Page 1

Installation and Maintenance Manual IM 1033-3

Group: Chillers

Part Number: 331499601

Date: July 2012

Supersedes: May 2012

MagnitudeMagnetic Bearing Centrifugal Chillers

Model WME

400 to 700 tons (1400 to 2461 kW)

3/60/460-575

R-134a

© 2012 McQuay International

Page 2

Note: The unit shown is for the default configuration; your unit may be configured differently. Refer to your selection for configuration.

Page 3

Contents

©2012 McQuay International. Illustrations and data cover the Daikin McQuay product at the time of publication and we reserve

the right to make changes in design and construction at anytime without notice. ™® The following are trademarks or registered

trademarks of their respective companies: BACnet from ASHRAE; L

ONMARK, LonTalk, LONWORKS, and the LONMARK logo are

managed, granted and used by L

ONMARK International under a license granted by Echelon Corporation; Modbus from Schneider

Electric; MicroTech E, Open Choices from McQuay International; LEED from the U.S. Green Building Council.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

System Water Volume . . . . . . . . . . . . . . . . . . . 5

Water Piping . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Relief Valves . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chiller Identification. . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electrical Notes . . . . . . . . . . . . . . . . . . . . . . . 14

Field Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . 15

Dimension Drawings . . . . . . . . . . . . . . . . . . . . . . . 16

Safety labels used in this manual:

Cautions indicate potentially hazardous situations, which can result in personal injury or equipment

damage if not avoided.

Warnings indicate potentially hazardous situations, which can result in property damage, severe

personal injury, or death if not avoided.

Dangers indicate a hazardous situation which will result in death or serious injury if not avoided.

Standard Head Connection Dimensions . . . . 27

Marine Water Box Dimensions . . . . . . . . . . . 28

Optional External Harmonic Filter Dimensions 29

Physical Data & Weights. . . . . . . . . . . . . . . . . . . . 31

Lifting and Mounting Weights . . . . . . . . . . . . 31

Physical Data - Evaporator . . . . . . . . . . . . . . 32

Physical Data - Condenser . . . . . . . . . . . . . . 32

Refrigeration Diagram . . . . . . . . . . . . . . . . . . . . . . 33

Optional External Harmonic Filter . . . . . . . . . . . . 34

Optional External Harmonic Filter . . . . . . . . . 34

Startup, Operation, and Storage . . . . . . . . . . . . . 37

Long Term Storage . . . . . . . . . . . . . . . . . . . . 39

CAUTION

WARNING

DANGER

Page 4

Introduction

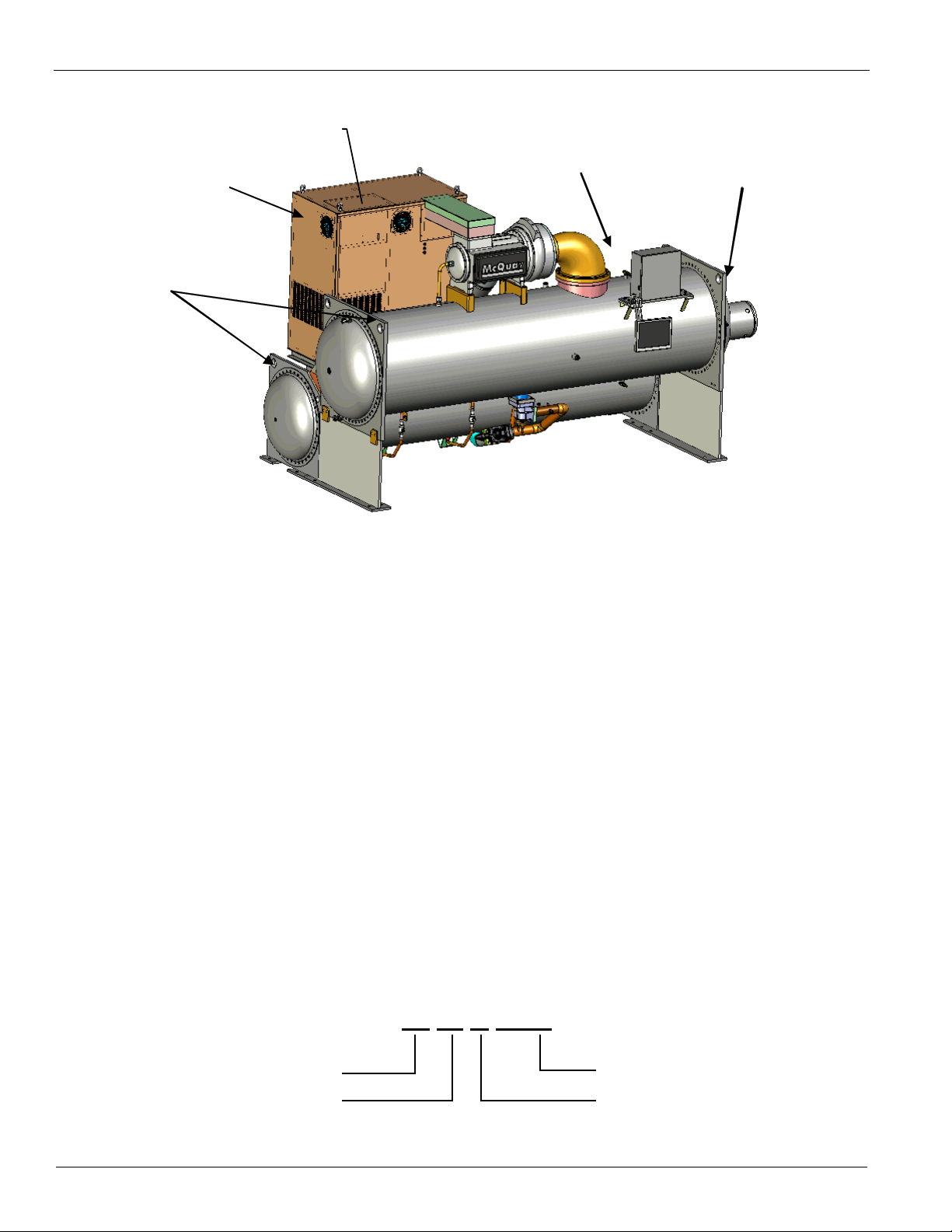

Lifting Points

Lifting P oint

Lifting Point (Outside

Corner Hidden)

VFD Power

Panel

Power Cable Entry

Note: This drawing is for general reference only. Refer to dimension drawings for actual location of components.

W M E 0500

Water-cooled

Magnetic Bearing

Vintage

Chiller Model

Introduction

Figure 1: Required Lifting Arrangement

General Description

Daikin McQuay Magnitude model WME frictionless

centrifugal chillers are complete, self-contained, automatically

controlled fluid chilling units. Each unit is completely

assembled and factory tested before shipment. Model WME is

cooling-only.

Each Magnitude Model WME unit features one compressor

connected to a condenser and evaporator. The chillers use

refrigerant R-134a to reduce the size and weight of the

package compared to negative pressure refrigerants and since

R-134a operates at a positive pressure over the entire operation

range, no purge system is required. The controls are pre-wired,

adjusted and tested. Only normal field connections such as

piping, electrical and interlocks, etc. are required, thereby

simplifying installation and increasing reliability. Most

necessary equipment protections and operating controls are

factory-installed in the control panel.

The chillers are designed for indoor, non-freezing locations. If

indoor freezing temperatures are possible, special procedures

Figure 2: Nomenclature

described in this manual must be followed to drain the unit.

Outdoor locations require a special weatherproof design. For

WME chillers selected with optional Retrofit Knockdown,

refer to IM Knockdown, available on www.daikinmcquay.com

for detailed dimensions and installation instructions.

Application

The procedures presented in this manual apply to standard

Model WME chillers. Refer to the Operating Manual, OMM

1034 for detailed information about chiller operation and the

MicroTech-E unit controller.

All Daikin McQuay centrifugal chillers are factory tested prior

to shipment and must be initially started at the job site by a

factory trained McQuay service technician. Failure to follow

this startup procedure can affect the equipment warranty.

The standard limited warranty on this equipment covers parts

that prove defective in material or workmanship. Specific

details of this warranty can be found in the warranty statement

furnished with the equipment.

4 IM 1033-3

Page 5

Installation

Installation

Installation

Receiving and Handling

The unit should be inspected immediately after receipt for

possible damage.

All Daikin McQuay centrifugal water chillers are shipped FOB

factory and all claims for handling and shipping damage are

the responsibility of the consignee.

Insulation corners from the evaporator's rigging hole locations

are shipped loose and should be glued in place after the unit is

finally placed. Neoprene vibration pads are also shipped loose.

Check that these items have been delivered with the unit.

If so equipped, leave the shipping skid in place until the unit is

in its final position. This will aid in handling the equipment.

Extreme care must be used when rigging the equipment to

prevent damage to the control panels or refrigerant piping. See

the certified dimension drawings included in the job submittal

for the center of gravity of the unit. Consult the local Daikin

McQuay sales office for assistance if the drawings are not

available.

The unit can be lifted by fastening the rigging hooks to the

four outside corners of the unit where the rigging eyes are

located. Lengthwise and crossway spreader bars must be used

between the rigging lines to prevent damage to the control

panels, piping and especially the large Variable Frequency

Drive (VFD) power panel located at one end of the unit. See

Figure 1, page 4.

outside edge of the feet. Most Model WME units have six

mounting feet although only the outer four are required. Six

pads are shipped and the installer can place pads under the

middle feet if desired.

Mounting

Make sure that the floor or structural support is adequate to

support the full operating weight of the unit.

It is usually not necessary to bolt the unit to the mounting slab

or framework; but should this be desirable, 1 1/8" (28.5 mm)

mounting holes are provided in the unit support at the four

corners.

CAUTION

Note: Units are shipped with refrigerant valves closed to isolate

the refrigerant for shipment. Valves must remain closed until

start-up by the McQuay technician.

Nameplates

There are several identification nameplates on the chiller:

"The unit nameplate is located on the side of the VFD panel.

This plate also lists the unit refrigerant charge, electrical data

and the unit model number and serial number, which should be

used when communicating with McQuay International.

"Vessel nameplates are located on the evaporator and

condenser. Along with other information, they have a National

Board Number (NB) and serial number, either of which

identifies the vessel (but not the entire unit).

Location and Mounting

The unit must be mounted on a level concrete or steel base and

must be located to provide service clearance at one end of the

unit for possible removal of evaporator tubes and/or condenser

tubes. The length of the vessel should be allowed at one end

for this purpose. Doors or removable wall sections can be

utilized for tube clearance. Evaporator and condenser tubes are

rolled into the tube sheets to permit replacement if necessary.

Minimum clearance at all other points, including the top, is 3

feet (1 meter) unless greater clearance is required by other

codes or job conditions. The National Electric Code (NEC)

can require four feet or more clearance in and around electrical

components and must be checked.

Location

The WME chillers are intended only for installation in an

indoor or weather protected area consistent with the NEMA 1

rating on the chiller, controls, and electrical panels. Equipment

room temperature for operating and standby conditions is 40°F

to 122°F (4.4°C to 50°C).

Vibration Pads

The shipped-loose neoprene vibration pads should be located

under the corners of the unit (unless the job specifications state

otherwise). They are installed to be flush with the sides and

"A compressor nameplate is located on the compressor itself

and contains identification numbers.

System Water Volume

All chilled water systems need adequate time to recognize a

load change, respond to that load change and stabilize, without

undesirable short cycling of the compressors or loss of control.

In air conditioning systems, the potential for short cycling

usually exists when the building load falls below the minimum

chiller plant capacity or on close-coupled systems with very

small water volumes.

Some of the things the designer should consider when looking

at water volume are the minimum cooling load, the minimum

chiller plant capacity during the low load period and the

desired cycle time for the compressors.

Assuming that there are no sudden load changes and that the

chiller plant has reasonable turndown, a rule of thumb of

"gallons of water volume equal to two to three times the

chilled water gpm flow rate" is often used.

A properly designed storage tank should be added if the

system components do not provide sufficient water volume.

Note: Water volumes can be found in the Physical Data tables

on page 27.

