Operating Manual

Group: Chiller

Part Number: 330599503

Effective: October 2004

Supersedes: OM WGS

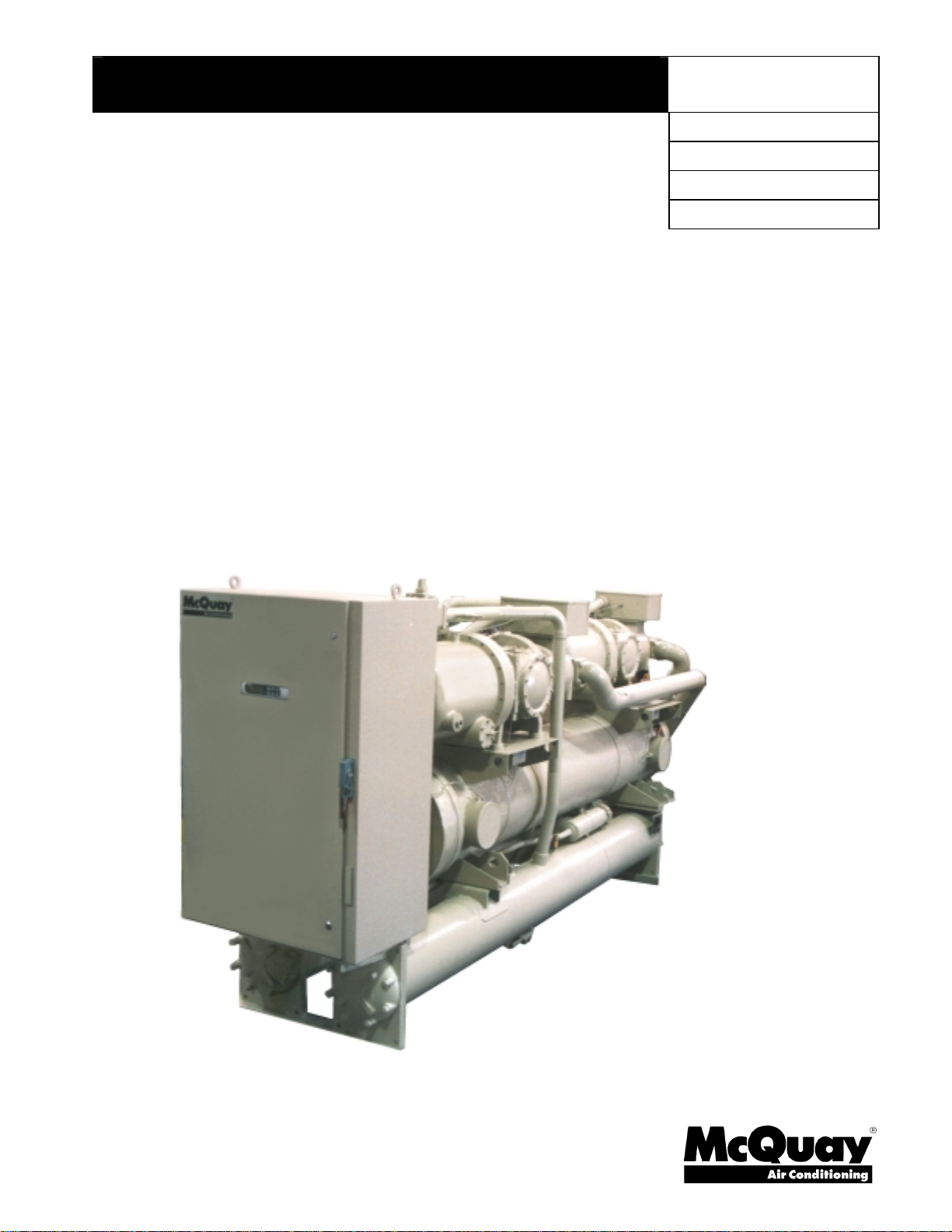

Water-Cooled Screw Compressor Chillers

WGS 130AW To WGS 190AW, Packaged Water-Cooled Chiller

WGS 130AA To WGS 190AA, Chiller with Remote Condenser

120 to 200 Tons, 420 to 700 kW

R-134a, 60 Hz

Software Version WGSD30101C

OM WGS-1

Table of Contents

Introduction........................................3

General Description .....................................3

Nomenclature...............................................3

Definitions...........................................4

Wiring Diagrams................................8

Control Panel Layout......................10

MicroTech II Controller..............13

System Arch itecture ...................................13

General Description ...................................14

Sequence of Operation ....................16

Start-Up and Shutdown...................22

Pre Start-up ................................................22

Start-up.......................................................22

Weekend or Temporary Shutdown.............23

Start-up after Temporary Shutdown...........23

Extended Shutdown....................................23

Start-up after Extended Shutdown..............23

Unit Controller.................................27

Unit Inputs/Outputs....................................27

Unit Setpoints.............................................27

Circuit Controller............................30

Circuit Inputs and Outputs .........................30

Circuit Setpoint Table ................................31

Alarms, W arnings, Events...............32

Stop Alarms (Shutdown)............................32

Events (Limit)............................................34

Unit Controller Functions...............35

Unit Enable ................................................36

Unit Mode Selection ..................................37

Unit States..................................................38

Evaporator Pump Control...........................39

Leaving Water Temperature (LWT) Reset..40

Planned Unit Capacity Overrides...............42

Condenser Pump and Tower Control..........43

Cooling Tower Control...............................44

Evaporative Condenser Control.................46

Circuit Controller Functions.......... 48

Refrigerant Calculations.............................48

Compressor Control...................................49

Internal Capacity Overrides........................52

Slide Positioning ........................................53

Expansion Valve Control............................55

Oil Heater Control......................................59

Starter Communications.............................59

Condenser Fan Control...............................61

Digital Output Control................................62

Using the Controller...................................63

Security ......................................................65

Entering Passwords....................................65

Editing Setpoints........................................65

Clearing Alarm s..........................................65

Menu Descriptions...........................66

Unit Controller...........................................66

Circuit Controller.......................................80

Editing Review...........................................86

BAS Interface...................................87

Troubleshooting Chart....................88

Troubleshooting Chart................................88

Unit controllers are LONMARK

certified with an optional L

communications module.

Illustrations and data cover McQuay International products at the time of publication and we reserve the right to

make changes in design and construction at anytime without notice.

The following are trademarks or registered trademarks of their respective companies:

BACnet from ASHRAE; L

GeneSys, McQuay and MicroTech II from McQuay International.

2 WGS 130A to WGS 190A OM WGS-1

2004 McQuay International

ONMARK and LONWORKS from Echelon Corporation;

ONWORKS

Introduction

General Description

McQuay Model WGS water chillers are designed for indoor installations and are available

with factory-mounted water-cooled condensers (Model WGS AW), or arranged for use with

remote air-cooled or evaporative condensers (Model WGS AA). Each water-cooled unit

(WGS-AW) is completely assembled and factory wired before factory evacuation, charging

and testing. The units consist of two semi-hermetic rotary screw compressors, a two-circuit

shell-and-tube evaporator, two shell-and-tube water-cooled condensers, and complete

refrigerant piping.

Units manufactured for use with remote condensers (Models WGS-AA) have all refrigerant

specialties factory-mounted and have two sets of connection points for refrigerant discharge

and liquid lines to and from the remote condenser. Discharge valves are included

Each circuit’s liquid line components are manual liquid line shutoff valve, charging valve,

filter-drier, liquid line solenoid valve, sight glass/moisture indicator, and electronic

expansion valve.

The electrical control center includes a MicroTech II microprocessor control system and

equipment protection and operating controls necessary for dependable, automatic operation.

The compressor circuits are equipped with individual circuit breakers and a unit disconnect

switch is available as an option over the standard power block.

Water-Cooled Condensing

Rotary Screw Compressor

Nominal Capacity (Tons)

Global

Nomenclature

W G S 130 - A W

W = Water-Cooled Condenser

A = Unit Less Condenser

Design Vintage

OM WGS-1 WGS 130A to 190A 3

Definitions

Active Setpoint

The active setpoint is the setting in effect at any given moment. This variation occurs on

setpoints that can be altered during normal operation. Resetting the chilled water leaving

temperature setpoint by one of several methods, such as return water temperature, is an

example.

Active Capacity Limit

The active setpoint is the setting in effect at any given moment. Any one of several external

inputs can limit a compressor’s capacity below its maximum value.

Condenser Recirc Timer

A timing function, with a 30-second default, that holds off any reading of condenser water

for the duration of the timing setting. This delay allows the water sensors (especially water

temperatures) to take a more accurate reading of the condenser water system conditions.

Condenser Saturated Temperature Target

The saturated condenser temperature target is calculated by first using the following

equation:

Sat condenser temp target raw = 0.833(evaporator sat temp) + 68.34

The “raw” value is the initial calculated value. This value is then limited to a range defined

by the Condenser Saturated Temperature Target minimum and maximum setpoints. These

setpoints simply cut off the value to a working range, and this range can be limited to a

single value if the two setpoints are set to the same value.

CPU Error

These are problems caused by a malfunction of the central processing unit.

Dead Band

The dead band is a set of values associated with a setpoint such that a change in the

variable occurring within the dead band causes no action from the controller. For example,

if a temperature setpoint is 44°F and it has a dead band of ± 2 degrees, nothing will happen

until the measured temperature is less than 42°F or more than 46°F.

DIN

Digital input, usually followed by a number designating the number of the input.

Discharge Superheat

Discharge superheat shall be calculated for each circuit using the following equation:

Discharge Superheat = Discharge Temperature – Condenser Saturated Temperature

Error

In the context of this manual, “Error” is the difference between the actual value of a

variable and the target setting or setpoint.

Evaporator Approach

The evaporator approach is calculated for each circuit. The equation is as follows:

Evaporator Approach = LWT – Evaporator Saturated Temperature

4 WGS 130A to 190A OM WGS

Evap Recirc Timer

A timing function, with a 30-second default, that holds off any reading of chilled water for

the duration of the timing setting. This delay allows the chilled water sensors (especially

water temperatures) to take a more accurate reading of the chilled water system conditions.

EXV

Electronic expansion valve, used to control the flow of refrigerant to the evaporator,

controlled by the circuit microprocessor.

High Saturated Condenser – Hold Value

High Cond Hold Value = Max Saturated Condenser Value – 5°F

This function prevents the compressor from loading whenever the pressures approach

within 5 degrees of the maximum discharge pressure. The purpose is to keep the

compressor online during periods of possibly temporary elevated pressures.

High Saturated Condenser – Unload Value

High Cond Unload Value = Max Saturated Condenser Value – 3°F

This function unloads the compressor whenever the pressures approach within 3 degrees of

the maximum discharge pressure. The purpose is to keep the compressor online during

periods of possibly temporary elevated pressures.

High Superheat Error

The degrees of temperature difference between 40°F and the actual discharge temperature.

Light load Stg Dn Point

The percent load point at which one of two operating compressors will shut off, transferring

the unit load to the remaining compressor.

Load Limit

An external signal from the keypad, the BAS or a 4-20 ma signal that limits the compressor

loading to a designated percent of full load. Frequently used to limit unit power input.

Load Balance

Load balance is a technique that equally distributes the total unit load among the running

compressors.

Low Ambient Lockout

Prevents the unit from operating (or starting) at ambient temperatures below the setpoint.

Low Pressure Hold Setpoint

The psi evaporator pressure setting at which the controller will not allow further

compressor loading.

Low/High Superheat Error

The difference between actual evaporator superheat and the superheat target.

LWT

Leaving water temperature. The “water” is any fluid used in the chiller circuit.

OM WGS-1 WGS 130A to 190A 5

LWT Error

Error in the controller context is the difference between the value of a variable and the

setpoint. For example, if the LWT setpoint is 44°F and the actual temperature of the water

at a given moment is 46°F, the LWT error is +2 degrees.

LWT Slope

The LWT slope is an indication of the trend of the water temperature. It is calculated by

taking readings of the temperature every few seconds and subtracting them from the

previous value, over a rolling one-minute interval.

ms

Milli-second

Maximum Saturated Condenser Temperature

The maximum saturated condenser temperature allowed is calculated based on the

compressor operational envelope.

NC

Normally closed - usually refers to a contactor or valve.

NO

Normally open - usually refers to a contactor. or valve.

OAT

Outside ambient air temperature.

Offset

Offset is the difference between the actual value of a variable (such as temperature or

pressure) and the reading shown on the microprocessor as a result of the sensor signal. See

notes on page 32 for explanation of sensor off set.

pLAN

Peco Local Area Network is the proprietary name of the network connecting the control

elements.

Rapid Stop

A compressor stop process that circumvents the normal pumpdown cycle.

Refrigerant Saturated Te mperature

Refrigerant saturated temperature is calculated from the pressure sensor readings for each

circuit. The pressure is fitted to an R-134a temperature/pressure curve to determine the

saturated temperature.

Soft Load

Soft Load is a control sub-routine that allows the chiller to load up gradually. It requires

setpoint inputs of selecting it by Yes or No inputs, by selecting the percent load to start

ramping up, and by selecting the time to ramp up to full load (up to 60 minutes).

SP

Setpoint

SSS

Solid state starter as used on McQuay screw compressors.

Suction Superheat

Suction superheat is calculated for each circuit using the following equation:

Suction Superheat = Suction Temperature – Evaporator Saturated Temperature

6 WGS 130A to 190A OM WGS

Stage Up/Down Accumulator

The accumulator can be thought of as a bank storing occurrences that indicate the need for

an additional fan.

Stageup/Stagedown Delta-T

Staging is the act of starting or stopping a compressor or fan when another is still operating.

Startup and Stop is the act of starting the first compressor or fan and stopping the last

compressor or fan. The Delta-T is the “dead band” on either side the setpoint in which no

action is taken.

