Page 1

Product Manual

Reciprocating Chillers

WHR 017EW To WHR 210EW, Packaged Water-Cooled

WHR 017EA To WHR 210EA, Remote Condenser

17 to 210 Tons, 60 to 740 kW

R-22, R134a

60 Hz

PM WHR-2

Group: Chiller

Effective: May 2000

Supersedes: PM WHR-1

© 1997 McQuay International

Page 2

Table of Contents

Introduction......................................................................................................................................3

Features and Benefits.....................................................................................................................4

Design Advantages ..........................................................................................................................6

Temperature Control ......................................................................................................................9

Standard Control.......................................................................................................................9

Optional Control........................................................................................................................9

Optional Network Master Panel............................................................................................12

Optional Remote Monitoring and Sequence Panel............................................................12

Monitor software.....................................................................................................................13

Open Protocol..........................................................................................................................13

MicroTech BACdrop Gateway..........................................................................................13

Selection Procedure......................................................................................................................14

EW Water-Cooled, R-22.........................................................................................................14

EW Water-Cooled, R-134a.....................................................................................................15

EA Remote Condenser, R-22.................................................................................................15

EA Remote Condenser, R-134a .............................................................................................17

Selection Adjustment Factors .....................................................................................................17

Ethylene and Propylene Glycol Factors...............................................................................17

Evaporator and Condenser Delta-T Factors .......................................................................18

Fouling Factor..........................................................................................................................18

Performance Data..........................................................................................................................19

EW Water-Cooled...................................................................................................................19

Part Load Data (EW Only).....................................................................................................25

EA Remote Condenser...........................................................................................................26

Pressure Drop Curves..................................................................................................................30

Electrical Data................................................................................................................................33

Field Wiring Diagram..............................................................................................................44

Physical Data..................................................................................................................................45

EW Water-Cooled...................................................................................................................45

EA Remote Condenser...........................................................................................................50

Dimensional Data..........................................................................................................................53

EW Water-Cooled...................................................................................................................53

EA Remote Condenser...........................................................................................................57

Sound Data......................................................................................................................................61

Application Data.............................................................................................................................65

Optional Features..........................................................................................................................69

Optional Remote Monitoring and Sequencing Panel (RMS)............................................69

Product Specifications..................................................................................................................71

Water-Cooled, WHR 017 through 030.................................................................................71

Water-Cooled, WHR 040E through WHR 210E..................................................................75

Remote Condenser Chiller, WHR 017 through 030............................................................80

Remote Condenser Chiller, WHR 040E - WHR 210E..........................................................84

Our Facility is

"McQuay" is a registered trademark of McQuay International

"Illustrations cover the general appearance of McQuay International products at the time of publication and we

reserve the right to make changes in design and construction at anytime without notice"

1997 McQuay International

ARI Certification Applies to EW

Water-Cooled Units Only

2 WHR 017E - 210E Product Manual WHR-2

Page 3

Introduction

McQuay International offers a complete line of water-cooled chillers from 17 to 2500 tons (60

to 8800 kW) utilizing reciprocating and centrifugal compressors.

The WHR packaged reciprocating compressor chillers are a product of the McQuay

commitment to offer energy efficient equipment design. A design approach carefully

combining high quality compressors, efficient shell-and-tube heat exchangers, and state-ofthe-art controls into a unit of uncompromised operating efficiency and reliability.

Model WHR-EW are equipped with factory-mounted water-cooled condensers.

Model WHR-EA have no condensers mounted and are intended for use with remote

evaporative or air-cooled condensers. See McQuay catalog PM ACAQ for a complete line of

matching air-cooled condensers.

Efficiency

• WHR-EW are in compliance with ASHRAE 90.1

• Cross-circuit compressor unloading

• Liquid subcooling

• Copeland DISCUS compressor

• Maximum capacity reduction

ARI Standard 550/590-98 Certified

The ARI Certification Program does not include chillers with remote condensers.

Therefore, Model WHR-EA, Remote Condenser Chillers, ratings are not ARI certified.

Model WHR-EW, Water-Cooled Chillers are ARI certified.

Reliability

• Rugged compressor design

• Factory installed operating and safety controls

Flexibility

• Complete factory assembly

• 25 available sizes

• Factory installed options

Serviceability

• Semi-hermetic compressors

• Suction and discharge service valves

• Dual refrigerant circuits (WHR040 and above)

Full Factory Testing

• Assures trouble-free start-up and operation

Product Manual WHR-2 3

Page 4

Features and Benefits

Efficiency

WHR-EW Water-Cooled and WHR-EA Air-Cooled, (depending on remote condenser selection) meet

ASHRAE 90-1 efficiency levels - the world’s standard for chiller efficiency.

The “E” vintage WHR-EA reciprocating chillers offer some of the highest operating efficiencies

available today through the use of highly efficient components and efficiency oriented packaging.

Operating economy at reduced load is increased by operating each refrigerant circuit partially

unloaded, rather than one circuit off and the other circuit fully loaded. At unloaded conditions each

compressor will operate at lower compression ratios with substantial power savings.

Optional steps of capacity reduction are accomplished by the most efficient method of cylinder

unloading in the industry today.

To McQuay, operating economy means more than just energy efficiency. The WHR chillers reduce

operating costs not only through energy efficiency, but by offering high unit reliability, easy

serviceability, full factory testing and the backing of a factory trained sales, service and parts

organization.

Flexibility

The WHR chillers come in 25 sizes between 17 and 210 nominal tons (60 and 710 kW). The small

capacity increments provide a selection that will closely match the required job capacity.

The WHR water chillers come completely factory assembled, piped, wired, and shipped in one piece;

ready for water piping and wiring connections. The EA remote condenser models are ready for field

piping to the remote condenser. Single main supply power terminal block can be supplied by one field

installed main supply power disconnect switch.

Many optional features can been added to fit your needs. A unit mounted non-fused disconnect

switch eliminates the need for a field installed disconnect. Phase failure/reversal protection, high

return water unloading, and acoustical sound enclosures around compressor are all optional features

that can be factory installed.

Reliability

The McQuay WHR chillers use the most advanced and efficient reciprocating compressors in the

industry, the Copeland DISCUS valve compressors. These heavy-duty, industrial quality, semihermetic compressors are designed for R 22 or R-134a.

All WHR chillers are factory run tested to assure unit functionality. All safety and operating controls

are checked and calibrated. Chillers for remote condensers are connected to slave condensers for

testing purposes. This extensive testing assures trouble-free start-ups.

To protect the unit from abnormal operating conditions, a complete set of safety controls for each

circuit is used. Safety controls include compressor crankcase heater(s), freeze protection

pressurestats (manual reset), oil switches (manual rest), high pressure safety switches (manual reset),

and compressor motor overload protectors. Standard operating controls include time delay relays for

20-second sequence starting of compressors, manual pumpdown switches, low pressure controls,

compressor lead-lag switches (WHR-040EW-210EW) and chilled water temperature controller. All

controls and wiring are completely factory labeled for ease of service.

4 Product Manual WHR-2

Page 5

Serviceability

Semi-hermetic, 1750 rpm induction type motors are employed. The motors are refrigerant gas cooled.

A finned motor housing helps dissipate motor heat. Solid-state modules in the motor terminal box

respond to temperature sensors imbedded in all three motor windings to provide inherent thermal

overload protection for all run and start conditions.

Serviceable compressors offer reduced

maintenance costs because if problems

develop with components such as oil

pumps, unloaders, and pistons, they

can be serviced in the field without

replacing the compressor. Both suction

and discharge service valves are

provided to allow isolation of the

compressor from the refrigerant circuit.

All multiple compressor units utilize

two independent refrigerant circuits.

Dual refrigerant circuits permit

shutdown and routine maintenance and

service of one circuit while the second

circuit maintains system operation

where two or more compressors are

supplied.

Refrigerants

Models WHR 017 through WHR 210 utilize R-22 as the standard refrigerant. Models WHR 040

through WHR 210 can be furnished with R-134a refrigerant.

Full factory testing

Extensive quality control checks and individual performance tests assure that the units will meet the

requirements of the application and start-up and perform reliably. EA remote condenser models are

shipped with a holding charge of refrigerant, EW water-cooled units are shipped with a complete

operating charge.

Each unit is pressure tested, evacuated and charged with refrigerant for test purposes. Extensive

quality control checks and individual unit performance tests, at full load, ensure that each control is

properly adjusted and operates correctly. EA remote condenser models are connected to factory slave

condensers for testing. Each unit is then rechecked for refrigerant leakage.

Code Approvals

All WHRhb units are constructed and/or rated with the latest ANSI/ASHRAE 15 Safety Code,

National Electrical Code and ASME Boiler and Pressure Vessel Code. All models are ETL approved or

cETL listed.

Product Manual WHR-2 5

Page 6

Design Advantages

Unit Arrangements

The McQuay water chillers are completely factory assembled, piped, wired and shipped in one piece,

ready for field connection of refrigerant (EA models) and water piping. Each unit consists of motor

compressors, insulated DX cooler and centralized electrical control panel containing all necessary

safety and operating controls, and compressor starting controls. Arrangement “EW” units come

complete with water-cooled condensers with integral subcooler circuits. Arrangement “EA” units are

provided without condensers to allow for remote installation of air-cooled or evaporative condensing

equipment.

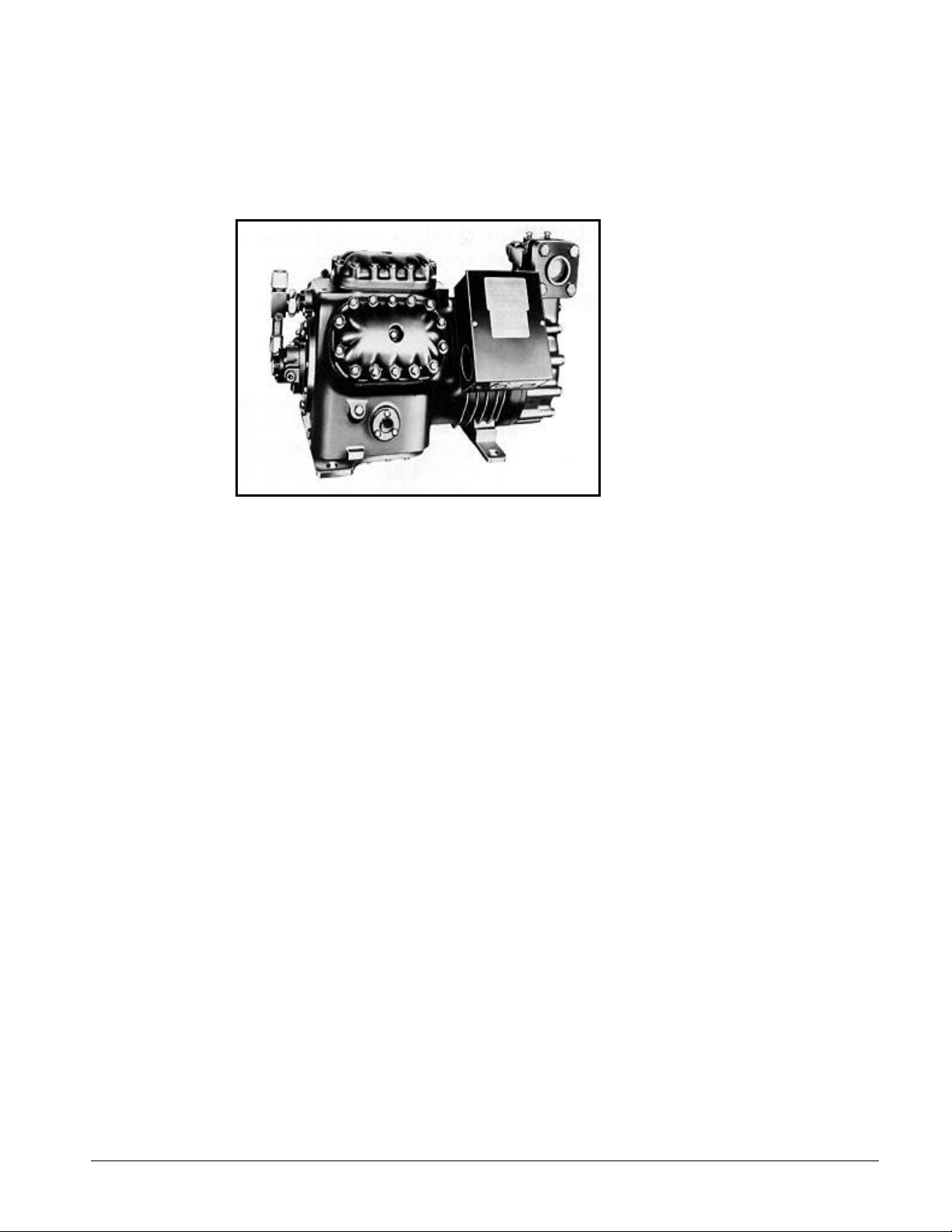

Compressors

WHR chillers use Copeland DISCUS semi-hermetic compressors. These compressors are designed

for R 22 and R-134a.

Semi-hermetic, 1750 rpm induction type motors are used. The motors are refrigerant gas cooled. Solidstate modules in the motor terminal box respond to temperature sensors imbedded in all three motor

windings, providing inherent thermal overload protection for all run and start conditions.

The compressor housing is constructed from close grained, high nickel content, alloy cast-iron with

no bolted joint between the motor and compressor. The housing includes a cast-iron cylinder head

and stator cover, and a crankcase oil sightglass. A suction strainer built into the compressor in the gas

stream between the suction service valve and the motor, filters out foreign and abrasive particles. An

internal relief valve relieves discharge pressure to the suction side for safety protection at high

compression ratios as required by ANSI/ASHRAE 15 Safety Code.

Main bearings are solid cast bronze insert type with oversized bearing area resulting in ultra-low

bearing loading.

The crankshaft is die-forged, high strength iron alloy with integral counterweights, statically and

dynamically balanced for smooth operation.

Connecting rods are lightweight aluminum with integral bearing surfaces on the crankshaft and piston

ends. Pistons are close grain cast iron with oil and compression rings. Piston pins are full floating

type for long life.

Compressors have a forced-feed lubrication system with positive oil displacement, a reversible oil

pump, and an operating oil charge. The pump feeds oil through rifle-drilled passages in the crankshaft

to all bearing surfaces. Magnetic plugs trap particles that enter the crankcase. The oil supply filters

through a large area oil strainer. During start-up, a crankcase heater minimizes oil being diluted by

refrigerant.

Factory Installed Liquid Line Components

Each refrigerant circuit has a filter-drier, liquid line sightglass/moisture indicator, solenoid valve,

manual liquid line shutoff valve and thermal expansion valve.

Short Circuit Protection

(WHR 017 through 030, WHR 095 through 210)

Each compressor is individually protected against short circuit and locked rotor conditions by factory

installed circuit breakers. Separate fusing protects the control circuit. WHR-040 through 090 can have

circuit breakers factory installed as an option.

6 Product Manual WHR-2

Page 7

Part Load Efficiencies

Part load efficiencies and Integrated Part Load Values (IPLV) for EW units are calculated according to

the requirements of the latest ARI Standard 550/590-98 and meet or exceed ASHRAE Efficiency

Standard 90.1. Since most air conditioning systems operate at less than design full load a majority of

the time, IPLV is an excellent method for comparing chillers' efficiencies.

Noise

All McQuay WHR chillers are equipped with hot gas discharge line mufflers in each refrigerant circuit

to reduce the overall sound levels. An optional insulated acoustical compressor enclosure to further

reduce sound levels is also available for most units. Sound level ratings are contained in the Sound

Rating section of this manual.

Unit Base

Designed for easy handling, the units are mounted on a compact, rugged formed steel base. Isolator

mounting holes are provided.

