Megadyne Synchronous V-Belts MAINTENANCE MANUAL

MAINTENANCE

MANUAL

Synchronous & V-Belts

www.megadynegroup.com

Founded in 1957 in

Mathi, Italy, Megadyne

is a manufacturer of

industrial belting for

power transmission,

product handling and

linear positioning

applications.

Complementing our

line of belting products

we also market a line of “Jason by Megadyne”

industrial and hydraulic hose. Our position in

the industry as a global leader is due to our

worldwide manufacturing, numerous fabrication

and distribution locations and commitment

to investment in product and process

development.

WARNING: This document is recognized as a Maintenance Manual with its main

intent to be product application/installation/trouble-shooting use training. While this

is not a selling document, we do recognize some items include chemicals that are

on the California Prop 65 list. The chemicals identified within rubber v and timing

belts described through this manual include carbon black chemical ingredient

within the belt material. Additionally references to metal pulleys could include

lead. Both materials are identified in the California Prop 65 list effective August

30, 2018. For more information on CA Prop 65 visit www.P65Warnings.ca.gov.

For specific warnings related to the identified chemical refer to the shipping label

accompanying receipt of this product. Always wash your hand after handling belts,

pulleys and sheaves.

The following trademarks are registered in the United

States Patent and Trademark Office by their owners:

HTB® and Accu-Link® are registered trademarks of Jason Industrial

(Megadyne Group)

RPP® is a registered trademark of the Timken company (formerly Carlisle)

Poly Chain® and HTD® are registered trademarks of the Gates Corporation

ISORAN® is a registered trademark of Dayco Europe S. R. L.

B

TABLE OF CONTENTS

Foreword

Why Preventive Maintenance is Important

Safety

Belt Storage

Best Practices

Using the Tension Tester Gauge

Belt Installation Checklist

Tensioning & Installation - V-Belts

Troubleshooting V-Belt Drives

Tensioning & Installation – Isoran RPP Synchronous Belts

Tensioning & Installation – Platinum Synchronous Belts

Troubleshooting Synchronous Belts

Flange Requirements – Synchronous Belts

Idler Usage – Synchronous Belts

Alignment

Belt Guard Design

Failed Belt Analysis – V-Belts

Failed Belt Analysis – Synchronous Belts

Ultimate Solution - Belt Drive Data Sheet

1

FOREWORD

FOREWORD

The implementation of a

preventative maintenance

program including proper

belt drive installation,

tensioning procedures

and best practices will

increase productivity,

reduce downtime and yield

the additional benet of

improved workplace safety.

The majority of power

transmission drive

problems are attributed to

improper installation and

maintenance. This manual

is intended to provide

guidance in avoiding

drive problems, extending

drive life and maximizing

performance while

maintaining a safe working

environment.

NOTE:

The metal components used with v-belt and synchronous

belts are commonly referred to as pulleys. Where it’s

necessary to distinguish between the two, we refer to

v-belt pulleys as “sheaves” and synchronous pulleys as

“sprockets”. Where the information is the same for both

the term “pulleys” will be used.

2

WHY PREVENTIVE MAINTENANCE

WHY PREVENTIVE MAINTENANCE

IS IMPORTANT

When compared to the cost

of production downtime and

the labor costs associated

with a belt failure, the cost

of a belt is relatively insignificant. Generally speaking,

at any given production facility, 80% of the downtime

related to power transmission belts can be found on

20% of the drives in the

plant. In other words 80%

of the drives are working

ne, day in and day out. The

remaining 20% are “problem

LET US TROUBLE-SHOOT YOUR

PROBLEM DRIVES

Megadyne is uniquely

positioned to partner with

you to keep production at

a maximum and “problem

drives” at a minimum.

Megadyne is at your service

to offer drive designs to

eliminate the problem

drives in your facility. We

offer one of the widest

selections in the industry

of power transmission and

product handling belts.

We can provide a vast

array of synchronous and

non-synchronous product

in rubber or polyurethane.

Additionally, we can

customize belts for any

application imaginable.

drives” that are a constant

headache, requiring frequent

attention and replacement.

Additionally, it’s not uncommon for a large industrial

facility to spend thousands

of dollars annually to determine what type of replacement belt is needed for a

particular drive. Worn belts

are often difcult to identify

as their part numbers sometimes become impossible to

read after lengthy service.

Whether you have a

low or high temperature

application, a need for

non-marking compound,

electrical conductivity or

resistance, silicone-free

product, special backings,

chemical resistance or

ultra-high torque power

transmission capability,

Megadyne can provide

a belt that will improve

performance on your

application.

