EN

USE AND INSTALLATION MANUAL

8901141800

USE AND MAINTENANCE MANUAL

Contents

page

2

INTRODUCTION....................................................................................................................................4

Document revisions ...............................................................................................................................4

Manual care..........................................................................................................................................4

How to consult the manual.....................................................................................................................4

1. WARNINGS AND GUARANTEE TERMS...............................................................................................5

1.1. GENERAL SAFETY WARNINGS..........................................................................................................5

1.2. OPERATIONAL WARNINGS ..............................................................................................................5

1.3. GUARANTEE TERMS........................................................................................................................6

1.3.1. Guarantee limits.......................................................................................................................6

1.3.2. Exclusions................................................................................................................................6

1.4. IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE PRODUCT IN ACCORDANCE WITH EC

DIRECTIVE 2002/96/EC .............................................................................................................................6

2. INSTALLATION RECOMMENDATIONS IN COMPLIANCE WITH UNI 10683 ......................................7

2.1. THE OPERATING ENVIRONMENT .....................................................................................................7

2.2. POSITIONING.................................................................................................................................8

2.2.1. Safe distances..........................................................................................................................8

2.3. CONNECTING THE COMBUSTION AIR INLET PIPE.............................................................................9

2.4. EXTERNAL AIR INLET......................................................................................................................9

2.5. FLUE PIPE CONNECTION...............................................................................................................11

2.6. CONNECTING THE STOVE TO THE FLUE PIPE.................................................................................11

2.7. AIR HUMIDIFIER (accessory).........................................................................................................12

2.8. FLUE PIPE....................................................................................................................................12

2.8.1. Flue pipe examples.................................................................................................................13

2.9. CHIMNEY .....................................................................................................................................14

3. DIMENSIONS AND TECHNICAL SPECIFICATIONS..........................................................................15

3.1. KASAI STOVE ...............................................................................................................................15

3.1.1. Technical specifications...........................................................................................................16

4. INSTALLATION AND ASSEMBLY .....................................................................................................17

4.1. PREPARATION AND UNPACKING....................................................................................................17

4.2. FOOT ASSEMBLY AND ADJUSTMENT..............................................................................................18

4.3. SIDE CLADDING ASSEMBLY...........................................................................................................18

5. OPERATION.....................................................................................................................................22

5.1. WARNINGS PRIOR TO START-UP...................................................................................................22

5.2. FUEL............................................................................................................................................22

5.3. USING THE STOVE .......................................................................................................................23

5.3.1. FUEL LOADING ......................................................................................................................23

5.3.2. COMBUSTION CONTROL.........................................................................................................23

5.3.3. FIRST START-UP....................................................................................................................25

5.4. AIR DIFFUSION SYSTEMS .............................................................................................................27

5.4.1. Natural..................................................................................................................................27

5.4.2. Air (optional kit) .....................................................................................................................27

5.4.3. Comfort Air (optional kit) ........................................................................................................27

6. MAINTENANCE AND CLEANING......................................................................................................28

6.1. CLEANING UNDER THE USER'S RESPONSIBILITY ............................................................................28

6.1.1. Cleaning the glazing ...............................................................................................................28

6.1.2. Cleaning the upper Calorite deflectors ......................................................................................28

6.1.3. Ash removal...........................................................................................................................28

6.1.4. Cleaning stainless and matt steel surfaces................................................................................28

6.1.5. Cleaning painted parts ............................................................................................................29

6.1.6. Cleaning the flue pipe.............................................................................................................29

6.2. CLEANING UNDER THE RESPONSIBILITY OF SPECIALISED STAFF....................................................29

Contents Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

QUICK RESPONSE.........................................................................................................................29

6.3.

Contents

page

3

Contents Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

Introduction

page

4

INTRODUCTION

Dear customer,

Thank you for purchasing this MCZ appliance. We are

convinced that, as you operate it, you will appreciate

the high quality of this appliance, which is the result

of painstaking design and thorough testing. Our aim is

to combine technology with simple use and, first and

foremost, safety.

Products built with OYSTER technology, where

appropriately installed, due to their fully watertight

structure, do not draw on the oxygen inside the room.

Instead, they draw air from the outside environment

and can therefore be fitted in all well-insulated homes

and in passive houses. This technology eliminates all

risk of smoke being released into the room and

ventilation grilles are no longer required.

Consequently, there will be no more flows of cold air

into the room, making it less comfortable and

compromising the overall efficiency of the system.

In the case of forced ventilation or rooms that may be

in a negative vacuum compared to the outside, a

sealed stove can be installed.

To allow optimal operation of the stove and to

benefit fully from the heat and sense of wellbeing distributed throughout your home, we

advise you to read this manual carefully before

starting it up for the first time; in the event of

faults or if in doubt, please contact your

retailer, who will provide all the necessary

assistance.

How to consult the manual

Any vital topics or those requiring special

attention are printed in “bold text”.

“Italic text”

the explanatory figures beside it or to check other

sections in the manual which may provide an

additional explanation.

NOTE: the “NOTE” provides the reader with

additional information about the topic.

These symbols indicate specific messages

found in this manual

is used to invite the user to observe

CAUTION!

This warning symbol indicates you should

read carefully and understand the

message it refers to since failure to

observe the instructions given could

damage the stove seriously and also

endanger the person using it.

INFORMATION:

This symbol is used to highlight the

information that is deemed important for

the correct functioning of the stove.

Failure to observe the instructions

provided will jeopardise the use of the

appliance, the functioning of which may

prove unsatisfactory

Document revisions

In order to improve the product and to update this

document, the Manufacturer reserves the right to

make any changes without notice.

All reproduction, including partial, of this manual is

strictly prohibited without the Manufacturer's

authorisation.

Manual care

Take care of this manual and keep it in an easily

and rapidly accessible place.

