Page 1

Operating manual

for MELAG-Autoclaves

Type 15 Type 17 Type 23

Dear Doctor:

Thank you very much for the trust which you have shown by purchasing this

autoclave.

For 50 years now, MELAG - a medium-sized family-owned and -operated company has specialised in the production of sterilization equipment for medical practice.

During this period, MELAG has succeeded in becoming a leading manufacturer of

sterilization equipment. More than 335 000 MELAG units sold throughout the world

testify to the exceptional quality of our products, which are manufactured exclusively

in Germany.

As all other MELAG products, this autoclave was manufactured and tested according

to strict quality criteria. Before placing this unit into operation, please read this

Operating Manual carefully. The long-term functional effectiveness and the

preservation of the value of your autoclave will depend on careful preparation of

instruments before sterilization, and on proper care of the unit.

The staff and management of MELAG

Page 2

To ensure the functional effectiveness of this unit and to

preserve its value:

1. Prepare the instruments to be sterilized carefully

2. Take proper care of the autoclave

3. Use only pure distilled or demineralised water

Content:

Page

1 INTRODUCTION.........................................................................................................................................2

1.1 F

1.2 TECHNICAL DATA ....................................................................................................................................2

1.3 PREPARING INSTRUMENTS FOR STERILIZATION .........................................................................................3

1.4 RUST FORMATION = DRAG-IN RUST..........................................................................................................3

1.5 TAKING CARE OF YOUR AUTOCLAVE .........................................................................................................3

1.6 INSTRUCTIONS FOR INSPECTION AND CARE OF THE DOOR AND DOOR-LOCK COMPONENTS...........................4

1.7 CHECKING THE AUTOCLAVE.....................................................................................................................5

2 INSTALLATION ..........................................................................................................................................5

2.1 S

2.2 FILLING THE STORAGE CONTAINER...........................................................................................................6

2.3 VDE - REGULATIONS ..............................................................................................................................6

RONT OF THE AUTOCLAVE .....................................................................................................................2

ETTING UP THE AUTOCLAVE...................................................................................................................5

3 FOR EACH STERILIZATION .....................................................................................................................6

TEMS TO BE STERILIZED .........................................................................................................................6

3.1 I

3.2 STERILIZATION PROCESS.........................................................................................................................7

3.3 PROCESS CONTROL ................................................................................................................................7

3.4 PROGRAM TERMINATION .........................................................................................................................7

3.5 R

EMOVING DRY LOADS............................................................................................................................7

3.6 STERILIZATION FREQUENCY.....................................................................................................................7

4 FURTHER INFORMATION ABOUT STERILIZATION ..............................................................................8

4.1 D

URATION OF STERILIZATION (COMPLETE PROCESS).................................................................................8

4.2 USE OF DISTILLED OR DEMINERALISED WATER ..........................................................................................9

5 NOTES ON OPERATING MALFUNCTIONS ...........................................................................................10

5.1 L

OW PRESSURE READING FROM THE PRESSURE GAUGE..........................................................................10

5.2 PRESSURE READING FROM PRESSURE GAUGE TOO HIGH.........................................................................10

5.3 P

5.4 O

RESSURE READING TOO LOW...............................................................................................................11

VERHEATING IN THE CHAMBER............................................................................................................11

5.5 RESIDUAL WATER IN THE CHAMBER........................................................................................................12

5.6 SIGNAL LAMP 'POWER' STAYS ON CONTINUOUSLY ...................................................................................12

5.7 SIGNAL LAMP 'POWER' DOESN'T LIGHT UP ..............................................................................................12

6 SAFETY INSTRUCTIONS ........................................................................................................................12

7 TAKING THE AUTOCLAVE OUT OF OPERATION/TRANSPORT/RE-INSTALLATION ......................12

8 ANNEX ......................................................................................................................................................13

8.1 S

8.2 I

PARE PARTS.......................................................................................................................................13

NSIDE THE AUTOCLAVE.........................................................................................................................13