Contact your Megadyne

sales representative to work

with you to trouble-shoot

your problem drives.

3

SAFETY

WARNING: Failure to follow these

instructions may result in personal

injury or death!

Power transmission products are potentially dangerous.

Failing to follow recommended application information

and procedures for installation, care, maintenance and

storage of products may result in serious bodily injury or

death. Make sure that product selected for any application

is recommended for that service. Always follow the

recommendations of the original equipment manufacturer.

Contact Megadyne for specic information.

• Before doing any maintenance work on power

drives, ALWAYS switch off the power and lock-

out the drive. A tag should be attached stating

– Danger – DO NOT OPERATE.

• One should ALWAYS try to operate the

equipment after shutdown to make sure you

have locked-out the proper switchbox, ensuring

that the switchbox is operating properly and

also to release any stored energy.

• Use belt guards to provide protection for

personnel from contact with drive components.

NEVER test or operate belt drives without

guards in place.

• ALWAYS wear gloves to protect from sharp

edges and hot surfaces.

• NEVER wear loose or bulky clothing in close

proximity to an unguarded drive where it could

become entangled in the drive and cause injury

to personnel.

4

SAFETY

WARNING: Failure to follow these

instructions may result in personal

injury or death!

• ALWAYS be aware of pinch points where hands

and ngers can be injured, especially where the

belt enters the sheave or sprocket.

• ALWAYS keep the area around the drive free of

clutter and debris.

• NEVER re-use damaged pulleys. They should

be replaced if not repairable.

• ALWAYS use static dissipating belts in

conjunction with industry approved methods to

dissipate electrical charges on drives used in

hazardous atmospheres.

• NEVER use Megadyne belts for aircraft

applications. Megadyne belts are not designed for

or intended for use on aircraft propellers, rotors

or accessory drives. Do not use on helicopters

or private, commercial, ultralight or any other

airborne aircraft application.

5

BELT STORAGE

BELT STORAGE

Proper belt storage is

the rst step for good

performance and long

drive life. When belts are

improperly stored they can

be damaged and reduce

performance and product

life before they are even

installed. Properly stored

belts will not undergo

signicant changes in

properties for several

years. However, exposure

to extreme environmental

conditions will have a

negative effect. Belts should

be stored in dry conditions

BELTS MUST BE STORED:

• In an environment between 40°F & 86 °F (5°C/30°C).

Extreme temperatures, in particular higher temperatures

can cause damage to the belt due to the deformation of

the supercial structure. These effects can lead to reduced

performance. Belts could swell and not run straight and

smooth. Lower temperatures are also not suggested and

cause an undesirable increase in stiffness of the belt.

with protection from light,

dirt and dust. Avoid high

ozone concentrations,

moisture, chemicals,

solvents, fuels, lubricants,

and acids.

Ensure that belts are stored

in a stress-free way without

excessive tension, pressure

or other deformation

as this could result in a

permanent deformation or

the occurrence of cracks.

Belts must not be bent to

avoid damage to the internal

tensile reinforcements.

• Away from equipment generating ozone, such as high

voltage electrical machines or uorescent light sources. Also

combustion gases and vapors that can cause ozone should

be avoided.

• In a dry place. Storage rooms must be kept free from

moisture. The humidity must not exceed a maximum of

50%. Polyurethane and rubber belts have hygroscopic

properties and will absorb moisture. This can cause

deterioration of the compound and oxidation of steel tensile

cord. Storage in excessively high humidity will reduce belt life.

6

BELT STORAGE

BELTS MUST BE STORED:

• With original packaging intact until the belt is ready to be

used. The packaging delivered by Megadyne is designed to

provide protection from environmental conditions.

• In a way that protects against light, particularly against

direct sunlight and articial light with a high ultraviolet

concentration.

• To ensure they are not crimped or bent in handling or

storage. Belt damage occurs when bent to a diameter

smaller than the minimum recommended pulley diameter for

a particular belt. Use a crescent shaped saddle rather than

a peg or hook to lessen the amount of bend when hanging

v-belts from walls. Synchronous timing belts should never be

hung from a peg. They are best stored laid at on a shelf.