Should you misplace or destroy the manual or

should it be damaged irreparably, ask your

retailer or the Manufacturer for another copy,

specifying the product identification data.

Introduction Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

1. WARNINGS AND GUARANTEE

TERMS

1.1. GENERAL SAFETY WARNINGS

Installation, electrical connection,

functional check and maintenance of this

device must only be performed by qualified

or authorised personnel.

Install the stove in accordance with all the

local and national laws, and the applicable

European Standards in force in the place,

region or country of installation.

This appliance must not be used by anyone

(including children) with limited physical,

sensory or mental skills or with little

experience and knowledge, unless they are

supervised or have been instructed to use

the device by the person in charge of its

safety.

Only use the fuel recommended by MCZ.

The appliance must not be used as an

incinerator. The use of liquid fuel is strictly

forbidden.

The instructions provided in this manual must

always be observed to ensure the correct use of

this stove and of any appliances connected to it

as well as to avoid any accidents.

The user - or whoever is operating the stove -

must read and fully understand the contents of

this instruction manual before beginning any

operation.

The stove must only be used for its intended use.

Any other use is to be considered incorrect and

therefore dangerous.

Do not use the stove as a ladder or supporting

structure.

Do not place laundry in the stove to dry; any

clothes airers or similar items should be kept at a

safe distance from the stove. Fire hazard.

Assess the static conditions of the surface on

which the weight of the stove will bear and

provide suitable insulation if it is made of

flammable material (e.g. wood, fitted carpet,

plastic).

Avoid installing the appliance in rooms containing

type B gas appliances, or hoods with or without

an extractor fan, heat pumps, or collective

ventilation ducts (If Oyster technology is not

implemented).

Avoid having several operational flue ducts in the

room, or the proximity of a stair well and make

sure that there are no appliances in adjacent

All liability for the incorrect use of the product lies

All unauthorised tampering or replacement with

Parts of the surface of the stove can get very hot

Incorrect installation or poor maintenance (not

1.2. OPERATIONAL WARNINGS

Use the appliance in accordance with all the

Turn off the stove in the event of a failure or

Install the stove in premises which are suitably

Do not use volatile and/or flammable substances

INFORMATION:

Please contact your retailer or MCZ's qualified

Check and clean the smoke outlet pipe regularly

Keep this instruction manual in a safe place, as it

Chapter 1

page

5

communicating rooms, the concurrent use of

which causes a vacuum in one of the two rooms.

fully with the user and relieves MCZ of any civil

and criminal liability.

non-original stove spare parts could endanger the

operator and relieves MCZ of any civil and

criminal liability.

(door, handle, glass, smoke outlet pipe, etc.).

Please therefore avoid coming into contact with

these parts without wearing suitable protective

clothing or using appropriate measures, such as

heat protective gloves.

conforming to the instructions provided herein)

could cause personal injury or harm animals or

cause property damage. In this case, MCZ is

relieved of any civil and criminal liability.

local and national laws, and the applicable

European Standards in force in the place,

region or country of use.

malfunctioning.

protected against fire hazards and equipped with

all the utilities such as supplies (air and

electricity) and smoke exhaust.

(petrol-alcohol-etc.) to ignite the fire.

authorised personnel for any issues, and in the

event of repairs, demand original spare parts.

in accordance with the provisions of the

applicable regulations in the country of installation

should accompany the stove along its entire life

cycle. If the stove is sold or transferred to another

user, always ensure that the manual accompanies

the appliance.

Warnings and guarantee terms Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

1.3. GUARANTEE TERMS

MCZ guarantees the product, with the exception of

parts subject to normal wear specified below, for

two years from the date of purchase, provided that

proof of purchase is supplied in a document specifying

the name of the retailer and the date the sale was

made and that the completed guarantee certificate

was sent within 8 days of said purchase. The product

must also be installed and tested by a specialised

fitter and in accordance with the detailed instructions

provided in the instruction manual that accompanies

the product.

The guarantee covers the replacement or free repair

of parts recognised as being faulty at source

due to manufacturing defects.

1.3.1. Guarantee limits

The guarantee does not cover parts subject to normal

wear, such as: seals, glazing, and all the

removable parts of the combustion chamber.

The parts replaced will be guaranteed for the

remaining guarantee cover period starting from the

original date of purchase of the product.

The glazing in particular is

guaranteed until an authorised MCZ

fitter certifies that it is perfectly

intact at the time of completion of

installation.

1.3.2. Exclusions

The guarantee does not cover all parts found to

be faulty due to negligence or inappropriate

use, incorrect maintenance, or installation not

performed in compliance with MCZ's

instructions (see relevant chapters in this use

manual).

MCZ will not be held liable for any damage which may

- either directly or indirectly - be caused to property,

or personal injury or harm to animals ensuing from

failure to observe all the instructions provided herein

and specifically concerning the warnings regarding

installation, use and maintenance of the device.

Please contact your retailer and/or local importer in

the event of product failure.

Damage caused by transport and/or handling are not

covered by the guarantee.

Reference must be made solely to the manual

provided for product installation and use.

Chapter 1

page

6

The guarantee is not valid for damage caused by

tampering with the device, atmospheric agents,

natural disasters, electrical discharges, fires, faults in

the electrical and plumbing system and caused by

failure to perform maintenance or by incorrect

maintenance in compliance with the Manufacturer's

instructions.

Service call

Service calls must be made to the

retailer, who will forward the call to

the MCZ technical support

department.

MCZ cannot be held liable if the

product and any of its accessories are

used incorrectly or modified without

authorisation.

Only original MCZ spare parts must

be used for replacements.

1.4. IMPORTANT INFORMATION FOR

CORRECT DISPOSAL OF THE PRODUCT

IN ACCORDANCE WITH EC DIRECTIVE

2002/96/EC

.

At the end of its working life, the product must not be

disposed of as urban waste.

It must be taken to a special local authority

differentiated waste collection centre or to a dealer

providing this service.

