Mega H-550A Instruction Manual

AUTOMATIC BANDSAW

H-550A

INSTRUCTION MANUAL

MEGA MACHINE CO., LTD.

DOC NO

:

H550A-100.U

CTRL NO

:

06

UPDATE

:

1998/07/27

DOC VER

:

A

FOREWORD

We hope that the owner of this heavy-duty bandsaw machine will

have years of trouble-free service. The machine has been built

to the highest standards to enable fast accurate cutting to be obtained.

In order that the best results can be achieved from your MEGA band

saw we would ask all operators and maintenance engineers to READ

THIS MANUAL CAREFULLY BEFORE STARTING UP THE MACHINE.

The manual contains full instructions on installation, operation, lubrication,

maintenance and trouble-shooting.

As MEGA MACHINE COMPANY LIMITED is constantly improving the

design of its machines, there may be some instance where this book differs

somewhat from the machine with which you are concerned. So, always

quote the Serial Number of your machine, when ordering spare parts

or in correspondence relating to the machine.

MODEL : H550A

Serial Number :

Request for service and spare parts should be made to :

ADDRESS: NO. 180, INDUSTRIAL ROAD, TAI-PING CITY, 41107 TAICHUNG,

TAIWAN R. O. C.

E-MAIL: mega@ms1.hinet.net; mega@mail.mold.net.tw

URL: www.bandsaw.com.tw

TEL: 886 4 22712877(PRES.) FAX:886 4 22715016

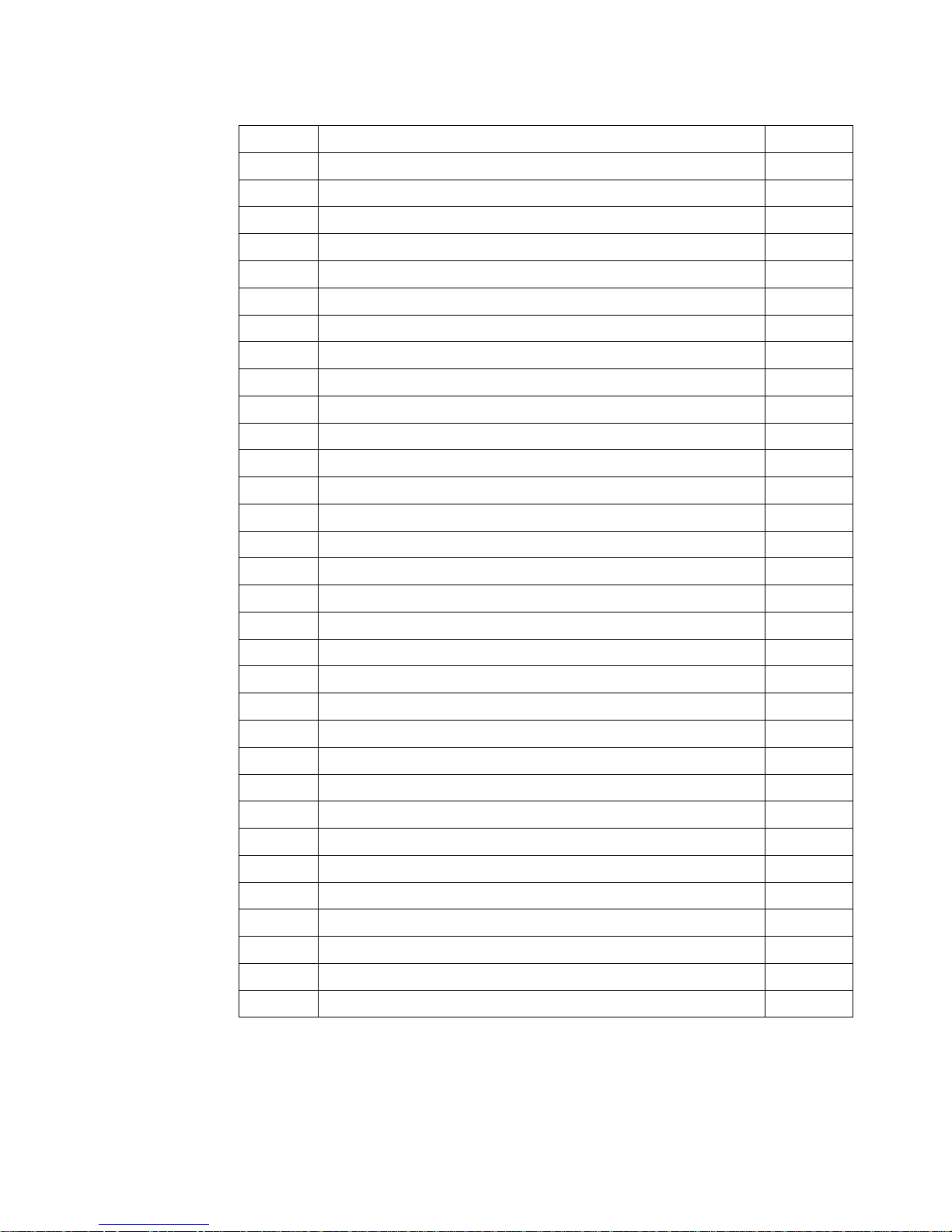

TABLE OF CONTENTS

Item

Unit

Page

1 Introductory Illustrations 1-1

1.1

Principal parts

1-1

2 Specifications

2.1 Specifications 2-1

2.2 Standard Accessories 2-1

