查询MLX90269LUF-1供应商

Features and Benefits

Absolute Integrated Pressure sensor

Less than ±1% error range overall

Programmable through the connector (3 pins)

Trimmable offset and sensitivity

On-Chip Signal Conditioning

Output proportional to the applied pressure

Ratiometric output

Rail-to-rail output

Diagnostics of broken supply wires and broken sensor

Output protected against short-circuits at both battery terminals

Different pressure ranges available

Application Examples

Water pressure

Oil pressure

Manifold Air Pressure

MLX90269

Absolute Integrated Pressure Sensor

Ordering Information

Part No. Temperature Suffix Package Code Option Description

MLX90269 L (-40°C to 150°C) UF (die on foil) - 1 1.2 to 3 Bar Full Scale

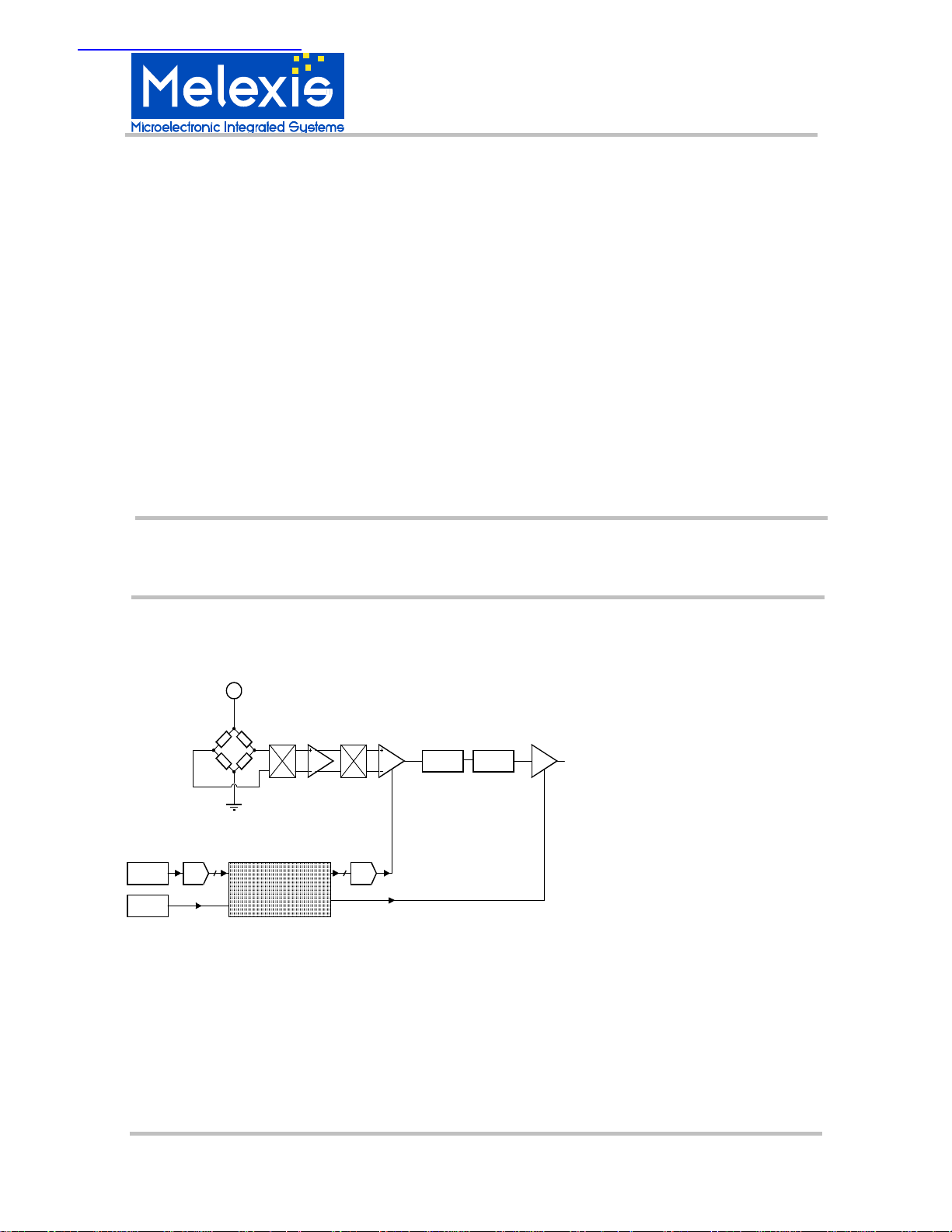

1. Functional Diagram

VDD

Chopper

demodulator

Temperature

sensor

Diagnostics

applied pressure with an adjustable slope and offset. It is ratiometric and goes rail-to-rail with a 3mA

source and sink capability. Different pressure ranges are available (from 1.2 to 7 Bar full scale ranges,

see above ordering information).

