTIES WITH RESPECT TO THE EQUIPMENT, INCLUDING ANY WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

8. Limitations of Liability

EXCEPT AS EXPRESSLY AGREED UPON, UNDER NO CIRCUMSTANCES SHALL MSS HAVE

ANY LIABILITY, WHETHER DIRECTLY OR BY WAY OF INDEMNITY, FOR SPECIAL, INCIDENTAL,

INDIRECT, CONSEQUENTIAL, PUNITIVE, EXEMPLARY, STATUTORY OR OTHER DAMAGES,

INCLUDING, BUT NOT LIMITED TO, DAMAGES FOR INJURIES TO PERSONS OR TO PROPERTY

OR LOSS OF PROFITS OR LOSS OF FUTURE BUSINESS OR REPUTATION, LOSS OF USE

OF EQUIPMENT, COST OF DOWN TIME OR COST OF SUBSTITUTE EQUIPMENT, WHETHER

BASED ON BREACH OF CONTRACT, BREACH OF WARRANTY, TORT, STRICT OR PRODUCTS

LIABILITY, INFRINGEMENT OF PATENTS, TRADE SECRETS, TRADEMARKS, COPYRIGHTS OR

OTHER PROPRIETARY RIGHTS, OR ANY OTHER LEGAL THEORY IN CONNECTION WITH THE

SALE OF THE EQUIPMENT, ITS USE, INSTALLATION OR APPLICATION OR IN CONNECTION

WITH THE PERFORMANCE BY MSS HEREUNDER.

OPERATING MANUAL

V3.0

3

Page 4

EN

WARRANTY MCD

MSS/Cana represents and warrants that the Products will (1) conform to McD’s current Standards;

(2) be merchantable; (3) be free from defects in design, construction, workmanship, materials and

packaging; (4) be t and sufcient for the purpose for which it is intended and/or which is stated

on any packaging, labeling or advertising; and (5) be equivalent in materials, quality, t, nish,

workmanship, performance and design to samples, if any, submitted to and approved by McD.

EXCEPT AS OTHERWISE PROVIDED IN THE AGREEMENT BETWEEN MSS AND MCD, THE

WARRANTIES PROVIDED IN THIS PARAGRAPH SHALL BE IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

MSS/Cana further represents and warrants that (1) the manufacture, use, distribution or sale of the

Products will not violate or infringe any proprietary or intellectual property rights of any person or

entity; (2) the Products will be produced, packaged, tagged, labeled, packed, shipped and invoiced in

compliance with the applicable requirements of federal, state and local laws, regulations, ordinances

and administrative orders and rules of the United States, its territories and all other countries in

which the Products are produced or delivered; (3) they will strictly adhere to all applicable federal,

state and local laws, regulations, ordinances and administrative orders and rules of the United

States, its territories and all other countries in which the Product are produced or delivered with

respect to the operation of their production facilities and their other business and labor practices,

including laws, regulations and prohibitions governing the working conditions, wages, hours and

minimum age of work force; (4) MSS/Cana will not discriminate based upon gender, race, sexual

orientation, national origin or any other basis prohibited by law in their employment practices and

that the Products are not produced or manufactured, in whole or in part, by child labor or by convict

or forced labor; (5) upon request from McD, MSS/Cana will provide McD with specic information, in such detail as McD may reasonably request, as to the location(s) and methods(s) of the

manufacture of the Products; (6) upon reasonable notice and during regular business hours, McD,

its designated representatives and any independent inspectors approved by McD may inspect any

production facility at which the Products or any components of the Products are being produced;

(7) if McD determines that a Product must be inspected prior to its shipment to the United States

or other country, such inspection will be performed at the sole expense of MSS/Cana by an independent inspector approved by McD and any inspection or documentation thereof, and corrective

actions, if any, taken by MSS/Cana with respect to such Approved Product will not be deemed

an acceptance of any such Product, or a waiver or any nonconformities or defects in any such

Product and will not excuse any failure by MSS/Cana to deliver such Product in accordance with

this Agreement or the terms of any Purchase Order; (8) MSS/Cana will strictly adhere to the

McDonald’ s Code of Conduct for Suppliers, as it may change over time; (9) MSS/Cana will not

use any trade name, trademark, service mark or other intellectual property of McD, or any other

trade name, trademark or service mark incorporating the „Mc“ or „Mac“ formative, in any manner

whatsoever, including, without limitation, on or in connection with any Product or other products or

services, without rst obtaining the written consent of McD; and (10) they will at all times remain

in compliance with the Foreign Corrupt Practices Act, as it may be amended from time to time.

4

V3.0

OPERATING MANUAL

Page 5

INTRODUCTION

The c5 coffee machine is a fully automatic coffee

machine which can dispense pre-programmed

coffee- and milk products through a height-adjustable product outlet into the product cup.

The beverage required is selected via ve beverage selection buttons.

Power Connection

The c5 coffee machine is permanently connected

to main power during normal operation.

Depending on the form of the power connection,

the coffee machine is disconnected from mains

power via power plug and socket, or via a circuit

breaker on the mains panel.

EN

Two separate bean hoppers allow for two different coffee types, e.g. regular and decaffeinated

coffees.

For hot milk processing with integrated, automatic

cleaning, the Cana conforms to NSF/ANSI /

Standard 4.

The patented, Automatic Coffee quality System

(ACS) continually monitors relevant parame-

ters such as neness of grind, coffee powder

weighed-in quantity, infusion time and water

temperature.

The piston system is optimally controlled via a

Variable Pressure System (VPS).

NOTE:

The c5 coffee machine does not have a power

switch of its own.

Water Connection

The c5 is connected to a water purication

system (RO) in the building by a stop valve –

quick disconnect – screen lter – and a backow

preventer. In case of a problem on the c5, the

coffee machine can be shut off or disconnected

quickly from the main water supply.

stop valve

quick disconnect

Water is drained from the c5 into the waste water system with permanent connection to the

sewer.

OPERATING MANUAL

water ow

direction

back ow preventer

V3.0

screen lter

to c5

5

Page 6

SAFETY

Warnings

Safety information in these Operating

Instructions

EN

Warning symbols used

The following warning symbols may be afxed

to the equipment.

Low voltage

• Warning of dangerous electrical

voltage.

• Electric shocks can lead to serious

injury or death.

• Only authorized technical personnel

may perform work on electrical installations.

• The technical safety instructions must

be followed.

• Unplug equipment before carrying out

any work on electrical installations.

Hot surface / hot internal components

• Warning of heat which could lead to

injury.

In these Operating Instructions, you will nd the

following three levels of safety information:

• Level 1

WARNING

• A warning refers to signicant hazards.

Failure to follow the relevant safety

instruction could lead to injury or

death.

Depending on the type of danger, instead of

STOP, one of the following symbols could be

combined with the word WARNING.

WARNING

• Warning of electric shock.

WARNING

• Warning of heat.

• Allow hot surfaces and compo-nents

to cool before carrying out any work

on these component parts.

• If necessary, wear heat resistant

gloves.

Places where warning symbols are af-

xed

NOTE

• The equipment comes supplied with

warning symbols (stickers) afxed

wherever appropriate.

• If any of the warning symbols should

fall off during operation or following

cleaning work, the operator must stick

these warning symbols back again

immediately.

• Level 2

CAUTION

• The CAUTION symbol stresses

important instructions. Failure to

observe these instructions could lead

to damage to the equipment or to

other material assets.

• Level 3

NOTE

• Notes contain additional information

aimed at raising the general level of

safety and at lightening the user’s

workload.

6

V3.0

OPERATING MANUAL

Page 7

Basic safety instructions

Proper use

General

Proper use includes, in addition to the specic

provisions set out below, observing these Operating Instructions and complying with the supplier’s

obligatory maintenance and repair instructions.

c5 coffee machine

The c5 coffee maker is used solely to dispense

coffee products, coffee and milk combined

products, hot water, steam and to heat and froth

milk.

No other use of the c5 coffee maker will be

deemed to be proper.

WARNING

• Hot liquid comes out from the bottom

of the beverage outlet. There is a

danger of scalding.

WARNING

• Never interfere with the electricity

supply connection or modify it. This

could result in fatal injury.

• Never remove the screw- mounted

covers. There is a danger of fatal

injury upon contact with live components.

NOTE

EN

Specic hazards and instructions

c5 coffee machine

WARNING

• Never insert either the hands or any

rod-shaped object into a bean hopper

or into the lling chute while the c5

coffee machine is connected to the

mains power supply.

• Only coffee beans may be introduced

to the bean hopper.

WARNING

• When handling the combination

cleaning tablets „COMBI-Tabs“, the

manufacturer’s warnings and instructions that are printed on the cleaning

tablet container must be observed

and complied with.

• Regardless of type conguration, the

c5 coffee machine should not be used

in large kitchens.

• Electrical equipment which does

not have adequate electro-magnetic

protection should not be operated

close to the c5 coffee machine.

• The drip tray serves solely to collect

drip water. It must not be used as a

sink.

OPERATING MANUAL

V3.0

7

Page 8

EN

CAUTION

• Never interfere with the water mains

connection or modify it. There is a

danger of ooding.

• Only operate the c5 coffee machine

in covered locations, avoid places

where there is a risk of water splash.

There is a risk of damage.

CAUTION

• Never spray the c5 coffee machine

with a water hose during cleaning.

There is a risk of damage.

• Always empty the coffee waste

drawer in the correct manner. There

is a danger of overow.

• Always insert the key card dry and in

the correct position into the slot. Do

not insert any foreign objects or chip

cards for other systems into the slot.

There is a risk of damage.

• Do not leave key card in the slot

during operation.

Key cards

CAUTION

• Keep key cards dry, cool and in

the plastic pockets provided for this

purpose. There is a risk of damage.

• Never put a key card on a hot surface

or expose to direct sunlight. There is

a risk of damage.

• Never put a key card down in an environment where there is a risk of water

splash. There is a risk of damage.

• Always clean key cards including chip

contacts with a clean, slightly moist

cloth without using any household

cleaner. There is a risk of damage.

• Never bend or fold a key card or

use it as a tool. There is a risk of

damage.

• In an environment that is likely to be

electrostatic, always ensure that you

have earthed yourself (e.g. by touching

a radiator) before handling a key card.

There is a risk of damage.

• If the internal relieve pressure valve

Refrigerator

CAUTION

• When relling with milk, always use

• Always close the refrigerator door.

is actuated due to excessive pressure

or temperature increase, switch the

c5 coffee machine off immediately.

Secure the c5 coffee machine against

unintentional switching on and report

to Customer Support.

pre-cooled milk that is no warmer than

40°F. There is a hygiene risk.

