Page 1

Installation Maintenance Manual

IMM WMC-1

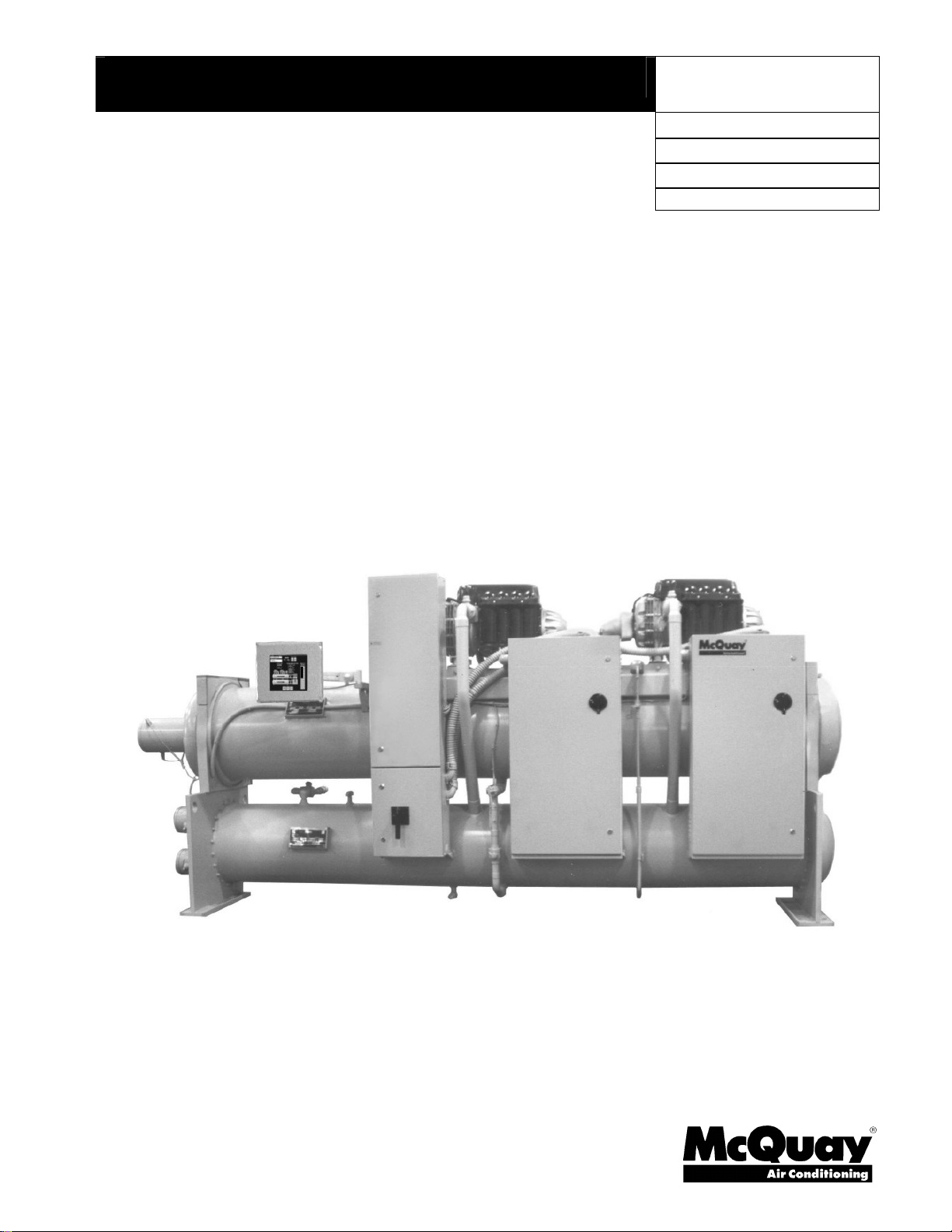

Dual Compressor Centrifugal Chillers

with Magnetic Bearings

Model WMC-035T, Cooling Only

50/60 Hertz

R-134a

Group: Chiller

Part Number: 331374601

Effective: June 2005

Supersedes: IMM WMC

Page 2

Table of Contents

p

Introduction...........................................3

General Description........................................3

Nomenclature .................................................3

Installation.............................................4

Receiving and Handling.................................4

Location and Mounting...................................5

Water Piping...................................................5

Field Insulation...............................................7

Physical Data and Weights..............................8

Dimensions.....................................................9

Pressure Drop Curves...................................12

Relief Valves.................................................13

Electrical.......................................................14

Power Wiring................................................14

Electrical Data..............................................15

Use with On-Site Generators........................16

System Pumps...............................................17

Field Wiring Diagram...................................19

Multiple Chiller Setup..................................22

Prestart System Checklist .............................24

Operation.............................................25

Operator Responsibilities.............................25

Compressor Operation .................................25

Operating Limits:.........................................25

MicroTech II™ Control................................27

Building Automation Systems............27

Capacity Control System..............................29

Surge and Stall.............................................30

Condenser Water Temperature.....................30

Normal Unit Startup/Shutdown....................32

Annual Unit Startup/Shutdown.....................33

Maintenance........................................34

Pressure/Temperature Chart.........................34

Routine Maintenance....................................35

Repair of System..........................................36

Maintenance Schedule........................38

Service Programs................................39

Operator Schools................................39

Warranty Statement ...........................39

Unit controllers are LONMARK certified with an

o

tional LONWORKS communications module.

Manufactured in an ISO Certified Facility

Information and illustrations cover the McQuay International products at the time of publication and we reserve the right to make

®™ The following are trademarks or registered trademarks of their respective companies: BACnet from ASHRAE; Modbus from Gould, Inc;

L

ONMARK and LONWORKS from Echelon Corporation; and MicroTech II from McQuay International; Victaulic from Victaulic Company;

changes in design and construction at anytime without notice.

¤2005 McQuay International

2 Centrifugal Chillers IMM WMC-1

Page 3

Introduction

General Description

The McQuay Model WMC Centrifugal Water Chiller is a complete, self-contained, automatically

controlled, fluid-chilling unit featuring dual, oil-free, magnetic bearing compressors. Each unit is

completely assembled and factory tested before shipment.

The WMC chillers are equipped with two compressors operating in parallel with a single evaporator

and single condenser.

The chillers use refrigerant R-134a that operates at a positive pressure over the entire operation

range, so no purge system is required.

The controls are pre-wired, adjusted and tested. Only normal field connections such as water piping,

relief valve piping, electric power and control interlocks are required, thereby simplifying

installation and increasing reliability. Necessary equipment protection and operating controls are

included.

All McQuay centrifugal chillers are factory-tested prior to shipment and must be commissioned by a

factory-trained McQuay service technician. Failure to follow this startup procedure can affect the

equipment warranty.

The standard limited warranty on this equipment covers parts that prove defective in material or

workmanship. Specific details of this warranty can be found in the warranty statement furnished

with the equipment.

Cooling towers used with McQuay centrifugal chillers are normally selected for condenser water

inlet water temperatures between 75°F and 90°F (24°C and 32°C). Lower entering water

temperatures are desirable from the standpoint of energy reduction, but a minimum does exist. For

recommendations on optimum entering water temperature and cooling tower fan control, consult the

“Condenser Water” section on page 30.

Nomenclature

W = Water-cooled

M = Magnetic B earings

Centrifugal Compressor

W

M C 035 T

Twin Compressors

Impeller Diameter

3.5 inches

IMM WMC-1 Centrifugal Chillers 3

Page 4

Installation

k

t

Receiving and Handling

The unit should be inspected immediately after receipt for possible damage.

All McQuay centrifugal water chillers are shipped FOB factory and all claims for handling and

shipping damage are the responsibility of the consignee.

On units with factory-installed insulation, the insulation is removed from the vessel lifting hole

(also used for transportation tie-downs) locations and are shipped loose. They should be glued in

place after the unit is finally placed. Neoprene vibration pads are also shipped loose. Check that

these items have been delivered with the unit. They are usually placed in a control panel.

If so equipped, leave the shipping skid in place until the unit is in its final position. This will aid

in handling the equipment.

Extreme care must be used when rigging the unit to prevent damage to the control panels and

refrigerant piping. See the certified dimension drawings included in the job submittal for the

center of gravity of the unit. If the drawings are not available, consult the local McQuay sales

office for assistance.

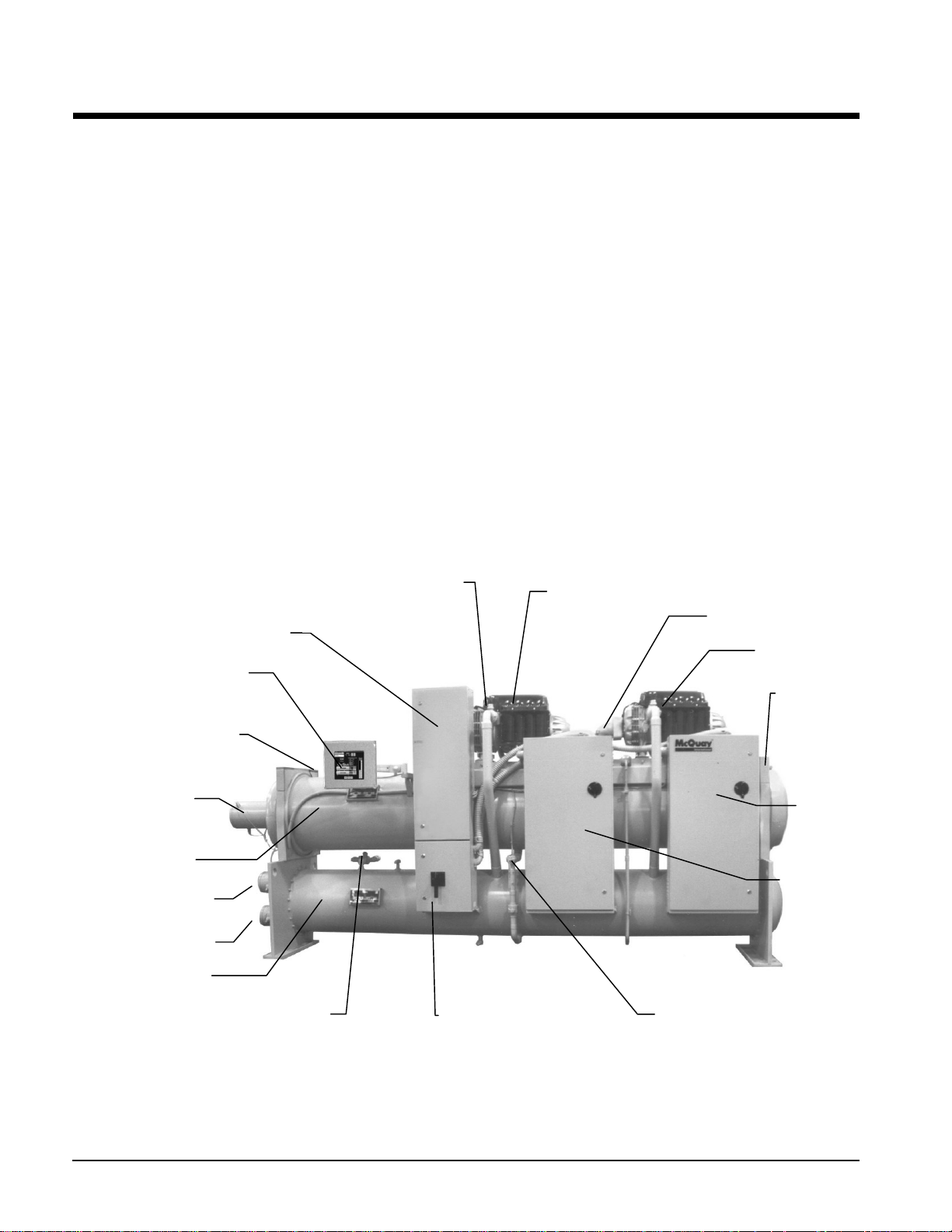

The unit can be lifted by fastening the rigging hooks to the four corners of the unit where the

rigging eyes are located (see Figure 1). Spreader bars must be used between the rigging lines to

prevent damage to the control panels, piping and electrical panels.

