MANUAL FOR USE AND

INSTALLATION

EN 14785 - 2006

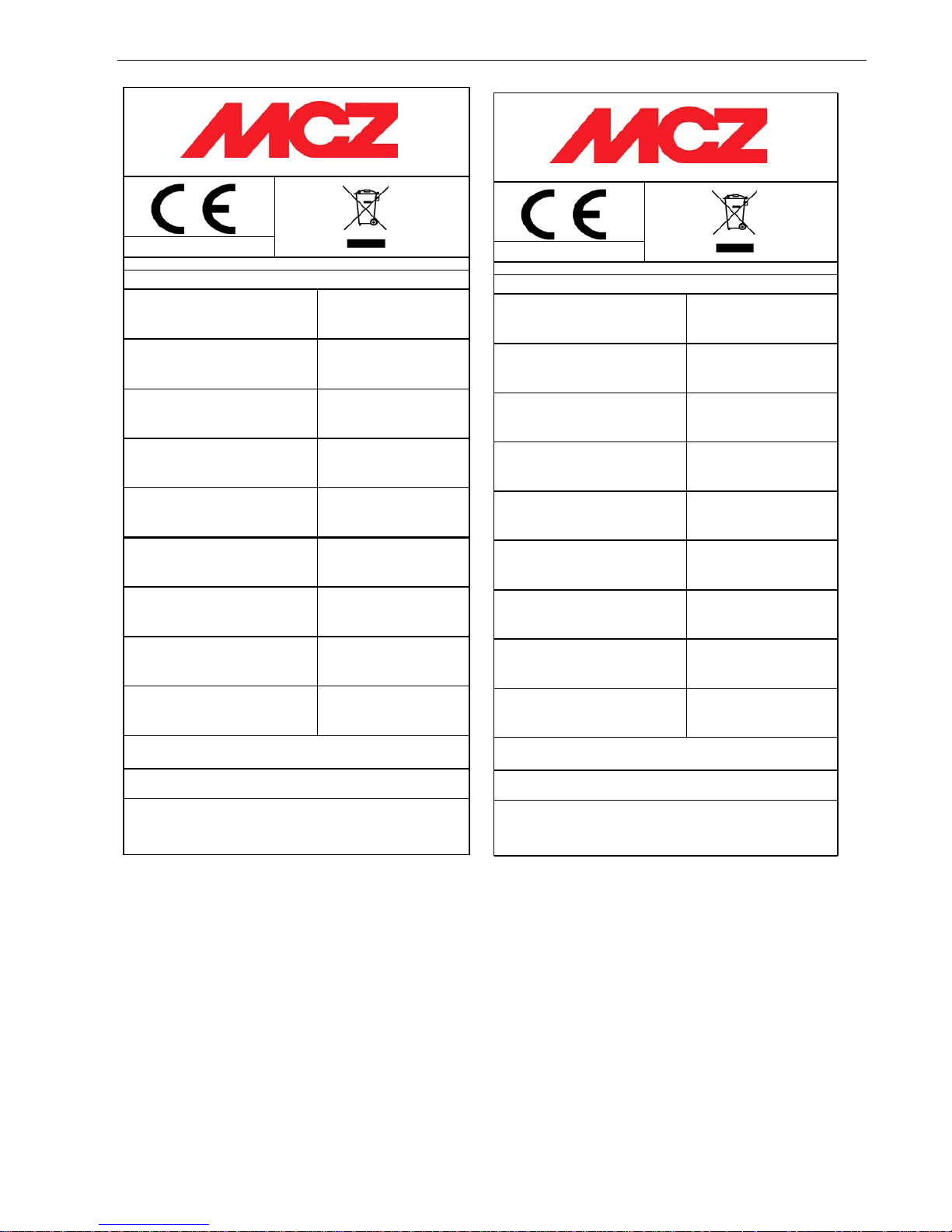

Potencia nominal (agua - aire):

Potência nominal (água - ar):

Nominal heat output (water - air):

Brændværdi (vand - luft):

Emisión CO

(

al 13% de O2):

Emissão CO (13% de O2):

CO emission (at 13% O2)

CO emission (ved 13% O2):

Eficiencia:

Eficiencia:

Efficiency:

Virkningsgrad:

Temperadura humos:

Tempretura dos fumos:

Flue gas temperature:

Røggastemperatur:

Presión máxima de agua:

Pressão máxima da água:

Permissible max. water pressure:

Max. vandtryk :

A

sorbimiento electr ico max:

Max. elektrisk effekt:

Tensión de funcionamiento:

Tensão electrica funcionamento:

Rated volta

g

e:

Netspænding:

Distan cia s de segu r ida d (ret ro):

Distancia de segurança (trasiera):

Safety clarence distance (back):

Sikkerhedsafstand (bag):

Dis tan ci a s de seguridad (lat e r al es ):

Distancia de segurança (lat eral):

Safety clarence distance (side):

Sikkerhedsafstand (side):

Utilizar sólo con combu st ib les ad a ptados. Utiliza r somente combustivel adaqu ado . Use

only recommended fuels. Anvend kun anbefalede brændsler.

Leer y seguir las instrucciones! Leia atentamente e siga as instruções!

Leggere e seguire le istruzioni! Read and follow the operating

instructions! Følg fabrikantens brugervejledning!

COD: 89008010

230 V - 50 Hz.

200 mm

100 mm

Producto confor m e a la in s talació n de tubos mú ltiples. Produto co nfor m e pa r a

instalação em condutas multiplas. Appliance suitable for installation in a shared flue.

Appa rat e t kan bruges i e n r øggassaml eledning.

0,017%

0,045%

P max

P min

91,0%

94,0%

190 °C

2,5 bar

300 W

Potência electrica absorbida:

Max. electrical power supply:

MCZ S.p.A. - Via G.Oberdan 86, I - 33074 Vigonovo (PN) Italy.

07

Art. 15a B -V G - VKF AEAI

ATHOS HYDRO

Max 14,0kW (10,4kW - 3,6kW)

Min 4,0k W ( 1,4 k W - 2,6k W )

P max

P min

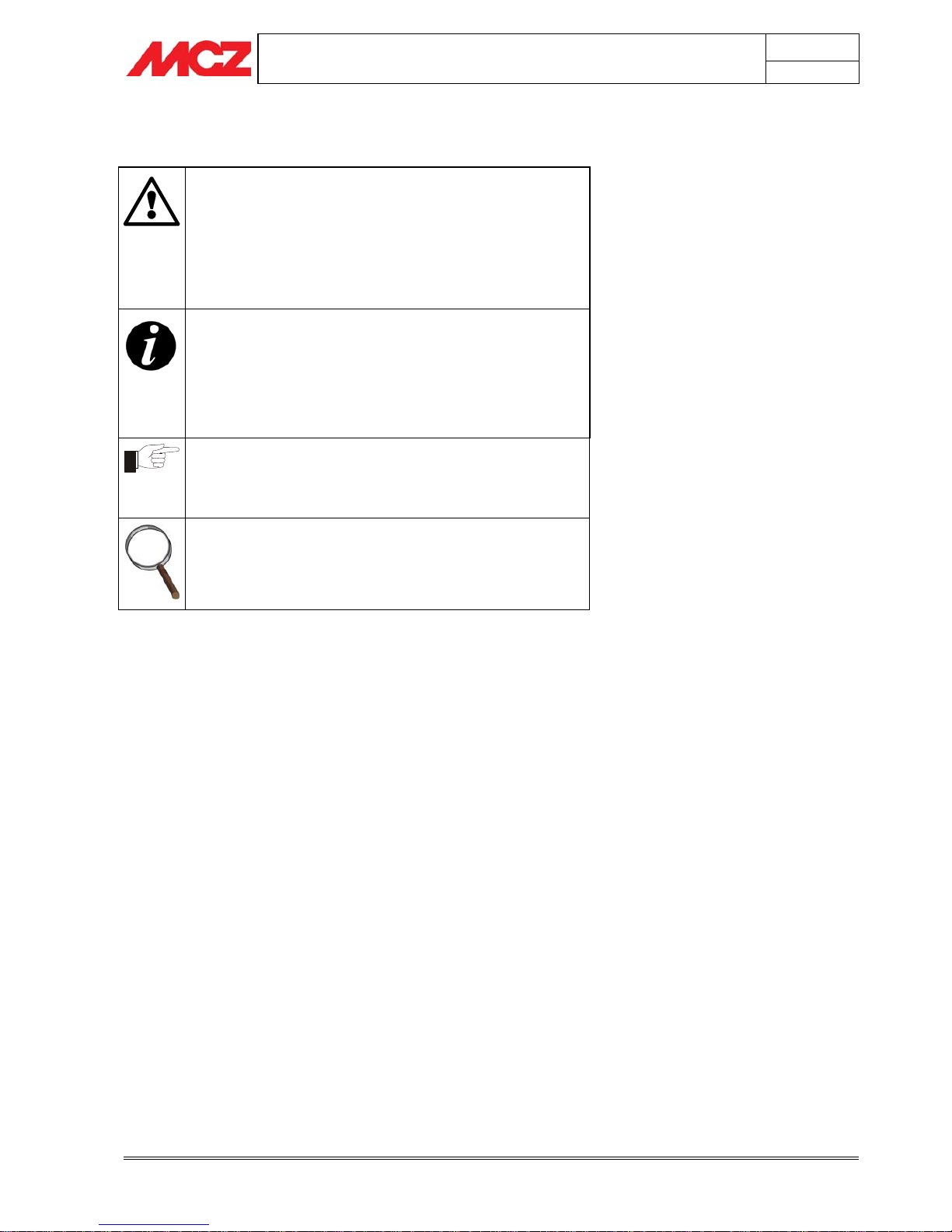

EN 14785 - 2006

Potencia nominal (agua - aire):