Disposing of a appliance separately avoids possible

negative consequences for the environment and

health deriving from inappropriate disposal and

enables the constituent materials to be recovered to

obtain significant savings in energy and resources.

As a reminder of the need to dispose of appliances

separately, the product is marked with a crossed-out

wheeled dustbin.

Warnings and guarantee terms Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

Chapter 2

page

7

2. INSTALLATION RECOMMENDATIONS IN COMPLIANCE WITH UNI

10683

2.1. THE OPERATING ENVIRONMENT

For the correct functioning and an even distribution of heat, the stove

should be positioned where the air required for combustion is

accessible, in accordance with the installation instructions and the

applicable standards in force in the country of installation.

3

The volume of the room should be no less than 60 m

The air should enter through permanent apertures made in the walls

(near the stove) onto the outside with a minimum cross-section of 150

2

(in the case of non-Oyster installation).

cm

These apertures (air inlets) must be made in such a way as not to

obstruct them in any way.

Air may also be taken from adjoining rooms to the one to be ventilated,

provided they are equipped with an external air inlet and that they are

not used as a bedroom or bathroom or where there is no fire hazard,

such as: garages, timber storerooms, warehouses of flammable

materials, observing under all circumstances the provisions of all the

applicable standards in force.

If the floor is wood, lay the floor guard down, in

compliance with the applicable standards in

force in the country of installation.

If the walls are not flammable, position the

stove with a minimum rear clearance of at least

10 cm.

Extreme proximity between the stove and the

wall could cause overheating and damage the

plaster (yellowing, cracking, etc.)

Stove installation and assembly must be

performed by qualified staff.

The stove must be connected to a flue pipe or a

vertical duct that can discharge the smoke at the

highest point of the home.

The stove must be connected to a flue pipe or

internal or external vertical duct, in accordance

with the applicable standards in force.

The smoke does however result from combustion

of wood essences, and may therefore soil walls if

released in contact with or close to the latter.

Before positioning the stove, drill the hole for

the external air inlet (not in the case of

installation with Oyster technology).

.

Installation recommendations in compliance with UNI 10683 Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

Chapter 2

page

2.2. POSITIONING

In the case of concurrent installation with other heating appliances,

provide the appropriate air inlets for each one (according to the

instructions for each appliance).

Installing the stove in a bedroom or bathroom is not

permitted, nor in any room where another heating

appliance is installed without an independent air

inflow.

It is forbidden to position the stove in rooms with an

explosive atmosphere.

The floor of the room where the stove is installed

must be suitably sized to withstand its weight.

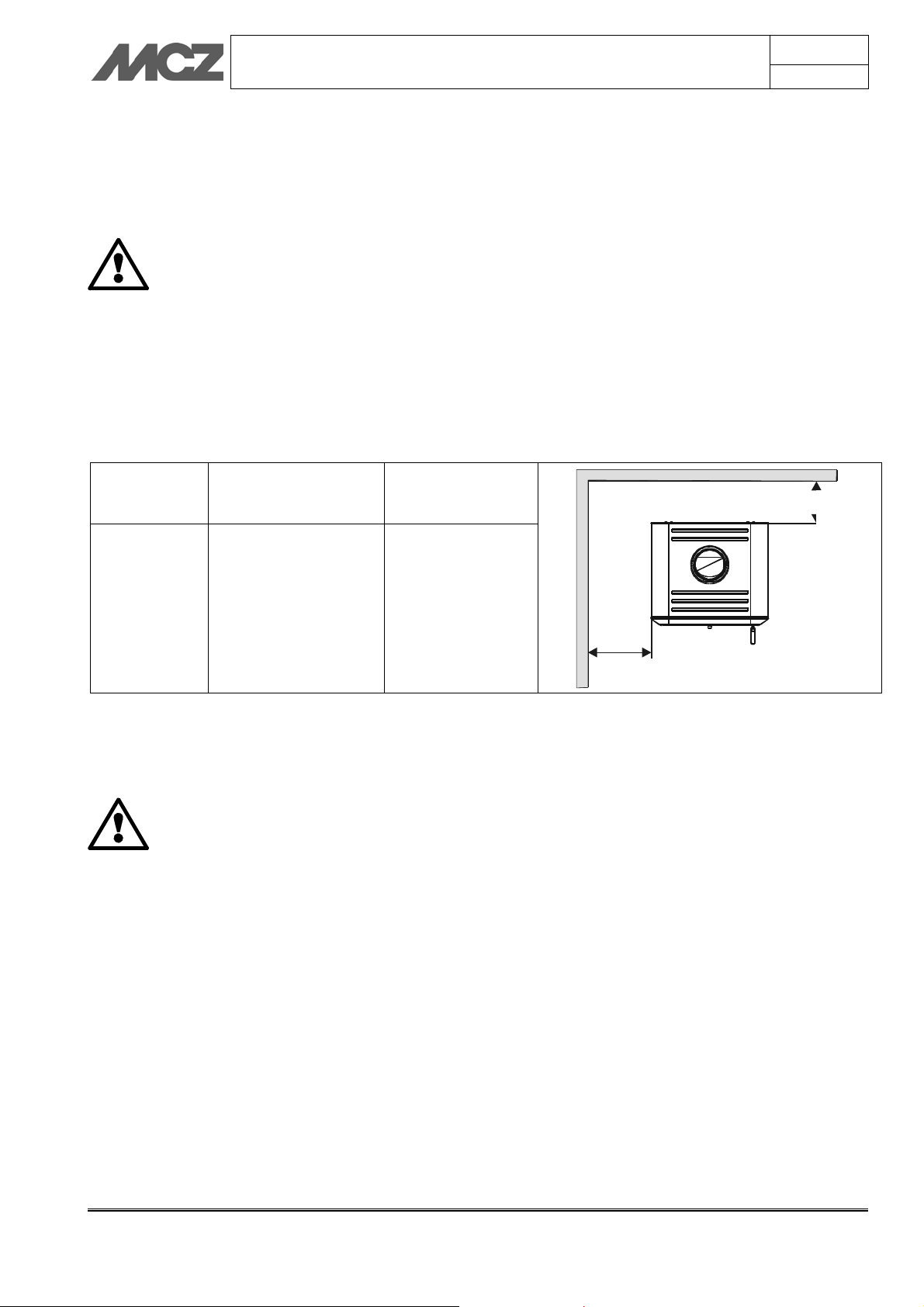

2.2.1. Safe distances

KASAI Non-flammable

A=15cm

* Leave an appropriate distance from the walls in any case in order to allow easier appliance maintenance.