7

BEST PRACTICES

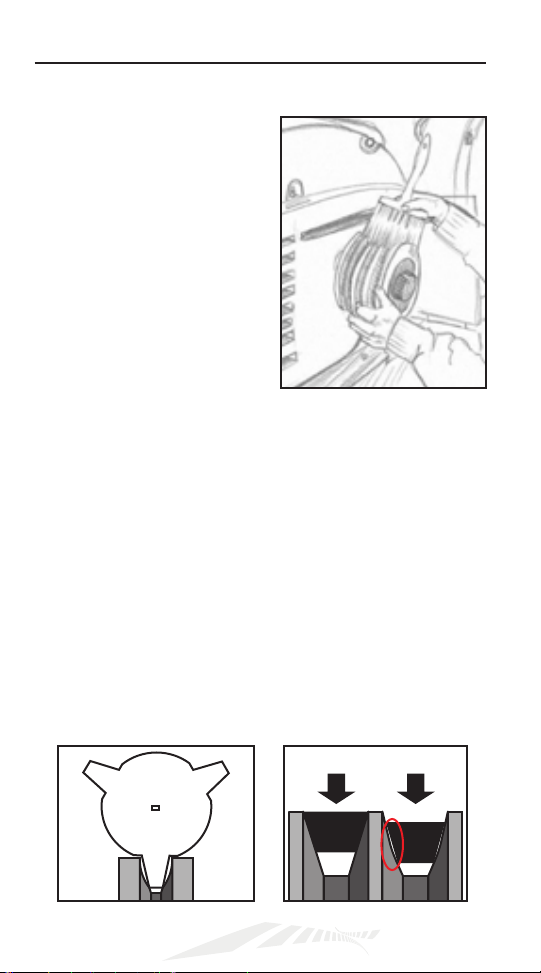

INSPECT PULLEYS

A stiff brush can be used to

remove rust and dirt. Use a

soft cloth to wipe off oil and

grease.

For the sprockets used

on synchronous timing

belt drives the tolerance is

normally minus zero, plus a

few thousandths of an inch.

If you can visually detect

or feel any wear, it is worn

beyond the tolerance range

and should be replaced.

SHEAVE GAUGES/INSPECTION

For V-belts select the proper

sheave groove gauge and

template for the sheave

diameter. Insert the gauge

in the groove and look for

gaps that indicate dishing or

other abnormal wear.

• You should not see a gap

between the belt sidewall

and the sheave sidewall.

• If more than a 1/16” gap is

present the sheave should

be replaced.

As a general rule, the worn

sheave will most likely be

the smallest sheave in the

drive. This is referred to as

the “critical” sheave, the

most likely to slip. All life

calculations and total drive

performance is based on the

critical sheave. On a typical

speed reduction two sheave

drive, the driver (critical)

sheave will be replaced

many more times than the

driven sheave.

3

8

°

0

v

e

r

1

7

.

O

F

D

Standard

Section

FD

12.0 to 12.99

34°

36°

D

F

13.0 to 17.0

LIKE THIS NOT THIS

8

BEST PRACTICES

IDENTIFY THE CORRECT BELT

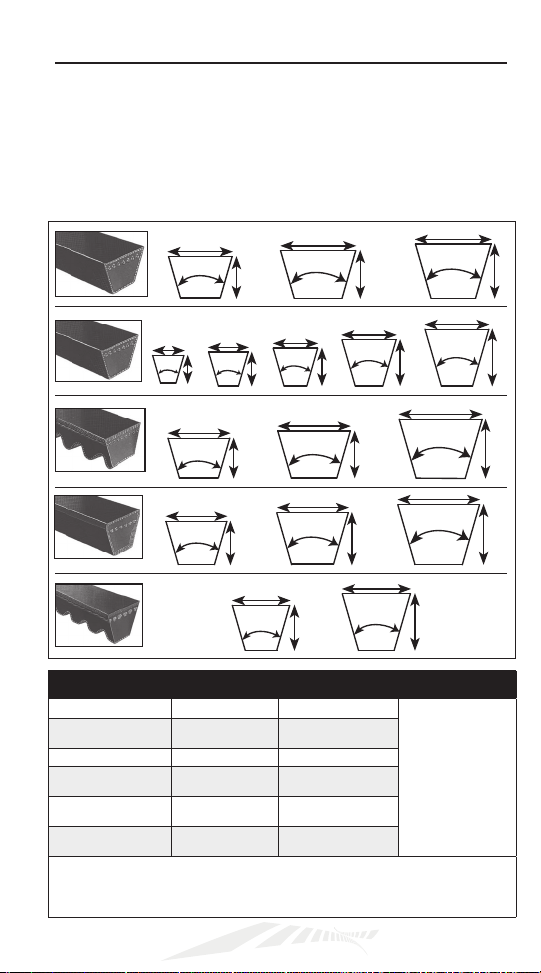

V-Belt - Always select the correct cross section of v-belt

to match sheave grooves. Use a sheave groove gauge to

determine the correct belt cross section. Use a v-belt gauge

to verify v-belt cross section and length when markings are no

longer legible on the belt back.

