Page 1

Installation, and Maintenance Manual

Water-Cooled Scroll Compressor Chillers

WGZ 030CW to WGZ 200CW, Packaged Water-Cooled Chiller

WGZ 030CA to WGZ 200CA, Chiller with Remote Condenser

30 to 200 Tons, 105 to 700 kW

60 Hz, R-410A

IMM WGZC

Group: Chiller

Part Number: 331975201

Effective: October 2008

Supercedes: June 2008

Page 2

Table of Contents

r

Introduction.......................................3

Nomenclature........................................3

Installation .........................................4

Vibration Isolators................................. 6

Water Piping ....................................10

Flow Switch ........................................ 13

Glycol Solutions.................................. 13

Condenser Water Piping...................... 15

Pressure Drops.................................15

Refrigerant Piping...........................

Unit with Remote Condenser.............. 18

Factory-Mounted Condenser............... 23

Dimensions.......................................

Packaged Chillers................................ 24

Chillers with Remote Condenser......... 27

Physical Data....................................30

Packaged Chillers................................ 30

Chillers with Remote Condenser......... 33

Operating Limits ................................. 34

Components ........................................ 35

Wiring...............................................36

Unit Configuration..........................37

Electrical Data .................................38

18

24

Field Wiring Diagram ......................... 53

Control Panel Layout .......................... 55

Motor Protection Module....................55

Start-Up and Shutdown..................

Pre Start-up.......................................... 56

Start-up................................................ 56

Weekend or Temporary Shutdown...... 57

Start-up after Temporary Shutdown.... 57

Extended Shutdown ............................ 57

Start-up after Extended Shutdown...... 58

System Maintenance....................... 59

General................................................ 59

Electrical T erm inals.............................60

Compressor Lubrication ...................... 60

Sightglass and Moisture Indicator....... 60

Crankcase Heaters............................... 61

Optional Controls................................ 61

Phase/Voltage Monitor (Optional) ...... 61

Hot Gas Bypass (Optional) ................. 62

Maintenance Schedule.................... 63

System Service................................. 64

Troubleshooting Chart ........................ 66

Warranty Statement ....................... 67

56

Cover Picture: WGZ 200C, Nominal 200 ton chille

Manufactured in an ISO Certified facility

©2007 McQuay International. Illustrations and data cover the McQuay International product at the time of publication and we reserve the right to

make changes in design and construction at anytime without notice. ™® The following are trademarks or registered trademarks of their respective

companies: BACnet from ASHRAE;

International under a license granted by Echelon Corporation; Compliant Scroll from Copeland Corporation; ElectroFin from AST ElectroFin Inc.;

Modbus from Schneider Electric; FanTrol, MicroTech II, Open Choices, and SpeedTrol from McQuay International

LONMARK, LonTalk, LONWORKS, and the LONMARK logo are managed, granted and used by LONMARK

2 WGZ 030C through 200C IMM WGZC

Page 3

Introduction

General Description

McQuay Type WGZ water chillers are designed for indoor installations and are available with water-cooled condensers

(Model WGZ-CW), or arranged for use with remote, air-cooled or evaporative condensers (Model WGZ-CA). Each

water-cooled unit is completely assembled and factory wired before evacuation, charging and testing. They consist of

hermetic scroll compressors, brazed-plate evaporators on Models WGZ 030 to 130( shell-and-tube on Models WGZ

150 to 200), water-cooled condenser (WGZ-CW), and complete refrigerant piping.

Units manufactured for use with remote condensers (Models WGZ-CA) have all refrigerant specialties factory-mounted

and connection points for refrigerant discharge and liquid lines.

Liquid line components that are included are manual liquid line shutoff valves, charging valves, filter-driers, liquid line

solenoid valves, sight glass/moisture indicators, and thermal expansion valves.

Other features include compressor crankcase heaters, and a MicroTech II microprocessor controller.

The electrical control center includes all equipment protection and operating controls necessary for dependable

automatic operation.

The compressors are not fused as standard, but can be protected by optional circuit breakers or fuses, or can rely on a

field-installed, fused disconnect switch for protection.

Nomenclature

W G Z 100 - C W

Water-Cooled

Global

Scroll Compressor

Inspection

When the equipment is received, all items should be carefully checked against the bill of lading to be sure of a

complete shipment. All units must be carefully inspected for damage upon arrival. All shipping damage must be

reported to the carrier and a claim must be filed with the carrier. The unit serial plate should be checked before

unloading the unit to be sure that it agrees with the power supply available. Physical damage to unit after acceptance is

not the responsibility of McQuay.

Note: Unit lifting weights are given in the physical data tables beginning on page

are given on page 6

W = Water-Cooled Condenser

A = Unit Less Condenser

Design V intage

Nominal Capacity (Tons)

5. Corner operating weights

IMM WGZC WGZ 030C through 200C 3

Page 4

Installation

Note: Installation and maintenance are to be performed only by qualified personnel who are familiar with

local codes and regulations, and experienced with this type of equipment.

!

WARNING

Avoid contact with sharp edges. Personal injury can result

Handling

Every model WGZ-CW water chiller with water-cooled condensers is shipped with a full refrigerant charge. For

shipment, the charge is contained in the condenser and is isolated by the condenser liquid shutoff valve and the

compressor discharge valve common to a pair of compressors.

A holding charge is supplied in remote condenser models, WGZ-CA. The operating charge must be field supplied

and charged.

!

WARNING

If the unit has been damaged, allowing the refrigerant to escape, there can be danger of suffocation in the area since the

refrigerant will displace the air. Be sure to review Environmental Protection Agency (EPA) requirements if damage occurred.

Avoid exposing an open flame to the refrigerant

Moving the Unit The skid option is strongly recommended for ease of handling and to help prevent damage if a

crane is not available for rigging at site.

Figure 1, Lifting the Unit

SPREADER BARS MUST

BE USED FOR STABILITY

DURING LIFTING OF

ALL SIZE UNITS

(2) 2”

Lifting

Holes

Removable

Lifting

WGZ150-200C

UNIT SHOWN

331926901 REV. 0A

Bar

It is recommended that all moving and handling be performed with skids or dollies under the unit and that they not

be removed until the unit is in the final location. Never put the weight of the unit against the control box.

In moving, always apply pressure to the base on the skids only and not to the piping or other components. A long

bar will help move the unit easily. Avoid dropping the unit at the end of the roll.

If the unit must be hoisted, lift the unit from the removable lifting arms factory-bolted to each end of the unit

adjacent to the tube sheet by attaching cables or chains to the end of the arms. A spreader bar must be used to

protect the piping, control panel and other areas of the chiller (see

). The arms should be removed and discarded

after use.

4 WGZ 030C through 200C IMM WGZC

Page 5

Do not attach slings to piping or equipment. Do not attempt to lift the unit by lifting points mounted on the

compressors. They are for lifting only the compressor should one need to be removed from the unit. Move unit in

the upright horizontal position at all times. Set unit down gently when lowering from the truck or rollers.

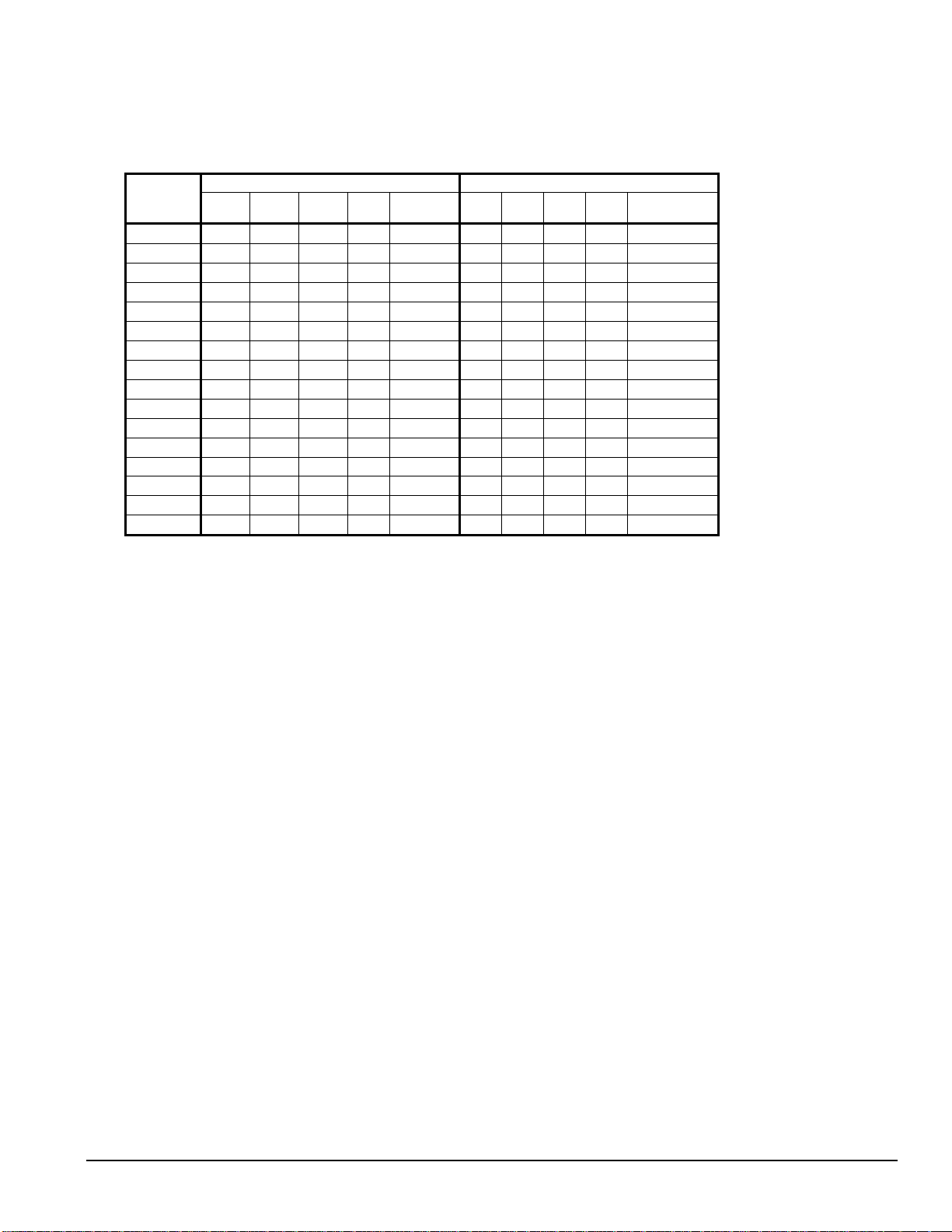

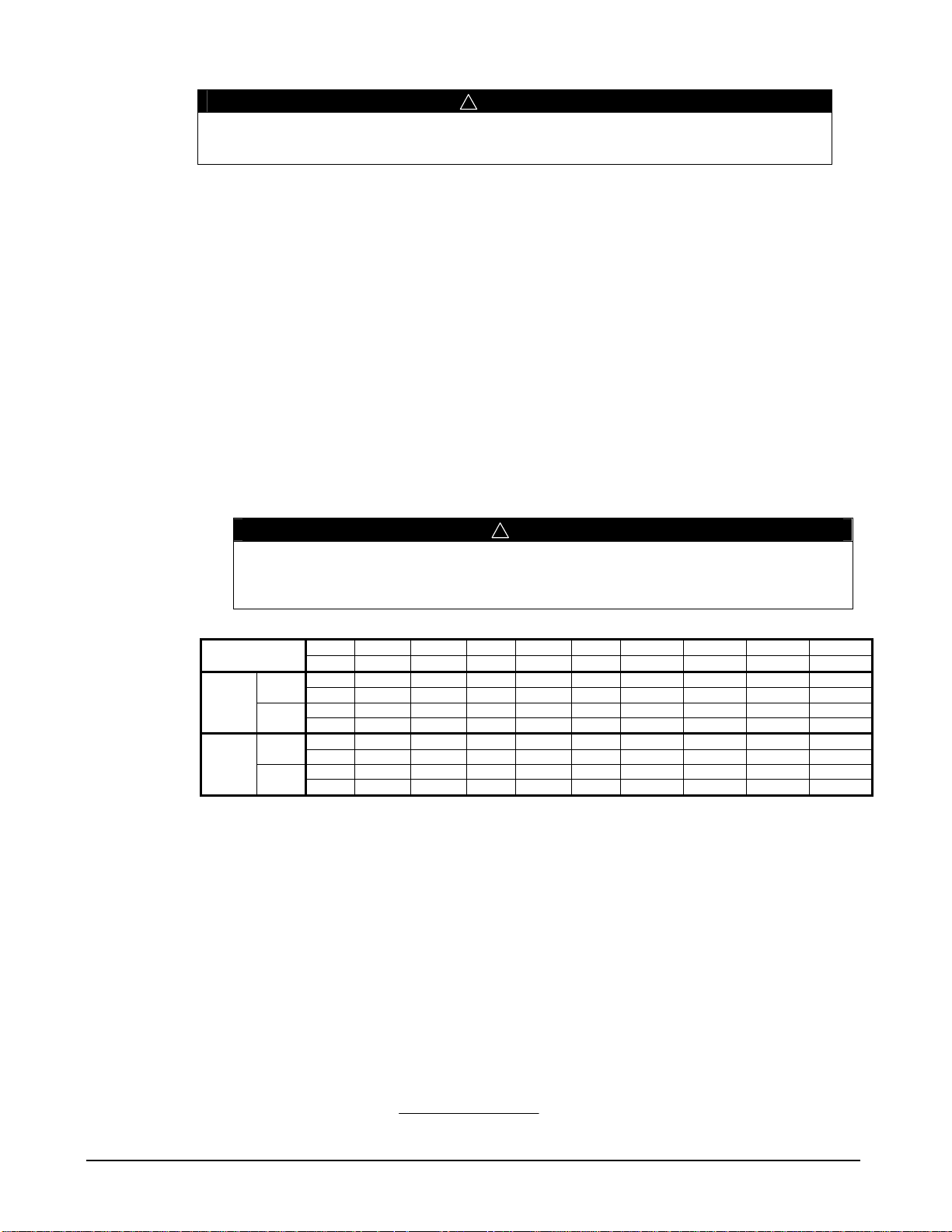

Table 1, Lifting Loads

Model

WGZ-C

WGZ 030

WGZ 035

WGZ 040

WGZ 045

WGZ 050

WGZ 055

WGZ 060

WGZ 070

WGZ 080

WGZ 090

WGZ 100

WGZ 115

WGZ 130

WGZ 150

WGZ 175

WGZ200

WGZ-CW Package Units (lbs.) WGZ CA Less Condenser Units (lbs)