Content

Page 3

Operating manual for type 15/17/23

1 Introduction

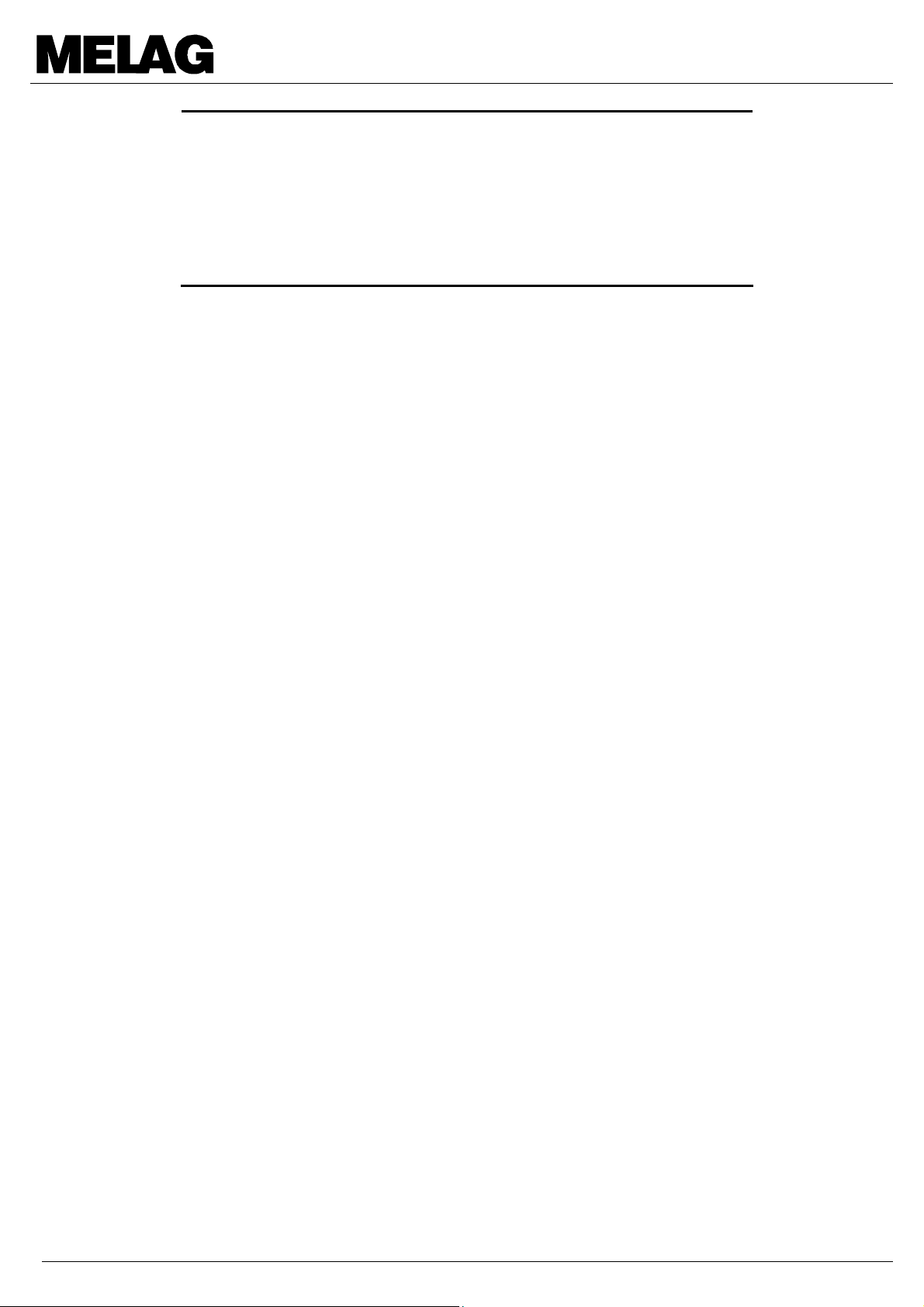

1.1 Front of the autoclave____________________________________________________

1

2

Autoklav23

Trocknen

Manometer

3

2

-1

Thermometer

5-

6

0

Netz

3

4

5

100

15O

200

6

7

8

9

10

Wasserentleerung

Zeitschaltuhr

Druckschalter

b

2

r

a

5030

0

1 bar

11121311

1 Housing lid 6 Thermometer 12 Outlet for draining

2 Cooling rests 7 Signal lamp "Heating" distilled or demineralised water

(for trays, etc.) 8 Timer switch 13 Inspection cut-away for

3 Pressure gauge 9 Switch "Water inlet" examining the water level

4 Switch "Drying" 10 Pressure selection

5 Signal lamp "Power" 11 Adjustable feet

1.2 Technical data __________________________________________________________

Type 15 Type 17 Type 23

Sterilization chamber (diameter X depth) 15 X 38 cm 18 X 42 cm 23 X 45 cm

Max. load:

Instruments (with trays) 2 kg 3 kg 4 kg

Textiles 150 g 200 g 500 g

Electrical power supply, (AC) 230 V / 1560 W 230 V / 1350 W 230 V / 1970 W

Water consumption per sterilization

280 ml 300 ml 300 ml

cycle

Pressure range: 1 bar program - 1.0 bar (121°C) up to 1.4 bar (126°C)

Pressure range: 2 bar program 2.0 bar (134°C) up to 2.5 bar (138°C)

Operating time: 1 bar program - 50 minutes 50 minutes

Operating time: 2 bar program 30 minutes 30 minutes 30 minutes

Break between 2 sterilization cycles 30 minutes 30 minutes 30 minutes

Mains-fuse 2x 12,5A/T 12,5A/T 12,5A/T

Drying time As required

Page 2

Page 4

1.3 Preparing instruments for sterilization ______________________________________

MELAG - non-rusting materials

All parts of MELAG autoclaves which come into

contact with steam are made of non-rusting

materials. The pressure chamber, storage container,

and tray rack assembly are of stainless steel, pipes

carrying steam are made of copper, the chamber

door is made of chrome-plated brass, and the trays

are made of eloxated aluminium.

Drag-in rust

The use of non-rusting materials excludes the

formation of rust as a result of the components of

the autoclave. Where rust forms in the autoclave or

on the items being sterilized, investigations have

repeatedly shown that this rust has been brought in

from other sources. It should be borne in mind that

rust can form even on the best quality stainless steel

instruments, for example as a result of improper

treatment with chemical agents or disinfectant

during preparation for sterilization.

Preparations of items for sterilization

The example of drag-in rust shows how important it

is to prepare items properly for sterilization. In

particular, the following points should be observed:

The instruments should be disinfected and cleaned

immediately after use in accordance to UVV/VBG

103 with a disinfectant and/or cleaning solution. The

solutions should be used in the correct

concentration and care should be taken to adhere

precisely to the correct immersion times! It is

advisable to make use of appropriate cleaning aids

such as an ultrasound cleaning unit, or a thermodesinfector.

Cleaning the instruments before sterilization is also

very important in order to avoid introducing dirt and

contamination which can separate from the

instruments under steam pressure and block the

filters, jets, and valves of the autoclave! Above all,

locks, joints and hinges of instruments must be

thoroughly cleaned with a brush. Cleaning and

disinfecting agents should be washed off thoroughly

with clear water, again using a brush. Residues of

cleaning and disinfectant chemicals must under no

circumstances find their way into the autoclave,

since they can give rise to corrosion! Finally, swill

with demineralised water and then dry the

instruments well.

Brand-new instruments

The cleaning procedures described above are also

necessary for brand-new instruments, since these

often carry small amounts of oil, fat and soiling from

the manufacturing process.

1.4 Rust formation = Drag-in rust _____________________________________________

As already explained, the non-rusting materials used

in the autoclave cannot give rise to rust formation in

the autoclave!

Where rust forms this is "drag-in rust". This

originates from instruments or other metallic objects

carrying traces of rust, even though they are made

of stainless steel, or are made of normal steel but

have a damaged galvanic coating. Often a single

rusty instrument is enough to pass rust on to other

instruments or to lead to film rust forming in the

autoclave and resulting to corrosion damage.

Therefore the pressure chamber should be wiped

out regularly, in order to avoid the formation of film

rust. Rust which forms on the pressure chamber,

storage container, or on the tray rack assembly must

be removed using small amounts of a mild

commercial cleaning agent for stainless steel. Do

not use steel wool or a steel brush! In order to clean

the pressure chamber withdraw the tray rack

assembly. Dispose of instruments which are causing

rust!