3 Installation

3.1 Moving and lifting 3-1

3.2 Foundation layout and Set-up 3-2

3.2.1 Foundation 3-2

3.2.2 Leveling 3-3

3.2.3 Cleaning and oiling 3-3

3.2.4 Power Source Connection 3-4

4 Operation

4.1 Control Panel 4-1

4.2 Operating preparation 4-3

4.3 Manual Operation 4-4

4.4 Automatic operation 4-5

4.5 Special Operation 4-5

4.6 Break -In Operation 4-5

5 Maintenance

5.1 Hydraulic Circuit 5-1

5.2 Oiling and Lubrication 5-2

5.3 Others 5-3

6 Trouble Shooting Guide

6.1 Sawing Problems and Solution 6-1

6.2 Minor Operating Troubles and Remedies 6-2

6.3 Error information 6-3

7 Reference Charts

7.1 Standard cutting Chart 7-1

7.2 Standard cutting Chart 7-2

7.3 Standard cutting Chart 7-3

Electrical Circuit

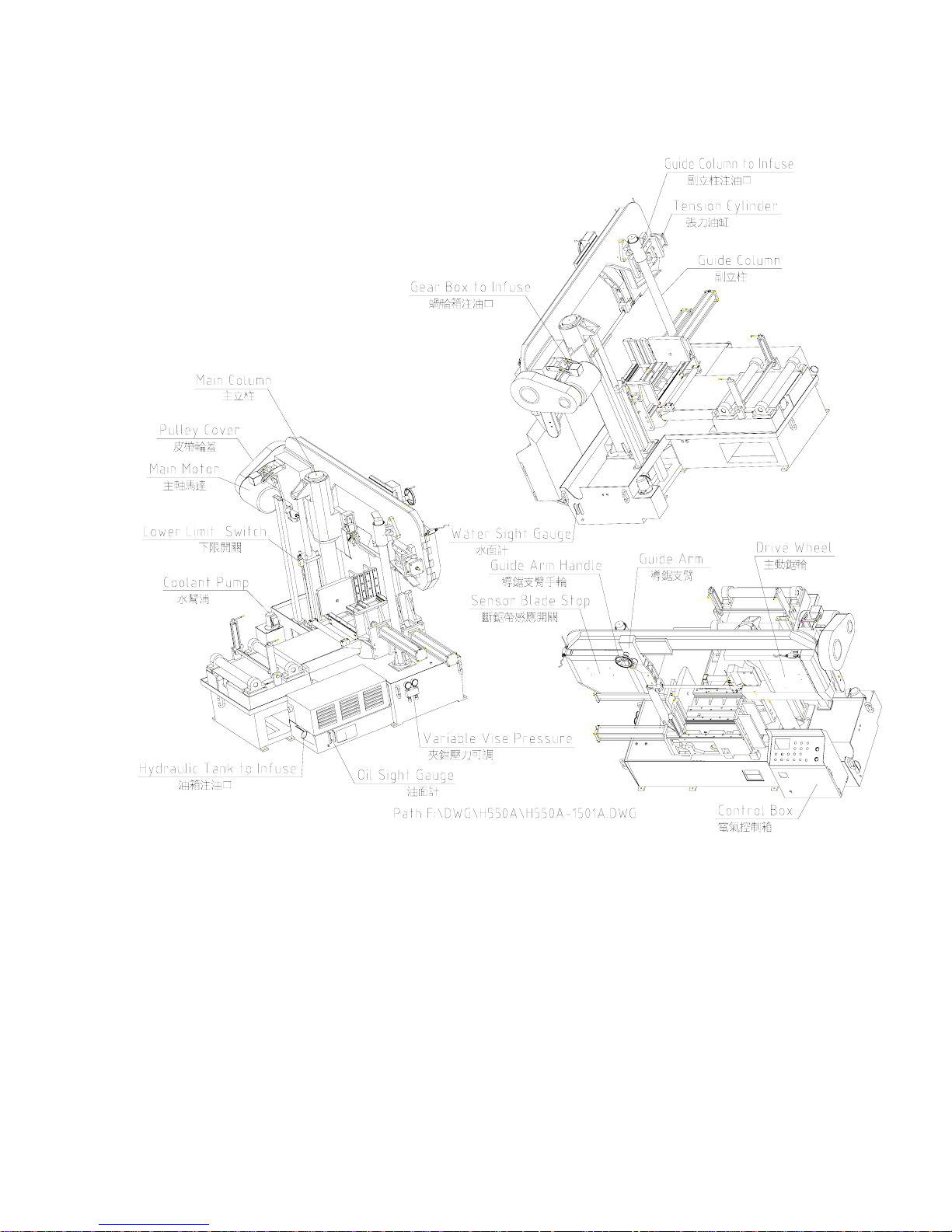

