Page 1

Operating Manual

OM WMC-3

Group: Chiller

Part Number: 331374701

Effective: August 2007

Supersedes: OM WMC-2

WMC Magnetic Bearing Compressor Chillers

Model WMC 145S – 290D,

50/60 Hertz

Model WMM 145S, 60 Hertz

OITS Software Version: 2.01.01

Control Software Version: WMCU3UU02B

Page 2

Table of Contents

Introduction.............................................3

Features of the Control Panel.................4

Definitions ................................................5

General Description ................................8

Control Panel.........................................10

Use with On-Site Generators................11

Sequence of Operation..........................12

Multi-Chiller Setup ...............................13

Operating Limits:..............................................14

Operating the Control System..............15

Interface Panel On/Off......................................15

Start/Stop Unit..................................................15

Change Setpoints..............................................15

Alarms ..............................................................15

Component Failure...........................................16

Component Description........................16

Operator Interface Touch Screen......................16

Unit/Compressor Controller Description..........16

Navigating ........................................................17

Unit Controller.......................................19

Unit Controller Setpoints..................................19

Faults, Problems, Warnings ..............................21

Unit Controller Functions.................................22

Compressor Controller......................... 23

Compressor Controller Setpoints......................24

Compressor Faults, Problems, Warnings..........25

Compressor Controller Functions.....................26

Compressor On-Board

Controllers............................................. 30

Interface Touch Screen......................... 32

Navigation ........................................................32

Screen Descriptions..........................................34

VIEW Screens ..................................................34

SET Screens......................................................39

SERVICE Screen..............................................52

HISTORY Screens............................................53

Download Data.................................................54

ACTIVE ALARM Screen ................................55

Unit Controller Menu Screens.............57

Menu Matrix.....................................................58

Compressor Controller Menu

Screens ................................................... 75

Menu Matrix.....................................................75

BAS Interface........................................77

*

Manufactured in an ISO Certified Facility

©2007 McQuay International. Illustrations and data cover the McQuay International product at the time of publication and we reserve the

right to make changes in design and construction at anytime without notice. ™® The following are trademarks or registered trademarks of

their respective companies: BACnet from ASHRAE;

used by L

from AST ElectroFin Inc.; Modbus from Schneider Electric; FanTrol, MicroTech II, Open Choices, and SpeedTrol from McQuay

International. References to ARI and ETL apply to the WMC only.

ONMARK International under a license granted by Echelon Corporation; Compliant Scroll from Copeland Corporation; ElectroFin

LONMARK, LonTalk, LONWORKS, and the LONMARK logo are managed, granted and

2 OM WMC-3

Page 3

Introduction

This manual provides setup, operating, and troubleshooting information for McQuay WMC centrifugal chillers

with the MicroTech ΙΙ® controller. Please refer to the current version of IMM WMC for information relating to

the unit itself.

! WARNING

Electric shock hazard. Improper handling of this equipment can cause personal injury or equipment damage. This

equipment must be properly grounded. Connections to and service of the MicroTech II control panel must be performed

only by personnel that are knowledgeable in the operation of the equipment being controlled..

! CAUTION

Static sensitive components. A static discharge while handling electronic circuit boards can cause damage to the

components. Discharge any static electrical charge by touching the bare metal inside the control panel before performing

any service work. Never unplug any cables, circuit board terminal blocks, or power plugs while power is applied to the

panel.

NOTICE

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with this

instruction manual, may cause interference to radio communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to correct the interference at the owner’s own expense.

McQuay disclaims any liability resulting from any interference or for the correction thereof.

Temperature and humidity considerations

The unit controllers are designed to operate within an ambient temperature range 20°F to 130°F

(-7°C to 54°C) with a maximum relative humidity of 95% (non-condensing).

HAZARD IDENTIFICATION INFORMATION

!

DANGER

Dangers indicate a hazardous situation which will result in death or serious injury if not avoided.

!

WARNING

Warnings indicate potentially hazardous situations, which can result in property damage, severe

personal injury, or death if not avoided.

!

CAUTION

Cautions indicate potentially hazardous situations, which can result in personal injury or

equipment damage if not avoided.

OM WMC-3 3

Page 4

Features of the Control Panel

Control of leaving chilled water within a ±0.2°F (±0.1°C) tolerance. •

Display of the following temperatures and pressures on a 15-inch Super VGA touch-screen operator

•

interface (depending on date of manufacture):

• Entering and leaving chilled water temperature

• Enter and leaving condenser water temperature

• Saturated evaporator refrigerant temperature and pressure

• Saturated condenser temperature and pressure

• Outside air temperature (optional)

• Suction line, liquid line and discharge line temperatures, calculated superheat for discharge and suction

lines, and calculated subcooling for liquid line

Automatic control of primary and standby evaporator and condenser pumps.

•

Control of up to 4 stages of cooling tower fans plus modulating bypass valve and/or tower fan VFD.

•

Although fan staging is available, continuous, modulated control of tower capacity is preferred and

recommended.

History trend feature that will constantly log chiller functions and setpoints. The controller will store and

•

display all accumulated data for recall in a graphic format on the screen. Data can be downloaded for

archival purposes.

Three levels of security protection against unauthorized changing of setpoints and other control

•

parameters.

Plain language warning and fault diagnostics to inform operators of most warning or fault conditions.

•

Warnings, problems and faults are time and date stamped for identification of when the fault condition

occurred. In addition, the operating conditions that existed just prior to shutdown can be recalled to aid in

resolving the cause of the problem.

Twenty-five previous faults and related operating conditions are available from the display. Data can be

•

exported for archival purposes via a 3.5-inch floppy drive or other device (depending on date of

manufacture).

Soft loading feature reduces electrical consumption and peak demand charges during system loop

•

pulldown.

Remote input signals for chilled water reset, demand limiting and unit enable.

•

Manual control mode allows the service technician to command the unit to different operating states.

•

Useful for system checkout.

BAS communication capability via L

•

BAS manufacturers.

Service Test mode for troubleshooting controller outputs.

•

Pressure transducers for direct reading of system pressures.

•

Preemptive control of low evaporator and high discharge pressure conditions to take corrective action prior

•

to a fault trip.

ONTALK®, Modbus® or BACnet® standard open protocols for most

4 OM WMC-3

Page 5

Definitions

Active Setpoint

The active setpoint is the parameter setting in effect at any given moment. This variation can occur on

setpoints that can be altered during normal operation. Resetting the chilled water leaving temperature setpoint

by one of several methods such as return water temperature is an example.

Active Capacity Limit

The active capacity setpoint is the setting in effect at any given moment. Any one of several external inputs

can limit a compressor’s capacity below its maximum value.

Active-Amp-Limit

Active amp limit is the actual amp limit imposed by an outside signal such as the load limit function.

Condenser Recirc (Recirculation) Timer

A timing function, with a 30-second default, that holds off any reading of condenser water for the duration of

the timing setting. This delay allows the sensors to take a more accurate reading of the condenser water

temperature.

Dead Band

The dead band is a set of values associated with a setpoint such that a change in the variable occurring within

the dead band causes no action from the controller. For example, if a temperature setpoint is 44°F and it has a

dead band of ± 2.0 degrees F, nothing will happen until the measured temperature is less than 42°F or more

than 46°F.

DIN

Digital input usually followed by a number designating the number of the input.

Discharge Superheat

Discharge superheat is calculated using the following equation:

Discharge Superheat = Discharge Temperature – Condenser Saturated Temperature

Error

In the context of this manual, “Error” is the difference between the actual value of a variable and the target

setting or setpoint.

Evaporator Approach

The evaporator approach is calculated for each circuit. The equation is as follows:

Evaporator Approach = LWT – Evaporator Saturated Temperature

Evap Hold-loading

This is a setpoint that establishes the minimum evaporator pressure to which the chiller is allowed to go. It

signals that the unit is at full load so the no further loading will occur that would lower the pressure even

further.

Evap Recirc (Evaporation Recirculation) Timer

A timing function, with a 30-second default, that holds off any reading of chilled water for the duration of the

timing setting. This delay allows the chilled water sensors to take a more accurate reading of the chilled water

temperature.

EXV

Electronic expansion valve, used to control the flow of refrigerant to the evaporator, controlled by the circuit

microprocessor.

OM WMC-3 5

Page 6

Load Limit

An external signal from the keypad, the BAS, or a 4-20 ma signal that limits the compressor loading to a

designated percent of full load. Used to limit unit power input.

Load Balance

Load balance is a technique that equally distributes the total unit load between two or more running

compressors.

Low Pressure Hold (Inhibit) Setpoint

The psi evaporator pressure setting at which the controller will not allow further compressor loading.

“Hold” and “Inhibit” are used interchangeably.

Low Pressure Unload Setpoint

The psi evaporator pressure setting at which the controller will unload the compressor in an effort to

maintain the minimum setting.

LWT

Evaporator leaving water temperature. The “water” is any fluid used in the chiller circuit.

LWT Error

Error in the controller context is the difference between the value of a variable and the setpoint. For

example, if the LWT setpoint is 44°F and the actual temperature of the water at a given moment is 46°F,

the LWT error is +2 degrees.

LWT Slope

The LWT slope is an indication of the trend of the chilled water temperature. It is calculated by taking

readings of the temperature every few seconds and subtracting them from the previous value over a rolling

one-minute interval.

ms

Milli-second

Maximum Saturated Condenser Temperature

The maximum saturated condenser temperature allowed is calculated based on the compressor operational

envelope.

OAT

Outside ambient air temperature

Offset

Offset is the difference between the actual value of a variable (such as temperature or pressure) and the

reading shown on the microprocessor as a result of the sensor signal.

OITS

Operator Interface Touch Screen, one screen per unit provides operating data visually and accommodates

setpoint entry.

pLAN

Peco Local Area Network is the proprietary name of the network connecting the control elements.

Refrigerant Saturated Temperature

Refrigerant saturated temperature is calculated from the pressure sensor readings. The pressure is fitted to

an R-134a temperature/pressure curve to determine the saturated temperature.

Soft Load

Soft Load is a control sub-routine that allows the chiller to load up gradually. It requires setpoint inputs of

selecting it by Yes or No inputs by selecting the percent load to start ramping up and by selecting the time to

ramp up to full load (up to 60 minutes).

6 OM WMC-3

Page 7

SP

Setpoint

Suction Superheat

Suction superheat is calculated for each circuit using the following equation:

Suction Superheat = Suction Temperature – Evaporator Saturated Temperature

Stageup/Stagedown Delta-T

Staging is the act of starting or stopping a compressor or fan when another is still operating. Startup and Stop

is the act of starting the first compressor or fan and stopping the last compressor or fan. The Delta-T is the

“dead band” on either side the setpoint in which no action is taken.

Stage Up Delay

The time delay from the start of the first compressor to the start of the second.

Startup Delta-T

Number of degrees above the LWT setpoint required to start the first compressor.

Stop Delta-T

Number of degrees below the LWT setpoint required for the last compressor to stop.

VDC

Volts, Direct Current; sometimes noted as vdc.

VFD

Variable Frequency Drive, a device located on the compressor used to vary the compressor speed.

OM WMC-3 7

Page 8

elie

General Description

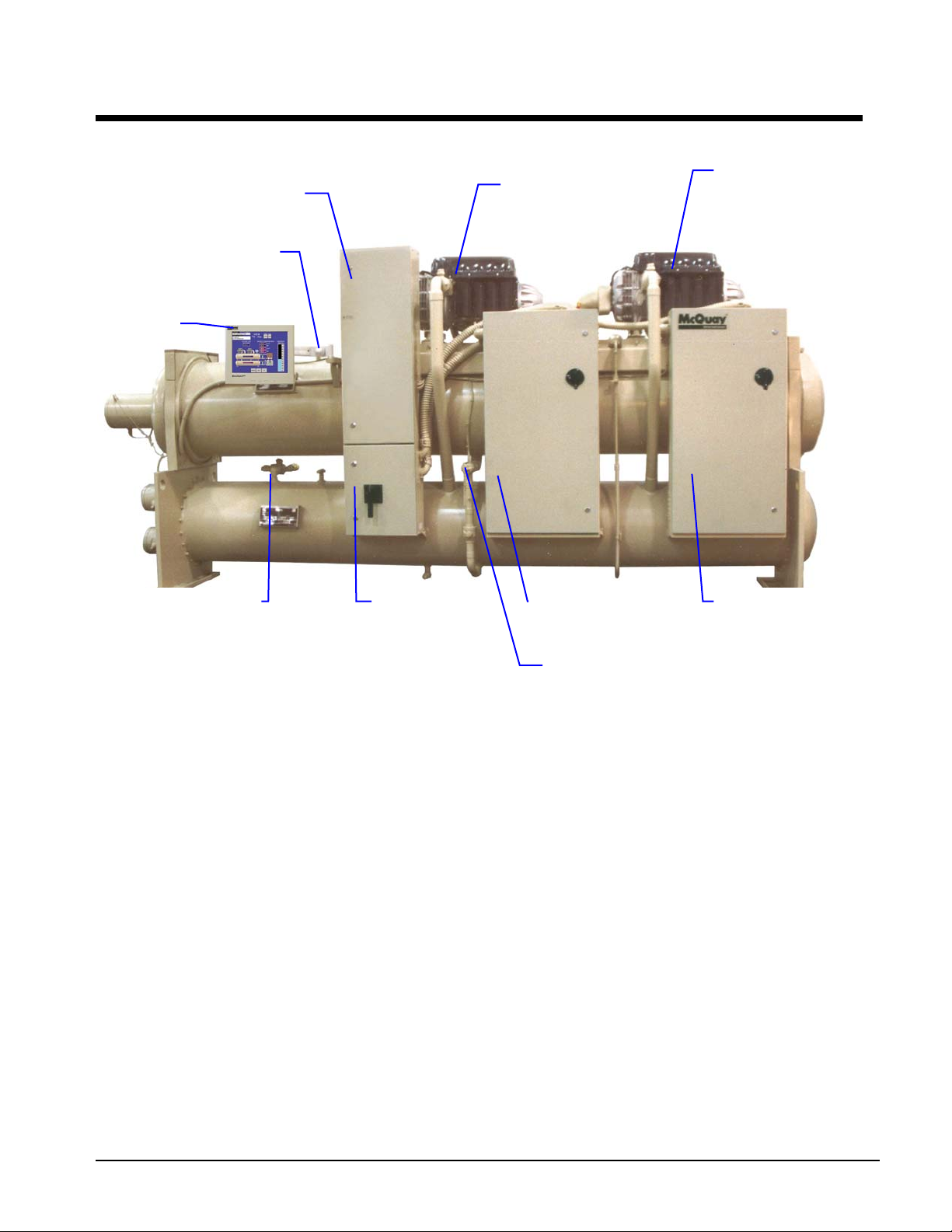

Major Components

Figure 1, Major Component Location

Unit Control Panel

Evaporator

Relief Valve

Operator

Interface

Panel

Condenser

f

R

Optional Unit

Disconnect

Switch & Single

Point Power

Connection

Compressor #1 with

On-Board Controls

Circuit #1

Power Panel

Electronic Expansion Valve

Compressor #2

with On-Board

Controls

Circuit #2

Power

General Description

The centrifugal MicroTech ΙΙ control system consists of microprocessor-based controllers in the control panel,

as well as on-board the compressors, providing monitoring and control functions required for the controlled,

efficient operation of the chiller. The system consists of the following components:

• Operator Interface Touch Screen (OITS), one per unit-provides unit information and is the primary setpoint

input instrument. It has no control function.

