INSTALLATION AND USE MANUAL

Contents

page

1

INTRODUCTION....................................................................................................................................3

1. WARNINGS AND WARRANTY CONDITIONS.....................................................................................4

1.1. SAFETY WARNINGS ........................................................................................................................4

1.2. OPERATING WARNINGS..................................................................................................................4

1.3. WARRANTY CONDITIONS................................................................................................................4

1.3.1. Restrictions..............................................................................................................................4

1.3.2. Exclusions................................................................................................................................5

2. INSTALLATION CONCEPTS ACCORDING TO UNI 10683...................................................................6

2.1. OPERATING AREA...........................................................................................................................6

2.2. PRECAUTIONS................................................................................................................................6

2.3. EXTERNAL AIR OUTLET...................................................................................................................7

2.4. CONNECTION TO THE FLUE PIPE.....................................................................................................8

2.5. CHIMNEY FLUE...............................................................................................................................8

2.5.1. Examples of chimney flues ......................................................................................................10

2.6. CHIMNEY POT ..............................................................................................................................11

3. DIMENSIONS AND TECHNICAL SPECIFICATIONS..........................................................................12

3.1. SMARTBOX ..................................................................................................................................12

3.2. CLIMASYSTEM..............................................................................................................................13

3.3. SUPERCLIMA ................................................................................................................................15

4. INSTALLATION AND ASSEMBLY .....................................................................................................17

4.1. PREPARATION AND UNPACKING....................................................................................................17

4.2. MAKING THE ELECTRICAL CONNECTIONS ...................................................................................... 17

4.3. GENERAL ASSEMBLY RULES ..........................................................................................................18

4.4. ASSEMBLY OF THE INSERTS (all models)........................................................................................18

4.5. CONNECTION TO THE CHIMNEY FLUE (all models) ......................................................................... 18

4.5.1. Direct connection between insert and flue pipe .........................................................................18

4.5.2. Connection using the telescopic connection ..............................................................................19

4.6. PARTICULARITIES OF THE SUPERCLIMA MODEL.............................................................................19

4.6.1. Superclima as a self-supporting structure .................................................................................19

4.6.2. Insertion of Superclima in a firebox..........................................................................................19

4.7. HOT AIR OUTLET KIT ASSEMBLY for CLIMASYSTEM and SMARTBOX................................................21

4.8. HOT AIR OUTLET KIT ASSEMBLY SUPERCLIMA...............................................................................21

4.9. FORCED VENTILATION KIT ASSEMBLY for SUPERCLIMA .................................................................. 22

4.10. PERFORATED COMPENSATION FRAME KIT ASSEMBLY .................................................................24

4.11. COMPENSATION FRAME ASSEMBLY ............................................................................................24

4.12. BEAM PROTECTION KIT ASSEMBLY ............................................................................................24

4.13. SUMMARY DIAGRAM FOR IDEAL CONNECTION OF THE INSERTS..................................................25

5. OPERATION.....................................................................................................................................27

5.1. PRE-LIGHTING WARNINGS............................................................................................................27

5.2. FUEL............................................................................................................................................27

5.3. USE OF THE INSERT .....................................................................................................................28

5.3.1. LOADING THE FUEL ...............................................................................................................28

5.3.2. COMBUSTION CONTROL.........................................................................................................28

5.3.3. FIRST LIGHTING....................................................................................................................29

5.4. FORCED VENTILATION OPERATION for the SMARTBOX MODELS .....................................................30

5.4.1. Manual operation ...................................................................................................................30

5.4.2. Automatic operation ...............................................................................................................30

5.5. SMARTBOX F80 VN NATURAL VENTILATION...................................................................................31

5.6. FORCED VENTILATION OPERATION for the CLIMASYSTEM MODELS.................................................31

5.7. FORCED VENTILATION OPERATION for the SUPERCLIMA MODELS...................................................31

5.7.1. FC 715 control unit operation ..................................................................................................31

5.7.1.1. Radio remote control........................................................................................................32

5.7.1.2. Switching on and off ........................................................................................................32

Contents Technical service - MCZS.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Contents

page

2

5.7.1.3.

Manual mode ..................................................................................................................32

5.7.1.4. Automatic mode ..............................................................................................................32

5.7.1.5. Other functions of the FC 715 control unit..........................................................................33

5.7.1.6. Setting the transmission code of the radio remote control ...................................................33

5.8. EMERGENCY TREATMENT .............................................................................................................34

6. MAINTENANCE AND CLEANING......................................................................................................36

6.1. CLEANING TO BE PERFORMED BY THE USER..................................................................................36

6.1.1. Cleaning the glass ..................................................................................................................36

6.1.2. Cleaning upper calorite deflectors ............................................................................................36

6.1.3. Cleaning out the ashes ...........................................................................................................36

6.1.4. Cleaning of stainless steel and satin-finish surfaces ...................................................................36

6.1.5. Cleaning of painted parts ........................................................................................................36

6.1.6. Cleaning and characteristics of marble and potstone cladding. ...................................................37

6.1.7. Cleaning the chimney flue .......................................................................................................37

6.2. CLEANING BY SPECIALISED PERSONNEL........................................................................................37

Contents Technical service - MCZS.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

INTRODUCTION

Dear customer,

We would like to thank you for choosing MCZ

products. We are sure that, with use, you will

appreciate the quality of an attentively designed and

tested product. Our goal is to combine technology

with easy use and, above all, safety.

For best operation of the product and to fully

enjoy the heat and sense of well being it will

spread throughout your home, we suggest you

carefully read this booklet before use; please

contact your retailer for full assistance in

resolving any doubts or problems.

Congratulations on your choice and remember, the

product MUST NEVER be used by children who

should always be kept at a safe distance!

Introduction

page

3

CAUTION:

This warning symbol found at various

points in the manual indicates that the

user should carefully read and understand

the message to which it refers since

neglecting to follow these

instructions could cause serious

product damage or injury to the user.

INFORMATION:

This symbol emphasizes important

information for good operation. Failure to

observe these instructions could jeopardize

product use and cause unsatisfactory

operation.

Revisions to the publication

In order to improve the product, the Manufacturer

reserves the right to modify and update this

publication without prior notice.

Reproduction, even partial, of this manual without the

Manufacturer's authorisation is prohibited.

Manual preservation.

• Please preserve this manual and keep it handy.

• If this manual should be lost or destroyed, or if it

is in poor condition, ask for a copy from your

retailer or directly from the manufacturer,

providing product identification data.

How to read the manual

• An essential item or an item that requires special

attention is printed in “bold face”.

“Italics”

•

illustrations or check other manual sections that

may provide more in-depth explanations.

• NOTE: the “NOTE” provides the reader with

additional information on the subject.

These symbols mark specific messages in this

booklet

are used to invite the user to review the

Introduction Technical service - MCZS.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

1. WARNINGS AND WARRANTY

CONDITIONS

Chapter 1

page

may cause injury to persons or animals or

damage to property. MCZ is not civilly or

criminally liable in these cases.

4

1.1. SAFETY WARNINGS

• Only qualified or authorised personnel should

install, check and maintain the product.

• Install the product according to current local,

regional or state regulations.

• For correct product and accessory use and to

prevent accidents, always follow the instructions

in this booklet.

• Before beginning any operation, the user, or

whoever is working on the product, must have

read and understood the entire contents of this

instruction booklet.

• The appliance must only be used as intended. Any

other use is considered improper and therefore

hazardous.

• Do not use the product as a ladder or support

surface.

• Do not dry clothing on the appliance. Any drying

racks or similar devices must be kept at a suitable

distance from the product. Fire hazard.

• Assess the static conditions of the surface that

will hold the product's weight and adequately

insulate if made of flammable material (i.e. wood,

carpet, plastic).

• Avoid installation in rooms with B type gas

devices, hoods with or without exhaust, heat

pumps, collective ventilation conduits.

• Avoid installing several operating chimney flues in

the same room or the vicinity of a stair well and

make sure there is no equipment in adjacent and

communicating rooms whose simultaneous use

would cause a depression.

• The user is fully liable for improper product use,

releasing MCZ from any civil or criminal liabilities.

• Any tampering or unauthorised non-original part

replacement may be hazardous to the user and

releases MCZ from any civil or criminal liability as

well as terminates the warranty.

• Surface parts are very hot (door, handle, glass,

smoke outlet pipe, etc.). Therefore, avoid direct

contact with these parts unless wearing protective

clothing or specific means such as, for example,

heat protective gloves or "cold" activation devices.

• Carefully explain this hazard to elderly people,

disabled people and particularly to all children,

keeping them away from the product while it is in

operation.

• Incorrect installation or poor maintenance (non-

compliance with that indicated in this manual)

1.2. OPERATING WARNINGS

• Do not use the product in the event of failure or

poor operation.

• Install the appliance in rooms that meet fire

safety standards and are equipped with all the air

intake and smoke exhaust services.

• Do not start fires with flammable materials.

INFORMATION:

• For any problem, please contact your retailer or

MCZ qualified and authorised personnel and

always request original spare parts for repairs.

• Only use the fuel stated by MCZ.

• Check and periodically clean the smoke exhaust

duct as foreseen by current regulations in the

country of installation.

• Carefully preserve this instruction manual since it

should be kept with the product for its entire

working life. If the product is sold or transferred

to another user, make sure the manual

accompanies the product.

• If lost, please request a copy from an authorised

retailer or from MCZ.

