Contents

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

EN

ANTHEA –MYRIA-LUNA-QUASAR-NADIR-PULSAR-SIRIO-ZENIT-VENUS-

COMETA-ALPHA-ORION – MODULO LEGNA

NuTech Renewables Ltd

Unit 11, Warrenpoint Enterprise Centre

Newry Road, Warrenpoint

Co.Down, BT34 3LA

Tel: + 44 28 417 53031

Email: info@nutechrenewables.com

www.NuTechrenewables.com

Contents

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

07

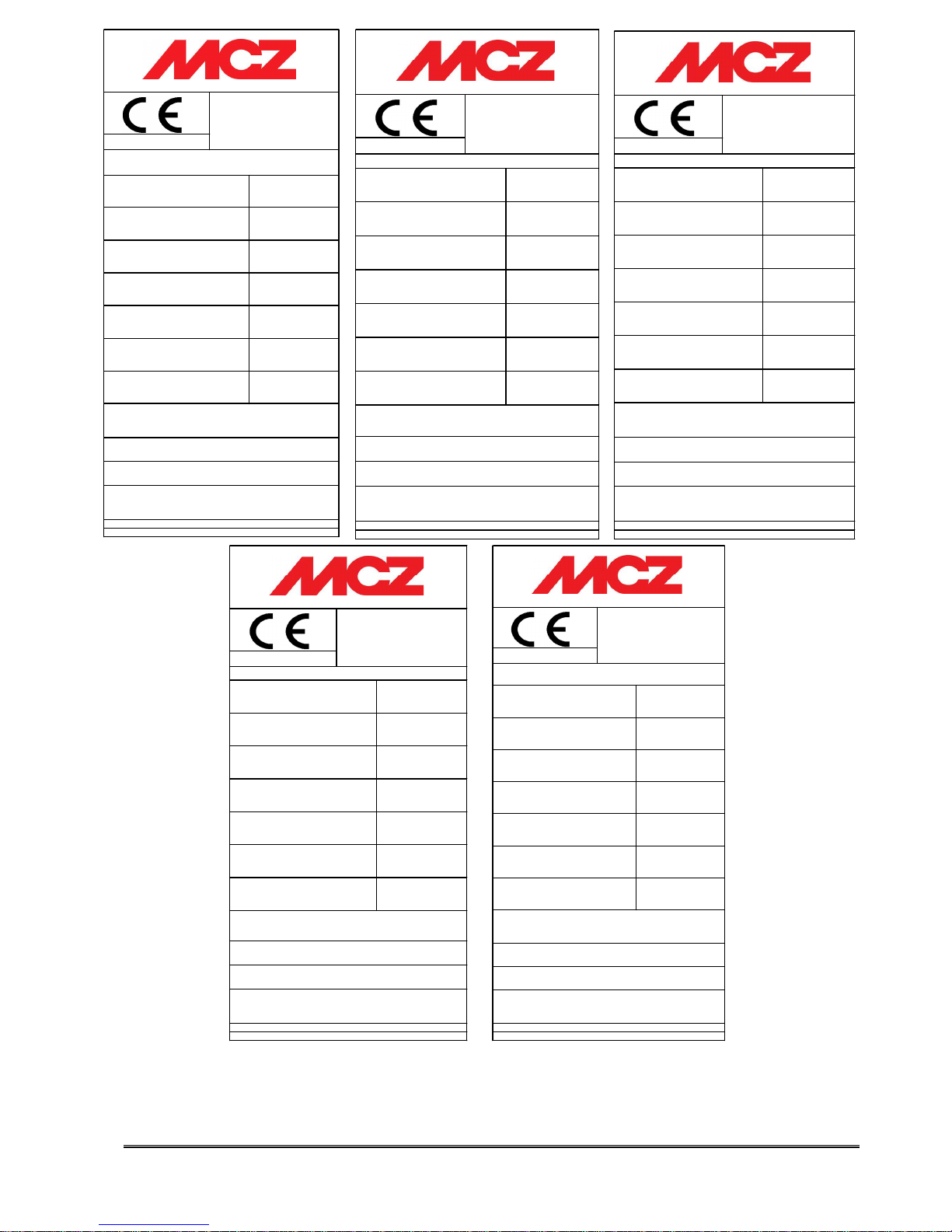

EN 13240:2001, AC:2003,

AC:2006, A2:2004,

Made in Italy

Sicherheitsabstände (Seitlich):

270 °C

Sicherheitsabstände (Hinten):

Veiligheidsafstand (achteraan):

Stäub:

Stofdeeltjes:

Distanze di sicurezza (retro):

Distances de sécurité (postérieures):

300 mm

Rendimento :

Potenza nominale:

Puissance nominale:

Heizleistung:

Nominaal vermogen:

Mittlere Abgastemperatur:

Temperatuur rook:

500 mm

14 mg/Nm3 (13% O2)

9 mg/MJ

Veiligheidsafstand (zijdelings):

Particolato:

Poussieres:

COD: 89070079

Prodotto conforme all'installazione in canna multipla. Produit conforme à l'installation

dans un conduit multiple. Gerät ist für eine Mehrfachbelegung des Schornsteins

geeignet.Product conform de installatie in een multi-rookkanaal.

Leggere e seguire le istruzioni! Lire et suivre les

instructions! Bedienungsanleitung lesen und

beachten!Lees en respecteer de aanwijzingen!

MCZ GROUP S.p.A. - Via La Croce 8, I - 33074 Vigonovo di Fontanafredda (PN) Italy.

Utilizzare solo con combustibile adatto. A utiliser seulement avec un combustible

conforme. Nur zugelassennen Brennstoff verwenden.Gebruik enkel gepaste pellets.

Apparecchio a funzionamento intermittente. Produit à fonctionnement intermittent.

Zeitbrand Feuerstätte. Apparatuur voor intermitterende werking.

78,3%

BImSchV

Art. 15a B-VG

VKF AEAI

Regensburger Münchener

BStV erfüllt

7,9 kW

0,11%

Emissione CO (al 13% O

2):

Emissions CO (Bez.13% O2):

Mittlere CO- Emission (Bez.13% O

2):

QUASAR

CO-emissie (bij 13% O2):

Rendement :

Energieeffizenz:

Rendement:

Temperatura fumi:

Température des fumées:

Distanze di sicurezza (lato):

Distances de sécurité (laterales):

EN 13240:2001, AC:2003,

AC:2006, A2:2004,

Made in Italy

Temperatura fumi:

Température des fumées:

Mittlere Abgastemperatur:

Veiligheidsafstand (zijdelings):

Veiligheidsafstand (achteraan):

Distanze di sicurezza (lato):

Distances de sécurité (laterales):

Sicherheitsabstände (Seitlich):

Sicherheitsabstände (Hinten):

Temperatuur rook:

Distanze di sicurezza (retro):

Distances de sécurité (postérieures):

Rendimento :

Rendement :

Energieeffizenz:

Rendement:

Particolato:

Poussieres:

Stäub:

Stofdeeltjes:

Emissione CO (al 13% O

2):

Emissions CO (Bez.13% O2):

Mittlere CO- Emission (Bez.13% O

2):

CO-emissie (bij 13% O2):

Puissance nominale:

Heizleistung:

MODULO LEGNA

Nominaal vermogen:

Potenza nominale:

07

55 mg/Nm3 (13% O2)

33 mg/MJ

12 kW

0,11%

87,6%

300 °C

MCZ GROUP S.p.A. - Via La Croce 8, I - 33074 Vigonovo di Fontanafredda (PN) Italy.

BImSchV

Art. 15a B-VG

VKF AEAI

Regensburger BStV erfüllt

300 mm

500 mm

Leggere e seguire le istruzioni! Lire et suivre les

instructions! Bedienungsanleitung lesen und

beachten!Lees en respecteer de aanwijzingen!

COD: 89070082

Prodotto conforme all'installazione in canna multipla. Produit conforme à l'installation

dans un conduit multiple. Gerät ist für eine Mehrfachbelegung des Schornsteins

geeignet.Product conform de installatie in een multi-rookkanaal.

Apparecchio a funzionamento intermittente. Produit à fonctionnement intermittent.

Zeitbrand Feuerstätte. Apparatuur voor intermitterende werking.