ADC

DIGITAL CORE

DAC

Gain

calibration

OUT

2. Description

The MLX90269 is an integrated

absolute pressure sensor (0 Bar

= vacuum) realized in CMOS

technology with micromachining

options. It consists of an analog

signal chain that interacts with

the digital core and on-chip

temperature sensor in order to

provide uniform overall sensing

characteristics after calibration

and to cancel the temperature

related parameter drifts.

The output is proportional to the

3901090269 Page 1 of 9 Data Sheet

Rev. 006 Mar/08

Absolute Integrated Pressure Sensor

TABLE OF CONTENTS

MLX90269

1. FUNCTIONAL DIAGRAM...................................................................................................................... 1

2. DESCRIPTION....................................................................................................................................... 2

3. ABSOLUTE MAXIMUM RATINGS ....................................................................................................... 3

4. MLX90269 ELECTRICAL SPECIFICATIONS ...................................................................................... 3

5. GENERAL DESCRIPTION .................................................................................................................... 4

6. UNIQUE FEATURES ............................................................................................................................. 4

7. PERFORMANCE GRAPHS................................................................................................................... 5

8. APPLICATION INFORMATION ............................................................................................................ 6

9. DIE DIMENSION AND PAD COORDINATES....................................................................................... 7

10. CALIBRATION AND PROGRAMMING PROCEDURE ........................................................................ 7

11. ESD PRECAUTIONS............................................................................................................................. 8

12. DISCLAIMER ......................................................................................................................................... 9

3901090269 Page 2 of 9 Data Sheet

Rev. 006 Mar/08

MLX90269

Absolute Integrated Pressure Sensor

3. Absolute Maximum Ratings

Parameter Min Max

Supply Voltage, VDD -14V 16V

Output Voltage, V

Storage Temperature Range, TS

ESD Sensitivity (AEC Q100 002) -2 kV 2 kV

Exceeding the absolute maximum ratings may cause permanent damage. Exposure to absolutemaximum-rated conditions for extended periods may affect device reliability.

4. MLX90269 Electrical Specifications

DC Operating Parameters TA = -40oC to 150oC, VDD = 5V (unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Units

-0.5V 16V

out

-55°C 165°C

OPERATIONAL FEATURES

Supply Voltage VDD Operating 4.5 5 5.5 V

Supply Current IDD V

= 5V ± 10%, excluding

DD

4 6 10 mA

output current

Output Current Capability I

Pressure output @ zero pressure V

Pressure output @ full scale pressure V

Low Clamping Level

High Clamping Level

DIAGNOSTIC FEATURES

V

out

out

out

V

out

V

out

= 5V -3 3 mA

DD

V

= 5V 0.46 0.5 0.54 V

DD

V

= 5V 4.46 4.5 4.54 V

DD

5

90

10

95 % VDD

% V

DD

Output when sensor is broken Sensor broken 2 % VDD

Output when VDD is broken Pull-Up > 4.7K 5

Output when VSS is broken Pull-Down > 10K

95

% VDD

% VDD

Response Time (to reach 1% error) 2 ms

3901090269 Page 3 of 9 Data Sheet

Rev. 006 Mar/08

MLX90269

Absolute Integrated Pressure Sensor

5. General Description

This chip integrates a pressure sensor and the associated signal conditioning on the same die. The

supply voltage VDD directly supplies the pressure sensor.

A chopped instrumentation stage amplifies the differential output signal of the sensor. The gain of this

amplifier can be adjusted with 3 bits. The input stage is followed by a differential to single-ended

conversion. The reference voltage for this stage is generated by a 10 bit DAC and varies linearly with

temperature in order to perform the offset and offset drift compensation. A digital hardware multiplier

calculates this compensation. The temperature signal, serving as input for this multiplier, is generated

from the ADC of the output signal of the internal temperature sensor.