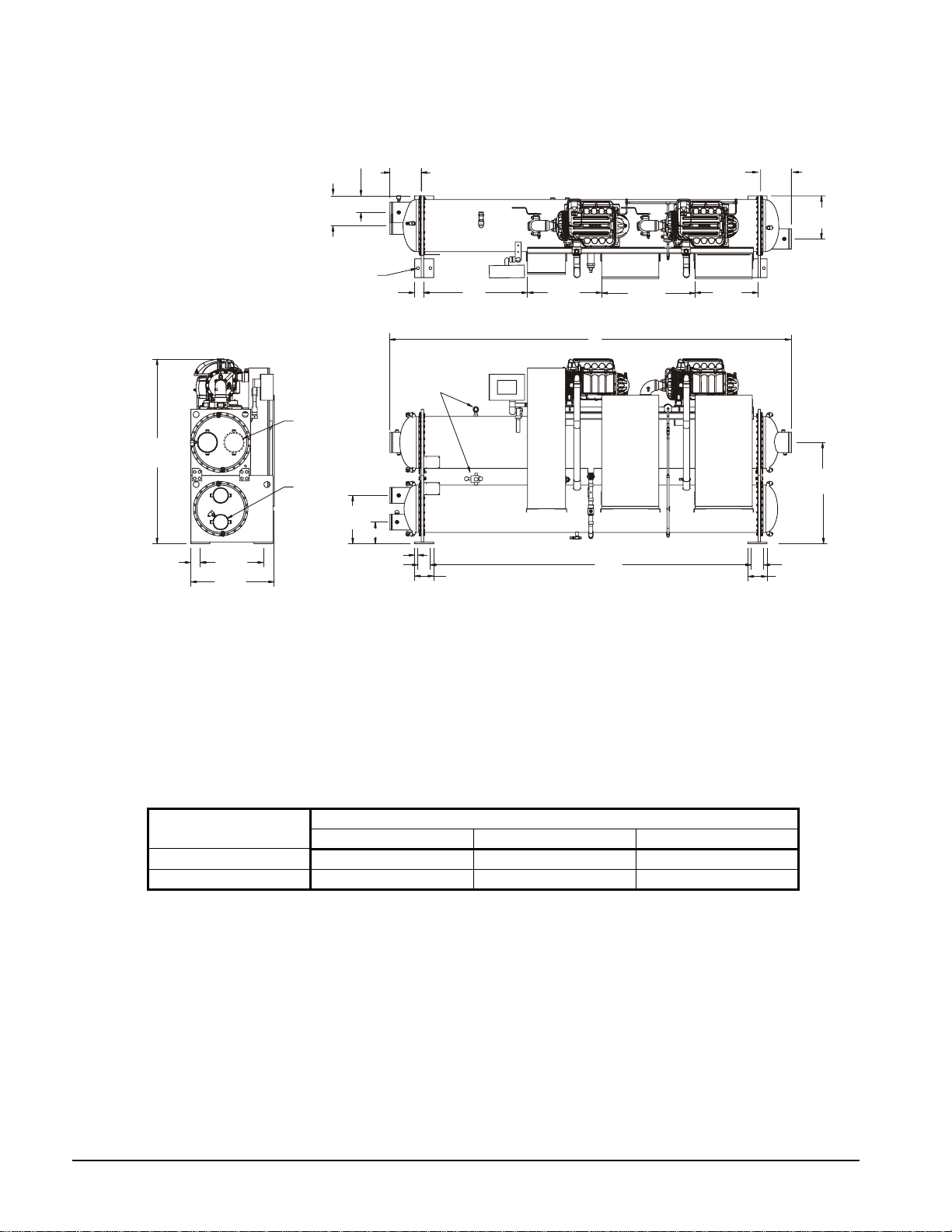

Figure 1, WMC Major Component Locations

Control Panel

Operator Interface

Touch Screen, OITS

Evaporator Relief Valve

Combined

Discharge Chec

Compressor #1

Suction Shutoff Valve

Compressor #2

Rigging Holes

Each Corner

Outle

Evaporator

Outlet

Inlet

Condenser

Condenser

Relief Valves

Optional Single-Point

Power Block or

Disconnect Switch

Electronic Expansion Valve

4 Centrifugal Chillers IMM WMC-1

Circuit #2

Power Panel

Circuit #1

Power Panel

Page 5

Location and Mounting

Clearance

The unit must be mounted on a level concrete or steel base and must be located to provide service

clearance at one end of the unit for possible removal of evaporator and/or condenser tubes. Evaporator

and condenser tubes are rolled into the tube sheets to permit replacement if necessary. The length of the

vessel should be allowed at one end. Doors or removable wall sections can be utilized for tube clearance.

Clearance at all other points, including the top, is 3 feet (1 meter). The U.S. National Electric Code

(NEC) can require more clearance in and around electrical components (4-feet in front of electrical

panels) and must be checked.

Vibration Pads

The shipped-loose neoprene vibration pads should be located under the corners of the unit (unless the job

specifications state otherwise). They are installed to be flush with the sides and outside edge of the feet.

Mounting

Make sure that the floor or structural support is adequate to support the full operating weight of the

complete unit.

It is not necessary to bolt the unit to the mounting slab or framework; but should this be desirable, 1 1/8"

(28.5 mm) mounting holes are provided in the unit support at the four corners.

Note: Units are shipped with refrigerant valves closed to isolate the refrigerant in the unit

condenser. Valves must remain closed until start-up by the McQuay technician.

Nameplates

There are several identification nameplates on the chiller:

• The unit nameplate is located on the Unit Control Panel. It has a Model No. XXXX and Serial No.

XXXX. Both are unique to the unit and will identify it. These numbers should be used to identify

the unit for service, parts, or warranty questions. This plate also has the unit refrigerant charge.

• Vessel nameplates are located on the evaporator and condenser. Along with other information, they

have a National Board Number (NB) and a serial number, either of which identify the vessel (but

not the entire unit).

Water Piping

Evaporator and Condenser Water Piping

All evaporators and condensers come standard with groove-type nozzles for Victaulic couplings (also

suitable for welding), or optional flange connections. The installing contractor must provide matching

mechanical connections of the size and type required.

CAUTION

Freeze Notice: Neither the evaporator nor the condenser is self-draining;

both must be blown out to help avoid damage from freezing.

The piping should include thermometers at the inlet and outlet connections and air vents at the high points.

The water heads can be interchanged (end for end) so that the water connections can be made at either end of

the unit. If this is done, new head gaskets must be used and control sensors relocated.

In cases where the water pump noise can be objectionable, vibration isolation sections are recommended at

both the inlet and outlet of the pump. In most cases, it will not be necessary to provide vibration eliminator

sections in the condenser inlet and outlet water lines. But they can be required where noise and vibration are

critical.

IMM WMC-1 Centrifugal Chillers 5

Page 6

Important Notes on Welding

If welding is to be performed on the mechanical or flange connections:

1. Remove the solid-state temperature sensor, thermostat bulbs and optional nozzle mounted

flow switches (if so equipped) from the wells to prevent damage to those components.

2. Properly ground the unit or severe damage to the MicroTech II unit controller can occur.

Welding should never be performed on a vessel shell or tube sheet, as this will revoke the ASME

certification.

Water pressure gauge connection taps and gauges must be provided in the field piping at the inlet

and outlet connections of both vessels for measuring the water pressure drop. The pressure drops

and flow rates for the various evaporators and condensers are job specific and the original job

documentation can be consulted for this information. Refer to the nameplate on the vessel shell

for identification.

Connections

Be sure that water inlet and outlet connections match certified drawings and stenciled nozzle

markings. The condenser is connected with the coolest water entering at the bottom connection

to maximize subcooling. The evaporator outlet is on the side of the unit with the two power

panels, regardless of which end the connections are on. See Figure 1.

CAUTION

When common piping is used for both building heating and cooling modes, care must

be taken to provide that water flowing through the evaporator cannot exceed 110°F

which can cause the relief valve to discharge refrigerant or damage controls.

Piping must be supported to eliminate weight and strain on the fittings and connections. Chilled

water piping must be adequately insulated. A cleanable 20-mesh water strainer must be installed

in both water inlet lines. Sufficient shutoff valves must be installed to permit draining the water

from the evaporator or condenser without draining the

complete system.

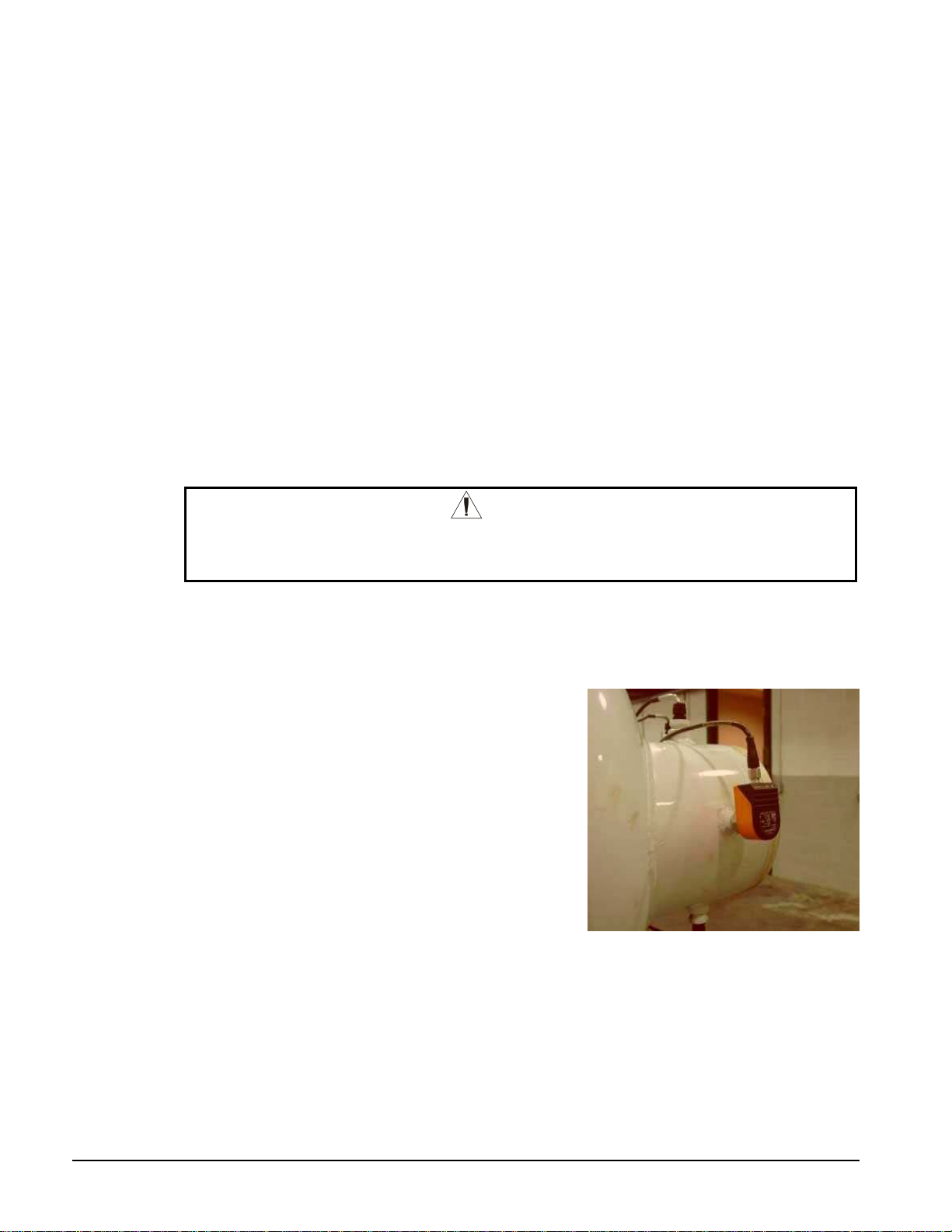

Figure 2, Unit-Mounted Flow Switch

Flow Switch

Chiller units must be provided with flow switches for

the evaporator and condenser. McQuay furnishes

factory-installed and wired, thermal-type flow

switches as standard equipment on WMC chillers.

They prevent the unit from starting without sufficient

water flow through the vessels. They also serve to

shut down the unit in the event that water flow is

interrupted to guard against evaporator freeze-up or

excessive discharge pressure.

Additionally, for a higher margin of protection,

normally open auxiliary contacts in the pump starters

can be wired in series with the flow switches as shown in the Field Wiring Diagram.

Cooling Towers

The condenser water flow rate must be checked to be sure that it conforms to the system design.

A tower bypass valve is required to control the minimum condenser entering temperature. Unless

the system and chiller unit are specifically designed for them, condenser bypass or variable

condenser flow is not recommended, since low condenser flow rates can cause unstable operation

and excessive tube fouling.