Utilizzare solo con combustibile adatto. A utiliser seulement avec un combustible

conforme. Nur zugelassennen Brennstoff verwenden.Gebruik enkel gepaste pellets.

EN 13240:2001, AC:2003,

AC:2006, A2:2004,

Made in Italy

Distances de sécurité (laterales):

Sicherheitsabstände (Seitlich):

Veiligheidsafstand (zijdelings):

Distances de sécurité (postérieures):

Sicherheitsabstände (Hinten):

Veiligheidsafstand (achteraan):

Distanze di sicurezza (lato):

Poussieres:

Stäub:

Stofdeeltjes:

Distanze di sicurezza (retro):

Température des fumées:

Mittlere Abgastemperatur:

Temperatuur rook:

Particolato:

CO-emissie (bij 13% O2):

Nominaal vermogen:

Emissione CO (al 13% O

2):

Emissions CO (Bez.13% O2):

Mittlere CO- Emission (Bez.13% O

2):

Rendimento :

Rendement:

Temperatura fumi:

28 mg/Nm3 (13% O2)

19 mg/MJ

MCZ GROUP S.p.A. - Via La Croce 8, I - 33074 Vigonovo di Fontanafredda (PN) Italy.

07

BImSchV

Art. 15a B-VG

VKF AEAI

Regensburger Münchener

BStV erfüllt

300 mm

500 mm

Rendement :

84,6%

Energieeffizenz:

Puissance nominale:

Heizleistung:

7,4 kW

SIRIO / ZENIT / VENUS /

COMETA / ALPHA / ORION

Prodotto conforme all'installazione in canna multipla. Produit conforme à l'installation

dans un conduit multiple. Gerät ist für eine Mehrfachbelegung des Schornsteins

geeignet.Product conform de installatie in een multi-rookkanaal.

Apparecchio a funzionamento intermittente. Produit à fonctionnement intermittent.

Zeitbrand Feuerstätte. Apparatuur voor intermitterende w erking.

Utilizzare solo con combustibile adatto. A utiliser seulement avec un combustible

conforme. Nur zugelassennen Brennstoff verwenden.Gebruik enkel gepaste pellets.

250 °C

0,10%

Leggere e seguire le istruzioni! Lire et suivre les

instructions! Bedienungsanleitung lesen und

beachten!Lees en respecteer de aanwijzingen!

COD: 89070081

Potenza nominale:

EN 13240:2001, AC:2003,

AC:2006, A2:2004,

Made in Italy

07

Particolato:

Poussieres:

Stäub:

Stofdeeltjes:

Temperatura fumi:

Température des fumées:

Veiligheidsafstand (zijdelings):

Distanze di sicurezza (retro):

Distances de sécurité (postérieures):

Sicherheitsabstände (Hinten):

Veiligheidsafstand (achteraan):

Distanze di sicurezza (lato):

Distances de sécurité (laterales):

Sicherheitsabstände (Seitlich):

Heizleistung:

Nominaal vermogen:

Emissione CO (al 13% O

2):

Emissions CO (Bez.13% O2):

Mittlere CO- Emission (Bez.13% O

2):

CO-emissie (bij 13% O2):

Mittlere Abgastemperatur:

Temperatuur rook:

COD: 8901027300

Prodotto conforme all'installazione in canna multipla. Produit conforme à l'installation

dans un conduit multiple. Gerät ist für eine Mehrfachbelegung des Schornsteins

geeignet.Product conform de installatie in een multi-rookkanaal.

Apparecchio a funzionamento intermittente. Produit à fonctionnement intermittent.

Zeitbrand Feuerstätte. Apparatuur voor intermitterende werking.

Leggere e seguire le istruzioni! Lire et suivre les

instructions! Bedienungsanleitung lesen und

beachten!Lees en respecteer de aanwijzingen!

MCZ GROUP S.p.A. - Via La Croce 8, I - 33074 Vigonovo di Fontanafredda (PN) Italy.

Utilizzare solo con combustibile adatto. A utiliser seulement avec un combustible

conforme. Nur zugelassennen Brennstoff verwenden.Gebruik enkel gepaste pellets.

NADIR / PULSAR

300 mm

500 mm

67 mg/Nm3 (13% O2)

42 mg/MJ

Potenza nominale:

8 kW

0,09%

85,0%

Rendement:

Rendimento :

Rendement :

Energieeffizenz:

Puissance nominale:

BImSchV

Art. 15a B-VG

VKF AEAI

Regensburger Münchener

BStV erfüllt

240 °C

EN 1324 0:2001, AC:2003,

AC:2006, A2:20 04,

Made in Italy

49 mg/Nm3 (13% O2)

31 mg/MJ

87,6%

Stäub:

Distances de sécurité (postérieures):

Veiligheidsafstand (zijdelings):

Sicherheitsabstände (Hinten):

Veiligheidsafstand (achteraan):

Distanze di sicurezza (lato):

Distances de sécurité (laterales):

Sicherheitsabstände (Seitlich):

Emissione CO (al 13% O

2):

Emissions CO (Bez.13% O2):

Mittlere CO- Emission (Bez.13% O

2):

ANTHEA (1) / MYRIA (2) / LUNA (3)

Distanze di sicurezza (retro):

300 mm

Stofdeeltjes:

Potenza nominale:

Puissance nominale:

Heizleistung:

Nominaal vermogen:

CO-emissie (bij 13% O2):

Rendimento :

Rendement :

Energieeffizenz:

Rendement:

500 mm

12,0 kW

(1)

11,0 kW

(2)

10,0 kW

(3)

Temperatura fumi:

0,11%

Température des fumées:

Mittlere Abgastemperatur:

Temperatuur rook:

Particolato:

Poussieres:

300 °C

MCZ GROUP S.p.A. - Via La Croce 8, I - 33074 Vigonovo di Fontanafredda (PN) Italy.

07

BImSchV

Art. 15a B-VG

VKF AEAI

Regensburger BStV erfüllt

Prodotto conforme all'installazione in canna multipla. Produit conforme à l'installation

dans un conduit multiple. Gerät ist für eine Mehrfachbelegung des Schornsteins

geeignet.Product conform de installatie in een multi-rookkanaal.

Apparecchio a fu nzionamento intermittente. Produit à fonctionnement intermittent.

Zeitbrand Feuerstätte. Apparatuur voor intermitterende werking.

Utilizzare solo con combustibile adatto. A utiliser seulement avec un combustible

conforme. Nur zugelassennen Brennstoff verwenden.Gebruik enkel gepaste pellets.

Leggere e seguire le istruzioni! Lire et suivre les

instructions! Bedienungsanleitung lesen und

beachten!Lees en respecteer de aanwijzingen!

COD: 890 70080

Contents

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

INTRODUCTION

Revisions to the publication ...................................................................................................................... 4

Manual preservation. ............................................................................................................................... 4

How to read the manual .......................................................................................................................... 4

1. WARNINGS AND WARRANTY CONDITIONS ...................................................................................... 5

1.1. SAFETY WARNINGS .......................................................................................................................... 5

1.2. OPERATING WARNINGS .................................................................................................................... 5

1.3. WARRANTY CONDITIONS ................................................................................................................. 5

1.3.1. Restrictions ................................................................................................................................ 6

1.3.2. Exclusions .................................................................................................................................. 6

2. NOTIONS FOR INSTALLATION ACCORDING TO UNI 10683 ............................................................. 7

2.1. OPERATING AREA ............................................................................................................................. 7

2.2. PRECAUTIONS .................................................................................................................................. 7

2.3. EXTERNAL AIR OUTLET .................................................................................................................... 8

2.4. CHIMNEY FLUE CONNECTIONS .......................................................................................................... 9

2.5. CHIMNEY FLUE ................................................................................................................................. 9

2.5.1. Examples of chimney flues ........................................................................................................ 10

2.6. CHIMENYPOT ................................................................................................................................. 11

3. DIMENSIONS AND TECHNICAL SPECIFICATIONS .......................................................................... 12

3.1. PRESTIGE LINE .............................................................................................................................. 12

3.2. DESIGN LINE .................................................................................................................................. 15

3.3. MODULO LINE ................................................................................................................................ 18

4. INSTALLATION AND ASSEMBLY ...................................................................................................... 19

4.1. PREPARATION AND UNPACKING...................................................................................................... 19

4.2. POSITIONING ................................................................................................................................. 19

4.3. ASSEMBLY AND FEET ADJUSTMENT ................................................................................................. 20

4.4. CERAMICS ASSEMBLY ..................................................................................................................... 20

4.5. FRAME ASSEMBLY (WOOD MODULE) ............................................................................................... 20

5. OPERATION ..................................................................................................................................... 21

5.1. PRE-LIGHTING WARNINGS .............................................................................................................. 21

5.2. FUEL .............................................................................................................................................. 21

5.3. STOVE USE .................................................................................................................................... 22

5.3.1. LOADING THE FUEL ................................................................................................................. 22

5.3.2. CONTROL OF COMBUSTION ..................................................................................................... 22

5.3.2.1.