Stage Up Delay

The time delay from the start of the first compressor to the start of the second.

Startup Delta-T

Number of degrees above the LWT setpoint required to start the first compressor.

Stop Delta-T

Number of degrees below the LWT setpoint required for the last compressor to stop.

VAC

Volts, Alternating current, sometimes noted as vac.

VDC

Volts, Direct current, sometimes noted as vdc.

VFD

Variable Frequency Drive, a device used to vary an electric motor’s speed.

OM WGS-1 WGS 130A to 190A 7

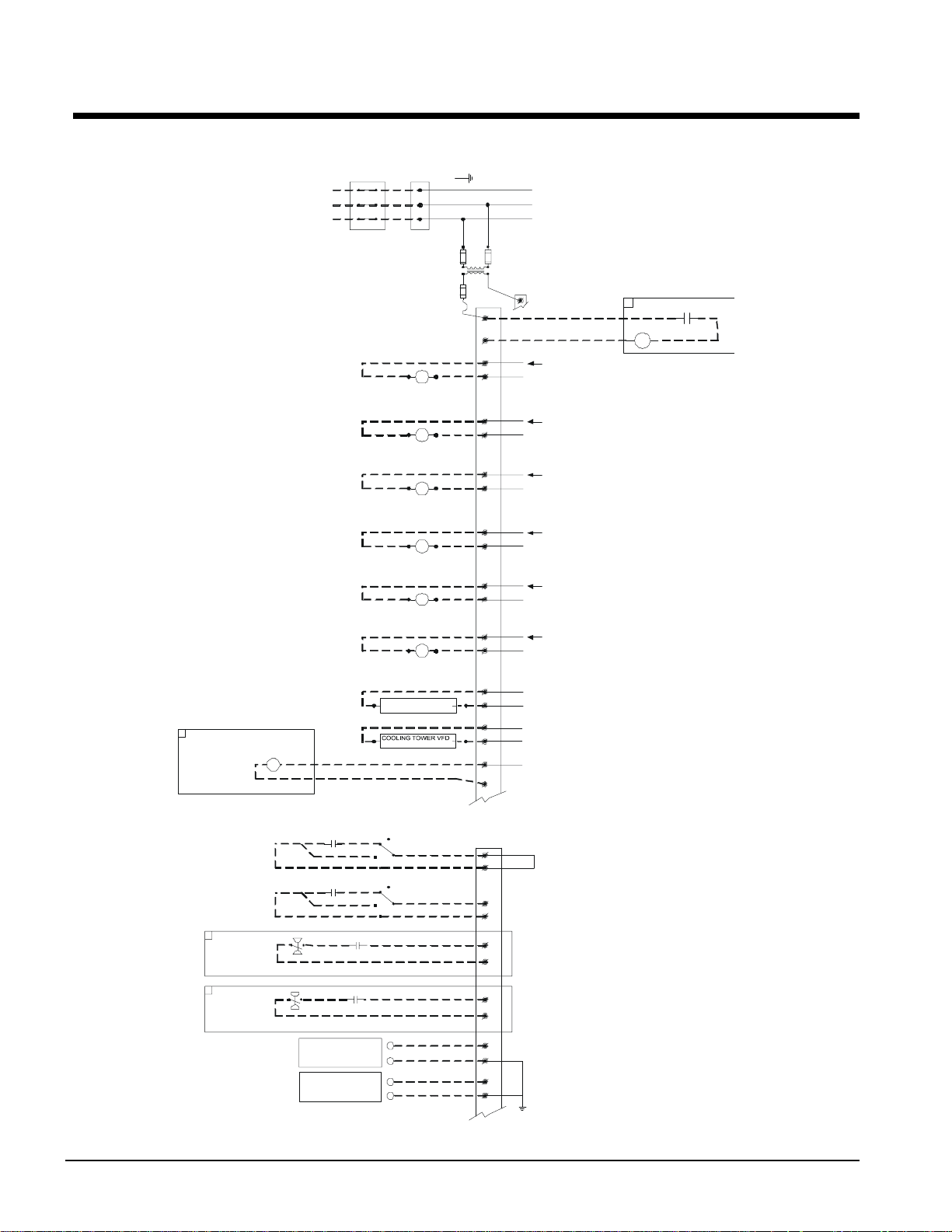

Wiring Diagrams

A

A

A

A

A

Figure 1, WGS 130AW – 190AW Field Wiring Diagram (Optional Single Point Connection)

3 PHASE

POWER

SUPPLY

DISCONNECT

(BY OTHERS)

UNIT MAIN

TERMINAL BLOCK

GND LUG

TO COMPRESSOR(S)

NOTE: ALL FIELD WIRING TO BE

INSTALLED AS NEC CLASS 1

WIRING SYSTEM WITH CONDUCTOR

RATED 600 VOLTS

FACTORY SUPPLIED ALARM

FIELD WIRED

ALARM BELL

OPTION

ABR

LARM BELL RELAY

FUSED CO N T RO L

CIRCUIT TRANSFORMER

CHWR

EVAP. PUMP RELAY #1

(BY OTHERS)

120 VAC 1.0 AMP MAX

CHWR

EVAP. PUMP RELAY #2

(BY OTHERS)

120 VAC 1.0 AMP MAX

CWR

COND. PUMP RELAY #1

(BY OTHERS)

120 VAC 1.0 AMP MAX

CWR

COND. PUMP RELAY #2

(BY OTHERS)

120 VAC 1.0 AMP MAX

M11

TOWER FAN #1

(BY OTHERS)

120 VAC 1.0 AMP MAX

M12

TOWER FAN #2

(BY OTHERS)

120 VAC 1.0 AMP MAX

COOLING TOWER BYPASS

(BY OTHERS)

(BY OTHERS)

FU4 FU5

120 VAC

FU7

TB1

(115 VAC)

1

2

82

2

85

2

86

2

87

2

88

2

89

2

78

77

80

79

81

75

TB1-2

N

24 VAC

120 VAC

N

120 VAC

N

120 VAC

N

120 VAC

N

120 VAC

N

120 VAC

N

0-10VDC

N

0-10VDC

BELL

12

LARM BELL

RELAY

COM NO

LARM BELL OPTION

TIME

REMOTE STOP

SWITCH

(BY OTHERS)

ICE MODE

SWITCH

(BY OTHERS)

EVAP. FLOW

SWITCH

(BY OTHERS)

*MANDATORY IF FACTORY FLOW SWITCH OPTION IS NOT SELECTED

COND. FLOW

SWITCH

(BY OTHERS)

*MANDATORY IF FACTORY FLOW SWITCH OPTION IS NOT SELECTED

CLOCK

NOR. OPEN PUMP AUX.

CONTACTS (OPTIONAL)

NOR. OPEN PUMP AUX.

CONTACTS (OPTIONAL)

4-20MA FOR

EVAP. WATER RESET

(BY OTHERS)

4-20MA FOR

DEMAND LIMIT

(BY OTHERS)

UTO

ON

MANUAL

UTO

ON

MANUAL

OFF

OFF

TB1

(24 VAC OR 30 VDC)

60

66

IF REMOTE STOP CONTROL

897

IS USED, REMOVE LEAD 897

FROM TERM. 40 TO 53.

60

68

60

67

60

76

+

-

+

-

72

70

71

70

DWG. 330588201 REV . 0B

GND

8 WGS 130A to 190A OM WGS

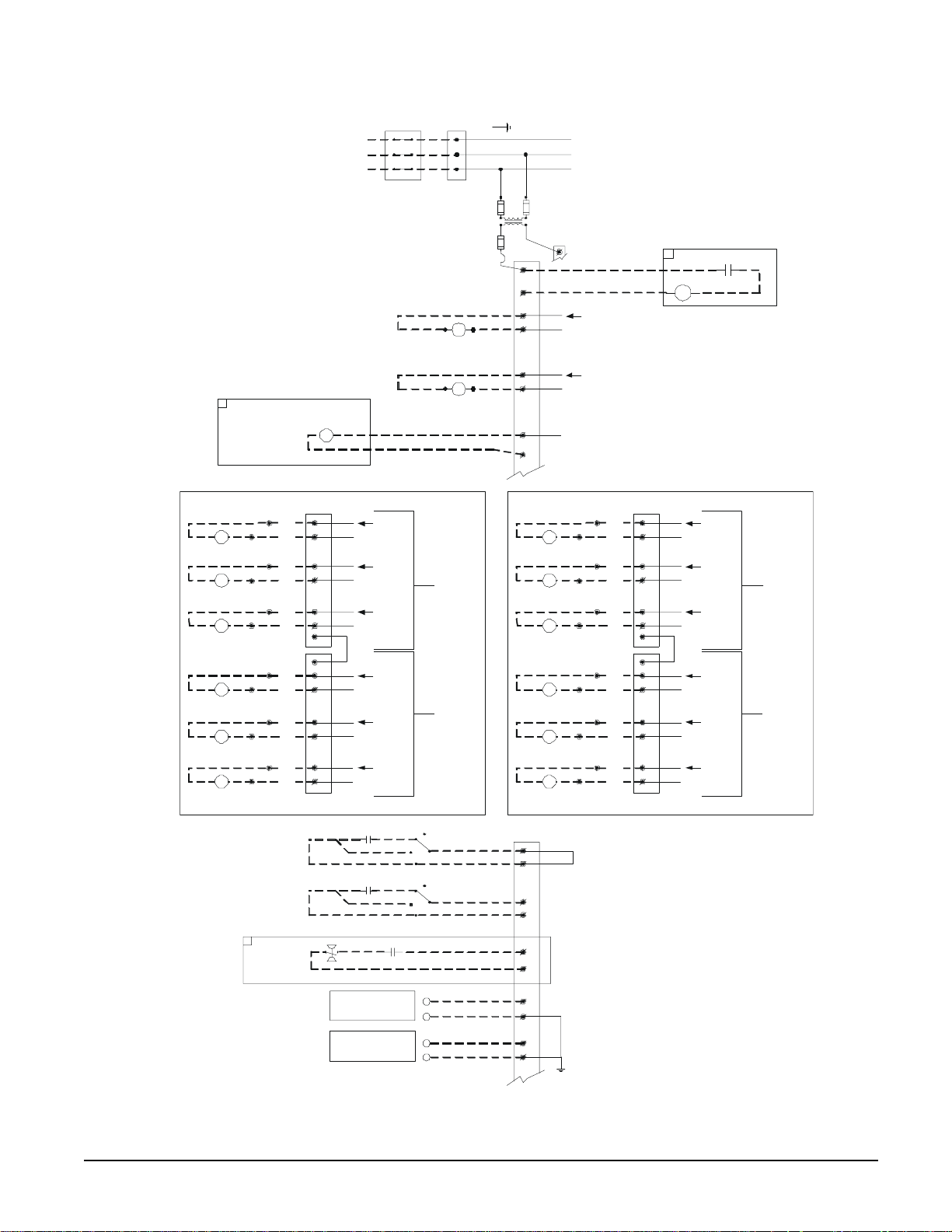

Figure 2, WGS 130AA – 190AA Field Wiring Diagram (Remote Air-cooled Condenser)

UNIT MAIN

A

A

A

A

3 PHASE

POWER

SUPPLY

DISCONNECT

(BY OTHERS)

TERMINAL BLOCK

GND LUG

TO COMPRESSOR(S)

NOTE: ALL FIELD WIRING TO BE

INSTALLED AS NEC CLASS 1

WIRING SYSTEM WITH CONDUCTOR

RAT E D 60 0 V OLTS

FACTORY SUPPLIED ALARM

ALARM BELL

OPTION

CIRCUIT #1

M11

CONDENSER FAN

CONTACTOR COIL #1

M12

CONDENSER FAN

CONTACTOR COIL #2

M13

CONDENSER FAN

CONTACTOR COIL #3

M14

CONDENSER FAN

CONTACTOR COIL #4

M15

CONDENSER FAN

CONTACTOR COIL #5

M16

CONDENSER FAN

CONTACTOR COIL #6

FIELD WIRED

TB6

92

144

98

145

93

146

98

145

94

148

98

145

95

150

98

145

96

152

98

145

97

154

98

145

REMOTE STOP

SWITCH

(BY OTHERS)

ICE MODE

SWITCH

(BY OTHERS)

ABR

ALARM BELL RELAY

NO1

2

NO2

2

NO3

2

C

C

NO4

2

NO5

2

NO6

2

FUSED CONTROL

CIRCUIT T RANSFORMER

EVAP. PUMP RELAY #1

120 VAC 1.0 AMP MAX

EVAP. PUMP RELAY #2

120 VAC 1.0 AMP MAX

120 VAC

N

120 VAC

N

120 VAC

N

(LOCATED ON

CONTROLLER)

120 VAC

N

120 VAC

N

(LOCATED ON

CONTROLLER)

120 VAC

N

TIME

CLOCK

UTO

ON

MANUAL

UTO

ON

MANUAL

OFF

OFF

CHWR

(BY OTHERS)

CHWR

(BY OTHERS)

J12

CIRCUIT

J13

CIRCUIT

FU4

120 VAC

FU7

TB1

(115 VAC)

CIRCUIT #2

CONDENSER FAN

CONT A CTOR COIL #1

CONDENSER FAN

CONTA CTOR COIL #2

CONDENSER FAN

CONTA CTOR COIL #3

CONDENSER FAN

CONT A CTOR COIL #4

CONDENSER FAN

CONTA CTOR COIL #5

CONDENSER FAN

CONTA CTOR COIL #6

TB1

(24 VAC)

FU5

TB1-2

1

2

82

2

85

2

81

120 VAC

N

120 VAC

N

24 VAC

BELL

2

1

LARM BELL OPTION

LARM BELL

RELAY

COM

NO

75

TB7

92

244

245

246

245

248

245

250

245

252

245

254

245

NO1

2

NO2

2

NO3

2

C

C

NO4

2

NO5

2

NO6

2

98

M21

93

98

M22

94

98

M23

95

98

M24

96

98

M25

97

98

M26

60

66

IF REMOTE STOP CONTROL

897

IS USED, REMOVE LEAD 897

FROM TERM. 40 TO 53.

