PELLET STOVES

INSTALLATION AND USE MANUAL

Index

page

1

INTRODUCTION ....................................................................................................................................3

1. WARNINGS AND GUARANTEE CONDITIONS.....................................................................................5

1.1. SAFETY WARNINGS........................................................................................................................5

1.2. OPERATING WARNINGS..................................................................................................................6

1.3. GUARANTEE CONDITIONS ..............................................................................................................7

1.3.1. Limitations...............................................................................................................................7

1.3.2. Exclusions................................................................................................................................7

2. THEORETICAL NOTIONS ON INSTALLATION....................................................................................9

2.1. PELLETS ........................................................................................................................................9

2.2. PRINCIPLES OF OPERATION ..........................................................................................................10

2.2.1. Section plane of an MCZ pellet stove ........................................................................................11

2.3. WORKING ENVIRONMENT.............................................................................................................12

2.4. PRECAUTIONS..............................................................................................................................13

2.5. CONNECTION TO THE EXTERNAL AIR INTAKE................................................................................13

2.6. CONNECTION OF THE SMOKE DISCHARGE PIPE............................................................................. 14

2.7. CONNECTION TO THE FLUE PIPE...................................................................................................15

2.8. CONNECTION TO AN EXTERNAL FLUE WITH INSULATED OR DOUBLE-SKINNED PIPE........................15

2.9. CONNECTION TO FLUE PIPE OR SMOKE DUCT ...............................................................................15

2.10. OPERATING ABNORMALITIES DUE TO FLUE DRAUGHT PROBLEMS...............................................16

ENGLISH

3. INSTALLATION AND ASSEMBLY......................................................................................................17

3.1. DRAWINGS AND TECHNICAL CHARACTERISTICS............................................................................17

3.1.1. SATURN ................................................................................................................................17

3.1.2. OMEGA..................................................................................................................................18

3.1.3. PLANET.................................................................................................................................19

3.1.4. MERCURY..............................................................................................................................20

3.1.5. TECHNICAL CHARACTERISTICS...............................................................................................21

3.2. PREPARATION AND PACKAGING....................................................................................................22

3.3. INSTALLATION OF THE CERAMIC CLADDING FOR OMEGA-PLANET ..................................................23

3.4. ELECTRICAL CONNECTION............................................................................................................23

4. OPERATION .....................................................................................................................................24

4.1. WARNINGS PRIOR TO FIRST LIGHTING.........................................................................................24

4.2. CHECK PRIOR TO FIRST LIGHTING................................................................................................25

4.3. LOADING PELLETS........................................................................................................................25

4.4. CONTROL PANEL and REMOTE CONTROL.......................................................................................25

4.4.1. REM O T E C ONTR O L a n d BAT T E R Y R E P L A CEME N T........................................................................26

4.5. SETTINGS TO BE MADE PRIOR TO FIRST LIGHTING.......................................................................26

4.5.1. Setting current time................................................................................................................26

4.5.2. Scelta della lingua del display..................................................................................................27

4.6. SELECTION OF RECIPE .................................................................................................................27

4.6.1. HOW TO IDENTIFY THE RECIPE:.............................................................................................27

4.6.2. Procedure for recipe selection .................................................................................................29

4.6.3. Memorization of recipe on stove..............................................................................................29

4.7. FIRST LIGHTING ..........................................................................................................................29

4.7.1. Lighting from panel ................................................................................................................29

4.7.2. Lighting from remote control...................................................................................................30

4.7.3. Switching off from panel.........................................................................................................30

4.7.4. Switching off with the remote control.......................................................................................30

4.8. VIEWING THE FLAME....................................................................................................................31

4.8.1. The shape .............................................................................................................................31

4.8.2. The colour.............................................................................................................................31

4.8.3. Character ..............................................................................................................................31

4.9. OPERATING MODES......................................................................................................................32

4.9.1. Manual and automatic ............................................................................................................32

Index Technical service - Rights reserved MCZ S.p.A. –Reproduction prohibited

PELLET STOVES

INSTALLATION AND USE MANUAL

Index

page

2

4.9.2. Manual mode.........................................................................................................................32

4.9.2.1. Changing from manual to automatic mode.........................................................................33

4.9.3. Automatic mode.....................................................................................................................33

4.9.3.1. Internal digital thermostat (equipped in the stove) .............................................................33

4.9.3.2. External thermostat (optional) ..........................................................................................33

4.9.3.3. Changing from automatic to manual mode.........................................................................34

4.9.4. Automatic mode with ECO-STOP .............................................................................................34

4.9.4.1. ECO-STOP mode activation...............................................................................................35

4.9.5. Programmed mode.................................................................................................................35

4.9.5.1. Current date and clock.....................................................................................................35

4.9.5.2. Timer activation...............................................................................................................35

4.9.5.3. Programme.....................................................................................................................36

4.10. SAFETIES..................................................................................................................................38

4.10.1. Alarm indications ................................................................................................................39

4.10.2. Other alarm signals.............................................................................................................40

4.10.3. Lockout of the stove............................................................................................................40

4.11. SHUTTING DOWN THE STOVE ...................................................................................................41

5. MAINTENANCE AND CLEANING ......................................................................................................42

5.1. CLEANING TO BE DEALT WITH BY USER........................................................................................42

5.2. CLEANING TO BE DONE BY A SPECIALIZED TECHNICIAN ................................................................43

5.3. CHECK OF INTERNAL COMPONENTS..............................................................................................44

ENGLISH

6. PROBLEMS / CAUSES / SOLUTIONS ...............................................................................................45

7. ELECTRICAL DIAGRAMS AND SPARE PARTS...................................................................................47

7.1. ELECTRICAL DIAGRAM SATURN - OMEGA - PLAMET........................................................................47

7.2. ELECTRICAL DIAGRAM MERCURY ..................................................................................................48

7.3. Maintenance and/or replacement of the electronic board..................................................................49

7.4. SPARE PARTS COMMON TO SATURN, OMEGA AND PLANET.............................................................50

7.5. SPARE PARTS MERCURY ...............................................................................................................56

Index Technical service - Rights reserved MCZ S.p.A. –Reproduction prohibited

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

INTRODUCTION

Dear Customer,

We would like to thank you for the preference which you have decided

to bestow on MCZ products, and particularly for choosing one of the

MCZ Pellet range.

We are convinced that as you use it, you will appreciate the quality of

the product, which is the fruit of careful planning and meticulous

testing. Our object is to combine technological complexity with

simplicity of use, and, above all, with safety.

In order to get the best performance from your stove and to

enjoy to the full the warmth and the sense of well-being which

the flame will diffuse through the home, we recommend that

you read this booklet carefully before lighting the stove for the

first time.

Once you have learnt the basics, you will be able manage to best

advantage the various levels of power and the potential for presetting,

and you will also pick up a few little hints about cleaning and setting.

While thanking you again, may we remind you that the stove MUST

NOT be used by children, and that they must always be kept at a safe

distance from it!

page

3

ENGLISH

Revisions of this publication

In order to improve the product, the manufacturer reserves the right to

make modifications to this publication without any advance notice.

Even partial reproduction of this manual is prohibited without the

manufacturer's authorization.

Care of manual

• Take care of this manual and store it in a place that can be easily

and quickly reached

• If this manual is lost or destroyed, or if it is in any case in poor

condition, you may ask for another copy from your retailer or

directly form the manufacturer, specifying the product identification

data.

How to read the manual

• An essential item or one that requires special attention is shown in

"bold face print".

"Italics"

•

additional clarifications.

• NOTE: a "NOTE" provides the reader with additional information

on the topic.

are used for messages provided by the stove or for

Introduction Technical service - Rights reserved MCZ S.p.A. –Reproduction prohibited

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

The following symbols stand for specific messages in

this booklet

ATTENTION:

This warning sign, used at various points in this booklet,

indicates that the message to which it refers should be

carefully read and understood, because failure to comply

with what these notices say can cause serious

damage to the stove and put the user's safety at risk.

INFORMATION:

This symbol is intended to highlight important information

for the proper functioning of the stove. Failure to comply

with what these notices say will compromise the use of the

stove and is likely to result in unsatisfactory operation.

REFER TO MANUAL:

This symbol tells the final reader to refer to this use and

installation manual because there are specific instructions

concerning the operation to be performed.

SEQUENCE OF OPERATIONS:

This indicates a series of buttons to push to access a menu

or to make adjustments.

VIEW MESSAGES:

This symbol tells the user to view the messages shown on

the control display.

page

4

ENGLISH

Introduction Technical service - Rights reserved MCZ S.p.A. –Reproduction prohibited

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

1. WARNINGS AND GUARANTEE CONDITIONS

1.1. SAFETY WARNINGS

• Installation of the stove, making the electrical

connections, checking its operation, and

maintenance are all tasks which should be carried

out by qualified and authorised personnel.

• Install the stove in accordance with the

regulations in force in your local area, region and

country.

• For the correct use of the stove and of the electronic

apparatus connected to it, and to prevent accidents, the

instructions given in this booklet must always be

followed.

• In addition, adjustment and regulation must be carried

out by adults. Errors or incorrect settings can give rise

to hazardous conditions and/or bad running.

• Before beginning any operation, the user, or whoever is

preparing to work with the stove, must read and

understand the entire contents of this instruction

booklet.

• The stove must only be used for its intended purpose.

Any other use is to be considered improper and

therefore dangerous.

• Do not stand on the stove or use it as a support.

• Do not place laundry to dry on the stove. Laundry

hangers and the like must be placed at an appropriate

distance from the stove – there is a fire hazard.

• All responsibility for improper use is taken entirely by

the user and such use relieves MCZ of any civil or

criminal responsibility.

• Any kind of tampering or unauthorised substitution of

non-original spare parts can be hazardous for the safety

of the operator and relieves MCZ of any civil or criminal

responsibility.

• A number of the surfaces of the stove are hot (door,

handle, glass, smoke outlet pipes, etc.). It is therefore

necessary to avoid touching these parts without suitable

safety gear, for example insulated gloves or handprotection systems.

• Carefully explain this hazard to elderly people, disabled

people and particularly to all children, keeping them

away from the stove while it is running.

• The stove must not be operated with the door

open or the glass broken.

• Do not touch the stove with wet hands, in view of the

fact that it is an electrical appliance. Always disconnect

the supply cable before doing anything to the unit.

• Before carrying out any cleaning or maintenance

operation, make sure in advance that the stove is

disconnected from the mains electricity supply, by

turning off the main switch located on the back of the

stove, or by unplugging the supply cable.

page

5

ENGLISH

Warning and guarantee conditions Technical service – Rights reservedMCZ S.p.A. Reproduction prohibited

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

6

• The stove must be connected to an electrical system

which is equipped with an earth conductor, as laid down

in directives 73/23 EEC and 93/98 EEC.