Model adjustments: LUNA – MYRIA – ANTHEA – MODULO ................................................... 23

5.3.2.2.

Model adjustments: QUASAR – ORION – SIRIO – VENUS – COMETA – ZENIT – ALPHA .......... 23

5.3.2.3.

Model adjustments: PULSAR – NADIR ................................................................................. 23

5.3.3. FIRST LIGHTING ...................................................................................................................... 23

5.4. EMERGENCY TREATMENT ............................................................................................................... 25

6. MAINTENANCE AND CLEANING ...................................................................................................... 26

6.1. CLEANING TO BE PERFORMED BY THE USER ................................................................................... 26

6.1.1. Cleaning the glass .................................................................................................................... 26

6.1.2. Cleaning upper calorite deflectors ............................................................................................. 26

6.1.3. Cleaning out the ashes ............................................................................................................. 26

6.1.4. Cleaning of stainless steel and satin-finish surfaces .................................................................... 26

6.1.5. Cleaning of painted parts .......................................................................................................... 27

6.1.6. Cleaning and characteristics of marble and steatite cladding. ...................................................... 27

6.1.7. Cleaning flue pipe .................................................................................................................... 27

6.2. CLEANING BY SPECIALISED PERSONNEL ......................................................................................... 27

INSTALLATION AND USE MANUAL

Introduction

page

4

Introduction

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

INTRODUCTION

Dear customer,

We would like to thank you for your choice of MCZ

products. We are sure that, with use, you will

appreciate the quality of an attentively designed and

tested product. Our goal is to combine technology

with easy use and, above all, safety.

For best stove operations and to fully enjoy the

heat and sense of well being it will spread

throughout your home, we suggest you

carefully read this booklet before use; please

contact your dealer for full assistance in

resolving any doubts or problems.

Congratulations on your choice and remember, the

stove MUST NEVER be used by children who should

always be kept at a safe distance from your stove!

Revisions to the publication

In order to improve the product, the Manufacturer

reserves the right to modify and update this

publication without prior notice.

Reproduction, even partial, of this manual without the

Manufacturer's authorisation is prohibited.

Manual preservation.

• Please keep and store this manual handy.

• If this manual should be lost or destroyed, or if it

is in poor condition, ask for a copy from your

retailer or directly from the manufacturer,

providing product identification data.

How to read the manual

• An essential item or one that requires specific

attention is published in “bold”.

•

“Script”

is used to invite the user to review the

illustrations or check other manual sections that

may provide more in-depth explanations.

• NOTE: the “NOTE” provides the reader with

additional information on the subject.

These symbols signal specific messages in this

booklet

WARNING:

This warning symbol found in various

points in this manual indicates that the

user should carefully read and understand

the message to which it refers since

neglect to follow these instructions

could cause serious stove damages or

injury to the user.

INFORMATION:

This symbol intends to emphasise

important information for good stove

operations. Failure to observe these

instructions could jeopardise product use

and operations may be unsatisfactory

INSTALLATION AND USE MANUAL

Chapter 1

page

5

Warnings and warranty conditions

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

1. WARNINGS AND WARRANTY

CONDITIONS

1.1. SAFETY WARNINGS

• Only qualified or authorised personnel should

install, check and maintain the stove.

• Install the stove according to correct local,

regional or state regulations.

• For correct stove and accessory use and to

prevent accidents, always follow the instructions

in this booklet.

• Before beginning any operation, the user, or

whoever is operating the stove, must have read

and understood the entire contents of this

instruction booklet.

• The stove must only be used as intended. Any

other use is considered improper and therefore

hazardous.

• Do not use the stove as a ladder or support surface.

• Do not dry clothing on the stove. Any drying

racks or similar devices must be kept a certain

distance from the stove. Fire hazard.

• Assess the static conditions of the surface that will hold

the stove's weight and adequately insulate if made of

flammable material (i.e. wood, carpet, plastic).

• Avoid installation in rooms with B type gas

devices, hoods with or with exhaust, heat pumps,

collective ventilation conduits.

• Avoid installing several operating chimney flues in

the same room or the vicinity of a stair well and

make sure equipment whose simultaneous use

would cause a depression in adjacent and

communicating rooms.

• The user is fully liable for improper product use,

releasing MCX from any civil or penal liabilities.

• Any tampering or unauthorised and non original

part replacement may be hazardous to the user

and releases MCZ from any civil or penal liability.

• Some parts of the stove surface are very hot

(door, handle, glass, smoke stack, etc.).

Therefore, avoid direct contact with these parts

unless wearing protective clothing or specific

means such as, for example, heat protective

gloves or "cold" activation devices.

• Explain these hazards to the elderly, the

handicapped and especially to all children,

keeping them far from the stove when operating.

• Incorrect installation or poor maintenance (non

conform with that indicated in this manual) may

cause damages to persons, animals or property.

MCZ is not civilly or criminally liable in these

cases.

1.2. OPERATING WARNINGS

• Turn off the stove in the event of faults or poor

operations.

• Install the stove in rooms that meet fire safety

standards and equipped with all the air intake and

smoke exhaust services.

• Do not start fires with flammable materials.

INFORMATION:

• For any problem, please contact your dealer or

MCZ qualified and authorised personnel and

always request original spare parts for repairs.

• Only use the fuel stated by MCZ.

• Check and periodically clean the smoke exhaust

stack as foreseen by current regulations in the

country of installation.

• Carefully preserve this instruction manual since it

should be kept with the stove for its entire

working life. If the stove is sold or transferred to

another user, make sure the manual accompanies

the product.

• If lost, please request a copy from your dealer or

from MCZ.

1.3. WARRANTY CONDITIONS

MCZ guarantees the product, except for the

elements subject to normal wear listed below, for

two years from the date of purchase proven by a

document that indicates the dealer's name and date

of sale, if the completed warranty certificate was

returned within 8 days and if the product was installed

and inspected by a specialised installation technician

and according to the detailed instructions indicated in

the instruction manual supplied with the product.

The warranty includes the free replacement or repair

of parts recognised as factory defective.

INSTALLATION AND USE MANUAL

Chapter 1

page

6

Warnings and warranty conditions

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

1.3.1. Restrictions

The warranty does not cover parts subject to normal

wear such as: gaskets, glass, and all removable

furnace parts.

Replaced parts will be guaranteed for the remaining

warranty period from the date of product purchase.

Specifically, glass is guaranteed

from the moment the MCZ

installation technician certifies its

integrity when installation is

completed.

1.3.2. Exclusions

The warranty does not cover any part that may

be defective due to negligence or careless use,

incorrect maintenance, installation non

compliant with that specified by MCZ (see

relevant chapters in this manual).

MCZ is not liable for any damages, direct or indirect,

to persons, animals or property consequent to neglect

to observe all the instructions indicated in this manual

and especially concerning the installation, use and

maintenance warnings.

In the event of product inefficiency, please contact

your dealer and/or area importer.

Damages caused by transport and handling are not

covered by the warranty.

Exclusively refer to the supplied manual for product

installation and use.

The warranty is null and void in the event of damages

due to tampering, weather, natural calamities,

lightening, fire, defective electrical and hydraulic

systems and the lack or incorrect maintenance as per

the manufacturer's instructions.

SERVICE REQUESTS

Service requests must be addressed

to the dealer who shall forward the

request to MCZ technical assistance.

MCZ is not liable in the event the

product and any other accessory is

improperly used or modified without

authorisation.

Only original MCZ spare parts must be

used for all replacements.

