EN

INSTALLATION AND USE

MANUAL

8901158500

INSTALLATION AND USE MANUAL

Contents

page

2

MCZ GROUP S.p.A. - Via La Croce 8, I - 33074 Vigonovo di Fontanafredda (PN) Italy.

09

EN 13229:2001, A 1:2003,

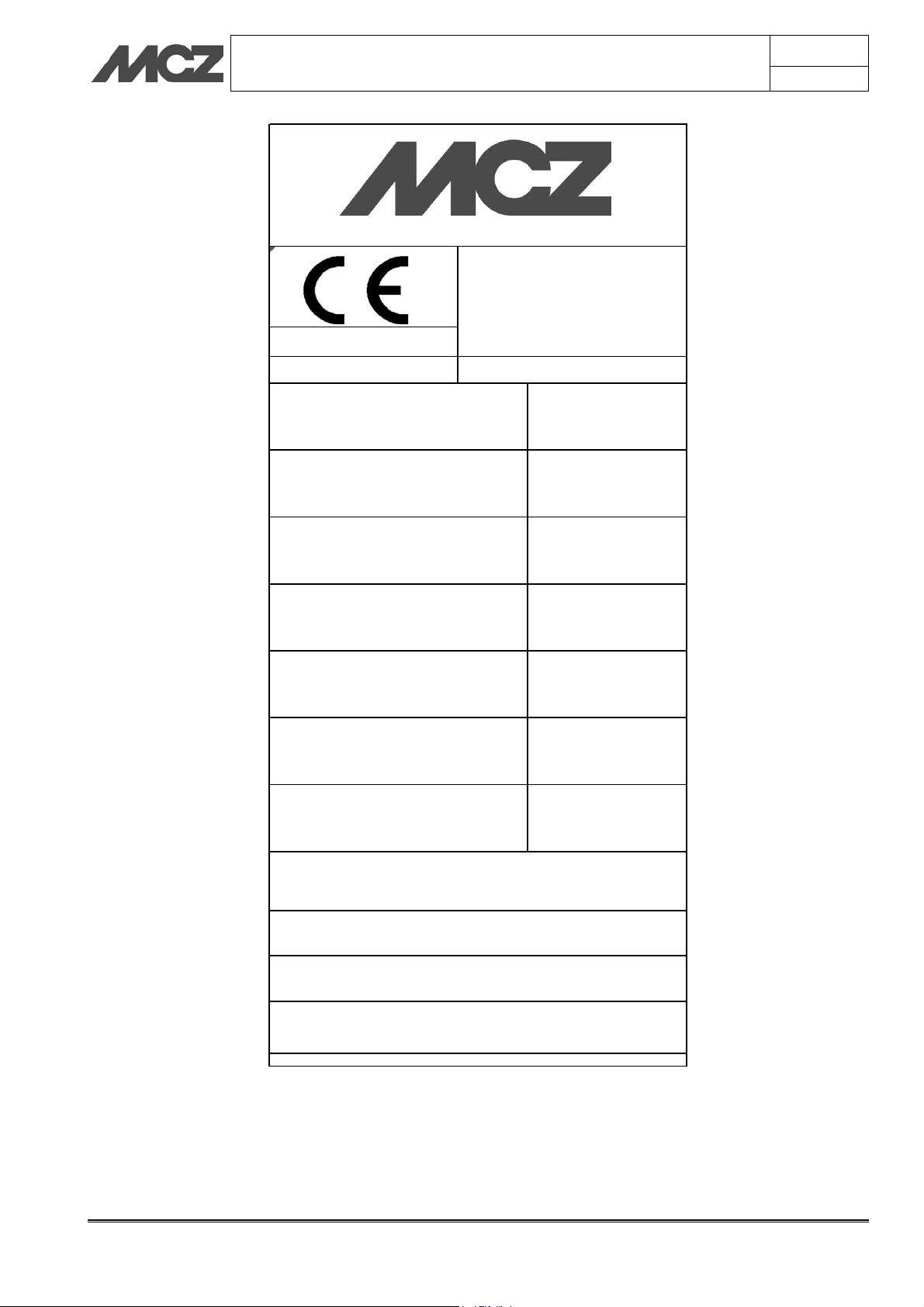

HY DROTHERM 80

Potencia nominal:

Potência nominal:

Nominal heat output:

Brændværdi:

E misió n CO ( al 13% de O2) :

E missão CO ( 13% de O 2) :

CO emission ( at 13% O2)

CO emissi on (ved 13% O2):

Eficiencia:

Eficiencia:

Efficiency:

Virkningsgrad:

Temperadura humos:

Tempretura dos fumos:

Flue gas temperature:

Røggastemperatur:

Distan cias de seg urid ad (retro):

Distan cia de seg urança (t rasiera):

Safety clarence distan ce ( back):

Sikkerhedsaf st and (bag):

Distan cias de seg urid ad (l ater ales):

Distan cia de seg urança (lateral ):

Safety cl arence di st ance (side):

Sikkerhedsaf st and (side):

Presión máxima de agua:

Pressão máxima da água:

Permi ssibl e max. water pressu re:

Max. vandtryk:

Producto conforme a la instalación de tubos múltiples. Produto conforme

para instalação em condutas multiplas. Appliance suitable for installation in

a shared flue. Apparatet kan bruges i en røggassamleledning.

Aparato de funcionamiento intermitente. Aparelho com funcionamento

intermitente . Intermitte ntly operating unit. Apparat me d inte r mitterende

funktion.

Utilizar sólo con combustibles adaptados. Utilizar somente combustivel

adaquado. U se only recommended fuels. Anvend kun anbefalede

brændsler.

Leer y se guir las instrucciones! Leia atentamente e siga a s

instruções! Read and follow the operating instructions! Følg

fabrika ntens brugervejl edni ng!

CO D : 8901028600

HY DRO T HERM 80E

26,2 kw

(15,2 kW H

0,61%

77,1%

333°C

180 mm

180 mm

1,5 bar

(150 kPa)

2

O)

Contents Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Contents

page

3

MCZ GROUP S.p.A. - Via La Croce 8, I - 33074 Vigonovo di Fontanafredda (P N) Italy.

09

EN 13229:2001, A 1:2003,

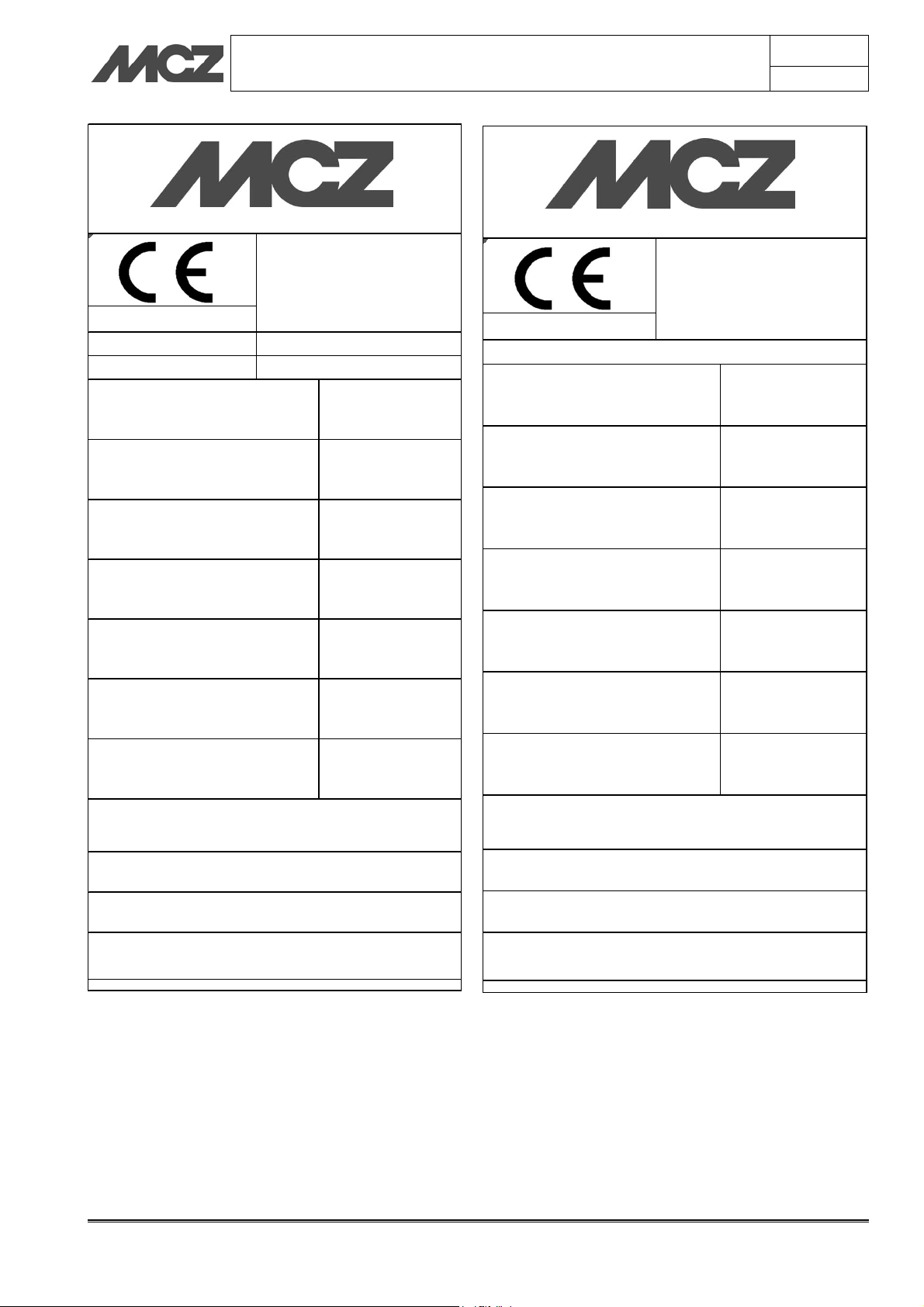

HYDROTHERM 70

HY DROTHERM 70DX

Potencia nominal:

Potência nominal:

Nominal heat output:

Brændværdi:

Emisión CO ( al 13% de O2):

E missão CO (13% de O2):

CO emission (at 13% O2)

CO emission (ved 13% O2):

Eficiencia:

Eficiencia:

Efficiency:

Virkningsgrad:

Temp erad ura hu mo s:

Temp retura do s f u mos:

Flue gas temperature:

Røggastemperatur:

Distanci as de seguridad ( ret ro):

Distanci a de segurança (trasiera) :

Safety claren ce d istance (back):

Sikkerh edsafstand (bag ):

Distanci as de seguridad ( laterales):

Distanci a de segurança (lateral):

Safety claren ce d istance (side):

Sikkerh edsafstand (side):

Presión máxima de agua:

Pressão máxima da ág ua:

Permissible max. water pressure:

Max. vand t ryk:

Producto conforme a la instalación de tubos múltiples. Produto conforme

para instalação em condutas multiplas. Appliance suitable for installation in

a shared flue. Apparatet kan bruges i en røggassamleledning.

