Page 1

Installation, Operation and Maintenance Manual

Group: Chiller

Part Number: 330389301

Effective: October 2004

Supercedes: IOMM WGZ

Water-Cooled Scroll Compressor Chillers

WGZ 030AW To WGZ 100AW, Packaged Water-Cooled Chiller

WGZ 030AA To WGZ 100AA, Chiller with Remote Condenser

30 to 100 Tons, 105 to 350 kW

R-22, 60 Hz

IOMM WGZ-1

Page 2

Table of Contents

Introduction........................................3

General Description .....................................3

Nomenclature...............................................3

Inspection.....................................................3

Installation..........................................4

Vibration Isolators........................................6

Water Piping.......................................9

Flow Switch...............................................11

Glycol Solutions.........................................12

Condenser Water Piping.............................13

Water Pressure Drop ..................................14

Refrigerant Piping...........................17

Unit with Remote Condenser .....................17

Factory-Mounted Condenser......................20

Dimensional Data.............................21

Physical Data....................................26

AW Water-Cooled ......................................26

AA Remote Condenser...............................28

Operating Limits........................................29

Components ...............................................29

Wiring...............................................30

Unit Configuration ..........................31

Electrical Data..................................32

Field Wiring Diagram s...............................39

Control Panel Layout.................................41

Motor Protection Module...........................41

Start-Up and Shutdown...................42

Pre Start-up ................................................42

Start-up.......................................................42

Weekend or Temporary Shutdown.............43

Start-up after Temporary Shutdown............43

Extended Shutdown....................................43

Start-up after Extended Shutdown..............44

Sequence of Operation....................45

Standard MicroTech II Controller. 47

General Description....................................47

Setpoints.....................................................50

Equipment Protection (Shutdown) Alarms.51

Limit Alarm s...............................................52

Staging Parameters.....................................54

Capacity Overrides.....................................54

Digital Output Control................................55

Analog Output Control...............................56

Using the Controller...................................58

Menu Screens............................................. 60

Menu Descriptions.....................................61

Optional Controls............................75

Phase/Voltage Monitor (Optional)..............75

Hot Gas Bypass (Optional).........................75

System Maintenance........................76

General.......................................................76

Electrical Terminals....................................77

Compressor Lubrication .............................77

Sight glass and Moisture Indicator.............77

Crankcase Heaters......................................77

Maintenance Schedule .................... 78

System Service.................................79

Troubleshooting Chart................................81

Warranty Statement........................ 82

Our facility is ISO Certified

"McQuay" is a registered trademark of McQuay International

Illustrations and data cover McQuay International products at the time of publication and we reserve the right to

make changes in design and construction at anytime without notice.

2 WGZ 030A through 100A IOMM WGZ-1

2003 McQuay International

Page 3

Introduction

General Description

McQuay Type WGZ water chillers are designed for indoor installations and are available with watercooled condensers (Model AW), or arranged for use with remote air-cooled or evaporative condensers

(Model AA). Each water-cooled unit is completely assembled and factory wired before evacuation,

charging and testing. They consist of hermetic scroll compressors, brazed-plate evaporator, watercooled condenser (WGZ-AW), and complete refrigerant piping.

Units manufactured for use with remote condensers (Models WGZ-AA) have all refrigerant

specialties factory-mounted and connection points for refrigerant discharge and liquid lines.

Liquid line components that are included are manual liquid line shutoff valves, charging valves, filterdriers, liquid line solenoid valves, sight glass/moisture indicators, and thermal expansion valves.

Other features include compressor crankcase heaters, and a MicroTech II¥ microprocessor controller.

The electrical control center includes all equipment protection and operating controls necessary for

dependable automatic operation.

The compressors are not fused as standard, but can be protected by optional circuit breakers or fuses,

or can rely on a field-installed, fused disconnect switch for protection.

Nomenclature

W G Z 100 - A W

Water-Cooled Condensing

Scroll Compressor

Nominal Capacity (Tons)

Global

W = Water-Cooled Condenser

A = Unit Less Condenser

Design Vintage

Inspection

When the equipment is received, all items should be carefully checked against the bill of lading to be

sure of a complete shipment. All units must be carefully inspected for damage upon arrival. All

shipping damage must be reported to the carrier and a claim must be filed with the carrier. The unit

serial plate should be checked before unloading the unit to be sure that it agrees with the power

supply available. Physical damage to unit after acceptance is not the responsibility of McQuay.

Note: Unit shipping and operating weights are given in the physical data tables beginning on

page 26.

IOMM WGZ-1 WGZ 030A through 100A 3

Page 4

Installation

Note: Installation and maintenance ar e to be perform ed only by qualified personnel who are

familiar with local codes and regulations, and experienced with this type of equipment.

WARNING

Avoid contact with sharp edges. Personal injury can result.

Handling

Every model WGZ-AW water chiller with water-cooled condensers is shipped with a full refrigerant

charge. For shipment, the charge is contained in the condenser and is isolated by the condenser liquid

shutoff valve and the compressor discharge valve common to a pair of compressors.

A holding charge is supplied in remote condenser models, WGZ-AA. The operating charge must be

field supplied and charged.

WARNING

If the unit has been damaged, allowing the refrigerant to escape, there can be danger

of suffocation in the equipment area since the refrigerant will displace the air. Be

sure to review Environmental Protection Agency (EPA) requirements if damage

occurred. Avoid exposing an open flame to the refrigerant.

Moving the Unit

Some means such as dollies or skids must be field furnished to protect the unit from accidental

damage and to permit easy handling and moving.

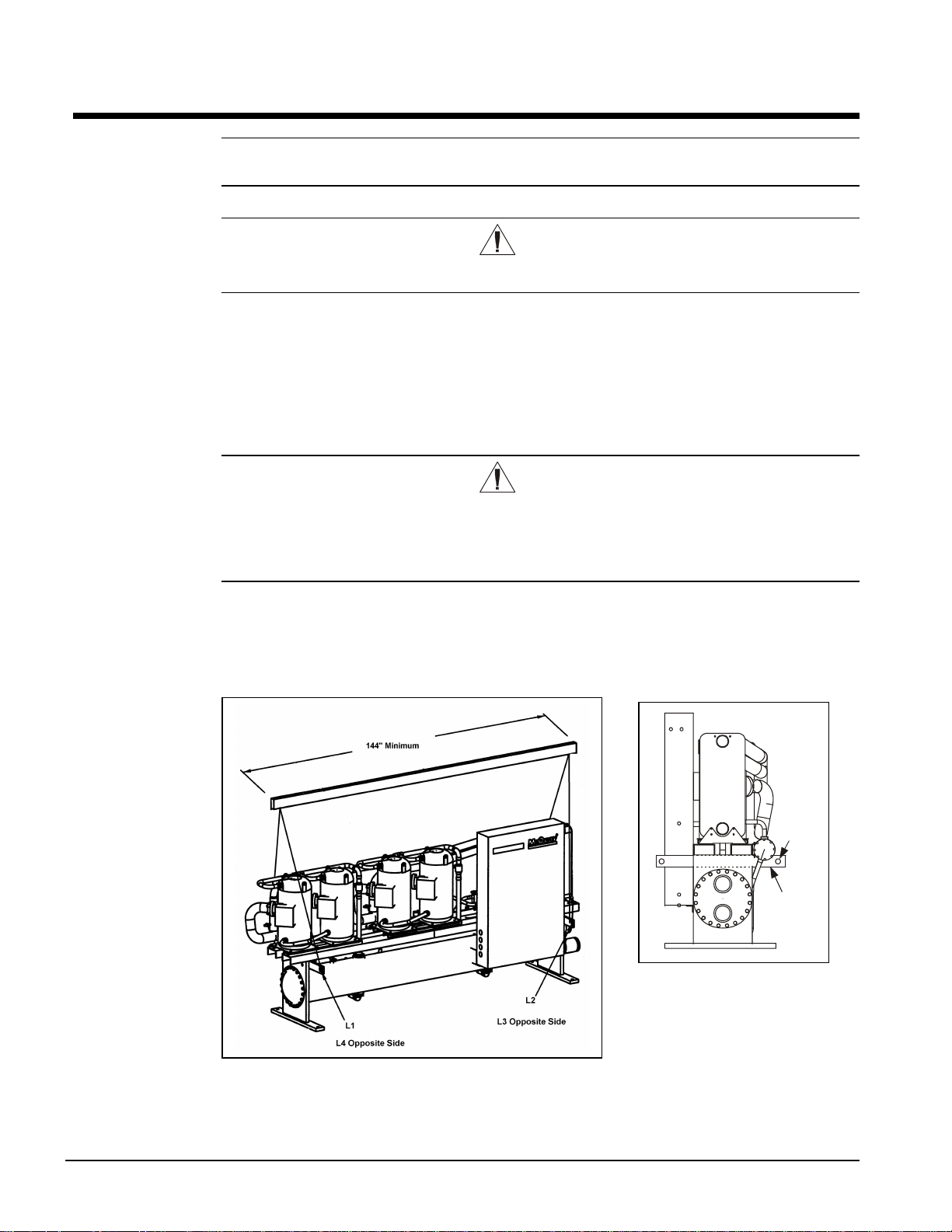

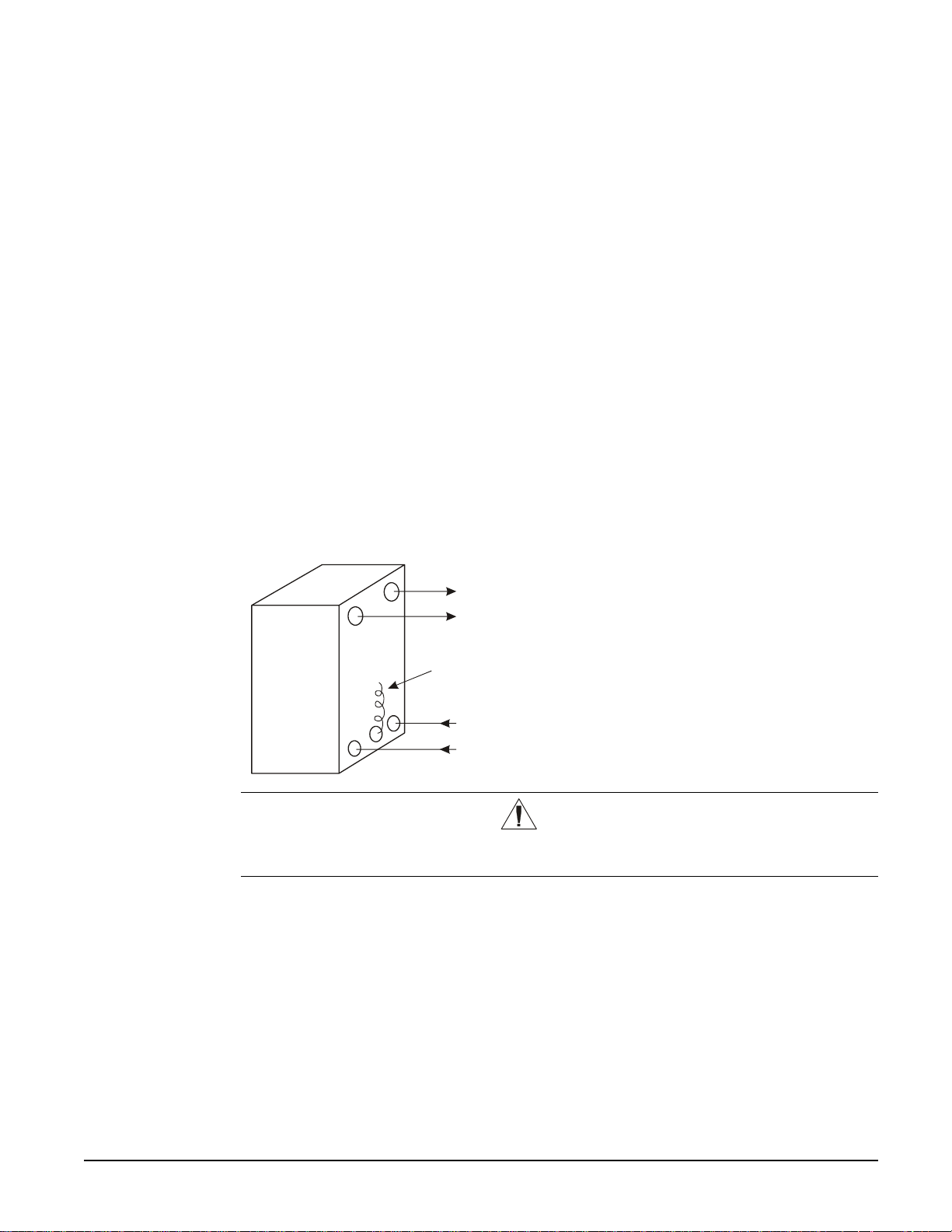

Figure 1, Lifting the Unit

(2) 2”

Lifting

Holes

Removable

Lifting

Bar

It is recommended that all moving and

handling be performed with skids or

dollies under the unit when possible

and that they not be removed until the

unit is in the final location.

Never put the weight of the unit against the control box.

In moving, always apply pressure to the base on the skids only and not to the piping or other

components. A long bar will help move the unit easily. Avoid dropping the unit at the end of the roll.

4 WGZ 030A through 100A IOMM WGZ-1

Page 5

If the unit must be hoisted, lift the unit from the removable lifting arms factory-bolted to each end of

the unit adjacent to the tube sheet by attaching cables or chains to the end of the arms. A spreader bar

must be used to protect the piping, control panel and other areas of the chiller (see Figure 1). The

arms should be removed and discarded after use.

Do not at tach sl ings to pip ing or e quipment. Do not attempt to lift the unit by lifting points mounted

on the compressors. They are for lifting only the compressor should one need to be removed from the

unit. Move unit in the upright horizontal position at all times. Set unit down gently when lowering

from the truck or rollers.