L1 L2 L3 L4

606 633 599 573 2410 415 430 374 361

632 646 616 603 2496 442 445 392 390

639 659 630 611 2539 443 451 399 392

639 667 639 612 2558 444 460 407 393

655 689 664 631 2639 451 468 416 400

655 698 673 632 2658 451 476 425 402

655 712 688 633 2688 451 484 433 404

929 874 942 1001 3746 649 595 556 606

1066 927 1001 1151 4145 765 635 598 720

1076 849 1059 1343 4327 806 653 623 770

1059 781 1118 1515 4474 829 681 657 801

1054 802 1146 1506 4508 830 710 689 805

1055 828 1181 1505 4568 831 737 716 807

1684 1516 1602 1780 6581 1204 1142 1184 1249

1814 1528 1637 1943 6921 1245 1149 1198 1299

1829 1550 1677 1979 7036 1265 1178 1235 1326

Shipping

Weight

L1 L2 L3 L4

Shipping

Weight

1580

1670

1685

1704

1735

1754

1771

2406

2717

2851

2968

3035

3091

4779

4891

5004

See Figure 2 on the following page for location of lifting points.

Location

WGZ chillers are designed for indoor application and must be located in an area where the surrounding

ambient temperature is 40°F (4°C) or above. A good rule of thumb is to place units where ambient temperatures

are at least 5°F (3°C) above the leaving water temperature.

Because of the electrical control devices, the units should not be exposed to the weather. A plastic cover over

the control box is supplied as temporary protection during shipment. A reasonably level and sufficiently strong

floor is required for the water chiller. If necessary, additional structural members should be provided to transfer

the weight of the unit to the nearest beams.

Space Requirements for Connections and Servicing

The chilled water and condenser water (on units with a water-cooled condenser) piping enters and leaves the

unit from the right side when looking at the control panel. Left-hand condenser connections are an option. A

clearance of at least 3 feet (1219 mm), or more if codes require, should be provided beyond this piping and on

all other sides and ends of the unit for general servicing or for changing the compressors, if it ever becomes

necessary.

IMM WGZC WGZ 030C through 200C 5

Page 6

On units equipped with a water-cooled condenser (Type WGZ-CW) clearance should also be provided for

cleaning or removal of condenser tubes on one end of the unit. The clearance for cleaning depends on the type

of apparatus used, but can be as much as the length of the condenser (10 feet, 3050 mm). Tube replacement

requires the tube length of 10 feet (3050 mm) plus one to two feet of workspace. This space can often be

provided through a doorway or other opening.

Allow a minimum of 4-foot clearance in front of the control panel.

Placing the Unit

The small amount of vibration normally encountered with the water chiller makes this unit particularly

desirable for basement or ground floor installations where the unit can be mounted directly to the floor. The

floor construction should be such that the unit will not affect the building structure, or transmit noise and

vibration into the structure.

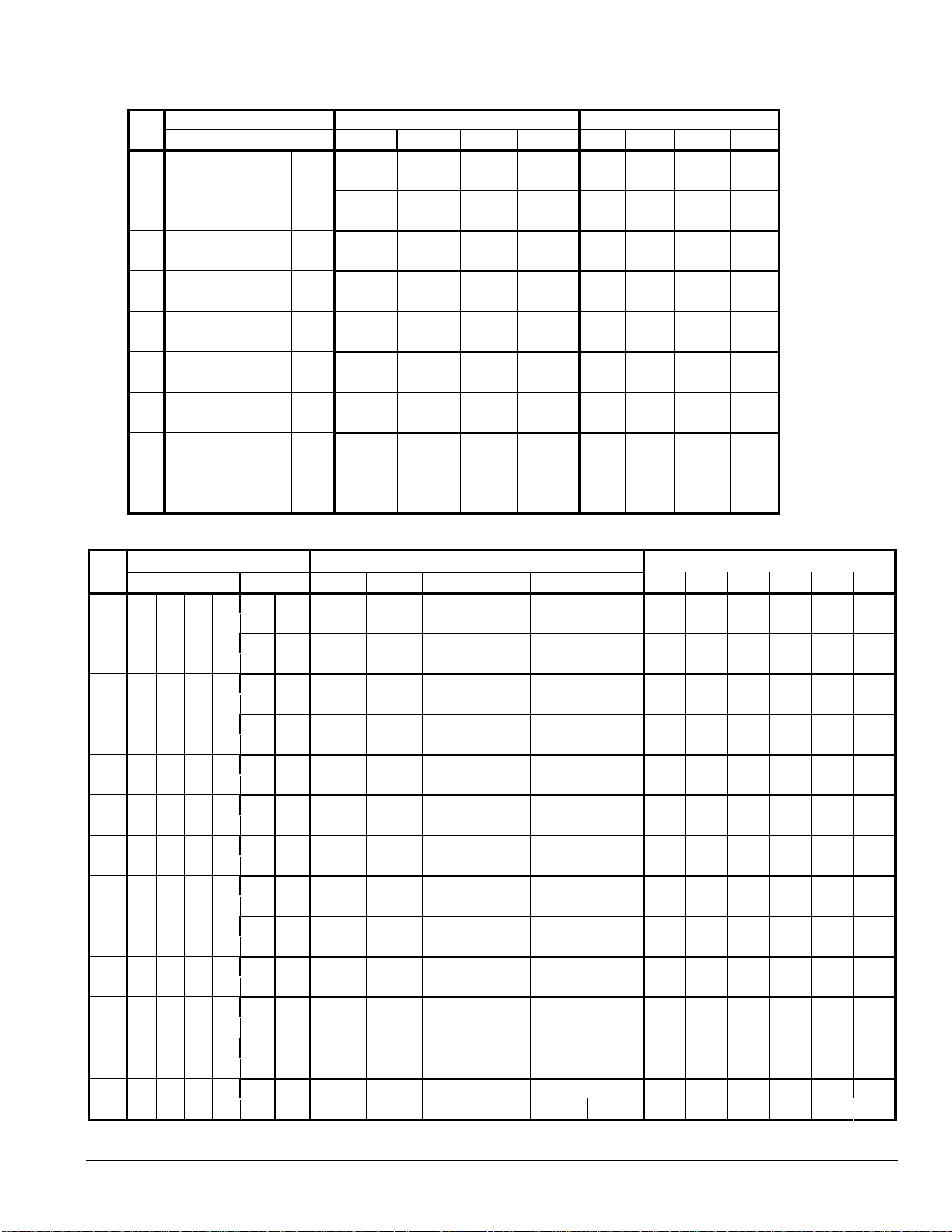

Vibration Isolators

It is recommended that isolators be used on all upper level installations or in areas where vibration transmission

is a consideration.

Figure 2, Isolator Locations

4

LB

1

LF

Control Panel

RB

FRF

3

Wate r

Connections

2

A rubber anti-skid pad should be used under isolators if hold-down bolts are not used.

Installation of spring isolators requires flexible piping connections and at least three feet of flexible electrical

conduit to avoid straining the piping and transmitting vibration and noise.

Transfer the unit as indicated under “Moving the

Unit.” In all cases, set the unit in place and level with

a spirit level. When spring-type isolators are required,

install springs running under the main unit supports.

The unit should be set initially on shims or blocks at

the listed spring free height. When all piping, wiring,

flushing, charging, etc., is completed, the springs are

adjusted upward to loosen the blocks or shims that

are then removed.