INSTALLATION AND USE MANUAL

Chapter 2

page

7

Theoretic notions for installation

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

2. NOTIONS FOR INSTALLATION ACCORDING TO UNI 10683

2.1. OPERATING AREA

For good operations and good heat distribution, the stove should be

positioned in a place where the air required for combustion can flow (at

least 60 m3/h must be available) according to installation standards and

current regulations in the country of installation.

The room volume must not be less than 60 m3.

Air must enter through permanent apertures on the walls (near the

stove) that open outdoors with a minimum section of 150 cm2.

These apertures (air vents) must be made so as not to be obstructed in

any way.

Air can also be taken from adjacent rooms as long as these are

equipped with outdoor air vents and not bedrooms or bathrooms or

rooms where fire hazards do not exist such as garages, wood sheds,

flammable material warehouses, strictly observing that stated in current

regulations.

• Stoves may not be installed in bedrooms,

bathrooms and where another heating device is

installed without autonomous air flow (chimney,

stove, etc.).

• Placing the stove in explosive environments is

prohibited.

• The floor of the room where the stove is installed

must be adequately dimensions to support its

weight.

• In the event of wood floors, install a protective

covering in accordance with current regulations

in the country of installation.

• If walls are not flammable, install the stove at

least 5 cm. from the walls.

• The stove could cause overheating and damages

to plaster (yellowing, cracking, etc.) if

excessively close to the wall.

2.2. PRECAUTIONS

The stove must be installed in a suitable surface that permits routine

opening and maintenance operations.

The room must be:

• set for room operating conditions

• equipped with an adequate smoke exhaust system

• equipped with outdoor ventilation

INSTALLATION AND USE MANUAL

Chapter 2

page

8

Theoretic notions for installation

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

IMPORTANT!

• The stove must be installed and assembled by

qualified personnel.

• The stove must be connected to a chimney flue or

other vertical smoke stack that can discharge

smoke at the highest point of the house.

• The stove must be connected to the internal or

external chimney flue or smoke stack, according

to current regulations.

• Smoke is generated from burning wood and,

therefore, may dirty adjacent or nearby walls.

• Before installing the stove, drill a hole for the

external air outlet.

2.3. EXTERNAL AIR OUTLET

The room where the stove is installed must have at least as much air as

requested by normal device combustions and by room ventilation. They

may occur through permanent apertures in the room walls that lead

directly outdoors or ventilated rooms according to UNI 10683 REV.

For this purpose, drill a hole with minimum 150 cm² free section near

the stove (15 cm diameter or a 10x15cm rectangle), protected by an

indoor and outdoor grill.

The air intake must also:

directly communicate with the installation room

• be protected by a grill, made of metallic anti-insect mesh or a

suitable protection as long as it does not reduce the minimum

section.

• be installed so as to avoid obstruction

• in the event of conduits, up to 3.5 ml, increase the section by

about 5% while increased by 15% for larger measurements.

Remember that the ventilation grill always have a cm2 useful

section on one side. When selecting the grill and hole

dimension, make sure the useful grill section is greater than

or equal to the section required by MCZ for product

operations.

Connecting the air outlet directly to the stove is not

mandatory but the abovementioned section must guarantee

about 50 m³/h of air. See regulation UNI10683 REV.

IMPORTANT!

Air flow may also be obtained from a room adjacent

to the installation room as long as this flow is free

through permanent apertures that directly

communicate with the outdoors; avoid air outlets

connecting with heating units, garages, kitchens or

bathrooms.

INSTALLATION AND USE MANUAL

Chapter 2

page

9

Theoretic notions for installation

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

2.4. CHIMNEY FLUE CONNECTIONS

Connections to the chimney flue is important and should be conducted

with care and attention. Stoves have top or rear smoke exhausts.

The smoke exhaust pipe must be assembled to guarantee seals during

product operations in depression and avoid the formation and transport

of condensation to the stove.

Any manual draft adjustment devices inserted in the pipe must not

hermetically close the internal conduit section. These gates must be

equipped with a mechanism that prevents the full rotation of the valve

in the closed position. The minimum safety opening surface must be

3% of the passage section and not less than 10 cm². If the smoke

conduit has a horizontal segment, this must have a minimum upward

gradient of 3-5% (3-5 cm per meter).

The tilted horizontal part must not be longer than 2 ml.

The use of flexible and cement fibre pipes is

prohibited. The smoke stack must not cross rooms

where the installation of combustion devices is

prohibited. The use of pipes in counter-slope is

prohibited.

2.5. CHIMNEY FLUE

The chimney flue is a fundamental element in discharging smoke and

therefore must have the following requisites:

• It must be waterproof and thermally insulated.

• It must be made with heat resistant materials, resistant to

combustion products and any condensation.

• It must have a vertical slope with axis deviations not over 45°

and without narrowing.

• It must meet the requisites indicated in the technical table for

the internal chimney section and height.

• It must preferably have a circular interior section.

• If pre-existent and previously operative, it must be clean.

The chimney flue is of primary importance for the

correct operations and safety of your stove.

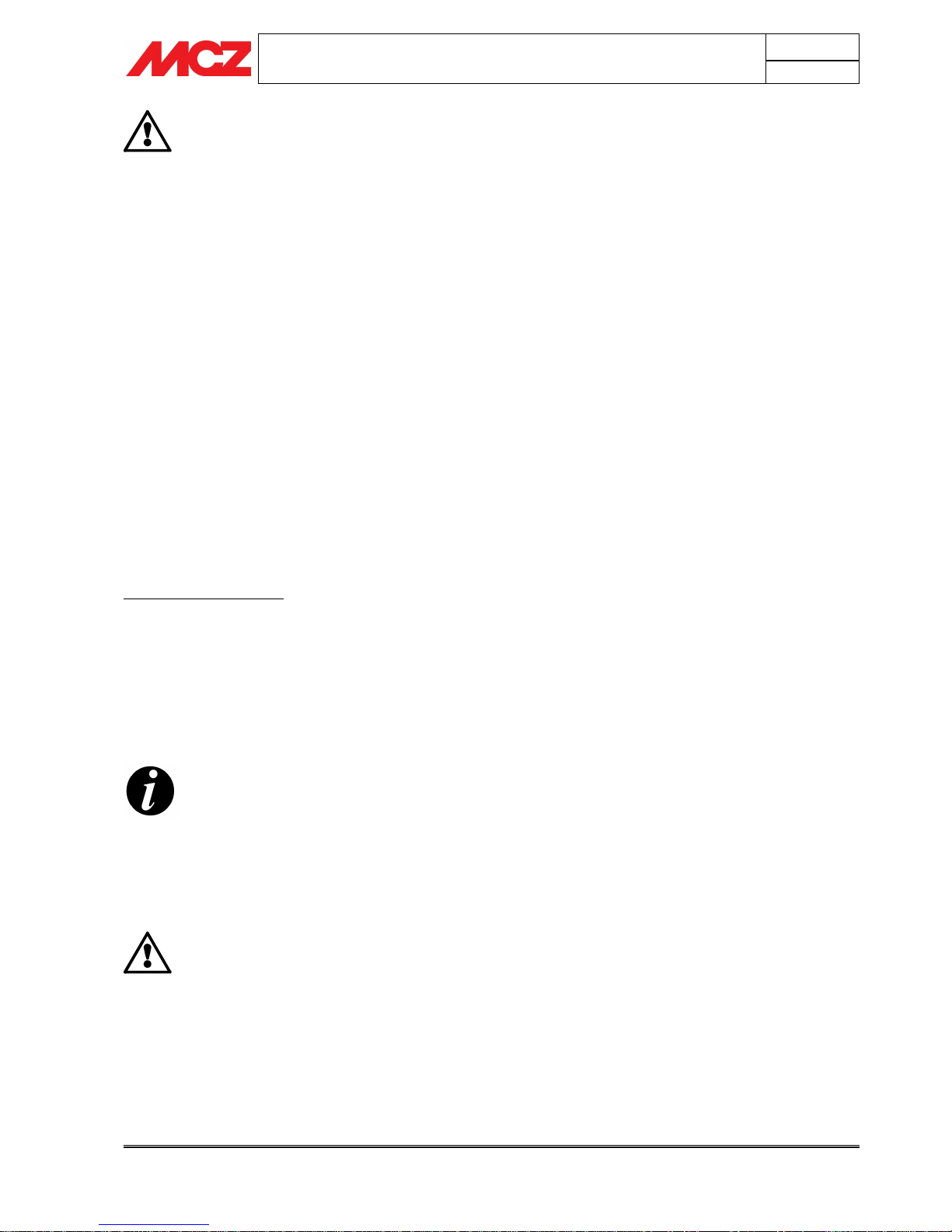

Illustration of a correctly constructed

chimney flue with a chamber and sealed

door for solid combustion product collection

and discharge at the foot of the external

ascending segment.

