Page 1

ACC5703

Operating Instructions

inertialSENSOR ACC5703

MICRO-EPSILON MESSTECHNIK GmbH & Co. KG

Königbacher Str. 15 · 94496 Ortenburg / Germany

Tel. +49 (0) 8542 / 168-0 · Fax +49 (0) 8542 / 168-90

info@micro-epsilon.de · www.micro-epsilon.com

Page 2

3-axes acceleration sensor

MICRO-EPSILON

MESSTECHNIK

GmbH & Co. KG

Königbacher Strasse 15

94496 Ortenburg / Germany

Tel. +49 (0) 8542 / 168-0

Fax +49 (0) 8542 / 168-90

e-mail info@micro-epsilon.de

www.micro-epsilon.com

Page 3

Contents

1. Safety ........................................................................................................................................ 5

1.1 Symbols Used ................................................................................................................................................. 5

1.2 Warnings .......................................................................................................................................................... 5

1.3 Notes on CE Marking ...................................................................................................................................... 6

1.4 Intended Use ................................................................................................................................................... 6

1.5 Proper Environment ......................................................................................................................................... 7

2. Functional Principle, Technical Data ...................................................................................... 8

2.1 Functional Principle ........................................................................................................................................ 8

2.2 Structure and Electrical Connection................................................................................................................ 8

2.3 Technical Data ................................................................................................................................................. 9

3. Delivery .................................................................................................................................. 12

3.1 Unpacking, Included in Delivery.................................................................................................................... 12

3.2 Storage ......................................................................................................................................................... 12

4. Installation and Assembly ...................................................................................................... 13

4.1 Sensor Cable Assembly ................................................................................................................................ 13

4.2 Sensor Assembly ........................................................................................................................................... 13

4.3 Pin Assignment .............................................................................................................................................. 15

4.4 Current and Voltage Output .......................................................................................................................... 15

4.5 Configuration of Sampling Rate and Low- and High-pass Filter .................................................................. 19

4.6 Digital Output RS485 ..................................................................................................................................... 20

5. Operation ................................................................................................................................ 21

6. Liability for Material Defects ................................................................................................. 21

4.4.1 Continuous Operation Mode ........................................................................................................ 16

4.4.2 Switching Operation Mode ........................................................................................................... 17

ACC5703

7. Service, Repair ...................................................................................................................... 22

8. Decommissioning, Disposal ................................................................................................. 22

Page 4

Appendix

A 1 Accessories ............................................................................................................................ 23

A 2 PC Software sensorTOOL ...................................................................................................... 23

A 3 Factory Settings ..................................................................................................................... 23

A 4 Digital Interface RS485 .......................................................................................................... 24

A 4.1 Hardware Interface ........................................................................................................................................ 24

A 4.2 Protocol .......................................................................................................................................................... 24

A 4.2.1 Reading Measurement Data......................................................................................................... 25

A 4.2.2 Example Transmission of a Measurement Value ......................................................................... 29

ACC5703

Page 5

Safety

1. Safety

System operation assumes knowledge of the operating instructions.

