MCZ Club AIR User Manual

8901166500

EN

INSTALLATION AND USE

MANUAL

PELLET STOVES

Chapter 1

INSTALLATION AND USE MANUAL

page 2

Introduction

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

INTRODUCTION .................................................................................................................................... 4

1. WARNINGS AND GUARANTEE CONDITIONS ..................................................................................... 5

1.1. SAFETY INSTRUCTIONS .................................................................................................................... 5

1.2. OPERATING WARNINGS .................................................................................................................... 6

1.3. IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE PRODUCT IN ACCORDANCE WITH EC

DIRECTIVE 2002/96/EC ............................................................................................................................... 7

1.4. GUARANTEE CONDITIONS ................................................................................................................ 7

1.4.1. Limitations ................................................................................................................................. 8

1.4.2. Exclusions .................................................................................................................................. 8

2. THEORETICAL NOTIONS FOR INSTALLATION ................................................................................... 9

2.1. PELLETS ........................................................................................................................................... 9

2.2. PRECAUTIONS FOR INSTALLATION ................................................................................................. 10

2.3. OPERATING AREA ........................................................................................................................... 11

2.4. CONNECTION TO THE EXTERNAL AIR INTAKE ................................................................................. 12

2.5. CONNECTION OF SMOKE DISCHARGE PIPE ...................................................................................... 12

2.6. CONNECTION TO THE FLUE PIPE .................................................................................................... 14

2.7. CONNECTION TO AN EXTERNAL FLUE WITH INSULATED OR DOUBLE-WALL PIPE .............................. 14

2.8. CONNECTION TO THE FLUE PIPE .................................................................................................... 14

2.9. OPERATING PROBLEMS CAUSED BY DRAUGHT DEFECTS IN THE FLUE .............................................. 15

3. INSTALLATION AND ASSEMBLY ...................................................................................................... 16

3.1. DRAWINGS AND TECHNICAL CHARACTERISTICS.............................................................................. 16

3.1.1. Dimensions CLUB mod. AIR – COMFORT AIR ............................................................................. 16

3.1.2. Dimensions SUITE mod. AIR – COMFORT AIR ............................................................................ 16

3.1.3. Dimensions MUSA mod. AIR- COMFORT AIR .............................................................................. 17

3.1.4. Dimensions TOBA mod. AIR-COMFORT AIR ............................................................................... 17

3.1.5. Dimensions SAGAR mod. AIR .................................................................................................... 18

3.1.6. Dimensions NIMA mod. COMFORT AIR ...................................................................................... 19

3.1.7. Technical characteristics ........................................................................................................... 20

3.2. PREPARATION AND UNPACK ING .................................................................................................... 22

3.3. CONNECTIONS OF HOT AIR DUCTS FOR SUITE/CLUB/MUSA/NIMA AND TOBA COMFORT AIR MODEL. 25

3.4. INSTALLATION OF CERAMIC CLADDING FOR SUITE AND CLUB ......................................................... 26

3.4.1. Assembly of the lower panel – Suite and Club Stoves ................................................................. 26

3.4.2. Installation of side tiles ............................................................................................................. 27

3.4.3. Installation of ceramic top ........................................................................................................ 27

3.4.4. Assembly of sides on the MUSA stove ........................................................................................ 28

3.4.5. Assembly of ceramic side tiles onto NIMA stove ......................................................................... 29

3.4.6. Assembling the frontal/side panel and top on the Toba stove ...................................................... 30

3.4.7. Assembling side panels and top on the Sagar stove .................................................................... 33

3.5. INSTALLATION OF AIR FILTER ........................................................................................................ 35

3.6. OPENING/CLOSING OF ATHOS STOVE DOOR ................................................................................... 35

3.7. MAKING THE ELECTRICAL CONNECTIONS ....................................................................................... 35

4. OPERATION ..................................................................................................................................... 36

4.1. PRE-LIGHTING WARNINGS .............................................................................................................. 36

4.2. PRE-LIGHTING CHECK .................................................................................................................... 37

4.2.1. Note on first ignition ................................................................................................................. 37

4.3. LOADING THE PELLETS ................................................................................................................... 37

5. LCD REMOTE CONTROL ................................................................................................................... 38

5.1. Characteristics of the remote control ................................................................................................ 38

5.2. Graphic appearance ........................................................................................................................ 38

5.3. Operation of the remote control ....................................................................................................... 39

5.3.1. General rules ........................................................................................................................... 39

5.4. Initial settings ................................................................................................................................. 39

5.4.1. Adjusting the time .................................................................................................................... 39

PELLET STOVES

Chapter 1

INSTALLATION AND USE MANUAL

page 3

Introduction

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

5.4.2. °C – °F setting. ........................................................................................................................ 39

5.5. Setting the operating mode ............................................................................................................. 39

5.5.1. MANUAL mode (indicated by MAN) ............................................................................................ 39

5.5.2. AUTOMATIC mode (indicated by AUTO) .................................................................................... 39

5.5.3. TIMER mode (indicated by TIMER) ............................................................................................ 40

5.5.4. ECO mode (indicated by ECO ) ................................................................................................. 40

5.6. Various settings .............................................................................................................................. 41

5.6.1. Room ventilation ...................................................................................................................... 41

5.6.2. Sleep function .......................................................................................................................... 41

5.7. TIMER settings ............................................................................................................................... 42

5.7.1. TIMER time frame display ......................................................................................................... 42

5.7.2. Modifying the TIMER time frames ............................................................................................. 42

5.7.3. Enabling the TIMER-ECO time frames ........................................................................................ 42

6. EMERGENCY PANEL ......................................................................................................................... 43

6.1. Start-up/shutdown from emergency panel ........................................................................................ 44

6.2. SYNCHRONIZATION OF REMOTE CONTROL ..................................................................................... 44

7. SAFETY DEVICES AND ALARMS ....................................................................................................... 45

7.1. SAFETY DEVICES ............................................................................................................................ 45

7.2. ALARM SIGNALLING ........................................................................................................................ 46

7.3. Exiting alarm condition .................................................................................................................... 48

7.3.1. Mechanical shutdown of the stove ............................................................................................. 48

8. MAINTENANCE AND CLEANING ....................................................................................................... 49

8.1. DAILY AND WEEKLY CLEANING BY THE USER .................................................................................. 49

8.1.1. Before each lighting ................................................................................................................. 49

8.1.2. Check every 2/3 days ............................................................................................................... 49

8.1.3. Cleaning the glass .................................................................................................................... 50

8.1.4. Cleaning of the air filter ............................................................................................................ 50

8.2. PERIODIC CLEANING BY A SPECIALISED TECHNICIAN ..................................................................... 51

8.2.1. Cleaning of the heat exchanger ................................................................................................. 51

8.2.1.1.

8.2.1.2.

8.2.1.3.

8.2.1.4.

8.2.1.5.

8.2.1.6.

8.2.1.7.

Musa stove (steel sides) COMFORT AIR version

................................................................... 51

Suite and Club stove (ceramic sides) COMFORT AIR version

Nima Stove Version COMFORT AIR

Suite and Club stove (ceramic sides) AIR version

Sagar Stove Version AIR

Toba Stove AIR Version

.................................................................................................... 57

..................................................................................................... 58

Toba Stove COMFORT AIR Version

..................................................................................... 55

................................................................. 56

..................................................................................... 59

................................................. 53

8.2.2. CLEANING THE LOWER COMPARTMENT .................................................................................... 60

8.2.3. Shutting the stove down (end of season) ................................................................................... 60

8.2.4. Check of internal components ................................................................................................... 60

9. PROBLEMS / CAUSES / SOLUTIONS ................................................................................................ 62

10. ELECTRICAL DIAGRAMS ................................................................................................................ 64

PELLET STOVES

Chapter 1

INSTALLATION AND USE MANUAL

page 4

Introduction

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

ATTENTION

This warning sign indicates that the message to which it

refers should be carefully read and understood, because

failure to comply with what these notices say can cause

serious damage to the stove and put the user's safety at

risk.

INFORMATION

This symbol is used to highlight information which is

important for proper stove operation. Failure to comply with

these provisions will compromise use of the stove and its

operation will not be satisfactory.

OPERATING SEQUENCES:

Indicates a sequence of buttons to be pushed to access

menus or to make adjustments.

MANUAL

Indicates that you should carefully read this manual or the

related instructions.

INTRODUCTION

Dear Customer,

We wish to thank you for choosing an MCZ product, specifically a stove

of the MCZ pellet line.

In order to get the best performance from your stove and to

enjoy to the full the warmth and the sense of well-being which

the flame will diffuse through the home, we recommend that

you read this booklet carefully before lighting the stove for the

first time.

While thanking you again, may we remind you that the stove MUST

NOT be used by children, and that they must always be kept at a safe

distance from it!

Revisions to the publication

In order to improve the product, to keep this publication up to date the

manufacturer reserves the right to make modifications without any

advance notice. Any reproduction, even in part, of this manual without

the consent of the manufacturer is prohibited.

Care of the manual and how to consult it

Take good care of this manual and keep it in a place which can

easily and quickly be reached.

If this manual should be lost or destroyed, or if it is in poor

condition, ask for a copy from your retailer or directly from the

manufacturer, providing product identification data.

Information which is essential or that requires special attention is

shown in bold text.

Italic text

is used to call your attention to other paragraphs in the

manual or for any additional clarifications.