Potência nominal (água - ar ):

Nominal heat output (water - air):

Brændværdi (vand - luft):

Emisión CO

(

al 13% de O2):

Emissão CO (13% de O2):

CO emission (at 13% O2)

CO emission (ved 13% O2):

Eficiencia:

Eficiencia:

Efficiency:

Virkningsgrad:

Temperadura humos:

Tempretura dos fumos:

Flue gas tem pe ra tur e :

Røggastemperatur:

Presión máxima de agua:

Pres sã o máxim a da águ a :

Permissible max. water pressure:

Max . va n d tr yk :

Asorbimiento electrico max:

Max. elektrisk effekt:

Tensión de funcionamiento:

Tensão electrica funcionamento:

Rated volta

g

e:

Netspænding:

Distancias de seguridad (retro):

Distancia de segurança (trasiera):

Safety clarence distance (back):

Sikkerhedsafstand (bag):

Distancias de seguridad (laterales):

Distancia de segurança (lateral):

Safety clarence distance (side) :

Sikkerhedsafstand (side):

Max 23,7kW (16,2kW - 7,5kW)

Min 6,2 k W (3, 7k W - 2,5 k W)

MCZ S.p.A. - Via G.Oberdan 86, I - 33074 Vigonovo (PN) Italy.

07

Potência electrica absorbida:

500 mm

Leer y seguir las instrucciones! Leia atentamente e siga as instruções!

Leggere e segu ire le istruzi oni! R e ad and follow the operating

instructions! Følg fabrikantens brugervejledning!

Max. electr ical power supply :

320 W

COD: 89009025 00

Producto conforme a la instalación de tubos múltiples. Produto conforme para

instalação em condutas multiplas. Appliance suitable for installation in a shared flue.

Apparatet kan bruges i en røggassamleledning.

Utilizar sólo con combustibles adaptados. Utilizar somente combustivel adaquado. Use

only recommended fuels. Anvend kun anbefalede brændsler.

Art. 15a B-VG - VKF AEAI

230 V - 50 Hz.

200 mm

Polar / Nova / Athos Power HYDRO

250 °C

2,5 bar

P max

P min

0,019%

0,055%

P max

P min

92,0%

93,0%

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

3

Introduction Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

INTRODUCTION ....................................................................................................................................5

1. WARNINGS AND GUARANTEE CONDITIONS ....................................................................................7

1.1. SAFETY INSTRUCTIONS..................................................................................................................7

1.2. OPERATING WARNINGS..................................................................................................................8

1.3. GUARANTEE CONDITIONS ..............................................................................................................9

1.3.1. Limitations...............................................................................................................................9

1.3.2. Exceptions...............................................................................................................................9

2. THEORETICAL NOTIONS FOR INSTALLATION................................................................................11

2.1. PELLETS ......................................................................................................................................11

2.2. OPERATING AREA.........................................................................................................................13

2.3. PRECAUTIONS..............................................................................................................................14

2.4. CONNECTION TO THE EXTERNAL AIR INTAKE................................................................................14

2.5. CONNECTION OF SMOKE DISCHARGE PIPE....................................................................................15

2.6. CONNECTION TO THE FLUE PIPE...................................................................................................16

2.7. CONNECTION TO AN EXTERNAL FLUE WITH INSULATED OR DOUBLE-WALL PIPE.............................16

2.8. CONNECTION TO FLUE PIPE OR SMOKE DUCT ...............................................................................16

2.9. OPERATING PROBLEMS CAUSED BY DRAUGHT DEFECTS IN THE FLUE.............................................17

2.10. PLUMBING CONNECTION...........................................................................................................18

3. INSTALLATION AND ASSEMBLY .....................................................................................................19

3.1. DRAWINGS and TECHNICAL CHARACTERISTICS.............................................................................19

3.1.1. Dimensions of POLAR-NOVA in HYDRO version with no kit for the production of domestic hot water

19

3.1.2. Dimensions of POLAR-NOVA in HYDRO version with kit for the production of domestic hot water..19

3.1.3. Dimensions of ATHOS POWER in HYDRO version with no kit for the production of domestic hot

water 20

3.1.4. Dimensions of ATHOS POWER in HYDRO version with kit for the production of domestic hot water

20

3.1.5. ATHOS HYDRO Dimensions.....................................................................................................21

3.1.6. TECHNICAL CHARACTERISTICS...............................................................................................21

3.2. PREPARATION AND UNPACKING....................................................................................................23

3.3. INSTALLATION OF CERAMIC CLADDING FOR POLAR AND NOVA......................................................24

3.3.1. Installation of upper panel ......................................................................................................24

3.3.2. Installation of lower panel.......................................................................................................24

3.3.3. Installation of side tiles...........................................................................................................24

3.3.4. Removal of sides on the ATHOS stove......................................................................................25

3.3.5. Installation of ceramic top.......................................................................................................26

3.4. PLUMBING SYSTEM CONNECTION .................................................................................................26

3.4.1. Connections to the system......................................................................................................28

3.4.2. System filling .........................................................................................................................28

3.4.3. Water characteristics..............................................................................................................28

3.5. EXAMPLE INSTALLATION DIAGRAMS .............................................................................................29

3.5.1. Heating installation diagram Heating system installation diagram without water kit (POLAR-NOVA-

ATHOS POWER)..................................................................................................................................30

3.5.2. Heating installation diagram with domestic hot water kit (POLAR–NOVA-ATHOS POWER).............30

3.5.3. Diagram for installation combined with external boiler (POLAR-NOVA-ATHOS POWER).................31

3.5.4. Heating installation diagram in combination with a boiler (POLAR-NOVA-ATHOS-ATHOS POWER).31

3.5.5. Heating installation in combination with a storage tank (POLAR-NOVA-ATHOS-ATHOS POWER)....32

3.6. OPENING/CLOSING OF ATHOS STOVE DOOR..................................................................................32

3.7. MAKING THE ELECTRICAL CONNECTIONS.....................................................................................32

4. OPERATION.....................................................................................................................................33

4.1. PRE-LIGHTING WARNINGS............................................................................................................33

4.2. PRE-LIGHTING CHECK ..................................................................................................................34

4.3. LOADING THE PELLETS.................................................................................................................34

4.4. CONTROL PANEL..........................................................................................................................34

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

4

Introduction Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

4.5. SETTINGS TO CARRY OUT BEFORE FIRST LIGHTING......................................................................35

4.5.1. SETTING CURRENT TIME........................................................................................................35

4.6. SELECTION OF RECIPE .................................................................................................................35

4.6.1. OPERATIONS FOR IDENTIFICATION OF THE RECIPE:...............................................................35

4.6.1.1. Identification of type of pellet...........................................................................................36

4.6.2. Procedure for recipe selection .................................................................................................36

4.6.3. Memorization of recipe on stove.............................................................................................. 36

4.7. CONTROL OF WATER TEMPERATURE IN BOILER ............................................................................37

4.8. FIRST LIGHTING ..........................................................................................................................37

4.8.1. Lighting the stove...................................................................................................................37

4.8.2. Extinguishing the stove...........................................................................................................38

4.9. VIEW OF THE FLAMES ..................................................................................................................38

4.9.1. The shape .............................................................................................................................38

4.9.2. The colour.............................................................................................................................39

4.9.3. The character ........................................................................................................................39

4.10. OPERATION..............................................................................................................................39

4.10.1. Operating concept...............................................................................................................39

4.10.2. Operating modes ................................................................................................................40

4.10.2.1. Internal thermostat - Position of internal room sensor........................................................41

4.10.2.2. Operation by means of external thermostat.......................................................................41

4.10.2.3. Connection of external thermostat....................................................................................41

4.10.3. Setting of ECO-STOP mode..................................................................................................41

4.10.3.1.

Activation /de-activation of ECO-STOP mode

..................................................................... 43

4.10.3.2. OPERATION TO BE CARRIED OUT BY THE INSTALLER.......................................................43

4.10.4. Programmed mode (with timer) ........................................................................................... 43

4.10.4.1.

Start day (code on display UT 01)

..................................................................................... 43

4.10.4.2.

Clock (code on display UT 02 and UT 03)

.......................................................................... 44

4.10.4.3.