There is a hygiene risk.

Personal safety

WARNING

If handled improperly, the equipment

could cause serious or fatal injury.

Anyone using and maintaining the equipment must be trained in the correct

handling of the equipment and must

have read and understood the safety

instructions in these Operating Instructions before starting to use or maintain

the equipment.

8

V3.0

OPERATING MANUAL

Page 9

WARNING

Authorized persons

Never modify or remove any safety

mechanisms.

Do not disable any safety mechanisms

by modifying the equipment.

If there are any warning symbols afxed

to the equipment (dependent on nationality), never remove these. Replace

any lost or defective warnings symbols

immediately.

WARNING

Never operate the equipment in a

damaged condition.

Report any irregularities to your superior immediately, especially if they affect

safety.

Safety mechanisms

As well as the warning symbols (dependent on

nationality) afxed to the equipment, the equipment

also has several active safety mechanisms.

General

EN

Only persons who are authorized to do so may

work on or with the equipment.

A person is deemed to be authorized if he/she

satises the minimum training and knowledge

requirements listed in this chapter and has been

assigned a xed area of responsibility.

Areas of responsibility of personnel

Manager

As the most senior person from a legal point of

view, the manager is responsible for the proper

use of the equipment and for the training and

deployment of authorized personnel.

Se encarga de registrar las competencias

empreHe/she records the competencies of authorized persons, including whether they have the

authority to give orders, for his business.

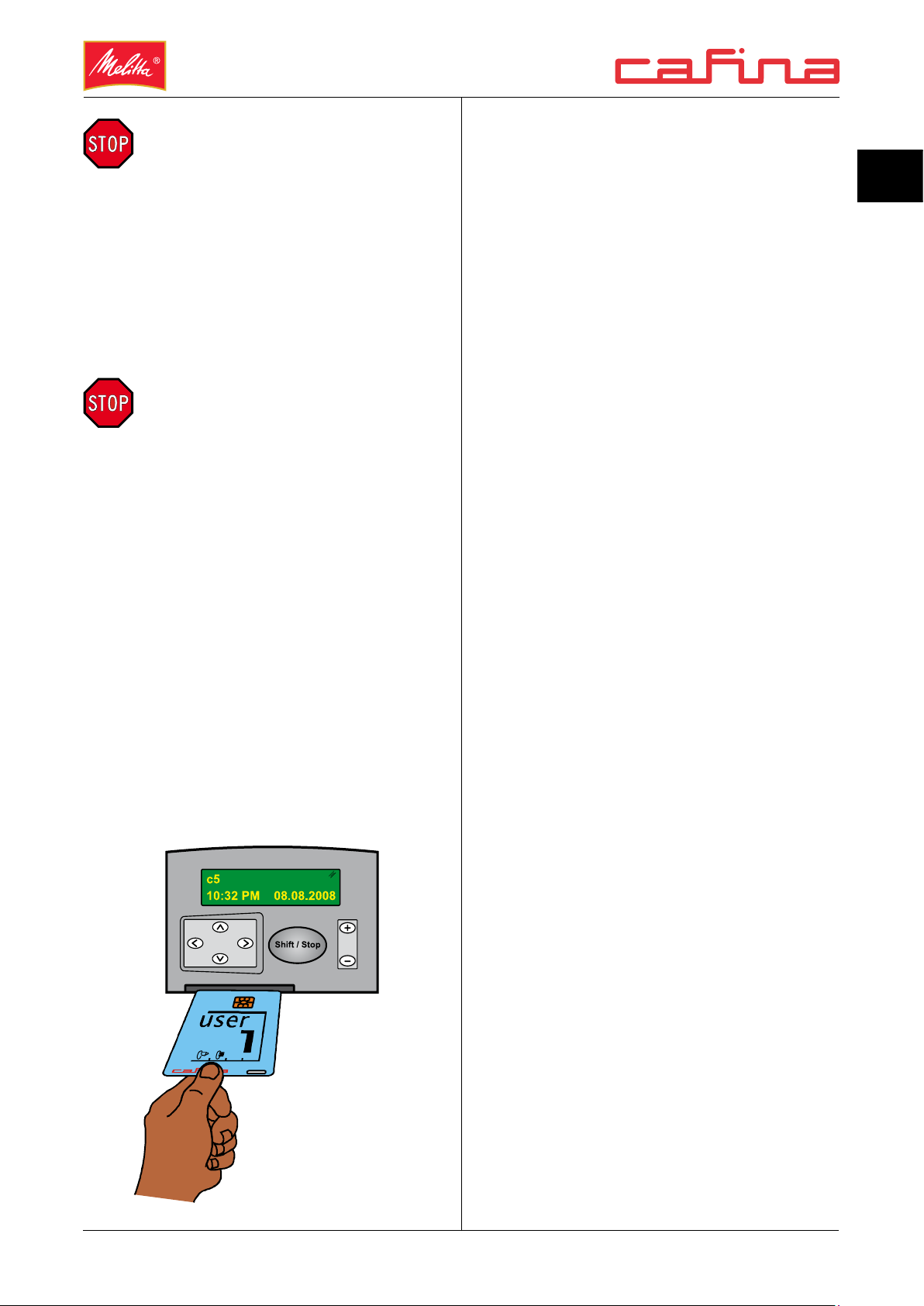

Power switch

c5 coffee machine power switch.

Activation with key card.

His/her tasks include the following:

• He/she sets or resets the equipment to the

beverages that are currently to be dispen-sed,

if he/she wishes to dispense different beve-

rages than those that the supplier congured

upon delivery or installation of the equipment.

User

He/she is responsible for the following tasks:

• Adjusts the equipment to the beverages

currently to be dispensed.

• Rells consumables, e.g. coffee, milk.

• Starts the equipment and monitors it.

• Cleans and services the equipment.

• Pinpoints problems and organiser problem

rectication.

OPERATING MANUAL

V3.0

9

Page 10

EN

PARTS IDENTIFICATION /

FUNCTIONS AND EXPLODED VIEW

Bean Hopper

1

5

8

1

4

6

7

2

3

Bean Hopper slider

2

3

Chute for coffee cleaning tablets

Foamer head cover

4

5

Holding screw foamer head cover

6

Display

Product selection keypad

7

Preselection keypad

8

9

10

11

Adjustable coffee / milk spout

9

10

Drip tray

Coffee waste drawer

11

10

V3.0

OPERATING MANUAL

Page 11

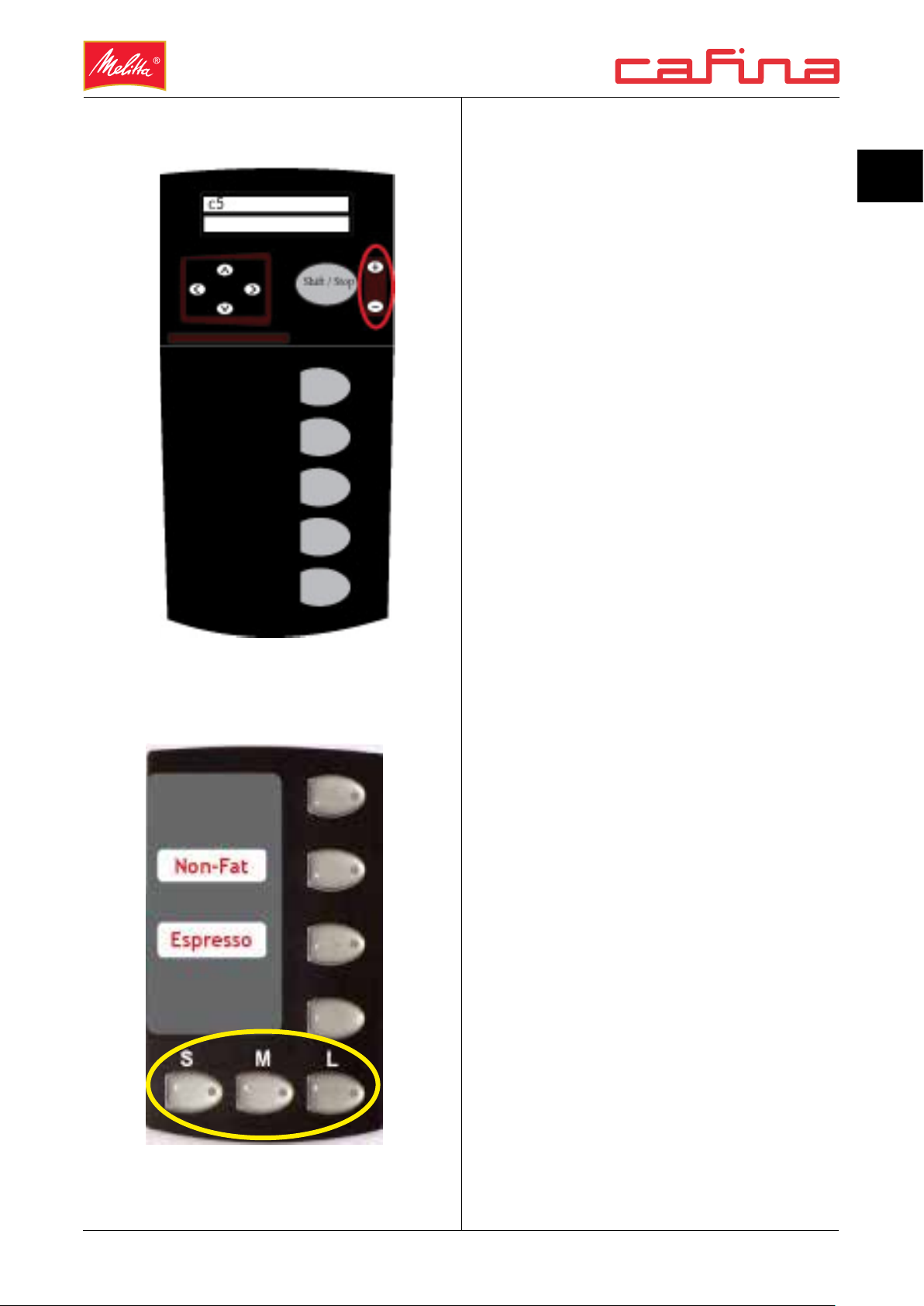

PRODUCT SELECTION

EN

1) Display

PRESELECTION KEYPAD

2) Product selection keys

3) Product labels

1) Not labeled, but function of Decaf

OPERATING MANUAL

2) Non - or low fat milk instead of whole milk

3) Espresso - allows for an extra shot

4) Cup size

V3.0

11

Page 12

EQUIPMENT SET-UP AND

CLOSE PROCEDURES

Fill milk

EN

NOTE

• The c5 coffee machine has a „standby“

operating mode.