• Unit Controller, one per chiller-controls unit functions and communicates with all other controllers. It is

the secondary location for setpoint input if the OITS is inoperative. It is located in the control panel that is

adjacent to the OITS Panel.

• Compressor Controller for each compressor-controls compressor functions. They are located in the control

panel.

• On-board compressor controller mounted on each compressor that monitors compressor operation and

controls bearing operation.

The operator can monitor all operating conditions by using the unit-mounted OITS. In addition to providing

all normal operating controls, the MicroTech II control system monitors equipment protection devices on the

unit and will take corrective action if the chiller is operating outside of its normal design conditions. If a fault

condition develops, the controller will shut a compressor, or the entire unit, down and activate an alarm output.

Important operating conditions at the time an alarm condition occurs are retained in the controller’s memory to

aid in troubleshooting and fault analysis.

8 OM WMC-3

Page 9

The system is password protected and only allows access by authorized personnel. The operator must enter the

password into the touch screen (or one of the controller's keypad) before any setpoints can be altered.

NOTE: It is important to understand that the OITS is the operator interface device under normal conditions.

If, and only if, it is unavailable, should the unit controller be used to change setpoints or operate the chiller.

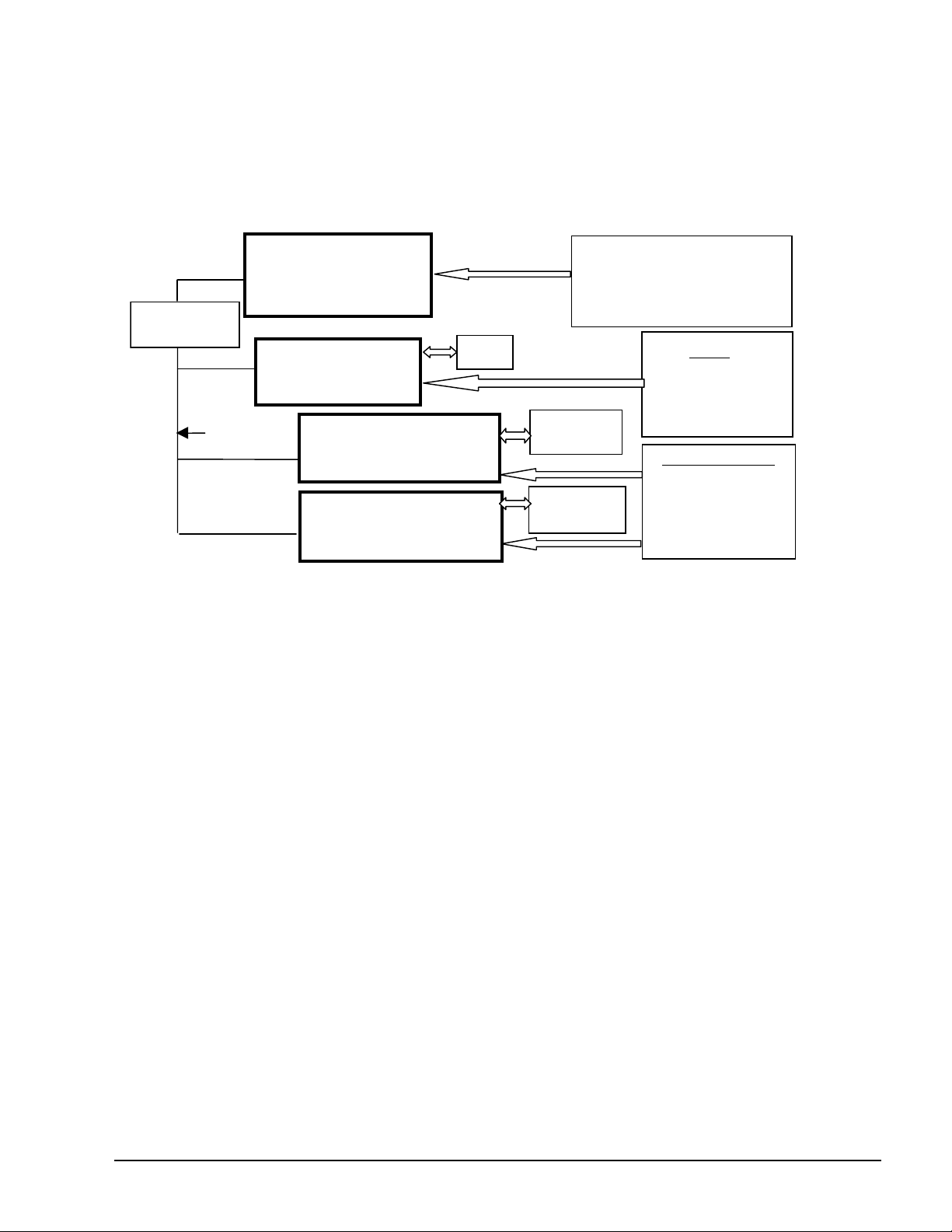

Figure 2, Major Control Components

Comm. Module

Universal

pLAN

OPERATOR

INTERFACE

TOUCH-SCREEN

UNIT

CONTROLLER

#1 COMPRESSOR

CONTROLLER

#2 COMPRESSOR

CONTROLLER

BAS

Onboard

Control

Onboard

Control

Color Graphics

Touch-Screen Interface

View Data, Input Setpoints

Stores History

UNIT

Analog Inputs

Analog Outputs

Digital Inputs

Digital Outputs

COMPRESSOR

Analog Inputs

Analog Outputs

Digital Inputs

Digital Outputs

OM WMC-3 9

Page 10

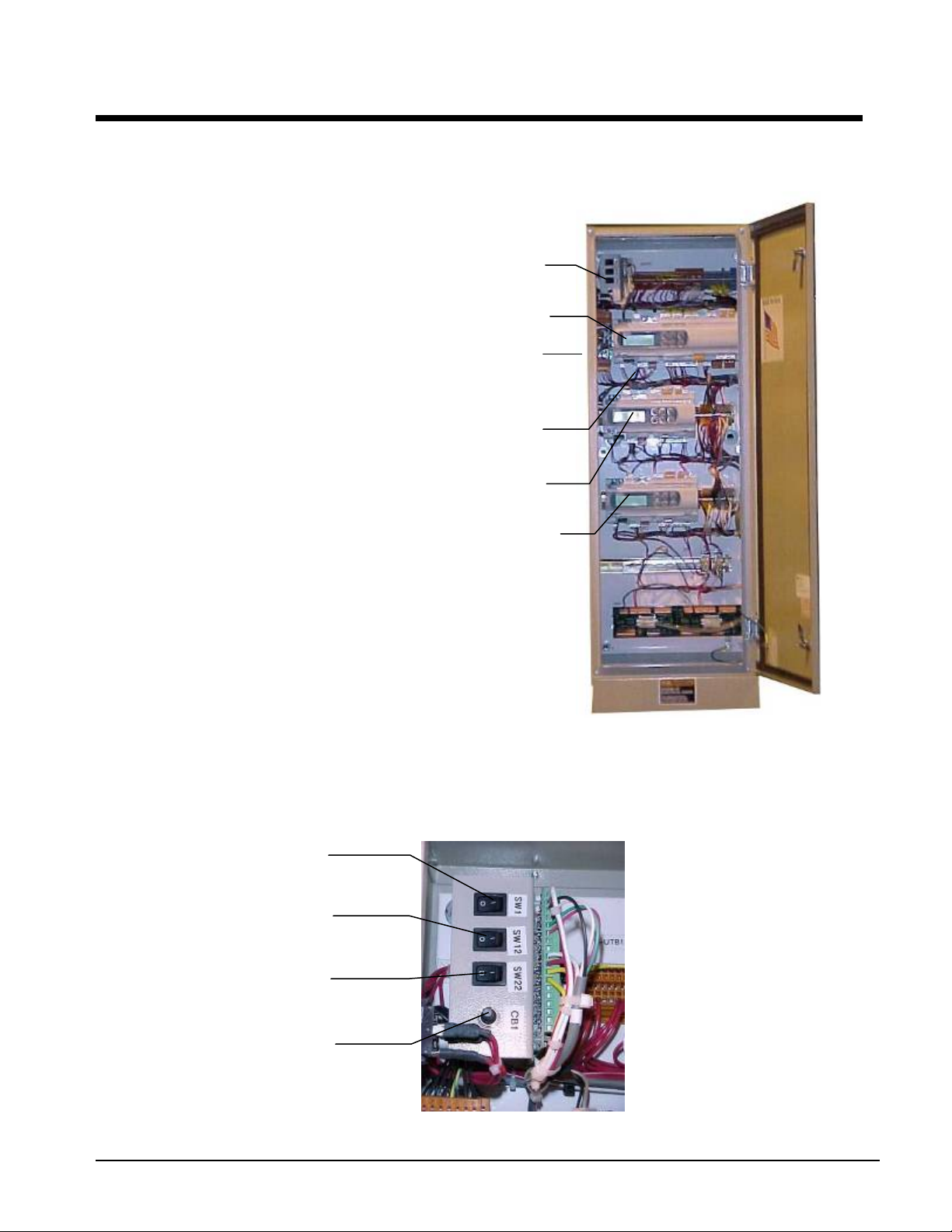

Control Panel

The unit and compressor

controllers along with unit and

compressor on/off switches are

mounted in the unit control panel

which is mounted adjacent to the

OITS panel. See

Figure 1. The

switches are designated “I” for on

and “0” for off. The compressor

on/off switch should only be used

when an immediate stop is required

since the normal shut down

sequence is bypassed.

The switch panel also has a Circuit

Breaker that interrupts power to the

cooling tower fans, valves, and

evaporator and condenser pumps,

if any of these are tied into the

MicroTech II controller for control

of their operation. If these

components operate independently

from the chiller control, the

breaker has no effect.

The unit controller's primary

function is processing data relating

to the entire chiller

unit operation

as compared to data relating to the

compressor operation. The unit

controller processes information

and sends data to the compressor

controllers and devices and relays information to the OITS for graphic display. It has a 4x20 LCD display and

keys for accessing data and changing setpoints. The controller LCD can display most of the same information

as the OITS and can operate the chiller independently if the OITS is not available.

Figure 3, Control Panel Interior

Switch Panel and

Switches, See Below.

Unit Controller

SW5, Emergency

Shutdown Switch,

Outside Panel

USB Port Located on

PC Located in this Area

Compressor #1

Controller

Compressor #2

Controller

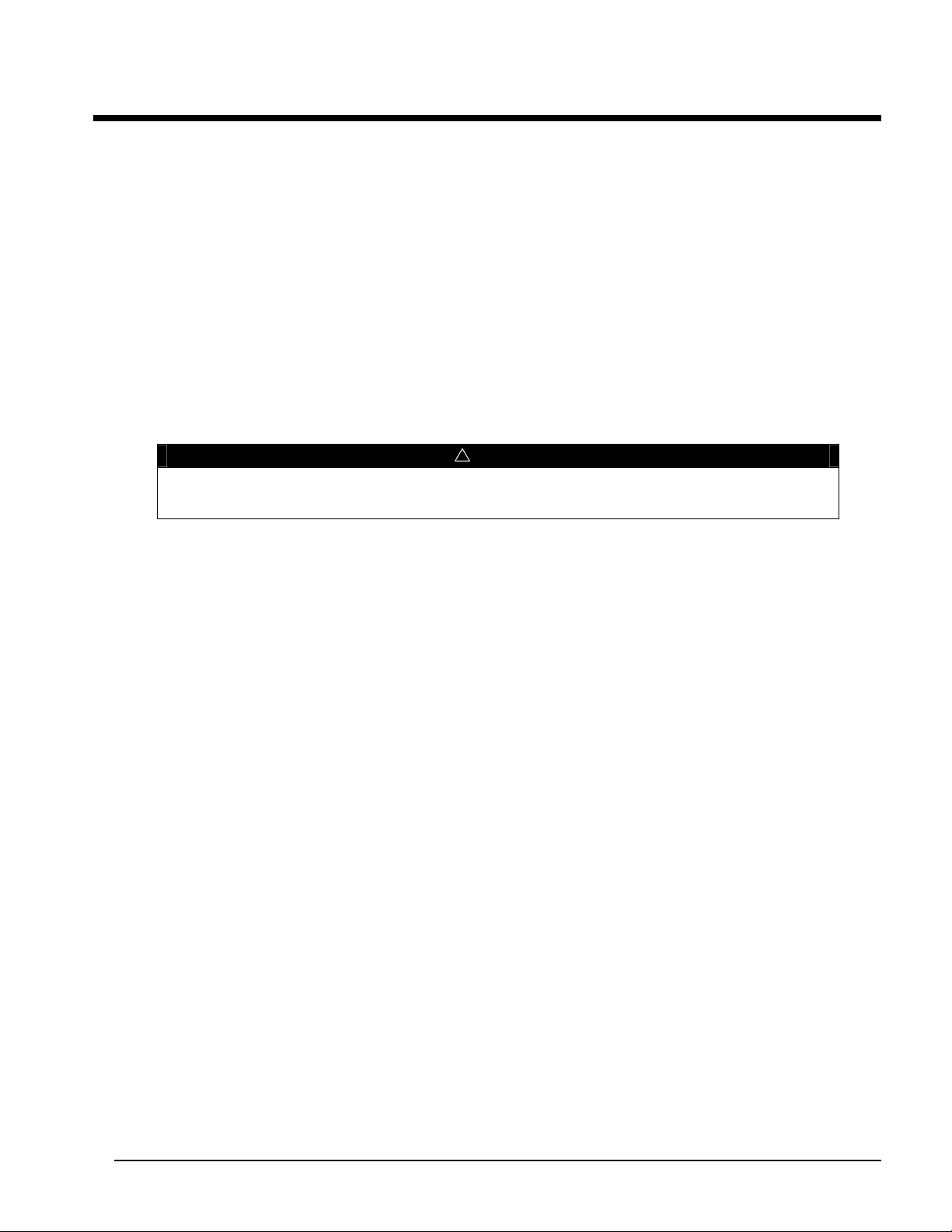

Figure 4, Switch Locations

Compressor #1 Switch

Compressor #2 Switch

Unit Switch

Circuit breaker

10 OM WMC-3

Page 11

Use with On-Site Generators

WMC chillers have their total tonnage divided between two compressors that start sequentially and they are

operated with variable frequency drives. These features make WMC chillers especially appropriate for use in

applications where they may be required to run with on-site electrical generators. This is particularly true when

the generators are used for temporary power when the utility power is lost.