Programme

..................................................................................................................... 45

4.11. EXAMPLE OF PROGRAMMING.....................................................................................................47

4.12. SAFETY DEVICES.......................................................................................................................49

4.12.1. Alarm signalling ..................................................................................................................51

4.12.2. Other signals on the display.................................................................................................52

4.12.3. Lockout of the stove............................................................................................................52

4.12.3.1.

Boiler bulb thermostat

..................................................................................................... 52

4.12.3.2.

Pellet hopper safety thermostat

........................................................................................ 53

4.12.3.3.

Smoke expulsion

............................................................................................................. 53

4.13. SHUTTING THE STOVE DOWN ...................................................................................................53

4.14. DOMESTIC WATER PRODUCTION KIT (optional) For POLAR-NOVA-ATHOS POWER stoves only.......54

5. MAINTENANCE AND CLEANING ......................................................................................................55

5.1. CLEANING TO BE PERFORMED BY THE USER..................................................................................55

5.1.1. Cleaning prior to each lighting.................................................................................................55

5.1.2. Check every 2/3 days .............................................................................................................55

5.1.3. Cleaning the glass..................................................................................................................55

5.1.4. Cleaning the heat exchanger and the pipe unit .........................................................................56

5.1.5. Cleaning of stainless steel and satin-finish surfaces...................................................................56

5.1.6. Cleaning of painted parts........................................................................................................56

5.2. CLEANING TO BE PERFORMED BY SPECIALIZED TECHNICIAN..........................................................57

5.2.1. Cleaning of the heat exchanger...............................................................................................57

5.2.2. Shutting the stove down (end of season) .................................................................................57

5.3. CHECK OF INTERNAL COMPONENTS..............................................................................................58

6. PROBLEMS / CAUSES / SOLUTIONS ...............................................................................................59

7. ELECTRICAL DIAGRAMS .................................................................................................................62

7.1. ELECTRICAL DIAGRAM OF POLAR-NOVA-ATHOS POWER Hydro WITH NO DOMESTIC HOT WATER KIT

62

7.2. ELECTRICAL DIAGRAM OF POLAR-NOVA-ATHOS POWER Hydro WITH DOMESTIC HOT WATER KIT....63

7.3. WIRING DIAGRAM for ATHOS Hydro without DOMESTIC HOT WATER KIT........................................64

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

5

Introduction Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

INTRODUCTION

Dear Customer,

We would like to thank you for selecting MCZ products, and particularly

for choosing one of the MCZ Pellet range.

We are convinced that as you use it, you will appreciate the quality of

the MCZ pellet line, which is the result of careful planning and

meticulous testing. Our aim is to combine technological complexity with

simplicity of use and, above all, with safety.

In order to get the best performance from your stove and to

enjoy to the fullest the warmth and the sense of well-being

which the flame will spread through the home, we recommend

that you read this booklet carefully before lighting the stove

for the first time.

Once you have learnt the basics, you will be able manage to best

advantage the various levels of power and the potential for presetting,

and you will also pick up a few little hints about cleaning and setting.

While thanking you again, may we remind you that the stove MUST

NOT be used by children, and that they must always be kept at a safe

distance from it!

Revisions to the publication

In order to improve the product, to keep this publication up to date the

manufacturer reserves the right to make modifications without any

advance notice.

Any reproduction, even in part, of this manual without the consent of

the manufacturer is prohibited.

Care of the manual

• Take good care of this manual and keep it in a place which can

easily and quickly be reached.

• If this manual should be lost or destroyed, or if it is in poor

condition, ask for a copy from your retailer or directly from the

manufacturer, providing product identification data.

How to read the manual

• Information which is essential or that requires special attention is

shown in bold text.

•

“Italic text”

is used to direct the user's attention to explanatory

figures, or to ask the user to refer to other sections of the manual

for a more detailed explanation.

• NOTE: a NOTE provides the reader with additional information on

a specific topic.

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

6

Introduction Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

These symbols indicate specific messages included

in this booklet

ATTENTION:

This warning sign, used at various points in this booklet,

indicates that the message to which it refers should be

carefully read and understood, because failure to comply

with what these notices say can cause serious

damage to the stove and put the user's safety at risk.

INFORMATION:

This symbol is intended to highlight information important

for the proper functioning of the stove. Failure to comply

with what these notices say will compromise the use of the

stove and is likely to result in unsatisfactory operation.

OPERATING SEQUENCES:

Indicates a sequence of buttons to be pushed to access

menus or to make adjustments.

SEE MESSAGES:

This symbol instructs the user to see the messages shown

on the control display.

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

7

Warnings and guarantee conciliations Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

1. WARNINGS AND GUARANTEE CONDITIONS

1.1. SAFETY INSTRUCTIONS

• Installation of the stove, making the electrical

and plumbing connections, checking its

operation, and maintenance are all tasks which

should be carried out ONLY by qualified and

authorised personnel.

• Install the stove in accordance with the

regulations in force in your local area, region and

country.

• For the correct use of the stove and of the electronic

apparatus connected to it, and to prevent accidents, the

instructions given in this booklet must always be

followed.

• In addition, adjustment and regulation must be carried

out by adults. Errors or incorrect settings can give rise

to hazardous conditions and/or bad running.

• Before beginning any operation, the user, or whoever is

preparing to operate on the stove, must have read and

understood the entire contents of this instruction

booklet.

• The stove is to be used only for its intended purpose.

Any other use is to be considered improper and

therefore hazardous.

• Do not use the stove for standing on or as any kind of

support.

• Do not put clothes to dry on the stove Any clothes

hangers and the like must be kept a suitable distance

from the stove. Danger of fire.

• All responsibility for improper use is taken entirely by

the user. Such use relieves MCZ of any civil or criminal

responsibility.

• Any kind of tampering or unauthorised substitution of

non-original spare parts can be hazardous for the safety

of the operator and relieves MCZ of any civil or criminal

responsibility.

• Most of the surfaces of the stove are extremely

hot (the door, the handle, the glass, smoke

discharge pipes etc.). Avoid coming into contact

with these parts, therefore, without adequate

protective clothing or suitable implements, such

as gloves with thermal protection or implements

which keep the hands cool.

• Carefully explain this hazard to elderly people, disabled

people and particularly to all children, keeping them

away from the stove while it is in operation.

• Under no circumstances should the stove be

operated with the door open or the glass broken.

• Do not touch the stove with wet hands, in view of the

fact that it is an electrical appliance. Always disconnect

the supply cable before doing anything to the unit.

• Before carrying out any cleaning or maintenance

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

8

Warnings and guarantee conciliations Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

operation, make sure in advance that the stove is

disconnected from the mains electricity supply, by

turning off the main switch located on the back of the

stove, or by unplugging the supply cable.

• The stove must be connected to an electrical system

which is equipped with an earth conductor, as set forth

in directives 73/23 EEC and 93/98 EEC.

• The system must be of adequate rated capacity for the

stated electrical power of the stove.

• Incorrect installation or faulty maintenance (not

conforming to the requirements set out in this booklet)

can cause harm to people, animals or property. In such

cases MCZ is relieved of any civil or criminal

responsibility.

1.2. OPERATING WARNINGS

• Shut the stove down in the event of a breakdown or

bad running.

• Pellets must not be fed manually into the burner.

• Accumulated unburnt pellets in the burner after

repeated failed ignitions must be removed

before lighting.

• Do not wash the inside of the stove with water.

• Do not wash the stove with water. The water could get

inside the unit and damage the electrical insulation and

cause electric shocks.

• Do not expose your body to hot air for extended

periods. Do not overheat the room you are in and

where the stove is installed. This could cause injuries

and health problems.

• Do not expose plants or animals directly to a current of

hot air. Both plants and animals could be harmed by it.

• Do not put anything in the hopper other than wood

pellets.

• Install the stove in a location which is suitable for for

fire protection, and equipped with all services such as

air and electricity supply and provision for discharging

combustion gases.

• If there is a fire in the flue pipe, extinguish the stove,

disconnect it from the power supply and never open

the door. Then contact the competent authorities.

• If the stove and the ceramic cladding are in storage, it

should be in a place that is free of damp, and they

should not be exposed to extremes of temperature.

• It is inadvisable to base the stove directly on the floor,

and if the floor is made of flammable material, it must

be suitably insulated.

• Do not light the stove with flammable materials if the

ignition system breaks down.

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

9

Warnings and guarantee conciliations Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

INFORMATION

• In case of any problems, get in touch with your dealer,

or qualified personnel authorised by MCZ. If repair is

necessary, insist on the use of original spare parts.

• Use only the fuel recommended by MCZ (for Italy pellets

with a diameter of 6 mm and for other European

countries with a diameter of 6-8 mm) and provided only

with an automatic supply system.

• Periodically check and clean the smoke outlet ducts

(connection to the flue pipe).

• Accumulated unburnt pellets in the burner after

repeated failed ignitions must be removed before

lighting.

• The pellet stove is not a cooking appliance.

• Always keep the cover of the fuel hopper closed.