N

N

N

N

N

N

120 VAC

120 VAC

120 VAC

120 VAC

120 VAC

120 VAC

J12

(LOCATED ON

CIRCUIT

CONTROLLER)

J13

(LOCATED ON

CIRCUIT

CONTROLLER)

60

68

EVAP. FLOW

SWITCH

(BY OTHERS)

*MANDATORY IF FACTORY FLOW SWITCH OPTION IS NOT SELECTED.

NOR. OPEN PUMP AUX.

CONTACTS (OPTIONAL)

4-20MA FOR

EVAP. WATER RESET

(BY OTHERS)

4-20MA FOR

DEMAND LIMIT

(BY OTHERS)

+

-

+

-

60

67

72

70

71

70

GND

DWG. 330588101 REV. 0C

OM WGS-1 WGS 130A to 190A 9

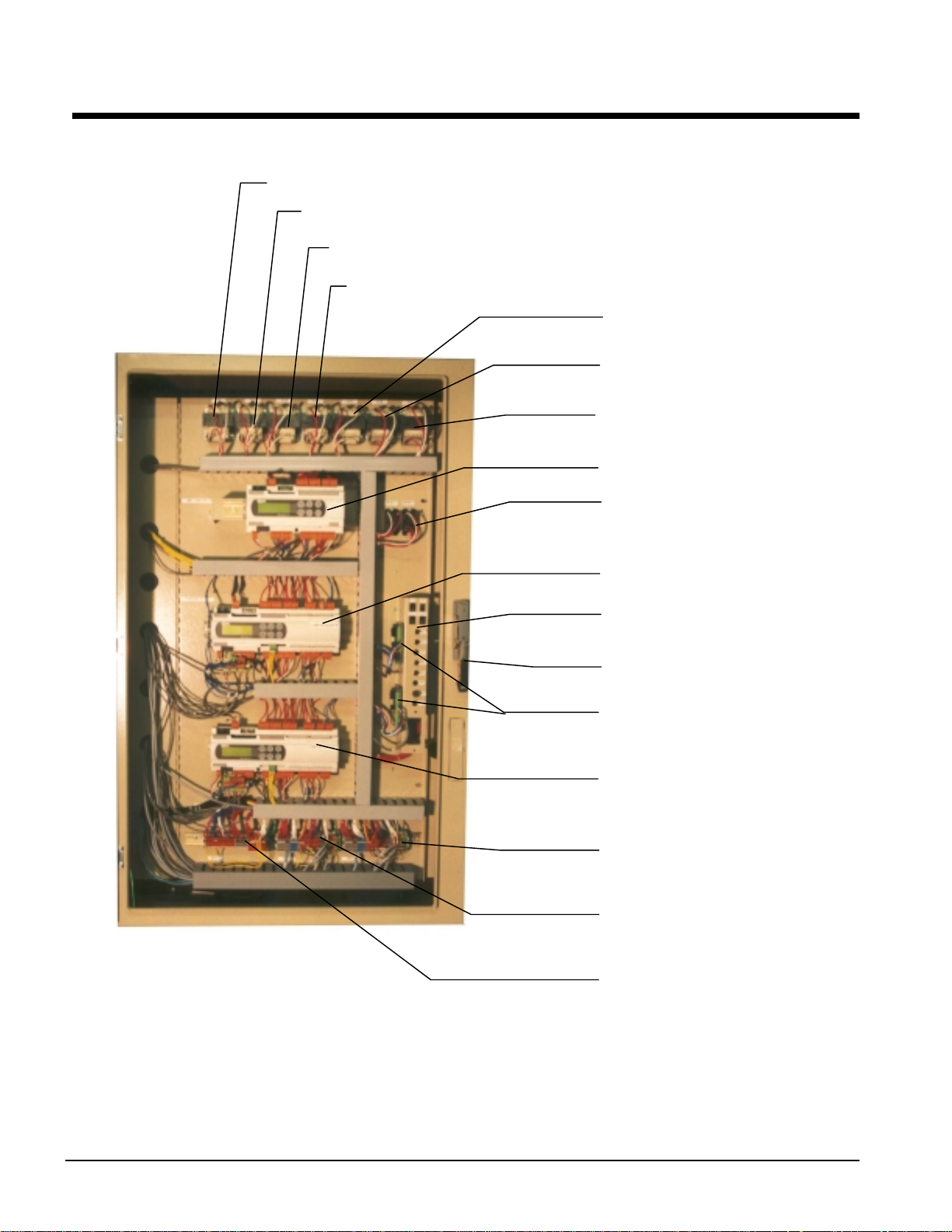

Control Panel Layout

r

r

Figure 3, Outer (Microprocessor) Panel

T2, Unit Controlle

T13, Circ#1 Controller

T14, Circ#1 Load Solenoid

T15, Circ#1 EXV Power

T23, Circ#2 Controlle

T24, Circ#2 Load Solenoid

T25, Circ#2 EXV Power

Unit Controller

MHPR11 &12, Mechanical

High Pressure Rel ay

Circ#1 Controller

Circuit Breaker &

Switch Panel

External Disconnect Handle

Circ#1 & 2 EXV Drivers

Circ#2 Controller

TB3, Circ#2 Controller

Terminal Board

TB2, Circ#1 Controller

Terminal Board

TB1 Unit Controller

Terminal Board

NOTES:

1. Transformers T2 through T25 are class 100, 120V to 12V.

2. Switches for MHPR 11 and 12 (Mechanical High Pressure Switches) are located on the compressors.

3. Mechanical High Pressure Switches Open at 310 psi, Close at 250 psi.

10 WGS 130A to 190A OM WGS

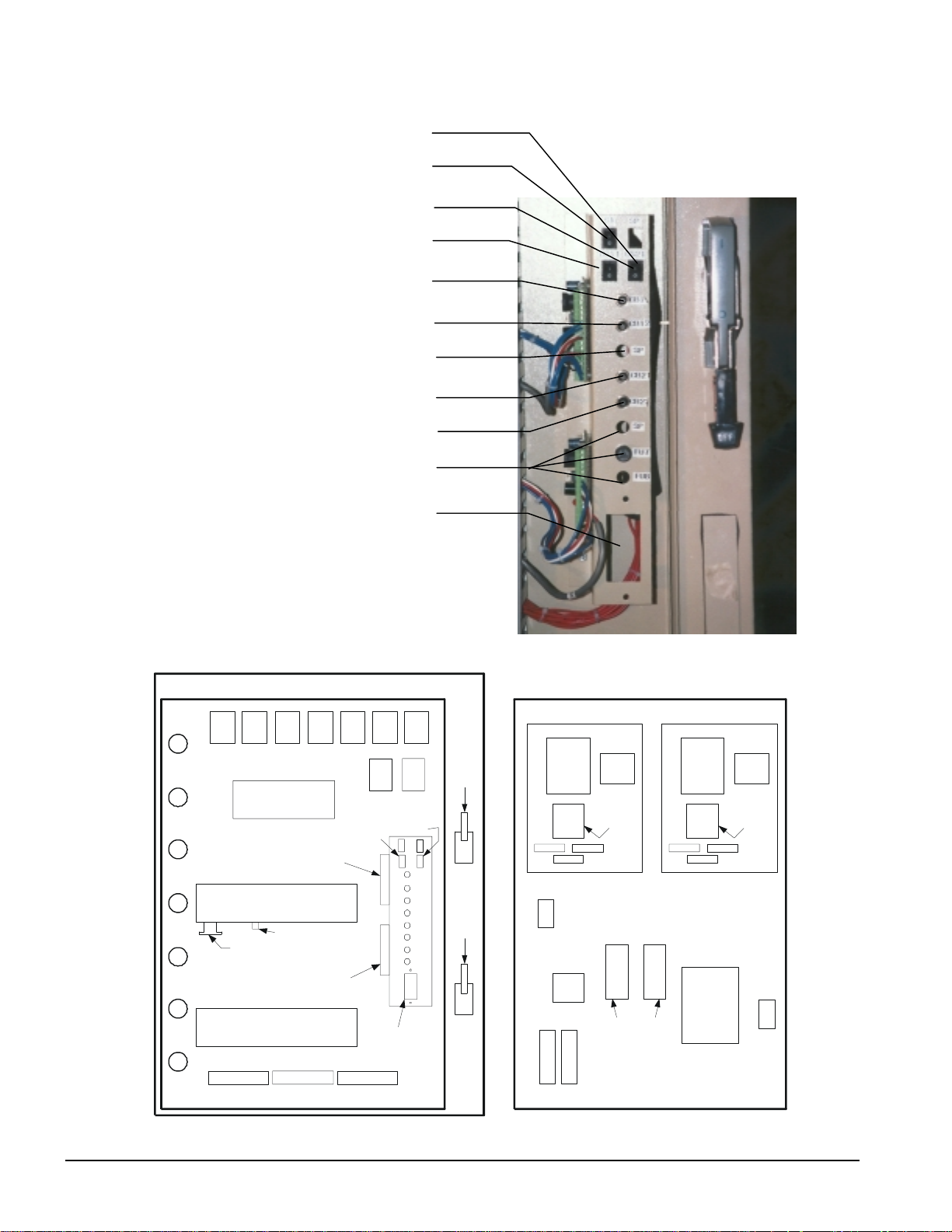

Figure 4, Inner (Power) Panel (Opti onal Single-Point Power wi th Disconnect Switches

Shown)

Circ#1 Solid State Starter

Circ#2 Solid State Starter

SSS1 Bypass Contactor

SSS2 Bypass Contactor

Secondary Fuses

External Disconnect Handle

Circ#1 Circuit Breaker

Circ#2 Circuit Breaker

Unit Disconnect Switch

W/ External Handle

T1, Supply Voltage to

120V Transf ormer

Primary Fuses

Outside (Microprocessor) Panel

OM WGS-1 WGS 130A to 190A 11

Figure 5, Circuit Breaker/Fuse Panel

d

n

t

r

Open Location

S1 Main Unit On-Off Switch

CS2, Circuit#2 On-Off Switch

CS1, Circuit#1 On-Off Switch

CB11 Circ#1 Circuit Breaker

CB12, Circ#1 Sump Heater

Open Locatio

CB21, Circ#2 Circui

CB22, Circ#2 Sump Heate

Open Locations

Location for Optional

115V Receptacle

OUTER PANEL INNER PANEL

T13T2 T14 T15 T23 T24 T25

UNIT

CONTROLLER

EXV.

DRIVER

#1

CIRCUIT CONTROLLER

#1

MODBUS CARD

CONVERTER BOARD

EXV.

DRIVER

#2

CIRCUIT CONTROLLER

#2

TB1

TB11 TB21

MHPR1MHPR

CS1

S1S

REC

OPTION

2

CS2

CB11

CB12

SP

CB21

CB22

SP

FU7

F3

SINGLE

POINT

OR

CIR. #1

DS

HANDLE

(MULTI-

POINT)

P

CIR. #2

DS

HANDLE

(MULTI-

POINT)

SSS #1 SSS #2

D3

CT2

T1

F

U

5

CONTACTOR

CT1

THERM-

ISTOR

CARD

BYPASS

C

B

1

(DS1 DS2

MULTIPOINT

POWER)

CT3

C

B

2

CONTR.

BRD.

CT3

F

U

6

F

U

4

D3

CONTR.

BRD.

CT2

DS1

CONTACTOR

CT1

THERM-

ISTOR

CARD

BYPASS

G

N

D

330589001 REV. 00 - Legen

12 WGS 130A to 190A OM WGS

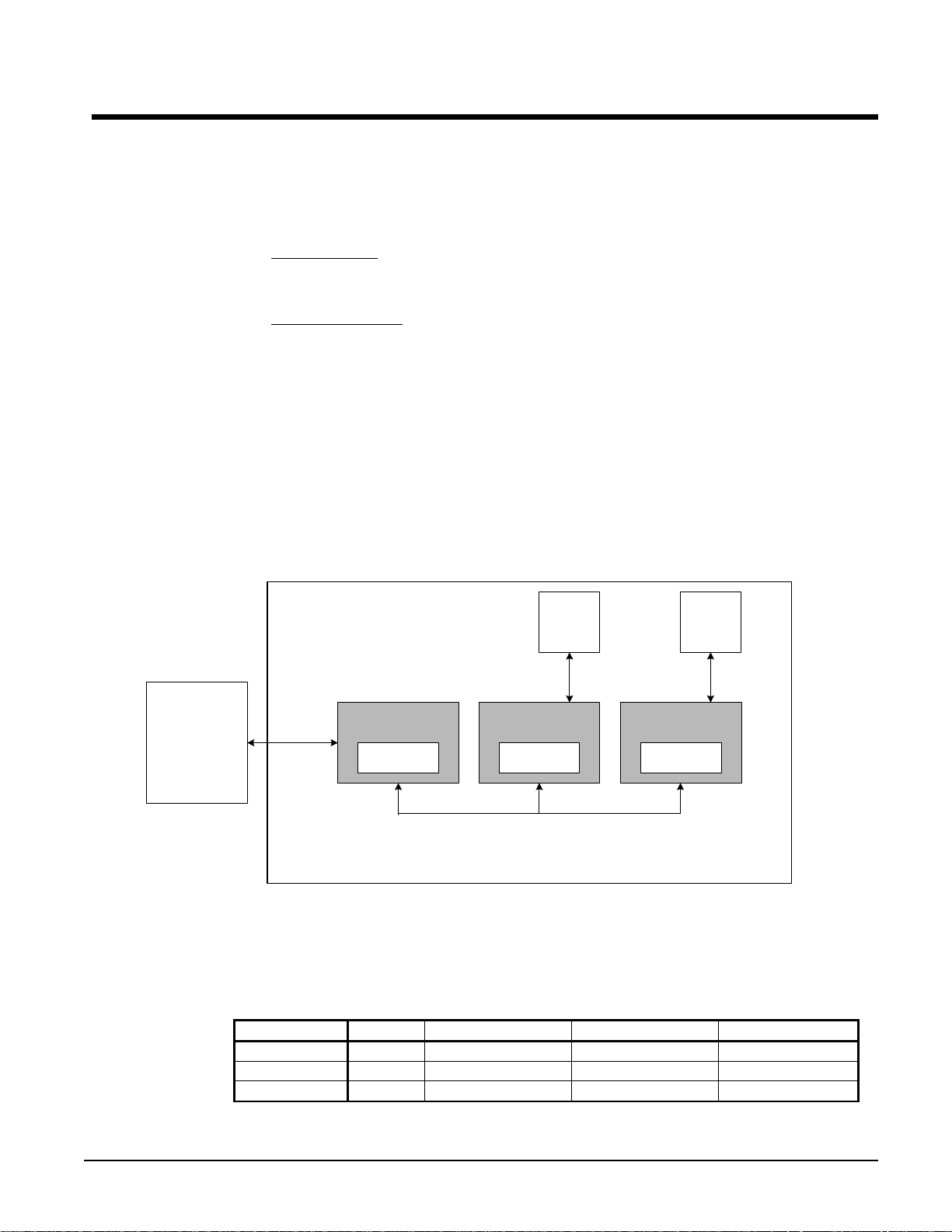

MicroTech II Controller

System A rchitecture

The WGS MicroTech ΙΙ distributed control system consists of multiple microprocessorbased controllers that provide monitoring and control functions required for the controlled,

efficient operation of the chiller. The system consists of the following components:

• Unit Controller

and communicates with the other controllers. It is located in the control panel and is

labeled “UNIT CONTROL”.

• Circuit Controllers

settings specific to the circuit. The controllers are located in the control panel and are

labeled “CIRCUIT CONROL”.

In addition to providing all normal operating controls, the MicroTech II control system

monitors equipment protection devices on the unit and will take corrective action if the

chiller is operating outside of its normal design envelope. If an alarm condition develops,

the controller will shut down the compressor, or entire unit, and activate an alarm output.

Important operating conditions at the time an alarm condition occurs are retained in the

controller’s memory to aid in troubleshooting and fault analysis.

The system is protected by a password scheme that allows access only by authorized

personnel. The operator must enter the operator password into the controller’s keypad

before any setpoints can be altered.

, one per chiller − controls functions and settings that apply to the unit

for each compressor/circuit that control compressor functions and

BAS Interface-

Modbus,

BACnet,

Lonworks

Chiller

RS485/

LON

Unit Controller

4x20 LCD

Carel pLAN

Circuit Controller

Solid

State

Starter

RS485 RS485

Circuit Control l e r

4x20 LCD

4x20 LCD

Solid

State

Starter

PLAN A ddressing

The pLAN (proprietary local area network) addressing is based on a commonly used

scheme among all applications using pLAN networked MicroTech II controllers. Only

three addresses are needed, and are designated as shown in the following table.

Controller Address Dip Sw 1 Position Dip Sw 2 Position Dip Sw 3 Position

Unit 5 Up Down Up

Circuit 1 1 Up Down Down

Circuit 2 2 Down Up Down

The Dip switches are located on the upper front of the controller above the screen.

OM WGS-1 WGS 130A to 190A 13

General Description

The MicroTech II controller’s design permits the chiller to run more efficiently, and it

simplifies troubleshooting if a system failure occurs. Every MicroTech II controller is

programmed and tested prior to shipment to assist in a trouble-free start-up. The

MicroTech II controller can be used to cycle fans on remote air-cooled condensers for head

pressure control when the setpoint Water Cooled=N is selected in one of the setpoint menu

screens. Water Cooled=Y sets the chiller for operation with the water-cooled condenser

and activates settings for cooling tower control. Remote evaporative condensers will have

to have self-contained, on-board, head pressure control systems.

Units of measure

Version “C”, as described in this manual, supports metric (SI) units of measure.

Inch-Pound SI

°F to 0.1°F °C to 0.1°C

psi to 0.1 psi KPa to 1.0 kPa

Distributed Control

The WGS units have three MicroTech II microprocessors, a Unit Controller plus a Circuit

Controller for each of the two circuits. The Circuit Controllers are independent such that

either one will operate its circuit if the other Circuit Controller is out of service.

Operator-friendly

The MicroTech II controller menu structure is separated into three distinct categories,

which provide the operator or service technician with a full description of the following:

1. Current unit status

2. Control parameters (setpoint settings and adjustment). Security protection prevents

unauthorized changing of the setpoints and control parameters.

3. Alarm notification and clearing

The MicroTech II controller continuously performs self-diagnostic checks, monitoring

system temperatures, pressures and protection devices, and will automatically shut down a

refrigerant circuit or the entire unit if a fault occurs. The cause of the shutdown and date

stamp are retained in memory and can be easily displayed in plain English for operator

review, which is an extremely useful feature for troubleshooting. In addition to displaying

alarm diagnostics, the MicroTech II controller also provides the operator with a warning of

pre-alarm limit conditions.

Staging

The two screw compressors are loaded and staged on and off as a function of leaving

chilled water temperature, number of starts and run-hours. See Sequence of Operation

beginning on page 13.

Equipment Protection

The unit is protected by alarms that shut it down and require manual reset, and also by limit

alarms that limit unit operation in response to some out-of-ordinary condition. Shutdown

alarms activate an alarm signal that can be wired to a remote device.

14 WGS 130A to 190A OM WGS

Unit Enable Selection

(4)

Enables unit operation from local keypad or digital input.

Unit Mode Selection

Selects standard cooling, ice, glycol, or test operation mode.

Keypad/Display

A 4-line by 20-character/line liquid crystal display and 6-key keypad is mounted on each

controller. Its layout is shown below.

Figure 6, Keypad and Display in MENU Mode

Air Condi ti oni ng

Key to Screen Pathway

<

ALARM

<

VIEW

<

Arrow Keys

SET

"Enter" Key and Green

Comp. Run Light

Red Alarm Light

Menu Key

The four arrow keys (UP, DOWN, LEFT, RIGHT) have three modes of use.

1. Scroll between data screens as indicated by the arrows (default mode).

2. Select a specific data screen in a hierarchical fashion using dynamic labels on the right

side of the display (this mode is entered by pressing the MENU key).

3. Change field values in edit mode according to the following table:

LEFT Default

RIGHT Cancel

UP Increment

DOWN Decrement

These four edit functions are indicated by one-character abbreviations on the right side of

the display (this mode is entered by pressing the ENTER key).

OM WGS-1 WGS 130A to 190A 15

Sequence of Operation

Compressor Heaters

With the control power on, 120V power is applied through the control circuit Fuse FU7 to

the compressor oil separator heater (HTR-OIL SEP).

Startup/Compressor Staging

During Cool Mode the following must be true to start a circuit operating. The evaporator

and condenser pump (WGS-AW only) outputs must be energized and flow must be

established for a period of time defined by the evaporator recirculate setpoint. Established

flow will be detected by evaporator and condenser water flow switches. The water

temperature leaving the evaporator must be greater than the Active Leaving Water

Temperature setpoint, plus the Startup Delta-T, before a circuit will start. The first circuit

to start is determined by sequence number. The lowest sequence numbered circuit will start

first. If all sequence numbers are the same (default), then the circuit with the fewest

number of starts will start first. During operation, the slide valves for loading and

unloading will be pulsed until the active leaving water temperature setpoint is maintained.

The second circuit start will occur once the first circuit has loaded to 75% slide capacity or

is in Capacity Limit and the water temperature leaving the evaporator is greater than the

active leaving water temperature Setpoint plus Stage Delta-T. The circuits will load or

unload simultaneously through a continuous capacity control to maintain the evaporator

leaving water temperature. If all sequence numbers are the same, the circuit with the most

run hours will be shut down first. The circuit with the most run hours will stop when the

water temperature leaving the evaporator is less than the Active Leaving Water

Temperature Setpoint minus Stage Delta-T. The last remaining circuit will shut down

when the water temperature leaving the evaporator is lower than the Active Leaving Water

Temperature Setpoint minus the Stop Delta-T.

Automatic Pumpdown

The Model WGS chiller has two separate refrigerant circuits so the refrigerant charge is

stored in the condenser when the circuit is off. Pumpdown to the condenser helps keep

refrigerant from migrating to the compressor. It also helps establish a pressure differential

on start for oil flow. In a normal shutdown, each circuit will close its expansion valve,

causing the evaporator pressure to reach a low-pressure setpoint. Once this setpoint is

reached, or a specified amount of time has elapsed, the running circuit will be shut down.

Chilled Water and Condenser Water Pumps

The chiller’s MicroTech II controller has a total of four pump outputs, two for the

evaporator and two for the condenser (WGS-AW only). There is a manual setting in the

software for the user to select either pump output 1 or 2. It is recommended that the

chiller’s outputs control the water pumps, as this will offer the most protection for the unit.

Cooling Tower Control

The MicroTech II controller can control the cooling tower fans and/or a tower bypass valve.

This provides a simple and direct method to control the unit’s discharge pressure.

Programming directions and the sequence of operation can be found on page 44. Some

means of discharge pressure control is recommended and must be installed if the entering

condenser water temperature to the condenser can fall below 60°F.

Condenser Fan Control

The MicroTech II controller can be programmed to cycle air-cooled condenser fans on and

off based on the discharge pressure. Details are on page 61.