• The system must be of adequate rated capacity for the

stated electrical power of the stove.

• Incorrect installation or faulty maintenance (not

conforming to the requirements set out in this booklet)

can cause harm to people, animals or property. In such

cases MCZ is absolved from any civil or criminal

responsibility.

1.2. OPERATING WARNINGS

• Shut the stove down in the event of a breakdown or

poor operation.

• Pellets must not be fed manually into the burner.

• The accumulation of unburned pellets in the burner

after repeated "ignition failures" must be removed

before lighting.

• Do not wash the inside of the stove with water.

• Do not wash the stove with water. Water may get into

the inside of the unit and damage the electrical

insulation, causing electrical shock.

• Do not expose the body to hot air for extended periods.

Do not overheat the room where you are and where

the stove is located. This may cause physical harm and

pose a health hazard.

• Do not expose plants and animals directly to the flow of

hot air. This may be harmful to plants and animals.

• Do not put anything in the hopper other than wood

pellets.

• Install the stove in a location which is suitable for

firefighting, and equipped with all services such as air

and electricity supply and provision for discharging

combustion gases.

• If the stove and the ceramic cladding are in storage, it

should be in a place that is free of humidity, and they

should not be exposed to temperature extremes.

• It is inadvisable to base the stove directly on the floor,

and if the floor is made of flammable material, it must

be suitably insulated.

• Do not light the stove with flammable materials if the

ignition system breaks down.

INFORMATION:

• In case of any problems, get in touch with your dealer,

or a qualified engineer authorised by MCZ, and if a

repair is necessary, insist on the use of original spare

parts.

• Only fuel recommended by MCZ must be used (for Italy

only pellets with a diameter of 6mm, for other European

countries with a diameter of 6-8mm) and provided

exclusively by the automatic supply system.

ENGLISH

Warning and guarantee conditions Technical service – Rights reservedMCZ S.p.A. Reproduction prohibited

INSTALLATION AND USE MANUAL

• Periodically check and clean the smoke outlet ducts

(connection to the flue pipe).

• The accumulation of unburned pellets in the burner after

repeated "ignition failures" must be removed before

lighting.

• The pellet stove is not a cooking appliance.

• Always keep the cover of the fuel hopper closed.

• Keep this instruction manual carefully because it must

stay with the stove throughout its working life. If the

stove is sold or transferred to another user, always

make sure that the booklet goes with the product.

• If it gets lost, ask MCZ or your authorised dealer for

another copy.

1.3. GUARANTEE CONDITIONS

MCZ guarantees the stove, excluding the components

listed below which are subject to normal wear and

tear, for a period of two years from the date of purchase,

as proved by a supporting document which gives the name

of the vendor and the date on which the sale took place.

The guarantee is conditional on the guarantee certificate

being filled in and returned within 8 days, and requires that

the product be installed and tested by a specialised installer,

according to the detailed instructions given in the instruction

booklet supplied with the product.

The term 'guarantee' is to be understood to denote the freeof-charge replacement or repair of parts recognised to

have been defective at the start by reason of

manufacturing defects.

PELLET STOVES Chapter 1

page

7

ENGLISH

1.3.1. Limitations

The above guarantee does not cover components relating to electrical

and electronic parts, or fans, on which the guarantee period is 1 year

from the purchase of the product, documented as specified above. The

guarantee also does not cover parts subject to normal wear and tear:

gaskets, glass, and all the removable parts of the firebox.

The replacement parts will be guaranteed for the remainder of the

guarantee period starting from the date of purchase of the product.

1.3.2. Exclusions

Variations in colour in the painted or ceramic parts, and crackling of the

glaze on the ceramics, do not constitute grounds for a claim under the

guarantee, as they are natural characteristics of the material and of the

use of the product.

The guarantee does not cover any parts which may be found to be

faulty as a result of negligence or carelessness in use, or of incorrect

maintenance, or of installation not complying with MCZ's specification

(see the relevant chapters in this user manual).

MCZ refuses to accept any responsibility for any damage which may be

caused, directly or indirectly, by persons, animals or things in

consequence of the failure to observe all the prescriptions laid down in

Warning and guarantee conditions Technical service – Rights reservedMCZ S.p.A. Reproduction prohibited

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

the instruction booklet, especially those concerning warnings on the

subject of installation, use and maintenance of the appliance.

In case of an unsatisfactory product, contact your retailer and/or the

local importer.

Damage caused by transport and/or handling is excluded from the

guarantee.

For installation and use of the product, reference must be made

exclusively to the booklet supplied.

The guarantee will be invalidated in the event of damage caused by

tampering with the appliance, atmospheric agents, natural disasters,

electrical discharges, fire, defects in the electrical system, and lack of,

or incorrect, maintenance in terms of the manufacturer's instructions.

REQUESTS FOR SERVICE:

Any request for service must be addressed to the

retailer, who will forward the claim to MCZ's

technical assistance service.

MCZ DECLARES THAT THE STOVE WHICH YOU HAVE

PURCHASED COMPLIES WITH EEC DIRECTIVE

89/336 and 72/23 and SUCCESSIVE AMENDMENTS

MCZ refuses to accept any responsibility in the event

that the stove or any other accessory have been

improperly used or modified without authorisation.

For all replacement of parts, only original MCZ spare

parts must be used.

page

8

ENGLISH

Warning and guarantee conditions Technical service – Rights reservedMCZ S.p.A. Reproduction prohibited

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

2. THEORETICAL NOTIONS ON INSTALLATION

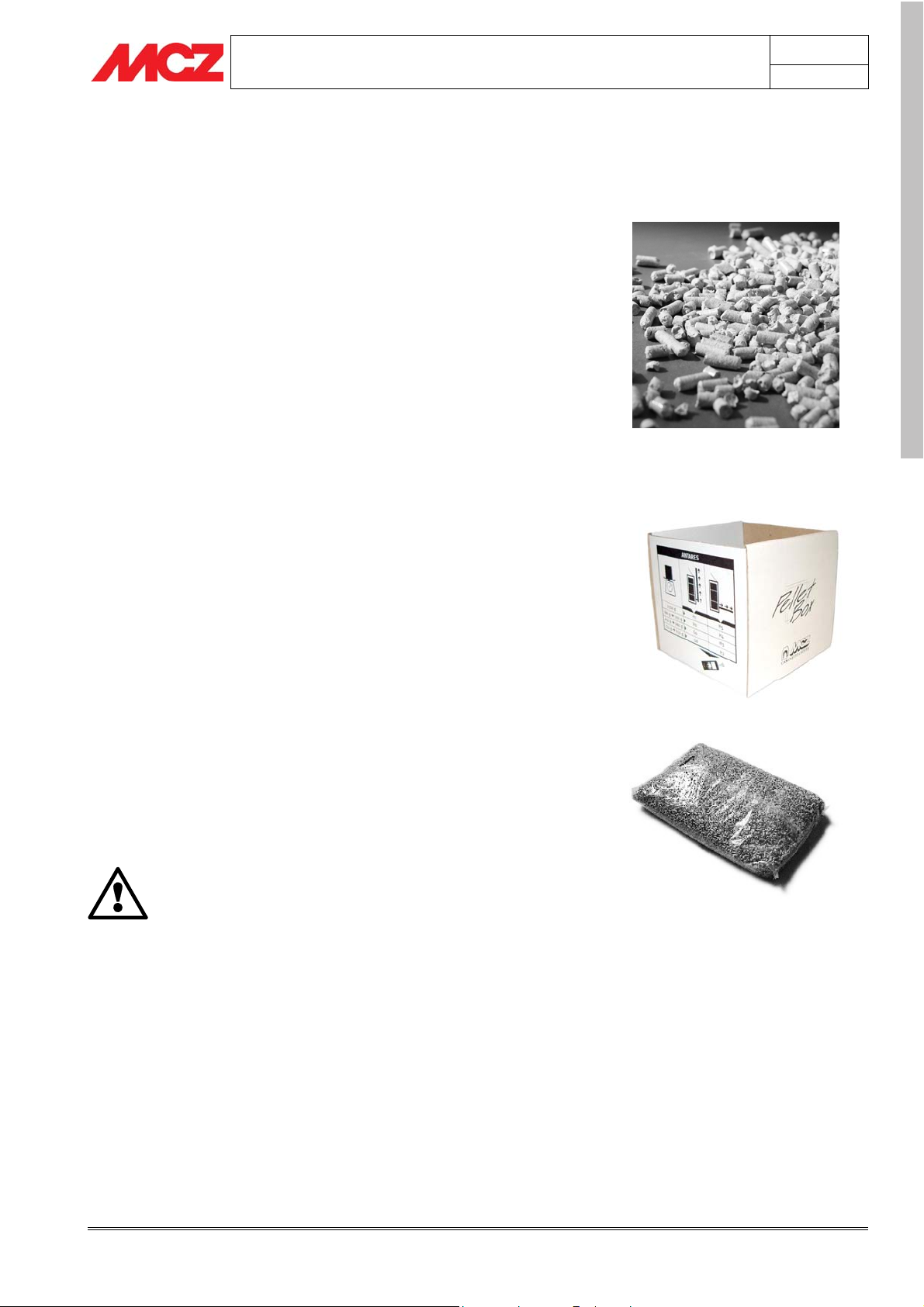

2.1. PELLETS

Wood pellets are manufactured by hot-extruding compressed sawdust

which is produced during the working of natural dried unpainted wood.

The compactness of the material comes from the lignin which is

contained in the wood itself, and allows the production of pellets

without the use of glues or binders.

The market offers different types of pellet with characteristics which

vary depending on what mixture of woods is used. The diameter goes

from 6 mm to 8 mm and the standard length is between 5 mm and 30

mm. A good quality pellet has a density between 550 kg/m

3

with a water content that is between 5% and 8% by weight.

kg/m

In order to guarantee the stated hourly consumption rates and

to optimise combustion, for pellet stoves MCZ has prepared a

patented method which makes it possible to identify and

classify any kind of pellet with a diameter of 6 mm and 8 mm

based on its specific weight and piece size.

By using the special PelletBox® and following the procedure set out in

the paragraph on lighting the stove, the user can determine the correct

settings for configuring the stove.

Along with being an ecological fuel which makes the best use of wood

residues thus producing cleaner combustion than that produced with

fossil fuels, pellets also have technical advantages. Whereas good wood

has a calorific power of 4.4 Kw/kg (with 15% humidity, so after about

18 months of seasoning), that of pellets is 5.3 Kw/kg.