• Keep this instruction manual carefully because it must

stay with the stove throughout its working life. If the

stove is sold or transferred to another user, always

make sure that the booklet goes with the product.

• If it gets lost, ask MCZ or your authorised dealer for

another copy.

1.3. GUARANTEE CONDITIONS

MCZ guarantees the stove, excluding the components

which are subject to normal wear, for a period of two

years from the date of purchase, as proved by a supporting

document which gives the name of the vendor and the date

on which the sale took place. The guarantee is conditional

on the guarantee certificate being filled in and returned

within 8 days, and requires that the product be installed

and tested by a specialised installer, according to the

detailed instructions given in the instruction booklet

supplied with the product.

The term 'guarantee' is to be understood to denote the

free-of-charge replacement or repair of parts recognised

to have been defective at the start by reason of

manufacturing defects.

1.3.1. Limitations

The above guarantee does not cover components relating to electrical

and electronic parts, or fans, on which the guarantee period is 1 year

from the purchase of the product, documented as specified above. The

guarantee does not cover parts subject to normal wear such as

gaskets, glass, and any parts with can be removed from the firebox.

The replacement parts will be guaranteed for the remainder of the

guarantee period starting from the date of purchase of the product.

1.3.2. Exceptions

Variations in colour in the painted or ceramic parts, and crackling of the

glaze on the ceramics, do not constitute grounds for a claim under the

guarantee, as they are natural characteristics of the material and of the

use of the product.

PELLET STOVES Chapter 1

INSTALLATION AND USE MANUAL

page

10

Warnings and guarantee conciliations Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

The guarantee does not cover any parts which may be found to be

faulty as a result of negligence or carelessness in use, or of incorrect

maintenance, or of installation not complying with MCZ's specification

(see the relevant chapters in this user manual).

MCZ refuses to accept any responsibility for any damage which may be

caused, directly or indirectly, by persons, animals or things as a result

of the failure to observe all the prescriptions laid down in the

instruction booklet, especially those concerning warnings on the subject

of installation, use and maintenance of the appliance.

If the product does not perform correctly, contact your local retailer

and/or importer.

Damage caused by transport and/or handling is excluded from the

guarantee.

For installation and use of the product, reference must be made

exclusively to the booklet supplied.

The guarantee will be invalidated in the event of damage caused by

tampering with the appliance, atmospheric agents, natural disasters,

electrical discharges, fire, defects in the electrical system, and lack of,

or incorrect, maintenance in terms of the manufacturer's instructions.

CLAIMS UNDER THE GUARANTEE

The request for action under the guarantee must be

addressed to the retailer, who will forward the claim

to MCZ's technical assistance service.

MCZ DECLARES THAT THE STOVE WHICH YOU HAVE

PURCHASED COMPLIES WITH EEC DIRECTIVE

89/336 AND 72/23 AND SUBSEQUENT

AMENDMENTS.

MCZ shall not be held liable if the stove or any other

accessory have been improperly used or modified

without authorisation.

For all replacement of parts, only original MCZ spare

parts must be used.

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

11

Theoretical notions for installation Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

2. THEORETICAL NOTIONS FOR INSTALLATION

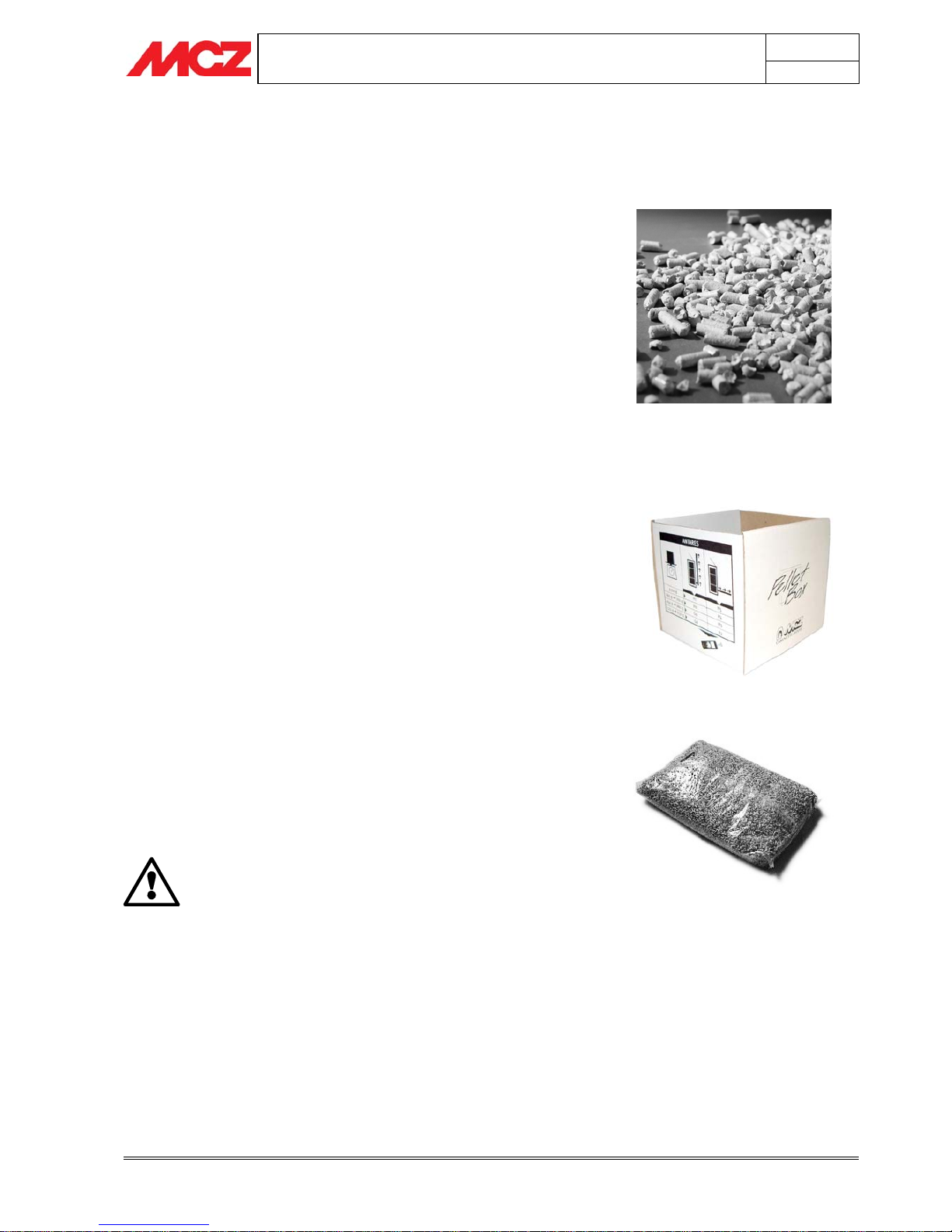

2.1. PELLETS

Wood pellets are manufactured by hot-extruding compressed sawdust

which is produced during the working of natural dried wood. The

compactness of the material comes from the lignin which is contained

in the wood itself, and allows the production of pellets without the use

of glues or binders.

The market offers different types of pellet with characteristics which

vary depending on what mixture of woods is used. The diameter varies

between 6 mm and 8 mm, with a standard length in the range 5 mm to

30 mm. Good quality pellets have a density which varies between 550

kg/m

3

to over 700 kg/m3, with a moisture content which varies from

5% to 8% by weight.

With the aim of guaranteeing the stated rate of fuel

consumption per hour and ensuring optimum combustion, MCZ

has devised a patented method which allows the identification

and cataloguing of any type of pellet with a 6 mm and 8 mm

diameter, in terms of its specific gravity and particle size.

By using the special PelletBox® and following the procedure set out in

the paragraph on lighting the stove, the user can determine the correct

settings for configuring the stove.

Besides being an ecological fuel (exploiting timber residues to the

maximum and achieving cleaner combustion than is possible with fossil

fuels), pellets also have technical advantages. While good-quality

timber has a calorific power of 4.4 kW/kg (with 15% moisture, after

about 18 months' seasoning), the equivalent figure for pellets is 5.3

kW/kg.

To ensure good combustion, the pellets must be stored in an area that

is free of humidity and protected from dirt. The pellets are usually

supplied in 15 kg. sacks, so storing them is very convenient.

Good quality pellets ensure good combustion, thus lowering the

emission of harmful agents into the atmosphere.

The poorer the quality of the fuel, the more

frequently will intervention be necessary for cleaning

the internal parts, such as the grate and the

combustion chamber.

The pellets must be produced from pure wood which has not been

treated chemically.

The standards DIN 51731 and ONORM M 7135 certify a high-quality

pellet with the following characteristics:

9 Calorific power: 5.3 kW/kg

9 Density: 700 kg/m

3

9 Water content: max 8% of weight

9 Percentage of ashes: max 1% of weight

Figure 1 - Pellet fuel

Figure 2 - PelletBox®

Figure 3 - Sack of fuel, 15 kg

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

12

Theoretical notions for installation Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

9 Diameter: 6 – 6.5mm

9 Length: max 30mm

9 Contents: 100% untreated wood, with no added bonding

substances (bark percentage 5% max)

9 Packaging: in sacks made from ecologically compatible or

biologically decomposing material

MCZ strongly recommends using certified fuel in its

stoves.