IM 1033-3 5

Page 6

Installation

30

35

40

45

50

55

60

65

0 102030405060708090100

ECWT (°F)

Percent Load

46°F LChW T

44°F LChW T

42°F LChW T

Bypass,MildWeatherOperation

Bypass,MildWeatherOperation

Condenser Water Temperature

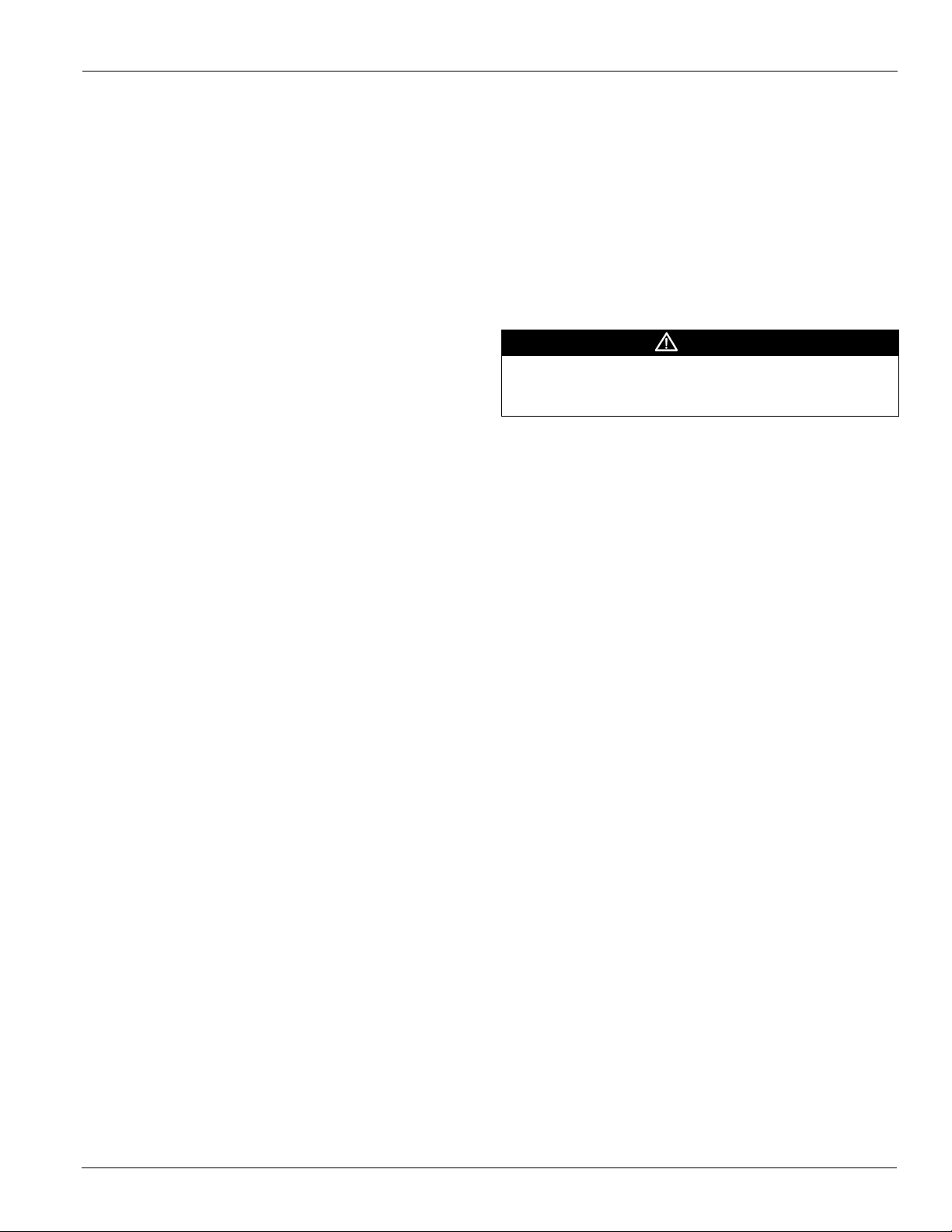

Figure 3: MODEL WME Minimum Entering Condenser

Water Temperature (EXV) (10 F Range at Full Load)

When the ambient wet bulb temperature is lower than design,

the entering condenser water temperature of Magnitude model

WME chillers can be lowered to improve chiller performance.

Chillers can start with entering condenser water temperatures

as low as 40°F (4.4°C). For short periods of time during

startup, the entering condenser water temperature can even be

lower than the leaving chilled water temperature.

Magnitude model WME chillers are equipped with electronic

expansion valves (EXV) and will run with entering condenser

water temperatures as low as shown in Figure 2 or as

calculated from the following equation on which the curves are

based:

MECWT = 5.25+(LWT)-0.75*DTFL*(PLD/100)+14 *(PLD/100)2

Figure 4 illustrates two temperature-actuated tower bypass

arrangements. The "Cold Weather" scheme provides better

startup under cold ambient air temperature conditions. The

bypass valve and piping are indoors and thus warmer, allowing

for warmer water to be immediately available to the condenser.

The check valve may be required to prevent air at the pump

inlet.

Figure 4: Possible Bypass Arrangements

Where:

MECWT = Min entering condenser water temperature

LWT = Leaving chilled water temperature

DTFL = Chilled Water Delta-T at full load

PLD = The percent chiller load point to be checked

For example; at 44°F LWT, 10°F Delta-T at full load, and 50%

full load operation, the entering condenser water temperature

could be as low as 49°F. This provides excellent operation

with water-side economizer systems.

Depending on local climatic conditions, using the lowest

possible entering condenser water temperature may be more

costly in total system power consumed than the expected

savings in chiller power would suggest, due to the excessive

fan power required.

In this scenario, cooling tower fans would continue to operate

at 100% capacity at low wet bulb temperatures. The trade-off

between better chiller efficiency and fan power should be

analyzed for best overall system efficiency. McQuay's Energy

Analyzer program can optimize the chiller/tower operation for

specific buildings in specific locales.

Even with tower fan control, some form of water flow control,

such as tower bypass, is recommended.

6 IM 1033-3

Condenser water temperature control

The standard MicroTech controller is capable of three stages of

tower fan control plus an analog control of either a three-way

tower-bypass valve or variable speed tower-fan motor. Stages

are controlled from condenser-water temperature. The threeway valve can be controlled to a different water temperature or

track the current tower stage. This allows optimum chilled

water plant performance based upon specific job requirements.

Pumps

The condenser water pump(s) must be cycled off when the last

compressor of the system cycles off. This will keep cold

condenser water from migrating refrigerant to the condenser.

Cold liquid refrigerant in the condenser can make start-up

difficult. In addition, turning off the condenser water pump(s)

when the chillers are not operating will conserve energy.

Include thermometers and pressure gauges at the chiller inlet

and outlet connections and install air vents at the high points of

piping. Where noise and vibration are critical and the unit is

Page 7

Installation

mounted on spring isolators, flexible piping and conduit

connections are necessary.

Variable Fluid Flow Rates and Tube Velocities

Many chiller system control and energy optimization strategies

require significant changes in evaporator and condenser water

flow rates. The Magnitude model WME chiller line is

particularly well suited to take full advantage of these energy

saving opportunities provided that the maximum and

minimum fluid flow rates are taken into consideration for a

specific application. The sales engineer has the flexibility to

use different combinations of shell size, number of tubes, and

pass arrangements to select the optimum chiller for each

specific application.

Both excessively high and excessively low fluid flow rates

should be avoided. Excessively high fluid flow rates and

correspondingly high tube velocities will result in high fluid

pressure drops, high pumping power, and potentially tube

corrosion and or tube corrosion damage. Excessively low fluid

flow rates and correspondingly low velocities should also be

avoided as they will result in poor heat transfer, high

compressor power, sedimentation and tube fouling.

Excessively high and low tube velocities can be particularly

problematic and damaging in open loop systems.

Rates of Fluid Flow Change

If it is decided to vary the evaporator water flow rate the rate

of change should not exceed 50% per minute and should not

exceed the minimum or maximum velocity limits as

determined by the Daikin McQuay chiller software program.

Vibration Mounting

The Magnitude model WME chillers are almost vibration-free.

Consequently, floor mounted spring isolators are not usually

required. Rubber mounting pads are shipped with each unit. It

is wise to continue to use piping flexible connectors to reduce

sound transmitted into the pipe and to allow for expansion and

contraction.

A properly designed storage tank should be added if the

system components do not provide sufficient water volume.

System Analysis

The McQuay Energy Analyzer program is an excellent tool to

investigate the entire system efficiency, quickly and accurately.

It is especially good at comparing different system types and

operating parameters. Contact your local Daikin McQuay sales

office for assistance on your particular application.

Water Piping

Vessel Drains at Start-up

Unit vessels are drained of water in the factory and are shipped

with the drain plugs in the heads removed and stored in the

control panel or with open ball valves in the drain hole. Be

sure to replace plugs or close the valves prior to filling the

vessel with fluid.

Evaporator and Condenser Water Piping

All evaporators and condensers come standard with ANSI/

AWWA C-606 grooved nozzles (also suitable for welding), or

optional flange connections. The installing contractor must

provide matching mechanical connections or transitions of the

size and type required.

CAUTION

If welding is to be performed on the mechanical or flange

connections, remove temperature sensors and thermal

dispersion flow switch from the nozzles to prevent damage to

those components. Also properly ground the unit or severe

damage to the MicroTech E unit controller can occur.

Water pressure gauge connection taps and gauges must be

provided in the field piping at the inlet and outlet connections

of both vessels for measuring the water pressure drops. The

pressure drops and flow rates for the various evaporators and

condensers are job specific and the original job documentation

can be consulted for this information.

System Water Volume

All chilled water systems need adequate time to recognize a

load change, respond to that load change and stabilize, without

undesirable short cycling of the compressors or loss of control.

In air conditioning systems, the potential for short cycling

usually exists when the building load falls below the minimum

chiller plant capacity or on close-coupled systems with very

small water volumes.

Some of the things the designer should consider when looking

Be sure that water inlet and outlet connections match certified

drawings and stenciled nozzle markings. The condenser is

connected with the coolest water entering at the bottom to

maximize subcooling.

CAUTION

When common piping is used for both heating and cooling

modes, care must be taken to provide that water flowing

through the evaporator cannot exceed 110°F which can cause

the relief valve to discharge refrigerant or damage controls.

at water volume are the minimum cooling load, the minimum

chiller plant capacity during the low load period and the

desired cycle time for the compressors.

The piping must be supported to eliminate weight and strain on

the fittings and connections. Piping must also be adequately

insulated. If a pump strainer is not close to a vessel, a

Assuming that there are no sudden load changes and that the

chiller plant has reasonable turndown, a rule of thumb of

cleanable 20-mesh water strainer must be installed in the water

inlet line. Sufficient shutoff valves must be installed to permit

"gallons of water volume equal to two to three times the

chilled water gpm flow rate" is often used.

IM 1033-3 7

Page 8

Installation

FactoryMountedFlowSwitch

Paddle‐typeFlowSwitch

draining the water from the evaporator or condenser without

draining the complete system.

CAUTION

Freeze Notice: Neither the evaporator nor the condenser is

self-draining; Both must be blown out to help avoid damage

from freezing.

The piping should also include thermometers at the inlet and

outlet connections and air vents at the high points.

The water heads can be interchanged (end for end) so that the

water connections can be made at either end of the unit. If this

is done, new head gaskets must be used and control sensors

relocated.

In cases where the water pump noise can be objectionable,

vibration isolation sections are recommended at both the inlet

and outlet of the pump. In most cases, it will not be necessary

to provide vibration eliminator sections in the condenser inlet

and outlet water lines. But they can be required where noise

and vibration are critical.

Mechanical Clamped Couplings

Use the following steps when installing clamped couplings:

1.Check for smooth pipe between the pipe end and the groove.

Remove any indentations, projections, or weld seams. Failure

to do this can result in a leaking joint.

bleed-off is operating. Atmospheric air contains many

contaminants, which increases the need for water treatment.

CAUTION

The use of untreated water will result in corrosion, erosion,

slime buildup, scaling, or algae formation. Water treatment

service must be used. McQuay International is not responsible

for damage or faulty operation from untreated or improperly

treated water.

Special care must be taken when utilizing open system water

that is usually not treated (such as lakes, rivers, and ponds).

Special tube and water head material may be required to

reduce damage from corrosion.