Starting/Stopping Procedure: The stopping of the chiller in the event of a power failure is typically

uneventful. The chiller will sense a loss of voltage and the compressors will stop, coasting down using power

generated from their dynamic braking to maintain the bearing magnetic field. The stop signal will initiate a

three-minute stop-to-start timer, effectively preventing compressor restart for three minutes. The timer is

adjustable from three to fifteen minutes, but the recommended and default value is three minutes. This interval

allows the generator sufficient time to get up to speed and stabilize. The chiller will restart automatically when

the start-to-start timer expires.

Transfer Back to Grid Power: Proper transfer from stand-by generator power back to grid power is essential

to avoid compressor damage.

!

WARNING

Stop the chiller before transferring supply power from the generator back to the utility power grid.

Transferring power while the chiller is running can cause severe compressor damage.

The necessary procedure for reconnecting power from the generator back to the utility grid is show below.

These procedures are not peculiar to McQuay units only, but should be observed for any chiller manufacturer.

1.

Set the generator to always run five minutes longer than the unit start-to-start timer, which could be set from 15

to 60 minutes. The actual setting can be viewed on the operator interface panel on the Setpoint/Timer screen.

2.

Configure the transfer switch, provided with the generator, to automatically shut down the chiller before transfer

is made. The automatic shut-off function can be accomplished through a BAS interface or with the “remote

on/off” wiring connection shown in

Figure 10 on page 31. A start signal can be given anytime after the stop

signal since the three-minute start-to-start timer will be in effect.

Chiller Control Power: For proper operation on standby power, the chiller control power must remain as

factory-wired from a unit-mounted transformer. Do not supply chiller control power from an external power

source because the chiller may not sense a loss of power and do a normal shutdown sequence.

OM WMC-3 11

Page 12

Sequence of Operation

Start-up of WMC Compressors:

“Next On” Status

If none of the “OFF” conditions are true, then all the MicroTech II compressor controls in a network of up to 2

units (four compressors) will pole the status of each to determine the one having “Next On” status, which is

usually the compressor with the least starts. This takes about one minute.

Evap (Evaporator) Pump Start

Once this is determined, the unit controller of the chiller with the “Next On” compressor (when there are two

chillers) will start the evaporator pump and determine if there is load based on the water temperature. This is

determined if the leaving evaporator water is above the “LWT Setpoint” plus “Startup Delta T”. If there is no

load, based on the temperature, the unit is in the state of ‘Awaiting Load’.

Interlock On

If there is load, the unit waits for the Evaporator Recirculation Timer period (default value of 30 seconds) and

starts the Interlock Timer for 10 seconds.

Cond (Condenser) Pump Start

After Interlock is confirmed, the controller starts the Condenser Pump and checks for condenser flow before

starting the first compressor.

Compressor Start

Starting the compressor is accomplished by setting the Demand to 25% of the MAX KW setpoint. When the

actual rpm of the compressor exceeds 350 rpm, the demand setting is allowed to be governed by the normal

control logic.

Compressor Run

The compressor that is running will signal all other compressors when it reaches full load.

Full load status is determined when

1.

Percent RLA exceeds 100% or the Active-Amp-Limit from an external-limiting source.

2.

Evap Saturation pressure drops below the Evap Hold-Loading pressure setpoint.

3.

Actual compressor RPM exceeds 97% of Max RPM limit from compressor.

any one of the following tests is true:

Lag Compressor Staging

The “Next On” compressor, will initiate the following staging sequence when it receives a Full Load indication

from the Lead compressor or all other running compressors in the case of a four compressor (two units) setup.

The lag compressor will start (Demand set to 25% of Max KW setpoint). When the actual RPM exceeds 350

rpm, the lead compressor will unload to 25% of the MAX KW setpoint. The lead compressor will maintain this

demand setting for a time period set by the Step-Down timer (found in Set COMP1 SPs (8) ). When the Step–

Down timer expires, both compressors should be nearly matched in capacity and can began amp balancing to

share the load equally.

Note: If the “Next On” compressor is on another chiller, the controller will start that chiller’s evaporator and

condenser pumps, if they are separate from the lead unit’s pumps. Only compressors on the same unit will

unload the lead compressor before starting the lag compressor.

Unloading compressors:

The setpoint of ‘Nominal Capacity’ is used for defining the point to unload a compressor on a single or twochiller system. With each compressor having its ‘Nominal Capacity’ defined, then the network, which is load

12 OM WMC-3

Page 13

balanced, continues to unload at 0.2 tenths or more below setpoint. Each compressor keeps computing the

spare capacity of the network. When the designated ‘Next Off’ sees enough spare capacity, it will turn off.

Then similarly, in about 40 seconds, a new compressor will be designated as the ‘Next Off’ and the spare

capacity will continue to be calculated between the remaining compressors. Compressors continue to unload

and stage off until there is only one compressor running. It will shut off when the water temperature reaches

the LWT Setpoint minus the Shutdown Delta T.

Multi-Chiller Setup

Component Description

Communication Setup

The communication wiring and setup required for dual compressor operation is setup in the factory

and should be reviewed when the chiller is initially started after installation or if there is any change

made in the chiller control hardware.

RS485 communication wiring between chillers should be field wired before start-up and installed as a

NEC Class 1 wiring system.

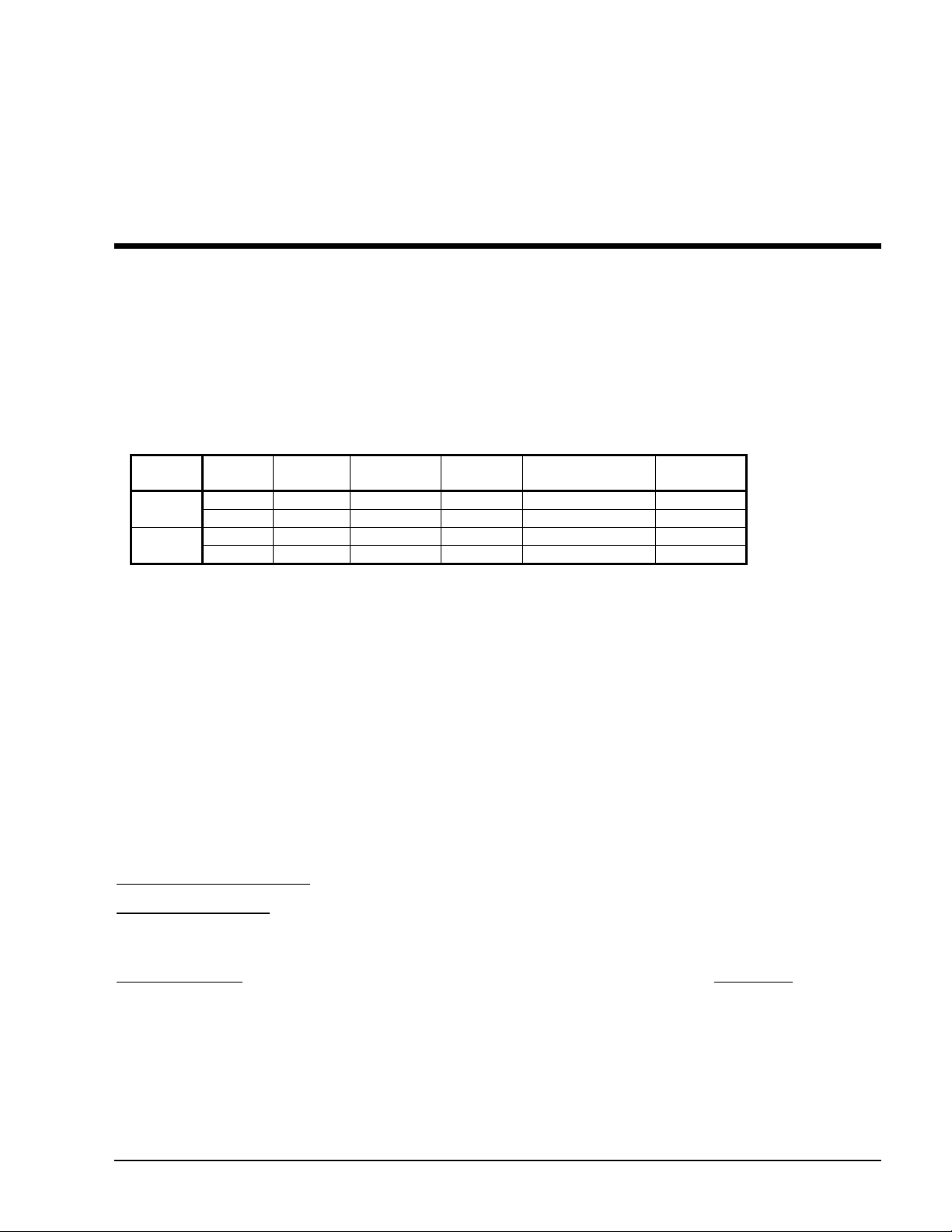

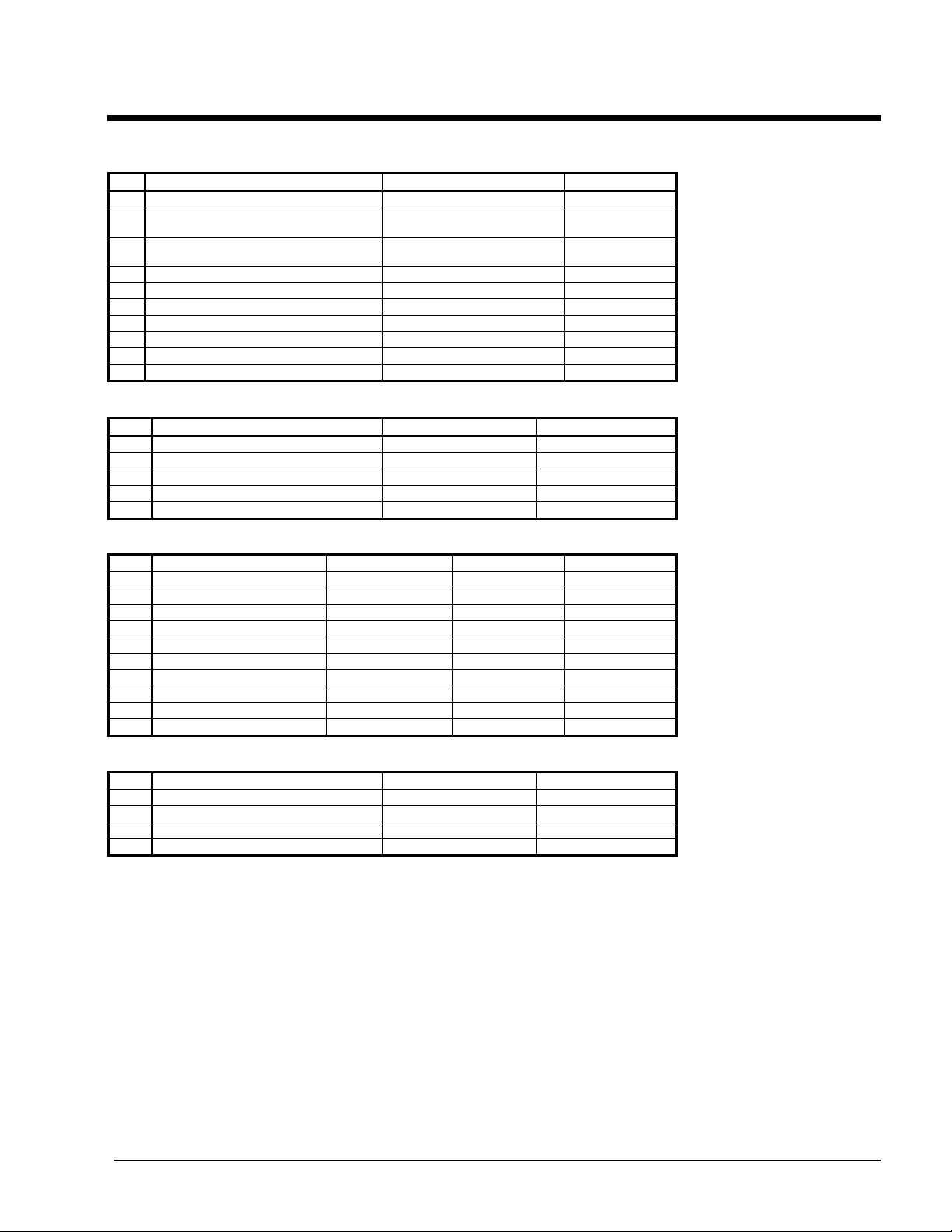

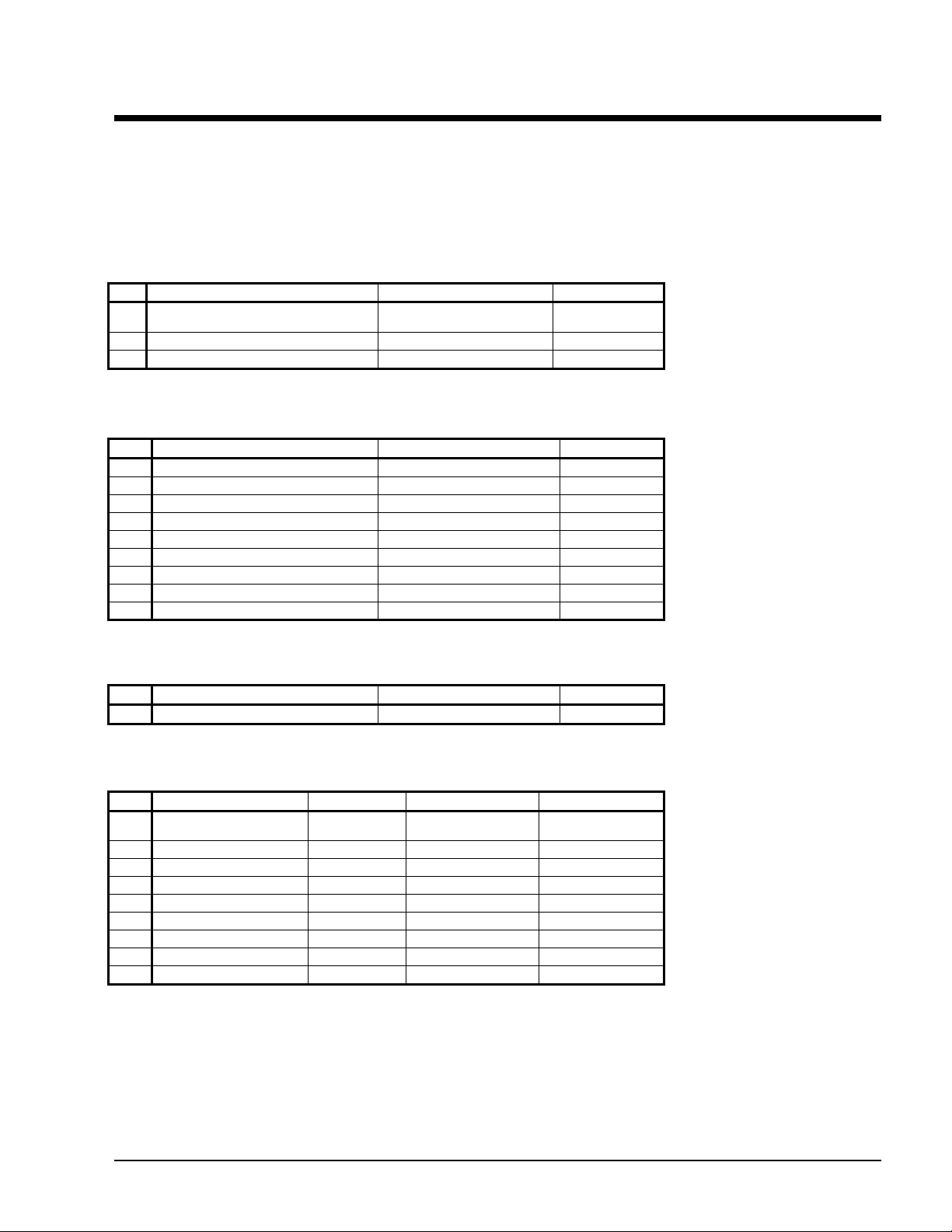

Table 1, Address DIP Switch Settings for Controllers Using Multi-chiller communication