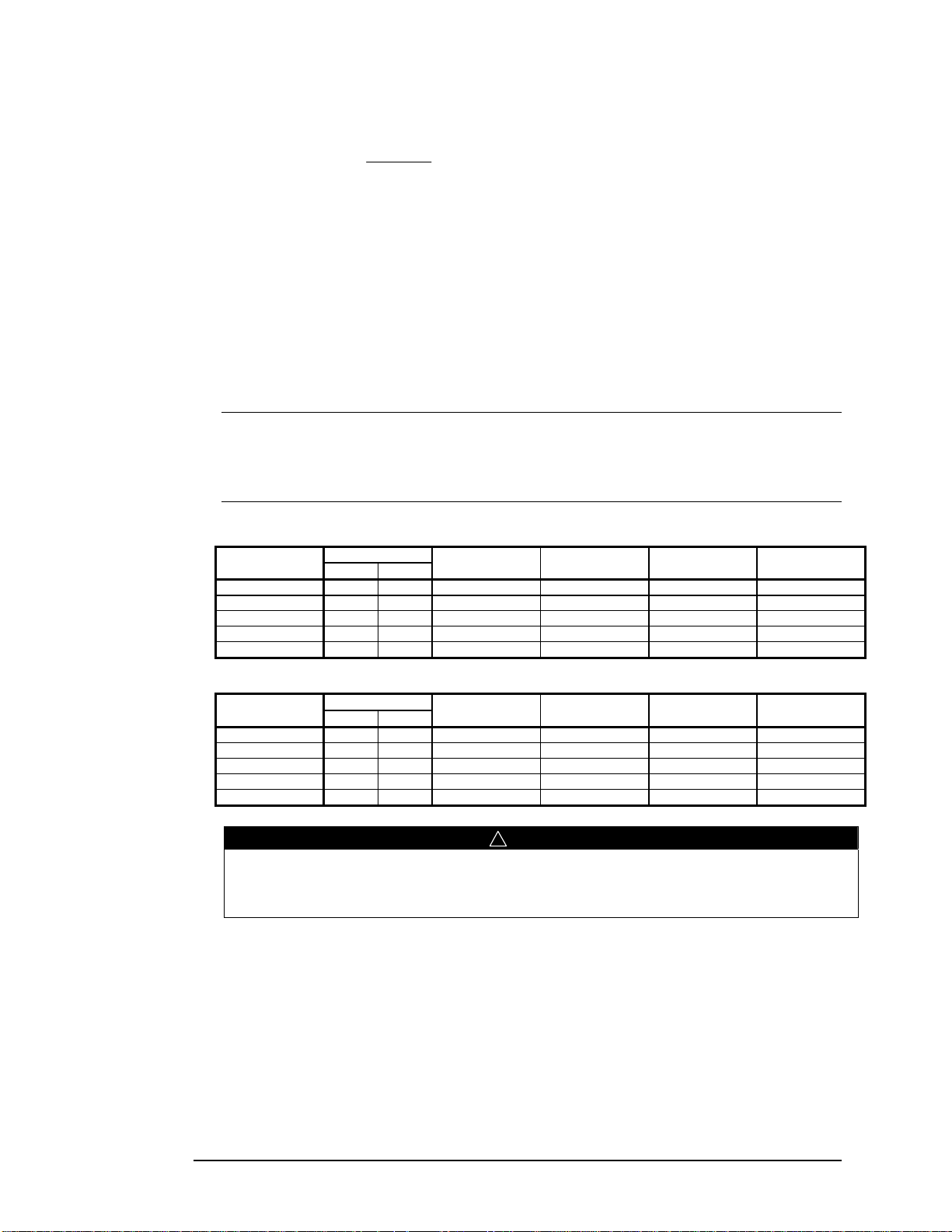

Table 2, WGZ-CW Packaged, Mounting Weights & Vibration Mounting Location

Mounting Weights, Lbs

Unit

Size M1 M2 M3 M4 M1 M2 M3 M4

625.0 653.0 618.0 591.0

030

651.0 665.0 635.0 621.0

035

662.0 683.0 653.0 633.0

040

662.0 691.0 662.0 634.0

045

683.0 718.0 692.0 659.0

050

683.0 727.0 702.0 659.0

055

682.0 742.0 717.0 660.0

060

CP-1-28 CP-1-28 CP-1-28 CP-1-28

CP-1-28 CP-1-28 CP-1-28 CP-1-28

CP-1-28 CP-1-28 CP-1-28 CP-1-28

CP-1-28 CP-1-28 CP-1-28 CP-1-28

CP-1-28 CP-1-28 CP-1-28 CP-1-28

CP-1-28 CP-1-28 CP-1-28 CP-1-28

CP-1-28 CP-1-28 CP-1-28 CP-1-28

Spring-Flex Mountings R-I-S Mountings

M1 M2 M3 M4

RP3 RP3 RP3 RP3

Green Green Green Green

Green Green Green Green

Green Green Green Green

Green Green Green Green

Green Green Green Green

Green Green Green Green

Green Green Green Green

Gray Gray Gray Gray

RP3 RP3 RP3 RP3

Gray Gray Gray Gray

RP3 RP3 RP3 RP3

Gray Gray Gray Gray

RP3 RP3 RP3 RP3

Gray Gray Gray Gray

RP3 RP3 RP3 RP3

Gray Gray Gray Gray

RP3 RP3 RP3 RP3

Gray Gray Gray Gray

RP3 RP3 RP3 RP3

Gray Gray Gray Gray

Continued next page

6 WGZ 030C through 200C IMM WGZC

Page 7

WGZ-CW Packaged, Mounting Weights & Vibration Mounting Location, Continued

Unit

Size

Mounting Weights, Lbs Spring-Flex Mountings R-I-S Mountings

M1 M2 M3 M4 M1 M2 M3 M4

964.0 907.0 978.0 1038.0

070

1106.0 962.0 1039.0 1195.0

080

1121.0 884.0 1103.0 1399.0

090

1108.0 817.0 1169.0 1585.0

100

1102.0 839.0 1198.0 1574.0

115

1102.0 865.0 1234.0 1572.0

130

1886.0 1697.0 1794.0 1993.0

150

2033.0 1712.0 1835.0 2178.0

170

2047.0 1735.0 1877.0 2215.0

200

CP-1-31 CP-1-31 CP-1-31 CP-1-31

Gray Gray Gray Gray

CP-2-27 CP-2-27 CP-2-27 CP-2-27

Orange Orange Orange Orange

CP-2-27 CP-2-27 CP-2-27 CP-2-28

Orange Orange Orange Green

CP-2-27 CP-2-27 CP-2-27 CP-2-28

Orange Orange Orange Green

CP-2-27 CP-2-27 CP-2-27 CP-2-28

Orange Orange Orange Green

CP-2-27 CP-2-27 CP-2-27 CP-2-28

Orange Orange Orange Green

CP-2-32 CP-2-31 CP-2-31 CP-2-32

White Gray Gray White

CP-2-32 CP-2-31 CP-2-31 CP-2-32

White Gray Gray White

CP-2-32 CP-2-31 CP-2-31 CP-2-32

White Gray Gray White

M1 M2 M3 M4

RP4 RP4 RP4 RP4

Black Black Black Black

RP4 RP4 RP4 RP4

Black Black Black Black

RP4 RP4 RP4 RP4

Red Red Red Red

RP4 RP4 RP4 RP4

Red Red Red Red

RP4 RP4 RP4 RP4

Red Red Red Red

RP4 RP4 RP4 RP4

Red Red Red Red

RP4 RP4 RP4 RP4

Green Green Green Green

RP4 RP4 RP4 RP4

Green Green Green Green

RP4 RP4 RP4 RP4

Green Green Green Green

Table 3, WGZ-CA, Remote Condenser, Mounting Weights & Vibration Mounting Location

Unit Mounting Weights, Lbs Spring-Flex Mountings Spring-Flex Mountings

Size M1 M2 M3 M4 M5 M6 M1 M2 M3 M4 M5 M6

476 501 322 307 N/A N/A

030

511 516 337 334 N/A N/A

035

511 525 344 335 N/A N/A

040

512 538 353 336 N/A N/A

045

520 549 362 342 N/A N/A

050

519 561 371 343 N/A N/A

055

519 574 380 344 N/A N/A

060

738 651 509 577 N/A N/A

070

884 675 532 697 N/A N/A

080

937 690 552 749 N/A N/A

090

963 724 585 778 N/A N/A

100

957. 764 621 778 N/A N/A

115

956 804 655 779 N/A N/A

130

CP-1-27 CP-1-27 CP-1-25 CP-1-25

Orange Orange Red Red

CP-1-27 CP-1-27 CP-1-25 CP-1-25

Orange Orange Red Red

CP-1-27 CP-1-27 CP-1-25 CP-1-25

Orange Orange Red Red

CP-1-27 CP-1-27 CP-1-25 CP-1-25

Orange Orange Red Red

CP-1-27 CP-1-27 CP-1-25 CP-1-25

Orange Orange Red Red

CP-1-27 CP-1-27 CP-1-25 CP-1-25

Orange Orange Red Red

CP-1-31 CP-1-31 CP-1-28 CP-1-28

Gray Gray Green Green

CP-1-31 CP-1-31 CP-1-28 CP-1-28

Gray Gray Green Green

CP-1-31 CP-1-31 CP-1-28 CP-1-28

Gray Gray Green Green

CP-1-32 CP-1-31 CP-1-31 CP-1-31

White Gray Gray Gray

CP-1-32 CP-1-31 CP-1-31 CP-1-31

White Gray Gray Gray

CP-1-32 CP-1-31 CP-1-31 CP-1-31

White Gray Gray Gray

CP-1-32 CP-1-31 CP-1-31 CP-1-31

White Gray Gray Gray

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

M1 M2 M3 M4 M5 M6

RP3 RP3 RP3 RP3

Green Green Green Green

RP3 RP3 RP3 RP3

Green Green Green Green

RP3 RP3 RP3 RP3

Green Green Green Green

RP3 RP3 RP3 RP3

Green Green Green Green

RP3 RP3 RP3 RP3

Green Green Green Green

RP3 RP3 RP3 RP3

Green Green Green Green

RP3 RP3 RP3 RP3

Green Green Green Green

RP3 RP3 RP3 RP3

Gray Gray Gray Gray

RP3 RP3 RP3 RP3

Gray Gray Gray Gray

RP3 RP3 RP3 RP3

Gray Gray Gray Gray

RP3 RP3 RP3 RP3

Gray Gray Gray Gray

RP3 RP3 RP3 RP3

Gray Gray Gray Gray

RP3 RP3 RP3 RP3

Gray Gray Gray Gray

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

N/A N/A

IMM WGZC WGZ 030C through 200C 7

Page 8

WGZ-CA, Remote Condenser, Mounting Weights & Vibration Mounting Location, Continued

Unit Mounting Weights, Lbs Spring-Flex Mountings Spring-Flex Mountings

Size M1 M2 M3 M4 M5 M6 M1 M2 M3 M4 M5 M6

821 793 763 931 968 1003

150

863 812 750 919 986 1047

170

875 831 784 947 1000 1057

200

CP-2-26 CP-2-26 CP-2-26 CP-2-27 CP-2-27 CP-2-27

Purple Purple Purple Orange Orange Orange

CP-2-26 CP-2-26 CP-2-26 CP-2-27 CP-2-27 CP-2-27

Purple Purple Purple Orange Orange Orange

CP-2-26 CP-2-26 CP-2-26 CP-2-27 CP-2-27 CP-2-27

Purple Purple Purple Orange Orange Orange

M1 M2 M3 M4 M5 M6

RP4 RP4 RP4 RP4 RP4 RP4

Black Black Black Black Black Black

RP4 RP4 RP4 RP4 RP4 RP4

Black Black Black Black Black Black

RP4 RP4 RP4 RP4 RP4 RP4

Black Black Black Black Black Black

Table 4, WGZ-CW, Packaged, Isolator Kit Numbers

Model Number 030-060 070 080 090-130 150-200

Spring-Flex 331987982 3319887983 350014861 350014895 331987984

R-I-S 350014853 350014849 350014849 350014845 350014843

Table 5, WGZ-CA, Remote Condenser, Isolator Kit Numbers

Model Number 030-055 060 070-080 090-130 150-200

Spring-Flex 350014838 331987985 331987985 350014894 331987986

R-I-S 350014887 350014887 350014853 350014853 331987954

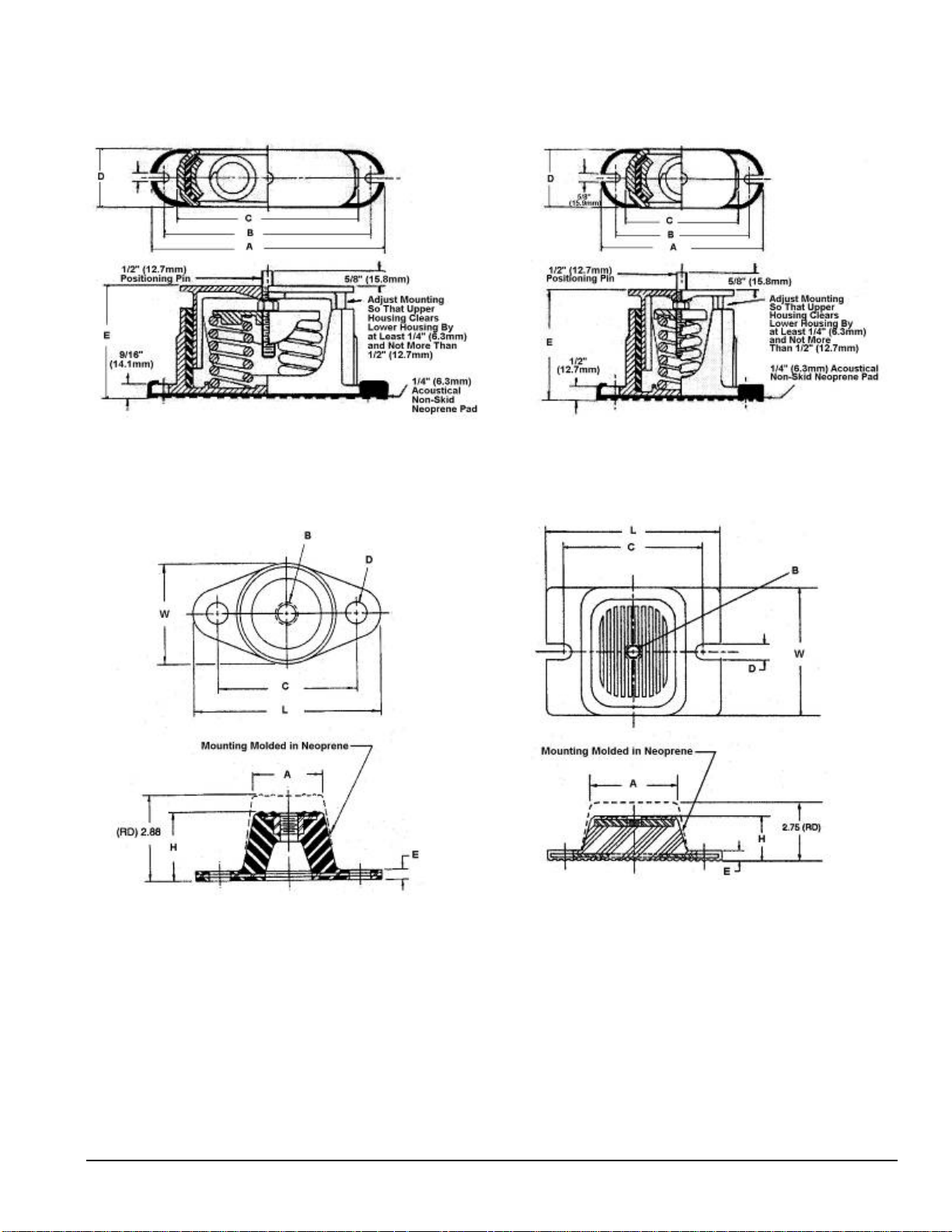

Table 6, Spring Flex Isolator Dimensions

6.0

(152.4)

6.0

(152.4)

6.0

(152.4)

6.0

(152.4)

6.0

(152.4)

6.0

(152.4)

9.0

(228.6)

Dimensions

In. (mm)

4.7

(119.4)

4.7

(119.4)

4.7

(119.4)

4.7

(119.4)

4.7

(119.4)

4.7

(119.4)

7.7

(195.6)

2.7

(68.6)

2.7

(68.6)

2.7

(68.6)

2.7

(68.6)

2.7

(68.6)

2.7

(68.6)

2.7

(68.6)

(139.7)

(139.7)

(139.7)

(139.7)

(139.7)

(139.7)

(146.0)

Housing

CP-1

CP-1

CP-1

CP-1

CP-1

CP-1

CP-2

NOTE: CP-1 housing contains one spring. CP-2 housing contains two identical springs.

Spring

Color

Red

Purple

Orange

Green

Gray

White

Green

Max. Load

Each

Lbs. (kg)

450

(204)

600

(272)

750

(340)

900

(408)

1100

(498)

1300

(589)

1800

(815)

Defl.

In. (mm)

1.22

(30.9

1.17

(29.7)

1.06

(26.9)

1.02

(25.9)

0.83

(21.0)

0.74

(18.7)

1.02

(25.9)

A B C D E

7.5

(190.5)

7.5

(190.5)

7.5

(190.5)

7.5

(190.5)

7.5

(190.5)

7.5

(190.5)

10.2

(259.1)

Table 7, Neoprene-in-Shear Isolators

4.1

4.1

5.0

Dimensions

In. (mm)

0.56

(14.2)

0.56

(14.2)

0.56

(14.2)

0.25

(6.4)

0.25

(6.4)

0.25

(6.4)

Type

RP-3 Green

RP-3 Gray

R-4 Black

NOTE: (1) "D" is the mounting hole diameter.

Max. Load

Each

Lbs. (kg)

750

(339)

1100

(498)

1500

(679)

Defl.

In. (mm)

0.25

(6.4)

0.25

(6.4)

0.25

(6.4)

A B C D (1) E H L W

2.5

(63.5)

2.5

(63.5)

3.75

(95.3)

0.5

(12.7)

0.5

(12.7)

0.5

(12.7)

(104.1)

(104.1)

(127.0)

Housing

Part Number

5.5

226102B-00 226115A-00

5.5

226102B-00 226116A-00

5.5

226102B-00 226117A-00

5.5

226102B-00 226118A-00

5.5

226102B-00 226119A-00

5.5

226102B-00 226120A-00

5.75

226103B-00 (2) 226118A-00

1.75

(44.4)

1.75

(44.4)

1.6

(41.1)

5.5

(165)

5.5

(165)

6.5

(165.1)

3.4

(85.7)

3.4

(85.7)

4.6

(116.8)

Spring

Part Number

McQuay

Part Number

216397A-03

216397A-05

216398A-04

8 WGZ 030C through 200C IMM WGZC

Page 9

Table 8, Spring Flex Mounting. CP-2

Table 9, Neoprene-in-Shear Mounting, RP-3

Table 10, Spring Flex Mounting, CP-1

Table 11, Neoprene-in-Shear, R4

IMM WGZC WGZ 030C through 200C 9

Page 10

W

Water Piping

Vessel Drains at Start-up

Condensers are drained of water in the factory and are shipped with the condenser drain plugs in the

heads removed and stored in a bag in the control panel. Be sure to replace plugs prior to filling the

vessel with fluid.