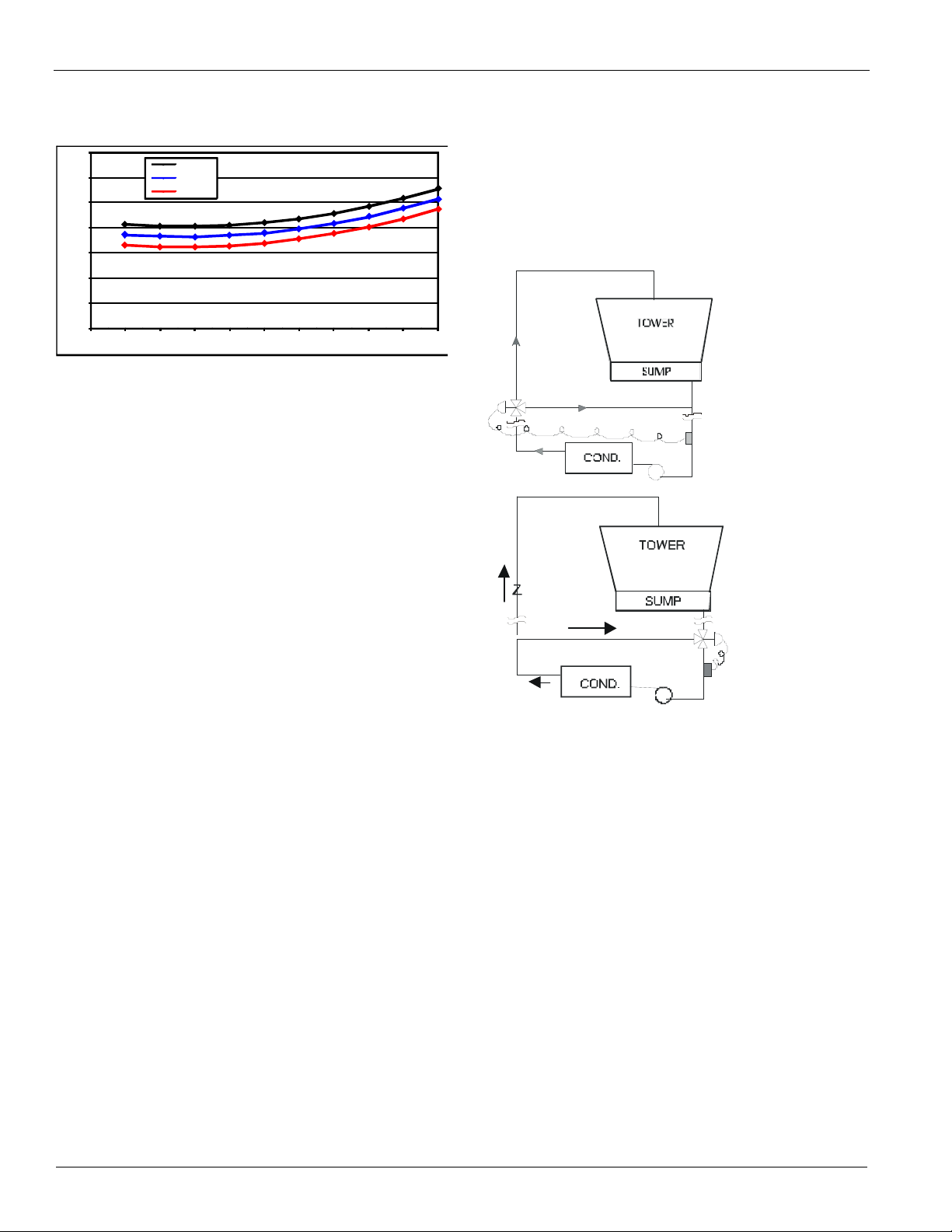

Flow Switches

Factory-mounted thermal dispersion flow switches are

provided as standard..

An additional paddle-type flow switch can be installed in the

vessel outlet piping as an added precaution to signal the

presence of adequate water flow to the vessels before the unit

can start. They also serve to shut down the unit in the event

that water flow is interrupted to guard against evaporator

freeze-up or excessive discharge pressure. They are not

necessary for unit operation.

Figure 5: Flow Switch Options

2.Apply a thin coat of Victaulic or silicon lubricant to the

gasket lips and exterior.

3.Position the gasket over the pipe end without overhanging

the pipe.

4.Join the pipes together and slide the gasket into position,

centering it between the groves.

5.Install the housing halves over the gasket, making sure that

the housing' keys engage the groves on both pipes.

6.Install the bolts and thread the nuts on hand tight. Make sure

that the oval heads of the bolts seat properly in the bolt holes.

7.Tighten the nuts evenly by alternating sides until metal to

metal contact is made on the housing bolt pads. Make sure that

the housing keys completely engage the pipe grooves.

Tower Filtering and Treatment

Owners and operators must be aware that if the unit is

operating with a cooling tower, cleaning and flushing the

cooling tower is required. Make sure tower blow-down or

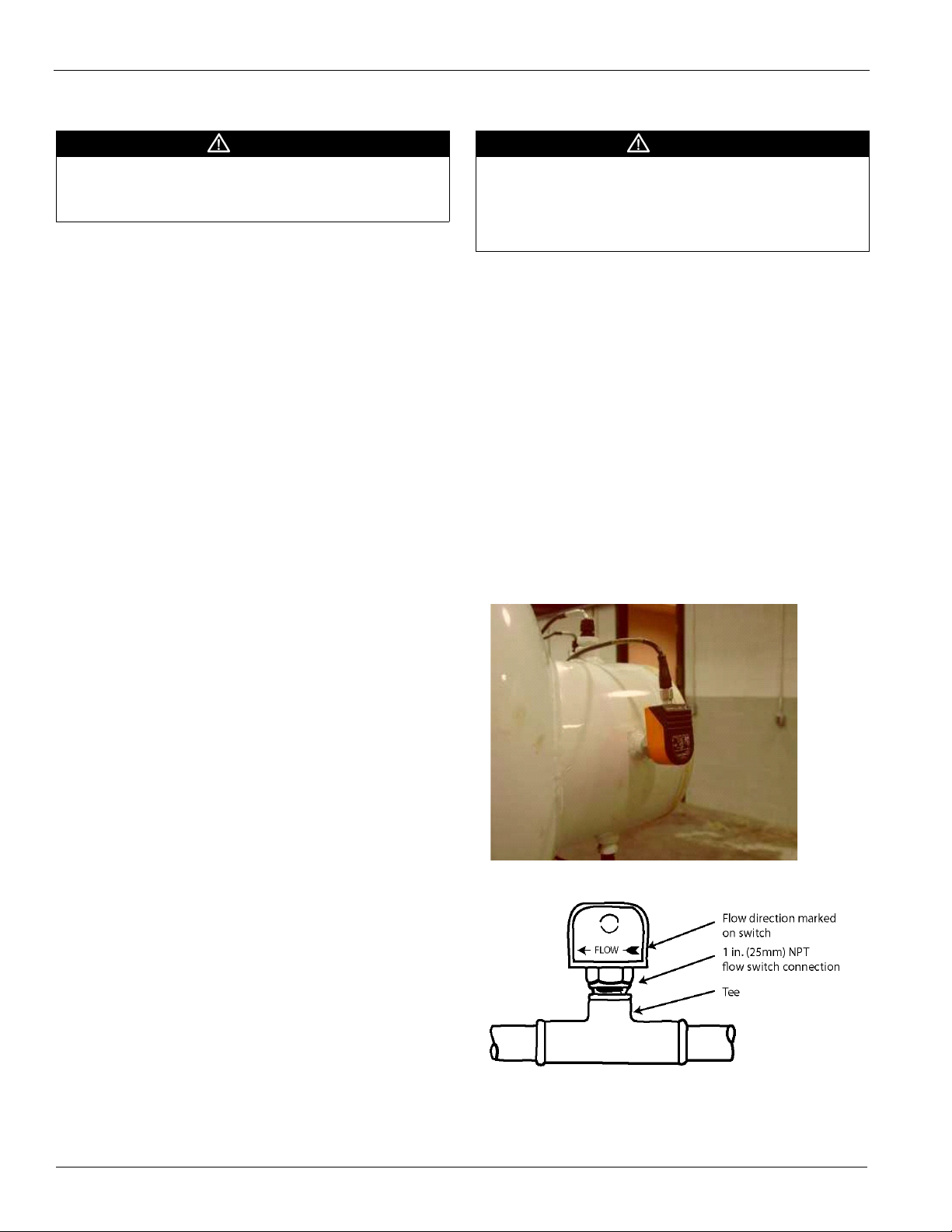

If field-mounted flow switches (normally paddle-type) are

being used, electrical connections in the Unit Control Panel

must be made per the field wiring diagram on page 14. The

8 IM 1033-3

Page 9

Installation

normally open contacts of the flow switch must be wired

between the terminals. Flow switch contact quality must be

separate conduit from any high voltage conductors (115 VAC

and higher).

suitable for 24 VAC, low current (16ma). Wire switches in

Pipe Size (NOTE)

Min.

Adjst.

Max.

Adjst.

Note 1: A segmented 3-inch paddle (1, 2, and 3 inches) is furnished mounted, plus a 6-inch paddle loose.

Note 2: Flow rates for a 2-inch paddle trimmed to fit the pipe.

Note 3: Flow rates for a 3-inch paddle trimmed to fit the pipe.

Note 4: Flow rates for a 3-inch paddle.

Note 5: Flow rates for a 6-inch paddle

Note 6: There is no data for pipe sizes above 8-inch. A switch minimum setting should provide protection against no flow and close well before design flow is

Flow

No Flow

Flow

No Flow

reached.

Freeze Notice: Neither the evaporator nor the condenser is

self-draining; Both must be blown out to help avoid damage

from freezing.

inch 1 1/4 1 1/2 2 2 1/2 3 4 5 6 8

mm 32 (2) 38 (2) 51 63 (3) 76 102 (4) 127 (4) 153 (4) 204 (5)

gpm

Lpm

gpm

Lpm

gpm

Lpm

gpm

Lpm

5.8 7.5 13.7 18.0 27.5 65.0 125.0 190.0 205.0

1.3 1.7 3.1 4.1 6.2 14.8 28.4 43.2 46.6

3.7 5.0 9.5 12.5 19.0 50.0 101.0 158.0 170.0

0.8 1.1 2.2 2.8 4.3 11.4 22.9 35.9 38.6

13.3 19.2 29.0 34.5 53.0 128.0 245.0 375.0 415.0

3.0 4.4 6.6 7.8 12.0 29.1 55.6 85.2 94.3

12.5 18.0 27.0 32.0 50.0 122.0 235.0 360.0 400.0

2.8 4.1 6.1 7.3 11.4 27.7 53.4 81.8 90.8

CAUTION

Field Insulation Guide

Factory insulation is an available option (0.75" or 1.5"). If

field insulated, the following components should be insulated

to prevent condensation on Magnitude model WME chillers.

The piping should also include thermometers at the inlet and

outlet connections and air vents at the high points.

The water heads can be interchanged (end for end) so that the

water connections can be made at either end of the unit. If this

is done, new head gaskets must be used and control sensors

relocated.

In cases where the water pump noise can be objectionable,

vibration isolation sections are recommended at both the inlet

and outlet of the pump. In most cases, it will not be necessary

to provide vibration eliminator sections in the condenser inlet

and outlet water lines. But they can be required where noise

and vibration are critical.

System Pumps

Operation of the chilled water pump can be to:

1 Cycle the pump with the unit enable

2 Operate continuously

3 Start automatically by a remote source

The cooling tower pump must cycle with the compressor. The

holding coil of the cooling tower pump motor starter must be

rated at 115 volts, 60 Hz, with a maximum volt-amperage

rating of 100. A control relay is required if the voltageamperage rating is exceeded. See the Field Wiring Diagram or

in the cover of control panel for proper connections.

Table 1: Insulation Guide

Evaporator

Motor Cooling

Stator cooling Evaporator Tube

Notes:

1 The discharge line can also be insulated for sound reduction, as an option.

2 The compressor body does not require insulation.

3 Insulation quantity: E3612=129 sq.ft. (12 m

Evaporator Water

Suction Elbow

2

), E3012=115 sq ft. (11 m2).

Expansion valve

VFD cooling

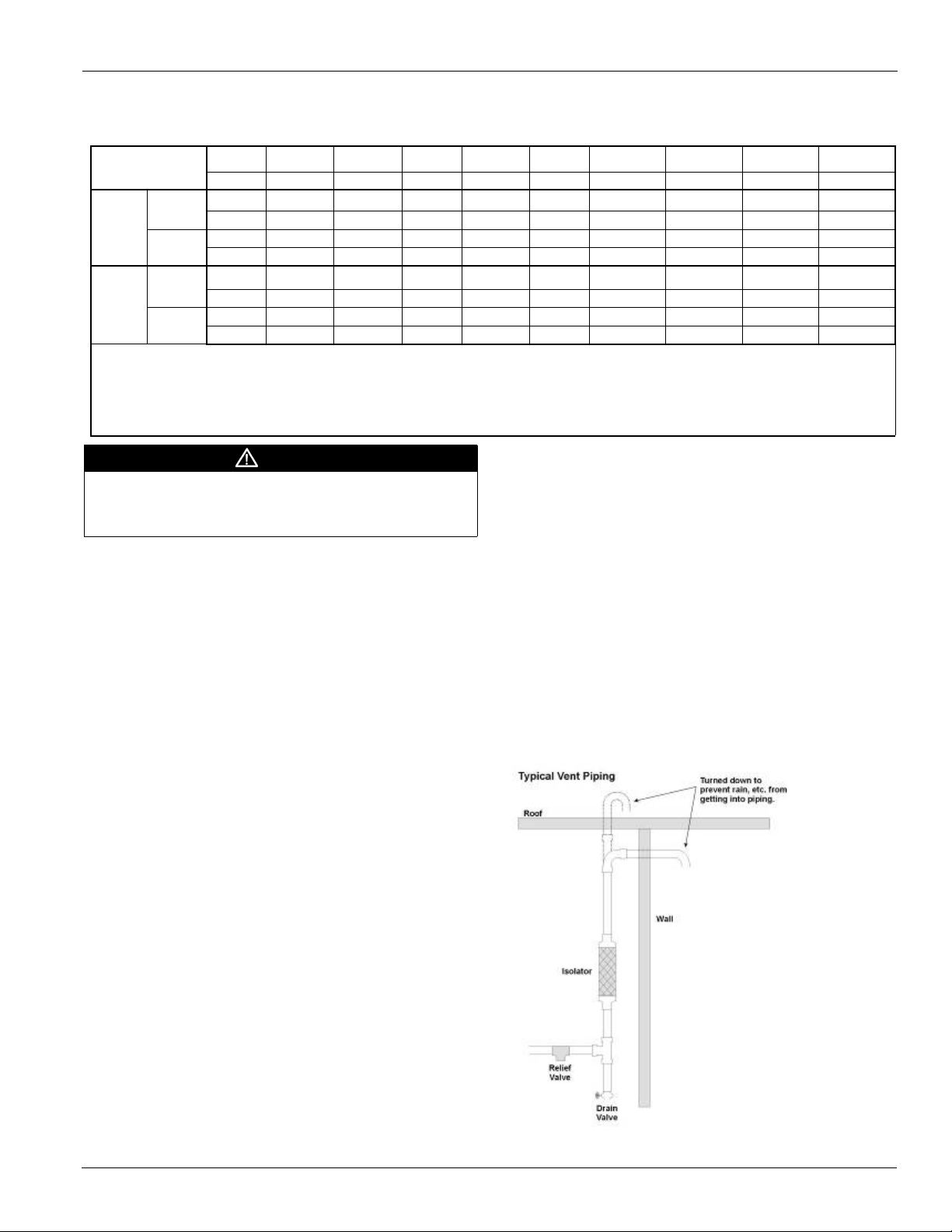

Relief Valves

Figure 6: Typical Vent Piping

All interlock contacts must be rated for no less than 10

inductive amps. The alarm circuit provided in the control

center utilizes 115-volts AC. The alarm used must not draw

more than 10 volt amperes.