SYMBOLS USED IN THE MANUAL

PELLET STOVES

Chapter 1

INSTALLATION AND USE MANUAL

page 5

Warnings and guarantee conciliations

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

Installation of the stove, making the electrical

connections, checking its operation, and

maintenance are all tasks which should be carried

out by qualified and authorised personnel.

Install the stove in accordance with the

regulations in force in your local area, region and

country.

This apparatus cannot be used by people

(including children with limited physical, sensorial

or mental abilities or with little experience and

know-how unless they have been viewed or

instructed on the use of the apparatus by the

person responsible for its safety.

For the correct use of the stove and of the electronic

apparatus connected to it, and to prevent accidents, the

instructions given in this booklet must always be

followed.

Use, adjustment and programming must be carried out

by adults. Errors or incorrect settings may cause

hazardous conditions and/or poor operation.

Before beginning any operation, the user, or whoever is

preparing to operate on the stove, must have read and

understood the entire contents of this instruction

booklet.

The stove is to be used only for its intended purpose.

Any other use is to be considered improper and

therefore hazardous.

Do not use the stove for standing on or as any kind of

support.

Do not put clothes to dry on the stove Any clothes

hangers and suchlike must be kept a suitable distance

from the stove. Danger of fire.

All responsibility for improper use is taken entirely by the

user and such use relieves MCZ of any civil or criminal

responsibility.

Any kind of tampering or unauthorised substitution of

non-original spare parts can be hazardous for the safety

of the operator and relieves MCZ of any civil or criminal

responsibility.

Most of the surfaces of the stove are extremely hot (the

door, the handle, the glass, smoke discharge pipes etc.).

Avoid coming into contact with these parts, therefore,

without adequate protective clothing or suitable

implements, such as gloves with thermal protection or

implements which keep the hands cool.

Under no circumstances should the stove be run

with the door open or the glass broken.

Do not touch the stove with wet hands, in view of the

fact that it is an electrical appliance. Always disconnect

the supply cable before doing anything to the unit.

1. WARNINGS AND GUARANTEE CONDITIONS

1.1. SAFETY INSTRUCTIONS

PELLET STOVES

Chapter 1

INSTALLATION AND USE MANUAL

page 6

Warnings and guarantee conciliations

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

Before carrying out any cleaning or maintenance

operation, make sure in advance that the stove is

disconnected from the mains electricity supply, by

turning off the main switch located on the back of the

stove, or by unplugging the supply cable.

If there is a fire in the flue pipe, extinguish the stove,

disconnect it from the power supply and never open the

door. Then contact the competent authorities.

The stove must be electrically connected to a system

equipped with an effective earth conductor.

The system must be of adequate rated capacity for the

stated electrical power of the stove.

Incorrect installation or faulty maintenance (not

conforming to the requirements set out in this booklet)

can cause harm to people, animals or property. In such

cases MCZ is absolved from any civil or criminal

responsibility.

Shut the stove down in the event of a breakdown or

bad running.

Pellets must not be fed manually into the burner.

Accumulated unburnt pellets in the burner after

repeated failed ignitions must be removed before

lighting.

Do not wash the inside of the stove with water.

Do not wash the stove with water. The water could get

inside the unit and damage the electrical insulation and

cause electric shocks.

Do not expose your own body to hot air for extended

periods. Do not overheat the room you are in and

where the stove is installed. This could cause injuries

and health problems.

Do not expose plants or animals directly to a current of

hot air. There could be harmful effects on them

Do not put any fuels in the hopper but wood pellets.

Install the stove in a location with adequate means of

fire-prevention and equipped with all services such as

power supply (air and electricity) and fume discharge.

If the stove and the ceramic cladding are in storage, it

should be in a place that is free of damp, and they

should not be exposed to extremes of temperature.

It is inadvisable to base the stove directly on the floor,

and if the floor is made of flammable material, it must

be suitably insulated.

Do not light the stove with flammable materials if the

ignition system breaks down.

1.2. OPERATING WARNINGS

PELLET STOVES

Chapter 1

INSTALLATION AND USE MANUAL

page 7

Warnings and guarantee conciliations

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

INFORMATION

In case of any problems, get in touch with your dealer, or a

qualified engineer authorised by MCZ, and if a repair is

necessary, insist on the use of original spare parts.

Use only the fuel recommended by MCZ (for Italy pellets

with a diameter of 6 mm and for other European

countries with a diameter of 6-8 mm) and provided only

with an automatic supply system.

Periodically check and clean the smoke outlet ducts

(connection to the flue pipe).

Accumulated unburnt pellets in the burner after

repeated failed ignitions must be removed before

lighting.

The pellet stove is not a cooking appliance.

Always keep the cover of the fuel hopper closed.

Keep this instruction manual carefully because it must

stay with the stove throughout its working life. If the

stove is sold or transferred to another user, always make

sure that the booklet goes with the product.

If it gets lost, ask MCZ or your authorised dealer for

another copy.

MCZ guarantees the stove, excluding the components

which are subject to normal, for a period of two years

from the date of purchase, as proved by a supporting

document which gives the name of the vendor and the date

on which the sale took place. The guarantee is conditional

on the guarantee certificate being filled in and returned

within 8 days, and requires that the product be installed and

tested by a specialised installer, according to the detailed

instructions given in the instruction booklet supplied with the

product.

1.3. IMPORTANT INFORMATION FOR CORRECT

DISPOSAL OF THE PRODUCT IN ACCORDANCE WITH

EC DIRECTIVE 2002/96/EC

.

At the end of its working life, the product must not be disposed of as

urban waste.

It must be taken to a special local authority differentiated waste

collection centre or to a dealer providing this service.

Disposing of a appliance separately avoids possible negative

consequences for the environment and health deriving from

inappropriate disposal and enables the constituent materials to be

recovered to obtain significant savings in energy and resources.

As a reminder of the need to dispose of appliances separately, the

product is marked with a crossed-out wheeled dustbin.

1.4. GUARANTEE CONDITIONS

PELLET STOVES

Chapter 1

INSTALLATION AND USE MANUAL

page 8

Warnings and guarantee conciliations

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

The term 'guarantee' is to be understood to denote the freeof-charge replacement or repair of parts recognised to

have been defective at the start by reason of

manufacturing defects.

CLAIMS UNDER THE GUARANTEE

the request for action under the guarantee must be

addressed to the retailer, who will forward the claim

to MCZ's technical assistance service.

MCZ refuses to accept any responsibility in the event

that the stove or any other accessory have been

improperly used or modified without authorisation.

For all replacement of parts, only original MCZ spare

parts must be used.

1.4.1. Limitations

The above guarantee does not cover components relating to electrical

and electronic parts, or fans, on which the guarantee period is 1 year

from the purchase of the product, documented as specified above. The

guarantee does not cover parts subject to normal wear such as gaskets,

glass, and any parts with can be removed from the firebox.

The replacement parts will be guaranteed for the remainder of the

guarantee period starting from the date of purchase of the product.

1.4.2. Exclusions

Variations in colour in the painted or ceramic parts, and crackling of the

glaze on the ceramics, do not constitute grounds for a claim under the

guarantee, as they are natural characteristics of the material and of the

use of the product.

The guarantee does not cover any parts which may be found to be

faulty as a result of negligence or carelessness in use, or of incorrect

maintenance, or of installation not complying with MCZ's specification

(see the relevant chapters in this user manual).

MCZ refuses to accept any responsibility for any damage which may be

caused, directly or indirectly, by persons, animals or things in

consequence of the failure to observe all the prescriptions laid down in

the instruction booklet, especially those concerning warnings on the

subject of installation, use and maintenance of the appliance.

If the product does not perform correctly, contact your local retailer

and/or importer.

Damage caused by transport and/or handling is excluded from the

guarantee.

For installation and use of the product, reference must be made

exclusively to the booklet supplied.

The guarantee will be invalidated in the event of damage caused by

tampering with the appliance, atmospheric agents, natural disasters,

electrical discharges, fire, defects in the electrical system, and caused

by lack of, or incorrect, maintenance in terms of the manufacturer's

instructions.

PELLET STOVES

Chapter 2

INSTALLATION AND USE MANUAL

page 9

Theoretical notions for installation

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

The poorer the quality of the fuel, the more

frequently will intervention be necessary for cleaning

the internal parts, such as the grate and the

combustion chamber.

Fuel pellets

15 Kg sack of fuel

2. THEORETICAL NOTIONS FOR INSTALLATION

2.1. PELLETS

Wood pellets are manufactured by hot-extruding compressed sawdust which

is produced during the working of natural dried wood. The compactness of the

material comes from the lignin which is contained in the wood itself, and

allows the production of pellets without the use of glues or binders.

The market offers different types of pellet with characteristics which

vary depending on what mixture of woods is used. The diameter varies

between 6 mm and 8 mm, with a standard length in the range 5 mm to

30 mm. Good quality pellets have a density which varies between 600

kg/m3 and 750 kg/m3, with a moisture content which varies from 5%

to 8% by weight.

Besides being an ecological fuel (exploiting timber residues to the

maximum and achieving cleaner combustion than is possible with fossil

fuels), pellets also have technical advantages. While good-quality timber

has a calorific power of 4.4 kW/kg (with 15% moisture, therefore after

about 18 months' seasoning), the equivalent figure for pellets is 4.9

kW/kg.