General

Due to the variety of piping practices, it is advisable to follow the recommendations of local

authorities for code compliance. They can supply the installer with the proper building and safety

codes required for a safe and proper installation.

Basically, the piping should be designed with a minimum number of bends and changes in elevation

to keep system cost down and performance up. Other piping design considerations include:

1. All piping should be installed and supported to prevent the chiller connections from bearing any

strain or weight of the system piping.

2. Vibration eliminators to reduce vibration and noise transmission to the building.

3. Shutoff valves to isolate the unit from the piping system during unit servicing.

4. Manual or automatic air vent valves at the high points of the system. Drains should be placed at

the lowest points in the system.

5. Some means of maintaining adequate system water pressure (e.g., expansion tank or regulating

valve).

6. Temperature and pressure indicators located within 3 feet (0.9 meters) of the inlet and outlet of

the vessels to aid in unit servicing.

7. A strainer or some means of removing foreign matter from the water before it enters the pump is

recommended. It should be placed far enough upstream to prevent cavitation at the pump inlet

(consult pump manufacturer for recommendations). The use of a strainer will prolong pump life

and thus maintain system performance.

Important Note

A cleanable 40-mesh strainer must also be placed in the water line just prior to the inlet

of the evaporator on Models WGZ 030 to 130. A 20-mesh is satisfactory on Models WGZ

150 to 200. This will aid in preventing foreign material from entering and decreasing the

performance of the evaporator.

8. If the unit is used as a replacement chiller on a previously existing piping system, the system

should be thoroughly flushed prior to unit installation. Regular water analysis and chemical

water treatment on the evaporator and condenser is recommended immediately upon equipment

start-up.

9. In the event glycol is added to the water system, as an afterthought for freeze protection,

recognize that the refrigerant suction pressure will be lower, cooling performance less, and

water side pressure drop will be higher. If the percentage of glycol is large, or if propylene

glycol is used instead of ethylene glycol, the added pressure drop and loss of performance

could be substantial. Reset the freezestat and low leaving water alarm temperatures. The

freezestat is factory set to default at 36°F (2.2°C). Reset the freezestat setting to approximately

4° to 5°F (2.3° to 2.8°C) below the leaving chilled water setpoint temperature. See the section

titled “Glycol Solutions” for additional information concerning the use of glycol.

10. A preliminary leak check of the water piping should be made before filling the system.

10 WGZ 030C through 200C IMM

Page 11

Note: A water flow switch or pressure differential switch must be mounted in the

A

evaporator outlet water line to signal that there is water flow before the unit will start.

Table 12, Typical Field Evaporator Water Piping, WGZ 030 to 130

Air

Vent

Strainer

Inlet

Isolation

Val ves

Flow

Outlet

P

Drain

Vibration

Eliminators

Switch

NOTE: Water piping must be supported independently from the unit.

Figure 3, Typical Field Evaporator Water Piping, WGZ 150 to 200

Liquid

Out

Drain

Vent

In

Vibration

Eliminator

Suction

Valved

Pressure

Gauge

Flow

Switch

Vibration

Eliminator

Balancing

Valve

Water

Strainer

Gate

Valve

Flow

Gate

Valve

Protect All Field Piping

Flow

gainst Freezing

NOTE: Inlet and outlet connections may be reversed on some units. Check unit

dimension drawing.

System Water Volume

It is important to have adequate water volume in the system to provide an opportunity for the chiller

to sense a load change, adjust to the change, and then stabilize. As the expected load change

becomes more rapid, a greater water volume is needed. The system water volume is the total

amount of water in the evaporator, air handling equipment, and associated piping. If the water

volume is too low, operational problems can occur including rapid compressor cycling, rapid

loading and unloading of compressors, erratic refrigerant flow in the chiller, improper motor

cooling, shortened equipment life and other undesirable occurrences.

For normal comfort cooling applications where the cooling load changes relatively slowly, a

minimum system volume of two to three minutes times the flow rate (GPM) is recommended. For

example, if the design chiller flow rate is 120 gpm, we recommend a system volume of 240 to 360

gallons.

For process applications where the cooling load can change rapidly, additional system water

volume is needed. A process example would be the quenching of hot metal objects. The load would

be very stable until the hot metal is dipped into the water tank. Then, the load would increase

drastically.

Since there are many other factors that can influence performance, systems can successfully operate

below these suggestions. However, as the water volume decreases below these guidelines, the

possibility of problems increases.

IMM WGZC WGZ 030C through 200C 11

Page 12

W

Variable Chilled Water Flow

Reducing chilled water flow in proportion to load can reduce total system power consumption.

Certain restrictions apply to the amount and rate of flow change. The rate of flow change should

be a maximum of 10 percent of the change, per minute. Do not reduce flow lower than the part

load minimum flows listed on page

15.

Chilled Water Piping

The system water piping must be flushed thoroughly prior to making connections to the unit

evaporator. It is required that a 40-mesh strainer be installed in the return water line before the

inlet to the chiller. Lay out the water piping so the chilled water circulating pump discharges into

the evaporator inlet.

The return water line must be piped to the evaporator inlet connection and the supply water line

must be piped to the evaporator outlet connection. If the evaporator water is piped in the reverse

direction, a substantial decrease in capacity and efficiency of the unit will be experienced.

A flow switch must be installed in the horizontal piping of the supply (evaporator outlet) water

line to prove water flow before starting the unit.

Drain connections should be provided at all low points in the system to permit complete drainage

of the system. Air vents should be located at the high points in the system to purge air out of the

system. The evaporators are not equipped with vent or drain connections and provision must be

made in the entering and leaving chilled water piping for venting and draining.

Pressure gauges should be installed in the inlet and outlet water lines to the evaporator. Pressure

drop through the evaporator should be measured to determine water flow from the flow/pressure

drop curves beginning on page

return water lines.

Chilled water piping should be insulated to reduce heat loss and prevent condensation. Complete

unit and system leak tests should be performed prior to insulating the water piping. Insulation

with a vapor barrier would be the recommended type of insulation. If the vessel is insulated, the

vent and drain connections must extend beyond the proposed insulation thickness for

accessibility.

Chillers not run in the winter should have their water systems thoroughly drained if subject to

sub-freezing temperatures. If the chiller operates year-round, or if the system is not drained for

the winter, the chilled water piping exposed to sub-freezing ambient temperatures should be

protected against freezing by wrapping the lines with a heater cable. In addition, an adequate

percentage of glycol should be added to the system to further protect the system during low

ambient temperature periods. It should be noted that water piping that has been left drained is

subject to more corrosion than if filled with water. Use of a Vapor Corrosion Inhibitor (VCI) or

some other protection should be considered.

16. Vibration eliminators are recommended in both the supply and

Figure 4 Thermostat Well Location, WGZ 030 - 130

The chilled water sensor is factory installed in the leaving water

Suction

Circuit #1

Suction

Circuit #2

Leaving Chilled

Water Sensor

Liquid

Circuit #2

Liquid

Circuit #1

12 WGZ 030C through 200C IMM

connection on the evaporator. Care should be taken not to damage

the sensor cable or lead wires when working around the unit. It is

also advisable to check the lead wire before running the unit to be

sure that it is firmly anchored and not rubbing on the frame or any

other component. If the sensor is ever removed from the well for

servicing, care must be taken to not wipe off the heat-conducting

compound supplied in the well.

Page 13

!

T

CAUTION

The thermostat bulb should not be exposed to water temperatures above 125°F (51.7°C)

since this will damage it.

Flow Switch

A water flow switch must be mounted in the leaving evaporator and condenser water lines to

prove adequate water flow before the unit can start. This will safeguard against slugging the

compressors on start-up. It also serves to shut down the unit in the event that water flow is

interrupted to guard against evaporator freeze-up.

Factory-mounted and wired evaporator and condenser flow switches are available as an option

If the optional factory flow switch is not supplied, a flow switch is available from McQuay under

part number 01750330. It is a “paddle” type switch and adaptable to any pipe size from 1 in. (25

mm) to 6 in. (152 mm) nominal. Certain flow rates are required to open the switch and are listed

Table 13. Wire from switch terminals Y and R to panel terminals 33 and 43 (chilled water) and

in

41 and 53 (condenser water). There is also a set of normally closed contacts on the switch that

could be used for an indicator light or an alarm to indicate when a “no flow” condition exists.

1. Apply pipe sealing compound to only the threads of the switch and screw unit into 1 in. (25 mm)

reducing tee. The flow arrow must be pointed in the correct direction.

2. Piping should provide a straight length before and after the flow switch of at least five times the

pipe diameter without any valves, elbows, or other flow restricting elements.

!

CAUTION

Make sure the arrow on the side of the switch is pointed in the direction of flow. The flow

switch is designed to handle the control voltage and should be connected according to the

wiring diagram

Table 13, Paddle-Type Flow Switch Flow Rates

No

No

inch 1 1/4 1 1/2 2 2 1/2 3 4 5 6 8 Pipe Size

mm 32 (2) 38 (2) 51 63 (3) 76 102 (4) 127 (4) 153 (4) 204 (5)

gpm 5.8 7.5 13.7 18.0 27.5 65.0 125.0 190.0 205.0

Lpm 1.3 1.7 3.1 4.1 6.2 14.8 28.4 43.2 46.6

gpm 3.7 5.0 9.5 12.5 19.0 50.0 101.0 158.0 170.0

gpm 13.3 19.2 29.0 34.5 53.0 128.0 245.0 375.0 415.0

Lpm 3.0 4.4 6.6 7.8 12.0 29.1 55.6 85.2 94.3

gpm 12.5 18.0 27.0 32.0 50.0 122.0 235.0 360.0 400.0

NOTES (x)

Min.

Adjst.

Max.

Adjst.

Flow

Flow Lpm 0.8 1.1 2.2 2.8 4.3 11.4 22.9 35.9 38.6

Flow

Flow Lpm 2.8 4.1 6.1 7.3 11.4 27.7 53.4 81.8 90.8

NOTES:

1. A segmented 3-inch paddle (1, 2, and 3 inches) is furnished mounted, plus a 6-inch paddle loose.

2. Flow rates for a 2-inch paddle trimmed to fit the pipe.

3. Flow rates for a 3-inch paddle trimmed to fit the pipe.

4. Flow rates for a 3-inch paddle.

5. Flow rates for a 6-inch paddle.

Glycol Solutions

Chiller capacity, flow rate, evaporator pressure drop, and power input for glycol solutions can be

calculated using the following formulas and reference to

propylene glycol.

1. Capacity, Capacity is reduced compared to that with plain water. To find the reduced value,

multiply the chiller’s capacity when using water by the capacity correction factor C to find

the chiller’s capacity when using glycol.

2. Flow, To determine evaporator gpm (or T) knowing T (or gpm) and capacity:

Table 14 for ethylene and Table 15 for

GPMGlycol

IMM WGZC WGZ 030C through 200C 13

24

CapacityGlycolx

TablesFromGCorrectionFlowx

Page 14

W

For Metric Applications -- Determine evaporator lps (or T) knowing T (or lps)

and kW:

LpsGlycol

kW

Tx

18.4

TablesfromGCorrectionFlowx

3. Pressure Drop, To determine glycol pressure drop through the cooler, enter the water

pressure drop graph on page

15 at the actual glycol flow. Multiply the water pressure

drop found there by P to obtain corrected glycol pressure drop.

4. Power, To determine glycol system kW, multiply the water system kW by factor K.

Test coolant with a clean, accurate, glycol solution hydrometer (similar to that found in

service stations) to determine the freezing point. Obtain percent glycol from the freezing

point found in

Table 14 or Table 15. On glycol applications the supplier normally

recommends that a minimum of 25% solution by weight be used for protection against

corrosion or the use of additional inhibitors.

Note: The effect of glycol in the condenser is negligible. As glycol increases in

temperature, its characteristics have a tendency to mirror those of water.

Therefore, for selection purposes, there is no derate in capacity for glycol in the

condenser.

Table 14, Ethylene Glycol

Glycol

10 26 -3 0.991 0.996 1.013 1.070

20 18 -8 0.982 0.992 1.040 1.129

30 7 -14 0.972 0.986 1.074 1.181

40 -7 -22 0.961 0.976 1.121 1.263

50 -28 -33 0.946 0.966 1.178 1.308

Freezing Point Percent

°F °C

C (Capacity) K (Power) G (Flow)

P (Pressure

Drop)

Table 15, Propylene Glycol

Glycol

10 26 -3 0.987 0.992 1.010 1.068

20 19 -7 0.975 0.985 1.028 1.147

30 9 -13 0.962 0.978 1.050 1.248

40 -5 -21 0.946 0.971 1.078 1.366

50 -27 -33 0.929 0.965 1.116 1.481

Freezing Point Percent

°F °C

C (Capacity) K (Power) G (Flow)

P (Pressure

Drop)

!

CAUTION

Do not use automotive antifreeze. Industrial glycols must be used. Automotive antifreeze

contains inhibitors that causes plating on copper tubes. The type and handling of glycol used

must be consistent with local codes.