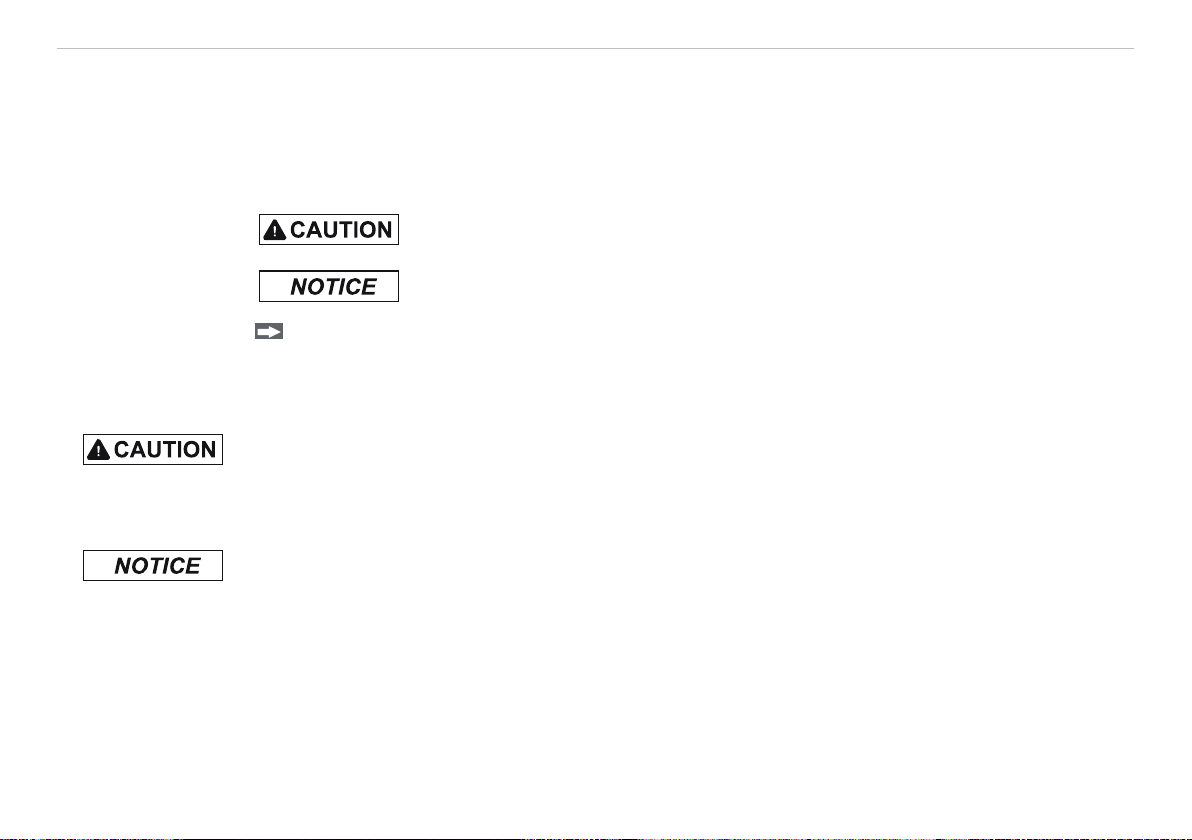

1.1 Symbols Used

The following symbols are used in these operating instructions:

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury.

Indicates a situation that may result in property damage if not avoided.

Indicates a user action.

i

1.2 Warnings

Connect the power supply and the display/output device according to the safety regulations for electrical

equipment.

> Risk of injury

> Damage to or destruction of the sensor

The supply voltage must not exceed the specified limits.

> Damage to or destruction of the sensor

Indicates a tip for users.

ACC5703

No sharp or heavy objects should be allowed to affect the cables. Avoid folding the cables. Do not bend

more tightly than the minimum bending radius of the cables.

> Damage or destruction of the cable, failure of the measuring device

Do not crush the cable. Protect the sensor cable against damage.

> Damage or destruction of the cable, failure of the measuring device, data loss

Ensure that the coupling nuts of the connectors are firmly tightened.

> Damage or destruction of the cable, failure of the measuring device

Page 5

Page 6

Safety

1.3 Notes on CE Marking

The following apply to the ACC5703:

- EU Directive 2014/30/EU

- EU Directive 2011/65/EU

Products which carry the CE mark satisfy the requirements of the EU directives cited and the European

harmonized standards (EN) listed therein. The EU Declaration of Conformity is available to the responsible

authorities according to EU Directive, article 10, at:

MICRO-EPSILON MESSTECHNIK

GmbH & Co. KG

Königbacher Straße 15

94496 Ortenburg /Germany

The measuring system is designed for use in industrial environments and meets the requirements.

1.4 Intended Use

The ACC5703 is designed for use in industrial applications. It is used for

measuring acceleration

measuring vibration of manoeuvrable components

- The system must only be operated within the limits specified in the technical data, see 2.3.

- The sensor must be used in such a way that no persons are endangered or machines and other material

goods are damaged in the event of malfunction or total failure of the sensor.

- Take additional precautions for safety and damage prevention in case of safety-related applications.

ACC5703

Page 6

Page 7

Safety

1.5 Proper Environment

- Protection class: 1 IP 67

- Operating temperature: -40 ... +85 °C (-40 ... +185 °F)

- Storage temperature: -40 ... +85 °C (-40 ... +185 °F)

- Ambient pressure: Atmospheric pressure

1) With M12 connector

ACC5703

Page 7

Page 8

Functional Principle, Technical Data

2. Functional Principle, Technical Data

2.1 Functional Principle

With the principle of an acceleration sensor, forces that change the velocity of an object are measured and

transformed into an electric output signal.

Therefore the sensor is mounted on the maneuverable component. The expected moves correspond to the

measurement axes. The included MEMS-Element converts the acceleration into a usable electric signal.

-z

Fig. 1 Three axes acceleration sensor

2.2 Structure and Electrical Connection

The sensor is ready for operation immediately after connecting the power supply and will provide the acceleration as electric value at the analog output.

The ACC5703 is available with analog (current, voltage and switching output) as well as RS485 interface for

configuring of the sensor using the software.

Power supply and signal output are connected through a 8-contact (M12) connector on the sensor’s housing.