1.3. WARRANTY CONDITIONS

MCZ guarantees the product, except for the

elements subject to normal wear listed below, for

two years from the date of purchase proven by a

document that indicates the retailer's name and date

of sale, if the completed warranty certificate was

returned within 8 days and if the product was

installed and inspected by a specialised installation

technician and according to the detailed instructions

indicated in the instruction manual supplied with the

product.

The warranty includes the free replacement or repair

of parts recognised as factory defective.

1.3.1. Restrictions

The warranty does not cover parts subject to normal

wear such as: gaskets, glass, and all removable

firebox parts.

Replaced parts will be guaranteed for the remaining

warranty period from the date of product purchase.

Warnings and warranty conditions Technical service - MCZS.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Specifically, glass is guaranteed

from the moment the MCZ

installation technician certifies its

integrity when installation is

completed.

1.3.2. Exclusions

The warranty does not cover any part that may

be defective due to negligence or careless use,

incorrect maintenance or installation which is

non-compliant with that specified by MCZ (see

relevant chapters in this manual).

MCZ is not liable for any damages, direct or indirect,

to persons, animals or property consequent to the

failure to observe all the instructions indicated in this

manual, especially concerning the installation, use

and maintenance warnings.

In the event of product inefficiency, please contact

your retailer and/or area importer.

Damages caused by transport and handling are not

covered by the warranty.

Exclusively refer to the supplied manual for product

installation and use.

The warranty is null and void in the event of damages

due to tampering, weather, natural calamities,

lightening, fire, defective electrical and hydraulic

systems and the lack or incorrect maintenance as per

the manufacturer's instructions.

SERVICE REQUESTS

Service requests must be addressed

to the retailer who shall forward the

request to MCZ technical assistance.

MCZ is not liable in the event the

product and any other accessory is

improperly used or modified without

authorisation.

Only original MCZ spare parts must

be used for all replacements.

Chapter 1

page

5

Warnings and warranty conditions Technical service - MCZS.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

2. INSTALLATION CONCEPTS ACCORDING TO UNI 10683

2.1. OPERATING AREA

For good operation and good heat distribution, the appliance should be

positioned in a place where the air required for combustion can flow (at

least 60 m

current regulations in the country of installation.

The room volume must not be less than 60 m

Air must enter through permanent openings on the walls (near the

product) that open outdoors with a minimum section of 150 cm

These openings (air vents) must be made so as not to be obstructed in

any way.

Air can also be taken from adjacent rooms as long as these are

equipped with outdoor air vents and are not bedrooms or bathrooms or

rooms where fire hazards exist such as garages, wood sheds or

flammable material warehouses, strictly observing that stated in current

regulations.

3

/h must be available) according to installation standards and

3

.

2

.

• The product may not be installed in bedrooms,

bathrooms and where another heating appliance

is installed without autonomous air flow

(chimney, stove, etc.).

• Placing the appliance in explosive environments

is prohibited.

• The floor of the room where the product is to be

installed must be strong enough to support its

weight.

• In the event of wood floors, install a protective

covering in accordance with current regulations

in the country of installation.

• If walls are not flammable, install the product at

least 5 cm. from the walls.

Chapter 2

page

6

2.2. PRECAUTIONS

The product must be installed in a suitable location that permits routine

opening and maintenance operations.

The room must be:

• set for room operating conditions

• equipped with an adequate smoke exhaust system

• equipped with outdoor ventilation

Theoretical concepts for installation Technical service - MCZS.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

IMPORTANT!

• The installation and assembly must be carried

out by qualified personnel.

• The product must be connected to a chimney flue

or other vertical conduit that can discharge

smoke at the highest point of the house in

compliance with current standards.

• Smoke is generated from burning wood and,

therefore, may dirty adjacent or nearby walls.

• Before installing the product, drill a hole for the

external air outlet.

2.3. EXTERNAL AIR OUTLET

The room where the product is installed must have at least as much air

flow as required by the normal combustion of the appliance and normal

room ventilation. This may occur through permanent openings in the

room walls that lead directly outdoors or to ventilated rooms according

to UNI 10683 REV.

For this purpose, drill a hole on an exterior wall with a minimum free

section of 150 cm² (a 15 cm diameter hole or a 10x15cm rectangle),

protected by an indoor and outdoor grille.

The air intake must also:

• directly communicate with the installation room;

• be protected by a grille, made of metallic anti-insect mesh or a

suitable protection as long as it does not reduce the minimum

section:

• be installed so as to avoid obstruction;

• in the event of conduits, up to 3.5 ml, increase the section by

about 5%, while for larger sizes increase it by 15%.

Remember that the ventilation grilles always have a cm

useful section on one side. When selecting the grille and

hole dimensions, make sure the useful grille section is

greater than or equal to the section required by MCZ for

product operation.

2

Chapter 2

page

7

Connecting the air intake directly to the product is not

mandatory but the aforesaid section must guarantee about

50 m³/h of air. See standard UNI10683 REV.

IMPORTANT!

Air flow may also be obtained from a room adjacent

to the installation room as long as this flow occurs

freely through permanent openings that

communicate directly with the outdoors; avoid air

intakes connecting with heating units, garages,

kitchens or bathrooms.

Theoretical concepts for installation Technical service - MCZS.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

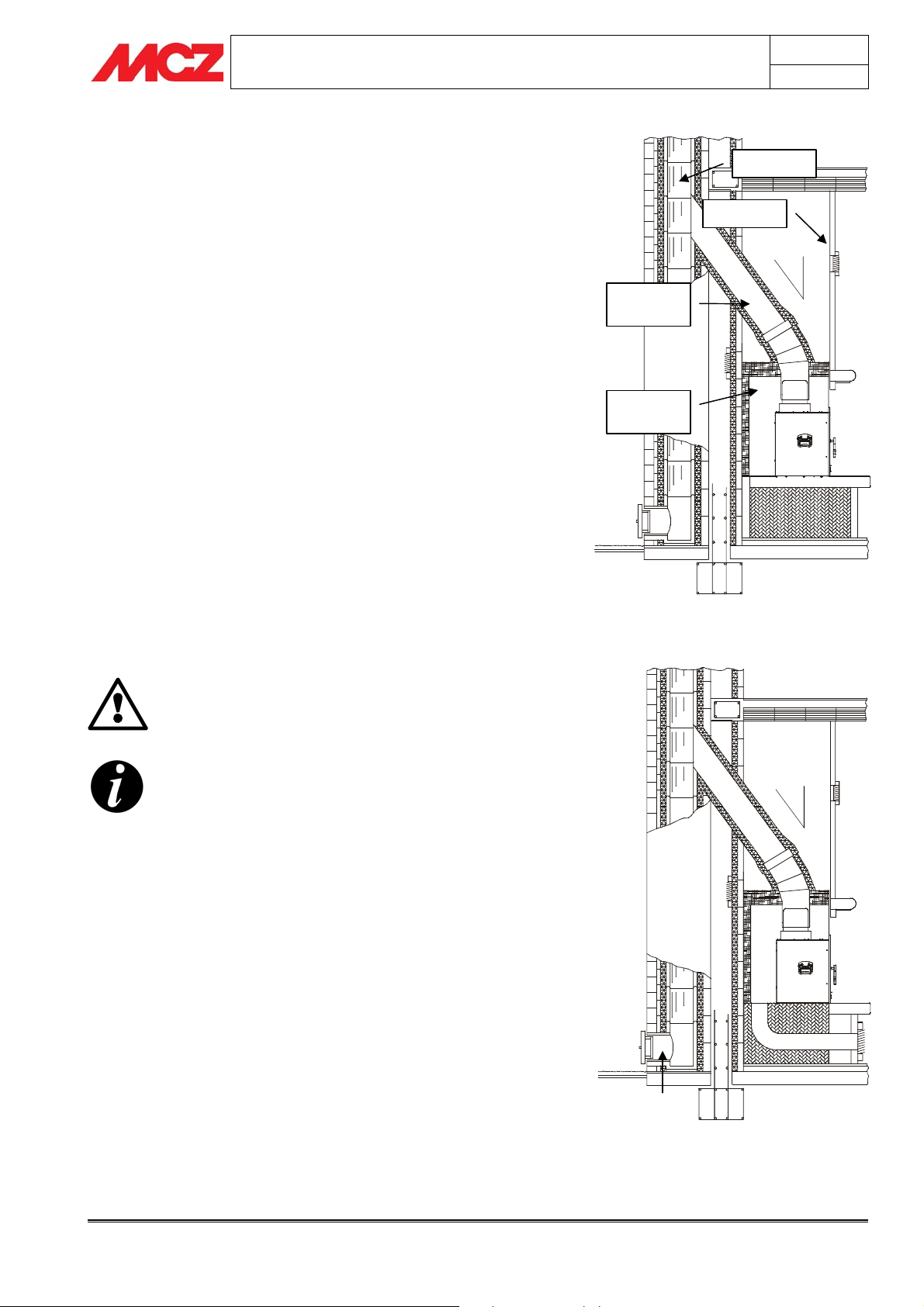

2.4. CONNECTION TO THE FLUE PIPE

Chapter 2

page

8

The connection to the flue pipe is a very important element. The

connection must be made with great care and attention, because it will

be very difficult to correct any construction anomalies or errors without

damaging the hood. The connection is also made in a part of the

fireplace where temperatures are very high, and thus it is important to

use heat-resistant materials that are also resistant to the acidity of the

fumes produced by combustion.