The chopped signal is demodulated with a switched capacitor stage. The buffered output serves as

reference for a 10 bit DAC to perform the span and span drift compensation. The DAC is controlled by the

digital part.

Finally the signal is given out by a class AB rail-to-rail amplifier capable of sourcing and sinking large

currents.

A 3-point temperature and 2-point pressure calibration is required (room temperature, a low temperature

and a high temperature), to achieve an error less than ±1% over the complete pressure and temperature

range (the output error is referred to the output span).

PTC (Programming Through Connector) protocol is used to perform calibration.

6. Unique Features

Diagnostic Limits

Diagnostic of broken sensor: The output will be forced to ground (or a very low level) when the sensor

membrane breaks.

Diagnostic of broken wires: The output will be forced to ground (or a very low level) when the supply wire

breaks, even when a pull-up is still connected to the output pin.

The output will be forced to the supply voltage (or a very high level) when the ground wire breaks, even

when a pull-down is still connected to the output pin.

Output Protection

The output is protected against short-circuits at either battery terminals. The output can handle voltages

between -0.5V and 16V (independent of supply voltage).

Memlock Function

The memory consists of ZAP cells. When all calibration parameters are programmed, the chip can be

locked. This to avoid unwanted data to be written into the memory cells.

Once the chip is locked in a normal application, it is not possible to unlock.

Clamping Levels

The user can enable the clamping of the output to ensure that the output can not enter the fault band in

normal application.

3901090269 Page 4 of 9 Data Sheet

Rev. 006 Mar/08

MLX90269

Vout versus Pressure with Ta = -50..150 C

Vout %Vdd

Absolute Integrated Pressure Sensor

7. Performance Graphs

The graphs below show measured output voltages (on a 4 Bar full scale sensor) taken at 15 pressure

points (500 mBar to 4000 mBar), at 21 ambient temperature points (-50 to 150 Celsius) and with Vdd set

to 4.5 V, 5 V and 5.5 V.

100

90

80

70

60

50

40

30

20

10

0

0 1 0 20 30 40 50 60 70 80 90 100

Note : FS means Output Voltage Full Scale (4 V).

Measured Error is below 1 % of FS for all ambient temperature and pressure points (see graphs below).

Error versus Ambient Temperature with P = 500..4000 mBar

1.5

Pressure %FS (FS = 4000 mBar)

1

0.5

0

Error in % of FS

-0.5

-1

-1.5

-50 -30 -10 10 30 50 70 90 110 130 150

Ambient Temperature C

3901090269 Page 5 of 9 Data Sheet

Rev. 006 Mar/08

MLX90269

Absolute Integrated Pressure Sensor

Error versus Pressure with Ta = - 50..150 C

1.5

1

0.5

0

Error in % of FS

-0.5

-1

-1.5

0 250 500 750 1000 1250 1500 1750 2000 2250 2500 2750 3000 3250 35 00 3750 4000

4.5V and 5.5V Ratiometricity Error versus Pressure with Ta = - 50..150 C

0.5

0.4

0.3

0.2

0.1

0

-0.1

Error in % of FS

-0.2

-0.3

-0.4

-0.5

0 250 500 750 1000 1250 1500 1750 2000 2250 2500 2750 3000 3250 35 00 3750 4000

Pressure mBar

Pressure mBar

8. Application Information

Very few off-chip components are needed (only 2 decoupling capacitors).

Only 3 pins are used (Vdd, Vss, Out), see pad layout drawing in paragraph 9.

Calibration and Programming is made through Out pin.

3901090269 Page 6 of 9 Data Sheet

Rev. 006 Mar/08

MLX90269

Absolute Integrated Pressure Sensor

9. Die dimension and pad coordinates

Available upon request.

10. Calibration and Programming Procedure

Programming in Temporary Memory

The programming is done through the connector: only the application pins (supply, ground and output)

need to be used. The programming can be enabled by forcing the supply high enough (VCC_T). Through

the OUT pin one can input the data. The data is Pulse Width Modulated.

At the end of the programming, keep OUT high until VCC has reached its normal level (VCC_N).

Thereafter disconnect OUT. The time in between should be less than 100us.

Zapping of the Permanent Memory

Only 1 bit can be zapped at a time. First program 1 bit to ‘1’. A higher supply (VCC_Z) is needed to be

able to zap the bit. The zapping is done when OUT is high (OUT_Z).