IM 1033-3 9

Page 10

Installation

D

Common

DD D

n

1

2

2

22

05

....

.

As a safety precaution and to meet code requirements, each

chiller is equipped with pressure relief valves located on the

condenser and evaporator vessels for the purpose of relieving

excessive refrigerant pressure (caused by equipment

malfunction, fire, etc.) to the atmosphere. Most codes require

that relief valves be vented to the outside of a building, and

this is a desirable practice for all installations. Relief piping

connections to the relief valves must have flexible connectors.

Whenever vent piping is installed, the lines must be run in

accordance with local code requirements; where local codes do

not apply, the latest issue of ANSI/ASHRAE Standard 15 code

recommendations must be followed.

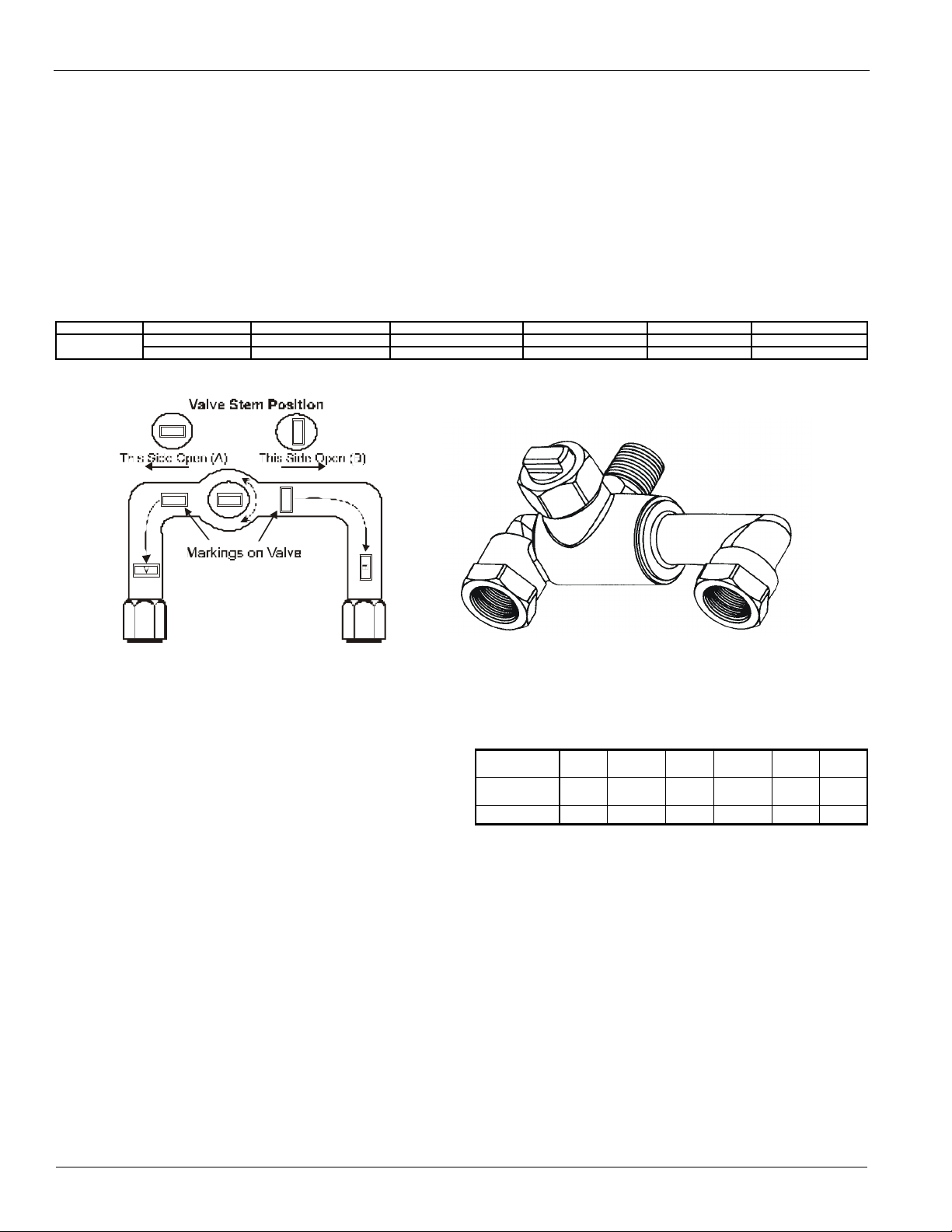

Condensers have two relief valves as a set with a three-way

valve separating the two valves (large condensers will have

two such sets). One valve remains active at all times and the

second valve acts as a standby.

Note: Remove plastic shipping plugs (if installed) from the

inside of the valves prior to making pipe connections.

Table 2: Relief Valve Data

Model Relief Valve Location Pressure Setting Discharge Cap. Conn. Size No. of Valves

WME

Figure 7: Condenser 3-Way Valve

Evaporator Top of Evaporator 200 psi 75.5 lb air/min 1 in. FPT 1

Condenser Top of Condenser 200 psi 75.5 lb air/min 1 in. FPT 2

Refrigerant Vent Piping

Twin relief valves mounted on a transfer valve are used on the

condenser so that one relief valve can be shut off and removed,

leaving the other in operation. Only one of the two is in

operation at any time.

Vent piping is sized for only one valve of the set since only one

can be in operation at a time. In no case would a combination

of evaporator and condenser sizes require more refrigerant

than the pumpdown capacity of the condenser. Condenser

pumpdown capacities are based on the current ANSI/

ASHRAE Standard 15 that recommends 90% full at 90°F

(32°C). To convert values to the older AHRI standard,

multiply pumpdown capacity by 0.888.

Sizing Vent Piping (ASHRAE Method)

Relief valve pipe sizing is based on the discharge capacity for

the given evaporator or condenser and the length of piping to

be run. Discharge capacity for R-134a vessels is calculated

using a complicated equation that accounts for equivalent

length of pipe, valve capacity, Moody friction factor, pipe ID,

outlet pressure and back pressure. The formula, and tables

derived from it, are contained in ASHRAE Standard 15-2001.

Using the ASHRAE formula and basing calculations on the

225 psi design yields a conservative pipe size, which is

summarized in Tabl e 3. The table gives the pipe size required

per relief valve. When valves are piped together, the common

piping must follow the rules set out in the following paragraph

on common piping.

Table 3: Relief Valve Piping Sizes

Equivalent

length (ft)

Pipe Size inch

(NPT)

Moody Factor 0.0209 0.0202 0.0190 0.0182 0.0173 0.0163

2.2 18.5 105.8 296.7 973.6 4117.4

1 1/4 1 1/2 2 2 1/2 3 4

NOTE: A 1-inch pipe is too small for the flow from the valves.

A pipe increaser must always be installed at the valve outlet.

Common Relief Valve Piping

According to ASHRAE Standard 15, the pipe size cannot be

less than the relief valve outlet size. The discharge from more

than one relief valve can be run into a common header, the

area of which cannot be less than the sum of the areas of the

connected pipes. For further details, refer to ASHRAE

Standard 15. The common header can be calculated by the

formula:

The above information is a guide only. Consult local codes

and/or latest version of ASHRAE Standard 15 for sizing data.

10 IM 1033-3

Page 11

Chiller Identification

ater-Cooled C

Unit Size

Single Circuit

Motor Code

M2 – Standard

M3 –

Low THD (WME0500)

Voltage Code, 3/60/480

A – 3/60/ 440V

R – 3/ 60/460V

S – 3/60/480V

Sound Package

Evap: Size, dia (in)

-length (ft)

Evap Tubes: B=Count, E=Type

Evap Heads: 2=Pass, R=Right, A=Conn, Type

Evap Design Press: Ref=200 psi

Waterside: C4=150 psi C5 =300 psi

Leaving Water Temp (x 10)

NOT USED

Cond: Size, dia (in) length (ft)

Cond. Tubes: Type and Count

Heads: 2=Pass, R=Right, A=Conn, Type

Evap Tube Sheet and Head Material

Refrigerant

Compressor Revision

WME 0500S S M2 S S AAB E3612 BE 2RA C4 440 CC Y A C3012 BYLL 2RA C4 1050 CC Y A A 134

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Passes: 1, 2, 3

Handednesss: R-Right; L-Left

Connection: A-Victaulic; B- Flanged; C/E-Marine Waterbox

Evaporator Revision

Passes: 1, 2, 3

Handednesss: R-Right; L-Left

Connection: A-Victaulic; B- Flanged; C/E-Marine Waterbox

Cond Design Press: Ref=200 psi

Waterside: C4=150 psi C5 =300 psi

Max. Leaving Water Temp F (x 10)

Cond. Tube Sheet and Head Material

NOT USED

Compressor Revision

ASME Pressure Vessel Code

M4 –

Low THD (WME0700)

t#$%wFWBQPSBUPSUVCFT

t&'(wFWBQPSBUPSUVCFT

t+,..JYFEFWBQPSBUPSUVCFT

If code begins with:

t-/1wFWBQPSBUPSUVCFT

t"#$wFWBQPSBUPSUVCFT

If code begins with:

Figure 8: Magnitude Code String Chiller Identification

Chiller Identification

W

IM 1033-3 11

hiller

Page 12

Chiller Identification

080 E1 YY EAYYY MBYYYYYY YYYY YY B 1 4 B Y Y 5 1 B A 0500 U Y H Y Y Y Y 2 B

26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52

Refrigerant Weight

Expansion Valve

NOT USED

Controls: MicroTech-E

BAS Card:

MB = Modbus; LY = LONworks; BM= Bacnet

NOT USED

Shell and Head Insulation:

H_ = 3/4” Insulation

3_ = 1.5” Insulation

YY = None

Flow Switch (standard)

Standard Finish

Crating:

4=Shipping Bag/Wood Skid (std.)

Refrigerant:

A - Full Charge

B/N - Holding Charge

Special

Future

Knockdown:

Y-None

1-Type I

2- Type II

3- Type III

Standard/Certied/Witness Test Option

ARI/ETL/CETL Listing

Unit Revision

Chiller Startup (Std on Domestic)

Extended Warranty

Refrigeration Tons

Standard 1st Year Warranty

Future

Future

Future

Future

Refrigerant Warranty

Delayed Start Warranty

Figure 9: Magnitude Code String Chiller Identification

12 IM 1033-3

Page 13

Electrical Data

Wiring, fuse and wire size must be in accordance with the

National Electric Code (NEC).

Important: Voltage unbalance not to exceed 2% with a

resultant current unbalance of 6 to 10 times the voltage

unbalance per NEMA MG-1, 1998 Standard. This is an

important restriction that must be adhered to.

Power Wiring

Power entrance is on top of the enclosure. Remove cover plate

when making hole to avoid entrance of foreign material into

the enclosure.

Power connection lug size is 3/0 AWG - 500kcmil, three

conductors per phase

The ground connection is a stand-off adjacent to the circuit

breaker, marked "MGND". Field provide a 3/8-16 x ¾ in.

screw with a flat washer and lock washer and appropriate "O"

terminal.

CAUTION

Qualified and licensed electricians must perform wiring.

Shock hazard exists.

Electrical Data

CAUTION

Connections to terminals must be made with copper lugs and

copper wire..