1.5 Taking care of your autoclave _____________________________________________

Every week

Cleaning the autoclave chamber

The autoclave chamber and the door surfaces

should be cleaned at least once a week. To do this,

the trays and the tray rack assembly should be

withdrawn from the chamber. The chamber can then

be wiped out with a soft cloth or a (non-abrasive)

sponge. Stubborn spots can be removed using small

quantities of a mild commercial steel cleaning agent,

taking care that none gets into the pipes attached to

the autoclave chamber. Do not use abrasive

cleaners such as steel wool or a wire brush. Alkaline

cleaning agents or products containing chlorine

alkaline must not be used. Spots on stainless steel

can be removed using 5% oxalic acid.

Door gasket

The door gasket should be checked once a week for

signs of wear and damage. It should be

cleaned with a mild commercial cleaning agent.

Every two weeks

Demineralized/distilled water storage container

Every two weeks, the demineralised/distilled water

storage container should be emptied by opening the

outlet (12). If necessary clean the container, e.g.

using a bottle cleaning brush and warm water with a

detergent additive. Swill out well with water and refill

with demineralized/distilled water (for the water

quality see Section 4.2).

Note!

Door spindle

The spindle of the door lock is important for the safe

operation of the autoclave, and must be regularly

lubricated with silicone grease. Any signs of wear

should be reported immediately to an authorised

technician, who will examine and if necessary

replace it.

Page 3

Page 5

Operating manual for type 15/17/23

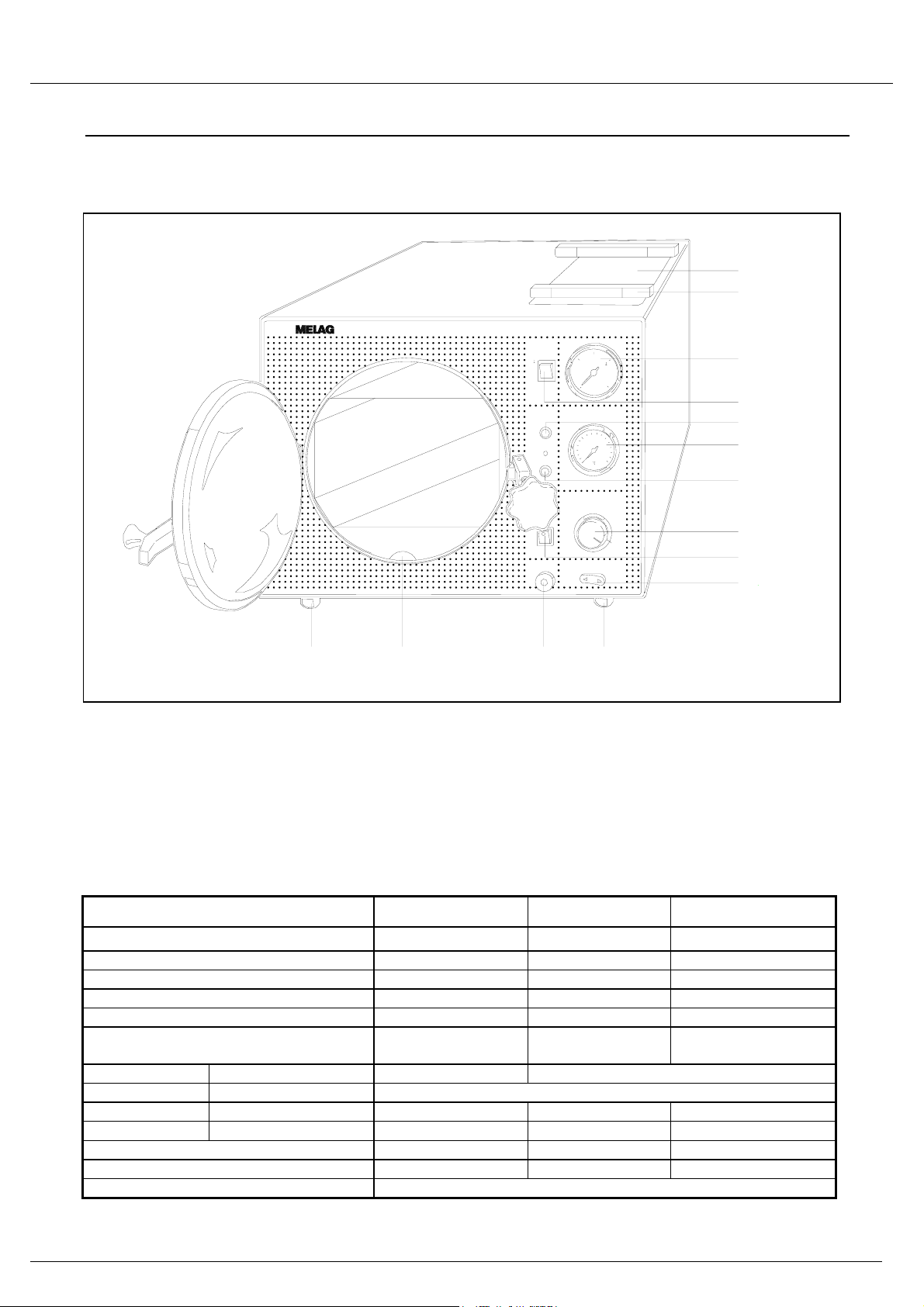

1.6 Instructions for inspection and care of the door and door-lock components ______

In order to prevent premature wear, it is absolutely necessary to keep the following components well

lubricated at all times: the threaded spindle of the palm grip hand knob, the hinges of the lock yoke, and the

pressure locking bar. Use the following lubricant: plain-bearing grease (Gleitfett, MELAG art. no. 24355), or

an equivalent silicone grease, or Molykote

The signs in the diagrams below indicate that the lock components of the door have become subject to

excessive wear. If any of the following signs appear, then the device must be inspected by a MELAG

customer-service representative, or an authorized technician from a specialist dealer:

• There is too much play in the

hinge of the pressure locking

bar (the door “hangs”)

Warning!

The hinge bolts must absolutely

remain completely inserted (flush) in

the latch and in the hinge yoke of the

locking pressure bar (left side)

®

.

• There is too much play in

the hinge of the lock yoke.

• Hard-metal screw-thread insert

which has been screwed out of the

latch

Warning!

If the bolt moves out of place upward or downward

as shown here, and is not flush, do not use the

autoclave. Call the technical customer service for

repair before using the device.

