Page 1

Operating Manual

Water-Cooled Scroll Compressor Chillers

WGZ 030AW To WGZ 120AW, Packaged Water-Cooled Chiller

WGZ 030AA To WGZ 120AA, Chiller with Remote Condenser

30 to 120 Tons, 105 to 420 kW

Software Version WGZD20102C

60 Hz, R-22, R-407C

OM WGZ-2

Group: Chiller

Part Number: 331374501

Effective: March 2005

Supercedes: OM WGZ-1

Page 2

Table of Contents

Introduction........................................3

General Description...............................3

Nomenclature........................................3

Water Pressure Drop..............................3

Operating Limits....................................6

Components...........................................6

Unit Configuration ............................7

Field Wiring Diagrams..........................8

Control Panel Layout ..........................10

Motor Protection Module....................10

Start-Up and Shutdown...................11

Pre Start-up.......................................... 11

Start-up................................................11

Weekend or Temporary Shutdown ......12

Start-up after Temporary Shutdown....12

Extended Shutdown.............................12

Start-up after Extended Shutdown ......13

Low Ambient Start ..............................13

Fan High Ambient Rapid Start............14

Sequence of Operation ....................14

Start-up/Compressor Staging...............14

MicroTech II Controller .................18

Controller Software Version................18

General Description.............................18

Setpoints..............................................21

Protection (Shutdown) Alarms............22

Event (Limit) Alarms...........................23

Staging Parameters..............................26

Capacity Overrides..............................26

Digital Output Control ........................27

Analog Output Control........................28

Using the Controller............................31

Menu Screens......................................34

Menu Descriptions ..............................34

Optional Controls............................51

Phase/Voltage Monitor (Optional) ......51

Hot Gas Bypass (Optional) .................51

Troubleshooting Chart.........................52

Warranty Statement........................53

Manufactured in an ISO Certified facility

"McQuay" is a registered trademark of McQuay International

Illustrations and data cover McQuay International products at the time of publication and we reserve the right to

make changes in design and construction at anytime without notice.

2 WGZ 030A through 120A OM WGZ-2

©2005 McQuay International

Page 3

Introduction

N

)

General Description

McQuay Type WGZ water chillers are designed for indoor installations and are available with watercooled condensers (Model AW), or arranged for use with remote air-cooled or evaporative condensers

(Model AA). Each water-cooled unit is completely assembled and factory wired before evacuation,

charging and testing. They consist of hermetic scroll compressors, brazed-plate evaporator, watercooled condenser (WGZ-AW), and complete refrigerant piping.

Units manufactured for use with remote condensers (Models WGZ-AA) have all refrigerant specialties

factory-mounted and connection points for refrigerant discharge and liquid lines.

Liquid line components that are included are manual liquid line shutoff valves, charging valves, filterdriers, liquid line solenoid valves, sight glass/moisture indicators, and thermal expansion valves. Other

features include compressor crankcase heaters, and a MicroTech II¥ microprocessor controller.

The electrical control center includes all equipment protection and operating controls necessary for

dependable automatic operation.

The compressors are not fused as standard, but can be protected by optional circuit breakers or fuses,

or can rely on a field-installed, fused disconnect switch for protection.

BOOT & BIOS

BOOT Version: 3.0F BIOS Version 3.56

Manuals: Information in unit initial installation and routine maintenance is contained in Installation

and Maintenance Manual IMM WGZ-2.

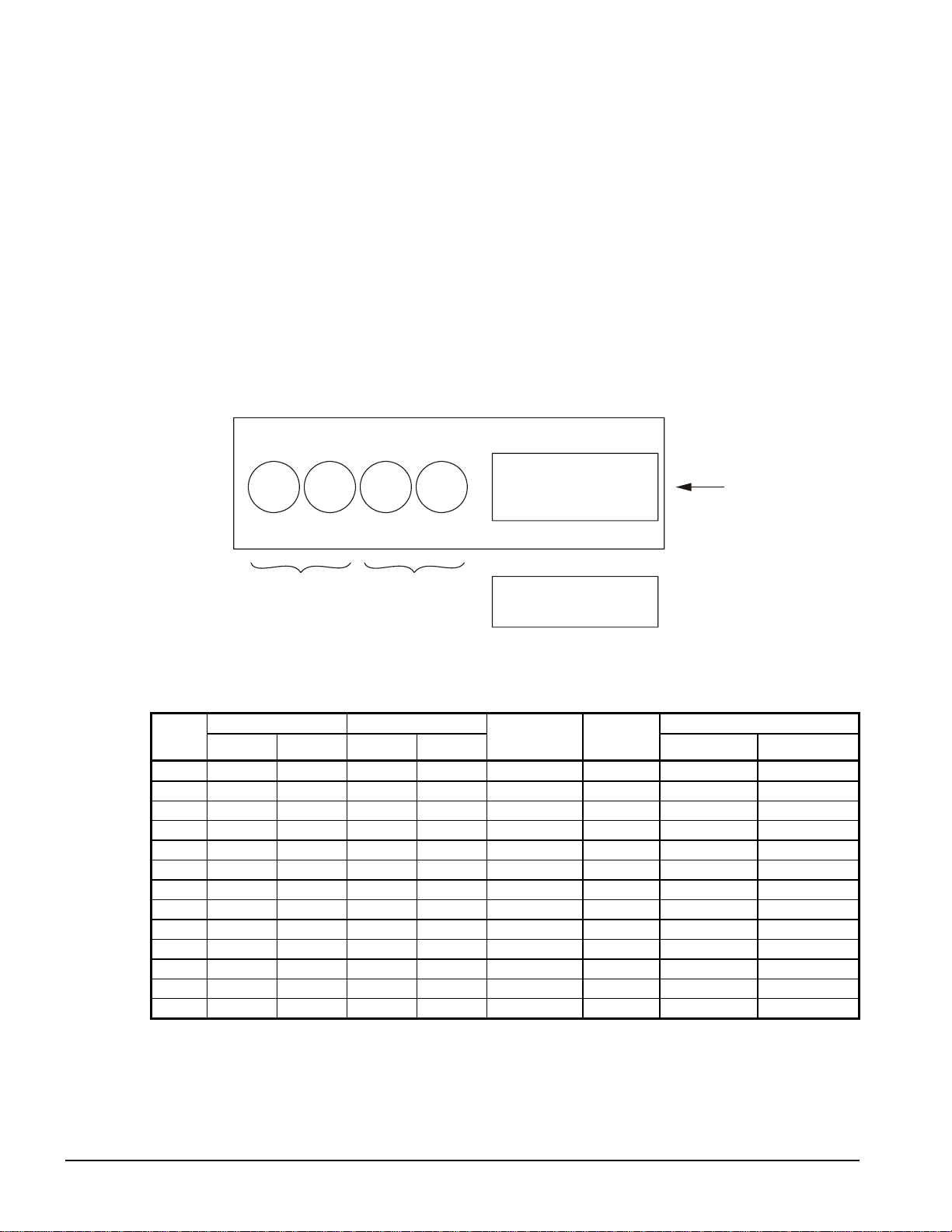

Nomenclature

W G Z 100 - A W

Water-Cooled

Global

Scroll Compressor

W = Water-Cooled Condenser

=

Design Vintage

ominal Capacity (Tons

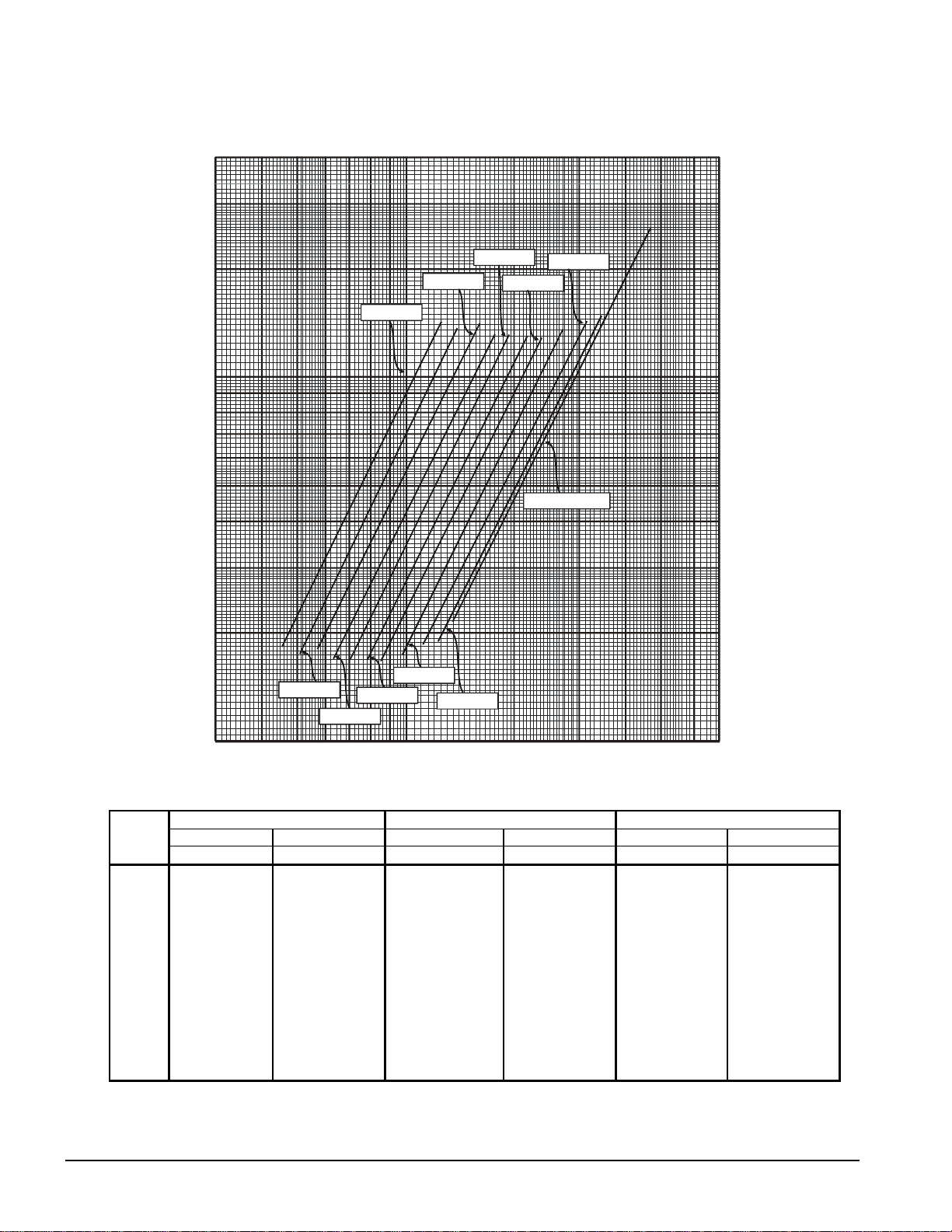

Water Pressure Drop

Water flow rates should be maintained as closely as possible to job design values. The vessel flow

rat es mu st f al l be twe en t he mi nimu m and maxi mum values shown on the appropriate evaporator and

condenser curves.

Measure the water pressure drop through the vessels at field-installed pressure taps and check the

flow rate using the following tables. Do not include valves or strainers in these readings.

The evaporator flow rates and pressure drops shown on the following page are for full load design

purposes. The maximum flow rate and pressure drop are based on a 6-degree temperature drop.

Avoid higher flow rates with resulting lower temperature drops to prevent potential control problems

resulting from very small control bands and limited start up/shut off temperature changes.

The minimum flow and pressure drop is based on a full load evaporator temperature drop of 16degrees.

Minimum Part Load Flow Rates: This full load design minimum flow is not to be confused with

the part load minimum flow rate that must be maintained for chillers operating in variable primary

flow pumping systems. As chiller capacity drops, the flow rate is reduced proportionally. See the

following table for the part load minimum flow rates.

Table 1, Minimum Part Load

WGZ Model 030 035 040 045 050 055 060 070 080 090 100 110 120

Min.Part Load GPM

30 33 38 43 47 53 58 67 74 83 91 102 113

Flow Rates

OM WGZ-2 WGZ 030A through 120A 3

Page 4

Figure 1, Evaporator Pressure Drop, WGZ 030 – WGZ 120

)

Flow Rate (L/s)

1.9 2.5 3.2 3.8 4.4 5.0 5.7 6.3

40

12.6 18.9

25.2

31.5 37.9

44.2

120

30

20

WGZ 040

WGZ 050

WGZ 060

WGZ 080

90

60

WGZ 030

Pressure Drop (kPa)

10

9

8

7

6

5

Pressure Drop (ft of water)

4

3

2

WGZ 100 - 120

30

27

24

21

18

15

12

9

6

WGZ 035

WGZ 055

WGZ 090

WGZ 045

WGZ 070

WGZ

Model

030

035

040

045

050

055

060

070

080

090

100

110

120

1

30 40 50 60 70 80 90 100 200 300 400 500 600

Flow Rate (GPM

Minimum Flow Nominal Flow Maximum Flow

Inch-Pound S.I. Inch-Pound S.I. Inch-Pound S.I.