14 WGZ 030C through 200C IMM

Page 15

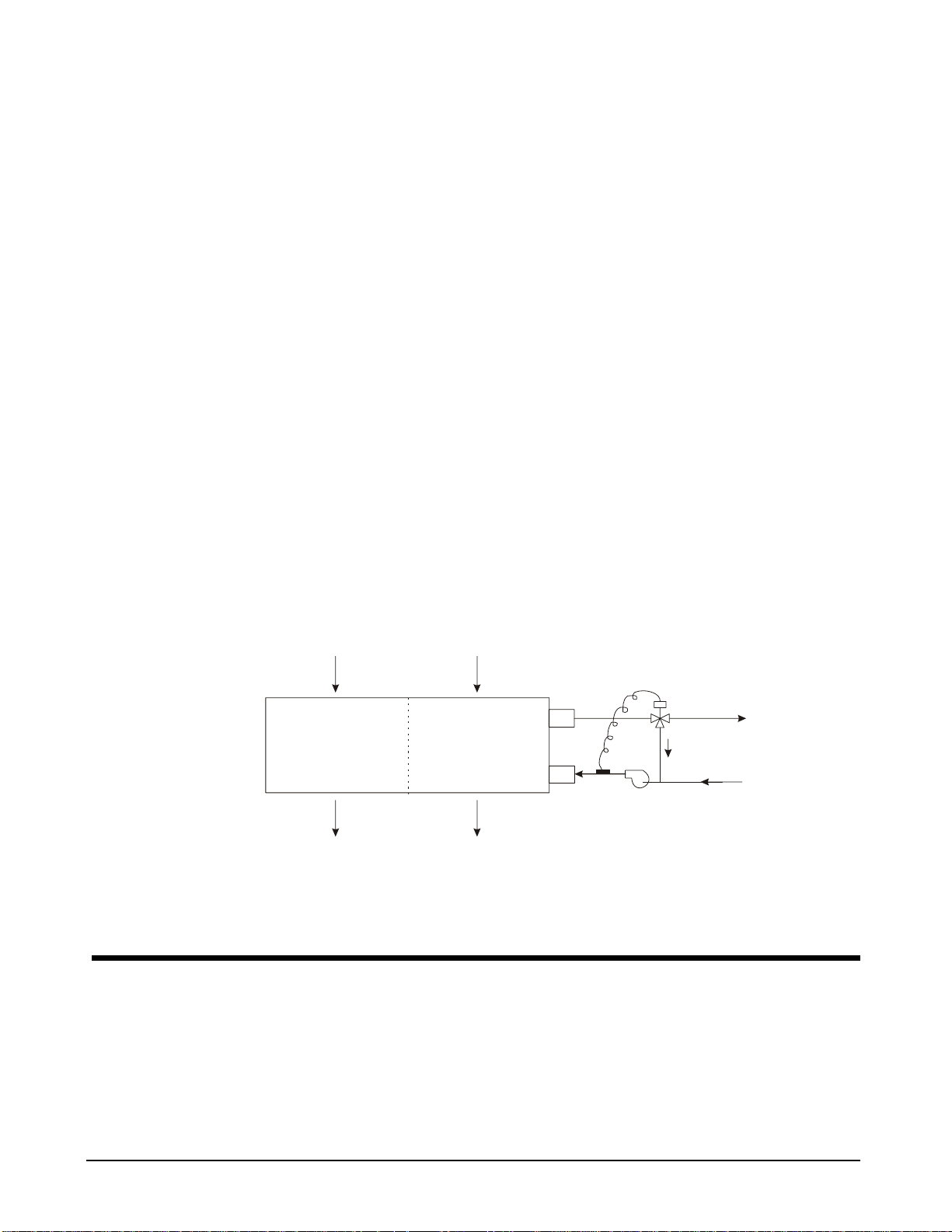

Condenser Water Piping

Arrange the condenser water so the water enters the bottom connection of the condenser.

The condenser water will discharge from the top connection. Failing to arrange the

condenser water as stated above will negatively affect the capacity and efficiency.

Install pressure gauges in the inlet and outlet water lines to the condenser. Pressure drop

through the condenser should be measured to determine flow on the pressure drop/flow

curves on page

water lines. Install a 20-mesh strainer in the inlet piping to the condenser.

Water-cooled condensers can be piped for use with cooling towers, well water, or heat

recovery applications. Cooling tower applications should be made with consideration of

freeze protection and scaling problems. Contact the cooling tower manufacturer for

equipment characteristics and limitations for the specific application.

Head pressure control must be provided if the entering condenser water can fall below

60F. The WGZ condenser has two refrigerant circuits with a common condenser water

circuit. This arrangement makes head pressure control with discharge pressure actuated

control valves difficult.

If the tower water temperature cannot be maintained at a 60F minimum, or when pond,

lake, or well water that can fall below 60F (15C) is used as the condensing medium,

special discharge pressure control must be used. A water recirculating system with

recirculating pump as shown in

advantage of maintaining tube velocity to help prevent tube fouling. The pump should

cycle with the chiller.

Table 16, Recirculating Discharge Pressure Control System

17. Vibration eliminators are recommended in both the supply and return

Table 16 is recommended. This system also has the

Circuit #1

Inlet

Circuit #2

Inlet

Temperature

Control

Val ve

Condenser

Condenser

Water

Circuit #1

Outlet

Circuit #2

Outlet

Pressure Drops

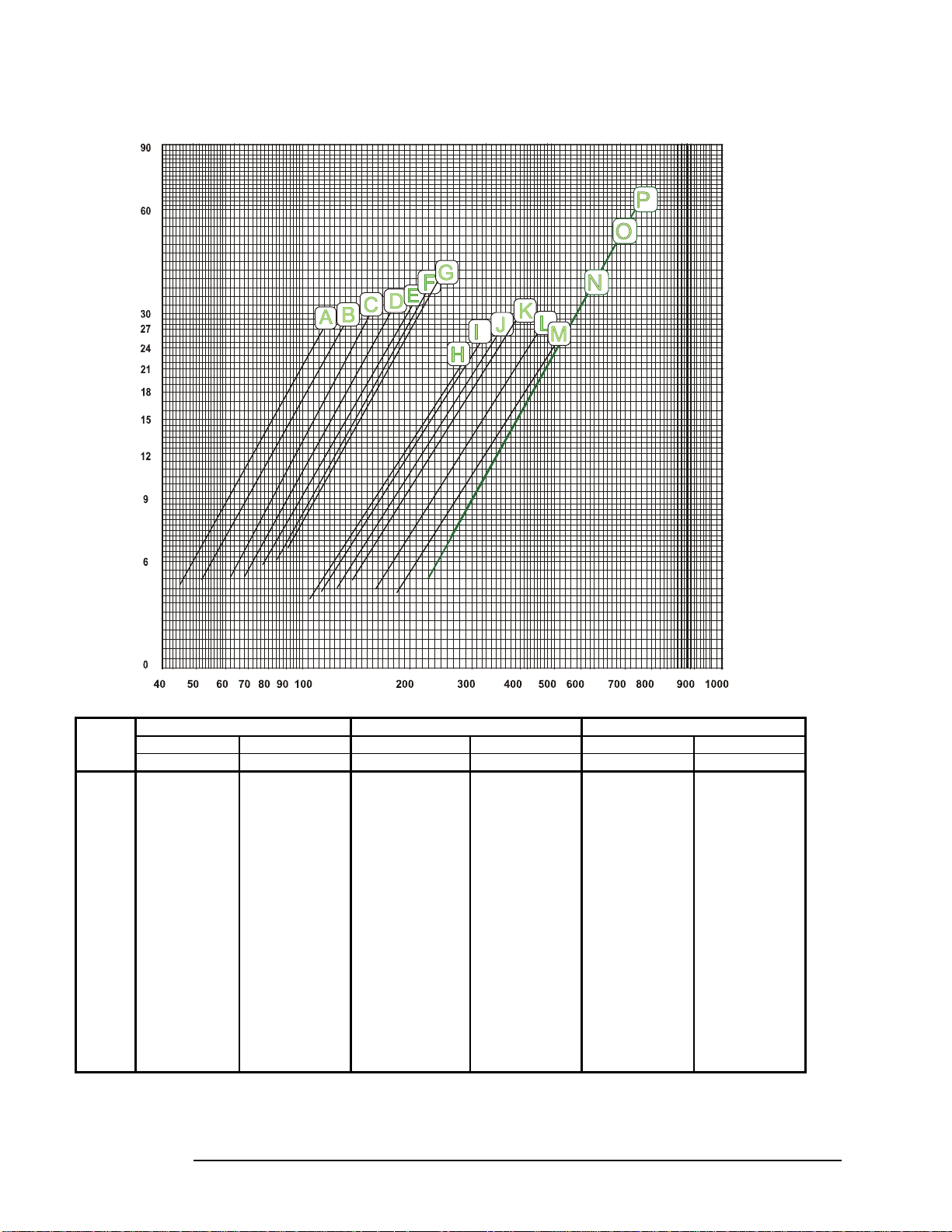

The evaporator flow rates and pressure drops shown on the following page (Figure 5) are for full load

design purposes. The maximum flow rate and pressure drop are based on a 6-degree temperature drop.

Avoid higher flow rates with resulting lower temperature drops to prevent potential control problems

resulting from very small control bands and limited start up/shut off temperature changes.

The minimum flow and pressure drop is based on a full load evaporator temperature drop of 16-degrees.

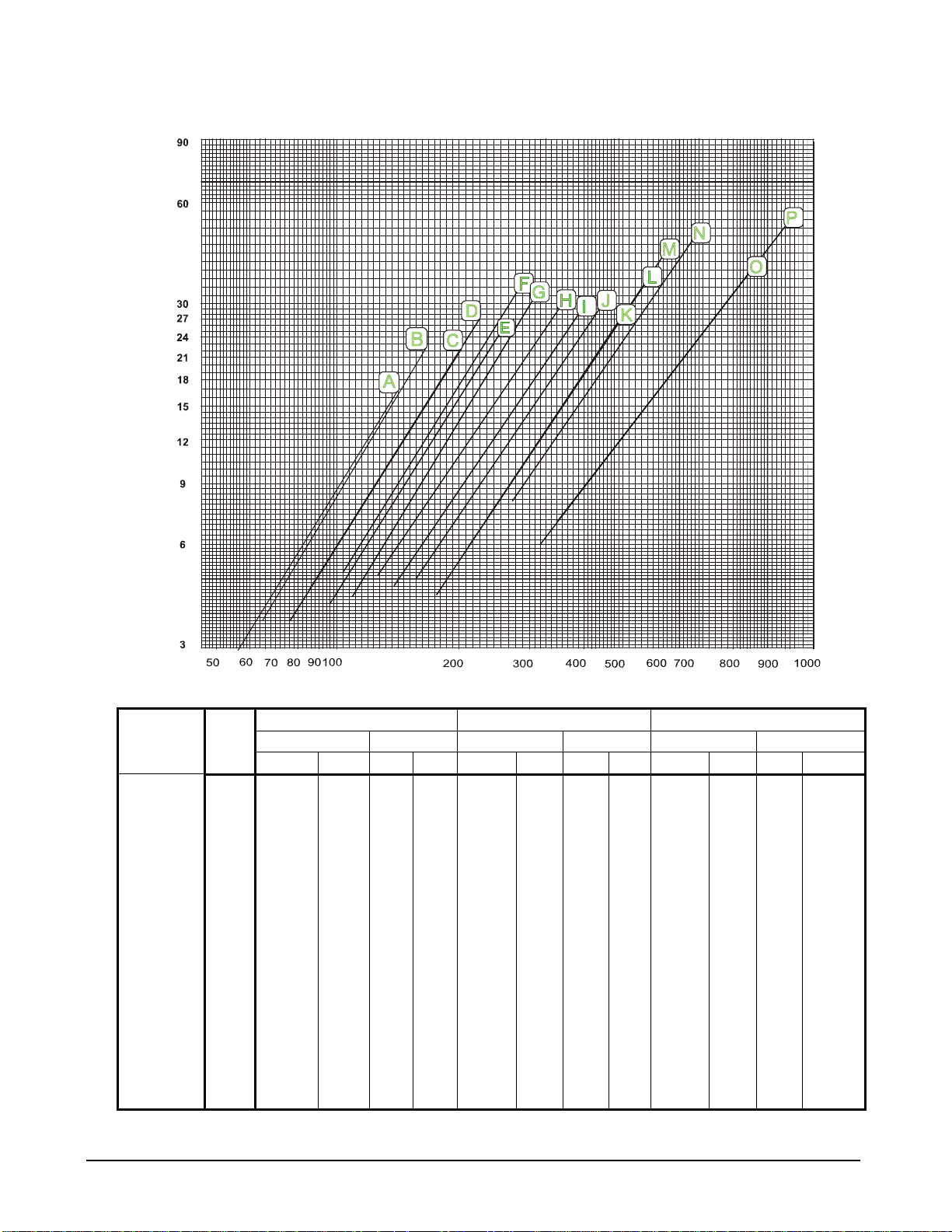

Condenser pressure drops are shown in

IMM WGZC WGZ 030C through 200C 15

Figure 6 on page 17.

Page 16

W

Figure 5, Evaporator Pressure Drop, WGZ 030C – WGZ 200C

)

Pressure Drop (ft of water)

WGZ-C

Model

030

035

040

045

050

055

060

070

080

090

100

115

130

150

175

200

Inch-Pound S.I. Inch-Pound S.I. Inch-Pound S.I.