Before beginning work it is necessary to pay attention to the following

points:

• The connecting pipe must have a maximum slope of 45

degrees. This is to avoid excessive deposit of condensation

produced in the initial phases of lighting the fireplace heating

system and/or the excessive accumulation of creosote. It also

avoids slowing down the evacuation of fumes.

• The connections must be metallic in aluminium-clad

steel with minimum thickness 20/10 or in stainless

steel 316 with minimum thickness 10/10. The use of

flexible pipes in stainless steel or aluminium is

prohibited because it compromises the safety of the

connection itself. Flexible pipes are liable to split or

crack, causing leakage of smoke.

• The components making up the connecting pipe must be

perfectly sealed.

• The joint to the flue pipe must not be too long (to avoid

obstructions), nor too short (to avoid smoke leakage).

If metal connecting pipes are used, it is essential

that they be insulated with suitable material such as

ceramic fibre matting in order to avoid deterioration

of the walls and the decorative hood.

IMPORTANT!

Any increase in the section of the connecting pipe

must be made immediately above the hood of the

insert and not part-way along the flue pipe.

Flue pipe

Hood grille

Max 45°

Flue gas

connection

Ceramic fibre

insulation

Example of insert connection

2.5. CHIMNEY FLUE

The chimney flue is a fundamental element in discharging smoke

and therefore must have the following requisites:

• It must be waterproof and thermally insulated.

• It must be made with suitable heat-resistant materials that are

also resistant to combustion products and any condensation.

• It must have a vertical slope with axis deviations not over 45°

and without narrowing.

• It must meet the requisites indicated in the technical table for

the internal chimney section and height.

• It must preferably have a circular interior section.

• If pre-existent and previously operative, it must be clean.

Theoretical concepts for installation Technical service - MCZS.p.A. all rights reserved - Reproduction prohibited

Illustration of a correctly constructed

chimney flue with a chamber and sealed

door for solid combustion product collection

and discharge at the foot of the external

ascending segment.

INSTALLATION AND USE MANUAL

Chapter 2

page

9

The chimney flue is of primary importance for the

correct operation and safety of your insert.

Theoretical concepts for installation Technical service - MCZS.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

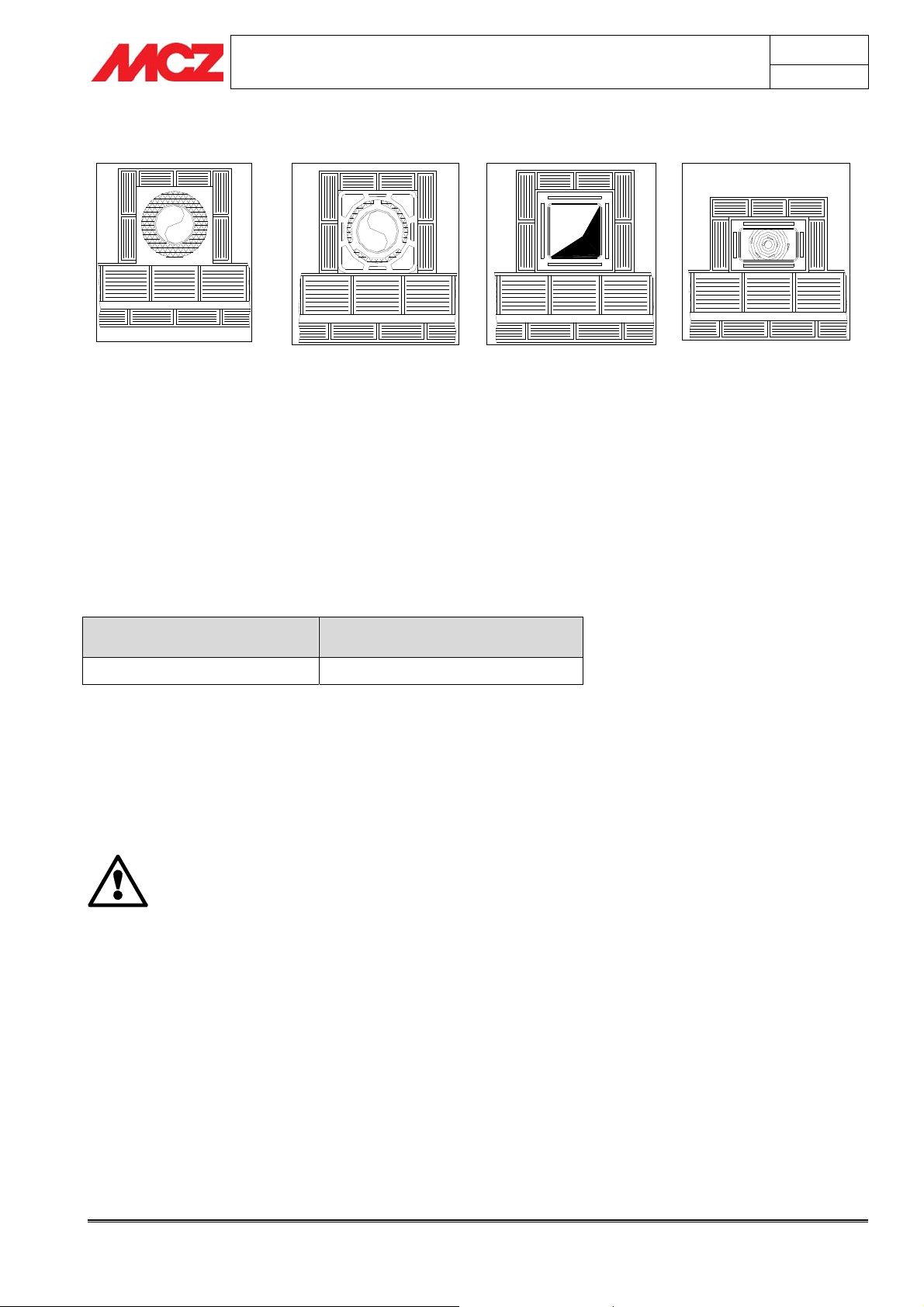

2.5.1. Examples of chimney flues

Chapter 2

page

10

AISI 304 stainless steel chimney

flue with dual chamber insulated

with ceramic wool or equivalent

resistant to 400°C.

EXCELLENT

Refractory chimney flue with

dual insulated chamber and

external concrete sleeve and

lightweight clay type

honeycomb material.

GOOD

Traditional square section clay

chimney flue with insulating

hollow inserts.

AVERAGE

Square or rectangular section chimney flues must have rounded

internal corners with radius not less than 20mm. For the rectangular

section, the ratio between internal dimensions must be ≤1.5.

The recommended section for a chimney flue according to its length is

listed in the table below:

Height (m) Section (cm²)

3 mt or more

400 (20x20 cm or ∅ 20 cm)

N.B. Too small or too large a section reduces draught and insulation.

For special sections or section or travel variations, functional smoke

exhaust inspections must be conducted as per UNI 9615.

The smoke conduit should be equipped with a solid material collection

chamber at the mouth of the smoke conduit to be easily opened with

an airtight door.

IMPORTANT!

If you have any doubts about your chimney flue

performance or if its dimensions are different from

those recommended, we highly advise you have an

authorised MCZ technician inspect and measure

chimney flue performance (micromanometer

measurements).

MCZ s.p.a. is not liable for poor product operation if

attributable to the use of a poorly dimensioned

chimney flue or installation of the same which fails

to meet the listed requirements.

Avoid chimney flues with

internal rectangular sections

whose larger side is double the

smaller such as 20x40 or

15x30.

POOR

Theoretical concepts for installation Technical service - MCZS.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