6 Centrifugal Chillers IMM WMC-1

Page 7

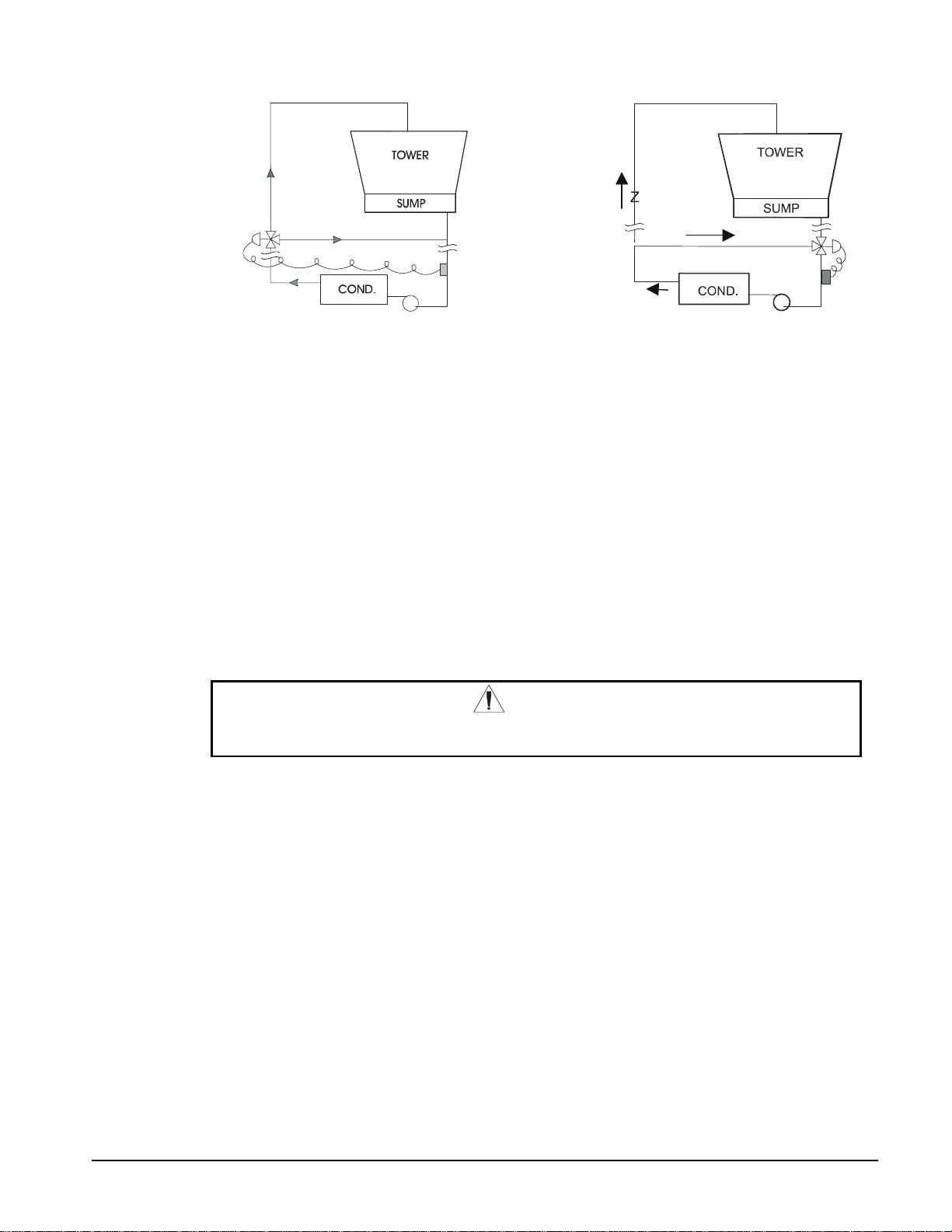

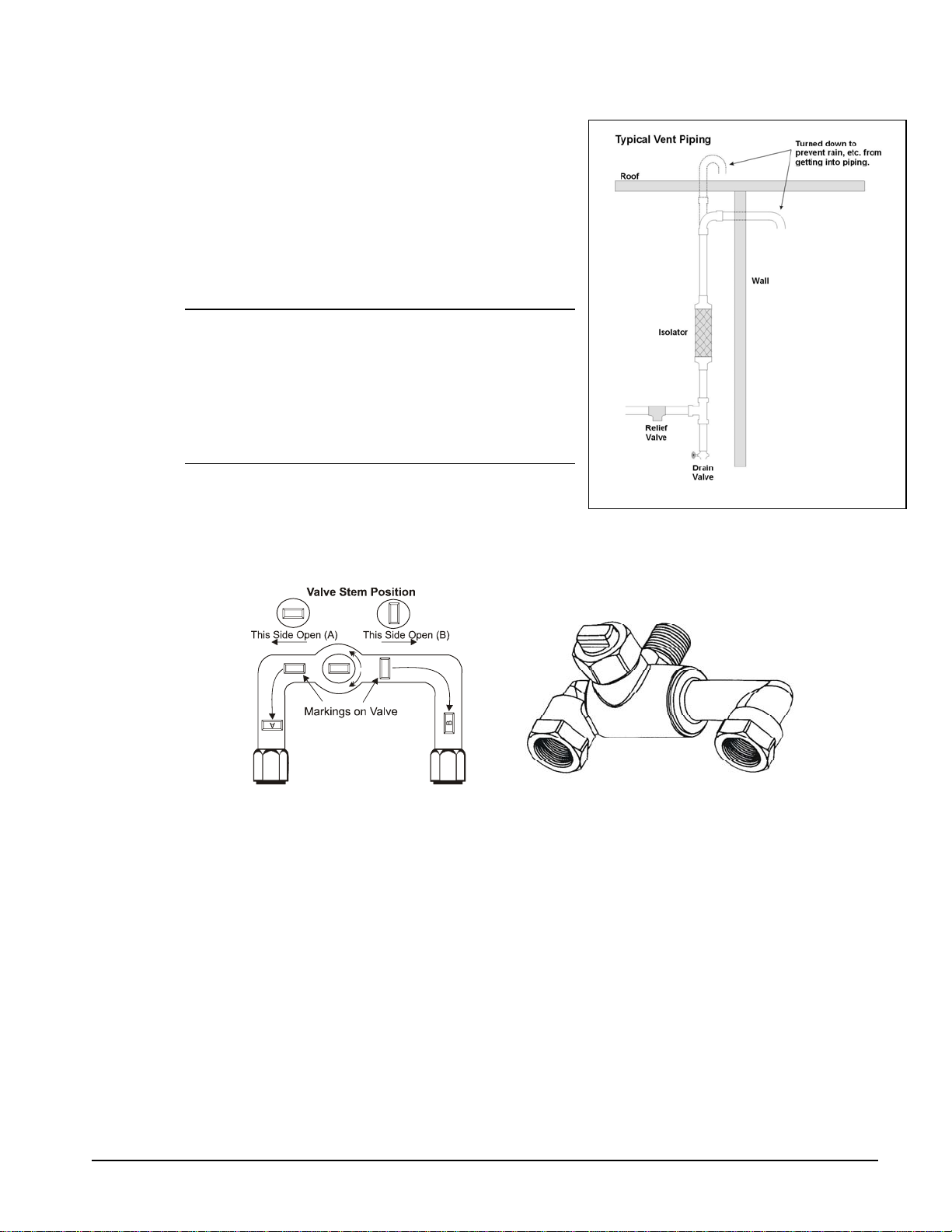

Figure 3, Bypass, Mild Weather Operation

Bypass, Cold Weather Operation

Low Condenser Water Temperature Operation

When ambient wet bulb temperature are lower than design, the entering condenser water

temperature can be allowed to fall to improve chiller performance. This is especially true of an

advanced design such as the McQuay WMC that features variable compressor speed.

It is an engineering fact that as the compressor discharge pressure is reduced the amount of power

to pump a given amount of gas also is reduced. The reduction can result in significant energy

savings.

However, as with most centrifugal chiller applications, a tower bypass valve must be installed.

Figure 16 illustrates two temperature actuated tower bypass arrangements. The “Cold Weather”

scheme provides better startup under cold ambient air temperature conditions. The check valve

may be required to prevent entraining air at the pump inlet.

Minimum Condenser Water Temperatur e

The McQuay WMC centrifugal chiller will start and run with 55°F (12.8°C) entering condenser

water temperature.

It is highly recommended that the condenser water pumps cycle on and off with the unit to reduce

the possibility of refrigerant migration to the condenser. See on page 19 for wiring details.

CAUTION

Tower water treatment is essential for continued efficient and reliable unit operation.

If not available in-house, competent water treatment specialists should be contracted.

Field Insulation

If the optional factory-installation of thermal insulation is not ordered, insulation should be field

installed to reduce heat loss and prevent condensation from forming. Insulation should cover the

evaporator barrel, tube sheet, and water heads, plus the suction line to the compressor flange and

the compressor end bell opposite the suction connection.

The optional factory-installed insulation of cold surfaces includes the evaporator and nonconnection water head, suction piping, compressor inlet, and motor housing.

Insulation is UL recognized (File # E55475). It is 3/4" thick ABS/PVC flexible foam with a skin.

The K factor is 0.28 at 75°F. Sheet insulation is fitted and cemented in place forming a vapor

barrier, then painted with a resilient epoxy finish that resists cracking.

The insulation complies to, or has been tested in accordance, with the following:

ASTM-C-177 ASTM-C-534 Type 2 UL 94-5V

ASTM-D-1056-91-2C1 ASTM E 84 MEA 186-86-M Vol. N

CAN/ULC S102-M88

IMM WMC-1 Centrifugal Chillers 7

Page 8

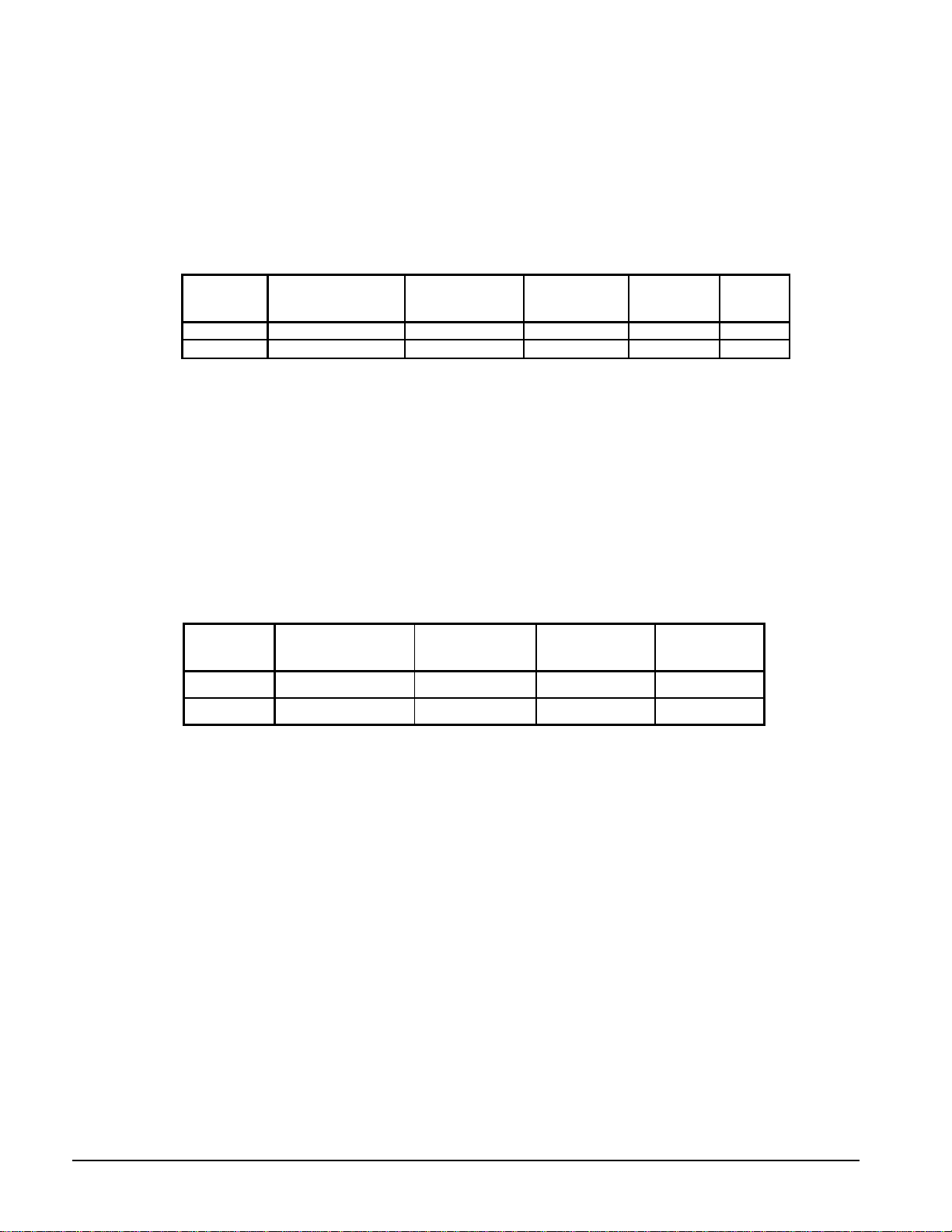

Physical Data and Weights

Evaporator

Refrigerant-side design pressure is 200 psi (1380 kPa). Water-side is 150 psi (1034 kPa).

In the event insulation is to be field-installed, none of the cold surfaces identified above will be

factory insulated. Approximate total square footage of insulation surface required for individual

packaged chillers is tabulated by evaporator code and can be found below.

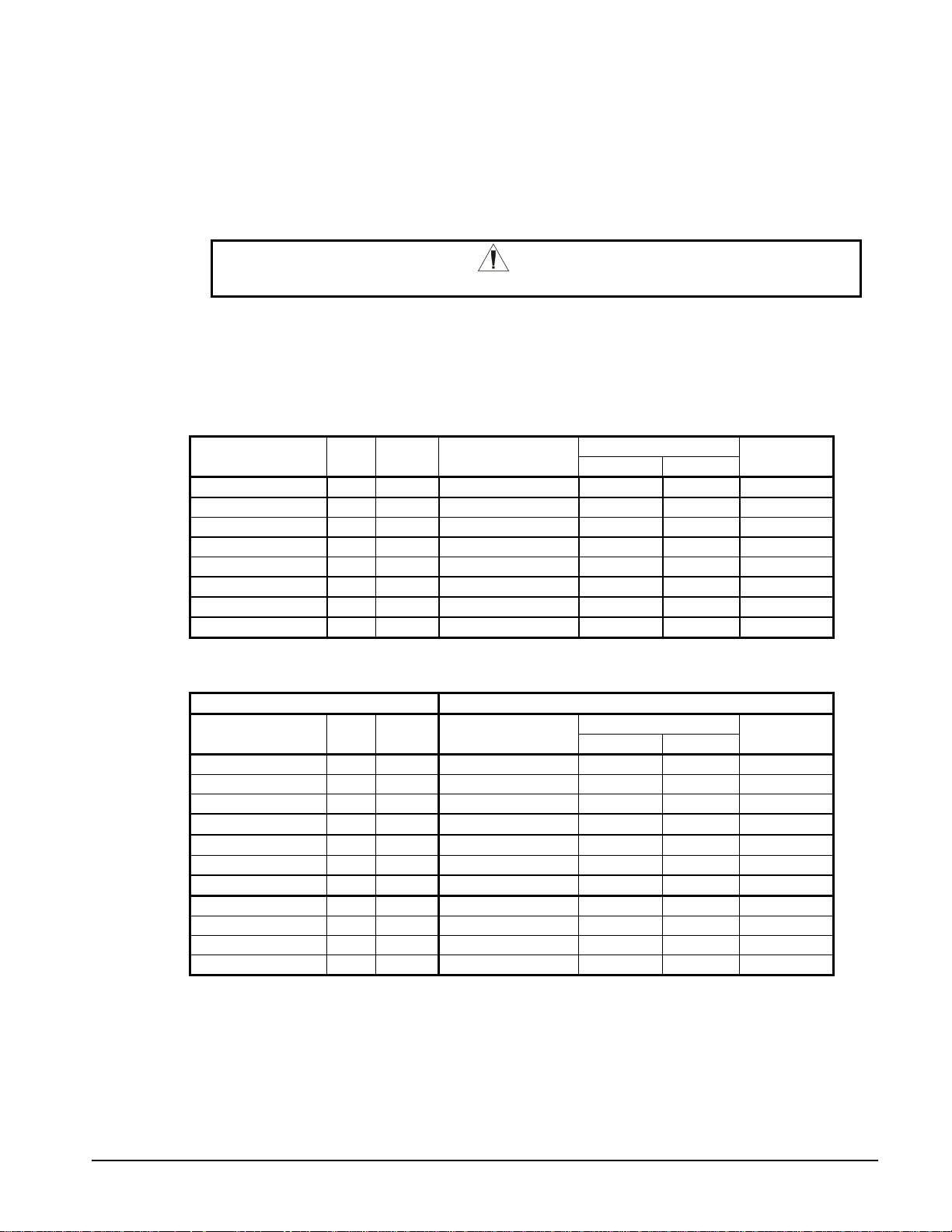

Table 1, Evaporator Physical Data

Evaporator

Code

E2209 590 (268) 38 (145) 66 (6.1) 2387 (1083) 1

E2212 790 (358) 45 (170) 90 (8.3) 2877 (1305) 1

Notes:

1. Refrigerant charge is for the entire unit and is approximate since the actual charge will depend on other variables.

Actual charge will be shown on the unit nameplate.