0.50”

A

40°

0.38”

0.50”

AX

0.38”

3V

38°

3L

40°

0.31”

40°

0.66”

40°

0.50”

0.31”

0.41”

0.38”

38°

0.88”

C

40°

0.66”

BX

0.63”

5V

0.31”

38°

40°

4L

40°

0.53”

1.25”

D

40°

0.41”

0.53”

0.63”

5VX

38°

0.22”

B

0.31”

0.31”

3VX

0.75”

0.66”

5L

40°

1.50”

E

40°

0.88”

CX

40°

1.00”

8V

38°

0.53”

0.41”

1.00”

0.53”

0.88”

V-Belt Type Identified By

Part Number

Example

Fractional HP (FHP) Effective Length 4L500

Classical Multi-Plus

Standard Length

Designation

A48

Fractional HP Effective Length 5L500

Classical Multi-Plus

Classical Cogged

Narrow Deep Wedge/

Cogged

NOTE: Length information values in the above table are approximate. Industry

standards require that to accurately measure a belt, it must be installed on a xture with

two pulleys of prescribed dimension and tensioned to a specic value. Accurate values

cannot be measured by hand on a free length of belt.

Standard Length

Designation

Standard Length

Designation

Effective Length

B47

AX48

5V500/5VX500

Outside Length

=

=

=

=

=

=

Approximate

50"

9

BEST PRACTICES

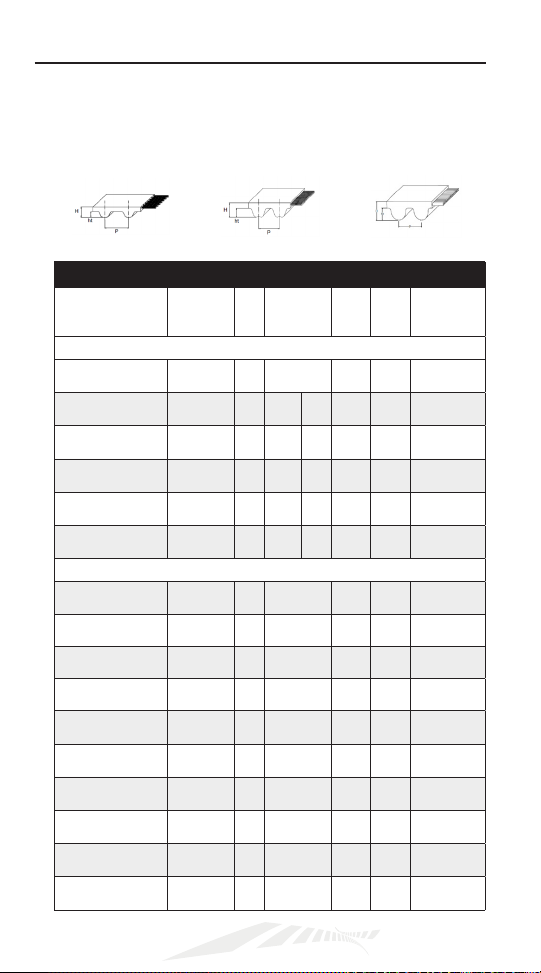

SYNCHRONOUS BELT

Conrm that belt pitch (distance between the teeth) and belt

tooth prole (shape of the belt tooth) are compatible with

those of the corresponding sprocket.

Trapezoidal Parabolic Curvilinear

Synchronous Belt Identification

Tooth

Belt Type / Pitch Code Service Duty

in or mmPitch

(P)

Trapezoidal

MXL

mini-extra

light

in 0.080 0.020 0.045

XL extra light in 0.200 1/5 0.050 0.094

L light in 0.375 3/8 0.075 0.140

H heavy in 0.500 1/2 0.090 0.173

XH extra heavy in 0.875 7/8 0.250 0.448

XXH

extra extra

heavy

in 1.250 1-¼ 0.375 0.600

Parabolic

RPP® 3 high torque mm 3 1.15 2.40 RPP® / HTD

RPP® 5 high torque mm 5 2.00 3.80 RPP® / HTD

RPP® 8 high torque mm 8 3.20 5.40 RPP® / HTD

RPP® 14 high torque mm 14 6.00 9.70 RPP® / HTD

RPP® Silver2

8M

RPP® Silver2

14M

RPP® Gold

8M

RPP® Gold

14M

RPC Platinum 8M

RPC Platinum 14M

extra high

torque

extra high

torque

super high

torque

super high

torque

ultra high

torque

ultra high

torque

mm 8 3.20 5.40 RPP® / HTD

mm 14 6.00 9.70 RPP® / HTD

mm 8 3.20 5.40 RPP® / HTD

mm 14 6.00 9.70 RPP® / HTD

mm 8 3.46 5.40

mm 14 6.10 9.70

Height

(ht)