1. INTRODUCTORY ILLUSTRATIONS

1.1 Principal Parts

1 – 1

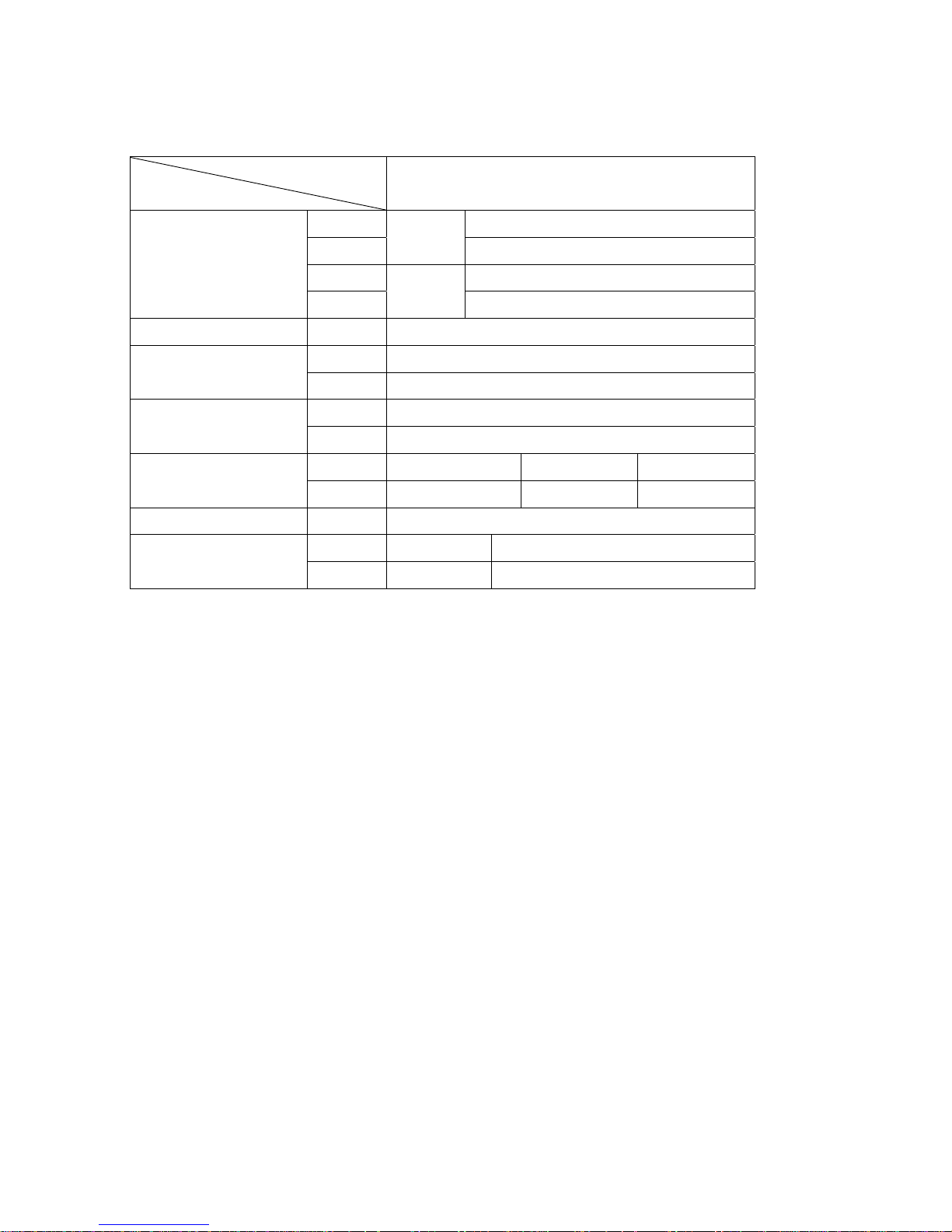

2. SPECIFICATIONS

2.1 SPECIFICATIONS

Model

Specifications

H-550A / H-550GA

(mm)

φ550 □550H*600W

(in)

Max

φ21 □21*23

(mm)

φ190 □ 550H * 190W

Cutting Capacity

(in)

Min

φ7.48 □ 21H * 7.48W

Bundle Cutting (mm) 250H*440W

(mm) 41W * 1.30t * 5800L

Blade Size

(in) 1-1/2W * 0.051t * 226L

(m/min ) 25,32,42,55,70,80

Blade Speed

(ft/min) 82,105,138,180,230,260

(kW) Blade 5.6 Hydraulic1.5 Coolant0.1

Motor Output

(HP) Blade 7.5 Hydraulic 2 Coolant 1/8

Hydraulic pressure (bar) 40

(kg) Net / Gross 3800 / 4500

Weight

( lb. ) Net / Gross 8360 / 9900

* Specifications subject to change without notice for improvement and modification.