Electrical Control Center

Shipped with all operating and safety controls and motor starting equipment factory wired,

operationally tested, and ready for operation. All controls are centrally located in a hinged control

center with keylocked doors.

Part-winding starters are standard on 208/230 volt applications and available as a special on 460/575

volts. Across-the-line starters are standard on 380/460/575 volts.

A five-minute, solid-state lockout timer is provided to delay compressor restart after safety cutout or

power interruption, or under irregular cooling load demands. A lead lag switch is standard on all units

(WHR 040 – WHR 210) not incorporating the single circuit hot gas bypass option.

Evaporator

The evaporator is a direct expansion, shell-and-tube type with water flowing in the baffled shell side

and refrigerant flowing through the tubes.

The evaporator is constructed with a carbon steel shell and seamless high efficiency copper tubes,

roller expanded into heavy carbon steel tube sheets. Water baffles are polypropylene to resist

corrosion.

Refrigerant heads are carbon steel with multi-pass baffles to ensure oil return and are removable to

permit access to the tubes from either end. For water removal, 3/8" (10mm) vent and drain plugs are

provided on the top and bottom of the shell. Two 1/2” (12.7mm) couplings on each water nozzle allow

for easy field installation of sensor equipment.

The evaporator is wrapped with 3/4” (19.1mm) thick vinyl nitrate polymer sheet insulation. The

insulation has a K factor of 0.28 at 75°F (24°C). The insulation is fitted and cemented in place, then

painted with a resilient vinyl base paint to resist cracking.

The tube side maximum working pressure is 225 psig (1552kPa). The waterside working pressure is 175

psig (1206kPa). All evaporators are designed, constructed, inspected and stamped according to the

requirements of the ASME Boiler and Pressure Vessel Code.

Product Manual WHR-2 7

Page 8

Water-Cooled Condensers

All water-cooled condensers are cleanable shell and tube type with water in the tubes and refrigerant

in the shell. Each condenser is capable of holding the circuit pumpdown capacity. Independent

condensers serve the dual refrigerant circuits.

Each condenser is constructed with a carbon steel shell and seamless integrally finned high efficiency

copper tubes roller expanded into steel tubesheets. Water heads have vent and drain connections

and are removable. Also included is a liquid shutoff valve, purge valve, 450 psi (3104 kPa) relief valve

per ANSI/ASHRAE Pressure Vessel Code, Section VIII.

Water side working pressure is 225 psi (1550 kPa), refrigerant side is 450 psi (3104 kPa).

Air-Cooled Condensers

The WHR-EA chillers are designed for use with

properly sized and configured remote air-cooled or

evaporative condensers. The McQuay AC/AQ line of

air-cooled condensers are designed for use with these

chillers. The AC/AQ condensers are available with

single or double row vertical discharge fans and are

fully described and rated in Product Manual PM

ACAQ. They are packed with features offering

tangible benefits to owners.

• Complete range of capacities from 10 to 210 tons

• Circuits matched to WHR chillers

• Direct drive fan motors at 1140 and 830 RPM

• Patented floating tube design to eliminate tube sheet leaks

• High efficiency coil and fan motor design

• Internal baffles between all fan cells

• Weatherproof control panel with door mounted disconnect switch

• G90 painted galvanized steel cabinets

• Single point power connection

• Independent fusing and contactors for each fan motor

• Integral pre-piped subcooler circuit

8 Product Manual WHR-2

Page 9

Temperature Control

The McQuay WHR-040EW through 210EW water chillers are available with any one of three

different temperature controls to satisfy your requirements: 1) the standard microprocessor leaving

water controller, 1a) the same controller but with an indicator light package, and 2) the MicroTech

Controller.

Standard Control

WHR-017 - 030

A return water electromechanical temperature controller is supplied on the WHR-17 through 030

when supplied with two stages. Three stage units are supplied with a solid state, return water

temperature controller.

On Model EA units for remote condensers this controller is equipped with terminals from which the

first fan motor can be energized on compressor start. These sizes have a single refrigerant circuit.

WHR 040 - 210

The UNT-33 microprocessor leaving water temperature controller is standard on all units from size

040 to 210 and provides precise temperature control based on leaving water temperature. The

control is preset and calibrated and no other adjustment is required other than setpoint. There is a

60 second interstage On Delay between stages. Each stage incorporates minimum on and off timers

with a maximum cycle rate of six cycles per hour. Reset of supply water temperature can be

accomplished from outside air temperature, zone temperature or a signal from an EMS system.

Condenser fan control (Model EA)

Some means of controlling discharge pressure is required on condensers applied to the WHR-EA

remote condenser units. The McQuay AC/AQ air-cooled condensers can be equipped with

pressure activated fan cycling switches or with variable speed drives. Neither method requires

interconnecting wiring between the chiller and condenser.

Optional Control

Optional Zone Terminal for use with the UNT Control

Provides for onboard (or remotely wired) monitoring or adjusting of certain functions.

• Monitoring

• Monitor up to three setting or sensed values

• Monitor 18 different on/off inputs

• Monitor alarm status via a flashing alarm light and flashing symbol

• Adjusting, allows adjustment of any flashing set points, three at a time, typically set up so that

the relationship between values can be viewed simultaneously. For example:

• Display 1 = Lvg Water temp

• Display 2 = Lvg Water SP

• Display 3 = % Unit Load

Product Manual WHR-2 9

Page 10

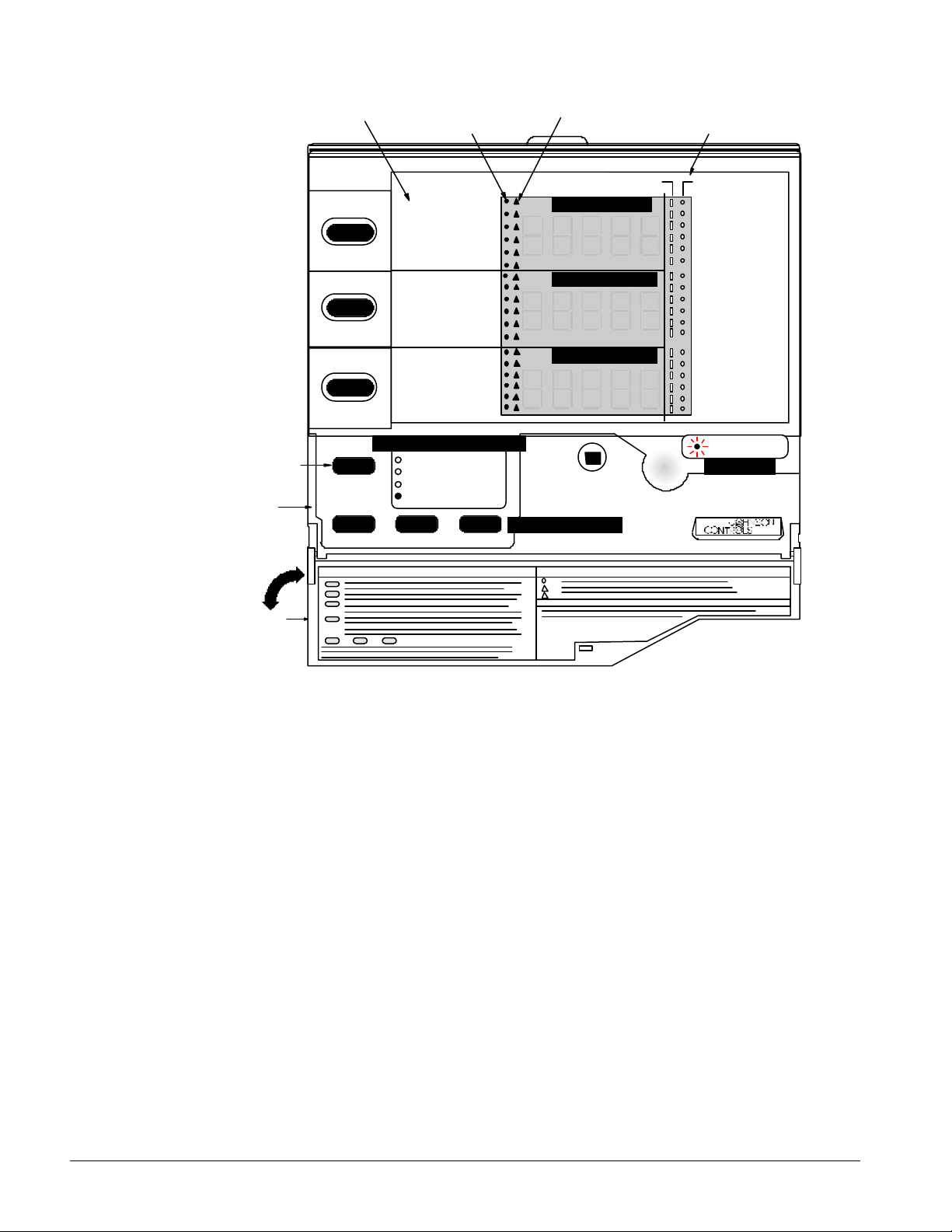

Figure 1, Zone Terminal Configuration

Display Item List

Display Indicator Dot

Warning Signal

On/Off Status

Display

Button 1

Mode

Selector

Button

Mode

Selector

Panel

Door

2

3

McQuay AGZ/AGR Global Chiller

Lvg Water Temp

Evap Pres #1

Evap Pres #2

OA/AI3 Input

OA/AI3 HiLimSP

OA/AI3 ResetSP

Lvg Water SP

LvgWtr RBnd SP

Contrl Band SP

Actual Lvg SP

Unoccpd Lvg SP

OA Lockout SP

% Unit Load

Lvg Low Lim SP

SoftSta Capcty

SoftStart Time

Cir #1 Starts

Cir #2 Starts

Opera ting Mode Indicator

MONITOR

ADJUST

TIME SCHEDULE

PASSWORD

ENTER

INSERT 10

Display Area 11

Display Area 21

Display Area 31

Up/Do wn Arrow K eys

ON OFF

Occupied

Flow Failure

OA Lockout

Cir#2Lead=On

Pmp/Stp #1=0

Pmp/Stp #2=0

Solenoid #1

Solenoid #2

Frzstat#1Alm

Frzstat#2Alm

MinLowPres#1

MinLowPres#2

Compressor 1

Compressor 2

Stage 3

Stage 4

Stage 5 Opt.

Stage 6 Opt.

Alarm Light

ALARM

AGZ-AGR

Optional MicroTech Chiller Controller

WHR-040 – 210 Only

The MicroTech reciprocating chiller controller surpasses all other microprocessor-based chiller

control systems available today. This powerful, user-friendly control system provides the flexibility

and performance needed for a stand-alone unit as well as multiple units tied into a network system.

MicroTech’s state-of-the-art design will not only permit your chiller to run more efficiently, but will

also simplify troubleshooting if a system failure occurs. Every MicroTech controller is programmed

and tested prior to shipment to ensure a trouble-free start-up.

Condenser fan control (Model EA)

Control of condenser fans is available through the MicroTech controller. The control steps

condenser fans or groups of fans based on discharge pressure. Field wiring is required between

the chiller and the remote condenser.

10 Product Manual WHR-2

Page 11

Operator-friendly

The 12-key, touch-sensitive, membrane keypad and 32-character display makes the MicroTech

system especially user-friendly. Inch-pound or SI units are optionally available.

The MicroTech menu structure is separated into three distinct categories, which provide the

operator or service technician with a full description of current unit status, control parameters, and

alarms. Security protection prevents unauthorized changing of the setpoints and control

parameters.

MicroTech continuously performs self-diagnostic checks, monitoring all system temperatures,

pressures and safeties, and will automatically shutdown a compressor, a refrigerant circuit of the

entire unit should a fault occur. The cause of the shutdown will be retained in memory and can be

easily displayed in plain English or metric units for operator review. The MicroTech chiller

controller can also retain and display the time the fault occurred and the operating conditions that

were present at the time of the fault, which is an extremely useful feature for troubleshooting. In

addition to displaying alarm diagnostics, the MicroTech chiller controller also provides the operator

with a warning of pre-alarm conditions.

Ice storage

The MicroTech control easily changes the leaving fluid setpoint via a remote signal to the

controller. The feature enables selection of chilled water or ice storage mode.

Enhanced chiller operating efficiencies

The MicroTech chiller controller offers many features to improve the operating efficiency of the

reciprocating chiller. In addition to monitoring water temperature and air temperatures, refrigerant

temperatures and pressures, and unit amperage, MicroTech also offers the following energy saving

features:

Programmable setpoints

The MicroTech chiller controller offers precise digital settings of the leaving chilled water

temperature setpoint and all other control parameters. This is extremely important in the setting of

safeties such as low leaving water temperature cutout, high pressure cutout, suction pressure

cutout, and freeze protection.

Compressor soft loading

Soft loading limits the number of cooling stages to prevent unnecessary electrical demand and

possible overshoot of the leaving chilled water temperature setpoint.

Demand limit control

Based on a 4-20mA DC signal, the controller will determine the maximum number of stages permitted

to operate, preventing additional demand charges during high usage periods.

Product Manual WHR-2 11

Page 12

Automatic circuit lead-lag

With the keypad, the operator can manually select either refrigerant circuit for the lead position or

the controller will automatically select the lead circuit based on the circuit with the fewest operating

hours.

Time clock, daily and holiday start/stop control

The operator can program daily start/stop schedules including weekends and up to fourteen

separate holidays without the need of an external time clock or EMS interface. If desired, an

external time clock can be used instead of the internal schedule.

Chilled water pump control

There is no need for an external time clock or EMS interface to control the pump start/stop

operation. The MicroTech chiller controller can accomplish this through a digital output. If an

alarm shuts down the chiller, the chilled water pump will remain on, providing any remaining cooling

to the loads.

Optional Network Master Panel

The MicroTech Network Master Panel (NMP) allows multiple reciprocating chiller controllers to be

incorporated into a building-wide network with other MicroTech units and auxiliary controllers. In

conjunction with a personal computer, it provides the building operator with the capability to

perform advanced equipment control and monitoring from a central or remote location. The

following features are provided by the optional NMP:

• Remote unit monitoring

• Advanced scheduling features

• Advanced alarm management features

• Global operator override

• Global unit shutdown input

• Demand metering

• Historical electrical data logging

Optional Remote Monitoring and Sequence Panel

One to three reciprocating chiller controllers can be incorporated into a network with the MicroTech

remote monitoring and sequencing (RMS) panel. The optional RMS panel provides the following

features:

• Remote chiller monitoring (up to 3)

• Automatic or manual chiller sequencing

• Automatic or manual lead-lag designation

• Common chiller scheduling

• Optimal start control

• Chilled water reset by outdoor air temperature or external 4-20 mA signal

• Chiller run time totalization by month, current year, and prior year

• Cooling degree-day totalization by month, current year, and prior year

The RMS panel is equipped with a keypad/display that is identical to the chiller controller’s

keypad/display. With a special keystroke combination, the RMS keypad/display can be interfaced

with any chiller controller. It then operates identical to the chiller-mounted keypad/display. Thus

the operator has full access to all networked chillers from a single remote location. Panel-mounted

LED’s clearly indicate which controller the RMS panel keypad/display is currently interfaced with.