Aparato de f uncionamie nto interm ite n te. Aparelho com funcioname nto

interm itente . Intermittently operating unit. Apparat med inte rmitter e nde

funktion.

Utilizar só lo con combustibles adaptados. Utilizar somente combustivel

adaquado. Use only recommended fuels. Anvend kun anbefalede

brændsler.

Lee r y seguir las instruccione s! Leia a tenta m e nte e siga a s

instruções! Read and follow the operating instructions! Følg

fabrikantens brugervejledni ng!

HY DROTHERM 7 0S X

COD : 8901028400

21,2 kw

(13,0 kW H

0,87%

75,2%

310°C

150 mm

150 mm

1,5 bar

(150 kPa)

2

O)

MCZ GROUP S.p.A. - Via La Croce 8, I - 33074 Vigonovo di Fontanafredda (PN) Italy.

09

EN 13229:2001, A1:2003,

HYDRO T HERM 70 V

Potencia nominal:

Potência nominal:

Nominal heat output:

Brændværdi:

E misió n CO ( al 13% de O2):

Emissão CO (13% de O2):

CO emissi on (at 13% O2)

CO emissi on (ved 13% O2):

Eficiencia:

Eficiencia:

Efficiency:

Virkningsgrad:

Temperadura humos:

Tempretura dos fumos:

Flu e gas temperature:

Røggastemperatur:

Distancias de segurid ad ( ret ro):

Distancia de segurança (t rasiera):

Safety claren ce distance (back):

Sikkerhedsafst and (b ag):

Distancias de segurid ad (lat erales):

Distancia de segurança (lateral) :

Safety claren ce distance (sid e) :

Sikkerhedsafst and (si de):

Presión máxima de agua:

Pressão máxima da água:

Permissibl e max. water pressure:

Max. vandtry k:

Producto conforme a la instalación de tubos múltiples. Produto conforme

para instalação em condutas multiplas. Appliance suitable for installation in

a shared flue. Apparatet kan bruges i en røggassamleledning.

Aparato de funcionamiento intermite nte. Aparelho com funcionamento

interm itente. Intermittently operating unit. Apparat med interm itte r e nde

funktion.

Utilizar sólo con combustibles adaptados. Utilizar somente combustivel

adaqua do. Use only recommended fuels. Anvend kun anbefalede

brændsler.

Leer y seguir las instrucciones! Leia atentamente e siga as

instruções! Read and follow the operating instructions! Følg

fabrikantens brugervejledning!

COD : 8901028500

21,2 kw

(13,0 kW H

0,87%

75,2%

310°C

150 mm

150 mm

2,0 bar

(200 kPa)

2

O)

Contents Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Contents

page

4

INTRODUCTION .................................................................................................................................... 6

1. WARNINGS AND WARRANTY CONDITIONS ..................................................................................... 7

1.1. SAFETY WARNINGS ........................................................................................................................ 7

1.2. OPERATING WARNINGS .................................................................................................................. 7

1.3. WARRANTY CONDITIONS ................................................................................................................ 7

1.3.1. Restrictions .............................................................................................................................. 8

1.3.2. Exclusions ................................................................................................................................ 8

1.4. IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE PRODUCT IN ACCORDANCE WITH EC

DIRECTIVE 2002/96/EC ............................................................................................................................. 8

2. INSTALLATION IN ACCORDANCE WITH UNI 10683 ......................................................................... 9

2.1. OPERATING AREA ........................................................................................................................... 9

2.2. PRECAUTIONS ................................................................................................................................ 9

2.3. CONNECTION TO THE EXTERNAL AIR INTAKE ................................................................................ 10

2.4. CONNECTION TO THE FLUE PIPE ................................................................................................... 11

2.4.1. Smoke valve (optional) ........................................................................................................... 11

2.5. FLUE PIPE .................................................................................................................................... 11

2.5.1. Examples of flue pipes ............................................................................................................ 12

2.6. COWL .......................................................................................................................................... 13

3. DIMENSIONS AND TECHNICAL SPECIFICATIONS .......................................................................... 14

4. INSTALLATION AND ASSEMBLY ...................................................................................................... 17

4.1. PREPARATION AND UNPACKING .................................................................................................... 17

4.2. POSITIONING ............................................................................................................................... 17

4.3. HEIGHT ADJUSTMENT .................................................................................................................. 18

4.4. RELEASE OF COUNTERWEIGHTS ................................................................................................... 18

4.5. MCZ CONTROL UNIT CONNECTION ................................................................................................ 19

4.5.1. The control unit MCZ .............................................................................................................. 19

4.5.2. Electrical connection of the control unit MCZ ............................................................................. 20

4.5.3. Operation of the control unit MCZ ............................................................................................ 21

4.6. PLUMBING CONNECTION .............................................................................................................. 23

4.6.1. Water characteristics .............................................................................................................. 23

4.6.2. Hydraulic connection with Open Tank ...................................................................................... 24

4.6.3. Hydraulic connection with Closed Tank ..................................................................................... 24

4.7. HYDRAULIC DIAGRAMS ................................................................................................................. 25

4.7.1. Diagram 1 OPEN TANK (KIT 1 OPEN TANK) .............................................................................. 25

4.7.2. Diagram 2 OPEN TANK (KIT 2 OPEN TANK) .............................................................................. 26

4.7.3. Diagram 3 OPEN TANK (KIT 3 OPEN TANK) .............................................................................. 27

4.7.4. Diagram 1 CLOSED TANK (KIT 1 CLOSED TANK) ...................................................................... 28

4.7.5. Diagram 2 CLOSED TANK ........................................................................................................ 29

4.8. THERMAL SAFETY DISCHARGE VALVE FOR CLOSED TANK CIRCUIT (HYDROTHERM 70V) ................. 30

4.8.1. Function ................................................................................................................................ 30

4.8.2. Technical specifications ........................................................................................................... 30

4.8.3. Installation ............................................................................................................................ 31

4.8.4. Maintenance .......................................................................................................................... 32

4.8.5. Safety ................................................................................................................................... 32

4.9. INSTALLATION KIT ....................................................................................................................... 33

4.9.1. Kit 1 OPEN TANK .................................................................................................................... 33

4.9.2. Kit 2 OPEN TANK .................................................................................................................... 34

4.9.3. Kit 3 OPEN TANK .................................................................................................................... 34

4.9.4. Kit 1 CLOSED TANK ................................................................................................................ 35

4.9.5. Kit 2 CLOSED TANK ................................................................................................................ 35

4.10. UNIT CLADDING ........................................................................................................................ 36

4.10.1. INSULATION OF FIREPLACE STOVE ...................................................................................... 36

4.10.2. INSULATING A WOODEN BEAM ............................................................................................ 36

Contents Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Contents

page

5

4.10.3.

Decorative hood .................................................................................................................. 36

5. OPERATION ..................................................................................................................................... 37

5.1. PRE-LIGHTING WARNINGS ............................................................................................................ 37

5.2. OPERATING TEST ......................................................................................................................... 37

5.3. CHOICE OF FUEL .......................................................................................................................... 39

5.4. LOADING THE FUEL ...................................................................................................................... 39

HEAT POWER ....................................................................................................................................... 39

KCAL/H ................................................................................................................................................ 39

5.5. CONTROL OF COMBUSTION .......................................................................................................... 40

5.6. FIRST LIGHTING .......................................................................................................................... 40

5.7. EMERGENCY SITUATIONS ............................................................................................................. 41

6. MAINTENANCE AND CLEANING ...................................................................................................... 42

6.1. CLEANING TO BE PERFORMED BY THE USER .................................................................................. 42

6.1.1. Cleaning the glass .................................................................................................................. 42

6.1.2. Cleaning the exchanger .......................................................................................................... 42

6.1.3. Cleaning out the ashes ........................................................................................................... 42

6.1.4. Cleaning flue pipe ................................................................................................................... 43

6.1.5. Lubrication and routine maintenance of the extensible guides .................................................... 43

7. DOOR ADDITIONAL WEIGHT KIT .................................................................................................... 44

7.1. Supplementary weight kits for door closure (only available for closed tank version) ............................ 44

Contents Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

INTRODUCTION

Dear customer,

Thank you for choosing an MCZ product, specifically a

fireplace stove of the Forma line.

We are sure that, with use, you will appreciate the

quality of an attentively designed and tested product.

Our goal is to combine technology with easy use and,

above all, safety.

For best fireplace stove operations and to fully

enjoy the heat and sense of well being it will

spread throughout your home, we suggest you

carefully read this booklet before use. Please

contact your dealer for full assistance in

resolving any doubts or problems.

Congratulations on your choice and remember, the

fireplace stove MUST NEVER be used by children

who should always be kept at a safe distance!

Revisions to the publication

In order to improve the product, the Manufacturer

reserves the right to modify and update this

publication without prior notice.

Reproduction, even partial, of this manual without the

Manufacturer's authorisation is prohibited.

Manual preservation

Please take care of this manual and keep it in a

place that can be quickly and easily reached.

If this manual should be lost or destroyed, or if it

is in poor condition, ask for a copy from your

retailer or directly from the manufacturer,

providing product identification data.

How to read the manual

An essential item or one that requires specific

attention is published in “bold”.

“Italics"

NOTE: the “NOTE” provides the reader with

additional information on the subject.

are used for any additional clarification.

Chapter 1

page

6

These symbols signal specific messages

in this booklet

WARNING:

This warning symbol found in various

points in this manual indicates that the

user should carefully read and understand

the message to which it refers since

neglect to follow these instructions

could cause serious fireplace stove

damage or injury to the user.

INFORMATION:

This symbol intends to emphasise

important information for good fireplace

stove operations. Failure to observe these

instructions could jeopardise product use

and operations may be unsatisfactory

Introduction Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

1. WARNINGS AND WARRANTY

CONDITIONS

1.1. SAFETY WARNINGS

Installation, electrical connection,

functional check and maintenance of this

appliance must only be performed by

qualified or authorised personnel.

Install the closed fireplace in compliance

with the applicable regulations in force in

the place, region or country.

This appliance must not be used by anyone

(including children) with limited physical,

sensory or mental skills or with little

experience and knowledge, unless they are

supervised or have been instructed to use

the device by the person in charge of its

safety.

Only use the fuel recommended by MCZ.

The appliance must not be used as an

incinerator. The use of liquid fuel is strictly

forbidden.

For correct use of the fireplace stove and

accessories, and to prevent accidents, always

follow the instructions in this booklet.

Before beginning any operation, anyone who

uses the stove must read and understand the

entire contents of this instruction booklet.

