Page 1

MELAG

Reset

maintenance

counter,

drain

double

jacket,

various

This

Do

The

autoclave

the

show

this

earlier

service”

document

not

service

manufacturer's

provide

room

period,

than

when

contains

it

meter

that

or

even

expected,

has

a

in

though

then

*

in-house

to

customers.

must

never

plant

also

been

in

the

warehouse

the

before

appear

information

be

used,

memory,

for

checked,

number

a

autoclave

the

in

the

autoclave

display

Annex

even

the

service

before

has

not

of

of

has

the

provided

when

meter

the

autoclave

weeks

been

been

unit.

the

is

already

or

months,

used.

in

actual

As

a

to

service

unit

leaves

is

then

This

result,

means

service

technicians.

placed

running:

the

factory.

the

that

for

it

is

important

into

the

operation

end

If

the

service

the

two

two

years.

to

of

production

autoclave

clock

years’

The

always

Premium-class

for

will

continue

service

report

reset

the

has

the

first

date

period

“Please

time.

is

remained

to

run

will

service

In

stored

an

in a

during

come

perform

meter

at

when

Resetting

version

1.

Select

2.

In

it

is

number

the

the

access

seconds.

3.

will

Set

now

your

change

first

the

The

put

service

display

cursor

into

service

on

the

operation,

menu

code,

will

leave

to

to

reset

meter

info

menu,

(the

briefly

then

system

for

press

change

the

and every

autoclaves

under

service

technical

interval

down

to

menu,

meter.

and

time

with

buttons

the

service

then

after

data)

has

2

service

software

been

and

menu.

briefly

press

4

has

up

permanently

at

the

down

been

to

and

same

buttons

performed.

including

set

time.

to

365

Then

and

3

version

days)

hold

4

at

down

the

BO

button

same

1.022

4

time.

(look

for

approx.

The

for

this

3

display

4.

Then

this

5.

Resetting

info

1.

From

2.

button

Press

menu,

Select

In

the

briefly

the

software

access

will

BACK

the

under

the

press

change

service

technical

menu

version

code,

the

button

to

0000.

button

meter

for

diagnosis

2.3

briefly

for

twice,

data)

and

with

+

after

press

service,

then

software

service

730

down

days

which

press

(BO

or

buttons

the

version

2.0-

2000

will

reset

STOP

2.2:

cycles

2

and

the

button.

BO

2.0

Service

41-B+43-B

4

at

the

SERVICE

This

and

later

interval

same

system

will

take

022

after

/

3000

time.

you

(look

730

cycles

Then

counter.

out

for

days,

hold

of

this

or

40-B+44-B).

down

The

the

version

number

service

1,000

button

shown

menu.

number

cycles.

4

for

approx.

over

on

the

3

seconds.

3.

Then

Set

press

The

your

0000

4.

Press

the

Pressure

Completely

double

Units

jacket

with

display

cursor

the

“Select”

BACK

to

button,

release

drain:

(Pressure

water

For

ring

will

“Reset

button

and

performing

release and

pump

then

and

change

the

for

then

drain

(14-B,

service

approx.

press

of

the

the

water).

40-B,

to

the

meter”

double

maintenance

sesvice

3

seconds.

the

STOP

jacket:

44-B):

menu.

and

then

The

button.

or

Select

for

choose

service

This

the

in

transport

the

“Select”.

meter

will

take

Service

will

you

of

the

Menu

The

then

out

autoclave

selected

be

of

AC-OUT,

reset,

the

service

it

is

Vacuum

line

and

will

the

menu.

necessary

pump

become

value

to

ACOUT

black

returns

drain

the

05

to

and

Units

activate

double

left-sided

Outputs

Only

example,

water,

«>

SMV

with

Cooling

them.

jacket

at

can

pressure

on

however,

Close

the

air

Select

will

the

be

the

door

water

cooling

ACOUT

DC-OUT

be

button.

emptied,

Is

switched

release:

steam

can

remain

and

go

(13-B,

Check

the

off

To

valve

to

jacket

again.

perform

or

in

the

the

04

41-B,

and

and

activate

the

without

work

on

device

the din

Service

activate

43-B):

indication

pressure

on

(to

Menu

them.

Select

in

DC-OUT

at

the

filters),

save

double

time

“DC

the

Outputs,”

Select

the

08

the

the

and

Service

SV Cooler

pressure

pressure

jacket

double

water).

DC-OUT

Menu

gauge

gauge

of

this

jacket

select

and

AC-OUT,

drain

behind

indicates

device,

must

DC-OUT

activate

and

then

the

Fan

the

O

above

not

be

SV

of

DC-OUT

cover

bar

the

under

or

internal

Rinse

cooler

06

at

the

less

water

pressure.

06.