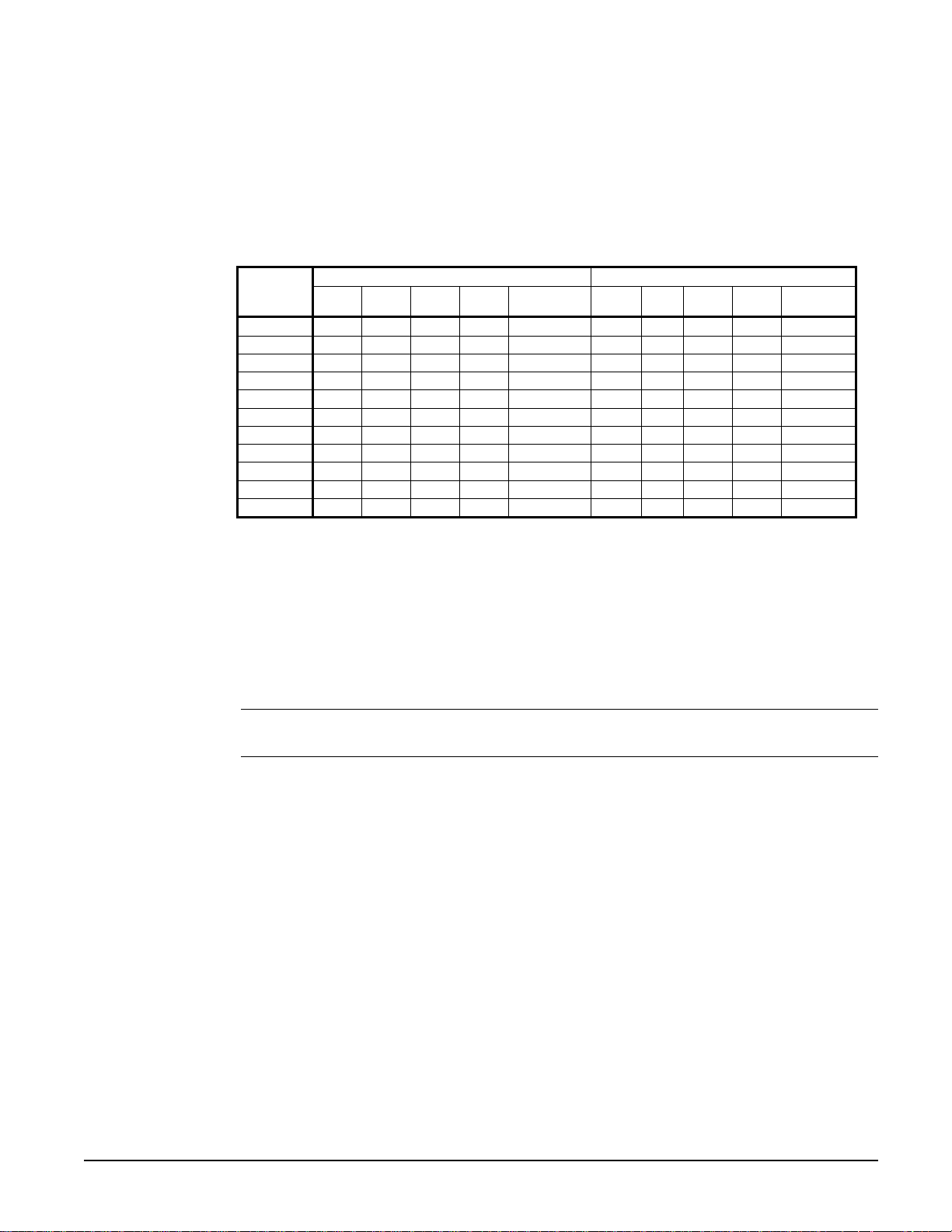

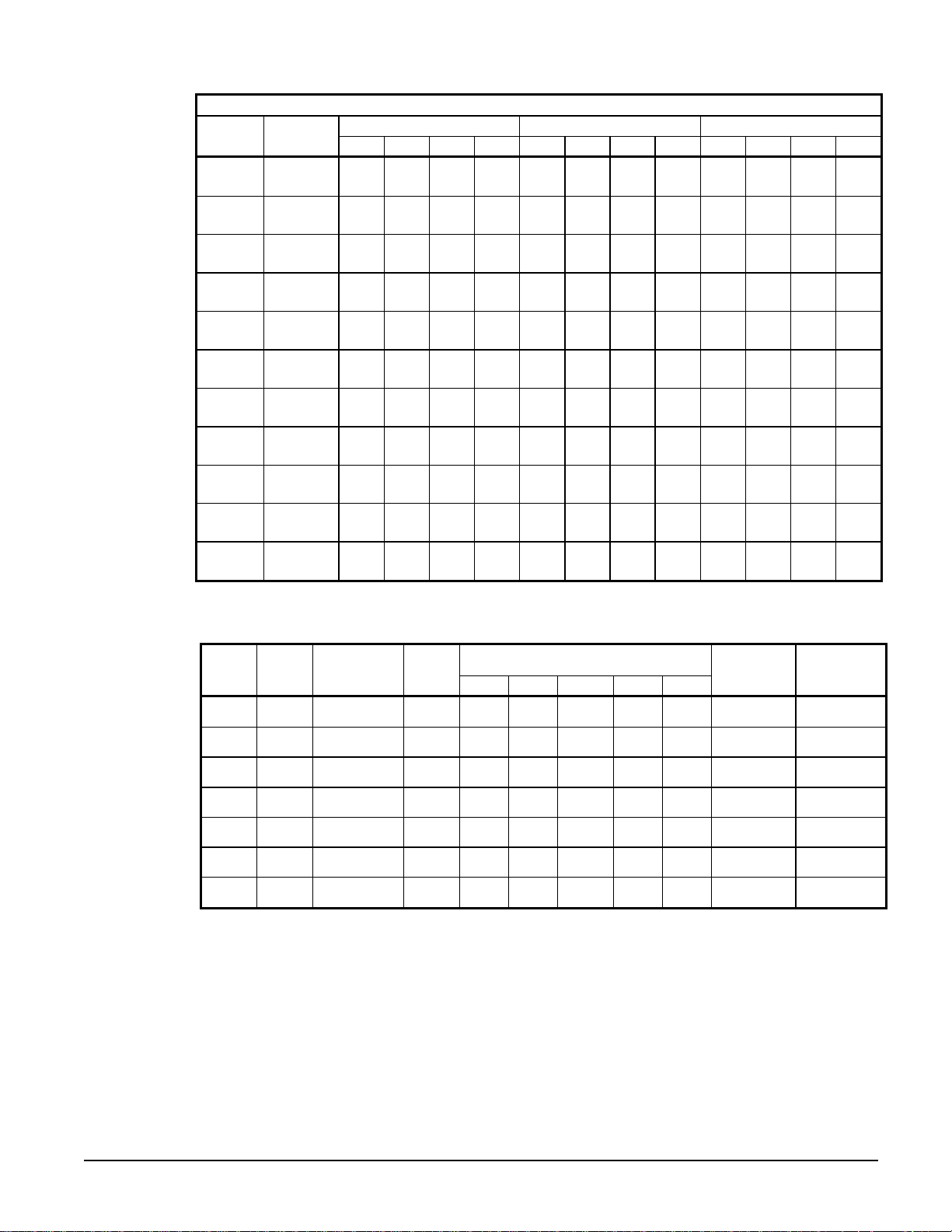

Table 1, Lifting Loads

Model

WGZ 030 564 616 655 715 2551 469 502 562 601 2134

WGZ 035 572 626 672 736 2606 473 507 576 617 2172

WGZ 040 584 641 695 764 2684 477 514 592 637 2219

WGZ 045 596 658 717 792 2763 486 525 610 659 2281

WGZ 050 604 668 739 817 2828 487 527 625 676 2315

WGZ 055 646 719 761 846 2973 526 577 643 705 2452

WGZ 060 800 892 855 953 3500 620 673 675 733 2701

WGZ 070 863 966 890 996 3716 673 735 700 764 2871

WGZ 080 900 1009 961 1077 3947 702 769 763 837 3071

WGZ 090 908 1021 1019 1145 4094 700 769 812 892 3172

WGZ 100 916 1031 1059 1191 4197 696 771 841 931 3238

L1 L2 L3 L4

Package Units (lbs. Less Condenser Units (lbs)

Shipping

Weight

L1 L2 L3 L4

Shipping

Weight

Location

WGZ chillers are designed for indoor application and must be located in an area where the

surrounding ambient temperature is 40°F (4°C) or above. A good rule of thumb is to place units

where ambient temperatures are at least 5°F (3°C) above the leaving water temperature.

Because of the electrical control devices, the units should not be exposed to the weather. A plastic

cover over the control box is supplied as temporary protection during shipment. A reasonably level

and sufficiently strong floor is required for the water chiller. If necessary, additional structural

members should be provided to transfer the weight of the unit to the nearest beams.

Note: Unit shipping and operating weights are given in Table 1 and in the physical data

tables beginning on page 26.

Space Requirements for Connections and Servicing

The chilled water and condenser water (on units with a water-cooled condenser) piping enters and

leaves the unit from the right side when looking at the control panel. Left-hand condenser

connections are an option. A clearance of at least 3 feet (1219 mm), or more if codes require, should

be provided beyond this piping and on all other sides and ends of the unit for general servicing or for

changing the compressors, if it ever becomes necessary.

On units equipped with a water-cooled condenser (Type WGZ-AW) clearance should also be

provided for cleaning or removal of condenser tubes on one end of the unit. The clearance for

cleaning depends on the type of apparatus used, but can be as much as the length of the condenser (10

feet, 3050 mm). Tube replacement requires the tube length of 10 feet (3050 mm) plus one to two feet

of workspace. This space can often be provided through a doorway or other aperture.

Placing the Unit

The small amount of vibration normally encountered with the water chiller makes this unit

particularly desirable for basement or ground floor installations where the unit can be mounted

directly to the floor. The floor construction should be such that the unit will not affect the building

structure, or transmit noise and vibration into the structure.

IOMM WGZ-1 WGZ 030A through 100A 5

Page 6

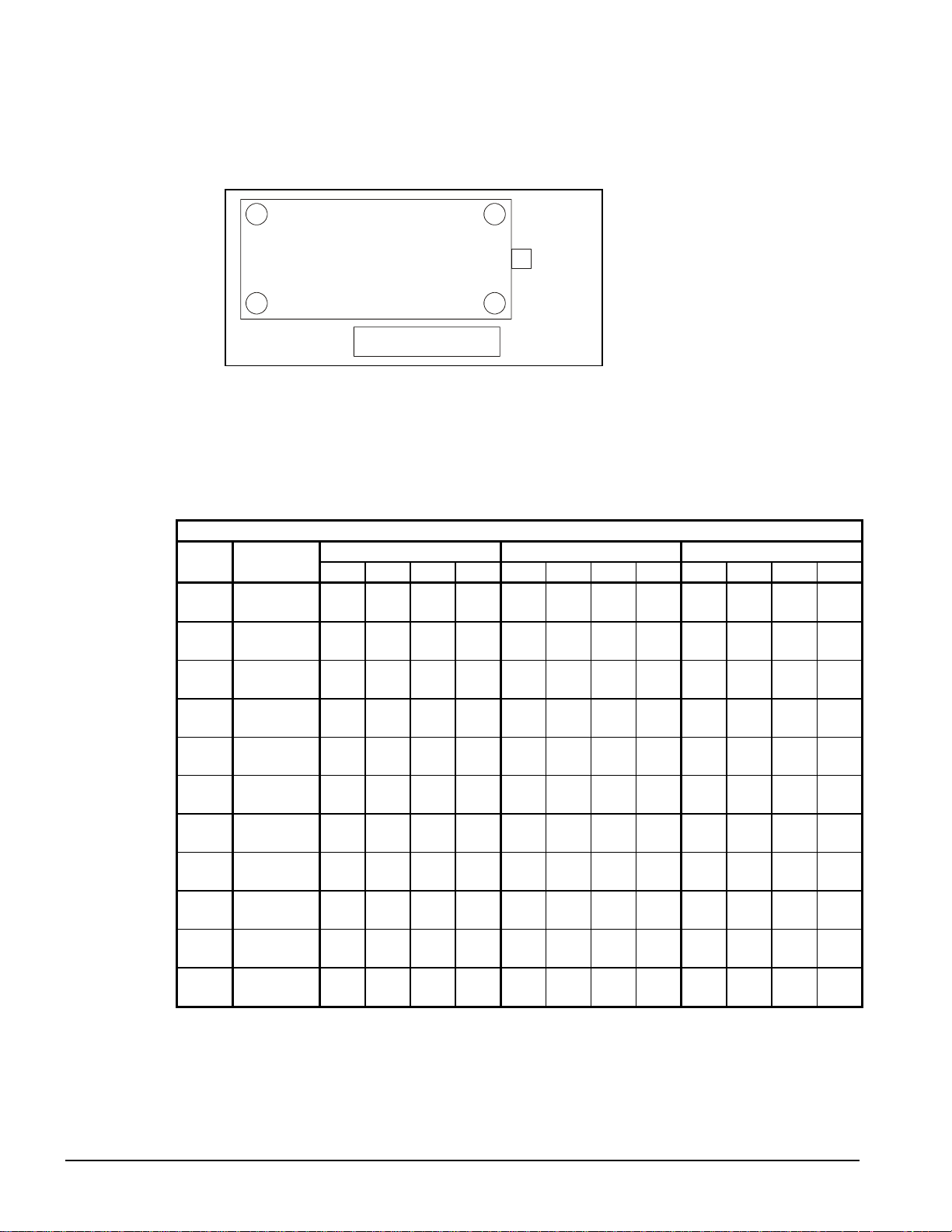

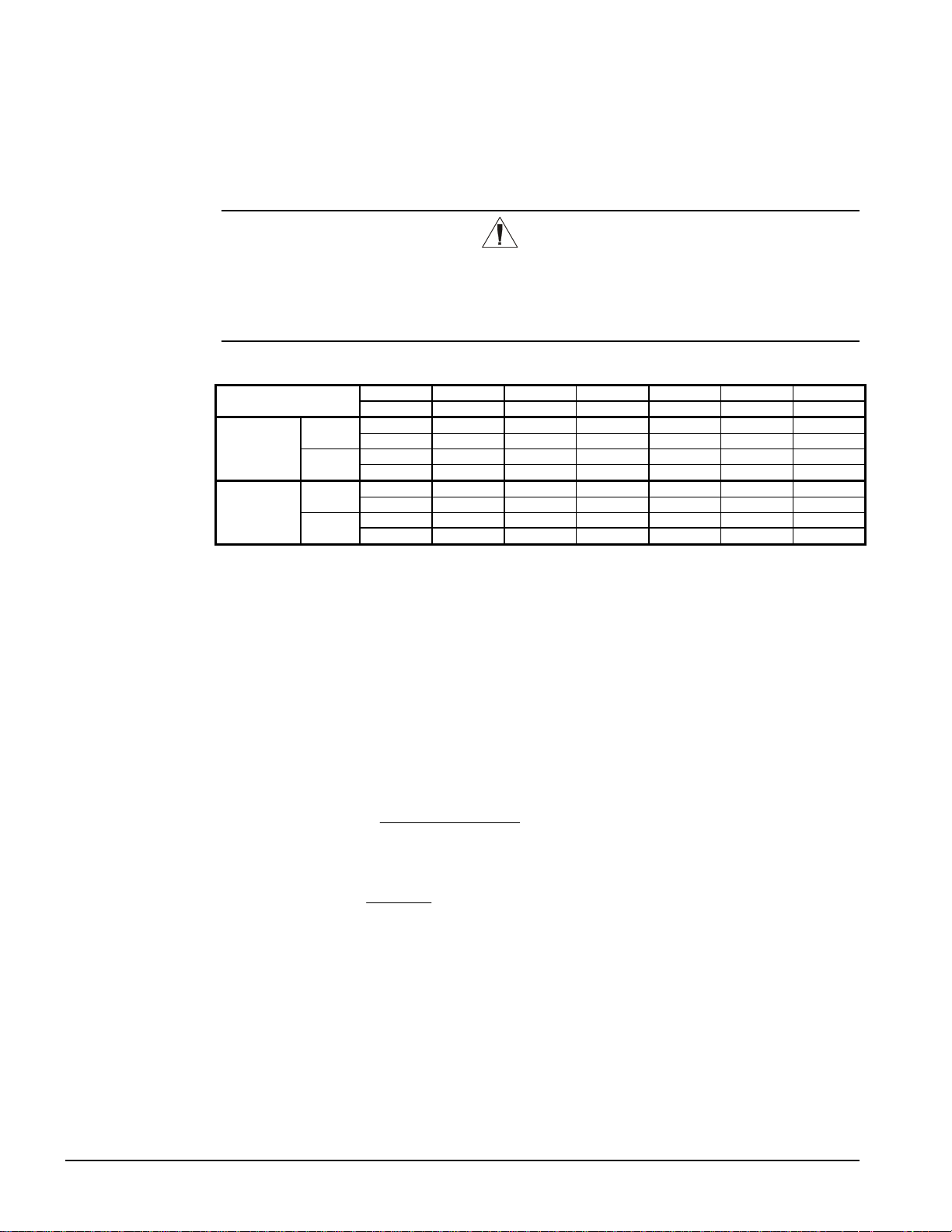

Vibration Isolators

It is recommended that isolators be used on all upper level installations or in areas where vibration

transmission is a consideration.

Figure 2, Isolator Locations

4

LB

1

LF

Control Panel

RB

FRF

3

Water

Connections

2

flushing, charging, etc., is completed, the springs are adjusted upward to loosen the blocks or shims

that are then removed.

A rubber anti-skid pad should be used under isolators if hold-down bolts are not used.

Installation of spring isolators requires flexible piping connections and at least three feet of flexible

electrical conduit to avoid straining the piping and transmitting vibration and noise.

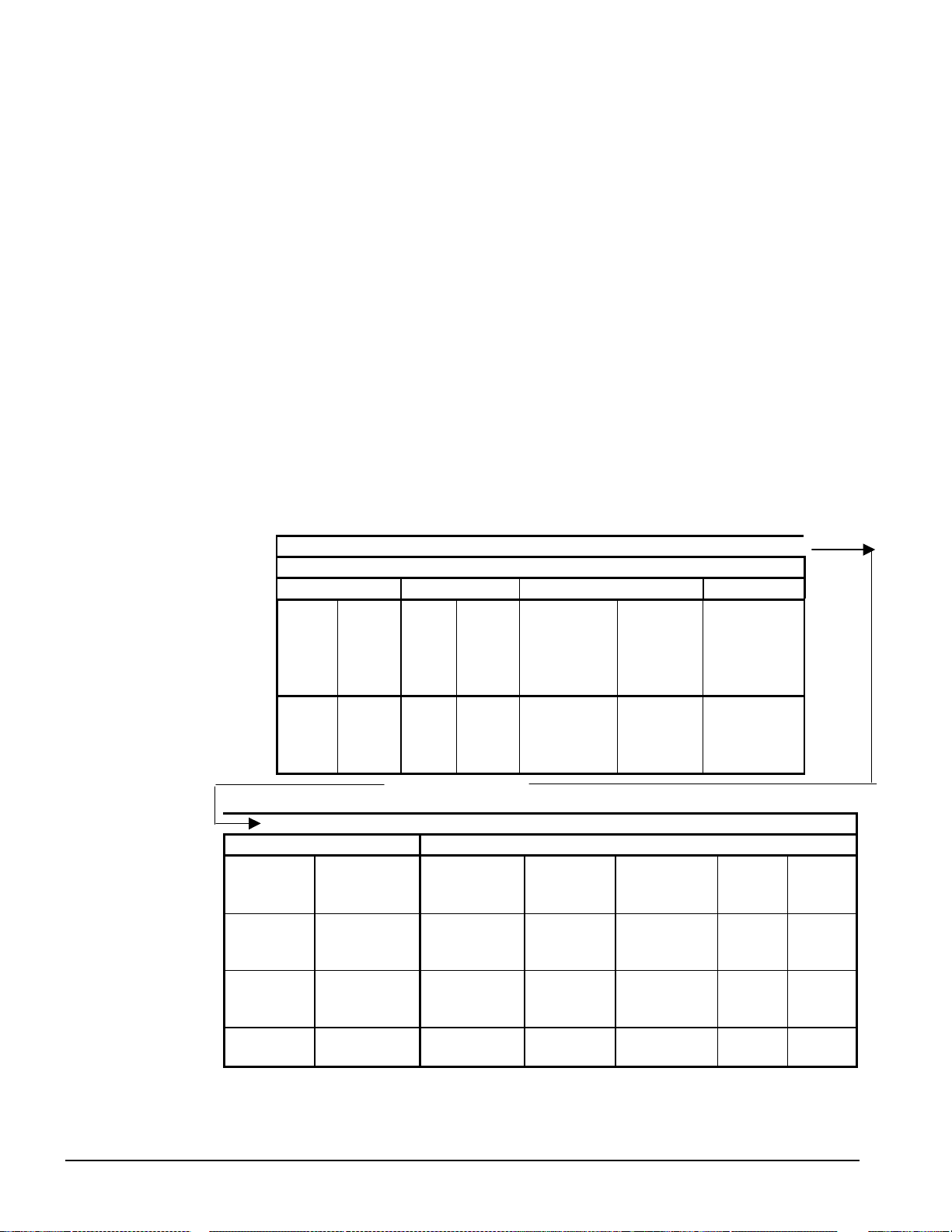

Table 2, Weights & Mountings

ARRANGEMENT WGZ-AW, WITH WATER-COOLED CONDENSERS

Unit

Size

030

035

040

045

050

055

060

070

080

090

100

Opr. Wt.

Lbs. (kg)

2692

(1219)

2760

(1250)

2866

(1298)

2966

(1344)

3058

(1385)

3213

(1455)

3809

(1725)

4025

(1823)

4289

(1943)

4484

(2031)

4627

(2096)

Corner Weight Lbs (kg) Neoprene-In-Shear Mountings Spring-Flex Mountings

1 2 3 4 1 2 3 4 1 2 3 4

589

648

692

762

RP-3

RP-3

(267)

(294)

(314)

(345)

Green

Green

599

661

713

787

RP-3

RP-3

(271)

(299)

(323)

(356)

Green

Green

616

682

744

824

RP-3

RP-3

(279)

(309)

(337)

(373)

Green

Green

632

702

773

860

RP-3

RP-3

(286)

(318)

(350)

(389)

Green

Green

644

718

802

894

RP-3

RP-3

(292)

(325)

(363)

(405)

Green

Green

688

772

826

927

RP-3

RP-3

(312)

(350)

(374)

(420)

Gray

Gray

853

959

940

1057

RP-3

RP-3

(386)

(435)

(426)

(479)

Gray

Gray

916

(415)

958

(434)

974

(441)

989

(448)

1033

(468)

1082

(490)

1103

(500)

1121

(508)

975

(442)

1056

(478)

1129

(511)

1179

(534)

1100

(498)

1193

(540)

1278

(579)

1337

(606)

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-4

Black

RP-4

Black

Transfer the unit as indicated under

“Moving the Unit.” In all cases, set

the unit in place and level with a spirit

level. When spring-type isolators are

required, install springs running under

the main unit supports.