+z

+y

-y

+x

-x

ACC5703

Page 8

Page 9

Functional Principle, Technical Data

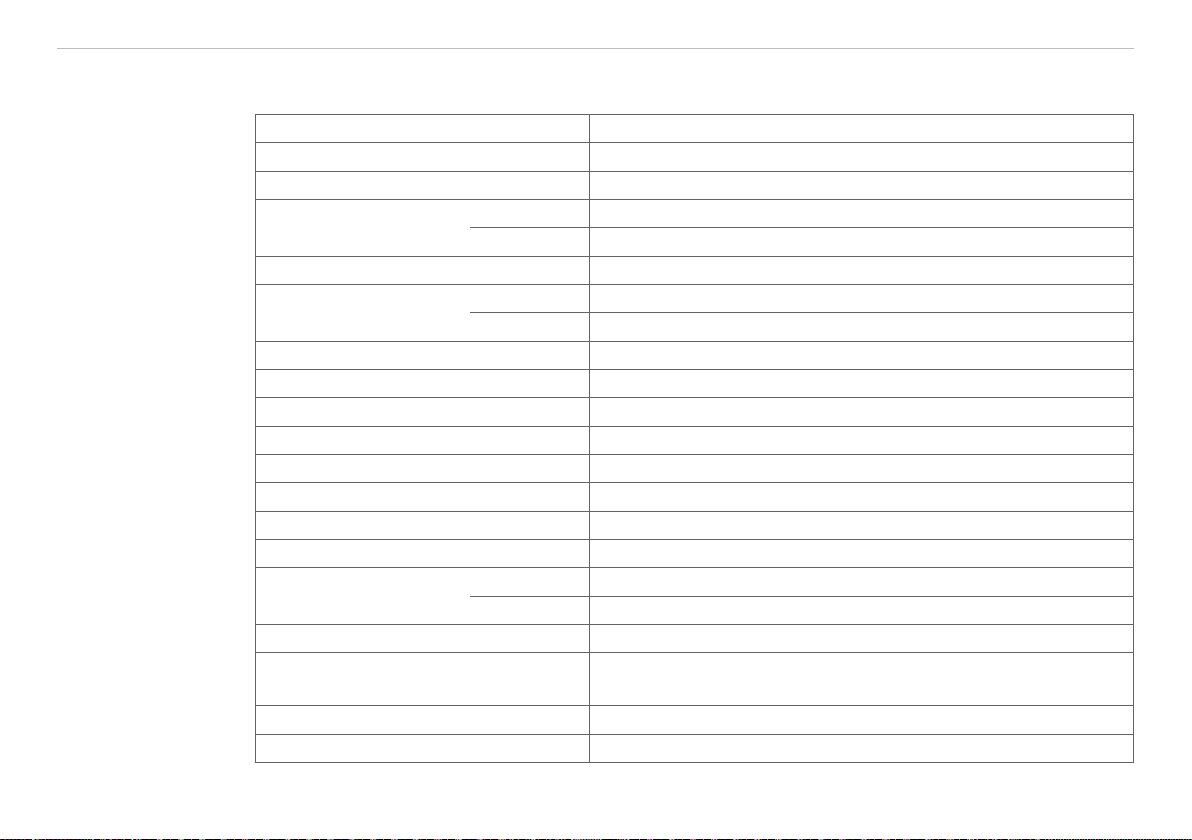

2.3 Technical Data

Model

Number of axes

Measuring range

Resolution

Noise

Sensitivity

(analog output)

Zero

Linearity

Frequency range

Sampling rate

Cross axis sensitivity

Temperature stability

Supply voltage

Power consumption

Temperature range

Digital interface

Analog output

Switching output

Protection class

Digital

Analog

Current

Voltage

Operation

Storage

ACC5703-8

3

± 0 g … ± 8 g (configurable)

0.016 mg

Current: < 0.24 mg / voltage < 0.31 mg

Typ. 30 µg / √Hz

< 4 mA/g

< 1 V/g

12 mA or 2.5 V

Typ. 0.45 % FSO

0 ... 1000 Hz (configurable)

Up to 4 kHz

1 % FSO

Typ. ± 0.2 mg / K

5 … 32 VDC

< 3 W

-40 … +85 °C (-40 ... +185 °F)

-40 … +85 °C (-40 ... +185 °F)

RS485

Current 4 … 20 mA (max. 390 Ω)

Voltage 0.5 … 4.5 V (min. 1 KΩ)

0 / 5 V (min. 1 KΩ)

IP 67 (plugged state)

ACC5703

Page 9

Page 10

Functional Principle, Technical Data

Model

Shock

Weight

Material

Installation

Connection

Start-up time

FSO = Full Scale Output

All specifications valid at a room temperature of +25 °C (+77 °F)