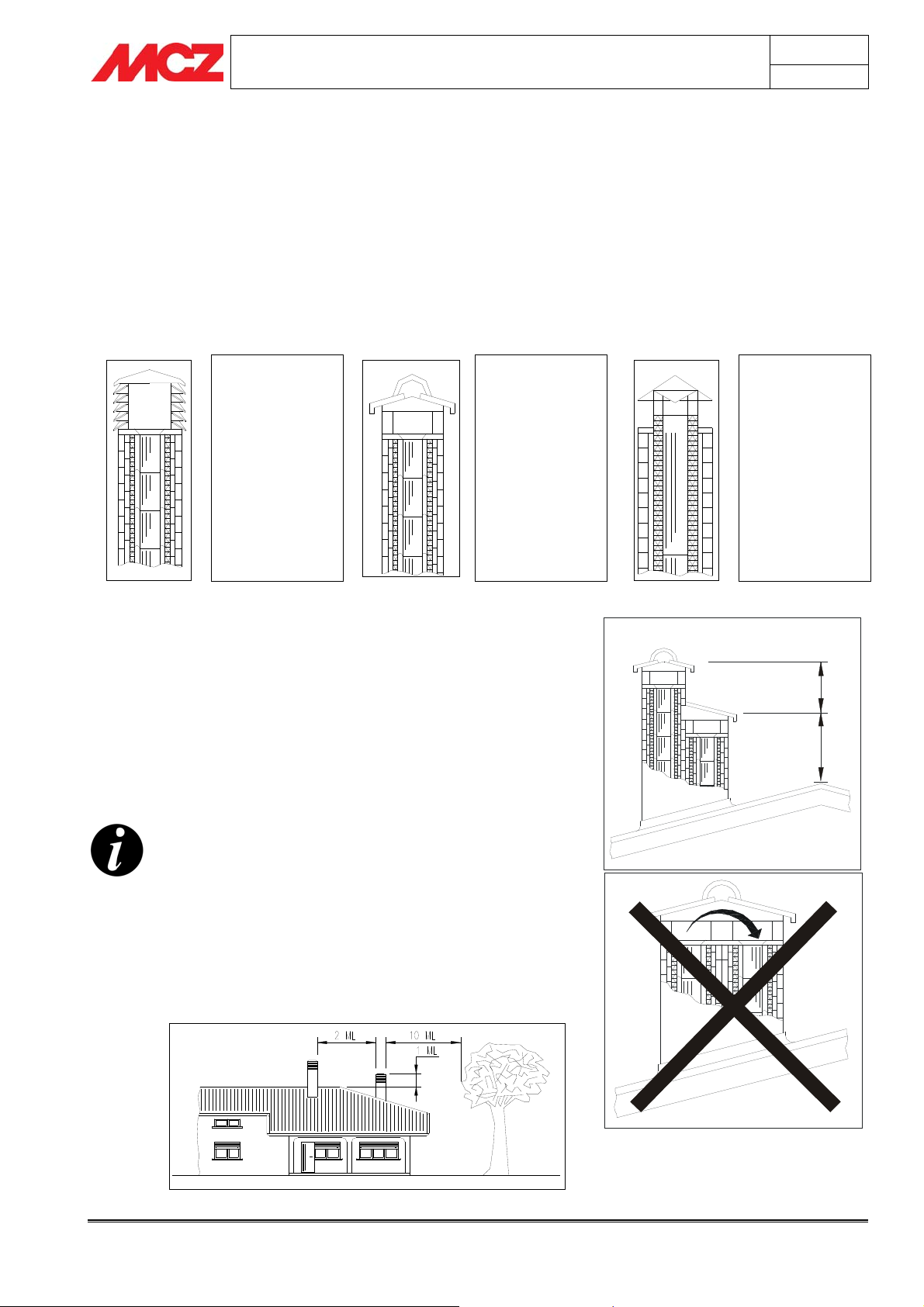

2.6. CHIMNEY POT

If underestimated, it is a terminal impediment to correct "chimney

system" operations.

Chimney flue draught is also a function of its chimney pot.

Therefore, if hand made, its four exhaust sections must correspond to

more than twice the internal section of the chimney flue.

Having to exceed the peak of the roof, the chimney pot will be

exposed to wind from all directions, thus an industrial type is

recommended.

Industrial chimney

pot with overlapping

prefabricated

elements.

Permits excellent

smoke exhaust.

Traditional hand

made chimney pot.

The right exhaust

section must be at

least twice the

internal section of

the chimney flue,

2.5 times is ideal.

Chapter 2

page

11

Steel chimney pot

for chimney flue with

internal smoke

deflector cone.

Permits excellent

smoke exhaust.

Chimney pots must meet the following requirements:

• It must have an internal section equal to that of the chimney.

• It must have a useful outlet section not less than twice that of

the internal section of the chimney flue.

• It must be built to prevent rain, snow and any foreign object

from getting into the chimney flue.

• It must be installed so as to guarantee suitable smoke

dispersion and, in any case, out of the reflux area where

counter-pressure formation is probable.

For paired chimney flues, the chimney pot for solid

combustion or the one for the upper floor must be at

least 50cm higher than the other to avoid pressure

transfers between paired flues.

The chimney pot must not have obstacles within 10 mt

such as walls, roof pitches or trees. Otherwise, raise it

at least 1 mt above the obstacle and, in the event of

other nearby chimney pots, keep them at least 2 mt

apart. In any case the chimney pot must exceed the

peak of the roof by at least 1mt.

t

m

5

,

0

t

m

1

Theoretical concepts for installation Technical service - MCZS.p.A. all rights reserved - Reproduction prohibited

0

INSTALLATION AND USE MANUAL

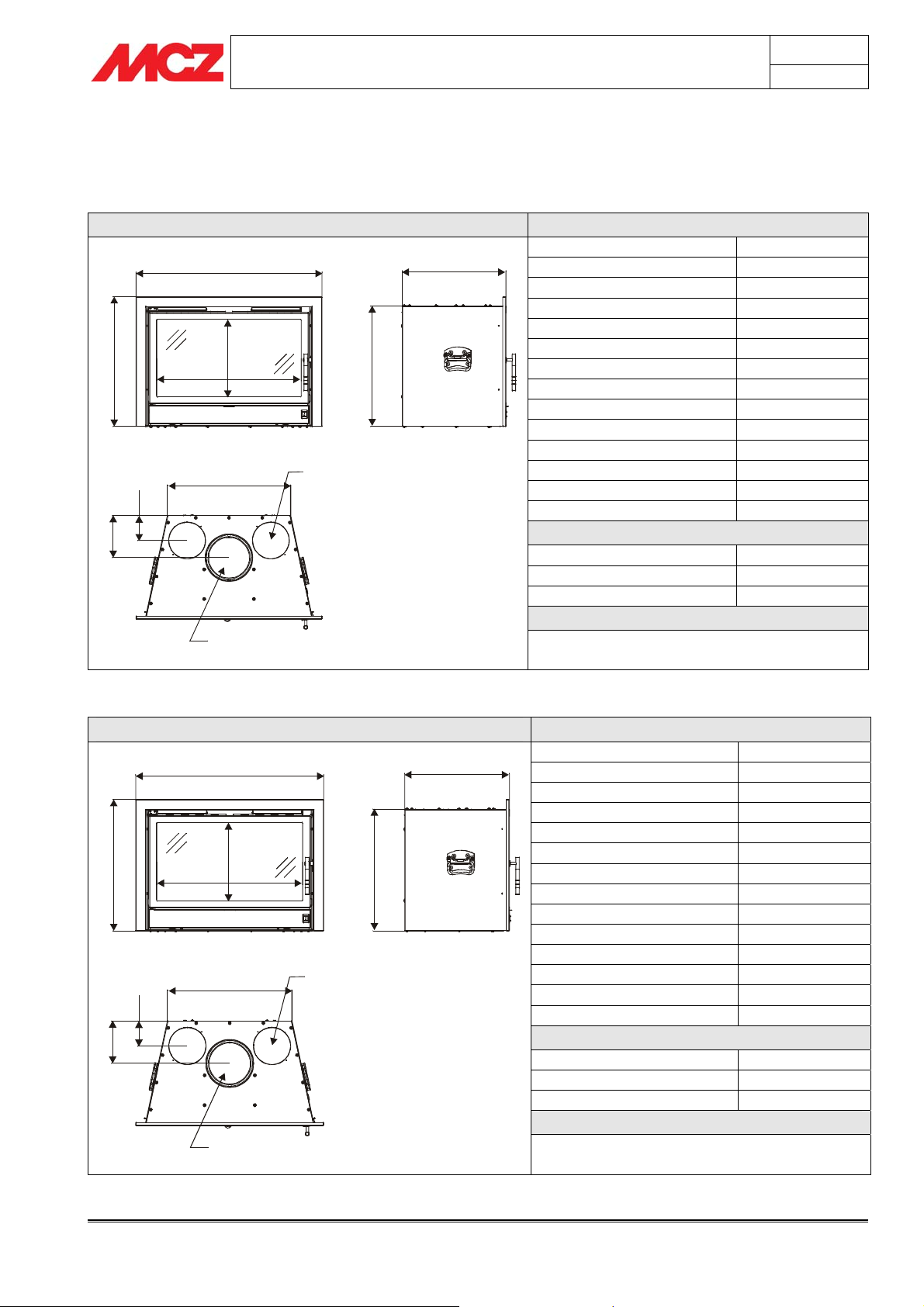

3. DIMENSIONS AND TECHNICAL SPECIFICATIONS

3.1. SMARTBOX

SmartBox F70 Technical specifications

Fuel type Wood - Chips

756

5

587

1

3

0

9

4

8

2

5

USCITA ARIA

1

500

0

1

1

7

1

CALDA Ø15 0

USCITA FUMI Ø 18

SmartBox F80 VN - VF Technical specifications

856

5

687

1

4

0

2

5

8

6

5

USCITA ARIA

0

578

0

1

1

7

1

CALDA Ø150

USCITA FUMI Ø 180

420

470

Hourly consumption 3.2 kg/h – 2.2 kg/h

Maximum thermal power kW 8.7 Kcal 7482

Minimum thermal power -

Efficiency 65%

Heatable volume * 187/40-214/35-249/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 400°C

Smoke outlet Ø 16 cm

Firebox dimensions 500x420

Net weight 100 Kg

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,22%

Mass throughput of smoke 13.55 g/s

Chimney flue

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

The insert is an intermittent combustion device

* Data may vary according to the fuel used

Fuel type Wood - Chips

Hourly consumption 3.2 kg/h – 2.2 kg/h

Maximum thermal power kW 8.7 Kcal 7482

Minimum thermal power -

Efficiency 65%

Heatable volume * 187/40-214/35-249/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 400°C

Smoke outlet Ø 16 cm

Firebox dimensions 578x470

Net weight 100 Kg

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,22%

Mass throughput of smoke 13.55 g/s

Chimney flue

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

The insert is an intermittent combustion device

* Data may vary according to the fuel used

Chapter 3

page

12

Technical features and technical specifications Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Chapter 3

page

13

3.2. CLIMASYSTEM

Climasystem F60 Technical specifications

Fuel type Wood - Chips

Hourly consumption 2.4 kg/h – 1.6 kg/h

Maximum thermal power kW 6.5 Kcal 5590

Minimum thermal power -

Efficiency 63%

Heatable volume * 140/40-160/35–186/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 330°C