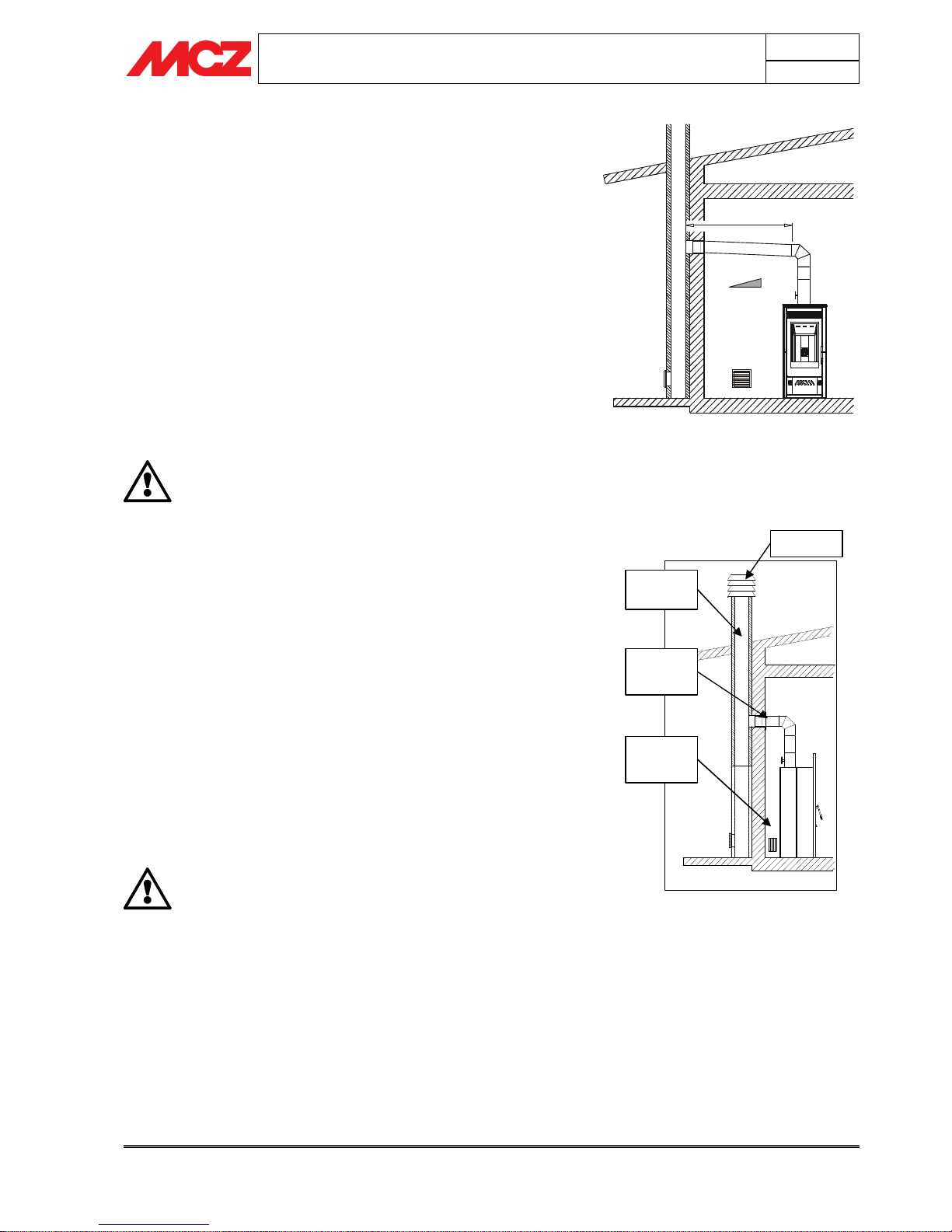

Example of a connection to the chimney flue

Cowl

Flue pipe

Air outlet

external

Smoke

connection

MAX 2 mt.

3 - 5 %

INSTALLATION AND USE MANUAL

Chapter 2

page

10

Theoretic notions for installation

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

2.5.1. Examples of chimney flues

AISI 304 stainless steel chimney

flue with dual chamber insulated

with ceramic wool or equivalent

resistant to 400°C.

EXCELLENT

Refractory chimney flue with

dual insulated chamber and

external concrete sleeve and

lightweight clay type

honeycomb material. GOOD

Traditional square section clay

chimney flue with insulating

hollow inserts.

AVERAGE

Avoid chimney flues with

internal rectangular sections

whose larger side is double the

smaller such as 20x40 or

15x30.

POOR

Square or rectangular section chimney flues must have rounded internal

corners with radius not less than 20mm. For the rectangular section,

the ratio between internal dimensions must be ≤1.5.

The recommended section for a chimney flue according to its length is

listed in the table below:

Height (m) Section (cm²)

Up to 5 mt (20x30 cm or ∅ 22 cm)

From 5 to 7 mt (20x20 cm or ∅ 20 cm)

Over 7 mt (18x18 cm or ∅ 18 cm)

N.B. Too small or too large a section reduces draught and insulation.

For special sections or section or travel variations, functional smoke

exhaust inspections must be conducted as per UNI 9615.

The smoke conduit should be equipped with a solid material collection

chamber at the mouth of the smoke conduit to be easily opened with an

airtight door.

IMPORTANT!

In the event of doubt on your chimney flue

operations or that its dimensions are different from

those recommended, we highly suggest an

authorised MCZ technician inspect and measure

chimney flue performance (micro-gauge

measurements)

MCZ s.p.a. is not liable for poor stove operations if

attributable to the use of a poorly dimensioned or

non conform installation of the chimney flue.

INSTALLATION AND USE MANUAL

Chapter 2

page

11

Theoretic notions for installation

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

2.6. CHIMENYPOT

If underestimated, it is a terminal impediment to correct "chimney

system" operations.

Chimney flue draught is also a function of its chimneypot.

Therefore, if hand made, its four exhaust sections must correspond to

the more than twice the internal section of the chimney flue.

Having to exceed the peak of the roof, the chimneypot will be

exposed to wind, therefore an industrial type is recommended.

Industrial

chimneypot with

overlapping

prefabricated

elements.

Permits excellent

smoke exhaust.

Traditional hand

made chimneypot.

The right exhaust

section must be at

least twice the

internal section of

the chimney flue,

2.5 times is ideal.

Steel chimneypot for

chimney flue with

internal smoke

deflector cone.

Permits excellent

smoke exhaust.

Chimneypots must meet the following requisites:

• They must have an internal section equal to that of the

chimney.

• They must have a useful output section not less that double

that of the internal section of the chimney flue.

• They must be built to prevent rain, snow and any foreign

object penetration in the chimney flue.

• They most be installed to guarantee excellent smoke

dispersion and out of the reflux are where counter-pressure

formation is favoured.

For paired chimney flues, the chimneypot for solid

combustion and the one for the upper floor must be at

least 50cm higher than the other to avoid pressure

transfers between paired flues.

The chimneypot must not have obstacles within 10 mt

such as walls, waterbeds and trees. Otherwise, raise it

at least 1 mt over the obstacle and, in the event of

other nearby chimneypots, keep them at least 2 mt

away and, in any case, the chimneypot must exceed

the peak of the roof by at least 1mt.