To guarantee good combustion, the pellets must be stored in a clean,

dry place. The pellets are usually supplied in 15 kg. sacks, therefore

storage is very handy.

Good quality pellets ensure good combustion, thus lowering the

emission of harmful agents into the atmosphere.

The poorer the quality of the fuel, the more

frequently will intervention be necessary for cleaning

the internal parts, such as the grate and the

combustion chamber.

The pellets must be produced from pure wood which has not been

treated chemically.

The standards DIN 51731 and ONORM M 7135 certify a high-quality

pellet with the following characteristics:

Calorific power: 5.3 kW/kg

Density: 700 kg/m

Moisture content: 8% max by weight

Ash percentage: 1% max by weight

Diameter: 6-6.5mm

Length: 30 mm max

3

3

and 700

Pellet fuel

PelletBox®

15 Kg fuel sack

page

9

ENGLISH

Theoretical notes for installation Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

Content: 100% untreated wood, with no added bonding

substances (bark percentage 5% max)

Packaging: in bags made from ecologically compatible or

biodegradable material

MCZ emphatically recommends using certified fuel

in its stoves.

The use of fuel of inferior quality or not conforming

to the specification given above compromises the

running of your stove and can therefore lead to the

termination of the guarantee and of the

manufacturer's responsibility for the product.

MCZ pellet stoves operate exclusively with pellets

with a diameter of 6 mm (only for Italy) and 6-8mm

(European countries) with a length between 5mm

and 30mm.

2.2. PRINCIPLES OF OPERATION

page

10

ENGLISH

The pellets are picked up from the hopper on board the stove and

transported by a feed screw. They are then introduced into the

combustion chamber and fall directly into the stainless steel grate.

The quantity of pellets introduced into the grate and the corresponding

air of combustion are predetermined, programmed and controlled by an

electronic board.

In the lighting phase, the electronic board activates the smoke

extraction fan and the ceramic sparkplug, which heats up and causes

the fuel to ignite at a temperature of about 200°C. After about 20

minutes, the lighting phase is complete, and the control unit puts the

stove into operating mode.

In this phase, on the basis of the instructions which we provide via the

infrared remote (5 power levels), the electronic board regulates the

exact relationship between quantity of fuel, combustion air and

convection air, and provides continuous monitoring of all the

components connected to it, indicating if necessary the presence of any

operating problems and stopping the process.

- SEE SECTION DRAWING ON NEXT PAGE -

Theoretical notes for installation Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

2.2.1. Section plane of an MCZ pellet stove

Pellet loading door

Pellet compartment sensor

Ceramic cladding

Control panel

page

11

Convection hot air outlet

Ventilated hot air outlet

Degflector grill

Glass cleaning air

Firebox in Alutec®

Door with glass (750° C)

Stainless steel grate

Secondary combustion air

Primary combustion air

Central ash drawer

Rear closing panel

Pellet hopper

Chamber (heat exchanger)

Pellet feeding

Pellet feed screw

Pellet duct

Electronic control board

Combustion air intake Ø 50

Smoke sensor

ENGLISH

Side ash drawer

Smoke discharge Ø 80

Hot air fan

Smoke aspirator

Door handle

-

Theoretical notes for installation Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

INSTALLATION AND USE MANUAL

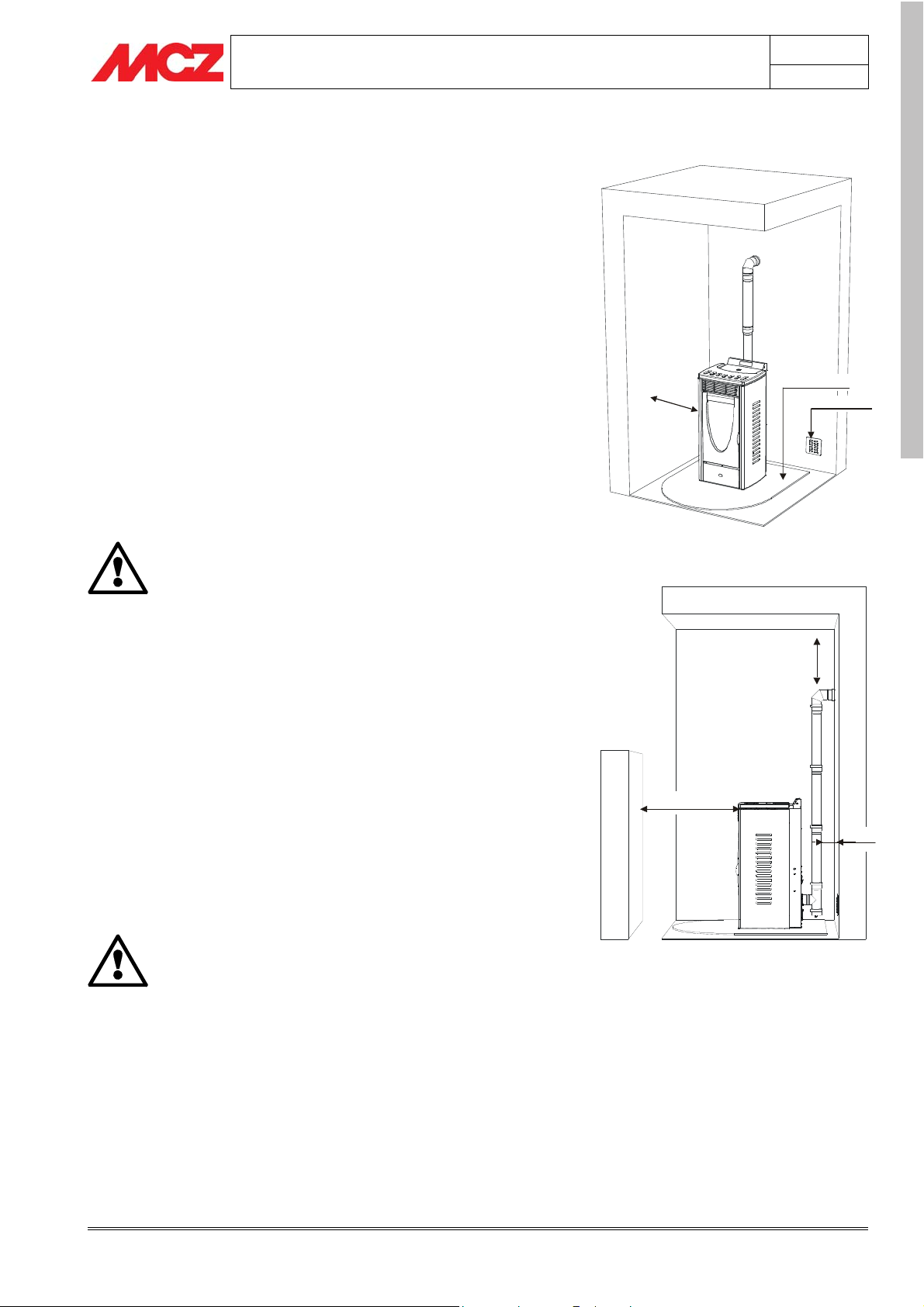

2.3. WORKING ENVIRONMENT

PELLET STOVES Chapter 2

page

12

For proper functioning and a good temperature distribution, the stove

should be positioned in a location where it is able to take in the air

necessary for combustion of the pellets (about 40 m

3

/h must be

available) ,as laid down in the standard governing the installation (UNI

- CIG 7129, 7131 and in accordance with national standards in effect).

3

The volume of the room must not be less than 30 m

.

The air must come in through permanent openings made in walls (in

proximity to the stove) which give onto the outside, with a minimum

cross-section area of 100 cm

2

.

These openings must be made in such a way that it is not possible for

them to be obstructed in any way.

Alternatively, the air may be drawn from rooms next door to the room

which needs ventilation, provided that these rooms have an air intake

from outdoors and are not used as bedrooms or bathrooms and

provided there is no fire risk such as there is for example in garages,

woodsheds, and storerooms.

It is not permissible to install the stove in bedrooms,

bathrooms or showers, and in a room where another

heating appliance is installed (fireplace, stove etc.)

which does not have its own independent air intake.

Locating the stove in a room with an explosive

atmosphere is prohibited.

The floor of the room where the stove is to be

installed must be strong enough to take its weight.

If the walls are not flammable, position the stove with a clearance to

the rear of at least 10 cm

In the case of walls made of flammable material, maintain a minimum

clearance to the rear of 20 cm, a clearance to the sides of 50 cm, and a

clearance to the front of 150 cm If the room contains objects which

are believed to be particularly delicate, such as hangings, sofas and

other furniture, their distance from the stove should be considerably

increased.

If there is wood flooring, place a floor protection

and adhere to national standards currently in effect.