Smoke outlet Ø 16 cm

Firebox dimensions 495x365

Net weight 100 Kg

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,20%

Mass throughput of smoke 11.2 g/s

Chimney flue

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

The insert is an intermittent combustion device

* Data may vary according to the fuel used

Climasystem 60 RH-LH Technical specifications

Fuel type Wood - Chips

Hourly consumption 2.4 kg/h – 1.6 kg/h

Maximum thermal power kW 6.5 Kcal 5590

Minimum thermal power -

Efficiency 63%

Heatable volume * 140/40-160/35-186/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 330°C

Smoke outlet Ø 16 cm

Firebox dimensions 495x365

Net weight 100 Kg

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,20%

Mass throughput of smoke 11.2 g/s

Chimney flue

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

The insert is an intermittent combustion device

* Data may vary according to the fuel used

Technical features and technical specifications Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Climasystem F70 Technical specifications

Fuel type Wood - Chips

Hourly consumption 2.9 kg/h – 2 kg/h

Maximum thermal power kW 8.5 Kcal 7310

Minimum thermal power -

Efficiency 67%

Heatable volume * 140/40-160/35-186/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 340°C

Smoke outlet Ø 16 cm

Firebox dimensions 560x485

Net weight 140 Kg

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,19%

Mass throughput of smoke 11.8 g/s

Chimney flue

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

The insert is an intermittent combustion device

* Data may vary according to the fuel used

Climasystem 70 RH-LH Technical specifications

Fuel type Wood - Chips

Hourly consumption 2.9 kg/h – 2 kg/h

Maximum thermal power kW 8.5 Kcal 7310

Minimum thermal power -

Efficiency 67%

Heatable volume * 140/40-160/35-186/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 340°C

Smoke outlet Ø 16 cm

Firebox dimensions 560x485

Net weight 140 Kg

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,19%

Mass throughput of smoke 11.8 g/s

Chimney flue

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

The insert is an intermittent combustion device

* Data may vary according to the fuel used

Chapter 3

page

14

Technical features and technical specifications Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Climasystem E70 Technical specifications

Fuel type Wood - Chips

Hourly consumption 2.9 kg/h – 2 kg/h

Maximum thermal power kW 8.5 Kcal 7310

Minimum thermal power -

Efficiency 67%

Heatable volume * 140/40-160/35-186/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 340°C

Smoke outlet Ø 16 cm

Firebox dimensions 560x485

Net weight 145 Kg

External combustion air outlet cm² 150

CO2 emission in smoke (13 %O2) 0,19%

Mass throughput of smoke 11.8 g/s

Chimney flue

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

The insert is an intermittent combustion device

* Data may vary according to the fuel used

Chapter 3

page

15

3.3. SUPERCLIMA

Superclima F70 Technical specifications

695 450

8

9

4

8

6

6

0

7

1

212,5212,5 270

5

,

7

6

1

0

6

1

Ø

0

0

1

Ø

265

Fuel type Wood - Chips

Hourly consumption 3.1 kg/h – 2.1 kg/h

Nominal thermal power kW 9 Kcal 7740

Efficiency 66,5%

Heatable volume* 194/40-221/35-258/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 350°C

Smoke outlet Ø 16 cm

Firebox dimensions 59x35 H31.5 cm

Net weight 140 Kg

External combustion air outlet cm² 150

CO emission in smoke (13 %O2) 0,12%

Mass throughput of smoke 13.6 g/s

Chimney flue

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

The appliance is an intermittent combustion device.

* Data may vary according to the fuel used

Technical features and technical specifications Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Superclima F80 Technical specifications

795 500

0

0

6

0

7

7

0

7

1

262,5262,5 270

5

,

7

6

1

0

6

1

Ø

0

0

1

Ø

265

Fuel type Wood - Chips

Hourly consumption 3.5 kg/h – 2.4 kg/h

Nominal thermal power kW 10 Kcal 8600

Efficiency 66,5%

Heatable volume * 215/40-246/35-287/30

Minimum draught 12 Pa / 0.12 mbar

Smoke temperature 360°C

Smoke outlet Ø 16 cm

Firebox dimensions 69x40 H40 cm

Net weight 150 Kg

External combustion air outlet cm² 150

CO emission in smoke (13 %O2) 0,12%

Mass throughput of smoke 13.6 g/s

Chimney flue

Up to 5 mt 20x30 cm Ø22

Between 5 and 7 mt. 20x20 cm Ø20

Over 7 mt 18x18 cm Ø18

Note

The appliance is an intermittent combustion device.

* Data may vary according to the fuel used

Chapter 3

page

16

Technical features and technical specifications Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

4. Installation and assembly

IMPORTANT!

The insert must be installed and connected to the

chimney flue by specialised technicians or skilled

personnel so that every local or national regulation is

met and, in any case, in accordance with the

standard UNI 10683 REV.

When the insert is unpacked, make sure all parts are in perfect

working order and check for damages due to transport. If the

insert is being installed in a place with difficult access, it is possible to

lighten the weight by removing the internal components which make up

the firebox. Remember to correctly reassemble all elements.

Any disassembly and assembly of internal parts

must, however, be carried out by skilled and

authorised personnel.

MCZ will not be held liable for any breakage in the

event the aforesaid warning is not observed.

Chapter 4

page

17

4.1. PREPARATION AND UNPACKING

Open the packaging, take off the bands, remove the insert from the

pallet and position it in the chosen location, taking care that its position

fully complies with the instructions.

The insert must always be kept in a vertical position during handling,

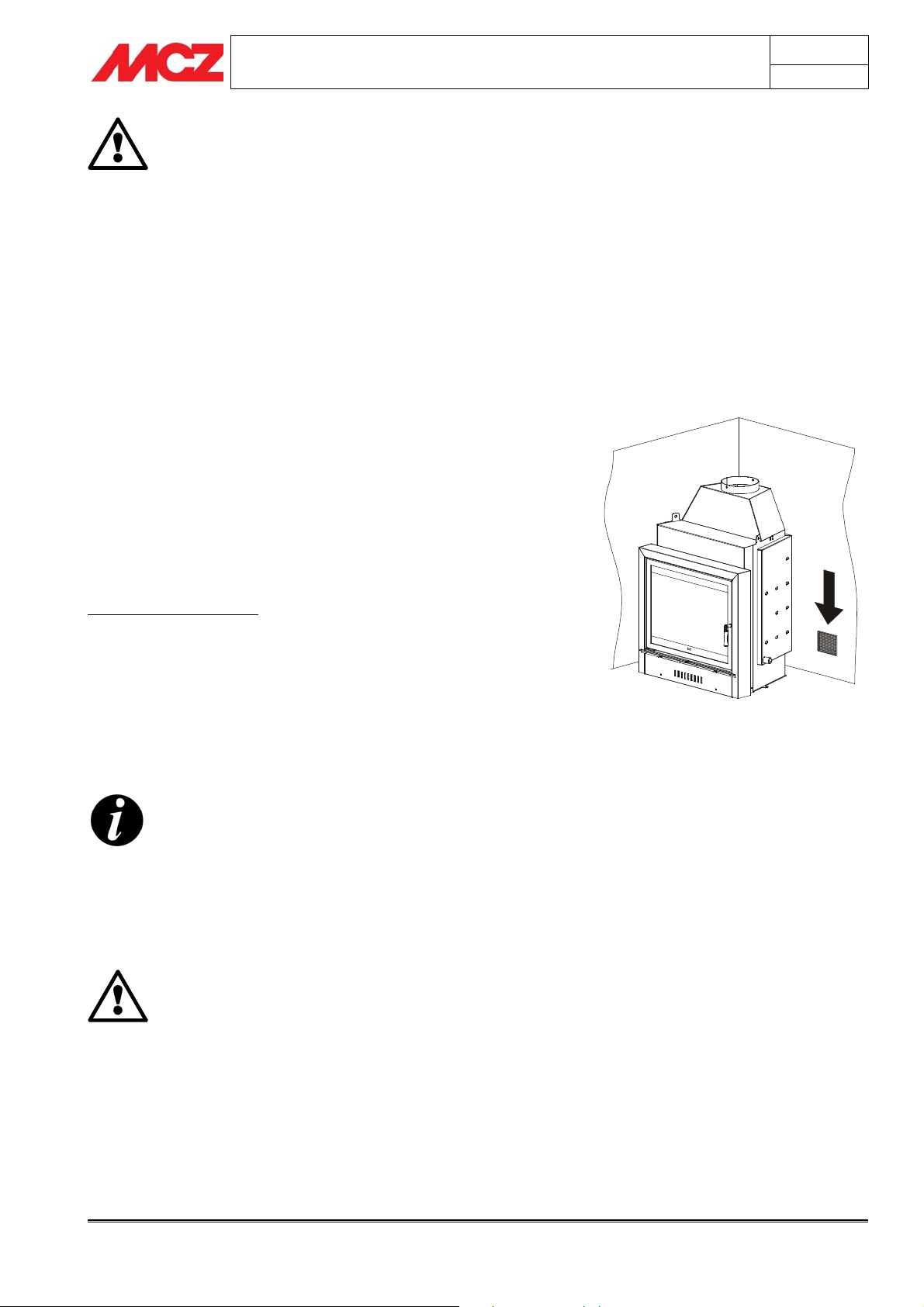

using the appropriate handles located on the sides. Be careful that the

door and its glass are protected from impacts that could jeopardise

their integrity. In any case, the product must always be handled with

care. If possible, unpack the insert in the area where it is to be

installed.