Chiller Comp 1 Comp 2

A

B

NOTES:

1 2 5 6 7 8

100000 010000 101000 011000 111000 000100

9 10 13 14 15 16

100100 010100 101100 011100 111100 000010

Unit

Controller

Reserved

1. Two WMC units can be interconnected.

2. The interface setting is not a DIP switch setting. The ‘Operator Interface Touch Screen’ (OITS) address is

selected by selecting the ‘service’ set screen. Then, with the Technician level password active, select the

‘pLAN Comm’ button. Buttons A(7), B(15), C(23), D(31) will appear in the middle of the screen, then select

the letter for the OITS address for the chiller that it is on. Then close the screen. Note that A is the default

setting from the factory.

There are six Binary DIP Switches: Up is ‘On’, indicated by ‘1’. Down is ‘Off’, indicated by ‘0’. They

3.

are slide and not rocker switches. They are located on the upper-left corner of the face of the controller.

Operator

Interface

Reserved

Operator Interface Touch Screen (OITS) Settings

Settings for any type of linked multiple compressor operation must be made to the MicroTech II controller.

Settings on a dual compressor unit are made in the factory prior to shipment, but must be verified in the field

before startup. Settings for multiple chiller installations are set in the field on the Operator Interface Touch

Screen as follows:

Maximum Compressors ON – SETPOINTS - MODES screen, Selection #10 = 2 for a WMC, 4 for 2 WMCs.

Sequence and Staging – SETPOINTS - MODES screen, Selection #11 & #13; #12 & #14. Sequence sets the

sequence in which compressors will start. Setting all to “1” evokes the automatic lead/lag feature and is the

preferred setting.

Nominal Capacity – SETPOINTS - MOTOR screen, Selection #10. The setting is the compressor design tons.

Compressors on dual units are always of equal capacity.

Communication Setup

1. With no communication connections between chillers, disconnect control power and set the DIP switches

as shown in

2.

With all manual switches off, turn on control power to each chiller and set each OITS address (see Note 2

above).

3.

Verify correct nodes on each OITS Service Screen.

OM WMC-3 13

Table 1.

Page 14

4. Connect chillers together (pLAN, RS485, between J6 connections on each unit’s isolation boards. The

boards are not furnished, separate RS485 isolators must be field supplied.

5.

Verify correct nodes on each OITS Service Screen. See Figure 28 on page 52.

Operating Limits:

Maximum standby ambient temperature, 130°F (55°C)

Minimum operating ambient temperature (standard), 35

Leaving chilled water temperature, 38

Maximum operating evaporator inlet fluid temperature, 66

Maximum startup evaporator inlet fluid temperature, 90

Maximum non-operating inlet fluid temperature, 100

Minimum condenser water entering temperature, 55

Maximum condenser entering temperature, 105F (40.6C)

Maximum condenser leaving temperature, 115F (46.1C)

°F to 60°F (3°C to 15°C)

Low Condenser Water Temperature Operation

When the ambient wet bulb temperature is lower than design, the entering condenser water temperature can

be allowed to fall to improve chiller performance. This is especially true of an advanced design such as the

McQuay WMC chiller that features variable compressor speed.

It is an engineering fact that as the compressor discharge pressure is reduced, the amount of power to pump a

given amount of gas also is reduced. The reduction can result in significant energy savings.

°F (2°C)

°F (19°C)

°F (32°C)

°F (38°C)

°F (12.8°C)

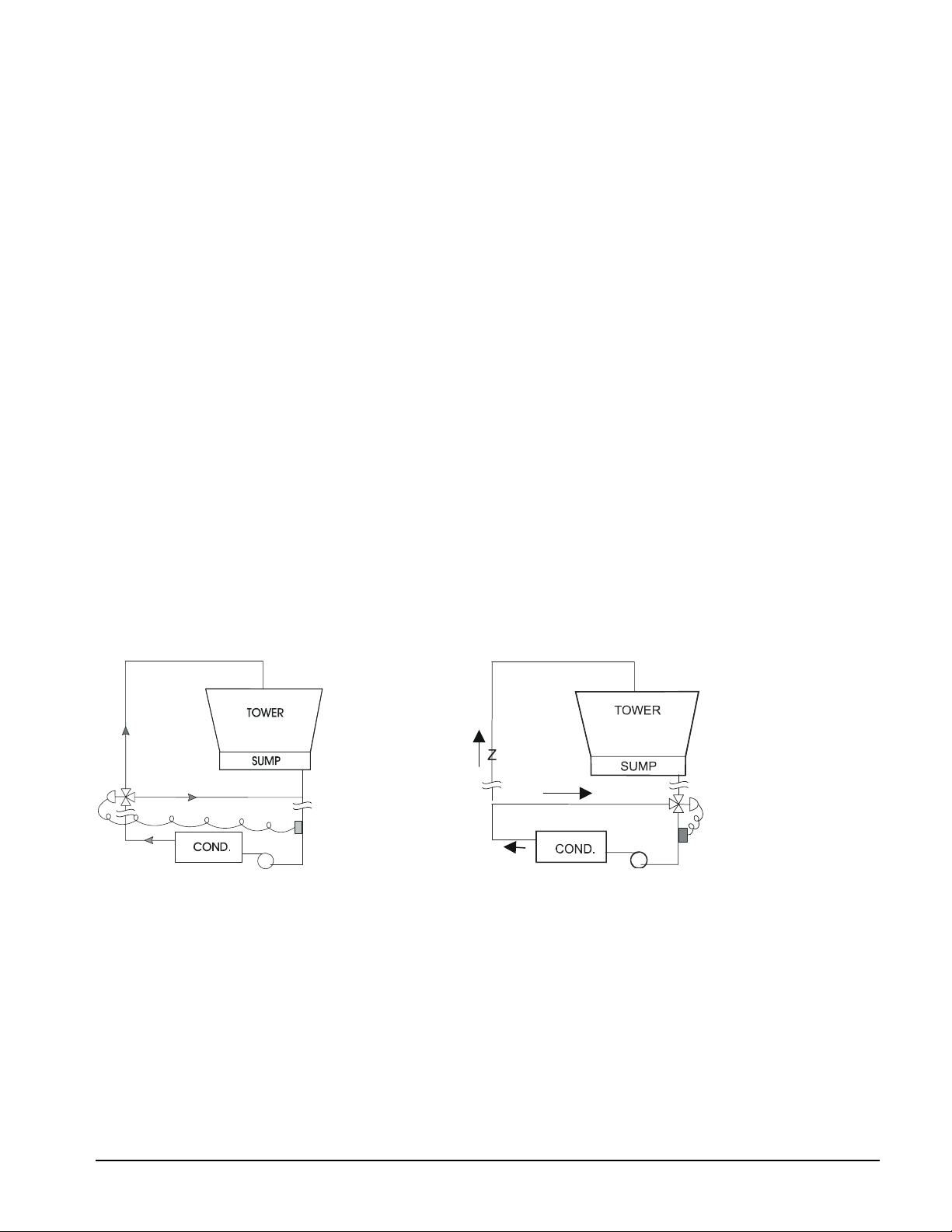

However, as with most centrifugal chiller applications, a tower bypass valve must be installed and must be

controlled by the chiller MicroTech II controller.

arrangements. The “Cold Weather” scheme provides better startup under cold ambient air temperature

conditions. The check valve may be required to prevent entraining air at the pump inlet.

Figure 5, Bypass, Mild Weather Operation

Figure 5 illustrates two temperature actuated tower bypass

Bypass, Cold Weather Operation

14 OM WMC-3

Page 15

Operating the Control System

Interface Panel On/Off

The Operator Interface Panel is turned on and off with a switch located at the lower front of the panel. Screen

control buttons are located to either side of it and elicit on-screen prompts when pressed.

The screen is equipped with a screen saver that blackens the screen. Touching the screen anywhere reactivates

the screen. If the screen is black, touch it first to be sure it is on before using the ON/OFF botton.

Start/Stop Unit

There are four ways to start or stop the chiller. Three are shown below and selected in SETPOINT\

MODE\SP3; the fourth way is through panel-mounted switches:

1. Operator Interface Panel (LOCAL)

Home Screen 1 has AUTO and STOP buttons that are only active when the unit is in "LOCAL

CONTROL." This prevents the unit from being accidentally started or stopped when it is normally under

control from a remote switch or BAS. When these buttons are pressed, the unit will cycle through its

normal starting or stopping sequence.

2. Remote SWITCH

Selecting SWITCH in SP3 will put the unit under the control of a remote switch that must be wired into

the control panel (see

Figure 10 on page 31).

3. BAS

BAS input is field-wired into a module that is factory-installed on the unit controller.

Control Panel Switches

The unit control panel, located adjacent to the Interface Panel, has switches inside the panel for stopping the

entire unit or individual compressors. When the UNIT switch is placed in the OFF position, the chiller will

shut down through the normal shutdown sequence whether one or two compressors are on.

The COMPRESSOR switches will immediately shut down the compressor without going through the

shutdown sequence when placed in the OFF position. It is equivalent to an emergency stop switch.

Change Setpoints

Setpoints are easily changed on the Operator Interface Touch Screen (OITS). A complete description of the

procedure begins on page

except in an emergency when the OITS is unavailable.

40. Setpoints can also be changed in the unit controller, but this is not recommended

Alarms

A red ALARM light in the lower middle of any screen is illuminated if there is an alarm. If the optional

remote alarm is wired in, it too will be energized.

There are three types of alarms:

• Fault, equipment protection alarms that shut a unit or compressor off.

• Problem, limit alarms that limit compressor loading in response to an out-of-normal condition. If the

condition that caused a limit alarm is corrected, the alarm light will be cleared automatically.

• Warning, notification only, no action taken by controller.

Any type will light the ALARM light. Procedures for dealing with alarms are shown below:

1.

Press the alarm light button. This will go directly to the ACTIVE ALARMS screen.

2.

The alarm description (with date stamp) will be shown.

3.

Press the ACKNOWLEDGE button to recognize the alarm.

OM WMC-3 15

Page 16

4. Correct the condition causing the alarm.

5.

Press the CLEAR button to clear the alarm from the controller. If the fault condition is not fixed, the alarm

will continue to be on and the unit will not be able to be restarted.

Component Failure

Chiller Operation without the Operator Interface Panel

The Interface Panel communicates with the unit and compressor controllers, displaying data and transmitting

touch screen inputs to the controllers. It does no actual controlling and the chiller can operate without it.

Should the Touch Screen become inoperable, no commands are necessary for continuing unit operation. All

normal inputs and outputs will remain functional. The unit controller can be used to view operational data, to

clear alarms and to change setpoints, if necessary.

Component Description

Operator Interface Touch Screen

The operator interface touch screen (OITS) is the primary device

for entering commands and entries into the control system.

(Settings can also be made directly into the unit controller.) The

OITS can also display controller data and information on a series

of graphic screens. A single OITS is used per unit.

Selected information from the OITS panel can be down-loaded

via a USB port located in the unit control panel.

The OITS panel is mounted on a moveable arm to allow

placement in a convenient position for the operator.

There is a screen-saver programed into the system. The screen is

reactivated by touching it anywhere.

Unit/Compressor Controller Description

Hardware Structure

The controllers are fitted with a microprocessor for running the control program. There are terminals for

connection to the controlled devices (for example: solenoid valves, tower fans, pumps). The program and

settings are saved permanently in FLASH memory, preventing data loss in the event of power failure without

requiring a back-up battery.

Each controller connects to other controllers, the on-board compressor microprocessors and the OITS via a

local communications network. The unit controller can also have an optional module to provide

communication for a BAS using standard open protocols.