If particularly delicate objects are present, such as furniture, curtains or

sofas, increase the stove clearances substantially.

If the stove is positioned on a flammable floor, we

recommend you ensure it is suitably insulated.

Heat-sensitive or flammable objects and parts

cannot be stored near the stove; keep such objects

or parts at a minimum front clearance of 100 cm

from the outermost point of the appliance.

walls *

B=20cm

Flammable walls

*

A=20cm

B=30cm

B

30 cm.

8

A

.

n

i

m

m

c

0

2

Installation recommendations in compliance with UNI 10683 Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

2.3. CONNECTING THE COMBUSTION AIR INLET

PIPE

The combustion air outlet does not necessarily have to be connected to

the outside; only if you wish to use Oyster technology do you need to

connect the combustion air inlet to the outside of the home.

Always use pipes and unions with appropriate seals

that guarantee air- and watertightness.

Products built with Oyster technology, due to their fully watertight

structure, do not draw on the oxygen inside the room. Instead, they

draw air from the outside environment and can therefore be fitted in all

well-insulated homes and in passive houses.

In order to satisfy these requirements, the 80 mm diameter connection

pipe for the combustion air inlet must be connected to the outside of

the building.

The air inlet should also:

be designed with a grille, insect-proof metal mesh or suitable

protection, provided it does not reduce the minimum crosssection.

be positioned in such a way as to not be obstructed

the maximum length permitted for ducting is 6 m, with two 90°

elbows

The stove must be connected to the external air inlet

using pipes and unions which guarantee

watertightness to comply with the requirements of

the sealed stove (OYSTER technology).

Chapter 2

Rear view of the Kasai stove:

1) Combustion air inlet

page

9

2.4. EXTERNAL AIR INLET

It is necessary for the room in which the stove is installed to provide at

least as much air as is required for regular combustion (not in the case

of installation with Oyster technology). This can be achieved through

permanent apertures made in the walls of the room to be ventilated

onto the outside or rooms aired in accordance with UNI 10683 REV.

To this end, drill a through hole in the external wall near the stove with

a minimum free cross-section of 150 cm². (15 cm diameter or 10x15

cm rectangular hole), protected by a grille on the inside and on the

outside.

The air inlet should also:

communicate directly with the installation setting

be designed with a grille, insect-proof metal mesh or suitable

protection, provided it does not reduce the minimum crosssection.

be positioned in such a way as to not be obstructed

Installation recommendations in compliance with UNI 10683 Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

in the case of ducting, up to 3.5 linear metres, increase the

cross-section by about 5% whereas for longer ducter, increase it

by 15%.

Remember that the ventilation grilles always feature an

indication of the useful cross-section in cm

When choosing the grille and hole size, check that the useful

cross-section of the grille is larger or the same as the cross-

2

on one side.

section required by MCZ for the appliance operation.

IMPORTANT!

The flow of air may also be taken from an adjoining

room to the one in which the stove is installed,

provided the air can flow freely through permanent

apertures communicating with the outside; avoid air

inlets connected to thermal power plants, garages,

kitchens or bathrooms.

Chapter 2

page

10

Installation recommendations in compliance with UNI 10683 Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

2.5. FLUE PIPE CONNECTION

The flue pipe connection is extremely important, and it should be

performed carefully and attentively. Stoves have a top or rear smoke

outlet.

The smoke outlet pipe must be fitted in such a way as to guarantee its

seal during the appliance's vacuum operation and avoid the formation

and conveying towards the stove of any condensation.

Any manual draught control devices inserted in the pipe should not

hermetically seal the internal section of the duct. These shutters should

be equipped with a suitable mechanism to avoid the complete rotation

of the valve in the closed position. The minimum safety opening surface

must be 3% of the through cross-section, and not less than 10 cm². If

the smoke duct has a horizontal section, the same should rise with a

minimum slope gradient of 3-5% (3-5 cm for every metre).

The tilted horizontal part should not be longer than 2 linear

metres.

The use of flexible pipes and fibre cement pipes is

forbidden. The smoke pipe must not cross rooms in

which it is forbidden to install combustion

appliances. The use of counter-sloping pipes is

forbidden.

MAX 2 mt.

3 - 5 %

Flue pipe connection example

Chapter 2

page

11

2.6. CONNECTING THE STOVE TO THE FLUE PIPE

The smoke outlet pipe is designed by MCZ for the outlet of smoke

towards the top of the stove.

It is possible to bring the smoke outlet to the rear of the stove, by

turning the outlet pipe by 180° and unscrewing the two screws and

knocking out the pre-perforated panel at the rear of the stove.

In both cases, it is compulsory to take the cord supplied and join it,

then insert it between the smoke union and the pipe, in order to avoid

any smoke leakages, for instance in the case of a dirty or clogged flue

pipe.

CORD

Installation recommendations in compliance with UNI 10683 Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

PIPE

SMOKE UNION

USE AND MAINTENANCE MANUAL

2.7. AIR HUMIDIFIER (accessory)

A vessel for correct air humidification is available for all models with

rear outlet (optional). Fragrances and essences can also be added for a

pleasant aromatherapy effect.