5

0

c

m

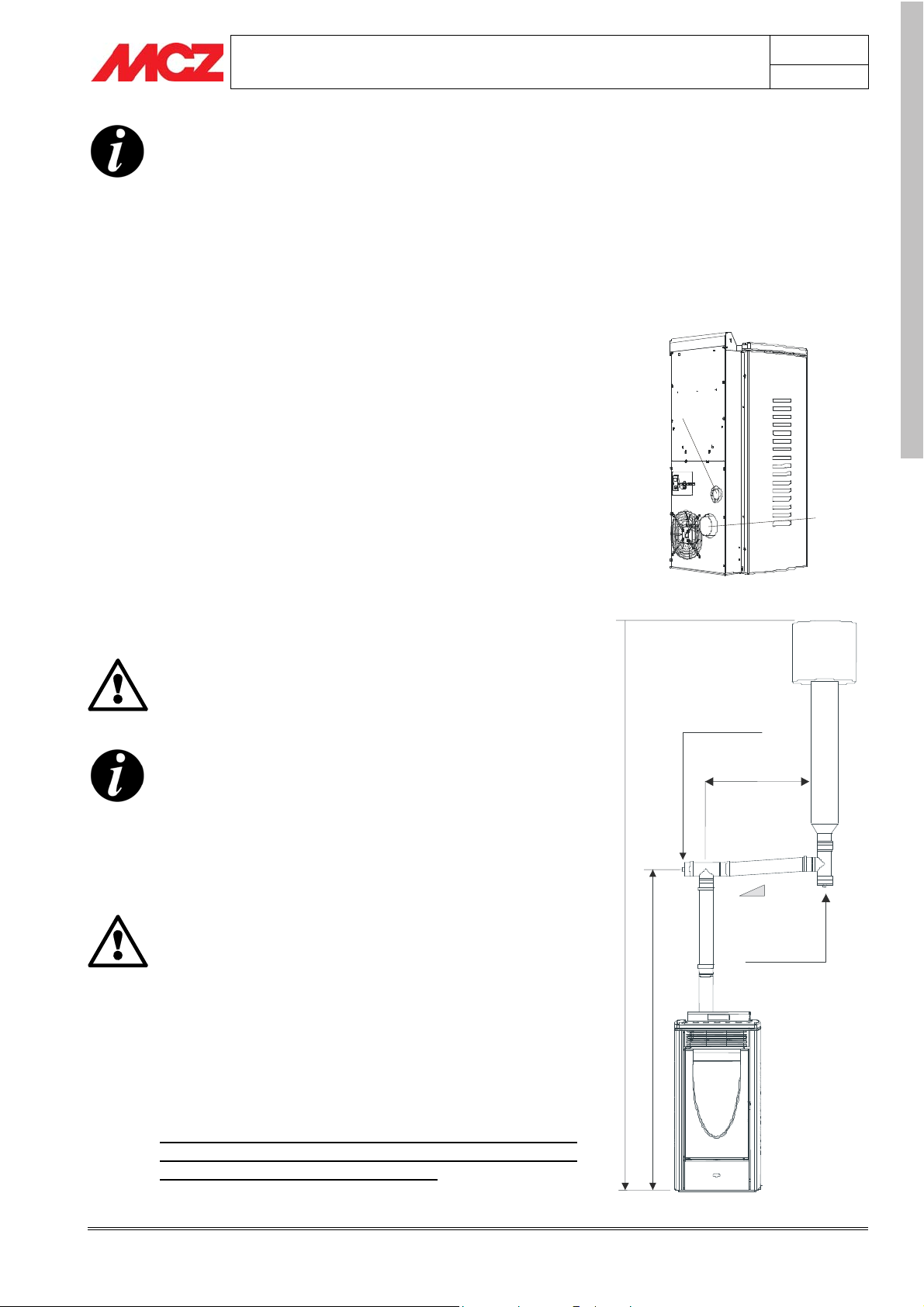

Example of installation with Saturn stove

150 cm

Example of installation with Saturn stove

Floor protection

Min. 100 cm

20 cm

ENGLISH

2

20 cm

Theoretical notes for installation Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

2.4. PRECAUTIONS

IMPORTANT !

Installation and assembly of the stove must be

carried out by a qualified engineer.

The stove must be installed in a suitable position to allow the normal

operations of opening and ordinary maintenance.

The site must be:

• capable of providing the environmental conditions for operation

• provided with 230V 50 Hz (EN73-23) electricity supply

• capable of taking an adequate system for smoke discharge

• provided with external ventilation

• provided with an earth connection complaint with CE standards

The stove must be connected to a flue pipe or an internal or

external vertical conduit conforming to the current standards.

The stove must be positioned in such a way that the electrical

plug is accessible.

IMPORTANT !

The stove must be connected to a flue pipe or a

vertical conduit which can discharge the fumes at the

highest point of the building.

The fumes are however derived from the combustion

of wood products, and if they come into contact with

or close to walls, they can make dirty marks.

Also take care because the fumes are very hot but

almost invisible, and can cause burns on contact.

The holes for the passage of the smoke pipe and for

the intake of air from outside should be made before

positioning the stove unit.

page

13

ENGLISH

2.5. CONNECTION TO THE EXTERNAL AIR INTAKE

It is essential that at least as much air must be able to flow into the

room where the stove is installed as is required for proper combustion

in the appliance and for the ventilation of the room.

To do this, make a hole in the external wall near the stove with a

clearance section of at least 100 cm². (12 cm diameter hole or square

10x10cm), protected by a grille on the outside.

The air intake must:

• communicate directly with the room where the stove is installed

• be protected by a grille, metal mesh or suitable guard, as long as

this does not reduce the area below the minimum.

• be positioned in such a way as to be impossible to obstruct

Theoretical notes for installation Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVES Chapter 2

t

Minimum 1,5

2m

INSTALLATION AND USE MANUAL

It is not compulsory to connect the air intake directly

with the stove (so that it draws air directly from

outside), but it is essential at all events to ensure an

airflow of 50 cubic metres per hour by the use of a

hole of the dimensions given.

See standard UNI 10683 REV.

2.6. CONNECTION OF THE SMOKE DISCHARGE PIPE

page

14

When making the hole for the passage of the smoke discharge pipe, it

is necessary to take into account the possible presence of flammable

materials. If the hole will be going through a wall made of wood or any

other material which is sensitive to heat, the INSTALLER MUST first

of all use the special wall union (diam.13cm minimum) and properly

insulate the pipe of the stove that passes through it, using adequate

insulation materials (thickness1.3—5 cm with minimum thermal

conductivity of 0.07 W/m°K).

The same is true if the stove pipe must run through vertical or

horizontal stretches passing in proximity (min.20cm) to the heatsensitive wall

As an alternative we recommend the use of insulated pipe, which can

also be used on the outside to avoid condensation.

The combustion chamber works in low pressure. The smoke duct for

the discharge of fumes will also be under low pressure when connected

to an efficient flue pipe as directed.

Pipes and unions with suitable gaskets must always

be used, to guarantee a hermetic seal.

All sections of the smoke duct must be accessible for

inspection and removable to enable periodic internal

cleaning. Tee connectors with inspection caps should be

used.

Position the stove in consideration of all the instructions and

considerations above.

IMPORTANT !

All 90 degree changes of direction in the flue pipe

must be fitted with suitable tee connectors to allow

the possibility of inspection (see the pellet stove

accessory list).

It is absolutely unacceptable to fit a grille on the end

of the discharge pipe, because it could lead to poor

running of the stove.

FOR FLUE PIPE CONNECTION DO NOT USE MORE

THAN 2-3 M. OF HORIZONTAL PIPES AND DO NOT

USE MORE THAN THREE 90° BENDS

Combustion

air

Height greater than 4 m

–

Example of installation with Saturn stove

View of Saturn stove

Inspection

2-3 m MAX.

ENGLISH

Smoke

outle

3-5 %

Inspection

Theoretical notes for installation Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVES Chapter 2

A

INSTALLATION AND USE MANUAL

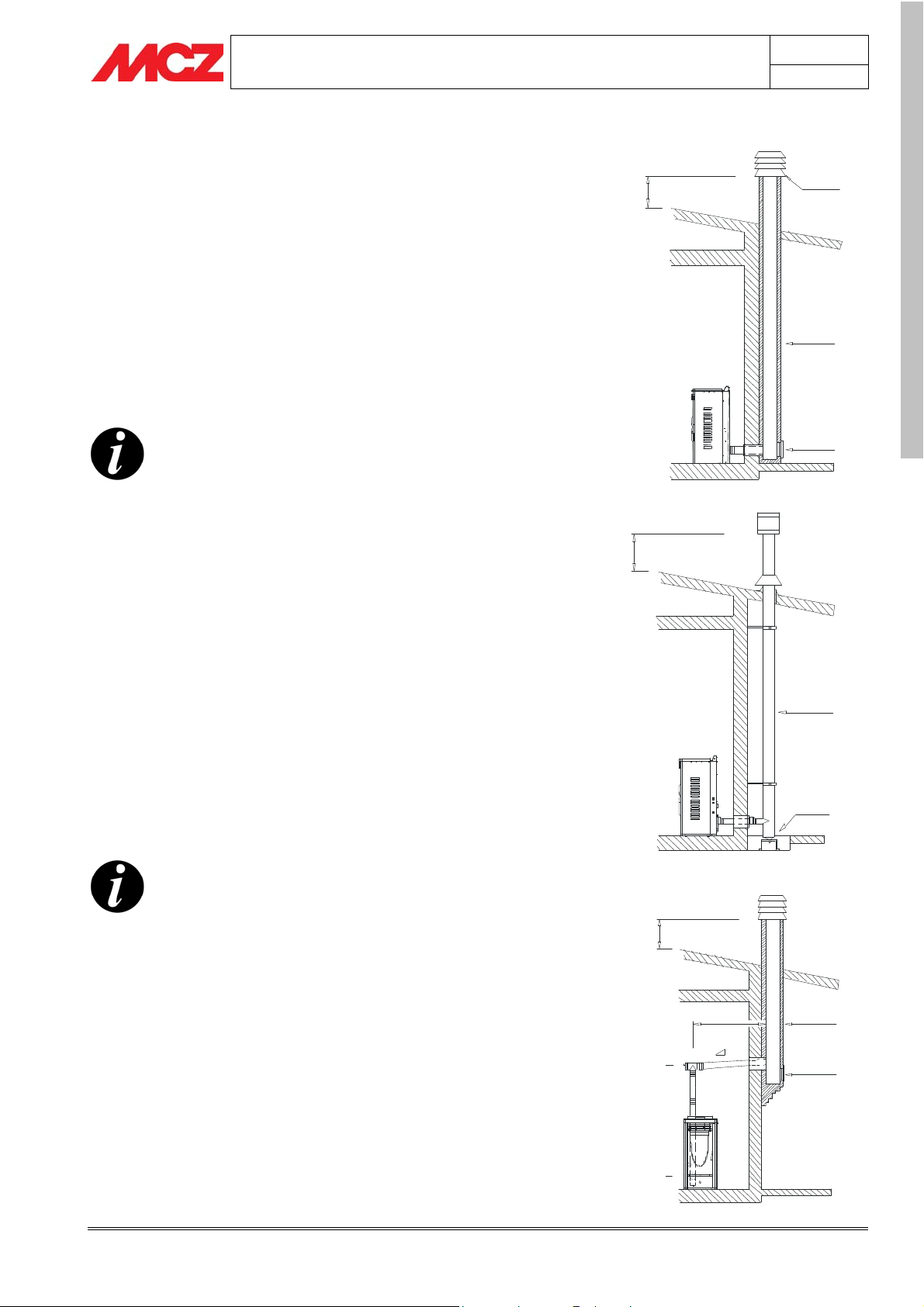

2.7. CONNECTION TO THE FLUE PIPE

The flue pipe must have internal dimensions not greater than 20x20

cm or a diameter of 20 cm; in the case of larger dimensions or poor

operation of the flue pipe (e.g. cracks, poor insulation, etc.) it is

advisable to insert a stainless steel pipe of a suitable diameter all the

way up to the top. Fig.5

Check with suitable instruments that there is a minimum draught of 10

Pa.

At the bottom of the flue pipe, provide an inspection cap to allow

periodic checking and cleaning, which must be done annually.

Make a gas-tight connection to the flue pipe, using pipes and

connectors as recommended by us.

It is compulsory to check that an anti-wind chimney has been installed,

in accordance with current standards.