12 Product Manual WHR-2

Page 13

Monitor software

When properly equipped with MicroTech Monitor software, a direct or remote connected PC can be

used for monitoring unit operation, changing setpoints, scheduling, trend logging, downloading

controller software, and diagnostics. For MicroTech network systems, the PC gives the operator

access to all unit and auxiliary controllers in the network. Specific controller or global data can be

displayed as desired. All keypad status information and control capability is available at the PC in a

full-screen format. Many additional unit control parameters, which are not available at the unit

controller’s keypad, are also available. Monitor software provides the following features:

• High resolution, unit-specific graphic representations

• One-touch function keys

• Multiple unit display screen

• Automatic screen refresher

• Help text

• Dial-up communications

• Alarm monitoring and management

• Scheduling

• Trend logging

• Downloading capability

• Multi-level password protection

• Controller Diagnostics

Open Protocol

MicroTech Open Protocol Master panel provides an interface between MicroTech unit controllers

and virtually all building automation systems (BAS). A protocol is a set of rules governing data

exchange between microprocessors, thereby permitting communications between unlike controllers.

As a result, building designers, owners and operators can obtain the advantages of McQuay

equipment, and the control versatility MicroTech has to offer. A low cost site license covering any

and all McQuay product is required.

MicroTech BACdrop Gateway

The McQuay BACdrop Gateway panel allows any BACnet based building automation system

(BAS) to communicate with MicroTech controllers. The panel translates between the standard

BACnet protocol (ANSI/ASHRAE 135-1995) and the MicroTech protocol. No modifications to the

MicroTech hardware or software are necessary. Since BACnet is a standard, public protocol no

license agreement is necessary.

Product Manual WHR-2 13

Page 14

Selection Procedure

EW Water-Cooled, R-22

1. Ratings are based and certified in accordance with ARI Standard 550/590-98.

2. Ratings in Table 5 through Table 10 may be interpolated for any chiller water temperature

between 40°F and 50°F (4.4°C and 10.0°C) but cannot be extrapolated.

3. Chilled water quantities - Ratings are based on a 10 degree F (5.6 degree C) chilled water range

(2.4 gpm/ton) and can be used for a delta-T range of 6 to 16 degrees F (3.3 to 8.8 degrees C) by

adjustments from Table 3.

4. Figure 2 through Figure 4 give the evaporator water pressure drop data. Water flow rates

should be maintained within these limits, which are based on minimum and maximum flow.

5. Ratings are based on 0.0001 fouling factor for the evaporator. For other fouling factors,

multiply ratings by evaporator factors from Table 3. For applications using a glycol solution,

see Table 1 and Table 2.

6. Ratings are based on condenser flow of 3 gpm/ton (10 degree F, 5.6 degree C delta-T) and

0.00025 fouling factor. Corrections for other conditions are in the following Application

Section.

Selection Procedure

Knowing the required chiller capacity in tons, the leaving water temperature and either the chilled

water temperature range (Delta T) or the flow, determine the unknown quantity using the formula:

= Tons

Knowing the required chiller capacity (tons), the entering condenser water temperature, and either

the condenser water temperature range-delta T, or the GPM, determine the unknown quantity using

the formula:

With the above data, the appropriate unit can be selected from Table 5 through Table 10. Pressure

drop for evaporators and condensers can be found in Figure 2 through Figure 4.

24

TDeltaGPM ×

=GPM Condenser

THR

×

=

.Cond TDelta500

aterRangeCondenserW

30Capacity Cooling Tons Nominal

×

Sample Selection

Given: Cool 165 GPM of water from 54°F to 44°F with condenser water available at 85°F.

Condenser water temperature rise to be 10 degrees. Fouling factor of 0.0001 in the evaporator and

0.00025 in the condenser.

Find:

A. WHR packaged water chiller selection

B. Compressor power input

C. Condenser water flow rate

D. Evaporator and condenser water pressure drop

14 Product Manual WHR-2

Page 15

Solution:

1. Chilled water range: 54°F - 44°F = 10°F (Temperature Difference).

2.

3. From Table 6, a model WHR-070EW has the capacity to meet the job requirement. For an

evaporator leaving water temperature of 44°F and condenser water entering temperature of

85°F with a 10 degree rise, the unit capacity rating table indicates:

Capacity: 70.5 Tons

Power: 62.4 kW

4. Determine condenser water from the following:

Condenser GPM =

5. From Figure 2 for the WHR-070EW, evaporator pressure drop at 165 GPM is 6.2 feet

6. From Figure 3, the condenser pressure drop at 210.6 GPM is 12.5 feet water.

×

=Capacity

24

Tons Cooling Capacity 30

Nominal Condenser Water Range

Range Water ChilledGPM

165 1024×

= 68.8 tons

×

30 tons70.5

= =

×

degrees 10

GPM 211

EW Water-Cooled, R-134a

Use the same selection procedures as with R-22 except multiply the values in the R-22 Performance

Tables as follows: Capacity x 0.68, Power x 0.65, EER x 1.05.

EA Remote Condenser, R-22

Selection Method

The performance of the WHR chillers is listed by LWT (leaving chilled water temperature) and by

Condensing Temperature. Tons, Power, and THR (Total Heat Rejection) are given. This data can

then be used to select any condenser from its own capacity data. For a McQuay AC/AQ air-cooled

condenser, use product manual PM ACAQ.

1. Ratings may be interpolated for any chiller water temperature between 42°F and 50°F but

cannot be extrapolated (contact factory for ratings outside this range).

2. Chilled water quantities - Ratings are based on a 10 degree F chilled water range and are

applicable from a minimum of 6 degrees F to a maximum of 16 degrees F differential between

entering and leaving chilled water temperatures.

3. Ratings are based on .00025 fouling factor for both condenser and evaporator. For other

fouling factors, multiply ratings by cooler factors from Table 3 and Table 4. For applications

using a glycol solution, see Table 1 and Table 2.

Selection Procedure

Normally the required chiller capacity in tons, the entering and leaving chilled water temperature

and flow and the design outdoor air temperature are known. Determine any unknown quantity

using the formula:

Tons = gpm x delta T / 24

Capacity data is in Table 12 and Table 13 for IP units and Table 14 and Table 15 for SI units. Rating

are based on:

• Leaving chilled water temperatures from 42°F to 50°F (6°C to 10°C) with a 10 degree delta-T.

Selections can be interpolated between these leaving temperatures but not extrapolated.

Product Manual WHR-2 15

Page 16

Correction factors for delta-Ts other than 10 degrees are in Table 3 and Table 4. Exceeding the

Delta-T range of 6 to 16 degrees will cause problems controlling unit unloading.

• Condensing temperatures (CT) from 105°F to 125°F (40°C to 55°C).

• Total Heat Rejection (THR) is given and used to select the condenser, whether it be a dry air-

cooled condenser or an evaporative condenser.

Several different size condensers can usually be matched to any given WHR-EA unit depending on

the condensing temperature that typically ranges from 20 to 30 degrees F above the design outdoor

temperature. Increasing condensing temperatures will reduce the chiller capacity, increase its power

consumption and result in a smaller condenser being required.

Normally a WHR-EA is selected to meet or exceed the required cooling capacity at some

condensing temperature and a condenser then selected with sufficient capacity to handle the heat

rejection with the selected temperature difference (TD, difference between design outdoor dry bulb

temperature and condensing temperature).

A more accurate solution can be achieved by plotting the capacity of the chiller and the condenser

as a function of the TD and observing the curves intersection that is the system balance point. An

example is shown in the following "Selection Example" section.

Sample Selections

Given: Required capacity of 100 tons cooling 240 gpm of water from 54°F to 44°F with 95°F design

dry bulb temperature. Evaporator fouling factor of .00025.

Find:

1. WHR water chiller and AC/AQ condenser selection

2. Compressor power input, chilled water pressure drop

Solution:

1) From Table 13, several WHR selections are possible:

a) WHR 110EA at 110°F CT; 102.5 tons, 107.3 kW, 1596.5 THR, 1.05 kW/ton

b) WHR 115EA at 115°F CT; 101.0 tons, 112.8 kW, 1597.3 THR, 1.12 kW/ton

c) WHR 120EA at 125°F CT; 103.4 tons, 135.1 kW, 1701.5 THR, 1.30 kW/ton

Note that the condensing temperature has significant influence on the chiller efficiency.

Progressing from a) to c) above will require smaller condensers, offset by larger, more

expensive chillers and lessening efficiency.

2) A condenser can be selected with the above information. For this example, a McQuay Model

ACAQ air-cooled condenser will be selected using selection procedures and data contained in

Product Manual PM ACAQ. A model ACD (double row of fans, standard fan speed) will be

used.

a) For the WHR 110EA at a TD of 15 degrees F (110°F - 95°F) no selection appears possible

based on the simple selection method. However, it is close and the graphical method may

give a solution.

b) For the WHR 115EA at a TD of 20 degrees, a Model 175A will do the service.

c) For the WHR 120 EA at a TD of 30 degrees, a Model 115A will do the service.

Selection c) will prove to be considerably lower in first cost but carries a 16 percent efficiency

penalty.

16 Product Manual WHR-2

Page 17

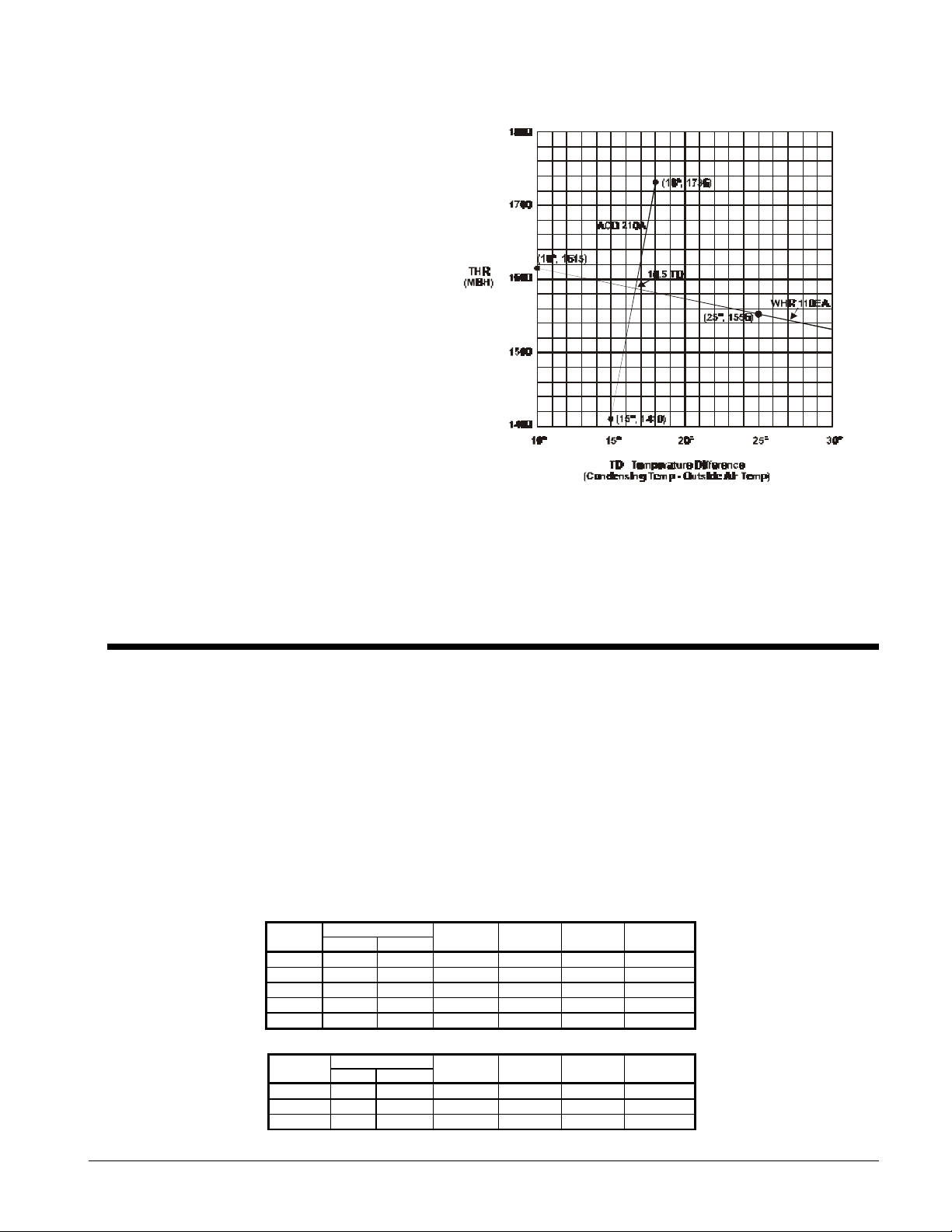

3) Graphical solution to Case a) is shown below.

d) The THR for the WHR

110EA is plotted using two

points; TD=10 degrees

(105°F-95°F) and TD=25

degrees (120°F-95°F).

e) The THR for the ACD 210A

is plotted using its capacity

at TD+15 degrees and

TD=18 degrees.

f) The curves intersect at

TD=16.5 degrees or 111.5°F

condensing temperature.

g) Extrapolating the WHR

capacity at 111.5°F gives

101.5 tons which will meet

the job requirements. It will

be the highest cost but

most efficient unit.

EA Remote Condenser, R-134a

Use the same selection procedures as with R-22 except multiply the values in the R-22 Performance

Tables as follows: Capacity x 0.68, Power x 0.65, EER x 1.05.

Selection Adjustment Factors

Ethylene and Propylene Glycol Factors

WHR units are designed to operate with a leaving chilled fluid temperature from 21°F (-6.1°C) to

60°F (16°C). Leaving chilled fluid temperatures below 40°F (4.6°C) result in suction temperatures at

or below the freezing point of water and a glycol solution is required. The use of glycol in the

evaporator will reduce the performance of the unit. The reduction in performance depends upon

the glycol concentration. This should be taken into consideration during initial system design.

McQuay encourages a minimum concentration of 25% be provided on all glycol applications.

Glycol concentrations below 25% are too diluted for long-term corrosion protection of ferrous

metals and corrosion inhibitors may need to be recalculated. Glycol in the condenser will have a

negligible effect on performance because glycol at higher temperatures will perform with

characteristics similar to water.

Table 1, Adjustment Factors for Ethylene Glycol

E.G

10 26 -3 0.991 0.966 1.013 1.070

20 18 -8 0.982 0.992 1.040 1.129

30 7 -14 0.972 0.986 1.074 1.181

40 -7 -22 0.961 0.976 1.121 1.263

50 -28 -33 0.946 0.966 1.178 1.308

Freeze PointPercent

°F °C

Table 2, Adjustment Factors for Propylene Glycol

P.G

10 26 -3 0.987 0.992 1.010 1.068

20 19 -7 0.975 0.985 1.028 1.147

30 9 -13 0.962 0.978 1.050 1.248

Freeze PointPercent

°F °C

Cap. Power Flow PD

Cap. Power GPM PD

Product Manual WHR-2 17

Page 18

40 -5 -21 0.946 0.971 1.078 1.366

NOTE: Glycol applications are not included in the ARI certification program.

Evaporator and Condenser Delta-T Factors

Performance tables are based on a 10°F (5°C) temperature difference through the evaporator and

condenser. A temperature difference other than 10°F (5°C) will result in unit performance being

different from what is shown. Adjustment factors for applications having temperature drops

between 6°F and 16°F (3.3°C to 8.9°C) can be found in Table 3 and Table 4.

Fouling Factor

Performance tables are based on water with a fouling factor of 0.0001 ft2 x hr x °F/BTU (0.0176 m2 x

°C/kW) in the evaporator and 0.00025 ft2 x hr x °F/BTU (0.044 m2 x °C/kW) in water-cooled

condensers according to ARI 550/590-98. As fouling is increased, performance decreases. See

Table 3 and Table 4 for performance with other fouling factors.

To ensure optimum unit operation, proper water treatment must be maintained. Scaling and dirt in a

system will vary significantly depending on local water conditions. Water treatment should be

based on characteristics of the area’s water. Improper or untreated water may lead to scale build up,

erosion and corrosion in both the condenser and evaporator. McQuay will not accept

responsibility for poorly or improperly treated water.