Use only copper supply wires with ampacity based on 75°C

conductor rating. (Exception: for equipment rated over 2000

volts, 90°C or 105°C rated conductors should be used).

The VFD nameplate will indicate the RLA setting required in

the MicroTech-E controller. The RLA setting is for the VFD

output amps not the input amps. Follow name plate values for

output RLA.

Power Factor Correction Capacitors

Do not use power factor correction capacitors with WME

chillers. They can cause harmful electrical resonance in the

system. Correction capacitors are not necessary since VFDs

inherently maintain high power factors.

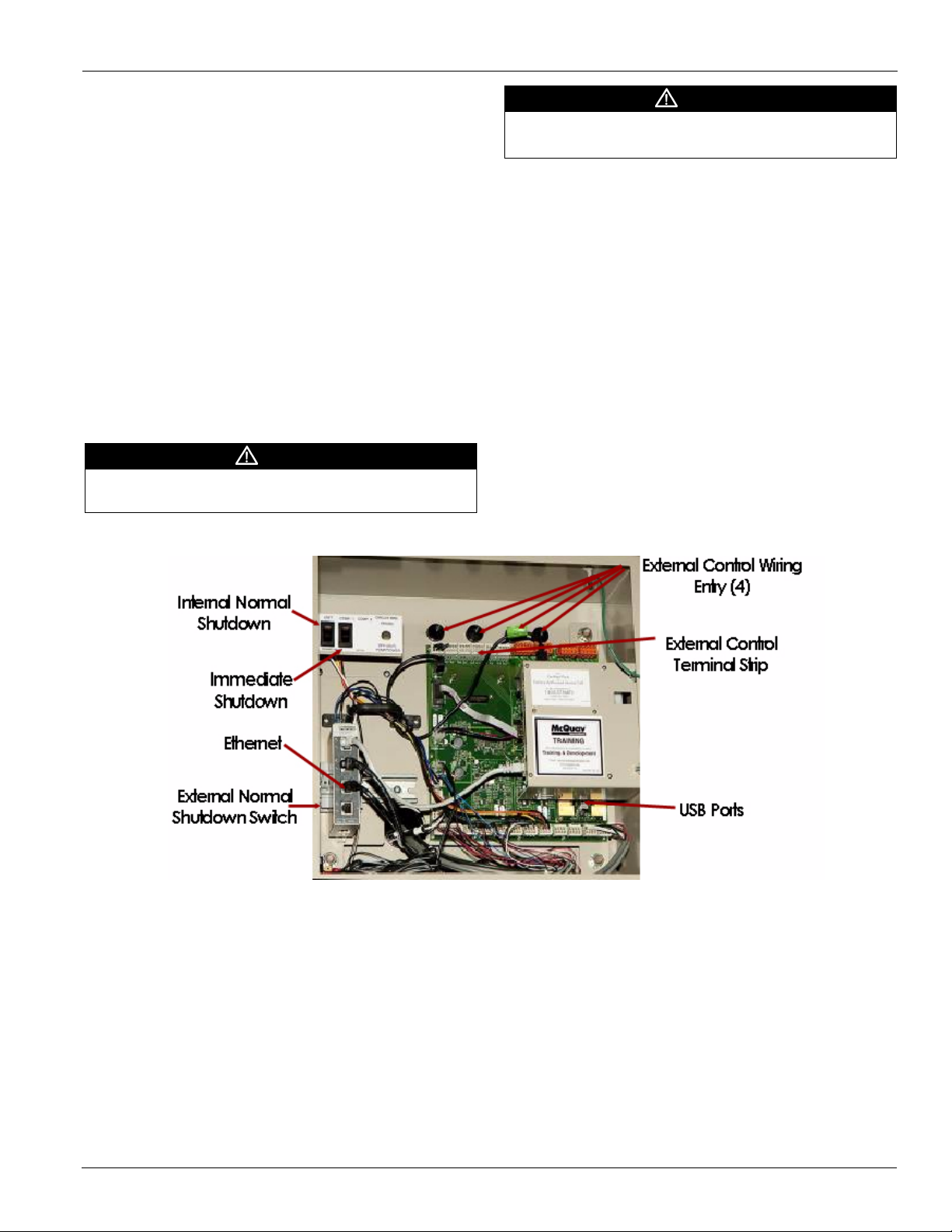

Control Wiring

The control circuit power on Magnitude model WME chillers

is supplied by the unit-mounted VFD.

Figure 10: Unit Control Panel

IM 1033-3 13

Page 14

Electrical Data

Electrical Notes

1 Units are available for 460 or 440 to 480 VAC at 60 Hz.

2 Wiring, fuse and wire size must be in accordance with

the National Electric Code (NEC).

3 Important: Voltage unbalance not to exceed 2%.

Power Wiring

Use only copper supply wires with ampacity based on 75°C

conductor rating. Connections to terminals must be made with

copper lugs and copper wire.

Lug size range is: (3) 3/0 AWG - 500 kc mil.

Power Factor Correction Capacitors

Do not use power factor correction capacitors with(WME

chillers. Doing so can cause harmful electrical resonance in the

system. Correction capacitors are not necessary since VFDs

inherently maintain high power factors

Short Circuit Current Ratings

The standard short circuit rating is 35kA for 460 V. Optional

high short circuit current ratings are available for 65kA, and

100kA with a matching circuit breaker.

The optional circuit breaker must be sized to meet these

ratings.

3-Phase vs. 6-phase Motors

WME 500 motors are designated as M2 or M3.

• "M2 motors are standard 3-phase and the VFD performs

similar to a 6-pulse drive.

• "M3 motors are 6-phase (connected to a 3-phase power

supply) and the VFD performs similar to a 12-pulse drive.

They provide increased protection against harmonic

distortion, but are not required on most applications.

Notes for field wiring diagram

1 All line-side wiring must be in accordance with the NEC

and be made with copper wire and copper lugs only.

2 A customer furnished 24 to 240 Vac power for alarm

relay coil may be connected at J18. Maximum rating of

the alarm relay coil is 25 VA.

3 Remote on/off control of unit can be accomplished by

connecting a set of isolated dry contacts at J25.

4 If field supplied pressure differential flow switches are

used, they must be installed across the vessel and not the

pump. They must provide isolated dry contacts at J27.

5 An optional customer supplied 25 VA maximum coil

rated, chilled water pump relay (one or two) may be

wired as shown. This option will cycle the chilled water

pump in response to chiller demand.

6 The condenser water pump must cycle with the unit. A

customer supplied 25 VA maximum coil rated,

condenser water pump relay (one or two) must be wired

as shown. Units used in a free-cooling application must

have condenser water above 50°F before starting.

7 Optional customer supplied 25 VA maximum coil rated

cooling tower fan relays may be wired as shown. This

option will cycle the cooling tower fans as prescribed by

the tower control set points.

8 External 4-20mA signals can be wired to J23 for leaving

(chilled) water reset and to J26 for demand limit.

WME 700 motors are 6-phase and designated as M4. The VFD

performs similar to a 12-pulse drive.

14 IM 1033-3

Page 15

Field Wiring Diagram

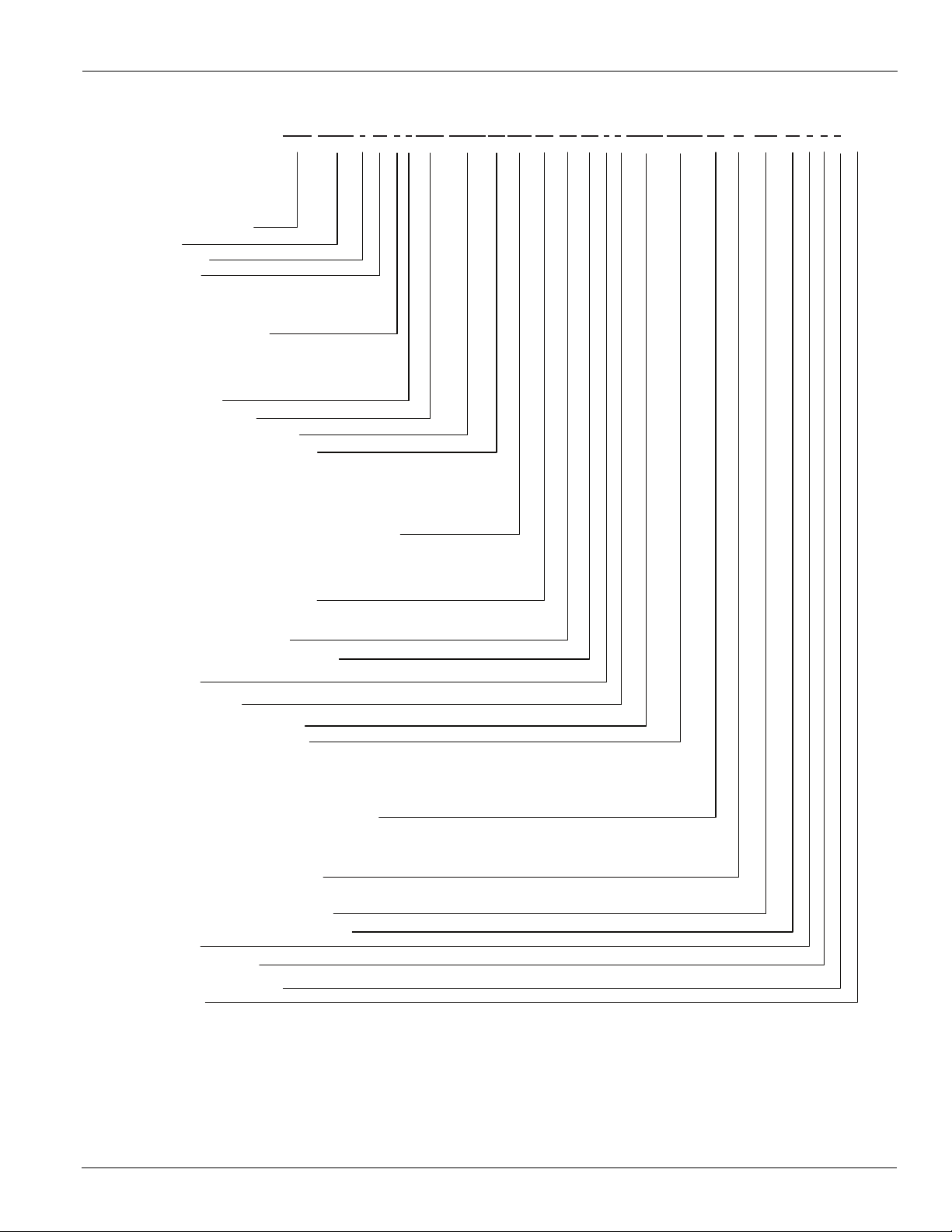

Figure 11: Field Wiring Diagram

Field Wiring Diagram

IM 1033-3 15

Page 16

Dimension Drawings

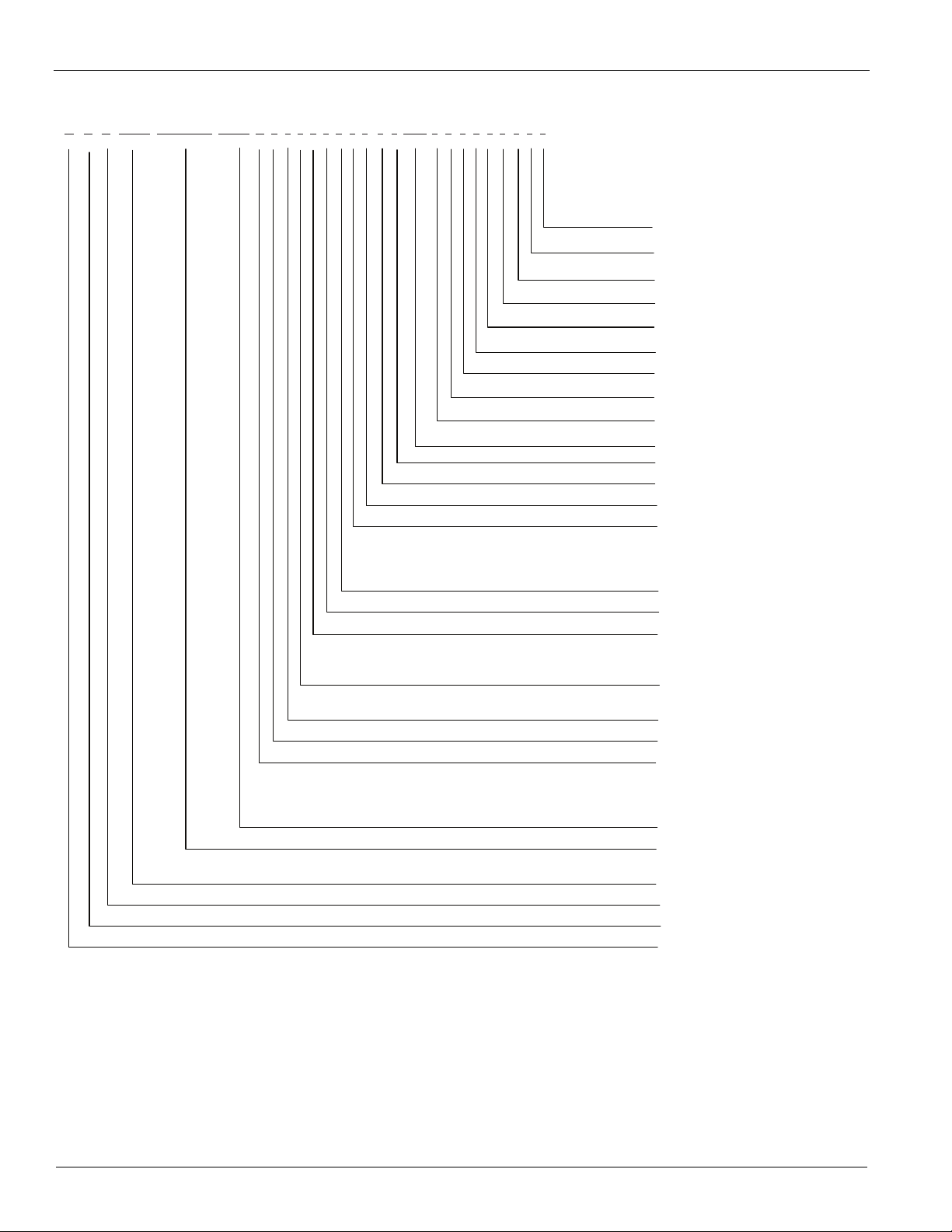

Minimum 14’ Clearance for tube removal

TOP VIEW

Minimum 3’ Clearance

Minimum 3’ Clearance on all sides and top of chiller; Minimum 14’ clearance on one side for tube removal.