2.2 STANDARD ACCESSORIES

1. Tools with tool box ..................... 1 set

2. 7 ft.(2M) long roller table ............. 1 set

3. Band-cleaning wire brush ................ 2 pieces

4. Band saw blade .......................... 1 piece

5. Vertical guide rollers .................. 1 set

6. Instruction manual ...................... 1 copy

2-1

3. INSTALLATION:

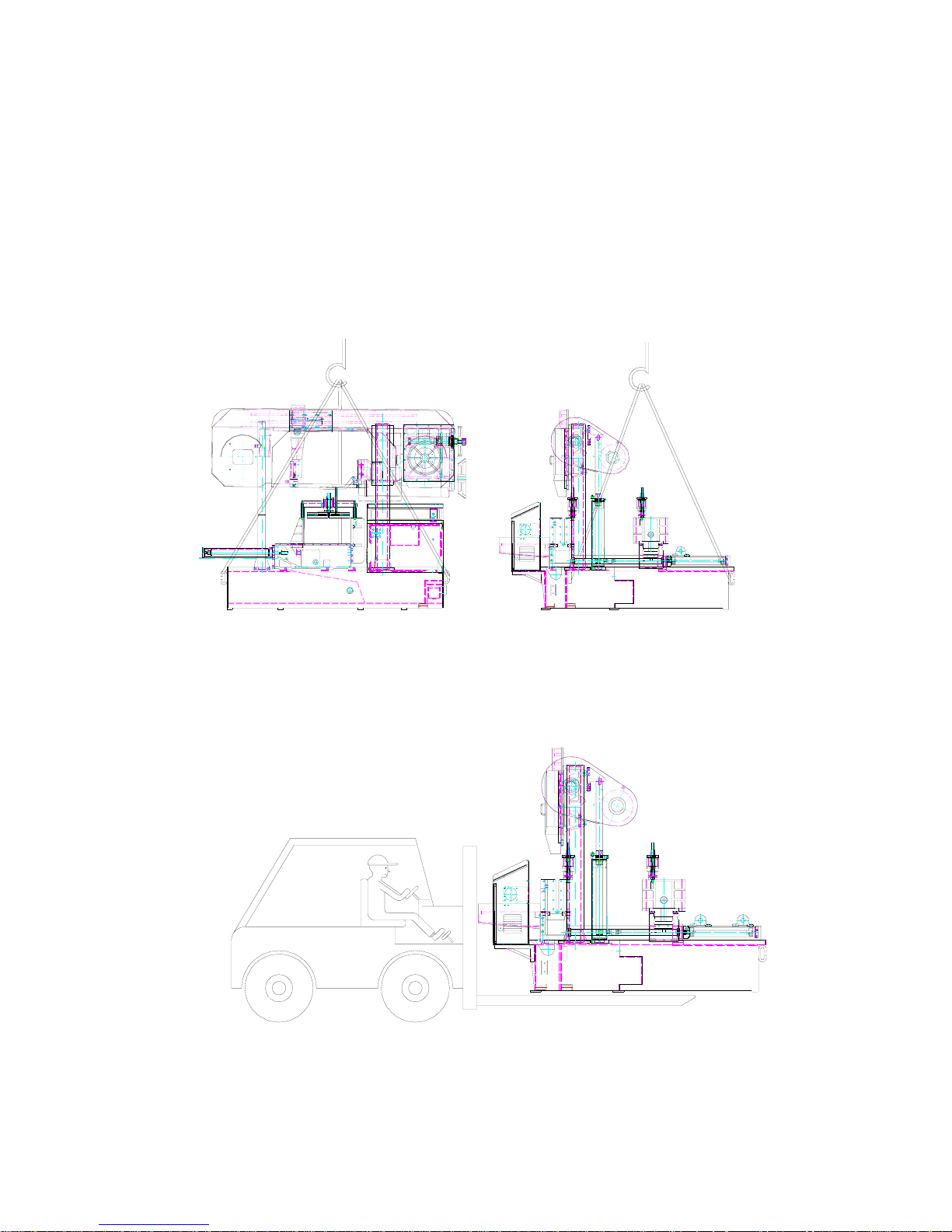

3.1 Moving and lifting:

Unpack your machine carefully, and use a crane or forklift to set it in position.

If a crane is used to lift the machine attach the lifting cable carefully to the machine as shown in the

fig 2. If forklift is used then fig 3.

Sufficient space should be left around the machine to allow safe handling of materials , and inspection

and maintenance operation. Should there be other machinery causing vibration or dust that near your

machine ,then precautions must be taken to keep your machine away from of vibration and dust.