• Too much play in the

threaded spindle of the

palm grip hand knob (the

spindle rattles in the latch)

• The threaded spindle

become definitely hard to

turn

Page 4

Page 6

1.7 Checking the autoclave __________________________________________________

Regular check

The operator of the autoclave can use the control

instruments and the sterilization times as a check

that the sterilization is effective. In Program 2 bar the

pressure gauge should show between 2 and 2.1 bar

(or for 1 bar between 1 and 1.1 bar) for at least 5

minutes (20 minutes) and at the same time the

thermometer should read 134 to 135

121°C).

Periodical check (every half year )

DIN 58 946 Part 8 Section 3.2 recommends:

"The periodical inspection shall be carried out in situ

at regular intervals, e.g. every six months. This shall

establish that the small sterliser when used in

accordance with the operating instructions sterlises

properly."

Hygiene Institutes and other official medicinal test

laboratories are able to supply test spores, evaluate

these after sterilization, and provide confirmation of

the results on a test certificate.

In accordance with DIN 58 946 Part 4 and DAB 10

(Deutsches Arzneimittelbuch) the testing of steamautoclaves shall be carried out with spores of

"Bacillus Stearothermophilus" (e.g. ATCC 7953,

Paper Spore Strips, Oxoid, Cd. No.: BR 23).

{

C (120 to

For the MELAG Types 15, 17 and 23 (chamber

volume >5 dm³), DIN 58 946 Part 8 specifies the use

of five bioindicators (plus one positive control

sample).

Prepacked test spores (e.g. spore strips in packed in

paper, or test tubes, e.g. "Attest") shall not be

packed again before being placed in the

autoclave.

Note:

If the spores are contained in a tube which only has

perforations at one end (e.g. "Attest", 3M, which has

the perforations in the brown end cap), then this

should never be placed in the autoclave so that the

perforations are on top. The autoclave works using

gravitation drainage, so the perforations should be

at the bottom, or at least on the side, as is the case

if the tubes are laid in the autoclave.

If you receive "hand made" spore samples, which

have already been sealed in a paper-foil packaging,

then care must be taken that the steam has full

access to the paper side of the packaging. As

above, the items to be sterilized should be placed in

the autoclave with the paper either facing

downwards or to the side.

2 Installation

2.1 Setting up the autoclave__________________________________________________

Space requirements

The autoclave must be installed at least 10 cm away

from an adjacent wall or upright surface on each

side. The clear space above the autoclave shall be

at least 30 cm. The correct positioning of the

autoclave is very important for good sterilization

results. The installation, and reinstallation if the

autoclave is moved to another position, should be

carried out with great care.

Setting up correctly - horizontally

This MELAG autoclave is filled directly with water.

This convenient feature requires that the autoclave

is set up horizontally on a flat, stable surface. The

chamber is installed in the autoclave at a slight

angle so that the distilled / demineralised water can

only be seen in the inspection cut-away (13) when

the necessary quantity of water has been filled in the

chamber.

Setting up incorrectly - "sloping forward"

However, if the surface on which the autoclave has

been installed slopes forward, then the distilled or

demineralised water will already be visible at the

inspection cut-away before the necessary amount

has been introduced into the chamber. This means

that there will not be enough distilled or

demineralised water to reach the required pressure

in the chamber, and the pressure of 2 bar will not be

reached and held for approx. 5 minutes, or the

constant pressure of 1 bar will not be maintained for

the necessary 20 minutes.

Setting up incorrectly - "sloping backward"

If the autoclave is set up on a surface that slopes

backwards, then too much distilled or demineralised

water will be filled into the autoclave. The distilled or

demineralised water not used during the sterilization

will remain in the autoclave, but this will not be

harmful for the operation of the autoclave.

Adjusting

In order to check that the autoclave is set up

properly, a graduated measuring beaker is provided.

The autoclave has been set up properly when: for

Type 15: 280 ml , or for Types 17 and 23: 300 ml

distilled / demineralised water has been filled into

the empty autoclave from the front and the water

can be seen in the inspection cut-away (13). If

necessary, the feet at the front of the autoclave (11)

should be adjusted until the water is visible.

Page 5

Page 7

Operating manual for type 15/17/23

2.2 Filling the storage container ______________________________________________

To fill the storage container, remove the housing lid

(1) on top of the autoclave and take off the lid of the

storage container underneath it (see Sections 1.1

and 8.2).

The storage container should be filled with

approximately 3 litres of demineralised/distilled

water. Care should be taken to ensure that the water

does not exceed the "MAX" level (C, 8.2), because

the opening for the cooling loop (E) of flow nozzle at

(B) must not be covered with water, otherwise it will

not be possible to reach the necessary pressure. In

order to condense the steam and to avoid excess

steam emission and the resultant increased use of

distilled / demineralised water, the cooling loop (E)

of the flow injector (B) and the pressure release (G)

in the storage container should be well covered with

water. The distilled / demineralised water should

therefore be refilled at regular intervals, or even

better, residual water should be drained away by

opening the drainage tap (12) and the autoclave

filled up with new distilled / demineralised water.

2.3 VDE - regulations _______________________________________________________

Under current VDE-regulations, this autoclave is not

suited for use in areas where there are risks of

explosion.

The autoclave must only be serviced and repaired

by MELAG or by its authorised representatives

(specialist dealers or customer services).

Warning !

The door frame, the autoclave chamber and the

sterilized items are hot during and after the

sterilization!

3 For each sterilization

3.1 Items to be sterilized_____________________________________________________

Tray rack assembly

In order to prevent the items being sterilized from

overheating as a result of the radiated heat in the

chamber, the autoclave must not be operated

without using the enclosed MELAG tray rack

assembly. Trays or racks on which the items to be

sterilized are laid, or containers (with or without lid)

must be perforated (as described in detail in the

BGA-Guidelines "Carrying out Sterilization 2.1.4.a

Containers, as Annex to Section 7.1 of the

"Richtlinie für die Erkennung, Verhütung und

Bekämpfung von Krankenhausinfektionen").