To ensure good combustion, the pellets must be stored in an area that

is free of humidity and protected from dirt. The pellets are usually

supplied in 15 kg. sacks, so storing them is very convenient.

Good quality pellets ensure good combustion, thus lowering the

emission of harmful agents into the atmosphere.

The main certifications of quality for pellets in the European market are

DINplus and Ö-Norm M7135; these ensure respect of:

Calorific power: 4,9 kW/kg

Water content: max 10% of weight

Percentage of ashes: max 0,5% of weight

Diameter: 5 – 6mm

Length: max 30mm

Contents: 100% untreated wood, with no added bonding

substances (bark percentage 5% max)

Packaging: in sacks made from ecologically compatible or

biologically decomposing material

PELLET STOVES

Chapter 2

INSTALLATION AND USE MANUAL

page 10

Theoretical notions for installation

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

MCZ strongly recommends using certified fuel in its

stoves (DINplus e Ö-Norm M7135).

The use of fuel of inferior quality or not conforming

to the specification given above compromises the

running of your stove and can therefore lead to the

termination of the guarantee and of the

manufacturer's responsibility for the product.

MCZ pellet stoves run exclusively on pellets with a

diameter of 6 mm (only for Italy) and 6-8 mm

(European countries) with lengths that go from 5

mm to 30 mm.

IMPORTANT!

Installation and assembly of the stove must be

carried out by qualified personnel.

IMPORTANT!

The stove must be connected to a flue pipe or a

vertical duct which can discharge the fumes at the

highest point of the building.

The fumes are however derived from the combustion

of wood products, and if they come into contact with

or close to walls, they can make dirty marks.

Also take care because the fumes are very hot but

almost invisible, and can cause burns on contact.

The holes for the passage of the smoke pipe and for

the intake of air from outside should be made before

positioning the stove unit.

2.2. PRECAUTIONS FOR INSTALLATION

The stove must be installed in a suitable position to allow the normal

operations of opening and ordinary maintenance.

The site must be:

capable of providing the environmental conditions for operation

equipped with power supply 230V 50 Hz

capable of taking an adequate system for smoke discharge

provided with external ventilation

provided with an earth connection complying with CEI 64-8

The stove must be connected to a flue pipe or an internal or

external vertical duct conforming to current standards UNI

7129 - 7131 9615.

The stove must be positioned in such a way that the electrical

plug is accessible.

PELLET STOVES

Chapter 2

INSTALLATION AND USE MANUAL

page 11

Theoretical notions for installation

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

It is not permissible to install the stove in bedrooms,

bathrooms or showers, or in a room where another

heating appliance is installed (fireplace, stove etc.)

which does not have its own independent air intake.

Locating the stove in a room with an explosive

atmosphere is prohibited.

The floor of the room where the stove is to be

installed must be strong enough to take its weight.

If the floor is wooden, we recommend the use of a

floor guard in compliance with the applicable

standards in force in the country of installation.