GPM Ft. L/S kPa GPM Ft. L/S kPa GPM Ft. L/S kPa

45.0 4.7 2.8 14.1 72.0 11.0 4.5 32.9 120.0 27.6 7.6 82.4

51.9 4.9 3.3 14.6 83.0 11.4 5.2 34.0 138.3 28.5 8.7 85.4

61.1 5.1 3.9 15.2 97.8 11.8 6.2 35.4 163.0 29.7 10.3 88.8

68.2 5.2 4.3 15.5 109.1 12.1 6.9 36.1 181.8 30.2 11.5 90.4

76.7 5.8 4.8 17.2 122.6 13.4 7.7 40.1 204.4 33.6 12.9 100.6

84.6 6.1 5.3 18.1 135.4 14.1 8.5 42.2 225.6 35.4 14.2 105.9

90.8 6.6 5.7 19.7 145.2 15.6 9.2 46.5 242.0 39.2 15.3 117.1

106.3 3.7 6.7 10.9 170.0 8.6 10.7 25.6 283.4 21.2 17.9 63.3

117.5 4.3 7.4 12.8 187.9 10.0 11.9 29.9 313.2 25.0 19.8 74.9

132.1 4.5 8.3 13.3 211.3 10.5 13.3 31.3 352.1 26.1 22.2 78.1

146.6 4.9 9.3 14.6 234.6 11.4 14.8 34.1 391.1 28.7 24.7 85.8

169.3 4.5 10.7 13.5 270.9 10.5 17.1 31.4 451.5 26.4 28.5 78.9

188.1 4.2 11.9 12.6 301.0 9.8 19.0 29.5 501.6 24.7 31.6 73.9

219.9 5.0 15.0 351.8 12.8 38.3 586.4 35.5 106.1

254.0 7.2 21.5 406.3 18.5 55.3 677.2 51.4 153.6

282.2 8.6 25.7 451.4 22.0 65.8 752.4 61.0 182.3

Notes:

1. Minimum, nominal, and maximum flows are at a 16-degree F, 10-degree F, and 6-degree F chilled water temperature range

respectively and at ARI tons.

Minimum Flow Nominal Flow Maximum Flow

Flow Rate (GPM

16 WGZ 030C through 200C IMM

Page 17

Figure 6, Condenser Pressure Drop, WGZ 030C – WGZ 200C

)

Pressure Drop (ft of water)

Flow Rate (GPM

Unit Model

WGZ030C 30 56.1 2.4 3.5 7.2 89.7 6.3 5.7 18.8 149.5 17.4 9.4 52.0

WGZ035C 35 64.9 3.4 4.1 10.2 103.8 8.6 6.5 25.7 173.0 23.9 10.9 71.4

WGZ040C 41 76.3 2.7 4.8 8.1 122.1 6.9 7.7 20.6 203.5 19.3 12.8 57.7

WGZ045C 46 85.3 3.6 5.4 10.8 136.5 9.2 8.6 27.5 227.5 25.7 14.4 76.8

WGZ050C 51 96.4 2.9 6.1 8.7 154.2 7.5 9.7 22.4 257.0 20.7 16.2 61.9

WGZ055C 57 105.8 3.8 6.7 11.4 169.2 9.7 10.7 29.0 282.0 26.8 17.8 80.1

WGZ060C 63 113.4 4.5 7.2 13.5 181.5 11.6 11.5 34.7 302.5 32.3 19.1 96.5

WGZ070C 71 132.8 4.1 8.4 12.3 212.4 10.4 13.4 31.1 354.0 29.0 22.3 86.7

WGZ080C 78 146.8 3.7 9.3 11.1 234.9 9.5 14.8 28.4 391.5 26.5 24.7 79.2

WGZ090C 88 165.0 3.4 10.4 10.2 264 8.8 16.7 26.3 440.0 24.5 27.8 73.2

WGZ100C 98 183.4 3.4 11.6 10.2 293.4 8.8 18.5 26.3 489.0 24.4 30.9 72.9

WGZ115C 113 211.7 4.8 13.4 14.3 338.7 12.3 21.4 36.8 564.5 34.1 35.6 101.9

WGZ130C 128 235.1 6.1 14.8 18.2 376.2 15.5 23.7 46.3 627.0 43.1 39.6 128.8

WGZ150C 147 274.9 6.2 17.3 18.5 439.8 15.8 27.7 47.2 733.0 43.8 46.2 130.9

WGZ170C 169 317.4 5.5 20.0 16.4 507.9 14.0 32.0 41.8 846.5 38.9 53.4 116.3

WGZ200C 188 352.7 7.4 22.3 22.1 564.3 18.8 35.6 56.2 940.5 52.3 59.3 156.3

Nom

Tons

Min. Flow & PD Nom. Flow & PD Max. Flow & PD

IP SI IP SI IP SI

GPM Ft. L/S kPa GPM Ft. L/S kPa GPM Ft. L/S kPa

IMM WGZC WGZ 030C through 200C 17

Page 18

W

Refrigerant Piping

Unit with Remote Condenser

General

Refrigerant piping, to and from the unit, should be sized and installed according to the

latest ASHRAE Handbook. It is important that the unit piping be properly supported with

sound and vibration isolation between tubing and hanger, and that the discharge lines be

looped at the condenser and trapped at the compressor to prevent refrigerant and oil from

draining into the compressors. Looping the discharge line also provides greater line

flexibility.

NOTE: Do not install any refrigerant piping underground.

The discharge gas valves, liquid line solenoids, filter-driers, moisture indicators, and

thermostatic expansion valves are all factory mounted as standard equipment with the

water chiller.

For remote condenser application (WGZ-CA) such as air-cooled or evaporative

condenser, the chillers are shipped with an R-410A holding charge. The unit is evacuated

in the factory to 500 microns before charging with the holding. The unit is leak tested

after charging and before shipment.

The liquid line has a shutoff valve upstream from the liquid line solenoid valve and a

copper tube cap to be brazed on this line after test to seal this line for shipment.

The discharge line has a ball valve installed between the compressor and the discharge

stub tube with a copper tube cap brazed on the line after test to seal it for shipment.

The discharge gas valves, liquid line solenoids, filter-driers, moisture indicators, and

thermostatic expansion valves are all factory-mounted as standard equipment with the

water chiller.

!

DANGER

Do not apply heat, such as a brazing torch, to a sealed unit, vessel, or component. Internal

gases can increase the internal pressure and cause a life-threatening explosion. Open the

system when heating. The short line between a valve and brazed end cap can be drilled to

vent it. Note that the valve may leak and the entire unit charge may be open to the cap.

It is important that the unit be kept tightly closed until the remote condenser is installed,

piped to the unit and the high side evacuated. NOTE: it is possible to maintain a positive

refrigerant pressure in the unit when a small leak is present. Therefore, add refrigerant to

the unit to achieve sufficient pressure to allow a good leak test and carefully leak test the

unit. Correct any leaks found.

When the field piping has been leak tested, evacuated, and is ready to charge, the unit

valves can be opened and the system charged.

Alternate method: an alternate method is to open up the unit to the field piping and to

pressure test, evacuate and charge the entire system together at one time. Many people

feel that this is a more straight-forward approach.

After the equipment is properly installed, leak tested, and evacuated, it can be charged

with R-410A, and run at design load conditions. Add charge until the liquid line sight

glass is clear, with no bubbles flowing to the expansion valve. Total operating charge will

depend on the air-cooled condenser used and volume of the refrigerant piping.

18 WGZ 030C through 200C IMM

Page 19

NOTE: On WGZ-CA units (units with remote condensers), the installer is required to

record the refrigerant charge by stamping the total charge and the charge per circuit on

the serial plate in the appropriate blocks provided for this purpose.

The following discussion is intended for use as a general guide to the piping of air-cooled

condensers.

Discharge lines must be designed to handle oil properly and to protect the compressor

from damage that can result from condensing liquid refrigerant in the line during

shutdown. Total friction loss for discharge lines of 3 to 6 psi (20.7 to 41.4 kPa) is

considered good design. Careful consideration must be given for sizing each section of

piping to insure that gas velocities are sufficient at all operating conditions to carry oil. If

the velocity in a vertical discharge riser is too low, considerable oil can collect in the riser

and the horizontal header, causing the compressor to lose its oil and result in damage due

to lack of lubrication. When the compressor load is increased, the oil that had collected

during reduced loads can be carried as a slug through the system and back to the

compressor, where a sudden increase of oil concentration can cause liquid slugging and

damage to the compressor.

Any horizontal run of discharge piping should be pitched away from the compressor

approximately 1/8 inch (6.4 mm) per foot (meter) or more. This is necessary to move, by

gravity, any oil lying in the header. Oil pockets must be avoided because oil needed in the

compressor would collect at such points and the compressor crankcase can become

starved.

It is recommended that any discharge lines coming into a horizontal discharge header rise

above the centerline of the discharge header. This is necessary to prevent any oil or

condensed liquid from draining to the compressor heads when the compressor is not

running.

In designing liquid lines, it is important that the liquid reach the expansion valve without

flash gas since this gas will reduce the capacity of the valve. Because “flashing” can be

caused by a pressure drop in the liquid line, the pressure losses due to friction and

changes in static head should be kept to a minimum.

A check valve must be installed in the liquid line in all applications where the ambient

temperature can drop below the equipment room temperature. This prevents liquid

migration to the condenser, helps maintain a supply of refrigerant in the liquid line for

initial start-up, and keeps liquid line pressure high enough on “off” cycle to keep the

expansion valve closed.

On systems as described above, a relief valve or relief-type check valve, must be used in

the liquid line as shown in piping systems (shown in

and Its purpose is to relieve

dangerous hydraulic pressures that could be created as cool liquid refrigerant trapped in

the line between the check valve and the expansion or shutoff valve warms up. Install a

relief device in the hot gas piping at the condenser coil as shown in

and Figure 8. Install

a discharge check valve in the discharge line, in a horizontal run, close to the condenser.

Recommended Line Sizing

The following tables provide recommended line sizing for the field piping. Final design

should be based on ASHRAE design standards.

IMM WGZC WGZ 030C through 200C 19

Page 20

W

Table 17, Equivalent Feet for Fittings

Fitting Type 7/8 1 1/8 1 3/8 1 5/8 2 1/8 2 5/8 3 1/8

Elbows

90º Standard 2.0 2.6 3.3 4.0 5.0 6.0 7.5

90º Long Radius 1.4 1.7 2.3 2.6 3.3 4.1 5.0

90º Street 3.2 4.1 5.6 6.3 8.2 10 12

45º Standard 0.9 1.3 1.7 2.1 2.6 3.2 4.0

45º Street 1.5 2.1 3.0 3.4 4.5 5.2 6.4

180º Bend 3.2 4.1 5.6 6.3 8.2 10 12

Tees

Full Size 1.4 1.7 2.3 2.6 3.3 4.1 5.0

Reducing 2.0 2.6 3.3 4.0 5.0 6.0 7.5

Valves

Globe Valve, Open 22 29 38 43 55 69 84

Gate Valve, Open 0.9 1.0 1.5 1.8 2.3 2.8 3.2

Angle Valve, Open 9.0 12 15 18 24 29 35

Table 18, Maximum Line Size for Oil Carry Up a Discharge Riser, R-410A

Unit Size

Line

Size (in.)

Unit Size

Line

Size (in.)

WGZ

030

1 5/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8

WGZ

100

2 5/8 3 1/8 3 1/8 2 5/8 3 1/8 3 1/8

WGZ

035

WGZ

115

WGZ

040

WGZ

130

WGZ

045

WGZ

150

WGZ

050

WGZ

170

WGZ

055

WGZ

200

WGZ

060

WGZ

070

WGZ

080

Table 19, Recommended Liquid Line Size, R-410A

Unit Model

WGZ-CB

WGZ 030 7/8" 7/8 " 7/8 " 7/8 " 7/8 " 7/8 "

WGZ 035 7/8" 7/8 " 7/8 " 7/8 " 7/8 " 1 1/8 "

WGZ 040 7/8" 7/8 " 7/8 " 7/8 " 1 1/8 " 1 1/8 "

WGZ 045 7/8" 7/8 " 7/8 " 7/8 " 1 1/8 " 1 1/8 "

WGZ 050 7/8" 7/8 " 7/8 " 7/8 " 1 1/8 " 1 1/8 "

WGZ 055 7/8" 7/8 " 7/8 " 1 1/8” 1 1/8 " 1 1/8 "

WGZ 060 7/8" 7/8 “ 7/8 " 1 1/8 " 1 1/8 " 1 1/8 "

WGZ 070 1 1/8” 1 1/8” 1 1/8 " 1 1/8 " 1 1/8 " 1 1/8”

WGZ 080 1 1/8” 1 1/8 " 1 1/8 " 1 1/8” 1 1/8” 1 1/8”

WGZ 090 1 1/8” 1 1/8 " 1 1/8 " 1 1/8” 1 1/8” 1 1/8”

WGZ 100 1 1/8” 1 1/8 " 1 1/8 " 1 1/8” 1 1/8” 1 1/8”

WGZ 115 1 1/8” 1 1/8 " 1 1/8 " 1 1/8” 1 3/8” 1 3/8”

WGZ 130 1 1/8” 1 1/8 " 1 3/8” 1 1/8” 1 3/8” 1 3/8”

WGZ 150 1 3/8” 1 3/8” 1 1/8 " 1 3/8” 1 3/8” 1 3/8”

WGZ 170 1 3/8” 1 3/8” 1 1/8 " 1 3/8” 1 3/8” 1 3/8”

WGZ-200 1 3/8” 1 3/8” 1 1/8 " 1 3/8” 1 3/8” 1 3/8”

Connection

Size at Unit

(in.)

Up to Up to Up to Up to Up to

50 Equiv. Ft 75 Equiv. Ft 100 Equiv. Ft 125 Equiv. Ft 150 Equiv. Ft

Recommended Liquid Line Size (in.)