A high current will flow during zapping. It is recommended to limit this current to 200mA.

The memlock-bit should be zapped as last bit, as this disables programming function.

3901090269 Page 7 of 9 Data Sheet

Rev. 006 Mar/08

MLX90269

Absolute Integrated Pressure Sensor

In order to check zapping, one can program Test Mode 22 = 10110b. Also 1 bit of the temporary memory

should be ‘1’. If the zap cell – corresponding to the place of the ‘1’ in the temporary memory – is zapped,

then the supply current will be at least 35mA. Otherwise the supply current will be approximately the same

as in normal mode (maximum 10mA). Values in between indicate a bad zap.

Parameters

Parameter Minimum Maximum Meaning

t0n 1us 100us Rise Time of Supply from 0V to VCC_N

t0p 2us 200us Rise Time of Supply from 0V to VCC_P

tpz 1us 100us Rise Time of Supply from VCC_P to VCC_Z

tpn 1us 100us Fall Time of Supply from VCC_P to VCC_N

tz0 2us 300us Fall Time of Supply from VCC_Z to 0V

tr 0.5us 5us Rise Time of Out from OUT_L to OUT_H

tf 0.5us 5us Fall Time of Out from OUT_H to OUT_L

trz 0.5us 15us Rise Time of Out from OUT_H to OUT_Z

tfz 0.5us 20us Fall Time of Out from OUT_Z to OUT_L

th0 50us 100us High Time for 0

tl0 200us 300us Low Time for 0

th1 200us 300us High Time for 1

tl1 50us 100us Low Time for 1

tz 5ms 6ms zap time

tz0 100us 1ms OUT & VCC = Z & 0V

td0 100us 1ms OUT & VCC = OUT_L & 0V

tdp 100us 1ms OUT & VCC = OUT_L & VCC_P

tuz 100us 1ms OUT & VCC = OUT_H & VCC_Z

tun 5us 50us OUT & VCC = OUT_H & VCC_N

tdz 5us 50us OUT & VCC = OUT_L & VCC_Z

VCC_N 4.5V 5.5V Normal Supply

VCC_P 8V 12V Programming Supply

VCC_Z 14V 16V Zapping Supply

OUT_L 0V 1V Low Output

OUT_H 4V 5V High Output

OUT_Z 12V 14V Output for zapping

An application note describes in more details this calibration procedure.

Calibration software is also available on request.

11. ESD Precautions

Electronic semiconductor products are sensitive to Electro Static Discharge (ESD).

Always observe Electro Static Discharge control procedures whenever handling semiconductor products.

3901090269 Page 8 of 9 Data Sheet

Rev. 006 Mar/08

MLX90269

Absolute Integrated Pressure Sensor

12. Disclaimer

Devices sold by Melexis are covered by the warranty and patent indemnification provisions appearing in

its Term of Sale. Melexis makes no warranty, express, statutory, implied, or by description regarding the

information set forth herein or regarding the freedom of the described devices from patent infringement.

Melexis reserves the right to change specifications and prices at any time and without notice. Therefore,

prior to designing this product into a system, it is necessary to check with Melexis for current information.

This product is intended for use in normal commercial applications. Applications requiring extended

temperature range, unusual environmental requirements, or high reliability applications, such as military,

medical life-support or life-sustaining equipment are specifically not recommended without additional

processing by Melexis for each application.

The information furnished by Melexis is believed to be correct and accurate. However, Melexis shall not

be liable to recipient or any third party for any damages, including but not limited to personal injury,

property damage, loss of profits, loss of use, interrupt of business or indirect, special incidental or

consequential damages, of any kind, in connection with or arising out of the furnishing, performance or

use of the technical data herein. No obligation or liability to recipient or any third party shall arise or flow

out of Melexis’ rendering of technical or other services.

© 2002 Melexis NV. All rights reserved.

For the latest version of this document. Go to our website at

www.melexis.com

Or for additional information contact Melexis Direct:

Europe and Japan: All other locations:

Phone: +32 1367 0495 Phone: +1 603 223 2362

3901090269 Page 9 of 9 Data Sheet

Rev. 006 Mar/08

E-mail: sales_europe@melexis.com E-mail: sales_usa@melexis.com

ISO/TS 16949 and ISO14001 Certified

Loading...

Loading...