This type of connection ensures the evacuation of the

fumes even in the event of a temporary power cut.

Fig. 5

0,5 m

page

15

nti-wind

chimney

Flue pipe

ENGLISH

Inspection

2.8. CONNECTION TO AN EXTERNAL FLUE WITH

INSULATED OR DOUBLE-SKINNED PIPE

The outside flue must have minimum internal dimensions of 10X10 or a

diameter of 10 cm and maximums 20x20 cm or a diameter of 20 cm;

Check with suitable instruments that there is a minimum draught of 10

Pa. Fig.6

The only type of pipe which is permissible is insulated (double-walled)

stainless steel, smooth on the inside, fixed to the wall. Flexible stainless

steel pipe must not be used.

At the bottom of the flue pipe, provide an inspection cap to allow

periodic checking and cleaning, which must be done annually.

Make a gas-tight connection to the flue pipe, using pipes and

connectors as recommended by us.

It is compulsory to check that an anti-wind chimney has been installed,

in accordance with current standards.

This type of connection ensures the evacuation of the

fumes even in the event of a temporary power cut.

2.9. CONNECTION TO FLUE PIPE OR SMOKE DUCT

0,5 m

Insulted

external

Fig. 6

duct

Inspection

0,5 m

For proper functioning, the connecting pipe between the stove and the

2 - 3 m MAX.

Flue pipe

chimney or flue duct must have a slope of not less than 3%. The length

of the horizontal stretch must not exceed 2/3 metres, and the vertical

distance between one tee connector and another (change of direction)

must not be less than 1.5m.

Check with suitable instruments that there is a minimum draught of 10

Pa. Fig.7

At the bottom of the flue pipe, provide an inspection cap to allow

periodic checking and cleaning, which must be done annually.

.

t

m

2

-

5

,

1

o

m

i

n

i

M

3-5 %

Inspection

Fig. 7

Minimum 1,5 – 2 m

Make a gas-tight connection to the flue pipe, using pipes and

connectors as recommended by us.

Theoretical notes for installation Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVES Chapter 2

y

INSTALLATION AND USE MANUAL

It is compulsory to check that an anti-wind chimney has been installed,

in accordance with current standards.

This type of connection ensures the evacuation of the

fumes even in the event of a temporary power cut.

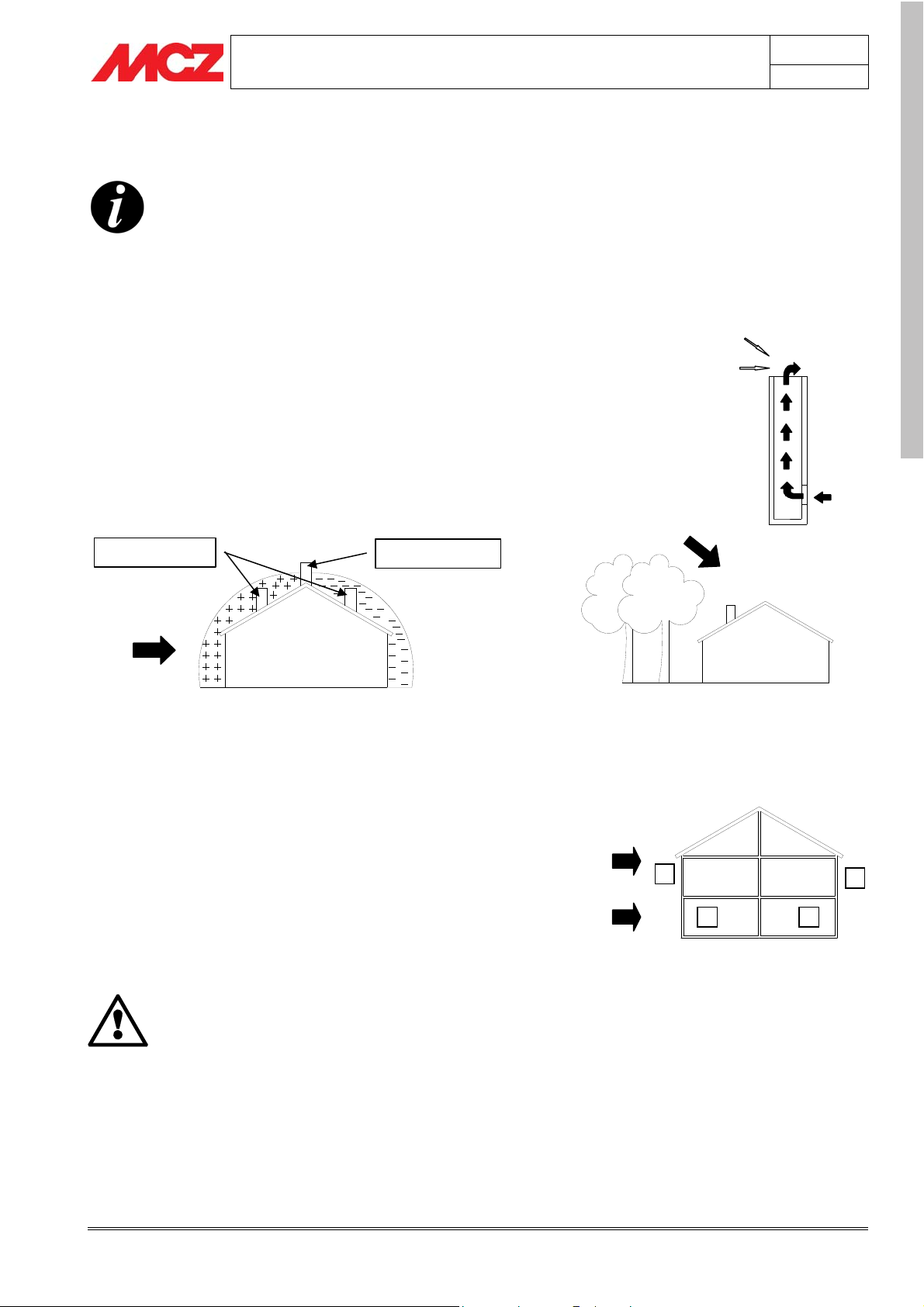

2.10. OPERATING ABNORMALITIES DUE TO FLUE

DRAUGHT PROBLEMS

45° down draft at 8m/sec. High

pressare of 17 Pa

page

16

Of all the meteorological and geographical factors which affect the

operation of a flue pipe (rain, fog, snow, altitude a.s.l., exposure to

sun, exposure to cardinal points, etc.) the wind is undoubtedly the most

important one. In fact, apart form the thermal difference caused by

the temperature difference inside and outside the chimney, there is

another kind of pressure difference: the dynamic pressure caused by

the wind. Updrafts always increase the depression and hence draft.

Horizontal wind increases draught if the chimney has been properly

installed. A downdraft always decreases the depression, at times

inverting it.

Least favorable position

Most favorable position

WIND

Pressure area

Depression area

Besides the direction and force of the wind, the position of the flue and

the cowl with respect to the roof of the building and the surrounding

landscape is important.

The wind also indirectly affects the operation of the fireplace, creating

high and low pressure areas not only outside but also inside dwellings.

In rooms directly exposed to the wind (2) a high pressure area may be

created which may favour the draught of stoves and fireplaces, but

which may be contrasted by high external pressure if the chimney is

exposed to the wind (1). On the contrary, in rooms opposite to the

direction of the wind (3) there may be a dynamic low pressure area

which competes with the natural thermal depression in the fireplace,

which may however at times be compensated by placing the smoke

duct on the side opposite from the wind (4)

IMPORTANT !

The operation of the pellet stove is noticeabl

sensitive to the conformation and position of the flue

which is adopted.

Hazardous conditions can only be overcome by

suitable setting-up of the stove carried out by

qualified MCZ personnel.

Horizontal wind 8m/sec.

Depression of 30 Pa

Down draft

WIND

1

2 3

1-2 = High pressure area

3-4 = Low pressure area

ENGLISH

4

Theoretical notes for installation Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVE Chapter 3