UPPER FLOOR OR

SOLID COMBUSTION

LOWER FLOOR

1

m

t

0

,

5

m

t

YES

NO

INSTALLATION AND USE MANUAL

Chapter 3

page

12

Technical features and technical specifications

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

3. DIMENSIONS AND TECHNICAL SPECIFICATIONS

3.1. PRESTIGE LINE

LUNA Technical specifications

1

0

0

1

640

8

7

2

620

594

556

5

9

4

5

2

0

1

6

0

Ø150

Fuel type Wood - Chips

Hourly consumption 2,6 kg/h – 1,8 kg/h

Maximum thermal power kW 10 Kcal 8600

Minimum thermal power kW 4,5/ Kcal 3870

Efficiency 87,6%

Heatable volume * 215/40 - 246/35 - 287/30

Minimum draught 12 Pa / 0,12 mbar

Smoke temperature 300 °C

Smoke outlet Ø 15 cm

Furnace dimensions 42,5 x 40 - h 43.5

Net weight Kg 250

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,11 %

Massive smoke capacity 10,8 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

MYRIA Technical specifications

1

1

5

0

640

620

1

0

2

1

594

556

5

9

4

5

2

0

1

6

0

Ø150

Fuel type Wood - Chips

Hourly consumption 2,9 kg/h – 2,0 kg/h

Maximum thermal power kW 11 Kcal 9460

Minimum thermal power kW 4,5/ Kcal 3870

Efficiency 87,6%

Heatable volume * 237/40 - 270/35 - 315/30

Minimum draught 12 Pa / 0,12 mbar

Smoke temperature 300 °C

Smoke outlet Ø 15 cm

Furnace dimensions 42,5 x 40 - h 43.5

Net weight Kg 250

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,11 %

Massive smoke capacity 11,0 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

INSTALLATION AND USE MANUAL

Chapter 3

page

13

Technical features and technical specifications

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

ANTHEA Technical specifications

594

556

5

9

4

5

2

0

1

6

0

Ø150

620620

1

3

0

6

1

1

7

6

Fuel type Wood - Chips

Hourly consumption 3.1 kg/h – 2.2 kg/h

Maximum thermal power kW 12 Kcal 10320

Minimum thermal power kW 4.5 Kcal 3870

Efficiency 87,6%

Heatable volume * 258/40 - 295/35 - 344/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 300 °C

Smoke outlet Ø 15 cm

Furnace dimensions 42.5 x 40 - h 43.5

Net weight Kg 250

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,11 %

Massive smoke capacity 11.2 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

QUASAR Ceramics Technical specifications

1

1

2

4

4

8

0

4

2

5

1

2

3

524

320

Ø150

Fuel type Wood - Chips

Hourly consumption 2.3 kg/h – 1.6 kg/h

Maximum thermal power kW 7.9 Kcal 6,794

Minimum thermal power kW 3.9 Kcal 3354

Efficiency 78,3 %

Heatable volume * 170/40 - 194/35 - 226/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 270 °C

Smoke outlet Ø 15 cm

Furnace dimensions 33 x 32.5 - h 40

Net weight Kg 180

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,11 %

Massive smoke capacity 9 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

INSTALLATION AND USE MANUAL

Chapter 3

page

14

Technical features and technical specifications

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

QUASAR Steel Technical specifications

4

9

0

4

2

5

1

2

3

524

320

Ø150

1

1

1

0

Fuel type Wood - Chips

Hourly consumption 2.3 kg/h – 1.6 kg/h

Maximum thermal power kW 7.9 Kcal 6,794

Minimum thermal power kW 3.9 Kcal 3354

Efficiency 78,3 %

Heatable volume * 170/40 - 194/35 - 226/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 270 °C

Smoke outlet Ø 15 cm

Furnace dimensions 33 x 32.5 - h 40

Net weight Kg 175

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,11 %

Massive smoke capacity 9 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

PULSAR Technical specifications

1

1

1

5

4

6

0

299

428

548

274

1

3

7

4

6

8

Ø

1

5

0

9

5

1

2

3

3

174

274

214

Ø

1

5

0

Fuel type Wood - Chips

Hourly consumption 2.3 kg/h – 1.5 kg/h

Maximum thermal power kW 8 Kcal 6880

Minimum thermal power kW 3.9 Kcal 3354

Efficiency 85 %

Heatable volume * 172/40 - 197/35 - 229/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 240 °C

Smoke outlet Ø 15 cm

Furnace dimensions 29 x 29.5 - h 30

Net weight Kg 140

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,09 %

Massive smoke capacity 8.8 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

INSTALLATION AND USE MANUAL

Chapter 3

page

15

Technical features and technical specifications

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

NADIR Technical specifications

1

1

1

5

4

6

0

299

428

520

260

4

8

7

1

5

6

Ø

1

5

0

260

214

Ø

1

5

0

9

5

1

2

3

3

174

Fuel type Wood - Chips

Hourly consumption 2.3 kg/h – 1.5 kg/h

Maximum thermal power kW 8 Kcal 6880

Minimum thermal power kW 3.9 Kcal 3354

Efficiency 85 %

Heatable volume * 172/40 - 197/35 - 229/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 240 °C

Smoke outlet Ø 15 cm

Furnace dimensions 29 x 29.5 - h 30

Net weight Kg 150

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,09 %

Massive smoke capacity 8.8 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

3.2. DESIGN LINE

VENUS Technical specifications

1

0

2

0

540

462

1

2

5

270

Ø

1

5

0

Fuel type Wood - Chips

Hourly consumption 2.0 kg/h – 1.4 kg/h

Maximum thermal power kW 7.4 Kcal 6364

Minimum thermal power kW 3.9 Kcal 3354

Efficiency 84,6 %

Heatable volume * 159/40 - 182/35 - 212/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 250 °C

Smoke outlet Ø 15 cm

Furnace dimensions 32.5 x 32 - h 40

Net weight Kg 170

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,10 %

Massive smoke capacity 8.5 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

INSTALLATION AND USE MANUAL

Chapter 3

page

16

Technical features and technical specifications

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

ORION Technical specifications

520

1

0

2

6

4

2

0

1

2

8

Ø

1

5

0

Fuel type Wood - Chips

Hourly consumption 2.0 kg/h – 1.4 kg/h

Maximum thermal power kW 7.4 Kcal 6364

Minimum thermal power kW 3.9 Kcal 3354

Efficiency 84,6 %

Heatable volume * 159/40 - 182/35 - 212/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 250 °C

Smoke outlet Ø 15 cm

Furnace dimensions 32.5 x 32 - h 40

Net weight Kg 170

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,10 %

Massive smoke capacity 8.5 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

ALPHA Technical specifications

1

1

5

Ø

1

5

0

1

1

5

5

500

423

Fuel type Wood - Chips

Hourly consumption 2.0 kg/h – 1.4 kg/h

Maximum thermal power kW 7.4 Kcal 6364

Minimum thermal power kW 3.9 Kcal 3354

Efficiency 84,6 %

Heatable volume * 159/40 - 182/35 - 212/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 250 °C

Smoke outlet Ø 15 cm

Furnace dimensions 32.5 x 32 - h 40

Net weight Kg 170

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,10 %

Massive smoke capacity 8.5 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

INSTALLATION AND USE MANUAL

Chapter 3

page

17

Technical features and technical specifications

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

ZENIT Technical specifications

1

2

4

2

520

447

1

1

0

Ø

1

5

0

Fuel type Wood - Chips

Hourly consumption 2.0 kg/h – 1.4 kg/h

Maximum thermal power kW 7.4 Kcal 6364

Minimum thermal power kW 3.9 Kcal 3354

Efficiency 84,6 %

Heatable volume * 159/40 - 182/35 - 212/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 250 °C

Smoke outlet Ø 15 cm

Furnace dimensions 32.5 x 32 - h 40

Net weight Kg 170

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,10 %

Massive smoke capacity 8.5 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

SIRIO Technical specifications

1

3

1

3

520

420

1

2

0

Ø

1

5

0

Fuel type Wood - Chips

Hourly consumption 2.0 kg/h – 1.4 kg/h

Maximum thermal power kW 7.4 Kcal 6364

Minimum thermal power kW 3.9 Kcal 3354

Efficiency 84,6 %

Heatable volume * 159/40 - 182/35 - 212/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 250 °C

Smoke outlet Ø 15 cm

Furnace dimensions 32.5 x 32 - h 40

Net weight Kg 170

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,10 %

Massive smoke capacity 8.5 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

INSTALLATION AND USE MANUAL

Chapter 3

page

18

Technical features and technical specifications

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

COMETA Technical specifications

1

2

5

540

462

270

Ø

1

5

0

1

3

1

2

Fuel type Wood - Chips

Hourly consumption 2.0 kg/h – 1.4 kg/h

Maximum thermal power kW 7.4 Kcal 6364

Minimum thermal power kW 3.9 Kcal 3354

Efficiency 84,6 %

Heatable volume * 159/40 - 182/35 - 212/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 250 °C