WGZ

090

20 WGZ 030C through 200C IMM

Page 21

Table 20, Recommended Horizontal or Downflow Discharge Line Size, R-410A

Unit Model

AGZ-CB

WGZ 030 1 3/8" 1 1/8" 1 1/8" 1 1/8" 1 1/8" 1 1/8"

WGZ 035 1 3/8" 1 3/8" 1 3/8" 1 3/8" 1 3/8" 1 3/8"

WGZ 040 1 3/8" 1 3/8" 1 3/8" 1 3/8" 1 3/8" 1 3/8"

WGZ 045 1 3/8" 1 3/8" 1 3/8" 1 3/8" 1 3/8" 1 3/8"

WGZ 050 1 3/8" 1 3/8" 1 3/8" 1 3/8" 1 3/8" 1 3/8"

WGZ 055 1 3/8" 1 3/8" 1 3/8" 1 3/8" 1 3/8" 1 3/8"

WGZ 060 1 3/8" 1 3/8" 1 5/8” 1 5/8” 1 5/8” 1 5/8”

WGZ 070 1 3/8" 1 3/8" 1 5/8” 1 5/8” 1 5/8” 1 5/8”

WGZ 080 1 5/8” 1 5/8” 1 5/8” 1 5/8” 1 5/8” 1 5/8”

WGZ 090 1 5/8” 1 5/8” 1 5/8” 1 5/8” 1 5/8” 1 5/8”

WGZ 100 1 5/8” 1 5/8” 1 5/8” 1 5/8” 1 5/8” 1 5/8”

WGZ 115 1 5/8” 1 5/8” 1 5/8” 2 1/8" 2 1/8" 2 1/8"

WGZ 130 1 5/8” 1 5/8” 2 1/8" 2 1/8" 2 1/8" 2 1/8"

WGZ 150 2 1/8" 2 1/8" 2 1/8" 2 1/8" 2 1/8" 2 1/8"

WGZ 170 2 1/8" 2 1/8" 2 1/8" 2 1/8" 2 1/8" 2 1/8"

WGZ 200 2 1/8" 2 1/8" 2 1/8" 2 1/8" 2 1/8" 2 5/8"

Connection

Size

At Unit

Up to Up to Up to Up to Up to

50 Equiv. Ft 75 Equiv. Ft 100 Equiv. Ft 125 Equiv. Ft 150 Equiv. Ft

Recommended Discharge Line Sizes

T ypical Arrangement s

Figure 7 illustrates a typical piping arrangement involving a remote air-cooled condenser

located at a higher elevation than the compressor and receiver. This arrangement is commonly

encountered when the air-cooled condenser is on a roof and the compressor and receiver are on

grade level or in a basement equipment room.

Notice, in both illustrations, that the hot gas line is looped at the bottom and top of the vertical

run. This is done to prevent oil and condensed refrigerant from flowing back into the

compressor and causing damage. The highest point in the discharge line should always be

above the highest point in the condenser coil. It is advisable to include a purging vent at this

point to extract non-condensables from the system.

Figure 8 illustrates another very common application where the air-cooled condenser is located

on essentially the same level as the compressor and receiver. The discharge line piping in this

case is not too critical. The principal problem encountered with this arrangement is that there

is frequently insufficient vertical distance to allow free drainage of liquid refrigerant from the

condenser coil to the receiver.

The receiver is used when it is desired to have refrigerant storage capacity, in addition to the

pumpdown capability of the condenser.

IMM WGZC WGZ 030C through 200C 21

Page 22

W

Figure 7, Condenser Above Compressor and Optional Receiver Installation

Check Valve

Relief Valve

Purge Valve

Condenser

h

c

t

i

P

Discharge Line

Loop

Relief Valve

(Vent to Outdoors

or to Condenser Side

of Liquid Line

Check Valve)

Preferred

Subcooler

Hook-up

Subcooler

To

Evap.

Receiver

Bypass

Check

Valve

Receiver

Figure 8, Condenser and Compressor on Same Level, Optional Receiver

Installation

The receiver shown is optional and not used on many installations. It is bypassed during

normal operation.

Relief Valve

(Vent to Outdoors

or to Condenser Side

of Liquid Line

Check Valve)

Preferred

Subcooler

Hook-up

Condenser

Subcooler

Relief Valve

To

Evap.

Receiver

Bypass

Receiver

Check Valve

h

c

t

i

P

Check

Valve

Check

Valve

Purge Valve

Discharge Line

22 WGZ 030C through 200C IMM

Page 23

Factory-Mounted Condenser

Units with the standard water-cooled, factory-mounted condenser are provided with

complete refrigerant piping and full operating refrigerant charge at the factory.

There is a remote possibility on water-cooled units utilizing low temperature pond or

river water as a condensing medium, and if the water valves leak, that the condenser and

liquid line refrigerant temperature could drop below the equipment room temperature on

the “off” cycle. This problem only arises during periods when cold water continues to

circulate through the condenser and the unit remains off due to satisfied cooling load.

If this condition occurs:

1. Cycle the condenser pump off with the unit.

2. Check the liquid line solenoid valve for proper operation.

Relief Valve Piping

The ANSI/ASHRAE Standard 15, Safety Standard for Refrigeration Systems, specifies

that pressure relief valves on vessels containing Group 1 refrigerant (R-22) “shall

discharge to the atmosphere at a location not less than 15 feet (4.6 meters) above the

adjoining ground level and not less than 20 feet (6.1 meters) from any window,

ventilation opening or exit in any building.” The piping must be provided with a rain cap

at the outside terminating point and with a drain at the low point on the vent piping to

prevent water buildup on the atmospheric side of the relief valve. In addition, a flexible

pipe section should be installed in the line to eliminate any piping stress on the relief

valve(s).

The size of the discharge pipe from the pressure relief valve should not be less than the

size of the pressure relief outlet. When two or more vessels are piped together, the

common header and piping to the atmosphere should not be less than the sum of the area

of each of the lines connected to the header.

NOTE: Fittings should be provided to permit vent piping to be easily

disconnected for inspection or replacement of the relief valve.

Table 21, Relief Valve Piping

IMM WGZC WGZ 030C through 200C 23

Page 24

W

Dimensions

C

Packaged Chillers

Figure 9, WGZ 030CW through WGZ 060CW

L4 / M4

L1 / M1

CIRCUIT 2

VENT

DRAIN

REF.

3.8

98

WGZ MODEL

NUMBER

WGZ030C

WGZ035C

WGZ040C

WGZ045C

WGZ050C

WGZ055C

WGZ060C

"A"

MICROTECH II US ER INTERFACE

CIRCUIT 1

" Y "

RELIEF VALVES

121.1

3075

134.6

3419

CHILLER WATER CONNECTION

SIZE (NOM) VICTAULIC

IN (MM) A IN (MM) X Y Z

2.5 (64) 107.4 (2728) 4 (102) 59.2 22.4 14.1

2.5 (64) 108.4 (2753) 4 (102) 59.9 22.8 14.2

2.5 (64) 109.8 (2789) 4 (102) 59.6 22.8 14.2

2.5 (64) 111.5 (2832 4 (102) 59.2 22.9 14.2

2.5 (64) 113.3 (2878) 4 (102) 59.0 23.3 14.2

2.5 (64) 115.0 (2921) 4 (102) 58.7 23.4 14.2

2.5 (64) 116.7 (2965) 4 (102) 58.0 23.6 14.3

CONTROL BOX

" X "

L3 / M3

WATER

CONNECTIONS

L2 / M2

CONTROL

CONNECTION

.88 KNOCKOUTS

ON OPPOSITE SIDE

REMOVABLE

DISC. HANDLE

POWER

CONNECTIONS

3.9

100

OUTLET

CONDENSER

INLET

9.7

246

.88 KNOCKOUTS

CONDENSER WATER

CONNECTION SIZE

(NOM) VICTAULIC

23.5

597

2.0

51

63.4

1609

20.0

508

" Y "

12.4

314

" Z "

.875 DIA MOUNTING HOLES (4)

CENTER OF GRAVITY

32.8

832

30.1

763

OUTLET

29.0

737

32.0

813

INLET

40.0

1016

13.3

338

EVAPORATOR

REMOVE BRKT.

FOR SHIPPING

ONLY

8.0

204

WGZ030C-060

44.9

1139

29.2

742

14.0

354

Packaged Unit

331929701

24 WGZ 030C through 200C IMM

Page 25

Figure 10, WGZ 070CW through WGZ 130CW

W

L1 / M1 L2 / M2

CIRCUIT 2

MICROTECH II USER INTERFACE

CIRCUIT 1

"A"

CONTROL BOX

VENT

DRAIN

"T"

RELIEF VALVES

121.1

3075

"L"

" X "

L3 / M3L4 / M4

INLET

EVAPORATOR

OUTLET

14.2

361

WATER

CONNECTIONS

CONTROL

CONNECTION

.88 KNOCKOUTS

ON OPPOSITE SIDE

REMOVABLE

DISC. HANDLE

4.0

CONNECTIONS

102

OUTLET

CONDENSER

INLET

POWER

" Y "

.88 KNOCKOUTS

40.2

1021

"W"

32.3

821

23.5

597

10.0

253

REMOVE BRKT.

FOR SHIPPING

ONLY

57.6

1462

32.8

834

17.9

454

WGZ070-130C

Packaged Chiller

331929801

2.0

51

"H"

20.0

508

14.5

369

13.0

330

" Z "

29.0

737

.875 DIA MOUNTING HOLES (4)

32.0

813

40.0

1016

WGZ MODEL

NUMBER

WGZ070C

WGZ080C

WGZ090C

WGZ100C

WGZ115C

WGZ130C

MAXIMUM OVERALL

DIMENSIONS

IN (MM)

“L” “W” “H”

143.3

(3639)

149.6

(3799)

149.4

(3795)

149.4

(3795)

149.4

(3795)

149.4

(3795)

35.0

(889)

35.0

(889)

35.0

(889)

35.0

(889)

35.0

(889)

35.0

(889)

65.5

(1664)

65.5

(1664)

65.5

(1664)

65.5

(1664)

65.5

(1664)

65.5

(1664)

CHILLER

WATER

CONNECTION

IN(MM)

VICTAULIC

SIZE (NOM)

3 (76)

3 (76)

3 (76)

3 (76)

3 (76)

3 (76)

“A”

114.9

(2918)

115.3

(2930)

117.1

(2975)

118.0

(2997)

121.6

(3088)

124.7

(3167)

CONDENSER

WATER

CONNECTION

IN(MM)

VICTAULIC

SIZE (NOM)

4 (102)

4 (102)

4 (102)

4 (102)

4 (102)

4 (102)

“T”

8.0

(203)

14.3

(363)

14.1

(359)

14.1

(359)

14.1

(359)

14.1

(359)

CENTER OF GRAVITY

“X” “Y” “Z”

62.4 28.6 15.0

64.8 29.3 15.1

67.7 29.6 16.1

69.7 29.9 17.1

68.8 30.2 17.1

67.8 30.4 17.1

IMM WGZC WGZ 030C through 200C 25

Page 26

W

Figure 11, WGZ 150CW through WGZ 200CW

W

23.5

596

EVAPORATOR

OUTLET

77.2

1961

EVAPORATOR

INLET

1.3

34

CIRCUIT 2

CIRCUIT 1

VENT

VENT

" Y "

145.1

3685

170.2

4322

RELIEF VALVES

" X "

DRAIN

10.9

276

DRAIN

MICROTECH II USER INTERFACE

4.0

102

CONDENSER

14.2

361

OUTLET

INLET

CONTROL

CONNECTION

.88 KNOCKOUTS

ON OPPOSITE SIDE

REMOVABLE

DISC HANDLE

POWER

CONNECTIONS

77.7

1973

.88 KNOCKOUT

17.0

23.5

597

2.0

51

432

5.0

127

15.5

394

41.2

1046

36.5

927

T.B . D .

33.8

859

13.3

" Z "

337

29.0

737

.875 DIA MOUNTING HOLES (4)

32.0

813

40.0

1016

REMOVE BRKT.

FOR SHIPPING

ONLY

36.9

938

EVAP

INLET/

OUTLET

18.3

464

9.6

243

WGZ150CW-200C

Packaged Chiller

331929901

WGZ MODEL

NUMBER

WGZ150C

WGZ170C

WGZ200C

CHILLER WATER

CONNECTION SIZE

(NOM) VICTAULIC

CONDENSER WATER

CONNECTION SIZE

(NOM) VICTAULIC

CENTER OF GRAVITY

IN (MM) IN (MM) X Y Z

8 (203) 5 (127) 68.7 38.6 14.9

8 (203) 5 (127) 66.3 38.3 15.0

8 (203) 5 (127) 66.6 38.7 15.1

26 WGZ 030C through 200C IMM

Page 27

T

20.2

512

Chillers with Remote Condenser

Figure 12, WGZ 030CA through WGZ 060CA

" A "

INLET

25.9

657

CIRCUIT 2

OUTLET

27.4

696

41.5

1054

6.0

152

WGZ MODEL

NUMBER

WGZ030CA 2.5 (64) 21.6 (550) 4 (102) 67.3 22.8 13.3

WGZ035CA 2.5 (64) 20.6 (523) 4 (102) 68.3 23.8 13.4

WGZ040CA 2.5 (64) 19.2 (488) 4 (102) 67.9 23.9 13.5

WGZ045CA 2.5 (64) 17.5 (444) 4 (102) 67.3 24.0 13.5

WGZ050CA 2.5 (64) 15.8 (400) 4 (102) 67.2 24.5 13.5

WGZ055CA 2.5 (64) 14.0 (356) 4 (102) 66.6 24.6 13.5

WGZ060CA 2.5 (64) 12.3 (312) 4 (102) 66.1 24.7 13.6

38.2

971

MICROTECH II USER INTERFACE

CIRCUIT 1

137.0

3480

CHILLER WATER CONNECTION

30.3

770

87.9

2234

98.8

2509

11. 4

289

" Y "

" X "

12.3

312

10.4

263

1.38 DISCHARGE

CONNECTIONS

.88 LIQUID

CONNECTIONS

CONNECTIONS

REMOVABLE

DISC. HANDLE

POWER

.88 KNOCKOUTS

23.5

597

2.0

51

20.0

508

CONNECTION

.88 KNOCKOUTS

ON OPPOSITE SIDE

INLET

OUTLET

6.0

152

" Z "

ISOLATOR HOLES (4)

40.0

1016

CONTROL

34.0

864

CONDENSER WATER

SIZE (NOM) VICTAULIC

CONNECTION SIZE

(NOM) VICTAULIC

CENTER OF GRAVITY

IN (MM) A IN (MM) X Y Z

30.0

762

EVAPORATOR

60.0

1524

REMOVE BRKT.