(1) Use Crane :

Fig 2

(2) Use Forklift :

Fig 3

3 - 1

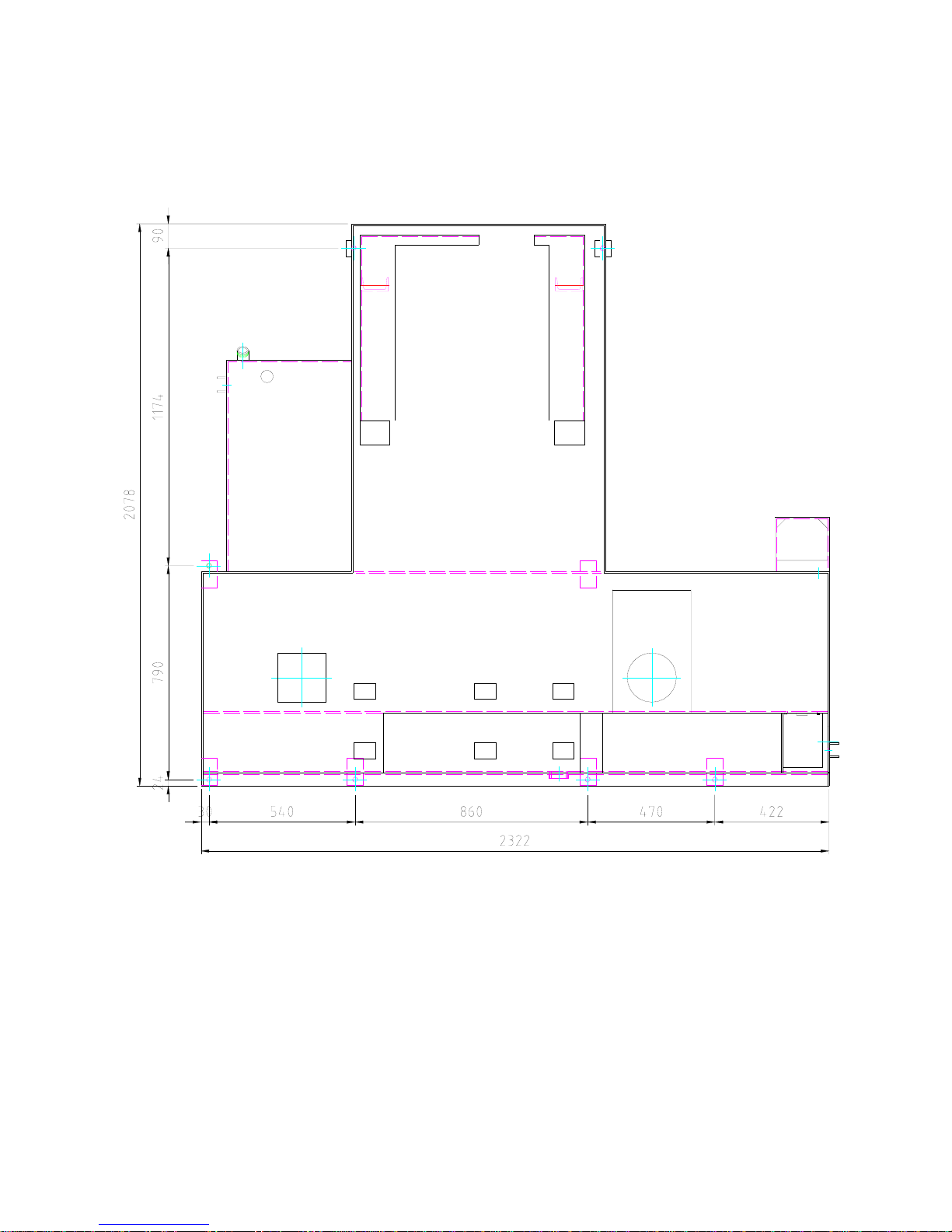

3.2 Foundation layout and set-up:

(1) Foundation:

The foundation should be constructed of reinforced concrete and must be level and flat. After the proper

leveling position has been obtained, anchor the machine with anchor bolts. The position of anchor bolts

and floor dimensions are shown in fig 4:

□ Contact portion with floor

○ Position of anchor bolts

Fig. 4

※ All leveling bolts should support the weight of the machine evenly .