This tray is placed above the ceramic top, on top of the hole through

which the vertical flue pipe passes.

Important:

The air humidifier gets very hot. Please therefore

avoid coming into contact with it without wearing

suitable protective clothing, such as heat protective

gloves.

2.8. FLUE PIPE

The flue pipe is vital for the disposal of smoke and should therefore

comply with the following requisites:

Be waterproof and thermally insulated.

Be made of suitable heat-proof materials, resistant to the

effects of the combustion products and any possible

condensation.

Have a prevalently vertical arrangement with deviations from

the axis of no more than 45° and without kinks.

must be suitable for the specific operating conditions of the

product and marked EC (EN1856-1, EN1443).

must be suitably sized to accommodate the draught/smoke

disposal requirements necessary for the correct functioning of

the product (EN13384-1).

Have an internal section which is preferably circular.

If it is existing and has operated beforehand, it should be

cleaned.

The flue pipe is vital for the correct functioning and

safety of your stove.

Chapter 2

page

12

Chimney

Flue pipe

Smoke union

Air inlet

- external

Typical diagram of a correctly laid flue pipe

with, at the foot of the external rising

section, the positioning of a chamber with a

sealed hatch to collect and remove the solid

materials produced during combustion.

Installation recommendations in compliance with UNI 10683 Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

2.8.1. Flue pipe examples

USE AND MAINTENANCE MANUAL

Chapter 2

page

13

AISI 316 steel flue pipe with

double chamber insulated with

fibreglass or similar, resistant to

400 °C.

EXCELLENT

Refractory flue pipe with double

insulated chamber and external

concrete cladding lightened with

honeycomb material such as

clay.

GOOD

Traditional square-section clay

flue pipe with empty insulating

inserts.

MEDIOCRE

For square- or rectangular-section flue pipes, the internal corners

should be rounded with a radius of no less than 20 mm. For the

rectangular cross-section, the ratio between the internal dimensions

should be ≤1.5.

The sections/lengths of the flue pipe shown in the technical data table

are guidelines for correct installation. Any alternative configurations

must be suitably sized in accordance with EN13384-1.

You are advised to fit a chamber to the smoke duct to collect solid

materials located beneath the mouth of the smoke duct. This chamber

should be easy to open and inspect from the airtight flap.

IMPORTANT!

If you have doubts about the performance of your

flue pipe or if the dimensions of the latter differ from

the recommended values, it is highly advisable to

have an authorised MCZ fitter perform a prior survey

and instrumental measurement of the performance

of the flue pipe (measurement with micro pressure

gauge)

MCZ s.p.a. will not be held liable for any stove

malfunctioning if the same is ascribable to the use of

a poorly sized flue pipe installed in a way that does

not comply with the requisites listed herein.

Avoid flue pipes with

rectangular cross-sections

where the larger side is twice

the smaller one, such as 20x40

or 15x30.

POOR

Installation recommendations in compliance with UNI 10683 Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

2.9. CHIMNEY

Often, if it is underestimated, it prevents the correct functioning of the

"chimney system".

The draught of the flue pipe also depends on its chimney.

It is therefore vital that, if it has been hand-crafted, the development of

the four relief sections correspond to more than twice the internal

cross-section of the flue pipe.

Since it should always be higher than the ridge of the roof, the

chimney will be exposed to all weather, and so an industrialtype chimney is recommended.

Industrial chimney

with prefabricated

stacked elements.

Allows excellent

smoke disposal.

Traditional handcrafted chimney.

The correct outlet

cross-section should

be at least twice the

internal crosssection of the flue

pipe, ideally 2.5

times its size.

Chapter 2

page

14

Steel flue pipe

chimney with

internal smokedeflector cone.

Allows excellent

smoke disposal.

The chimney must:

Have an inner section equal to that of the flue.

Have a working outlet section of at least double that of the

inner section of the flue pipe.

Be built in such a ways as to prevent rain, snow and any

foreign bodies from penetrating the flue pipe.

Be positioned so as to ensure adequate dispersion of smoke

and, in all cases, outside the reflux area in which backpressures are likely to form.

In the case of paired flue pipes, the solid

combustibility or upper storey chimney shall be at

least 50 cm higher than the others in order to avoid

the transfer of pressure from one paired pipe to the

other.

The chimney must not have any obstacles within a

range of 10 metres, including walls, pitches and trees.

If this is the case, then raise it at least 1 metre above

the obstacle and in the event of other chimneys

nearby, space them at least 2 metres apart and in all

cases the chimney must protrude from the ridge of the

roof by at least 1 metre.

UPPER STOREY OR SOLID

COMBUSTIBILITY

LOWER STOREY

t

m

5

,

0

t

m

1

YES

NO

Installation recommendations in compliance with UNI 10683 Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

3. DIMENSIONS AND TECHNICAL SPECIFICATIONS

3.1. KASAI STOVE

474.5

474,5

540

270

Chapter 3

page

3

8

R

1

6

1

15

5

,

4

7

4

474.5

7

9

0

1

6

1

3

1

1

1

3

1

1

1

0

8

Ø

9

5

2

2

5

9

270

534

268

0

5

1

Ø

3

9

1

Dimensions and technical specifications Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

3.1.1. Technical specifications

Technical specifications Kasai natural/air/comfort air

Fuel type Wood - logs

Hourly consumption 2,3 kg/h – 1,2 kg/h

Global heat output Max kW 9/Kcal 7740

Global heat output Min: kW 4,5/Kcal 3440

Efficiency 78,2%

Heatable volume m3 194/40 – 221/35 – 258/30 *

Recommended draught 12 Pa / 0,12 mbar

Smoke temperature 320 °C

Particulate 25 mg/Nm3 (13% O2)

17 mg/MJ

Smoke outlet Ø 15 cm

Chapter 3

page

16

Combustion chamber dimensions 35x28xH46 cm

Net weight 150 kg

External combustion air inlet 200 cm2

CO emission in the smoke (13% O2) 0,1%

Smoke flow rate 7,9 g/s

Flue pipe

Flue pipe cross-section 18x18 cm Ø18

Minimum flue pipe height 4 m

Notes

The stove is an intermittent combustion appliance

* These data may vary according to the type of fuel

used

Dimensions and technical specifications Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

4. INSTALLATION AND ASSEMBLY

IMPORTANT!