Article designation

ACC 5703 -8 -SA -U/I

Output

U = voltage 0.5 ... 4.5 V,

I = current 4 ... 20 mA,

switching output 0 / 5 V

Connection:

SA = axial plug

Measuring range in g

High Performance acceleration sensor

(1500 g, 0.5 ms, half-sine shock, 3 x in each direction)

Screw connection via mounting holes (M4)

ACC5703-8

DIN EN 60068-2-27

Approx. 250 g

Die-cast aluminum

M12 connector, 8-pin

< 500 ms

ACC5703

Page 10

Page 11

Functional Principle, Technical Data

Response time

Sampling frequency [Hz] Time [ms]

4000 0.88

2000 1.25

1000 2.03

500 3.51

250 6.52

125 12.59

62.5 24.43

31.25 47.84

15.625 96.5

7.813 189.83

3.906 384.56

Fig. 2 Table response time

ACC5703

Page 11

Page 12

Delivery

3. Delivery

3.1 Unpacking, Included in Delivery

1 Sensor ACC5703

1 Operating Instructions

Carefully remove the components of the measuring system from the packaging and ensure that the

goods are forwarded in such a way that no damage can occur.

Check the delivery for completeness and shipping damage immediately after unpacking.

If there is damage or parts are missing, immediately contact the manufacturer or supplier.

Optional accessories are available in the appendix, see A 1.

3.2 Storage

Storage temperature: -40 ... +85 °C (-40 ... +185 °F)

Humidity: 5 - 95 % (non-condensing)

ACC5703

Page 12

Page 13

Installation and Assembly

4. Installation and Assembly

4.1 Sensor Cable Assembly

No sharp or heavy objects should be allowed to affect the cables. Avoid folding the cables. Do not bend

more tightly than the minimum bending radius of the cables.

> Damage or destruction of the cable, failure of the measuring device

Do not crush the cable. Protect the sensor cable against damage.

> Damage or destruction of the cable, failure of the measuring device

Ensure that the coupling nuts of the connectors are firmly tightened.

> Damage or destruction of the cable, failure of the measuring device

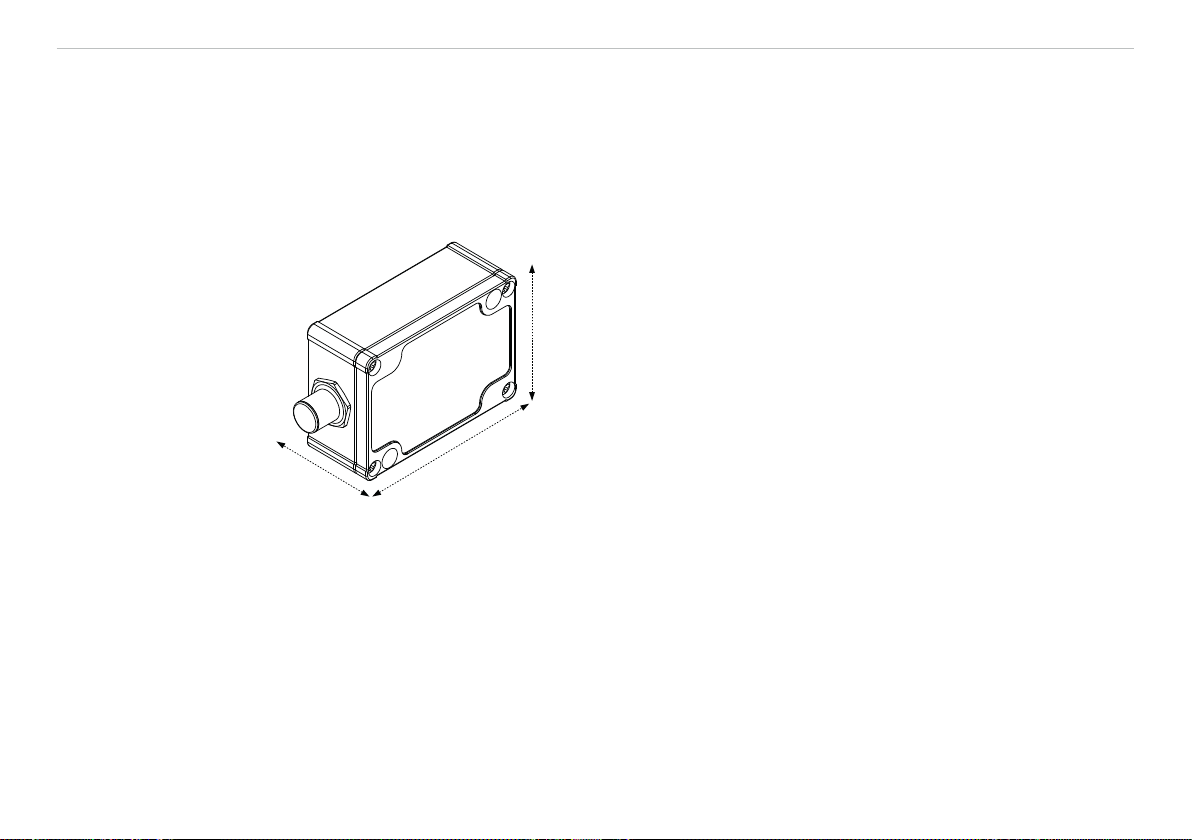

4.2 Sensor Assembly

The sensor is fixed into place with the help of two through bores for M4 screws.