Sterilization wrapping

The items to be sterilized can be sealed in a

transparent foil packaging, e.g. MELAfol

paper, one side foil). The paper side of the

packaging must face downwards. These sealed

items must not be placed one on top of another on a

tray. In order to improve drying, it is advisable to

using a MELAG drying rack for the items in

transparent packaging (MELAG Art. No. 283; fits

only in Type 23). When sealing items, ensure that

(one side

the seal itself is in accordance with German

standard DIN 58953 Part 7 and has a minimum

width of 8 mm. The MELAG foil sealing machine

MELAseal

Sterilizing plastic articles

When sterilizing plastic articles pay careful

attention to the maximum sterilization

temperature specified by the manufacturer.

Direct contact of the products with the tray rack

assembly should be avoided, since the items being

sterilized may be damaged by the heat given off by

the autoclave.

Plastic articles such as pipette tips should always be

placed on the middle tray if possible. it is advisable

to place them on a sheet of filter paper in order to

avoid direct contact with the tray or container.

Liquids

These autoclaves are not suitable for the

sterilization of liquids!

101 produces a seal that is 10 mm wide.

Page 6

Page 8

3.2 Sterilization process ____________________________________________________

1. Max. pressure indicator

Reset the red maximum pressure indicator of the

pressure gauge (3) to "0".

2. Loading

Trays or containers should be filled loosely with

the instruments to be sterilized and inserted.

Textiles should not be folded tightly or pressed

into the sterilization containers. The maximum

load for textiles must not be exceeded.

3. Pressure selection (only type 17 and type 23)

Depending on the type of load, the pressure

selection (10) should be set to 1 bar or 2 bar (1

bar =120°C) is for rubber, textiles, etc.; 2 bar

(=134°C) is for metal, glass, etc.; type 15 has

only the 2 bar program).

4. Filling with water

The "water inlet" switch (9) is then set to "I".

When water is visible in the inspection cut-out

(13) return the switch to the "0" setting.

5. Timer switch

The timer switch (8) is set to correspond to the

selected pressure (10) at either the 30 minutes

or 50 minutes mark (Type 15: only 30 minutes).

When the power is then switched on, the signal

lamps (5) and (7) will light up. The electronic

temperature regulator controls by means of the

heating the temperature and the pressure; the

white signal lamp "Heating" (7) goes on and off

correspondingly.

6. Close the door tightly

Important! Only close the door after the timer

switch has been set.

7. End of the sterilization

At the end of the time set with the timer (8) the

power will be switched off and the solenoid valve

for the "Rapid pressure release" opens

automatically. The signal lamps (5) and (7) go

out.

Warning! Do not open the door until the moving

pressure gauge indicator has returned to "0".

8. Drying

In order to be able to cope with difficult drying

tasks, the autoclave has a switch for "Drying" (4).

It is possible to preselect the drying option before

beginning the sterilization or to select it after the

automatic rapid pressure release. The "Power"

signal lamp will be on permanently and the

"Heating" signal lamp will go on and off at

intervals in order to maintain a temperature of

approx. 120°C in the autoclave chamber until the

"Drying" switch is returned to the "0" setting (the

"Power" and "Heating" signal lamps will go out).

For best drying results the door should be kept

slightly open.

Warning! The chamber, door, trays, and

sterilized instruments are hot! During the drying

phase the thermometer will not display the

temperature in the autoclave chamber.

3.3 Process control _________________________________________________________

The red indicator on the pressure gauge (3) shows

the maximum pressure reading during the

sterilization cycle, which should correspond to the

pressure selected with the switch (10).

3.4 Program termination_____________________________________________________

A program can be terminated at any time. Proceed

as follows:

1. Turn timer switch (8) to "0"

2. Turn "Drying" switch (4) to "0" (if drying had been

selected)

3. Observe the pressure gauge (3) until the display

falls to "0"

4. The door can now be opened.

3.5 Removing dry loads _____________________________________________________

A way of ensuring that the load removed from the

autoclave is dry and ready for use is to set "Drying"

switch (4) to "I" immediately after the automatic

release of pressure (pressure gauge reading "0").

The "Power" signal lamp (5) will be on continuously

and the "Heating" signal lamp will go on and off at

regular intervals. The door of the autoclave chamber

should be kept ajar. The drying can go on as long as

required for the load in question. To end the drying

phase the "Drying" switch should be returned to "0".

The "Power" and "Heating" signal lamps go out.

Warning! Door, chamber and load are hot!

During the drying the thermometer will not display

the temperature in the autoclave chamber.

Filter paper

It has proved helpful to place a layer of filter paper in

the tray on which to lay the instruments to be

sterilized, and then to cover these with another

sheet of filter paper.

Cellulose or gauze

Soaked cellulose or gauze should not be used to lay

instruments on or to cover them, because the steam

can dissolve out substances which can leave spots

and discolorations on the items being sterilized.

3.6 Sterilization frequency ___________________________________________________

Page 7

Page 9

The MELAG autoclaves can be used for

approximately 8 sterilization cycles every day. This

large number of cycles is possible because of the

MELAG system, which only involves a relatively

small amount of distilled / demineralised water being

turned into steam for the sterilization and then

condensed again afterwards.

Breaks between cycles

A sterilization cycle is completed when the timer has

4 Further information about sterilization

4.1 Duration of sterilization (complete process) _________________________________

returned to "O" or the "Drying" switch (4) has been

switched off. It is important to allow a break of at

least 30 minutes before starting the next sterilization

cycle. Otherwise the residual heat in the thick-walled

autoclave chamber can lead to the thermostat

switching off too soon during the following

sterilization cycle so that the desired pressure will

not be reached, or will not be maintained for a

sufficiently long period.

Running time

at 2 bar (134°C) : 30 min

at 1 bar (120°C) : 50 min

Once the switch (8) has been set to 1 bar or 2 bar,

the sterilization proceeds automatically until the

rapid pressure release, without any need for further

manual intervention. For the autoclave type 15,

which is fixed at 2 bar (134°C), the running time is

30 minutes.

Operational phases

The overall running time for a sterilization cycle

consists of various phases: a heating phase,

ventilation phase, rise and equalisation phases, as

well as the sterilization proper and an extra safety

period which together make up the sterilization

phase.

Autoclave temperature

The specified operating times must always be

adhered to, whether starting with a cold or a hot

autoclave, in order to ensure that the chamber is

filled with saturated steam. Air is expelled through

the flow nozzle (B) and the time required for this is

constant, even if the autoclave is not starting from

cold.