Smoke outlet Ø 15 cm

Furnace dimensions 32.5 x 32 - h 40

Net weight Kg 170

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,10 %

Massive smoke capacity 8.5 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

3.3. MODULO LINE

MODULO Technical specifications

470

4

3

5

4

3

5

6

3

0

1

5

0

0

1

3

1

0

485,5

32

1

0

3

2

625

1

3

1

,

5

Ø

1

5

0

900

Fuel type Wood - Chips

Hourly consumption 3.1 kg/h – 2.2 kg/h

Maximum thermal power kW 12 Kcal 10320

Minimum thermal power kW 4.5 Kcal 3870

Efficiency 87,6%

Heatable volume * 258/40 - 295/35 - 344/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 300 °C

Smoke outlet Ø 15 cm

Furnace dimensions 42.5 x 40 - h 43.5

Net weight Kg 215

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,11%

Massive smoke capacity 11.2 g/s

Flue pipe

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

A stove is an intermittent combustion device

* Data may vary according to the fuel used

INSTALLATION AND USE MANUAL

Chapter 4

page

19

Installation and assembly

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

4. INSTALLATION AND ASSEMBLY

IMPORTANT!

The stove must be installed and connected to the

chimney flue by specialised technicians or skilled

personnel so that every local or national regulation is

met and, in any case, in accordance with regulation

UNI 10683 REV.

When the stove and frame is unpacked, make sure all parts are in

perfect working order and check for damages due to transport.

If the stove is installed in a place that is difficult to access, the weight

can be reduced by removing internal elements in the furnace. Please

remember to correctly reassemble all elements.

4.1. PREPARATION AND UNPACKING

Open the packaging, remove the brackets, remove the stove from the

platform and position it in the selected area making sure it meets that

foreseen.

The stove must always be kept upright and exclusively moved with a

trolley. Pay careful attention that the door and its glass are protected

from mechanical collisions that could jeopardise their integrity.

Moving the product must always be done with care. If possible, unpack

the stove in the area where it is to be installed.

Packaging material is non-toxic, therefore it does not require special

disposal.

The end use must store, dispose or recycle packaging material in

accordance with local regulations.

4.2. POSITIONING

Always assess the static conditions of the floor that will hold the weight.

If the rear wall is made of flammable material, insulate it and

place the stove at least 30 cm from the wall. Lateral insulation

must reach at least 50 cm from the right, left and top corners.

If the stove is installed on a flammable floor,

adequate insulation is recommended.

Heat sensitive or flammable parts and objects cannot

be stored near the stove: keep these object or parts

at least 100 cm away from the most protruding stove

part.

Stove packaging example

1000

500

3

0

0

M

i

n

INSTALLATION AND USE MANUAL

Chapter 4

page

20

Installation and assembly

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

4.3. ASSEMBLY AND FEET ADJUSTMENT

Some models require the assembly of support feet whose purpose is to

level the stove to be well-aligned and stable. For the Wood Module, the

feet also lift the structure to prevent the decorative frame from coming

into contact with the floor. Correct adjustment requires the frame to be

about 0.5 cm above the floor.

The feet are screwed into the structure base and can be installed as

illustrated and adjusted using a screwdriver.

4.4. CERAMICS ASSEMBLY

For the assembly of ceramics for each specific wood stove model,

please see the ceramics installation manual in the latter's packaging.

Assembly instructions for the Modulo product decorative frame are

included below.

4.5. FRAME ASSEMBLY (WOOD MODULE)

For stove frame assembly, after unpacking, remove the top of the

stove, unscrewing the four screws on the top, place the frame on the

structure and continue as indicated below

PHASE 1

Near and fit the lower frame supports in the slots on the lower part of

the stove structure.

PHASE 2

Near the frame and fit the top edge of the structure so the screws

match the holes on the structure. Secure the frame with the fastening

screws as illustrated.

After levelling the last tile, make sure the cornice is fastened

correctly to the structure of the heater, checking that the

latter is firmly anchored.

Phase 2 Match the frame to the structure as illustrated and secure using the

fastening screws and bolts

Phase 1 Fit the lower frame supports on

the lower part of the structure

INSTALLATION AND USE MANUAL

Chapter 5

page

21

Operation

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

5. OPERATION

5.1. PRE-LIGHTING WARNINGS

Make sure you have read and completely understood the contents of

this instruction booklet.

Remove any components which might burn from the stove and door

(various instructions and adhesive labels).

Remove the stickers from the ceramic glass or the high temperature

could melt them and irreparably damage the glass. In this case, the

MCZ warranty does not cover the glass.

The stove can be installed in a corner or against a wall.

Avoid touching the stove the first time it is used since its

paint completes drying and hardens in this phase.

It is good practice to provide plenty of ventilation in the room

during the initial lighting, as the stove will give off a small

amount of smoke and smell of paint.

If necessary, touch up the paint with the aerosol spray in the

original colour (see "stove accessories”)

Do not stay near the stove, and as previously mentioned, ventilate the

room. The smoke and the smell of paint will vanish after about one

hour of operation. There are no health risks involved.

The stove will be subject to expansion and contraction

during the stages of lighting and cooling down, and

may therefore make slight creaking noises.

This phenomenon is absolutely normal, the structure

being made of sheet steel, and must not be considered

a fault.

It is extremely important to be sure not to take the

stove to full heat straight away, but to bring it

gradually up to temperature.

This avoids damages to seals and the steel structure.

Do not demand full heating

performance straight away!

5.2. FUEL

FUEL: Wood

To get the best performance from your stove, it is of prime importance

to use firewood with suitable characteristics.

It is possible to use firewood such as oak, beech, ash, robinia or

ilex, or manmade logs from compressed wood without added resins.

These have a high calorific power and must be used with

caution to avoid overheating which could damage the stove.

INSTALLATION AND USE MANUAL

Chapter 5

page

22

Operation

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

Fuels such as poplar, pine, lime and chestnut have a low calorific value,

being soft woods, soft in the sense of being pulpy, and they do not burn

long. For all listed types, the humidity contained in them is a

fundamental factor.

A high percentage of moisture produces condensation in the

smoke duct causing an alteration in the draught and

generating smoke and a significant deposit of soot in the

firebox, on the glass of the door and in the flue pipe with a

possible risk of a chimney fire later on. It also causes a

considerable overall drop in efficiency.

The use of damp or treated wood emits a higher quantity of

smoke than normal that can dirty glass faster. Also the low

performance of the chimney flue can jeopardise glass

cleanliness since smoke remains in the combustion chamber

longer than normal.

Do not use treated fuels (such as painted or varnished

wood) or unsuitable materials (such as plastics and

derivatives), which could release toxic or polluting

substances.

Do not burn rubbish.

The gases produced by combustion based on the use

of unsuitable fuels cause damage to the stove and the

chimney, they cause pollution and can significantly

compromise your health.

5.3. STOVE USE

5.3.1. LOADING THE FUEL

To load fuel, simply open the door by rotating/lifting the handle and

pulling the door open.

During use, the metal parts and the glass reach high temperatures, so it

is necessary to use the special thermal glove supplied.

During combustion, the combustion chamber door must remain

closed.

Loading quantities of fuel over those indicated in the

technical sheets for each single product is prohibited.

Excessive quantities of fuel in the combustion

chamber could damage and deform the furnace and

stove structure.

MCZ is not liable for any damages caused by

overloaded fuel of the use of fuel that does not meet

specifications.

5.3.2. CONTROL OF COMBUSTION

According to the stove model, combustion regulation and therefore

combustion air intake is slightly different but always adjustable using a

simple lever or knob. Simply moving or rotating this lever increases or

decreases the quantity of air entering the combustion chamber.

Entering air is divided in:

Wood drying

time (i.e. beech)

%

humidity

Heat

power

Kcal/h

Freshly cut 50 /

3 months

40 2410

6 months 35 2700

9 months 30 2900

12 months 25 3150

15 months 20 3400

18 months 15 3710

21 months 10 3980

INSTALLATION AND USE MANUAL

Chapter 5

page

23

Operation

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

PRIMARY AIR:

Primary air is that emitted at the base of the flame to promote stove

lighting

SECONDARY AIR:

Secondary air emission is set and used to partially clean the glass

permitting the combustion process to be completed. Thanks to this, if

well calibrated, stove yield and heating performance is improved.