The sensor is mounted at the manoeuvrable component. The orientation of the measurement axes x, y, z is to

be respected in relation to the expected moves of the component.

+y

ACC5703

-y

+x

-z

-x

+z

Fig. 3 Installation orientation, measurement axis

Page 13

Page 14

Installation and Assembly

12.5 (.49)

12 (.47)

5.5 (.22)

ACC5703

Mounting holes

for M4 screws

53 (2.09)

5.5 (.22)

12 (.47)

76 (2.99)

Fig. 4 Dimensional drawing, dimensions in mm (inches), not to scale

26.5 (1.04)

6 (.24)

24 (.94)

Page 14

Page 15

Installation and Assembly

4.3 Pin Assignment

Connect the open cable end in accordance with the color coding, see Fig. 5.

Pin 1Color

2

Description

45 °

1 White Output channel 2

2 Brown GND (Output)

3 Green Output channel 3

2

3

4

8

1

4 Yellow RS485+

5 Gray Output channel 1

6 Black/pink GND (Supply)

5

7

6

7 Blue RS4858 Red Supply + View of solder pin side, 8-pin,

A-coded, female connector

Fig. 5 Pin assignment of the 8-pin, A-coded, female connector

1) - SA - Connector

2) PCx/8-M12 Power supply and output cable, see A 1.

4.4 Current and Voltage Output

The sensor makes the acceleration value available as analog output variable either as current or voltage

value on separate pins.

Three output channels can be configured independently with the following settings.

Each output channel can be operated in continuous operation mode or switching operation mode.

Versorgungsspannung 5 - 32 V

Analogausgangskanal 1

Sensor

Analogausgangskanal 2

Analogausgangskanal 3

Digitalausgang RS485

ACC5703

Fig. 6 Current and voltage output

Page 15

Page 16

Installation and Assembly

Selection of measurement axis (x, y, z) at every channel possible

Off (zero output)

Continuous mode, current 4 - 20 mA

Continuous mode, voltage 0.5 - 4.5 V

Switching mode, voltage 0 - 5 V

Fig. 7 Operation modes of the analog output channels

4.4.1 Continuous Operation Mode

The sensor makes the acceleration value available as analog output variable either as current or voltage

value on separate pins, depending on the configuration using the software tool of Micro-Epsilon.

In this process, the symmetrical measurement range in the unit g is scaled to the respective analog range.

The sensitivity increases with decreasing measurement range as only a small acceleration range is scaled to

the same output range, see Fig. 8, see Fig. 9.

ACC5703

20

18

16

14

12

10

8

6

Current in mA

4

-2 g

-4 g

-8 g

0 g

Acceleration in g

+2 g

+4 g

+8 g

5

4.5

4

3.5

3

2.5

2

1.5

Voltage in V

1

0.5

0

-2 g

-4 g

-8 g

0 g

Acceleration in g

Fig. 8 Scaling of the acceleration measurement range to analog output variable current or voltage

+2 g

+4 g

+8 g

Page 16

Page 17

Installation and Assembly

Range digital [g] Resolution digital

RS485 [mg]

Resolution analog

current [mg]

Resolution analog

voltage [mg]

Sensitivity analog

current [mA/g]

Sensitivity analog

voltage s[V/g]

±2 0.004 0.06 0.076 4.0 1.0

±4 0.008 0.12 0.15 2.0 0.5

±8 0.016 0.24 0.31 1.0 0.25

Fig. 9 Examples of resolution (mg) and sensitivity (mA/g) depending on the configured measurement range

4.4.2 Switching Operation Mode

The switching mode, configurable via Software, switches the analog voltage output to 5 V when the acceleration value reaches

the trigger-level “on-level” and switches back to 0 V when the acceleration value falls below the “off-level”.

Selection of measurement axis (x, y, z) (vector addition (xy, xz, yz, xyz)

(x

2

+ y

2

2

possible at every channel)

+ z

)

On-level [g] Switching hysteresis

Off-level [g] Rise- / Fall-time < 10 μs

Edge triggered (switching when reaching the level considering the minimum hold time, see Fig. 13)

Edge triggered with delay (switching after specified time during which the level is reached permanently)

Fig. 10 Settings of switching mode

That functionality can be used, for example, as safety feature which switches off a machine if high vibrations occur. The triggerlevels take effect symmetrically, i.e. in the positive and negative acceleration range at the same absolute value, see Fig. 11.