Drying time and temperature

Drying time: as required

Temperature: approx. 120°C

After operating the "Drying" switch (4) the autoclave

chamber is heated to 120°C, and this temperature is

maintained until the drying is switched off again.

Warning! The chamber, door, trays, and sterilized

instruments are hot!

Seite 8

Page 10

4.2 Use of distilled or demineralised water _____________________________________

Quality requirements

For the steam sterilization it is important to use

either distilled or demineralised water of sufficient

quality.

A guideline for the preferred water quality is given in

the following table which lists values in accordance

with the European CEN Standard EN 285.

Conductivity

Evaporation residues

Silicone , SiO2

Iron

Cadmium

Lead

Other heavy metals

Chloride

Phosphate

15

≤

10 mg/l

≤

1 mg/l

≤

0,2 mg/l

≤

0,005 mg/l

≤

0,05 mg/l

≤

0,1 mg/l

≤

2 mg/l

≤

0,5 mg/l

≤

µS/cm*

pH - value 5 bis 7

Appearance colourless, clear, without

residues

Hardness

0,02 mmol/l

≤

*) µS/cm = Mikro Siemens per centimeter

However, for the Type 15, 17 and 23 autoclaves it is

also sufficient to use demineralised water in

accordance with VDE 510, as long as the VDE

requirements are strictly adhered to (conductivity on

demineralisation ≤ 10 µS/cm*

≤ 30 µS/cm*

identical with EN 285, and for evaporation residues

similar).

)

Demineralised water meeting the specifications of

VDE 510 or a local equivalent is widely available.

The quality of the water (compliance with VDE 510)

must be specifically mentioned on the label.

Problems with impure water

If water is used which is not sufficiently pure this can

lead to the formation of scaling in the steam piping,

on valves, and in the flow nozzle, and as a result the

autoclave will no longer operate properly. The use of

aggressive water (pH < 5 or > 7) can result in

corrosion and other harmful effects in the autoclave.

Formation of surface marks

The extent to which marks are formed on the

surface of the instruments being sterilized depends

also on the quality of the water used for steam

generation.

Use only demineralised or distilled water for the

steam sterilization.

)

)

. Specifications for the pH-value are

, as well as before use

4.2.1 Consumption _________________________________________________________

The amount of water in the storage container is

reduced for every sterilization by the amount which

is not recovered but escapes as steam. The extent

of such losses is dependent on various factors.

Frequency of sterilization

If sterilizations are carried out very frequently, this

can result in the distilled / demineralised water in the

storage container becoming too warm to cool the

steam from the autoclave chamber sufficiently for

this to condense, and some steam will escape from

the storage container.

Cooling coils

If the storage container has not been refilled with

distilled / demineralised water for a long time, the

water level may drop so low that the cooling coils

(E,G) are not covered, and the outgoing steam will

again not condense properly.

4.2.2 Exchanging the water in the storage container _____________________________

If impurities are found

If there are impurities in the water in the storage

container this is usually because the instruments

have not been cleaned properly before sterilization.

It is important to check at regular intervals that the

water is still clean. If there are signs of impurities,

cloudiness, or if a surface film has formed or there is

scaling on the walls and base of the storage

container, then it is essential that the distilled /

demineralised water be exchanged. The storage

container must be cleaned before it is refilled. Fatty

deposits can be removed using small amounts of a

mild detergent cleaner and warm water and a softbristled bottle-brush. Then rinse out the storage

container with clear water (on the water quality see

Section 4.2).

4.2.3 Emptying the storage container __________________________________________

After opening the screw stopper of the outlet (12) by

turning anti-clockwise, the water to be discarded can

be allowed to run out into a suitable container.

Then replace the screw stopper of the water outlet

and refill the storage container up to the "MAX" level

(C) with approximately 3 litres of unused

demineralised or distilled water.

Page 9

Page 11

Operating manual for type 15/17/23

5 Notes on operating malfunctions

The following notes on operating malfunctions are

intended to help with repairing small defects or to

describe problems in more detail to the authorised

dealer / depot / customer services.

5.1 Low pressure reading from the pressure gauge ______________________________

After a sterilization, if the red maximum pressure

indicator does not show at least the pressure

corresponding to the program that has been

selected, then the following points should be

checked.

Connection to the power supply

Is the autoclave connected to the mains power

supply, and is the power switched on? When the

timer is turned on the "Power" and "Heating" signal

lamps should light up.

Pressure gauge

Is the pressure gauge (3) working properly? If the

thermometer (6) is showing a temperature that is

appropriate for the selected program, but the

pressure gauge is not showing any pressure

reading, then the pressure gauge is probably

defective. In order to generate dry steam, at a

temperature of 134°C there should be a pressure of

2.0 bar. Otherwise, the pressure gauge may need to

be exchanged.

5.2 Pressure reading from pressure gauge too high ______________________________

"Pressure swing"

The most common cause of excessive pressure in

the autoclave is the "pressure swing". This usually

happens if the autoclave is still very hot from a

previous sterilization and is then restarted with only

a small load. This combination means that the

heating causes the pressure to rise very rapidly so

that the required pressure is reached before it has

been physically possible to expel all the air from the

chamber. This results in an additional increase in

pressure until the overall pressure rises above the

selected sterilization pressure. The steam in the

chamber is not saturated, and the values shown on

the pressure gauge (3) and thermometer (6) deviate

from the values for the production of saturated

steam. However, because all MELAG autoclaves

are fitted with an electronic temperature control, the

selected sterilization temperature will still not be

exceeded and the "pressure swing" will balance

itself out before the end of the sterilization period by

the continued exclusion of air. This can be

determined by checking that the reading of the

pressure gauge (white indicator) 5 minutes before

the end of the program (2 bar program) is within the

selected pressure range.

Max. pressure indicator is sticking

If the red maximum pressure indicator gets stuck, it

can obstruct the moving indicator of the pressure

gauge (3). If the max. pressure indicator then

suddenly becomes unstuck, the momentum can

send it some way past the correct pressure reading.

In this case it might, for example, appear to indicate

that there had been a maximum pressure of 4.5 bar,

even though the pressure had in fact been normal

throughout the sterilization. This can be checked by

observing the pressure gauge during a sterilization

cycle.