Table 3, Evaporator Adjustment Factors

Chilled Water

Delta-T

°F °C Cap. Power Cap. Power Cap. Power

6 3.3 0.992 0.995 0.985 0.993 0.962 0.986

8 4.4 0.995 0.997 0.988 0.995 0.965 0.988

10 5.6 1.000 1.000 0.993 0.998 0.970 0.991

12 6.7 1.005 1.002 0.998 1.000 0.975 0.993

14 6.8 1.010 1.005 1.003 1.003 0.980 0.996

16 8.9 1.014 1.007 1.007 1.005 0.984 0.998

0.0001 (0.0176) 0.00025 (0.044) 0.00075 (0.132)

Fouling Factor

Table 4, Condenser Adjustment Factors

Condenser

Water Delta-T

°° F °° C Cap. Power Cap. Power

6 3.3 1.003 0.999 0.984 1.035

8 4.4 1.002 1.000 0.982 1.037

10 5.5 1.000 1.000 0.980 1.038

12 6.6 0.984 0.973 0.977 1.042

14 7.7 0.976 0.960 0.963 1.067

16 8.8 0.968 0.946 0.948 1.092

0.00025 (0.044 0.00075 (0.132)

Fouling Factor

18 Product Manual WHR-2

Page 19

Performance Data

EW Water-Cooled

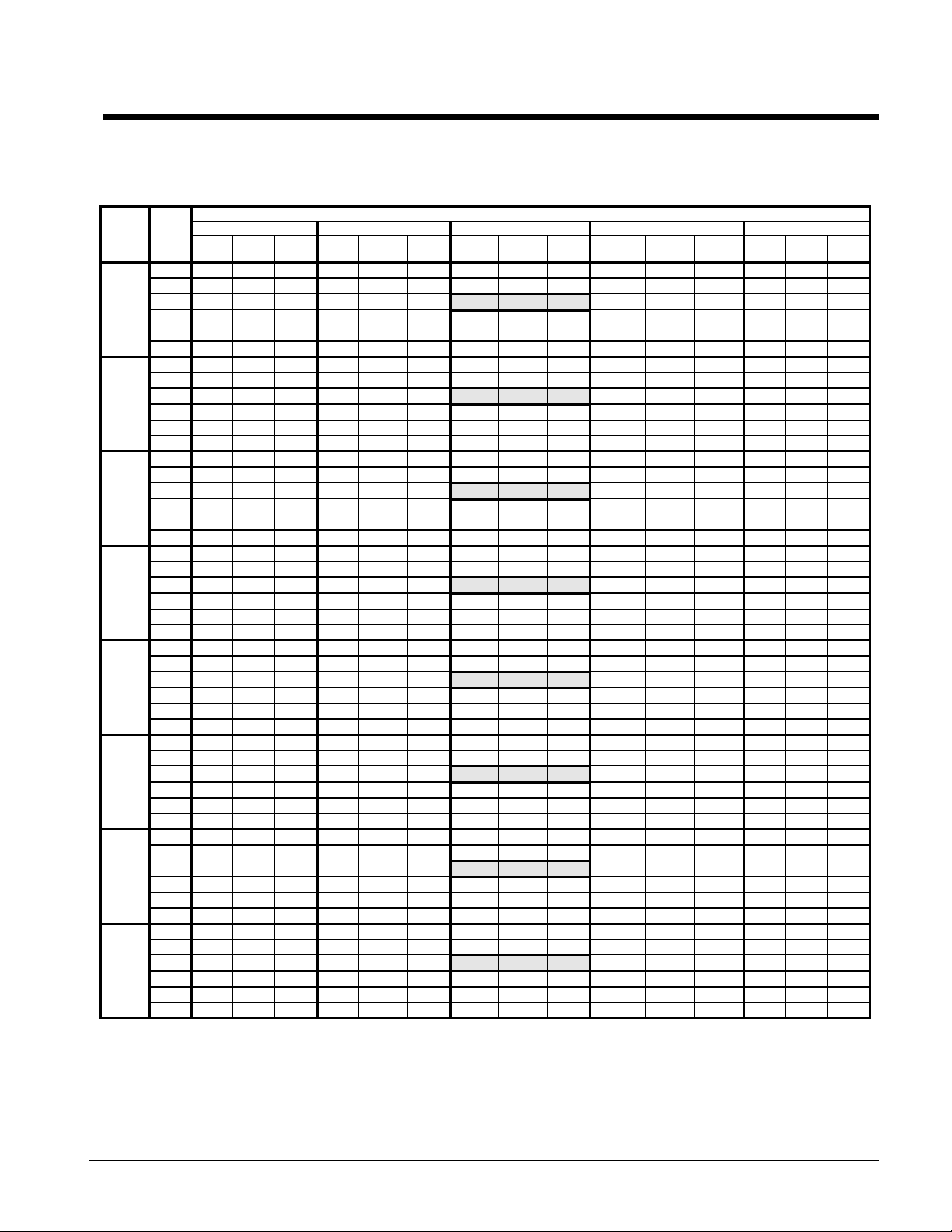

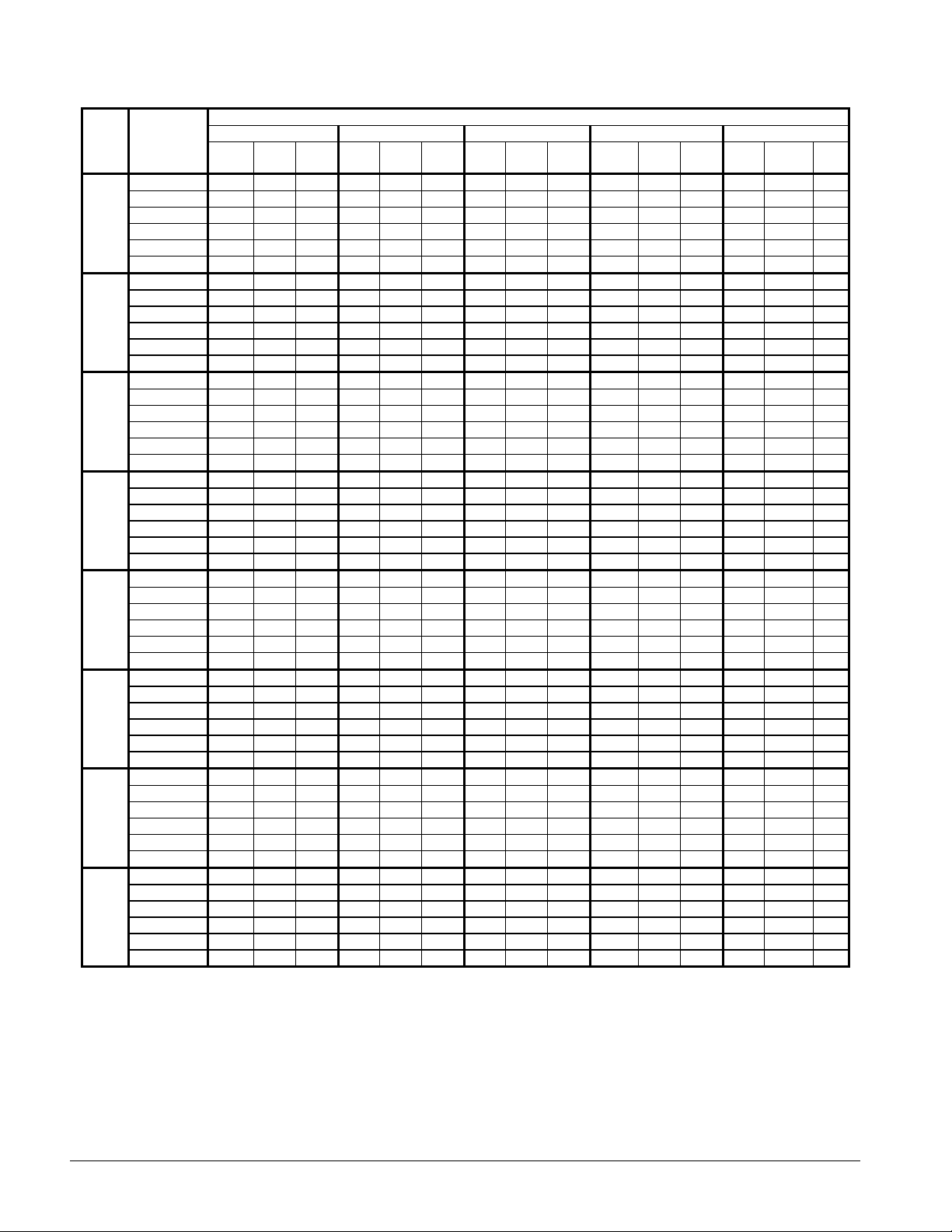

Table 5, WHR 017EW - WHR 060EW, 60 Hz, IP Units

WHR

017EW 44.0 19.1 11.8 18.3 18.2 13.2 15.6 17.7 13.9 14.4 16.7 15.4 12.4 15.7 16.7 10.7

020EW 44.0 23.4 15.7 17.1 22.3 17.5 14.6 21.7 18.4 13.5 20.5 20.3 11.6 19.3 22.1 10.1

025EW 44.0 29.2 19.8 17.0 27.8 22.1 14.5 27.0 23.3 13.4 25.5 25.7 11.5 24.0 28.0 10.0

030EW 44.0 32.6 22.0 17.1 31.0 24.5 14.6 30.2 25.8 13.5 28.5 28.5 11.6 26.8 31.0 10.1

040EW 44.0 41.6 27.2 17.8 39.3 30.2 15.1 38.0 31.7 14.0 35.9 34.6 12.1 33.7 37.6 10.4

045EW 44.0 48.2 30.9 18.2 45.5 34.3 15.4 44.0 36.0 14.3 41.6 39.3 12.4 39.1 42.7 10.7

050EW 44.0 56.4 38.7 17.0 53.3 43.0 14.5 51.5 45.1 13.4 48.7 49.3 11.6 45.7 53.5 10.0

060EW 44.0 64.1 42.0 17.8 60.5 46.7 15.1 58.5 49.0 14.0 55.3 53.6 12.1 51.9 58.1 10.4

Notes:

1. Bold box areas certified in accordance with ARI Standard 550/590-98.

2. Ratings based on HCFC-22, evaporator fouling of 0.0001, 2.4 gpm/ton; condenser fouling of 0.00025, 3 gpm/ton.

3. For 208V units multiply capacity and EER by 0.98.

4. Ratings are based on circuit #1 in lead position and circuit #2 in lag position.

5. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the ratings shown.

6. For LWT of 40°F and below please refer to Application Adjustment Factors section.

SIZE

LWT

(°F)

40.0 17.8 11.7 17.1 16.9 13.1 14.7 16.5 13.7 13.7 15.6 15.0 11.8 14.6 16.3 10.2

42.0 18.4 11.8 17.7 17.6 13.1 15.1 17.1 13.8 14.1 16.2 15.2 12.1 15.1 16.5 10.4

46.0 19.8 11.9 18.7 18.9 13.3 16.0 18.3 14.0 14.8 17.3 15.5 12.6 16.3 17.0 10.9

48.0 20.4 11.9 19.4 19.5 13.3 16.6 19.0 14.1 15.3 18.0 15.6 13.1 16.9 17.1 11.3

50.0 21.2 12.0 19.9 20.1 13.5 17.0 19.6 14.2 15.7 18.6 15.8 13.4 18.1 17.4 11.7

40.0 21.8 15.5 16.1 20.7 17.3 13.8 20.2 18.2 12.8 19.1 19.9 11.1 17.9 21.6 9.6

42.0 22.6 15.6 16.6 21.5 17.4 14.2 20.9 18.3 13.2 19.8 20.1 11.3 18.6 21.8 9.8

46.0 24.3 15.7 17.6 23.1 17.6 15.0 22.5 18.6 13.9 21.2 20.5 11.9 20.0 22.4 10.3

48.0 25.1 15.8 18.2 23.9 17.7 15.5 23.3 18.7 14.3 22.0 20.7 12.3 20.7 22.6 10.6

50.0 26.0 15.8 18.7 24.7 17.8 15.9 24.1 18.8 14.7 22.8 20.9 12.6 22.1 23.0 10.9

40.0 27.1 19.6 15.9 25.8 21.9 13.7 25.1 23.0 12.7 23.8 25.2 11.0 22.3 27.4 9.5

42.0 28.1 19.8 16.5 26.8 22.0 14.1 26.1 23.2 13.1 24.7 25.4 11.3 23.1 27.6 9.7

46.0 30.2 19.9 17.4 28.8 22.3 14.9 27.9 23.5 13.7 26.3 25.9 11.8 24.8 28.4 10.2

48.0 31.2 19.9 18.1 29.7 22.4 15.4 28.9 23.6 14.2 27.4 26.2 12.2 25.8 28.7 10.5

50.0 32.4 20.1 18.6 30.7 22.6 15.8 29.9 23.8 14.6 28.4 26.5 12.5 27.5 29.1 10.9

40.0 30.4 21.7 16.1 28.8 24.3 13.8 28.1 25.5 12.8 26.6 27.9 11.1 24.9 30.3 9.6

42.0 31.4 21.9 16.6 30.0 24.4 14.2 29.1 25.7 13.2 27.6 28.1 11.3 25.8 30.6 9.8

46.0 33.8 22.1 17.6 32.2 24.6 15.0 31.3 26.0 13.9 29.4 28.7 11.9 27.8 31.5 10.3

48.0 34.9 22.1 18.2 33.2 24.8 15.5 32.4 26.2 14.3 30.7 29.0 12.3 28.8 31.7 10.6

50.0 36.2 22.2 18.7 34.3 25.0 15.9 33.5 26.3 14.7 31.7 29.3 12.6 30.8 32.3 10.9

40.0 38.8 26.8 16.8 36.6 29.7 14.3 35.5 31.1 13.3 33.5 33.9 11.5 31.3 36.6 9.9

42.0 40.2 27.0 17.2 38.0 30.0 14.7 36.9 31.4 13.7 35.1 34.3 11.8 32.5 37.1 10.2

46.0 43.1 27.5 18.3 40.8 30.5 15.5 39.6 32.0 14.4 37.3 35.0 12.5 35.0 38.0 10.6

48.0 44.6 27.6 18.8 42.2 30.7 16.0 41.0 32.3 15.2 38.7 35.4 12.7 36.3 38.5 11.0

50.0 46.1 27.7 19.3 43.7 31.0 16.5 42.5 32.6 15.2 40.0 35.8 13.0 37.5 38.9 11.3

40.0 44.9 30.4 17.1 42.4 33.7 14.6 41.1 35.4 13.6 38.8 38.5 11.7 36.3 41.6 10.2

42.0 46.5 30.7 17.6 44.0 34.0 15.0 42.7 35.6 14.0 40.7 39.0 12.0 37.6 42.1 10.4

46.0 49.9 31.2 18.7 47.2 34.6 15.9 45.9 36.4 14.7 43.2 39.8 12.7 40.5 43.2 10.9

48.0 51.6 31.3 19.2 48.8 34.9 16.4 47.5 36.7 15.5 44.8 40.2 13.0 42.0 43.7 11.2

50.0 53.4 31.5 19.7 50.6 35.2 16.8 49.2 37.0 15.5 46.3 40.6 13.3 43.5 44.2 11.5

40.0 52.5 38.1 16.0 49.6 42.3 13.7 48.2 44.3 12.7 45.4 48.2 11.0 42.4 52.1 9.5

42.0 54.4 38.5 16.5 51.5 42.6 14.1 50.0 44.6 13.1 47.6 48.8 11.3 44.0 52.8 9.8

46.0 58.5 39.1 17.5 55.3 43.3 14.9 53.7 45.6 13.8 50.5 49.8 11.9 47.4 54.1 10.2

48.0 60.4 39.2 18.0 57.2 43.7 15.3 55.6 46.0 14.5 52.4 50.4 12.2 49.2 54.8 10.5

50.0 62.5 39.5 18.5 59.2 44.1 15.7 57.6 46.4 14.5 54.2 50.9 12.5 50.9 55.4 10.8

40.0 59.7 41.4 16.8 56.3 45.9 14.3 54.7 48.1 13.3 51.5 52.4 11.5 48.2 56.6 9.9

42.0 61.8 41.8 17.2 58.5 46.3 14.7 56.7 48.5 13.7 54.1 53.0 11.8 50.0 57.3 10.2

46.0 66.4 42.4 18.3 62.8 47.1 15.5 61.0 49.5 14.4 57.4 54.1 12.5 53.8 58.8 10.6

48.0 68.6 42.6 18.8 64.9 47.5 16.0 63.2 50.0 15.2 59.6 54.7 12.7 55.9 59.5 11.0

50.0 71.0 42.9 19.3 67.2 47.9 16.5 65.4 50.4 15.2 61.6 55.3 13.0 57.8 60.2 11.3

70°F 80°F 85°F 95°F 105°F

Cap. PWR Cap. PWR Cap. PWR Cap. PWR Cap. PWR

Tons kWi

EER

Tons kWi

Entering Condenser Water Temperature (10°F Delta T.)