16 OM WMC-3

Page 17

A

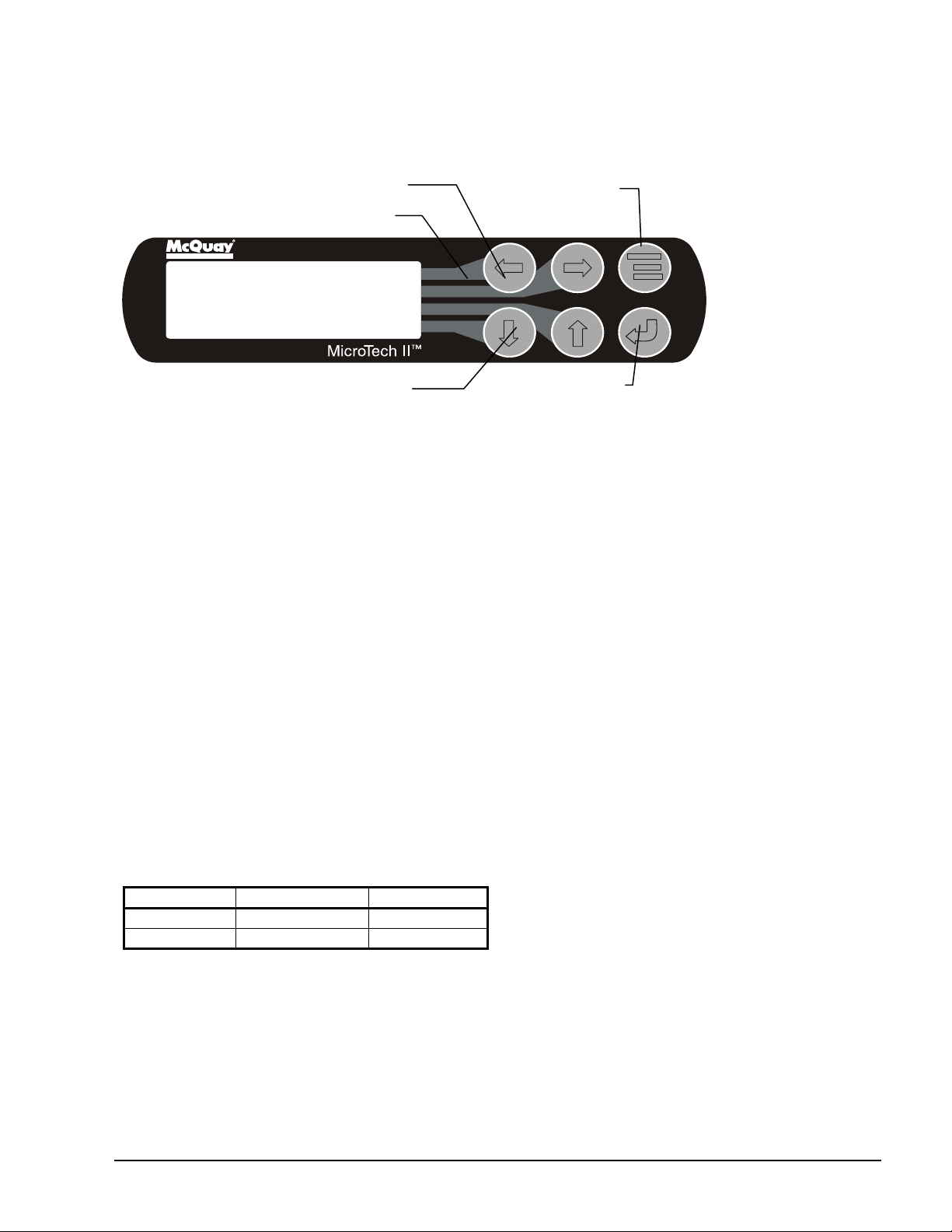

Keypad

A 4-line by 20-character/line liquid crystal display and 6-button keypad is mounted on the unit and compressor

controllers. Its layout is shown below.

Figure 6, Controller Keypad

Key-to-Screen Pathway

Air Conditioni ng

<

LARM

<

VIEW

<

SET

MENU Key

ARROW Keys (4)

ENTER Key with

Green Run Light

Behind

The four arrow keys (UP, DOWN, LEFT, RIGHT) have three modes of use:

• Scroll between data screens in the direction indicated by the arrows (default mode).

• Select a specific data screen in the menu matrix using dynamic labels on the right side of the display such

as ALARM, VIEW, etc (this mode is entered by pressing the MENU key). For ease of use, a pathway

connects the appropriate button to its respective label on the screen.

• Change field values in setpoint programming mode according to the following table:

LEFT key = Default RIGHT key = Cancel

UP key = Increase (+) DOWN key = Decrease (-)

These four programming functions are indicated by one-character abbreviation on the right side of the display.

This programming mode is entered by pressing the ENTER key.

Getting Started

There are two basic procedures to learn in order to utilize the MicroTech II controller:

1.

Navigating through the menu matrix to reach a desired menu screen, and knowing where a particular

screen is located.

2.

Knowing what is contained in a menu screen and how to read that information, or how to change a setpoint

contained in the menu screen.

Navigating

The menus are arranged in a matrix of screens across a top horizontal row. Some of these top-level screens

have sub-screens located under them. The location of each controller’s screens can be found in the following

table:

Controller Screen Matrix Screen Details

Unit Page 58 Page 60

Compressor Page 75 Not Applicable

There are two ways to navigate through the menu matrix to reach a desired menu screen.

1)

One is to scroll through the matrix from one screen to another using the four ARROW keys.

2)

Another way is to use shortcuts to work through the matrix hierarchy. From any menu screen,

a)

Pressing the MENU key will take you to the top level of the hierarchy. The display will show

ALARM, VIEW, and SET as shown in

Figure 6. One of these choices can then be selected by pressing

the key connected to it via the pathway shown in the figure.

OM WMC-3 17

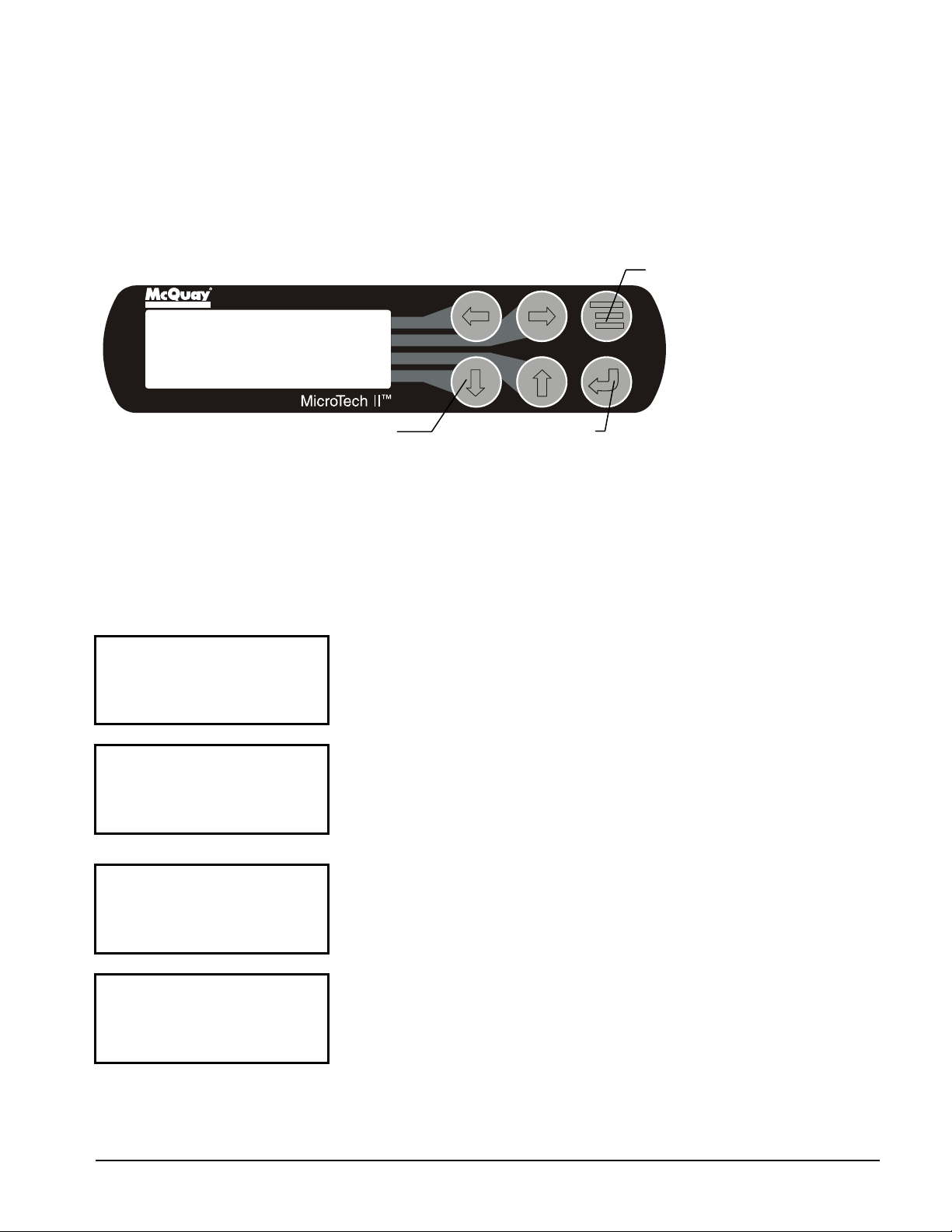

Page 18

b) Depending on the top-level selected, a second level of screens will appear. For example, selecting

ALARM will go the next level of menus under ALARM (ALARM LOG or ACTIVE ALARM).

Selecting VIEW will go the next level of menus (VIEW COMPRESSOR STATUS, VIEW UNIT

STATUS, VIEW EVAPORATOR, or VIEW CONDENSER). Selecting SET will go to a series of

menus for looking at and changing setpoints.

After selecting this second level, the desired screen can be acquired using the arrow keys. A typical

c)

final screen is shown below.

Pressing the MENU key from any menu screen will automatically return you to the MENU mode.

Figure 7, Typical Menu Display and Keypad Layout

MENU Key

Air Conditioni ng

VIEW UNIT STATUS

Unit = COOL

Compr. #1/#2=OFF/OFF

Evap Pump = RUN

ARROW Keys

ENTER Key

Menu Screens

A hierarchical menu structure is used to access the various screens. Each menu screen can have one to four

lines of information. Optionally, the last menu selection can access one of a set of screens that can be

navigated with the UP/DOWN arrow keys (see the scrolled menu structure below). Menu selection is initiated

by pressing the MENU key, which changes the display from a data screen to a menu screen. Menu selections

are then made using the arrow keys according to labels on the right side of the display (the arrows are ignored).

When the last menu item is selected, the display changes to the selected data screen. An example follows

showing the selection of the “VIEW COMPRESSOR (n) screen. Suppose the initial screen is:

ALARM LOG

(data)

(data)

After pressing the MENU button, the top-level menu screen will

show:

(data)

< ALARM

< VIEW

< SET

After pressing the “VIEW” menu button, a menu screen will

show:

<

VIEW < COMPRESSOR

< UNIT

< EVAPORATOR

After pressing the “COMPRESSOR” menu button, the selected

data screen will show;

< CONDENSER

VIEW COMP (n)

(screen n data)

(screen n data)

(screen n data)

.

18 OM WMC-3

Where “n” is the number of the last viewed COMPRESSOR

screen. The arrow keys will automatically return to the

“scroll” mode at this time. Different compressor screens can

then be selected with the UP/DOWN arrow keys.

Page 19

Unit Controller

Table 2, Unit Controller, Analog Inputs

# Description Signal Source Range

1 Reset of Leaving Water Temperature 4-20 mA Current 0-(10 to 80°F)

Entering Evaporator Water

2

Temperature

Entering Condenser Water

3

Temperature

4 Leaving Condenser Water Temperature NTC Thermistor (10k@25°C) -58 to 212°F

5 Liquid Line Refrigerant Temperature NTC Thermistor (10k@25°C) -58 to 212°F

6 Demand Limit 4-20 mA Current 0-100 %RLA

7 Evaporator Water Flow 4 to 20 mA Current 0 to 10,000 gpm

8 Condenser Water Flow 4 to 20 mA Current 0 to 10,000 gpm

9 Refrigerant Leak Sensor 4 to 20 mA Current 0 to 100 ppm

10 Spare

Table 3, Unit Controller, Digital Inputs

# Description Signal Signal

1 Unit OFF Switch 0 VAC (Stop) 24 VAC (Auto)

2 Remote Start/Stop 0 VAC (Stop) 24 VAC (Start)

3 Not Used

4 Evaporator Water Flow Switch 0 VAC (No Flow) 24 VAC (Flow)

5 Condenser Water Flow Switch 0 VAC (No Flow) 24 VAC (Flow)

NTC Thermistor (10k@25°C) -58 to 212°F

NTC Thermistor (10k@25°C) -58 to 212°F

Table 4, Unit Controller, Digital Outputs

# Description Load Output OFF Output ON

1 Evaporator Water Pump #1 Pump Contactor Pump OFF Pump ON

2 Evaporator Water Pump #2 Pump Contactor Pump OFF Pump ON

3 Condenser Water Pump #1 Pump Contactor Pump OFF Pump ON

4 Condenser Water Pump #2 Pump Contactor Pump OFF Pump ON

5 Tower Fan #1 Fan Contactor Fan OFF Fan ON

6 Tower Fan #2 Fan Contactor Fan OFF Fan ON

7 Spare

8 Alarm Alarm Indicator Alarm OFF Alarm ON

9 Tower Fan #3 Fan Contactor Fan OFF Fan ON

10 Tower Fan #4 Fan Contactor Fan OFF Fan ON

Table 5, Unit Controller, Analog Outputs

# Description Output Signal Range

1 Cooling Tower Bypass Valve Position 0 to 10 VDC 0 to 100% Open

2 Cooling Tower VFD Speed 0 to 10 VDC 0 to 100%

3 EXV signal to IB Valve Control Bd. 0 to 10 VDC 0 to 100%

4 Y3 Electronic Expansion Valve 0 to 10 VDC 0 to 100% Open

Unit Controller Setpoints

The following parameters are remembered during power off, are factory set to the Default value, and can be

adjusted to any value in the

The “Type” column defines whether the setpoint is part of a coordinated set of duplicate setpoints in different

controllers. There are three possibilities as given below:

Range column.

N = Normal setpoint - Not copied from, or copied to, any other controller.

M = Master setpoint - Setpoint is copied to all controllers in the “Sent To” column.

S = Slave setpoint - Setpoint is a copy of the master setpoint (in the unit controller).

OM WMC-3 19

Page 20

At power-up the slave node checks if the master node is operational and if so, it sets its copy of the setpoint

equal to the master’s. Otherwise, the setpoint remains unchanged. During normal operation, any time the

master setpoint changes, the slave is updated as well.

The PW (password) column indicates the password that must be active in order to change the setpoint. Codes

are as follows:

O = Operator, M = Manager, T = Technician (not available through the 4x20 display/keypad).

The following table groups setpoints that relate to the entire unit operation and are stored, for the most part, in

the unit controller. All settings are made through the OITS, indiscriminately as to whether they are “unit” or

“compressor.”