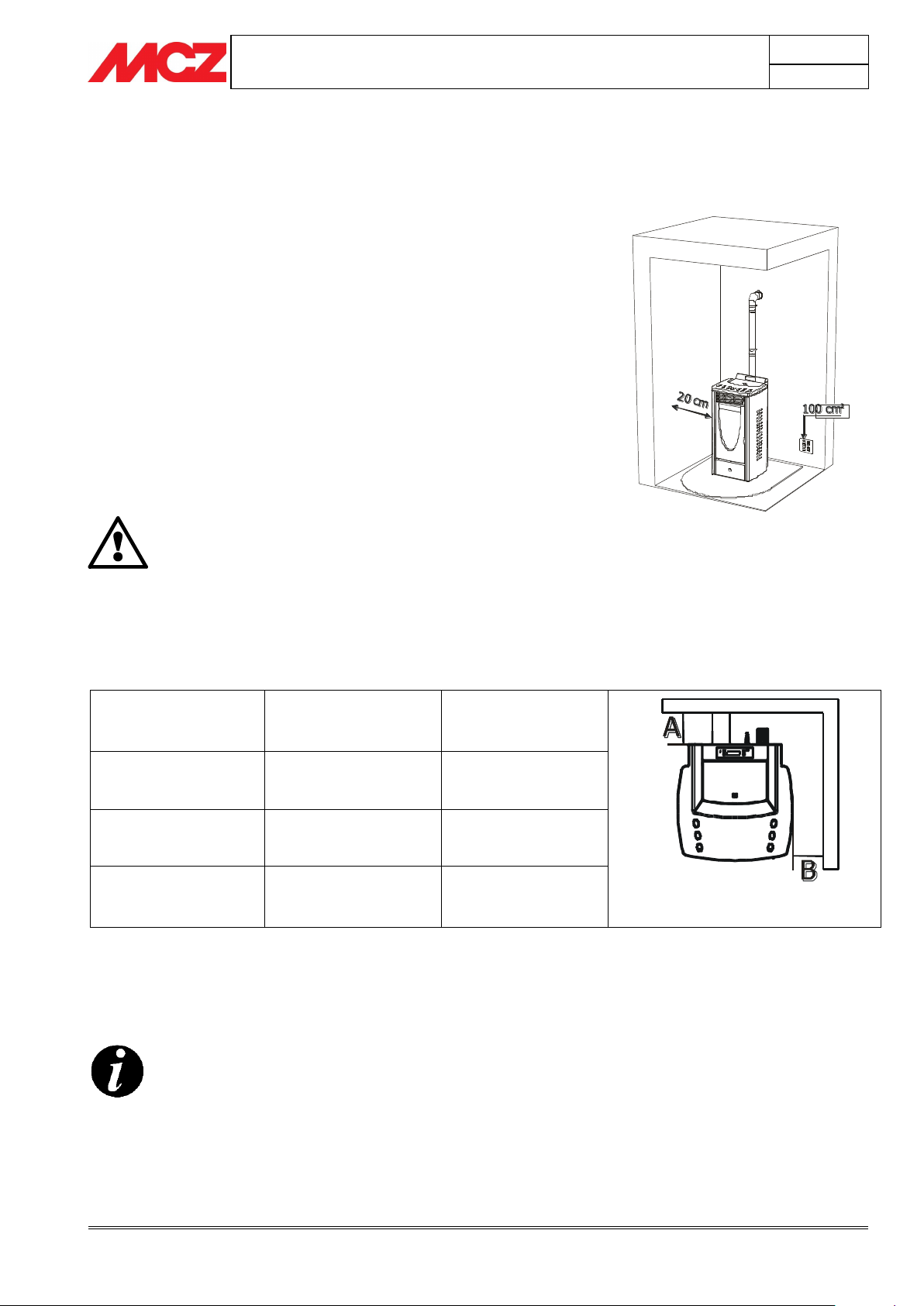

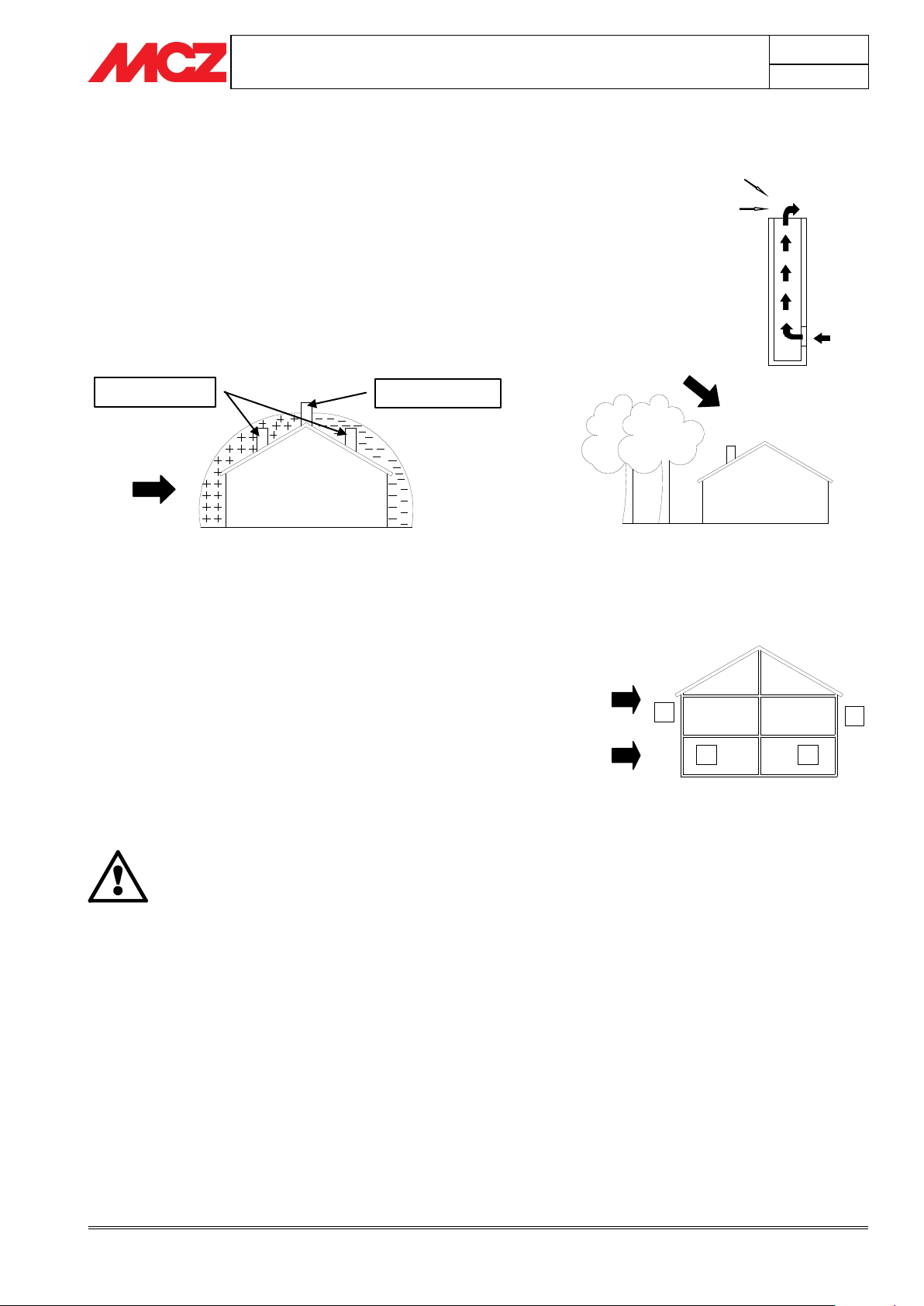

Example of pellet stove installation

SUITE/CLUB/MUSA/

NIMA/TOBA

Non-flammable

walls

Flammable walls

Air version

A=5cm

B=5cm

A=5cm

B=10cm

Comfort Air version

with diffuser

A=15cm

B=15cm

A=20cm

B=20cm

Ducted Comfort Air

version

A=5cm

B=15cm

A=5cm

B=20cm

2.3. OPERATING AREA

For proper functioning and a good temperature distribution, the stove

should be positioned in a location where it is able to take in the air

necessary for combustion of the pellets (about 40 m3/h must be

available), as laid down in the standard governing the installation and

in accordance with local national standards.

The volume of the room must not be less than 30 m3.

The air must come in through permanent openings made in walls (in

proximity to the stove) which give onto the outside, with a minimum

cross-section area of 100 cm2.

These openings must be made in such a way that it is not possible for

them to be obstructed in any way.

Alternatively, the air can be taken from rooms adjacent to the one

which needs ventilating, as long as they are provided with an air intake

from the outside, and are not used as bedrooms or bathrooms, and

provided there is no fire risk such as there is for example in garages,

woodsheds, and storerooms, with particular reference to what is laid

down in current standards.

If the room contains objects which are believed to be particularly

delicate, such as drapes, sofas and other furniture, their distance from

the stove should be considerably increased.

PELLET STOVES

Chapter 2

INSTALLATION AND USE MANUAL

page 12

Theoretical notions for installation

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

1

2

It is not compulsory to connect the air intake directly

with the stove (so that it draws air directly from

outside), but it is essential at all events to ensure an

airflow of 50 cubic metres per hour by the use of a

hole of the dimensions given.

See standard UNI 10683.

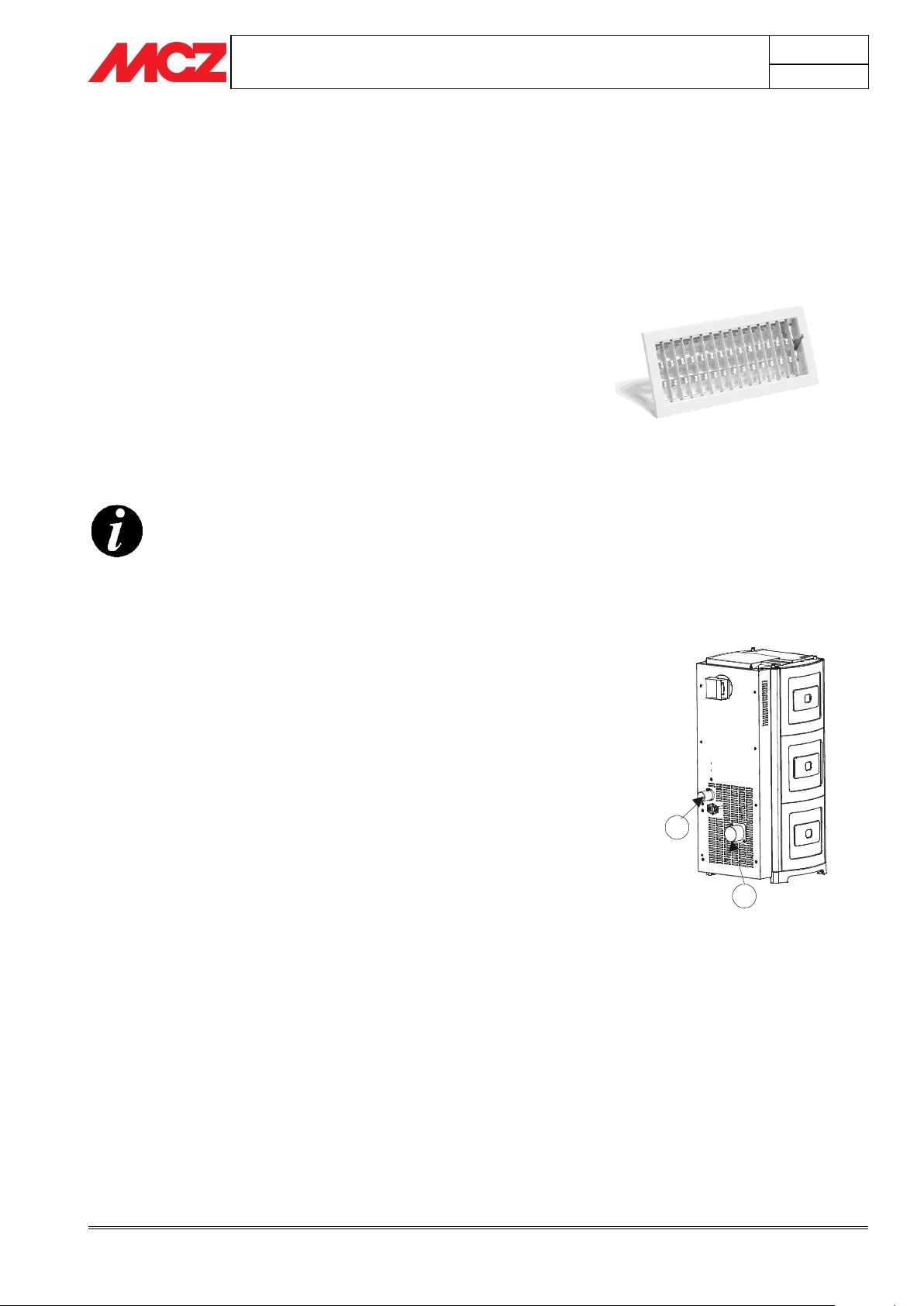

Rear view of a pellet stove

1) Smoke outlet

2) Combustion air intake

2.4. CONNECTION TO THE EXTERNAL AIR INTAKE

It is essential that at least as much air must be able to flow into the

room where the stove is installed as is required for proper combustion

in the appliance and for the ventilation of the room. This can be

effected by means of permanent openings in the walls of the room to

be ventilated, which give onto the outside, or by single or collective

ventilation ducts.

For this purpose, on the external wall near the stove, a hole must be

made with a minimum free cross-section of 100 cm². (equivalent to a

round hole of 12 cm diameter or a square hole 10x10 cm), protected by

a grille on the inside and the outside.

The air intake must also:

communicate directly with the room where the stove is installed

be protected by a grille, metal mesh or suitable guard, as long as

this does not reduce the area below the minimum.

be positioned in such a way as to be impossible to obstruct

2.5. CONNECTION OF SMOKE DISCHARGE PIPE

When making the hole for the passage of the smoke discharge pipe, it

is necessary to take into account the possible presence of flammable

materials. If the hole has to pass through a wall made of wood or

thermolabile material, THE FITTER MUST under all circumstances

observe the minimum safe distance from all combustible materials

(value stated on the pipe certification label) and provide any additional

insulation using appropriate materials (thickness 1.35cm with minimum

thermal conductivity of 0.07 W/m°K).

The same is true if the stove pipe must run through vertical or

horizontal stretches passing in proximity (min.20cm) to the heatsensitive wall

As an alternative we recommend the use of insulated pipe, which can

also be used on the outside to avoid condensation.

The combustion chamber works in low pressure. The smoke duct for

the discharge of fumes will also be under low pressure when connected

to an efficient flue pipe as directed.