The unit should be set initially on

shims or blocks at the listed spring

free height. When all piping, wiring,

RP-3

RP-3

CP-1

CP-1

Green

Green

RP-3

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-4

Black

RP-4

Black

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-4

Black

RP-4

Black

RP-4

Black

RP-4

Black

Orange

CP-1

Orange

CP-1

Orange

CP-1

Orange

CP-1

Orange

CP-1

Orange

CP-1

Green

CP-1

Gray

CP-1

Gray

CP-1

Gray

CP-1

Gray

Orange

CP-1

Orange

CP-1

Orange

CP-1

Orange

CP-1

Orange

CP-1

Gray

CP-1

Green

CP-1

Gray

CP-1

Gray

CP-1

White

CP-1

White

Orange

Orange

Orange

Green

Green

White

White

CP-1

CP-1

CP-1

CP-1

CP-1

CP-1

Gray

CP-1

Gray

CP-1

Gray

CP-1

Gray

CP-1

CP-1

CP-1

Green

CP-1

Green

CP-1

Orange

CP-1

Green

CP-1

Green

CP-1

Gray

CP-1

Gray

CP-1

White

CP-1

White

CP-2

Green

CP-2

Green

6 WGZ 030A through 100A IOMM WGZ-1

Page 7

Unit

Size

030

035

040

045

050

055

060

070

080

090

100

Opr. Wt.

Lbs. (kg)

2162

(979)

2204

(998)

2257

(1022)

2329

(1055)

2370

(1074)

2505

(1135)

2771

(1255)

2942

(1333)

3154

(1429)

3271

(1482)

3346

(1516)

ARRANGEMENT WGZ-AA, FOR REMOTE CONDENSER

Corner Weight Lbs (kg) Neoprene-In-Shear Mountings Spring-Flex Mountings

1 2 3 4 1 2 3 4 1 2 3 4

468

502

575

616

RP-3

RP-3

RP-3

RP-3

CP-1

CP-1

CP-1

CP-1

(212)

(227)

(260)

(279)

Green

Green

Green

Green

Purple

Purple

Orange

Orange

472

507

590

634

RP-3

RP-3

RP-3

RP-3

CP-1

CP-1

CP-1

CP-1

(214)

(230)

(267)

(287)

Green

Green

Green

Green

Purple

Purple

Orange

Orange

477

514

609

657

RP-3

RP-3

RP-3

RP-3

CP-1

CP-1

CP-1

CP-1

(216)

(233)

(276)

(297)

Green

Green

Green

Green

Purple

Purple

Orange

Orange

487

526

633

684

RP-3

RP-3

RP-3

RP-3

CP-1

CP-1

CP-1

CP-1

(220)

(238)

(287)

(310)

Green

Green

Green

Green

Purple

Purple

Orange

Orange

488

528

650

704

RP-3

RP-3

RP-3

RP-3

CP-1

CP-1

CP-1

CP-1

(221)

(239)

(295)

(319)

Green

Green

Green

Green

Purple

Purple

Orange

Orange

526

578

668

734

RP-3

RP-3

RP-3

RP-3

CP-1

CP-1

CP-1

CP-1

(238)

(262)

(303)

(332)

Green

Green

Green

Green

Purple

Purple

Orange

Orange

619

674

707

770

RP-3

RP-3

RP-3

RP-3

CP-1

CP-1

CP-1

CP-1

(280)

(305)

(320)

(349)

Green

672

(304)

702

(318)

700

(317)

697

(316)

736

(333)

771

(349)

771

(349)

773

(350)

732

(332)

801

(363)

857

(388)

890

(403)

801

(363)

880

(399)

944

(427)

987

(447)

RP-3

Green

RP-3

Green

RP-3

Green

RP-3

Green

Green

Green

RP-3

RP-3

Gray

RP-3

Gray

RP-3

Gray

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

RP-3

Gray

Orange

CP-1

Orange

CP-1

Orange

CP-1

Orange

CP-1

Orange

Orange

CP-1

Orange

CP-1

Green

CP-1

Green

CP-1

Green

Green

CP-1

Green

CP-1

Green

CP-1

Green

CP-1

Green

Green

CP-1

Green

CP-1

Gray

CP-1

Gray

CP-1

Gray

Table 3, Spring Flex Isolators

6.0

(152.4)

6.0

(152.4)

6.0

(152.4)

6.0

(152.4)

6.0

(152.4)

6.0

(152.4)

9.0

(228.6)

Dimensions

In. (mm)

4.7

(119.4)

4.7

(119.4)

4.7

(119.4)

4.7

(119.4)

4.7

(119.4)

4.7

(119.4)

7.7

(195.6)

Housing

CP-1

CP-1

CP-1

CP-1

CP-1

CP-1

CP-2

NOTE: CP-1 housing contains one spring. CP-2 housing contains two identical springs.

Spring

Color

Red

Purple

Orange

Green

Gray

White

Green

Max. Load

Each

Lbs. (kg)

450

(204)

600

(272)

750

(340)

900

(408)

1100

(498)

1300

(589)

1800

(815)

Defl.

In. (mm)

0.5

(12.7)

0.5

(12.7)

0.5

(12.7)

0.5

(12.7)

0.5

(12.7)

0.5

(12.7)

0.5

(12.7)

A B C D E

7.5

(190.5)

7.5

(190.5)

7.5

(190.5)

7.5

(190.5)

7.5

(190.5)

7.5

(190.5)

10.2

(259.1)

2.7

(68.6)

2.7

(68.6)

2.7

(68.6)

2.7

(68.6)

2.7

(68.6)

2.7

(68.6)

2.7

(68.6)

5.5

(139.7)

5.5

(139.7)

5.5

(139.7)

5.5

(139.7)

5.5

(139.7)

5.5

(139.7)

5.75

(146.0)

Housing

Part Number

226102B-00 226115A-00

226102B-00 226116A-00

226102B-00 226117A-00

226102B-00 226118A-00

226102B-00 226119A-00

226102B-00 226120A-00

226103B-00 (2) 226118A-00

Spring

Part Number

IOMM WGZ-1 WGZ 030A through 100A 7

Page 8

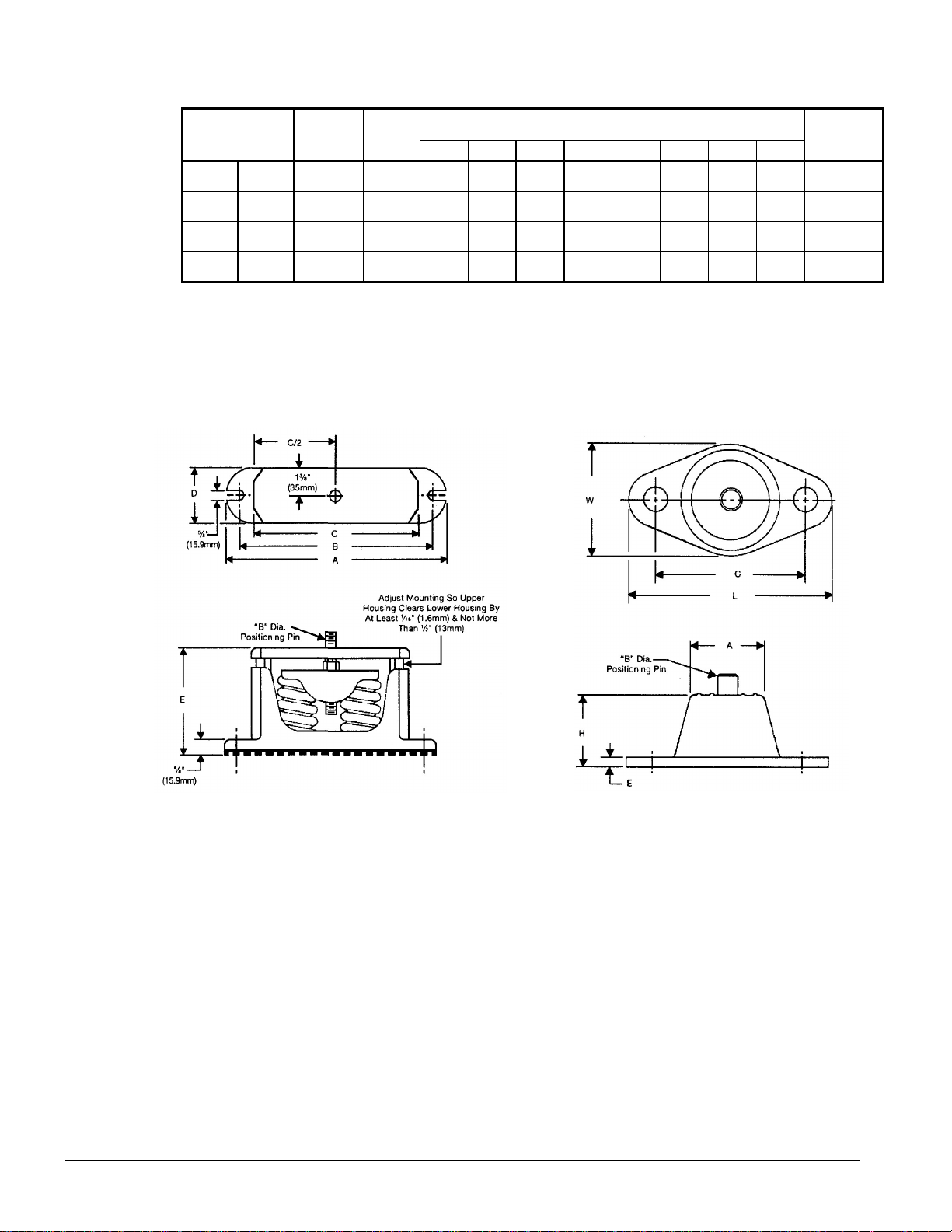

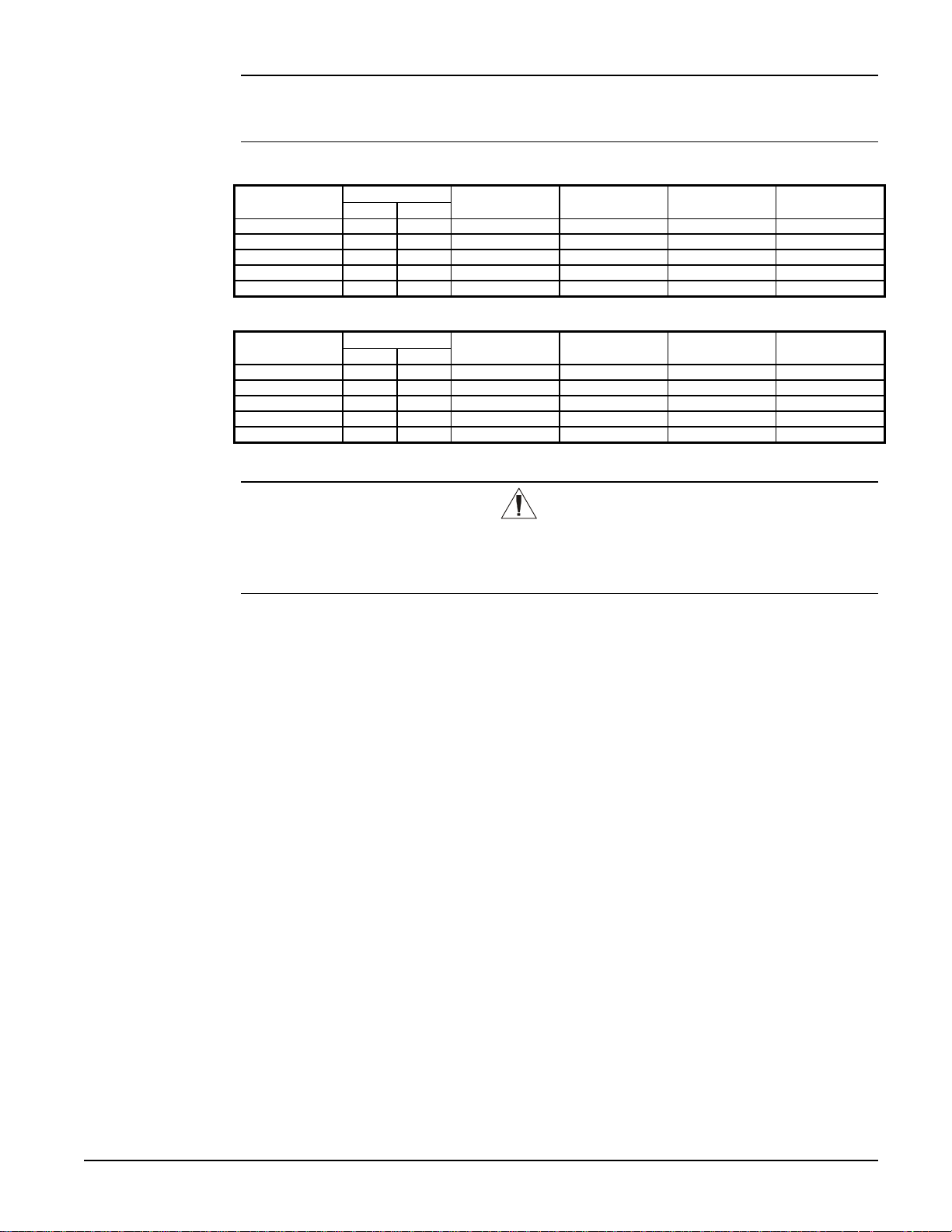

Table 4, Neoprene-in-Shear Isolators

4.1

4.1

5.0

5.0

Dimensions

In. (mm)

0.56

(14.2)

0.56

(14.2)

0.56

(14.2)

0.56

(14.2)

0.25

(6.4)

0.25

(6.4)

0.25

(6.4)

0.25

(6.4)

1.75

(44.4)

1.75

(44.4)

1.6

(41.1)

1.6

(41.1)

5.5

(165)

5.5

(165)

6.5

(165.1)

6.5

(165.1)

3.4

(85.7)

3.4

(85.7)

4.6

(116.8)

4.6

(116.8)

McQuay

Part Number

216397A-03

216397A-05

216398A-04

216398A-01

Type

RP-3 Green

RP-3 Gray

RP-4 Black

RP-4 Red

Max. Load

Each

Lbs. (kg)

750

(339)

1100

(498)

1500

(679)

2250

(1019)

Defl.

In. (mm)

0.25

(6.4)

0.25

(6.4)

0.25

(6.4)

0.25

(6.4)

A B C D (1) E H L W

2.5

(63.5)

2.5

(63.5)

3.75

(95.3)

3.75

(95.3)

0.5

(12.7)

0.5

(12.7)

0.5

(12.7)

0.5

(12.7)

(104.1)

(104.1)

(127.0)

(127.0)

Note (1) "D" is the mounting hole diameter.

Figure 3, Spring Flex Mountings Figure 4, Single Neoprene-in-Shear

Mounting

8 WGZ 030A through 100A IOMM WGZ-1

Page 9

Water Piping

General

Due to the variety of piping practices, it is advisable to follow the recommendations of local

authorities for code compliance. They can supply the installer with the proper building and safety

codes required for a safe and proper installation.

Basically, the piping should be designed with a minimum number of bends and changes in elevation

to keep system cost down and performance up. Other piping design considerations include:

1. All piping should be installed and supported to prevent the chiller connections from bearing any

2. Vibration eliminators to reduce vibration and noise transmission to the building.

3. Shutoff valves to isolate the unit from the piping system during unit servicing.

4. Manual or automatic air vent valves at the high points of the system. Drains should be placed at

5. Some means of maintaining ad equate system water pressure ( e.g., expansion ta nk or regulating

6. Temperature and pressure indicators located within 3 feet (0.9 meters) of the inlet and outlet of

7. A strainer or some means of removing foreign matter from the water before it enters the pump is

strain or weight of the system piping.

the lowest points in the system.

valve).

the vessels to aid in unit servicing.

recommended. It should be placed far enough upstream to pr event cavitation at the pump inlet

(consult pump manufacturer for recommendations). The use of a strainer will prolong pump life

and thus maintain system performance.

Important Note

A cleanable 40-mesh strainer must also be placed in the water line j ust prior to the inlet of

the evaporator. This will aid in preventing foreign material from entering and decreasing the

performance of the evaporator.

8. If the unit is used as a replacement chiller on a previously existing piping system, the system

should be thoroughly flushed prior to unit installation. Regular water anal ysis a nd chemical

water treatment on the evaporator and condenser is recommended immediately upon equipment

start-up.

9. In the event glycol is added to the water system, as an afterthought for freeze protection,

recognize that the refrigerant suction pressure will be lower, cooling performance less, and water

side pressure drop will be higher. If the percentage of glycol is large, or if propylene glycol is

used instead of ethylene glycol, the added pressure drop and loss of performance could be

substantial. Reset the freezestat and low leaving water alarm temperatures. The freezestat is

factory set to default at 36°F (2.2°C). Reset the freezestat setting to approximately 4° to 5°F

(2.3° to 2.8°C) below the leaving chilled water setpoint temperature. See the section titled

“Glycol Solutions” for additional information concerning the use of glycol.

10. A preliminary leak check of the water piping should be made before filling the system.

Note: A water f low switch or pressur e differential switch m ust be m ounted in the evaporator

outlet water line to signal that there is water flow before the unit will start.

IOMM WGZ-1 WGZ 030A through 100A 9

Page 10

Figure 5, Typical Field Evaporator Water Piping

Ai

r

Vent

Inlet

Strainer

Isolation

Valves

Outlet

P

Drain

Vibration

Eliminators

Flow

Switch

NOTE: Water piping must be supported independently from the unit.

System Water Volume

It is important to have adequate water volume in the system to provide an opportunity for the chiller

to sense a load change, adjust to the change, and then stabilize. As the expected load change becomes

more rapid, a greater water volume is needed. The system water volume is the total amount of water

in the evaporator, air handling equipment, and associated piping. If the water volume is too low,

operational problems can occur including rapid compressor cycling, rapid loading and unloading of

compressors, erratic refrigerant flow in the chiller, improper motor cooling, shortened equipment life

and other undesirable occurrences.

For normal comfort cooling applications where the cooling load changes relatively slowly, we

recommend a minimum system volume of four minutes times the flow rate (GPM). For example, if

the design chiller flow rate is 120 gpm, we recommend a minimum system volume of 480 gallons

(120 gpm x 4 minutes).

For process applications where the cooling load can change rapidly, additional system water volume

is needed. A process example would be the quenching of hot metal objects. The load would be very

stable until the hot metal is dipped into the water tank. Then, the load would increase drastically.