INSTALLATION AND USE MANUAL

3. INSTALLATION AND ASSEMBLY

3.1. DRAWINGS AND TECHNICAL CHARACTERISTICS

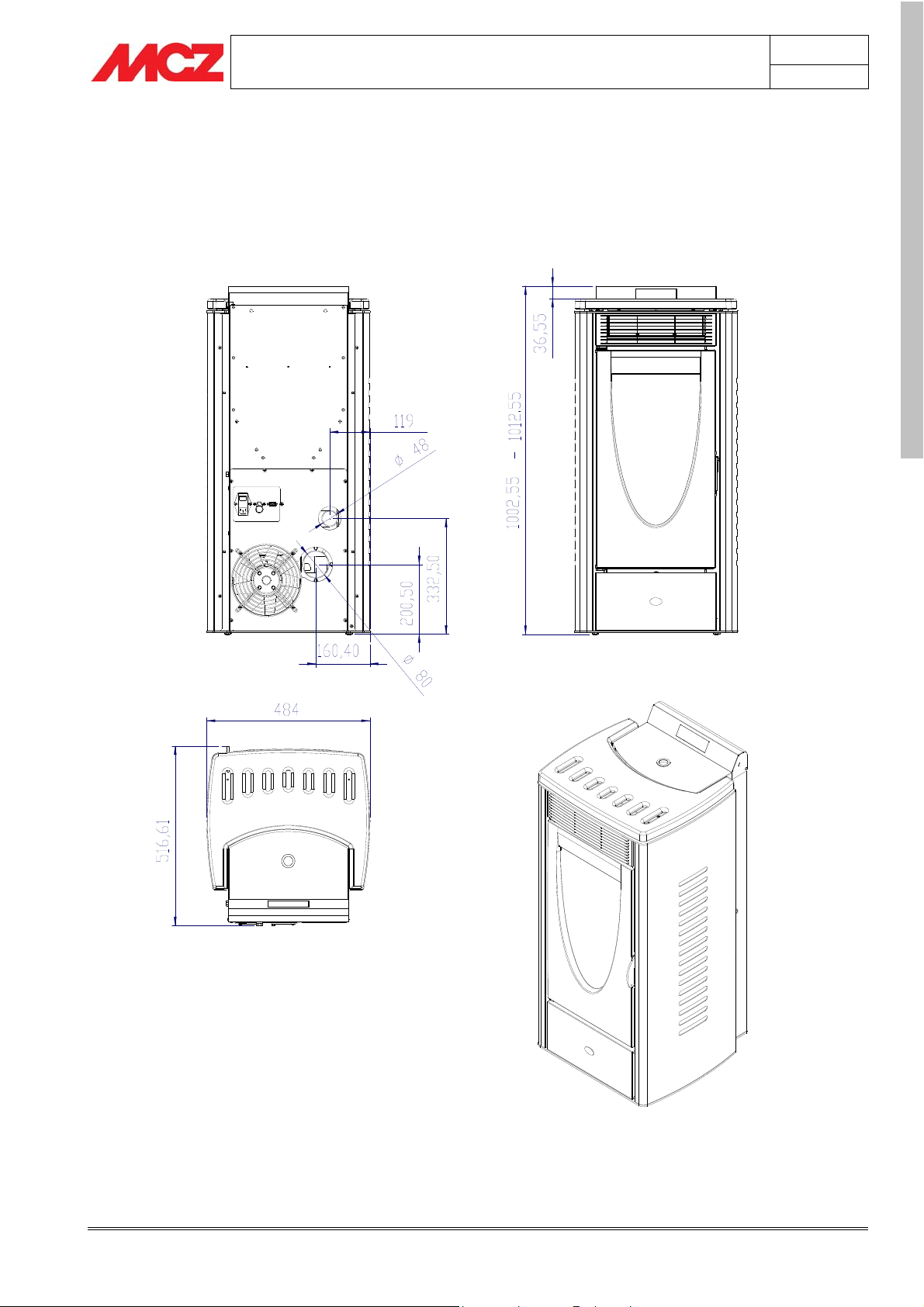

3.1.1. SATURN

page

17

ENGLISH

Installation and assembly Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

3.1.2. OMEGA

PELLET STOVE Chapter 3

INSTALLATION AND USE MANUAL

page

18

ENGLISH

Installation and assembly Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

3.1.3. PLANET

PELLET STOVE Chapter 3

INSTALLATION AND USE MANUAL

page

19

ENGLISH

Installation and assembly Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

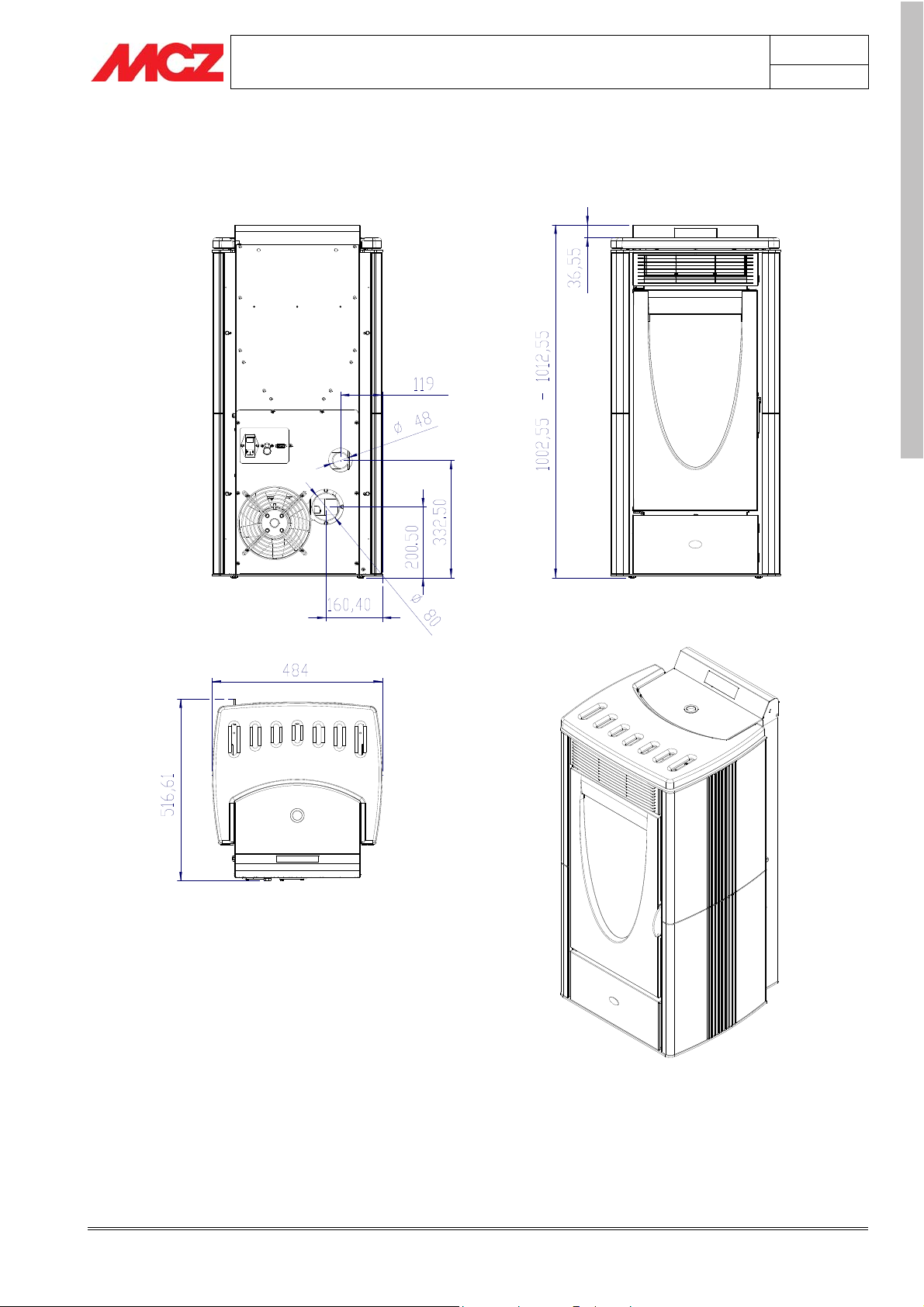

3.1.4. MERCURY

PELLET STOVE Chapter 3

INSTALLATION AND USE MANUAL

page

20

ENGLISH

Installation and assembly Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVE Chapter 3

INSTALLATION AND USE MANUAL

3.1.5. TECHNICAL CHARACTERISTICS

Technical characteristics Saturn – Omega - Planet

Overall thermal power Max 7 kW / 6020 kcal

Overall thermal power Min: 1.8 ÷ 2.2 KW / 1548 ÷ 1900 Kcal

Efficiency > 80 %

Smoke temperature 120 / 210 °C

page

21

CO at 13% O

min – max 0.02 — 0.10%

²

Minimum draught 0.1 mbar / 10 Pa

Hopper capacity 25 litres

Fuel pellet type ** Pellet diameter 6-8 mm Piece size 5/30 mm

Pellet consumption per hour Min. 0.6 kg/h Max. 1.7 KG/h *

Runtime between feeds At min. 27 h * At max. 10 h *

Combustion air inlet External diameter 50 mm.

Smoke outlet External diameter 80 mm.

Net weight 120 kg.

Weight with packaging 140 kg.

Max nominal electrical power 270 W

Supply voltage 230 V -50 Hz.

Technical characteristics Mercury

Overall thermal power Max. 6 KW / 5160 Kcal

Overall thermal power Min. 2.5 KW / 2150 Kcal

Efficiency > 80 %

ENGLISH

Smoke temperature 120 / 190°C

CO at 13%O

min – max 0.01— 0.10%

²

Minimum draught 0,1 mbar—10 Pa

Hopper capacity 25 litri

Fuel pellet type ** Pellet diameter 6-8 mm Piece size 5/30 mm

Pellet consumption per hour Min 0,6 KG/h * Max. 1,4 KG/h *

Operating time between re-fuelling At min 27 h * At max. 12 h *

Combustion air inlet External diameter 50 mm.

Smoke outlet External diameter 80 mm.

Net weight 100 Kg.

Weight with packaging 120 Kg.

Max. nominal electrical power. 270 W

Supply voltage 230 V - 50 Hz.

* Data that may vary depending on the type of pellets used.

** For ITALY use only pellets with a diameter of 6mm

Installation and assembly Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVE Chapter 3

INSTALLATION AND USE MANUAL

3.2. PREPARATION AND PACKAGING

Saturn, Omega and Planet stoves are delivered in two packages:

The first contains the body (Fig. 1)

The second contains the ceramic cladding (Fig. 2)

Open the packaging, take off the bands, remove the stove unit from

the pallet and position it in the chosen location, taking care that its

position complies with the above instructions.

The main stove unit must always be moved in an upright position and a

trolley must always be used. Take particular care to see that the door

and its glass are protected from mechanical impact which could

damage them.

Moving the product must always be done with care.

If possible unpack the stove near the place where it will be installed.

The materials which make up the packaging are not toxic or harmful,

so no special procedures for disposal by required.

Their storage, disposal or possible recycling are therefore the

responsibility of the final user, in compliance with current legislation on

the subject.

Do not store the stove unit or its cladding without their packaging.

If the stove needs to be connected to a discharge pipe which goes

through the rear wall (to connect up with the flue), take the greatest

care to make sure that the joint is not stressed.

Adjust the 4 feet (J) the smoke discharge (S) and the pipe (H) are

coaxial.

If the smoke discharge of the pipe is forced or

improperly used to lift if or move, its operation will

be irreparably compromised.

page

22

ENGLISH

H

S

Installation and assembly Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

Seen

from

below

J

Foot J

1. Rotate the foot

clockwise to lower the

stove

2. Rotate the foot

counterclockwise to

raise the stove

PELLET STOVE Chapter 3

p

INSTALLATION AND USE MANUAL

page

23

3.3. INSTALLATION OF THE CERAMIC CLADDING

FOR OMEGA-PLANET

A LOOK AT THE STOVE

In the front part there are the hooks (A) which can be adjusted in

depth and width (there are two for each tile). They should already be

attached in the coorect position.

On the back are the hooks (B) which are tentatively attached to the

frame of the stove. Loosen the screw (Z) which holds them (without

removing it completely) so that they can be moved horizontally.

TILE INSTALLATION MUST ALWAYS START FROM

THE BOTTOM.

Take a tile from the package (with its pins already inserted), mov eto

the side of the stove, and insert the tile from the front so that the

hooks (A) touch the front pin.

Rest the tile against the frame of the stove, take the rear hook (B) and,

using the screw as a grip, make the hooked ends grasp the rear pin of

the tile.

Check that the position is correct and tighten the screw all the way

down.

Repeat the procedure for the other tiles.

Install the top last, resting it on the four rubber stoppers (K). Use finger

pressure to check that the top is in a stable position. If necessary, use

the rubber stopper and the washer below it for levelling.

3.4. ELECTRICAL CONNECTION

Connect the supply cable first at the rear of the stove and then to an

electrical outlet on the wall.

The main switch located on the rear of the stove should be switched on

only when you want to light the stove.

If you do not intend to use the stove, it is advisable

to keep it switched off.