The use of fuel of inferior quality or not conforming

to the specification given above compromises the

running of your stove and can therefore lead to the

termination of the guarantee and of the

manufacturer's responsibility for the product.

MCZ pellet stoves run exclusively on pellets with a

diameter of 6 mm (only for Italy) and 6-8 mm

(European countries) with lengths that go from 5

mm to 30 mm.

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

13

Theoretical notions for installation Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

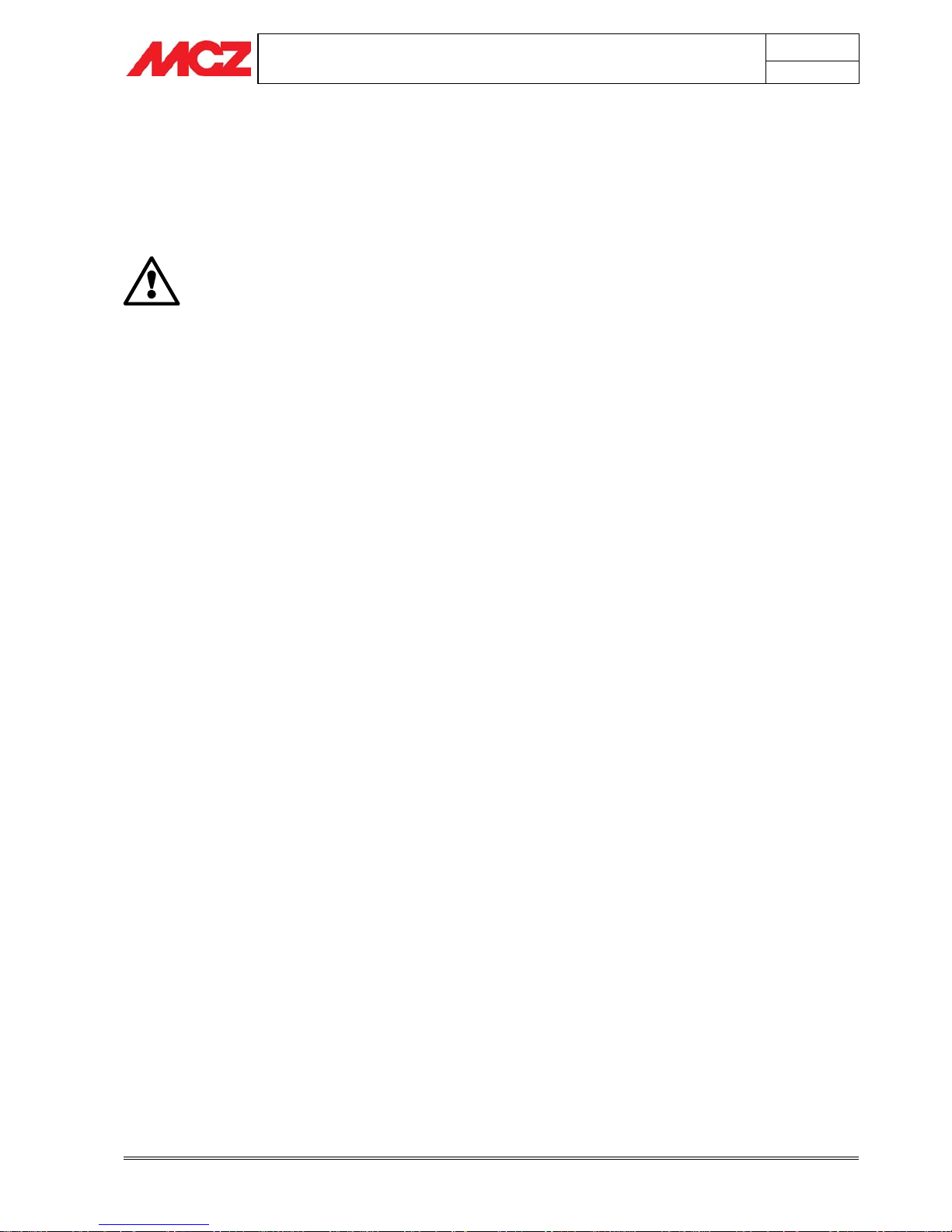

2.2. OPERATING AREA

For proper functioning and good temperature distribution, the stove

should be positioned in a location where it is able to take in the air

necessary for combustion of the pellets (about 40 m

3

/h must be

available), as set forth in the standard governing the installation and in

accordance with local national standards.

The volume of the room must not be less than 30 m

3

.

The air must come in through permanent openings made in walls (in

proximity to the stove) which give onto the outside, with a minimum

cross-section area of 100 cm

2

.

These openings must be made in such a way that it is not possible for

them to be obstructed in any way.

Alternatively, the air can be taken from rooms adjacent to the one

which needs ventilating, as long as they are provided with an air intake

from the outside, and are not used as bedrooms or bathrooms, and

provided there is no fire risk such as there is for example in garages,

woodsheds, and storerooms, with strict compliance with the provisions

of current standards.

It is not permissible to install the stove in bedrooms,

bathrooms or showers, or in a room where another

heating appliance is installed (fireplace, stove etc.)

which does not have its own independent air intake.

Locating the stove in a room with an explosive

atmosphere is prohibited.

The floor of the room where the stove is to be

installed must be strong enough to support its

weight.

If the walls are not flammable, position the stove with a clearance to

the rear of at least 10 cm.

In the case of walls made of flammable material, maintain a minimum

clearance to the rear of 20 cm, a clearance to the sides of 50 cm, and a

clearance to the front of 150 cm. If the room contains objects which

are believed to be particularly delicate, such as curtains, sofas and

other furniture, their distance from the stove should be considerably

increased.

If the flooring is made of wood, provide a floor

protection surface in compliance with current

national standards.

Figure 4 - Example of installation with Polar stove

Figure 5 - Example of installation with Polar stove

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

14

Theoretical notions for installation Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

2.3. PRECAUTIONS

IMPORTANT!

Installation and assembly of the stove must be

carried out by qualified personnel.

The stove must be installed in a suitable position to allow the normal

operations of opening and ordinary maintenance.

The site must be:

• capable of providing the environmental conditions for operation

• equipped with power supply 230V 50 Hz (EN73-23)

• capable of taking an adequate system for smoke discharge

• provided with external ventilation

• provided with an earth connection complying with CEI 64-8

The stove must be connected to a flue pipe or an internal or

external vertical duct conforming to current standards UNI

7129 - 7131 9615.

The stove must be positioned in such a way that the electrical

plug is accessible.

IMPORTANT!

The stove must be connected to a flue pipe or a

vertical duct which can discharge the fumes at the

highest point of the building.

The fumes are however derived from the combustion

of wood products, and if they come into contact with

or close to walls, they can make dirty marks.

Also take care because the fumes are very hot but

almost invisible, and can cause burns on contact.

The holes for the passage of the smoke pipe and for

the intake of air from outside should be made before

positioning the stove unit.

2.4. CONNECTION TO THE EXTERNAL AIR INTAKE

It is essential that at least as much air must be able to flow into the

room where the stove is installed as is required for proper combustion

in the appliance and for the ventilation of the room. This can be

effected by means of permanent openings in the walls of the room to

be ventilated, which give onto the outside, or by single or collective

ventilation conduits.

For this purpose, on the external wall near the stove, a hole must be

made with a minimum free cross-section of 100 cm². (equivalent to a

round hole of 12 cm diameter or a square hole 10x10 cm), protected by

a grille on the inside and the outside.

The air intake must also:

• communicate directly with the room where the stove is installed

• be protected by a grille, metal mesh or suitable guard, as long as

this does not reduce the cross-section below the minimum.

• be positioned in such a way as to be impossible to obstruct

It is not compulsory to connect the air inlet of the

stove directly with the exterior, but an air flow must

be guaranteed of at least 50 m³/h. Refer to current

standards.

Figure 6 – Air intake grille

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

15

Theoretical notions for installation Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

2.5. CONNECTION OF SMOKE DISCHARGE PIPE

When making the hole for the passage of the smoke discharge pipe, it

is necessary to take into account the possible presence of flammable

materials. If the hole will be going through a wall made of wood or any

other material which is sensitive to heat, the INSTALLER MUST first

of all use the special wall union (diam. 13cm minimum) and properly

insulate the pipe of the stove that passes through it, using adequate

insulation materials (thickness 1.3 - 5cm with minimum thermal

conductivity of 0.07 W/m°K).

The same is true if the stove pipe must run through vertical or

horizontal stretches passing in proximity (min. 20cm) to the heatsensitive wall.

As an alternative we recommend the use of insulated pipe, which can

also be used on the outside to avoid condensation.

The combustion chamber works in low pressure. The smoke duct for

the discharge of fumes will also be under low pressure when connected

to an efficient flue pipe as directed.