The fireplace stove must be used only for its

intended purpose. Any other use is considered

improper and therefore hazardous.

Check the conditions of the surface that will

support the weight of the stove. If it is made of

flammable material such as wood, carpet, or

plastic, provide suitable insulation.

Avoid installation in rooms with B type gas

devices, hoods with or without exhaust, heat

pumps, collective ventilation conduits.

Do not install several flue pipes in one room, and

avoid having a stairwell in the vicinity. Check that

in adjacent connected room there are not any

units whose simultaneous use would create

negative pressure in one of the two rooms.

The user is fully liable for improper product use,

releasing MCZ from any civil or penal liabilities.

Any tampering with the fireplace stove, or use of

non-original spare parts, may be hazardous to

the user and releases MCZ from any civil or penal

liability.

Parts of the surfaces of the fireplace stove are

very hot (door, handle, glass). Therefore, avoid

direct contact with these parts unless wearing

protective clothing or specific means such as, for

Chapter 1

page

7

example, heat protective gloves or "cold"

activation devices.

Incorrect installation or poor maintenance (not

compliant with the provisions of this manual)

may cause damages to persons, animals or

property. MCZ is not civilly or criminally liable in

these cases.

1.2. OPERATING WARNINGS

Turn off the fireplaces stove in the event of faults

or poor operations.

Never place flammable materials closer than 150

cm to the fireplace stove.

If the chimney flue draught is poor (due to bad

weather or improper installation), start the fire

decisively while keeping the door slightly ajar.

When you close the door, keep the air register

completely open. Use small pieces of dry wood.

If combustion problems continue, please contact

a specialized technician.

Install the fireplace stove in a location which is

suitable for fire fighting, and equipped with all

services such as air, water and electricity supply

and smoke discharge.

Do not light the fire with flammable materials.

To clean the appliance's chimney, remove the

smoke deflector. To remove it correctly, lift the

front and at the same time slide it forward in

order to free it from rear support.

INFORMATION:

For any problem, please contact your dealer or

MCZ qualified and authorised personnel and

always request original spare parts for repairs.

Check and periodically clean the smoke exhaust

stack as foreseen by current regulations in the

country of installation.

If there is a fire in the flue pipe, keep the door of

the fireplace stove and the combustion air

register closed at all times. Request assistance

from the competent authorities.

Carefully conserve the instruction booklet. It

must remain with the fireplace stove for its entire

life cycle. If the stove is sold or transferred to

another user, make sure the manual

accompanies the product.

If lost, please request a copy from your dealer or

from MCZ.

1.3. WARRANTY CONDITIONS

MCZ guarantees the product, except for the

elements subject to normal wear listed below, for

Warnings and warranty conditions Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

two years from the date of purchase proven by a

document that indicates the dealer's name and date

of sale, if the completed warranty certificate was

returned within 8 days and if the product was

installed and inspected by a specialised installation

technician and according to the detailed instructions

indicated in the instruction manual supplied with the

product.

The warranty includes the free replacement or repair

of parts recognised as factory defective.

1.3.1. Restrictions

The above guarantee does not cover components

relating to electrical parts, on which the guarantee

period is 1 year from the purchase of the product,

documented as specified above. The warranty does

not cover parts subject to normal wear such as:

gaskets, glass, and all removable fire box parts.

Replaced parts will be guaranteed for the remaining

warranty period from the date of product purchase.

Specifically, glass is guaranteed from

the moment the MCZ installation

technician certifies its integrity when

installation is completed.

1.3.2. Exclusions

The warranty does not cover any part that may

be defective due to negligence or careless use,

incorrect maintenance, installation non

compliant with that specified by MCZ (see

relevant chapters in this manual).

MCZ refuses to accept any responsibility for any

damage which may be caused, directly or indirectly,

by persons, animals or things as a result of the failure

to observe all the provisions set forth in the

instruction booklet, especially those concerning

warnings on the subject of installation, use and

maintenance of the appliance.

In the event of product inefficiency, please contact

your dealer and/or area importer.

Damages caused by transport and handling are not

covered by the warranty.

Exclusively refer to the supplied manual for product

installation and use.

The warranty is null and void in the event of damage

due to tampering, weather, natural calamities,

lightening, fire, defective electrical and hydraulic

systems and the lack or incorrect maintenance as per

the manufacturer's instructions.

SERVICE REQUESTS

Service requests must be addressed

to the dealer who shall forward the

request to MCZ technical assistance.

Chapter 1

page

8

MCZ is not liable in the event the

product and any other accessory is

improperly used or modified without

authorisation.

Only original MCZ spare parts must be

used for all replacements.

1.4. IMPORTANT INFORMATION FOR

CORRECT DISPOSAL OF THE PRODUCT

IN ACCORDANCE WITH EC DIRECTIVE

2002/96/EC

.

At the end of its working life, the product must not be

disposed of as urban waste.

It must be taken to a special local authority

differentiated waste collection centre or to a dealer

providing this service.

Disposing of a appliance separately avoids possible

negative consequences for the environment and

health deriving from inappropriate disposal and

enables the constituent materials to be recovered to

obtain significant savings in energy and resources.

As a reminder of the need to dispose of appliances

separately, the product is marked with a crossed-out

wheeled dustbin.

Warnings and warranty conditions Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

2. INSTALLATION IN ACCORDANCE WITH UNI

10683

2.1. OPERATING AREA

For good operations and good heat distribution, the fireplace stove

should be positioned in a place where the air required for combustion

can flow (at least 60 m

standards and current regulations in the country of installation.

The room volume must not be less than 60 m

Air must enter through permanent apertures on the walls (near the

fireplace stove) that open outdoors with a minimum section of 360 cm

These apertures (air vents) must be made so as not to be obstructed in

any way.

Air can also be taken from adjacent rooms as long as these are

equipped with outdoor air vents and not bedrooms or bathrooms or

rooms where fire hazards do not exist such as garages, wood sheds,

flammable material warehouses, strictly observing the provisions of

current regulations.

Fireplace stoves may not be installed in

bedrooms, bathrooms and where another

heating device is installed without autonomous

air flow (fireplace, stove, etc.).

Placing the fireplace stove in explosive

environments is prohibited.

The floor of the room where the fireplace stove

is to be installed must be strong enough to

support its weight.

In the event of wood floors, install a protective

covering in accordance with current regulations

in the country of installation.

If walls are not flammable, install the fireplace

stove at least 5 cm from the walls.

3

/h must be available) according to installation

3

.

2

.

Chapter 2

page

9

2.2. PRECAUTIONS

The fireplace stove must be installed in a suitable surface that permits

routine opening and maintenance operations.

The room must be:

suitable for room operating conditions

equipped with power supply 230V 50 Hz

equipped with an adequate smoke exhaust system

equipped with outdoor ventilation

provided with an earth connection complying with CEI 64-8

Theoretical notions for installation Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

IMPORTANT!

The fireplace stove must be installed and

assembled by qualified personnel.

The fireplace stove must be connected to a flue

pipe or other vertical smoke stack that can

discharge smoke at the highest point of the

house.

The fireplace stove must be connected to a flue

pipe or an internal or external vertical duct

conforming to current standards UNI 7129 7131 9615.

Smoke is generated from burning wood and,

therefore, may dirty adjacent or nearby walls.

Before positioning the fireplace stove, you must

make a hole for the intake of external air.

2.3. CONNECTION TO THE EXTERNAL AIR INTAKE

Chapter 2

page

10

The room where the stove is installed must have at least as much air as

requested by normal combustion of the equipment and by room

ventilation. This may take place through permanent apertures in the

room walls that lead directly outdoors or ventilated rooms according to

UNI 10683.

For this purpose, drill a hole with minimum 360 cm² free section near

the fireplace stove (22 cm diameter or a 20x18cm rectangle), protected

by an indoor and outdoor grille.

The air intake must also:

directly communicate with the installation room

be protected by a grill, made of metallic anti-insect mesh or a

suitable protection as long as it does not reduce the minimum

section.

be installed so as to avoid obstruction

for ducts, up to 3.5 linear metres, increase the section by about

5% while increased by 15% for larger measurements.

Remember that the ventilation grills always have a cm

2

useful section on one side. When selecting the grill and hole

dimension, make sure the useful grill section is greater than

or equal to the section required by MCZ for product

operations.

Connecting the air outlet directly to the fireplace stove is not

mandatory but the above mentioned section must guarantee

about 50 m³/h of air. See standard UNI 10683.

IMPORTANT!

Air flow may also be obtained from a room adjacent

to the installation room as long as this flow is free

through permanent apertures that directly

communicate with the outdoors; avoid air outlets

connecting with heating units, garages, kitchens or

bathrooms.

Theoretical notions for installation Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