GPM Ft. L/S kPa GPM Ft. L/S kPa GPM Ft. L/S kPa

45.5 1.85 2.87 5.54 75.8 5.15 4.78 15.40 126.3 14.31 7.97 42.77

50.3 1.76 3.17 5.27 83.8 4.90 5.29 14.65 139.7 13.62 8.81 40.70

57.7 1.83 3.64 5.46 96.2 5.07 6.07 15.15 160.3 14.08 10.12 42.10

63.7 1.71 4.02 5.10 106.1 4.74 6.69 14.17 176.8 13.16 11.16 39.35

70.0 1.70 4.41 5.08 116.6 4.72 7.36 14.12 194.3 13.12 12.26 39.21

78.2 1.70 4.93 5.08 130.3 4.72 8.22 14.10 217.2 13.11 13.70 39.17

85.8 1.67 5.41 5.00 143.0 4.65 9.02 13.90 238.3 12.91 15.04 38.60

97.9 1.75 6.18 5.24 163.2 4.87 10.30 14.54 272.0 13.51 17.16 40.40

112.3 1.86 7.09 5.56 187.2 5.17 11.81 15.45 312.0 14.36 19.68 42.92

123.5 1.91 7.79 5.70 205.9 5.29 12.99 15.82 343.2 14.71 21.65 43.96

134.9 2.14 8.51 6.39 224.9 5.94 14.19 17.74 374.8 16.49 23.65 49.29

152.9 2.75 9.65 8.21 254.9 7.63 16.08 22.79 424.8 21.18 26.80 63.31

168.8 3.34 10.65 9.99 281.3 9.29 17.75 27.76 468.8 25.80 29.58 77.11

3

700

Note: Minimum, nomin a l, and maximum flows are at a 16°F, 10°F, and 6°F chilled water temperature range respectively and at ARI tons.

4 WGZ 030A through 120A OM WGZ-2

Page 5

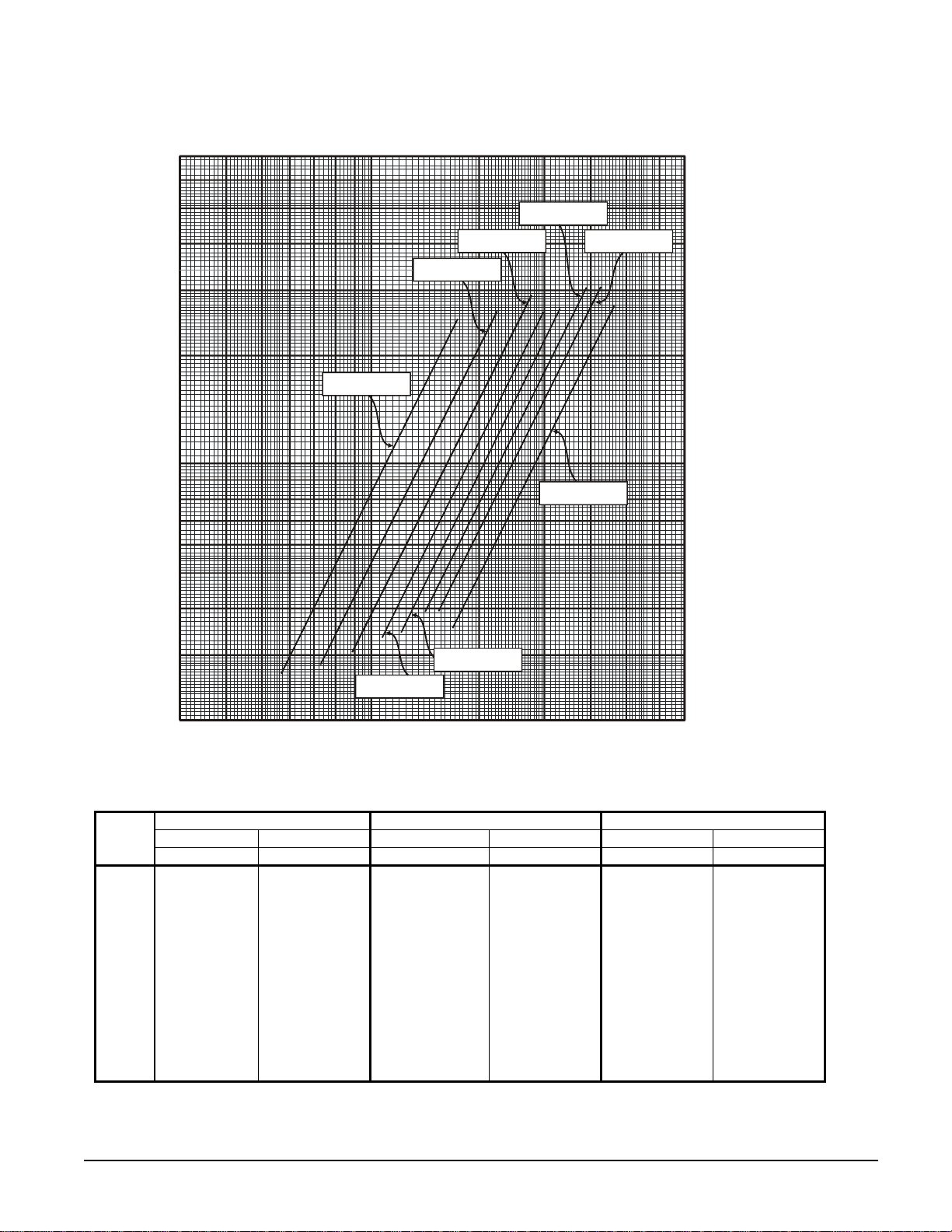

Figure 2, Condenser Pressure Drop, WGZ 030 – WGZ 120

Flow Rate (L/s)

1.9 2.5 3.2 3.8 4.4 5.0 5.7 6.3

70

60

12.6 18.9

25.2

31.5 37.9

44.2

210

180

50

40

WGZ 050, 055

WGZ 080

WGZ 090

150

120

WGZ 040, 045

30

20

90

60

Pressure Drop (kPa)

WGZ 030, 035

10

9

8

Pressure Drop (ft of water)

7

6

5

4

3

WGZ 070

WGZ 100 - 120

30

27

24

21

18

15

12

9

WGZ

Model

030

035

040

045

050

055

060

070

080

090

100

110

120

WGZ 060

2

30 40 50 60 70 80 90 100 200 300 400 500 600

Flow Rate (GPM)

6

700

Minimum Flow Nominal Flow Maximum Flow

Inch-Pound S.I. Inch-Pound S.I. Inch-Pound S.I.

GPM Ft. L/S kPa GPM Ft. L/S kPa GPM Ft. L/S kPa

56.9 2.66 3.59 7.96 94.8 7.40 5.98 22.11 158.0 20.55 9.97 61.43

62.8 3.25 3.96 9.71 104.7 9.02 6.61 26.97 174.5 25.07 11.01 74.93

72.2 2.83 4.55 8.45 120.3 7.85 7.59 23.46 200.5 21.80 12.65 65.17

79.6 3.43 5.02 10.26 132.6 9.54 8.37 28.51 221.0 26.49 13.94 79.18

87.5 3.02 5.52 9.02 145.8 8.38 9.20 25.05 243.0 23.28 15.33 69.58

97.7 3.77 6.17 11.26 162.9 10.46 10.28 31.27 271.5 29.06 17.13 86.85

107.3 3.38 6.77 10.11 178.8 9.39 11.28 28.07 298.0 26.09 18.80 77.97

122.4 3.45 7.72 10.31 204.0 9.58 12.87 28.64 340.0 26.62 21.45 79.56

140.4 3.92 8.86 11.72 234.0 10.89 14.76 32.56 390.0 30.26 24.61 90.45

154.4 3.95 9.74 11.81 257.4 10.97 16.24 32.80 429.0 30.48 27.07 91.11

168.7 3.55 10.64 10.62 281.1 9.87 17.73 29.50 468.5 27.41 29.56 81.94

191.2 4.56 12.06 13.64 318.6 12.68 20.10 37.89 531.0 35.21 33.50 105.26

211.0 5.56 13.31 16.61 351.6 15.44 22.18 46.15 586.0 42.89 36.97 128.19

OM WGZ-2 WGZ 030A through 120A 5

Page 6

Operating Limits

• Maximum allowable condenser water pressure is 232 psig (1599 kPa).

• Maximum allowable cooler water pressure is 363 psig (2509 kPa).

• Maximum design saturated discharge temperature is 140°F (60°C).

• Maximum allowable water temperature to cooler in a non-operating cycle is 100°F

(37.8°C). Maximum entering water temperature for operating cycle is 90°F (32.2°C)

(during system changeover from heating to cooling cycle).

• Minimum leaving water temperature from the cooler without freeze protection is 40°F

(4.4°C).

• Minimum entering tower condenser water temperature is 60°F (15.6°C).

Components

Figure 3, Compressor Locations

Evaporator and

423

1

Evaporator

Condenser

Connections

Circuit 2 Circuit 1

Control Panel

Table 2, Major Components

Unit

Size

030 ZR90K3 ZR90K3 ZR11M3 ZR11M3 AC250-70DQ C1010-046 OVE-20-CP100 OVE-20-CP100

035 ZR11M3 ZR11M3 ZR11M3 ZR11M3 AC250-78DQ C1010-046 OVE-20-CP100 OVE-20-CP100

040 ZR12M3 ZR12M3 ZR12M3 ZR12M3 AC250-90DQ C1010-058 OVE-20-CP100 OVE-20-CP100

045 ZR12M3 ZR12M3 ZR16M3 ZR16M3 AC250-102DQ C1010-058 OVE-30-CP100 OVE-30-CP100

050 ZR16M3 ZR16M3 ZR16M3 ZR16M3 AC250-114DQ C1010-070 OVE-30-CP100 OVE-30-CP100

055 ZR16M3 ZR16M3 ZR19M3 ZR19M3 AC250-130DQ C1010-070 OVE-30-CP100 Y929-VCP100

060 ZR19M3 ZR19M3 ZR19M3 ZR19M3 AC250-146DQ C1410-078 Y929-VCP100 Y929-VCP100

070 ZR19M3 ZR19M3 ZR250KC ZR250KC AC250-166DQ C1410-090 OVE-40-CP100 OVE-40-CP100

080 ZR250KC ZR250KC ZR250KC ZR250KC AC250-194DQ C1410-098 OVE-40-CP100 OVE-40-CP100

090 ZR250KC ZR250KC ZR300KC ZR300KC AC250-230DQ C1410-110 OVE-55-CP100 OVE-55-CP100

100 ZR300KC ZR300KC ZR300KC ZR300KC AC250-250DQ C1410-122 OVE-55-CP100 OVE-55-CP100

110 ZR300KC ZR300KC ZR380KC ZR380KC AC250-250DQ C1410-122 OVE-55-CP100 OVE-70-CP100

120 ZR380KC ZR380KC ZR380KC ZR380KC AC250-250DQ C1410-122 OVE-70-CP100 OVE-70-CP100

System #1 System #2 Expansion Valve

Comp. #1 Comp. #3 Comp. #2 Comp. #4

Evap.

Vessel

Size

Cond.

Vessel

Size

System #1 System #2

6 WGZ 030A through 120A OM WGZ-2

Page 7

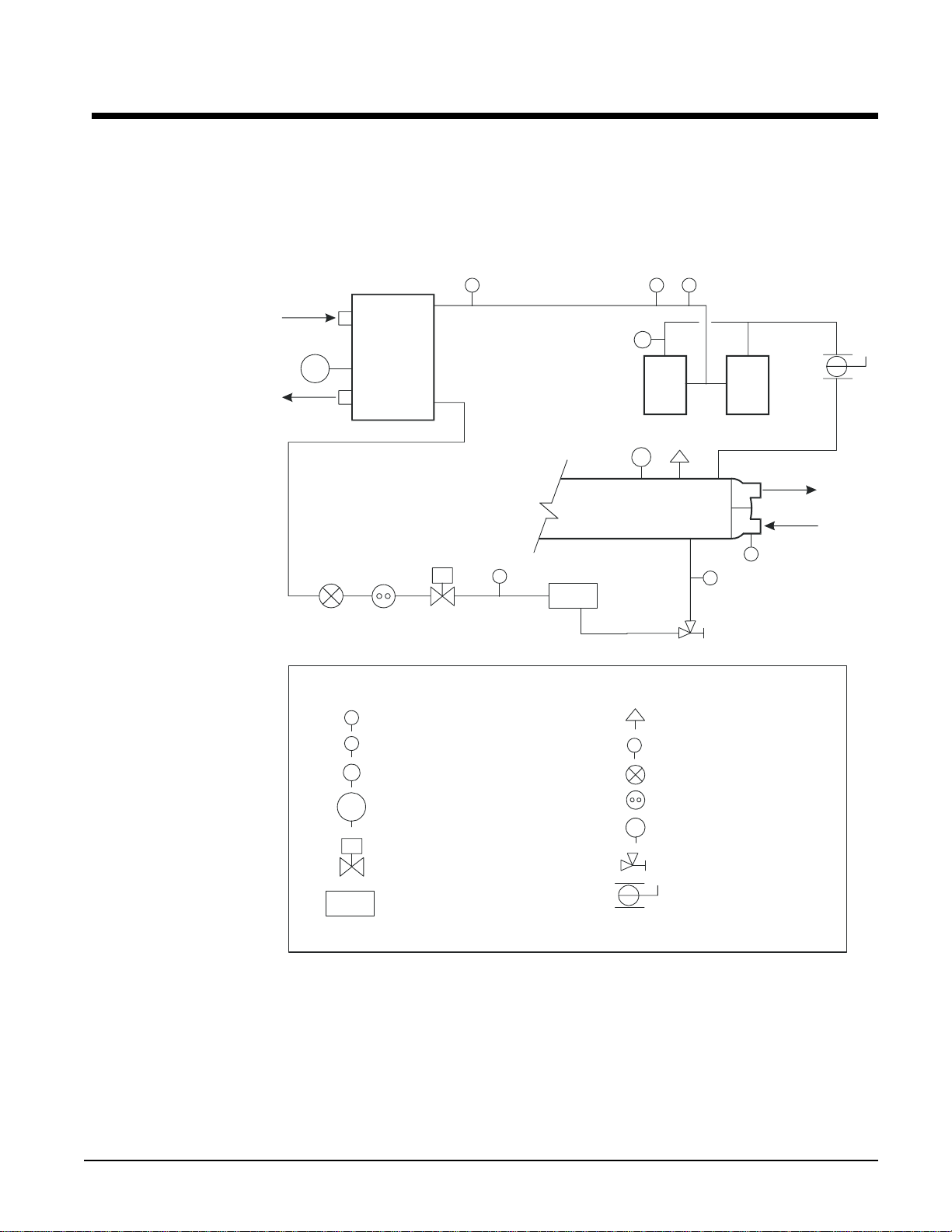

Unit Configuration

The chiller unit has two refrigerant circuits, two tandem scroll compressors (total of four), a

single two-circuited brazed plate evaporator, a single two-circuited water-cooled condenser,

interconnecting refrigerant piping and a control panel with associated sensors and

transducers.