Minimum 3’ Clearance

Minimum 3’ Clearance

Dimension Drawings

Drawing Notes

1 All dimensions are in inches [millimeters] unless noted

otherwise.

2 Final connections must allow for 0.5 inch +/- (12.7mm)

manufacturing tolerances.

3 1.00-inch FPT [25.4 mm] evaporator and condenser

relief valves must be piped per ANSI / ASHRAE 15.

Number of relief valves is 1 per evaporator and 2 per

condenser.

4 .375 inch [9 mm] suction nozzle relief valve must be

piped per ANSI / ASHRAE 15.

5 MinimumClearances (See Figure 12):

• Installation layout should be designed by qualified personnel familiar with local codes.

• Allow a minimum of 3 ft. on all for sides and the top

sides of chiller to allow for service access.

• Provide a minimum of 3 ft. clearance in front of chiller

starter panel or according to NEC or local codes.

• Provide a minimum of 14 ft. clearance on one end of the

chiller for tube removal.

6 Electric Panels- Most codes require 48 inches (1219 mm)

clearance in front of control boxes and electrical panels.

Check codes for your location.

7 3.25-inch [83mm] diameter lifting holes are provided.

See installation manual IM 1033 (available on

www.daikinmcquay.com) for lifting instructions.

8 All water connections are given in standard U.S. pipe

sizes. Standard connections are suitable for welding or

victaulic couplings.

Figure 12: Minimum Clearances

9 Unit shown has standard right-hand water connections.

Left-hand connections are available for either vessel. For

right hand evaporator the inlet and outlet nozzles are

reversed. ANSI-flanged connections are available upon

request. When using ANSI-flanged connections add 0.5

inch [13 mm] to each flanged end.

10 Dimensions shown are for units (evaporator / condenser)

with standard design pressures. The waterside design

pressure is 150 PSI {1034 kPa}. Consult the factory for

unit dimensions with higher design pressures.

11 The unit vibration isolator pads are provided for field

installation and when fully loaded are 0.250 inches [6

mm] thick.

12 These values are for units with standard wall thickness

copper tubing only.

13 The shipping skid adds 4.00 inches [105 mm] to the

overall unit height.

14 If main power wiring is brought up through the floor, this

wiring must be outside the envelope of the unit.

15 The unit is shipped with an operating charge of

refrigerant.

16 Optional marine water box connections are available

upon request.

17 To determine the evaporator and condenser tube size,

compare the Code Item Report generated by the selection

program with Figure 3, page 8. Code items 9 and 17 will

give the evaporator and condenser tube sizes,

respectively.

18 When equipped with the factory-mounted harmonic filter

WME 500 units with the M2 motor have the two-door

power panel as shown in Figure 14 and Figure 16.

16 IM 1033-3

Page 17

Dimension Drawings

5.3

133

145.4

3694

5.3

133

170.4

EVAP. (UNIT OVERALL)

4329

169.0

COND.

4292

36.6

COND.

RELIEF

VALVE

931

68.3

EVAP.

RELIEF

VALVE

1734

3

3

5, 8, 9

5, 8, 9

5, 8, 9

FRONT VIEW

X

Y

COND

EVAP

UNIT

CONT.

BOX

6

60.5

VHD

HEIGHT

1537

19.3

489

47.0

1195

69.0

1753

77.0

UNIT O/A

1956

96.8

UNIT

O/A

2460

13.8

349

52.3

1327

68.5

1741

2.5

63

5

5, 11,13

RIGHT VIEW

Z

Y

17.0

433

3.1

80

7.6

193

46.9

1192

13.7

348

148.2

3764

3

3

TOP VIEW

O.I.T.S.

X

Z

LB

LF

RF

RB

148.2

3764

16.0

406

7.2

183

40.3

1023

1.4

TYP.

35

40.1

1019

92.7

2356

4.0

TYP.

102

25.5

646

8.0

TYP.

203

1.13

TYP.

MTG

HOLE

29

77.0

1956

5.1

129

UNIT CONT.

BOX

6, 14

ENVELOPE OF UNIT

14

MOUNTING FEET

X

Z

TOP VIEW

ALL DIMENSIONS ARE IN DECIMAL

INCHES AND [MILLIMETERS]

333904501

DRAWING NUMBER00REV.

This information is accurate at time of

printing. McQuay reserves the right to

change design, specication and product

data without notice. Purchaser must

determine that the equipment is t and

sucient for the job specications. No

change to this data may be made unless

approved in writing by McQuay. McQuay's

Limited Product Warranty applies to all

McQuay equipment.

WME0500 M2: 440V (60Hz), 460V (60Hz),

480V (60Hz)

Figure 13: WME0500 - E3612/C3012 - 2-pass - M2 Standard Motor (60Hz - 440/460/480V) (See page 16 for drawing notes.)

IM 1033-3 17

Page 18

Dimension Drawings

5.3

133

145.4

3694

5.3

133

170.4

EVAP. (UNIT OVERALL)

4329

169.0

COND.

4292

36.6

COND.

RELIEF

VALVE

931

68.3

EVAP.

RELIEF

VALVE

1734

3

3

5, 8, 9

5, 8, 9

5, 8, 9

FRONT VIEW

X

Y

COND

EVAP

UNIT

CONT.

BOX

19.3

489

47.0

1195

69.0

1753

77.0

UNIT O/A

1956

13.8

349

52.3

1327

68.5

1741

2.5

63

60.0

VFD

HEIGHT

1523

96.3

UNIT

O/A

2446

5

5, 11,13

RIGHT VIEW

Z

Y

17.0

433

3.1

80

7.6

193

46.9

1192

13.7

348

148.2

3764

3

3

TOP VIEW

O.I.T.S.

X

Z

LB

LF

RF

RB

148.2

3764

16.0

406

7.2

183

1.4

35

40.1

1019

83.5

2122

4.0

TYP.

102

27.8

707

8.0

TYP.

203

1.13

TYP.

MTG

HOLE

29

77.0

1956

5.1

129

54.0

1372

UNIT CONT.

BOX

6, 14

ENVELOPE OF UNIT

14

MOUNTING FEET

X

Z

TOP VIEW

6

333904601

DRAWING NUMBER00REV.

ALL DIMENSIONS ARE IN DECIMAL

INCHES AND [MILLIMETERS]

WME0500 M2: 380V (50Hz), 400V (50Hz),

415V (50Hz), 380V (60Hz),

575V (60Hz).

WME0500 M3: 380V (50Hz), 400V (50Hz),

415V (50Hz), 380V (60Hz),

440V (60Hz), 460V (60Hz),

480V (60Hz), 575V (60Hz).

This information is accurate at time of

printing. McQuay reserves the right to

change design, specication and product

data without notice. Purchaser must

determine that the equipment is t and

sucient for the job specications. No

change to this data may be made unless

approved in writing by McQuay. McQuay's

Limited Product Warranty applies to all

McQuay equipment.

Figure 14: WME0500 - E3612/C3012 - 2-pass - M2 Standard Motor (50Hz 380/400/415V - 60Hz 380/575V)

WME0500 - E3612/C3012 - 2-pass - M3 Low THD Motor (50Hz 380/400/415V - 60Hz 380/440/460/480/575V)

WME0500 - E3612/C3012 - 2-pass - M2 Standard Motor (60Hz 380/460V) with Factory-mounted Harmonic Filter

(See page 16 for drawing notes.)

18 IM 1033-3

Page 19

32.6

COND

RELIEF

VALVES

829

61.1

EVAP

RELIEF

VALVE

1551

5.3

133

164.6

COND.

4181

145.4

3694

5.3

133

169.0

EVAP. UNIT OVERALL

4292

5, 8, 9

5, 8, 9

3

3

5, 8, 9

Y

X

FRONT VIEW

UNIT

CONT.

BOX

58.0

1473

68.4

UNIT O/A

1737

42.8

1087

92.9

UNIT

O/A

2359

48.6

1235

15.6

397

61.8

1568

66.0

1676

17.3

438

60.5

VFD

HEIGHT

1537

2.5

63

5,11,13

5

Z

Y

SIDE VIEW

148.2

3764

13.7

348

38.9

989

5.1

130

17.0

433

3.1

80

3

3

X

Z

TOP VIEW

O.I.T.S.

LB

LF

RF

RB

66.0

1676

1.4

35

40.1

1019

16.0

406

7.2

183

4.0

TYP.

102

8.0

TYP.

203

148.2

3764

1.13

TYP.

MTG.

HOLE

29

21.0

533

92.7

2356

40.3

1023

25.4

645

2.6

65

148.2

3764

X

Z

TOP VIEW

UNIT CONT.

BOX

ENVELOPE OF UNIT

MOUNTING FEET

6

6, 14

14

ALL DIMENSIONS ARE IN DECIMAL

INCHES AND [MILLIMETERS]

333904101

DRAWING NUMBER00REV.

WME0500 M2: 440V (60Hz), 460V (60Hz),

480V (60Hz)

This information is accurate at time

of printing. McQuay reserves the

right to change design, specication

and product data without notice.

Purchaser must determine that the

equipment is t and sucient for the

job specications. No change to this

data may be made unless approved

in writing by McQuay. McQuay's

Limited Product Warranty applies to

all McQuay equipment.

Dimension Drawings

Figure 15: WME0500 - E3012/C2612 -2-pass, M2 Standard Motor (60 Hz 440/460/480V) (See page 16 for drawing notes.)

IM 1033-3 19

Page 20

Dimension Drawings

32.6

COND

RELIEF

VALVES

829

61.1

EVAP

RELIEF

VALVE

1551

5.3

133

164.6

COND.

4181

145.4

3694

5.3

133

169.0

EVAP.(UNIT OVERALL)

4292

5, 8, 9

5, 8, 9

3

3

5, 8, 9

FRONT VIEW

Y

X

UNIT

CONT.

BOX

58.0

1473

70.7

UNIT OVALL

1796

42.8

1087

61.8

1568

66.0

1676

17.3

438

60.0

VFD

HEIGHT

1523

51.0

1294

18.0

456

92.3

UNIT

O/A

2345

2.5

63

5,11,13

5

SIDE VIEW

Y

Z

148.2

3764

13.7

348

38.9

989

5.1

130

17.0

433

3.1

80

3

3

TOP VIEW

LB

LF

RF

RB

O.I.T.S.

X

Z

66.0

1676

1.4

TYP.

35

40.1

1019

16.0

406

7.2

183

30.1

764

83.5

2122

54.0

1372

4.0

TYP.

102

23.4

594

8.0

TYP.

203

148.2

3764

2.6

65

148.2

3764

1.13

TYP.

MTG.

HOLE

29

TOP VIEW

ENVELOPE OF UNIT

MOUNTING FEET

UNIT CONT.

BOX

X

Z

14

6, 14

6

ALL DIMENSIONS ARE IN DECIMAL

INCHES AND [MILLIMETERS]

333904201

DRAWING NUMBER00REV.

This information is accurate at time

of printing. McQuay reserves the

right to change design, specication

and product data without notice.

Purchaser must determine that the

equipment is t and sucient for the

job specications. No change to this

data may be made unless approved

in writing by McQuay. McQuay's

Limited Product Warranty applies to

all McQuay equipment.