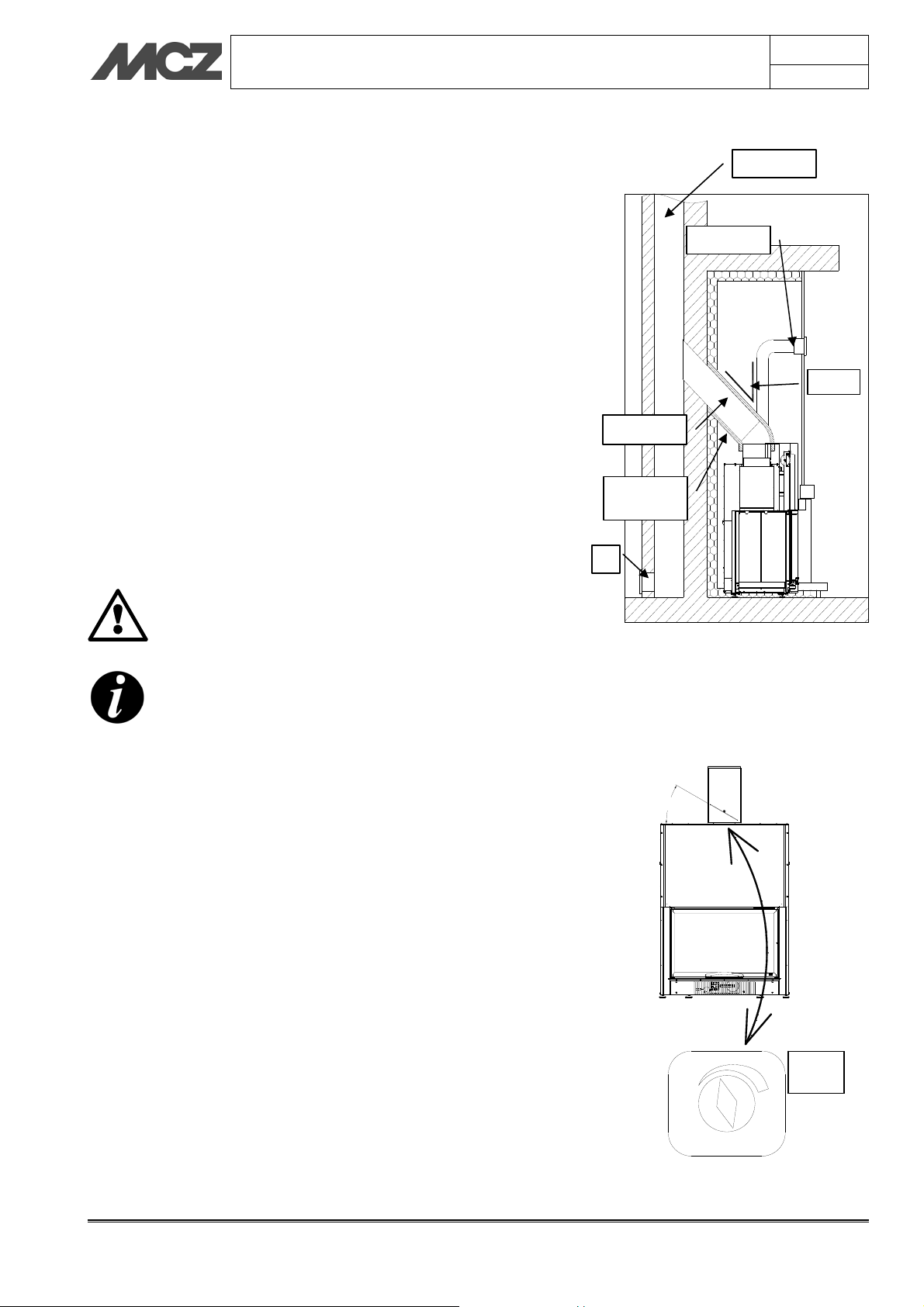

2.4. CONNECTION TO THE FLUE PIPE

Chapter 2

page

11

The connection to the flue pipe is a very important element. The

connection must be made with a great deal of care; in the event of

erroneous or anomalous construction, it is extremely difficult to remedy

without damaging the hood liner. In addition, the connection is made in

a part of the stove where temperatures are very high, and for this

reason it is important to use materials that are capable of resisting heat

and also the acidity of the fumes produced by combustion.

Before beginning work, please note the following:

The connecting pipe must have a maximum slope of 45

degrees. This is to avoid excessive deposit of condensation

produced in the initial phases of lighting the fireplace stove,

and/or the excessive accumulation of creosote. It also keeps

the release of smoke from being slowed down.

The unions must be made of metal and suitable for the

specific operating conditions of the product and marked

EC (EN1856-2). The use of flexible and extending metal

pipes is not permitted.

The components making up the connecting pipe must be

perfectly sealed.

The joint to the flue pipe must not be too long (to avoid

obstructions), nor too short (to avoid smoke leakage).

If metal connecting pipes are used, they must be

insulated with suitable material such as ceramic fibre

matting, to avoid deterioration of the masonry and of

the decorative hood liner.

IMPORTANT!

Any increase in the section of the connecting pipe

must start immediately above the hood of the

fireplace and not along the flue pipe section.

Flue pipe

Hood grille

45° max

Smoke

Ceramic fibre

insulation

A

Example of fireplace stove connection in

flue chimney

Illustration of a correctly constructed

chimney flue with a chamber and sealed

door (A) for solid combustion product

collection and discharge at the foot of the

external ascending segment.

2.4.1. Smoke valve (optional)

30°

In case of excessive draught in the flue chimney, combustion may

become unbalanced and consequently less efficient. In this case, in

order to improve combustion efficiency, it is advisable to install the

smoke valve (optional) directly at the output of the fireplace stove. If

you wish to position the control knob (B in the figure) at the front of

the product, it is necessary to place a 25 cm extension of the smoke

duct between the fireplace stove and the valve.

2.5. FLUE PIPE

The flue pipe is a fundamental element in discharging smoke and

therefore must have the following requisites:

It must be waterproof and thermally insulated.

It must be made with heat resistant materials, resistant to

combustion products and any condensation.

have a vertical arrangement with deviations from the axis of

no more than 45° and without kinks.

must be suitable for the specific operating conditions of the

Smoke valve

product and marked EC (EN1856-1, EN1443).

Theoretical notions for installation Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

B

INSTALLATION AND USE MANUAL

must be suitably sized to accommodate the draught/smoke

disposal requirements necessary for the correct functioning of

the product (EN13384-1).

It must preferably have a circular interior section.

If pre-existing and previously used, it must be cleaned.

The flue pipe is of primary importance for the correct

functioning and safety of your fireplace stove.

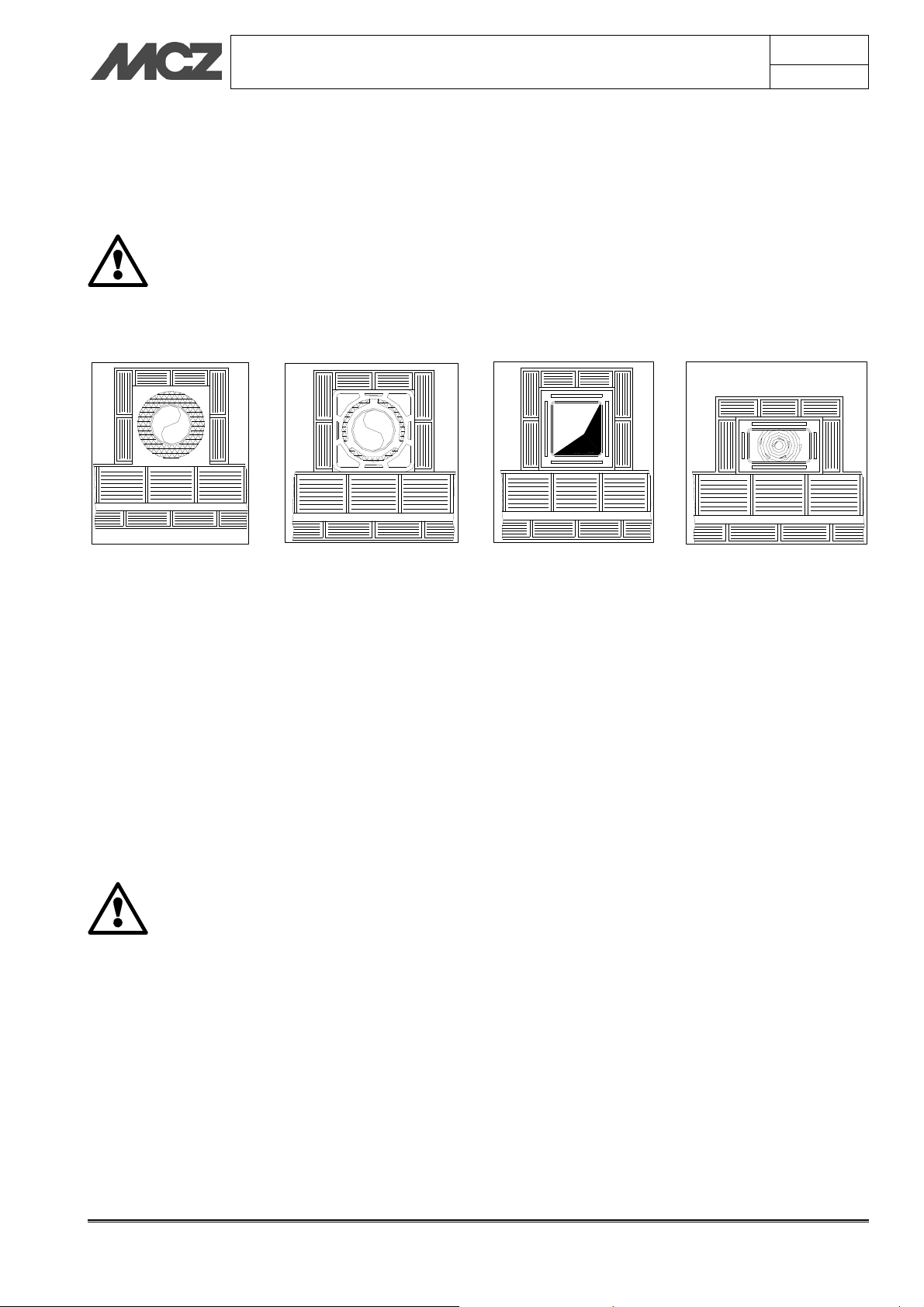

2.5.1. Examples of flue pipes

Stainless steel 316 flue

pipe with dual chamber

insulated with ceramic wool

or equivalent resistant to

400°C.

EXCELLENT

Flue pipe in refractory brick

with insulated double wall and

external coat of cement mix

lightened with honeycomb

material such as clay.

GOOD

Traditional square section

clay flue pipe with insulating

hollow inserts.

GOOD

Square or rectangular section flue pipes must have rounded internal

corners with radius not less than 20mm. For the rectangular section,

the ratio between internal dimensions must be ≤1.5.

The sections/lengths of the flue pipe shown in the technical data table

are guidelines for correct installation. Any alternative configurations

must be suitably sized in accordance with EN13384-1.

The smoke duct should be equipped with a solid material collection

chamber at the mouth of the smoke duct to be easily opened with an

airtight door.

IMPORTANT !

In the event of doubt on your chimney flue

operations or that its dimensions are different from

those recommended, we highly suggest an

authorised MCZ technician inspect and measure

chimney flue performance (micro-gauge

measurements)

MCZ s.p.a. shall not be held liable for poor operation

of the fireplace stove that is due to a flue pipe of

improper size or installation that does not comply

with provided requirements.

Chapter 2

page

12

Avoid flue pipes with internal

rectangular sections whose

larger side is double the smaller

such as 20x40 or 15x30.