The output values at the digital interface in switching mode are either zero or equal to the “on-level” as long as the trigger condition is met.

The duration of the rising and falling edge is t < 10 μs, see Fig. 12.

Two different modes are selectable:

- Edge triggered, i.e. immediate switching when reaching the trigger-level.

- Edge triggered with delay, i.e. switching after specified time during which the trigger-level is reached permanently.

The minimum hold time of the switching status depends on the selected sampling rate, see Fig. 13.

ACC5703

Page 17

Page 18

Installation and Assembly

5

4.5

4

3.5

3

2.5

2

1.5

Voltage in V

1

0.5

0

-2 g

on-level off-level off-level on-level

-4 g

-8 g

0 g

Acceleration in g

+2 g

+4 g

+8 g

Fig. 11 Hysteresis of the trigger-levels in switching

operation

5

4.5

4

3.5

3

2.5

2

Trigger

1.5

Voltage in V

1

0.5

Trigger

Sampling rate (Hz) Minimum hold time of

switching status (ms)

4000 25

2000 25

1000 25

500 26

250 28

125 32

62.5 32

31.25 32

15.625 64

7.8125 128

3.90625 256

Fig. 13 Minimum hold time of the switching status

0

5 10 15

0

20 25

30

35 40 45

50

t in µs

Fig. 12 Rising and falling edge of the voltage output in

switching mode, t < 10 µs

ACC5703

Page 18

Page 19

Installation and Assembly

Amplitude in g

4.5 Configuration of Sampling Rate and Low- and High-pass Filter

Parameters, like sampling rate or filter frequencies, are adaptable in a wide range in order to match the respective application.

The high-pass is configured to reduce influences of low frequencies especially to hide earth acceleration. The

low-pass is configured to hide disturbances at high frequency.

ACC5703

1

Frequency in Hz

Fig. 14 Configuration of filter to reduce influences

2

1 Highpass to hide earth acceleration

2 Lowpass to hide disturbances

Page 19

Page 20

Installation and Assembly

Different low-pass filter settings, see Fig. 15, cause the sampling rate to change respectively. The chosen lowpass frequencies furthermore have influence on the available high-pass filter options.

Low-pass f

(configurable)

1000 4000

500 2000

LP

[Hz]

Sampling rate [Hz] High-pass f HP [Hz]

(optional, configurable)

1

1

0.00952 … 9.88

0.00476 … 4.94

250 1000 0.00238 … 2.47

125 500 0.00119 … 1.235

62.5 250 0.000595 … 0.6175

31.25 125 0.0002975 … 0.30875

15.625 62.5 0.00014875 … 0.154375

7.813 31.25 7.4375e-5 … 0.0771875

3.906 15.625 3.71875e-5 … 0.03859

1.953 7.813 1.859e-5 … 0.0193

0.977 3.906 9.296e-6 … 0.009648

Fig. 15 Table dependency between sampling rate and low- and high-pass settings

1) Digital interface RS485 is enabled only up to 1000 Hz sampling rate. At higher rates only the analog output

is active.

4.6 Digital Output RS485

You can read out the measured data in digital form using the RS485 interface in a sampling rate up 1000 Hz.

For higher sampling rates only the analog operation is possible. The PC software sensorTool, see A 2,

permits configuration of the sensor and the visualization of the measured data, see A 1. The bus protocol

required to read out the measured data in your own applications is described in the appendix, see A 4.

Additionally, you can use the IF1032/ETH interface converter by MICRO-EPSILON MESSTECHNIK GmbH &

Co. KG, to read out the measured data via Ethernet.

ACC5703

Page 20

Page 21

Operation

5. Operation

The measurement device is already calibrated when delivered. Calibration by the user is not necessary. After

connection to the operating voltage, the sensor is immediately ready for operation and independently initiates

the measurement.

Additionally, the digital RS485 interface is ready to react to enquiries by the master (periodic retrieval of measured data).

For sensor configuration please use the power supply and output cable with USB/RS485 converter, see A 1

as well as the software of MICRO-EPSILON.

Allow the sensor to warm up for approximately 10 minutes after connection of the voltage supply.

i

6. Liability for Material Defects

All components of the device have been checked and tested for functionality at the factory. However, if defects occur despite our careful quality control, MICRO-EPSILON or your dealer must be notified immediately.

The liability for material defects is 12 months from delivery.