16 WGS 130A to 190A OM WGS

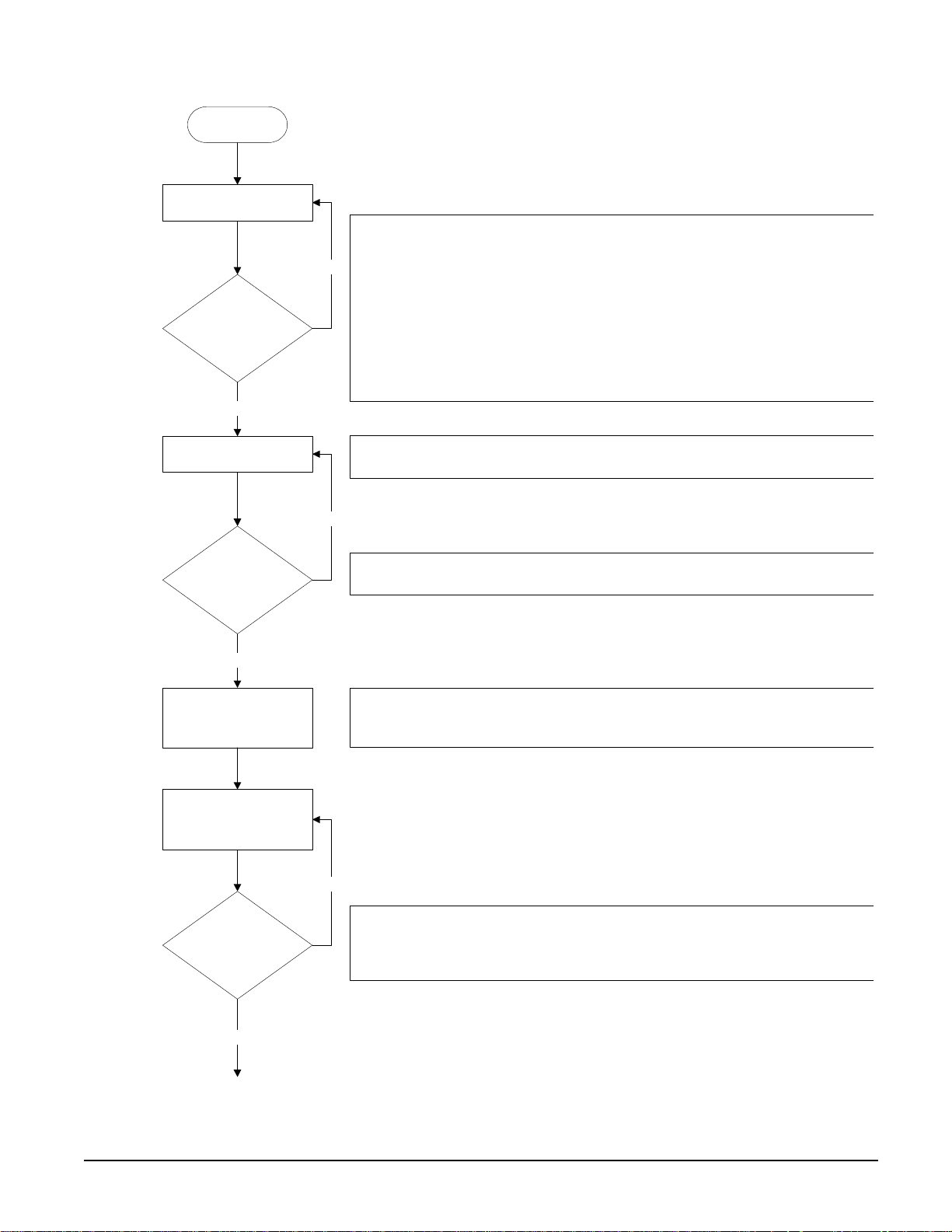

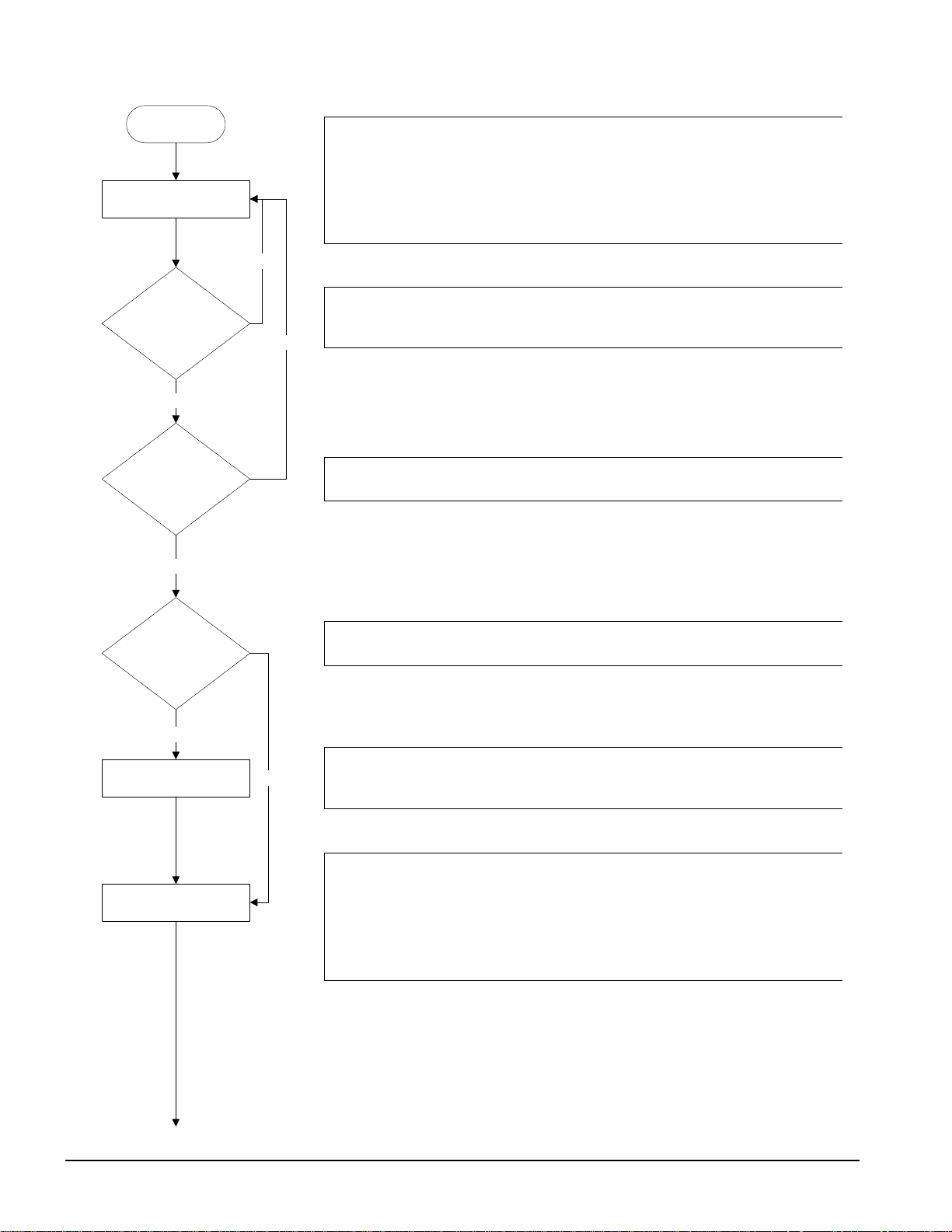

Unit Controller Sequence of Operation

Unit power up

Unit in Off state

The chiller may be disabled via the unit switch, the remote switch, the keypad

enable setting, or the BAS network. In addition, the chiller will be disabled if both

circuits are disabled, either because of an alarm or the circuit pumpdown switch on

No

each circuit, or if there is a unit alarm. If the chiller is disabled, the unit status

display will reflect this and also show why it is disabled.

Is unit enabled?

Yes

Evaporator pump output on

Is flow present?

Yes

Wait for chilled water loop to

recirculate.

If the unit switch is off, the unit status will be

disabled due to network command, the unit status will be

the remote switch is open, the unit status will be

alarm is active, the unit status will be

are enabled, the unit status will be

Off:All Cir Dis abl e d

Off:Unit Switch

Off:Remote Switch

Off:Unit Alarm

. If the chiller is

Off:BAS Disa bl e

. When a unit

. In cases where no circuits

.

If the chiller is enabled, then the unit will be in the Auto state and the evaporator

water pump output will be activated.

No

The chiller will then wait for the flow switch to close, during which time the unit

status will be

Auto:Wait for flow

.

After establishing flow, the chiller will wait some time to allow the chilled water loop

to recirculate for an accurate reading of the leaving water temperature. The unit

status during this time is

Auto:Evap Recirc

.

. When

Keep evaporator pump

output on while unit is

enabled.

No

The chiller is now ready to start if enough load is present. If the LWT is not high

Is there enough load to

start chiller?

Yes

enough to start, the unit status will be

If the LWT is high enough to start, the unit status will be

Auto:Wait Evap Flow

Auto

.

.

OM WGS-1 WGS 130A to 190A 17

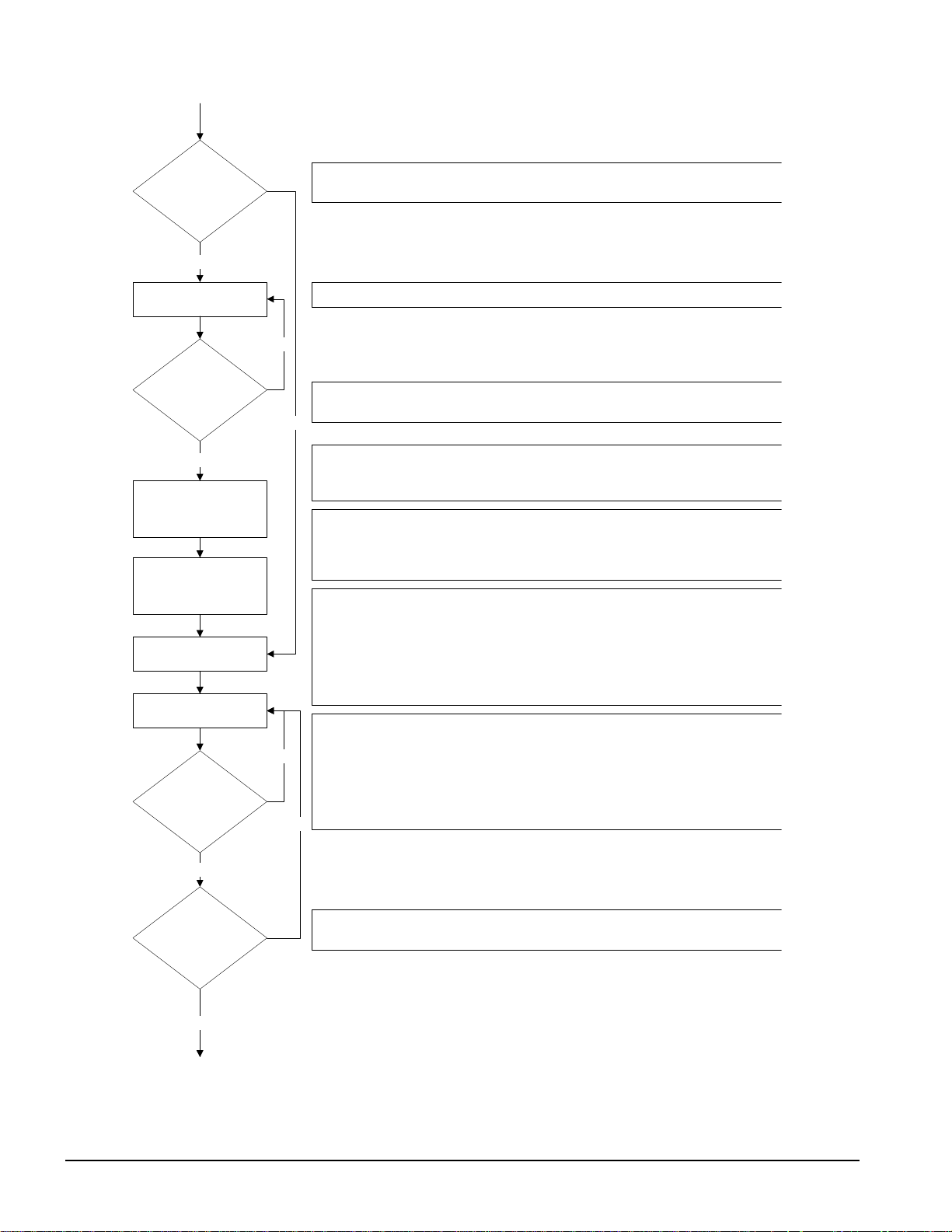

Is unit watercooled?

Yes

If the unit is configured as watercooled, the condenser pump will need to be started.

Otherwise, the unit can start the first circuit at this point.

Condenser pump output on

Is flow present?

Yes

Wait for condenser water

loop to recirculate.

Keep condenser pump

output on while u n it is

enabled and load is present.

Start first circuit.

Load/unload as needed to

satisfy load.

Is more capacity

needed to satisfy load?

If load is present, the condenser water pump output will be activated.

No

The chiller will then wait for the condenser flow switch to close, during which time

the unit status will be

No

Auto:Wait Cond Flow

.

After establishing condenser flow, the chiller will wait some time to allow the

condenser water loop to recirculate and guarantee consistent flow. The unit status

during this time is

Auto:Cond Recirc

.

Once the condenser flow has been present for enough time, the unit status will

become

Auto

. The tower control logic will start working to control the condenser

water temperature, using outputs from the unit controller to control tower fans,

bypass valves, and vfd's as determined by the tower set points.

The first circuit to start is generally the one with the least number of starts, or circuit

one if there is a tie. This circuit will go through its start sequence at this point.

A number of fans may be started with the compressor based on the OAT. Fan

stages will be added/removed as needed to control condenser pressure. The EXV

will begin controlling at this point as well. The compressor cannot start loading until

it has at least 22

o

discharge superheat for more than 30 seconds.

The first circuit will load and unload as needed in an attempt to satisfy the load. It

will eventually get to a point where it is considered to be at full load. A circuit is at

No

full load when it reaches 75% slide target, it reaches the max slide target setting, or

it encounters a problem and is running in an inhibited state.

If a single circuit is not enough to satisfy the load, the second circuit will need to be

started.

No

Yes

Has the stage up time

delay expired?

Yes

A minimum time must pass between the start of the first circuit and the second

circuit.

18 WGS 130A to 190A OM WGS

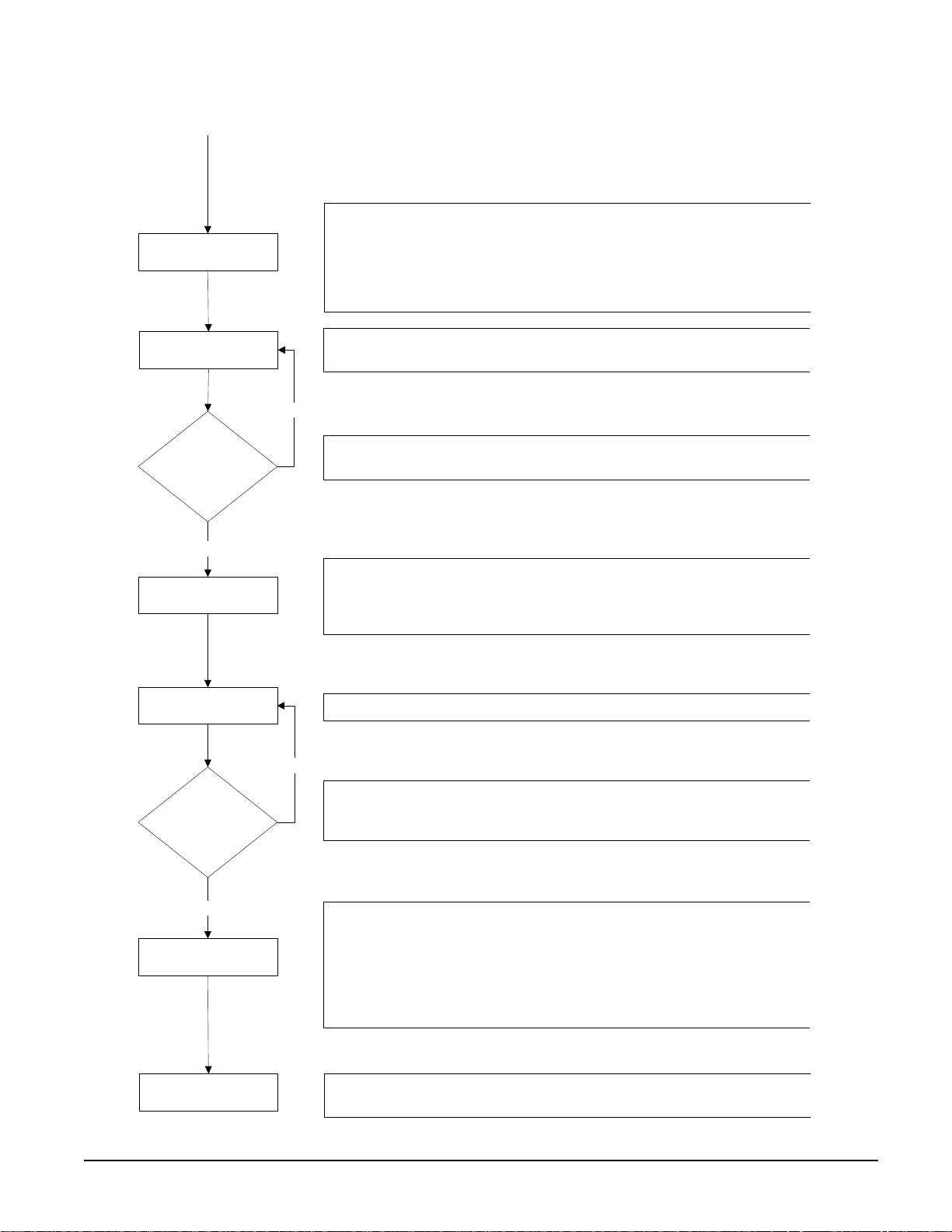

The second circuit will go through its start sequence at this point.