3 ─ 2

(2) Leveling:

The production accuracy of all precision machinery depends on the accuracy which the machine is

installed. Manufacturing tolerance of the machine can only be guaranteed if the machine is firmly and

properly installed . Once the machine is lowered on the prepared foundation. Machinist levels should be

Used alternately on the vise slide plates and the work feed table , and adjust the left-and-right and

fore-and-aft level of the machine with leveling bolt .

The fore-and-aft level should be adjusted so that the level of the rear end is approximately 10 mm (3/8" -

1/2") higher than the level of the front end , to provide proper return of the cutting fluid , and easy

operation of car feeding .

The left-and-right level should be adjusted so that the level of the left end is approximately 3 mm (1/8")

higher than the level of the right end , to provide proper return of the cutting fluid , After the proper

leveling position has been obtained anchor the machine with anchor bolts .

CAUTION : All leveling bolts should support the weight of the machine evenly .

Leveling as fig 5 below :

FIG 5

(3) Cleaning and oiling :

After the machine has been placed in position , thoroughly remove its rust preventive coating using a

suitable cleaning solvent and then apply a coat of machine oil . To clean the machine , Kerosene is

preferable to gasoline . It does not evaporate and level dried slushy compound on finished surfaces.

Rags are better than waste as they leave no lint or strings. The machine as received by you. has been

completely drained of all oil. Before any attempt is made to run it . Before any motor connections are

made .... every detail of the following oiling instruction must be complied with. Refer to the oiling chart in

chapter 7. Especially, don't forget to fill up the cutting fluid mixture. Usually, the ratio of cutting fluid to

water should be 1:30 - 1:50. Check the sight gauge to ascertain the fluid level in the tank every day.

Transmission gear box, bar feed gear box, hydraulic oil tank should to topped up monthly. Oil levels

should

be strictly observed, for it is of primary importance for proper operation and long life.

(4) Power Source Connection :

A. Power Source - This machine is equipped with 7.5HP main motor and 2HP hydraulic motor, and

1/8HP coolant pump. Connect the power supply cable to the circuit breaker (N.F.B.) terminals.

The power supply to your machine should agree with the wring voltage that is indicated on the label

attached to the electrical enclosure and main motor.

B. Earth - Be sure to connect the earth cable to the earth terminal.

C. Starting - After making the necessary wiring connections, turn the power switch on the control panel

clockwise to turn power on, depress the vise limit switch (if necessary, e.g. if there is no stock bar clamped

in the vise) and push the button to see if the saw head moves upward.

If the saw head does not rise , the hydraulic pump motor is rotating in the wrong direction.

If the motor runs in the wrong direction, turn off the power switch and disconnect the power supply cable,

Then interchange any two phase connections.