Since there are many other factors that can influence performance, systems can successfully operate

below these suggestions. However, as the water volume decreases below these guidelines, the

possibility of problems increases.

Variable Chilled Water Flow

Reducing chilled water flow in proportion to load can reduce total system power consumption.

Certain restrictions apply to the amount and rate of flow change. The rate of flow change should be a

maximum of 10 percent of the change, per minute. Do not reduce flow lower than the minimum

flows listed in the pressure drop data on page 15.

Chilled Water Piping

The system water piping must be flushed thoroughly prior to making connections to the unit

evaporator. It is required that a 1.0 mm (16 to 20 mesh) strainer be installed in the return water line

before the inlet to the chiller. Lay out the water piping so the chilled water circulating pump

discharges into the evaporator inlet.

The return water line must be piped to the evaporator inlet connection and the supply water line must

be piped to the evaporator outlet connection. If the evaporator water is piped in the reverse direction,

a substantial decrease in capacity and efficiency of the unit will be experienced.

A flow switch must be installed in the horizontal piping of the supply (evaporator outlet) water line to

prove water flow before starting the unit.

10 WGZ 030A through 100A IOMM WGZ-1

Page 11

g

Drain connections should be provided at all low points in the system to permit complete drainage of

the system. Air vents should be located at the high points in the system to purge air out of the system.

The evaporators are not equipped with vent or drain connections and provision must be made in the

entering and leaving chilled water piping for venting and draining.

Pressure gauges should be installed in the inlet and outlet water lines to the evaporator. Pressure drop

through the evaporator should be measured to determine water flow from the flow/pressure drop

curves on page 15. Vibration eliminators are recommended in both the supply and return water lines.

Chilled water piping should be insulated to reduce heat loss and prevent condensation. Complete unit

and system leak tests should be performed prior to insulating the water piping. Insulation with a

vapor barrier would be the recommended type of insulation. If the vessel is insulated, the vent and

drain connections must extend beyond the proposed insulation thickness for accessibility.

Chillers not run in the winter should have their water systems thoroughly drained if subje ct to subfreezing temperatures. If the chiller operates year-round, or if the system is not drained for the winter,

the chilled water piping exposed to sub-freezing ambient temperatures should be protected against

freezing by wrapping the lines with a heater cable. In addition, an adequate percentage of glycol

should be added to the system to further protect the system during low ambient temperature periods.

It should be noted that water piping that has been left drained is subject to more corrosion than if

filled with water. Use of a Vapor Corrosion Inhibitor (VCI) or some other protection should be

considered.

Chilled Water Sensor

Figure 6, Thermostat Well Location

Suction

Circuit #1

Suction

Circuit #2

Leavin

Chilled

Water Sensor

The chilled water sensor is factory installed in the

leaving water connection on the evaporator. Care

should be taken not to damage the sensor cable or

lead wires when working around the unit. It is

also advisable to check the lead wire before

running the unit to be sure that it is firmly

anchored and not rubbing on the frame or any

Liquid

Circuit #2

Liquid

Circuit #1

other component. If the sensor is ever removed

from the well for servicing, care must be taken to

not wipe off the heat-conducting compound

supplied in the well.

CAUTION

The thermostat bulb should not be exposed to water temperatures above 125°F

(51.7°C) since this will damage it.

Flow Switch

A water flow switch must be mounted in the leaving evaporator and condenser water line to prove

adequate water flow before the unit can start. This will safeguard against slugging the compressors

on start-up. It also serves to shut down the unit in the event that water flow is interrupted to guard

against evaporator freeze-up.

A flow switch is available from McQuay under part number 01750330. It is a “paddle” type switch

and adaptable to any pipe size from 1 in. (25 mm) to 6 in. (152 mm) nominal. Certain minimum flow

rates are required to close the switch and are listed in Table 5. Electrical connections in the unit

control center should be made at terminals 33 and 43 (chilled water) and 41 and 53 (condenser

water). The normally open contacts of the flow switch should be wired between these two terminals.

There is also a set of normally closed contacts on the switch that could be used for an indicator light

or an alarm to indicate when a “no flow” condition exists.

IOMM WGZ-1 WGZ 030A through 100A 11

Page 12

1. Apply pipe sealing compound to only the threads of the switch and screw unit into 1 in. (25 mm)

T

reducing tee. The flow arrow must be pointed in the correct direction.

2. Piping should provide a straight length before and after the flow switch of at least five times the

pipe diameter without any valves, elbows, or other flow restricting elements.

3. Trim flow switch paddle if needed to fit the pipe diameter. Make sure paddle does not hang up in

pipe.

CAUTION

Make sure the arrow on the side of the switch is pointed in the direction of flow. The

flow switch is designed to handle the control voltage and should be connected

according to the wiring diagram (see wiring diagram inside control box door).

Incorrect installation will cause improper operation and possible evaporator damage.

Table 5, Flow Switch Flow Rates

Pipe Size

Minimum

Adjustment

Maximum

Adjustment

Flow

No

Flow

Flow

No

Flow

inch 2 2 1/2 3 4 5 6

mm 51 63 76 102 (125) (150)

gpm 13.7 17.9 24.2 35.3 48.6 60.3

Lpm 51.8 67.8 91.6 134.0 184.0 228.0

gpm 9.4 12.1 16.4 27.0 37.4 46.8

Lpm 35.6 45.8 62.1 102.0 142.0 177.0

gpm 56.4 71.3 89.0 118.0 178.0 245.0

Lpm 214.0 270.0 337.0 446.0 674.0 927.0

gpm 47.4 59.2 72.5 105.0 160.0 225.0

Lpm 179.0 224.0 274.0 397.0 606.0 852.0

Glycol Solutions

When using a glycol solution, the chiller capacity, flow rate, evaporator pressure drop, and chiller

power input can be calculated using the following formulas and reference to Table 6 for ethylene

glycol and Table 7 for propylene glycol.

1. Capacity, Capacity is reduced compared to that with plain water. To find the reduced value,

multiply the chiller’s capacity when using water by the capacity correction factor C to find the

chiller’s capacity when using glycol.

2. Flow, To determine evaporator gpm (or ∆T) knowing ∆T (or gpm) and capacity:

GPMGlycol

24

=

For Metric Applications -- Determine evaporator lps (or ∆T) knowing ∆T (or lps) and kW:

LpsGlycol

3.

Pressure Drop, To determine glycol pressure drop through the cooler, enter the water p ressure

kW

=

∆

18.4

drop graph on page 15 at the actual glycol flow. Multiply the water pressure drop found there by

P to obtain corrected glycol pressure drop.

4.

Power, To determine glycol system kW, multiply the water system kW by factor K.

CapacityGlycolx

∆

TablesfromGCorrectionFlowx

Tx

TablesFromGCorrectionFlowx

Test coolant with a clean, accurate, glycol solution hydrometer (similar to that found in service

stations) to determine the freezing point. Obtain percent glycol from the freezing point found in

Table 6 or Table 7. On glycol applications the supplier normally recommends that a minimum of

25% solution by weight be used for protection against corrosion or the use of additional inhibitors.

12 WGZ 030A through 100A IOMM WGZ-1

Page 13

Note: The effect of glycol in the condenser is negligible. As glycol increases in temperature,

its characteristics have a tendency to mirror those of water. Therefore, for selection

purposes, there is no derate in capacity for glycol in the condenser.

Table 6, Ethylene Glycol

Glycol

10 26 -3 0.991 0.996 1.013 1.070

20 18 -8 0.982 0.992 1.040 1.129

30 7 -14 0.972 0.986 1.074 1.181

40 -7 -22 0.961 0.976 1.121 1.263

50 -28 -33 0.946 0.966 1.178 1.308

Freezing Point Percent

°F °C

C (Capacity) K (Power) G (Flow)

P (Pressure

Drop)

Table 7, Propylene Glycol

Glycol

10 26 -3 0.987 0.992 1.010 1.068

20 19 -7 0.975 0.985 1.028 1.147

30 9 -13 0.962 0.978 1.050 1.248

40 -5 -21 0.946 0.971 1.078 1.366

50 -27 -33 0.929 0.965 1.116 1.481

Freezing Point Percent

°F °C

C (Capacity) K (Power) G (Flow)

P (Pressure

Drop)

CAUTION

Do not use automotive grade antifreeze. Industrial grade glycols must be used.

Automotive antifreeze contains inhibitors which cause plating on copper tubes. The

type and handling of glycol used must be c onsistent with local codes.

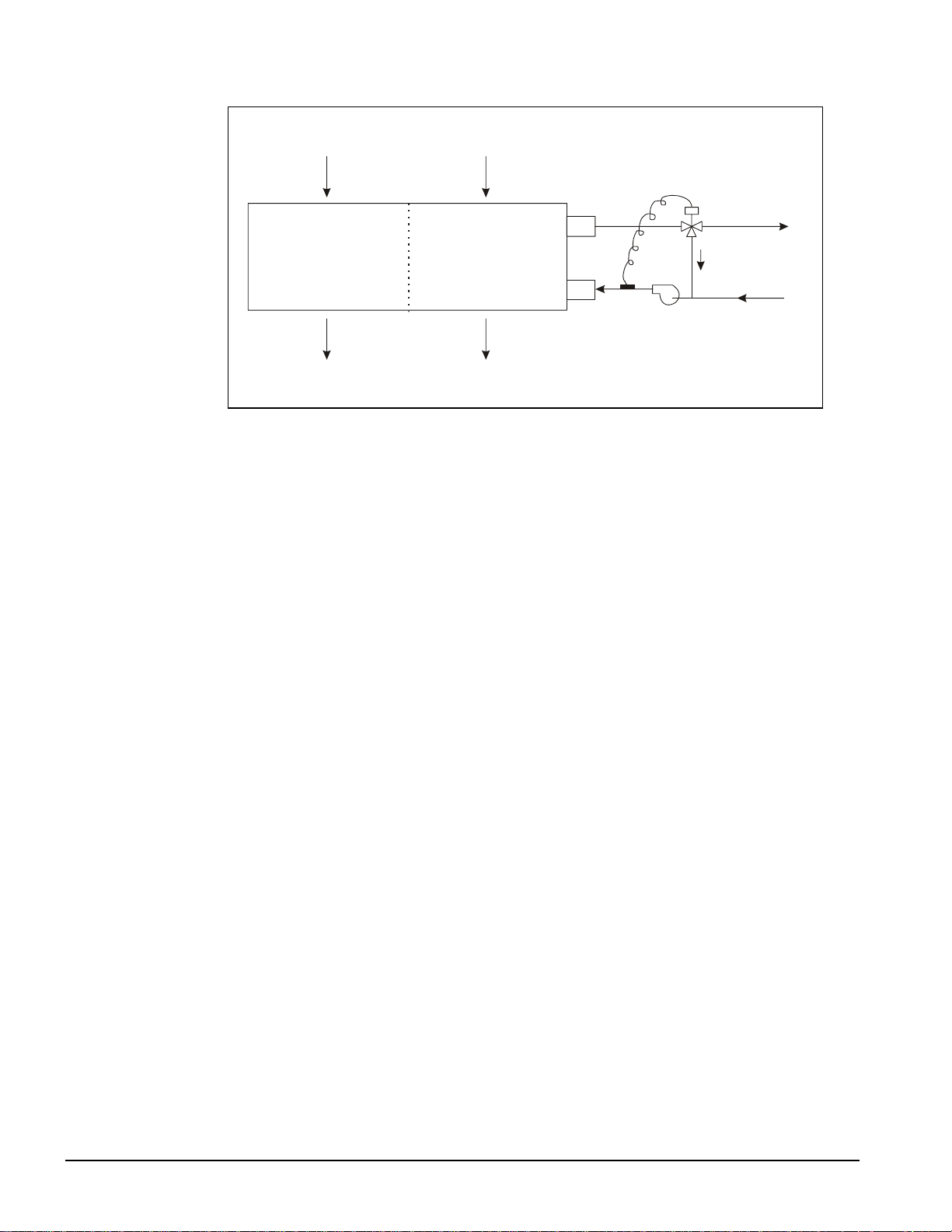

Condenser Water Piping

Arrange the condenser water so the water enters the bottom connection of the condenser. The

condenser water will discharge from the top connection. Failing to arrange the condenser water as

stated above will negatively affect the capacity and efficiency.

Pressure gauges should be installed in the inlet and outlet water lines to the condenser. Pr essure drop

through the c ondenser should be measured to determine flo w on the pressure drop/flow curves on

page 16. Vibration eliminators are recommended in both the supply and return water lines.

Water-cooled condensers can be piped for use with cooling towers, well water, or heat recovery

applications. Cooling tower applications should be made with consideration of freeze protection and

scaling problems. Contact the cooling tower manufacturer for equipment characteristics and

limitations for the specific application.

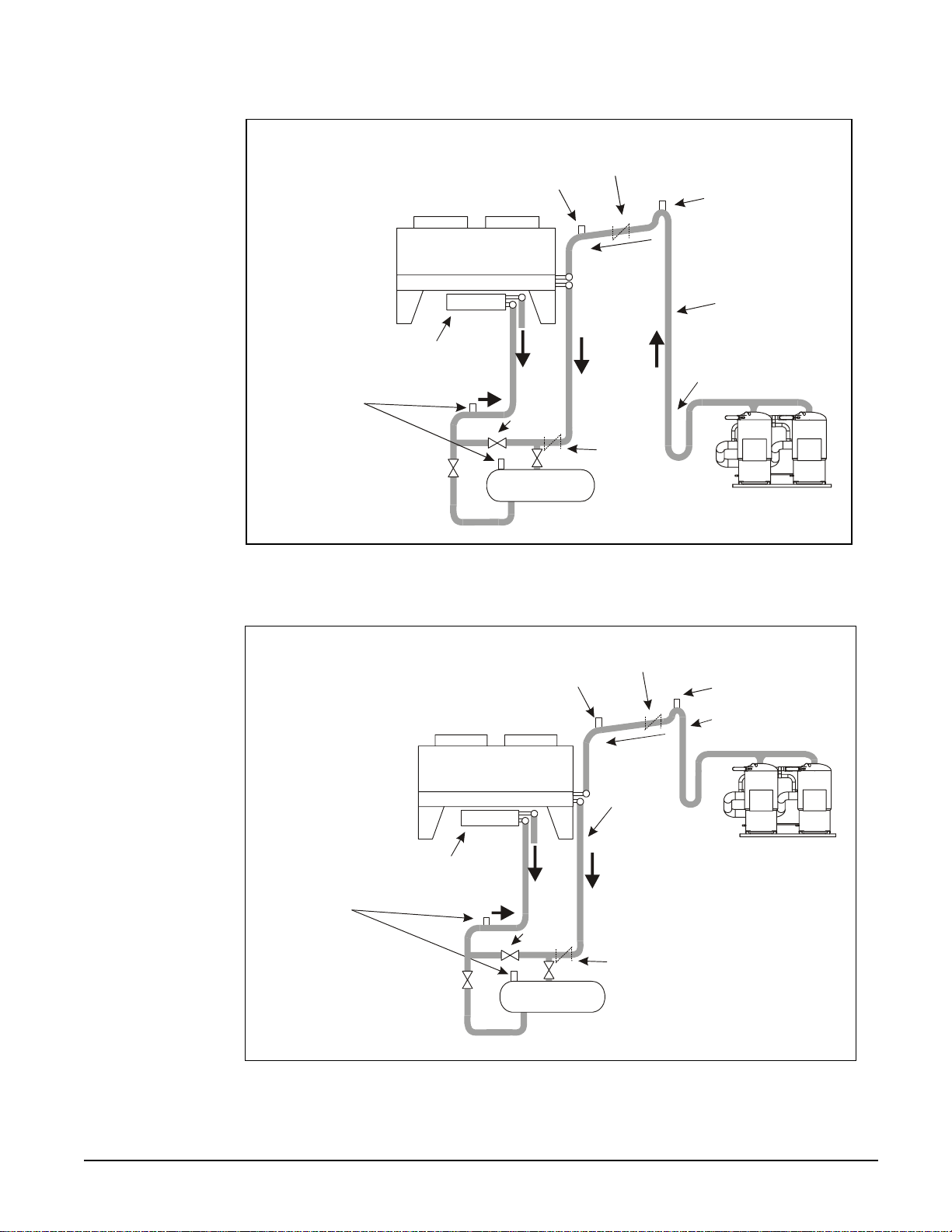

Head pressure control must be provided if the entering condenser water can fall below 60°F. T h e

WGZ condenser has two refrigerant circuits with a common condenser water circuit. This

arrangement makes head pressure control with discharge pressure actuated control valves difficult.

If for some reason the tower water temperature cannot be maintained at a 60°F minimum, or whe n

pond, lake, or well water that can fall below 60°F (15°C) is used as the condensing medium, special

discharge pressure control must be used. A water recirculating system with recirculating pump as

shown in Figure 7 is recommended. This system also has the advantage of maintaining tube velocity

to help prevent tube fouling. The pump should cycle with the chiller.