WME0500 M2: 380V (50Hz), 400V (50Hz),

415V (50Hz), 380V (60Hz),

575V (60Hz).

WME0500 M3: 380V (50Hz), 400V (50Hz),

415V (50Hz), 380V (60Hz),

440V (60Hz), 460V (60Hz),

480V (60Hz), 575V (60Hz).

Figure 16: WME0500 - E3012/C2612 - 2-pass M2 Standard Motor (50Hz 380/400/415V) (60Hz 380/575V)

WME0500 - E3012/C2612 - 2-pass M3 Low THD Motor (50Hz 380/400/415) (60Hz 380/440/460/480/575V)

WME0500 - E3012/C2612 - 2-pass M2 Standard Motor (50Hz 380/400/460V) with Factory-mounted Harmonic Filter

(See page 16 for drawing notes.)

20 IM 1033-3

Page 21

Dimension Drawings

5.3

133

145.4

3694

169.0

CONDENSER

4292

36.6

COND

RELIEF

VALVE

931

61.8

EVAP

RELIEF

VALVE

1570

5.3

133

169.0

EVAP. UNIT OVERALL

4292

3

3

5, 8, 9

5, 8, 9

5, 8, 9

FRONT VIEW

X

Y

COND

EVAP

UNIT

CONT.

BOX

63.0

1600

71.0

UNIT OVERALL

1803

49.2

1249

13.7

347

43.6

1107

62.5

1589

19.3

489

96.8

UNIT

O/A

2460

60.5

VFD

HEIGHT

1537

2.5

63

5

5,11,13

RIGHT VIEW

Z

Y

7.6

193

43.9

1116

17.0

433

3.1

80

13.7

348

148.2

3764

3

3

RB

RF

LF

LR

TOP VIEW

O.I.T.S.

X

Z

71.0

1803

148.2

3764

8.0

TYP.

203

1.4

TYP.

35

40.1

1019

16.0

406

7.2

183

5.1

129

4.0

TYP.

102

92.7

2356

40.3

1023

25.5

646

1.13

TYP.

MTG.

HOLE

29

25.4

645

UNIT CONT.

BOX

6, 14

ENVELOPE OF UNIT

14

MOUNTING FEET

X

Z

TOP VIEW

6

ALL DIMENSIONS ARE IN DECIMAL

INCHES AND [MILLIMETERS]

333904301

DRAWING NUMBER00REV.

This information is accurate at time

of printing. McQuay reserves the

right to change design, specication

and product data without notice.

Purchaser must determine that the

equipment is t and sucient for the

job specications. No change to this

data may be made unless approved

in writing by McQuay. McQuay's

Limited Product Warranty applies to

all McQuay equipment.

WME0500 M2: 440V (60Hz), 460V (60Hz),

480V (60Hz)

Figure 17: WME0500 - E30C30 - 2 pass, M2 Standard Motor (60Hz 440/460/480V ( See page 16 for drawing notes.)

IM 1033-3 21

Page 22

Dimension Drawings

Figure 18: WME500 E3012/C3012, M2 Motor (50 HWMEz, 380-415V / 60Hz, 380-575V)

WME500 E3012/C3012, M3 Motor (50 Hz, 400-415 / (60 Hz, 380-575V)

WME500 E3012/C3012, M2 Motor with Internal Harmonic Filter (60 Hz, 380-460V)

22 IM 1033-3

Page 23

Dimension Drawings

Figure 19: Model WME0700 - E3612/C3012 - 2-pass, M4 motor, 3/4” tubes (To determine tube size, see note 17 on page 16)

148.2

46.9

1192

LB

4.0

101

13.7

348

3764

3

RB

68.3

1736

EVAP

RELIEF

VALVE

Z

LF

16.8

427

X

3

36.7

3

931

COND

RELIEF

VALVES

Y

16.0

406

VICTAULIC 150 PSI WATERSIDE

EVAP.

COND.

X

EVAPORATOR HEAD 2-PASS

O.I.T.S.

6.2

157

169.0

4292

170.4

4329

CONTR.

UNIT

BOX

COND.

4,6,7

TOP VIEW

EVAP. (UNIT OVERALL)

4,6,7

VFD

145.4

3694

M4

5.3

133

4,6,7

3

5.3

133

FRONT VIEW

C

L

NOM.

TYP.

C

L

9.8

248

INLET

6,7

9.8

248

OUTLET

RF

2.5

63

60.0

1523

VFD

HEIGHT

96.3

2446

UNIT O.A.

4,9,11

19.3

489

4.0

Y

102

REF.

Z

12.0

305

16.0

406

CONDENSER HEAD 2-PASS

VICTAULIC 150 PSI WATERSIDE

UNIT O.A.

77.3

1962

52.3

1327

13.8

349

77.0

1956

RIGHT VIEW

C

L

6,7

4

69.0

1753

68.5

1741

47.0

1195

10.0

[254]

NOM.

C

L

TYP.

8.1

207

OUTLET

8.1

207

INLET

148.2

3764

ENVELOPE OF UNIT

12

TYP.

8.0

203

1.13

29

MNTG. HOLE

TYP.

MOUNTING FEET

77.0

1956

4.0

102

TYP.

Z

1.4

35

TYP.

X

40.1

1019

5.1

129

UNIT CONTR.

84.2

2139

7.2

183

30.1

16.0

406

764

BOX

4

M4

VFD

4,12,13

54.0

1372

27.8

707

*333564404002*

WME700 - E3612 BE 2RA C3012 BLYY 2RA M4 150PSI

WME0700 E36C30 Right-hand 3/4” tubes

This information is accurate at time of printing. McQuay reserves

the right to change design, specication and product data without

notice. Purchaser must determine that the equipment is t and

sucient for the job specications. No change to this data may be

made unless approved in writing by McQuay. McQuay's Limited

Product Warranty applies to all McQuay equipment.

IM 1033-3 23

Page 24

Dimension Drawings

170.4

EVAP. (UNIT OVERALL)

4329

68.3

EVAP

RELIEF

VALVE

1736

36.7

COND

RELIEF

VALVES

931

169.0

COND.

4292

5.3

133

145.4

3694

5.3

133

FRONT VIEW

4,6,7

UNIT

CONTR.

BOX

COND.

EVAP.

M4

VFD

3

3

4,6,7

4,6,7

X

Y

69.0

1753

77.0

1956

19.3

489

96.3

UNIT O.A.

2446

60.0

VFD

HEIGHT

1523

47.0

1195

52.3

1327

13.8

349

2.5

63

4.0

REF.

102

77.3

UNIT O.A.

1962

68.5

1741

RIGHT VIEW

4

Y

Z

4,9,11

148.2

3764

16.8

427

6.2

157

46.9

1192

4.0

101

13.7

348

TOP VIEW

Z

LF

O.I.T.S.

RF

RB

LB

3

3

X

333564401

WME700 - E3612 EG 2RA C3012 EBYY 2RA M4 150PSI

8.1

OUTLET

207

8.1

INLET

207

TYP.

10.0

[254]

NOM.

C

L

C

L

16.0

406

77.0

1956

148.2

3764

8.0

TYP.

203

1.13

MOUNTING. HOLE

TYP.

29

27.8

707

1.4

TYP.

35

5.1

129

7.2

183

30.1

764

84.2

2139

54.0

1372

40.1

1019

16.0

406

4.0

TYP.

102

ENVELOPE OF UNIT

12

X

Z

4

4,12,13

UNIT CONTR.

BOX

M4

VFD

TYP.

12.0

[305]

NOM.

9.8

OUTLET

248

9.8

INLET

248

C

L

C

L

16.0

406

6,7

CONDENSER HEAD 2-PASS

VICTAULIC 150 PSI WATERSIDE

6,7

EVAPORATOR HEAD 2-PASS

VICTAULIC 150 PSI WATERSIDE

This information is accurate at time of printing. McQuay reserves

the right to change design, specication and product data without

notice. Purchaser must determine that the equipment is t and

sucient for the job specications. No change to this data may be

made unless approved in writing by McQuay. McQuay's Limited

Product Warranty applies to all McQuay equipment.

MOUNTING FEET

Figure 20: Model WME0700 - E3612/C3012 - 2-pass, M4 motor, 1” tubes (To determine tube size, see note 17 on page 16)

24 IM 1033-3

Page 25

Dimension Drawings

74.1

EVAP

RELIEF

VALVE

1882

42.7

COND

RELIEF

VALVES

1084

170.4

COND.

4329

5.3

133

5.3

133

145.4

3694

170.4

EVAP. (UNIT OVERALL)

4329

FRONT VIEW

UNIT

CONTR.

BOX

COND.

EVAP.

M4

VFD

3

4,6,7

4,6,7

4,6,7

3

22.3

565

102.3

UNIT O.A.

2599

60.0

VFD

HEIGHT

1523

74.3

1887

16.8

425

2.5

63

79.2

UNIT O.A.

2012

4.0

REF.

102

75.0

1905

83.0

2108

52.8

1341

58.3

1480

RIGHT VIEW

4

4,9,11

6.2

157

13.7

348

148.2

3764

16.8

427

7.0

178

52.9

1345

TOP VIEW

LF

O.I.T.S.

RF

RB

LB

3

3

Z

X

X

Y

Y

Z

333564504

WME700 - E3612 BE 2RA C3612 BLYY 2RA M4 150PSI

148.2

3764

6.9

176

7.2

183

30.1

764

84.2

2139

54.0

1372

40.1

1019

16.0

406

1.13

MOUNTING HOLE

TYP.

29

31.9

810

8.0

TYP.

203

1.4

TYP.

35

83.0

2108

4.0

102

ENVELOPE OF UNIT

12

4

4,12,13

UNIT CONTR.

BOX

M4

VFD

TYP.

12.0

[305]

NOM.

9.8

OUTLET

248

9.8

INLET

248

C

L

C

L

16.0

406

TYP.

12.0

[305]

NOM.

9.8

INLET

248

9.8

OUTLET

248

C

L

C

L

16.0

406

6,7

CONDENSER HEAD 2-PASS

VICTAULIC 150 PSI WATERSIDE

6,7

EVAPORATOR HEAD 2-PASS

VICTAULIC 150 PSI WATERSIDE

This information is accurate at time of printing. McQuay reserves

the right to change design, specication and product data without

notice. Purchaser must determine that the equipment is t and

sucient for the job specications. No change to this data may be

made unless approved in writing by McQuay. McQuay's Limited

Product Warranty applies to all McQuay equipment.

MOUNTING FEET

Z

X

Figure 21: Model WME0700 - E3612/C3612 - 2-pass, M4 motor, 3/4” tubes (To determine tube size, see note 17 on page 16)

IM 1033-3 25

Page 26

Dimension Drawings

170.4

EVAP. (UNIT OVERALL)

4329

74.1

EVAP

RELIEF

VALVE

1882

42.7

COND

RELIEF

VALVES

1084

170.4

COND.

4329

5.3

133

5.3

133

145.4

3694

FRONT VIEW

4,6,7

UNIT

CONTR.

BOX

COND.

EVAP.

M4

VFD

3

3

4,6,7

4,6,7

22.3

565

102.3

UNIT O.A.

2599

60.0

VFD

HEIGHT

1523

52.8

1341

74.3

1887

58.3

1480

16.8

425

2.5

63

79.2

UNIT O.A.

2012

4.0

REF.

102

75.0

1905

83.0

2108

RIGHT VIEW

4

4,9,11

6.2

157

13.7

348

148.2

3764

16.8

427

7.0

178

52.9

1345

TOP VIEW

LF

O.I.T.S.

RF

RB

LB

3

3

Z

X

X

Y

Y

Z

333564501

WME700 - E3612 EG 2RA C3612 EBYY 2RA M4 150PSI

148.2

3764

6.9

176

7.2

183

30.1

764

84.2

2139

54.0

1372

40.1

1019

16.0

406

1.13

MOUNTING HOLE

TYP.

29

31.9

810

8.0

TYP.

203

1.4

TYP.

35

83.0

2108

4.0

102

ENVELOPE OF UNIT

12

4

4,12,13

UNIT CONTR.

BOX

M4

VFD

9.8

OUTLET

248

9.8

INLET

248

TYP.

12.0

[305]

NOM.

C

L

C

L

16.0

406

TYP.

12.0

[305]

NOM.

9.8

OUTLET

248

9.8

INLET

248

C

L

C

L

16.0

406

6,7

CONDENSER HEAD 2-PASS

VICTAULIC 150 PSI WATERSIDE

6,7

EVAPORATOR HEAD 2-PASS

VICTAULIC 150 PSI WATERSIDE

This information is accurate at time of printing. McQuay reserves

the right to change design, specication and product data without

notice. Purchaser must determine that the equipment is t and

sucient for the job specications. No change to this data may be

made unless approved in writing by McQuay. McQuay's Limited

Product Warranty applies to all McQuay equipment.