Pipes and unions with suitable gaskets must always

be used, to guarantee a hermetic seal.

All sections of the smoke duct must be inspectable and

removable to enable periodic internal cleaning. Tee

connectors with inspection caps should be used.

Position the stove bearing in mind all the instructions and

considerations above.

IMPORTANT!

All 90 degree changes of direction in the flue pipe

must be fitted with suitable tee connectors to allow

the possibility of inspection (see the pellet stove

accessory list).

It is absolutely prohibited to fit a grille on the end of

the smoke discharge pipe, because it could lead to

poor operation of the stove.

FOR CONNECTION TO THE FLUE PIPE, NOT MORE

THAN 2-3 METRES OF HORIZONTAL PIPE MUST BE

USED AND NOT MORE THAN THREE 90° CURVES

MUST BE USED

NOT ADVISABLE TO EXCEED A LENGTH OF 6 LINEAR

METRES OF PIPE Ø 80 mm.

THE DIRECT DISCHARGE OF THE

COMBUSTION PRODUCTS MUST BE

PROVIDED ON THE ROOF, AND THE SMOKE

DUCT MUST SATISFY THE SPECIFICATIONS

PROVIDED FOR BY CURRENT LAWS AND

STANDARDS ON THE SUBJECT (UNI 10683)

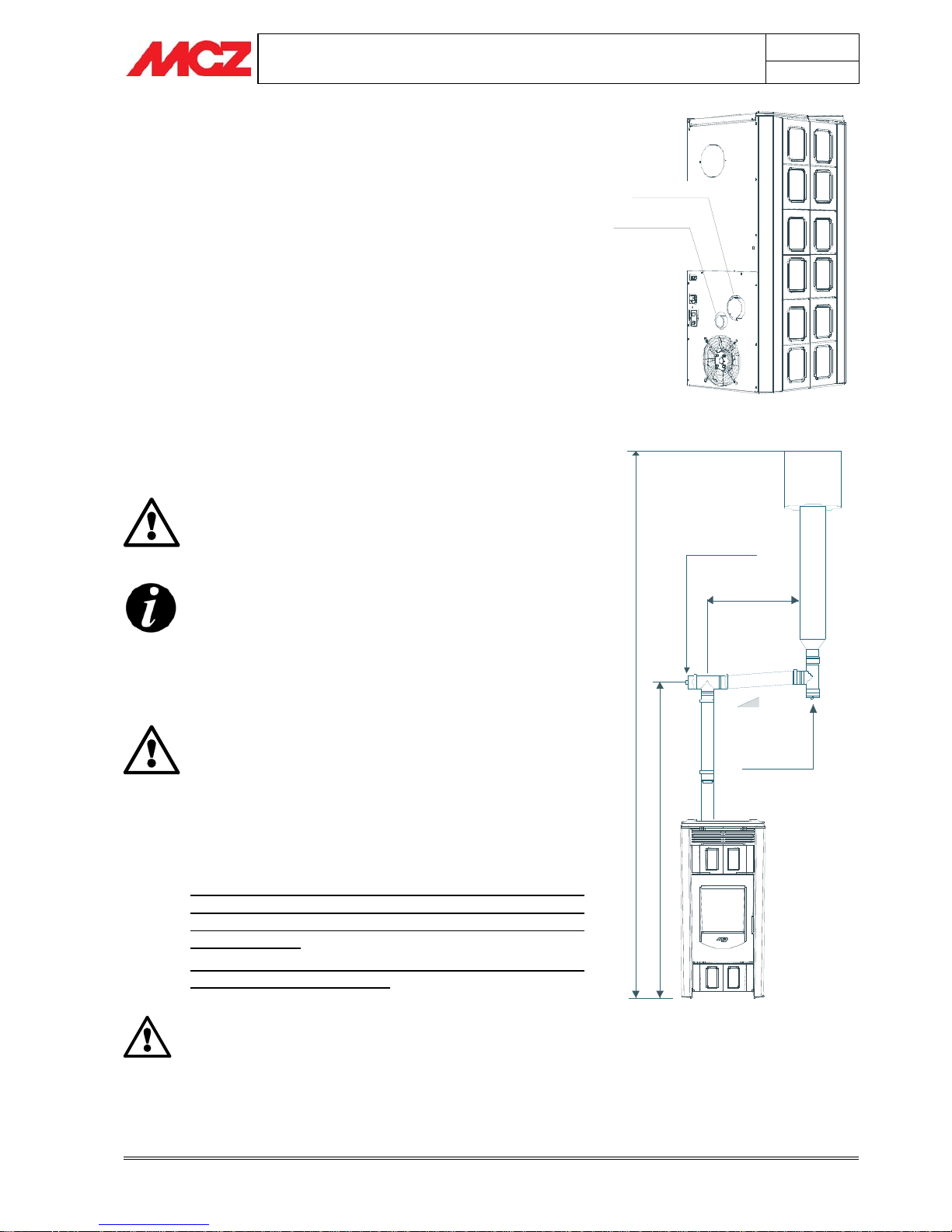

Figure 7 – Back of POLAR/NOVA stove

Figure 8 – Example of installation of POLAR/NOVA stove

Air intake

Smoke outlet

3-5 %

2 - 3 mt. MAX

Ispection cover

M

i

n

1

,

5

-

2

m

t

H

e

i

g

h

t

g

r

e

a

t

e

r

t

h

e

n

4

m

t

.

Ispection cover

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

16

Theoretical notions for installation Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

Ispezione

Condotto

esterno

isolato

0,5 mt.

3-5 %

2 - 3 mt. MAX

Minimo 1,5 - 2 mt.

Ispezione

0, 5 mt.

Canna fumaria

Comignolo

antivento

2.6. CONNECTION TO THE FLUE PIPE

The flue pipe must have internal dimensions not larger than 20 x 20

cm, or diameter 20 cm. In the event of larger dimensions, or of the flue

pipe being in poor condition (for example cracks, poor insulation, etc.),

it is advisable to fit a stainless steel pipe of suitable diameter inside the

flue pipe throughout its length, right up to the top.

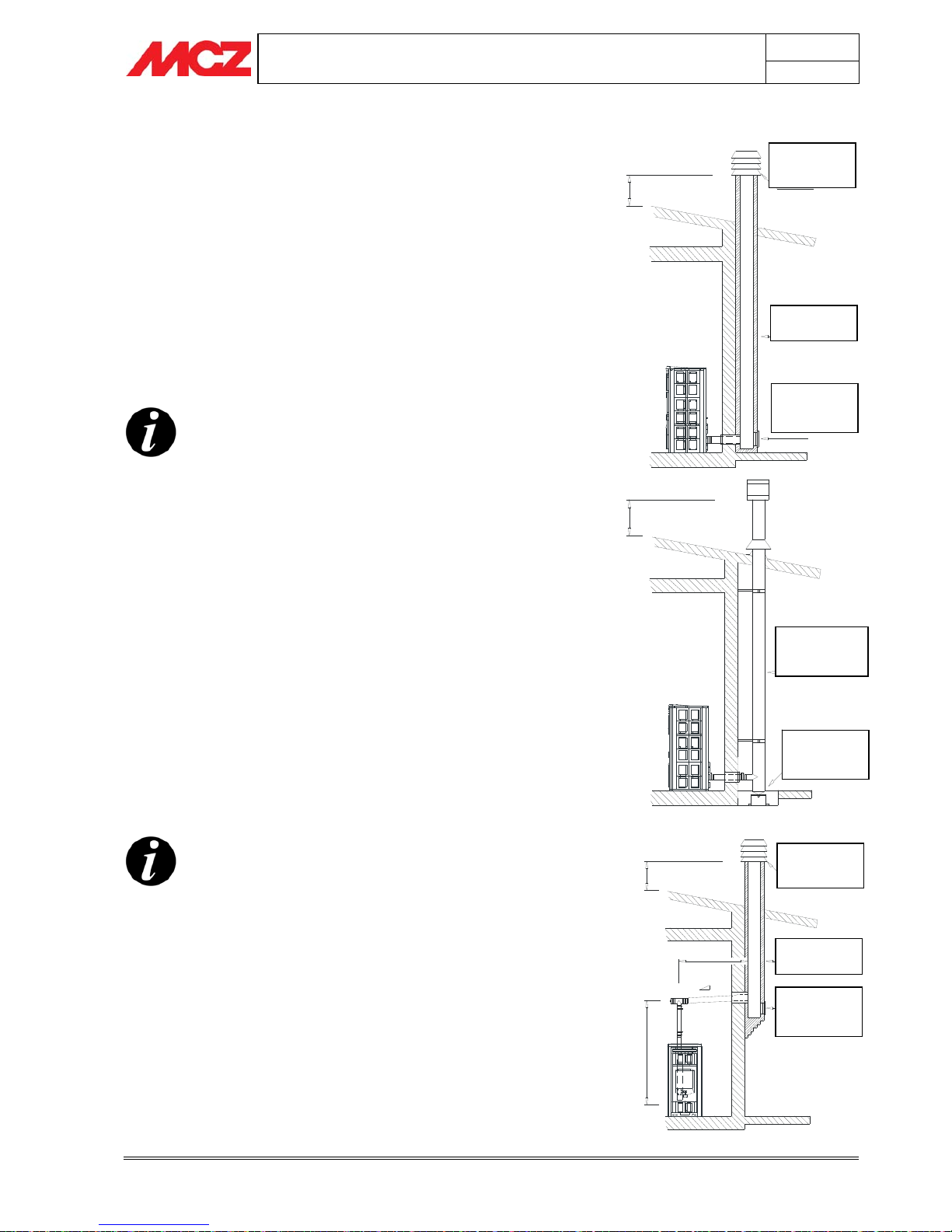

Figure 9

Check with suitable instruments that there is a minimum draught of 10 Pa.