AVERAGE

Theoretical notions for installation Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

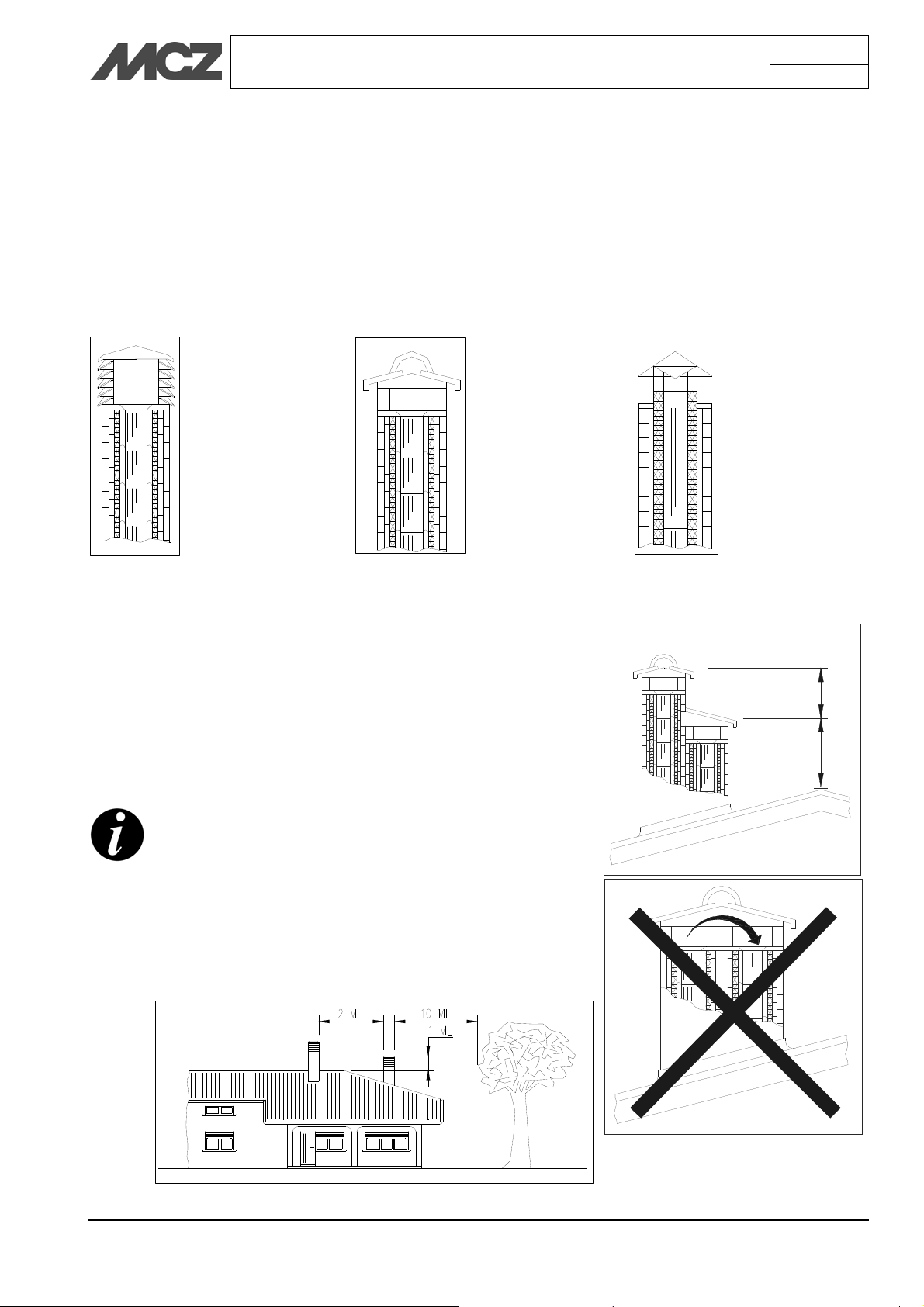

2.6. COWL

If underestimated, it is a severe impediment to correct "chimney

system" operations.

Flue pipe draught also depends on its cowl.

Therefore, if hand made, its four exhaust sections must correspond to

more than twice the internal section of the flue pipe.

Having to exceed the peak of the roof, the cowl will be

exposed to wind, therefore an industrial type is recommended.

An industrial cowl,

with prefabricated

sections fitting

together, allows

optimal disposal of

the flue gases.

The cowl must meet the following requisites:

It must have an internal section equal to that of the chimney.

It must have a useful output section not less that double that

of the internal section of the flue pipe.

It must be built to prevent rain, snow and any foreign objects

from getting into the flue pipe.

They must be installed to guarantee adequate smoke

dispersion and out of the reflux area where negative pressure

forms.

For paired flue pipes, the cowl for solid combustion

and the one for the upper floor must be at least 50cm

higher than the other to avoid pressure transfers

between paired flues.

The cowl must not have obstacles within 10 m such as

walls, roof slopes and trees. Otherwise, raise it at least

1 m over the obstacle and, in the event of other

nearby cowls, keep them at least 2 m away. In any

case, the cowl must exceed the peak of the roof by at

least 1m.

A traditional

handmade cowl.

The right exhaust

section must be at

least twice the

internal section of

the flue pipe, 2.5

times is ideal.

Chapter 2

page

13

Steel cowl for flue pipe

with internal smoke

deflector cone.

t

m

5

,

0

t

m

1

Theoretical notions for installation Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

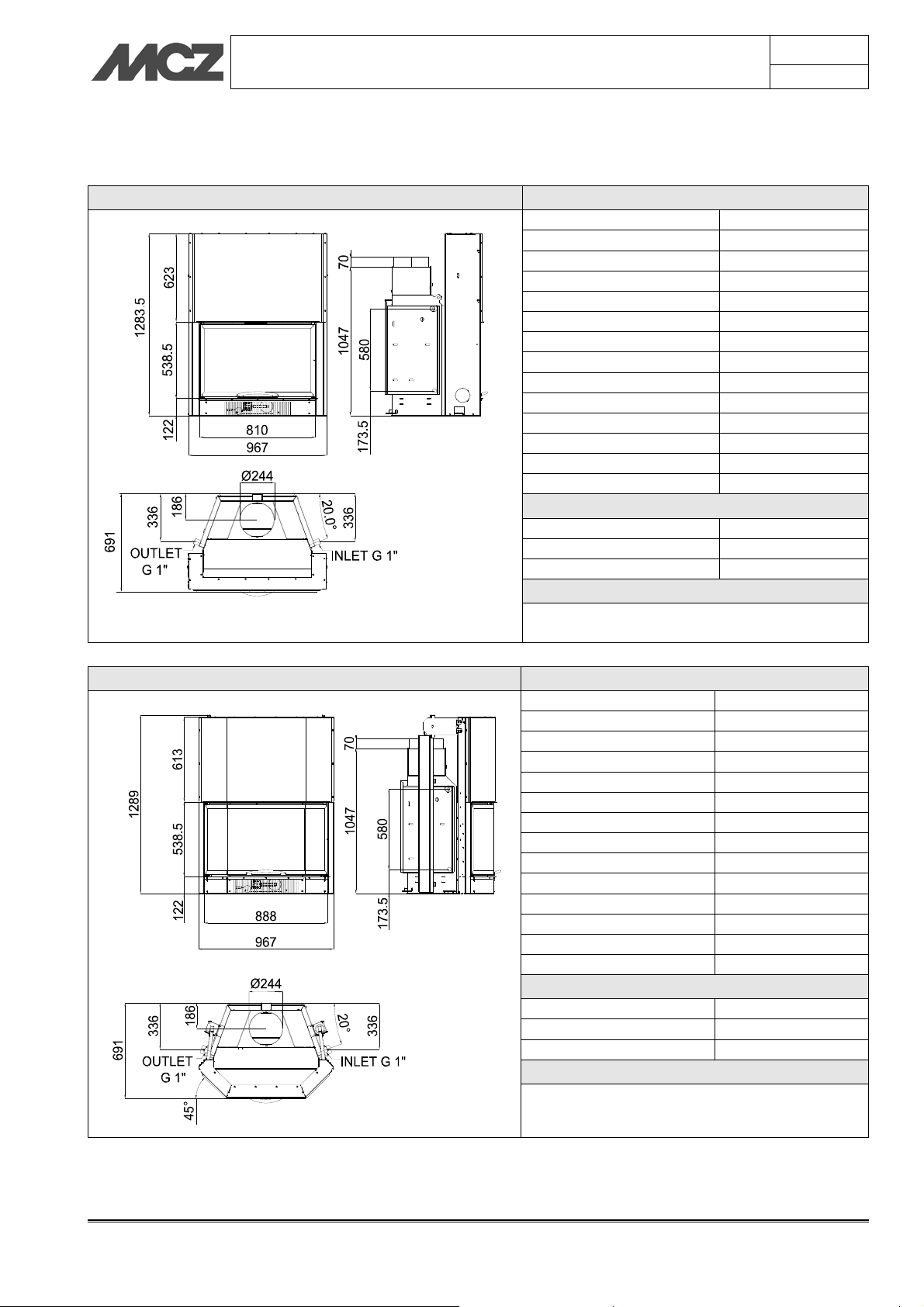

3. DIMENSIONS AND TECHNICAL SPECIFICATIONS

HYDRO THERM 80 Technical specifications

Fuel type Wood

Hourly consumption 7,1 kg/h

Nominal thermal power kW 26,2 - Kcal 22.532

H2O thermal power kW 15,2 - Kcal 13.072

Efficiency 77,1%

Heatable volume * 563/40-644/35-751/30

Recommended draught 12 Pa / 0,12 mbar

Smoke temperature 333 °C

Smoke outlet Ø 25 cm

Net weight 232 Kg

External combustion air outlet cm² 200

CO emission in smoke (13 %O2) 0,61%

Massive smoke capacity 17,7 g/s

Permissible max. water pressure 1,5 bar

Flue pipe

Up to 5 m 30x30 cm Ø30

Over 5 m 25x25 cm Ø25

Note

Intermittent combustion unit

* Data may vary according to the fuel used

HYDRO THERM 80E Technical specifications

Fuel type Wood

Hourly consumption 7,1 kg/h

Nominal thermal power kW 26,2 - Kcal 22.532

H2O thermal power kW 15,2 - Kcal 13.072

Efficiency 77,1%

Heatable volume * 563/40-644/35-751/30

Recommended draught 12 Pa / 0,12 mbar

Smoke temperature 333 °C

Smoke outlet Ø 25 cm

Net weight 235 Kg

External combustion air outlet cm² 200

CO emission in smoke (13 %O2) 0,61%

Massive smoke capacity 17,7 g/s

Permissible max. water pressure 1,5 bar

Flue pipe

Up to 5 m 30x30 cm Ø30

Over 5 m 25x25 cm Ø25

Note

Intermittent combustion unit

* Data may vary according to the fuel used

Chapter 3

page

14

Dimensions and technical specifications Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

HYDRO THERM 70 Technical specifications

Fuel type Wood

Hourly consumption 6,5 kg/h

Nominal thermal power Kw 21,2 - Kcal 18.232

H2O thermal power kW 13,0 - Kcal 11.180

Efficiency 75,2 %

Heatable volume * 456/40-521/35-608/30

Recommended draught 12 Pa / 0,12 mbar

Smoke temperature 310 °C

Smoke outlet Ø 20 cm

Net weight 195 Kg

External combustion air outlet cm² 200

CO emission in smoke (13

%O

)

2

Massive smoke capacity 14,4 g/s

Permissible max. water

pressure

Flue pipe

Up to 5 m 25x25 cm Ø25

Over 5 m 20x20 cm Ø20

Note

Intermittent combustion unit

* Data may vary according to the fuel used

HYDRO THERM 70V Technical specifications

Fuel type Wood

Hourly consumption 6,5 kg/h

Nominal thermal power kW 21,2 - Kcal 18.232

H2O thermal power kW 13,0 - Kcal 11.180

Efficiency 75,2 %

Heatable volume * 456/40-521/35-608/30

Recommended draught 12 Pa / 0,12 mbar

Smoke temperature 310 °C

Smoke outlet Ø 20 cm

Net weight 212 Kg

External combustion air outlet cm² 200

CO emission in smoke (13

%O

)