3 ─ 3

4. OPERATION

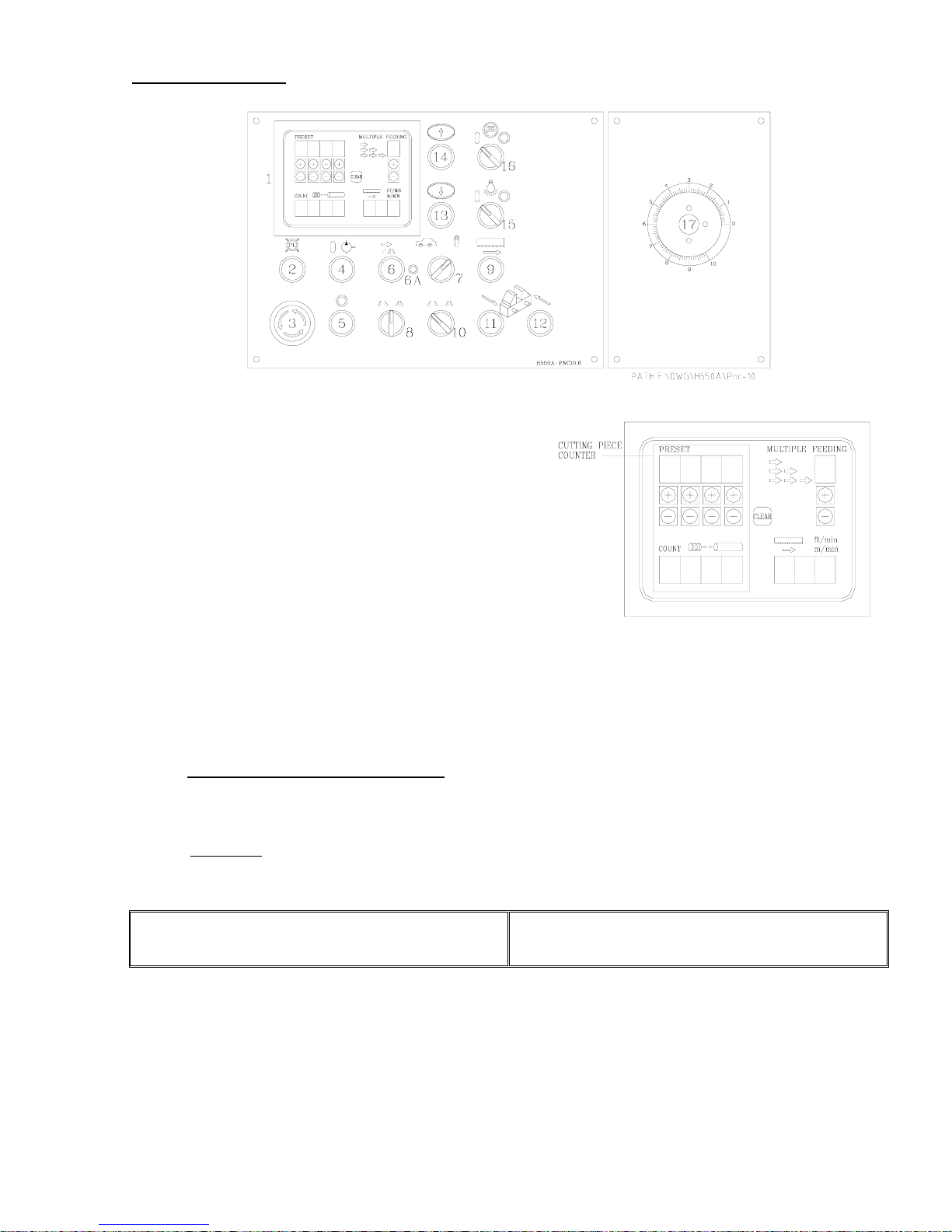

4.1 Control Panel

(1) PNC Control Panel

Cutting Piece Counter – This counter is used to preset

the number of cuts required on the automatic operation.

When the counter reaches the preset number, the machine

stops automatically . To activate the counter, preset the

counter switch with number at least “1”.

Clear – This key is used to clear the counted number cut

already and to have new number input available.

Multiple stroke feed counter – This counter makes it

possible to multiply the number of index cycles when off-cut pieces longer than 500mm are required.

Maximum 9-time stroke can be set.

Blade speed LED-Display -- This blade speed tachometer indicates how fast the saw blade is running in

meter per minute by LED display.

To see digital cut length counter

L (length req.) + K (blade thickness)

S =

N (multiple feed times)

- K

EXAMPLE:

1200 +1.5

S =

3

-1.5 = 400.5-1.5 = 399

L = Required cut length N = Multiple feeding times

K = Cutting loss ( Blade thickness ) S = Digital counter length setting

Total bar feed needed = length + blade thickness

Single step feed = length + K

Multiple step feed only needs 1 allowance for blade

Thickness ...hence…L + K divided by number of steps

Then less K = Digital counter setting length….

4 - 1

Loading...

Loading...