Figure 4, Schematic Piping Diagram (One of Two Circuits)

Chilled

Water

LWT

Evaporator

S

Legend:

T

T

Temperature Sensor

P

T

Pressure Transducer

P

Pressure (High Pressure Cutout)

1

T

T

P

CV

Condenser

S

F-D

S

T

SP

1

Comp

#1

Relief Valve

Schrader Fitting

Thermal Expansion Valve

Comp

#2

T

S

Condenser

Water

Temperataure Sensor, Leaving

LWT

Chilled Water Control

S

Solenoid Valve

F-D

Filter-Drier

Sight Glass / Moisture Indicator

CV

Charging Valve

Angle Valve

Ball Valve

OM WGZ-2 WGZ 030A through 120A 7

Page 8

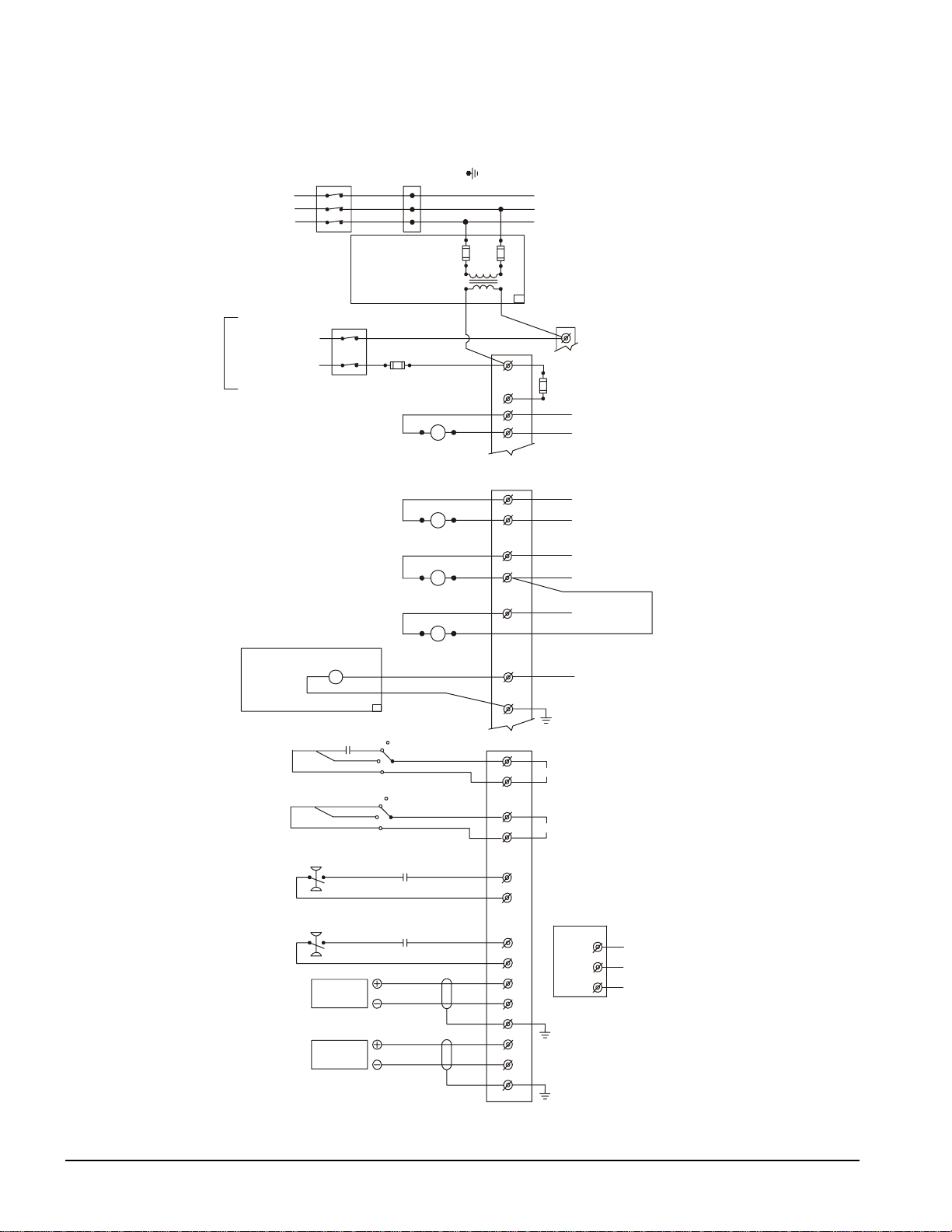

Field Wiring Diagrams

SCO

A

A

A

N

Figure 5, WGZ 030AW – 120AW Field Wiring Diagram

DI

3 PHASE

POWER

SUPPLY

FIELD

SUPPLIED

OPTION

CONTROL POWER

FACTORY SUPPLIED ALARM

FIELD WIRED

LARM BELL

OPTION

REMOTE STOP SWITCH

(BY OTHERS)

ICE MODE SWITCH

(BY OTHERS)

CHW FLOW SWITCH

--MANDATORY-(BY OTHERS)

CDW FLOW SWITCH

--MANDATORY-(BY OTHERS)

4-20 MA FOR

CHW RESET

(BY OTHERS)

4-20 MA FOR

DEMAND LIMIT

(BY OTHERS)

NNECT

(BY OTHERS)

DISCONNECT

(BY OTHERS)

N

120VAC

CDW PUMP RELA Y

(BY OTHERS)

120 VAC 1.0 AMP MAX

TOWER FAN #1 COIL

(BY OTHERS)

120 VAC 1.0 AMP MAX

ALARM BELL

RELAY

TIME

CLOCK

UNIT MAIN

TERMINAL BLOCK

FUSED CONTROL

CIRCUIT

TRANSFORMER

10A

FUSE

(BY OTHERS)

CHW PUMP RELA Y

(BY OTHERS)

120 VAC 1. 0 AMP MAX

TOWER FAN #2 COI L

(BY OTHERS)

120 VAC 1. 0 AMP MAX

OFF

UTO

ON

MANUAL

OFF

UTO

ON

MANUAL

NOR. OPEN PUMP A UX.

CONTACTS (OPTIONAL)

NOR. OPEN PUMP AUX.

CONTACTS (OPTIONAL)

GND LUG

120 VAC

TB1

CONTROLLER

J15-N08

TB1-12

J16-N09

TB1-12

J16-N10

TB2

TO COMPRESSOR(S)

TB1-20

1

CONTROL

CIRCUIT

FUSE

2

11

14

10

15

GND

40

53

42

55

IF REMOTE STOP CONTROL

897

IS USED, REMOVE LEAD 897

FROM TERM 40 TO 53.

IF ICE MODE IS USED

900

REMOVE LEAD

FROM TERM 42 TO 55.

33

43

CONTROLLER

Rx-/Tx-

41

Rx+/Tx+

53

38

48

49

GND

38

50

51

GND

N

N

N

120VAC

J11

GND

120 VAC

120 VAC

120 VAC

120 VAC

1

*

COMMUNICATIO

2

3

330258901-R4

PORT

8 WGZ 030A through 120A OM WGZ-2

Page 9

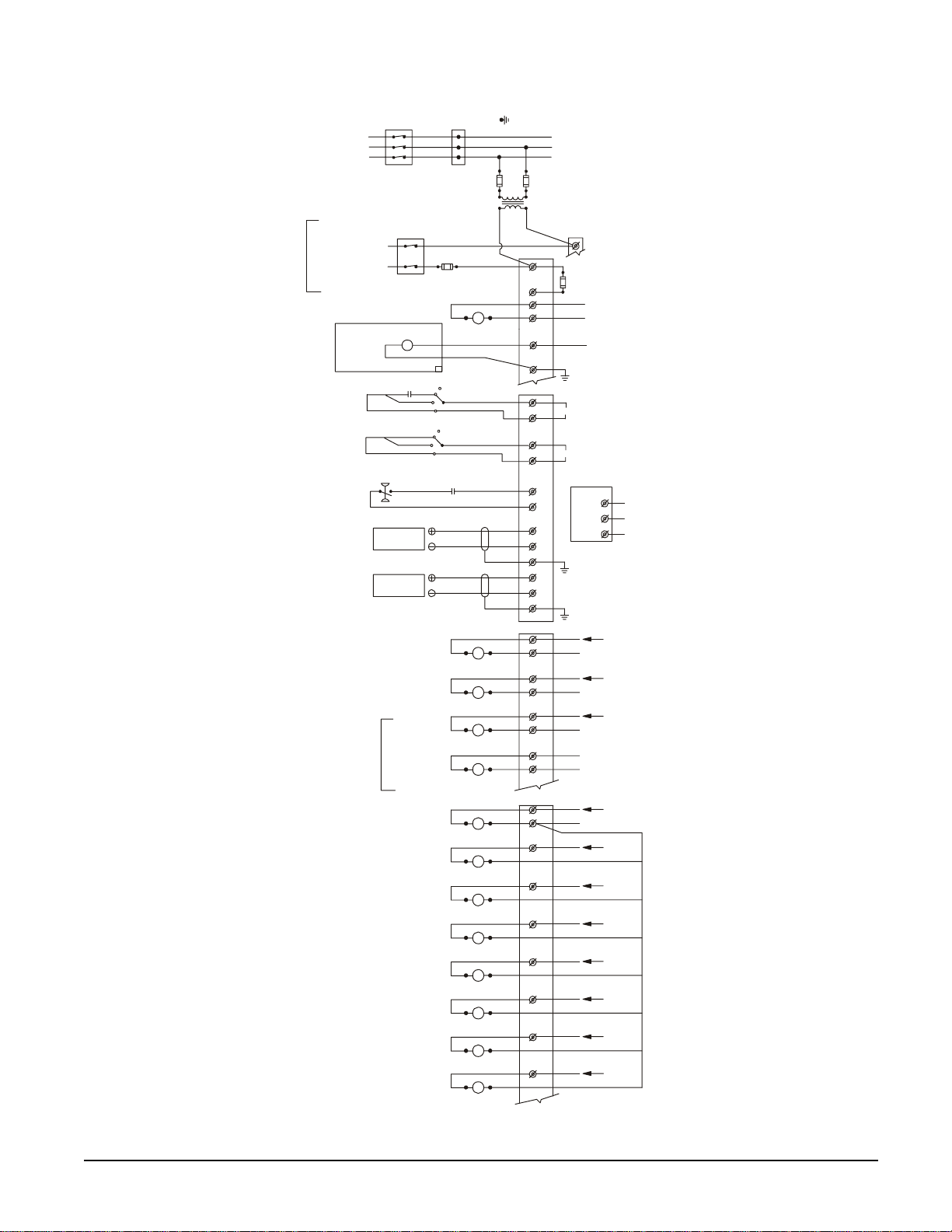

Figure 6, WGZ 030AA – 120AA Field Wiring Diagram (Remote Condenser)

UNIT MAIN

A

A

N

0

3 PHASE

FIELD

SUPPLIED

OPTION

REMOTE STOP SWITCH

NOTE:

CONDENSER FAN MOTORS

CAN ALSO BE CONTROLLED

BY PRESSURE SWITCHES

ON THE CONDENSER.

CONTROL POWER

(BY OTHERS)

ICE MODE SWITCH

(BY OTHERS)

CHW FLOW SWITCH

4-20 MA FOR

CHW RESET

(BY OTHERS)

4-20 MA FOR

DEMAND LIMIT

(BY OTHERS)

330259001-R4

DISCONNECT

(BY OTHERS)

POWER

SUPPLY

FUSED CONTROL

TRANSFORMER

DISCONNECT

(BY OTHERS)

N

120VAC

FACTORY SUPPLIED ALARM

FIELD WIRED

ALARM BELL

OPTION

ALARM BELL RELAY

TIME

CLOCK

ON

UTO

ON

--MANDATORY--

(BY OTHERS)

LIQUID LINE #1 SOLENOID

LIQUID LINE #2 SOLENOID

OPTIONAL

HOT GAS BYPASS #1 SOLENOID

HOT GAS BYPASS #2 SOLENOID

FAN MOTOR #1 COIL

FAN MOTOR #2 COIL

FAN MOTO R #3 COIL

FAN MOTO R #4 COIL

FAN MOTOR #5 COIL

FAN MOTO R #6 COIL

FAN MOTO R #7 COIL

FAN MOTOR #8 COIL

TERMINAL BLOCK

CIRCUIT

10A

FUSE

(BY OTHERS)

CHW PUMP RELAY

(BY OTHERS)

120 VAC 1.0 AMP MAX

OFF

UTO

MANUAL

OFF

MANUAL

NOR. OPEN PUMP AUX.

CONTACTS (OPTIONAL)

24 VAC AMP MAX

24 VAC AMP MAX

24 VAC AMP MAX

24 VAC AMP MAX

(BY OTHERS)

120 VAC 1.0 AMP MAX

(BY OTHERS)

120 VAC 1.0 AMP MAX

(BY OTHERS)

120 VAC 1.0 AMP MAX

(BY OTHERS)

120 VAC 1.0 AMP MAX

120 VAC 1.0 AMP MAX

120 VAC 1.0 AMP MAX

(BY OTHERS)

120 VAC 1.0 AMP MAX

(BY OTHERS)

VAC 1.0 AMP MAX

12

120

VAC

(BY OTHERS)

(BY OTHERS)

GND LUG

TB1

1

2

11

14

10

15

TB2

40

53

42

55

33

43

38

48

49

38

50

51

TB3

62

65

63

65

67

70

68

70

CONTROLLER

J15-N08

TB1-12

J16-N09

J16-N010

J16-N011

J18-N013

J22-N016

J22-N017

J22-N018

TO COMPRESSOR(S)

TB1-20

CONTROL

CIRCUIT

FUSE

120 VAC

N

120VAC

GND

IF REMOTE STOP CONTROL

897

IS USED, REMOVE LEAD 897

FROM TERM 40 TO 53.