Within this period, defective parts, except for wearing parts, will be repaired or replaced free of charge, if the

device is returned to MICRO-EPSILON with shipping costs prepaid. Any damage that is caused by improper

handling, the use of force or by repairs or modifications by third parties is not covered by the liability for material defects. Repairs are carried out exclusively by MICRO-EPSILON.

Further claims can not be made. Claims arising from the purchase contract remain unaffected. In particular,

MICRO-EPSILON shall not be liable for any consequential, special, indirect or incidental damage. In the interest of further development, MICRO-EPSILON reserves the right to make design changes without notification.

For translations into other languages, the German version shall prevail.

ACC5703

Page 21

Page 22

Service, Repair

7. Service, Repair

If the sensor is defective, please send us the affected

parts for repair or exchange.

If the cause of a fault cannot be clearly identified, please

send the entire measuring system to:

MICRO-EPSILON MESSTECHNIK

GmbH & Co. KG

Königbacher Str. 15

94496 Ortenburg / Germany

Tel. +49 (0) 8542 / 168-0

Fax +49 (0) 8542 / 168-90

info@micro-epsilon.de

www.micro-epsilon.com

8. Decommissioning, Disposal

Remove the power and output cable from the sensor.

Incorrect disposal may cause harm to the environment.

Dispose of the device, its components and accessories, as well as the packaging materials in compli-

ance with the applicable country-specific waste treatment and disposal regulations of the region of use.

ACC5703

Page 22

Page 23

Appendix | Accessories

Appendix

A 1 Accessories

Designation Description

PC3/8-M12 Power supply and output cable, 3 m long

PC5/8-M12 Power supply and output cable, 5 m long

PC10/8-M12 Power supply and output cable, 10 m long

PC10/8-M12 Power supply and output cable, for drag chain use, 10 m long

PC15/8-M12 Power supply and output cable, 15 m long

PC2/8-Sub-D Power supply and output cable with USB / RS485 converter, 2,8 m long

A 2 PC Software sensorTOOL

You will find the software for the sensor for free at:

www.micro-epsilon.com

A 3 Factory Settings

Low-pass filter: 62,5 Hz

Sampling rate: 250 Hz

High-pass filter: Disabled

Measurement range: ±2 g

Sensitivity: 4 mA/g or 1 V/g

Output signal: 4 ... 20 mA

Active axes: Channel 1: “x”, channel 2: “y”, channel 3: “z”, see Fig. 3

ACC5703

Page 23

Page 24

Appendix | Digital Interface RS485

A 4 Digital Interface RS485

A 4.1 Hardware Interface

The interface is a half-duplex RS485 interface, which means that one cable pair is jointly used for sending and

receiving.

Baud rate 230400 b/s

Data format 1 start bit, 8 data bits, 1 parity bit even, 1 stop bit

Bus address 126

Fig. 16 Settings of the RS485 interface

A terminating resistance of 120 Ω is required between the A- and B-line of the RS485 interface at the beginning and the end of the RS485 bus. A terminating resistor of the RS485 line is not incorporated in the sensor.

It is therefore allowed to connect several sensors to one bus cable.

A 4.2 Protocol

The sensor acts as RS485 slave. As the system uses a half-duplex protocol, only the master can initiate

communication. Each device at the RS485 bus requires its own address. The master sends an enquiry with

the destination address to the bus and only the slave with this address answers accordingly.

ACC5703

Page 24

Page 25

Appendix | Digital Interface RS485

A 4.2.1 Reading Measurement Data

Master: Request data

Byte: SD DA SA FC FCS ED

Value: 0x10 x x 0x4C x 0x16

Slave: Response data

Byte: SD LE LE

Value: 0x68 x x 0x68 x x 0x08 x x 0x16

Designations

SD Start Delimiter

LE Length (number of bytes without SD, LE, LE rep, SD rep, FCS, ED)

LE rep LE repeated

SD rep SD repeated

DA Destination Address (default 0x7E = 126)

SA Source Address (e. g. 0x01)

FC Function Code

FCS Checksum

ED End Delimiter

Data[] Measurement data, variable number, little endian

The measurement data consists of one status byte, one measured values counter, number of measured values, and the measured data. The measured values counter increases continuously with each sampled value.

It represents the number of measured values buffered in the sensor since the last enquiry by the master and

therefore represents the number of the measured values transmitted in this package (floats).

FCS

SD

rep

(0x10: datagram without data, 0x68: datagram with variable length)

(sum of all bytes without SD, LE, LE rep, SD rep, FCS, ED, overflow at 256)

rep

DA SA FC Data[] FCS ED

FCS

ACC5703

Page 25

Page 26

Appendix | Digital Interface RS485

A new sampled measurement value is saved to the internal buffer of the sensor. The maximum number of

values which can be saved is 19 for each measurement axis. Therefore, an enquiry by the master must reach

the sensor within a certain time, that depends on the set sampling rate, in order to read the content from the

internal memory and ensure uninterrupted sampling (periodic enquiry).