• None of the product elds are lit up.

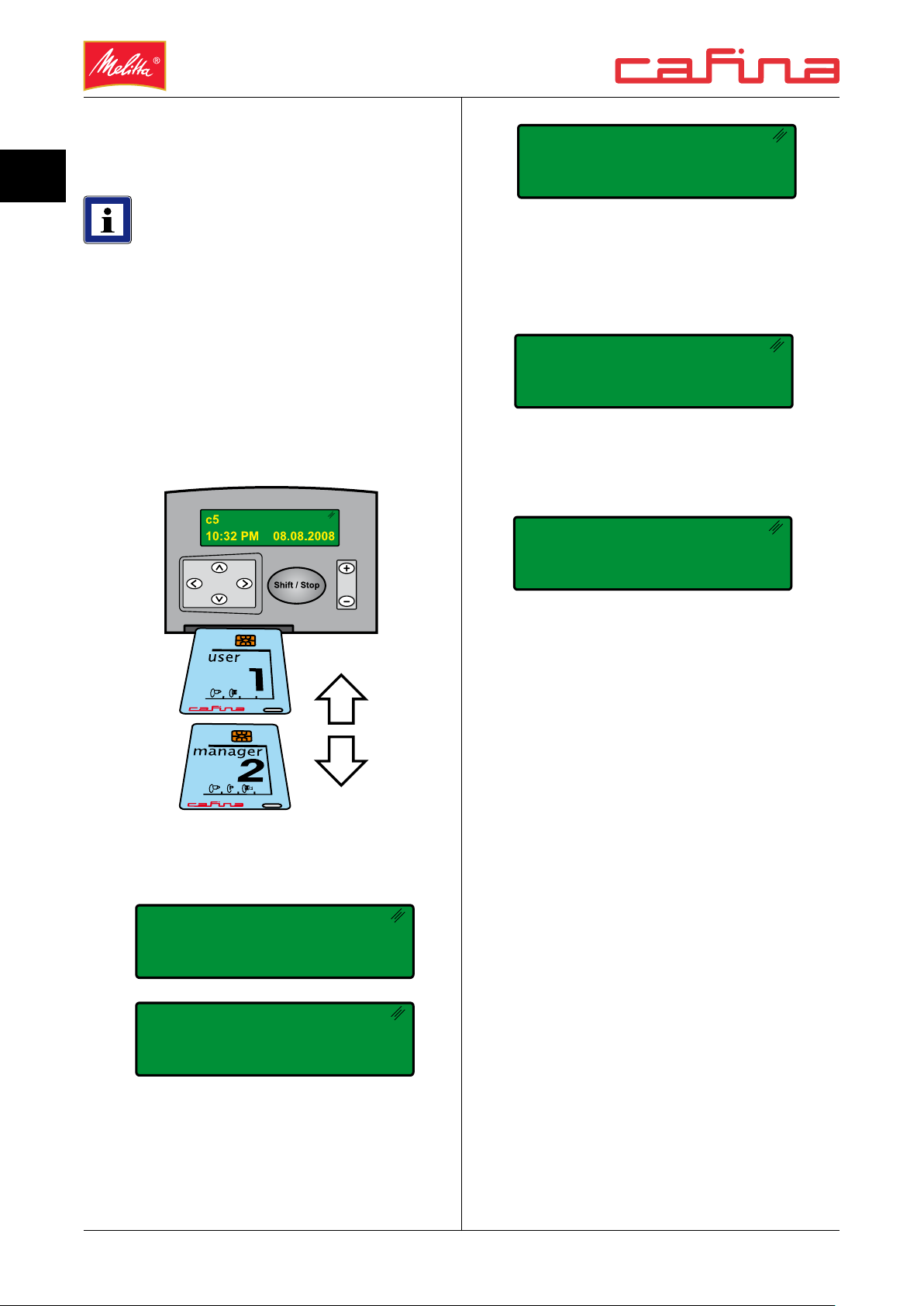

Switching on

1. Insert “user” or “manager” key card and then

remove.

Please conrm (SH)

3. After the coffee machine has heated up,

the “Fill milk” prompt will appear. Insert the

milk bag(s) and put the corresponding milk

connectors into the container and conrm.

4. All ve product elds are illuminated.

Please wait

10:32 PM 08.08.2008

The coffee machine is now lling the milk

system.

Select beverage

10:34 PM 08.08.2008

The coffee machine is now ready to dispense

beverages.

2. The c5 coffee machine heats up. The

second line ashes:

TURN ON

prog.197°F act. 161°F

TURN ON

Steam temp. too low

12

V3.0

OPERATING MANUAL

Page 13

Dispensing of beverages

Reference products

Dispensing normal coffee

The following description of how to dispense

beverages assumes the following allocation to

the beverage selection buttons:

Product elds from top to bottom...

Select Beverage

09:03 AM 06.1.2012

Shift /Stop

Mocha

Latte

NOTE

* after the product in the display

means „reference product from bean

hopper 1“.

** after the product in the display

means „reference product from bean

hopper 2“.

General sequence

1. Push the beverage outlet upwards.

2. Select desired coffee cup.

3. Place 1 coffee cup under the beverage outlet.

4. Push the beverage outlet downwards until the

coffee cup can be removed without having

to push the beverage outlet upwards again.

5. When this message is displayed, the coffee

machine is ready to dispense beverages ...

EN

Iced Mocha /Latte

Hot Chocolate

Add hot milk

Select beverage

10:34 PM 08.08.2008

Select:

• On the preselection keypad:

- Product: Decaf / Non-Fat (if appli-cable).

- Size of beverage: Small / Medium / Large.

• On the product selection keypad:

- Product on key level 1 – direct key stroke.

- Product on key level 2 – “Shift” + product

key.

Stopping the product ow...

You can interrupt the ow of beverage at any time

by pressing the Shift/Stop button [

].

OPERATING MANUAL

V3.0

13

Page 14

Change milk bag

Rell coffee beans

EN

1. The following message indicates that there is

no milk in the milk bag.

Select beverage

Change milk bag

2. Change the empty milk bag and conrm that

by pressing the Shift/Stop button [

].

Please wait

10:34 PM 08.08.2008

3. The coffee machine is now priming the milk

system.

Select beverage

The bean hoppers are monitored as regards

coffee bean content. If the bean hopper becomes

empty, this is displayed during the dispensing of

a beverage.

The following message appears...

Bean hopper 1 empty

Please conrm

or

Bean hopper 2 empty

Please conrm

1. Fill coffee beans into bean hopper 1, right

hand side.

or ll coffee beans into bean hopper 2, left

hand side

10:34 PM 08.08.2008

You can now dispense beverages as required.

2. Press Shift/Stop button to conrm.

14

V3.0

OPERATING MANUAL

Page 15

Emptying the coffee waste drawer

NOTE

• The coffee waste drawer is full to

capacity when it contains a weight

of 0.7 kg. (1,5 lbs).

When this occurs, the message

„Empty drawer!“ is displayed.

• The coffee waste drawer is 80 %

full when it contains a weight of

0.56 kg. (1,25 lbs).

When this occurs, the message

„Drawer almost full!“ is displayed.

1. Empty the coffee waste drawer, clean with

warm water and dry.

2. Push the coffee waste drawer in. The following message appears...

Drawer emptied?

Please conrm (SH)

Press Shift/Stop button [

3. The following message appears...

].

Select beverage

EN

CAUTION

• If the coffee waste drawer overows,

this will cause serious dirt accumulation inside the c5 coffee machine.

• Always empty the coffee waste drawer

correctly when the c5 coffee machine

is switched on.

1. The following displays indicate how full the

coffee waste drawer is...

...Coffee waste drawer is 80 % full.

Select beverage

Drawer almost full

...Coffee waste drawer is 100 % full.

11:30 PM 08.08.2008

4. You can now dispense beverages as

required.

Select beverage

Empty drawer!

2. Push the beverage outlet all the way up.

3. Pull out the coffee waste drawer. The following

message appears...

Select beverage

Drawer missing!

OPERATING MANUAL

V3.0

15

Page 16

Cleaning the drip tray

Close Procedures

EN

1. The drip grille and drip tray must be cleaned

at regular intervals.

2. Press the drip grille at the back right or back

left corner downwards a little.

NOTE

• Only use combination cleaning tablets

“COMBI-Tabs”.

• Get out three combination cleaning

tablets “COMBI-Tabs”.

• Get the cleaning container

3. Remove drip grille and clean.

4. Clean drip tray and clean out the drain holes

if they are blocked.

5. Place the drip grille in the correct position

on the drip tray, i.e. with the transverse rods

underneath.