The stove must be installed and connected to the flue

pipe by a specialised technician or by competent

staff so that all local or national regulations are

complied with and in all cases in accordance with the

provisions of standard UNI 10683 REV.

When you unwrap the stove and related frame, make sure that

every part is in perfect working order or check for any damage

due to transport. If the stove is installed in a difficult to access place,

the weight can be lightened by removing the internal elements making

up the combustion chamber. We recommend you reposition each

element correctly.

4.1. PREPARATION AND UNPACKING

Chapter 4

page

17

The Kasai stove is delivered with three different packagings:

one contains the stove (fig.2)

one contains the metal sides fig.3 pieces “6-7-8-9”

one contains the metal top fig.4 pieces “1-2-3-4-5”

Open the package and remove the two brackets that secure the stove

to the pallet (fig.1).

Remove the two screws (A) from the bracket at the bottom right and

left of the stove.

Then remove the other three screws (B) securing the bracket to the

pallet and position the stove in the chosen location, making sure it

complies with the applicable provisions.

Figure 1 - Removing the packaging

screws (Kasai stove)

A

BRACKET

STAFFA

A

Figure 2 - Kasai stove packaging

Figure 3 - Kasai stove sides packaging

B

B

B

Installation and assembly Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

Figure 4 - Kasai stove ceramic packaging

The stove must always be handled very carefully in vertical position and

only with trolleys. Pay special attention to the door and its glazing, to

protect them from mechanical knocks which would compromise their

good working order.

If possible, unwrap the stove near the chosen place of installation.

The materials making up the packaging are neither toxic nor harmful,

and so require no particular disposal measures.

Storage, disposal or any recycling is under the responsibility of the end

user in compliance with the applicable laws in force.

USE AND MAINTENANCE MANUAL

4.2. FOOT ASSEMBLY AND ADJUSTMENT

Some models envisage the assembly of support feet, designed to level

the stove so that it is aligned and stable on the floor. The feet are

screwed into the base of the structure, and they can be installed as

illustrated in the figure and adjusted with a screwdriver, inserting it into

the tip of the feet.

Chapter 4

page

18

4.3. SIDE CLADDING ASSEMBLY

The installation of the metal sides does not present any particular

difficulties.

1. Take the central piece “3” and a side piece (“4” or “5”) out of

the packaging and, using the two trilobe screws “c”, screw it

onto piece “3” to achieve the piece as shown in figure 5.

Repeat the operation on the other side part.

5

4

3

Figure 5 - Kasai stove base

To facilitate threading, it is advisable to carry out the

threading first without metal sheet to avoid any

impediments.

c

3

5

4

Installation and assembly Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

2. Take the base, consisting of pieces “3-4-5” and secure it to

the stove using the screws “d” to the left and right of the stove

figure 6.

USE AND MAINTENANCE MANUAL

Figure 6 – Fastening the base (Kasai stove)

Chapter 4

page

19

3. Take the profiles (“8 and 9”) and secure them to the sides

(“6 and 7”) using two self-tapping screws in position “e” (one

above and the other below) figure 7.

Figure 7 – Fastening profiles 8-9 to side

6-7 (Kasai stove)

e

e

6

8

7

9

e

Installation and assembly Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

4. The metal sides (“6-7”) with the profiles (“8-9”) assembled

previously should be secured to the structure of the stove,

inserting the purpose-provided pins “B” featured in the lower

part of the side in holes “b” featured in the stove.

Subsequently, on the upper part of the side, secure the two

screws “A” (one to the left and the other to the right) to the

edges of the structure where the holes are featured.

Repeat the same procedure for the other side (fig.8).

Insert the spacers (rubber pad “U” + washer “V”) into the

holes at the top of the sides for the top to rest on.

1

2

Installation and assembly Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

8

3

USE AND MAINTENANCE MANUAL

A

U

V

6 + 7

Figure 8 - Side cladding (Kasai stove)

9

b

4 + 5

prohibited

Chapter 4

page

B

B

20

USE AND MAINTENANCE MANUAL

5. Fix part “2” to the top “1” using four trilobe screws, figure 9.

1

Figure 9 - Top (Kasai stove)

2

Chapter 4

page

21

1

2

6. Rest the metal top on top of the sides, making sure the pins

“s” of the sides correspond with the holes “h” in the top.

f

s

Figure 10 - Position of metal Top (Kasai

stove)

h

Installation and assembly Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

5. OPERATION

5.1. WARNINGS PRIOR TO START-UP

Make sure you have read and fully understood the contents of this

instruction manual.

Remove all components which could burn from the stove and door

(instructions and various adhesive labels).

Remove the stickers from the glass ceramic otherwise the high

temperature could melt them and cause irreparable damage to the

glass. If this is the case, MCZ will not guarantee the glass.

The stove can be positioned either in a corner or up against a wall.

Avoid touching the stove during the initial start-up, since the

paint completes its drying process during this time and

hardens.

It is good practice to guarantee the efficient ventilation in the

room during the initial start-up, since the stove will release

some smoke and paint smells, which is completely normal!

If necessary, touch up the paint with the spray can of the

dedicated colour. (see "Stove accessories”)

Do not stand close to the stove and as mentioned, air the room. The

smoke and paint smell will disappear after about an hour of operation,

but remember that they are not in any case harmful.

The stove will undergo expansion and contraction

during the start-up and cooling phases, so it may

squeak slightly.

This is completely normal, since the structure is made

of laminated steel and should therefore not be

considered a defect.