FOR SHIPPING

ONLY

6.0

151

16.5

419

LIQUID

CONNECTIONS

EVAP. AND

DISCHARGE

CONNECTIONS

2.0

51

WGZ030-060CA

REMOTE CONDENSER UNI

331929711

IMM WGZC WGZ 030C through 200C 27

Page 28

W

Figure 13, WGZ 070CA through WGZ 130CA

.

21.0

95.0

21.0

2.0

51

533

CIRCUIT 2

2413

CIRCUIT 1

533

M3M4

L3L4

30.0

762

EVAP WATER

CONNECTIONS

L1

2.0

51

M1 M2

%%c.75

19

ISOLATOR HOLES IN THE

BOTTOM OF THE BASE

CIRCUIT 1CIRCUIT 2

MICROTECH II USER INTERFACE

" Y "

" T "

INLET

"A "

137.0

3480

CONTROL BOX

" X "

32.3

L2

23.5

597

2.0

51

REMOVABLE

DISC. HANDLE

152

12.3

312

6.0

CONNECTIONS

23.2

588

POWER

.88 KNOCKOUTS

20.0

508

821

6.0

152

" Z "

ISOLATOR HOLES (4)

30.0

762

34.0

864

40.0

1016

15.5

394

CONNECTION

.88 KNOCKOUTS

ON OPPOSITE SIDE

INLET

OUTLET

60.0

1524

4.0

101

2.0

51

WGZ070-130CA

Unit less condenser

331929811

CONTROL

EVAPORATOR

REMOVE BRKT

FOR SHIPPING

ONLY

LIQUID

CONNECTIONS

EVAP. AND

DISCHARGE

CONNECTIONS

52.0

1322

OUTLET

27.3

694

12.4±.25

316±6.35

38.2

971

89.2

2266

98.8

2509

13.3

338

DISCHARGE CONNECTIONS "B"

LIQUID CONNECTIONS "C"

18.5

469

WGZ

MODEL

NUMBER

CHILLER WATER

CONNECTION SIZE

(NOM) VICTAULIC

IN (MM) A IN (MM) B DISC. C LIQ.

WGZ070C 3 (76) 14.1 (359) 4 (102) 1.38 OD 1.13 OD N/A 71.5 29.3 14.9

WGZ080C 3 (76) 13.7 (348) 4 (102) 1.62 OD 1.13 OD 6.3 (161) 74.9 30.1 15.0

WGZ090C 3 (76) 11.9 (303) 4 (102) 1.62 OD 1.13 OD 6.6 (167) 75.7 30.4 15.1

WGZ100C 3 (76) 11.0 (280) 4 (102) 1.62 OD 1.13 OD 6.6 (167) 75.2 30.6 15.2

WGZ115C 3 (76) 7.5 (190) 4 (102) 1.62 OD 1.13 OD 6.6 (167) 73.8 30.8 15.2

WGZ130C 3 (76) 4.4 (111) 4 (102) 1.62 OD 1.13 OD 6.6 (167) 72.6 30.9 15.3

COND.

WATER

CONN. SIZE

VICTAULIC

REFRIGERANT

PIPING

CONNECTION SIZE

T

LEFT

OVERHANG

CENTER OF GRAVITY

(IN.)

X Y

Z

28 WGZ 030C through 200C IMM

Page 29

Figure 14, WGZ 150CA through WGZ 200CA

21.0

2.0

51

533

L4

54.0

1372

CIRCUIT 2

M5

1473

58.0

CIRCUIT 1

21.0

533

M4M6

L3

30.0

762

2.0

L1

51

CIRCUIT 2

M1 M3

.75

19

ISOLATOR HOLES IN THE

BOTTOM OF THE BASE

CIRCUIT 1

M2

CONTROL BOX

L2

3.0

76

" Y "

154.0

3912

" X "

MICROTECH II

USER INTERFACE

REMOVABLE

DISC. HANDLE

POWER

CONNECTIONS

(QTY 3)

2.0

51

.88 KNOCKOUTS

35.5

902

2.0

51

12.0

305

5.0

127

12.0

305

5.0

127

" Z "

ISOLATOR HOLES (6)

30.0

762

34.0

864

40.0

1016

75.0

1905

2.0

51

CONTROL

CONNECTION

.88 KNOCKOUTS

ON OPPOSITE SIDE

REMOVE BRKT.

FOR SHIPPING

ONLY

LIQUID

CONNECTIONS

4.0

101

23.2

588

6.0

152

33.9

862

42.1

1069

106.5

2705

119. 3

3030

1.62 O.D. DISCHARGE

CONNECTIONS

CIRCUIT 1 CIRCUIT 2

CHILLER WATER

WGZ MODEL

NUMBER

CONNECTION SIZE

(NOM) VICTAULIC

IN (MM) X Y Z

WGZ150C 8 (203) 79.1 43.2 15.3

WGZ170C 8 (203) 80.1 43.6 15.4

WGZ200C 8 (203) 79.7 44.0 15.4

OUTLETINLET

74.7

1898

CENTER OF GRAVITY

1.38 O.D. LIQUID

CONNECTIONS

24.9

631

34.2

867

17.4

443

14.5

368

DISCHARGE

2.3

CIRCUIT 1

60

EVAPORATOR

INLET/OUTLET

3.6

90

13.4

340

DISCHARGE

7.9

CIRCUIT 2

200

WGZ150-200CA

REMOTE CONDENSER UNIT

331929911

IMM WGZC WGZ 030C through 200C 29

Page 30

W

Physical Data

Packaged Chillers

Table 22, WGZ 030CW – WGZ 055CW

WGZ UNIT SIZE 30 35 40 45 50 55

Unit capacity @ ARI tons, (kW) 30.0 (105.5) 34.6 (121.7) 40.7 (143.1) 45.5 (160.0) 51.4 (180.8) 56.4 (198.4)

No. Circuits 2 2 2 2 2 2

COMPRESSORS

Nominal Tons 7.5 7.5 9 9 10 10 12 12 13 13 13 15

Number Per Circuit 2 2 2 2 2 2 2 2 2 2 2 2

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Staging, Circuit #1 in Lead 25 / 50 / 75 / 100 25 / 50 / 75 / 100 25 / 50 / 75 / 100 25 / 50 / 75 / 100 25 / 50 / 75 / 100 23 / 50 / 73 / 100

Staging, Circuit #2 in Lead 25 / 50 / 75 / 100 25 / 50 / 75 / 100 25 / 50 / 75 / 100 25 / 50 / 75 / 100 25 / 50 / 75 / 100 27 / 50 / 77 / 100

Oil Charge per Compressor oz., (l) 85 (2.5) 110 (3.3) 110 (3.3) 110 (3.3) 110 (3.3) 110 (3.3)

CONDENSER

Number 1 1 1 1 1 1

No. Refrigerant Circuits 2 2 2 2 2 2

Diameter, in., (mm) 10 (254) 10 (254) 10 (254) 10 (254) 10 (254) 10 (254)

Tube Length, in., (mm) 120 (3048) 120 (3048) 120 (3048) 120 (3048) 120 (3048) 120 (3048)

Design W.P.PSIG, (kPa):

Refrigerant Side 500 (3447) 500 (3447) 500 (3447) 500 (3447) 500 (3447) 500 (3447)

Water Side 232 (1599) 232 (1599) 232 (1599) 232 (1599) 232 (1599) 232 (1599)

Pump-Out Capacity, lb., (kg) (3) 245.8 (111.7) 245.8 (111.7) 228.2 (103.7) 228.2 (103.7) 205.4 (93.4) 205.4 (93.4)

Conn.In & Out, in, (mm) Victaulic 4 (102) 4 (102) 4 (102) 4 (102) 4 (102) 4 (102)

Relief Valve, Flare In., (mm) ⅝ (15.9) ⅝ (15.9) ⅝ (15.9) ⅝ (15.9) ⅝ (15.9) ⅝ (15.9)

Purge Valve, Flare In., (mm) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7) ½ (12.7)

Vent & Drain, in. (mm) NPT ¼ (6.4) ¼ (6.4) ¼ (6.4) ¼ (6.4) ¼ (6.4) ¼ (6.4)

Liquid Subcooling Integral Integral Integral Integral Integral Integral

EVAPORATOR, BRAZED-PLATE

Number 1 1 1 1 1 1

No. Refrigerant Circuits 2 2 2 2 2 2

Water Volume, gallons, (l) 1.9 (7.1) 2.2 (8.3) 2.4 (9.1) 2.9 (11.0) 3.4 (12.8) 3.7 (14.0)

Refrig. Side D.W.P. Psig, (kPa) 450 (3102) 450 (3102) 450 (3102) 450 (3102) 450 (3102) 450 (3102)

Water Side D.W.P,. psig, (kPa) 653 (4500) 653 (4500) 653 (4500) 653 (4500) 653 (4500) 653 (4500)

Conn. In & Out, in. (mm) Victaulic 2.5 (65) 2.5 (65) 2.5 (65) 2.5 (65) 2.5 (65) 2.5 (65)

Relief Valve, Flare in., (mm) ⅝ (15.9) ⅝ (15.9) ⅝ (15.9) ⅝ (15.9) ⅝ (15.9) ⅝ (15.9)

Vent & Drain Field Field Field Field Field Field

UNIT DIMENSIONS

Length In., (mm) 136.0 (3455) 136.0 (3455) 136.0 (3455) 136.0 (3455) 136.0 (3455) 136.0 (3455)

Width In., (mm) 32.8 (832) 32.8 (832) 32.8 (832) 32.8 (832) 32.8 (832) 32.8 (832)

Height In., (mm) 63.4 (1609) 63.4 (1609) 63.4 (1609) 63.4 (1609) 63.4 (1609) 63.4 (1609)

UNIT WEIGHTS

Operating Weight, lb., (kg) 2486 (1128) 2572 (1167) 2631 (1193) 2650 (1202) 2752 (1248) 2771 (1257)

Shipping Weight, lb., (kg) 2410 (1093) 2496 (1132) 2539 (1152) 2558 (1160) 2639 (1197) 2658 (1206)

Cir # 1,Opn. Charge, lb.,(kg) R410a 45 (20.5) 45 (20.5) 47 (21.4) 47 (21.4) 47 (21.4) 50 (22.7)

Cir # 2,Opn. Charge, lb.,(kg) R410a 45 (20.5) 45 (20.5) 47 (21.4) 47 (21.4) 47 (21.4) 50 (22.7)

Notes:

1. Certified in accordance with ARI Standard 550/590-2003.

2. 90% Full R-410a at 90°F (32°C) per unit.

30 WGZ 030C through 200C IMM

Page 31

Table 23, WGZ060CW - WGZ100CW

WGZ UNIT SIZE 60 70 80 90 100

Unit capacity @ ARI tons, (kW) (1) 60.5 (212.8) 70.8 (249.0) 78.3 (275.4) 88.0 (309.5) 97.8 (344.0)

No. Circuits 2 2 2 2 2

COMPRESSORS

Nominal Tons 15 15 15/20 15/20 20 20 20 26 26 26

Number per Circuit4 2 2 2 2 2 2 2 2 2 2

CAPACITY REDUCTION STEPS - PERCENT OF COMPRESSOR DISPLACEMENT

Staging, 4 Stages, Circuit #1 in Lead 25 / 50 / 75 / 100 22 / 50 / 72 / 100 25 / 50 / 75 / 100 25 / 50 / 75 / 100 25 / 50 / 75 / 100

Staging, 4 Stages, Circuit #2 in Lead 25 / 50 / 75 / 100 22 / 50 / 72 / 100 25 / 50 / 75 / 100 25 / 50 / 75 / 100 25 / 50 / 75 / 100

Oil Charge, per compressor oz. (l) 110 (3.3)

CONDENSER

Number 1 1 1 1 1

No. Refrigerant Circuits 2 2 2 2 2

Diameter, in. (mm) 10 (254) 14 (356) 14 (356) 14 (356) 14 (356)

Tube Length, in. (mm) 120 (3048) 120 (3048) 120 (3048) 120 (3048) 120 (3048)

Design W.P., psig (kPa):

Refrigerant Side 500 (3447) 500 (3447) 500 (3447) 500 (3447) 500 (3447)

Water Side 232 (1599) 232 (1599) 232 (1599) 232 (1599) 232 (1599)

No. of Passes 2 2 2 2 2

Pump-Out Capacity lb., (kg) (3) 205.4 (93.4) 415.1 (188.7) 397.5 (180.7) 371.1 (168.7) 344.7 (156.7)

Conn. In & Out, in., (mm) Victaulic 4 (102) 4 (102) 4 (102) 4 (102) 4 (102)