2. Water capacity is based on s tandard t ube configuration and standard dished heads.

Maximum

Refrigerant Charge

lb. (kg)

Evaporator

Water

Capacity, gal (L)

Insulation

Area

sq. ft. (m

Vessel

2

)

Weight

lb. (kg)

Condenser

With positive pressure systems, the pressure variance with temperature is always predictable, and

the vessel design and pressure relief protection are based upon pure refrigerant characteristics.

R-134a requires ASME vessel design, inspection and testing and uses spring-loaded pressure

relief valves. When an over pressure condition occurs, spring-loaded relief valves purge only that

refrigerant required to reduce system pressure to their set pressure, and then close.

Refrigerant-side design pressure is 200 psi (1380 kPa). Water-side design is 150 psi (1034 kPa).

Number

of Relief

Valves

Table 2, Condenser Physical Data

Condenser

Code

C2009 728 (330) 47 (147) 2130 (965) 2

C2012 971 (440) 62 (236) 2528 (1147) 2

Notes:

1. Condenser pumpdown capacity based on 90% full at 90°F.

2. Water capacity based on standard conf i guration and standard heads and can be less with lower tube counts.

3. See Relief Valves section for additional information.

Maximum

Pumpdown

Capacity lb. (kg)

Water Capacity

gal. (L)

Vessel Weight

lb. (kg)

Number of

Relief Valves

Pumpdown

To facilitate compressor service, all McQuay centrifugal chillers are designed to permit

pumpdown and isolation of the entire refrigerant charge in the unit’s condenser. Model WMC

chillers are equipped with suction and discharge shutoff valves and the refrigerant charge can also

be pumped down into the evaporator.

8 Centrifugal Chillers IMM WMC-1

Page 9

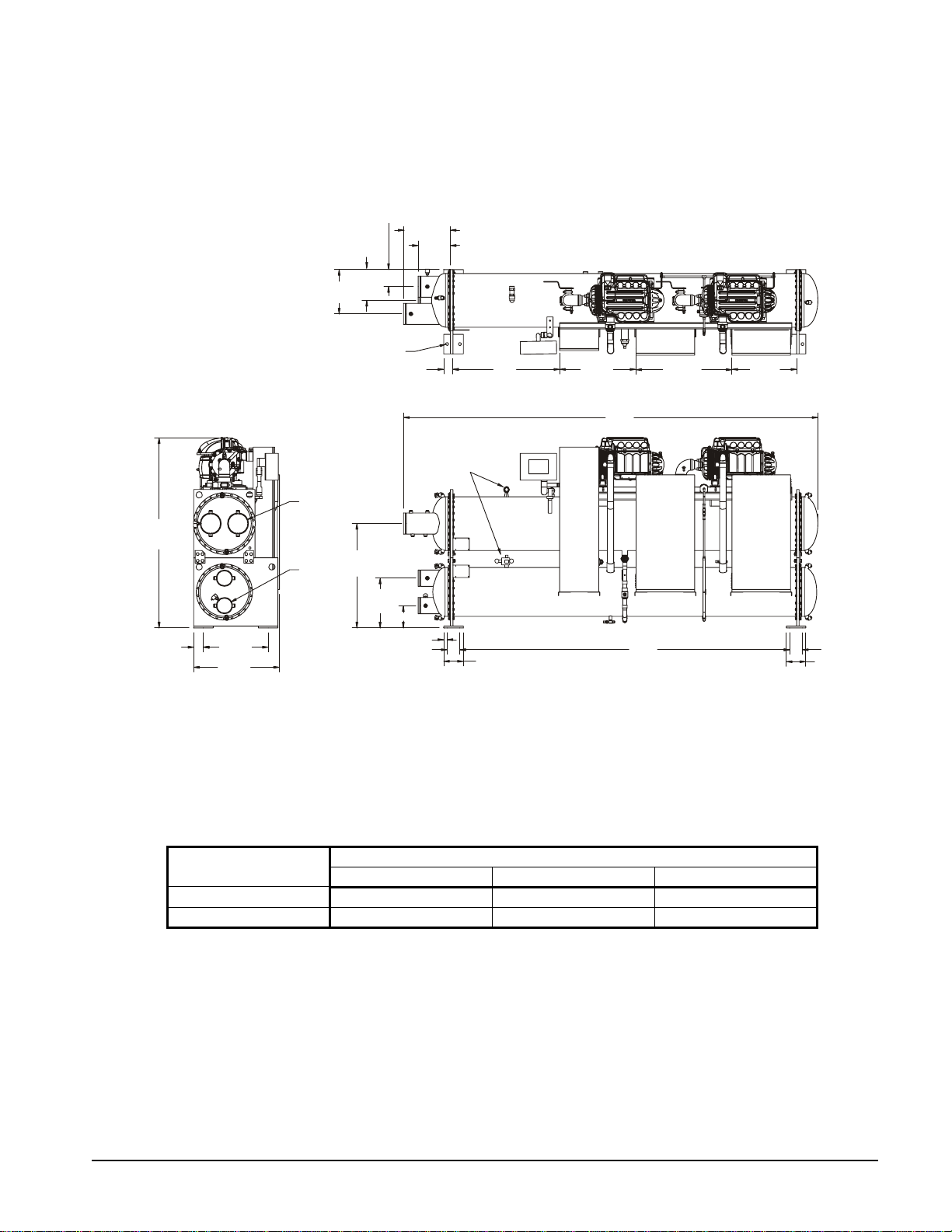

Dimensions

Figure 4, Dimension Drawing WMC 2 Pass Evaporator, 2 Pass Condenser

6.9

78.0

(1981.2)

4.0

(101.6)

26.5

(673.1)

35.0

(889.0)

Out

In

8.0”

QTY. 2

6.0”

QTY. 2

18.2

(462.3)

(1084.6)

12.6

(320.0)

42.7

(175.3)

01.13

QTY. 8

20.4

(518.2)

3.7 (93.9)

9.1 (231.1)

1.4 (35.5)

5.2 (132.1)

19.2 (487.7)

13.2 (335.3)

Inlet

Outlet

1.0” FPT

Relief Valves

Condenser

8.0 (203.2)

“A”

Evaporator

31.2

(792.5)

39.3

(998.2)

“B”

“C” 5.2 (132.1)

330654401 R01 Production Unit

26.5

(673.1)

8.0 (203.2)

NOTES:

1. The dimension drawing above is for standard production units. Certain early production units will have a different control panel

arrangement and a greater height dimension.

2. Left-hand connections shown. Right-hand connections are available for either vessel.

WMC Unit

A B C

9 Foot Shells 31.2 (792.4) 134.7 (3421.4) 100.1 (2542.5)

12 Foot Shells 43.7 (1109.9) 169.6 (4307.8) 134.9 (3426.5)

Dimensions Inches (mm)

IMM WMC-1 Centrifugal Chillers 9

Page 10

Figure 5, Dimension Drawing WMC 3 Pass Evaporator, 2 Pass Condenser

6.9

(175.3)

12.6

(320.0)

13.2 (335.3)

13.2 (335.3)

78.0

(1981.2)

(101.6)

NOTES:

4.0

26.5

(673.1)

35.0

(889.0)

Out

In

5.0”

QTY. 2

6.0”

QTY. 2

01.13

QTY. 8

20.4

(518.2)

3.7 (93.9)

9.1 (231.1)

1.4 (35.5)

5.2 (132.1)

Inlet

1.0” FPT

Relief Valves

Condenser

8.0 (203.2)

“A”

Evaporator

31.2

(792.5)

39.3

(998.2)

“B”

“C” 5.2 (132.1)

330654401_3-Pass Evap Production Unit

26.5

(673.1)

(462.3)

Outlet

(1084.6)

8.0 (203.2)

18.2

42.7

1. The dimension drawing above is for standard production units. Certain early production units will have a different

control panel arrangement and a greater height dimension.

2. Left-hand connections shown. Right-hand connections are available for either vessel.

3. For right-hand evaporator, the inlet and outlet are reversed. That is, the inlet is on the right end and looking at the head,

the connection is on the left side.

WMC Unit

A B C

9 Foot Shells 31.2 (792.4) 134.2 (3408.7) 100.1 (2542.5)

12 Foot Shells 43.7 (1109.9) 169.1 (4295.1) 134.9 (3426.5)

Dimensions Inches (mm)

10 Centrifugal Chillers IMM WMC-1

Page 11

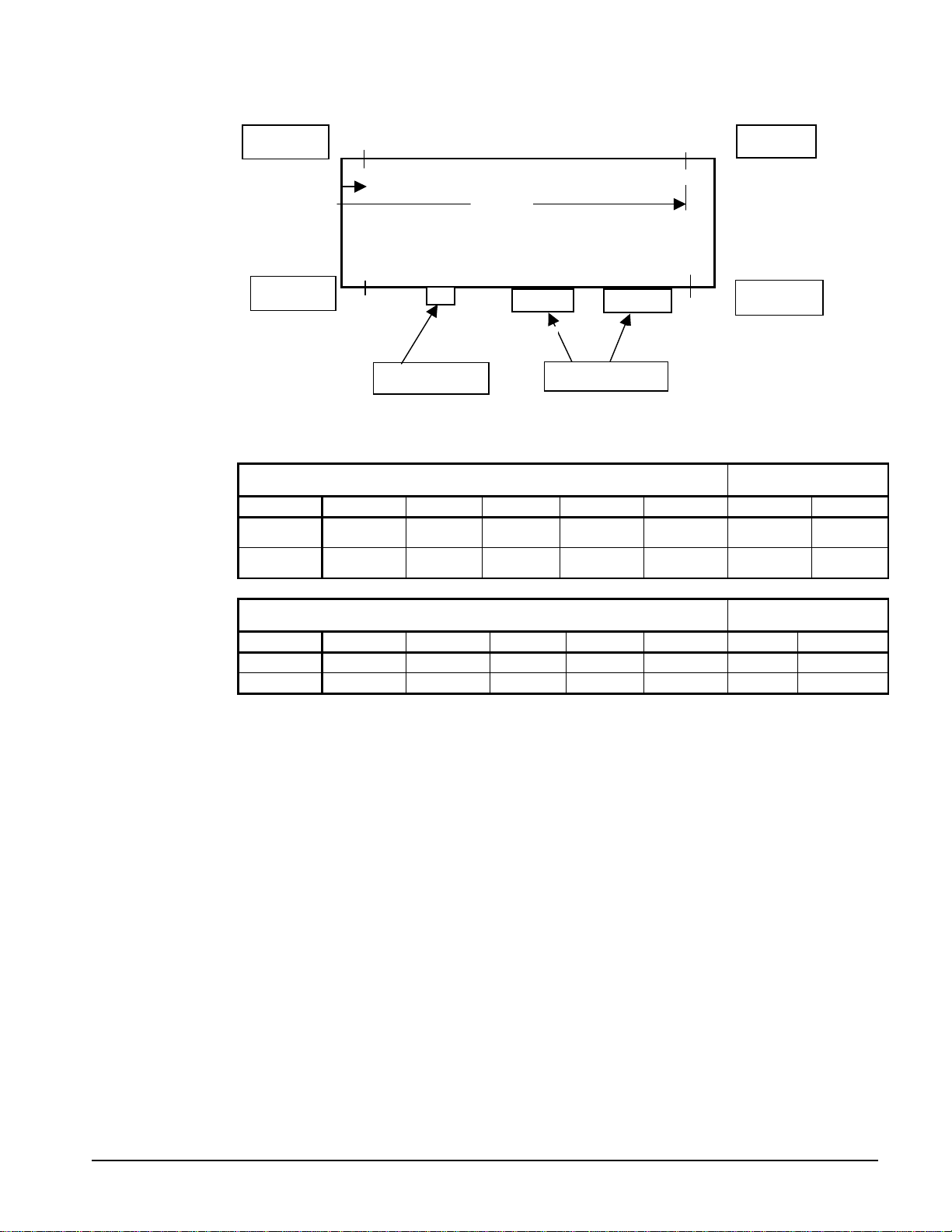

Figure 6, Mounting/Lifti ng Weights

Corner 3 Corner 4

“A

“B”

Corner 1

Corner 2

Circuit #1

Circuit #2

Control Panel

Electric Panels

Mounting Weight, lbs (kg)

Unit Size Corner 1 Corner 2 Corner 3 Corner 4 Total

9 Ft Shells 1562 (709) 1516 (688) 1459 (662) 2350 (1067) 7887 (3581)

12 Ft Shells 2712 (1231) 2122 (963) 2161 (981) 1691 (768) 8686 (3943)

Shipping Weight, lbs (kg)

Unit Size Corner 1 Corner 2 Corner 3 Corner 4 Total “A” “B”

9 Ft Shells 1396 (634) 2249 (1021) 1305 (592) 2102 (954) 7052 (3202) 4.0 (102) 112. 0 (2845)

12 Ft Shells 2450 (1112) 1918 (871) 1965 (892) 1528 (694) 7851 (3564) 4.0 (102) 147. 0 (3734)

NOTE:

1. The block shown above is the mounting footprint, not the entire unit footprint.

Mounting Location

inch (mm)

See

Figure 4

See

Figure 4

Lifting Location

inch (mm)

See

Figure 4

See

Figure 4

2. Lifting holes in the top of the tube sheets are 2.5 inch diameter. Mounting holes in the feet are

1.125 inch diameter.