Clogging of the flow nozzle

If instruments are not prepared carefully before

sterilization, this can result in partial or total

blockage of the flow nozzle (B). During the heating

up phase air is expelled through this nozzle. If it is

totally or partially blocked then the air that remains in

the autoclave chamber exerts an additional partial

pressure during the sterilization phase. The flow

nozzle can be unblocked carefully using a wire or

similar instrument with a diameter of less than 0.5

mm. An indicator of a clogged flow nozzle and

residual air in the autoclave chamber is a

thermometer reading of less than 134 °C for a

pressure gauge reading of 2 bar or higher.

Page 10

Page 12

5.3 Pressure reading too low _________________________________________________

Load

If the autoclave has a load that is appreciably above

the maximum load specified in the technical data

section (1.2) then it will take longer to heat up and

as a result there will not be sufficient time for the

actual sterilization process, or the necessary

pressure may not be reached at all. The specified

maximum load (see Section 1.2) should therefore

never be exceeded.

Breaks between sterilization

If the break between sterilization cycles is less than

30 minutes, then too much heat will be retained in

the autoclave and the heater will switch off too early,

so that the necessary pressure will either not be

reached, or will not be maintained throughout the

sterilization phase.

Safety valve

Is the safety valve (D) leaking? The safety valve is

located in the storage container underneath the

"Max" water level marker. If it is already releasing

steam when the pressure gauge shows 2.5 bar or

less, then the safety valve should be replaced.

Timer knob

If the timer knob (8) is turned too quickly and forced

past the stopper then this can lead to the knob

rotating relative to its axis. In this case the timer will

no longer point to the correct time. Does the knob

point exactly to the "0" when the autoclave is

switched off? To adjust this, lift the cap on the timer

knob, and loosen the fastening nut slightly (do not

remove it!). Reposition the knob, retighten the nut

and replace the cap.

5.4 Overheating in the Chamber ______________________________________________

Overheating is almost always a result of insufficient

water in the autoclave chamber.

If your autoclave overheats:

- Switch the power off

- Turn the timer knob to "0"

- Open the door and leave it to cool for half-an-

hour

Before starting operations again check for the

following possible causes and take appropriate

steps.

Flow nozzle

If instruments are not prepared properly for the

sterilization then the distilled / demineralised water

and thus also the steam will contain impurities and

after frequent use of the autoclave or after a long

period, the flow nozzle (B) will become worn by the

passage of the solid particles and its diameter will

be increased. This can lead to an excessive loss of

steam. The flow nozzle must be replaced.

Solenoid valves

Soiling as a result of inadequate preparation of

instruments can leads to leaks through the solenoid

valves for the water inlet and the rapid pressure

release.

Rapid pressure release

If there is a leak of the solenoid valve for the rapid

pressure release then during the pressure phase

steam or water droplets form at the end of the

cooling loop for the rapid pressure release (G). If a

lot of steam or water is emitted then the solenoid

valve is defective, or dirt particles have collected on

the seal of the solenoid valve which the

maintenance technician will be able to remove.

Water inlet

If there is a leak of the solenoid valve for the water

inlet then during the phase of pressure increase air

bubbles will be seen forming at the filter of the water

inlet (F). It is often possible to remove a dirt particle

from the seal of the solenoid valve that is

responsible for causing the leak as follows: After

reaching the maximum possible pressure, the switch

for the water inlet (9) can be turned on and the

steam flowing through the solenoid valve will blow

the seal clean. This leads to a loss of pressure in the

chamber. It is very important that after the switch

has been returned to the "0" position, the timer is

also turned back to "0". Otherwise the shortage of

water or of steam in the chamber can lead to

overheating.

Timer knob

The timer knob (8) no longer has the correct

alignment (see Section 5.3).

Textiles

Textiles retain large quantities of condensed steam,

so that when they are being sterilized it is very

important to ensure that the autoclave is not

overloaded (for maximum load, see above, 1.2).

Safety valve

The safety valve is located in the storage container

under the MAX water level marker. If it already

releases steam when the pressure gauge is reading

less than 2.5 bar then it must be exchanged.

Page 11

Page 13

Operating manual for type 15/17/23

5.5 Residual water in the chamber ____________________________________________

A small amount of residual water in the autoclave

chamber is unavoidable. As the chamber cools

down, steam in it condenses on those parts which

cool first (door, chamber floor).

Larger amounts of residual water can have various

causes:

Chamber filter

After completion of the operating cycle a small

amount of water remains in all MELAG autoclaves,

which serves during the sterilization to prevent

overheating of the steel chamber vessel. At the end

of the time set for the cycle using the timer switch,

the water will be pressed down with the outflowing

steam back into the water storage container. A filter

is installed at the outlet to prevent dirt and impurities

from entering into the piping system, and if this

becomes clogged then a residual amount of water

will remain in the chamber.

Solenoid valve - Water inlet

If instruments have not been prepared properly then

dirt and impurities can prevent the solenoid valve of

the water inlet from closing properly so that small

drops of water still enter the chamber from the

storage container after the sterilization. In this case,

this is not actually residual water. This can be

checked by removing the tray rack assembly and

wiping the chamber out with a dry cloth. It should still

be dry after some hours. If it is wet again, then the

solenoid valve should be cleaned (see also 5.4.

"Water inlet").

5.6 Signal lamp 'Power' stays on continuously __________________________________

The "Power" signal lamp (5) lights continuously,

and the "Heating" signal lamp (7) lights at intervals.

The pressure gauge shows a pressure of no more

than 0.3 bar with the door closed after the timer

switch has switched off (8). Check the "Drying"

switch (4) and if appropriate switch it to "0". The

pressure should then decline, and both signal

lamps go out. The door can then be opened.

5.7 Signal lamp 'Power' doesn't light up ________________________________________

The "Power" signal lamp (5) does not light up

although there is a power supply to the mains

socket. The autoclave does not work and there are

no displays. This can occur if one of the screw-in

fuses (on the rear-side of the autoclave) has

blown as a result of a short-circuit in the

autoclave. As this malfunction can indicate a

serious fault, you should inform customer

services.

6 Safety instructions

After opening the door of the autoclave do not

touch exposed metal parts. These may be hot and

could cause burns! To remove and handle hot

trays you should use a tray lifter, and for other

sterilization containers use suitable hand

protection.

Empty the water storage container before any

transport, do not tilt the autoclave if it is filled with

water.