EER

Tons kWi

EER

Tons kWi

EER

Tons kWi

EER

Product Manual WHR-2 19

Page 20

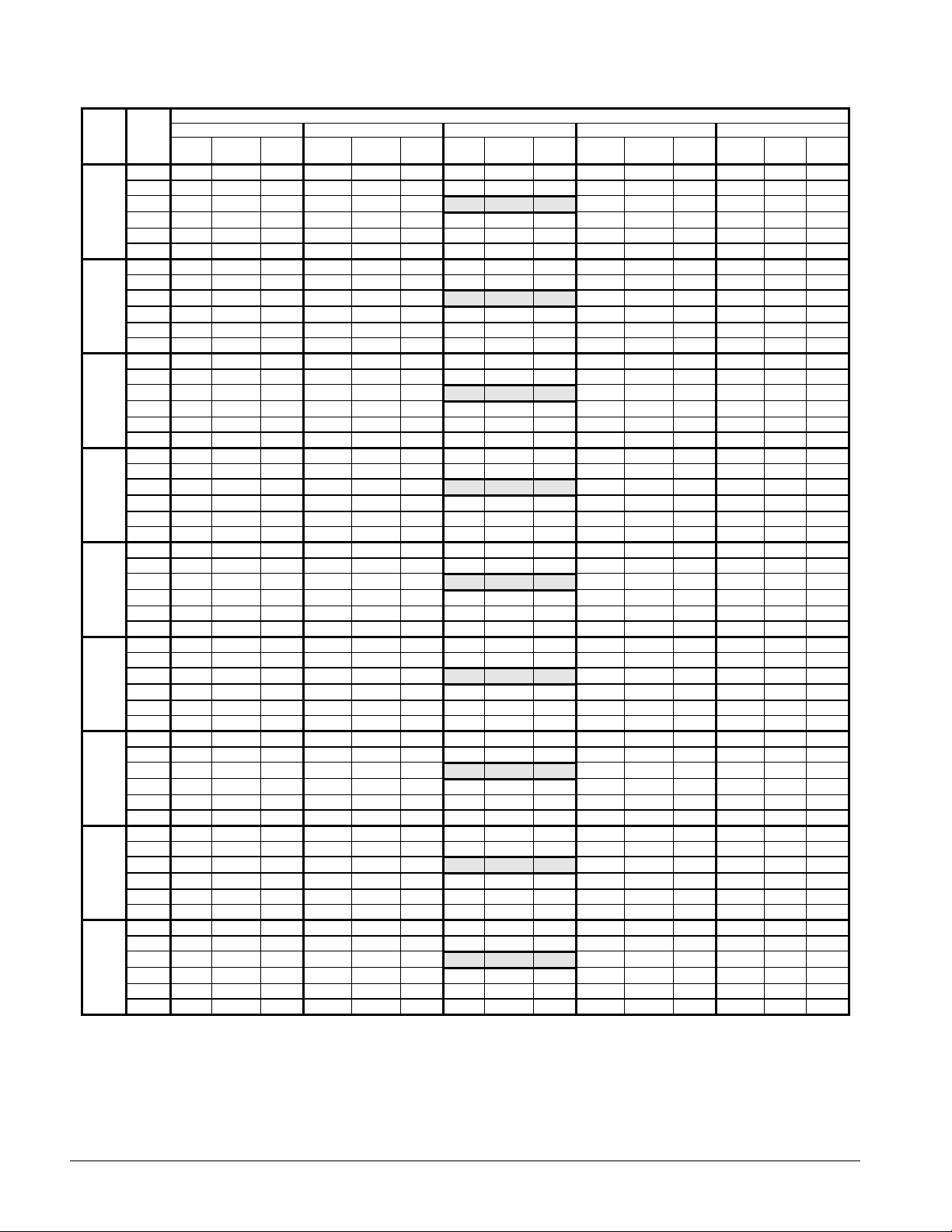

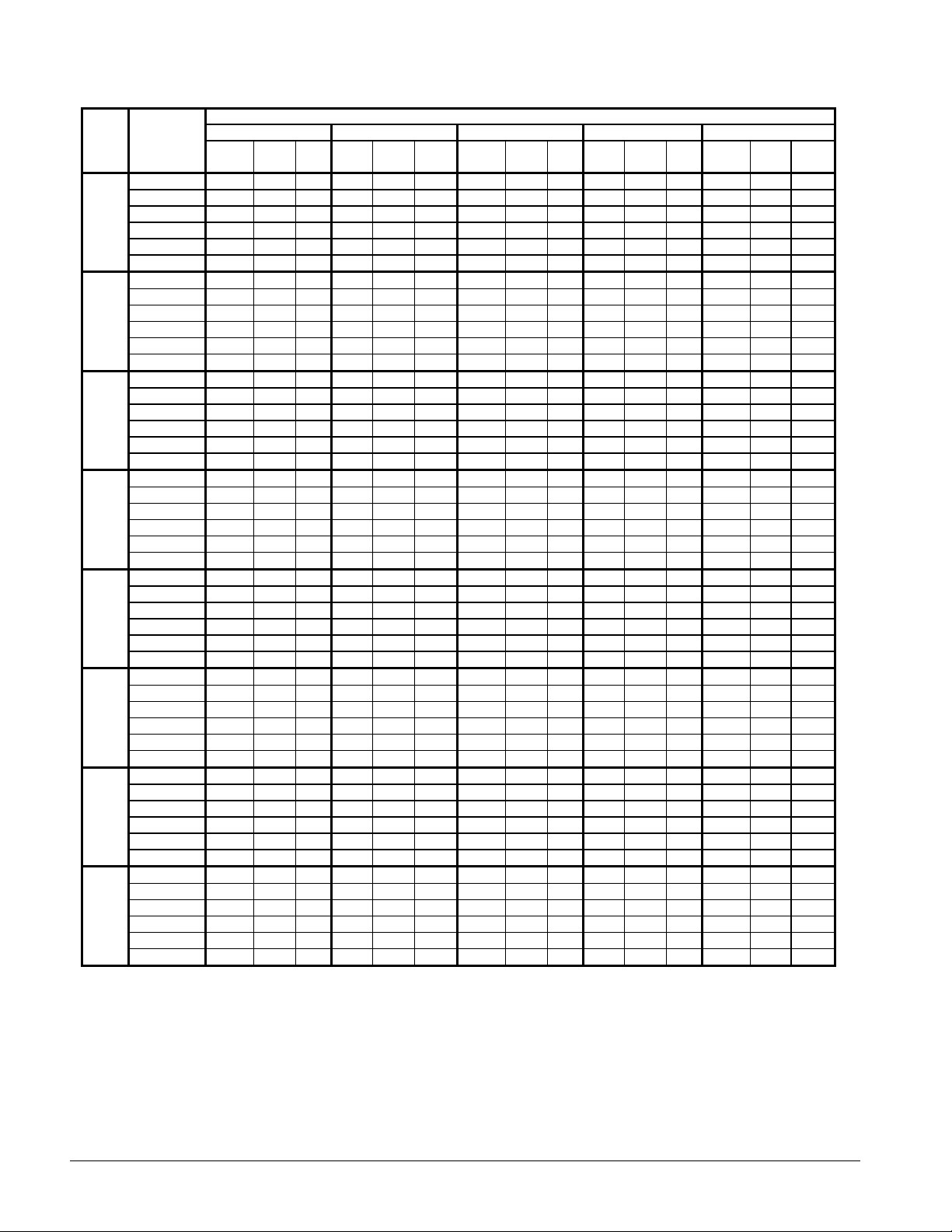

Table 6, WHR 070EW - WHR 120EW, 60 Hz, IP Units

WHR

LWT

SIZE

070EW 44.0 77.2 53.5 17.0 73.0 59.5 14.5 70.5 62.4 13.4 66.7 68.2 11.6 62.6 74.0 10.0

080EW 44.0 83.8 58.2 16.9 79.2 64.8 14.4 76.5 67.9 13.3 72.4 74.2 11.5 67.9 80.6 9.9

085EW 44.0 93.1 62.2 17.7 88.0 69.3 15.0 85.0 72.6 13.9 80.4 79.4 12.0 75.5 86.1 10.4

090EW 44.0 100.2 65.5 18.0 94.7 72.9 15.3 91.5 76.4 14.2 86.6 83.5 12.3 81.3 90.6 10.6

095EW 44.0 104.0 68.9 17.9 98.7 77.2 15.1 96.0 81.3 14.0 90.6 89.5 12.0 85.0 97.4 10.4

100EW 44.0 110.5 73.2 17.9 104.9 82.0 15.1 102.0 86.4 14.0 96.3 95.1 12.0 90.3 103.6 10.4

110EW 44.0 120.8 81.2 17.6 114.6 91.0 14.9 111.5 95.9 13.8 105.3 105.6 11.8 98.7 114.9 10.2

115EW 44.0 122.9 81.3 17.9 116.7 91.1 15.1 113.5 96.0 14.0 107.1 105.7 12.0 100.4 115.1 10.4

120EW 44.0 132.1 89.2 17.6 125.4 99.9 14.9 122.0 105.3 13.8 115.2 115.9 11.8 108.0 126.2 10.2

Notes:

1. Bold box areas certified in accordance with ARI Standard 550/590-98.

2. Ratings based on HCFC-22, evaporator fouling of 0.0001, 2.4 gpm/ton; condenser fouling of 0.00025, 3 gpm/ton.

3. For 208V units multiply capacity and EER by 0.98.

4. Ratings are based on circuit #1 in lead position and circuit #2 in lag position.

5. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the ratings shown.

6. For LWT of 40°F and below please refer to Application Adjustment Factors section.

(°F)

40.0 71.9 52.8 16.0 67.9 58.5 13.7 65.9 61.3 12.7 62.1 66.7 11.0 58.1 72.1 9.5

42.0 74.5 53.2 16.5 70.5 59.0 14.1 68.4 61.8 13.1 65.1 67.5 11.3 60.3 73.0 9.8

46.0 80.0 54.0 17.5 75.6 60.0 14.9 73.5 63.0 13.8 69.2 69.0 11.9 64.9 74.9 10.2

48.0 82.7 54.3 18.0 78.3 60.5 15.3 76.1 63.6 14.5 71.8 69.7 12.2 67.3 75.8 10.5

50.0 85.5 54.6 18.5 81.0 61.0 15.7 78.8 64.2 14.5 74.2 70.4 12.5 69.7 76.6 10.8

40.0 78.0 57.4 15.9 73.7 63.6 13.6 71.5 66.7 12.6 67.4 72.6 10.9 63.0 78.4 9.4

42.0 80.9 57.9 16.4 76.5 64.2 14.0 74.2 67.2 13.0 70.7 73.5 11.2 65.4 79.4 9.7

46.0 86.8 58.8 17.4 82.1 65.3 14.8 79.8 68.6 13.7 75.0 75.0 11.8 70.4 81.5 10.1

48.0 89.7 59.1 17.8 84.9 65.9 15.2 82.6 69.3 14.4 77.9 75.8 12.1 73.1 82.5 10.4

50.0 92.8 59.4 18.4 87.9 66.4 15.6 85.5 69.9 14.4 80.6 76.6 12.4 75.6 83.4 10.7

40.0 86.7 61.4 16.6 81.9 68.0 14.2 79.5 71.3 13.2 74.9 77.6 11.4 70.0 83.9 9.9

42.0 89.8 61.9 17.1 85.0 68.6 14.6 82.5 71.9 13.6 78.5 78.6 11.7 72.7 84.9 10.1

46.0 96.5 62.9 18.1 91.2 69.8 15.4 88.7 73.3 14.3 83.4 80.2 12.4 78.2 87.1 10.6

48.0 99.7 63.2 18.6 94.4 70.4 15.9 91.8 74.1 15.1 86.5 81.1 12.6 81.2 88.2 10.9

50.0 103.1 63.5 19.2 97.7 71.0 16.3 95.0 74.7 15.1 89.5 81.9 12.9 84.0 89.2 11.2

40.0 93.3 64.6 17.0 88.1 71.6 14.5 85.6 75.0 13.5 80.6 81.7 11.6 75.4 88.2 10.1

42.0 96.7 65.2 17.5 91.5 72.2 14.9 88.8 75.6 13.9 84.5 82.7 11.9 78.2 89.4 10.4

46.0 103.9 66.2 18.5 98.2 73.4 15.8 95.4 77.2 14.6 89.8 84.4 12.6 84.2 91.7 10.8

48.0 107.3 66.5 19.0 101.6 74.1 16.3 98.8 77.9 15.4 93.1 85.3 12.9 87.4 92.8 11.1

50.0 111.0 66.9 19.6 105.1 74.7 16.7 102.3 78.6 15.4 96.3 86.2 13.2 90.4 93.8 11.4

40.0 96.9 68.4 16.7 91.8 76.3 14.2 89.2 80.2 13.2 84.3 87.9 11.3 79.2 95.5 9.8

42.0 100.3 68.7 17.2 95.2 76.7 14.7 92.5 80.7 13.6 87.5 88.7 11.6 82.2 96.5 10.1

46.0 107.6 69.1 18.5 102.1 77.5 15.6 99.5 81.8 14.4 94.0 90.2 12.4 88.5 98.5 10.6

48.0 111.5 69.3 19.0 105.8 77.9 16.0 103.6 82.1 15.1 97.2 90.9 12.7 92.6 98.8 11.0

50.0 115.2 69.3 19.7 109.4 78.2 16.5 106.4 82.7 15.3 100.7 91.5 13.0 95.0 99.6 11.3

40.0 102.9 72.7 16.7 97.5 81.0 14.2 94.8 85.3 13.2 89.6 93.4 11.3 84.1 101.5 9.8

42.0 106.6 73.0 17.2 101.2 81.6 14.7 98.3 85.8 13.6 92.9 94.3 11.6 87.3 102.6 10.1

46.0 114.3 73.4 18.5 108.5 82.3 15.6 105.7 86.9 14.4 99.9 95.8 12.4 94.0 104.6 10.6

48.0 118.4 73.6 19.0 112.4 82.8 16.0 110.1 87.3 15.1 103.3 96.6 12.7 98.4 105.0 11.0

50.0 122.4 73.7 19.7 116.3 83.1 16.5 113.0 87.9 15.3 107.0 97.3 13.0 101.0 105.8 11.3