IMM WMC-1 Centrifugal Chillers 11

Page 12

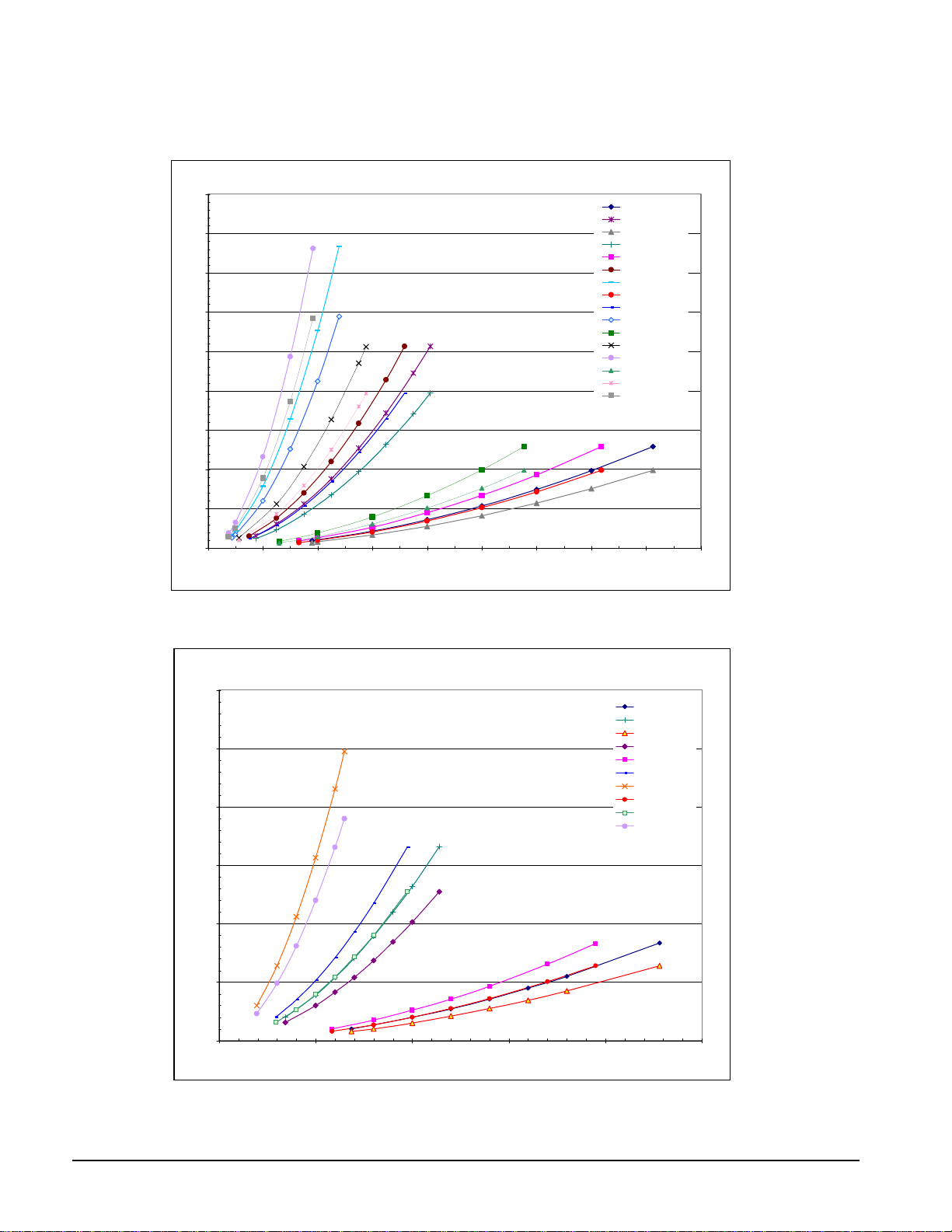

Pressure Drop Curves

Figure 7, Evaporator Pressure Drops

WMC Evap - Water Side Pressure Drop

90

80

70

60

50

EPD - ft

40

30

20

10

0

0 200 400 600 800 1000 1200 1400 1600 1800

EGPM - gpm

E2212-B 1 pass

E2212-B 2 pass

E2209-B 1 pass

E2209-B 2 pass

E2212-C 1 pass

E2212-C 2 pass

E2212-C 3 pass

E2209-C 1 pass

E2209-C 2 pass

E2209-C 3 pass

E2212-D 1 pass

E2212-D 2 pass

E2212-D 3 pass

E2209-D 1 pass

E2209-D 2 pass

E2209-D 3 pass

Figure 8, Condenser Pressure Drops

WMC Cond - Water Side Pressure Drop

60.0

50.0

40.0

30.0

CPD - ft

20.0

10.0

0.0

0 500 1000 1500 2000 2500

CGPM - gpm

C2012-B 1 pass

C2012-B 2 pass

C2009-B 1 pass

C2009-B 2 pass

C2012-C 1 pass

C2012-C 2 pass

C2012-C 3 pass

C2009-C 1 pass

C2009-C 2 pass

C2009-C 3 pass

12 Centrifugal Chillers IMM WMC-1

Page 13

Relief Valves

As a safety precaution and to meet code requirements,

each chiller is equipped with pressure relief valves

located on the condenser and evaporator for the purpose

of relieving excessive refrigerant pressure (caused by

equipment malfunction, fire, etc.) to the atmosphere.

Most codes require that relief valves be vented to the

outside of a building, and this is a desirable practice for

all installations. Relief piping connections to the relief

valves must have flexible connectors.

Note: Remove plastic shipping plug s (if installed)

from the inside of t he valves prior to making pipe

connections. Whenever vent piping is installed,

the lines must be run in accordance with local

code requirements; where local codes do not

apply, the latest issue of ANSI/ASHRAE Standard

15 code recommendations must be followed.

Condensers have two relief valves as a set with a threeway valve separating the two valves. One valve

remains active at all times and the second valve acts as a standby.

Figure 9, Condenser 3-Way Relief Valve

Refrigerant Vent Piping

Relief valve connection sizes are one-inch FPT and are in the quantity shown in Table 1 and Table

2 on page 8. Twin relief valves mounted on a transfer valve are used on the condenser so that one

relief valve can be shut off and removed, leaving the other in operation. Only one of the two is in

operation at any time.

Vent piping is sized for only one valve of the set (but connected to both) since only one can be in

operation at a time. In no case would a combination of evaporator and condenser sizes require

more refrigerant than the pumpdown capacity of the condenser. Condenser pumpdown capacities

are based on the current ANSI/ASHRAE Standard 15 that recommend 90% full at 90°F (32°C). To

convert values to the older ARI standard, multiply pumpdown capacity by 0.888.

Sizing Vent Piping (ASHRAE Method)

Relief valve pipe sizing is based on the discharge capacity for the given evaporator or condenser

and the length of piping to be run. Discharge capacity for R-134a vessels is calculated using a

complicated equation that accounts for equivalent length of pipe, valve capacity, Moody friction

IMM WMC-1 Centrifugal Chillers 13

Page 14

factor, pipe ID, outlet pressure and back pressure. The formula, and tables derived from it, are

contained in ASHRAE Standard 15-2001.

The McQuay WMC centrifugal units have a relief valve setting of 200 psi.

Using the ASHRAE formula and basing calculations on the 225 psi design yields a conservative

pipe size, which is summarized in Table 3. The table gives the pipe size required per relief valve.

When valves are piped together, the common piping must follow the rules set out in the following

paragraph on common piping.

Table 3. Relief Valve Piping Sizes

Equivalent length (ft) 2.2 18.5 105.8 296.7 973.6 4117.4

Pipe Size inch (NPT) 1 1/4 1 1/2 2 2 1/2 3 4

Moody Factor 0.0209 0.0202 0.0190 0.0182 0.0173 0.0163

NOTE: A 1-inch pipe is too small to handle these valves. A pipe increaser must always be installed at the valve outlet.

Common Piping

According to ASHRAE Standard 15, the pipe size cannot be less than the relief valve outlet size.

The discharge from more than one relief valve can be run into a common header, the area of which

cannot be less than the sum of the areas of the connected pipes. For further details, refer to

ASHRAE Standard 15. The common header can be calculated by the formula:

05

.

·

¸

n

¹

122

22

....

§

D

Common

¨

DDD

=+

©

The above information is a guide only. Consult local codes and/or latest version of ASHRAE

Standard 15 for sizing data.

Electrical

Wiring, fuse and wire size must be in accordance with the National Electric Code (NEC).

Important: The voltage to these units must be within ±10% of nameplate voltage, and the voltage

unbalance between phases must not

exceed 2%. Since a 2% voltage

unbalance will cause a current

unbalance of 6 to 10 times the voltage

unbalance per NEMA MG-1, 1998

Standard, it is most important that the

unbalance between phases be kept at a

minimum.

Power Wiring

The standard power wiring connection

to WMC chillers is multi-point, i.e. a

separate power supply to each circuit’s

terminal box. Single-point connection

to a terminal box, located under the

low voltage control panel, is available

as an option, in which case the

individual circuit breakers for each

circuit are retained. The single point

connection is to a standard power block

or optional single unit disconnect

switch.

Figure 10, Electrical Panel, Mul t i-Point

Connection

(3) Controller

Transformers

120V-24V

Control Power

Transformer

480V-120V

Power

Entry

Incoming

Lugs

Circuit

Breaker

Line

Reactors

14 Centrifugal Chillers IMM WMC-1

Page 15

The electrical panel (as shown to the right) contains the circuit breaker/ disconnect (standard on

both multi-point connection and single-point connection), a line reactor, and a radio frequency (RF)

filter. The circuit breakers provide compressor overload protection.

Proper phase sequence to the unit is not required as far as the unit operation is concerned. Correct

motor rotation is established by the chiller control system regardless of the connected phase

sequence.

WARNING

Qualified and licensed electricians must perform wiring. Shock hazard exists.

The RLA for use in the following tables is obtained by the selection of a specific unit by McQuay.

When shipped, a unit will bear the specific RLA, stamped on the nameplate, for the selected

operating conditions.

Electrical Data

Table 4, Multi-Point Connection, Each Circuit – 1 Compressor per Ci rcuit

(Per Compressor)

52 to 55 Amps 72 60 65 to 69 3 4 GA 110 Amps

56 to 65 Amps 72 60 70 to 82 3 4 GA 125 Amps

68 to 77 Amps 94 50, 60 85 to 97 3 3 GA 150 Amps

78 to 85 Amps 94 50, 60 98 to 107 3 2 GA 175 Amps

89 to 91 Amps 124 50, 60 112 to 114 3 2 GA 200 Amps

92 to 103 Amps 124 50, 60 115 to 129 3 1 GA 200 Amps

104 to 110 Amps 124 50, 60 130 to 138 3 1/0 225 Amps

111 to 113 Amps 124 50, 60 139 to 142 3 1/0 250 Amps

LRA Hz

Minimum Circuit

Ampacity (MCA)

Field Wire RLA

Quantity Wire GA

Max Fuse

Size

Table 5, Single Point Connection, Total Unit – 2 Compressors per Unit

Per Compressor Per Unit

(Per Compressor)

52 to 53 Amps 72 50 117 to 120 3 1 GA 150 Amps

54 to 57 Amps 72 50 122 to 129 3 1 GA 175 Amps

58 to 61 Amps 72 50 131 to 138 3 1/0 175 Amps

62 to 65 Amps 72 50 140 to 147 3 1/0 200 Amps

68 to 69 Amps 94 50, 60 153 to 156 3 2/0 200 Amps

70 to 76 Amps 94 50, 60 158 to 171 3 2/0 225 Amps

77 to 85 Amps 94 50, 60 174 to 192 3 3/0 250 Amps

89 to 92 Amps 124 50, 60 201 to 207 3 4/0 250 Amps

93 to 102 Amps 124 50, 60 210 to 230 3 4/0 300 Amps

103 to 107 Amps 124 50, 60 232 to 241 3 250 300 Amps

108 to 113 Amps 124 50, 60 243 to 255 3 250 350 Amps

LRA Hz

Minimum Circuit

Ampacity (MCA)

Field Wire RLA

Quantity Wire GA

Max Fuse

Size

IMM WMC-1 Centrifugal Chillers 15

Page 16

Table 6, Single Point and Multi-point Connect i on

RLA

(Per Compressor)

Type of Connection Disconnect Switch Only Power Block Disconnect Switch

52 to 65 Amps 100 Amps

68 to 85 Amps 150 Amps 335 Amps 400 Amps

89 to 113 Amps 175 Amps

See Note 1 See Note 2 See Note 2

NOTES 1: Disconnect Switch will also be a Circuit Breaker.