IF ICE MODE IS USED

900

REMOVE LEAD

FROM TERM 42 TO 55.

CONTROLLER

J11

GND

N

N

N

N

N

1

2

3

24 VAC

24 VAC

24 VAC

24 VAC

120 VAC

120 VAC

120 VAC

120 VAC

120 VAC

120 VAC

120 VAC

120 VAC

Rx-/TxRx+/Tx+

GND

GND

*

COMMUNICATIO

PORT

OM WGZ-2 WGZ 030A through 120A 9

Page 10

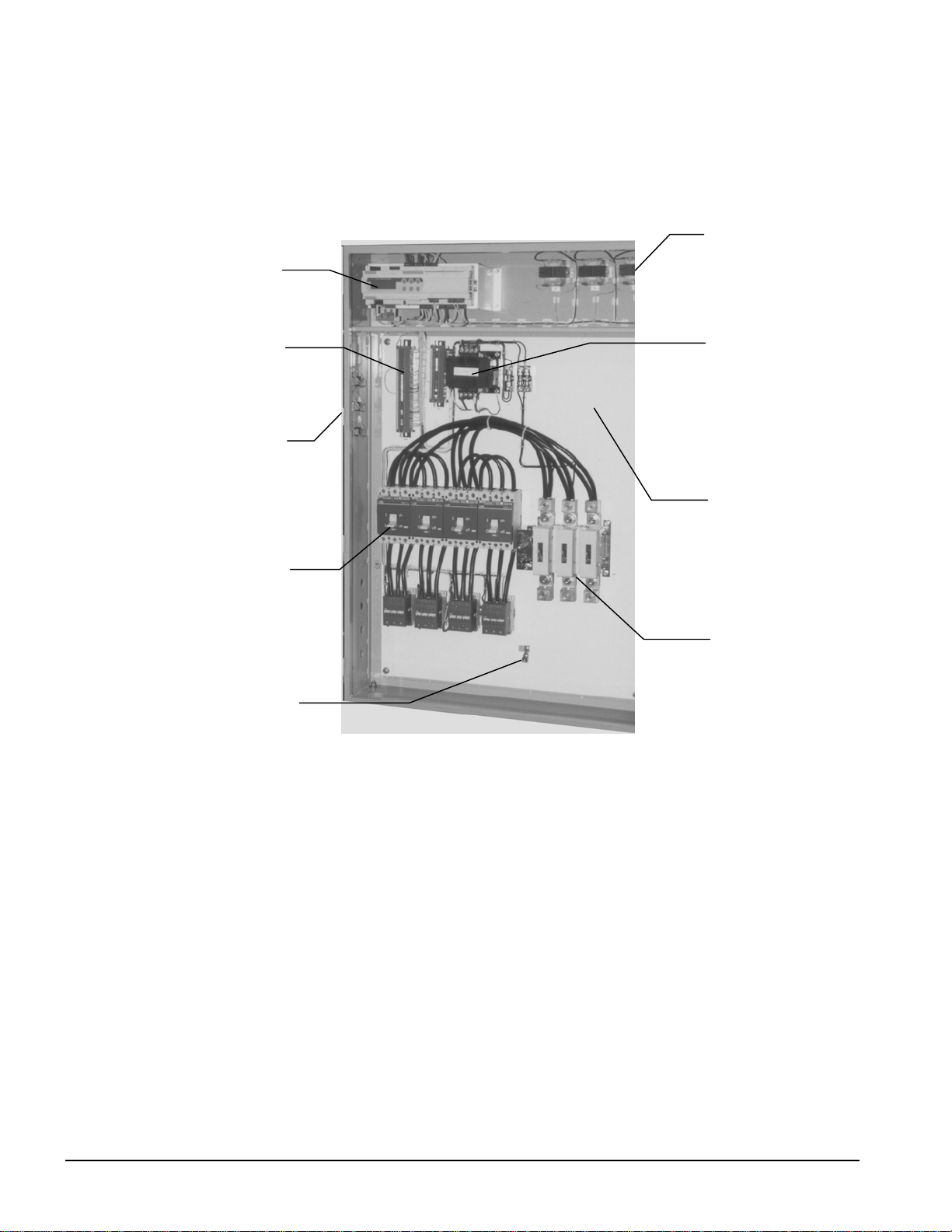

Control Panel Layout

Figure 7, Typical Control Panel

MicroTech II Unit

Controller

(3) 24V Controller

Transformers

Terminal Strips

S1, PS1, PS2

(4) Compressor

Grounding Lug

Switches

Contactors

110V Control

Space for

Optional Circuit

Breakers and

Multi-point

Connection

Disconnect

Switch

NOTES:

1. Additional space provided in the upper right section for extra components required for

optional multiple point power connection and optional circuit breakers.

2. Front door has opening on top for access to the MicroTech II controller for viewing

display and making keypad entries without opening the panel door.

Motor Protection Module

The motor protection system consists of an external control module, located on each

compressor, connected to a series of thermistors located in the motor windings and the

compressor discharge port. If the windings experience an over-temperature condition or the

discharge temperature is excessive, the module will trip and shut off the compressor for a

30-minute time delay.

10 WGZ 030A through 120A OM WGZ-2

Page 11

Start-Up and Shutdown

Pre Start-up

1. The chilled-water system should be flushed and cleaned. Proper water treatment is

required to prevent corrosion and organic growth.

2. With main disconnect open, check all electrical connections in control panel and starter

to be sure they are tight and provide good electrical contact. Although connections are

tightened at the factory, they can loosen enough in shipment to cause a malfunction.

3. Check and inspect all water piping. Make sure flow direction is correct and piping is

made to correct connection on evaporator and condenser.

4. Open all water flow valves to the condenser and evaporator.

5. Flush the cooling tower and system piping to be sure the system is clean. Start

evaporator pump and manually start condenser pump and cooling tower. Check all

piping for leaks. Vent the air from the evaporator and condenser water circuit, as well

as from the entire water system. The cooler circuit should contain clean, treated, noncorrosive water.

6. Check to see that the evaporator water thermostat sensor is securely installed.

7. Making sure control stop switch S1 is open (off) and pumpdown switches PS1 and PS2

are on “manual pumpdown,” place the main power and control disconnect switches to

“on.” This will energize the crankcase heaters. Wait a minimum of 12 hours before

starting the unit.

8. Check compressor oil level. Prior to start-up, the oil level should cover at least onethird of the oil sight glass located in the equalizing line between the compressors or on

the compressor.

9. Note the water pressure drop across evaporator and condenser on pages Error!

Bookmark not defined. and Error! Bookmark not defined. and check that water

flow is correct per the system design flow rates.

10. Check the actual line voltage to the unit to make sure it is the same as called for on the

compressor nameplate, within + 10%, and that phase voltage unbalance does not

exceed 3%. Verify that adequate power supply and capacity is available to handle load.

11. Make sure all wiring and fuses are of the proper size. Also make sure that all interlock

wiring is completed per McQuay diagrams.

12. Verify that all mechanical and electrical inspections by code authorities have been

completed.

13. Make sure all auxiliary load and control equipment is operative and that an adequate

cooling load is available for initial start-up.

Start-up

1. Open the compressor discharge shutoff valves until backseated. Always replace valve

seal caps.

2. Open the two manual liquid line shutoff valves.

3. Check to see that the unit circuit breakers are in the “off” position.

4. Check to see that the pumpdown switches, PS1 and PS2, are in the “manual

pumpdown” position and the control system switch S1 is in the “off” position.

5. Put the main power and control circuit disconnects to the “on” position.

OM WGZ-2 WGZ 030A through 120A 11

Page 12

6. Verify crankcase heaters have operated for at least 12 hours prior to start-up.

Crankcase should be warm to the touch.

7. Check that the MicroTech II controller is set to the desired chilled water temperature.

8. Start the system auxiliary equipment for the installation by turning on the time clock,

ambient thermostat and/or remote on/off switch and water pumps.

9. Check resets of all equipment protection controls.

10. Switch on the unit circuit breakers.

11. Set pumpdown switches PS1 and PS2 to “auto” for restart and normal operation.

12. Start the system by setting the system switch S1 to on.

13. After running the unit for a short time, check the oil level in each compressor

crankcase, rotation of condenser fans (if any), and check for flashing in the refrigerant

sight glass.

14. After system performance has stabilized, it is necessary that the “Compressorized

Equipment Warranty Form” (Form No. 206036A) be completed to establish

commencement of the warranty period. Be sure to list the pressure drop across both

vessels. This form is shipped with the unit and after completion should be returned to

the McQuayService Department through your sales representative.

Weekend or Temporary Shutdown

Move pumpdown switches PS1 and PS2 to the “manual pumpdown” position. After the

compressors have pumped down, turn off the chilled water pump. Note: With the unit in

this condition, it will not restart until these switches are turned back on. The unit has onetime pumpdown. It is important that the compressors pump down before the water flow to

the unit is interrupted to avoid freeze-up in the evaporator.

Leave S1 on and power to the unit so that the crankcase heaters will remain energized.

Start-up after Temporary Shutdown

1. Start the water pumps.

2. With the control system switch S1 in the “on” position, move the pumpdown switches

PS1 and PS2 to the “auto pumpdown” position.

3. Observe the unit operation for a short time, noting unusual sounds or possible cycling

of compressors.

4. Check compressor crankcase heaters.

Extended Shutdown

1. Close the manual liquid line shutoff valves.

2. After the compressors have pumped down, turn off the water pumps.

3. Turn off all power to the unit.

4. Move the control service switch S1 to the “off” position.

5. Close the discharge shutoff valves on the compressor(s) and the liquid outlet valves at

the condenser.

6. Tag all opened disconnect switches to warn against start-up before opening the

compressor suction and discharge valves.

7. Drain all water from the unit evaporator, condenser, and chilled water piping if the unit

is to be shut down during the winter and exposed to below freezing temperatures. Do

not leave the vessels or piping open to the atmosphere over the shutdown period.

12 WGZ 030A through 120A OM WGZ-2

Page 13

Start-up after Extended Shutdown

1. Inspect all equipment to see that it is in satisfactory operating condition.

2. Remove all debris that has collected on the surface of the condenser coils (remote

condenser models) or check the cooling tower, if present.

3. Open the compressor discharge valves until backseated. Always replace valve seal caps.

4. Open the manual liquid line shutoff valves.

5. Check circuit breakers. They must be in the “off” position.

6. Check to see that the pumpdown switches PS1 and PS2 are in the “manual shutdown”

position and the control system switch S1 is in the “off” position.

7. Put the main power and control circuit disconnects to the “on” position.

8. Allow the crankcase heaters to operate for at least 12 hours prior to start-up.

9. Start the chilled water pump and purge the water piping as well as the evaporator in the

unit.

10. Start the system auxiliary equipment for the installation by turning on the time clock,

ambient thermostat and/or remote on/off switch.

11. Check that the MicroTech II controller is set to the desired chilled water temperature.

12. Check resets of all equipment protection controls.

13. Switch the unit circuit breakers to “on.”

14. Start the system by setting the system switch S1 to “on.”

CAUTION

Most relays and terminals in the control center are powered when S1 is

closed and the control circuit disconnect i s on. Therefore, do not close S1

until ready for start-up or serious equipment damage can occur.

15. Set pumpdown switches PS1 and PS2 to the “auto pumpdown” position for restart and

normal operation.

16. After running the unit for a short time, check the oil level in the compressor oil sight

glass or in the compressor’s equalizing lines for flashing, indicating possible refrigerant

in the oil.

Low Ambient Start

The low ambient start logic is for starting units with remote air-cooled condensers during

periods of low ambient air temperatures.

A low ambient start takes place if the saturated condenser temperature is less than 85.0°F

when the first compressor starts. The low ambient start is active for a time defined by the

Low OAT Start Timer set point. This set point is found on screen three in the alarm set

points menus.

During the low ambient start, the freezestat logic for the low-pressure stop alarm and the

low-pressure events are disabled. The low-pressure stop alarm can still be triggered if the

evaporator pressure drops below 5.0 psi at any time while the circuit is in the ‘Run’ state.

Also, during the low ambient start, the second compressor is not allowed to start. The

evaporator pressure is checked at the end of the low ambient start time frame. If the

pressure is less than the low pressure unload set point, then the low ambient start is not

successful and the compressor will shut off. This will not be a manual reset alarm until

three consecutive attempts have failed. The circuit alarm triggered after the third failed

OM WGZ-2 WGZ 030A through 120A 13

Page 14

F

F

F

F

attempt is a Low OAT Restart fault. The Low OAT Restart faults are Circuit alarms so each

circuit will attempt to start either compressor three times before the Low OAT Restart fault

is indicated.

Fan High Ambient Rapid Start

The following logic exists to get condenser fans started earlier than normal during unit

starts with warm ambient air temperatures.

• If the outside air temperature higher than 75.0°F the condenser fan staging logic

changes to bring on the first fan on when the condenser pressure is greater than 140 psi.

• The standard condenser fan staging logic would start the first condenser fan when the

condenser pressure is higher than 200.0 psi.

• The last condenser fan on each circuit will not shut down until the condenser pressure

drops below 140.0 psi regardless of the outside air temperature

Sequence of Operation

The following sequence of operation is typical for WGZ water chiller models. The

sequence can vary slightly depending upon options.

Compressor Heaters

With the control circuit power on and the control stop switch S1 off, 115V power is applied

through the control circuit fuse Fl to the compressor crankcase heaters HTR1, HTR2,

HTR3, and HTR4.

Start-up/Compressor Staging

When compressors start and stop.

Stage Up Temp is the LWT temperature at which the next compressor to start will stage up

(start) after at least one compressor on the unit has started and is running.