At the bottom of the flue pipe, provide an inspection cap to allow

periodic checking and cleaning, which must be done annually.

Make a gas-tight connection to the flue pipe, using pipes and

connectors as recommended by us.

You must ensure that a windproof cowl is fitted which complies with

current standards.

This type of connection ensures the evacuation of the

fumes even in the event of a temporary power

outage.

2.7. CONNECTION TO AN EXTERNAL FLUE WITH

INSULATED OR DOUBLE-WALL PIPE

The external fluepipe must have internal dimensions of minimum 10x10

cm or 10 cm diameter, and maximum 20x20 cm or 20 cm diameter.

Check with suitable instruments that there is a minimum draught of 10 Pa.

Figure 10

The only type of pipe which is permissible is insulated (double-walled)

stainless steel, smooth on the inside, fixed to the wall. Flexible stainless

steel pipe must not be used.

At the bottom of the flue pipe, provide an inspection cap to allow

periodic checking and cleaning, which must be done annually.

Make a gas-tight connection to the flue pipe, using pipes and

connectors as recommended by us.

You must ensure that a windproof cowl should be fitted which complies

with the standards in force.

This type of connection ensures the evacuation of the

fumes even in the event of a temporary power cut.

2.8. CONNECTION TO FLUE PIPE OR SMOKE DUCT

For proper operation, the connection between the stove and the flue

pipe or smoke duct must have a slope of not more than 3%. The length

of the horizontal segment must not exceed 2/3 m. and the vertical

distance between one tee connector and another (change of direction)

must not be less than 1.5m.

Check with suitable instruments that there is a minimum draught of 10 Pa.

Figure 11

At the bottom of the flue pipe, provide an inspection cap to allow

periodic checking and cleaning, which must be done annually.

Figure 9

Figure 10

Figure 11

Canna fumaria

Comignolo

antivento

Ispezione

0,5 mt.

Windproof

cowl

Flue pipe

Inspection

cover

Inspection

cover

Insulated

external pipe

Inspection

cover

Flue pipe

Windproof

cowl

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

17

Theoretical notions for installation Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

Make a gas-tight connection to the flue pipe, using pipes and

connectors as recommended by us.

You must ensure that a windproof cowl is fitted which complies with

current standards.

This type of connection ensures the evacuation of the

fumes even in the event of a temporary power cut.

2.9. OPERATING PROBLEMS CAUSED BY DRAUGHT

DEFECTS IN THE FLUE

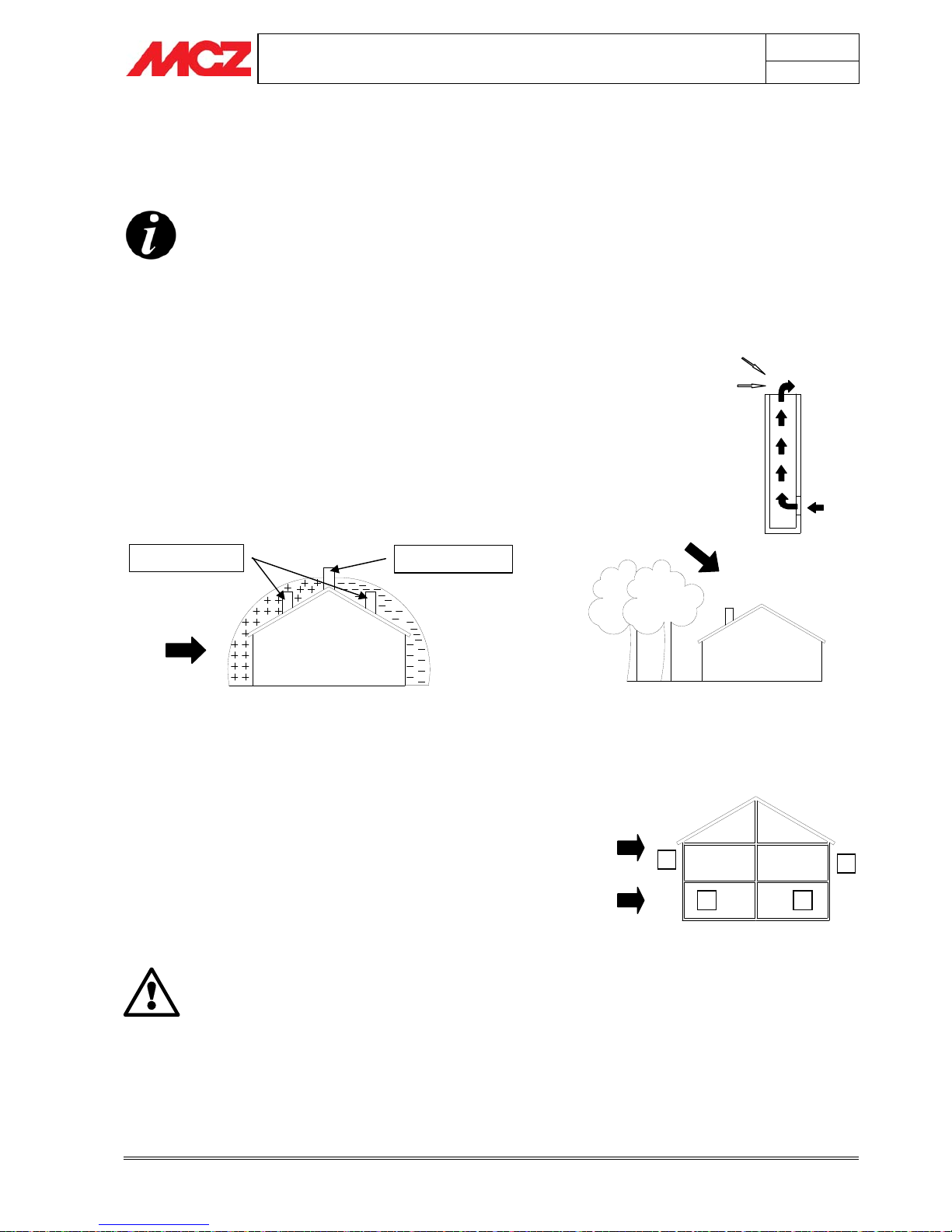

Of all the weather and geographical conditions which affect the

operation of a flue pipe (rain, fog, snow, altitude a.s.l., exposure to

sunlight, direction of facing), the wind is unquestionably the most

decisive. In fact, along with thermal depression caused by the

difference in temperature inside and outside of the chimney, there is

another type of depression or over-pressure: dynamic pressure caused

by the wind. An updraft always increases depression and hence

draught. A crosswind increases depression provided the cowl has been

installed properly. A downdraft always decreases depression, at times

inverting it.

Besides the direction and force of the wind, the position of the flue and

the cowl with respect to the roof of the building and the surrounding

landscape is important.

The wind also influences the operation of the chimney indirectly by

creating high-pressure and low-pressure zones, not only outside the

building but inside as well. In rooms directly exposed to the wind (2),

an indoor high-pressure area can be created which can augment the

draught in stoves and fireplaces, but it can be counteracted by the

external high pressure if the cowl is situated on the side exposed to the

wind (1). On the other hand, in the rooms on the opposite side from

the direction of the wind (3), a dynamic depression can be created

which competes with the natural thermal depression developed by the

chimney, but this can be compensated for (sometimes) by locating the

flue on the opposite side from the direction of the wind (4).

IMPORTANT!

The operation of the pellet stove is noticeabl

y

sensitive to the conformation and position of the flue

which is adopted.

Hazardous conditions can only be overcome by

suitable setting-up of the stove carried out by

qualified MCZ personnel.

1

2 3

4

E.g. Crosswind 2: 8 m/sec:

Depression of 30Pa

E.g. Downdraft at 45° of 8m/sec.

Overpressure of 17 Pa

1-2 = High-pressure zones

3-4 = Low-pressure zones

WIND

Least favourable points

Most favourable position

WIND

Downdraft

High-pressure

Low-pressure zone

PELLET STOVES Chapter 2

INSTALLATION AND USE MANUAL

page

18

Theoretical notions for installation Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

2.10. PLUMBING CONNECTION

IMPORTANT!

The connection of the stove to the plumbing system

must be carried out ONLY

by specialized personnel

who are capable of carrying out installation properly,

in compliance with current standards in the country

of installation.