2: Circuit Breaker in each circuit after Power Block or Molded Case Disconnect Switch.

3: A high short circuit current rated (HSCCR) panel rated at 65 kA is an option.

Connections to terminals must be made with copper lugs and copper wire.

Multi-Point Connection Single Point Connection

CAUTION

Care must be taken when attaching leads to compressor terminals.

Control Wiring

The control circuit on the McQuay centrifugal packaged chiller is designed for 115-volts. Control

power is supplied from a factory-wired transformer located in the electrical box.

Use with On-Site Generators

WMC chillers have their total tonnage divided between two compressors that start sequentially and

they are operated with variable frequency drives. These features make WMC chillers especially

appropriate for use in applications where they may be required to run with on-site electrical

generators. This is particularly true when the generators are used for temporary power when the

utility power is lost.

Generator Sizing: Gas and diesel generators are sensitive to the compressor’s locked-rotor

characteristics when the chillers start up. Use the electrical data supplied with the performance

output sheet, obtained from the McQuay sales office, for generator sizing purposes. The chiller

data sheet will show the RLA, which is for both compressors. Refer to Table 4or Table 5 on the

previous page to determine the LRA, based on the RLA. It is important to size the generator to

handle the LRA at start up.

Starting/Stopping Procedure: The stopping of the chiller in the event of a power failure should be

uneventful. The chiller will sense a loss of voltage and the compressors will stop, coasting down

using power generated from their dynamic braking to maintain the bearing magnetic field. The stop

signal will initiate a three-minute stop-to-start timer, effectively preventing compressor restart for

three minutes. The timer is adjustable from three to fifteen minutes, but the recommended, and

default value, is three minutes. This interval allows the generator sufficient time to get up to speed

and stabilize. The chiller will restart automatically when the start-to-start timer expires.

Transfer Back to Grid Power: Proper transfer from stand-by generator power back to grid power

is essential to avoid compressor damage.

CAUTION

Stop the chiller before transferring supply power from the generator back

to the utility power grid. Transferring power while the chiller is running can

cause severe compressor damage.

16 Centrifugal Chillers IMM WMC-1

Page 17

The necessary procedure for reconnecting power from the generator back to the utility grid is show

below. These procedures are not peculiar to McQuay units only, but should be observed for any

chiller manufacturer.

1. Set the generator to always run five minutes longer than the unit start-to-start timer, which

could be set from 15 to 60 minutes. The actual setting can be viewed on the operator interface

panel on the Setpoint/Timer screen.

2. Configure the transfer switch, provided with the generator, to automatically shut down the

chiller before transfer is made. The automatic shut-off function can be accomplished through a

BAS interface or with the “remote on/off” wiring connection shown in Figure 11. A start signal

can be given anytime after the stop signal since the three-minute start-to-start timer will be in

effect.

Chiller Control Power: For proper operation on standby power, the chiller control power must

remain as factory-wired from a unit-mounted transformer. Do not supply chiller control power

from an external power source because the chiller may not sense a loss of power and do a normal

shutdown sequence.

System Pumps

Operation of the chilled water pump can be to 1) cycle the pump with the compressor, 2) operate

continuously, or 3) start automatically by a remote source.

The cooling tower pump must cycle with the machine. The holding coil of the cooling tower pump

motor starter must be rated at 115 volts, 60 Hz, with a maximum volt-amperage rating of 100. A

control relay is required if the voltage-amperage rating is exceeded. See the Field Wiring Diagram

on page 19 or in the cover of control panel for proper connections.

All interlock contacts must be rated for no less than 10 inductive amps. The alarm circuit provided

in the control center utilizes 115-volts AC. The alarm used must not draw more than 10 volt

amperes.

IMM WMC-1 Centrifugal Chillers 17

Page 18

Field Wiring Diagram Notes (Page 19)

1. Compressor terminal boxes are factory-mounted and wired. All line-side wiring must be in accordance with the NEC

and be made with copper wire and copper lugs only. Power wiring between the terminal box and compressor terminals

is factory installed.

2. Minimum wire size for 115 VAC is 12 ga. for a maximum length of 50 feet. If greater than 50 feet refer to McQuay for

recommended wire size minimum. Wire size for 24 VAC is 18 ga. All wiring to be installed as NEC Class 1 wiring

system. All 24 VAC wiring must be run in separate conduit from 115 VAC wiring. Wiring must be wired in

accordance with NEC and connection to be made with copper wire and copper lugs only.

3. A customer furnished 24 or 120 Vac power for alarm relay coil may be connected between UTB1 terminals 84 power

and 81 neutral of the control panel. For normally open contacts wire between 82 & 81. For normally closed wire

between 83 & 81. The alarm is operator programmable. Maximum rating of the alarm relay coil is 25VA.

4. Remote on/off control of unit can be accomplished by installing a set of dry contacts between terminals 70 and 54.

5. If field supplied pressure differential switches are used, they must be installed across the vessel and not the pump. They

must be suitable for 24vac and low current application. Field wiring not required with the standard factory-mounted

flow switches.

6. Customer supplied 115 VAC 20 amp power for optional evaporator and condenser water pump control power and tower

fans is supplied to unit control terminals (UTB1) 85 power / 86 neutral, PE equipment ground.

7. Optional customer supplied 115 VAC, 25 VA maximum coil rated, chilled water pump relay (ep1 & 2) may be wired as

shown. This option will cycle the chilled water pump in response to chiller demand.

8. The condenser water pump must cycle with the unit. A customer supplied 115 VAC 25 VA maximum coil rated,

condenser water pump relay (CP1 & 2) is to be wired as shown. Units with free-cooling must have condenser water

above 60°F before starting.

9. Optional customer supplied 115 VAC 25 VA maximum coil rated cooling tower fan relays (C1 - C2 standard, C3-C4

optional) may be wired as shown. This option will cycle the cooling tower fans in order to maintain unit head pressure.

10. Auxiliary 24 VAC rated contacts in both the chilled water and condenser water pump starters should be wired as shown.

11. Optional Control Inputs. The following 4-20 ma optional inputs are connected as shown:

• Demand Limit; Terminals 58 and 71 common

• Chilled Water Reset; Terminals 51 and 71 common

• Evaporator Water Flow; Terminals 59 and 71 common

• Condenser Water Flow; Terminals 60 and 71 common

12. Optional Control Power Source. 115 volt control power can be supplied from a separate circuit and fused at 20 amps

inductive load. Connection is to terminals 85 and 86 common.

13. 4-20mA external signal for chilled water reset are wired to terminals 71 and 51 on the unit controller; load limit is wired

to terminals 71 and 58 on the unit controller.

18 Centrifugal Chillers IMM WMC-1

Page 19

A

* COOLING

CROTECH CO

A

A

A

TOWER

FOURTH

STAGE

STARTER

* COOLING

TOWER

THIRD

STAGE

STARTER

* COOLING

TOWER

SECOND

STAGE

STARTER

* COOLING

TOWER

FIRST

STAGE

STARTER

Field Wiring Diagram

Figure 11, Field Wiring Diagram

MI

BOX TERMINALS

(115V) (24V)

GND

POWER

*

NOTE 6

NEUTRAL

NOTE 9

*

H

O

C4

A

NOTE 9

*

H

O

C3

A

NOTE 9

*

H

O

C2

A

NOTE 9

*

H

O

C1

A

COMMON

*

NOTE 3

POWER

NTROL

UTB1

PE

54

70

55

CF1

EF1

EF2

CF2

(NOTE 5)

SWITCH

DELTA P

FLOW OR

EVAP.

*ALARM RELAY

A

(NOTE 3)

85

86

80

74

86

86

79

73

78

77

76

75

81

82(NO)

83(NC)

84

*

MODE SWITCH

(NOTE 5)

SWITCH

DELTA P

FLOW OR

COND.

* REMOTE

ON/OFF

(NOTE 4)

*NOTE 7

EP2

NOTE 10

NOTE 7

*

EP1

NOTE 10

O

EWI-2

O

EWI-1

*

NOTE 8

NOTE 10

H

H

CP2

C

* CHILLED

WATER

PUMP

STARTERS

C

H

O

C

CWI-2

* CONDENSER

WATER

PUMP

STARTERS

*COOLING TOWER BYPASS VALUE

*COOLING TOWER VFD

0-10 VDC

0-10 VDC

52

71

71

53

NOTE 8

*

NOTE 10

CP1

H

O

CWI-1

C

330617801 REV. 00

See notes on page 18.

IMM WMC-1 Centrifugal Chillers 19

Page 20

VFD Line Harmonics

Despite their many benefits, care must be taken when applying VFDs due to the effect of

line harmonics on the building electric system. VFDs cause distortion of the AC line

because they are nonlinear loads, that is, they don't draw sinusoidal current from the line.

They draw their current from only the peaks of the AC line, thereby flattening the top of the

voltage waveform. Some other nonlinear loads are electronic ballasts and uninterruptible

power supplies.

Line harmonics and their associated distortion can be critical to ac-drives for three reasons:

1. Current harmonics can cause additional heating to transformers, conductors,

and switchgear.

2. Voltage harmonics upset the smooth voltage sinusoidal waveform.

3. High-frequency components of voltage distortion can interfere with signals

transmitted on the AC line for some control systems.

th

The harmonics of concern are the 5

divisible by three, and high magnitude harmonics are usually not a problem.

Current Harmonics

An increase in reactive impedance in front of the VFD helps reduce the harmonic currents.

Reactive impedance can be added in the following ways:

1. Mount the drive far from the source transformer.

2. Add line reactors. They are standard equipment on WMC chillers.

3. Use an isolation transformer.

4. Use a harmonic filter.

Voltage Harmonics

Voltage distortion is caused by the flow of harmonic currents through a source impedance.

A reduction in source impedance to the point of common coupling (PCC) will result in a

reduction in voltage harmonics. This can be done in the following ways:

, 7th, 11th, and 13th. Even harmonics, harmonics

1. Keep the PCC as far from the drives (close to the power source) as possible.

2. Increase the size (decrease the impedance) of the source transformer.

3. Increase the capacity (decrease the impedance) of the busway or cables from

the source to the PCC.

4. Make sure that added reactance is "downstream" (closer to the VFD than the

source) from the PCC.

Line Reactors

Five-percent line reactors are standard equipment on WMC chillers and located in each

compressors power panel. They are employed to improve the power factor by reducing the

effects of harmonics.

Harmonic Filter

The harmonic filter is an option for field mounting and wiring outside of the power panel.

It works in conjunction with the line reactor to further minimize harmonic distortion. It is

wired between the line reactor and compressor. IEEE 519-1991 Standard defines

acceptable limits.

See the WMC certified drawings for harmonic filter dimensions and wiring information.

EMI (Electro Magnetic Interference) and RFI (Radio Frequency Interference) Filter

This filter is a factory-installed option. The terms EMI and RFI are often used

interchangeably. EMI is actually any frequency of electrical noise, whereas RFI is a

specific subset of electrical noise on the EMI spectrum. There are two types of EMI.

Conducted EMI is unwanted high frequencies that ride on the AC wave form.

20 Centrifugal Chillers IMM WMC-1

Page 21

EMI-Radiated EMI is similar to an unwanted radio broadcast being emitted from the power

lines. There are many pieces of equipment that can generate EMI, variable frequency

drives included. In the case of variable frequency drives, the electrical noise produced is

primarily contained in the switching edges of the pulse width modulation (PWM)

controller.

As the technology of drives evolves, switching frequencies increase. These increases also

increase the effective edge frequencies produced, thereby increasing the amount of

electrical noise.

The power line noise emissions associated with variable frequency and variable speed

drives can cause disturbances in nearby equipment. Typical disturbances include:

• Dimmer and ballast instability

• Lighting disturbances such as flashing

• Poor radio reception

• Poor television reception

• Instability of control systems

• Flow meter totalizing

• Flow metering fluctuation

• Computer system failures including the loss of data

• Thermostat control problems

• Radar disruption

• Sonar disruption

RFI

Three-phase filters are supplied as an option for factory mounting in the compressor power

panels. They use a combination of high frequency inductors and capacitors to reduce noise

in the critical 150kHz to 30MHz frequency range. The inductors act as open circuits and

the capacitors act as short circuits at high frequencies while allowing the lower power line

frequencies to pass untouched. The filters assist with cost effective compliance to Electro

Magnetic Compatibility (EMC) directives, in a compact, efficient, light-weight design. The

high common mode and differential mode reduction in the critical 150kHz to 30MHz

frequencies assures that potential interference from AC drives is reduced or eliminated.

The filters are current-rated devices. In order to properly size a filter, it is necessary to

know the operating voltage, and the input current rating of the drive. No derating or rerating is necessary when applying the filter at voltages that are less than or equal to the

maximum voltage listed on the filter.

The IEEE 519-1991 Standard

The Institute of Electrical and Electronics Engineers (IEEE) has developed a standard that

defines acceptable limits of system current and voltage distortion. A simple form is

available from McQuay that allows McQuay to determine compliance with IEEE 519-1991.

Line reactors, isolation transformers, or phase-shifting transformers can be required on

some installations.

IMM WMC-1 Centrifugal Chillers 21

Page 22

Figure 12, Typical WMC Power Wiring

WMC Wiring

GND

Contactor

Optional

EMI

Filter

AC Input

Voltage

L1

L2

L3

(1)

C

Manual

Disconnect

Optional

Notes:

(1) Single hole, crimp type compression terminal required.

(2) Connect to filter circuit breaker lugs.

(3) Conductors to be sized for 125 minimum circuit ampacity.

Size 1 AWG, 75°C wire recommended.