K

Hook B

Z

Hook A

Hook B

Z

ENGLISH

Rear

ceramic

pin

Hook A

Font ceramic

in

Installation and assembly Technical service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVE Chapter 4

INSTALLATION AND USE MANUAL

4. OPERATION

4.1. WARNINGS PRIOR TO FIRST LIGHTING

Avoid touching the stove during initial lighting, since

the paint hardens during this phase. If you touch the

paint, the steel surface underneath may be

uncovered.

If necessary, touch up the paint with the spray paint of the appropriate

colour. (see "Accessories for pellet stoves")

It is good practice to provide plenty of ventilation of

the room during the initial lighting, as the stove will

give off a small amount of fumes and smell of paint.

Do not stay near the stove and as previously stated ventilate the room.

The smoke and the smell of paint will go away after the first hour of

operation. They are not harmful to your health.

The stove will be subject to expansion and contraction during the

stages of lighting and cooling down, and may therefore make slight

creaking noises.

This is absolutely normal, the structure being made of sheet steel, and

must not be considered a fault.

It is very important not to heat the stove up all at once, but to bring it

up to temperature gradually.

If in 'Manual' mode, use the lower heating levels (1st, 2nd, 3rd). On

subsequent lightings, you will be able to enjoy the full heating power

available (including 4th and 5th levels), but remember not to keep the

stove running on full power for more than 60-90 minutes.

In this way you will avoid damage to the ceramic panels, the welds and

the steel structure.

The first time the stove is lit, leave it in "Manual" mode and

use only moderate power settings, such as “on1”-”on2”-”on3”.

page

24

ENGLISH

Do not demand full heating

performance straight away!

Try to get familiar with the commands given form the control panel or

remote control.

Try to memorize the messages that the stove sends you by means of

the display panel.

Operation Technical Service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVE Chapter 4

INSTALLATION AND USE MANUAL

4.2. CHECK PRIOR TO FIRST LIGHTING

Check that all the safety conditions described above have been met.

Make sure you have read and completely understood the contents of

this instruction booklet.

Remove everything from the stove firebox and door which might burn

(instructions and various adhesive labels).

Check that the grate A is properly positioned and rests firmly on the

base.

After long periods of disuse, remove from the hopper (using

a vacuum cleaner with an extension) any remains of

pellets which have lain there for some time, since they may

have absorbed moisture, which changes their original

characteristics and makes them unsuitable for burning.

Check that the electrical connection is correct (230 V 50 Hz), and turn

on the main switch located on the rear panel of the stove.

Check that on the control panel the display is lit up with the alternating

message

OFF / CURRENT TIME

.

A

page

25

ENGLISH

4.3. LOADING PELLETS

fuel is loaded from the upper part of the stove by opening the door.

Pour the pellets into the hopper. When empty it will hold about a 15 kg

sack.

It is easier to perform this task if it is done in two steps:

• Pour half the contents into the hopper and wait for the fuel to

settle to the bottom.

• Then pour in the second half.

Never remove the protective grille from inside the

hopper. When loading pellets, avoid the bag coming

into contact with hot surfaces.

4.4. CONTROL PANEL and REMOTE CONTROL

6

9

2

3

1

Operation Technical Service – Rights reserved MCZ S.p.A. – Reproduction prohibited

8

5

4

7

PELLET STOVE Chapter 4

INSTALLATION AND USE MANUAL

BUTTONS

1. Decrease set temperature / navigation - menu modifications

2. Increase set temperature / navigation - menu modifications

3. Set stove power

4. Set fan power

5. Stove lighting / shutdown

6. Menu / selection

7. Infrared receiver

8. Indicators (see specification)

DISPLAY

9. Display

INDICATORS

Timer active/inactive

Sparkplug in operation

Cycle where the screw delivers pellets

Hot air fan in operation/stopped

Operation in manual mode

General alarm (see specification)

4.4.1. REMOTE CONTROL and BATTERY REPLACEMENT

BUTTONS

1. Scroll down through menu / decrease set

temperature

2. Increase set temperature / programming

functions

3. Increase stove power

4. Increase fan power

Button 2+3 Lighting / Shutdown

BATTERY REPLACEMENT

The battery operates with a 12V 8LR932 alkaline battery (like those

used in gate-opening remote controls) and it is advisable to replace it

annually.

Procedure for replacement:

Put the tip of a flathead screwdriver into slot (X) of the remote control.

Turn the screwdriver clockwise so as to pry out the lid (Y).

Pull the lid (Y) completely out and replace the battery, placing it so

that its (+) is aligned with the polarity (+) marked on the body of the

remote control.

Put back the lid (Y)

Dispose of used batteries in accordance with current regulations.

page

2 3

Y

X

1 4

Polarity +

26

ENGLISH

4.5. SETTINGS TO BE MADE PRIOR TO FIRST

SWITCH

LIGHTING

Set the main switch on the rear of the stove to position (I).

The display (8) on the control panel will show the alternating message

OFF / CURRENT TIME.

If the time shown is not correct, it can be reset by the procedure

described below.

Keep in mind that the exact time is needed only when you perform

weekly programming with the TIMER (see relative chapter). On the

other hand, if the time is not up-to-date, this does not in any

compromise the operation of the stove.

4.5.1. Setting current time

Press the MENÙ key twice. The display will show the message SET

DAY and it is possible to set the day of the week using the buttons

Operation Technical Service – Rights reserved MCZ S.p.A. – Reproduction prohibited

or

LUN

SET

DAY

12:

HOUR

PELLET STOVE Chapter 4

INSTALLATION AND USE MANUAL

. If you press the

and it is possible to set the current time, again using the buttons

MENÙ key again, the message HOUR will appear

or

to increase or decrease the displayed value. To confirm the hour

selection, press the button

procedure to set the minutes on the next screen display. After confirming

the minutes with the MENÙ

complete and the display automatically exits setting and goes back to the

initial page.

You can exit time setting also by pressing the button

interrupt the procedure for more than 60 seconds, the display goes back

to the initial page.

EXITING THE MENÙ: to exit any menu screen page,

press key 5 or leave the keyboard inactive for 60

seconds

‘

MENÙ . There will then be the same

button, setting of the current time is

or if you

page

27

ENGLISH

4.5.2. Choice of display language

The LCD can communicate with the user in the following languages:

Italian, English, German, French and Spanish.

The default language is Italian. If you want to change languages,

you can easily do so as follows:

Press the MENU button , select MENU 3 using buttons or and

press the MENU button again to access language selection mode.

Modify the desired language using buttons or . To confirm the

choice you have made and exit the menu, press the button

. The

display will now operate in the desired language.

4.6. SELECTION OF RECIPE

This is an exclusive MCZ evaluation criteria which allows the

user to identify the type of pellet he has at his disposal and

therefore to set the stove up in the most appropriate manner.

This helps to avoid excessive fuel use, ensures the intended

heating potential is achieved and protects the integrity of the

product.

THE CHOICE OF RECIPE IS TO BE MADE AFTER FIRST

INSTALLATION AND EACH TIME YOU CHANGE THE

TYPE OF PELLET.

MENU 3

SET

LINGUA

LINGUA

ITALIANO

SPRACHE

DEUTSCH

(E.g. when you change supplier or when you visually detect differences

in colour or piece size)

4.6.1. HOW TO IDENTIFY THE RECIPE:

• Identification of the type of installation or connection to the flue

pipe

• Identification of type of fuel

• Identification of installation (horizontal = o,

vertical = v) see

First, identify the type of connection to the flue pipe, considering the

following:

Operation Technical Service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PelletBox®

PELLET STOVE Chapter 4

INSTALLATION AND USE MANUAL

ATTENTION !

Installation is to be made exclusively to a flue pipe,

and therefore the following evaluation criteria for

identifying the installation are to be considered valid

in compliance with current standards and are the

following:

If horizontal stretches have been realized that total more

than 1.5 and there is at least one 90° bend, the type of

setting to be considered for the choice of the recipe is

unquestionably HORIZONTAL.

If it is necessary to make 3 or more curves of 45° or 90° for

connection to the flue pipe, the setting to be considered in

choosing the recipe is certainly HORIZONTAL (0).

If instead the connection to the flue pipe includes almost

all vertical stretches, or if the stove is connected directly to

the flue pipe, the setting to be considered is VERTICAL (V).

If the smoke expulsion stretch is at least 1 m long and is

horizontal and without curves, it is in any case possible to

choose a VERTICAL (V) type of setting.

The Saturn and Omega-Planet type stoves have a

default HORIZONTAL setting (for Italy, France and

Spain) which allows them to work even in the most

demanding conditions, and VERTICAL for other

European countries.

Connections which are not to the flue pipe are

generally to be considered HORIZONTAL.

For complex, segmented installations we recommend

contacting specialized personnel or authorized MCZ

service centres.

MCZ discourages other kinds of installation (with

emission that is not into a flue pipe) and declines any

responsibility for malfunctions or abnormalities.

page

28

ENGLISH

• Now let us identify the type of pellet we have available

Material requirements:

• Scales (measuring up to 4 kg) with graduations down to 10 g

• MCZ pellet measuring container supplied with stove (PelletBox®)

• A stick

• Pellets (fuel)

• Type of installation (horizontal or vertical smoke outlet) needs to

have been chosen.

Fill the measure generously with pellets without compacting it (i.e.

without banging the measure on the table or pressing the pellets down

with the hands) – Fig. 18.

Rest the batten (or ruler, blade or pencil) on the top edge of the container

and level the material by scraping off the excess. Fig. 19 and 20.

Weigh the total (measure + pellets) and note the weight.

Take the measure, empty it and turn it so as identify the graphic data

that is used for the choice of the recipe. Fig.21

Operation Technical Service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVE Chapter 4

INSTALLATION AND USE MANUAL

4.6.2. Procedure for recipe selection

In the left-hand column, marked 'Weight', identify which row contains

the weight which was noted earlier.

Following the row across to the right, you will see two numbers which,

depending on the type of installation of the stove (with smoke outlet

predominantly vertical or horizontal) will allow you to select the

optimum recipe for the type of pellet being used.

Example:

Let us suppose that it has been decided to install the stove in the

configuration with vertical smoke outlet, and that the weight of the

measure complete with pellets is 680 grams.

First of all, identify the stove model you are dealing with (for example

SATURN), then look at the corresponding table located on a side of the

measure and you will see that on the column "Weight" that 680g is

found in the line titled “from 660 to 700”.

Staying on the same line, you will now identify the code "L2" which

corresponds to the column which has as its symbol a stove with a

vertical flue pipe. The recipe to program the stove with is L2.