IOMM WGZ-1 WGZ 030A through 100A 13

Page 14

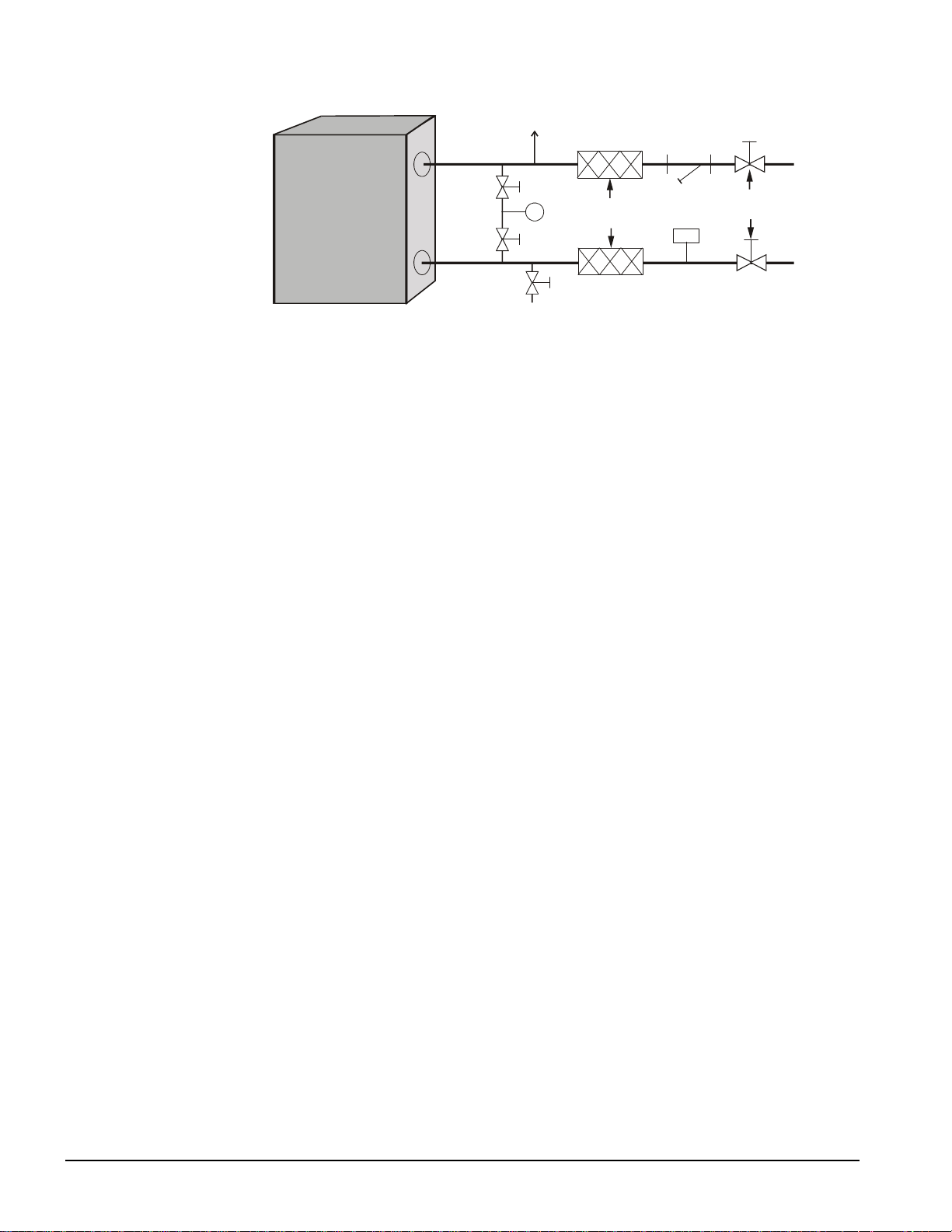

Figure 7, Recirculating Discharge Pressure Control System

Circuit #1

Inlet

Circuit #2

Inlet

Condenser

Temperature

Control

Valve

Condenser

Water

Circuit #1

Outlet

Circuit #2

Outlet

Water Pressure Drop

The vessel flow rates must fall between the minimum and maximum values shown on the appropriate

evaporator and condenser curves. Flow rates below the minimum values shown will result in laminar

flow that will reduce efficiency, cause erratic operation of the electronic expansion valve and could

cause low temperature cutoffs. On the other hand, flow rates exceeding the maximum values shown

can cause erosion in the evaporator.

Measure the chilled water pressure d rop through the evaporator at fie ld-installed pressure ta ps. It is

important not to include valves or strainers in these readings.

14 WGZ 030A through 100A IOMM WGZ-1

Page 15

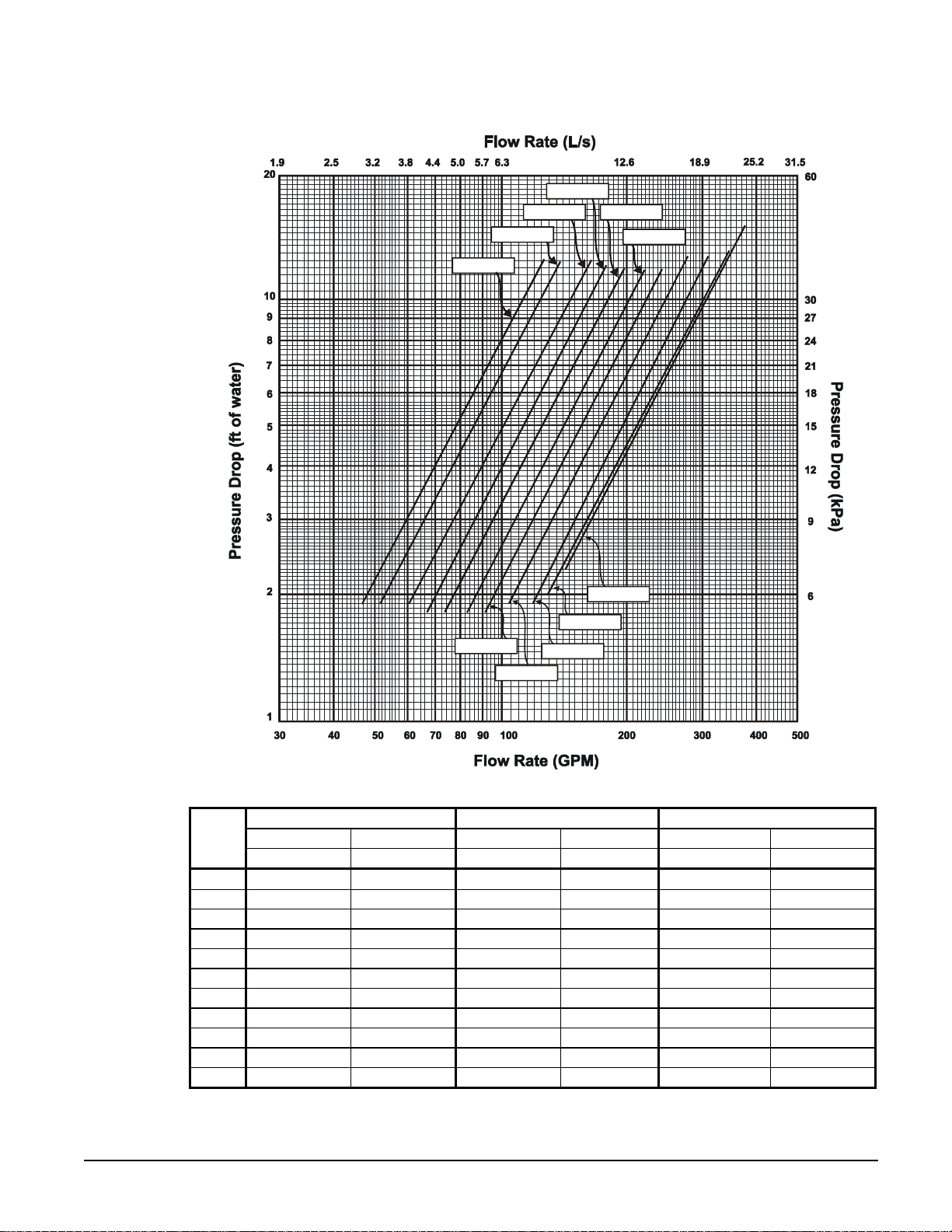

Figure 8, Evaporator Water Pressure Drop, WGZ 030A through 100A

WGZ 045

WGZ 040

WGZ 035

WGZ 030

WGZ 050

WGZ 055

WGZ 100

WGZ 090

WGZ 060

WGZ 080

WGZ 070

WGZ

Model

gpm L/s Ft. kPa gpm L/s Ft. kPa gpm L/s Ft. kPa

030 47.0 3.0 1.6 4.8 75.2 4.7 3.9 11.7 125.3 7.9 10.9 32.4

035 51.9 3.3 1.6 4.8 83.1 5.2 3.9 11.7 138.5 8.7 11.1 33.0

040 60.1 3.8 1.8 5.5 96.2 6.1 4.2 12.4 160.4 10.1 12.0 35.8

045 66.9 4.2 1.8 5.5 107.0 6.8 4.2 12.4 178.4 11.3 11.8 35.1

050 73.6 4.6 1.8 5.5 117.8 7.4 4.6 13.8 196.3 12.4 12.0 35.8

055 82.3 5.2 2.1 6.2 131.7 8.3 4.2 12.4 219.5 13.9 11.8 35.1

060 91.0 5.7 2.1 6.2 145.6 9.2 4.2 12.4 242.7 15.3 12.9 38.5

070 104.1 6.6 1.8 5.5 166.6 10.5 4.4 13.1 277.7 17.5 12.2 36.5

080 115.9 7.3 1.8 5.5 185.4 11.7 4.4 13.1 309.1 19.5 12.2 36.5

090 129.2 8.1 1.8 5.5 206.6 13.0 4.2 12.4 344.4 21.7 11.8 35.1

100 142.4 9.0 1.8 5.5 227.8 14.4 4.9 14.5 379.7 24.0 13.4 39.9

Minimum Flow Nominal Flow Maximum Flow

Flow Rate Pressure Drop Flow Rate Pressure Drop Flow Rate Pressure Drop

Note : Mi ni mum, no mina l , a nd max imu m fl ows ar e a t a 1 6°F, 10°F, and 6°F chilled water temperature range

respectively, and at ARI tons.

IOMM WGZ-1 WGZ 030A through 100A 15

Page 16

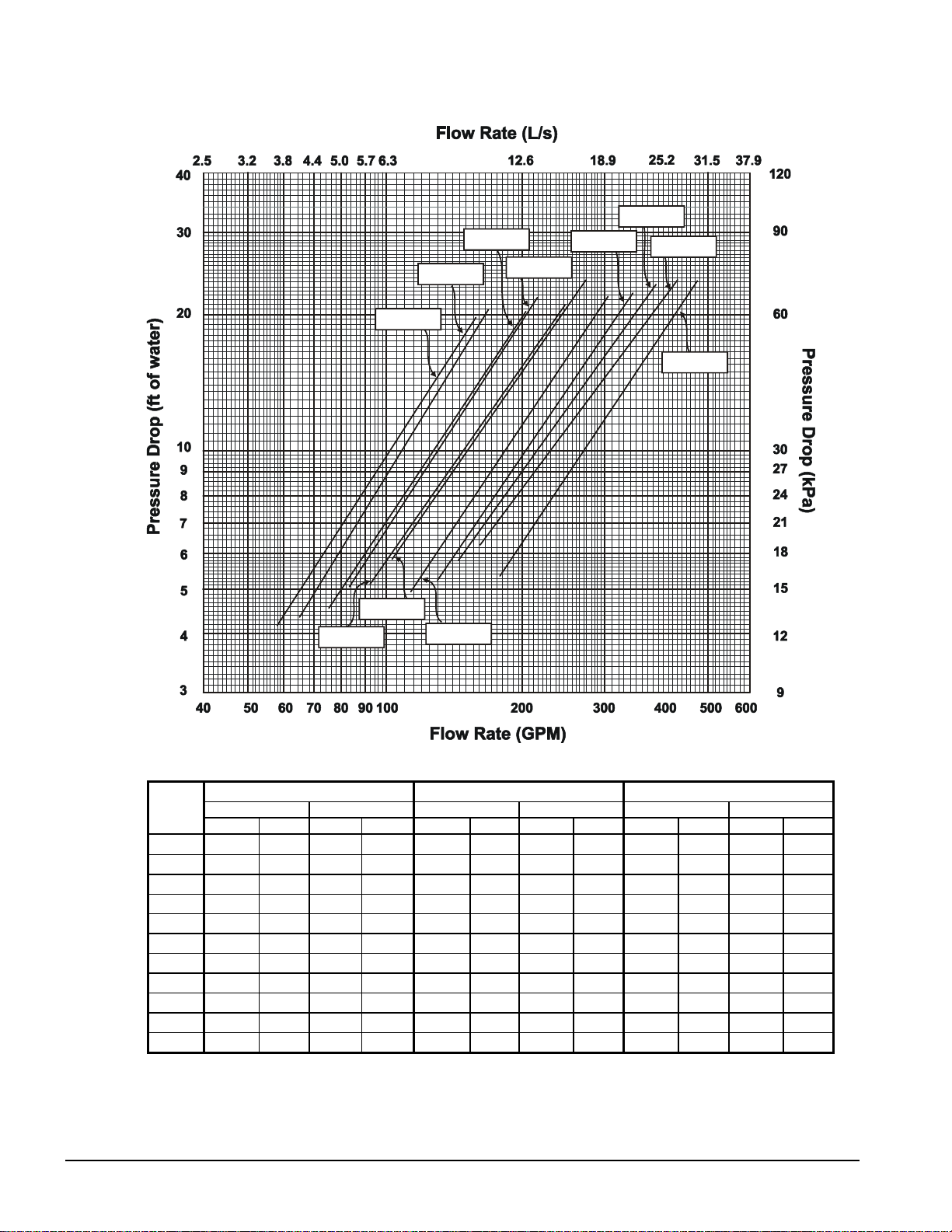

Figure 9, Condenser Water Pressure Drop, WGZ 030AW through 100AW

WGZ 080

WGZ 035

WGZ 030

WGZ 040

WGZ 045

WGZ 070

WGZ 090

WGZ 100

WGZ 055

WGZ 050

WGZ 060

WGZ

Model

030 58.7 3.8 4.2 12.5 94.0 6.0 8.6 25.8 156.6 10.0 20.0 59.9

035 64.9 4.2 4.4 13.1 103.8 6.6 8.9 26.6 173.1 11.1 20.4 61.2

040 75.2 4.8 4.6 13.7 120.3 7.7 9.0 26.9 200.5 12.8 20.2 60.7

045 83.6 5.4 5.0 15.1 133.8 8.6 9.7 29.1 223.0 14.3 21.7 65.0

050 92.0 5.9 5.1 15.3 147.3 9.4 9.5 28.6 245.4 15.7 20.8 62.5

055 102.9 6.6 5.9 17.6 164.6 10.5 10.7 32.0 274.4 17.6 23.1 69.2

060 113.8 7.3 5.0 14.9 182.0 11.6 9.7 29.2 303.3 19.4 21.9 65.9

070 130.2 8.3 5.3 15.8 208.3 13.3 10.0 30.0 347.2 22.2 22.0 66.1

080 144.9 9.3 5.8 17.4 231.8 14.8 10.7 32.1 386.4 24.7 23.2 69.6

090 161.4 10.3 6.2 18.7 258.3 16.5 11.1 33.2 430.5 27.6 23.4 70.2

100 178.0 11.4 5.4 16.1 284.8 18.2 10.1 30.4 474.7 30.4 22.4 67.1

gpm L/s Ft. kPa gpm L/s Ft. kPa gpm L/s Ft. kPa

Minimum Flow Nominal Flow Maximum Flow

Flow Rate Pressure Drop Flow Rate Pressure Drop Flow Rate Press ure Drop

16 WGZ 030A through 100A IOMM WGZ-1

Page 17

Refrigerant Piping

Unit with Remote Condenser

General

For remote condenser application (WGZ-AA) such as air-cooled or evaporative condenser, the

chillers are shipped with an R-22 holding charge. It is important that the unit be kept tightly closed

until the remote condenser is installed, piped to the unit and the high side evacuated.

Refrigerant piping, to and from the unit, should be sized and installed according to the latest

ASHRAE Handbook. It is important that the unit piping be properly supported with sound and

vibration isolation between tubing and hanger, and that the discharge lines be looped at the condenser

and trapped at the compressor to prevent refrigerant and oil from draining into the compressors.

Looping the discharge line also provides greater line flexibility.

The discharge gas valves, liquid line solenoids, filter-driers, moisture indicators, and thermostatic

expansion valves are all factory mounted as standard equipment with the water chiller.

A liquid line shutoff valve must be added in the field on remote condenser units between the liquid

line filter-drier and remote condenser.

After the equipment is properly installed, leak tested, and evacuated, it can be charged with R-22, and

run at design load conditions. Add charge until the liquid line sight glass is clear, with no bubbles

flowing to the expansion valve. Total operating charge will depend on the air-cooled condenser used

and volume of the refrigerant piping.

Note: On the arrangement WGZ-AA units (units with remote condensers), the installer is

required to record the refrigerant charge by stamping the total charge and the charge per

circuit on the serial plate in the appropriate blocks provided for this purpose.

The following discussion is intended for use as a general guide to the piping of air-cooled condensers.

Discharge lines must be designed to handle oil properly and to protect the compressor from damage

that can result from condensing liquid refrigerant in the line during shutdown. Total friction loss for

discharge lines of 3 to 6 psi (20.7 to 41.4 kPa) is considered good design. Careful consideration must

be given for sizing each section of piping to insure that gas velocities are sufficient at all operating

conditions to carry oil. If the velocity in a vertical discharge riser is too low, co nsiderable oil can

collect in the riser and the horizontal header, causing the compressor to lose its oil and result in

damage due to lack of lubrication. When the compressor load is increased, the oil that had collected

during reduc ed lo ad s ca n b e ca rr ie d a s a slug t hro ugh the system and ba ck t o t he c ompr esso r, where a

sudden increas e of oil concentration can cause liquid slugging and da mage to the compressor.

Any horizontal run of discharge piping should be pitched away from the compressor approximately

1/8 inch (6.4 mm) per foot (meter) or more. This is necessary to move, by gravity, any oil lying in the

header. Oil pockets must be avoided because oil needed in the compressor would collect at such

points and the compressor crankcase can become starved.

It is recommended that any discharge lines coming into a horizontal discharge header rise above the

centerline of the discharge header. This is necessary to prevent any oil or condensed liquid from

draining to the compressor head s when the compressor is not running.

IOMM WGZ-1 WGZ 030A through 100A 17

Page 18

In designing liquid lines, it is important that the liquid reach the expansion valve without flash gas

since this gas will reduce the capacity of the valve. Because “flashing” can be caused by a pressure

drop in the liquid line, the pressure losses due to friction and changes in static head should be kept to

a minimum.

A check valve must be installed in the liquid line in all applications where the ambient temperature

can drop below the equipment room temperature. This prevents liquid migration to the condenser,

helps maintain a supply of refrigerant in the liquid line for initial start-up, and keeps liquid line

pressure high enough on “off” cycle to keep the expansio n valve closed.

On systems as described above, a relief valve or relief-type check valve, must be used in the liquid

line as shown in piping systems (shown in Figure 11) to relieve dangerous hydraulic pre ssures that

could be created as cool liquid refrigerant in the line between the check valve and the expansion or

shutoff valve warms up. A relief device is also recommended in the hot gas piping at the condenser

coil as shown in Figure 10 and Figure 11.

T y pical A rrangement s

Figure 10 illustrates a typical piping arrangement involving a remote air-cooled condenser located at

a higher elevation than the compressor and receiver. This arrangement is commonly encountered

when the air-cooled condenser is on a roof and the compressor and receiver are on grade level or in a

basement equipment room.

Notice, in both illustrations, that the hot gas line is looped at the bottom and top of the vertical run.