16

V3.0

OPERATING MANUAL

Page 17

SYSTEM SETUP /

OPERATION

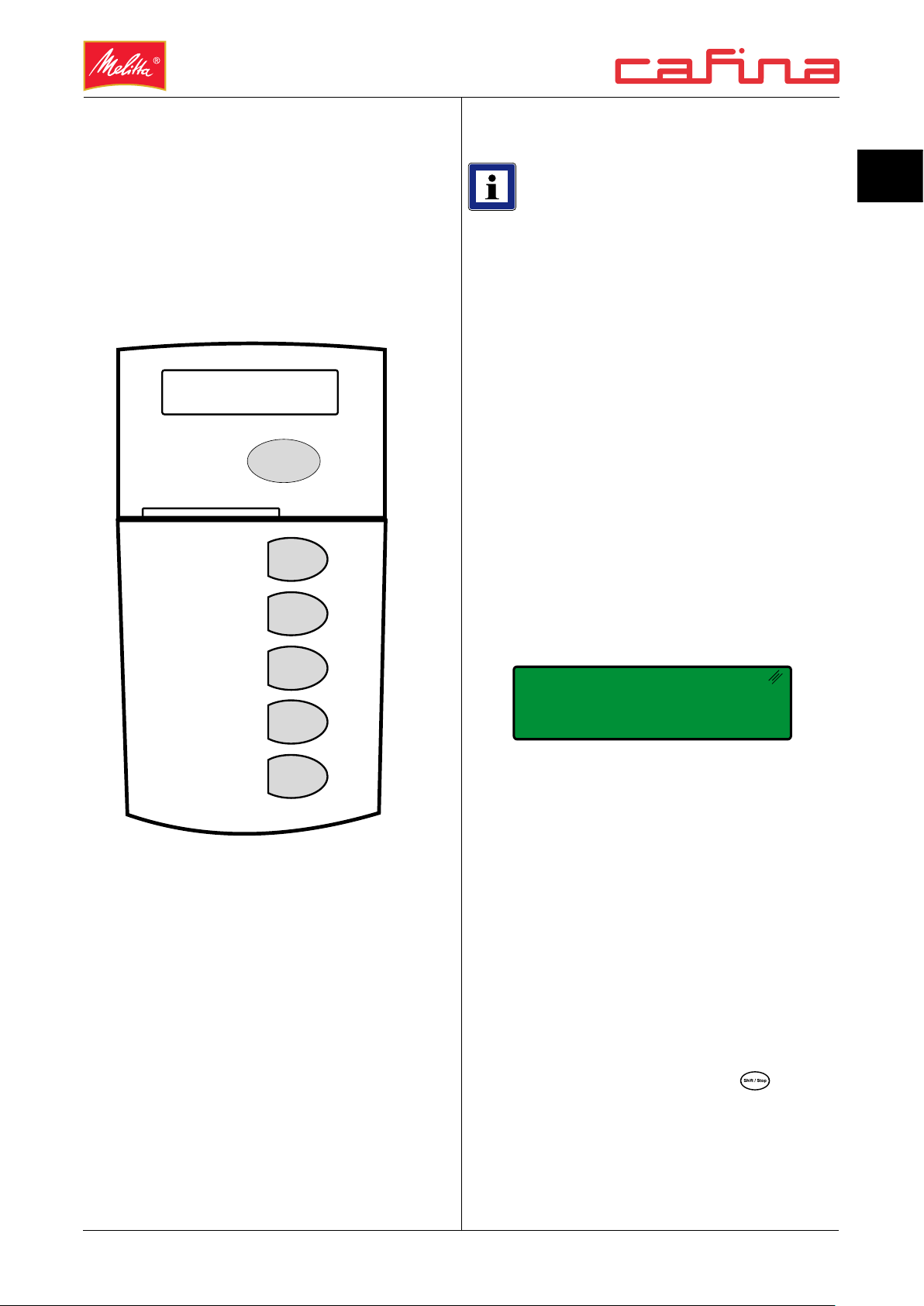

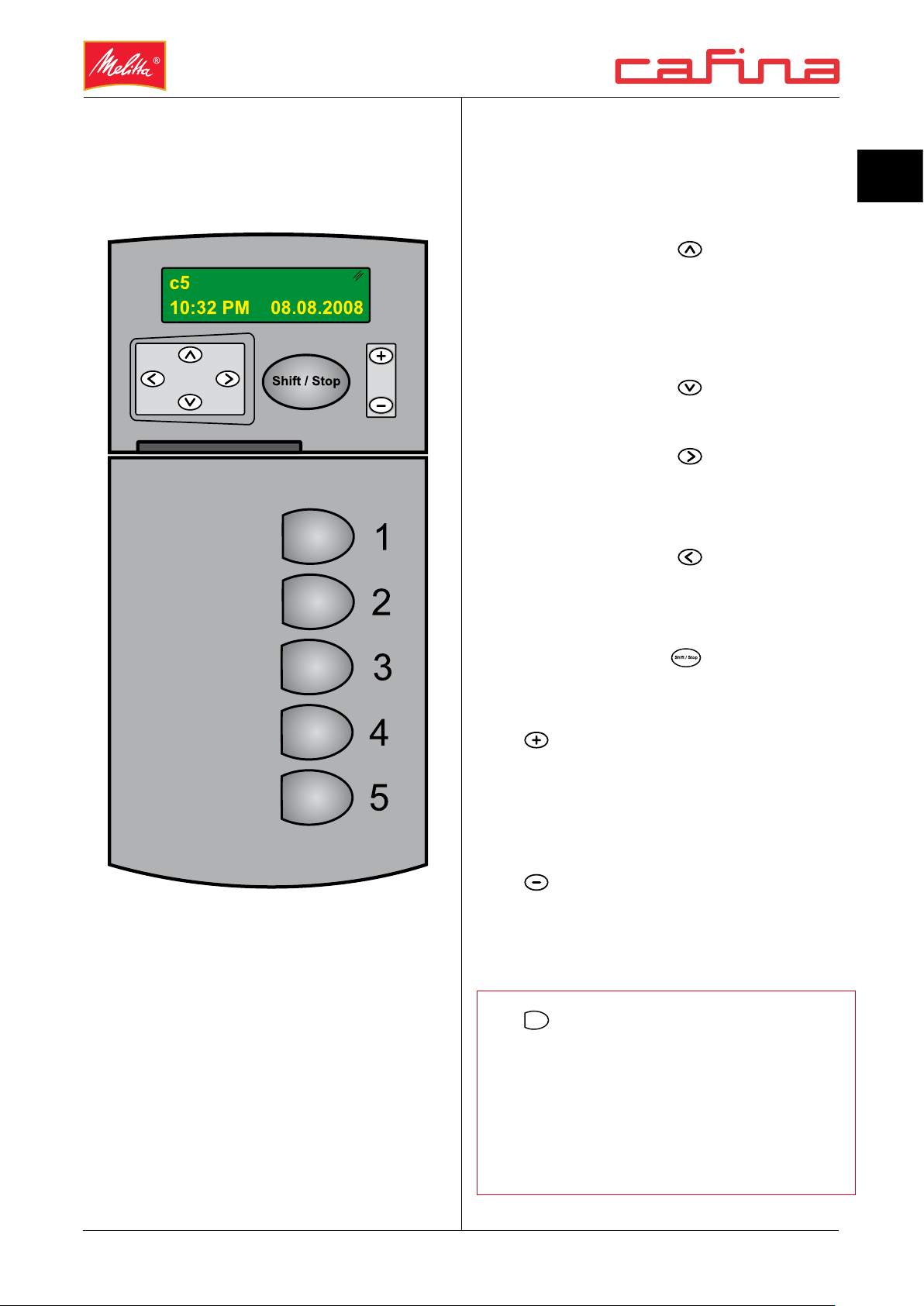

♦ Liquid crystal display

Control panel and button layout

○ Displays information on the correspon-

ding function.

♦ Navigation button [

○ One level higher in the structure

○ Used to conrm queries / or adjusment

values.

♦ Navigation button [

○ One level down in the structure.

♦ Navigation button [

○ One position horizontally to the right in

the structure.

♦ Navigation button [

○ One position horizontally to the left in

the structure.

]

]

]

]

EN

♦ Shift/Stop button [

○ Not allocated.

♦ [

♦ [

♦ [

] button

○ Used to raise the adjustment value in

predened steps.

○ Used to enter “Yes”.

] button

○ Used to lower the adjustment value in

predened steps.

○ Used to enter “No”.

] button (no invisible)

○ 1 = “Yes” in response to textual

questions.

]

OPERATING MANUAL

V3.0

○ 2 to 4 unallocated.

○ 5 = “no” in response to textual

questions.

17

Page 18

EN

Cards

Card handling:

1. Insert key card.

2. Wait until LC-display changes.

3. Remove key card.

♦ “user” key card

• Insertion of the card has the effect

of switching the coffee machine on

or off.

• Insertion of the card has the effect of

granting access to basic functions.

Operation with critical problem

DPxx

• In this condition, the coffee machine is

connected to the main power and water

mains.

• It is not possible to dispense any beverages.

Operation with non-critical problem

♦ “manager” key card

• Insertion of the card has the effect

of granting access to advanced functions.

• Insertion of the card after the adjustment values have been changed

has the effect of conrming the new

settings.

Operating modes

In operation

Select beverage

18:21 PM 08.08.2008

• In this condition, the coffee machine is

connected to the main power and water

mains.

Select beverage

Error coffee part DP16

• In this condition, the coffee machine is

connected to the main power and water

mains.

• There are restrictions on the dispensing of

beverages.

“Stand by” operation (switched off)

c5

18:21 PM 08.08.2008

• In this condition, the coffee machine is

connected to the main power and water

mains.

• There are no restrictions on the dispensing

of beverages.

Out of order (de-energised)

• In this condition, the coffee machine is

disconnected from the main power and water

mains.

• It is not possible to dispense any beverages.

18

V3.0

• It is not possible to dispense any beverages.

OPERATING MANUAL

Page 19

Structure of the functions

Access with the “user” key card

♦

♦ Menu Cleaning

○ Cleaning

♦ Menu Daily counter

○ Coffee total

• Setting 0 - 100 000

○ Other products

• Setting 0 - 100 000

Access with the “manager” key card

♦ Menu Cleaning

○ Cleaning

♦ Menu Daily counter

○ Coffee total

• Setting 0 - 100 000

○ Other products

• Setting 0 - 100 000

♦ Menu Coff. quant. ±1g

○ Coffee products

• Setting ±1g

♦ Menu Flow period water

○ Hot water products

• Setting 0,4 - 120s

♦ Menu Pre-infusion 1 milk

○ Milk / coffee products

• Setting 0 - 50s

♦ Menu Pre-infusion 2 milk

○ Milk / coffee products

• Setting 0 - 50s

♦ Menu Post-infusion milk

○ Milk / coffee products

• Setting 0 - 50s

♦ Menu Flow period milk

○ Milk products

• Setting 0,4 - 120s

EN

○ Reset counter

• Setting yes / no

♦ Menu Total counter

○ Coffee total

• Setting 0 - 1 000 000

○ Milk total

• Setting 0 - 1 000 000

♦ Menu Functions

○ EXTERNAL

• function disabled

○ Self-service

• Setting yes / no

○ ON / OFF timer

• Setting yes / no

○ Memoswitch

• function disabled

○ Milk

• function disabled

♦ Menu Flow period steam

○ disabled

♦ Menu Price do not use

○ For all products

• Setting 0 - 25.00

♦ Menu No charge do not use

○ For all products

• Setting yes / no

♦ Menu Clock / date

○ Hours

• Setting HH

○ Minutes

• Setting MM

○ Day

• Setting DD

○ Month

• Setting MM

○ Disable buttons

• Setting yes / no

♦ Menu Water quantity

○ Coffee products

• Setting 0 - 995ml

OPERATING MANUAL

V3.0

○ Year

• Setting YY

19

Page 20

Brief description of functions

EN

Daily counter

○ With “user” key card

Queries the current counter status for

all products. Deletion of counters is not

possible.

○ With “manager” key card

Queries the current counter status for all

products. Deletion of counters is generally possible.

Total counter

○ Coffee / Milk

Queries the current counter status for

specied products.

Deletion of counters is not possible.