PELLET STOVES

Chapter 2

INSTALLATION AND USE MANUAL

page 13

Theoretical notions for installation

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

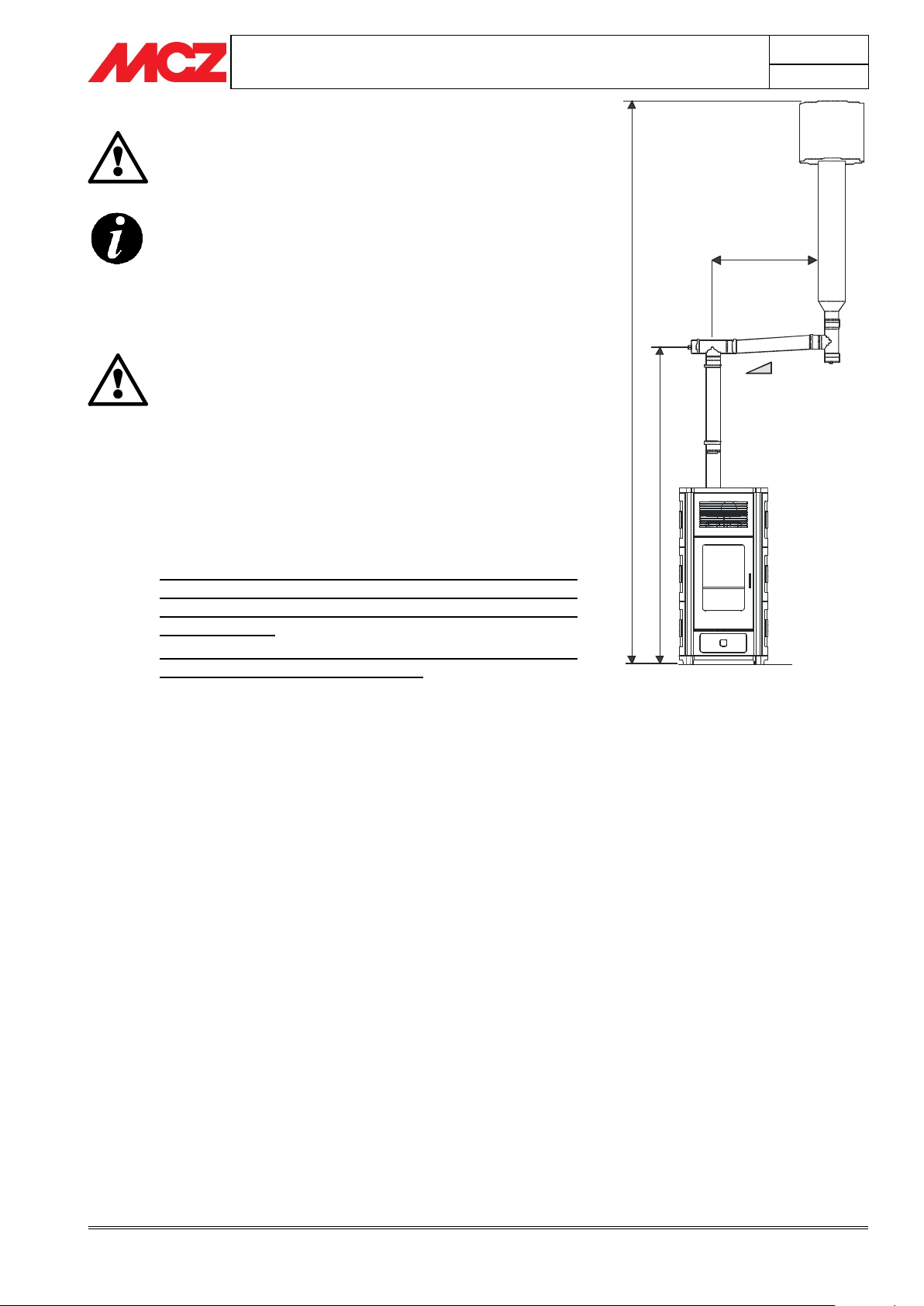

3-5 %

2 - 3 mt. MAX

H

>

4

m

t

.

H

>

1

,

5

m

t

.

Pipes and unions with suitable gaskets must always

be used, to guarantee a hermetic seal.

All sections of the smoke duct must be inspectable and

removable to enable periodic internal cleaning. Tee

connectors with inspection caps should be used.

IMPORTANT!

All 90 degree changes of direction in the flue pipe

must be fitted with suitable tee connectors to allow

the possibility of inspection. (see accessories for

pellet stove)

It is absolutely prohibited to fit a grille on the end of

the discharge pipe, because it could lead to poor

running of the stove.

FOR CONNECTION TO THE FLUE PIPE, NOT MORE

THAN 2-3 METRES OF HORIZONTAL PIPE MUST BE

USED AND NOT MORE THAN THREE 90° CURVES

MUST BE USED

IT IS ALSO ADVISABLE NOT TO EXCEED 6 METRES IN

LENGTH WITH THE PIPE Ø 80 mm

Example of pellet stove installation

Position the stove bearing in mind all the instructions and considerations

above.

PELLET STOVES

Chapter 2

INSTALLATION AND USE MANUAL

page 14

Theoretical notions for installation

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

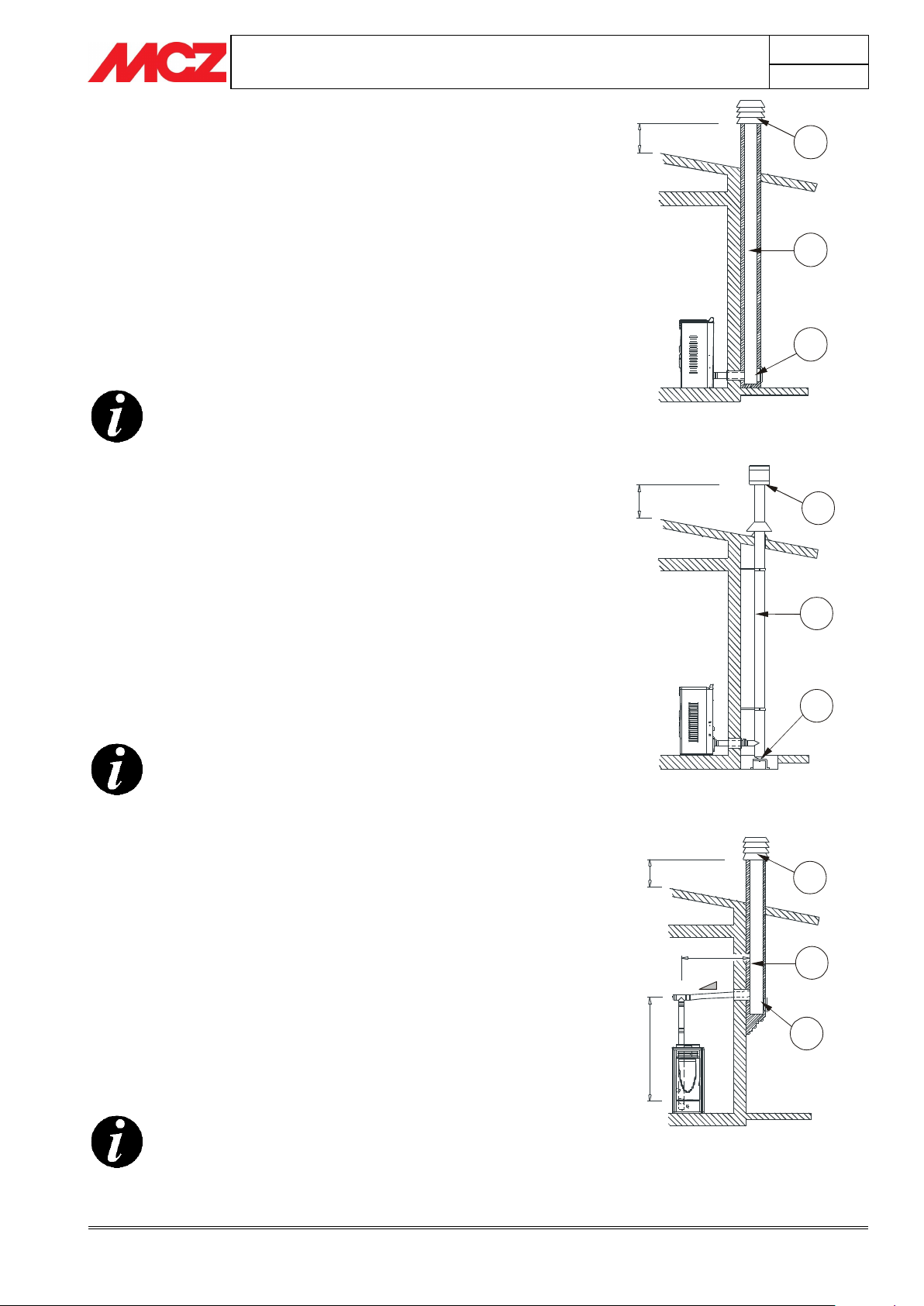

This type of connection ensures the evacuation of the

fumes even in the event of a temporary power cut.

This type of connection ensures the evacuation of the

fumes even in the event of a temporary power cut.

This type of connection ensures the evacuation of the

fumes even in the event of a temporary power cut.

0,5 mt.

1

2

3

1) Windproof cowl

2) Flue pipe

3) Inspection

0,5 mt.

2

1

3

1) Windproof cowl

2) Flue pipe

3) Inspection

3-5 %

2 - 3 mt. MAX

0,5 mt.

H

>

1

,

5

m

t

.

3

2

1

1) Windproof cowl

2) Flue pipe

3) Inspection

2.6. CONNECTION TO THE FLUE PIPE

The flue pipe must have internal dimensions not larger than 20 x 20 cm,

or diameter 20 cm. In the event of larger dimensions, or of the flue

pipe being in poor condition (for example cracks, poor insulation, etc.),

it is advisable to fit a stainless steel pipe of suitable diameter inside the

flue pipe throughout its length, right up to the top.

Check with suitable instruments that there is a minimum draught of 10 Pa.

At the bottom of the flue pipe, provide an inspection cap to allow

periodic checking and cleaning, which must be done annually.

Make a gas-tight connection to the flue pipe, using pipes and

connectors as recommended by us.

You must ensure that a windproof cowl should be fitted which complies

with the standards in force.