This is done to prevent oil and condensed refrigerant from flowing back into the compressor and

causing damage. The hi ghest point i n the discharge line should always be above t he highest point in

the condenser coil. It is advisable to include a purging vent at this point to extract non-condensables

from the system.

Figure 11 illustrates another very common application where the air-cooled condenser is located on

essentially the same level as the compressor and receiver. The discharge line piping in this case is not

too critical. The principal problem encountered with this arrangement is that there is frequently

insufficient vertical distance to allow free drainage of liquid refrigerant from the condenser coil to the

receiver.

The receiver is used when it is desired to have refrigerant storage capacity, in addition to the

pumpdown capability of the condenser.

18 WGZ 030A through 100A IOMM WGZ-1

Page 19

Figure 10, Condenser Above Compressor and Receiver

Check Valve

(Preferred)

Relief Valve

Purge Valve

Relief Valve

(Vent to Outdoors

Condenser

Preferred

Subcooler

Hook-up

Subcooler

To

Evap.

c

t

Pi

or to Condenser Side

of Liquid Line

Check Valve)

Receiver

Bypass

Check

Valve

Receiver

Figure 11, Condenser and Compressor on Same Level

Check Valve

(Preferred)

Relief Valve

h

Discharge Line

Loop

Purge Valve

Relief V a l v e

(Vent to Outdoors

or to Condenser Side

of Liquid Line

Check Valve)

Condenser

Preferred

Subcooler

Hook-up

Subcooler

To

Evap.

Receiver

Bypass

Receiver

i

P

Check

Valve

Check

Valve

Discharge Line

h

c

t

IOMM WGZ-1 WGZ 030A through 100A 19

Page 20

Factory-Mounted Condenser

Units with the standard water-cooled, factory-mounted condenser are provided with complete

refrigerant piping and full operating refrigerant charge at the factory.

There is a remote possibility on water-cooled units utilizing low temperature pond or river water as a

condensing medium, and if the water valves leak, that the condenser and liquid line refrigerant

temperature could drop below the equipment room temperature on the “off” cycle. This problem only

arises during periods when cold water continues to circulate through the condenser and the unit

remains off due to satisfied cooling load.

If this condition occurs:

1. Cycle the condenser pump off with the unit.

2. Check the liquid line solenoid valve for proper operation.

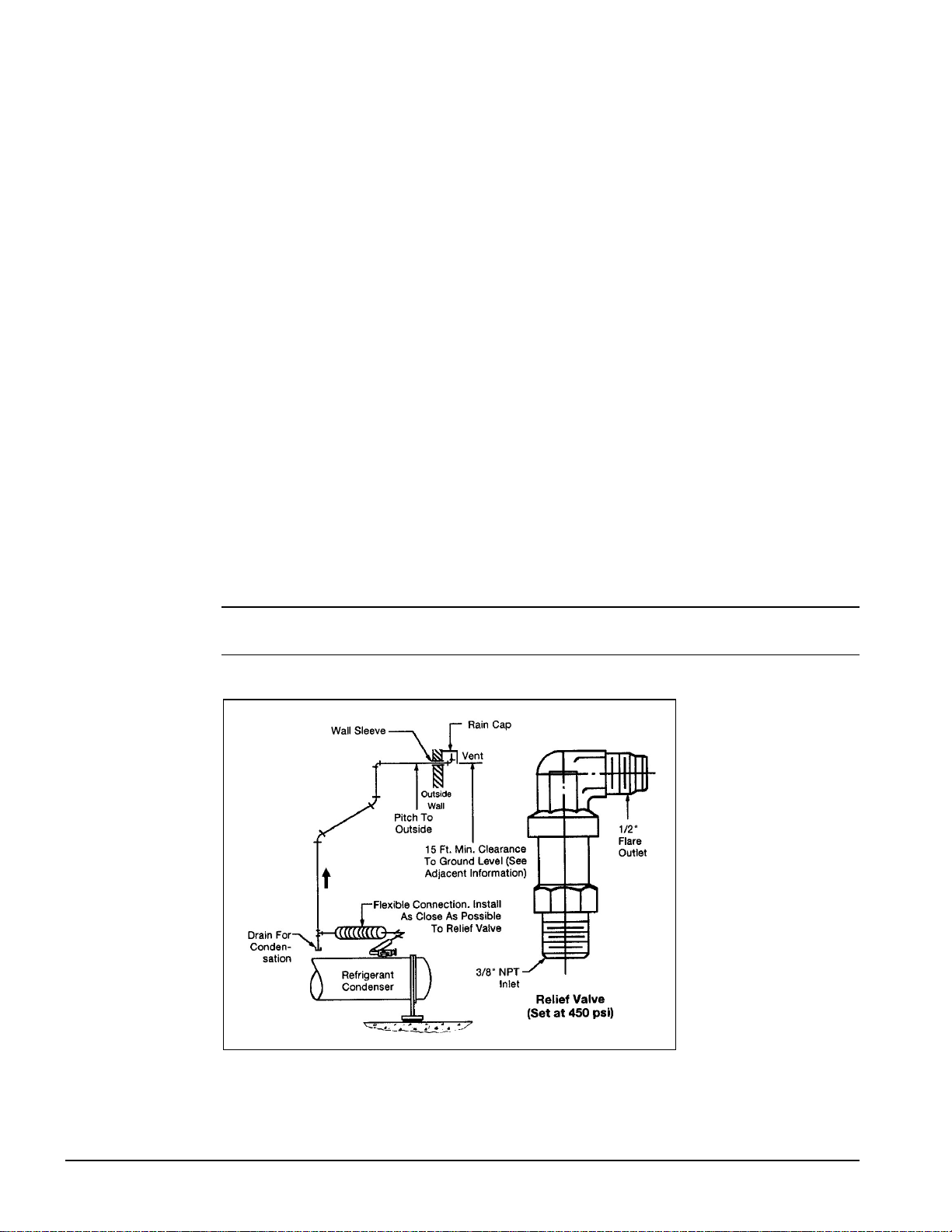

Relief Valve Piping

The ANSI/ASHRAE Standard 15, Safety Standard for Refrigeration Systems, specifies that pressure

relief valves on vessels containing Group 1 refrigerant (R-22) “shall discharge to the atmosphere at a

location not less than 15 feet (4.6 meters) above the adjoining ground level and not less than 20 feet

(6.1 meters) from any window, ventilation opening or exit in any building.” The piping must be

provided with a rain cap at the outside terminating point and with a drain at the low point on the vent

piping to prevent water buildup on the atmospheric side of the relief valve. In addition, a flexible pipe

section should be installed in the line to eliminate any piping stress on the relief valve(s).

The size of the discharge pipe from the pressure relief valve should not be less than the size of the

pressure relief outlet. When two or more vessels are piped together, the common header and piping

to the atmosphere should not be less than the sum of the area of each of the lines connected to the

header.

NOTE: Fittings should be provided to permit vent piping to be easily disconnected for

inspection or replacement of the relief valve.

Figure 12, Relief Valve Piping

20 WGZ 030A through 100A IOMM WGZ-1

Page 21

Dimensional Data

s

WGZ-AW Water-Cooled

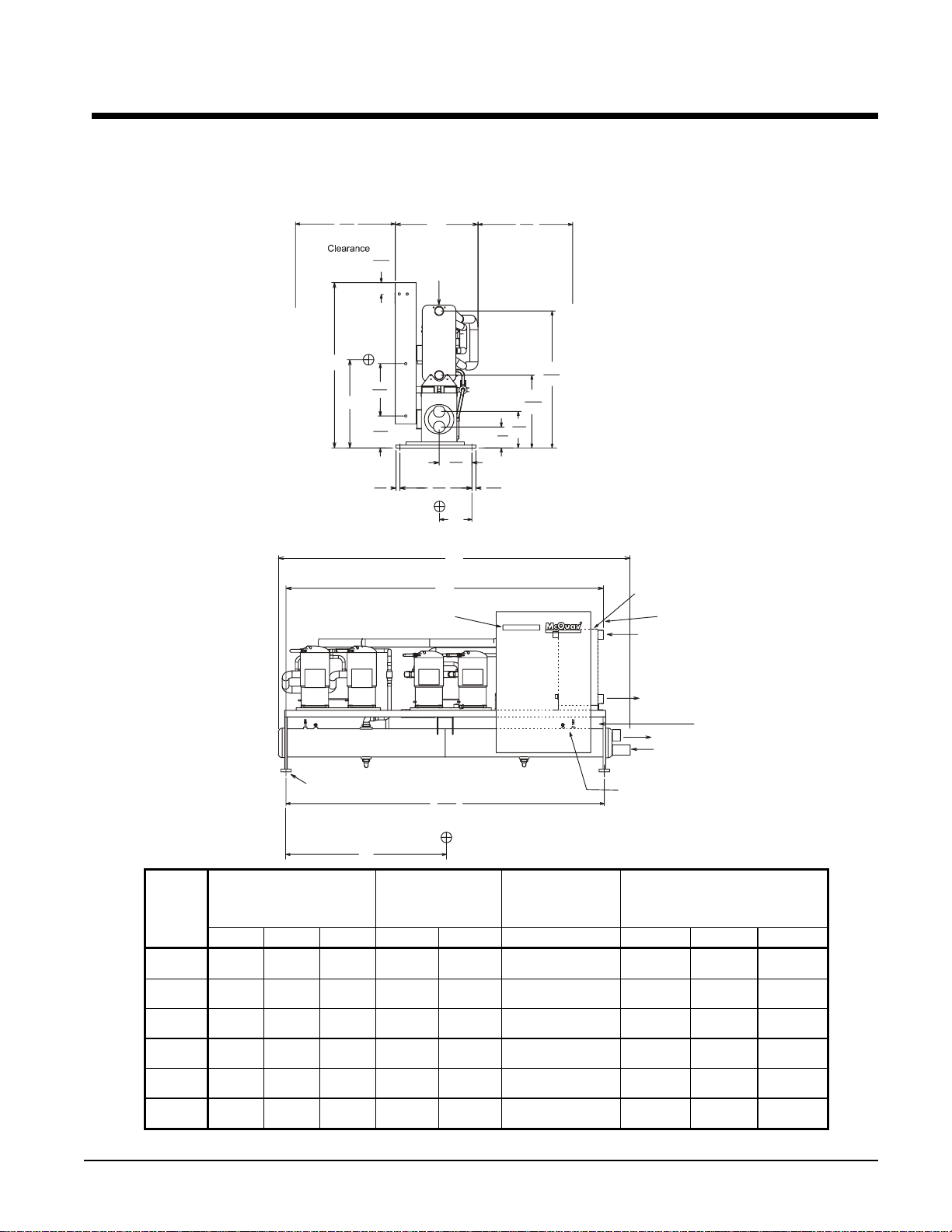

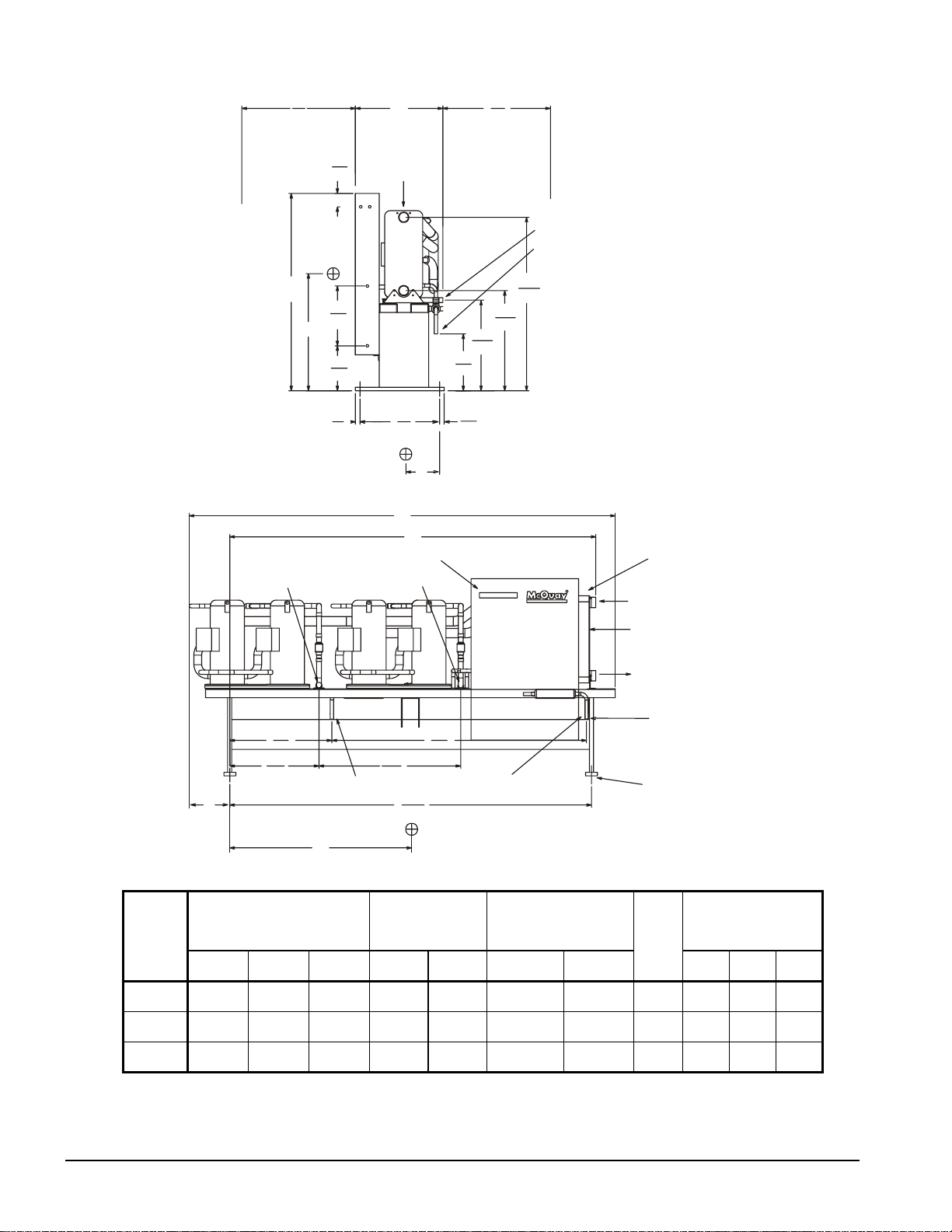

Figure 13, WGZ 030AW through WGZ 055AW

38

965

Door Swing

4.5

114

W

Evaporator

36

915

Recommended

for Servicing

H

Y

MicroTech II User Interface

(4) .875" (22 mm)

Mounting Holes

20

508

12.3

311

1.5

38

Condenser

29

711

121.4

3085

13.25

A

337

L

52.4

1331

27.8

707

14

8

354

204

1.5

38

Z

Evaporator

Control Connection

Inlet

Outlet

Power Connection

Outlet

(2) .875" (22 mm)

Inlet

Relief Valves

(1) Each End

WGZ

Model

Number

030

035

040

045

050

055

X

Maximum Overall

Dimensions

in. (mm)

Chiller Water

Connection

Victaulic, in. (mm)

Condenser Water

Connections

Victaulic, in. (mm)

Center of Gravity

in. (mm)

L W H Size A Size X Y Z

134.1

(3406)

134.1

(3406)

134.1

(3406)

134.1

(3406)

134.1

(3406)

134.1

(3406)

32

(813)

32

(813)

32

(813)

32

(813)

32

(813)

32

(813)

63.5

(1613)

63.5

(1613)

63.5

(1613)

63.5

(1613)

63.5

(1613)

63.5

(1613)

3”

(76)

3”

(76)

3”

(76)

3”

(76)

3”

(76)

3”

(76)

115.5

(2394)

116.4

(2957)

117.7

(2991)

119

(3024)

120.4

(3058)

121.1

(3075)

4”

(102)

4”

(102)

4”

(102)

4”

(102)

4”

(102)

4”

(102)

66

(1676)

66.3

(1684)

66.7

(1694)

67.1

(1704)

67.5

(1714)

66.4

(1687)

27.5

(698)

27.5

(698)

27.4

(696)

27.6

(701)

27.4

(696)

27.5

(698)

14.4

(366)

14.4

(366)

14.3

(363)

14.3

(363)

14.3

(363)

14.2

(361)