40.0 112.5 80.7 16.5 106.6 90.0 14.0 103.6 94.7 13.0 97.9 103.7 11.2 91.9 112.7 9.7

42.0 116.5 81.0 17.0 110.6 90.5 14.5 107.5 95.2 13.4 101.6 104.6 11.5 95.4 113.8 9.9

46.0 125.0 81.5 18.2 118.6 91.4 15.4 115.5 96.5 14.2 109.2 106.4 12.2 102.8 116.1 10.5

48.0 129.5 81.7 18.8 122.9 91.9 15.8 120.4 96.9 14.9 112.9 107.2 12.5 107.6 116.6 10.8

50.0 133.8 81.8 19.4 127.1 92.3 16.3 123.5 97.5 15.1 116.9 108.0 12.8 110.4 117.5 11.2

40.0 114.5 80.7 16.7 108.5 90.0 14.2 105.5 94.8 13.2 99.7 103.8 11.3 93.6 112.8 9.8

42.0 118.6 81.1 17.2 112.6 90.6 14.7 109.4 95.3 13.6 103.4 104.7 11.6 97.2 114.0 10.1

46.0 127.2 81.6 18.5 120.8 91.5 15.6 117.6 96.6 14.4 111.1 106.5 12.4 104.6 116.3 10.6

48.0 131.8 81.8 19.0 125.1 92.0 16.0 122.5 97.0 15.1 115.0 107.3 12.7 109.5 116.7 11.0

50.0 136.2 81.9 19.7 129.4 92.4 16.5 125.8 97.6 15.3 119.0 108.1 13.0 112.4 117.6 11.3

40.0 123.1 88.6 16.5 116.6 98.8 14.0 113.4 103.9 13.0 107.1 113.8 11.2 100.6 123.7 9.7

42.0 127.5 89.0 17.0 121.0 99.4 14.5 117.6 104.6 13.4 111.1 114.9 11.5 104.4 125.0 9.9

46.0 136.8 89.5 18.2 129.8 100.4 15.4 126.4 105.9 14.2 119.4 116.8 12.2 112.5 127.5 10.5

48.0 141.6 89.7 18.8 134.4 100.9 15.8 131.7 106.4 14.9 123.6 117.7 12.5 117.7 128.0 10.8

50.0 146.4 89.8 19.4 139.1 101.3 16.3 135.2 107.1 15.1 128.0 118.6 12.8 120.8 129.0 11.2

70°F 80°F 85°F 95°F 105°F

Cap. PWR Cap. PWR Cap. PWR Cap. PWR Cap. PWR

Tons kWi

EER

Tons kWi

Entering Condenser Water Temperature (10°F Delta T.)

EER

Tons kWi

EER

Tons kWi

EER

Tons kWi

EER

20 Product Manual WHR-2

Page 21

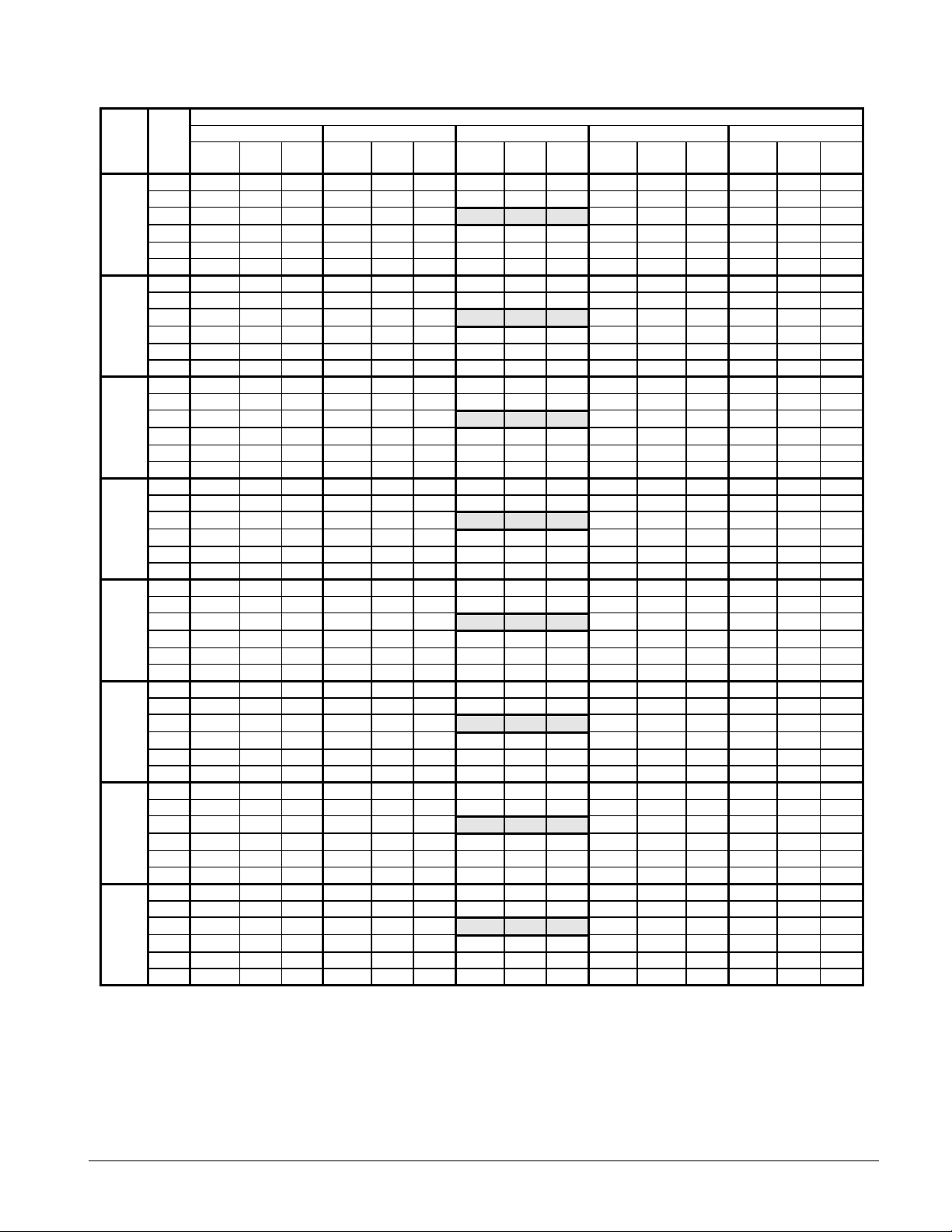

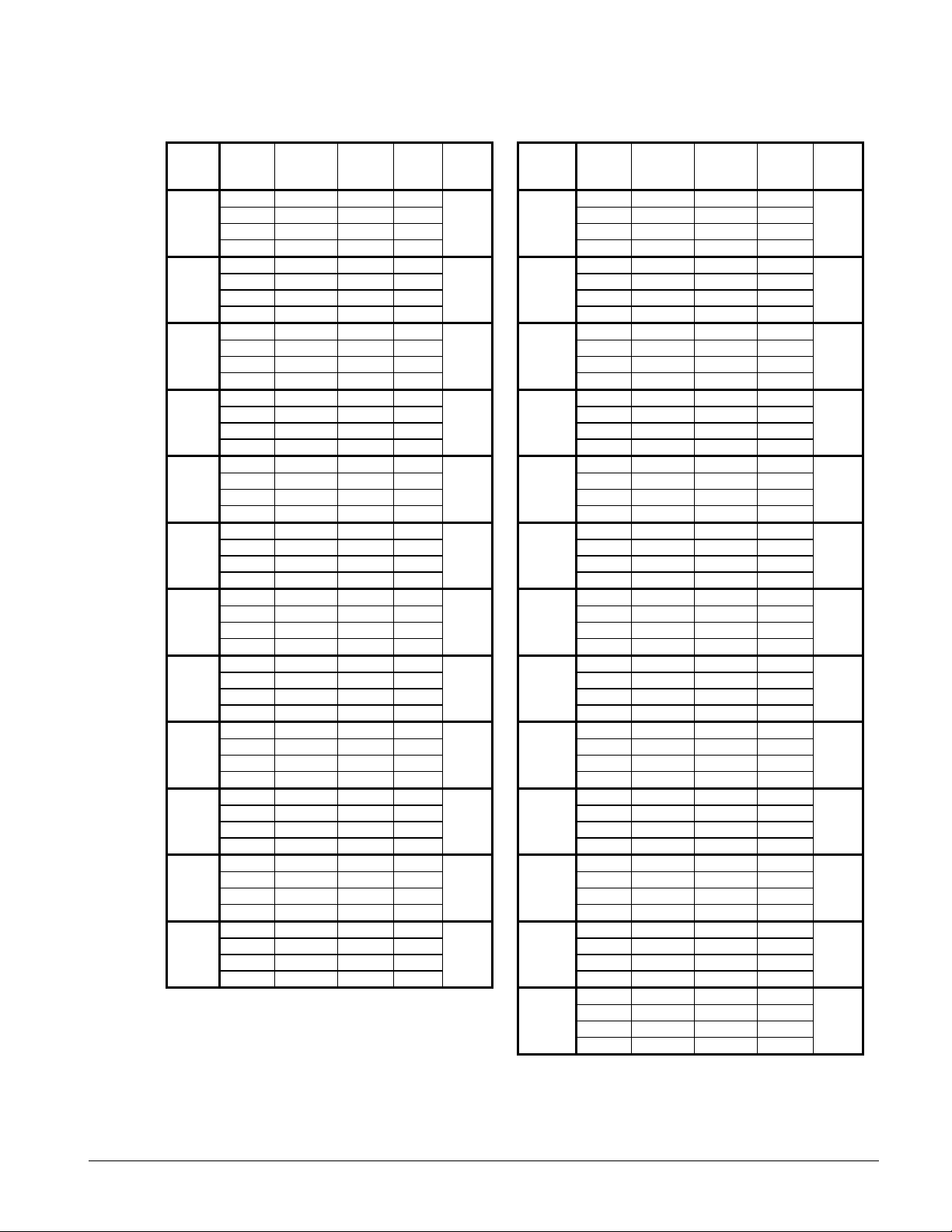

Table 7, WHR 130EW - WHR 210EW, 60 Hz, IP Units

Entering Condenser Water Temperature (10°F Delta T.)

WHR

LWT

SIZE

130EW

145EW

155EW

165EW

175EW

185EW

195EW

210EW

Notes:

1. Bold box areas certified in accordance with ARI Standard 550/590-98.

2. Ratings based on HCFC-22, evaporator fouling of 0.0001, 2.4 gpm/ton; condenser fouling of 0.00025, 3 gpm/ton.

3. For 208V units multiply capacity and EER by 0.98

4. Ratings are based on circuit #1 in lead position and circuit #2 in lag position.

5. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the ratings shown.

6. For LWT of 40°F and below please refer to Application Adjustment Factors section.

°F

40.0 133.2 98.4 16.0 126.2 109.7 13.6 122.7 115.5 12.6 115.9 126.5 10.9 108.8 137.5 9.4

42.0 137.9 98.9 16.5 130.9 110.4 14.1 127.2 116.2 13.0 120.3 127.6 11.1 113.0 138.9 9.6

44.0 143.0 99.1 17.1 135.7 111.0 14.5

46.0 148.0 99.5 17.7 140.4 111.5 14.9 136.8 117.7 13.8 129.2 129.8 11.9 121.7 141.7 10.2

48.0 153.3 99.7 18.2 145.5 112.1 15.3 142.5 118.2 14.5 133.7 130.8 12.1 127.4 142.2 10.5

50.0 158.4 99.8 18.8 150.5 112.6 15.8 146.3 119.0 14.7 138.4 131.7 12.5 130.7 143.3 10.9

40.0 145.3 101.8 17.0 137.7 113.6 14.4 133.8 119.5 13.3 126.4 130.9 11.5 118.7 142.3 9.9

42.0 150.5 102.3 17.5 142.8 114.3 14.9 138.8 120.3 13.8 131.2 132.1 11.8 123.3 143.7 10.2

44.0 156.0 102.6 18.1 148.0 114.9 15.3

46.0 161.4 102.9 18.7 153.2 115.4 15.8 149.2 121.8 14.6 141.0 134.3 12.6 132.8 146.7 10.8

48.0 167.2 103.2 19.3 158.7 116.0 16.3 155.4 122.3 15.3 145.9 135.4 12.9 139.0 147.2 11.1

50.0 172.8 103.3 20.0 164.2 116.5 16.8 159.6 123.2 15.5 151.0 136.4 13.2 142.6 148.3 11.5

40.0 151.9 109.9 16.4 143.9 122.6 13.9 139.9 129.0 12.9 132.1 141.3 11.1 124.1 153.6 9.6

42.0 157.3 110.4 16.9 149.3 123.4 14.4 145.1 129.8 13.3 137.1 142.6 11.4 128.8 155.1 9.9

44.0 163.0 110.7 17.5 154.7 124.0 14.8

46.0 168.7 111.1 18.1 160.1 124.6 15.3 155.9 131.5 14.1 147.3 144.9 12.1 138.8 158.3 10.4

48.0 174.7 111.4 18.6 165.9 125.2 15.7 162.5 132.0 14.8 152.5 146.1 12.4 145.2 158.9 10.8

50.0 180.6 111.5 19.2 171.6 125.7 16.2 166.8 132.9 15.0 157.8 147.2 12.7 149.0 160.1 11.1

40.0 164.5 118.8 16.5 155.8 132.5 14.0 151.5 139.5 13.0 143.1 152.7 11.2 134.4 166.0 9.7

42.0 170.3 119.4 17.0 161.7 133.4 14.5 157.1 140.3 13.4 148.5 154.2 11.5 139.5 167.7 9.9

44.0 176.5 119.7 17.6 167.6 134.1 14.9

46.0 182.7 120.1 18.2 173.4 134.7 15.4 168.9 142.1 14.2 159.6 156.7 12.2 150.3 171.1 10.5

48.0 189.2 120.4 18.8 179.6 135.4 15.8 176.0 142.7 14.9 165.1 158.0 12.5 157.3 171.8 10.8

50.0 195.6 120.5 19.4 185.8 135.9 16.3 180.6 143.7 15.1 171.0 159.1 12.8 161.4 173.1 11.2

40.0 178.6 130.3 16.3 169.2 145.3 13.8 164.5 152.9 12.8 155.4 167.4 11.0 145.9 182.0 9.5

42.0 185.0 130.9 16.7 175.6 146.2 14.3 170.6 153.8 13.2 161.2 169.0 11.3 151.5 183.9 9.8

44.0 191.7 131.2 17.3 182.0 147.0 14.7

46.0 198.4 131.7 18.0 188.3 147.6 15.2 183.4 155.8 14.0 173.3 171.8 12.0 163.2 187.6 10.3

48.0 205.5 132.0 18.5 195.1 148.4 15.6 191.1 156.4 14.7 179.3 173.2 12.3 170.8 188.3 10.7

50.0 212.4 132.1 19.1 201.8 149.0 16.0 196.1 157.5 14.9 185.6 174.4 12.6 175.2 189.8 11.0

40.0 186.7 130.4 17.0 176.9 145.4 14.4 172.0 153.0 13.3 162.4 167.6 11.5 152.5 182.1 9.9

42.0 193.3 131.0 17.5 183.5 146.3 14.9 178.3 153.9 13.8 168.5 169.1 11.8 158.4 184.0 10.2

44.0 200.4 131.3 18.1 190.2 147.1 15.3

46.0 207.4 131.8 18.7 196.8 147.7 15.8 191.7 155.9 14.6 181.1 171.9 12.6 170.6 187.7 10.8

48.0 214.8 132.1 19.3 203.9 148.5 16.3 199.7 156.6 15.3 187.4 173.3 12.9 178.5 188.4 11.1