Multiple Chiller Setup

WMC dual compressor units have the four main control components; two compressor

controllers, one unit controller, and the operator interface panel with touchscreen (OITS).

factory wired to a pLAN local area network so that they can communicate with each other.

Two dual compressor chillers can be interconnected and operated in unison by simple field

RS485 interconnecting wiring and the addition of some MicroTech II control settings.

pLAN Setup

To interconnect multiple chillers, MicroTech II pLAN RS485 wiring must be installed by

the installing contractor prior to start-up.

1. With no pLAN connections between chillers, disconnect unit control power and set the

DIP switches as shown in Table 7. They are located on the upper-front of the

controllers, above the screen.

Standard

Line

Reactor

(3)

(2) Hamonic

Filter with

Circuit Breaker

2. With all manual switches off, turn on control power to each chiller and set each OITS

address (see Note 2 on page 23).

3. Verify correct nodes on each OITS Service Screen.

4. Connect chillers together (pLAN, RS485 wiring) between J6 connections on each unit

controller’s isolation board. Wiring should be 22 ga., twisted pair, shielded cable.

5. Verify correct nodes on each OITS Service Screen.

22 Centrifugal Chillers IMM WMC-1

Page 23

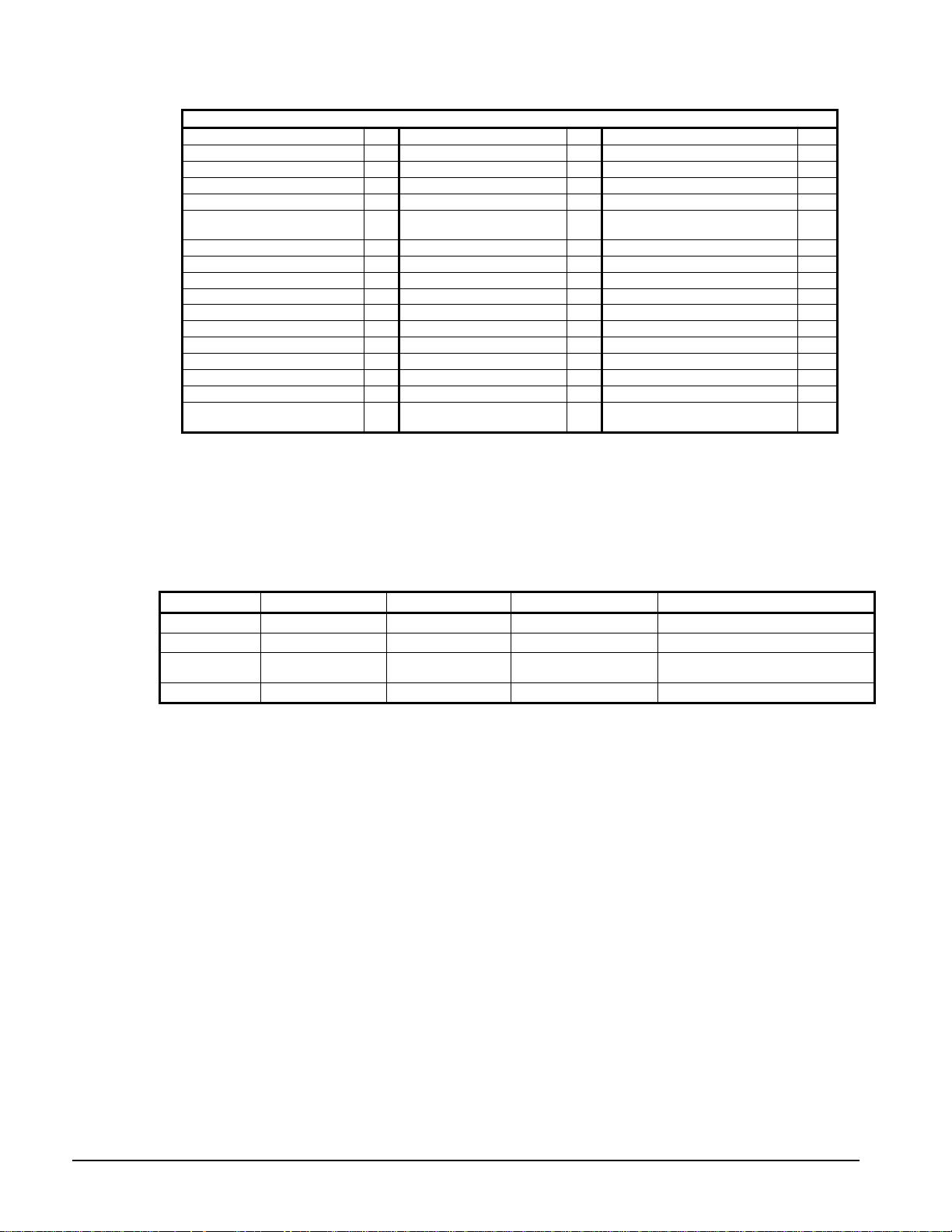

Table 7, Address DIP Switch Settings for Controllers Usi ng pLAN.

Chiller Comp

1

1

2

1

2

2

NOTES:

1. Up to four compressors can be interconnected.

2. The Operator Interface Touch Screen (OITS) setting is not a DIP switch setting. The OITS

address is selected by selecting the ‘service’ set screen. Then, with the Technician level password

active, select the ‘pLAN Comm’ button. Buttons A(7), B(15), C(23), D(31) will appear in the

middle of the screen, then select the letter for the OITS address for the chiller that it is on. Then

close the screen. Note that A is the default setting from the factory.

3. Six Binary Switches: Up is ‘On’, indicated by ‘1’. Down is ‘Off’, indicated by ‘0’

Comp 1

Controller

1 2 5 6 7 8

100000 010000 101000 011000 111000 000100

9 10 13 14 15 16

100100 010100 101100 011100 111100 000010

17 18 21 22 23 24

100010 010010 101010 011010 111010 000110

25 26 29 30 31 32

100110 010110 101110 011110 111110 000001

Comp 2

Controller

Unit

Controller

Reserved

Operator

Interface (2)

Reserved

.

MicroTech II Operator Interface Touch Screen (OITS) Settings

Settings for any type of linked multiple compressor operation must be made to the

MicroTech II controller. Settings on a dual compressor unit are made in the factory prior to

shipment, but must be verified in the field before startup. Settings for multiple chiller

installations are set in the field on the Operator Interface Touch Screen as follows:

Maximum Compressors O N

– SETPOINTS - MODES screen, Selection #9 = 2 for a dual, 4

for 2 duals.

Sequence and Staging

– SETPOINTS - MODES screen, Selection #10 & #12; #11 & #13.

Sequence sets the sequence in which compressors will start. Setting all to “1” evokes the

automatic lead/lag feature and is the preferred setting.

Nominal Capacity

compressor

design tons. Compressors on dual units are always of equal capacity.

– SETPOINTS - MOTOR screen, Selection #14. The setting is the

Operating Sequence

For multiple-chiller, parallel operation, the MicroTech II controllers are tied together by a

pLAN network and stage and control compressor loading among the chillers. Each chiller,

will stage on or off depending on the sequence number programmed into it. If all are set to

“1”, the automatic lead/lag will be in effect.

When chiller #1 is fully loaded, the leaving chilled water temperature will rise slightly.

When the Delta-T above setpoint reaches the Staging Delta-T, the next chiller scheduled to

start will receive a start signal and start its pumps. This procedure is repeated until all

chillers are running. The compressors will load-balance themselves.

IMM WMC-1 Centrifugal Chillers 23

Page 24

Prestart System Checklist

Yes No N/A

Chilled Water

Piping complete................................................................................................................. V V V

Water system filled, vented................................................................................................

Pumps installed, (rotation checked), strainers cleaned......................................................

Controls (3-way, face and bypass dampers, bypass valves, etc.) operable.........................

Water system operated and flow balanced to meet unit design requirements....................

Condenser Water

Cooling tower flushed, filled and vented .......................................................................... V V V

Pumps installed, (rotation checked), strainers cleaned .....................................................

Controls (3-way, bypass valves, etc.) operable .................................................................

Water system operated and flow-balanced to meet unit requirements ..............................

Electrical

Power leads connected to the unit power panel(s) ............................................................ V V V

All interlock wiring complete between control panel and complies with specifications ...

Pump starters and interlock wired ....................................................................................

Cooling tower fans and controls wired .............................................................................

Wiring complies with National Electrical Code and local codes ......................................

Condenser pump starting relay (CWR) installed and wired ..............................................

Miscellaneous

Relief valve piping complete ............................................................................................ V V V

V V V

V V V

V V V

V V V

V V V

V V V

V V V

V V V

V V V

V V V

V V V

V V V

Thermometer wells, thermometers, gauges, control wells, controls, etc., installed ..........

Minimum system load of 80% of machine capacity available for testing

and adjusting controls .......................................................................................................

Control wiring between multiple units, if applicable.........................................................

V V V

V V V

V V V

Note: This checklist must be completed and sent to the local McQuay service location two

weeks prior to start-up.

24 Centrifugal Chillers IMM WMC-1

Page 25

Operation

Operator Responsibilities

It is important that the operator become familiar with the equipment and the system before

attempting to operate the chiller.

During the initial startup of the chiller, the McQuay technician will be available to answer any

questions and instruct in the proper operating procedures.

It is recommended that the operator maintain an operating log for each individual chiller unit. In

addition, a separate maintenance log should be kept of the periodic maintenance and servicing

activities.

Now that you have made an investment in modern, efficient McQuay® equipment, its care and

operation should be a high priority. For training information on all McQuay HVAC products, please

visit us at www.mcquay.com and click on Training or phone 540-248-0711 and ask for the Training

Department. These sessions are structured to provide basic classroom instruction and include handson operating and troubleshooting exercises.

Compressor Operation

The WMC compressors are two-stage. Suction gas enters the compressor through inlet guide vanes

that can be opened and closed to control refrigerant flow as the cooling load changes. The suction

gas enters the first stage impeller, is compressed, travels through the vaned radial diffuser to the

second stage impeller where compression is completed. The gas travels to the condenser via the

discharge volute, which converts any remaining velocity pressure to static pressure.

Motor cooling is accomplished by utilizing the refrigerant effect of high-pressure refrigerant from

the condenser expanded to a gas within the compressor. The refrigerant cools heat sinks and the

motor.

A five-axis magnetic bearing system supports the motor/compressor shaft, resisting radial and thrust

forces. The bearing control system uses shaft position feedback to continually adjust the bearing to

keep the shaft in the correct position. In the event of a power failure, the compressor motor acts as a

generator and powers the bearing support system during coastdown. There is also a system to gently

de-levitate the shaft.

Many controls are mounted directly on the compressor where they monitor and control compressor

operation. These compressor controls are interfaced with the conventional MicroTech II controls to

provide a complete chiller control system.

Operating Limits:

Maximum standby ambient temperature, 130°F (55°C)

Minimum operating ambient temperature (standard), 35°F (2°C)

Leaving chilled water range, 38°F to 60°F (3°C to 15°C)

Maximum operating evaporator inlet fluid temperature, 66°F (19°C)

Maximum startup evaporator inlet fluid temperature, 90°F (32°C)

Maximum non-operating inlet fluid temperature, 100°F (38°C)

Minimum condenser water entering temperature, 55°F (12.8°C)

Maximum entering condenser water temperature, 105°F (40.6°C)

Maximum leaving condenser water temperature, 115°F (46.1°C)

IMM WMC-1 Centrifugal Chillers 25

Page 26

System Water Volume

It is important to have adequate water volume in the system to provide an opportunity for the chiller

to sense a load change, adjust to the change, and stabilize. As the expected load change becomes

more rapid, a greater water volume is needed. The system water volume is the total amount of water

in the evaporator, air handling products and associated piping. If the water volume is too low,

operational problems can occur including rapid compressor cycling, rapid loading and unloading of

compressors, erratic refrigerant flow in the chiller, improper motor cooling, shortened equipment life

and other undesirable consequences.

For normal comfort cooling applications, where the cooling load changes relatively slowly, we

reco mmend a min imu m syst em vo lume of t hre e min ute s times the flow rate (gpm). For example, if

the design chiller flow rate is 300 gpm, we recommend a minimum system volume of 900 gallons

(300 gpm x 3 minutes).

For process applications where the cooling load can change rapidly, additional system water volume

is needed. A process example would be a quenching tank. The load would be very stable until the

hot material is immersed in the water tank. Then, the load would increase drastically. For this type

of application, system volume may need to be increased.

Since there are many other factors that can influence performance, systems may successfully operate

below these suggestions. However, as the water volume decreases below these suggestions, the

possibility of problems increases.

Variable Speed Pumping

Variable water flow involves inversely changing the water flow through the evaporator as the load

changes. McQuay chillers are designed for this duty provided that the rate of change in water flow

is slow and the minimum and maximum flow rates for the vessel, as shown in Figure 7 on page 12

are not exceeded.

The recommen ded max imum cha nge in wa ter fl ow is 10 percent of the allowable flow change per

minute. Flow is usually not reduced below 50 percent of design flow (provided vessel minimum

flow rates are not exceeded).

For example, a 150 ton chiller might have chilled water flow of 360 gpm, reduced to 50 percent,

would be 180 gpm. However, the minimum flow rate is 216 gpm, so the flow change would be 360

gpm minus 216 gpm, or 144 gpm. This means that the allowable flow rate change would be 10

percent of 144 or 14.4 gpm per minute.

26 Centrifugal Chillers IMM WMC-1

Page 27

MicroTech II™ Control

Figure 13, MicroTech II Control Panel

The WMC chillers are equipped with the

McQuay MicroTech II control system consisting

of:

• Operator interface touchscreen panel

(shown at the left). It contains of a 12-inch

Super VGA color screen.

• Control Panel containing the MicroTech II

unit

compressor

the compressor-mounted controls, and

various switches and field connection

terminals.