5.3.2.1. Model adjustments: LUNA – MYRIA –

ANTHEA – MODULO

Move the regulation lever to the right to increase combustion air

entrance in the combustion chamber. Vice versa, move the lever to the

left to reduce entrance.

Primary and secondary air entrance is set; moving the lever

automatically sets the quantity of incoming primary and secondary air.

5.3.2.2. Model adjustments: QUASAR – ORION –

SIRIO – VENUS – COMETA – ZENIT – ALPHA

Pull out the regulation lever to increase the entrance of combustion air

in the combustion chamber. Vice versa, push in the lever to decrease it.

Primary and secondary air entrance is set; moving the lever

automatically sets the quantity of incoming primary and secondary air.

5.3.2.3. Model adjustments: PULSAR – NADIR

Combustion air regulation in these model is slightly different than the

previous in that primary and secondary air regulation are independent.

PRIMARY AIR or START LEVER

The left lever, marked “START” on the wood door, brings a large

quantity of primary air under the furnace fire surface to quickly and

efficiently light the fire. To do this, push the lever to the limit stop.

15 minutes after light the fire, this lever should be closed pulling

it out to its limit stop. From this moment, regulations are only made

with the secondary air knob.

SECONDARY AIR AND POST-COMBUSTION KNOB

Use this knob to regulate secondary air entrance to the combustion

chamber. As mentioned, secondary air is the one that permits

combustion to complete and improves yield. Rotate the knob counterclockwise to increase the quantity of incoming air; vice versa, rotate the

knob clockwise to reduce the quantity of air in the combustion chamber.

5.3.3. FIRST LIGHTING

It is advisable to approach the first lighting with caution, using

good-quality, well-seasoned wood.

Combustion air entrance must be fully open. Once combustion has

started, pieces of wood of normal size may be added.

MAX

MIN

INSTALLATION AND USE MANUAL

Chapter 5

page

24

Operation

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

The flame must have as far as possible a smooth and laminar flow.

On the various occasions when the stove needs reloading, the

door should be opened slowly, to avoid blowbacks of smoke

into the room.

Proceed as follows:

• Place a small amount of balled paper in the stove.

• Cover the paper with a small quantity of twigs and a few

pieces of wood.

• Fully open the combustion air regulator.

• Light the paper and, if necessary, keep the door open for

several minutes until the combustion chamber and chimney

flue are heated.

• When the twigs are burning, the door can be closed.

As the fire burns, add wood. Never overload the stove with wood (see

technical specifications in the table).

As soon as the flames have died down and a bed of embers has

formed, load the stove in the normal way.

Small loads of wood are preferable to large ones for

combustion.

We suggest this fuel loading method is adopted even in subsequent

product use.

To obtain nominal power, place the load of wood indicated

in the technical specifications table in the combustion

chamber (

chapter 3

). Stove autonomy is about 45 minutes.

When the fire dies down, load the stove again.

Attention

• Do not use volatile, flammable substances

(petrol, alcohol etc.) for lighting the fire.

• Do not use fuels which could release toxic

substances or pollutants.

• Do not put the fire out by throwing water on it.

• Check the external and internal air intakes, and

the flue pipe, at least once a year, arranging for

them to be cleaned.

• During use, the metal parts and the glass reach

high temperatures. For all jobs of loading the

stove, adjustment or cleaning the ash drawer,

use the insulating glove provided..

• Never leave children unattended near the stove

when it is in use.

• The risk of burns from contact with hot surfaces

is very high.

• In the event of poor weather conditions for stove

use (low pressure, temperate temperatures,

wind) reversed draught may occur in the chimney

flue. If this occurs, use a small quantity of paper

to heat the chimney flue and restore normal

draught. Afterwards, proceed with normal stove

lighting.

INSTALLATION AND USE MANUAL

Chapter 5

page

25

Operation

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

5.4. EMERGENCY TREATMENT

If for any reason the stove fire needs to be suddenly and quickly put

out or a fire in the chimney flue needs to be put out, proceed as

follows:

• If time allows, remove the grate and ashes, using a metal

container.

• Put the fire out rapidly by means of a dry carbon dioxide (CO

2

)

extinguisher

INSTALLATION AND USE MANUAL

Chapter 6

page

26

Maintenance and cleaning

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

6. MAINTENANCE AND CLEANING

ATTENTION!

All cleaning operations of all parts should be

conducted with the stove cold.

6.1. CLEANING TO BE PERFORMED BY THE USER

6.1.1. Cleaning the glass

Specific products can be used to clean the glass (see our pricelist), a

cloth dampened with water and ammonia or a bit of white ash and a

newspaper. Any soot and dirt accumulations take longer to clean.

ATTENTION!

Do not spray the product on the painted parts or on

the gaskets of the door (ceramic fibre cord)

The ceramic glass installed on MCZ products are resistant to

heat up to 750°C and are tested and inspected before and

after assembly to check for cracks, bubbles and holes.

Glass, although highly resistant to temperatures, is a fragile

element and therefore the door should be handled with care

without slamming or forcing it. Glass, since it is not elastic,

can break.

This type of glass does not burst or shatter but if it should

break, due to the above, it will only crack.

6.1.2. Cleaning upper calorite deflectors

They do not require particular care. With prolonged use, however, the

effective but porous material of which the deflectors inside the firebox

are made, wears out or can get damaged. Only when their thickness is

reduced by half or they break is it necessary to replace them.

6.1.3. Cleaning out the ashes

This operation should be performed with the stove off. Adequate ash

drawer cleaning is also recommended for correct combustion.

Ashes which are still hot must not be dumped outside in an

uncontrolled manner or put in the dustbin. Leave them to cool

down in the open air in a metal container.

6.1.4. Cleaning of stainless steel and satin-finish surfaces

Normally these surfaces do not need to be treated, but if they do,

avoid cleaning them with abrasive materials. For surfaces in stainless

and satin brushed steel we recommend cleaning with a paper towel or a

clean dry cloth moistened with a detergent based on non-ionic

surfactants ( < 5%). A spray glass cleaner may be used.

INSTALLATION AND USE MANUAL

Chapter 6

page

27

Maintenance and cleaning

Technical service - MCZ S.p.A. all rights reserved - Reproduction prohibited

6.1.5. Cleaning of painted parts

Do not clean the painted parts with wet rags when the unit is in

operation or hot to prevent thermal shock to the paint which may cause

it to detach. Do not use abrasive or aggressive products or materials.

Clean with damp cotton or paper towels.

The silicon paints used to paint MCZ products possess the

highest quality technical characteristics that make them

resistant to very high temperatures.

There is however a physical limit (380°-400°) beyond which

the paint begins to fade or (over 450°) to vitrify; it may then

flake and detach from the steel surface. If these effects are

noticed, it means temperatures have been reached that are

well above those at which the product should properly

operate. Therefore, you should use the amount of fuel

specified in the technical tables.

6.1.6. Cleaning and characteristics of marble and

steatite cladding.

Steatite and marble are natural materials taken from

blocks of stone and then worked. Therefore, veins,

colour variations or other characteristics are natural

parts of the stone and should not be considered

defects.

It is important to clean carefully and with the correct

products. Cleaning the cladding incorrectly may stain

or damage the finish of the stone or marble.

Cleaning of these materials is very important and delicate. It must be

done using materials that are specifically for stone/marble.

Carefully follow the instructions on the packages of the special products

used for cleaning. Generally, you should always use water-based

materials and a soft cotton cloth.

6.1.7. Cleaning flue pipe

Mechanical cleaning of the flue pipe is recommended at least once a

year. Excessive deposits of unburnt solid material can cause problems

with the evacuation of smoke, and gives rise to a risk of chimney fires

6.2. CLEANING BY SPECIALISED PERSONNEL

WARNING:

The frequency with which the stove is cleaned should

be determined based on the type of use that is made

of the stove and the type of installation.

MCZ suggests relying on an authorized service centre

for end-of-season cleaning and maintenance, who will

carry out all of the previously mentioned work and

make a general check of the stove's components.

Loading...

Loading...