2.7. CONNECTION TO AN EXTERNAL FLUE WITH

INSULATED OR DOUBLE-WALL PIPE

The external fluepipe must have internal dimensions of minimum 10x10

cm or 10 cm diameter, and maximum 20x20 cm or 20 cm diameter.

Check with suitable instruments that there is a minimum draught of 10 Pa.

The only type of pipe which is permissible is insulated (double-walled)

stainless steel, smooth on the inside, fixed to the wall. Flexible stainless

steel pipe must not be used. At the bottom of the flue pipe, provide an

inspection cap to allow periodic checking and cleaning, which must be

done annually. Make a gas-tight connection to the flue pipe, using

pipes and connectors as recommended by us.

You must ensure that a windproof cowl should be fitted which complies

with the standards in force.

2.8. CONNECTION TO THE FLUE PIPE

For proper functioning, the connecting pipe between the stove and the

chimney or flue duct must have a slope of not less than 3% in the

horizontal stretches, the length of which must not exceed 2/3

metres, and the vertical distance between one tee connector and

another (change of direction) must not be less than 1.5m.

Check with suitable instruments that there is a minimum draught of 10 Pa.

At the bottom of the flue pipe, provide an inspection cap to allow

periodic checking and cleaning, which must be done annually.

Make a gas-tight connection to the flue pipe, using pipes and

connectors as recommended by us.

You must ensure that a windproof cowl should be fitted which complies

with the standards in force.

PELLET STOVES

Chapter 2

INSTALLATION AND USE MANUAL

page 15

Theoretical notions for installation

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

IMPORTANT!

The operation of the pellet stove is noticeably

sensitive to the conformation and position of the flue

which is adopted.

Hazardous conditions can only be overcome by

suitable setting-up of the stove carried out by

qualified MCZ personnel.

1

2 3

4

E.g. Crosswind 2: 8 m/sec

Depression of 30Pa

E.g. Downdraft at 45° of

8m/sec. Overpressure of 17

Pa

1-2 = High-pressure zones

3-4 = Low-pressure zones

WIND

Least favourable points

Most favourable position

WIND

Downdraft

High-pressure zone

Low-pressure zone

2.9. OPERATING PROBLEMS CAUSED BY DRAUGHT

DEFECTS IN THE FLUE

Of all the weather and geographical conditions which affect the

operation of a flue pipe (rain, fog, snow, altitude a.s.l., exposure to

sunlight, direction of facing), the wind is unquestionably the most

decisive. In fact, along with thermal depression caused by the

difference in temperature inside and outside of the chimney, there is

another type of depression or over-pressure: dynamic pressure caused

by the wind. An updraft always increases depression and hence

draught. A crosswind increases depression provided the cowl has been

installed properly. A downdraft always decreases depression, at times

inverting it.

Besides the direction and force of the wind, the position of the flue and

the cowl with respect to the roof of the building and the surrounding

landscape is important.

The wind also influences the operation of the chimney indirectly by

creating high-pressure and low-pressure zones, not only outside the

building but inside as well. In rooms directly exposed to the wind (2),

an indoor high-pressure area can be created which can augment the

draught in stoves and fireplaces, but it can be counteracted by the

external high pressure if the cowl is situated on the side exposed to the

wind (1). On the other hand, in the rooms on the opposite side from

the direction of the wind (3), a dynamic depression can be created

which competes with the natural thermal depression developed by the

chimney, but this can be compensated for (sometimes) by locating the

flue on the opposite side from the direction of the wind (4).