If installation of the stove will involve interaction

with another, pre-existing system complete with

heating equipment (gas boiler, methane boiler, fuel

oil boiler, etc.), it is even more advisable to call in

qualified personnel, who subsequently will be

responsible for conformity of the system with current

applicable law.

MCZ will not be held responsible for damage to

persons or things in the event of failed or incorrect

operation if the aforementioned warnings are not

complied with.

For connection of the plumbing system to the stove, the user should

refer to chapter 3, INSTALLATION AND ASSEMBLY; specifically,

paragraph 3.4, CONNECTION TO PLUMBING SYSTEM

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

19

Installation and assembly Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

3. INSTALLATION AND ASSEMBLY

3.1. DRAWINGS and TECHNICAL CHARACTERISTICS

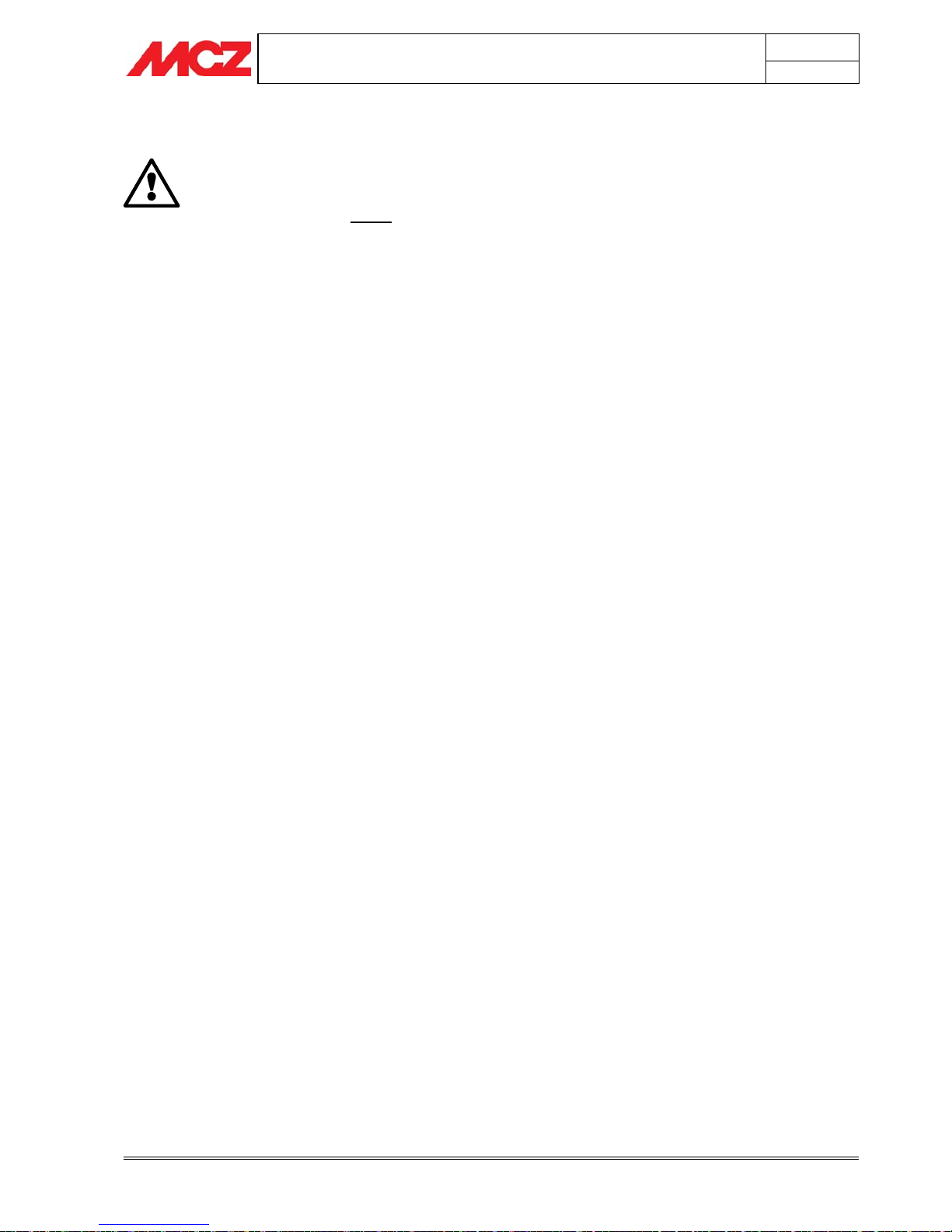

3.1.1. Dimensions of POLAR-NOVA in HYDRO version with no kit for the

production of domestic hot water

192

275

334

281

Ø80

Ø48

3.1.2. Dimensions of POLAR-NOVA in HYDRO version with kit for the production

of domestic hot water

192

275

334

281

Ø80

Ø48

PELLET STOVES Chapter 3

INSTALLATION AND USE MANUAL

page

20

Installation and assembly Technical service - Rights reserved MCZ S.p.A. - Reproduction prohibited

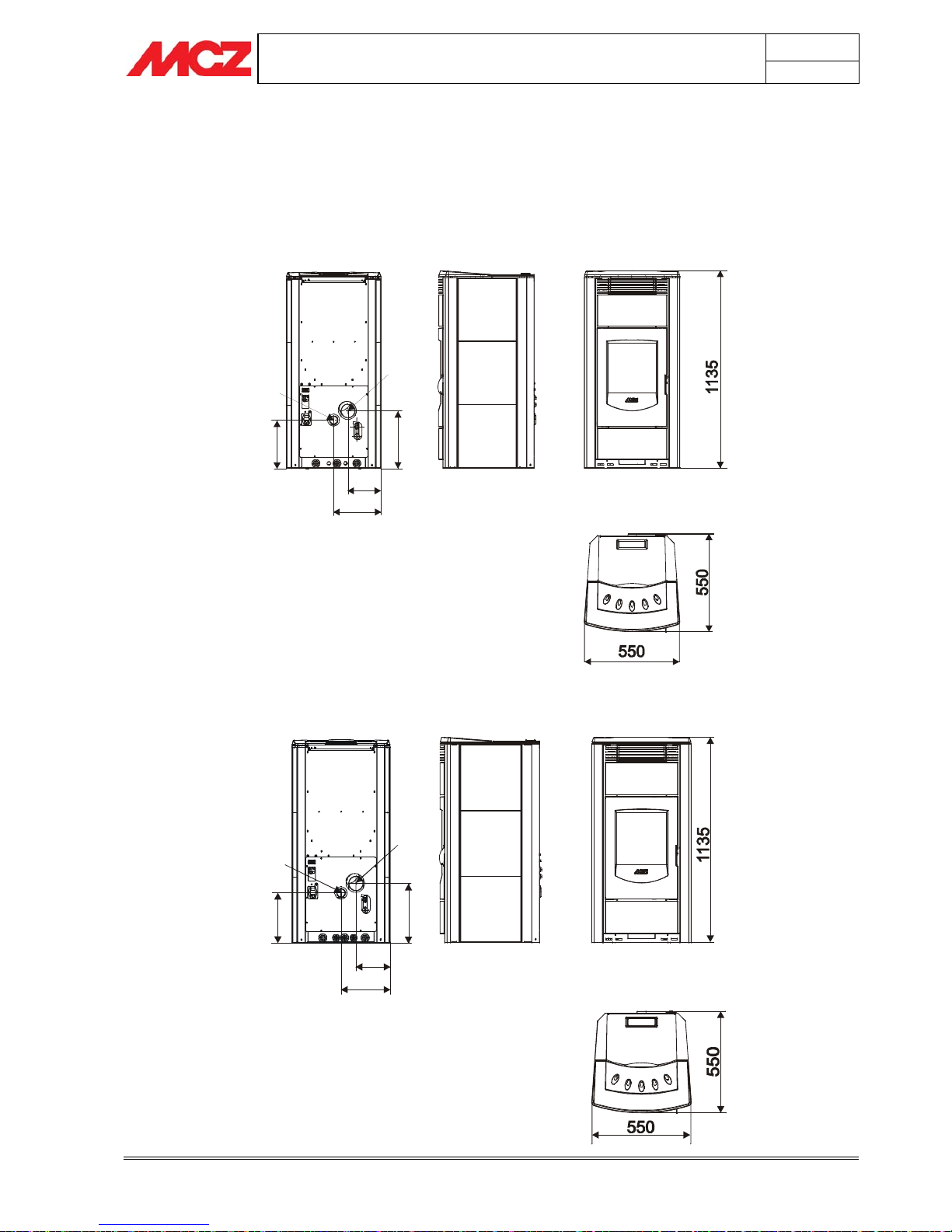

1120

578

643

198

364

281

330

1120

578

643

198

364

330

281

3.1.3. Dimensions of ATHOS POWER in HYDRO version with no kit for the

production of domestic hot water

3.1.4. Dimensions of ATHOS POWER in HYDRO version with kit for the

production of domestic hot water

Loading...

Loading...