Do not open the door until the pressure in the

autoclave has been equalised (pressure gauge

display shows "0"): Small amounts of residual

steam may be released from the autoclave

chamber when the door is opened.

The autoclave may only be serviced by persons

authorised by MELAG, using original spare parts.

Before opening the enclosure of the autoclave

ensure that the plug is removed from the mains

power socket.

This autoclave is not suitable for the

sterilization of liquids.

7 Taking the autoclave out of operation/Transport/Re-installation

When taking the autoclave out of operation for a

longer period or before transportation of the

autoclave proceed as follows:

• Disconnect from the mains power supply and

allow the autoclave to cool down

• Empty the water from the storage container

by opening the "Outlet" valve (12).

• If the autoclave is to be transported with tray

rack and/or trays in place, then place a foam

sheet or similar protection between the door

and the pressure chamber to avoid scratching

and other damage.

• After moving it to another location or after

repairs, then reinstall the autoclave in

accordance with the "installation" procedure

(see above).

Note! To avoid damage during transport use

the original packing for the autoclave.

Page 12

Page 14

A

8 Annex

8.1 Spare parts ____________________________________________________________

Art.-no. Name of spare part

34125 Flow nozzle (M6, width 8 mm)

16005 Safety valve (calibrated)

32150 Door gasket for type 15

32670 Door gasket for type 17

34150 Door gasket for type 23

34010 Filter for pressure chamber

33890 Timer switch

34165 Pressure gauge

40100 Thermometer

29560 Solenoid for solenoid valve

587400 Overheating protection switch (mounted on pressure chamber )

34365 Door locking latch ( always exchange latch and star grip knob together)

34360 Door star grip knob

12690 Mains fuse 12,5A/T (2x)

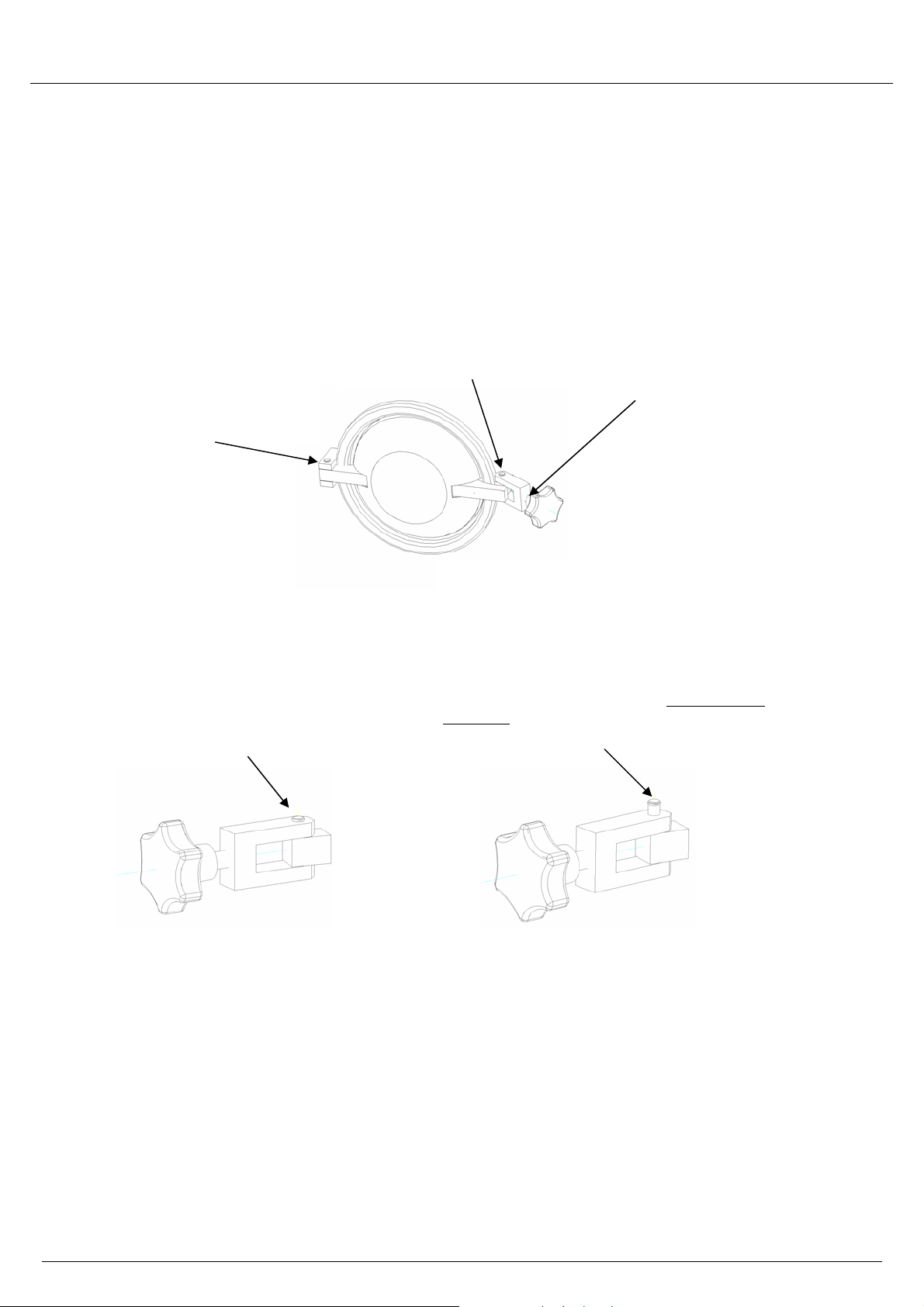

8.2 Inside the autoclave _____________________________________________________

Q

GEBCD

K

L

H

P

I

M

15- 23

N

A Drainage outlet of storage container I Control electronics

B Flow nozzle K NTC Temperature sensor for control electronics

C Water level ("MAX") L filter for pressure chamber

D Safety valve M Mains-fuse

E Cooling coil N Potentiometer

F Impurity filter (for the water inlet) O Solenoid valve - water inlet

G Cooling loop (of rapid pressure release) P Solenoid valve pressure release

H Capillary tube controller „drying“ Q Flow line filter(screwed in from inside)

Page 13

F

O

Page 15

Operating manual for type 15/17/23

15-23BA-eng.doc Revision 9 - 02/170 Page 14

Loading...

Loading...