PELLET STOVES

Chapter 3

INSTALLATION AND USE MANUAL

page 16

Installation and assembly

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

1

0

0

9

2

5

9

226

187

4

3

9

60

6

0

413

1

1

4

9

6

0

3

0

578

5

5

8

7

3

6

3

Ø48

Ø80

323

1

4

0

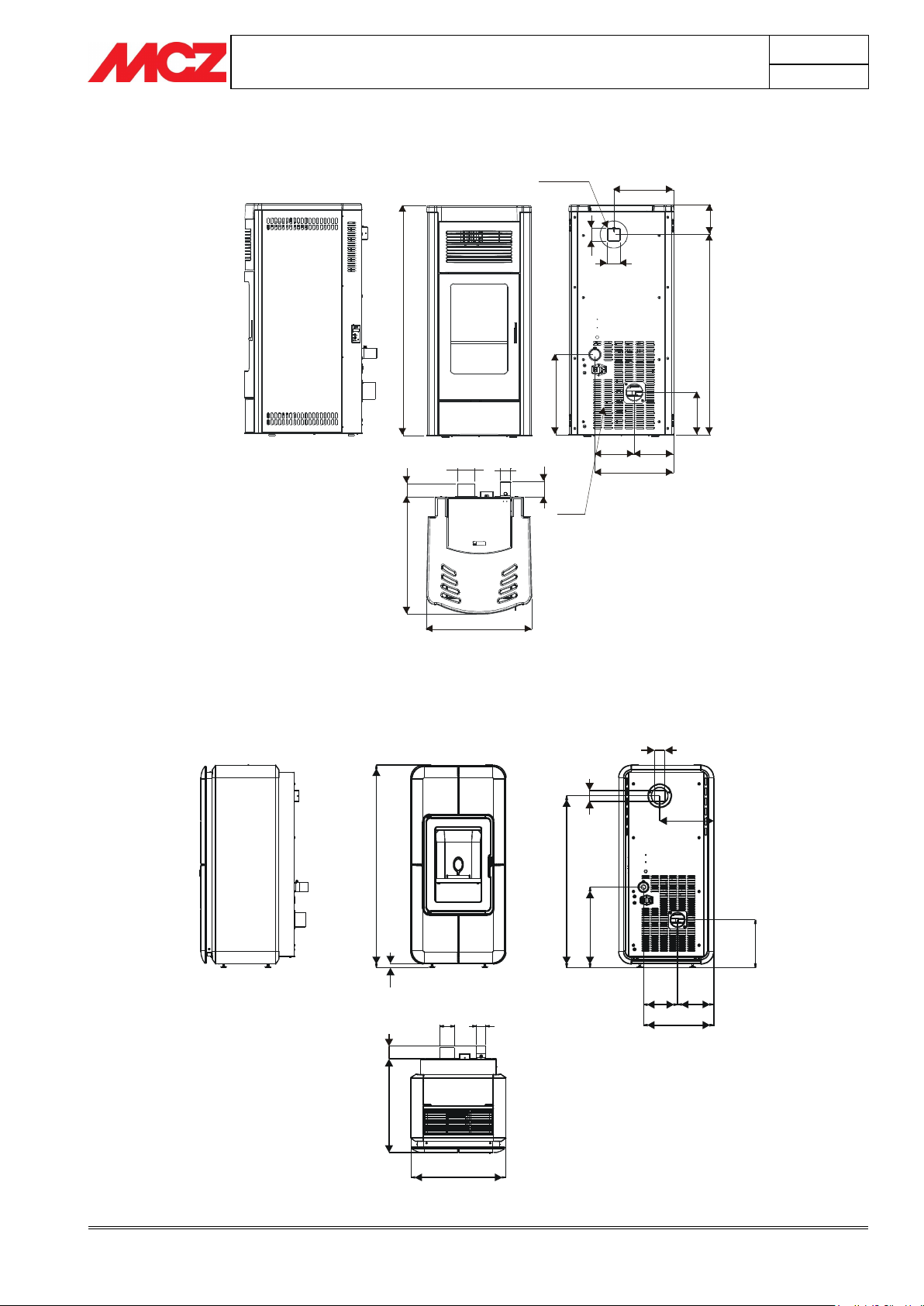

COLD AIR INLET

COMFORT AIR

HOT AIR OUTLET

1

1

4

9

323

1

0

0

9

2

5

9

413

226

187

4

3

9

60

6

0

6

0

30

5

5

8

578

7

1

6

3

Ø48

Ø80

1

4

0

COMFORT AIR

HOT AIR OUTLET

3. INSTALLATION AND ASSEMBLY

3.1. DRAWINGS AND TECHNICAL CHARACTERISTICS

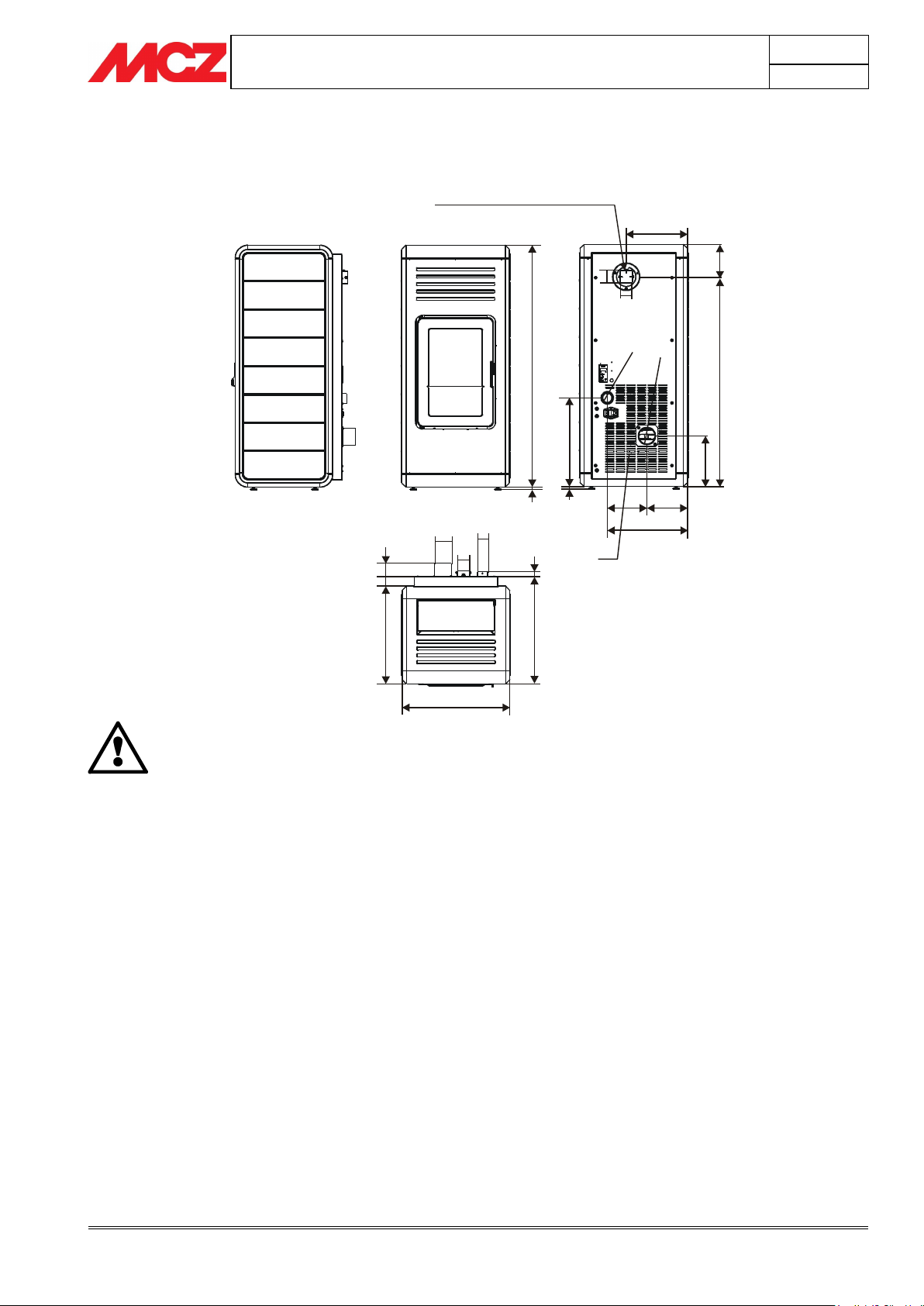

3.1.1. Dimensions CLUB mod. AIR – COMFORT AIR

3.1.2. Dimensions SUITE mod. AIR – COMFORT AIR

PELLET STOVES

Chapter 3

INSTALLATION AND USE MANUAL

page 17

Installation and assembly

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

1

0

9

3

9

5

2

2

0

2

284

60

6

0

373

186

187

3

8

2

502

5

5

9

6

3

Ø80

Ø48

7

3

1

4

1

COLD AIR INLET

COMFORT AIR

HOT AIR OUTLET

1

1

1

0

2

0

2

6

2

387

200

187

4

4

2

9

4

2

60

298

6

0

523

5

1

4

7

0

Ø80

Ø48

3.1.3. Dimensions MUSA mod. AIR- COMFORT AIR

3.1.4. Dimensions TOBA mod. AIR-COMFORT AIR

PELLET STOVES

Chapter 3

INSTALLATION AND USE MANUAL

page 18

Installation and assembly

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

384

197

2

4

1

4

2

1

40

1

0

8

1

522

5

1

1

7

0

Ø80

Ø48

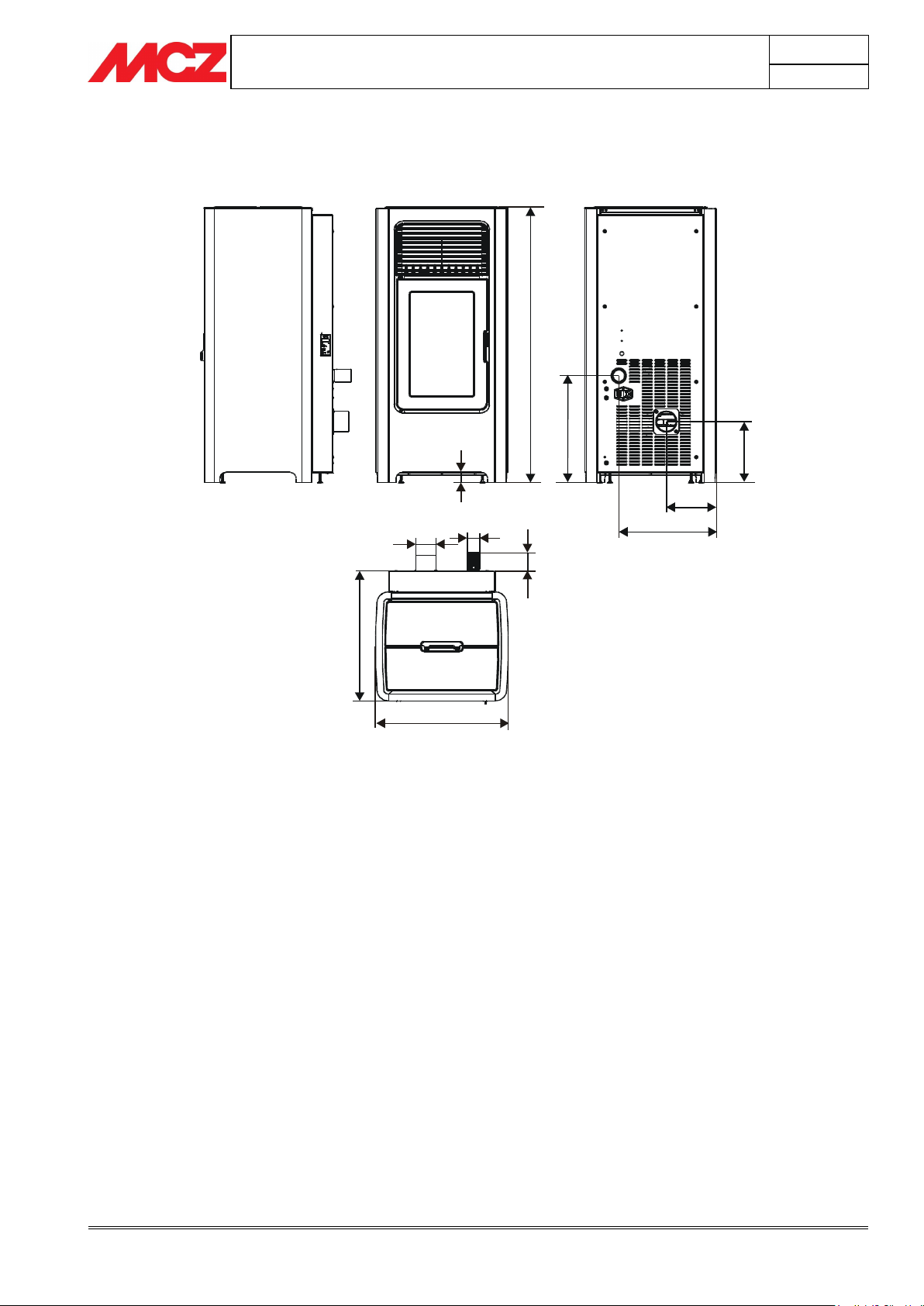

3.1.5. Dimensions SAGAR mod. AIR

PELLET STOVES

Chapter 3

INSTALLATION AND USE MANUAL

page 19

Installation and assembly

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

1

1

4

0

1

2

293

4

1

8

1

2

187 195

382

9

8

8

1

5

2

2

3

8

5

0

4

515

2

3

4

6

0

4

4

6

4

Ø80

Ø48

60

Ø

4

8

Ø

8

0

6

0

60

COMFORT AIR

HOT AIR OUTLET

COLD AIR INLET

IMPORTANT!

The hole in CLUB, SUITE, MUSA, NIMA and TOBA

stoves for hot air outlet, located at the top to the rear

of the stove, is only present for the COMFORT AIR

model.