○ EXTERNAL

disabled

○ Memoswitch

disabled

○ Milk

disabled

Water quantity

○ Every individual coffee product

The water quantity can be altered in

predened steps.

Coffee quantity ±1g

○ Every individual coffee product

The powder quantity can be altered in

predened steps.

Functions

○ Self-service

Switches coffee machine to self-service

operation.

The products intended can be dis-pensed

directly.

○ ON/OFF timer

Sets coffee machine to automatic switching on and off.

The switch-on / switch-off times must

have been previously specied by a

service engineer.

○ Disable buttons

Locking and release of the control buttons

on the coffee machine.

Flow period hot water

○ Hot water beverages

The ow time can be altered in predened steps.

Preinfusion 1 milk

○ Every “coffee-milk” beverage

The milk ow time can be altered in

predened steps.

Coffee is then added.

Preinfusion 2 milk

○ Every “coffee-milk” beverage

The milk ow time can be altered in

predened steps.

Coffee is then added.

20

V3.0

OPERATING MANUAL

Page 21

Post-infusion milk

Use of the functions

○ Every “coffee-milk” beverage

The milk ow time can be altered in

predened steps.

Coffee is output rst.

Flow period milk

○ Cold milk

The ow time can be altered in predened steps.

○ Hot milk

The ow time can be altered in predened steps.

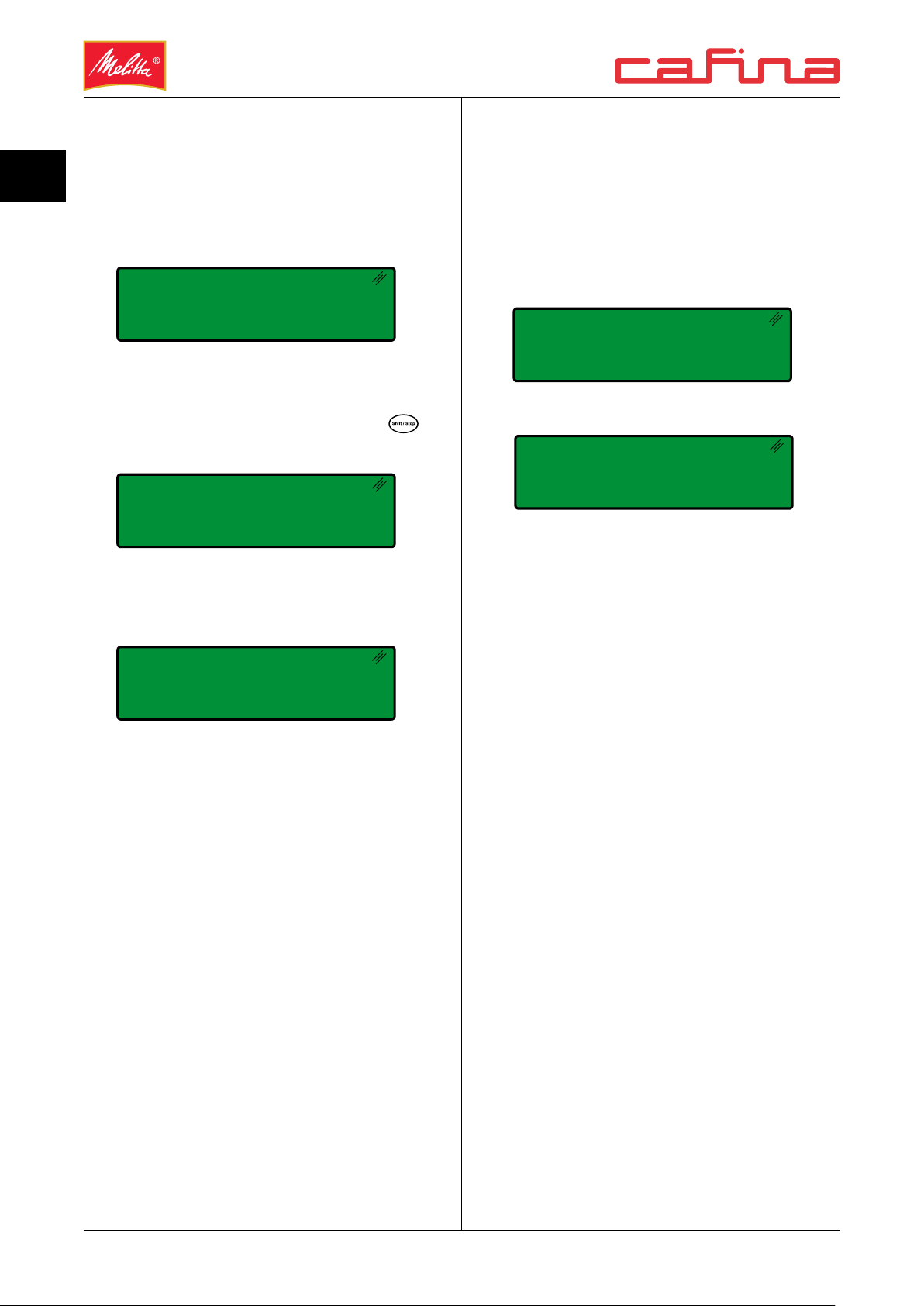

Cleaning

• Card: “user” key card

1. Insert / remove card.

Cleaning?

Please conrm (SH)

2. [

3. Start of cleaning procedure.

].button

EN

Flow period steam

disabled

Price do not use

No charge do not use

Clock / date

○ Clock

Used to set the time in the format

«00:10PM»

○ Date

Used to set the date in the format

«Wednesday 10.09.2008»

OPERATING MANUAL

V3.0

21

Page 22

Daily counter

Daily counter

EN

• Card: “user” key card.

1. Insert / remove card.

Cleaning?

Please conrm (SH)

2. 1x [

] button.

Cleaning

3. 1x [

] button.

Daily counter

4. 1x [

] button.

Coffee total

• Card: “manager” key card.

1. Insert / remove card.

Cleaning?

1x

Please conrm (SH)

2. 1x [

] button.

Daily counter

3. 1x [

] button.

Coffee total

xx

4. [

] or [ ] button.

Other beverages

Cleaning

xx

5. [

] or [ ] button.

Other beverages

yy

6. Insert / remove card.

Select beverage

18:21 PM 08.08.2008

yy

5. [

] or [ ] button.

Reset counter

6. 1x [

] button.

Reset counter

7. 1x [

] button.

Daily counter

8. Insert / remove card.

Select beverage

22

V3.0

18:21 PM 08.08.2008

OPERATING MANUAL

Page 23

Total counter

Functions

• Card: “manager” key card.

1. Insert / remove card.

Cleaning

2. 1x [

] button.

Total counter

3. 1x [

] button.

Coffee total

312

4. 1x [

] button.

NOTE

• Only those functions which have

orange background (activated) can

be altered.

• Card: “manager” key card.

1. Insert / remove card.

2. 3x [

] button.

Functions

3. 1x [

] button.

Self-service

1x [

] button.

ON/OFF timer

EN

Tea total

252

5. 1x [

] button.

Steam total

512

6. 1x [

] button.

Milk total

125

7. 1x [

] button.

Total counter

8. Insert / remove card.

1x [

] button.

Disable buttons

4. 1x [

] button.

Self-service

1x [

] button.

ON/OFF timer

1x [

] button.

Disable buttons

5. 1x [

] button.

Functions

Select beverage

18:21 PM 08.08.2008

OPERATING MANUAL

6. IInsert / remove card.

Select beverage

18:21 PM 08.08.2008

V3.0

23

Page 24

EN

Clock / date

• Card: “manager” key card.

8. 1x [

] button.

Clock / date Day

1. Insert / remove card.

Cleaning?

Please conrm (SH)

2. 1x [

] button.

Cleaning

3. 1x [

] button.

Clock / date

4. 1x [

] button.

Clock / date Hours

Wednesday 06.08.2008

9. e.g.1x [

] button.

06

Clock / date Day

Thursday 07.08.2007

10. 1x [

] button.

Clock / date Month

Thursday 03.07.2008

11. e.g.1x [

] button.

07

Clock / date Month

Sunday 03.07.2008

12. 1x [

] button.

08

Clock / date Year

09:27 AM

09

5. e.g.1x [

] button.

Clock / date Hours

09:27 AM

10

6. 1x [

] button.

Clock / date Minutes

10:27 AM

7. e.g.5x [

] button.

Clock / date Minutes

10:27 AM

27

32

Saturday 11.08.2007

13. e.g.1x [

] button.

2007

Clock / date Year

Monday 11.08.2008

14. 1x [

] button.

2008

Clock / date

15. Insert / remove card.

Select beverage

10:32 AM 14.08.2008

After switching off the coffee machine a message

like this appears...

24

V3.0

c5

10:32 AM 14.08.2008

OPERATING MANUAL

Page 25

Resetting to initial installation default

settings

4. The following message appears…

This function is used to reset the coffee machine

software to the default settings that applied upon

rst installation.

The coffee machine reads in from the “memory”

key card all the data which the service technician wrote to the card (“memory” key card) last

time.

NOTE

• All the software modications which

have been made to the functions

using the “manager” card are lost

when machine is reset!

♦ Cards:

c5

Read memory card (+)

10:32 PM 04/16/2008

5. 1x [

] button.

Reading memory card

Remove card

6. Remove “memory” key card.

c5

EN

&

1. To disconnect the coffee machine from the

mains power supply:

○ Pull out the plug

or

○ set separate power switch to OFF.

2. Insert the “memory” key card.

3. To connect the coffee machine from the mains

power supply:

7. Insert / remove “user” key card.

Calibration

Please wait

TURN ON

8. Coffee machine reset is complete.

Select beverage

○ Insert plug

or

○ set separate power switch to ON.

OPERATING MANUAL

V3.0

25

Page 26

EN

MAINTENANCE

This chapter deals exclusively with prevenive maintenance of the equipment. In case of problems,

please consult page 33 “Troubleshooting”

Maintenance schedule

Cleaning intervals

Cleaning area Daily Weekly Monthly

Cover of beverage outlet .................................. ●

Beverage outlet ................................................ ●

Outer panel surfaces ........................................ ●

Control button ................................................... ●

Bean hoppers ................................................... ●

Coffee waste drawer ......................................... ●

Recess for coffee waste drawer ....................... ●

Liquid crystal display ........................................ ●

Milk hoses / refrigerator .................................... ●

Cleaning procedure .......................................... ●

Area underneath the equipment ....................... ●

Drip grille .......................................................... ●

Drip tray ............................................................ ●

Intervals between services

Your c5 coffee machine must be serviced with an

approved McDonald‘s Preventative Maintenance

plan.