The materials which make up the packaging are not toxic or harmful,

so no special disposal procedures are required.

The end user must store, dispose of or recycle packaging material in

accordance with current regulations.

4.2. MAKING THE ELECTRICAL CONNECTIONS

Before positioning the insert, a 230V - 50 Hz electrical power outlet

must be prepared near the insert in order to connect the electrical cable

that powers the fans.

The power outlet must be equipped with an earth connection.

The wiring must be carried out by first cutting off the

electricity supply in the home.

When preparing the connection of the electrical cable

provided with the insert, be very careful not to crush

the cable while inserting the product. This could

cause short circuits that can damage the entire

electrical system.

Packaging example

Installation and assembly Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

4.3. GENERAL ASSEMBLY RULES

The insert can either be inserted on existing fireboxes or inserted as an

autonomous firebox thanks to its self-supporting structure.

If the insert is positioned in an existing firebox,

check that the dimensions of the firebox are

compatible for insertion.

If the insert is positioned over a floor or close to

walls made of flammable materials, these surfaces

should be suitably insulated in a safe manner.

The Superclima model has special requirements for

positioning and assembly. The installer should refer

to section 4.5

4.4. ASSEMBLY OF THE INSERTS (all models)

To facilitate insertion of the insert, especially on an irregular existing

firebox surface, the optional INSERTION GUIDE FRAME can be

used, while the flue gas connection can be made using the optional

.

TELESCOPIC CONNECTION

the SmartBox model.

For this operation just fix the frame (A) to the firebox surface using the

plugs (D) provided and, if necessary, use shims to level the frame.

Together with the insertion guide it is recommended to also use the

telescopic connection (B) that can be screwed onto the insertion guide

using the anchorings (C) and allows to make the connection to the

chimney flue before inserting the product

The "Insertion guide" and "Telescopic connection"

accessories are not available for the Smartbox

model.

These accessories are not available for

(see section 4.5.2)

Chapter 4

page

18

B

C

A

D

Insertion guide positioning and telescopic

connection

4.5. CONNECTION TO THE CHIMNEY FLUE (all models)

We recommend connecting the insert to the chimney flue using pipes

and bends in aluminium-clad steel, capable of withstanding the high

temperatures reached in that section of pipe and resisting corrosion

from the fumes. These connecting pipes are available on request in

various sizes (see MCZ accessories), and they simplify installation since

they are assembled by fitting one into another.

Flexible pipes in steel or aluminium cannot be used

to connect the insert to the chimney flue as they are

prohibited by current regulations.

4.5.1. Direct connection between insert and flue

pipe

Drill and disassemble the existing clay hood and engage the elements

in the chimney flue, being careful not to exceed the 45° inclination and

to correctly carry out any infilling necessary in order to prevent soot or

ashes of the chimney flue from settling above the insert.

(Figure 3)

Infill of direct flue gas connection

Installation and assembly Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

A

INSTALLATION AND USE MANUAL

4.5.2. Connection using the telescopic connection

To simplify assembly of the insert it is possible to use the telescopic

connection, an optional accessory that MCZ makes available to its

installers and that allows to easily install the flue gas connection and

the SmartBox.

The telescopic connection can be fixed to the top part of the prehood

ring and, thanks to this accessory, the smoke outlet of the insert is

precisely determined and it is possible to freely create the entire

connection to the chimney flue without being obstructed by the volume

of the machine.

Once the connection has been completed, seal the section between the

pipe and entrance with refractory mortar or ceramic fibre. This

operation requires great care, and the seal must be airtight

since any passage of air may compromise the draught.

Any increase in the section of the connecting pipe

must start immediately above the hood of the

fireplace and not part-way along the flue pipe

section

When the installation is complete, the connecting

pipe must be insulated with ceramic fibre or other

material capable of withstanding temperatures of at

least 600 °C.

When the infilling operations are finished and the product is inserted,

just extract the upper deflector from inside the fire mouth of the

SmartBox, insert your hand inside the smoke outlet of the insert, turn

the handle inside the telescopic connection and pull downwards. The

telescopic connection will descend perfectly to the smoke outlet of the

SmartBox, thus completing the connection to the chimney flue.

(figure 4)

Infill of flue gas connection

Chapter 4

page

19

4.6. PARTICULARITIES OF THE SUPERCLIMA MODEL

Unlike the SmartBox and ClimaSystem inserts, the Superclima has a

compartment (M) located under the insert that contains the fan. This

compartment can be used as a support if cladding is built around the

self-supporting structure of the insert, or it must be inserted on the fire

bed of the firebox if Superclima is used to recover an old fireplace.

4.6.1. Superclima as a self-supporting structure

For those who are building the entire fireplace structure around the

Superclima or have an existing fire mouth available which is large

enough to allow full-height assembly of the insert, the two front

support brackets (B), provided in the package, can be used to balance

the structure which rests only on the fan compartment box.

For installation, unscrew the two front screws (A), attach the supports

(B) as shown in the figure and screw the screws (A) back on.

Otherwise, for those who are unable to use this installation procedure,

proceed as described in the following section.

4.6.2. Insertion of Superclima in a firebox

To install Superclima inside a firebox, first of all you must disassemble

the motor housing (M) and all the internal components

according to diagram 1 and create the compartment to hold this

A

B

Installation and assembly Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

component, enlarging the existing ash pit of the firebox or creating it

by drilling the fire bed.

The motor housing has the dimensions: L 270 x H 170 x D 265

You must also provide space for the connection of the two air ducts

with 100 mm diameter, to be connected to the flanges (P) of the motor

housing. Insert the motor housing (M) inside the hole that has been

made in the old fire bed of the firebox.

Now, during this phase, make the air duct connections for the fan by

connecting one end of the flexible piping to the flanges (P) and the

other to the air intakes prepared previously (see next page).

Make a hole as well for the passage of the electrical wiring (N-H) that

connects the control unit (Q) to the motor and the thermostatic probe.

A compartment distant from the hot body of the insert must also

be provided to house the control unit so that it can be accessed for any

maintenance

(see the “Ventilation assembly kit” section).

INSTALLATION AND USE MANUAL

L

M

Chapter 4

page

20

P

B

D

A

C

DIAGRAM 1 - Superclima internal components disassembly and assembly

Internal components disassembly/assembly procedures:

1. Extract the cast iron fire beds A

2. Take out the removable bottom C by unscrewing the screws B

3. Remove the deflector E by unscrewing the two screws D

4. Disconnect the probe cable H, unscrew the two nuts F and

extract the motor support G

5. Disconnect the fan motor cable N (mark the position of the

connectors) and

6. Unscrew the screws L that fasten the motor housing and

remove the housing.

7. To reassemble Superclima, repeat the operations in the reverse

order from 6 to 1.

Connect the air ducts as follows:

One of the two outside the home so that it can draw in fresh clean air

and the other inside the room where the insert is being installed. This

procedure allows for proper mixing of the air inside the installation

room and better cooling of the insert structure.

F

E

G

H

N

P

M

Q

Installation and assembly Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

For those who do not have the possibility to perform this type of

connection, it is in any case required to connect both air ducts

regardless of whether they are both connected to the exterior or the

interior. Depending on the choice of connection, the operating

temperature will be slightly higher or lower than average, but this does

not compromise correct operation.

When the installation of the fan compartment box and air ducts is

finished, proceed to the next phases for connection of the chimney flue

and the ventilation kit.

All the ventilation components can be assembled

from inside the fire mouth of the insert except the

motor housing which, however, we have already

installed beforehand.

INSTALLATION AND USE MANUAL

(Figure 1)

4.7. HOT AIR OUTLET KIT ASSEMBLY for

CLIMASYSTEM and SMARTBOX

If it is desired to use additional fan-assisted air outlets, we can attach

one or two HOT AIR OUTLET KITs (optional)

assemble the hot air ducts, it is necessary to break through the semi-

sheared plugs (A), screw on the flanges (B) and insert the flexible

pipes (D) fastening them with the appropriate pipe clamps (E). At the

opposite end of the flexible piping, attach the adjustable air outlets (C)

which will later be fixed to the decorative hood.

It is advisable to:

• Position the hot air outlets at a height of at least 2 mt. above

the floor so that the hot air does not flow directly onto people.

• Insulate the air duct pipes.

• Do not exceed 1.5 mt of ducting for each outlet.

• It is advisable to insulate the ducting pipes to avoid the

vibrations transmitted by the fans and forced air and to

keep the outcoming air warmer.

The front hot air outlet cannot be excluded even

though in the SmartBox model, by manually turning

the fins located above the fire door, it is possible to

direct more hot air through the top outlet pipes and

the hood outlets.

(figure 5).

To

E

C

Hot air outlet kit assembly

Chapter 4

page

21

D

B

A

D

4.8. HOT AIR OUTLET KIT ASSEMBLY SUPERCLIMA

E

If it is desired to use additional fan-assisted air outlets, we can attach

one or two HOT AIR OUTLET KITs (optional).

To assemble the hot air ducts, it is necessary to break through the

semi-sheared plugs (A), screw on the flanges (B) and insert the

flexible pipes (D) fastening them with the appropriate pipe clamps (E).