Start Up Temp is the LWT at which the first compressor starts. The start up temperature

equals the stage up temperature plus the Start Delta temperature. A high Start Delta will

keep the unit off longer and reduce unit cycling at low loads. However, this high Start

Delta will cause a larger excursion from the LWT setpoint before the unit starts.

Stated another way, the Start Delta is the number of degrees above the Evap LWT setpoint,

plus ½ the Dead Band, that determines when the first compressor starts. The Start Delta is

in effect for only the first start after all compressors have been off. Additional compressor

starts and stops are determined by the LWT in respect to the dead band only. The dead

band is automatically set of 30% of the EvapDeltaT selected in menu 3. The following

sequence would occur for the settings shown below:

EvapDelta T=10.0°F Dead Band=3.0°F StartDelta=5.0°F StopDelta=2.0°F

LWT=40.0°F

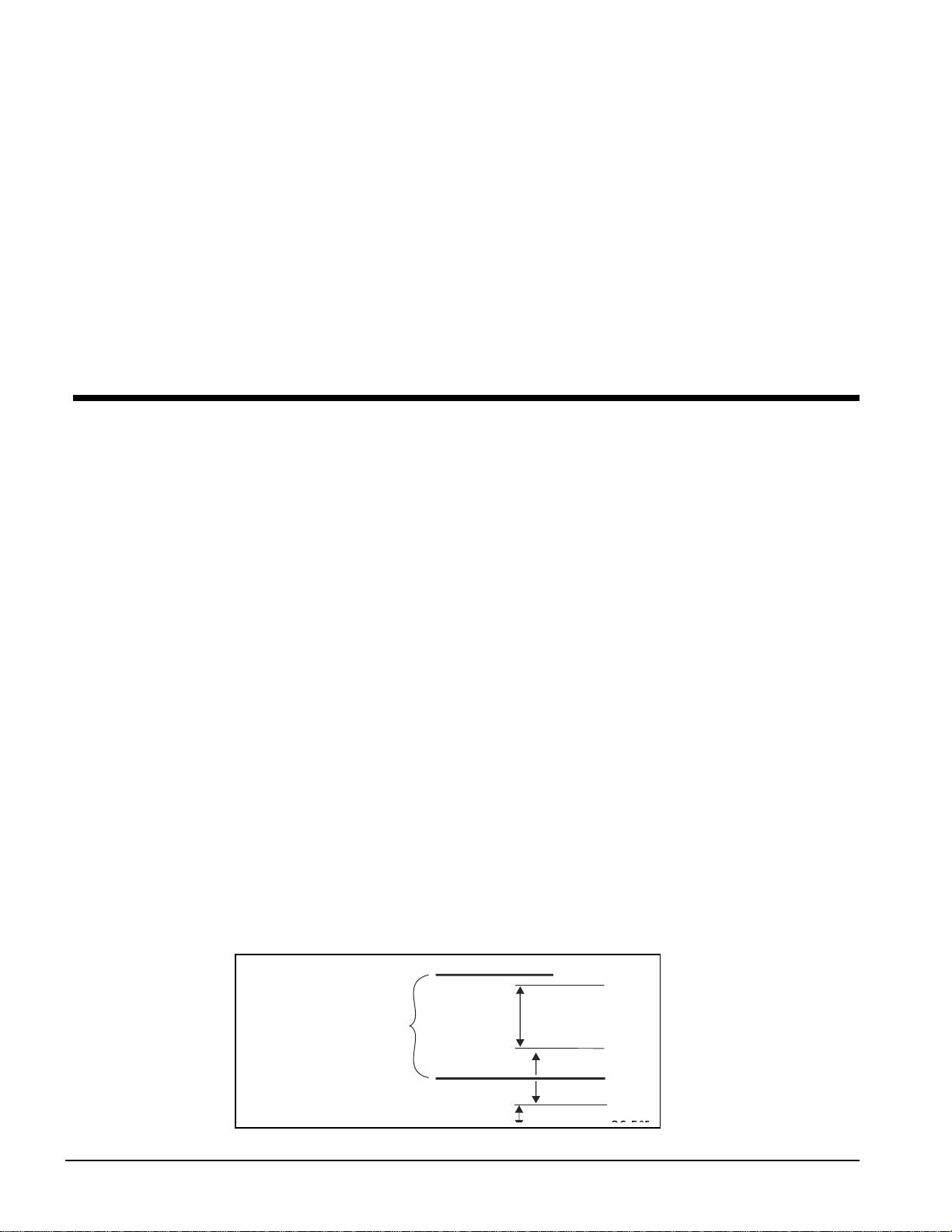

Figure 8, Staging/Starting Temperatures

EWT

Evap Delta-T Set

LWT Set

50.0°F

10.0°F

40.0°F

Start Del ta T

½DB

½DB

46.5°

41.5°

40.0°

38.5°

For a warm start-up (no

compressors running), the

first compressor will start

at any temperature above

46.5°F. Each subsequent

compressor will start after

the Stage Up Timer has

timed out and if the

temperature is above the

14 WGZ 030A through 120A OM WGZ-2

Page 15

dead band, 41.5°F in this case. If the LWT stays above 41.5°F, all of three remaining

compressors will eventually stage on after the Stage Up Timer times out between each

stage.

At some point, the chilled water temperature will be dropping and begin to approach the

point when compressors should begin staging off, which is the LWT setpoint minus ½ of

the Dead Band, 38.5°F in this case. If the LWT remains below LWT setpoint minus ½

Dead Band and the Stage Down Timer times out, additional compressor will stage off. The

last compressor will stage off when the LWT falls below the LWT Setpoint minus ½ the

Dead Band minus the Stop Delta T. The stop Delta T is in effect for only the last

compressor running.

If the temperature climbs above 38.5°F all running compressors will remain on. No

compressor staging occurs within the Dead Band. The next-on compressor will start when

the chilled water temperature reaches 41.5°F and the Stage Up Timer times out.

However, in some circumstances this methodology can cause the LWT to drop to

dangerously low levels, with the evaporating temperature below the freeze point, before

stopping. In the example shown in Figure 8, the Shutdown Temp (last compressor off)

would be 36°F.

This would result in a refrigerant evaporating temperature approaching freezing, so the rule

is amended to read:

If the Cool Leaving Water Temperature (LWT) set point is less than half the

Control Band above 39.0° F the Stage Down temperature is calculated as:

Stage Down Temperature = Cool LWT – (Cool LWT - 39.0

Shutdown Temperature = Cool LWT – (Cool LWT - 39.0

°

F), and the

°

F) – Stop Delta T

This keeps the Stage Down Temp above 39°F and the Shutdown Temp above 36°F, as the

maximum Stop Delta T allowed is 3-degrees.

Which compressor starts and stops. One compressor per circuit will start before starting

the second compressor on any circuit. In other words, the compressor with the lowest

number of starts will start first. The compressor with the lowest number of starts on the

other circuit will start next, so that one compressor on each circuit will be running. The

third compressor on will be the compressor on either circuit with the fewest starts. The

remaining compressor will be the last on. If a circuit is unavailable for any reason, the

second compressor. on the operating circuit will stage on. Only two compressors (on the

one circuit) will be operating.

There is a 150 second delay after power-up before any compressor is allowed to start.

When staging down, one compressor on each circuit will be left on until each circuit has

only one compressor running. In other words, the compressor, on either circuit, with the

most run-hours will stop first. The compressor with the most run-hours on the other circuit

will stop next. One compressor on each circuit will be running. The third compressor off

will be the one, on either circuit, with the most run-hours. The remaining compressor will

be the last off. See the following description of pumpdown.

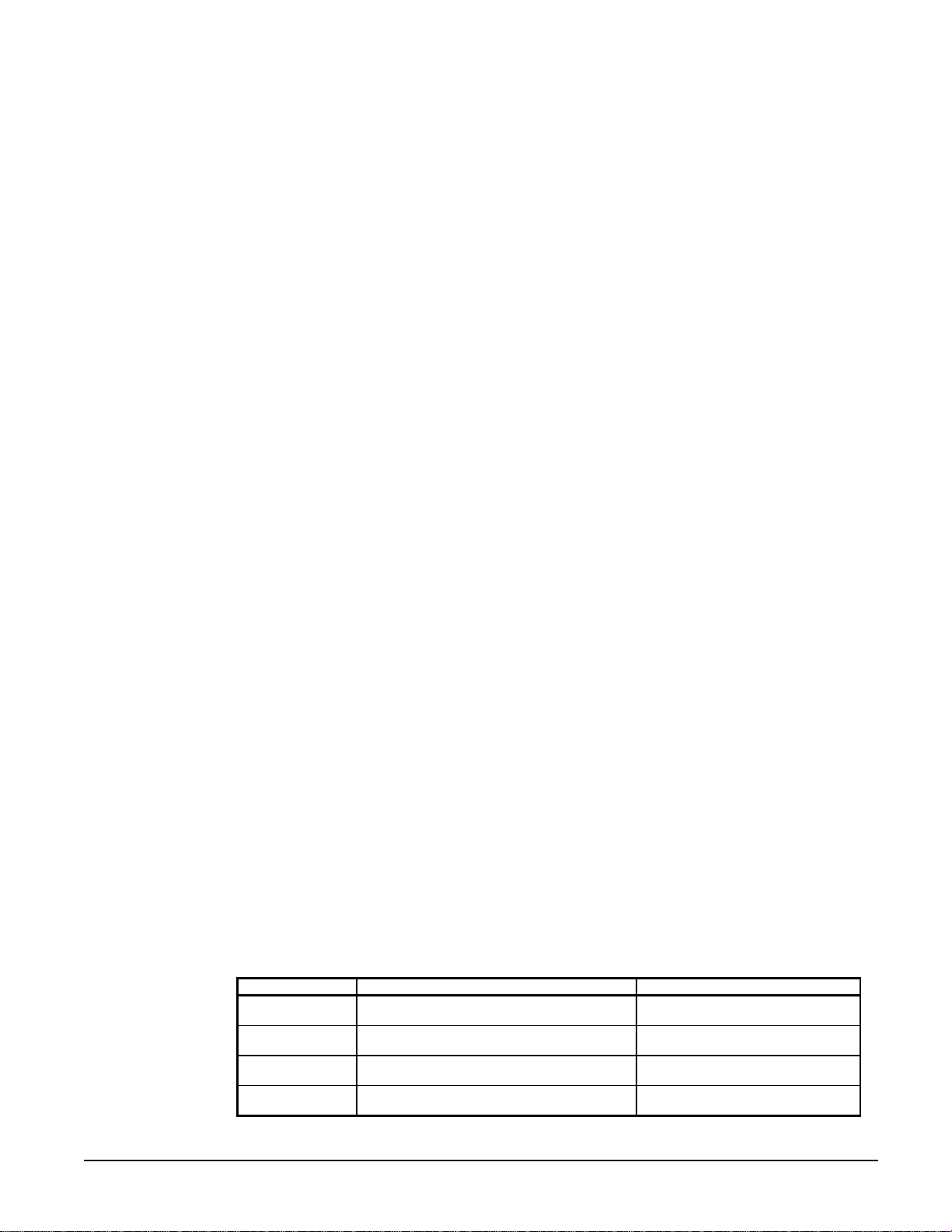

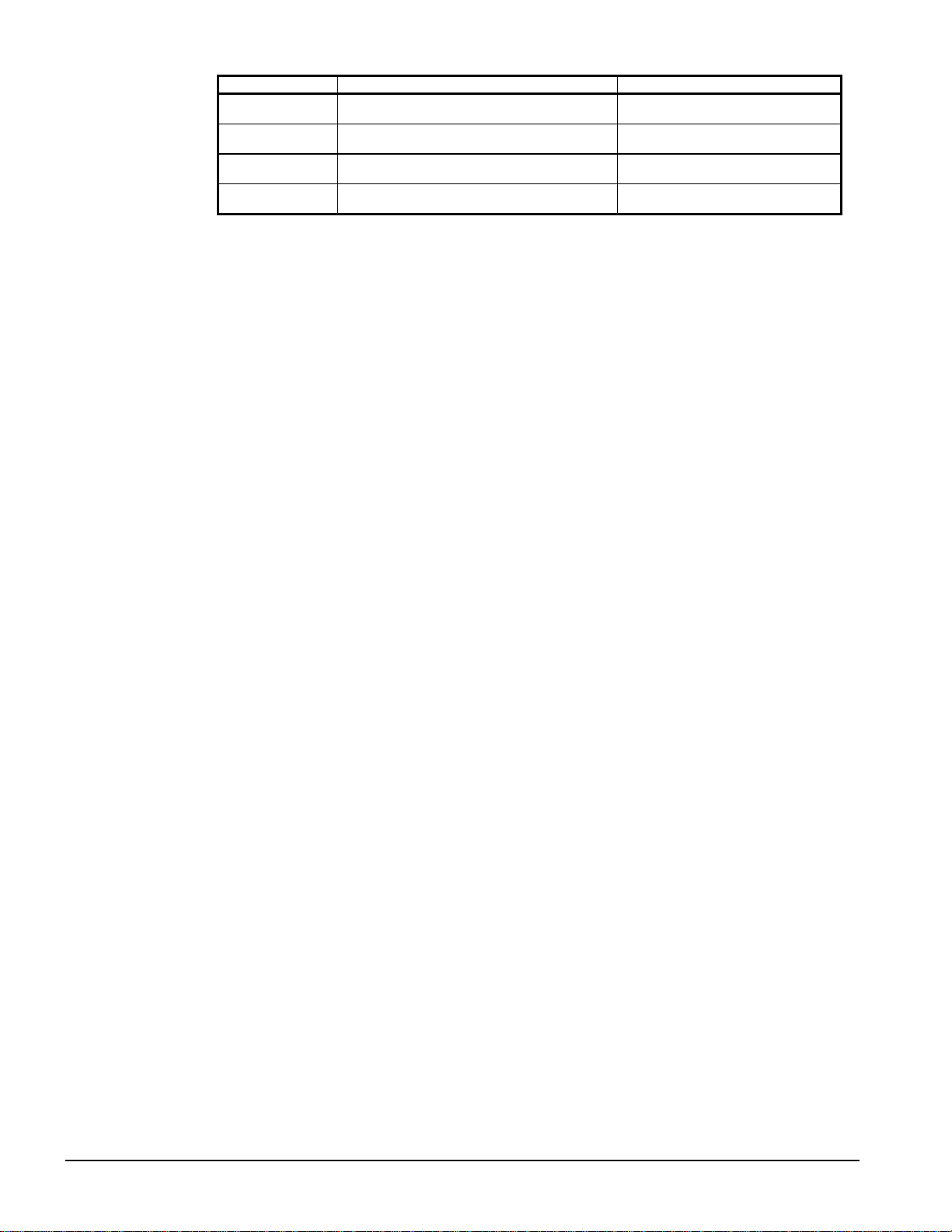

Table 3, Staging in Cool and Glycol Mode

Description Occurs When: Action Taken

Stage #1 ON

(See Notes Below)

Stage #2 ON After Stage Up Delay times out then, LVG Evap

Stage #3 ON After Stage Up Delay times out, then LVG Evap

Stage #4 ON After Stage Up Delay times out then, LVG Evap

Lvg Evap T > Evap LWT SP + (DB/ 2) + S t artup

Delta T

T > Evap LWT SP + (DB/2)

T > Evap LWT SP + (DB/2)

T > Evap LWT SP + (DB/2)

Available compressor with l east

starts, ON

Available compressor on the other

circuit with least starts, ON

Available compressor on ei ther circuit

with least starts, ON

Remaining compressor, ON

Continued next page.