26

V3.0

OPERATING MANUAL

Page 27

Cleaning

Cleaning work

CAUTION

• Only use non-corrosive, non-abrasive

household cleaners.

• Only use non-abrasive cloths.

• Do not use any of the normal (rapid)

decalcifying agents.

• Only use combination cleaning tablets

“COMBI-Tabs” for cleaning procedures

Cleaning area

Cover of beverage outlet ..................................

Beverage outlet ................................................

Outer panel surfaces ........................................

Control buttons .................................................

Bean hoppers ...................................................

Coffee waste drawer .........................................

..........................................................................

..........................................................................

Recess for coffee waste drawer .......................

Liquid crystal display ........................................

Milk hoses / refrigerator ....................................

..........................................................................

..........................................................................

Cleaning procedure ..........................................

Drip grille ..........................................................

Drip tray ............................................................

EN

Cleaning work

Clean using damp cloth.

Clean using damp cloth.

Clean using damp cloth.

Clean using damp cloth.

Clean using dry cloth.

Rinse out with warm (not hot) water every time

that it is emptied.

Rub dry with cloth.

Clean using damp cloth.

Clean using dry cloth.

Following the cleaning procedure, clean only the

outside of the milk hose, using a dry cloth.

Clean inside of refrigerator with damp cloth.

For further details, see next point.

Clean using damp cloth.

Clean using damp cloth.

OPERATING MANUAL

V3.0

27

Page 28

EN

Cleaning procedure

Because of the high amount of milk beverages

served from the c5, frequent cleaning cycles are

absolutely required to keep the coffee machine

operational at all times.

The cleaning procedure needs to be performed

daily, and it will start at every shut down procedure. The coffee machine can not be shut off without

cleaning the whole system.

The cleaning process can be performed at any given time by inserting the “user” or “manager” key

card.

The cleaning process consists of a coffee system

cleaning cycle and a milk system cleaning cycle.

The milk cleaning cycle is divided into the actual

system cleaning, the system sanitizing cycle, and

once per week, the system deliming cycle.

a). Coffee cleaning cycle

The coffee cleaning cycle is fully automatic. The

only thing, the operator has to do, is to insert a

cleaning tablet at a prompt in the menu.

b). Milk cleaning cycle

For the milk system cleaning, the operator has to

prepare the sanitizer solution prior to starting the

cleaning process. During the milk cleaning cycle,

the operator will be prompted to change cleaning

jugs by audible and visual messages.

The deliming cycle once a week, using a special

deliming agent, helps to clean the milk system

more thoroughly than with the daily cleaning tablets.

A step by step cleaning procedure is provided with

the coffee machine, and can also be found in the

appendix to this operating manual.

28

V3.0

OPERATING MANUAL

Page 29

TROUBLESHOOTING

Fault display, troubleshooting and fault

acknowledgement

During operation, the control system monitors the operating status continually. Faults are

displayed on the liquid crystal display. In case of

malfunctions, the user or operator can intervene

in accordance with the procedures described

in this chapter an attempt to trouble- shoot the

problem.

Brief description of troubleshooting process:

Checklist for fault diagnosis and troubleshooting

Quick Fix

EN

A quick troubleshooting guide can be found in

the appendix to this operating manual. The same

document should always be available close to the

coffee machine.

More detailed trouble shooting information is

described in the next chapter.

Textual error messages

♦ LCD messages:

- Analyse message on the liquid crystal display.

The possibilities are as follows:

○ Text message.

○ Text message plus diagnosis point (DP)

display.

- First of all insert / remove the “user” or

“manager” key card. If this clears the malfunction, then the coffee machine will be once

more ready to dispense beverages. Otherwise

see below.

- To troubleshoot the problem, proceed as

described in “Textual error messages” and

“Error messages displayed via diagnosis

points (DP)”.

- Insert / remove “user” or “manager” key card

a second time.

○ Temp. too high.

○ Temp. too low.

○ Boiler temp. too high.

○ Boiler temp. too low.

♦ Cause of fault:

○ Unknown hardware or software error.

○ Static charge.

○ Effect of storm (overvoltage due to

storm).

♦ Troubleshooting measure(s):

Disconnect / connect to mains power

supply.

1. Disconnect the coffee machine from the mains

power supply.

2. Wait at least 20 seconds.

3. Connect coffee machine.

- If this clears the malfunction, then the coffee

machine will be once more ready to dispense

beverages. If not, disconnect the coffee

machine from mains power by pulling the plug

from the wall socket and reconnect after about

20 seconds, or via the circuit breaker on the

mains panel.

OPERATING MANUAL

4. Insert “user” or “manager” key card to switch

machine ON.

5. Decision:

If the textual error message is no longer

shown, there is no need for any action.

If the textual error messages are still visible,

notify Customer Support.

V3.0

29

Page 30

♦ LCD messages:

♦ LCD messages:

EN

○ Change milk bag.

♦ Cause of fault:

○ Milk level too low.

♦ Troubleshooting measure(s):

Check if milk connectors are fully inserted in

milk bag.

○ check milk level.

○ change milk bag, if required.

See also “Change milk bag” page 14.

♦ LCD messages:

○ No milk available.

○ No water.

♦ Cause of fault:

○ Check water connection:

Connect Disconnect

♦ Troubleshooting measure(s):

Open stopcock in the external fresh water

feeder hose.

Check that the quick disconnect (can be metal

or white plastic) is fully inserted. Push together to make sure, if is fully connected.

Clean or replace external water lter.

♦ Cause of fault:

○ Acknowledge of message “Milk lled”

with “no”.

○ Shortage of water while cleaning.

♦ Troubleshooting measure(s):

Unplug and reconnect coffee machine and

conrm with “yes”.

♦ LCD messages:

○ Drawer missing!

♦ Cause of fault:

○ Coffee waste drawer not inserted or

not pushed in far enough.

♦ Troubleshooting measure(s):

♦ LCD messages:

○ Bean hoppers (1 or 2).

♦ Cause of fault:

○ Bean hopper 1 or 2 is empty.

♦ Troubleshooting measure(s):

Rell coffee beans, see also “Rell coffee

beans” page 14.

Use coffee waste drawer correctly.

See also “Emptying the coffee waste drawer”

page 15.

30

V3.0

OPERATING MANUAL

Page 31

♦ LCD messages:

♦ Troubleshooting measure(s):

○ Boiler level.

♦ Cause of fault:

○ Water level too low.

○ Too much time elapses during the lling

operation.

♦ Troubleshooting measure(s):

There may be a water leak or the water feed

may be insufcient.

The coffee machine is still in operation;

however it is necessary to keep an eye on

it.

Contact Customer Support.

♦ LCD messages:

○ Filter.

♦ Cause of fault:

The coffee machine is still in operation;

however it is necessary to keep an eye on

it.

Contact Customer Support.

♦ LCD messages:

○ Service Coffee.

○ Service Milk.

♦ Cause of fault:

○ The whole system needs servicing.

○ The milk system needs servicing.

♦ Troubleshooting measure(s):

The coffee machine is still in operation;

however it is necessary to keep an eye on

it.

EN

○ The main water lter has reached the

end of its life cycle and needs to be

replaced.

♦ Troubleshooting measure(s):

The coffee machine is still in operation;

however it is necessary to keep an eye on

it.

Contact Customer Support.

♦ LCD messages:

○ Grinder correction.

♦ Cause of fault:

○ The automatic coffee bean grinding

calibration is not working. This results

in reduced quality of the beverages

dispensed.

Contact Customer Support.

♦ LCD messages:

○ Foamer replacement.

♦ Cause of fault:

○ Cover plate on foamer head casting has

been removed, or has not been xed

property.

♦ Troubleshooting measure(s):

Put cover back and x with 2 screws.

OPERATING MANUAL

V3.0

31

Page 32

♦ LCD messages:

♦ Diagnosis point (DP):

EN

○ Reboot system.

♦ Cause of fault:

○ Fatal system error.

♦ Troubleshooting measure(s):

Unplug machine or switch off at circuit breaker

on mains panel. Wait for 20 seconds and

reconnect.

Error messages displayed via diagnosis

points (DP)

♦ Diagnosis point (DP):

○ 0 / 1 / 2 / 4 / 5

♦ Cause of fault:

○ 8 / 9 / 10 / 16 / 17 / 18 / 22 / 23

♦ Cause of fault:

○ System fault.

♦ Troubleshooting measure(s):

Contact Customer Support.

Extended Troubleshooting functions with

“Troubleshooter” key card

Delivered with every c5 coffee machine is a “Troubleshooter” or “Machine status” key card.

This card can be used between the service organization and the coffee machine user to track down

a specic problem on the coffee machine.

○ System fault.

♦ Troubleshooting measure(s):

Contact Customer Support.

♦ Diagnosis point (DP):

○ 7

♦ Cause of fault:

○ Coffee waste block too high.

♦ Troubleshooting measure(s):

Check coffee waste drawer:

○ empty coffee waste drawer correctly.

More details can be found on the separate chart

in the appendix to this document.

see also “Emptying the coffee waste drawer”

page 15.

If the fault persists, contact Customer

Support.

32

V3.0

OPERATING MANUAL

Page 33

ORDERING PARTS / SERVICE

Technical information

The c5 coffee machine representative for the

USA:

Melitta USA Inc.

665 Tollgate Road, Suite B

Elgin, IL 60123 (EE. UU.)

Teléfono: (847) 214 8088

Fax: (847) 214 8061

www.melitta.com

For quick reference when calling service, please

note the following:

c5 machine serial number:

NON-SCHEDULED MAINTENANCE

EN

WARNING

• Inspection, testing, and repair of

electrical equipment should only

be performed by qualied service

personnel.

WARNING

• All electrical connections should be

disconnected and the hood circuit

breaker should be turned off when

servicing the clamshell grill.

McD store number:

APPENDICES

♦ Circuit diagram c5-FF 34

♦ Circuit diagram FOST PCB 35

♦ QUICK OPERATING MANUAL 36

♦ Daily Cleaning 47

♦ Weekly Cleaning 49

♦ Sanitizing Procedure 51

♦ Foamer head 53

♦ Machine status key card 55

OPERATING MANUAL

V3.0

33

Page 34

EN

34

V3.0

OPERATING MANUAL

Page 35

EN

OPERATING MANUAL

V3.0

35

Page 36

Short Cupping/Low Temp Basic Troubleshooting

EN

Drinks are short lling

Drink temperatures are low

● Change foamer head

● Clean the lower foamer head tting with

a clean brush

● Run a cleaning cycle

Check refrigerator temperature

● No cooler than 36 f.