IOMM WGZ-1 WGZ 030A through 100A 21

Page 22

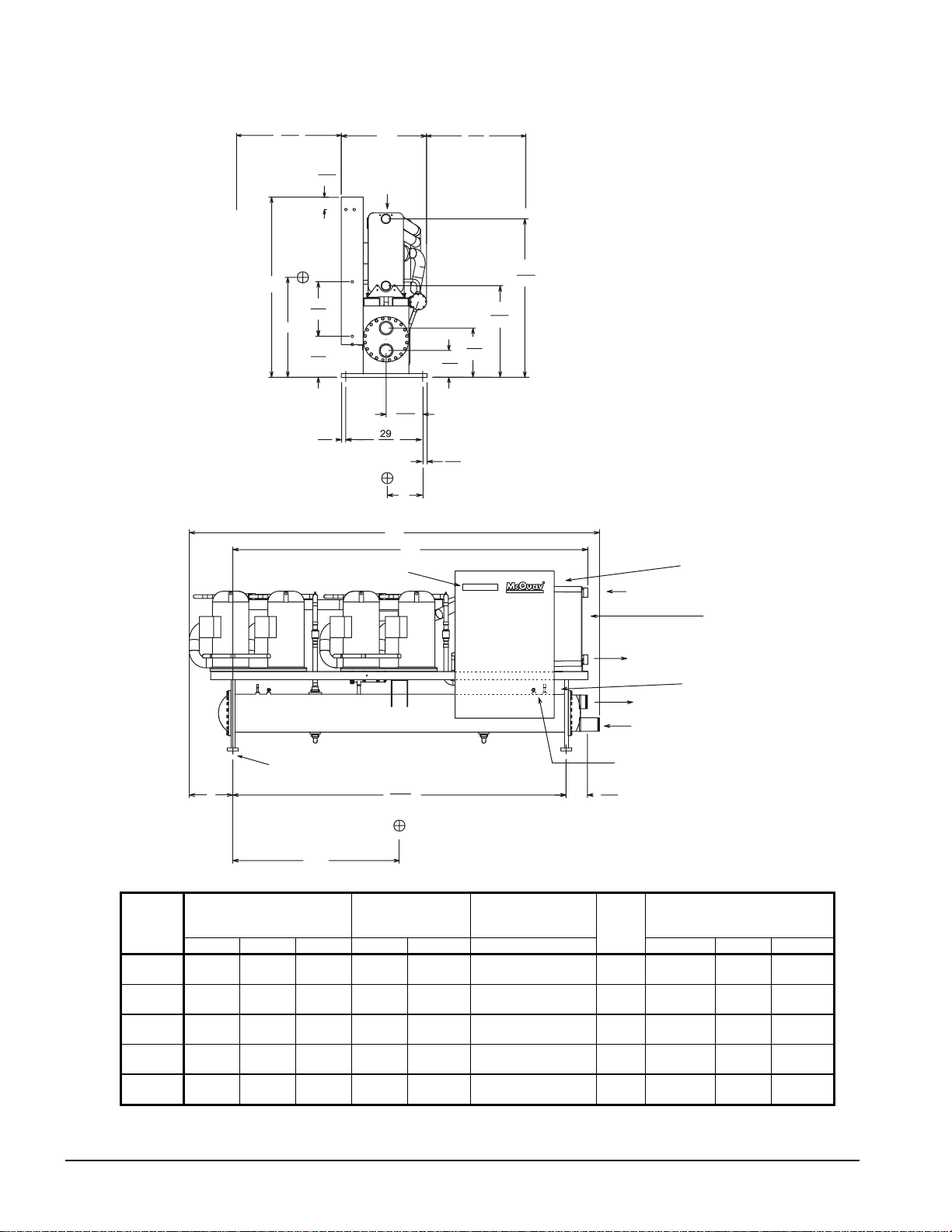

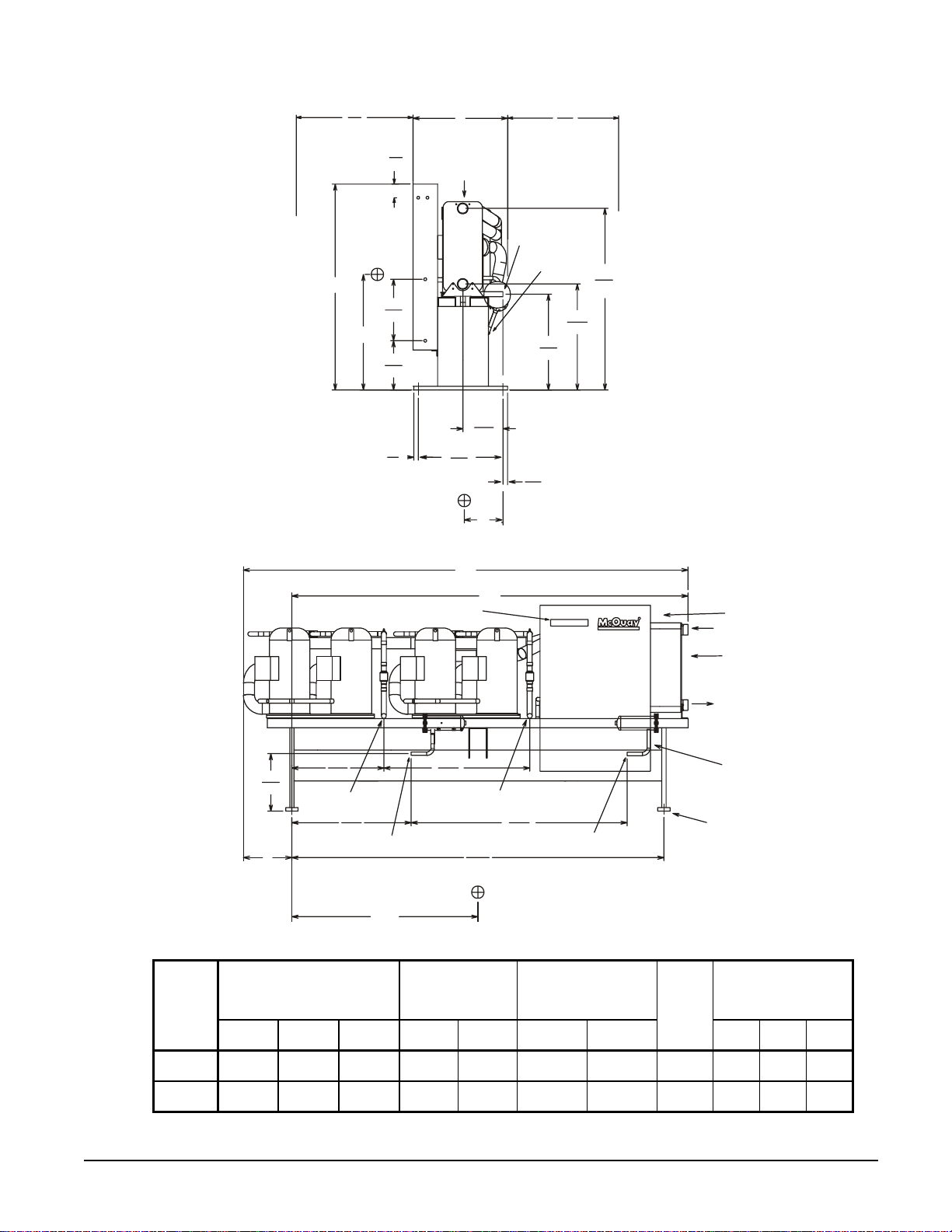

Figure 14, WGZ-060AW through WGZ-100AW

n

38

965

Door Swing

Clearance

H

4.5

114

20

508

Y

15

382

1.5

38

MicroTech II User Interface

W

Evaporator

13.25

337

737

L

Z

A

36

915

Recommended

for Servicing

18

458

9.8

248

1.5

38

33.5

852

58.1

1476

Control Connectio

Inlet

Evaporator

WGZ

Model

Number

060

070

080

090

100

Condenser

(4) .875" (22 mm)

Diameter Mounting Holes

T

X

Maximum Overall

Dimensions

in. (mm)

121.1

3075

Chiller Water

Connection

Victaulic, in. (mm)

Condenser Water

Connections

Victaulic, in. (mm)

L W H Size A Size

144.2

(3663)

146.7

(3726)

146.7

(3726)

149

(3784)

149

(3784)

32

(813)

32

(813)

32

(813)

32

(813)

32

(813)

66

(1676)

66

(1676)

66

(1676)

3

(76)

3

(76)

3

(76)

66

(1676) 3 (76)

66

(1676)

3

(76)

117.2

(2978)

118.8

(3018)

122.5

(3112)

126.6

(3216)

128.9

(3274)

5

(127)

5 (127)

5

(127)

5

(127)

5

(127)

Relief Valves

(1) Each End

7.7

196

T

11.0

(280)

12.0

(306)

12.0

(306)

15.8

(401)

15.8

9401)

Outlet

Power Connections

(2) .875" (22 mm)

Outlet

Inlet

Center of Gravity

in. (mm)

X Y Z

64.1

(1628)

63

(1600)

62.4

(1585)

62

(1575)

66.3

(1684)

31

(787)

32

(813)

32.7

(831)

33.4

(848)

33.1

(841)

13.9

(354)

13.9

(354)

13.8

(352)

13.8

(352)

13.4

(341)

22 WGZ 030A through 100A IOMM WGZ-1

Page 23

WGZ-AA Remote Condenser

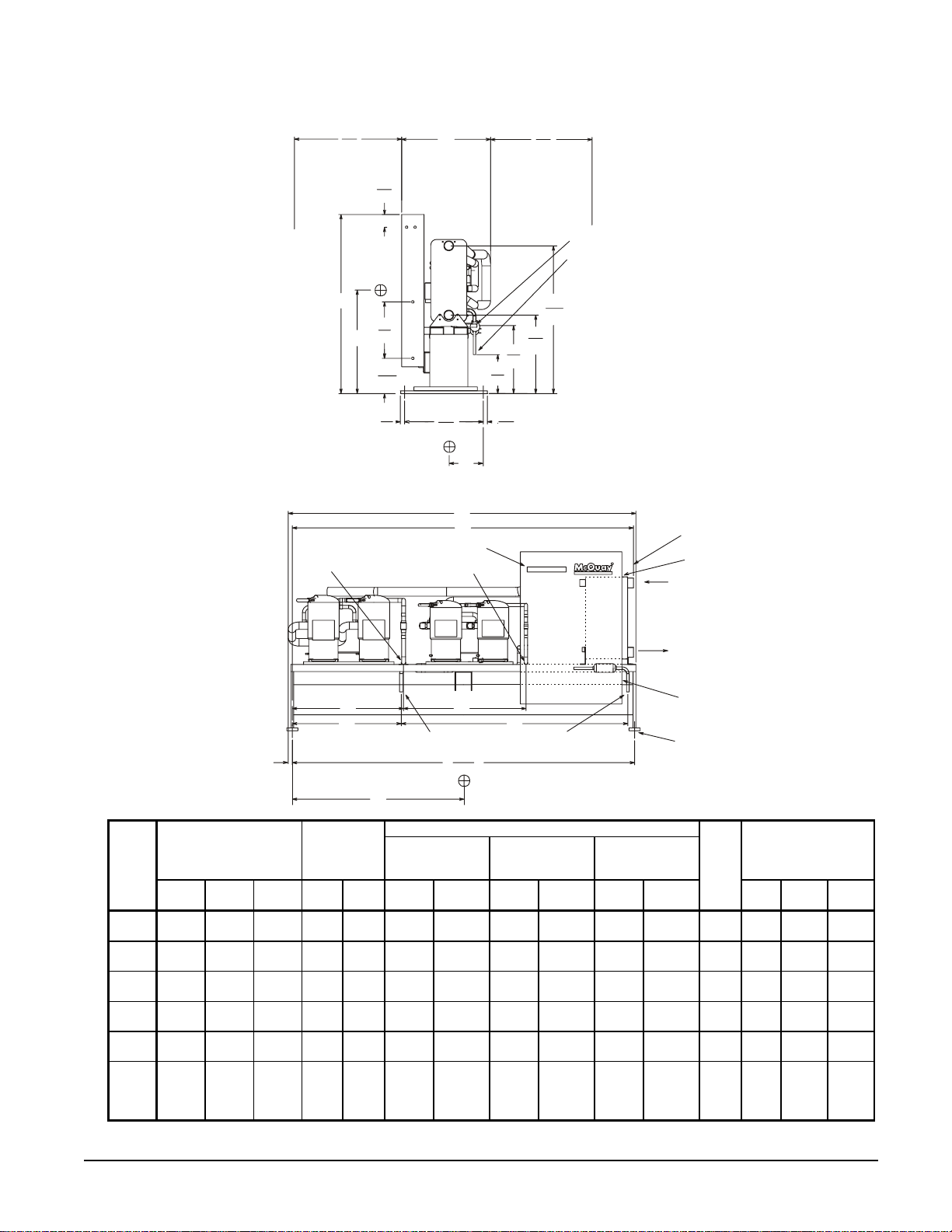

Figure 15, Dimensions, WGZ 030AA – WGZ 055AA

38

965

Door Swing

Clearance

4.5

114

H

20

508

Y

12.5

318

1.5

38

MicroTech II User Interface

"G" Disch. System #2 "G" Disch. System #1

W

29

737

Recommended

for Servicing

27.8

707

24.1

613

13.8

350

1.5

38

Z

L

A

36

915

52.4

1331

"G" Disch Conn

"E" Liquid Conn

Control Connection

Evaporator

Inlet

WGZ

Model

Number

030

035

040

045

050

055

B C

D F

T

Maximum Overall

Dimensions

in. (mm)

Chiller Water

Connection

Victaulic

in. (mm)

L W H Size A

122.4

(3109)

122.4

(3109)

122.4

(3109)

122.4

(3109)

122.4

(3109)

123.4

(3134)

32

(813)

32

(813)

32

(813)

32

(813)

32

(813)

32

(813)

63.5

(1613)

63.5

(1613)

63.5

(1613)

63.5

(1613)

63.5

(1613)

63.5

(1613)

3

(76)

3

(76)

3

(76)

3

(76)

3

(76)

3

(76)

"E" Liquid System #2 "E" Liquid System #1

121.4

3085

X

Refrigerant Connections

System #1 System #2 Connection Size

Liquid F Disch. C Liquid D Disch. B Liquid E Disch.

115.5

(2394)

116.4

(2957)

117.7

(2991)

119

(3024)

120.4

(3058)

121.1

(3075)

67

(1702)

67

(1702)

67

(1702)

67

(1702)

67

(1702)

80.2

(2037)

38.2

(970)

38.2

(970)

38.2

(970)

38.2

(970)

38.2

(970)

43.4

(1102)

52

(1320)

52

(1320)

52

(1320)

52

(1320)

52

(1320)

38.6

(980)

42.9

(1090)

42.9

(1090)

42.9

(1090)

42.9

(1090)

42.9

(1090)

39.5

(1003)

.875

(22)

.875

(22)

.875

(22)

.875

(22)

.875

(22)

.875

(22)

1.125

(29)

Outlet

Power Connections

(2) - .875 (22 mm)

(4) - .875 (22 mm)

Mounting Holes

G

1.125

(29)

1.125

(29)

1.125

(29)

1.125

(29)

1.125

(29)

1.125

(29)

1.375

(35)

T

2.9

(74)

2.9

(74)

2.9

(74)

2.9

(74)

2.9

(74)

2.9

(74)

Center of Gravity

in. (mm)

X Y Z

66.7

31.2

31.3

31.5

31.7

31.9

32

14.7

(373)

14.6

(371)

14.6

(371)

14.6

(371)

14.5

(368)

14.5

(368)

(1694)

67.3

(1709)

67.9

(1725)

68.4

(1737)

69.2

(1758)

67.8

(1722)

(792)

(795)

(800)

(805)

(810)

(813)

IOMM WGZ-1 WGZ 030A through 100A 23

Page 24

Figure 16, Dimensions WGZ 060AA – 080AA

s

38

36

965

Door Swing

Clearance

4.5

114

W

Evaporator

915

Recommended

for Servicing

"G" Disch Conn

"E" Liquid Conn

H

20

508

Y

15.1

382

1.5

38

MicroTech II User Interface

"G" Disch. System #2 "G" Disch. System #1

34.2

868

29.8

758

T

47.5

1206

29

737

L

121.1

3075

58.1

1476

33.5

852

30.3

770

19

483

1.5

38

Z

A

Control Connection

Inlet

Evaporator

Outlet

Power Connection

85.3

2166

"E" Liquid System #1"E" Liquid System #2

(2) - .875 (22mm)

(4) - .875 (22mm)

Mounting Holes

X

WGZ

MODEL

Dimensions

in. (mm)

NO.

L W H Size A

Maximum Overall

060

070

080

140

(3556)

142.5

(3620)

142.5

(3620)

32

(813)

32

(813)

32

(813)

66

(1676)

66

(1676)

66

(1676)

24 WGZ 030A through 100A IOMM WGZ-1

Evaporator Water

Connections

Victaulic

in. (mm)

3

(76)

3

(76)

3

(76)

117.2

(2978)

118.8

(3018)

122.5

(3112)

Refrigerant Connections

(OD)

in. (mm)

Liquid E Discharge

G

1.125

(29)

1.125

(29)

1.125

(29)

1.375

(35)

1.375 (35)

1.625 (41)

1.625

(41)

T

11

(280)

12

(306)

12

(306)

Center of Gravity

in. (mm)

X Y Z

64.3

(1633)

63

(1600)

64.3

(1633)

33.8

(859)

36.6

(930)

(965)

38

14.2

(362)

14.1

(359)

14.1

(359)

Page 25

Figure 17, Dimensions WGZ 090AA – 100AA

n

8

3

965

Door Swing

Clearance

H

Y

4.5

114

20

508

16

407

1.5

38

W

Evaporator

13.25

377

29

737

"G" Discharge Conn

"E" Liquid Conn

1.5

38

Z

915

Recommended

for Servicing

31.2

792

36

59.1

1501

34.5

877

WGZ

MODEL

NO.