2

Massive smoke capacity 14,4 g/s

Permissible max. water

pressure

Flue pipe

Up to 5 m 25x25 cm Ø25

Over 5 m 20x20 cm Ø20

Note

Intermittent combustion unit

* Data may vary according to the fuel used

Chapter 3

page

15

0,87%

1,5 bar

0,87%

2,0 bar

Dimensions and technical specifications Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

HYDRO THERM 70SX Technical specifications

Fuel type Wood

Hourly consumption 6,5 kg/h

Nominal thermal power kW 21,2 - Kcal 18.232

H2O thermal power kW 13,0 - Kcal 11.180

Efficiency 75,2 %

Heatable volume * 456/40-521/35-608/30

Recommended draught 12 Pa / 0,12 mbar

Smoke temperature 310 °C

Smoke outlet Ø 20 cm

Net weight 204 Kg

External combustion air outlet cm² 200

CO emission in smoke (13

)

%O

2

Massive smoke capacity 14,4 g/s

Permissible max. water

OUTLET

G 1"

INLET G 1"

pressure

Flue pipe

Up to 5 m 25x25 cm Ø25

Over 5 m 20x20 cm Ø20

Note

Intermittent combustion unit

* Data may vary according to the fuel used

HYDRO THERM 70DX Technical specifications

Fuel type Wood

Hourly consumption 6,5 kg/h

Nominal thermal power kW 21,2 - Kcal 18.232

H2O thermal power kW 13,0 - Kcal 11.180

Efficiency 75,2 %

Heatable volume * 456/40-521/35-608/30

Recommended draught 12 Pa / 0,12 mbar

Smoke temperature 310 °C

Smoke outlet Ø 20 cm

Net weight 204 Kg

External combustion air outlet cm² 200

CO emission in smoke (13

%O

)

2

Massive smoke capacity 14,4 g/s

INLET G 1"

OUTLET

G 1"

Permissible max. water

pressure

Flue pipe

Up to 5 m 25x25 cm Ø25

Over 5 m 20x20 cm Ø20

Note

Intermittent combustion unit

* Data may vary according to the fuel used

Chapter 3

page

16

0,87%

1,5 bar

0,87%

1,5 bar

Dimensions and technical specifications Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

4. INSTALLATION AND ASSEMBLY

IMPORTANT!

The fireplace stove must be installed and connected

to the smoke duct only by a specialized technician, so

that all local and national regulations are complied

with.

Installation must in any case by carried out in

compliance with UNI 10683.

When the fireplace is unpacked, check for perfect operation of all

its parts or any damage which may have occurred during

shipping. The retailer or the carrier must be immediately

informed of any damage.

If the fireplace stove is installed in a place that is difficult to reach, its

weight can be reduced by removing the internal parts that make up the

fire box. However, be sure to put all of the parts back in place.

This operation is to be carried out only by specialized

personnel.

MCZ shall not be held liable if the preceding warning is not

complied with.

Chapter 4

page

17

4.1. PREPARATION AND UNPACKING

Open the packaging, remove the stove unit from the pallet and position

it in the chosen location, taking care that its position complies with the

above instructions.

The fireplace stove must always be kept VERTICAL

while moving and only using hand trucks. Do not

drag the unit as this may damage the support feet.

Be especially careful that the door and its glass are protected from

mechanical collisions that could jeopardise their integrity.

Moving the product must be done with care. If possible, unpack the

fireplace stove in the area where it is to be installed.

The materials which make up the packaging are not toxic or harmful,

so no special procedures for disposal are required.

The final user must store, dispose or recycle packaging material in

accordance with local regulations.

4.2. POSITIONING

The HYDROTHERM fireplace stove can be placed in a corner or along a

wall. You can customize with MCZ claddings or install them during

construction with materials that are resistant to high temperatures.

The fireplace stoves are self-supporting single-piece units that simplify

installation and do not require any additional support.

Always evaluate the structural condition of the surface which

will take the weight, and always leave a minimum 5 cm

airspace between the stove and any walls.

Install dry the fire bed of the cladding leaving an opening of 1 cm

for the insulation.

5 cm

m

c

1

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

For installation near flammable material, comply with the following

minimum safe distances:

Distance from the sides and back= 100 mm

Height above floor = 80 mm

Insulating material on sides and back= 80 mm

Insulating material on the floor = 25 mm

If the stove is positioned over a floor or close to

walls made of flammable materials, it is advisable to

use sufficient insulation.

The hot air outlets must be placed at least 300 mm

from other materials (e.g. curtains)

4.3. HEIGHT ADJUSTMENT

The Hydrotherm fireplace stove is equipped with adjustment feet,

whose purpose is to allow the easy levelling of the fire bed. The feet

allow an adjustment of about 6-7 cm and are mounted on the pre-set

brackets (See figure)

If you want to raise the fireplace stove by more than 6-7 cm, you need

to create a masonry pedestal to set the product on. Do not eliminate

the feet. They are indispensable for levelling.

If the fireplace stove is not placed level, there is the

risk that door will not close perfectly, and that the

internal counterweights strike the structure, causing

noise each time the door is raised or lowered.

It is possible to adjust the levelling of the fireplace

stove by checking the sliding of the door until it no

longer makes any noise.

Chapter 4

page

100 80

0

0

1

18

80

25

100

0

8

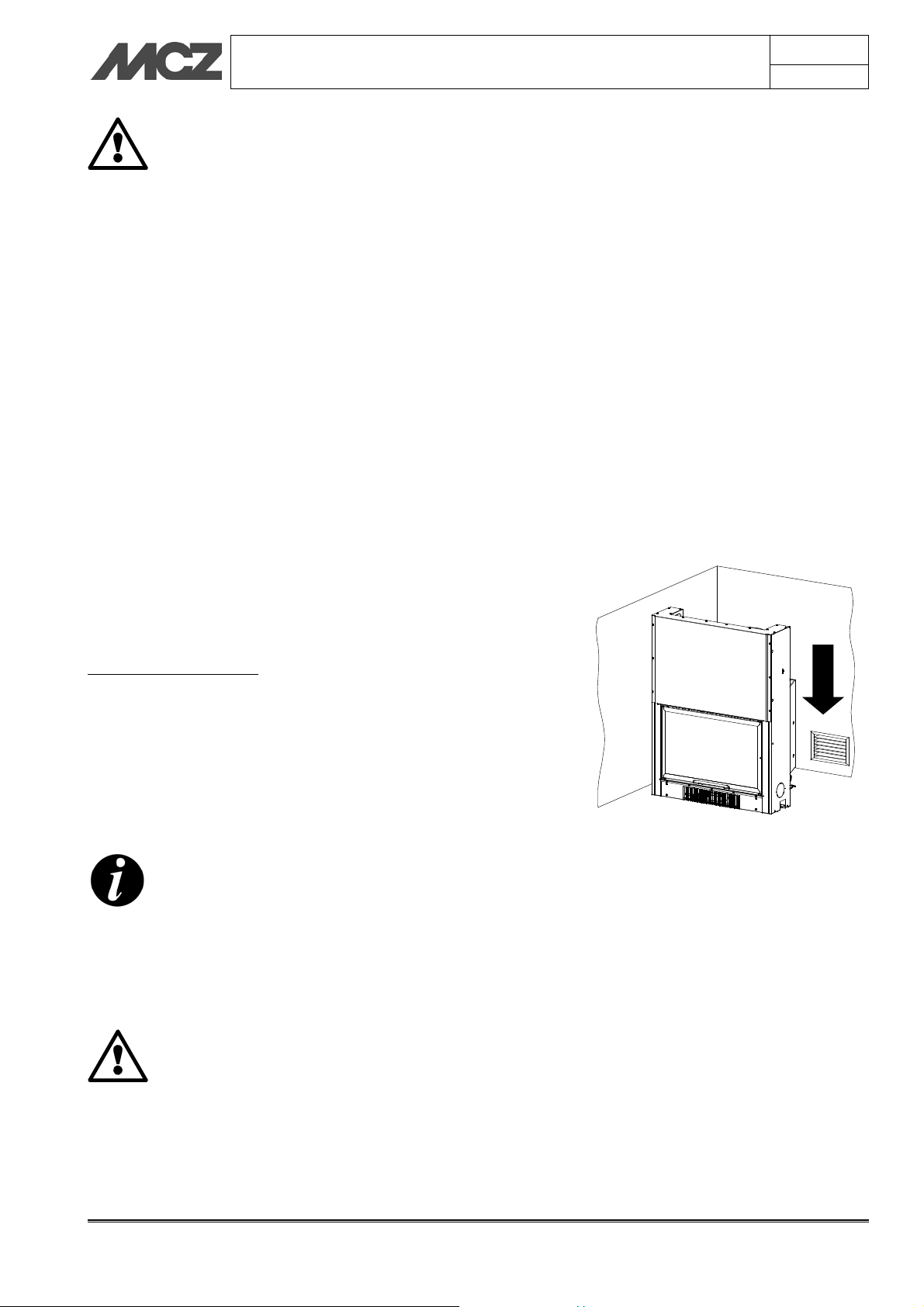

4.4. RELEASE OF COUNTERWEIGHTS

The fireplace stove is delivered with the sliding counterweights locked

in place. In this way, during shipping and handling, they will not strike

and damage the sliding parts, the door and the ceramic glass.

To release the counterweights and therefore also the door, remove the

screws as shown in

figure 2

Remove the screws that hold the counterweights

only after you have positioned the fireplace stove

and to ensure that the glass is in good condition.

DO NOT MOVE THE FIREPLACE STOVE WITHOUT THE

SCREWS THAT HOLD THE COUNTERWEIGHTS.

Damage caused by failure to observe this rule is the

responsibility of the client or his representative.

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

from both sides of the fireplace stove.

INSTALLATION AND USE MANUAL

4.5. MCZ CONTROL UNIT CONNECTION

MCZ shall not be held liable for any damage to

persons or objects due to incorrect connections or

improper use of the device.

The Hydrotherm fireplace stove must be managed by a control unit

fitted with temperature probe, to manage the activation of the pump

and the acoustic signal warning that the safety temperature has been

exceeded.

The MCZ control unit consists of:

Recessed box (S).

Temperature probe (T).

Cover plate (P).

Control unit body (C)

Instruction sheet (K).

The control panel must be installed far from heat

sources and in a way that the length of the cables

provided is sufficient.

The box must not be installed on the hood of the

cladding.