● No warmer than 40 f.

If problem persists, a service

call is required

Fault Reset Basic Troubleshooting

Insert the user card to clear a fault

and restart the machine

Use the 5 Button Reset Procedure if

the machine can not be restarted with

the User Card

● Any DP code on the screen

● Buttons are not functioning

● Steam temp too low

● No hot water

● No coffee from spout

● Change/No milk will not clear

● Bean Hopper error will not clear

● Boiler level low message

● Piston Normal position message

Press these 5 Buttons Simultaneously

1. 2. 3. 4. 5.

c5

Shi / Stop

A successful restart will make the screen

go blank and restart the machine

36

V3.0

OPERATING MANUAL

Page 37

No Water Basic Troubleshooting

Ensure that there is water

owing to the machine

● Check the water ltration/ R.O. system

● Is the water supply valve open?

● Check that the water line for the ma-

chine is not pinched and restricting

water ow

● Disconnect and Reconnect the water

line quick disconnect coupling. Push

together both ends of coupling until a

click is heard

● Still No Water?

A service call may be required.

Coffee Stick

Open Position

Quick disconnect

EN

Change Milk Bag/No Milk Basic Troubleshooting

Milk Bags

● Change empty milk bag

● Check that the milk bag

tops are pushed all the

way down in the slot

● Check that the lines

routed from the milk box

to the milk bags are not

pinched

● Check that milk connectors are pushed all the

way into the bag

● Check milk type

Was a yogurt bag used

by mistake?

Check refrigerator

temperature

● No cooler than 36 f.

● No warmer than 40 f.

● Check that milk lines are

not frozen

Swap milk bag connectors

Place whole milk connector

on non-fat milk bag

Place non-fat milk connector

on whole milk bag

Does the drink selection

work with the connectors

swapped?

● No, call for a service visit

● Yes, swap milk bags.

The machine may be used

with only one bag

until serviced

Non-emergency

service call required

OPERATING MANUAL

V3.0

37

Page 38

Wrong Card Basic Troubleshooting

EN

Clean the User card with a sanitizing towel User Card Still Does Not Work

● Try a different User or Manager card

● If a different card works, the rst User

card is bad

● A card from a different store may be

used

Dry and re-insert the cleaned User card

Call for a service technician if you are

unable to start or clean the machine

Replace Foamer Head Basic Troubleshooting

Check for proper connection of hose

ttings to the foamer head

● Verify that the cover plate is

seated correctly

● Check that cover plate screws

are fully tightened

Note: Foamer cover plate has a safety switch in-

stalled in the machine. If the limit switch screw does

not make contact with the safety switch,

the message will not clear.

Adjusting the foamer cover plate

limit switch screw

● Loosen retaining nut. Back off until it

touches the bottom of the screw head

● Tighten screw until it is fully seated

(should look like picture above)

● Loosen limit switch screw 2 full

revolutions and tighten nut

Note: Do not allow the limit switch screw

to turn while tightening the nut

38

V3.0

OPERATING MANUAL

Page 39

Drawer Missing/Empty Basic Troubleshooting

Drawer Missing

● Is the grounds drawer

pushed all the way in?

● If drawer is fully installed, clean the coffee

grounds drawer

● Clean area outside and

behind the coffee grounds

drawer to remove any

build up that may prevent

the drawer from closing

● Clean inside the coffee

grounds drawer

Empty Drawer

● Empty the coffee grounds

drawer

● Press the shift button to

con rm that drawer was

emptied

● Drawer must be removed

for ten seconds or the

message will not clear

EN

Bean Hopper Empty Basic Troubleshooting

Are there coffee beans

in the hopper?

● Stir the coffee beans and

check for obstruction.

● Is the bean gate open?

Remove the bean hopper

● Push beans down the

tube with a long handled

stirring spoon

● Replace hopper

● Open bean gate

● Make another drink

Note: Alternate grinder may be

used until service is available

Try the opposite Grinder

● Place hopper onto the

other hopper holder, and

open the bean gate

● Press the top button on

the Pre-selection pad

● Run an espresso drink

Note: Service is required if

grinders do not work or hopper

must be swapped to continue

production

OPERATING MANUAL

V3.0

39

Page 40

EN

Water leak Basic Troubleshooting

After cleaning cycle:

Approximately 2-3 ounces of water

is normal in:

● Waste drawer

● Milk box

During Normal Use:

Is water lling the drip tray and spilling

onto the refrigerator?

If drip tray is full:

● check for debris blocking drain

Remove and dry any excess water

from the waste drawer

Tilt milk box outside of the refrigerator to

drain condensation

Wait 1-2 hours and check for new water

If new water is found, a service call is

required

● verify that drain hose is not kinked,

pinched, or excessively sagging

Melitta SystemService

Service Hotline

866-910-9105

40

V3.0

OPERATING MANUAL

Page 41

without running a complete cleaning

cycle. Please follow the cleaning

instructions on page 7.

Insert User or Manager card face up.

Remove after the display shows please

conrm.

NOTE: Machine can not be switched OFF

Bean hopper 1

Bean hopper

slider

Operating panel

WARNING:

When beverages are dispensed,

there is a risk of scalding from

steam and hot liquids!

Proceed with care!

Coffee waste

drawer

Drip tray

EN

Revised 01/2010

Press preselect buttons for specia-1.

lity and cup size

Press product button. 2.

Press „Shift/Stop“ button rst to

access second level of products.

Select the desired beverage:

Display

Shift/Stop

button

Product

buttons

The c5 is ready to serve

beverages when the

display shows Select

beverage.

If message Fill milk is

displayed, refer to pro-

cedure on page 2 of this

document.

Specialty Coffee Machine

Insert User or

Manager card face up.

Remove card when

display shows Turn on.

Do not leave card in

machine.

-1-

Turn ON Machine Machine ready Turn OFF Machine

BASIC DAILY OPERATION

access cover

Foamer head

Bean hopper 2

WARNING:

Risk of scalding.

Hot water and steam ow from spout

during start up.

Display

Preselection

keypad

Drip grate

Beverage spout

Preselect

Machine Overview

Place one cup of the desired size

under the spout.

Dispensing Beverages

buttons

Adjust the spout height to be

approximately ½ inch above the

cup rim.

OPERATING MANUAL

V3.0

41

Page 42

EN

Revised 01/2010

If message „Bean Hopper em-

pty“ appears on display, Lift

the lid from the empty bean

hopper. Rell with fresh coffee

beans. Make sure to ll beans

evenly on both sides of insert

in the bean hopper.

Topping Up Coffee Beans

Slider

To remove a bean hopper for rell

or cleaning, move the slider all the

way in, hold bean hopper with both

hands on the conical section rotate

it slightly forth and back and lift it

Removal of Bean Hopper

upwards.

The mandatory daily system

cleaning procedure is described in

page 5 and 6 of this document.

Specialty Coffee Machine

If message „Fill milk“ or „Change Milk bag“ appears

open door on refrigerator, pull milk connector out of

the empty milk container and reinsert milk connector

into new bag. Close door to fridge. Push Shift/Stop

button to conrm.

Fill Milk / Change Milk bag

-2-

TOPPING UP AND MACHINE CLEANING

When the message „Empty

drawer“ appears on the display,

move the spout all the way up,

pull the waste drawer out and

empty it in the waste bin. Rinse

the drawer with warm water and

wipe dry with a cloth.

Emptying Coffee Waste Drawer

- Cover of beverage spout, spout itself

- Both bean hoppers

- Recess for coffee waste drawer

- Control panels

Daily Cleaning Daily System Cleaning

In addition to the automatic

cleaning cycle, the following parts

must be cleaned, using a

sanitizer soaked towel.

42

V3.0

OPERATING MANUAL

Page 43

c5

06:19 AM 12/01/2009

7.

Restart the machine with the User card

Select beverage

Error coffee part DP_ _

6. FAULT MESSAGE

Clear the fault with the User card

TURN ON

prog.197°F act. 191°F

Fault conrmed

Select beverage

06:20 AM 12/01/2009

c5

06:18 AM 12/01/2009

OK?

866-910-9105

NO? ( CALL SERVICE CENTER

EN

Revised 01/2010

Specialty Coffee Machine

4.

Check the milk level ►Are both bags full?

Select beverage

06:15 AM 12/01/2009

Are both milk pick up tubes fully inserted?

-3-

QUICK FIX

Coffee machine not working:

1.

Check power ►Is the Display lighted?

2.

Check water hose quick connector

5.

Check waste drawer

3.

Check bean hoppers ►Are both hoppers

Connected Disconnected

full?

Drawer pushed all the way in?

Check slider

must be open

OPERATING MANUAL

V3.0

43

Page 44

EN

tors and push Shift

Open bean hopper slider

are fully inserted and push Shift

To bean hopper up with coffee beans.

Check quick disconnect. Insert „User“ card

Check water connection to coffee machine.

power

Run complete cleaning cycle

before reinserting. Try another card

Revised 01/2010

Empty coffee waste drawer.

If fault persists, contact technical service

Put full milk container in fridge, make sure connectors

Place milk container(s) into refrigerator, insert connec-

Causes of Faults Steps to be Taken for Remedy

Reinsert card face up. Wipe card with damp cloth, dry

Specialty Coffee Machine

Disconnect / reconnect coffee machine from / to main

Drink temperature too low

Underlling / short cupping

<Display and buttons Frozen> Unplug unit for 3 sec.

44

Message

<Fill Milk> Start up message

<Change milk bag> Milk container in refrigerator is empty

LC-Display - Plain Text Error

-4-

Checklist for Tracking and Rectifying of Faults

ALARM HANDLING AND TROUBLESHOOTING

<No water> Fresh water ow insufcient

<Drawer missing> Coffee waste drawer missing or inserted incorrectly Insert coffee waste drawer correctly

<Wrong card> Key card inserted upside down or backwards

<Reboot System> System Error

<Bean hopper (1 or 2) empty> Coffee bean hopper 1 or 2 is empty

V3.0

<DP 7> Coffee waste drawer is over lled

Diagnostic Point Causes of Fault Steps to be taken for Remedy

Fault Display via Diagnostic Points (DP)

A number of machine faults are being displayed by „Diagnostic Points“ (DP). Most of these faults can only be rectied by trained service personnel.

Generally, to recover from a DP-error, insert the „User“ or „Manager“ card twice. If the error persists, contact technical service.