090

100

L

17.7

450

T

MicroTech II User Interface

29.9

760

38.8

986

"E" Liquid Conn System 2

X

47.5

1206

A

"G" Discharge Conn System 1"G" Discharge Conn System 2

121.1

3075

Maximum Overall

Dimensions

in. (mm)

L W H Size A

144.75

(3667)

144.75

(3667)

32

(813)

32

(813)

66

(1676)

66

(1676)

Evaporator Water

Connections

(Victaulic)

in. (mm)

3

(76)

3

(76)

126.6

(3216)

128.9

(3274)

70.3

1785

"E" Liquid Conn System 1

Refrigerant Connections

(OD)

Liquid E Discharge

G

1.125

(29)

1.125

(29)

1.625

(41)

1.625

(41)

Control Connectio

Inlet

Evaporator

Outlet

Power Connections

(2) .875" (22 mm)

(4) .875" (22 mm)

Diameter Mounting Holes

Center of Gravity

in. (mm)

T

15.8

(401)

15.8

(401)

X Y Z

63.1

(1603)

67.5

(1715)

38.4

(975)

38.6

(980)

14.1

(359)

13.6

(346)

IOMM WGZ-1 WGZ 030A through 100A 25

Page 26

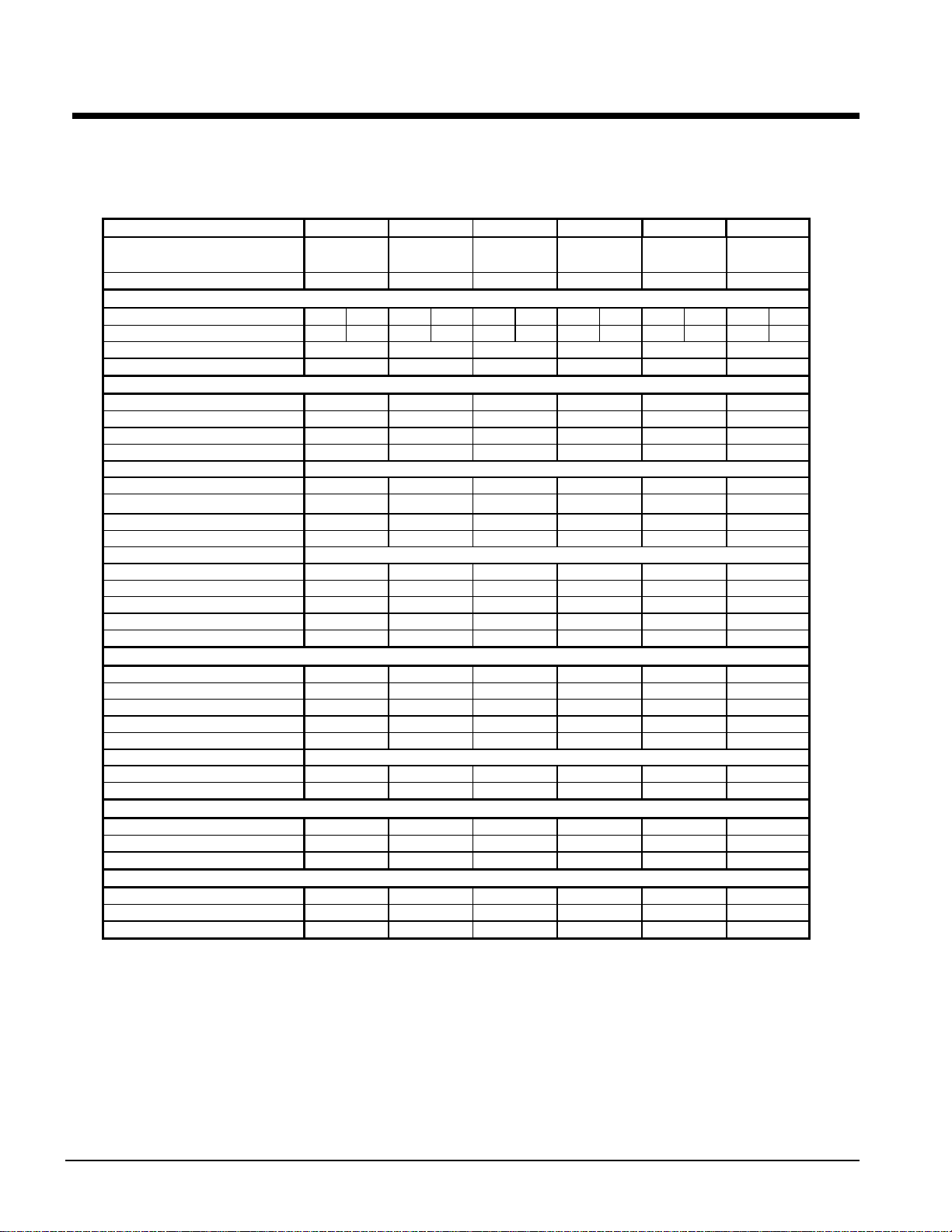

Physical Data

AW Water-Cooled

Table 8, WGZ-030AW - WGZ-055AW

WGZ UNIT SIZE 030 035 040 045 050 055

Unit capacity @ ARI condi tions

tons, (kW) (1)

No. Circuits 2 2 2 2 2 2

COMPRESSORS

Nominal Horsepower 7.5 9 9 9 10 10 13 10 13 13 13 16

Number (2) 2 2 2 2 2 2 2 2 2 2 2 2

Unloading Steps 27 / 50 / 77 25 / 50 / 75 25 / 50 / 75 28 / 50 / 78 25 / 50 / 75 27 / 50 / 77

Oil Charge per Compressor oz., (l ) 140 (4.1) 140 (4.1) 140 (4.1) 140 (4.1) 140 (4.1) 140 (4.1)

CONDENSER

Number 1 1 1 1 1 1

No. Refrigerant Circuits 2 2 2 2 2 2

Diameter, in., (mm) 10 (254) 10 (254) 10 (254) 10 (254) 10 (254) 10 (254)

Tube Length, in., (mm ) 120 (3048) 120 (3048) 120 (3048) 120 (3048) 120 (3048) 120 (3048)

Design W.P. psig, (kPa):

Refrigerant Side 450 (3102) 450 (3102) 450 (3102) 450 (3102) 450 (3102) 450 (3102)

Water Side 232 (1599) 232 (1599) 232 (1599) 232 (1599) 232 (1599) 232 (1599)

No. of Passes 2 2 2 2 2 2

Pump-Out Capacity, l b., (kg) (3) 279 (126.6) 273 (123.8) 260 (117.9) 253 (114.8) 240 (108.9) 234 (106.1)

Connections:

Water In & Out , in, (mm) victaul i c 4 (102) 4 (102) 4 (102) 4 (102) 4 (102) 4 (102)

Relief Valve, Flare In., (mm) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12. 7) ½ (12.7) ½ (12.7)

Purge Valve, Flare In., (m m) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12. 7)

Vent & Drain, in. (mm) FPT ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7)

Liquid Subcooling Integral Integral Integral Integral Integral Integral

EVAPORATOR

Number 1 1 1 1 1 1

No. Refrigerant Circuits 2 2 2 2 2 2

Water Volume, gallons, (l) 3.9 (14. 7) 4.3 (16.4) 5 (18.9) 5.7 (21.4) 6.3 (23.9) 7.2 (27.3)

Refrig. Side D.W.P., psig, (kP a) 450 (3102) 450 (3102) 450 (3102) 450 (3102) 450 (3102) 450 (3102)

Water Side D.W.P., psi g, (kPa) 363 (2503) 363 (2503) 363 (2503) 363 (2503) 363 (2503) 363 (2503)

Water Connecti ons :

Inlet & Outlet, in. , (mm) victaulic 3 (76) 3 (76) 3 (76) 3 (76) 3 (76) 3 (76)

Drain & Vent (NPT INT.) Field Field Field Field Field Field

UNIT DIMENSIONS

Length In., (mm) 134.1 (3406) 134.1 (3406) 134.1 (3406) 134.1 (3406) 134.1 (3406) 134.1 (3406)

Width In., (mm) 32 (813) 32 (813) 32 (813) 32 (813) 32 (813) 32 (813)

Height In., (mm) 63.5 (1613) 63.5 (1613) 63.5 (1613) 63.5 (1613) 63.5 (1613) 63.5 (1613)

UNIT WEIGHTS

Operating Weight, l b., (kg) 2692 (1219) 2760 (1250) 2866 (1298) 2966 (1344) 3058 (1385) 3213 (1455)

Shipping Weight, lb., (kg) 2551 (1157) 2606 (1182) 2684 (1217) 2763 (1253) 2828 (1283) 2973 (1349)

Operating Charge, lb., (kg) R-22 100 (45.4) 99 (44.9) 94 (42.6) 92 (41.7) 88 (39.9) 89 (40.4)

Notes:

1. Certified in accordance with ARI Standard 550/590-98.

2. All units have two compressors per circuit in parallel.

3. 80% full R-22 at 90°F (32°C) per unit.

31.6 (111.1) 34.9 (122.7) 40.1 (141) 44.2 (155) 48.6 (171) 54.3 (191)

26 WGZ 030A through 100A IOMM WGZ-1

Page 27

Table 9, WGZ-060AW - WGZ-100AW

WGZ UNIT SIZE 060 070 080 090 100

Unit capacity @ ARI condi tions

tons, (kW) (1)

No. Circuits 2 2 2 2 2

COMPRESSORS

Nominal Horsepower 16 16 16 20 20 20 20 25 25 25

Number (2) 2 2 2 2 2 2 2 2 2 2

Unloading Steps 25 / 50 / 75 28 / 50 / 78 25 / 50 / 75 27 / 50 / 77 25 / 50 / 75

Oil Charge, per compressor oz. (l) 140 (4.1) 140 (4.1) 148 (4.3) 148 (4.3) 200 (5.9) 200 (5.9 200 (5.9

CONDENSER

Number 1 1 1 1 1

No. Refrigerant Circuits 2 2 2 2 2

Diameter, in. (m m) 14 (356) 14 (356) 14 (356) 14 (356) 14 (356)

Tube Length, in. (mm) 120 (3048) 120 (3048) 120 (3048) 120 (3048) 120 (3048)

Design W.P., psig (kPa):

Refrigerant Side 450 (3102) 450 (3102) 450 (3102) 450 (3102) 450 (3102)

Water Side 232 (1599) 232 (1599) 232 (1599) 232 (1599) 232 (1599)

No. of Passes 2 2 2 2 2

Pump-Out Capacity

lb., (kg) (3)

Connections:

Water In & Out , i n., (mm) (4) 5 (127) 5 (127) 5 (127) 5 (127) 5 (127)

Relief Valve, Flare in., (mm) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7)

Purge Valve, Flare in. (mm) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7)

Vent & Drain, in. (mm) FPT ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7)

Liquid Subcooling Integral Integral Integral Integral Integral

EVAPORATOR

Number 1 1 1 1 1

No. Refrigerant Circuits 2 2 2 2 2

Water Volume, gallons (l) 8.1 (30.7) 9.2 (34.9) 10.8 (40.7) 12.8 (48.3) 13.9 (52.5)

Refrigerant Side D.W.P., psig,

(kPa)

Water Side D.W.P., psi g, (kPa) 363 (2503) 363 (2503) 363 (2503) 363 (2503) 363 (2503)

Water Connecti ons:

In & Out, in. (mm) victaulic 3 (76) 3 (76) 3 (76) 3 (76) 3 (76)

Drain & Vent Field Field Field Field Field

UNIT DIMENSIONS

Length, in. (mm) 144.2 (3663) 146.7 (3726) 146.7 (3726) 149 (3784) 149 (3784)

Width, in. (mm) 32 (813) 32 (813) 32 (813) 32 (813) 32 (813)

Height, in. (mm ) 66 (1676) 66 (1676) 66 (1676) 66 (1676) 66 (1676)

UNIT WEIGHTS

Operating Weight, l b. (kg) 3809 (1725) 4025 (1823) 4289 (1943) 4484 (2031) 4627 (2096)

Shipping Weight, lb. (kg) 3500 (1588) 3716 (1686) 3947 (1790) 4094 (1857) 4197 (1904)

R-22 Ref. Charge, lb. (kg) 173 (78.5) 167 (75.7) 163 (73.9) 151 (68.5) 151 (68.5)

Notes:

1. Certified in accordance with ARI Standard 550/590-98.

2. All units have two compressors per circuit in parallel.

3. 80% full R-22 at 90°F (32°C) per unit.

4. Victaulic connections.

60.3 (212) 68.0 (239) 75.6 (266) 84.4 (297) 93.7 (330)

481 (218.2) 462 (209.6) 449 (203.7) 429 (194.6) 409 (185.5)

450 (3102) 450 (3102) 450 (3102) 450 (3102) 450 (3102)

IOMM WGZ-1 WGZ 030A through 100A 27

Page 28

AA Remote Condenser

Table 10, WGZ-030AA - WGZ-055AA

WGZ UNIT SIZE 030 035 040 045 050 055

Cap @ 44°F LWT , 125°F SDT

tons, (kW)

No. Circuits 2 2 2 2 2 2

COMPRESSORS

Nominal Horsepower 7.5 9 9 9 10 10 13 10 13 13 13 16

Number (2) 2 2 2 2 2 2 2 2 2 2 2 2

Unloading Steps 27 / 50 / 77 25 / 50 / 75 25 / 50 / 75 28 / 50 / 78 25 / 50 / 75 27 / 50 / 77

Oil Charge, per compressor oz. (l) 140 (4.1) 140 (4.1) 140 (4.1) 140 (4.1) 140 (4.1) 140 (4.1)

Discharge Valve In., (mm) 1.125 (28) 1.125 (28) 1.125 (28) 1.125 (28) 1.125 (28)

EVAPORATOR

No. Refrigerant Circuits 2 2 2 2 2 2

Water Volume, gallons, (l) 3.9 (14.7) 4.3 (16.4) 5 (18.9) 5.7 (21.4) 6.3 (23.9) 7.2 (27.3)

Refrig. Side D.W.P. psig (kPa) 450 (3102) 450 (3102) 450 (3102) 450 (3102) 450 (3102) 450 (3102)

Water Side D.W.P. psig (k Pa) 363 (2503) 363 (2503) 363 (2503) 363 (2503) 363 (2503) 363 (2503)

Water Connecti ons :

Inlet & Outlet, in. , (mm) (1) 3 (76) 3 (76) 3 (76) 3 (76) 3 (76) 3 (76)

Drain & Vent Field Field Field Field Field Field

UNIT DIMENSIONS

Length In., (mm) 122.4 (3109) 122.4 (3109) 122.4 (3109) 122.4 (3109) 122. 4 (3109) 123.4 (3134)

Width In., (mm) 32 (813) 32 (813) 32 (813) 32 (813) 32 (813) 32 (813)

Height In., (mm) 63.5 (1613) 63.5 (1613) 63.5 (1613) 63.5 (1613) 63.5 (1613) 63.5 (1613)

UNIT WEIGHTS

Operating Weight, l b. (kg) 2162 (981) 2204 (1000) 2257 (1024) 2329 (1056) 2370 (1075) 2505 (1136)

Shipping Weight, lb. (kg) 2134 (968) 2172 (985) 2219 (1007) 2281 (1035) 2315 (1050) 2452 (1112)

Holding Charge, lb. (kg) R-22 6.0 (2.7) 6.1 (2.8) 6.4 (2.9) 6.6 (3) 7.0 (3.2) 9.7 (4.4)

29 (103) 31.6 (112) 36.6 (130) 40.7 (144) 44.7 (158) 49.8 (177)

1.125 (28)

1.375 (35)

Table 11, WGZ-060AA - WGZ-100AA

WHR UNIT SIZE 060 070 080 090 100

Cap @ 44°F LWT , 125°F

SDT tons, (kW)

No. Circuits 2 2 2 2 2

COMPRESSORS

Nominal Horsepower 16 16 16 20 20 20 20 25 25 25

Number (3) 2 2 2 2 2 2 2 2 2 2

Unloading Steps 25 / 50 / 75 28 / 50 / 78 25 / 50 / 75 27 / 50 / 77 25 / 50 / 75

Oil Charge oz 140 (4.1) 140 (4.1) 148 (4.3) 148 (4.3) 148 (4.3) 148 (4.3) 200 (5.9) 200 (5.9) 200 (5.9)

EVAPORATOR

No. Refrigerant Circuits 2 2 2 2 2

Water Volume, gallons (l) 8.1 (30. 7 9.2 (34.9) 10.8 (40.7) 12.8 (48. 3) 13.9 (52.5)

Refrigerant Side D.W.P., psig

(kPa)

Water Side D.W.P., psig

(kPa)

Water Connecti ons:

Inlet & Outlet, in. (mm) (1) 3 (76) 3 (76) 3 (76) 3 (76) 3 (76)

Drain & Vent Field Fiel d Field Field Fi el d

UNIT DIMENSIONS

Length, in. (mm) 140 (3556) 142.5 (3620) 142.5 (3620) 144.75 (3677) 144.75 (3677)

Width, in. (mm) 32 (813) 32 (813) 32 (813) 32 (813) 32 (813)

Height, in. (mm ) 66 (1676) 66 (1676) 66 (1676) 66 (1676) 66 (1676)

UNIT WEIGHTS

Operating Weight, l b. (kg) 2771 (1257) 2942 (1334) 3154 (1431) 3271 (1484) 3346 (1518)

Shipping Weight, lb. (kg) 2701 (1225) 2871 (1302) 3071 (1393) 3172 (1439) 3238 (1469)

Holding Charge, lb. (kg) R-22 10.0 (4.5) 10.5 (4.7) 11.1 (5) 11.8 (5.4) 12.3 (5.6)

Notes:

1. Victaulic connections.

2. All units have two compressors per circuit in parallel.

54.9 (195) 62.1 (220) 69.5 (246) 77.9 (276) 85. 9 (305)

450 (3102) 450 (3102) 450 (3102) 450 (3102) 450 (3102)

363 (2503) 363 (2503) 363 (2503) 363 (2503) 363 (2503)

28 WGZ 030A through 100A IOMM WGZ-1

Page 29

Operating Limits

• Maximum allowable condenser water pressure is 232 psig (1599 kPa).

• Maximum allowable cooler water pressure is 363 psig (2509 kPa).

• Maximum design saturated discharge temperature is 140°F (60°C).

• Maximum allowable water temperature to cooler in a non-operating cycle is 100°F (37.8°C).

Maximum entering water temperature for operating cycle is 90°F (32.2°C) (during system

changeover from heating to cooling cycle).

• Minimum leaving water temperature from the cooler without freeze protection is 40°F (4.4°C).

• Minimum entering tower condenser water temperature is 60°F (15.6°C).

Components

Figure 18, Compressor Locations

Evaporator and

423

1

Evaporator

Condenser

Connections

Circuit 2 Circuit 1

Control Panel

Table 12, Major Components

Unit

Size

030 ZR90K3 ZR90K3 ZR11M3 ZR11M3 AC250-70DQ C1007-068 OVE-20-CP100 OVE-20-CP100

035 ZR11M3 ZR11M3 ZR11M3 ZR11M3 AC250-78DQ C1007-076 OVE-20-CP100 OVE-20-CP100

040 ZR12M3 ZR12M3 ZR12M3 ZR12M3 AC250-90DQ C1007-084 OVE-20-CP100 OVE-20-CP100

045 ZR12M3 ZR12M3 ZR16M3 ZR16M3 AC250-102DQ C1207-092 OVE-30-CP100 OVE-30-CP100

050 ZR16M3 ZR16M3 ZR16M3 ZR16M3 AC250-114DQ C1207-108 OVE-30-CP100 OVE-30-CP100

055 ZR16M3 ZR16M3 ZR19M3 ZR19M3 AC250-130DQ C1407-120 OVE-30-CP100 Y929-VCP100

060 ZR19M3 ZR19M3 ZR19M3 ZR19M3 AC250-146DQ C1607-136 Y929-VCP100 Y929-VCP100

070 ZR19M3 ZR19M3 ZR250KC ZR250KC AC250-166DQ C1010-092 Y929-VCP100 Y929-VCP100

080 ZR250KC ZR250KC ZR250KC ZR250KC AC250-194DQ C1210-104 Y929-VCP100 Y929-VCP100

090 ZR250KC ZR250KC ZR300KC ZR300KC AC250-230DQ C1210-112 OVE-55-CP100 OVE-55-CP100

100 ZR300KC ZR300KC ZR300KC ZR300KC AC250-250DQ C1210-128 OVE-55-CP100 OVE-55-CP100

System #1 System #2 Expansion Valve

Comp. #1 Com p . #3 Comp. #2 Comp. #4

Evap.

Vessel

Size

Cond.

Vessel

Size

System #1 System #2

IOMM WGZ-1 WGZ 030A through 100A 29

Page 30

Wiring

Field Wiring, Power

The WGZ “A” vintage chillers are built standard with compressor contractors and power terminal

block, desi gned for single po wer suppl y to the unit. Optional power connec tions includ e a non-fused

disconnect switch mounted in the control box or multi-point power connection.

A factory installed control circuit transformer is standard. Optionally, a field-installed control power

source can be wired to the unit.

Circuit breakers for backup compressor short circuit protection are standard on all units.