Chapter 5

page

22

It is extremely important to make sure you do not

immediately overheat the stove, but instead raise the

temperature gradually.

This will avoid any damage to the welding and to the

steel structure.

Do not try to achieve the maximum

heating efficiency immediately!

5.2. FUEL

FUEL: Wood

In order to get the best efficiency from your stove, it is of vital

importance that you use wood with appropriate characteristics.

Heating wood can be used, such as oak-beech-ash-robinia or non-

resinated pressed logs. The latter have a high calorific value and

Operation Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

must be used with caution to avoid harmful overheating of the

stove

Fuels such as poplar-pine-linden-chestnut have a low calorific value as

the wood is soft, i.e. tender, and does not last long. The humidity

content is fundamental for all types of wood.

A high percentage humidity causes condensation to form in

the smoke duct, causing an alteration to the draught and

generating smoke and considerable soot deposits in the

combustion chamber, on the door glazing and on the flue

pipe, with the subsequent possible fire hazard in the same; in

addition, it leads to a much lower global efficiency.

The use of humid or treated wood releases a larger than

normal quantity of smoke, which could soil the glass more

quickly. The poor performance of the flue pipe can also

compromise the cleanliness of the glass, considering that the

smoke remains in the combustion chamber longer than usual.

Do not use treated fuels (painted or lacquered wood)

or non-compliant fuels (plastic or derivatives) which

could release toxic substances or pollutants.

Do not burn waste.

The gases produced by combustion resulting from the

use of unsuitable fuel could damage the stove, the

flue pipe, pollute and compromise your health.

Chapter 5

page

Wood drying

time (e.g. beech)

humidity

%

Calorific

value

Kcal/h

Freshly cut 50 /

3 Months 40 2410

6 Months 35 2700

9 Months 30 2900

12 Months 25 3150

15 Months 20 3400

18 Months 15 3710

21 Months 10 3980

23

5.3. USING THE STOVE

5.3.1. FUEL LOADING

To load the fuel, simply open the door by lifting the handle and pulling

the door towards you.

During use, the metal parts and the glazing reach very high

temperatures, so it is necessary to use a heat protective glove (not

included).

During combustion, the door to the combustion chamber must

remain closed.

It is forbidden to load larger quantities of fuel than

those specified in the technical datasheets of each

individual product.

Excessive quantities of fuel introduced into the

combustion chamber could damage and warp the

combustion chamber and the structure of the stove.

MCZ will not be held liable for any damage caused by

fuel overloads or by the use of fuels which do not

comply with the specifications.

5.3.2. COMBUSTION CONTROL

The combustion and therefore the combustion air inlet is controlled via

a single control lever.

The inlet air is either:

PRIMARY AIR:

Operation Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

p

USE AND MAINTENANCE MANUAL

Primary air is introduced at the base of the flame to encourage mostly

the stove start-up operation

SECONDARY AIR:

The introduction of secondary air is predetermined, and is used for the

partial cleaning of the glass and allows the completion of the

combustion process. Consequently, if it is well calibrated, the efficiency

and heating performance of the stove are higher.

5.3.2.1. KASAI stove air control

Turn the control lever anti-clockwise if you want more combustion air

to enter the combustion chamber. Vice-versa, turn the lever clockwise if

you want less air to enter.

The primary and secondary air inlet is predetermined; move the lever

to dose the quantity of primary and secondary inlet air.

Chapter 5

page

24

1

2

Fig.11 Primary air inlet

Start-u

Fig.12 Secondary air inlet

PRIMARY AIR LEVER (TURNED TOWARDS THE RIGHT)

The lever turned towards the right (pos.1) is designed to bring a large

quantity of primary air beneath the combustion chamber fire plane, to

allow rapid and effective ignition of the fire (fig.11).

SECONDARY AIR LEVER (TURNED DOWN)

Secondary air, as mentioned above, allows the completion of

combustion and increases the efficiency (lever in pos.2 - fig.12).

The position of the lever in fig.12 determines the nominal output,

minimizing primary air and the secondary air inlet.

LEVER TURNED TOWARDS THE LEFT

From this point, turn the lever clockwise to decrease the quantity of air

in the combustion chamber until position 3 is reached, where only a

minimum quantity of primary air is present (fig.13).

This position is used to prolong combustion (for instance, at night, or

when you are not at home) so that the stove is set to minimum for

auto-combustion, to save on fuel and keep the flame burning.

3

Fig.13 Minimum primary air

inlet

Operation Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

5.3.3. FIRST START-UP

We recommend that the first start-up be performed with

caution, using fine and seasoned wood.

The combustion air inlet must be completely open.

When combustion has started up, normal sized wood can be

introduced.

The flame must be as laminar as possible.

During the various reloading processes, the fire door must be

opened slowly to avoid smoke being released into the room.

Proceed as follows:

Place a small ball of scrunched up paper into the stove.

Cover the paper with a small quantity of twigs and a few

pieces of wood.

Open the combustion air damper completely (right-hand

lever).

Light the paper and if necessary keep the door open a few

minutes until the combustion chamber and the flue pipe begin

to warm up.

Once the twigs have caught alight, you can shut the door.

As the fire gradually burns, add wood. In all cases, never overload the

stove with wood (see the technical data in the table).

As soon as the flames have died down and a bed of embers has

formed, load the stove normally.

Small loads are preferable to large loads of wood for

combustion.

We recommend you implement this fuel loading method, also in all

subsequent appliance use.

To achieve the nominal heat output, introduce the wood

load indicated in the technical data table into the

combustion chamber (

is approximately 45 minutes. On completion of combustion,

reload the stove again.

chapter 3

). The stove's running time

Chapter 5

page

25

Operation Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

Chapter 5

page

26

Caution!

Do not use volatile and/or flammable substances

(petrol-alcohol-etc.) to ignite the fire.

Do not use fuels that could release toxic

substances or pollutants.