The cables must not remain in contact with the metal

structure.

When installing the control panel, a 230Vac-50Hz power supply cable

must be provided.

Chapter 4

page

19

K

4.5.1. The control unit MCZ

The thermal adjuster has the task of:

Detecting, measuring and displaying the temperature of the

boiler.

Control the control devices in the system.

Signal when the boiler exceeds the safety temperature through

an acoustic and luminous signal.

TECHNICAL CHARACTERISTICS

Power supply:

Power

consumption:

Temperature

probe:

230 Vac 10%~ 50 Hz; Protection fuse T3,15 A

2VA~

In silicone/pvc cable

Operating temperature: -50°C / 130 °C

Measure limits: 0 – 99 °C Precision: 1°C

PUMP output:

powered at 230 Vac - max flow 5A - 250 Vac

Outputs:

VALV output:

free contact - max flow 5A - 250 Vac

AUX output:

free contact - max flow 5A - 250 Vac

Dimensions: Recessed thermal adjuster: 120 x 80 x 50 [mm]

P Cover plate

C Control unit

S Recessed box

Temperature

T

probe

I Inputs

U Outputs

F Fuse

P1 MENU button

P2 Increase button

P3 Increase button

P4

ON/OFF button

1 Pump LED 1

2 3-way valve LED

3 Pump LED 2

4 Auxiliary LED

5 ON/OFF LED

6 Display

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

4.5.2. Electrical connection of the control unit MCZ

The thermal adjuster is made up of:

Recessed control unit.

Fruit box.

Thermal probe and well (included in the supply)

For correct operation and to avoid any damage to electrical/electronic

parts:

Place the device in a dry place far from direct heat sources.

Place the PROBE by using the specific manifold (optional) in a

way to read the correct temperature of the boiler, avoiding

direct or indirect contact with the flame.

Place the container-box without the control unit body.

The installation and the electrical connections must

be made by a qualified electrician using adequate

equipment.

Connection to the power supply network must be

made only after connecting the wires in the terminal

board.

Chapter 4

page

20

LINE

Connect the 230 Vac 10% -~50 Hz electric line to the terminal boards

[1] and [2] to power the control unit. Protection fuse T3.15 A

INPUTS (I)

Probe: Connection to the probe of the fireplace stove that detects the

system temperature.

Temperature range 0 – 100 °C

Flux: ON/OFF permission for the connection of a flow switch or

thermostat of a boiler for domestic hot water

OUTPUTS (U)

Pump: Connection of the water circulation pump in the heating

system. Terminals [3] and [4]

Valv: Connection of a possible 2/3 wire solenoid valve serving as

domestic valve. Terminals [5] [6] and [7]

Aux: Auxiliary connection to connect a gas boiler to control the

shutdown. Terminals [8] [9] and [10]

P2: Connection to the domestic hot water circulation pump.

Terminals [11] and [12]

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

4.5.3. Operation of the control unit MCZ

ON/OFF:

The control unit is turned on/off by pressing the P4 button for a

prolonged time (ON/OFF)

The OFF status is signalled by the lighting of the OFF LED

MAIN MENU:

Setting the THERMOSTATS for the operation of the controlled

outputs:

1. PUMP thermostat: to control the operation of the system pump

2. VALV thermostat: to directly control the solenoid valve or

another application

3. AUX thermostat: to integrate the gas boiler, solenoid valve

control or another application

How to change them:

By simply clicking the P1 (MENU) button, the values of the set

Thermostat scroll, as signalled by the flashing of the associated

PUMP / VALV / AUX LED

To make a change move to the value of the Thermostat to be

changed

Change the value using the buttons P3(+) and P2(-)

To save the change wait about 5 seconds or scroll the values

with the button P1(MENU)

Main menu

parameters:

PUMP thermostat 20 40 85

VALV thermostat 20 40 85

AUX thermostat 20 40 85

Min.

Default

values

Max

Chapter 4

page

21

ALARM FUNCTION:

If the temperature read by the PROBE exceeds the value of the Alarm

Thermostat

an acoustic and visual signal is triggered

SILENCE function: the acoustic signal may be deactivated for 5

After this time, if the alarm condition persists, the acoustic signal

If the PROBE does not work and/or the

an out of range downwards is signalled (Temperature below

If the PROBE does not work and/or the

Hi: indicates an out of range upwards (Temperature above

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

A01:

minutes by pressing any button.

is triggered again.

Lo alarm appears:

0°C): Probe interrupted

Hi alarm appears:

100°C): Probe in short circuit

INSTALLATION AND USE MANUAL

In this case it is advisable to immediately reduce the

combustion and eliminate the causes for the excessive

heating.

It is always advisable to use the hourly quantity of

wood set by MCZ to keep the temperature constant

and obtain the performance ensured (page 12)

ANTI-FREEZE FUNCTION:

If the temperature read by the probe goes below the set value of the

anti-freeze thermostat

The PUMP output is activated

A03:

Chapter 4

page

22

The display shows

ICE

STANDBY FUNCTION:

If the device is OFF

in condition of ALARM or ANTI-FREEZE

the device automatically switches to ON

PUMP ANTI-SEIZURE FUNCTION:

In case of inactivity of the pump for more than the anti-seizure timer

T01 (about a week)

the PUMP output is activated for T02 seconds

The display shows

This function is active also in STANDBY.

bLP

PUMP TEST FUNCTION:

By pressing the P3(+) button for a prolonged time

The PUMP output is activated while pressing the button

The display shows

tSt

SANITARY FUNCTION:

This function aims to manage any system for the production of

domestic hot water (flow switch, 3-way valve, etc..) completely from

the control unit. If the complete MCZ domestic hot water kit is

purchased, this function is not necessary since the various elements are

managed by the electronic board of the kit, suitably cabled.

For those who wish to use this function, instructions for the

connections can be found inside the packaging of the control unit.

MCZ shall not be held liable for any damage to the

product or the components provided (control unit) if

non MCZ components are connected.

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

4.6. PLUMBING CONNECTION

MCZ shall not be held liable for damage due to

incorrect connections or connections made by

unqualified personnel

IMPORTANT !!

The water system must be connected and the perfect

seal of the boiler must be checked also when the fire

is lit, before cladding the fireplace stove.

Failure to comply with the installation instructions

shall make the product guarantee void and lift MCZ

from any involvement concerning any damage to

people and objects.

In light of the above, MCZ shall not be held liable for

any possible break of the cladding in case the

compulsory preventive operating checks are not

performed.

To minimise the formation of limescale in the ducts,

in case of hard water being used, it is advisable to

install a softener filter.

Chapter 4

page

23

4.6.1. Water characteristics

The characteristics of the water used to fill the system are very

important to prevent the build-up of mineral salts and the formation of

incrustations along the pipes, in the boiler and in the heat exchangers.

Therefore, please GET YOUR PLUMBER'S ADVICE

CONCERNING:

Hardness of water circulating in the system, to prevent

problems of incrustation and limescale, especially in the

domestic water heat exchanger. (> 25° French)

Installation of a water softener (if water hardness

exceeds 25° French)

Filling the system with treated water (demineralised).

Possibly providing an anti-condensation circuit.

Installation of plumbing bumpers to prevent banging

along the fittings and pipes.

If you have very extensive systems, with a large amount of water, or

which require frequent refilling, the installation of water softening

systems.

It should be remembered that incrustations

drastically reduce performance due to low thermal

conductivity.

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

4.6.2. Hydraulic connection with Open Tank

In order to achieve a good running of the Hydrotherm fireplace stove

installed with open tank, please closely follow the installation rules

stated below:

The system must be loaded only by natural fall from the

expansion tank open in the del return of the fireplace stove

with a duct of 1”. Direct loading with the pressure from the

mains is prohibited. The maximum operating pressure is 1.5

bars.

The expansion tank must be of the open type with vent tube of

minimum Ø 1”. This must be placed at a height higher than 3

meters from the highest point of the radiators. If the kits in

diagrams 2 and 3 are used, the expansion tank can be

placed near the fireplace stove.

The vent tube of the expansion tank must feature no shut-off

valve or unneeded curves. Both the open expansion tank and

the vent tube must be protected against the cold.

Chapter 4

page

24

4.6.3. Hydraulic connection with Closed Tank

In order to achieve a good running of the Hydrotherm fireplace stove

installed with closed tank, please closely follow the installation rules

stated below:

The system must be loaded only with the pressure from

the mains. The maximum operating pressure is 1.5 bars.

The expansion tank must be of the closed type.

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Chapter 4

4.7. HYDRAULIC DIAGRAMS

The distance of the hydraulic kit, as stated in the

diagrams below within the speckled area, from the

fireplace stove must not exceed 1 metre.

The following diagrams are to be used only as a guideline.

For proper connection, follow the notes and the instructions

of the plumbing and heating installer, in compliance with

regulations in force.

4.7.1. Diagram 1 OPEN TANK (KIT 1 OPEN TANK)

DESCRIPTION: Fireplace stove as the only heat source with production of domestic hot water (DHW).

ACTIONS:

- fireplace stove heating;

- domestic hot water with fireplace.

page

25

1-Fireplace stove 6-Delivery circuit 11-Flow switch

2-Open expansion vessel with float 7-Return circuit 12-Domestic water

3-Control unit 8-Automatic vent valve 13-Radiator

4-Temperature probe 9- 3-way valve A- Aqueduct

5- Circulator 10 - Domestic hot water exchanger TA-Room thermostat

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Chapter 4

page

26

4.7.2. Diagram 2 OPEN TANK (KIT 2 OPEN TANK)

DESCRIPTION: Fireplace stove combined with gas boiler without production of domestic hot water. It is

composed of a main circuit (open tank heat source) and a secondary circuit (closed tank heat source). It allows

the expansion tank to be installed approx. 30 cm above the fireplace. The control unit is used to turn off the gas

boiler when the fireplace stove reaches the required temperature.

ACTIONS:

- fireplace stove heating;

- heating with boiler;

1- Fireplace stove 5- Circulator 9- Non-return valve

2- Open expansion vessel with float 6- Delivery circuit 10- Separation exchanger

3- Control unit 7- Return circuit 11- Boiler

4- Temperature probe 8- Safety valve 12- Radiator

TA-Room thermostat

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Chapter 4

page

27

4.7.3. Diagram 3 OPEN TANK (KIT 3 OPEN TANK)

DESCRIPTION: Fireplace stove combined with gas boiler with production of domestic hot water. It is composed

of a main circuit (open tank heat source) and two secondary circuits (heating and domestic water system). It

allows the expansion tank to be installed approx. 30 cm above the fireplace. The control unit is used to turn off

the gas boiler when the fireplace stove reaches the required temperature. It produces instantaneous hot

domestic water.

ACTIONS:

- heating with boiler;

- fireplace stove heating;

- hot water with fireplace stove.