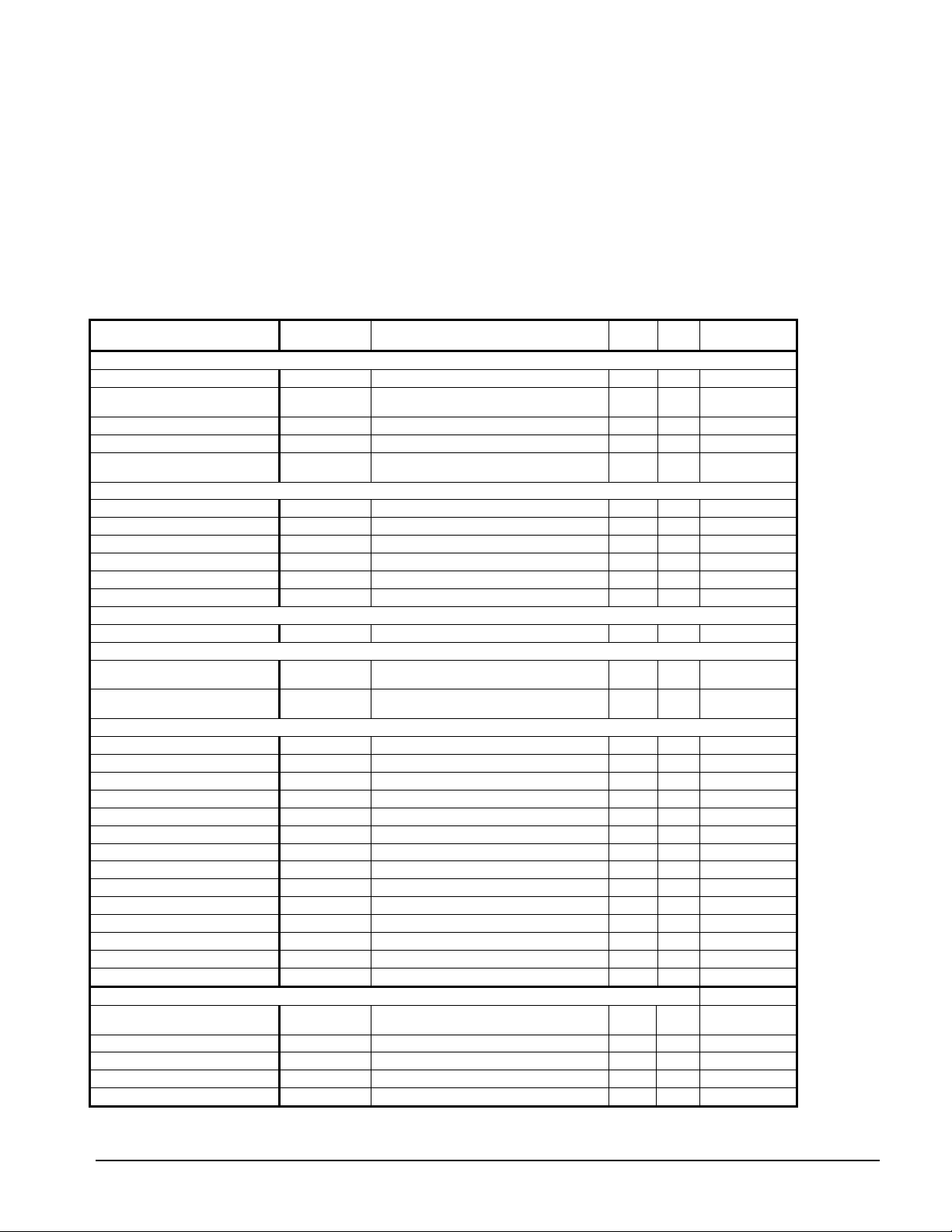

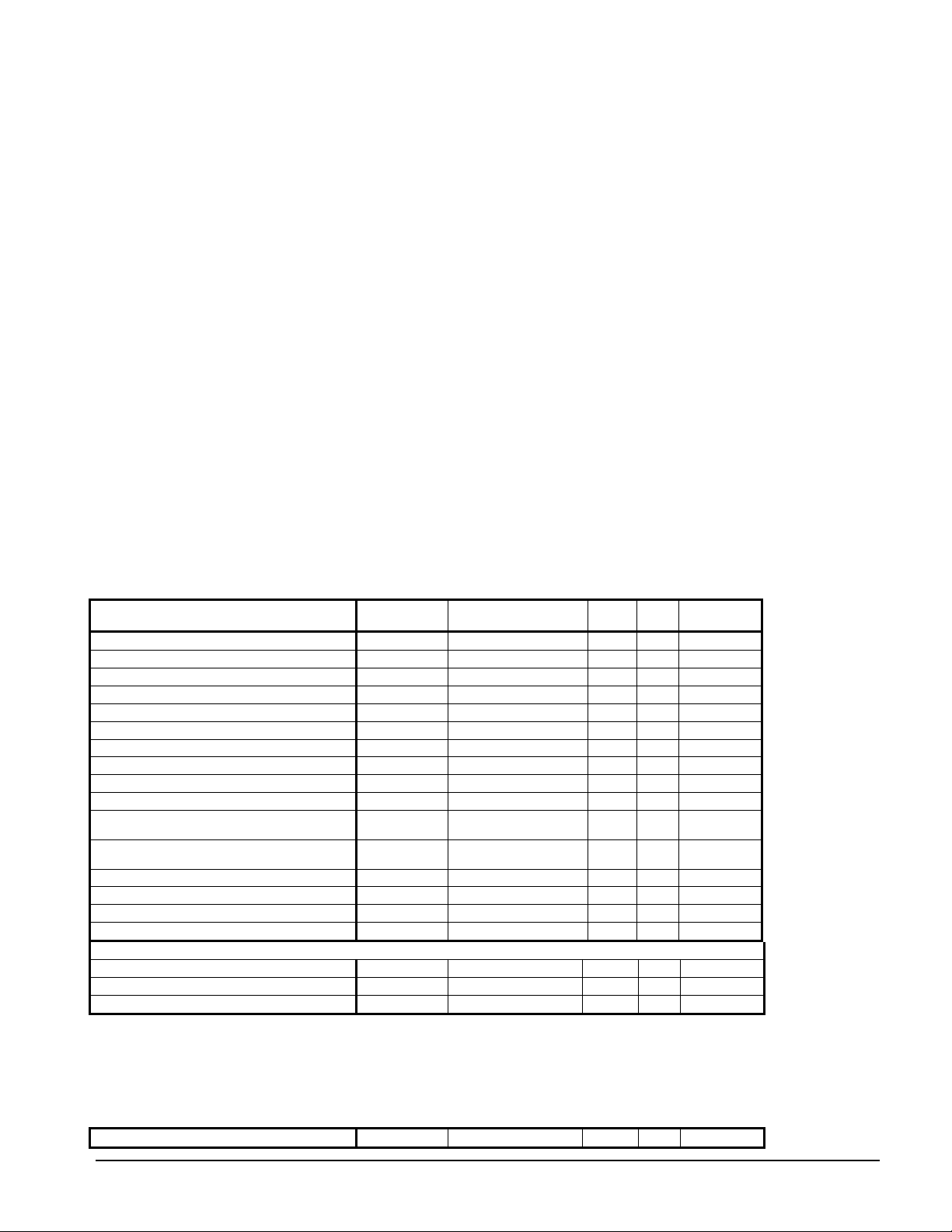

Table 6, Unit Controller Setpoints

Description Default Range Type PW

Unit

Unit Enable OFF OFF, ON M O Pg. 50

Control Source KEYPAD

Display Units N O --

Language ENGLISH ENGLISH, (TBD) N O -BAS Protocol NONE

Leaving Water

Cool LWT M O Pg. 11, Pg. 51

Startup Delta T M O Pg. 11, Pg. 51

Shutdown Delta T M O Pg. 11, Pg. 51

LWT Reset Type NONE NONE, RETURN, 4-20mA N M Pg. 22

Max Reset Delta T N M Pg. 22

Start Reset Delta T N M Pg. 22

Timers

Evap Recirculate 30 sec 15 sec to 5 min N M Pg. 5

Pumps

Evap Pump

Cond Pump

Cooling Tower

Tower Control None None, Temperature, Lift N M Pg. 46

Tower Stages 2 1 to 4 N M Pg. 46

Stage Up Time 2 min 1 to 60 min N M Pg. 46

Stage Down Time 5 min 1 to 60 min N M Pg. 46

Stage Differential (Temp) N M Pg. 46

Stage Differential (Lift) 6.0 psi 1.0 to 20.0 psi N M Pg. 46

Stage #1 On (Temp) N M Pg. 46

Stage #2 On (Temp) N M Pg. 46

Stage #3 On (Temp) N M Pg. 46

Stage #4 On (Temp) N M Pg. 46

Stage #1 On (Lift) 35 psi 10 to 130 psi N M Pg. 46

Stage #2 On (Lift) 45 psi 10 to 130 psi N M Pg. 46

Stage #3 On (Lift) 55 psi 10 to 130 psi N M Pg. 46

Stage #4 On (Lift) 65 psi 10 to 130 psi N M Pg. 46

Cooling Tower Valve / VFD

Valve/VFD Control None

Valve Setpoint (Temp) N M Pg. 46

Valve Setpoint (Lift) 30 psi 10 to 130 psi N M Pg. 46

Valve Deadband (Temp) N M Pg. 46

Valve Deadband (Lift) 4.0 psi 1.0 to 20.0 psi N M Pg. 46

°F/psi °F/psi, °C/kPa

44. 0°F 40.0 to 80.0 °F

3.0°F 0.0 to 10.0 °F

3.0°F 0.0 to 3.0 °F

0.0°F 0.0 to 20.0 °F

10. 0°F 0.0 to 20.0 °F

Pump #1

Only

Pump #1

Only

3.0 °F 1.0 to 10.0 °F

70 °F 40 to 120 °F

75 °F 40 to 120 °F

80 °F 40 to 120 °F

85 °F 40 to 120 °F

65 °F 40 to 120 °F

2.0 °F 1.0 to 10.0 °F

Pump #1 Only, Pump #2 Only, Auto

Pump #1 Only, Pump #2 Only, Auto

None, Valve Setpoint, Valve Stage,

VFD Stage, Valve SP/VFD Stage

KEYPAD, BAS,

DIGITAL INPUT

NONE, BACnet, LonWorks,

MODBUS, N2

Lead, #1 Primary, #2 Primary

Lead, #1 Primary, #2 Primary

N O Pg.

N M Pg.

N M Pg.

N M Pg.

N M Pg.

Continued on next page

Manual

Reference

50

50, Pg 77

65

65

46

20 OM WMC-3

Page 21

Description Default Range Type PW

Stage Down @ 20% 0 to 100% N M Pg. 46

Stage Up @ 80% 0 to 100% N M Pg. 46

Valve Control Range (Min) 10% 0 to 100% N M Pg. 46

Valve Control Range(Max) 90% 0 to 100% N M Pg. 46

Valve Type

Minimum Start Position 0% 0 to 100% N M Pg. 46

Minimum Position @ N M Pg. 46

Maximum Start Position 100% 0 to 100% N M Pg. 46

Maximum Position @ N M Pg. 46

Error Gain 25 10 to 99 N M Pg. 46

Slope Gain 25 10 to 99 N M Pg. 46

NC

(To Tower)

60 °F 0 to 100 °F

90 °F 0 to 100 °F

NC, NO N M Pg.

Manual

Referance

46

These setpoints are normally viewed or changed on the OITS.

Faults, Problems, Warnings

Faults (Equipment Protection Shutdowns)

There are no Unit protection shutdown alarms; all such alarms are handled through the compressor controllers.

Problems (Limit Alarms)

The following alarms limit operation of the chiller in some way as described in the Action Taken column.

Table 7, Unit Controller Limit Alarms

Description Occurs When: Action Taken Reset

Evaporator Pump #1

Fault

Evaporator Pump #2

Fault

Condenser Pump #1

Fault

Condenser Pump #2

Fault

Entering Evaporator

Water Temperature

Sensor Fault

No flow indicated for (5 sec) with Evaporator Pump #1 ON

AND [the other pump is available (per the Evap Pump SP)

AND has not faulted]

No flow indicated for (5 sec) with Evaporator Pump #2 ON

AND [the other pump is available (per the Evap Pump SP)

AND has not faulted]

No flow indicated for (5 sec) with Condenser Pump #1 ON

AND [the other pump is available (per the Evap Pump SP)

AND has not faulted]

No flow indicated for (5 sec) with Condenser Pump #2 ON

AND [the other pump is available (per the Evap Pump SP)

AND has not faulted]

Sensor fault AND leaving water reset is based on entering

water

Start pump #2 Manual

Start pump #1 Manual

Start pump #2 Manual

Start pump #1 Manual

Manual.

Reset mode is

set to No Reset

(Reset mode

goes back to

Entering

Water)

Warnings

The following “alarms” only generate a warning message to the operator. Chiller operation is not affected.

OM WMC-3 21

Page 22

Table 8, Unit Controller Warnings

Description Occurs When: Action Taken Reset

Entering Evaporator Temperature

Sensor Fault

Entering Condenser Temperature

Sensor Fault

Leaving Condenser Temperature

Sensor Fault

Liquid Line Refrigerant

Temperature Sensor Fault

Sensor is open or shorted Annunciation Automatic

Sensor is open or shorted Annunciation Automatic

Sensor is open or shorted Annunciation Automatic

Sensor is open or shorted Annunciation Automatic

Unit Controller Functions

Leaving Water Temperature (LWT) Reset

The Active Leaving Water variable shall be set to the current Leaving Water Temperature (LWT) setpoint

unless modified by one of the reset methods below. (The current LWT setpoint is Cool LWT as determined by

the chiller mode.) The type of reset in effect is determined by the LWT Reset Type setpoint.

Reset Type – NONE

The Active Leaving Water variable is set equal to the current LWT setpoint.

Reset Type – RETURN

The Active Leaving Water variable is adjusted by the return water temperature.

When the chiller mode = COOL, the Active Leaving Water variable is reset using the following parameters:

1.

Cool LWT setpoint

2.

Max Reset Delta T setpoint

3.

Start Reset Delta T setpoint

Reset is accomplished by changing the Active Leaving Water variable from the (Cool LWT setpoint) to the

(Cool LWT setpoint + Max Reset Delta T setpoint) when the evaporator (return – leaving) water temperature

delta varies from the (Start Reset Delta T setpoint) to 0.