50.0 222.0 132.2 20.0 210.9 149.1 16.8 205.0 157.6 15.5 194.0 174.5 13.2 183.2 189.9 11.5

40.0 198.8 141.4 16.7 188.3 157.7 14.2 183.1 165.9 13.2 173.0 181.7 11.3 162.4 197.5 9.8

42.0 205.9 142.0 17.2 195.4 158.7 14.7 189.9 166.9 13.6 179.5 183.4 11.6 168.6 199.5 10.1

44.0 213.4 142.4 17.9 202.5 159.5 15.1

46.0 220.8 142.9 18.5 209.6 160.2 15.6 204.1 169.1 14.4 192.9 186.4 12.4 181.6 203.6 10.6

48.0 228.7 143.2 19.0 217.1 161.0 16.0 212.7 169.8 15.1 199.6 187.9 12.7 190.1 204.3 11.0

50.0 236.4 143.4 19.7 224.6 161.7 16.5 218.3 171.0 15.3 206.6 189.3 13.0 195.0 205.9 11.3

40.0 212.9 150.7 16.8 201.7 168.1 14.3 196.1 176.9 13.3 185.3 193.7 11.4 174.0 210.6 9.9

42.0 220.5 151.4 17.3 209.3 169.2 14.8 203.4 177.9 13.7 192.2 195.5 11.7 180.6 212.7 10.2

44.0 228.5 151.8 18.0 216.9 170.1 15.2

46.0 236.5 152.3 18.6 224.5 170.8 15.7 218.6 180.3 14.5 206.6 198.7 12.5 194.5 217.0 10.7

48.0 245.0 152.7 19.2 232.5 171.7 16.1 227.8 181.0 15.2 213.7 200.3 12.8 203.6 217.8 11.1

50.0 253.2 152.9 19.8 240.5 172.4 16.6 233.8 182.2 15.4 221.3 201.8 13.1 208.9 219.5 11.4

70°F 80°F 85°F 95°F 105°F

Cap. PWR Cap. PWR Cap. PWR Cap. PWR Cap. PWR

Tons kWi

EER

Tons kWi

EER

Tons kWi

132.0 117.0 13.4

144.0 121.1 14.2

150.5 130.7 13.7

163.0 141.3 13.8

177.0 154.9 13.6

185.0 155.0 14.2

197.0 168.1 14.0

211.0 179.2 14.1

EER

Tons kWi

124.6 128.8 11.5 116.8 140.2 9.9

135.9 133.3 12.1 127.4 145.1 10.5

142.1 143.9 11.7 133.2 156.6 10.1

153.9 155.6 11.8 144.3 169.3 10.2

167.1 170.5 11.6 156.6 185.6 10.1

174.6 170.7 12.1 163.7 185.8 10.5

186.0 185.1 12.0 174.3 201.5 10.4

199.2 197.3 12.1 186.7 214.8 10.4

EER

Tons kWi

EER

Product Manual WHR-2 21

Page 22

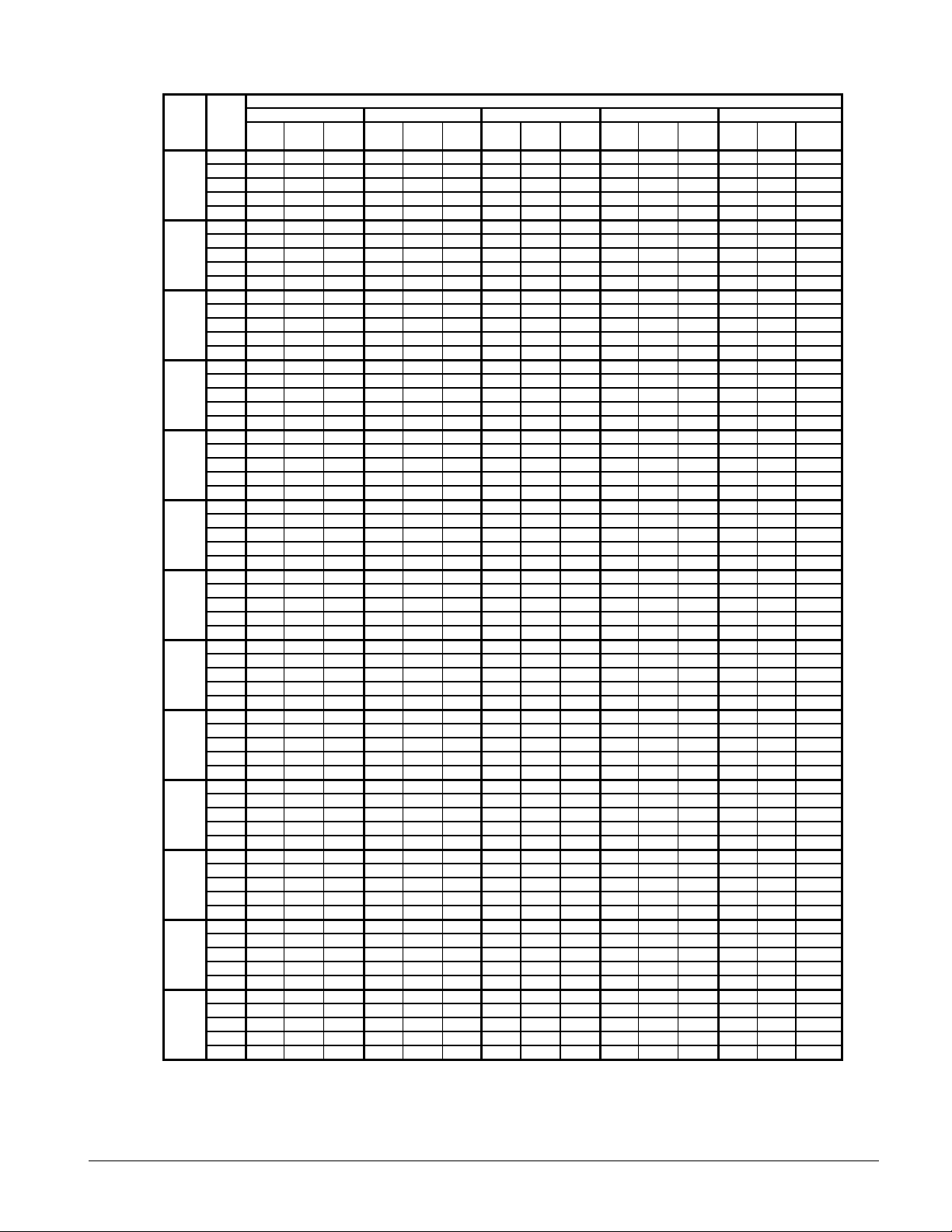

Table 8, WHR 017EW - WHR 060EW, 60 Hz, SI Units

Entering Condenser Water Temperature (°C)

WHR

SIZE

017EW

020EW

025EW

030EW

040EW

045EW

050EW

060EW

Notes:

1. Ratings based on HCFC-22, evaporator fouling of 0.0176, 0.043 L/s; condenser fouling of 0.044.

2. For 208V units multiply capacity and COP by 0.98.

3. Ratings are based on circuit #1 in lead position and circuit #2 in lag position.

4. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the ratings shown.

5. For LWT of 5°C and below please refer to Application Adjustment Factors section.

LWT

°C

5.0 (41.0°F) 64.5 11.4 5.1 61.7 12.7 4.5 58.5 13.9 3.9 54.7 15.0 3.4 52.8 16.3 2.9

6.0 (42.8°F) 66.8 11.5 5.3 63.6 12.8 4.7 60.8 14.1 4.1 56.8 15.2 3.4 54.3 16.5 3.0

7.0 (44.6°F) 69.1 11.6 5.5 65.3 12.8 4.8 63.1 14.1 4.1 58.8 15.3 3.6 56.5 16.7 3.1

8.0 (46.4°F) 70.2 11.6 5.5 67.0 12.9 4.8 64.0 14.2 4.2 60.8 15.5 3.7 57.6 16.7 3.2

9.0 (48.2°F) 72.8 11.6 5.8 69.4 12.9 5.0 67.7 14.3 4.4 63.1 15.6 3.8 59.7 16.9 3.2

10.0 (50.0°F) 75.1 11.7 6.0 72.0 13.0 5.1 68.5 14.4 4.4 65.4 15.8 3.9 61.9 17.1 3.4

5.0 (41.0°F) 79.1 15.2 4.9 75.6 16.8 4.3 71.7 18.4 3.7 67.1 19.9 3.2 64.7 21.5 2.8

6.0 (42.8°F) 81.9 15.3 5.0 78.0 16.9 4.4 74.5 18.6 3.8 69.6 20.1 3.3 66.6 21.8 2.9

7.0 (44.6°F) 84.7 15.3 5.2 80.1 17.0 4.5 77.3 18.7 3.9 72.1 20.3 3.4 69.3 22.1 3.0

8.0 (46.4°F) 86.1 15.3 5.3 82.2 17.0 4.6 78.4 18.8 4.0 74.5 20.5 3.5 70.6 22.2 3.0

9.0 (48.2°F) 89.2 15.4 5.5 85.1 17.1 4.7 83.0 18.9 4.1 77.4 20.7 3.6 73.1 22.4 3.1

10.0 (50.0°F) 92.1 15.4 5.7 88.3 17.2 4.9 84.0 19.0 4.2 80.2 20.9 3.7 75.9 22.6 3.2

5.0 (41.0°F) 98.4 19.2 4.8 94.1 21.3 4.1 89.2 23.3 3.6 83.5 25.1 3.1 80.5 27.3 2.7

6.0 (42.8°F) 101.9 19.3 4.9 97.1 21.4 4.3 92.7 23.6 3.7 86.6 25.4 3.2 82.8 27.7 2.8

7.0 (44.6°F) 105.4 19.4 5.1 99.7 21.5 4.4 96.2 23.7 3.8 89.7 25.7 3.3 86.2 28.0 2.9

8.0 (46.4°F) 107.2 19.4 5.1 102.3 21.6 4.5 97.6 23.8 3.9 92.7 25.9 3.4 87.8 28.1 3.0

9.0 (48.2°F) 111.0 19.5 5.3 105.9 21.7 4.6 103.3 24.0 4.0 96.3 26.2 3.5 91.0 28.3 3.0

10.0 (50.0°F) 114.5 19.6 5.6 109.9 21.8 4.8 104.6 24.1 4.1 99.8 26.5 3.6 94.4 28.6 3.1

5.0 (41.0°F) 110.0 21.2 4.9 105.2 23.6 4.3 99.8 25.8 3.7 93.4 27.8 3.2 90.1 30.2 2.8

6.0 (42.8°F) 113.9 21.4 5.0 108.6 23.7 4.4 103.7 26.1 3.8 96.9 28.1 3.3 92.6 30.6 2.9

7.0 (44.6°F) 117.8 21.5 5.2 111.5 23.8 4.5 107.6 26.2 3.9 100.3 28.4 3.4 96.4 31.0 3.0

8.0 (46.4°F) 119.9 21.5 5.3 114.4 23.9 4.6 109.1 26.4 4.0 103.7 28.7 3.5 98.2 31.1 3.0

9.0 (48.2°F) 124.2 21.5 5.5 118.4 24.0 4.7 115.5 26.5 4.1 107.7 29.0 3.6 101.8 31.4 3.1

10.0 (50.0°F) 128.1 21.7 5.7 122.9 24.2 4.9 117.0 26.7 4.2 111.6 29.3 3.7 105.6 31.7 3.2

5.0 (41.0°F) 140.1 26.4 5.1 134.7 28.8 4.4 127.7 31.1 4.0 119.8 34.1 3.3 112.9 36.6 3.0

6.0 (42.8°F) 145.4 26.5 5.3 138.3 29.0 4.6 131.1 31.9 4.0 124.2 34.5 3.5 117.3 37.0 3.1

7.0 (44.6°F) 150.4 26.7 5.4 143.0 29.0 4.7 136.0 32.1 4.1 128.8 34.9 3.6 121.7 37.5 3.2

8.0 (46.4°F) 152.9 26.8 5.5 145.9 29.1 4.8 138.5 32.3 4.2 131.3 35.0 3.7 123.7 37.7 3.2

9.0 (48.2°F) 158.4 26.9 5.7 150.8 29.3 4.9 143.3 32.6 4.3 136.0 35.4 3.7 128.3 38.2 3.3

10.0 (50.0°F) 163.7 27.1 5.9 156.2 29.5 5.1 148.4 32.9 4.4 140.7 35.8 3.8 133.0 38.6 3.3

5.0 (41.0°F) 162.2 29.9 5.2 156.0 32.7 4.5 147.9 35.4 4.1 138.7 38.7 3.4 130.7 41.5 3.1

6.0 (42.8°F) 168.3 30.0 5.4 160.1 32.9 4.7 151.8 36.2 4.1 143.8 39.2 3.6 135.8 42.0 3.1

7.0 (44.6°F) 174.2 30.3 5.5 165.6 33.0 4.8 157.5 36.5 4.2 149.1 39.6 3.7 140.9 42.6 3.2

8.0 (46.4°F) 177.1 30.4 5.7 168.9 33.1 4.9 160.4 36.7 4.2 152.0 39.8 3.7 143.3 42.8 3.3

9.0 (48.2°F) 183.4 30.6 5.9 174.6 33.3 5.0 165.9 37.0 4.4 157.5 40.2 3.8 148.6 43.4 3.3

10.0 (50.0°F) 189.6 30.7 6.1 180.8 33.5 5.2 171.8 37.4 4.5 162.9 40.6 3.9 154.0 43.9 3.4

5.0 (41.0°F) 189.8 37.5 4.9 182.6 41.0 4.2 173.1 44.3 3.8 162.3 48.5 3.2 153.0 52.0 2.9

6.0 (42.8°F) 197.0 37.6 5.1 187.4 41.2 4.4 177.7 45.3 3.9 168.3 49.1 3.4 158.9 52.7 3.0

7.0 (44.6°F) 203.9 38.0 5.2 193.9 41.3 4.5 184.4 45.7 3.9 174.6 49.6 3.4 164.9 53.3 3.0

8.0 (46.4°F) 207.3 38.1 5.3 197.7 41.5 4.6 187.7 45.9 4.0 177.9 49.9 3.5 167.7 53.7 3.1

9.0 (48.2°F) 214.7 38.3 5.5 204.4 41.7 4.7 194.2 46.4 4.1 184.4 50.4 3.6 173.9 54.3 3.1

10.0 (50.0°F) 221.9 38.5 5.7 211.6 42.0 4.9 201.1 46.8 4.2 190.7 50.9 3.7 180.3 54.9 3.2

5.0 (41.0°F) 215.6 40.7 5.1 207.4 44.5 4.4 196.7 48.1 4.0 184.4 52.7 3.3 173.8 56.5 3.0

6.0 (42.8°F) 223.8 40.9 5.3 212.9 44.8 4.6 201.9 49.2 4.1 191.1 53.3 3.5 180.5 57.2 3.1

7.0 (44.6°F) 231.6 41.3 5.4 220.2 44.9 4.7 209.4 49.7 4.1 198.3 53.9 3.6 187.3 57.9 3.2

8.0 (46.4°F) 235.4 41.4 5.6 224.6 45.0 4.8 213.2 49.9 4.2 202.1 54.2 3.7 190.5 58.3 3.2

9.0 (48.2°F) 243.9 41.6 5.8 232.1 45.3 4.9 220.6 50.4 4.3 209.4 54.7 3.7 197.5 59.0 3.3

10.0 (50.0°F) 252.1 41.8 5.9 240.4 45.6 5.1 228.4 50.9 4.4 216.6 55.3 3.9 204.8 59.7 3.3

20°C (68°F) 25°C (77°F) 30°C (86°F) 35°C (95°F) 40°C (104°F)

Cap. PWR Cap. PWR Cap. PWR Cap. PWR Cap. PWR

kW kWi

COP

kW kWi

COP

kW kWi

COP

kW kWi

COP

kW kWi

COP

22 Product Manual WHR-2

Page 23

Table 9, WHR 070EW - WHR 120EW, 60 Hz, SI Units

WHR

SIZE

070EW 7.0 (44.6°F) 279.1 52.6 5.2 265.4 57.2 4.5 252.4 63.3 3.9 239.0 68.6 3.4 225.7 73.8 3.0

080EW 7.0 (44.6°F) 302.9 57.2 5.2 288.0 62.2 4.5 273.9 68.9 3.9 259.3 74.7 3.4 244.9 80.3 3.0

085EW 7.0 (44.6°F) 336.5 61.2 5.4 320.0 66.5 4.6 304.3 73.6 4.0 288.1 79.8 3.5 272.2 85.8 3.1

090EW 7.0 (44.6°F) 362.2 64.4 5.5 344.4 70.0 4.8 327.6 77.5 4.1 310.1 84.0 3.6 293.0 90.3 3.2

095EW 7.0 (44.6°F) 375.7 67.3 5.5 358.6 74.8 4.7 341.7 82.4 4.1 324.4 89.8 3.6 307.7 97.1 3.1

100EW 7.0 (44.6°F) 399.2 71.6 5.5 381.0 79.5 4.7 363.0 87.6 4.1 344.7 95.4 3.6 326.9 103.2 3.1

110EW 7.0 (44.6°F) 436.4 79.4 5.4 416.5 88.2 4.6 396.8 97.2 4.0 376.8 105.9 3.5 357.4 114.6 3.1

115EW 7.0 (44.6°F) 444.2 79.5 5.5 424.0 88.3 4.7 403.9 97.3 4.1 383.5 106.0 3.6 363.8 114.7 3.2

120EW 7.0 (44.6°F) 477.5 87.2 5.4 455.7 96.9 4.6 434.2 106.7 4.0 412.2 116.3 3.5 391.0 125.8 3.1

Notes:

1. Ratings based on HCFC-22, evaporator fouling of 0.0176, 0.043 L/s; condenser fouling of 0.044.

2. For 208V units multiply capacity and COP by 0.98

3. Ratings are based on circuit #1 in lead position and circuit #2 in lag position.

4. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the ratings shown.