Start second circuit.

Load/unload as needed to

satisfy load.

Can one circuit handle

the load?

Yes

Shut down one circuit.

Load/unload as needed to

satisfy load.

A number of fans may be started with the compressor based on the OAT. Fan

stages will be added/removed as needed to control condenser pressure. The EXV

will begin controlling at this point as well. The compressor cannot start loading until

it has at least 22

o

discharge superheat for more than 30 seconds.

Both circuits will now load/unload as needed to satisfy the load. In addition, they will

load balance so that both circuits are providing nearly equal capacity.

No

As the load drops off, the circuits will unload accordingly. If the LWT gets low

enough, or both circuits unload enough, one circuit can shut off.

The first circuit to shut off is generally the one with the most run hours. The circuit

will do a pumpdown by closing the EXV and continuing to run the compressor until it

reaches the pumpdown pressure or exceeds the pumpdown time limit. Then, the

compressor and all fans will be turned off.

The single running circuit will load/unload as needed to satisfy the load.

No

With one circuit running, the load may drop off to the point where even minimum

Is load satisfied?

Yes

unit capacity is too much. The load has been satisfied when the LWT drops below

the shutdown point. At this time the only running circuit can shut down.

The last circuit running now shuts down. The circuit will do a pumpdown by closing

the EXV and continuing to run the compressor until it reaches the pumpdown

Shut down last circuit.

pressure or exceeds the pumpdown time limit. Then, the compressor and all fans

will be turned off.

The unit should be ready to start again when the LWT gets high enough. The unit

Turn off condenser pump

and tower control.

status at this time will be

Auto:Wait for load

The condenser pump and tower control outputs are turned off until the LWT is high

enough to start again.

.

OM WGS-1 WGS 130A to 190A 19

Circuit Controller Sequence of Operation

Unit power up

Circuit is in Off state

Next on?

Yes

Stage up now?

Yes

No

No

When the circuit is in the Off state the EXV is closed, compressor is off, and all fans

are off. The oil heater will be on at this time as long as oil is detected in the

separator.

If the compressor is ready to start when needed, the circuit status will be

Off:Ready

be

. When the circuit switch is off, the circuit cannot start and the status will

Off:Pumpdown Switch

.

If this compressor has the least starts, the other compressor is disabled for some

reason, or the other compressor is already running, then this compressor will be

designated as the next one on.

If there is a need for more cooling capacity , the compressor designated as next on

can start.

Is unit watercooled?

Yes

Preopen EXV

Start Compressor

No

If the unit is configured as watercooled, then the EXV preopen process must be

performed. Otherwise, this is skipped and the compressor can be sta rted.

At this point, the EXV will perform a preopen. While the compressor is off, the EXV

is opened for a period of time to prime the evapora tor an d avoid low pressure at

startup. The circuit status will display

EXV Preopen

.

When the compressor starts, the EXV will open (if not already open) and hold at

3000 steps for 15 seconds.

If the unit is aircooled, depending on the OAT, a number of fans may be started with

the compressor to keep condenser pressure from climbing too fast.

The circuit status will normally be

Run: Disc SH Low

after the compressor starts.

20 WGS 130A to 190A OM WGS

Run Compressor

Next off?

Yes

Stage down now?

Yes

When in the Run state, the compressor will load/unload as needed to satisfy the

load. The compressor will also load/unload to load balance with the other

compressor if it is running and not in a limited condition. However, it cannot load up

until the discharge superheat has been over 22 F for at least 30 seconds. After this,

the circuit status will be

Run:Normal

.

The EXV will operate in either Pressure Control or Superheat Control. In Pressure

Control, the evaporator pressure is controlled to a target pressure, which is adjusted

based on LWT and discharge superheat. In Superheat Control, the suction

No

superheat is controlled to a target that varies with discharge superheat.

If unit is aircooled, fans will be staged on and off to control the condenser pressure.

The condenser pressure is controlled to a target that is based on evaporator

pressure, with the target getting higher as the evaporator pressure gets higher.

No

If this compressor has the most run hours or the other compressor is already off,

then this compressor will be designated as the next one off.

If less cooling capacity is needed, the compressor designated as next off can shut

down. This condition may arise when either the LWT has dropped far enough below

the active set point or both circuits are running at a low capacity.

When the circuit does a normal shutdown, a pumpdown is performed. The EXV is

closed while the compressor continues to run. As soon as the pumpdown is

initiated, the compressor is unloaded to the minimum. The condenser fans

continue to control normally during this process. The circuit status during this time

Run:Pumpdown

is

.

Pumpdown circuit

After the evaporator pressure drops below the pumpdown pressure or enough time

has passed, the compressor and fans are shut off to end the pumpdown process.

The circuit status will normally be

Off:Cycle Timers

at this time.

OM WGS-1 WGS 130A to 190A 21

Start-Up and Shutdown

Pre Start-up

1. Flush and clean the chilled-water system. Proper water treatment is required to prevent

corrosion and organic growth.

Failure to flush and clean system and provide water treatment can damage the unit.

2. With the main disconnect open, check all electrical connections in control panel and

starter to be sure they are tight and provide good electrical contact. Connections are

tightened at the factory, but can loosen enough in shipment to cause a malfunction.

Lock and tag out all power sources when checking connections. Electrical shock can

3. Check and inspect all water piping. Make sure flow direction is correct and that piping

is made to the correct connection on evaporator and condenser.

4. Check that refrigerant piping on remote condensers is connected to the correct circuits

and not crossed and has been properly leak tested and evacuated.

5. Open all water flow valves to the condenser and evaporator.

6. Flush the cooling tower and system piping to be sure the system is clean. Start

evaporator pump and manually start condenser pump and cooling tower. Check all

piping for leaks. Vent the air from the evaporator and condenser water circuit, as well

as from the entire water system. The cooler circuit should contain clean, treated, noncorrosive water.

7. Check to see that the evaporator water temperature sensor is securely installed.

8. Make sure the unit control switch S1 is open OFF and the circuit switches CS1 and

CS2 are open. Place the main power disconnect switch to ON. This will energize the

compressor sump heaters. Wait a minimum of 12 hours before starting the unit.

9. Measure the water pressure drop across the evaporator and condenser, and check that

water flow is correct (on pages 25 and 26) per the design flow rates.

10. Check the actual line voltage to the unit to make sure it is the same as called for on the

compressor nameplate, within + 10%, and that phase voltage unbalance does not

exceed 2%. Verify that adequate power supply and capacity is available to handle load.

11. Make sure all wiring and fuses are of the proper size. Also make sure that all interlock

wiring is completed per McQuay diagrams.

12. Verify that all mechanical and electrical inspections by code authorities have been

completed.

13. Make sure all auxiliary load and control equipment is operative and that an adequate

cooling load is available for initial start-up.

CAUTION

CAUTION

cause severe personal injury or death.

Start-up

1. Open the compressor discharge shutoff valves until backseated. Replace valve seal

caps.

2. Open the two manual liquid line shutoff valves (king valves).

22 WGS 130A to 190A OM WGS

3. Verify that the compressor sump heaters have operated for at least 12 hours prior to

start-up. Crankcase should be warm to the touch.

4. Check that the MicroTech II controller is set to the desired chilled water temperature.

5. Start the system auxiliary equipment for the installation by turning on the time clock,

ambient thermostat and/or remote on/off switch and water pumps.

6. Switch on the unit circuit breakers.

7. Set circuit switches CS1 and CS2 to ON for normal operation.

8. Start the system by setting the unit system switch S1 to ON.

9. After running the unit for a short time, check the oil level in each compressor, rotation

of condenser fans (if any), and check for flashing in the refrigerant sight glass.

Weekend or Temporary Shutdown

Move circuit switches CS1 and CS2 to the OFF pumpdown position. After the compressors

have shut off, turn off the chilled water pump if not on automatic control from the chiller

controller or building automation system (BAS). With the unit in this condition, it will not

restart until these switches are turned back on.

Leave on the power to the unit (disconnect closed) so that the sump heaters will remain

energized.

Start-up after Temporary Shutdown

1. Start the water pumps.

2. Check compressor sump heaters. Compressors should be warm to the touch.

3. With the unit switch S1 in the ON position, move the circuit switches CS1 and CS2 to

the ON position.

4. Observe the unit operation for a short time, noting unusual sounds or possible cycling

of compressors.

Extended Shutdown

1. Close the manual liquid line shutoff valves.

2. After the compressors have shut down, turn off the water pumps.

3. Turn off all power to the unit.

4. Move the unit control switch S1 to the OFF position.

5. Close the discharge shutoff valves.

6. Tag all opened disconnect switches to warn against start-up before opening the

compressor suction and discharge valves.

7. Drain all water from the unit evaporator, condenser and chilled water piping if the unit

is to be shut down during the winter and exposed to below-freezing temperatures. To

help prevent excessive corrosion, do not leave the vessels or piping open to the

atmosphere over the shutdown period.

Start-up after Extended Shutdown

1. Inspect all equipment to see that it is in satisfactory operating condition.

2. Remove all debris that has collected on the surface of the condenser coils (remote

condenser models) or check the cooling tower, if present.

OM WGS-1 WGS 130A to 190A 23

3. Open the compressor discharge valves until backseated. Always replace valve seal

caps.

4. Open the manual liquid line shutoff valves.

5. Check circuit breakers. They must be in the OFF position.

6. Check to see that the circuit switches CS1 and CS2 and the unit control switch S1 are in

the OFF position.

7. Close the main power disconnect switch. The circuit disconnects switches should be

off.

8. Allow the sump heaters to operate for at least 12 hours prior to start-up.

9. Start the chilled water pump and purge the water piping as well as the evaporator in the

unit.

10. Start the system auxiliary equipment for the installation by turning on the time clock,

ambient thermostat and/or remote on/off switch.

11. Check that the MicroTech II controller is set to the desired chilled water temperature.

12. Switch the unit circuit breakers to ON.

13. Start the system by setting the system switch S1 and the circuit switches to ON.

CAUTION

Most relays and terminals in the control center are powered when S1 is

closed and the control circuit disconnect i s on. Therefore, do not close S1

until ready for start-up or serious equipment damage can occur.

14. After running the unit for a short time, check the oil level in the compressor oil sight

glass and check the liquid line sight glass for bubbles.