1-Fireplace stove 6-Delivery circuit 11- Hot water

2-Open expansion vessel with float 7-Return circuit 12- Non-return valve

3-Control unit 8- 3-way valve 13-Boiler

4-Temperature probe 9- Domestic hot water exchanger 14- Radiator

5- Circulator 10- Separation exchanger A- Aqueduct

TA-Room thermostat

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

4.7.4. Diagram 1 CLOSED TANK (KIT 1 CLOSED TANK)

DESCRIPTION: Fireplace stove without production of domestic hot water.

ACTIONS:

- heating with boiler;

- fireplace stove heating;

- domestic hot water with boiler and heating with fireplace.

Chapter 4

page

28

1-Hydrotherm fireplace stove 9-Return circuit Ø1” min. 17-Radiator

2-Expansion tank 10-Valve 18-Boiler

3-Control unit 11-Automatic vent valve 19-Thermal discharge valve

4-Manifold 12-Safety valve 20-Non-return valve

5-Temperature probe 13-3-way valve 21-Filling unit

6-Circulator 14-Separation exchanger* 24—Radiator system circulator*

7-Overflow drain 15-Pressure gauge

8-Delivery circuit Ø1” min 16-Hot water A- Aqueduct

* Not included in the kit. To be purchased separately.

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

4.7.5. Diagram 2 CLOSED TANK

DESCRIPTION: Fireplace stove with production of domestic hot water.

ACTIONS:

- heating with boiler;

- fireplace stove heating;

- domestic hot water with boiler and heating with fireplace stove;

- domestic hot water with fireplace stove and heating with boiler.

Chapter 4

page

29

1-Fireplace stove 8- Return circuit 15- Radiator

2-Open expansion vessel with float 9- Automatic vent valve 16- Boiler

3-Control unit 10- Safety valve 17- Thermal discharge valve

4-Temperature probe 11-3-way valve 18- Non-return valve

5- Circulator 12- Domestic hot water exchanger A- Aqueduct

6- Overflow drain 13- Flow switch TA-Room thermostat

7- Delivery circuit 14- Hot water

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Chapter 4

page

30

4.8. THERMAL SAFETY DISCHARGE VALVE FOR CLOSED TANK CIRCUIT

(HYDROTHERM 70V)

4.8.1. Function

The Hydrotherm 70V features a closed tank circuit. In this type of

installation it is compulsory to assemble the thermal discharge valve

(optional accessory). This is a device that limits the water temperature.

In case of boiler overheating it activates an emergency exchanger that

causes the immediate cooling of the water. Its use is regulated by the

standards EN 13229, I.S.P.E.S.L. (file “R” - ed. 2005) and UNI 10412-

2. It also complies with EN 14597 and can be used on systems

complying with EN 12828, concerning solid fuel boilers with non

automatic loading and a power of less than 100 kW.

A THERMAL SAFETY DISCHARGE VALVE FOR CLOSED

TANK CIRCUIT (HYDROTHERM 70V) MUST BE

INSTALLED

4.8.2. Technical specifications

543513

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Chapter 4

page

Materials: - body Brass EN 12165 CW617N

- control spindle Brass EN 12164 CW614N

- obturator seal EPDM

- seals EPDM

- spring Stainless steel

- protection cover POM

Max. working pressure 10 bar

Set temperature 95°C

Temperature range 5÷110°C

Discharge flowrate at 110°C and ∆p 1 bar 3000 l/h

Ambient temperature range 0÷80°C

Action type (EN 14597) 2 KP

Max temperature of the sensor 130°C

Medium water

PED category IV

Connections 3/4” F x 3/4” F

Probe connection 1/2” M

Capillary lenght 1300 mm

31

4.8.3. Installation

Before installing the thermal safety discharge valve, ensure that the

system has no impurities that may be deposited on the outlet housing.

An easy-to-open filter should be installed on the arrival of cold water

and its cleaning should be regularly checked. Upon reaching the

temperature of 95°C, the valve starts to discharge the quantity of water

necessary to maintain the temperature of the boiler within the safety

limits.

Check that the valve's discharge capacity is compatible with the limit

values indicated by the manufacturer of the boiler and the system. For

safety reasons, any cut-off valves placed upstream of the valve must be

open. You should install a pressure reducer at the inlet of water

from the water mains. The reducer must be calibrated at 2 bars at

least and assembled on the proposed pipe of each interception unit at a

distance not exceeding 0.5 m. After having assembled the valve on the

pipe, respecting the flow sense indicated on the valve body (fig.e),

house the part connected to the sensor in its housing (see position 8 of

fig. d). Therefore screw the knurled ring avoiding to tighten it (Fig. a).

Direct the output of the sheath that connects the probe by making the

black cap rotate (Fig. b). Completely tighten the knurled ring (Fig. c).

The diameter of the discharge pipe must correspond to the diameter of

the valve outlet; the maximum length must not exceed 2 m, no more

than two curves are acceptable. If these maximum values are exceeded

(2 curves, 2 m of piping) the diameter immediately superior must be

chosen for the discharge pipe. However, consider that more than three

curves and 4 m of piping are not acceptable. The discharge pipe must

not have upward sections. The discharge pipe of the safety valve must

be created in a way not to stop the regular function of the valves and

not to cause damage to people or objects. In compliance with the

current standards, the discharge of the safety valve must be visible and

channelled into suitable collection pipes.

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Installing a funnel with anti-reflow air intakes on the discharge pipe of

the valve. The diameter of the connection pipe between the funnel and

the discharge network must be at least double the diameter of the

valve.

1. Aqueduct intake F 1/2”

2. Thermal safety discharge valve attachment F1/2”

3. Thermal safety discharge valve F 3/4”

4. Attachment for discharge duct F 3/4”

5. Boiler water outlet F 3/4”

6. Control unit well probe F 1/2"

7. Delivery to the system F 3/4"

8. Thermal safety discharge valve probe M 1/2”

9. Combustion adjuster bulb

ATTENTION: assemble the thermal safety discharge

valve respecting the direction of the arrow, as in the

figure to the side.

1

Fig.d

2

9

Chapter 4

page

32

5

6

7

8

4

3

Fig.e

4.8.4. Maintenance

In the lower part of the valve a red button is located that lets you

perform the purging operations and check the function. It is necessary

for a technician check the function of the valve at least once a year.

4.8.5. Safety

MCZ SHALL NOT BE HELD LIABLE FOR ANY DAMAGE

TO PERSONS OR OBJECTS DUE TO INCORRECT

CONNECTIONS, DUE TO THE INSTALLATION OF A

VALVE NOT CORRESPONDING TO THE MODEL

ADVISED OR IMPROPER USE OF THE DEVICE.

The installation of the thermal safety discharge valve must be carried

out by qualified technical personnel according to the instructions

reported in this manual and in accordance with current standards.

If the valves are not installed, calibrated and maintained correctly

according to the instructions contained in this manual, they may not

function correctly and may place the user in danger. Ensure that all the

connection fittings are hydraulically sealed. In creating the hydraulic

connections, pay attention not to mechanically over stress the thread of

the valve body. In time it is possible that breakages may occur with

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

hydraulic leaks damaging people and/or objects. A water temperature

over 50°C may cause serious burns. During installation, calibration and

maintenance of the thermal safety valves, adopt the necessary

measures so that this temperature does not cause hazards to people.

4.9. INSTALLATION KIT

The Kits in question were designed to ease the tasks of the installers in

assembling the fireplace stoves. They actually include all the

components necessary for a correct installation of the product.

The devices included in the kits must be suitably

protected from the thermal radiation of the unit,

using insulating mats.

The Kits are installed in a vertical position as in the

images reported below in a way that the air vents

can work correctly.

Chapter 4

page

33

4.9.1. Kit 1 OPEN TANK

(Code MCZ 4015008022C)

1) Sheet metal support

2) Circulator

3) Non-return valve 1.5”

4) 3-way valve

5) Non-return valve ¾”

6) Flow switch

7) Vent valve

8) Domestic hot water exchanger

9) Electrical branching box

A) Aqueduct delivery ½”

B) Fireplace stove return ¾”

C) Fireplace stove hot water exchanger outlet ½”

D) Fireplace stove delivery ¾”

E) System delivery ¾”

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

4.9.2. Kit 2 OPEN TANK

(code MCZ 4015008023)

1) Sheet metal support

2) Circulator

3) Non-return valve 1.5”

4) Vent valve

5) Separation exchanger

6) Electrical branching box

A) System return ¾”

B) System delivery ¾”

C) Fireplace stove return ¾”

D) Fireplace stove delivery ¾”

INSTALLATION AND USE MANUAL

Chapter 4

page

34

4.9.3. Kit 3 OPEN TANK

(cod. MCZ 4015008024)

1) Sheet metal support

2) Circulator

3) Non-return valve 1.5”

4) Non-return valve ¾”

5) 3-way valve

6) Vent valve

7) Separation exchanger

8) Domestic hot water exchanger

9) Flow switch

10) Electrical branching box

A) System return ¾”

B) System delivery ¾”

C) Fireplace stove return ¾”

D) Fireplace stove delivery ¾”

E) Fireplace stove hot water exchanger outlet ½”

F) Boiler cold water exchanger delivery ½”

G) Aqueduct delivery ½”

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

4.9.4. Kit 1 CLOSED TANK

(cod. MCZ 4015008025)

1) Sheet metal support

2) Circulator

3) Non-return valve 1.5”

4) Non-return valve ¾”

5) 3-way valve

6) Vent valve

7) Automatic vent

8) Safety valve

9) Expansion tank 6L

10) Electrical branching box

A) Fireplace stove return ¾”

B) Fireplace stove delivery ¾”

C) System delivery ¾”

D) Expansion tank ¾”

INSTALLATION AND USE MANUAL

Chapter 4

page

35

4.9.5. Kit 2 CLOSED TANK

(cod. MCZ 4015008026)

1) Sheet metal support

2) Circulator

3) Non-return valve 1.5”

4) Non-return valve ¾”

5) 3-way valve

6) Vent valve

7) Automatic vent

8) Safety valve

9) Expansion tank 6L

10) Electrical branching box

11) Flow switch

12) Domestic hot water exchanger

A) Aqueduct delivery ½”

B) Fireplace stove return ¾”

C) Fireplace stove hot water exchanger outlet ½”

D) Fireplace stove delivery ¾”

E) System delivery ¾”

F) Expansion tank ¾”

Installation and assembly Technical service – MCZ GROUP S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

4.10. UNIT CLADDING

Only after finishing all the installation operations of

the fireplace stove, connecting the smoke duct,

electric and hydraulic connections and carrying out

the first lighting, is it possible to begin the cladding

of the unit

4.10.1. INSULATION OF FIREPLACE STOVE

The fireplace stove must also always be separated from nearby

walls and ceilings.