5. For LWT of 5°C and below please refer to Application Adjustment Factors section.

LWT

°C

5.0 (41.0°F) 259.8 51.9 4.9 249.9 56.7 4.2 237.0 61.3 3.8 222.2 67.1 3.2 209.5 72.0 2.9

6.0 (42.8°F) 269.7 52.1 5.1 256.6 57.0 4.4 243.3 62.7 3.8 230.3 67.9 3.3 217.6 72.9 2.9

8.0 (46.4°F) 283.7 52.7 5.3 270.7 57.4 4.5 257.0 63.6 4.0 243.5 69.0 3.5 229.6 74.3 3.0

9.0 (48.2°F) 293.9 53.0 5.5 279.8 57.7 4.7 265.8 64.2 4.1 252.4 69.7 3.6 238.0 75.2 3.1

10.0 (50.0°F) 303.8 53.3 5.6 289.7 58.1 4.8 275.3 64.8 4.2 261.0 70.4 3.7 246.8 76.0 3.2

5.0 (41.0°F) 282.0 56.4 4.9 271.2 61.7 4.2 257.2 66.7 3.8 241.1 73.0 3.1 227.3 78.4 2.8

6.0 (42.8°F) 292.7 56.7 5.1 278.4 62.0 4.4 264.0 68.2 3.8 250.0 73.9 3.3 236.1 79.3 2.9

8.0 (46.4°F) 307.9 57.4 5.3 293.7 62.4 4.5 278.8 69.2 4.0 264.3 75.1 3.5 249.1 80.8 3.0

9.0 (48.2°F) 318.9 57.7 5.5 303.6 62.8 4.7 288.5 69.8 4.1 273.9 75.8 3.5 258.3 81.8 3.1

10.0 (50.0°F) 329.6 58.0 5.6 314.4 63.2 4.8 298.7 70.5 4.2 283.2 76.6 3.7 267.8 82.7 3.1

5.0 (41.0°F) 313.3 60.4 5.1 301.3 65.9 4.4 285.7 71.3 3.9 267.9 78.0 3.3 252.5 83.8 3.0

6.0 (42.8°F) 325.2 60.6 5.3 309.3 66.3 4.6 293.3 73.0 4.0 277.7 79.0 3.5 262.3 84.8 3.0

8.0 (46.4°F) 342.1 61.3 5.5 326.3 66.7 4.7 309.8 73.9 4.1 293.6 80.3 3.6 276.8 86.4 3.2

9.0 (48.2°F) 354.3 61.7 5.7 337.3 67.2 4.9 320.5 74.6 4.3 304.3 81.1 3.7 287.0 87.5 3.2

10.0 (50.0°F) 366.2 62.0 5.9 349.3 67.6 5.0 331.9 75.3 4.3 314.7 81.9 3.8 297.5 88.4 3.3

5.0 (41.0°F) 337.2 63.5 5.2 324.4 69.4 4.5 307.6 75.1 4.0 288.4 82.1 3.3 271.9 88.2 3.0

6.0 (42.8°F) 350.1 63.8 5.4 333.0 69.8 4.7 315.7 76.8 4.1 299.0 83.2 3.5 282.4 89.2 3.1

8.0 (46.4°F) 368.2 64.5 5.6 351.3 70.2 4.8 333.5 77.8 4.2 316.1 84.5 3.7 297.9 90.9 3.2

9.0 (48.2°F) 381.4 64.9 5.8 363.1 70.7 5.0 345.0 78.6 4.4 327.6 85.3 3.8 309.0 92.0 3.3

10.0 (50.0°F) 394.3 65.2 6.0 376.0 71.1 5.1 357.3 79.3 4.4 338.8 86.2 3.9 320.3 93.1 3.3

5.0 (41.0°F) 350.2 66.9 5.1 334.0 74.2 4.4 317.8 81.3 3.9 301.8 88.3 3.3 285.5 95.1 3.0

6.0 (42.8°F) 363.0 67.2 5.3 346.0 74.5 4.6 329.8 81.8 3.9 312.8 89.1 3.5 296.3 96.2 3.1

8.0 (46.4°F) 382.3 67.4 5.6 365.0 75.0 4.8 347.8 82.6 4.1 330.4 90.2 3.6 313.2 97.6 3.2

9.0 (48.2°F) 395.7 67.5 5.8 377.1 75.2 4.9 362.4 83.1 4.3 342.1 90.9 3.7 324.7 98.5 3.2

10.0 (50.0°F) 409.2 67.6 6.0 390.9 75.6 5.1 372.7 83.5 4.4 354.0 91.5 3.8 336.1 99.4 3.3

5.0 (41.0°F) 372.1 71.1 5.1 354.8 78.9 4.4 337.7 86.4 3.9 320.7 93.9 3.3 303.4 101.1 3.0

6.0 (42.8°F) 385.7 71.4 5.3 367.7 79.2 4.6 350.4 87.0 3.9 332.4 94.7 3.5 314.8 102.2 3.1

8.0 (46.4°F) 406.2 71.6 5.6 387.8 79.7 4.8 369.6 87.8 4.1 351.0 95.8 3.6 332.7 103.7 3.2

9.0 (48.2°F) 420.4 71.7 5.8 400.6 80.0 4.9 385.1 88.3 4.3 363.5 96.6 3.7 345.0 104.7 3.2

10.0 (50.0°F) 434.7 71.8 6.0 415.3 80.4 5.1 396.0 88.8 4.4 376.1 97.3 3.8 357.1 105.7 3.3

5.0 (41.0°F) 406.8 78.9 5.1 387.9 87.5 4.4 369.1 95.9 3.9 350.6 104.2 3.3 331.6 112.2 2.9

6.0 (42.8°F) 421.6 79.3 5.2 401.9 87.9 4.5 383.0 96.5 3.9 363.3 105.1 3.4 344.1 113.5 3.0

8.0 (46.4°F) 444.1 79.5 5.5 423.9 88.4 4.7 404.0 97.5 4.1 383.7 106.4 3.6 363.7 115.1 3.1

9.0 (48.2°F) 459.6 79.6 5.7 437.9 88.8 4.9 421.0 98.0 4.2 397.3 107.2 3.7 377.1 116.2 3.2

10.0 (50.0°F) 475.2 79.7 5.9 454.0 89.2 5.0 432.9 98.5 4.3 411.2 108.0 3.8 390.4 117.3 3.3

5.0 (41.0°F) 414.1 79.0 5.2 394.9 87.6 4.5 375.7 96.0 3.9 356.8 104.3 3.3 337.6 112.3 3.0

6.0 (42.8°F) 429.2 79.3 5.3 409.1 88.0 4.6 389.9 96.6 4.0 369.9 105.2 3.5 350.3 113.6 3.1

8.0 (46.4°F) 452.0 79.6 5.6 431.5 88.5 4.8 411.2 97.6 4.2 390.6 106.5 3.7 370.2 115.2 3.2

9.0 (48.2°F) 467.8 79.7 5.8 445.8 88.9 5.0 428.5 98.2 4.3 404.4 107.3 3.7 383.8 116.3 3.2

10.0 (50.0°F) 483.7 79.8 6.0 462.2 89.3 5.1 440.6 98.6 4.4 418.5 108.1 3.8 397.4 117.4 3.3

5.0 (41.0°F) 445.1 86.7 5.1 424.4 96.1 4.4 403.9 105.3 3.8 383.6 114.4 3.3 362.8 123.2 2.9

6.0 (42.8°F) 461.3 87.0 5.2 439.8 96.5 4.5 419.1 106.0 3.9 397.6 115.4 3.4 376.6 124.6 3.0

8.0 (46.4°F) 485.9 87.3 5.5 463.8 97.1 4.7 442.0 107.0 4.1 419.8 116.8 3.6 398.0 126.4 3.1

9.0 (48.2°F) 502.8 87.4 5.7 479.2 97.5 4.9 460.6 107.7 4.2 434.7 117.7 3.7 412.6 127.6 3.2

10.0 (50.0°F) 520.0 87.5 5.9 496.8 97.9 5.0 473.6 108.2 4.3 449.9 118.6 3.8 427.2 128.8 3.3

20°C (68°F) 25°C (77°F) 30°C (86°F) 35°C (95°F) 40°C (104°F)

Cap. PWR Cap. PWR Cap. PWR Cap. PWR Cap. PWR

kW kWi

COP

kW kWi

Entering Condenser Water Temperature (°C)

COP

kW kWi

COP

kW kWi

COP

kW kWi

COP

Product Manual WHR-2 23

Page 24

Table 10, WHR 130EW - WHR 210EW, 60 Hz, SI Units

Entering Condenser Water Temperature (°C)

WHR

SIZE

130EW

145EW

155EW

165EW

175EW

185EW

195EW

210EW

Notes:

1. Ratings based on HCFC-22 evaporator fouling of 0.0176, 0.043 L/s; condenser fouling of 0.044.

2. For 208V units multiply capacity and COP by 0.98.

3. Ratings are based on circuit #1 in lead position and circuit #2 in lag position.

4. Interpolation is allowed; extrapolation is not permitted. Consult McQuay for performance outside the ratings shown.

5. For LWT of 5°C and below please refer to Application Adjustment Factors section.

LWT

°C

5.0 (41.0°F) 481.6 96.3 4.9 459.2 106.8 4.3 437.0 117.0 3.7 415.0 127.1 3.2 392.6 136.9 2.9

6.0 (42.8°F) 499.1 96.7 5.1 475.8 107.2 4.4 453.4 117.8 3.8 430.2 128.2 3.3 407.4 138.5 2.9

7.0 (44.6°F) 516.6 96.9 5.3 493.1 107.6 4.5 469.8 118.6 3.9 446.0 129.2 3.4 423.1 139.8 3.0

8.0 (46.4°F) 525.7 97.0 5.3 501.9 107.9 4.6 478.2 118.9 4.0 454.2 129.8 3.5 430.6 140.4 3.0

9.0 (48.2°F) 544.1 97.1 5.5 518.4 108.3 4.7 498.3 119.6 4.1 470.4 130.8 3.6 446.4 141.8 3.1

10.0 (50.0°F) 562.6 97.2 5.8 537.5 108.8 4.8 512.5 120.2 4.2 486.8 131.7 3.7 462.2 143.1 3.2

5.0 (41.0°F) 525.3 99.7 5.2 501.0 110.5 4.5 476.7 121.1 3.9 452.7 131.6 3.4 428.3 141.7 3.0

6.0 (42.8°F) 544.5 100.1 5.3 519.1 111.0 4.6 494.6 121.9 4.0 469.3 132.7 3.5 444.5 143.3 3.1

7.0 (44.6°F) 563.6 100.3 5.6 537.9 111.4 4.7 512.5 122.7 4.1 486.6 133.8 3.6 461.6 144.7 3.2

8.0 (46.4°F) 573.5 100.4 5.6 547.5 111.7 4.8 521.7 123.1 4.2 495.5 134.3 3.7 469.7 145.4 3.2

9.0 (48.2°F) 593.5 100.5 5.8 565.6 112.1 5.0 543.6 123.8 4.3 513.1 135.4 3.8 487.0 146.7 3.3

10.0 (50.0°F) 613.7 100.6 6.1 586.3 112.6 5.1 559.0 124.4 4.4 531.0 136.4 3.9 504.2 148.1 3.4

5.0 (41.0°F) 549.0 107.6 5.0 523.6 119.3 4.4 498.2 130.7 3.8 473.2 142.0 3.3 447.6 152.9 2.9

6.0 (42.8°F) 569.1 108.0 5.2 542.5 119.8 4.5 517.0 131.6 3.9 490.4 143.2 3.4 464.5 154.7 3.0

7.0 (44.6°F) 589.1 108.2 5.4 562.2 120.2 4.6 535.6 132.5 4.0 508.5 144.4 3.5 482.4 156.1 3.1

8.0 (46.4°F) 599.4 108.3 5.4 572.2 120.5 4.7 545.3 132.8 4.1 517.9 145.0 3.6 490.9 156.9 3.1

9.0 (48.2°F) 620.3 108.5 5.6 591.1 121.0 4.8 568.2 133.6 4.2 536.3 146.1 3.6 509.0 158.4 3.2

10.0 (50.0°F) 641.4 108.6 5.9 612.8 121.6 5.0 584.3 134.3 4.3 555.0 147.2 3.8 527.0 159.8 3.3

5.0 (41.0°F) 594.6 116.3 5.0 567.1 129.0 4.4 539.6 141.3 3.8 512.5 153.5 3.3 484.8 165.3 2.9

6.0 (42.8°F) 616.3 116.8 5.2 587.6 129.5 4.5 559.9 142.2 3.9 531.2 154.8 3.4 503.1 167.2 3.0

7.0 (44.6°F) 638.0 117.0 5.4 608.9 130.0 4.6 580.1 143.2 4.0 550.8 156.1 3.5 522.5 168.8 3.1

8.0 (46.4°F) 649.2 117.1 5.5 619.7 130.3 4.7 590.6 143.6 4.1 560.9 156.7 3.6 531.7 169.6 3.1

9.0 (48.2°F) 671.8 117.3 5.6 640.2 130.8 4.8 615.4 144.5 4.2 580.8 158.0 3.6 551.2 171.2 3.2

10.0 (50.0°F) 694.7 117.4 5.9 663.7 131.4 5.0 632.8 145.2 4.3 601.1 159.1 3.8 570.7 172.8 3.3