24 WGS 130A to 190A OM WGS

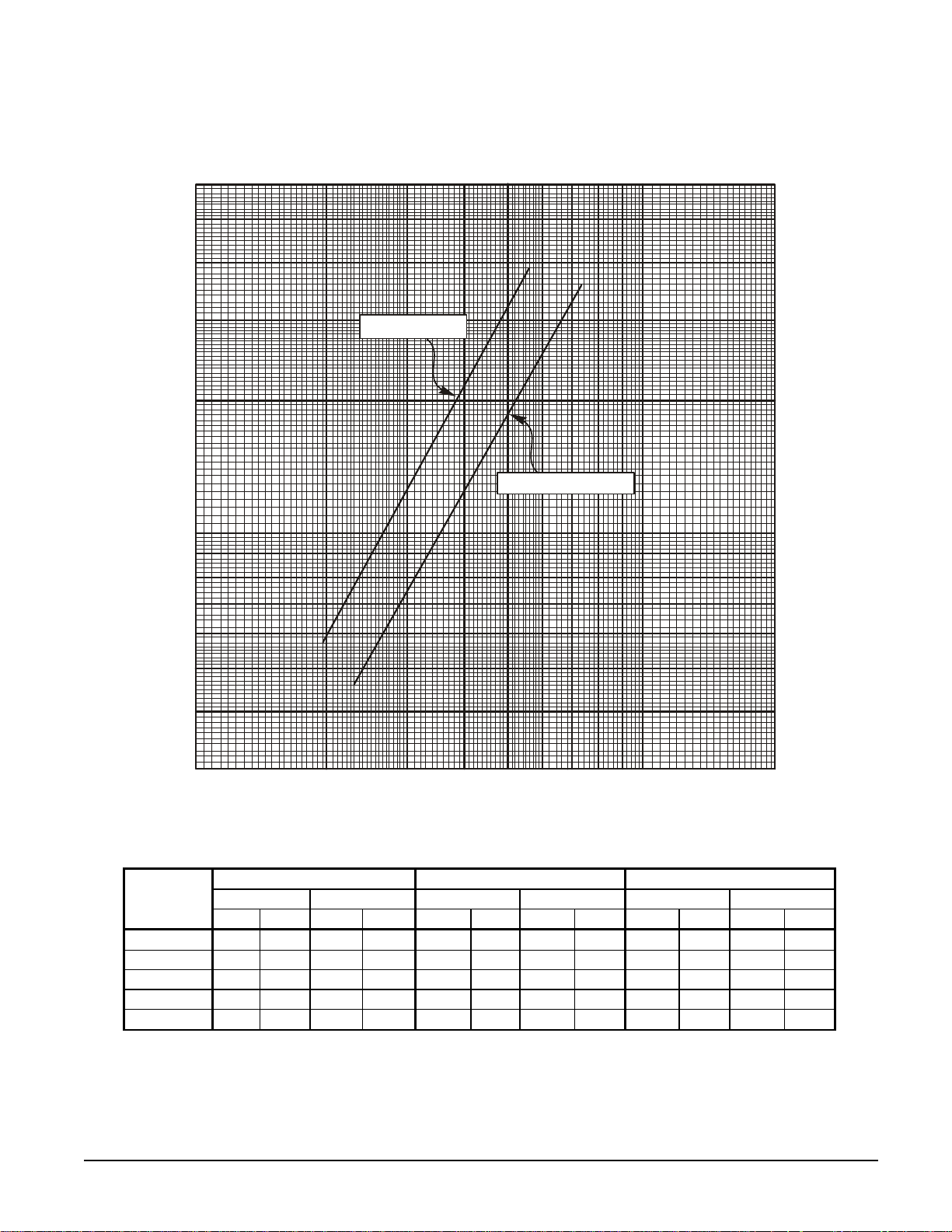

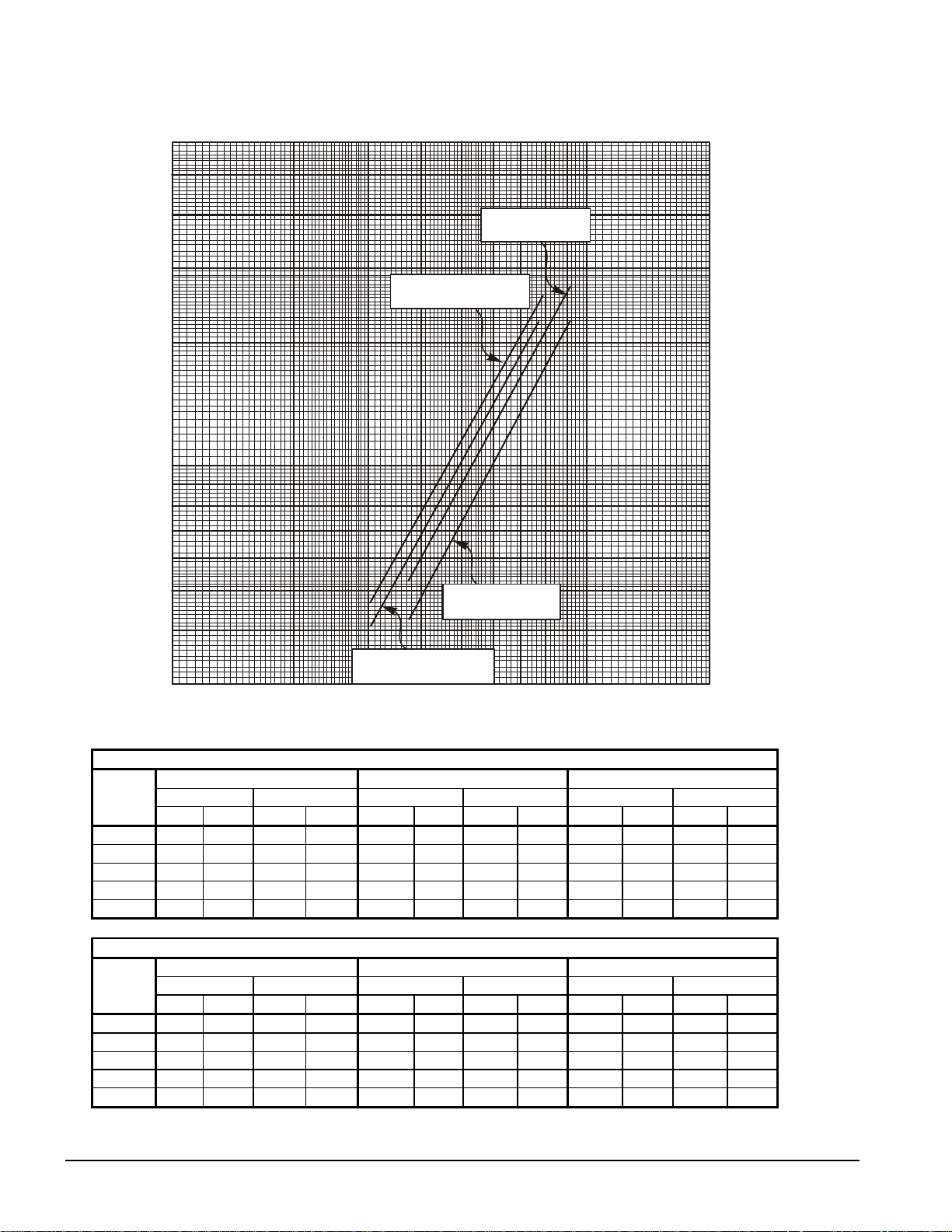

Figure 7, Evaporator Pressure Drop WGS 130 – WGS 190

(

)

Flow Rate (L/s)

6131925323844505763

60

126

180

50

40

30

20

10

9

8

Pressure Drop (ft of water)

7

6

5

WGS 130, 140

WGS 160, 170, 190

150

120

90

60

30

27

24

21

18

15

Pressure Drop

kPa

4

3

100 200 300 400 500 600 700

800

900

1000

12

9

2000

Flow Rate (GPM)

Minimum Flow Nominal Flow Maximum Flow

WGS Model

130AW/AA

140AW/AA

160AW/AA

170AW/AA

190AW/AA

Note: Minimum, nominal, an d maximum flows are at a 16°F, 10°F, and 6°F chilled water temperature range respectively and at ARI tons.

Flow Rate Pressure Drop Flow Rate Pressure Drop Flow Rate Pressure Drop

gpm L/s Ft. kPa gpm L/s Ft. kPa gpm L/s Ft. kPa

195 12.3 5.8 17.4 312 19.7 13.5 40.4 520 32.9 33.9 101.1

211 13.4 6.7 20.0 338 21.4 15.6 46.6 563 35.6 39.0 116.5

235 14.9 4.6 13.8 376 23.8 10.8 32.3 627 39.7 27.3 81.6

254 16.1 5.3 15.9 407 25.8 12.5 37.3 678 42.9 31.6 94.2

273 17.3 6.1 18.1 437 27.7 14.2 42.5 728 46.1 35.9 107.2

OM WGS-1 WGS 130A to 190A 25

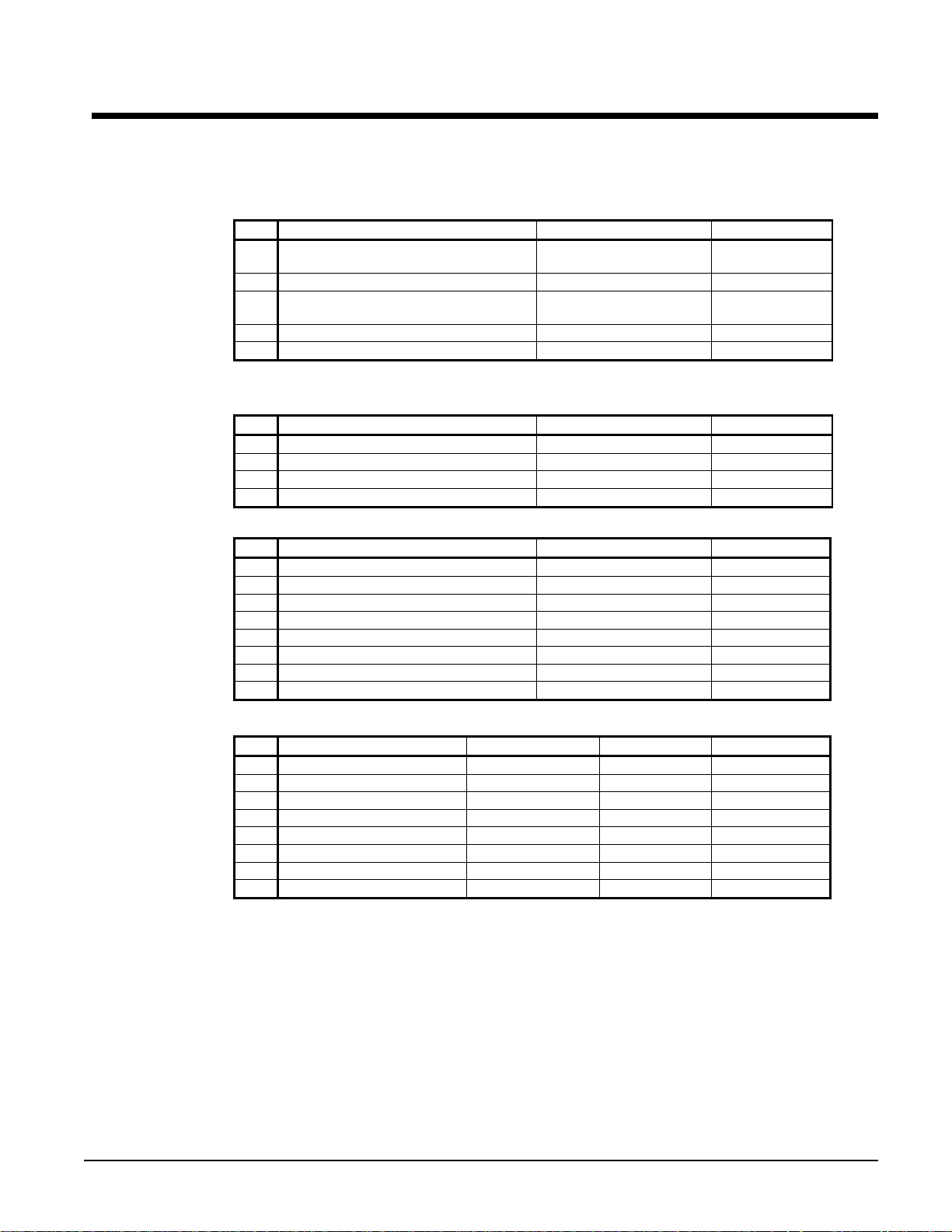

Figure 8, Condenser Pressure Drop WGS 130 – WGS 190

P

D

Flow Rate (L/s)

6131925323844505763

60

126

180

rop (ft of water)

ressure

WGS

Model

130AW

140AW

160AW

170AW

190AW

WGS

Model

130AW

140AW

160AW

170AW

190AW

50

40

WGS 170, 190

150

120

with Manifold

30

90

WGS 130, 140, 160

with Manifold

20

10

9

8

7

6

5

WGS 170, 190

60

30

27

24

21

18

15

without Manifold

4

12

WGS 130, 140, 160

3

100 200 300 400 500 600 700

without Manifold

800

900

1000

2000

Flow Rate (GPM)

Pressure Drop Without Optional Condenser Manifold

Minimum Flow Nominal Flow Maximum Flow

Flow Rate Pressure Drop Flow Rate Pressure Drop Flow Rate Pressure Drop

gpm L/s Ft. kPa gpm L/s Ft. kPa gpm L/s Ft. kPa

304 19.2 4.1 12.2 390 24.7 6.5 19.3 650 41.1 16.0 47.9

304 19.2 4.1 12.2 422 26.7 7.4 22.2 704 44.5 18.5 55.1

304 19.2 4.1 12.2 470 29.8 9.0 26.9 784 49.6 22.4 66.8

372 23.5 4.3 12.8 509 32.2 7.9 23.7 848 53.7 19.8 59.1

372 23.5 4.3 12.8 546 34.6 9.0 26.9 911 57.6 22.5 67.1

Pressure Drop With Optional Condenser Manifold

Minimum Flow Nominal Flow Maximum Flow

Flow Rate Pressure Drop Flow Rate Pressure Drop Flow Rate Pressure Drop

gpm L/s Ft. kPa gpm L/s Ft. kPa gpm L/s Ft. kPa

304 19.2 4.7 14.0 390 24.7 7.4 22.0 650 41.1 18.5 55.1

304 19.2 4.7 14.0 422 26.7 8.5 25.3 704 44.5 21.3 63.5

304 19.2 4.7 14.0 470 29.8 10.3 30.7 784 49.6 25.8 77.1

372 23.5 5.3 15.8 509 32.2 9.4 28.1 848 53.7 23.8 71.1

372 23.5 5.3 15.8 546 34.6 10.7 32.0 911 57.6 27.1 80.9

Pressure Drop (kPa)

9

26 WGS 130A to 190A OM WGS

Unit Controller

Unit Inputs/Outputs

Table 1, Analog Inputs

# Description Signal Source Range

1

2

3

4

5

C1 = Refrigerant Circuit #1, C2 = Refrigerant Circuit #2, UT = Unit

Table 2, Analog Outputs

# Description Output Signal Range

1

2

3

4

Table 3, Digital Inputs

# Description Signal Signal

1

2

3

4

5

6

7

8

Condenser EWT or Outdoor

Ambient Temp.

Demand Limit 4-20 mA Current 0 to 100% limit

Chilled Water Reset 4-20 mA Current

Leaving Evaporator Water Temp. Thermister (10k@25°C) -58 to 212°F

Entering Evaporator Water Temp. Thermister (10k@25°C) -58 to 212°F

Cooling Tower Bypass Valve Position 0 to 10 VDC 0 to 100%

Cooling Tower VFD Speed 0 to 10 VDC 0 to 100%

Open

Open

Unit Switch 0 VAC (Stop) 24 VAC (On)

Remote Switch 0 VAC (Stop) 24 VAC (Start)

Evaporator Water Flow Switch 0 VAC (No Flow) 24 VAC (Flow)

Mode Switch 0 VAC (Cool) 24 VAC (Ice)

Condenser Water Flow Switch 0 VAC (No Flow) 24 VAC (Flow)

Open

Open

Open

Thermister (10k@25°C) -58 to 212°F

0 to 10 degrees

60°F max.