Belt

Height

(H)

Sprocket

Compatibility

standard

timing

standard

timing

standard

timing

standard

timing

standard

timing

standard

timing

RPP® / HTD® /

Poly Chain

RPP® / HTD® /

Poly Chain

®

®

®

®

®

®

®

®

®

®

10

BEST PRACTICES

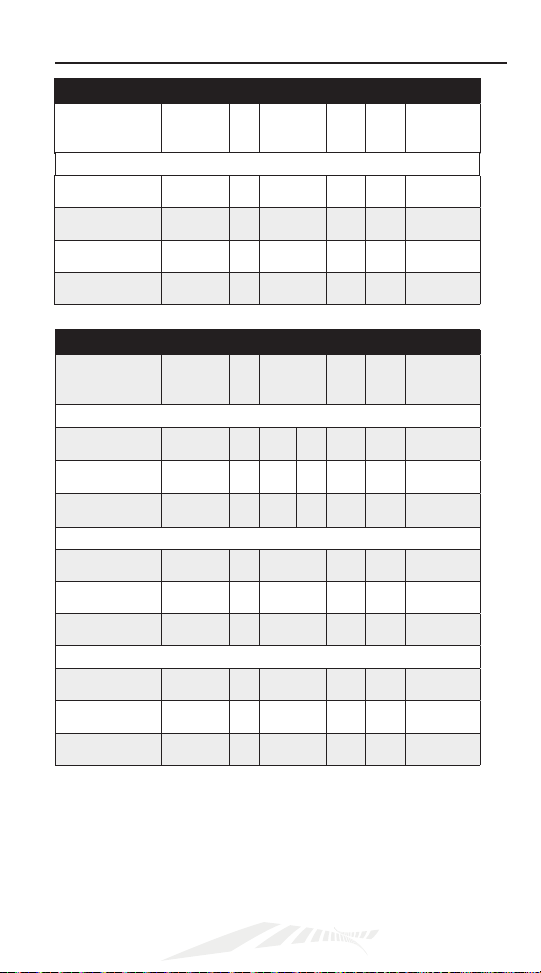

Synchronous Belt Identification

Tooth

Belt Type / Pitch Code Service Duty

in or mmPitch

(P)

Curvilinear

HTD®/HTB® 3M high torque mm 3 1.22 2.41 HTD

HTD®/HTB® 5M high torque mm 5 2.08 3.81 HTD

HTD®/HTB® 8M high torque mm 8 3.4 6.0 HTD

HTD®/HTB® 14M high torque mm 14 6.0 10.0 HTD

Dual Sided Synchronous Belt Identification

Belt Type / Pitch Code Service Duty

in or mmPitch

(P)

Trapezoidal

DXL extra light in 0.200 1/5 0.050 0.120

DL light in 0.375 3/8 0.075 0.180

DH heavy in 0.500 1/2 0.090 0.232

Parabolic

DRPP5 high torque mm 5 2.00 5.20 RPP® / HTD

DRPP8 high torque mm 8 3.20 7.80 RPP® / HTD

DRPP14 high torque mm 14 6.0 14.00 RPP® / HTD

Curvilinear

HTD®/HTB® 5M high torque mm 5 2.08 5.30 HTD

HTD®/HTB® 8M high torque mm 8 3.4 8.10 HTD

HTD®/HTB® 14M high torque mm 14 6.0 14.8 HTD

Height

(ht)

Tooth

Height

(ht)

Belt

Height

(H)

Belt

Height

(H)

Sprocket

Compatibility

®

®

®

®

Sprocket

Compatibility

standard

timing

standard

timing

standard

timing

®

®

®

®

®

®

Once the correct belts are identied, it is good practice for

maintenance personnel to label each drive with the correct

belt part number. When replacement belts are required it’s

as simple as obtaining the part number from the drive label.

Additionally, the installation date and installation tension for

each drive can be recorded on the label to further enhance

your preventive maintenance program.

11

Loading...

Loading...