At the opposite end of the flexible piping, attach the adjustable air

outlets (C) which will later be fixed to the decorative hood.

Installation and assembly Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

C

F

B

A

It is advisable to:

• Position the hot air outlets at a height of at least 2 mt. above

the floor so that the hot air does not flow directly onto people.

• Insulate the air duct pipes.

• Do not exceed 1.5 mt of ducting for each outlet.

The Superclima model also provides the possibility to install appropriate

buffers (F), which deflect the air flow to convey it inside the duct

piping. We recommend those using the air ducts to assemble these

flow deflectors for improved air flow to the outlets.

To install the buffers, they must be inserted in the appropriate

openings (G) after removing the semi-sheared plugs, and then blocked

with the appropriate screws provided.

Installation of the buffers allows to divide the air flow, sending about

70% towards the air ducts and 30% towards the front hot air outlet

grille.

The front hot air outlet cannot be completely

obstructed since it is necessary to cool the front part

of the structure.

It is also advisable to insulate the ducting pipes to

avoid the vibrations transmitted by the fans and

forced air.

INSTALLATION AND USE MANUAL

G

F

Chapter 4

page

22

4.9. FORCED VENTILATION KIT ASSEMBLY for SUPERCLIMA

THE COMPANY IS NOT LIABLE FOR DAMAGES DUE

TO INCORRECT CONNECTIONS OR IMPROPER USE

OF THE DEVICE.

The Superclima insert is supplied with a forced ventilation kit including:

(1) Radio control complete with internal battery

(2) Fan cable with plug and terminals

(3) Power supply cable with plug and socket

(4) FC700 or FC715 control unit with built-in radio receiver

3

(5) Centrifugal fan 300m

(6) Probe cable with rapid coupling connector and thermostat (MODEL FC700) or

(7) Probe cable with rapid coupling connector and thermostat (MODEL FC715)

/h 220v-50Hz

Installation and assembly Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Chapter 4

page

23

4

Forced ventilation kit

3

6

Yellow-green

Brown

Blue

Once all the installation phases have been completed for the connection

to the chimney flue, the compensation kit (if applicable) and the beam

protection kit, it is now possible to definitively insert Superclima inside

the firebox.

The insert, however, has all its internal parts disassembled so it is

necessary to reassemble them properly, beginning with the ventilation

(figure 5),

kit

1. Connect the electrical cable (2) coming from the control unit to

2. Connect the electrical cable of the thermostatic probe (6) to

3. Probe connection for the FC715 control unit

4. Insert the fan motor (5) in the motor housing and connect the

5. Connect the control unit (4), located externally as specified in

Installation and assembly Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

1

following the steps below:

the fan motor, as illustrated in

the cable coming from the control unit

Insert the probe M complete with support screws

(D+F+G+H+L) in the hole E following the procedure below:

(figure 7).

Screw the probe setscrew L onto the probe support G

without tightening, placing the bushing H in between.

Insert the entire probe support G+H+L in the hole E, inserting

the washer F beforehand and blocking the assembly with the

nut D from the side opposite the support.

Insert the probe M in the hole of the probe setscrew L

completely and gently tighten the screw L.

air ducts to the flanges.

section 4.2.2, to the home power distribution network and make

sure that the red LED located on the control unit turns on.

2

figure 5

(figure 5)

Probe assembly for the FC715 control unit

5

D

E

F

G

H

L

M

INSTALLATION AND USE MANUAL

CAUTION !!

• The control unit must be positioned in an accessible

location far from the insert

(see section 4.2.2)

to allow any

necessary maintenance or replacement of the internal fuse.

• The equipment must be powered with a voltage of 220 V

at 50 Hz and the power outlet must be accessible and

complete with an earth connection.

• Make sure that the cables do not come into contact with

the hot metal parts of the structure, as they could melt

and short circuit the electrical system.

• The equipment must be connected to a bipolar switch

complete with fuses.

Example of control unit positioning

Once the assembly of the ventilation kit is completed,

reassemble the fire bed and the internal components

according to the diagram and description of figure 1 on page

17.

4.10. PERFORATED COMPENSATION FRAME KIT

ASSEMBLY

Chapter 4

page

24

If there is a space of more than 1 cm between the insert and the

existing firebox, the appropriate compensation frame kit can be

installed which uses a frame in perforated aluminium-clad steel to fill

the cavity between the insert and the firebox.

The MCZ compensation frame has a standard width of 10 cm, while

the length is determined by the perimeter of the product being

installed.

Before inserting the unit, it is necessary to measure the exact

dimensions of the frames, cut them if necessary with sheet metal

scissors if they are too large and fix them with the appropriate selftapping screws in the holes already arranged on the outer sides and

roof of the Superclima insert.

Only after the compensation kit has been sized and assembled can the

insert be definitively inserted inside the firebox.

4.11. COMPENSATION FRAME ASSEMBLY

The SmartBox and SuperClima models (not available for the

ClimaSystem) also provide the possibility to assemble an exterior

finishing frame that covers all four sides of the product.

This (optional) frame is assembled only after the installation and

cladding are complete, and it anchors directly to the insert structure.

This frame is designed to finish and cover the crack that is formed

between the metal structure of the unit and the wall.

To assemble the frame, just open the fire door, fit the frame as shown

in the figure and use the four screws provided to fix it onto the stiles of

the structure, inside the profile of the door.

Compensation kit assembly

4.12. BEAM PROTECTION KIT ASSEMBLY

If there is a beam made of wood or other combustible material above

the hot air outlet opening, it is absolutely necessary to protect it

Installation and assembly Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

Compensation frame assembly

g

INSTALLATION AND USE MANUAL

with the BEAM PROTECTION KIT (optional) or with panels made of

insulating material (Ex: calorite).

To attach the protection, fix the panel to the beam using the

appropriate wood screws provided.

(figure 7)

4.13. SUMMARY DIAGRAM FOR IDEAL CONNECTION

OF THE INSERTS

The installation described below is ideal for inserts assembled on old or

new fireplaces; the insert must never be walled up but kept 5mm

detached from any masonry surface since it needs to be able to expand

when it is hot; furthermore, if it is walled up there is a significant drop

(30÷40%) in the thermal efficiency because the heat is not allowed out

completely but only in part.

Insulate the structure thorou

parts in wood or flammable material nearby.

SMOKE CONNECTION

hly only if there are

Beam protection kit assembly

Chapter 4

page

25

*TOP INSULATION

N

O

I

T

A

L

U

S

N

I

R

A

E

R

*

)

E

G

N

A

H

T

C

C

X

U

E

D

E

R

I

H

A

T

N

R

O

O

I

F

T

L

C

U

E

F

V

E

N

S

O

U

C

(

BEAM

BEAM

INSULATION

CONVECTION

AIR OUTLET

VENTILATION

AIR OUTLET

COMBUSTION AIR INLET

VENTILATION AIR INLET

*

CALORITE

INSULATION

CONVECTION AIR INLET

*Insulation is possible with rigid panels in CALORITE

or similar insulating material.

COMPENSATION KIT

CONVECTION

AIR INLET

Installation and assembly Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

SUPPORT IN MASONRY OR SIMILAR MATERIAL

INSTALLATION AND USE MANUAL

Chapter 4

page

26

Installation and assembly Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

5. OPERATION

5.1. PRE-LIGHTING WARNINGS

Make sure you have read and completely understood the contents of

this instruction booklet.

Remove all accessories and supplies which might burn (various

instructions and adhesive labels) from the firebox and door.

Remove the stickers from the ceramic glass or the high temperature

could melt them and irreparably damage the glass. In this case, the

MCZ warranty does not cover the glass.

Avoid touching the product the first time it is used since its

paint completes drying and hardens during the first lighting.

If you touch the paint, you may expose the steel surface.

It is good practice to provide plenty of ventilation in the room

during the initial lighting, as the product will give off a small

amount of smoke and smell of paint.

If necessary, touch up the paint with aerosol spray in the

original colour. (see the section "Accessories for fireplace

stoves and inserts").

Do not remain near the product and, as previously mentioned, ventilate

the room. The smoke and the smell of paint will vanish after about one

hour of operation. There are no health risks involved.

The structure will be subject to expansion and

contraction during the lighting and cooling down

stages, and may therefore make slight creaking

noises.

This phenomenon is absolutely normal, the structure

being made of sheet steel, and must not be

considered a fault.

Chapter 5

page

27

It is extremely important to be sure not to take the

product to full heat straight away, but to bring it

gradually up to temperature.

This avoids damages to seals and the steel structure.

Do not demand full heating

performance straight away!

5.2. FUEL

FUEL: Wood

To obtain the maximum performance from your product, it is of primary

importance to use wood with suitable characteristics.

It is possible to use firewood such as oak, beech, ash, robinia or

ilex, or manmade logs from compressed wood without added resins.

These have a high calorific value and must be used with

caution to avoid overheating which could damage the product.

Operation Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

Fuels such as poplar, pine, lime and chestnut have a low calorific value,

being soft woods, soft in the sense of being pulpy, and they do not

burn long. For all listed types, the humidity contained in them is a

fundamental factor.

A high percentage of moisture produces condensation in the

smoke duct causing an alteration in the draught and

generating smoke and a significant deposit of soot in the

firebox, on the glass of the door and in the flue pipe with a

possible risk of a chimney fire later on. It also causes a

considerable overall drop in efficiency.