OM WGZ-2 WGZ 030A through 120A 15

Page 16

Description Occurs When: Action Taken

Stage #4 OFF After Stage Down Delay times out then, LVG

Evap T < Evap LWT SP – (CB/2)

Stage #3 OFF After Stage Down Delay times out then, LVG

Evap T < Evap LWT SP – (DB/2)

Stage #2 OFF After Stage Down Delay times out then, LVG

Evap T < Evap LWT SP – (DB/2)

Stage #1 OFF After Stage Down Delay times out then, LVG

Evap T < Evap LWT SP – (DB/2)-StopDelta T

Note 1: DB (Dead Band) = Evap W ater Delta T x .3

Compressor with most run hours,

OFF

Compressor on the other ci rcuit with

most run hours, OFF

Compressor on either circuit with

most run hours, OFF

Remaining compressor, OFF

Manual Compressor Disable Logic

Logic is available that allows the operator to manually enable and disable compressors.

When a compressor is disabled, it is considered unavailable to start in the staging logic.

This allows a damaged compressor to be taken offline while the remaining compressor can

still provide some cooling

• The Compressor Disable set points are found on Compressor Set Points screens three

and four.

• A running compressor cannot be disabled until it has been shutdown.

• If all of the compressors on a circuit are disabled, then the circuit will be disabled.

• If both circuits have all of their compressors disabled, then the Unit State will remain

Off

Automatic Pumpdown

WGZ units are equipped with single pumpdown control. When the last compressor running

on either circuit is ready to shut off, the liquid line solenoid valve (LLSV) is closed first

and the compressor continues to run until the pumpdown pressure is reached, at which time

the compressor shuts off. The shut off pressure is set at 15 psi below the Low Evaporator

pressure Unload setpoint.

When the first compressor on a circuit starts, the LLSV opens simultaneously.

Manual Pumpdown

When the Pumpdown Switch is in the pumpdown position, Compressor #3 or #4

(depending on circuit) will shut off. Then the Liquid Line and Hot Gas Bypass Valves will

close. The operating compressor will pump out the refrigerant. When the Suction Pressure

is at 40 psig, the compressor will stop.

Chilled Water and Condenser Water Pumps

The chiller MicroTech II controller can be programmed to start and stop the system chilled

water and condenser water pumps. They may also be controlled by the BAS or manually.

Programming directions and the sequence of operation can be found beginning on page 30.

Cooling Tower Control

The cooling tower fans and/or the tower bypass valve can be controlled by the MicroTech II

controller. This provides a simple and direct method to control the unit’s discharge

pressure. Programming directions and the sequence of operation can be found on page 44.

Some means of discharge pressure control must be installed if the condenser water

temperature can fall below 60°F (16°C).

16 WGZ 030A through 120A OM WGZ-2

Page 17

Condenser Fan Control

Model AA chillers equipped with air-cooled or evaporative-cooled condensers usually

require some form of discharge pressure control. The MicroTech II controller can be

programmed to provide this function by cycling condenser fans based on the unit discharge

pressure. Directions on the pressure settings can be found on page 44.

ICE

In ICE mode, the compressors stage to 100% load until the LWT is less than the ICE LWT

SP. Then Compressors #3 and #4 shut down. Following that, Compressors #1 and #2 shut

down after going through normal pumpdown on both circuits. There is a programmable,

start-to-start, Ice Mode Start Delay that limits the frequency of starts when in the ice mode.

The timer can be manually cleared to force a restart.

OM WGZ-2 WGZ 030A through 120A 17

Page 18

MicroTech II Controller

Controller Software Version

This manual is based on software version WGZD20102B. The “02B” is the version

descriptor. The version installed in a unit can be viewed by pressing the MENU and

ENTER keys simultaneously. Then pressing MENU to return to the regular menu screen.

General Description

The MicroTech II controller’s state-of-the-art design will not only permit the chiller to run

more efficiently but will also simplify troubleshooting if a system failure occurs. Every

MicroTech II controller is programmed and tested prior to shipment to assist in a troublefree start-up. The MicroTech II controller can be used to cycle fans on remote air-cooled

condensers for head pressure control when the setpoint Water Cooled=N is selected in one

of the setpoint menu screens. Water Cooled=Y sets the chiller for operation with the watercooled condenser.

Operator Friendly

The MicroTech II controller menu structure is separated into three distinct categories,

which provide the operator or service technician with a full description of 1) current unit

status, 2) control parameters (setpoints), and 3) alarms. Security protection prevents

unauthorized changing of the setpoints and control parameters.

The MicroTech II controller continuously performs self-diagnostic checks, monitoring all

system temperatures, pressures and protection devices, and will automatically shutdown a

compressor, a refrigerant circuit or the entire unit should a fault occur. The cause of the

shutdown and date stamp are retained in memory and can be easily displayed in plain

English for operator review, which is an extremely useful feature for troubleshooting. In

addition to displaying alarm diagnostics, the MicroTech II chiller controller also provides

the operator with a warning of pre-alarm conditions.

Staging

The four scroll compressors are staged on and off as a function of leaving chilled water

temperature, number of starts and run-hours. See Sequence of Operation.

Equipment Protection

The unit is protected by alarms that shut it down and require manual reset, and also by limit

alarms that limit unit operation in response to some out-of-limit condition. Shut down

alarms activate an alarm signal that can be wired to a remote device.

Unit Enable Selection

Enables unit operation from local keypad or digital input.

Unit Mode Selection

Selects standard cooling, ice, glycol, or test operation mode.

18 WGZ 030A through 120A OM WGZ-2

Page 19

Keypad/Display

A 4-line by 20-character/line liquid crystal display and 6-key keypad is mounted on the unit

controller. Its layout is shown below.

Figure 9, Keypad and Display in MENU Mode

Air Condi ti oni ng

<

ALARM

<

VIEW

<

SET

Menu Key Key to Screen

Arrow Keys

"Enter" Key

The four arrow keys (UP, DOWN, LEFT, RIGHT) have three modes of use.

1. Scroll between data screens as indicated by the arrows (default mode).

2. Select a specific data screen in a hierarchical fashion using dynamic labels on the right

side of the display (this mode is entered by pressing the MENU key).

3. Change field values in edit mode according to the following table:

LEFT Default

RIGHT Cancel

UP Increment

DOWN Decrement

These four edit functions are indicated by one-character abbreviation on the right side of

the display (this mode is entered by pressing the ENTER key).

Inputs/Outputs

Table 4, Analog Inputs

C1 = Refrigerant Circuit #1, C2 = Refrigerant Circuit #2, UT = Unit

# Description Type Signal Source Range

1 Evaporator Refrigerant Pressure #1 C1 0.5 – 4.5 VDC (NOTE 1) 0 to 132 psi

2 Evaporator Refrigerant Pressure #2 C2 0.5 – 4.5 VDC (NOTE 1) 0 to 132 psi

3 Condenser Refrigerant Pressure #1 C1 0.5 – 4.5 VDC (NOTE 1) 3.6 to 410 psi

4 Leaving Evaporator Water Temperature UT

Condenser Entering or Outside

5

Ambient Temperature (NOTE 2)

6 Condenser Refrigerant Pressure #2 C2 0.1 to 0.9 VDC

7 Reset of Leaving Water Temperature UT 4-20 mA Current 0-(10 to 60°F)

8 Demand Limit UT 4-20 mA Current 0-100 % Load

9 Compressor Suction Temperature #1 C1

10 Compressor Suction Temperature #2 C2

NOTES:

1. Value at the converter board input. Value at the converter board output is 0.1 VDC – 0.9 VDC.

2. If Water Cooled = Y, then Entering Condens er. If Water Cooled = N, then Outside Ambient.

UT

Thermister (10k at 77°F,

25°C)

Thermister (10k at 77°F,

25°C)

Thermister (10k at 77°F,

25°C)

Thermister (10k at 77°F,

25°C)

-58 to 212°F

-58 to 212°F

3.6 to 410 psi

-58 to 212°F

-58 to 212°F

OM WGZ-2 WGZ 030A through 120A 19

Page 20

Table 5, Analog Outputs

# Description Output Signal Range

1 Cooling Tower Bypass Valve Position 0 to 10 VDC 0 to 100% Open

2 Cooling Tower VFD Speed 0 to 10 VDC 0 to 100%

Table 6, Digital Inputs

C1 = Refrigerant Circuit #1, C2 = Refrigerant Circuit #2, UT = Unit

# Description Type Signal Signal

1 Unit OFF Switch UT 0 VAC (Stop) 24 VAC (Auto)

2 Pump Down Switch #1 C1 0 VAC (Stop) 24 VAC (Start)

3 Evaporator Water Flow Switch UT 0 VAC (No Flow) 24 VAC (Flow)

4 Motor Protection #1 C1 0 VAC (Fault) 24 VAC (No Fault)

5 Open

6 Pump Down Switch #2 C2 0 VAC (Stop) 24 VAC (Start)

7 Motor Protection #2 C2 0 VAC (Fault) 24 VAC (No Fault)

8 Open

9 Phase Voltage Fault #1 (See Note 1) C1 0 VAC (Fault) 24 VAC (No Fault)

10 Phase Voltage Fault #2 (See Note 1) C2 0 VAC (Fault) 24 VAC (No Fault)

11 Ground Fault Prot. #1 (See Note 2) C1 0 VAC (Fault) 24 VAC (No Fault)

12 Ground Fault Prot. #2 (See Note 2) C2 0 VAC (Fault) 24 VAC (No Fault)

13 Remote Start/Stop UT 0 VAC (Stop) 24 VAC (Start)

14 Condenser Water Flow Switch UT 0 VA C (No Fl ow) 24 VAC (Flow)

15 Mechanical High Pressure #1 C2

16 Mechanical High Pressure #2 C2

17 Ice Mode Switch UT 0 VAC (Normal) 24 VAC (Ice)

18 Open

Note 1: See Equipment Protection Alarms Table for “Phase Voltage Protection”. Units with single point

electrical connection will have one PVM with Inputs 9 and 10 wired together. Units with multiple point

connection will have two PVM’s with Input 9 for Electrical Circuit #1 and Input 10 for Electrical Circuit #2.

Note 2: See Equipment Protection Alarms Table for “Ground Fault Protection”. Units with single point

electrical connection will have one GFP with Inputs 11 and 12 wired together. Units with multiple point

connection will have two GFP’s with Input 11 for Electrical Circuit #1 and Input 12 for Electrical Circuit #2.

0 VAC (High

Pressure/Off)

0 VAC (High

Pressure/Off)

24 VAC (OK )

24 VAC (OK )

Table 7, Digital Outputs

C1 = Refrigerant Circuit #1, C2 = Refrigerant Circuit #2, UT = Uni t

# Description Type Load Output OFF Output ON

1 Alarm

2 E vaporat or Water Pump UT Pump Contactor Pump OFF Pump ON

Condenser Fan #1 – Water Cooled

3

= N / Condenser Water P ump –

Water Cooled = Y

4 Motor Control Relay #1 = Compr#1 C1 Starter Compressor OFF Compressor ON

5 Motor Control Relay #3 = Compr#3 C1 Starter Compressor OFF Compressor ON

Condenser Fan #3– Water Cooled

6

=N /Tower Fan #2-Water Cooled=Y

7 Li qui d Li ne #1 C1 Solenoid Cooling OFF Cooling ON

Condenser Fan #2 – Water Cooled

8

=N /Tower Fan #1-Water Cooled=Y

9 Motor Control Relay #2 = Compr#2 C2 Starter Compressor OFF Compressor ON

10 Motor Control Relay #4 = Compr#4 C2 Starter Compress or OFF Compressor ON

11 Condenser Fan #4 C2 Fan Contactor Fan OFF Fan ON

12 Liquid Line #2 C2 Solenoid Cooling OFF Cooling ON

13 Condenser Fan #5 C1 Fan Contactor Fan OFF Fan ON

14 Hot Gas Bypass #1 C1 Solenoid Cooling OFF Cooling ON

15 Hot Gas Bypass #2 C2 Solenoid Cooling OFF Cooling ON

16 Condenser Fan #6 C2 Fan Contactor Fan OFF Fan ON

17 Condenser Fan #7 C1 Fan Contactor Fan OFF Fan ON

18 Condenser Fan #8 C2 Fan Contactor Fan OFF Fan ON

C1,C2,

UT

C1 /

UT

C1 /

UT

C2 /

UT

Alarm Indicator Alarm OFF Alarm ON

Fan Contactor/

Pump Contactor

Fan Contactor Fan OFF Fan ON

Fan Contactor Fan OFF Fan ON

Fan OFF Fan ON

20 WGZ 030A through 120A OM WGZ-2

Page 21

Setpoints

The following parameters are remembered during power off, are factory set to the Default

value, and can be adjusted to any value in the Range column.