MOUNTING FEET

Z

X

Figure 22: Model WME0700 - E3612/C3612 - 2-pass, M4 motor, 1” tubes (To determine tube size, see note 17 on page 16)

26 IM 1033-3

Page 27

Standard Head Connection Dimensions

ON "ZZ" BOLT CIRCLE

"XX" HOLES, "YY" DIAMETER

TYPICAL 150 CLASS ANSI

FLANGE CONNECTION

NOTE: FLANGE BOLT HOLES MUST STRADDLE

VERTICAL CENTERLINE ON CONNECTIONS

WW

VV

EVAPORATOR, 1 PASS

ALL UNITS

AA

*BB

FF TYP.

EVAPORATOR, 2 PASS

UNITS WITH 3/4" TUBING

OUT

IN

*BB

*GG

AA

FF TYP.

EVAPORATOR, 3 PASS

UNITS WITH 3/4" TUBING

OUT

IN

OUTLET HEAD POSITION

ON OPPOSITE END OF UNIT

*BB

AA

CONDENSER, 1 PASS

ALL UNITS

AA

*BB

FF TYP.

CONDENSER, 2 PASS

ALL UNITS

OUT

IN

AA

*BB

*GG

FF TYP.

CONDENSER, 3 PASS

ALL UNITS

IN

OUT

OUTLET HEAD POSITION ON

OPPOSITE END OF UNIT

AA

*BB

STANDARD RETURN DISHED HEAD

FOR EVAPORATOR AND CONDENSER

UU

FF TYP.

EVAPORATOR, 2 PASS

UNITS WITH 1" & MIX TUBING

IN

OUT

AA

*BB

*GG

EVAPORATOR DISHED HEAD SELECTION

NOTE: * - ADD .500 INCH FOR FLANGED CONNECTION

(SEE DETAIL LOWER LEFT)

NOTE: * - ADD .500 INCH FOR FLANGED CONNECTION

(SEE DETAIL LOWER LEFT)

RIGHT END REPRESENTATIVE VIEW

( TYPICAL OF ALL STACKS WITH 2 PASS

HEADS & 3/4" EVAP TUBING )

CONDENSER DISHED HEAD SELECTION

Figure 23: Standard Dished Head Connection Dimensions (Victaulic and Flanged)

Dimension Drawings

Table 4: Standard Dished Head Connection Dimensions - Victaulic Connections

Diamete

r

Evap AA BB AA BB FF GG AA BB FF UU

E30 14.00 16.00 10.75 16.00 8.13 16.00 6.63 16.00 10.19 9.78

E36 16.00 16.00 12.75 16.00 9.75 16.00 8.63 16.00 11.81 11.26

Cond AA BB AA BB FF GG AA BB FF UU

C26 10.75 13.00 8.63 13.00 7.07 13.00 6.63 13.00 8.07 8.38

C30 14.00 16.00 10.75 16.00 8.13 16.00 6.63 16.00 10.19 9.78

C36 16.00 16.00 12.75 16.00 9.75 16.00 8.63 16.00 11.81 11.26

Table 5: Standard Dished Head Connection Dimensions - Flanged Connections

Diamete

r

Evap AA BB AA BB FF GG AA BB FF UU

E30 14.00 16.50 10.75 16.50 8.13 16.50 6.63 16.50 10.19 9.78

E36 16.00 16.50 12.75 16.50 9.75 16.50 8.63 16.50 11.81 11.26

Cond AA BB AA BB FF GG AA BB FF UU

C26 10.75 13.50 8.63 13.50 7.07 13.50 6.63 13.50 8.07 8.38

C30 14.00 16.50 10.75 16.50 8.13 16.50 6.63 16.50 10.19 9.78

C36 16.00 16.50 12.75 16.50 9.75 16.50 8.63 16.50 11.81 11.26

Table 6: 150 Class ANSI Flange Connection Dimensions (Detail from Figure 23)

Nozzle

Dia.

6.63 11.00 1.56 8.00 0.88 9.50

8.63 13.50 1.75 8.00 0.88 11.75

10.75 16.00 1.94 12.00 1.00 14.25

12.75 19.00 2.19 12.00 1.00 17.00

14.00 21.00 2.25 12.00 1.12 18.75

16.00 23.50 2.50 16.00 1.12 21.25

IM 1033-3 27

1 PASS 2 PASS 3 PASS

1 PASS 2 PASS 3 PASS

VV WW XX YY ZZ

Drawing & Dimension Notes:

1 Dimensions in inches.

2 Flanges are ANSI raised face. Mating flanges by others.

3 Some condensers with flanges can have staggered connections due to flange interference. Consult

factory.

4 Flanges add 0.5 inches to the distance from the vertical centerline to the flange face compared to

Victaulic.

Return

Head

Return

Head

Page 28

Dimension Drawings

ON "ZZ" BOLT CIRCLE

"XX" HOLES, "YY" DIAMETER

TYPICAL 150 CLASS ANSI

FLANGE CONNECTION

NOTE: FLANGE BOLT HOLES MUST STRADDLE

VERTICAL CENTERLINE ON CONNECTIONS

WW

VV

STANDARD RETURN HEAD FOR

EVAPORATOR AND CONDENSER

UU

*BBB

AAA

EVAPORATOR, 1 PASS

ALL UNITS

*BBB

*GGG

FFF TYP.

AAA

EVAPORATOR, 2 PASS

UNITS WITH 3/4" TUBING

AAA

*BBB

FFF

EVAPORATOR, 3 PASS

UNITS WITH 3/4" TUBING

OUTLET HEAD POSITION

ON OPPOSITE END OF UNIT

EEE

DDD

CCC

DDD

EEE

CCC

OUT

IN

EEE

DDD

CCC

IN

TYP.

FFF

AAA

*GGG

*BBB

EVAPORATOR, 2 PASS

UNITS WITH 1" & MIX TUBING

EEE

DDD

CCC

OUT

IN

*BBB

AAA

CONDENSER, 1 PASS

*GGG

*BBB

TYP.

FFF

AAA

CONDENSER, 2 PASS

AAA

TYP.

FFF

*BBB

CONDENSER, 3 PASS

OUTLET HEAD POSITION

ON OPPOSITE END OF UNIT

EEE

DDD

CCC

EEE

DDD

CCC

IN

OUT

EEE

DDD

CCC

IN

NOTE: * - ADD .500 INCH FOR FLANGED CONNECTION

(SEE DETAIL LOWER LEFT)

EVAPORATOR MARINE WATER BOX SELECTION

CONDENSER MARINE WATER BOX SELECTION

NOTE: * - ADD .500 INCH FOR FLANGED CONNECTION

(SEE DETAIL LOWER LEFT)

RIGHT END REPRESENTATIVE VIEW

( TYPICAL OF ALL STACKS WITH 2 PASS

HEADS & 3/4" EVAP TUBES )

Note: On certain models connection dimensions may vary; some models will have rear-facing MWB connections. Consult your

Item Drawings for unit-specific configuration and dimensions.

Marine Water Box Dimensions

Marine water boxes with removable end covers are an available option on all evaporator and condenser sizes.

Figure 24: Marine Water Box Dimensions with Victaulic or Flanged Connections

Table 7: Marine Waterbox Dimensions - Victaulic Connections

Diameter 1 PASS 2 PASS 3 PASS

Evap AAA BBB CCC DDD EEE AAA BBB CCC DDD EEE FFF GGG AAA BBB CCC DDD EEE FFF UU

E30 14.00 21.00 27.75 26.50 13.25 10.75 21.00 27.75 26.50 13.25 8.13 21.00 6.63 21.00 27.75 26.50 13.25 10.19 9.78

E36 16.00 24.00 43.50 42.00 21.00 12.75 24.00 29.50 28.00 14.00 9.75 24.00 8.63 24.00 29.50 28.00 14.00 11.81 11.26

Cond AAA BBB CCC DDD EEE AAA BBB CCC DDD EEE FFF GGG AAA BBB CCC DDD EEE FFF UU

C26 10.75 19.00 21.25 20.00 10.00 8.63 19.00 21.25 20.00 10.00 7.07 19.00 6.63 19.00 21.25 20.00 10.00 8.07 8.38

C30 14.00 21.00 27.75 26.50 13.25 10.75 21.00 27.75 26.50 13.25 8.13 21.00 6.63 21.00 27.75 26.50 13.25 10.19 9.78

C36 16.00 24.00 43.50 42.00 21.00 12.75 24.00 29.50 28.00 14.00 9.75 24.00 8.63 24.00 29.50 28.00 14.00 11.81 11.26

Table 8: Marine Waterbox Dimensions - Flanged Connections

Diamete

r

Evap AAA BBB CCC DDD EEE AAA BBB CCC DDD EEE FFF GGG AAA BBB CCC DDD EEE FFF UU

E30 14.00 21.50 27.75 26.50 13.25 10.75 21.50 27.75 26.50 13.25 8.13 21.50 6.63 21.50 27.75 26.50 13.25 10.19 9.78

E36 16.00 24.50 43.50 42.00 21.00 12.75 24.50 29.50 28.00 14.00 9.75 24.50 8.63 24.50 29.50 28.00 14.00 11.81 11.26

Cond AAA BBB CCC DDD EEE AAA BBB CCC DDD EEE FFF GGG AAA BBB CCC DDD EEE FFF UU

1 PASS 2 PASS 3 PASS

C26 10.75 19.50 21.25 20.00 10.00 8.63 19.50 21.25 20.00 10.00 7.07 19.50 6.63 19.50 21.25 20.00 10.00 8.07 8.38

C30 14.00 21.50 27.75 26.50 13.25 10.75 21.50 27.75 26.50 13.25 8.13 21.50 6.63 21.50 27.75 26.50 13.25 10.19 9.78

C36 16.00 24.50 43.50 42.00 21.00 12.75 24.50 29.50 28.00 14.00 9.75 24.50 8.63 24.50 29.50 28.00 14.00 11.81 11.26

Table 9: 150 Class ANSI Flange Connection Dimensions (Detail from Figure 24)

Nozzle

Dia.

6.63 11.00 1.56 8.00 0.88 9.50

8.63 13.50 1.75 8.00 0.88 11.75

10.75 16.00 1.94 12.00 1.00 14.25

12.75 19.00 2.19 12.00 1.00 17.00

14.00 21.00 2.25 12.00 1.12 18.75

16.00 23.50 2.50 16.00 1.12 21.25

28 IM 1033-3

VV WW XX YY ZZ

Drawing & Dimension Notes:

1 Dimensions in inches.

2 Flanges are ANSI raised face. Mating flanges by others.

3 Some condensers with flanges can have staggered connections due to flange interference. Consult

factory.

4 Flanges add 0.5 inches to the distance from the vertical centerline to the flange face compared to

Victaulic.

Return

Head

Return

Head

Page 29

Optional External Harmonic Filter Dimensions

Cable

Entry/Exit

(Both Sides)

Figure 25: Model AUHF 300, 350, 400, Free Standing, 460Volt, Harmonic Filter

Dimension Drawings

Table 10: Model AUHF Dimensions from Figure 25

MODEL ABCDEFGHJKLWEIGHT

AUHF 300-460V

AUHF 350-460V

AUHF 400-460V

(mm)

in.

(mm)

in.

(mm)

26.2

(664)

32.0

(813)

32.0

(813)

25.0

(636)

29.5

(749)

29.5

(749)

45.0

(1143)

51.5

(1308)

51.5

(1308)

21.2

(538)

25.6

(651)

25.6

(651)

19.0

(483)

23.5

(597)

23.5

(597)

21.0

(533)

25.5

(648)

25.5

(648)

21.5

(546)

23.5

(597)

23.5

(597)

23.3

(591)

25.2

(641)

25.2

(641)

4.0

(102)

6.4

(164)

6.4

(164)

21.5

(546)

23.5

(597)

23.5

(597)

19.0

(483)

23.5

(597)

23.5

(597)

in.

Notes:

1 Requires front access only.

2 Allow 6-inches at rear for ventilation.

IM 1033-3 29

585 lbs

266 kg

800 lbs

363 kg

946 lbs

429 kg

Page 30

Dimension Drawings

Cable

Entry/Exit

(Both Sides)

Figure 26: Model ATL 300, 350, 400, Free Standing, 600Volt, Auto Transformer Harmonic Filter

Table 11: Model ATL Dimensions & Weights, 60Hz; 380V, 440V, 600V, from Figure 26

MODEL A B C D E F G H J K L WEIGHT

ATL 3 0 0

ATL 350V

ATL 400V

in.

(mm)

in.

(mm)

in.

(mm)

39.5

(1004)

44.0

(1119)

44.0

(1119)

34.1

(867)

38.0

(965)

38.0

(965)

59.0

(1499)

66.0

(1676)

66.0

(1676)

29.8

(756)

33.7

(855)

33.7

(855)

32.0

(813)

36.0

(914)

36.0

(914)

34.0

(864)

38.0

(965)

38.0

(965)

24.0

(610)

26..0

(660)

26..0

(660)

26.1

(663)

28.1

(714)

28.1

(714)

6.6

(167)

6.6

(167)

6.6

(167)