ACOUT

SV

front

and

Rinse.

of

the

the

activated

column

The

04

and

The

unit,

(for

feed

©

Switch

the

emergency

The

discharge

(located

can

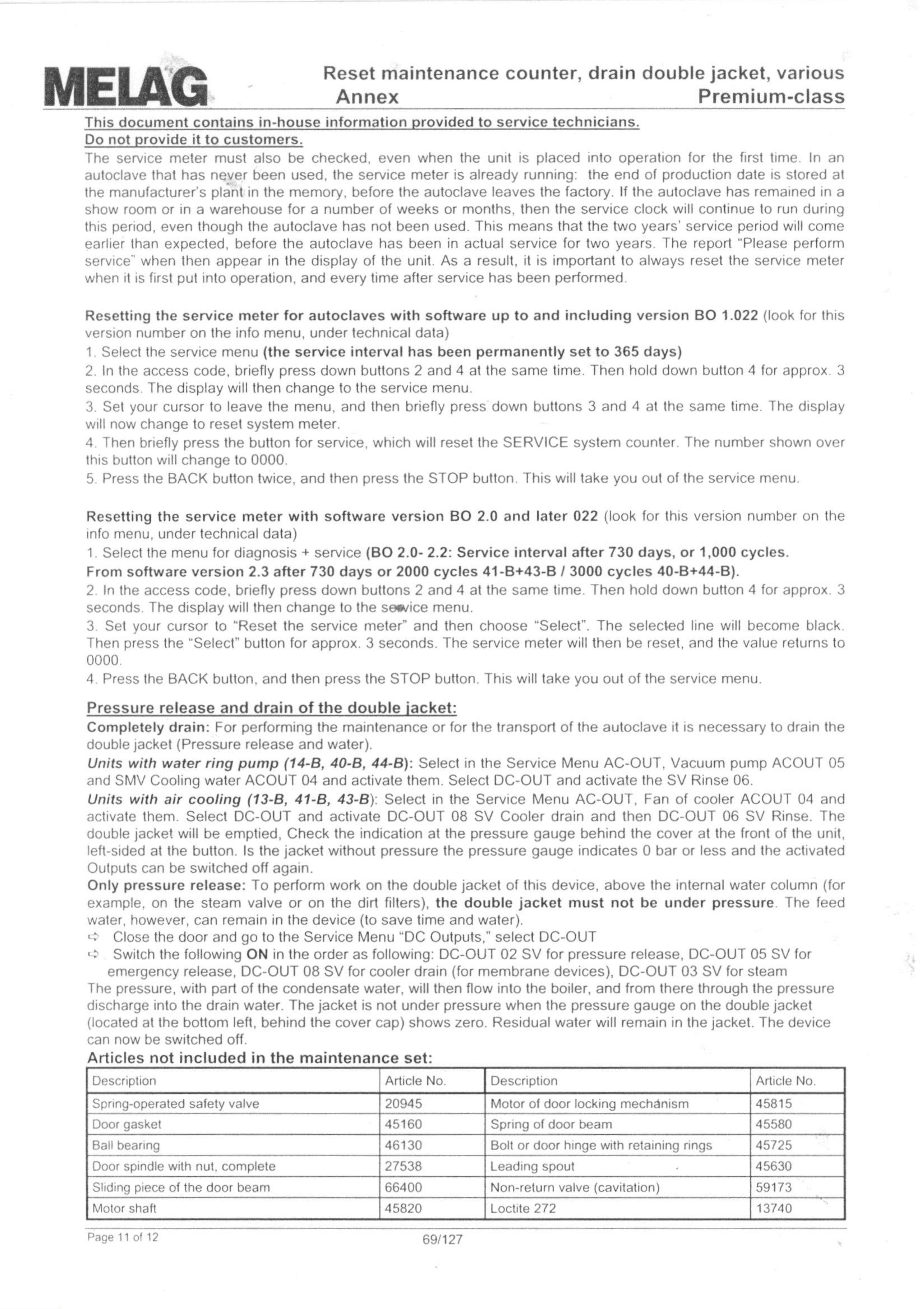

Articles

Spring-operated

pressure,

into

at

the

now

be

switched

not

following

release,

with

the

bottom

part

drain

left,

off.

included

safety

valve

ON

in

DC-OUT

of

the

condensate

water.

behind

in

the

the

The

order

08

SV

jacket

the

as

for

cover

maintenance

following:

cooler

water,

is

not

cap)

drain

will

under

shows

set:

DC-OUT

(for

then

membrane

flow

pressure

zero.

02

into

SV

the

when

Residual

Motor

of

door

for

pressure

devices),

boiler,

the

pressure

water

locking

and

will

release,

DC-OUT

from

there

gauge

remain

mechánism

in

DC-OUT

03

on

SV

through

the

the

jacket.

05

for

steam

the

double

The

SV

pressure

for

jacket

device

Door

Ball

Door

Sliding

Motor

Page

bearing

11 of

gasket

spindle

piece

shaft

12

with

of

the

nut,

complete

door

beam

Spring

69/127

Bolt

Leading

Non-return

Loctite

or

of

door

door

spout

valve

272

beam

hinge

(cavitation)

with

retaining

rings

-

|

45580

|

45725

|

45630

|

59173

Loading...

Loading...