The PW (password) column indicates the password level that must be active in order to

change the setpoint. Passwords are as follows:

O = Operator [0100]

M = Manager [2001]

Table 8, Setpoints

Description Default Range PW

Unit Enable OFF OFF, ON O

Unit Mode COOL COOL, COOL w/Glycol, ICE w/Glycol O

Control source DIGITAL INPUT KEYPAD, B A S , DIGITAL INPUT O

Available Modes COOL COOL, COOL w/Glycol, /ICE w/Glycol M

XXX Display Units

XXX Language ENGLISH ENGLISH, (TBD) O

BAS Protocol NONE NONE, BACnet, LonWorks, Modbus M

Ident Number 001 001-999 M

Baud Rate 9600 1200, 2400, 4800, 9600, 19200 M

Evap LWT (COOL & GLYCOL)

Ice LWT (ICE )

Evap Delta T

Startup Delta T

Stop Delta T

Max Pulldown Rate

Low Ambient Lockout (Water-cooled = No)

Demand Limit Off Off, On M

* Water Cooled N N,Y M

* Refrigerant Select None R22, R407c -* Phase Voltage Protect i on N N,Y M

* Ground Fault Protection N N,Y M

* Set at Factory

Speedtrol Option N N,Y M

Staging

Stage Up Delay 240 90 to 480 sec M

Stage Down Delay 30 20 to 60 sec M

Timers

Evap Recirculate Timer 30 sec 15 to 300 sec M

Cond Pump Recirculate Timer (Water-cool ) 30 sec 15 to 90 sec M

Low Evap Pressure Delay 30 sec 15 sec to 30sec M

LowOATTmr 60 sec 30 to 240 sec

Ice Time Delay 12 hrs 1-23 Hrs M

Clear Ice Timer No No, Yes M

Hot Gas Bypass Solenoid Val ve Del ay 30 sec 30 to 180 sec M

Start-Start 15 min 10 to 60 min M

Stop-Start 5 min 3 to 20 mi n M

Alarms

Evaporator Freeze

Condenser Freeze

Low Evap Pressure 58 psi 30 to 60 psi M

Evap Flow Proof 3 sec 1 to 10 sec M

High Condenser Pressure 380 psi 380 to 390 psi M

Events

Low Evap Pressure-Hold R22 59 psi 24 to 65 psi M

Low Evap Pressure-Hold R407c 52 psi 20 to 65 psi M

Low Evap Pressure-Unload R22 58 psi 24 to 65 psi M

Low Evap Pressure-Unload R407c 50 psi 20 to 65 psi M

High Condenser Stage Down 370 psi 365 to 375 psi M

Condenser Fans (Water Cooled = N)

Fans Per Circuit 2 2 to 4 M

Speedtrol; Option N N, Y M

C1/ C2 – Stage #1 / #2 On (OAT < 70°F)

C1/ C2 – Stage #3 / #4 On 290 psi 220 to 330 psi M

°F/psi °F/psi, °C/kPa

44. 0°F 20.0 to 60.0 °F

40. 0°F 20.0 to 40.0 °F

10. 0°F 6.0 to 16.0 °F

2.0°F 1.0 to 10.0 °F

0.5°F 0 to 3.0°F

1.0°F 0.5 to 5.0°F

35.0°F -2(35) to 70°F

36.0 °F 18 to 42 °F

34.0 °F 18 to 42 °F

200 psi 140 to 200 psi M

Continued next page

O

O

O

O

O

O

M

M

M

M

OM WGZ-2 WGZ 030A through 120A 21

Page 22

Description Default Range PW

C1/ C2 – Stage #5 / #6 On 300 psi 220 to 330 psi M

C1/ C2 – Stage #7/ #8 On 310 psi 220 to 330 psi M

C1/ C2 – Stage #3/ #4 Off 180 psi 150 to 220 psi M

C1/ C2 – Stage #5/ #6 Off 190 psi 150 to 220 psi M

C1/ C2 – Stage #7/ #8 Off 200 psi 150 to 220 psi M

Cooling Tower (Water Cooled = Y)

Tower Control None None, Temperature M

Tower Stages 2 0 to 2 M

Stage Up Time 2 min 1 t o 60 min M

Stage Down Time 5 min 1 to 60 min M

Stage Differential

Stage #1 On

Stage #2 On

Cooling Tower (Water Cooled = Y)

Valve / VFD

Valve/VFD Control None

Valve Setpoint

Valve Deadband

Stage Fan Down @ 20% 0 t o 100% M

Stage Fan Up @ 80% 0 to 100% M

Valve Control Range (Min) 10% 0 to 100% M

Valve Control Range(Max) 90% 0 to 100% M

Valve Type NC (To Tower)

Minimum Start P osition 0% 0 to 100% M

Minimum Position @

Maximum Start Posit i on 100% 0 to 100% M

Maximum Position @

Error Gain 25 10 to 99 M

Slope Gain 25 10 to 99 M

3.0 °F 1.0 to 10.0 °F

70 °F 40 to 120 °F

75 °F 40 to 120 °F

None, Valve Setpoint, Valve S tage, VFD

Stage, Valve SP/VFD Stage

65 °F 60 to 120 °F

2.0 °F 1.0 to 10.0 °F

Normally Closed (NC), Normal l y Open

(NO)

60 °F 0 to 100 °F

90 °F 0 to 100 °F

M

M

M

M

M

M

M

M

M

Protection (Shutdown) Alarms

Equipment protection alarms trigger a rapid compressor shutdown. The following table

identifies each equipment protection alarm, gives the condition that causes the alarm to

occur, and states the action taken because of the alarm. Most equipment protection alarms

require a manual reset. These alarms will energize a remote alarm if the unit is so wired in

the field.

Table 9, Equipment Protection Alarms

NOTE: SP = Setpoint

NOTE : UT = Rapid Stop for the entire unit (Both Circuit s), CT = Rapid St op for that circ uit only

Description Occurs When:

No Evaporator Water

Flow

No Condenser Water

Flow

Low Evaporator

Pressure

High Condenser

Pressure

Mechanical High

Pressure

Motor Protection

Phase Voltage

Protection (optional)

Ground Fault

Protection (optional)

Evap Pump State = RUN AND

Evap Flow Digital Input = No Flow & High Condenser

Pressure for > Evap Flow Proof SP]

Cond Flow Digital Input = No Flow for > Evap Flow Proof]

Note: Water Cooled = Y Onl y

Evaporator Press < Low Evap Pressure SP start Low Evap

Pressure Time Delay – if af ter Time Delay if Evap Press >

SP continue else stop

Condenser Press & Condenser Flow > High Condenser

Pressure SP

For C1, Motor Start #1 On & Digital I nput = High Pressure

For C2, Motor Start #2 On & Digital I nput = High Pressure

Digital Input = High Motor Temperat ure

On Power Up – Delay 150 Sec. Before check i ng

If Phase Voltage Protec tion = Y, Then

Digital Input = Phase/V ol t age Problem

If Ground Fault Protection = Y, Then

Digital Input = Ground Fault Protec tion Problem

Continued on next page.

Action

Taken

Rapid

Stop UT

Rapid

Stop UT

Rapid

Stop CT

Rapid

Stop CT

Rapid

Stop CT

Rapid

Stop CT

Rapid

Stop CT

Rapid

Stop CT

Reset

Manual

Manual

Manual

Manual

Manual

Manual

Manual

22 WGZ 030A through 120A OM WGZ-2

Page 23

Description Occurs When:

Re-Start Fault Re-Start = Third Time

Evap. Freeze Protect Evap LWT < Evaporator Freeze SP

Leaving Evap. Water

Temp. Sensor Fault

Evaporator Pressure

Sensor Fault

Condenser Pressure

Sensor Fault

Condenser Entering

or Outside Ambient

Temp. Sensor Fault

Sensor shorted or open

Sensor shorted or open

Sensor shorted or open

Sensor is open or shorted

Action

Taken

Rapid

Stop UT

Rapid

Stop CT

Rapid

Stop UT

Rapid

Stop CT

Rapid

Stop CT

Rapid

Stop UT

Reset

Manual

Manual

Manual

Manual

Manual

Manual

Event (Limit) Alarms

The following alarms do not cause a rapid shutdown but limit operation of the chiller in

some way as described in the Action Taken column. These alarms do not trigger a remote

alarm signal. They do appear in the Active Alarm menu, are logged, and light the Alarm

LED. A password must be active to view these events in the Event Log.

Table 10, Limit Alarms

NOTE: SP = Setpoint

NOTE: UT = Rapid Stop for the entire unit (Both Circuit s), CT = Rapid St op for that circ uit only

Description Occurs When: Action Taken Reset

Condenser Pressure

High – Unload

Low Ambient

Lockout

Evaporator Pressure

Low – Hold

Evaporator Pressure

Low – Unload

Condenser Freeze

Protect

Pressure > High Condenser

Stage Down setpoint

Outside Ambient < Low

Ambient Lockout S P

Note: Water Cooled = N Onl y

Pressure < Low Evap

Pressure–Hold setpoint

Pressure < Low Evap

Pressure–Unload setpoint

Cond Sat Refr Temp <

Condenser Freeze SP AND

Cond Pump State = OFF

Note: Water Cooled = Y Onl y

Stage off lag compressor

on the circuit

Stage down & Shutoff

Inhibit staging on lag

compressor on the ci rcuit

Stage off lag compressor

on the circuit

Start condenser pump

Note, See Table 11 for low pressure hold and unload setpoints.

Condenser Press

drops below

(SP – 100psi)

Outside Ambient >

Low Amb Lockout

(SP + 5ºF)

Evap Press rises

above (SP + 8psi)

Evap Press rises

above (SP + 10 psi

+ Stage Up Delta T)

Cond Sat Refr Temp

> (Condenser

Freeze SP + 2°F)

CT

UT

CT

CT

UT

Table 11, Ref ri gerant Sensitive Set Point Defaults and Adjustment Range

R22 Refrigerant R407c Refrigerant

Set Point Name

Low Evaporator

Pressure Hold Loading

Low Evaporator

Pressure Unload

Default

(psi)

59.0

58.0

Adjustment Range

(psi)

24.0 – 65.0 (with glycol)

55.0 – 65.0 (w/o glycol)

24.0 – 65.0 (with glycol)

55.0 – 65.0 (w/o glycol)

Default

(psi)

52.0

50.0

Adjustment Range

(psi)

20.0 – 75.0 (with glycol)

58.0 – 75.0 (w/o glycol)

20.0 – 75.0 (with glycol)

58.0 – 75.0 (w/o glycol)

Unit Enable

• Enabling and disabling the chiller is controlled by the Unit Enable Setpoint with

options of OFF and ON. This setpoint can be altered by the keypad, BAS, Unit OFF

input, and Remote input. The Control Source Setpoint determines which sources can

change the Unit Enable Setpoint with options of SWITCHES, KEYPAD or

NETWORK.

Changing the Unit Enable Setpoint can be accomplished according to the following table.

OM WGZ-2 WGZ 030A through 120A 23

Page 24

Table 12, Unit Enable Combinations

NOTE: An “x” indicates that the val ue is ignored.

Unit Off

Input

Control Source

Setpoint

Remote

Input

Keypad

Entry

BAS

Request

Unit

Enable

OFF x x x x OFF

x SWITCHES OFF x x OFF

ON SWITCHES ON x x ON

ON KEYPAD x OFF x OFF

ON KEYPAD x ON x ON

ON NETWORK x x OFF OFF

ON NETWORK OFF x x OFF

ON NETWORK ON x ON ON

Unit Mode Selection

The overall operating mode of the chiller is set by the Unit Mode Setpoint with options of

COOL, COOL w/Glycol, ICE w/Glycol, and TEST. This setpoint can be altered by the

keypad, BAS, and Mode input. Changes to the Unit Mode Setpoint are controlled by two

additional setpoints.

Available Modes Setpoint: Determines the operational modes available at any time with

options of COOL, COOL w/Glycol, COOL/ICE w/Glycol, and TEST.

Control Source Setpoint: Determines the source that can change the Unit Mode Setpoint

with options of KEYPAD, NETWORK, or SWITCHES.

Table 13, Unit Mode Combinations

Changing the Unit Mode Setpoint can be accomplished according to the following table.

NOTE: An “x” indicates that the value is ignored.

Control

Source

Setpoint

x x x x COOL COOL

x x x x COOL w/Glycol COOL w/Glycol

SWITCHES OFF x x COOL/ICE w/Glycol COOL w/Glycol

SWITCHES ON x x COOL/ICE w/Glycol ICE w/Glycol

KEYPAD x COOL w/Glycol x COOL/ICE w/Glycol COOL w/Glyco l

KEYPAD x ICE w/Glycol x COOL/ICE w/Glycol ICE w/Glycol

NETWORK x x COOL COOL/ICE w/Glycol COOL w/Glycol

NETWORK x x ICE COOL/ICE w/Glycol ICE w/Glycol

x x x x TEST TEST

Mode

Input

Keyp ad Entry

BAS

Request

Available Modes

Setpoint

Unit Mode

Low Ambient Start (Remote Condenser Only)

If Water Cooled = Y, then this function is not applicable.

If SpeedTrol = N, this step is bypassed and unit starts in the normal operation. If the

SpeedTrol = Y then unit starts per table below. This step will bypass the “Low Evaporator

Pressure” alarm until Low Ambient Start is completed.

When there is a call for Cooling the following steps are used.