The use of damp or treated wood emits a higher quantity of

smoke than normal that can dirty glass faster. Also the low

performance of the chimney flue can jeopardise glass

cleanliness since smoke remains in the combustion chamber

longer than normal.

Do not use treated fuels (such as painted or varnished

wood) or unsuitable materials (such as plastics and

derivatives), which could release toxic or polluting

substances.

Do not burn rubbish.

The gases produced by combustion based on the use

of unsuitable fuels cause damage to the product and

the chimney flue; they cause pollution and can

significantly compromise your health.

Chapter 5

page

28

Wood drying

time (i.e. beech)

Freshly cut 50 /

3 months 40 2410

6 months 35 2700

9 months 30 2900

12 months 25 3150

15 months 20 3400

18 months 15 3710

21 months 10 3980

humidity

%

Heat

power

Kcal/h

5.3. USE OF THE INSERT

5.3.1. LOADING THE FUEL

To load fuel, simply open the door by rotating/lifting the handle and

pulling the door open.

During use, the metal parts and the glass reach high temperatures, so

it is necessary to use the special thermal glove supplied.

During combustion, the combustion chamber door must remain

closed.

Loading quantities of fuel over those indicated in the

technical sheets for each single product is prohibited.

Excessive quantities of fuel in the combustion

chamber could damage and deform the firebox and

structure.

MCZ is not liable for any damages caused by

overloaded fuel or the use of fuel that does not meet

specifications.

5.3.2. COMBUSTION CONTROL

PRIMARY AIR

The insert is equipped with primary air emission from the part

underneath that guarantees proper combustion. Moving the lever

towards the base of the arrow provides total opening with a more rapid

combustion, while moving the lever towards the point of the arrow

provides partial closure with slower combustion.

Operation Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

SECONDARY AIR

The top part of the product provides emission of so-called secondary air

that produces post-combustion, increasing efficiency while reducing

polluting elements and helping to keep the glass clean. The same lever

used to adjust the primary air is used to proportionally dose the

secondary air in a calibrated manner, allowing the final user to enjoy

excellent combustion regulation.

5.3.3. FIRST LIGHTING

It is advisable to approach the first lighting with caution, using

good-quality, well-seasoned wood.

The combustion air entrance must be fully open.

Once combustion has started, normal-sized pieces of wood may be

added.

The flame must have as far as possible a smooth and laminar flow.

When reloading, the fire door should be opened slowly to avoid

blowbacks of smoke into the room.

Proceed as follows:

• Place a small amount of balled paper in the firebox.

• Cover the paper with a small quantity of twigs and a few

pieces of wood.

• Fully open the combustion air regulator.

• Light the paper and, if necessary, keep the door open for

several minutes until the combustion chamber and chimney

flue are heated.

• When the twigs are burning, the door can be closed.

As the fire burns, add wood. Never overload the product with wood

(see technical specifications in the table).

As soon as the flames have died down and a bed of embers has

formed, load the insert normally.

Small loads of wood are preferable to large ones for

combustion.

We recommend that this fuel loading method be used even during

subsequent product use.

To obtain nominal power, place the load of wood indicated

in the technical specifications table in the combustion

chamber (

hour. When the fire dies down, load the firebox again.

chapter 3

). The insert autonomy is about one

MIN

MAX

Chapter 5

page

29

Caution !

• Do not use volatile or flammable substances

(petrol, alcohol, etc.) for lighting the fire.

• Do not use fuels which could release toxic

substances or pollutants.

• Do not put the fire out by throwing water on it.

• Check the external-internal air intakes and the

chimney flue at least once a year, arranging for

them to be cleaned.

• During use, the metal parts and the glass reach

Operation Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

high temperatures. For all loading, adjustment or

ash cleaning operations, use the insulated glove

provided.

• Never leave children unattended near the insert

when it is in use.

• The risk of burns from contact with hot surfaces

is very high.

• In the event of poor weather conditions for

insert use (low pressure, moderate

temperatures, wind) back draught may occur in

the chimney flue. If this occurs, use a small

quantity of paper to heat the chimney flue and

restore normal draught. Afterwards, proceed

with normal product lighting.

5.4. FORCED VENTILATION OPERATION for the

SMARTBOX MODELS

The insert is equipped with two internal fans for forced propagation of

the air inside the cavities of the product. The fans are internally

mounted on the lower part of the insert structure.

The flow of hot air created by these fans is very slight in order

to keep the temperature of the air coming out of the outlet

very high and promote convection heating.

Using the control button located on the lower front panel

is possible to select the desired operation mode:

• Button on I = MANUAL operation

• Button on II = AUTOMATIC operation.

IT IS NOT POSSIBLE TO SWITCH THE VENTILATION

OFF IF THE INSERT IS ON; this is to prevent high

temperatures from damaging the structure.

(figure 10),

it

Fan control button.

Chapter 5

page

30

5.4.1. Manual operation

When the switch is positioned on I, the fans are always on, regardless

of whether or not there is a fire inside the mouth of the insert.

To switch the ventilation off, when the fire is out

, the switch must be

positioned on II; in fact, in this case the internal probe, if it is not at

temperature (~50°C), will not allow operation of the fans.

5.4.2. Automatic operation

When the switch is positioned on II the fans switch on/off exclusively

when the temperature of the probe is higher/lower than

50/60°C.

Operation Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

SmartBox panel setscrews

INSTALLATION AND USE MANUAL

The probe has a high setting because it is designed to operate as a

probe for switching off the ventilation rather than a probe for

lighting. In fact, it is more convenient that the fans switch off

automatically when you are not near the insert rather than at the

beginning when it is still carrying out the initial lighting.

The temperature probe is located behind the On button; it is easily

accessible and can be checked by disassembling the front panel

(SmartBox) or taking off the fan box (Climasystem) by first removing

the screws that secure it.

To check that the probe works properly, position the button

on II, heat the probe with a hair dryer and wait for the fans

to switch off. In this manner you can check that the probe is

intact.

Never perform this check by subjecting the probe

directly to open flames (cigarette lighter, matches,

etc.) since this could irreparably damage the probe.

If the reaction times of the probe are too long, then you should check

why the structure takes a long time to increase its temperature.

Normally this phenomenon is caused by unsuitable wood or wood with

a low heat yield (see section

“4.10 Choice of fuel”

) or because the

performance of the chimney flue does not allow suitable discharge of

the fumes and a correct combustion.

Chapter 5

page

Climasystem ventilation box setscrew

31

5.5. SMARTBOX F80 VN NATURAL VENTILATION

The insert can also operate by natural convection, which means that

the flow of hot air can pass through the entire structure even without

the aid of fans. The Smartbox F80VN maintains as a hot air outlet the

two fins located above the fire door

(figure 6)

from which a natural air

flow will emerge at high temperatures that will be uniformly dispersed

throughout the room.

5.6. FORCED VENTILATION OPERATION for the CLIMASYSTEM MODELS

The only substantial difference between the ventilation of the

Climasystem and that of the Smartbox is represented by the fact that

the Climasystem model has three fans which are more powerful and

that the button has three positions instead of two.

The operating concept, on the other hand, is the same for the

two models.

• Position I = MANUAL operation

• Position 0 = OFF

• Button on II = AUTOMATIC operation.

5.7. FORCED VENTILATION OPERATION for the SUPERCLIMA MODELS

5.7.1. FC 715 control unit operation

The device allows the speed of the fan, which is controlled by the radio

remote control, to be regulated in one of two modes:

Operation Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL

MANUAL The fan (5) runs at the set speed regardless of the

probe.

AUTOMATIC The fan (5) runs at the set speed with the consent of

the probe.

5.7.1.1. Radio remote control

The radio remote control has 4 buttons with which it is possible to

perform the following operations:

• On/off (blue button)

• Change operation mode from manual to automatic and vice

versa (red button)

• Variation of the 4 speeds of the fan (yellow buttons)

5.7.1.2. Switching on and off

SWITCHING ON: Prolonged pressure on the blue button of the

radio remote control switches on the fan at the

first speed in MANUAL mode. The control unit

emits one short beep that identifies the1

speed in manual mode.

SWITCHING OFF: Prolonged pressure on the blue button of the

radio remote control puts the device in STAND-

BY, which is signalled by 1 very long beep,

and stops the fan.

st

Chapter 5

page

32

5.7.1.3. Manual mode

In a predefined manner at the switch-on using the ON/OFF button or

through a simple click on the red MAN/AUT button, the system goes

into MANUAL mode. This mode can be recognized by the fact that all

the sound signals emitted by the control unit in this state are

short beeps and the fan is always on, regardless of the

temperature.

The yellow buttons + and - can be used to increase/decrease the fan

speed from the 1

responds with a number of beeps corresponding to the selected speed:

st

to the 4th speed and vice versa. The control unit

1st Speed = 1 short BEEP

nd

Speed = 2 short BEEPS

2

rd

Speed = 3 short BEEPS

3

th

Speed = 4 short BEEPS

4

Regardless of whether the insert is on or off, the ventilation switches

on and emits air according to the set speed.

5.7.1.4. Automatic mode

Once the ventilation has been switched on in manual mode, simply

pressing the red MAN/AUT button cause the device to go into

AUTOMATIC mode. This mode can be recognized by the fact that all

the sound signals emitted by the control unit in this state are

long beeps.

Operation Technical service – MCZ S.p.A. all rights reserved - Reproduction prohibited

INSTALLATION AND USE MANUAL