3.1.6. Dimensions NIMA mod. COMFORT AIR

PELLET STOVES

Chapter 3

INSTALLATION AND USE MANUAL

page 20

Installation and assembly

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

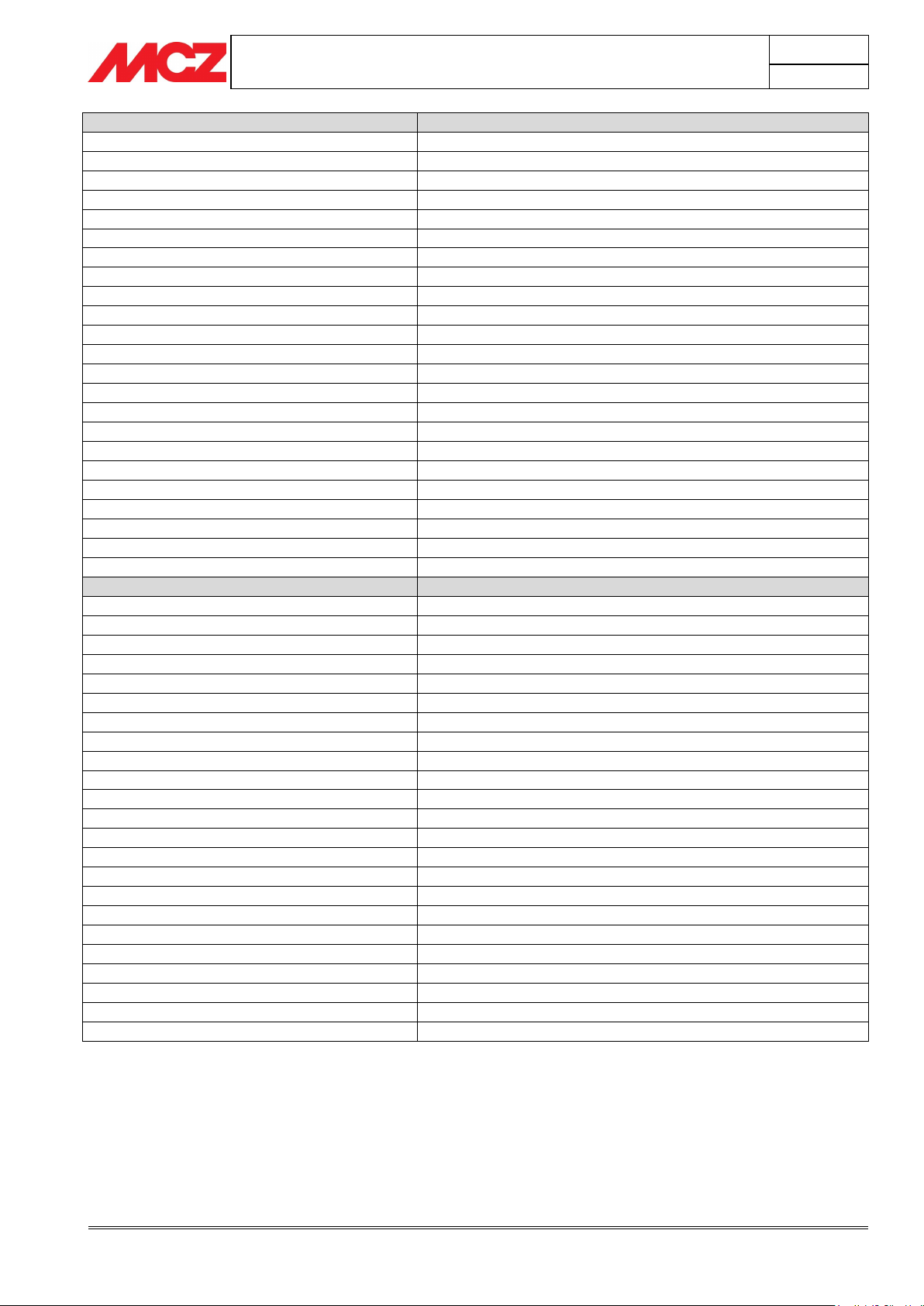

Technical characteristics

CLUB – SUITE – MUSA Mod. AIR

(Max) nominal output power

9,5 kW (8170 kcal/h)

Minimum output power

2,4 kW (2064 kcal/h)

Yield at maximum

91,7%

Yield at minimum

94,1%

Temperature of exhaust smoke at maximum

180°C

Temperature of exhaust smoke at minimum

100°C

Particulate/OGC / Nox (13%O2)

22 mg/Nm3 - 5 mg/Nm3 - 123 mg/Nm3

CO at 13%O

²

at minimum and maximum

0,025 – 0,014%

CO2 at minimum and maximum

5,7% - 8,7%

Mass of smoke

7,7 g/sec

Recommended draught at Max power

0,10 mbar – 10 Pa

Recommended draught at Min power

0,05 mbar – 5 Pa

Hopper capacity

44 litri

Fuel pellet type

Pellet diametro 6-8 mm. Con pezzatura 5/30 mm.

Pellet consumption per hour

Min~0,6 kg/h* Max~2,0 kg/h*

Operating time between re-fuelling

Al min~48 h* Al max~15 h*

Heatable volume m3

204/40-233/35-272/30 **

Combustion air inlet

External diameter 50 mm.

Smoke outlet

External diameter 80 mm.

Nominal electrical power (EN 60335-1).

Max. 420 W – Med. 80 W

Power supply frequency and voltage

230 Volt / 50 Hz

Net weight

160 Kg.

Weight with packaging

170 Kg.

Technical characteristics

CLUB – SUITE – MUSA - NIMA Mod. COMFORT AIR

(Max) nominal output power

11,5 kW (9890 kcal/h)

Minimum output power

2,4 kW (2064 kcal/h)

Yield at maximum

90,2%

Yield at minimum

94,1%

Temperature of exhaust smoke at maximum

190°C

Temperature of exhaust smoke at minimum

130°C

Particulate/OGC / Nox (13%O2)

20 mg/Nm3 - 8 mg/Nm3 - 133 mg/Nm3

CO at 13%O

²

at minimum and maximum

0,025 – 0,013%

CO2 at minimum and maximum

5,7% - 8,6%

Mass of smoke

9,9 g/sec

Recommended draught at Max power

0,10 mbar – 10 Pa

Recommended draught at Min power

0,05 mbar – 5 Pa

Hopper capacity

44 litri

Fuel pellet type

Pellet diametro 6-8 mm. Con pezzatura 5/30 mm.

Pellet consumption per hour

Min~0,6 kg/h* Max~2,2 kg/h*

Operating time between re-fuelling

Al min~48 h* Al max~13 h*

Heatable volume m3

247/40-283/35-330/30 **

Combustion air inlet

External diameter 50 mm.

Smoke outlet

External diameter 80 mm.

Nominal electrical power (EN 60335-1).

Max. 420 W – Med. 100 W

Power supply frequency and voltage

230 Volt / 50 Hz

Net weight

160 Kg.

Weight with packaging

170 Kg.

3.1.7. Technical characteristics

* Data that may vary depending on the type of pellets used.

**Heatable volume based on the requested power per m3 (respectively 40-35-30 Kcal/h per m3)

Tested according to EN 14785 accordance with Directive 89/106/EEC (Construction Products).

PELLET STOVES

Chapter 3

INSTALLATION AND USE MANUAL

page 21

Installation and assembly

Technical service - Rights reserved MCZ Group S.p.A. - Reproduction prohibited

Technical characteristics

SAGAR – TOBA Mod. AIR

(Max) nominal output power

8 kW (6880 kcal/h)

Minimum output power

2.4 kW (2064 kcal/h)

Yield at maximum

91,7 %

Yield at minimum

94,1 %

Temperature of exhaust smoke at maximum

170°C

Temperature of exhaust smoke at minimum

100°C

Particulate/OGC / Nox (13%O2)

22 mg/Nm3 - 6 mg/Nm3 - 121 mg/Nm3

CO at 13%O

²

at minimum and maximum

0.025 — 0.014%

CO2 at minimum and maximum

5,7% – 8,7%

Mass of smoke

6,6 g/sec

Recommended draught at Max power

0,10 mbar – 10 Pa

Recommended draught at Min power

0,05 mbar – 5 Pa

Hopper capacity

37 litri

Fuel pellet type

Pellet diametro 6-8 mm. Con pezzatura 5/30 mm

Pellet consumption per hour

Min ~ 0,6 kg/h * Max. ~ 1,8 kg/h *

Operating time between re-fuelling

Al min ~ 40 h * Al max. ~ 13 h *

Heatable volume m3

172/40 – 196/35 – 229/30 **

Combustion air inlet

External diameter 50 mm.

Smoke outlet

External diameter 80 mm.

Nominal electrical power (EN 60335-1).

Max. 420 W – Med. 80 W

Power supply frequency and voltage

230 Volt / 50 Hz

Net weight

140 Kg.

Weight with packaging

150 Kg.

Technical characteristics

TOBA Mod. COMFORT AIR

(Max) nominal output power

8 kW (6880 kcal/h)

Minimum output power

2.4 kW (2064 kcal/h)

Yield at maximum

91,7 %

Yield at minimum

94,1 %

Temperature of exhaust smoke at maximum

170°C

Temperature of exhaust smoke at minimum

100°C

Particulate/OGC / Nox (13%O2)

22 mg/Nm3 - 5 mg/Nm3 - 123 mg/Nm3

CO at 13%O

²

at minimum and maximum

0.025 — 0.014%

CO2 at minimum and maximum

5,7% – 8,7%

Mass of smoke

6,6 g/sec

Recommended draught at Max power

0,10 mbar – 10 Pa

Recommended draught at Min power

0,05 mbar – 5 Pa

Hopper capacity

35 litri

Fuel pellet type

Pellet diametro 6-8 mm. Con pezzatura 5/30 mm

Pellet consumption per hour

Min ~ 0,6 kg/h * Max. ~ 1,8 kg/h *

Operating time between re-fuelling

Al min ~ 40 h * Al max. ~ 13 h *

Heatable volume m3

172/40 – 197/35 – 229/30 **

Combustion air inlet

External diameter 50 mm.

Smoke outlet

External diameter 80 mm.

Nominal electrical power (EN 60335-1).

Max. 420 W – Med. 80 W

Power supply frequency and voltage

230 Volt / 50 Hz

Net weight

140 Kg.

Weight with packaging

150 Kg.

* Data that may vary depending on the type of pellets used.

**Heatable volume based on the requested power per m3 (respectively 40-35-30 Kcal/h per m3)

Tested according to EN 14785 accordance with Directive 89/106/EEC (Construction Products).

Loading...

Loading...