V

page

29

O

ENGLISH

4.6.3. Memorization of recipe on stove.

Press MENÙ and use the button until the message “SET

RECIPE is shown on the display. Then confirm with MENÙ

now see the message “SET RECIPE”. Again using the buttons

. You will

or

you will select the number of the desired recipe as shown in the

diagram on the BoxPellet® (measuring container);

To confirm the choice press MENÙ

. The display will show the

request for confirmation, to which you must answer “YES” or “NO”.

Choose one of the two options with the buttons

with the button MENÙ

. The confirmation of the setting is shown on

or and confirm

the display by the message “LOADED PARAM”. The display will

automatically go back to the initial screen.

If you interrupt the procedure for more than 60 seconds, the display

will automatically go back to the initial screen. You can also interrupt

the operation at any time manually, by holding down

for a few

seconds.

DEFAULT SETTING:

SATURN – OMEGA – PLANET = L2

MERCURY = M2

4.7. FIRST LIGHTING

MENU 4

SET

RECIPE

L2

SET

RECIPE

20.45

OFF

You are now ready to light your stove.

Below is a quick-start list for lighting and shutting down your stove, to

satisfy your curiosity and anticipation.

Afterwards, as you are sitting comfortably in your armchair enjoying the

warmth and the sight of your stove, there will be a more in-depth

description of all of the controls and programming sequences that will

allow you to use fully everything Omega-Planet and Saturn make

available to you (see paragraph 4.9)

4.7.1. Lighting from panel

Remote control keypad

To light the stove, press key for several seconds.

Operation Technical Service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVE Chapter 4

INSTALLATION AND USE MANUAL

4.7.2. Lighting from remote control

To light the stove, press buttons and at the same time for a few

seconds.

The stove will begin the START-UP phase, which lasts about 15

minutes. It will then begin normal operation. When lit for the first

time, the stove will be set in MANUAL operating mode.

Only after lighting, the control panel can be used to choose the desired

power and/or ventilation.

Button

following sequence:

whereas the 5 ventilations of hot air are adjusted with push button

in this sequeence:

In the "AUTO" position, ventilation autonomously adapts to the flame

power

Examples: Flame power P1 = Ventilation at 1

Flame power P2 = Ventilation at 2

……

Flame power P5 = Ventilation at 5

If after repeated failures to ignite, a flame still does not appear, even

though there is a proper flow of pellets into the burner, it indicates that

there could be a problem due to stove components or improper

installation.

is used to regulate the heating power of the stove in the

P3→P4→P5→P1→P2→P3 .

1st→2nd→3rd→4th→5th→AUTO→1

At the first lighting (and any time the pellets in the

hopper run out), it is possible that the fuel, having to

travel from the hopper to the burner, is not able to

arrive in the correct quantities and within the

required time for proper ignition. In this case the

burner will either be empty or will contain very few

pellets.

REMOVE ANY PELLETS FROM THE BURNER AND

REPEAT LIGHTING BY PRESSING BUTTON

FEW SECONDS.

REMOVE THE PELLETS FROM THE BURNER AND

REQUEST ASSISTANCE FROM AN AUTHORIZED MCZ

TECHNICIAN.

st .

st

speed

nd

speed

th

speed

FOR A

P - 3

SET

POWER

Variation of flame power

SET 3

FAN

Variation of fan speed

P - 3

20.45 21°C

ON

page

30

ENGLISH

4.7.3. Switching off from panel

To shut off the stove, press button for a few seconds.

4.7.4. Switching off with the remote control

Remote control keypad

To switch off the stove, press buttons and at the same time for a

few seconds.

The display (8) will show the message "OFF". The stove will now

automatically start the shutdown phase, during which it will interrupt

the flow of fuel and the flame will be extinguished. Ventilation will

Operation Technical Service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVE Chapter 4

INSTALLATION AND USE MANUAL

however continue for 20-30 minutes so that all of the heat retained by

the stove will be released into the room.

4.8. VIEWING THE FLAME

In order to obtain good operation from the stove, you need to know

how to "read" the flame. The characteristics that the user needs to pay

attention to are the basically:

• The shape

• The colour

• The character

page

31

4.8.1. The shape

In normal combustion, the flame should be tapered and lively, as

wide as the grate that it comes out of and with the tip roughly vertical

or pushed towards the Alutec70 back of the firebox. You should have

the sensation that the flame is pulled upward so that it does not beat

Fig. 1

against the glass of the door.

On the other hand a flame which at its base is bigger than the grate

and has a feeble character, whose tip is not "guided", or which beats

against the glass

(Fig. 2)

may be a symptom of poor setting of the fuel

loading and/or smoke aspiration, or the smoke duct is obstructed or

there are high pressure areas that do not allow for regular smoke

outflow.

In this case you will ALWAYS have operating problems. Request

assistance from specialized personnel or ask MCZ technicians for

advice.

4.8.2. The colour

The colour is in some way connected to the shape of the flame. A

colour which varies between orange and yellow with a dark tip usually

goes along with an enlarged flame (as previously described) which

lacks oxygen or in any case indicates improper combustion. As the

colour changes to light yellow-white, the shape of the flame changes,

becoming thinner, showing the presence of a greater quantity of

oxygen.

ENGLISH

Figure 1

NORMAL COMBUSTION

Shape: Tapered, compact, vertical

Character: Lively

Colour: Yellow – light yellow - white

4.8.3. Character

Lively or feeble, this is closely connected to the shape of the flame.

Figure 2

ABNORMAL COMBUSTION

Shape: enlarged irregular not

compact

Character:Tenuous - feeble

Colour:Orange - yellow

Operation Technical Service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVE Chapter 4

INSTALLATION AND USE MANUAL

4.9. OPERATING MODES

The SATURN and OMEGA-PLANET stoves basically have three operating

modes.

4.9.1. Manual and automatic

The stove can operate in one of these two different operating modes.

MANUAL mode allows only adjustment of the flame from power 1 to

power 5, ignoring any ambient temperature measurement. This mode

is indicated by the symbol on the display.

Automatic mode, on the other hand, lets you set the desired

temperature in the room of installation. The stove will control its power

autonomously in order to reach the established temperature. With this

mode you can also use an external thermostat as explained in

paragraph 4.9.3.2 of this manual.

At each lighting, the stove sets to the operating mode

that it was in the last time it shut down.

page

32

ENGLISH

4.9.2. Manual mode

In this mode you can only vary the thermal power provided by choosing

the flame power.

Using the button

the stove is at power 3, for example, the sequence will be:

Ventilation is also partitioned into 5 speeds (plus the AUTO position),

and it is possible to change it as you like using the key

is for example at power 3, the sequence will be:

In the "AUTO" position, ventilation autonomously adapts to the flame

power

Examples: Flame power P1 = Ventilation at 1

Flame power P2 = Ventilation at 2

……

Flame power P5 = Ventilation at 5

ATTENTION!

During stove operation, if there are conditions which

alter normal operating status, the main alarm

indicator light (6) will come on accompanied by a

beeping sound (see the paragraph "stove shutdown")

and the stove will react by starting the total

shutdown procedure.

If there is an electrical power outage during lighting

or operation of the stove, the stove will switch over to

cooling mode and it will start again when the

electricity supply is restored.

the 5 heating powers of the stove are adjusted. If

P3→P4→P5 →P1→P2→P3 .

. If ventilation

SET VENTOLA 3→4→5→AUTO→1→2→3 .

st

speed

nd

speed

th

speed

P – 3

SET

POWER

Variation of flame power

SET 1

FAN

Variation of fan speed

Stove in alarm and in lockout status

ALARM

NO

FIRE

Operation Technical Service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVE Chapter 4

INSTALLATION AND USE MANUAL

4.9.2.1.

Changing from manual to automatic mode

To change from MANUAL to AUTOMATIC operating mode, just press

the button two times in sequence. The display will show the mode

change, the light will go off and you will need to set the desired

temperature.

As a default value, as soon as you change from manual to automatic

mode, the SET TEMP ROOM is 40°C.

40°C

MODE

AUTO

page

33

4.9.3. Automatic mode

Whereas MANUALE mode lets you simply choose the thermal power

provided with no variation of operation over time, AUTOMATIC mode

lets you set a certain temperature to be reached in the room. In this

operating mode the stove will automatically vary the thermal power

provided so as to keep the temperature in the room constantly at the

set value.

Example:

If the room temperature detected by the local sensor located on the

stove is 15 C° and the temperature set on the thermostat is 20 C°, the

stove will go sequentially to the 5th power and when the requested

temperature is reached (20 C°) it will go to ECO mode (the display will

show the message “ECO”) thus switching down to the minimum power.

It should be remembered that the temperature assigned to the

thermostat is approximate and it is up the user to find the right value in

the room where the stove is installed (e.g. it may be necessary to set

the thermostat at 25C° in order to have a room temperature of 20C°).

This happens because the room thermostat is placed near the warm

body of the stove and therefore it detects the heat from the stove.

In this mode, lighting and shutdown are performed by the user by

holding down button

To set the temperature to be reached you can use the:

for a few seconds.

Changeover from MANUAL to AUTOMATIC

09:52 16°C

ON

ECO

Operation at minimum in automatic operating

mode

ENGLISH

4.9.3.1.

The stove includes an internal digital thermostat. By means of a

sensor, it measures the room temperature and compares it with the

temperature set by the user.

Internal digital thermostat (equipped in the stove)

21°C

SET TEMP

ROOM

To increase the set temperature in steps of 1 degree centigrade,

press the button

.

4.9.3.2.

External thermostat (optional)

. In the same way, to decrease use the button

Adjustment of room temperature to be

reached

The EXTERNAL THERMOSTAT is not included with

stove and its installation is to be handled by the user.

The stove can also be connected to an external room thermostat, which

would replace the one on the stove. In must be placed in a median

location in the room of installation, so as to better monitor the room

temperature.

The procedure to follow for the connection of the external thermostat is

the following:

Operation Technical Service – Rights reserved MCZ S.p.A. – Reproduction prohibited

PELLET STOVE Chapter 4

MCZ

l

INSTALLATION AND USE MANUAL

• Connect the two wires of the cable from the thermostat to the

terminal of the MCZ connector (not included with the stove).

Insert the connector in the appropriate serial socket located on

the back of the stove.

• In order for the stove to recognize the external thermostat,

press and hold the button

scrolling through the temperature

values below 6°C until the message “REMOTE TEMP.”

appears. This means that the external thermostat is now active

and overrides the internal one.

Wiring from

external thermostat

page

34

seria

connector

4.9.3.3.

Changing from automatic to manual mode

To change back from MANUAL mode to AUTOMATIC mode, do the

following: