Page 1

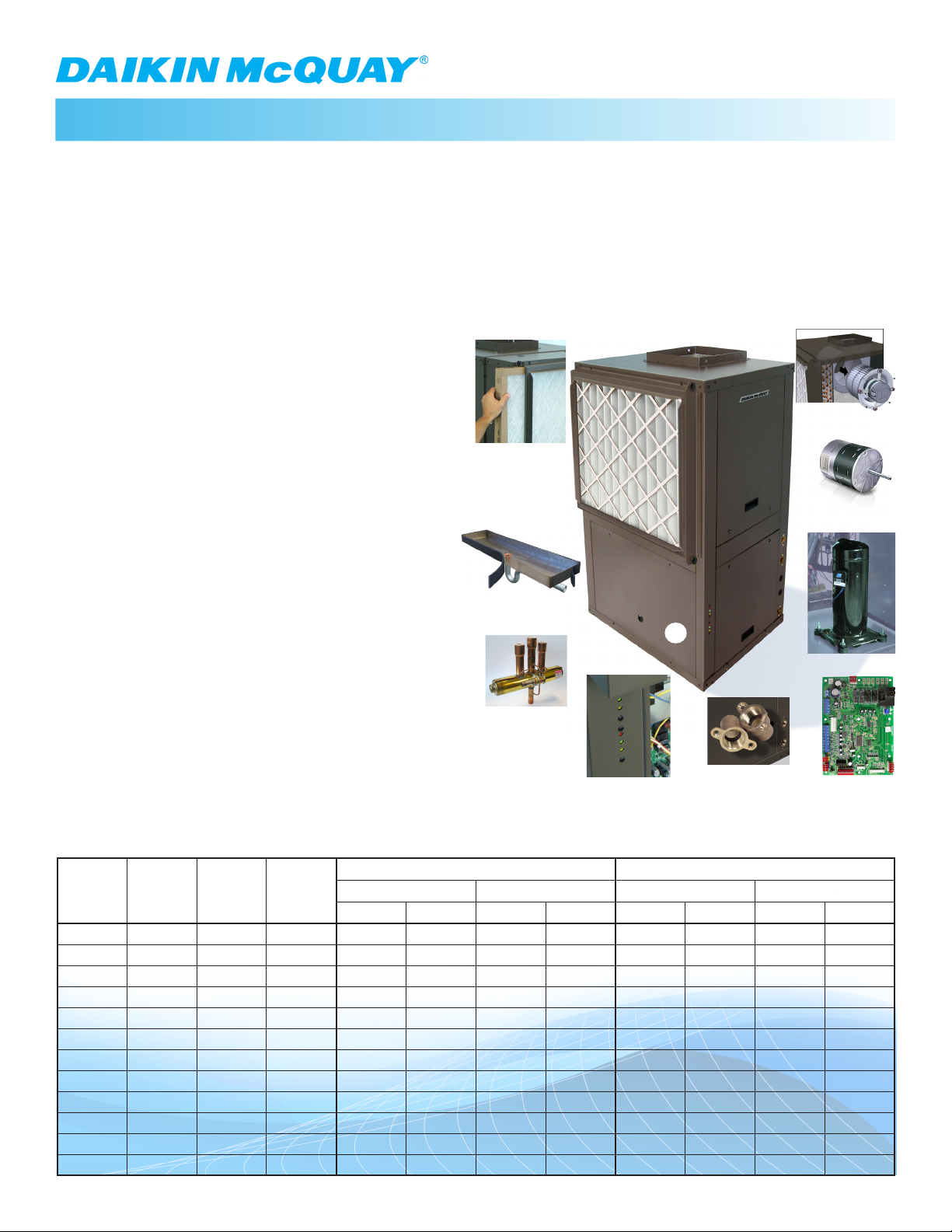

SmartSource™ Single-Stage Vertical Water Source Heat Pumps

SmartSource™ water source heat pumps are designed using

the latest technology to achieve some of the highest efficiency single-stage products in the market today. McQuay

is the first manufacturer to offer ECM variable fan motors as

a standard option across the whole product line, even in the

smallest cabinet sizes, for unmatched performance and comfort in the industry.

High EERs that far exceed ASHRAE 90.1 standards make these

units perfect for LEED projects and rebate opportunities. All

units are available geothermal ready from the factory with

many features to easily match your application requirements.

1. ECM Fan Motor: 4 field adjustable cfm settings and 28

programmed cfm values provide a wide range of airflow

selections for quieter operation and lower energy consumption.

2. Copeland K-5 Scroll: or LG Rotary available in a variety

of commercial voltages, mounted on a double isolation

system for reduced sound and vibration.

3. Refrigerant Circuit: Utilizes R-410A refrigerant with a bi-

flow thermal expansion valve for easy metering and four

way solenoid reversing valve.

4. MicroTech III Controls: Easy open-protocol integration

with optional LonWorks® or BACnet®.

5. Unit Status LED: Instant visuals on unit operation for

easy troubleshooting and advanced diagnostics.

6. 4-Sides Filter Rack with Standard 2” or Optional 4”

Filters: Designed for easy filter maintenance. MERV 8 &

13 filter options with gasketed filter rack meet LEED-NC

EQc5 applications with leakage rate at less than 4 CFM

per square foot of filter area at 0.5”ESP.

7. Stainless Steel Drain Plan: Sloped with lipless drain con-

nection for positive condensate flow, meets ASHRAE 62.1

Section 5.11.

8. Flush Mounted Fittings: Easy one wrench connection,

securely fastened to the cabinet corner posts.

9. Blower and Motor Orifice Ring: Easy service removal

without having to remove the blower housing or disconnecting the unit from the duct work.

10. Durable Cabinet Construction: Heavy gauge steel with

powder coated textured paint, lined with cleanable foilfaced insulation on the airside.

9

6

7

10

2

3

5

8

4

1

Performance Data

Unit Size Stage CFM GPM

007 Full Load 250 2.2 8000 16.8 9800 5.5 8400 19.8 6200 3.9

009 Full Load 300 2.4 9700 16.0 12000 5.5 10200 18.8 7500 3.8

012 Full Load 400 3.3 12700 15.5 15700 5.4 13300 18.1 10000 3.9

015 Full Load 500 3.8 15300 18.1 19100 5.9 16000 21.2 11700 4.1

019 Full Load 600 4.4 17500 17.3 22600 5.7 18700 20.6 13800 4.1

024 Full Load 800 6.5 26,200 18.8 28,900 6.0 27,500 22.2 17,700 4.1

030 Full Load 1,000 7.5 30,000 17.3 33,600 5.8 31,300 20.1 21,600 4.1

036 Full Load 1,250 9.0 37,300 19.2 40,800 6.0 38,500 22.0 26,200 4.3

042 Full Load 1,400 10.5 43,900 17.5 48,600 5.4 45,500 20.2 31,300 4.0

048 Full Load 1,600 12.2 50,500 17.2 57,100 5.3 52,700 19.9 36,900 4.0

060 Full Load 2,000 16.0 63,700 17.4 74,200 5.2 66,300 20.0 46,500 3.8

070 Full Load 2,160 17.5 73,400 15.9 89,000 5.0 75,700 18.0 55,800 3.7

Water Loop (Boiler Tower) Ground Loop (Geothermal)

Cooling Heating Cooling Heating

Btu/hr EER Btu/hr COP Btu/hr EER Btu/hr COP

Page 2

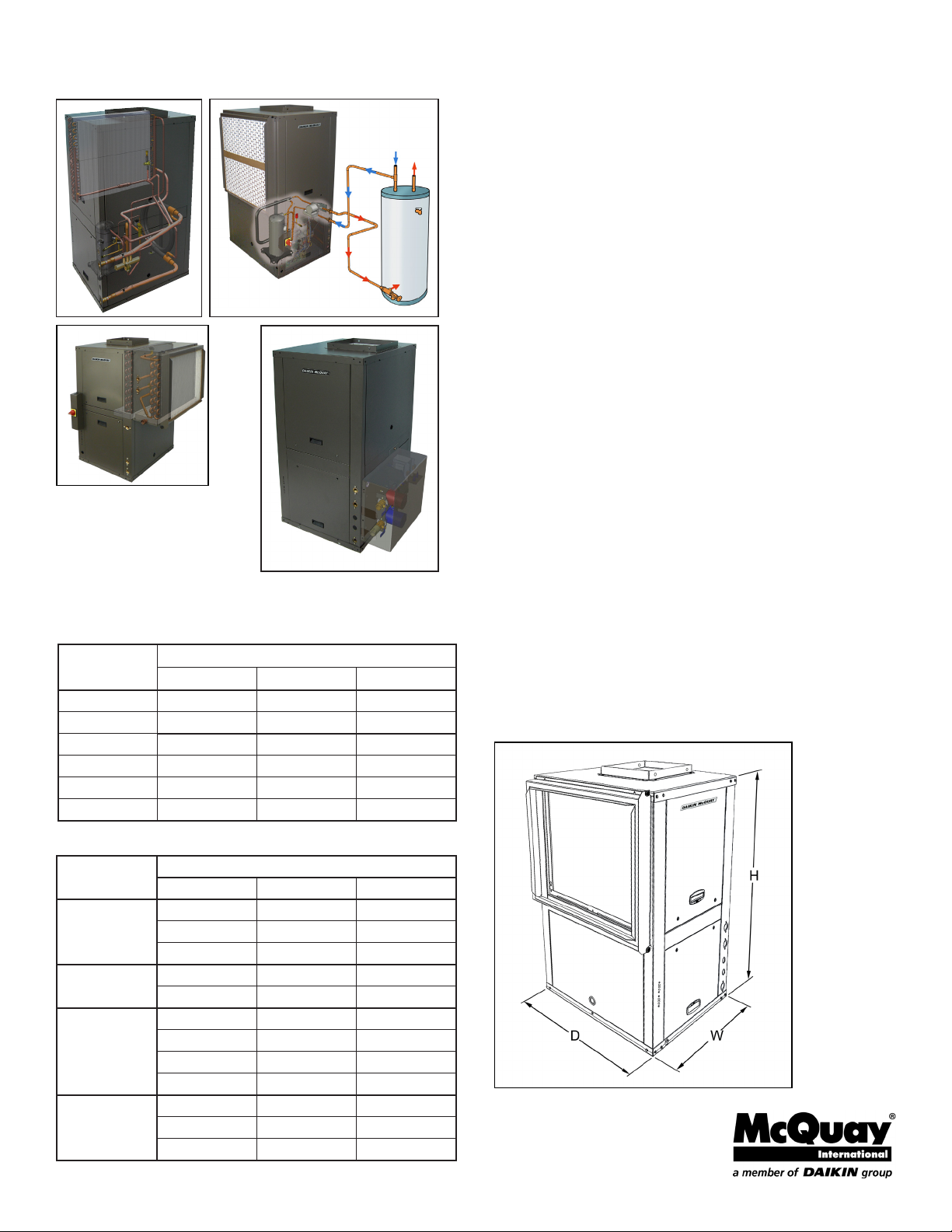

Many Factory-Mounted Options and Accessories

Four Unique Dehumidification Options:

• SmartDehumidification– Uses hot gas reheat, humidi-

stat, 2-stage thermostat & smart air flow management for

precise humidity control.

• SimplifiedDehumidification– Uses a 3-stage thermo-

stat to optimize unit capacity and fan speed for maximum

latent capacity while decreasing room humidity levels.

• HumidistatControlledDehumidification– Uses a hu-

midistat and 2-stage thermostat to control room humidity

levels.

1

2

3

1. Hot Gas Reheat

2. Desuperheater

3. Waterside Economizer

4

4. Loop Circulating Pumps

Dimensions in inches (mm)

Unit Size

007, 009, 012 21.60 (549) 22.65 (575) 34.50 (876)

015, 019 22.40 (569) 25.60 (650) 37.50 (953)

024, 030 22.40" (569) 26.00" (660) 48.00" (1219)

036 25.00" (635) 32.50" (826) 50.50" (1283)

042, 048 25.00" (635) 32.50" (826) 54.50" (1384)

060, 070 25.00" (635) 32.50" (826) 58.50" (1486)

Overall Cabinet Dimensions

W D H

• DehumidificationOnly– Uses a humidistat in cooling

only mode.

WatersideEconomizer– Reduces compressor energy con-

sumption by using a cold water coil for cooling under suitable

conditions.

LoopPumps– Convenient factory-mounted pumps with flow

and head capabilities for most geothermal applications.

5,10,15&20kWElectricHeat– Integral electric heat coil

with controls for primary, supplemental, boilerless or

emergency heat.

Desuperheater– For “free” domestic hot water.

Non-FusedDisconnectOption– Convenient Power shut-off

and lockout at the unit.

Extended Range Coaxial Heat Exchanger Coil and Piping

Insulation– for geothermal application.

InsulationOptions– Foil faced, closed cell or 1/2” standard

fiberglass options for the air and compressor side of the unit.

EpoxyCoatedCoils– For extra corrosion protection to meet

ASTM B-11 3000 hour salt spray test.

DeluxeSoundPackage– Reduces sound levels for quieter

operation.

5-YearExtendedPartsWarrantyAvailable

Voltages

Unit Size

007-012

019

024-036

042-070

©2012 McQuay International

A/SP 31-352

Vertical Unit

Volts Hz Phase

208-230 60 1

265 60 1

115 60 1

208-230 60 1

265 60 1

208-230 60 1

265 60 1

208-230 60 3

460 60 3

208-230 60 1

208-230 60 3

460 60 3

Loading...

Loading...