The Active Leaving Water variable is set equal to the Cool LWT setpoint if the reset signal is less than or equal

to 4 mA. It is set equal to (Cool LWT setpoint + Max Reset Delta T setpoint) if the reset signal equals or

exceeds 20 mA. The Active Leaving Water variable will vary linearly between these extremes if the reset

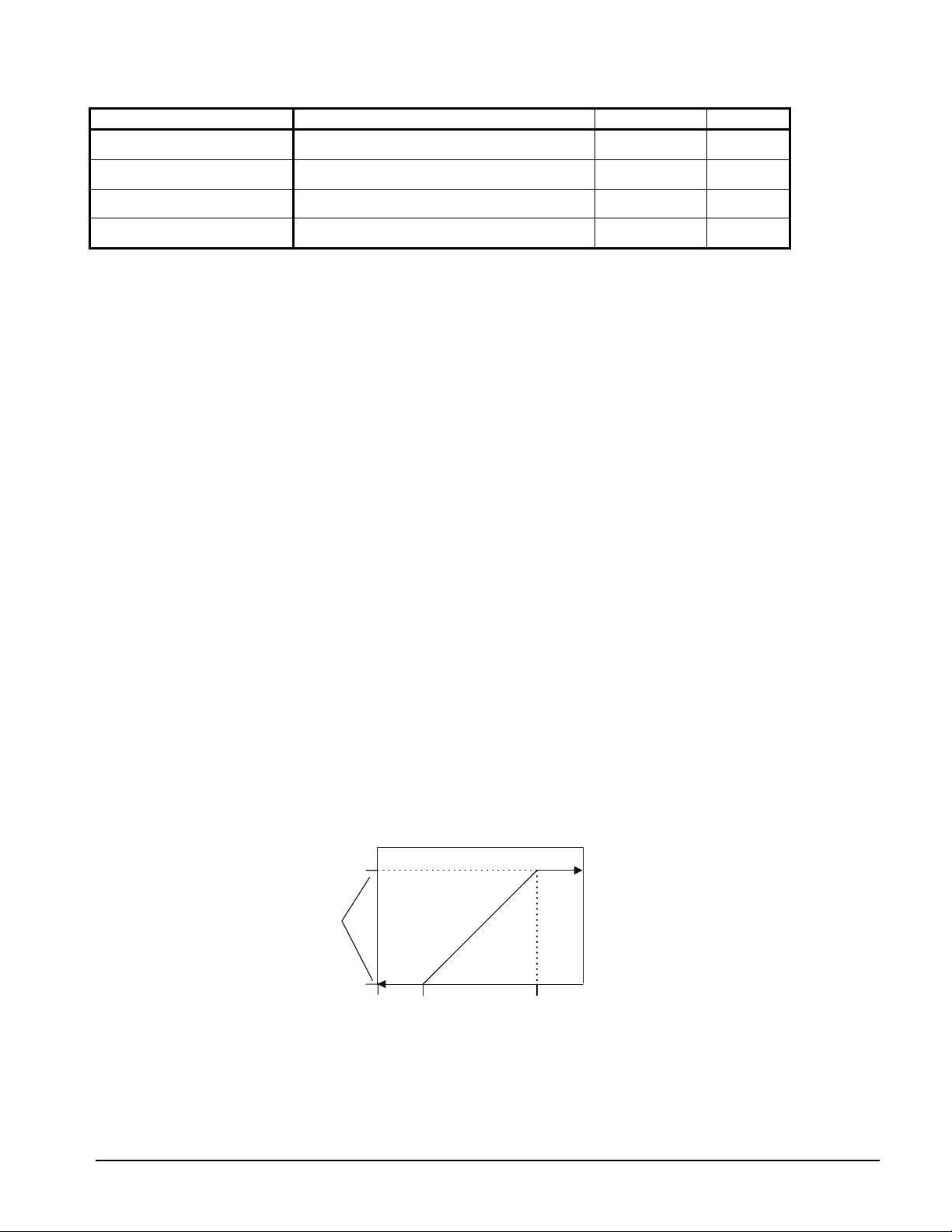

signal is between 4 mA and 20 mA. An example of this action is shown below.

LWT Reset (Cool mode)

(54.0°F)

(temperatures are examples only)

Max Reset Delta T

(10.0°F)

Cool LWT Set-Point

(44.0°F)

0 ma

4 ma

20 ma

22 OM WMC-3

Page 23

Compressor Controller

The compressor controller's primary function is controlling and protecting the compressor. No setpoints are

input to it. There is one compressor controller for each compressor on the unit. The compressor controller

receives, processes, and sends data to the unit controller, the compressor on-board microprocessors and to

external devices. With some operator intervention the compressor controller can operate the compressor if the

operator interface touch screen is unavailable. Inputs and outputs are as follows:

Table 9, Compressor Controller, Analog Inputs

# Description Signal Source Range

Leaving Evaporator Water

1

Temperature

2 Spare

3 Motor Current 0 to 5 VDC 0 to 125% RLA

Table 10, Compressor Controller, Digital Inputs

# Description Signal Signal

1 Manual Off 0 VAC (Off) 24 VAC (Auto)

2 Spare

3 Spare

4 Spare

5 Spare

6 Spare

7 Evaporator Water Flow Switch 0 VAC (No Flow) 24 VAC (Flow)

8 Condenser Water Flow Switch 0 VAC (No Flow) 24 VAC (Flow)

9 Spare

NTC Thermistor

(10k@25°C)

-58 to 212°F

Table 11, Compressor Controller, Analog Outputs

# Description Output Signal Range

1 Spare

Table 12, Compressor Controller, Digital Outputs

# Description Load Output OFF Output ON

1 Compressor Off Emer. Solenoid Circuit Breaker ON

2 Spare

3 Spare

4 Spare

5 Spare

6 Spare

7 Spare

8 Inter Lock Solenoid Comp Disabled OFF Comp. Enabled ON

9 Spare

Circuit Breaker

OFF

OM WMC-3 23

Page 24

Compressor Controller Setpoints

The following parameters in Table 13 are remembered during power off, are factory set to the Default value

and can be adjusted to any value in the

Type: column defines whether the setpoint is part of a coordinated set of duplicate setpoints in different

The “

controllers. The possibilities are given below:

• N = Normal setpoint - Not copied from or to any other controller.

• D = Duplicate setpoint. Setpoint is duplicated (same value) in all compressor controllers on the same

chiller.

• G = Group setpoint. Setpoint is duplicated (same value) in all compressor controllers on all chillers in a

group.

• M = Master setpoint - Setpoint is copied to all controllers in the “Sent To” column.

• S = Slave setpoint - Setpoint is a copy of the master setpoint (in the Unit controller).

At power-up the slave controller checks if the master is operational and if so, it sets its copy of the setpoint

equal to the master’s. Otherwise, the setpoint remains unchanged. During normal operation, any time the

master setpoint changes, the slave is updated as well.

PW (password) column indicates the password that must be active in order to change the setpoint. Codes

The

are as follows:

O = Operator, M = Manager, T = Technician (not available through the 4x20 display/keypad)

The following table groups setpoints that relate to compressor operation and are stored, for the most part, in the

compressor controllers. All settings are made through the OITS, indiscriminately as to whether they are “unit”

or “compressor.”

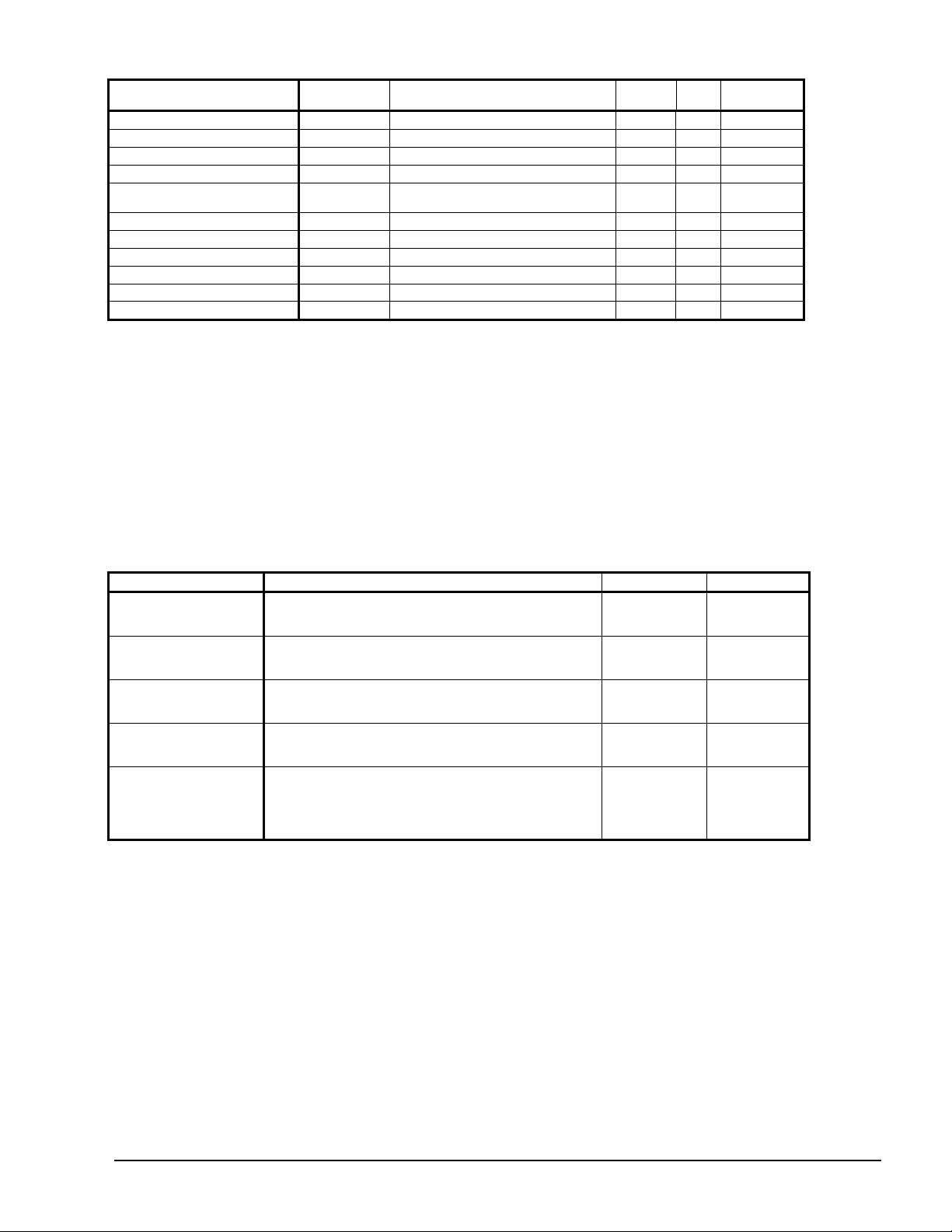

Table 13, Compressor Controller Setpoints

Description Default Range Type PW

Motor Amps

Demand Limit OFF OFF, ON N O

Minimum Amps 40% 20 to 80% N T

Maximum Amps 100% 40 to 100% N T

Soft Load OFF OFF, ON D M

Begin Amp Limit 40% 20 to 100% N M

Soft Load Ramp 5 min 1 to 60 min D M

Maximum Rate D M

Minimum Rate D M

Staging

Mode Normal

Sequence # 1

Maximum Compressors ON 16 1-16 G M

Stage Delta T 1.0 0.5-5.0 G M

Full Load 120 sec 30 to 300 sec N T

Absolute Capacity 100 Tons 0 to 9999 Tons D T

Timers

Start-Start 40 min 15 to 60 min N M

Stop-Start 3 min 3 to 20 min N M

Source No Start D T

Continued next page.

Description Default Range Type PW Manual

Range column.

0.5 °F/min 0.1 to 5.0 °F/min

0.1 °F/min 0.0 to 5.0 °F/min

Normal, Efficiency,

Pump, Standby

1,2, … (# of

Compressors)

70 °F 50 to 100 °F

Manual

Reference

N M

N M

24 OM WMC-3

Page 25

Reference

Alarms

Evaporator Freeze D T

Condenser Freeze D T

Low Evap Pressure 26 psi 10 to 45 psi D T

Low Evap Pressure-Inhibit 38 psi 20 to 45 psi D T

Low Evap Pressure-Unload 31 psi 20 to 45 psi D T

High Discharge Temperature-Shutdown N T

High Discharge Temperature-Load N T

High Condenser Pressure 140 psi 120 to 240 psi D T

Motor Current Threshold 10% 1 to 20% N T

Surge High Suction SH - Start N T

Surge High Suction SH - Run N T

Service

Vane Mode AUTO AUTO, MANUAL N T

Unload Timer 10 sec 10 to 240 sec N T

STOP Timer 1 sec 1 to 240 sec N T

34.0 °F -9.0 to 45.0 °F

34.0 °F -9.0 to 45.0 °F

190 °F 120 to 240 °F

170 °F 120 to 240 °F

50 °F 25 to 90 °F

25 °F 5 to 45 °F

These setpoints are normally viewed or changed on the OITS, but can be changed on the unit controller if the

OITS is not available.

Compressor Faults, Problems, Warnings

Faults (Equipment Protection Shutdowns)

Equipment protection faults cause rapid compressor shutdown. The compressor is stopped immediately (if the

compressor was running).

The following table identifies each alarm, gives the condition that causes the alarm to occur, and states the

action taken because of the alarm. All equipment protection alarms require a manual reset.

Table 14, Compressor Controller Faults (Equipment Protection Shutdowns)

Description Occurs When: Action Taken

Low Evaporator Pressure Evaporator Press < Low Evap Pressure SP Rapid Stop

High Condenser Pressure Cond Press > High Condenser Pressure SP Rapid Stop

Low Motor Current I < Motor Current Threshold with Compressor ON for 30 sec Rapid Stop

High Discharge Temperature Temp > High Discharge Temperature SP Rapid Stop

Mechanical High Pressure Digital Input = High Pressure Rapid Stop

High Motor Temperature Digital Input = High Temperature Rapid Stop

Surge High Suct SH-Starting

Surge High Suct SH-Running

No Compressor Stop

Starter Fault

Leaving Evaporator Water

Temperature Sensor Fault

Evaporator Pressure Sensor Fault Sensor shorted or open Rapid Stop

Condenser Pressure Sensor Fault Sensor shorted or open Rapid Stop

Suction Temperature Sensor Fault Sensor shorted or open Rapid Stop

Discharge Temperature Sensor

Fault

Evaporator Water Flow Loss Evaporator Flow DI = No Flow for > 10 sec Rapid Stop

Condenser Water Flow Loss Condenser Flow DI = No Flow for > 10 sec Rapid Stop

Temp > Surge High Suct SH-Start SP during first 5 minutes

of Compressor ON

Temp > Surge High Suct SH-Run SP after first 5 minutes of

Compressor ON

%RLA > Motor Current Threshold SP with Compressor OFF

for 30 sec

Starter Fault Digital Input = Fault AND Compressor State =

START, INTLOK, RUN, or UNLOAD

Sensor shorted or open Rapid Stop

Sensor shorted or open Rapid Stop

Rapid Stop

Rapid Stop

Annunciation

Rapid Stop

Compressor Controller Events (Limit Alarms)

The following alarms do not cause compressor shutdown but limit operation of the chiller as described in the

Action T aken column.