24 WGZ 030A through 120A OM WGZ-2

Page 25

Table 14, Low Ambient Start Sequence

NOTE: CT = Rapid Stop for that circuit only

Descriptio

n

Check #1

Check #2

Check #3

Check #4

Occurs When: Action Taken

After 15 Seconds after starting first

compressor, If the Evap Press is < 0.48 times

the Low Evap Pressure SP take action, else

continue

After 15 Seconds after Check #1, If the Evap

Press is < 0.66 times the Low Evap Pressure

SP take action, else continue (30 Sec Total)

After 15 Seconds after Check #2, If the Evap

Press is < 0.83 times the Low Evap Pressure

SP take action, else continue (45 Sec Total)

After 15 Seconds after Check #3, If the Evap

Press is < Low Evap Pressure SP take action,

else continue in normal operation (60 Sec

Total)

Rapid Stop – See

Low Ambient ReStart below

Rapid Stop – See

Low Ambient ReStart below

Rapid Stop – See

Low Ambient ReStart below

Rapid Stop – See

Low Ambient ReStart below

CT

CT

CT

CT

Low Ambient Re-Start

If the Evap Pressure fails during the low ambient start, the controller waits until the anticycle timers expire then tries to re-start. It will attempt a start 3 times, and reset the counter

if unit continues in normal operation. If it fails on the third attempt, it will initiate the Low

Ambient Re-Start Alarm Fault (Manual Reset).

Automatic A dj usted Limits

The following are setpoints that will be changed are based on the option selected.

Evaporator Leaving Water Temperature

Mode Range

Unit Mode = Cool

Unit Mode = Glycol, Ice

40 to 60°F

20 to 60°F

Evaporator Freeze Temperature

Mode Range

Unit Mode = Cool

Unit Mode = Glycol, Ice

36 to 42°F

18 to 42°F

Low Evaporator Pressure

Mode Range

Unit Mode = Cool 55 to 65 Psig

Unit Mode = Glycol, Ice 30 to 65 Psig

Low Evaporator Pressure Hold and Unload

Mode Range

Unit Mode = Cool 55 to 65 Psig

Unit Mode = Glycol, Ice 31 to 65 Psig

Low Ambient Lockout Temperature

SpeedTrol Range

SpeedTrol = N

SpeedTrol = Y

OM WGZ-2 WGZ 030A through 120A 25

35 – 60°F

-2 – 60°F

Page 26

Staging Parameters

Lockouts

There are conditions that shall prevent a start when the unit status is AUTO.

Low Ambient Lockout

If the unit status is AUTO, but no compressors have started, and the outside ambient

temperature drops below the low ambient lockout setpoint, the unit will transition to the

Low Ambient Lockout state. This condition will not trigger an alarm. The condition will

be indicated by showing the unit status as “Low Amb Lockout”. The chilled water pump

will shut off. If lockout occurs while the unit is running, the compressors will pump down.

Compressor start will be delayed until the outside ambient temperature rises to the setpoint

plus 5 degrees F.

Wait For Evap or Cond Water Flow

If the unit status is AUTO and the evap pump status is START, then the unit will wait for

the evaporator and condenser flow switches to close. During this time, the condition will

be indicated by showing the unit status as “Wait For Flow”. The water flow loss logic will

allow the Loss of Flow alarms to be automatically reset two times in any 24 hour period.

• If either water flow is lost any time a compressor is running the chiller will shutdown

all of the running compressors and each Cirucit’s status will become Off:Ready.

• The Unit status will become Auto:Wait For Flow and the Evaporator or

CondenserWater Pump status will change to Start. The Unit’s alarm output will be

turned On and the red LED behind the upper left key of the control will turn On.

• When the flow returns without interruption for the Evaporator Flow Recirculation Time

(30 seconds is the default time) the unit is allowed to start as the cycle and staging

timers are cleared.

• The alarm output and red LED will be turned off and normal start and staging logic is

allowed to proceed.

• If water flow is lost a second time with in 24 hours the procedure described above is

repeated.

• A third occurrence of evaporator flow loss in 24 hours triggers the standard Evaporator

or Condenser Water Flow Loss alarm. All circuits with running compressors shutdown

and the Unit status becomes Off:Alarm.

• The standard Evaporator or Condenser Water Flow Loss alarm must be manually

cleared before the unit is allowed to restart.

• The twenty four hour timer that limits the auto restarts is reset when the control’s clock

rolls over to 00:00 each night

Capacity Overrides

The following conditions override the capacity control mode when the chiller is in the cool

or ice mode. The purpose of the overrides is to keep the unit online (although at reduced

capacity) during certain abnormal operating condition. If and when the “off” condition

returns to normal, the override is eliminated and the unit returns to normal operation based

on the capacity control.

Low Evaporator Pressure

If the evaporator pressure drops below the Low Evaporator Pressure Hold setpoint and only

one compressor on that circuit is running, the second compressor is prevented from starting.

If the evaporator pressure drops below the Low Evaporator Pressure Unload setpoint, and

both compressors on the circuit are running, the “first off” compressor on that circuit is shut

off.

26 WGZ 030A through 120A OM WGZ-2

Page 27

Maximum LWT Rate

The maximum rate at which the leaving water temperature can drop is limited at all times

by the Maximum Rate setpoint (2°F/minute). If the rate exceeds this setpoint, no more

compressors will be started until the pulldown rate is less than 2°F/minute.

High Condenser Pressure

If the discharge pressure rises above the High Condenser Pressure Unload setpoint, and

both compressors on the circuit are running, the “first off” compressor on the circuit is shut

off.

Digital Output Control

Each digital output is be controlled according to the following rules. All outputs are

initialized to OFF at power on.

Alarm – (Terminals J12 – NO1)

This output is turned ON when any Equipment Protection ALARM occurs. It is turned

OFF when all alarms have been cleared.

Evaporator Pump – (Terminals J12 – NO2)

An Evaporator Water Pump output is ON if the Evap State is set to START or RUN.

Hot Gas Bypass Solenoid – (Terminals J21 – NO14, J21 – NO15)

This output shall be ON when the Lead Compressor per Circuit is the only compressor ON,

except during Pumpdown.

This output shall be ON when the Compressors are ON. It shall be OFF for all other cases.

Digital Output Control

Each digital output is controlled according to the following rules. All outputs are initialized

to OFF at power on.

Fan #1 to #8 (Air-Cooled Condensers)

[Water Cooled = N] – Condenser Fans Staging is based on condenser pressure as selected

by Fan Stage On & Off setpoints. Fans 1, 3, 5 and 7 are for circuit 1, and fans 2, 4, 6, and 8

are for circuit 2. Fans 1 and 2 start with the first compressor on the respective circuit when

the ambient temperature is greater than 75°F. Below 75°F, these fans start when the

condenser pressure gets up to the stage on setpoint.

Condenser Pump and Tower Fans (Water-Cooled Condenser)

[Water Cooled = Y] – Condenser Pump is on with first Compressor on. Tower fan control

is active when the Tower Control setpoint is set to Temperature and the condenser pump is

in the RUN state. Staging is based on Entering Condenser Water Temperature (ECWT).

Operation depends on the following parameters.

• Condenser pump state

• ECWT

• Stage up and stage down timer values

• Tower setpoints (Tower Control, Tower Stages, Stage Up Time, Stage Down Time,

Stage Differential, Stage #1 ON, Stage #2 ON, Stage Down @, Stage Up @)

OM WGZ-2 WGZ 030A through 120A 27

Page 28

When the condenser pump starts, the stage-up timer starts. The first stage turns ON when

the following conditions are met:

• The stage-up timer completes

• The ECWT is > Stage #1 ON setpoint

• Bypass valve position is > the Stage Up @ setpoint (only if Valve/VFD Control setpoint

= Valve Stage)

Additional stages turn on (up to the number specified by the Tower Stages setpoint) when

above conditions are met for the next stage plus the following condition:

• VFD Speed is > the Stage Up @ setpoint (only if Valve/VFD Control setpoint = VFD

Stage OR Valve SP/VFD Stage)

Down staging occur when the following conditions are met:

• The stage-down timer completes

• The ECWT is < Stage #X ON (Temp) setpoint – Stage Differential (Temp) setpoint

• Bypass valve position is < the Stage Down @ setpoint (only if Valve/VFD Control

setpoint = Valve Stage)

• VFD Speed is < the Stage Down @ setpoint (only if Valve/VFD Control setpoint =

VFD Stage OR Valve SP/VFD Stage)

Each stage-up or stage-down event restarts both the stage-up and-stage down timers. Only

one fan output is switched at a time (except that all outputs switch OFF when the condenser

pump state equals OFF).

Analog Output Control

Each analog output is controlled according to the following rules/algorithms and in

accordance with whether the Compressor Mode setpoint is set to AUTO or MANUAL

(normal operation). All outputs shall be initialized to 0 at power on.

Cooling Tower Bypass Valve

When the Valve/VFD Control setpoint is set to None or VFD Stage, this output is set to 0.

Otherwise, it is controlled as described below.

Initial Valve Position

When the condenser pump is not in the RUN state, the valve output is set as a function of

entering condenser water temperature (ECWT) per the following graph.

28 WGZ 030A through 120A OM WGZ-2

Page 29

Max Position @

Setpoint

(90°F)

Min Position @

Setpoint

(60°F)

Initial Valve Position

(values are examples only)

Min Start Position

Setpoint

(10%)

Max Start Position

Setpoint

(90%)

Operation Af ter Start

When the condenser pump is in the RUN state, the valve output is controlled in one of two

modes as specified by the Valve/VFD Control setpoint. The controlled parameter is the

condenser entering water temperature. When the desired output signal varies from 0 to

100%, the output voltage will vary as shown below.

• 0 to 10 VDC (Valve Type = NC)

• 10 to 0 VDC (Valve Type = NO)

Valve Setpoint Mode

This mode is operational when the Valve/VFD Control setpoint is set to Valve Setpoint or

Valve SP/VFD Stage. In this mode the valve output is varied with a proportional-derivative

(PD) algorithm (with deadband) in order to maintain the controlled parameter (CP) at the

desired value. The output is always limited between the Valve Control Range (Min)

setpoint and the Valve Control Range (Max) setpoint. A valve increment is computed once

every 5 seconds according to the following equation.

• Increment = [(Error) * (Error Gain setpoint)] + [(Slope) * (Slope Gain setpoint)]

Where: Error = ECWT – Valve Setpoint

Slope = (Present CP) – (Previous CP)

When the Error is > the Valve Deadband setpoint, the valve position analog output (% of

full scale) is updated according to the following equation.

• New %Position = Old %Position + Increment/10.

Valve Stage Mode

This mode is only operational when the Valve/VFD Control setpoint is set to Valve Stage.

In this mode the valve output is controlled as for Valve Setpoint mode (above) except that

the active setpoint for the controlled parameter is selected according to the following table.

# Of Fans ON Active Setpoint

0 Valve Setpoint

1 Stage #1 ON

2 Stage #2 ON

3 Stage #3 ON

4 Stage #4 ON

OM WGZ-2 WGZ 030A through 120A 29

Page 30

Cooling Tower Fan VFD

When the Valve/VFD Control setpoint is set to None, Valve Setpoint, or Valve Stage, this

output is set to 0. Otherwise, it is controlled in a manner identical to Valve Stage Mode

(above) except that (1) it is kept at zero until the first fan stage is ON and (2) the following

setpoints do not apply.

• Valve Control Range (Min)

• Valve Control Range (Max)

• Valve Type

Evaporator Water Pump State Control

Operation of the evaporator pump is controlled by the state-transition diagram shown

below. A state variable (Evap State) is used to maintain the current state (OFF, START, or

RUN). The fixed 30 second timer will start when flow is first indicated by the Evaporator

Water Flow Switch digital input. This timer is considered expired after 30 seconds.

TEST:

freeze) OR

Circuit alarm on both circuits OR

Unit enab le = off OR

Circuit PumpDn Switch = off for all

circuits (and pumpdn completed)

Power ON

Unit alarm (except evap

OFF

Unit Enable = On

TEST:

AND at least one circuit is

enabled an d no t in alarm

state OR

Evap Freeze Protection

Unit alarm (except evap

TEST:

freeze) OR

Circuit alarm on both circuits OR

Unit enable = off OR

Circuit PumpDn Switch = off for all

circuits (and pumpdn completed)

RUN

Flow OK for

TEST:

30 Seconds

START

Condenser Water Pump State Control

Operation of the Condenser pump is controlled by the state-transition diagram shown

below. A state variable (Cond State) is used to maintain the current state (OFF, START, or

RUN).

Condenser Pump State Diagram

Cond Flow Alarm OR

Unit State = Off OR

Evap Pump State = Start OR

No Circuit Available OR

LWT error < Start Delta]

AND

No Cond Refrig Freeze Event

AND

No Compressor Running

Run Start

Off

Cond Flow Alarm OR

[Unit State = Off OR

No Circuit Available OR

Evap Pump State = Start OR

LWT error < Start Delta]

AND

No Cond Refrig Freeze Event

AND

No Compressor Running

[Cond Pump State = Start

AND Flow Switch Closed]

for time > Cond Pmp

Recirc Time seconds

Unit State=Auto AND

Any Circuit Available AND

Stage up now = True]

OR

Cond Refrig Freeze Event

AND No Cond Flow Alarm

30 WGZ 030A through 120A OM WGZ-2

Page 31

Condenser Pump Control

The Condenser Flow Recirculation Time Set Point is found on the Unit Set Points Screen

Five, line four. The default value is 30 seconds and the set point is adjustable from 15

seconds to 90 seconds.

The condenser water pump starts if the control has detected sufficient load after the

evaporator water pump has started and evaporator water flow has been established.

The condenser water pump is enabled in the “Start” mode. It will remain in the “Start”

mode until condenser water flow has been established. If continuous flow has been

established for Condenser Flow Recirculation Time the condenser water pump mode

becomes “Run” and the first compressor is enabled.

If no flow is detected while the condenser water pump is in the “Start” mode, the logic

described on page 26 will be in effect

Inconsistent condenser water flow will hold the condenser water pump in the “Start” mode

until constant flow has been established for Condenser Flow Recirculation Time seconds.