Do not put the fire out by throwing water on it.

Check the external-internal air inlet and the flue

pipe at least once a year, cleaning them

thoroughly.

During use, the metal parts and the glazing reach

very high temperatures. Use suitable protections

when reloading or adjusting the appliance or

removing ash.

Never leave children unsupervised near the stove

when it is operating.

There is a very high risk of scalding due to

contact with hot parts.

In the event of poor weather conditions for the

operation of the stove (low pressure, external

temperatures not particularly harsh, windy day),

this may lead to inverse draught in the flue pipe.

If this is the case, we recommend you use a

small quantity of paper to heat the flue pipe and

restore normal draught. Then proceed with

normal stove start-up.

Operation Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

5.4. AIR DIFFUSION SYSTEMS

Heat is transmitted to the rooms in the following system:

1. Natural (standard)

2. Air (optional kit)

3. Comfort Air (optional kit)

5.4.1. Natural

The heat is transmitted in the room via natural convection.

The hot air that forms inside the stove is diffused uniformly and

naturally in the room.

5.4.2. Air (optional kit)

Heat is released through forced ventilation. Thanks to an optional kit to

be installed on the stove, the room can be heated up quickly and more

efficiently.

For further details, we recommend you read the instructions contained

in the kit.

Air kit (accessory)

Chapter 5

page

27

5.4.3. Comfort Air (optional kit)

The exclusive patented Comfort Air system conveys the warm air to

other rooms, even not communicating, to create a proper heating

system.

This system is possible through the installation of an optional kit.

For further details, we recommend you read the instructions contained

in the kit.

Comfort Air kit

(accessory)

Operation Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

USE AND MAINTENANCE MANUAL

6. MAINTENANCE AND CLEANING

CAUTION!

All the cleaning operations of all parts should be

performed with the stove completely cold.

6.1. CLEANING UNDER THE USER'S

RESPONSIBILITY

6.1.1. Cleaning the glazing

To clean the glazing, you may use specific products (see our price list),

a cloth dipped in water and ammonia solution or a little white ash and a

sheet of newspaper. Any soot build-up and dirt will prolong the glazing

cleaning time.

CAUTION!

Do not spray the cleaner onto the painted parts or

onto the seals of the door (ceramic fibre cord)

The glass ceramic installed on MCZ products have a heat

resistance of approximately 750 °C and are tested and

checked prior to and after assembly to check for any cracks,

bubbles and swelling.

Despite the high resistance to temperatures, the glazing is

nonetheless a fragile element and so it is advisable to handle

the door carefully without slamming it or forcing it open or

shut. Since it is not a flexible element, the glazing may

break.

In addition, this type of glazing does not shatter or burst and

should it break, for the above reasons, only a crack will form.

Chapter 6

page

28

6.1.2. Cleaning the upper Calorite deflectors

They require no special care. After prolonged usage, the efficient yet

porous material used to make the internal deflectors of the combustion

chamber wears and may get damaged. They will need to be replaced

only when their thickness is halved or they break.

6.1.3. Ash removal

This task must be performed with the stove turned off; we recommend

you clean the ash tray thoroughly to ensure correct combustion.

Open the door and remove the ash tray as shown in figure 14.

Hot ashes must not be stored outside unsupervised or thrown

into the rubbish bin. Allow it to cool in the open air in a metal

container.

6.1.4. Cleaning stainless and matt steel surfaces

Usually these surfaces do not need any special treatment and avoiding

cleaning them with abrasive materials is sufficient. For stainless and

matt steel surfaces, we recommend you clean these with a paper towel

or a dry, clean cloth dipped in detergent made with non ionic

surfactants (<5%); spray glass and mirror cleaner is recommended.

Maintenance and cleaning Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

Figure 14 - Ash tray

USE AND MAINTENANCE MANUAL

6.1.5. Cleaning painted parts

Avoid cleaning the painted parts when the product is in operation or

hot, with damp cloths to avoid the thermal shock of the paint and its

consequent detachment. Do not use abrasive or aggressive materials or

products.

Clean with a paper towel or damp cotton.

The silicone paints used to coat MCZ products have top

quality technical properties which ensure the resistance to

very high temperatures.

There is however a physical limit (380°-400°) beyond which

the paint loses its characteristics and begins to "whiten" or

(above 450°) “vitrifies” and can flake and peel away from the

steel surface. If this occurs, it means that temperatures well

above those at which the appliance should operate correctly

have been reached and consequently we recommend the use

of the quantity of fuel specified in the technical tables.

6.1.6. Cleaning the flue pipe

Chapter 6

page

29

We recommend the mechanical cleaning of the flue pipe at least once a

year; excess build-up of unburned waste could cause problems with the

smoke discharge and start a fire in the flue pipe itself.

6.2. CLEANING UNDER THE RESPONSIBILITY OF

SPECIALISED STAFF

CAUTION:

The frequency with which the stove is to be cleaned

should be determined according to its use and the

type of installation.

MCZ recommends you contact an authorised service

centre for the maintenance and cleaning of the entire

flue pipe system at the end of the season because in

addition to performing the above-mentioned

operations, a general check of the appliance will also

be performed.

6.3. QUICK RESPONSE

If for any reason it is necessary to put out the fire in the stove suddenly

and quickly or put out a fire that has started in the flue pipe, respond

as follows:

If you have time, remove the embers and ash using a metal

container.

Request urgent assistance from the competent authorities.

Maintenance and cleaning Technical dept. - All rights reserved by MCZ GROUP S.p.A. - Reproduction

prohibited

MCZ GROUP S.p.A.

Via La Croce 8

33074 Vigonovo di Fontanafredda (PN) – ITALY

Telephone: +39 0434/599599 PBX

Fax: +39 0434/599598

Internet: www.mcz.it

e-mail: mcz@mcz.it

8901141800 Rev 1 12/2011

Loading...

Loading...