- Example 1 kHz: 19 values * 1 ms = 19 ms

- Example 250 Hz: 19 values * 4 ms = 76 ms

If the enquiries are not made in time, error flag 0x01 is set in the status byte. The measurement is continued

anytime, i.e. the values in the buffer which are not read will be overwritten with updated measurements. The

buffer content is, therefore, always updated. The overflow error flag is deleted automatically as soon as the

master resumes its periodic enquiries.

The analog output remains unaffected by this. The first measurement value in the Data[] package is the oldest measured value. A measured value is represented as 4-byte float data type in the unit [g]1.

ACC5703

1 g = 9.81

1)

m

2

s

Page 26

Page 27

Appendix | Digital Interface RS485

Byte Meaning Data format

Data[0] Status byte (contains error flags, normally 0x00 8 bit

Data[1] Long term values counter [bit 0:7] Uint 32 bit

Data[2] Long term values counter [bit 8:15]

Data[3] Long term values counter [bit 16:23]

Data[4] Long term values counter [bit 24:31]

Data[5] Number of measured values in this package 8 bit

Data[6] Padding byte 8 bit

Data[7] Padding byte 8 bit

Data[8] Measured value 1 [bit 0:7] Float 32 bit

Data[9] Measured value 1 [bit 8:15]

Data[10] Measured value 1 [bit 16:23]

Data[11] Measured value 1 [bit 24:31]

Data[12] Measured value 2 [bit 0:7] Float 32 bit

Data[13] Measured value 2 [bit 8:15]

Data[14] Measured value 2 [bit 16:23]

Data[15] Measured value 2 [bit 24:31]

... ... ...

Data[n]

n=8+(4*Data [5])

Data[n+1] Measured value 1 y-axis [bit 8:15]

Data[n+2] Measured value 1 y-axis [bit 16:23]

Data[n+3] Measured value 1 y-axis [bit 24:31]

Measured value 1 y-axis [bit 0:7] Float 32 bit

ACC5703

Page 27

Page 28

Appendix | Digital Interface RS485

Byte Meaning Data format

Data[n+4] Measured value 1 y-axis [bit 0:7] Float 32 bit

Data[n+5] Measured value 1 y-axis [bit 8:15]

Data[n+6] Measured value 1 y-axis [bit 16:23]

Data[n+7] Measured value 1 y-axis [bit 24:31]

... ... ...

Data[n+m]

m=4*Data[5]

Data[n+m+1] Measured value 1 z-axis [bits 8:15]

Data[n+m+2] Measured value 1 z-axis [bits 16:23]

Fig. 17 Encoding of Measured Data in the Transmission Protocol

Measured value 1 z-axis [bits 0:7] Float 32 bit

ACC5703

Page 28

Page 29

Appendix | Digital Interface RS485

A 4.2.2 Example Transmission of a Measurement Value

Master: Request data

Byte: SD DA SA FC FCS ED

Value: 0x10 0x7E 0x01 0x4C 0xCB 0x16

DA = Destination Address = 0x7E = 126 (slave address)

SA = Source Address = 0x01 (master address)

FCS = Checksum = 0x7E + 0x01 + 0x4C = 0xCB

Slave: Response data

Byte: SD LE LE

Value: 0x68 1B 1B 0x68 0x01 0x7E 0x08 x 0x67 0x16

4 measured values = 4 x float = 4 x 4 bytes = 16 data bytes

LE = Length = 16 data bytes + 11 bytes (DA, SA, FC, 1xstatus, 4xstatus, 4xcounter, 1xnumber, 2xpadding

byte) = 0x1B = 27

DA = Destination Address = 0x01 (Master)

SA = Source Address = 0x7E = 126 (Slave)

FCS = Checksum = 0x01 + 0x7E + 0x08 + 0x00 (status) + 0x04 (counter) ... = 0x67 (note overflow at 256

each time = reset sum to zero)

FCS

= 126 + 1 + 76 = 203 (no overflow) at 256)

rep

SD

rep

DA SA FC Data[] FCS ED

FCS

ACC5703

Page 29

Page 30

MICRO-EPSILON MESSTECHNIK GmbH & Co. KG

Königbacher Str. 15 · 94496 Ortenburg / Germany

Tel. +49 (0) 8542 / 168-0 · Fax +49 (0) 8542 / 168-90

info@micro-epsilon.de · www.micro-epsilon.com

X9751392-A011068HDR

MICRO-EPSILON MESSTECHNIK

*X9751392-A01*

Loading...

Loading...