Operating instructions for the MicroTech II controller are contained in Operating

Manual OM WMC-2.

Building Automation Systems

controller, two MicroTech II

controllers with connections to

All MicroTech II controllers are capable of BAS communications, providing seamless

integration and comprehensive monitoring, control, and two-way data exchange with

industry standard protocols such as L

ONMARK®, Modbus® or BACnet®.

Protocol Selectability™ Benefits

• Easy to integrate into your building automation system of choice

• Factory-installed and tested communication module

• Comprehensive point list for system integration, equipment monitoring and alarm

notification

• Provides efficient equipment operation

• Owner/designer can select the BAS that best meets building requirements

• Comprehensive data exchange

Integration Made Easy

McQuay unit controllers strictly conform to the interoperability guidelines of the

L

ONMARK ® Interoperability Association and the BACnet Manufacturers Association.

They have received:

ONMARK certification with optional LONWORKS communication module

• L

Protocol Options

• BACnet MS/TP • LONWORKS® (FTT-10A)

• BACnet IP • Modbus RTU

• BACnet Ethernet

The BAS communication module can be ordered with a chiller and factory-mounted or can

be field-mounted at any time after the chiller unit is installed.

IMM WMC-1 Centrifugal Chillers 27

Page 28

Table 8, Typical Data Point Availability

Typical Data Points

Active Setpoint R Cond EWT R Evap Water Pump Status R

Actual Capacity R Cond Flow Switch St atus R Liquid Line Refrigerant Pres sure R

Capacity Limit Output R Cond LWT R Liquid Line Refrigerant Temp R

Capacity Limit Setpoint W Cond Pump Run Hours R Maximum Send Time W

Chiller Enable W Cond Refrigerant P ressure R Minimum Send Time W

Chiller Limited R

Chiller Local/Remote R Cond Wat er P ump Status R Pump Select W

Chiller Mode Output R Cool Setpoint W Run Enabled R

Chiller Mode Setpoint W Current Alarm R

Chiller On/Off R Default Values W

Chiller Status R Evap EWT R

Compressor Discharge Temp R Evap Flow Switch Status R

Compressor Percent RLA R Evap LWT for Unit R

Compressor Run Hours R Evap LWT for Compressor R

Compressor Select W Evap Pump Run Hours R

Compressor Starts R Evap Ref rigerant Pressure R

Compressor Suction Li ne

Temp

Cond Sat. Refrigerant

Temp

Evap Sat. Refrigerant

R

Temp

Note: Data points available are dependent upon options selected.

1

(W = Write, R = Read)

R Network Clear Alarm W

R

Connection to Chiller

Connection to the chiller for all BAS protocols will be at the unit controller. An interface card,

depending on the protocol being used, will have been factory installed in the unit controller if so

ordered, or it can be field installed.

Protocols Supported

Table 9, Standard Protocol Data

Protocol Physical Layer Data Rate Controller Other

BACnet®/IP

BACnet MSTP RS485 (TBD)

LonTalk®

ModbusRTU RS-485 (TBD)

NOTE: For additional information on the protocol data available through the BACnet or LonTalk

communications modules, reference McQuay ED 15062, MicroTech II Chiller Unit Controller

Protocol Information.

Modbus - When selected, the ident number and baud can also be changed to suit the application.

LONWORKS – When selected, the ident number and baud rate setpoints are not available. Baud

rate is locked at 4800.

BACnet – When selected, the ident number and baud rate setpoints are not available. Baud rate is

locked at 19200.

The factory installed kits on the MicroTech II™ controller are as follows:

If an interface module was ordered, one of the following BAS interface installation manuals was

shipped with the unit. If necessary, contact your local McQuay sales office for a replacement or

obtain from www.mcquay.com.

Ethernet 10 Base-T 10 Megabits/sec Color graphics SBC Reference ED 15057: BACnet PICS

FTT-10A 78kbits/sec

2

pCO

Unit Controller

2

pCO

Unit Controller

2

pCO

Unit Controller

Reference ED 15057: BACnet PI CS

LONMARK® Chiller Functional

Profile

• BACnet Kit P/N 350147404: BACnet/IP, BACnet MS/TP, or BACnet Ethernet

• LONWORKS Kit P/N 350147401: LonTalk (FTT-10A)

• ModbusRTU

• IM 735, L

ONWORKS® Communication Module Installation

• IM 736, BACnet® Communication Module Installation

• IM 743, Modbus® Communication Module Installation

28 Centrifugal Chillers IMM WMC-1

Page 29

Figure 14, Unit Control Panel

SW1, Unit Switch

SW12, Circ #1 Switch

SW22, Circ #2 Switch

Control Circuit Breaker

Unit T erminal Board

UTB1

Unit Controller

Circuit # 1 Controller

Circuit #1 Terminal

Board, TB1

MOD1, MOD2

Circuit # 2 Controller

Circuit #2 Terminal

Board, TB2

Ground

Capacity Control System

The capacity of the chiller is controlled by, 1) staging the compressors on and off, 2) by

adjusting the capacity of each compressor by opening or closing the inlet vanes to control

the quantity of refrigerant entering the impeller, and 3) varying compressor speed to change

capacity.

The speed control and vane control work in conjunction. As load decreases, compressor

speed is reduced as low as possible but above the point where stall might begin. If further

IMM WMC-1 Centrifugal Chillers 29

Page 30

capacity reduction is required, the guide vanes will close to whatever position is required to

match the compressor capacity to the load.

Surge and Stall

Stall and surge are a characteristic of all centrifugal compressors. These conditions can

occur at low load conditions when the operating point moves to the left of the compressor

surge line on the performance curve.

In surge, the discharge gas alternately flows backward and forward through the impeller

reversing about every two seconds. Increased noise, vibration and heat occur and motor

current varies widely. Surge can damage a compressor. The compressors are equipped with

safety features that help prevent surge from occurring.

Another instability is stall or incipient surge, which occurs a little to the left, or before, the

surge condition. Discharge gas in the diffuser forms rotating stall pockets or cells. The

compressor sound level will change and the impeller starts to heat up. Motor current

remains steady.

Condenser Water Temperature

When the ambient wet bulb temperature is lower than design, the entering condenser water

temperature can be allowed to fall, improving chiller performance.

McQuay chillers will start with entering condenser water temperature as low as 55°F

(12.8°C) providing the chilled water temperature is below the condenser water temperature.

Depending on local climatic conditions, using the lowest possible entering condenser water

temperature can be more costly in total system power consumed than the expected savings

in chiller power would suggest due to the excessive fan power required.

To obtain lower than 55°F (12.8°C) entering condenser water temperature with a tower

selected to produce 85°F (29.4°C) water temperature at design ambient air temperatures,

cooling tower fans must continue to operate at 100% capacity at low wet bulb temperatures.

As chillers are selected for lower kW per ton, the cooling tower fan motor power becomes a

higher percentage of the peak load chiller power. The offsets of compressor power and fan

power must be examined. On the other hand, the low condenser water temperatures can be

easy and economical to achieve in mild climates with low wet bulb temperatures.

Even with tower fan control, some form of water flow control such as tower bypass must be

used. The MicroTech II control is capable of controlling tower fans and bypass valve.

Figure 16 and Figure 17 illustrate two temperature actuated tower bypass arrangements.

The “Cold Weather” scheme provides better startup under cold ambient air temperature

conditions. The check valve may be required to prevent air at the pump inlet.

30 Centrifugal Chillers IMM WMC-1

Page 31

Figure 15, Tower Bypass Valve, Pressure Actuated

Figure 16, Tower Bypass, Mild Weather Operation

Figure 17, Tower Bypass, Cold Weather Operation

IMM WMC-1 Centrifugal Chillers 31

Page 32

Normal Unit Startup/Shutdown

Startup and shutdown, other than seasonal shutdowns, are considered to be normal

operation and the following procedures apply (assuming that the equipment room

temperature are above freezing). The procedures would be used for a weekend shutdown,

for example.

Note that the chiller is part of an entire building heating and cooling system that are usually

unique to a particular site. For example, the chilled water loop and chilled water pump can

also be used for heating and therefore must be operational year-around. The cooling tower

can be used for other equipment besides the chiller and may have to remain functional even

though the chiller is not. The following procedures, therefore, must take the peculiarities of

the entire system into account.

Shutdown

If the unit is to be secured for several days, and is already off due to lack of load, the UNIT

switch in the Unit Control Panel (and the remote Start/Stop switch, if used) should be

placed in the OFF position. If the chilled water pump and cooling tower are not required

for other purposes, they too can be turned off. If the pumps are controlled by the WMC

unit controller, they will shut down after the compressors.

If the chiller is running, the chilled water and condenser water pumps must remain on until

the compressors are stopped. This is true regardless of how the unit is turned off, whether

by the local switches or through a remote signal. The compressors go through a short

shutdown sequence, shutting guide vanes and performing other functions, before it finally

stops. The pumps must remain on during this shutdown period.

Once the compressors and pumps have stopped, no further action is required other than

opening disconnects, if so desired.

Startup

Any disconnects that were opened must be closed. The chilled water pump and cooling

tower should be turned on and flow verified. The chiller can then be started by placing the

UNIT switch (and the remote Start/Stop switch, if used) in the ON position. There is no

lube warm-up period required. The compressors go through a starting sequence and may

not start immediately. Once started, it is prudent to observe unit operation on the operator

interface screen for several minutes to check for normal functioning.

Start/Stop Switching

There are four ways to start/stop the chiller. Three are selected in SETPOINT\ MODE\SP3,

the fourth way is through panel-mounted switches:

1. Operator Interface Panel, (LOCAL) Home Screen 1 has AUTO and STOP buttons

that are only active when the unit is in "LOCAL CONTROL". This prevents the unit

from being accidentally started or stopped when it is under control from a remote

switch or BAS. When these buttons are pressed, the unit will cycle through its normal

starting or stopping sequence, both compressors will be stopped and normal dual

compressor starting procedure will be in effect.

2. Remote SWITCH, Selecting SWITCH in SP3 will put the unit under the control of a

remote switch that must be wired into the control. See Field Wiring Diagram, page 19.

3. BAS, BAS input is field-wired into a card that is factory-installed on the unit controller.

32 Centrifugal Chillers IMM WMC-1

Page 33

4. Control Panel Switches

Three On/Off switches are located in the upper left corner of the main Control Panel,

which is adjacent to the operator interface panel, and have the following function:

• UNIT

• COMPRESSOR

• CIRCUIT BREAKER

A fourth switch located on the left outside of the Unit Control Panel and labeled

EMERGENCY STOP SWITCH

with the COMPRESSOR On/Off switches.

shuts down the chiller through the normal shutdown cycle of unloading the

compressors.

one switch for each compressor on the unit, executes an

immediate shutdown without the normal shutdown cycle.

disconnects optional external power to system pumps and

tower fans.

stops the compressor immediately. It is wired in series

Annual Unit Startup/Shutdown

Annual Shutdown

Where the chiller can be subject to freezing temperatures, the condenser and chiller must be

drained of all water. Dry air blown through the condenser will aid in forcing all water out.

Removal of condenser heads is also recommended. The condenser and evaporator are not

self-draining and tubes must be blown out. Water permitted to remain in the piping and

vessels can rupture these parts if subjected to freezing temperature.

Forced circulation of antifreeze through the water circuits is one method of avoiding

freeze up.

1. Take measures to prevent the shutoff valve in the water supply line from being

accidentally turned on.

2. If a cooling tower is used, and if the water pump will be exposed to freezing

temperatures, be sure to remove the pump drain plug and leave it out so any water that

can accumulate will drain away.

3. Open the compressor disconnect switch. Set the manual COMPRESSOR and UNIT

ON/OFF switches in the Unit Control Panel to the OFF position.

4. Check for corrosion and clean and paint rusted surfaces.

5. Clean and flush water tower for all units operating on a water tower.

6. Remove condenser heads at least once a year to inspect the condenser tubes and clean if

required.

Annual Startup

1. Check and tighten all electrical connections.

2. Replace the drain plug in the cooling tower pump if it was removed at shutdown time

the previous season.

3. Install fuses in main disconnect switch (if removed).

4. Reconnect water lines and turn on supply water. Flush condenser and check for leaks.

IMM WMC-1 Centrifugal Chillers 33

Page 34

Maintenance

Pressure/Temperature Chart

Danger

Wait 10 minutes after compressor shutdown before opening any

compressor access panel. The DC link capacitors store enough

energy to cause electrocution.

HFC-134a Temperature Pressure Chart

°F PSIG °F PSIG °F PSIG °F PSIG

6 9.7 46 41.1 86 97.0 126 187.3

8 10.8 48 43.2 88 100.6 128 192.9

10 12.0 50 45.4 90 104.3 130 198.7

12 13.2 52 47.7 92 108.1 132 204.5

14 14.4 54 50.0 94 112.0 134 210.5

16 15.7 56 52.4 96 115.9 136 216.6

18 17.1 58 54.9 98 120.0 138 222.8

20 18.4 60 57.4 100 124.1 140 229.2

22 19.9 62 60.0 102 128.4 142 235.6

24 21.3 64 62.7 104 132.7 144 242.2

26 22.9 66 65.4 106 137.2 146 249.0

28 24.5 68 68.2 108 141.7 148 255.8

30 26.1 70 71.1 110 146.3 150 262.8

32 27.8 72 74.0 112 151.1 152 270.0

34 29.5 74 77.1 114 155.9 154 277.3

36 31.3 76 80.2 116 160.9 156 284.7

38 33.1 78 83.4 118 166.0 158 292.2

40 35.0 80 86.7 120 171.1 160 299.9

42 37.0 82 90.0 122 176.4 162 307.8