<DP 0 - DP 24> System fault Contact technical service

OPERATING MANUAL

Page 45

EN

Revised 01/2010

Specialty Coffee Machine

Lower Volume Stores (fewer than 500 drinks per week)

Follow this chart for machines that produce fewer than 500 drinks each week

The machine must also be cleaned two (2) times any single day producing more than 85 drinks

Monday Tuesday Wednesday Thursday Friday Saturday Sunday

-5-

top for coffee

LOWER VOLUME STORES

Cleaning tablet in

pitcher

1 bag Delimer

in milk cleaning

2 Cleaning tablets

powder in milk

pitcher

cleaning pitcher

Empty sanitizer

Install Clean

Foamer head

OPERATING MANUAL

V3.0

45

Page 46

EN

Revised 01/2010

Daytime Cleaning Night Cleaning

Specialty Coffee Machine

Follow this chart for machines that produce more than 500 drinks each week

Higher Volume Stores (more than 500 drinks per week)

See pages 7 & 8

Cleaning tablet in top for coffee

-6-

HIGHER VOLUME STORES

See pages 7 & 8

2 Cleaning tablets in milk cleaning pitcher

See pages 9 & 10

1 bag Delimer powder in milk cleaning pitcher

See pages 11 & 12

Empty Sanitizer pitcher

See page 13

Install Clean Foamer head

46

V3.0

OPERATING MANUAL

Page 47

Daily Cleaning

Why Daily cleaning of the machine

Time required 1 minutes to prepare 24 minutes to complete

Time of day at closing of store For 24-hour restaurants

Hazard icons

Tools and supplies

Mon. / Tues. /

Thurs. / Fri. / Sat.

Between 12:00 AM till 4:00 AM

nd

2

daily cleaning for higher volume stores

Anytime during the day - Managers preference

BE51D1

Cana c5-12C FF Daily BE51D1

Revised 01/2010

EN

«user» chip

card

Melitta Combi

Tabs

Procedure

Step 1

Insert the «user» card (chip

facing up) to start the clea-

ning cycle.

Specialty Coffee Machine

Step 2

Remove the card and

replace in the holder on the

side of the machine.

Step 3

Push button

Cleaning-Jug

«Delimer»

Step 4

Push

Step 5

Display alternates between

button to conrm

and

Push button

Drawer emptied

Please conrm (

Clean milk with

cleaner

Please conrm (SH)

SH

)

Lift the spout.

Empty and replace the cof-

fee waste drawer

-7-

DAILY CLEANING

OPERATING MANUAL

V3.0

47

Page 48

EN

Daily Cleaning (continued)

Step 6

Open the refrigerator and

remove the milk connectors

from the milk bags. Place the

milk lines in a empty jug. Make

sure the connectors are at the

bottom of the jug. Immediately

carry the remaining milk to the

walk-in cooler for storage.

Step 7

Step 12

Proceed to sanitizing

procedure

Cana c5-12C FF Daily BE51D1

Revised 01/2010

Push button

Step 8

Put 1 Melitta Combi Tablet in

the top of the machine after

the machine prompts «put

1 cleaning tab for coffee in

top» (after 4 min.).

Step 9

Push button

Step 10

to conrm

to conrm

Please conrm (SH)

Please conrm (SH)

Specialty Coffee Machine

Put 2 Melitta Combi Tablet

in the jug after machine

prompts «put 2 cleaning

tabs into jug».

48

Step 11

Push button

-8-

DAILY CLEANING - cont.

to conrm

Please conrm (SH)

WARNING: Never put Delimer Powder in the top of the machine.

Use only one Melitta Combi Tablet in the top.

V3.0

OPERATING MANUAL

Page 49

Weekly (Deliming 2x Week) Weds./Sun. BE51W1

Why Weekly cleaning of the machine remove milk stone

Time required 1 minutes to prepare 24 minutes to complete

Time of day at closing of store For 24-hour restaurants

Between 12:00 AM till 4:00 AM

nd

2

daily cleaning for higher volume stores

Anytime during the day - Managers preference

Hazard icons

Tools and supplies

Cana c5-12C FF Weekly BE51W1

Revised 01/2010

EN

«user» chip

card

Melitta Combi

Tabs

Procedure

Step 1

Insert the «user» card (chip

facing up) to start the clea-

Specialty Coffee Machine

Step 2

Remove the card and

replace in the holder on the

side of the machine.

Step 3

Push button

Cleaning-Jug

McD Delimer

ning cycle.

«Delimer»

bag

Step 4

Push

Step 5

Display alternates between

button to conrm

and

Push button

Drawer emptied

Please conrm (SH)

Clean milk with

delimer

Please conrm (SH)

Lift the spout.

Empty and replace the cof-

fee waste drawer

-9-

WEEKLY CLEANING

OPERATING MANUAL

V3.0

49

Page 50

EN

Weekly Deliming (continued)

Step 6

Open the refrigerator and

remove the milk connectors

from the milk bags. Place the

milk lines in a empty jug. Make

sure the connectors are at the

bottom of the jug. Immediately

carry the remaining milk to the

walk-in cooler for storage.

Step 7

Step 12

Proceed to sanitizing

procedure

Cana c5-12C FF Weekly BE51W1

Revised 01/2010

(4 min.

to conrm

).

to conrm

Please conrm (SH)

Please conrm (SH)

Push button

Step 8

Put 1 Melitta Combi Tablet in

the top of the machine after

the machine prompts «put 1

cleaning tab for coffee in top»

Step 9

Push button

Step 10

Specialty Coffee Machine

Put 1 bag McD Delimer in

the jug.

50

Step 11

Push button

-10-

WEEKLY CLEANING - cont.

to conrm

Please conrm (SH)

WARNING: Never put Delimer Powder in the top of the machine.

Use only one Melitta Combi Tablet in the top.

V3.0

OPERATING MANUAL

Page 51

Sanitizing procedure Daily BE51D2

Why to sanitize to the machine after daily or weekly cleaning cycle

Time required 1 minutes to prepare 3 minutes to complete

Time of day after daily or weekly cleaning cycle

Cana c5-12C FF Daily BE51D2

Revised 01/2010

EN

Hazard icons

Tools and supplies

Cleaning-Jug

«Sanitizer»

Procedure

Once the daily or weekly

cleaning cycle is completed,

the machine will beep and the

display alternates between

Specialty Coffee Machine

Step 1

and

Insert the empty jug for

sanitizing into fridge

Please conrm (SH)

Step 2

Push button to conrm

Display reads

Sanitizing with hot

water Temp. 200°F

Insert both milk tubes into the

cleaning jug labelled «Sani-

tizer», and making sure the

tubes are reaching the bottom

of the jug.

-11-

SANITIZING PROCEDURE

After the sanitizing cycle is

completed, the coffee machine

will be turned off and the dis-

play reads

The pitcher will be ¼ full of hot

water at the end of the sanitizing

cycle.

c5

7:21 PM 06/20/2008

OPERATING MANUAL

V3.0

51

Page 52

EN

Sanitizing procedure (continued)

Step 3

Remove the cleaning jug

containing hot water and wipe

the milk connectors with a sani-

tizer soaked towel.

Step 4

Wash the inside of the refrige-

rator and the milk hoses.

Allow to air dry.

Step 5

Take the coffee waste drawer

and the drip grille to the 3 com-

partment sink.

Wash, rinse, sanitize, allow

to air dry and replace on the

machine

Step 6

Wipe the beverage spout with

a Sanitizer towel, and allow to

air dry.

To start up the machine see

start up procedure.

Cana c5-12C FF Daily BE51D2

Revised 01/2010

Step 7

Specialty Coffee Machine

Wash the been hopper in warm

soapy water at the 3 compart-

ment sink. Do not place in ware

washer. Allow to dry before

lling with beans.

-12-

SANITIZING PROCEDURE - cont.

52

V3.0

OPERATING MANUAL

Page 53

Foamer head changing and cleaning

Why cleaning necessary, blocked unit

Time required 5 minutes to prepare 10 minutes to complete

Time of day after daily cleaning / deliming

Daily

Cana c5-12C FF Daily

EN

Revised 01/2010

Hazard icons

Tools and supplies

screwdriver milk jet unit milk jet unit brushes

Procedure

Step 1

Unscrew the 2 cover screws

with a screwdriver and re-

move the cover.

Specialty Coffee Machine

Step 2

Move all sliders back from

foamer head.

Step 4

Plug in the clen foamer head

into the lower connector,

push it over the pins and

move the sliders back into

position.

Step 5

Replace the cover and ligh-

ten the screws. Align pins

with the holes on left side.

Step 3

Lift the foamer head out,

then pull it out of the lower

-13-

FOAMER HEAD CHANGE

OPERATING MANUAL

connector.

V3.0

53

Page 54

EN

Foamer head changing and cleaning (continued)

Step 6

Clean dirty foamer head with

brush and soapy water as

shown.

Rinse with sanitizer and air

dry.

Cana c5-12C FF Daily

Revised 01/2010

Specialty Coffee Machine

-14-

FOAMER HEAD CLEANING

54

V3.0

OPERATING MANUAL

Page 55

EN

Troubleshooter / Machine Status Key Card

Besides the User-; Manager- and Memory key cards, the Cafina coffee machine is being shipped with either a “Troubleshooter” or a “Machine

Status” key card. The function of both cards is the same. The card helps the service organisation to define machine errors or preventative

maintenance work that is coming up in the near future. The card is being used in an interactive task by telephone between the support person of

the service organisation and someone using the key card on the coffee machine.

Listed below are the functions and data that can be accessed with the “Troubleshooter / Machine Status” key card:

Cleanings ► Grinding period ► Grinder corr. ► Reference 1 ►

◄ ◄ ◄ ◄

▼▲ ▼▲ ▼▲ ▼▲

Coffee 22 Grinder 1. 0.180s/g Grinder 1 +10 Latte* SML 12 ► Latte* SML 12 +

Milk 20 Grinder 2 0.263s/g Grinder 2 -5 Water quantity 55 ml ◄ System time Stop

Start +

Latte* SML 12

System time Handling

Latte* SML 12

System time 13.6s

Display of the coffee-

and milk system

cleaning cycles

performed.

Display of the actual

grinding times for

grinders 1 and 2

Display of the actual

grinder adjustment of

grinders 1 and 2

Run system time

Reference 1

Start the function with

the + button.

Reference 2 ► DP quantity ► Filter ► Service Coffee ►

Service Milk

◄ ◄ ◄ ◄

▼▲ ▼▲ ▼▲ ▼▲

Espresso** 13 ► Espresso** 13 DP quantity Total filter capacity Service Coffee interval Service Milk interval

Water quantity 45 ml ◄ System time Stop DP 8: 13 800.0l ► 50000 15000

Start +

◄► ◄► ◄► ◄►