OM WMC-3 25

Page 26

Table 15, Compressor Controller Events

Description Occurs When: Action Taken Automatic Reset

Low Evaporator Pressure

– Inhibit Loading

Low Evaporator Pressure

– Unload

Evaporator Freeze

Protect

Condenser Freeze

Protect

High Discharge

Temperature

Pressure < Low Evap Pressure–Inhibit

setpoint

Pressure < Low Evap Pressure–Unload

setpoint

Evap Sat Refr Temp < Evaporator Freeze

setpoint

Cond Sat Refr Temp < Condenser Freeze

Setpoint

Temperature > High Discharge

Temperature-Load SP AND

Suction superheat < 15°F

Inhibit loading

Unload

Start evaporator

pump

Start condenser

pump

Load

Evap Press rises above

(SP + 3psi)

Evap Press rises above

(SP + 3psi)

Temp > (Evaporator Freeze

SP + 2°F)

Temp > (Condenser Freeze

SP + 2°F)

Temp < (High Dsch Temp

Load SP – 3°F) OR

Superheat > 18°F

Warnings

Warnings advise that a non-catastrophic problem exists, such as failed temperature sensor that provides a

signal for information, not control purposes. There are no Warnings associated with the compressor

controllers.

Compressor Controller Functions

Each compressor determines if it has reached its maximum capacity (or maximum allowed capacity) and if so,

set its Full Load flag. The flag is based on a number of conditions.

Absolute Capacity

Each compressor estimates its absolute capacity from the present value of % RLA and the Absolute Capacity

setpoint from the equation:

Absolute Capacity = (%RLA Factor) * (Absolute Capacity setpoint)

where the %RLA Factor is interpolated from the following table.

%RLA 0 50 75 100 150

%RLA Factor 0 0.35 0.75 1.00 1.50

Multiple Compressor Staging

This section defines which compressor is the next one to start or stop. The next section defines when the start,

or stop, is to occur.

Functions

1. Can start/stop compressors according to an operator defined sequence.

2.

Can start compressors based on the number of starts (run hours if starts are equal) and stop on run hours.

3.

The above two modes can be combined so that there are two or more groups where all compressors in the

first group are started (based on number of starts/hours) before any in the second group, etc. Conversely,

all compressors in a group are stopped (based on run hours) before any in the preceding group, etc.

4.

An “efficiency priority” mode can be selected for two or more chillers where one compressor is started on

each chiller in the group before a second is started on any of them.

5.

A “pump priority” mode can be selected for one or more chillers where all compressors on a given chiller

are started before going to the next chiller in the group.

6. One or more compressor can be defined as “standby” where it is never used unless one of the normal

compressors is unavailable.

Required Parameters

1. Sequence number setpoint (SQ#_SP) for all compressors. Possible settings = (1-4).

2. Compressor Staging Mode setpoint (CSM_SP) for all compressors. Possible settings are:

26 OM WMC-3

Page 27

NORMAL

•

•

EFFICIENCY PRIORITY

•

•

PUMP PRIORITY

•

•

STANDBY

•

•

3. Maximum Number of compressors ON setpoint (MAX_ON_SP). Possible settings = (1-4). This setpoint

is the same for all compressors.

4.

Number of starts for all compressors.

5.

Number of run hours for all compressors.

6.

Status of all compressors (On-line, Available/Unavailable, Starting, Running, etc.)

Configuration Rules

1. Each standby compressor must have a sequence number greater than or equal to all non-standby

compressors for which it is in standby.

2.

All compressors in an “efficiency priority” or “pump priority” group must be set to the same sequence

number.

OM WMC-3 27

Page 28

m

p

Compressor State Control (Comp State)

Operation of the compressor is controlled by the state-transition diagram shown below. A state variable (Comp

State) shall be used to maintain the current state (OFF, START, INTLOK, RUN, UNLOAD, or STOP).

Transitions from one state to another are controlled by the condition statements in the

boxes indicate actions that must be performed.

Figure 8,Compressor State

TEST:

Power ON

TEST: Motor Current < Motor Current Threshold SP

& STOP Timer Ex

ired

OFF

Unit State=AUTO

Stage Up Now = YES & (Unit Mode NOT= HEAT OR

EvLWT Temperature > Source No Start SP) &

Start-Start Timer Expired & Stop-Start Timer Expired &

No Safety Alarms

TASK: Restart Start-Start Timer

& Evap State=RUN & Next On = Yes &

TEST boxes. TASK

VaneCloseDelay

TEST: Manual OFF DI = OFF OR

Vanes Closed

OR Unload Timer Expired OR Safety Alar

TASK: Start STOP Timer

Start Stop-Start Timer & Update Run Hours

OR Unit State = OFF

UNLOAD

TEST: Manual OFF DI = OFF

TEST: Unit State = AUTO

TEST: Manual OFF DI = OFF OR

Unit State = (OFF

OR Safety Alarm

OR Unit State = OFF

& Next Off = No

OR SHUTDOWN)

START

TASK: Start Interlok Timer (10sec)

InterLock

TEST: Unit State = SHUTDOWN OR

[Next Off = Yes

TASK: Start Unload Timer

& Stage Down Now = Yes]

RUN

TEST: Unit State= AUTO & Evap State=RUN &

Cond State = RUN & Vanes Closed &

InterLok Timer Expired

TASK: Increment # of starts

Compressor Capacity Control

Leaving Water Control Mode

Compressor capacity is determined by the status of the leaving chilled water temperature (LWT), which is a

direct indicator of whether the chiller is producing enough cooling to satisfy the cooling load. The LWT is

compared to the active chilled water setpoint, and compressor loading or unloading ensues, considering any

capacity overrides that may be in effect.

Capacity Overrides

The conditions described in the following subparagraphs override normal capacity control when the chiller is

in the COOL mode. These overrides are not in effect for loading and unloading when the Vane Mode is set to

MANUAL. Of the following limits, the one creating the lowest amp limit is in effect. The resulting present

limit value for compressor current is stored in the Active Demand Limit variable.

Low Evaporator Pressure

If the evaporator pressure drops below the Low Evaporator Pressure – Inhibit setpoint, the unit will inhibit

capacity increase. If the evaporator pressure drops below the Low Evaporator Pressure - Unload setpoint, the

unit will begin capacity decrease.

28 OM WMC-3

Page 29

High Discharge Temperature - Load

If the discharge temperature rises above the High Discharge Temperature - Load setpoint and the motor current

is < 50% RLA, the unit will begin capacity increase.

Soft Load

Soft Loading is a configurable function used at compressor startup to limit the maximum current draw on the

compressor in a ramp-up type manner. It is only active on the first compressor to start. The setpoints that

control this function are:

Soft Load – (ON/OFF)

•

•

Begin Amp Limit – (%RLA)

•

•

Maximum Amps – (%RLA)

•

•

Soft Load Ramp – (seconds)

•

•

The active soft load limit value (in % RLA) increases linearly from the Begin Amp Limit setpoint to the

Maximum Amps setpoint over the amount of time specified by the Soft Load Ramp setpoint. If the amp draw

rises above the currently active soft load limit value, the unit will inhibit capacity increases. If the amp draw

rises to 5% or more above this value, the unit will begin capacity decrease.

Maximum LWT Rate

The maximum rate at which the leaving water temperature can drop (chiller mode = COOL) is limited at all

times by the Maximum Rate setpoint. If the rate exceeds this setpoint, capacity increases is inhibited.

Demand Limit

The maximum amp draw of the compressor can be limited by a 4 to 20 mA signal on the Demand Limit analog

input. This function is only enabled if the Demand Limit setpoint is set to ON. The amp limit decreases

linearly from the Maximum Amp Limit setpoint (at 4 mA) to the Minimum Amp Limit setpoint (at 20mA). If

the amp draw rises above the limit value, the unit will inhibit capacity increases. If the amp draw rises to 5%

or more above this value, the unit will begin capacity decrease.

Network Limit

The maximum amp draw of the compressor can be limited by a value sent through a BAS network connection

and stored in the Network Limit variable. If the amp draw rises above the limit value, the unit will inhibit

capacity increases. If the amp draw rises to 5% or more above this value, the unit will begin capacity decrease.

Minimum Amp Limit

The minimum amp draw of the compressor can be limited by the Minimum Amps setpoint. If the amp draw

drops below the limit value, the unit will inhibit capacity decrease.

Maximum Amp Limit

The maximum amp draw of the compressor is always limited by the Maximum Amps setpoint. This limit has

priority over all other functions including manual capacity control. If the amp draw rises above the limit value,

the unit will inhibit capacity increases. If the amp draw rises to 5% or more above this value, the unit will

begin capacity decrease.

OM WMC-3 29

Page 30

Compressor On-Board Controllers

Each compressor is equipped with microprocessor controllers and sensors that provide control and data

acquisition. The data is transmitted to other controllers and the OITS via the multi-unit communication

network. The on-board controllers consist of:

• Compressor Controller: the compressor controller is the central processor of the compressor. It is

continually updated with critical data from the motor/bearing controller and external sensors. An

important function is to control the compressor speed and guide vanes operation in order to satisfy load

requirements, to avoid surge and to provide for optimum efficiency. The controller monitors over 60

parameters, including:

Refrigerant pressures and temperatures Line voltage

Phase failure detection Motor temperature

Silicone Rectifier (SCR) temperature Speed

Line currents Guide vane position

• Soft-Start Controller: the soft-start controller limits current inrush by temporarily inserting a charging

resistor between the ac line and the +DC bus. It works in conjunction with the variable-speed function.

• Motor/Bearing Controller: the motor/bearing system provides the measurements and control to calculate

and maintain the desired shaft position. An RS-485 link connects the bearing controller and the

compressor controller.

• Backplane: although not a controller, the backplane connects the on-board control modules with the soft-

start controller, power electronics, motor cooling solenoids and pressure/temperature sensors.

Figure 9, Compressor Electric/Electronic Components

1. Rectifiers

2. Main Power Block

3. Soft Start Controller

4. Insulated-gate

Bipolar Transistor

I.G.B.T Inverter

5. High Voltage DC-DC

Converter

6. Compressor, Bearing/Motor

Controllers

7. Interstage pressure /

temperature sensor

8. Suction Pressure /

temperature sensor

4

5

6

3

7

8

2

1

30 OM WMC-3

Page 31

A

CROTECH CO

A

A

A

Figure 10, Field Wiring Diagram

MI

BOX TERMINALS

(115V) (24V)

UTB1

PE

54

85

86

70

80

55

74

86

86

79

73

78

77

76

75

CF1

EF1

EF2

CF2

81

82(NO)

83(NC)

84

* COOLING

TOWER

FOURTH

STAGE

STARTER

* COOLING

TOWER

THIRD

STAGE

STARTER

* COOLING

TOWER

SECOND

STAGE

STARTER

* COOLING

TOWER

FIRST

STAGE

STARTER

GND

POWER

*

NOTE 6

NEUTRAL

NOTE 9

*

H

O

C4

A

NOTE 9

*

H

O

C3

A

*

NOTE 9

H

O

C2

A

NOTE 9

*

H

O

C1

A

COMMON

*

NOTE 3

POWER

NTROL

A

(NOTE 5)

SWITCH

DELTA P

FLOW OR

EVAP.

*ALARM RELAY

(NOTE 3)

*

MODE SWITCH

(NOTE 5)

SWITCH

DELTA P

FLOW OR

COND.

* REMOTE

ON/OFF

(NOTE 4)

*

NOTE 7

EP2

NOTE 10

*

NOTE 7

EP1

NOTE 10

O

O

EWI-1

*

NOTE 8

NOTE 10

H

EWI-2

H

CP2

C

* CHILLED

WATER

PUMP

STARTERS

C

H

O

C

CWI-2

* CONDENSER

WATER

PUMP

STARTERS

*COOLING TOWER BYPASS VALUE

*COOLING TOWER VFD

0-10 VDC

0-10 VDC

52

71

71

53

NOTE 8

*

NOTE 10

CP1

H

O

CWI-1

C

330617801 REV. 00

1. Compressor terminal boxes are factory-mounted and wired. All line-side wiring must be in accordance with the NEC and be made with copper

wire and copper lugs only. Power wiring between the terminal box and compressor terminals is factory installed.

Minimum wire size for 115 vac is 12 ga. for a maximum length of 50 feet. If greater than 50 feet refer to McQuay for recommended wire size

2.

minimum. Wire size for 24 vac is 18 ga. All w iring to be installed as N E C Class 1 w iring sy stem. All 24 vac wiring must be run in separate

conduit from 115 vac wiring. Wiring must be wired in accordance with NEC and connection to be made with copper wire and copper lugs only.

A customer furnished 24 or 120 vac power for alarm relay coil may be connected between UTB1 terminals 84 power and 81 neutral of the control

3.

panel. For normally open contacts wire between 82 & 81. For normally closed wire between 83 & 81. M aximum rating of the alarm relay coil is

25 VA.

Remote on/off control of unit can be accomplished by installing a set of dry contacts between terminals 70 and 54.

4.

5.

If field supplied pressure differential or flow switches are used, they must be installed across the vessel and not the pump. They must be suitable

for 24vac and low current application. The unit is shipped with factory-mounted and wired thermal dispersion flow switches.

6. Customer supplied 115 vac 20 amp power for optional evaporator and condenser water pump control power and tower fans is supplied to unit

control terminals (UTB1) 85 power / 86 neutral, PE equipment ground.

7. Optional customer supplied 115 vac, 25 VA maximum coil rated, chilled water pump relay (ep1 & 2) may be wired as shown. This option will

cycle the chilled water pump in response to chiller demand.

The condenser water pump must cycle with the unit. A customer supplied 115 vac 25 VA maximum coil rated, condenser water pump relay (CP1 &

8.

2) is to be wired as shown. Units with free-cooling must have condenser water above 60°F before starting.

Optional customer supplied 115 vac 25 VA maximum coil rated cooling tower fan relays (C1 - C2 standard, C3-C4 optional) may be wired as

9.

shown. This option will cycle the cooling tower fans in order to maintain unit head pressure.

10. Auxiliary 24 vac rated contacts in both the chilled water and condenser water pump starters should be wired as shown.

11.

Voltage unbalance not to exceed 2% with a resultant current unbalance of 6 to 10 times the voltage unbalance per NEMA MG-1, 1998 Standard

OM WMC-3 31

Page 32

Interface Touch Screen

Navigation

The home-view screen shown on page 34 is usually left on (there is a screen-saver built in that is reactivated

by touching the screen anywhere). This VIEW screen contains the STOP and AUTO buttons used to start and

stop the unit when in Local control. Other groups of screens can be accessed from the Home screen by

pressing one of three buttons on the bottom of the screen: HISTORY, VIEW, SET.

• HISTORY will go to the last history screens viewed and can toggle between the two history screens.

• Trend History

• Alarm History

• VIEW will go to the home View screen. Pressing again will go to the detail View screen used to look in detail