Table 4, Digital Outputs

# Description Load Output OFF Output ON

Evaporator Water Pump 1 Pump Contactor Pump OFF Pump ON

1

Evaporator Water Pump 2 Pump Contactor Pump OFF Pump ON

2

Condenser Water Pump 1 Pump Contactor Pump OFF Pump ON

3

Condenser Water Pump 2 Pump Contactor Pump OFF Pump ON

4

Tower Fan 1 Fan Contactor Fan OFF Fan ON

5

Tower Fan 2 Fan Contactor Fan OFF Fan ON

6

Remote Run Status All Circuits Off Any Circuit On

7

Alarm Remote Alarm No alarm Stop alarm

8

Unit Setpoints

The following parameters are retained during power off, are factory set to the Default

value, and can be adjusted to any value in the Range column.

The Type defines whether the setpoint is part of a coordinated set of duplicate setpoints in

different controllers. Types are as follows:

N = Normal setpoint – Not copied from, or copied to, any other controller

M = Master setpoint – Setpoint is copied to all controllers in the “Sent To” column

The PW (password) column indicates the password level that must be active in order to

change the setpoint. Passwords are as follows:

O = Operator [0100] M = Manager (8745)

OM WGS-1 WGS 130A to 190A 27

Toggle: Setpoints that have two choices, such as ON and OFF are toggled between the two

settings using the Up or Down keys on the controller.

NOTE: in some software versions the terms “inhibit” and “hold” are used interchangeably.

Table 5, Unit Controller Setpoints

Description Default Range Type PW

Unit

Unit Enable OFF OFF, ON N O

Unit Mode Cool Cool, Ice, Test M O

Control source Switches Switches, Keypad, Network N O

Available Modes Cool

Cool LWT

Ice LWT

Start Delta T

Stop Delta T

Stage Up Delta T

Stage Down Delta T

Max Pulldown

Evap Recirc Timer 30 0 to 300 seconds N M

Evap Pump Select #1 Only #1 Only, #2 Only, Auto N M

Water-cooled Yes No, Yes N M

Cond Recirc Timer (watercooled only)

Cond Pump Select (watercooled only)

LWT Reset Type NONE NONE, RETURN, 4-20mA, OAT N M

Max Reset

Start Reset Delta T

Soft Load Off Off, On N M

Begin Capacity Limit 40% 20-100% N M

Soft Load Ramp 20 min 1-60 minutes N M

Demand Limit Off Off, On N M

Low OAT Operation

(air-cooled only)

Low Ambient Lockout (air

cooled only)

Ice Time Delay 12 1-23 hours N M

Clear Ice Timer No No,Yes N M

Evap LWT sensor off set 0 -5.0 to 5.0 deg N T

Evap EWT sensor of fset 0 -5.0 to 5.0 deg N T

Cond EWT/OAT sensor offset 0 -5.0 to 5.0 deg N T

Cond LWT sensor off set 0 -5.0 to 5.0 deg N T

Units

BAS Protocol Modbus BACnet, LonWorks, Modbus N M

Ident number 1 0-200 N M

Baud Rate 19200 1200,2400,4800,9600,19200 N M

Compressors

Sequence # Cir 1 1 1-2 M M

Sequence # Cir 2 1 1-2 M M

Start-start timer 20 min 15-60 minutes M M

Stop-start tim er 5 min 3-20 minutes M M

Pumpdown Pressure 25 psi 10 to 40 psi M T

Pumpdown Time Limit 120 sec 0 to 180 s ec M T

Light Load Stg Dn Point 25% 20 to 50% M T

Stage Up Delay 5 min 0 to 60 min M T

44 °F 30(40) to 60 °F

25 °F 20 to 38°F

10 °F 0 to 10 °F

1.5 °F 0 to 3 °F

2 °F 0 to 3 °F

1 °F 0 to 3 °F

5 °F/min 0.5-5.0 °F /min

30 0 to 300 seconds N M

#1 Only #1 Only, #2 Only, A uto N M

0 °F 0 to 20 °F

10 °F 0 to 20 °F

No No, Yes N M

55 °F 0(35) to 70 °F

°F/psi °F/psi, °C/kPa

Continued next page

Cool, Cool w/Glycol, Cool/Ice

w/Glycol, ICE w/Glycol, TEST

N T

N O

N O

M O

M O

M O

M O

M M

N M

N M

N M

N M

28 WGS 130A to 190A OM WGS

Description Default Range Type PW

Alarms

Low Evap Pressure-Unload 28 psi [0,26] to 45 psi M T

Low Evap Pressure-Hold 30 psi [ 0,28] to 45 psi M T

Low Oil Level Delay 120 s ec 10-180 sec M T

High Oil Press Diff Delay 15 sec 0-60 sec M T

High Discharge Temperature

High Lift Pressure Delay 5 sec 0 to 30 sec M T

Evaporator Water Freeze

Evaporator Flow Proof 3 sec 3 to 10 sec N T

Low OAT Start Timer (air

cooled only)

Condenser Water Freeze

(water cooled only)

Condenser Flow Proof (water

cooled only)

Cooling Tower(available for Water cooled only)

Tower Control None None, Temperature N M

Tower Stages 2 0 to 2 N M

Stage #1 On

Stage #2 On

Stage Differential

Stage Up Time 2 min 1 to 60 min N M

Stage Down Time 5 min 1 to 60 min N M

Stage Fan Down @ 20% 0 to 100% N M

Stage Fan Up @ 80% 0 to 100% N M

Valve/VFD Control None

Valve Type NC to tower NC, NO N M

Valve Setpoint

Valve Deadband

Minimum Start P osition 0% 0 to 100% N M

Minimum Position @

Maximum Start Position 100% 0 to 100% N M

Maximum Position @

Valve Control Range (Min) 10% 0 to 100% N M

Valve Control Range(Max) 90% 0 to 100% N M

Error Gain 25 10 to 99 N M

Slope Gain 25 10 to 99 N M

200 °F

36 °F 15(36) to 42 °F

60 sec 20 to 90 sec M T

38 °F 34 to 42 °F

3 sec 3 to 10 sec N T

70 °F 40 to 120 °F

75 °F 40 to 120 °F

3.0 °F 1.0 to 10.0 °F

None, Valve Setpoint, Valve S t age,

VFD Stage, Valve SP/V FD Stage

65 °F 60 to 120 °F

2.0 °F 1.0 to 10.0 °F

60 °F 0 to 100 °F

90 °F 0 to 100 °F

150 to 200 F M T

N T

N T

N M

N M

N M

N M

N M

N M

N M

N M

Auto A dj usted Ranges

The following settings have different ranges of adjustment based on other settings.

Table 6, Cool LWT

Mode Range

Unit Mode = Cool 40 to 60oF

Unit Mode = Cool w/Glycol, Ice w/ Glycol 20 to 60oF

Table 7, Evaporator Water Freeze

Mode Range

Unit Mode = Cool 34 to 42oF

Unit Mode = Cool w/Glycol, Ice w/ Glycol 15 to 42oF

OM WGS-1 WGS 130A to 190A 29

Table 8, Low Evaporator Pressure Inhibit

Unit Mode = Cool 30 to 45 Psig

Unit Mode = Cool w/Glycol, Ice w/ Glycol 15 to 45 Psig

Table 9, Low Evaporator Pressure Unload

Unit Mode = Cool 28 to 45 Psig

Unit Mode = Cool w/Glycol, Ice w/ Glycol 15 to 45 Psig

Circuit Controller

Circuit Inputs and Outputs

Table 10, Analog Inputs

# Description Signal Source Range

1 Evaporat or Pressure 0.1 to 0.9 VDC

2 Condens er P ressure 0.1 to 0.9 VDC

3 Open

4 Suction Temperature NTC Thermister (10k@25°C) -58 to 212°F

5 Dis charge Temperature NTC Thermister (10k @25° C) -58 to 212°F

6 Open

7 Sl i de Load Indicator 4 to 20 mA

8 Condenser LWT (circuit 1, water c ool ed onl y) NTC Thermister (10k@25°C) -58 to 212°F

Mode Range

Mode Range

0 to 132 psi

3.6to 410 psi

0 to 100%

Table 11, Analog Outputs

# Description Output Signal Range

1 Fan VF D (ai r cooled only) 0 to 10 VDC 0 to 100% (1000 steps resol ution)

2 Open

3 EXV Driver 0 to 10 VDC 0 to 6386 steps (1000 steps res ol ution)

4 Open

Table 12, Digital Inputs

# Description Signal Signal

1 Circuit Switch 0 VAC (Off) 24 VAC (Auto)

2 Open

3 Open

4 VFD Fault 0 VAC (Fault) 24 VAC (No Fault)

5 Oil Differential Pressure Switch 0 VAC (Fault) 24 VAC (No Fault)

6 Mechanical High Pressure Switc h 0 VAC (Fault) 24 VAC (No Faul t )

7 Open

8 Open

9 Oil Level Sensor 0 VAC (Fault) 24 VAC (No Fault)

10-14 Open

The status of digital inputs may be viewed on Circuit Status screen 5, on the circuit

controllers only.

30 WGS 130A to 190A OM WGS

Table 13, Digital Outputs

# Description Output OFF Output ON

1 Fan 1 Contactor (air cooled only) Fan off Fan on

2 Fan 2 Contactor (air cooled only) Fan off Fan on

3 Fan 3 Contactor (air cooled only) Fan off Fan on

4 Fan 4 Contactor (air cooled only) Fan off Fan on

5 Fan 5 Contactor (air cooled only) Fan off Fan on

6 Fan 6 Contactor (air cooled only) Fan off Fan on

7 Load/Unl oad Pulse Hold load slide Move load slide

8 Load/Unload Select Unload Load

9 Compressor SSS Contact Compressor off Compressor on

10 Open

11 Oil Heater Heater off Heater on

12 Interstage Injection (future us e) Injection off Injection on

13 EXV Close Signal

EXV follows

0 –10 VDC

EXV closed, ignores 0 –

10 VDC

Circuit Setpoint Table

The following parameters must be remembered during power off, are factory set to the

Default value, and can be adjusted to any value in the Range column.

The PW (password) column indicates the password that must be active in order to change

the setpoint. Codes are as follows:

O = Operator (100) M = Manager T = Technician

Table 14, Circuit Setpoints

Description Default Range PW

Compressor

Circuit mode enable Disable, enable, test T

Slide control auto Auto, manual T

Slide target 0 0-100 T

Compressor Size 167 167, 179, 197 T

Clear Cycle Timers No No, Yes T

Maximum Slide Target 100.0 0-100.0% T

Motor FLA See Table 15 1 to 321 amps T

Motor RLA See Table 15 1 to 321 amps T

Ground Fault Enable Disable Disable, Enable T

Ground Fault Trip Level 1 0 to 100% T

EXV

EXV control Auto Auto, manual T

Manual EXV position 0 0-6386 T

Service Pumpdown No No,Yes T

Preopen Timer (water cooled only) 20 20 to 120 seconds T

Sensors (NOTE 1)

Evap pressure offset 0 -10.0 to 10.0 psi T

Cond pressure offset 0 -10.0 to 10.0 psi T

Suction temp offset 0 -5.0 to 5.0 deg T

Discharge temp offs et 0 -5.0 to 5.0 deg T

Slide Minimum Posi t i on Offset 0 -15 to 15% T

Slide Maximum Position Offset 0 -15 to 15% T

Continued next page

OM WGS-1 WGS 130A to 190A 31

Description Default Range PW

Fans (available for air-cooled only)

Fan VFD enable On Off, On T

Number of fans 4 4 to 6 T

Saturated Condenser Temp Target Min 90.0 80. 0-110.0

Saturated Condenser Temp Target Max 110.0 90.0-120.0 oF T

Stage 1 On Deadband 8.0 1.0-20.0 oF T

Stage 2 On Deadband 10.0 1.0-20.0 oF T

Stage 3 On Deadband 11.0 1.0-20.0 oF T

Stage 4 On Deadband 12.0 1.0-20.0 oF T

Stage 2 Off Deadband 20.0 1.0-25.0 oF T

Stage 3 Off Deadband 16.0 1.0-25.0 oF T

Stage 4 Off Deadband 11.0 1.0-25.0 oF T

Stage 5 Off Deadband 8.0 1.0-25.0 oF T

VFD Max Speed 100% 90 to 110% T

VFD Min Speed 25% 20 to 60% T

Forced Fantrol 1 2 1 to 4 T

Forced Fantrol 2 3 1 to 4 T

Forced Fantrol 3 4 1 to 4 T

Notes:

1. Offsets are used to fine-tune certain readings generated by sensors. For example, if the controller was

showing a 125 psi value and a calibrated pressure gauge at the same location showed 127 psi, an offset of

+2 psi would be entered and the controller would then read the corrected value of 127 psi.

o

F T

Table 15, RLA/FLA Values

Compressor 575V 460V 380V 230V 208V 400V (50Hz)

197 113 141 178 282 312 141

179 94 122 145 240 267 122

167 85 112 128 210 232 112

All 113 141 178 282 312 141

NOTE: Table values used for circuit controller input.

Alarms, Warnings, Events

Stop Alarms (Shutdown)

Equipment protection alarms trigger a rapid unit or compressor shutdown. The following

tables identify each equipment protection alarm, give the condition that causes the alarm to

occur, and states the action taken because of the alarm. All stop alarms require a manual

reset. These alarms will energize a remote alarm (if the unit is so wired in the field), will

energize a red light behind the left arrow button on the display and will be logged in the

Alarm Log.

Table 16, Unit

Alarm Description Occurs When: Action Taken Reset

No Evaporator

Water Flow

Continued next page

Stop Alarms, Shutdown

Evap Pump State = RUN AND Evap Flow

Digital Input = No Flow for time > Flow Proof

SP, OR Evap Pump State = START AND

Evap Flow Digital Input = No Flow for time >

RLA

FLA

Rapid Stop See Note

Evap Recirc Time SP

32 WGS 130A to 190A OM WGS

Alarm Description Occurs When: Action Taken Reset

Cond Pump State = RUN AND Cond Flow

No Condenser

Water Flow

Evaporator Water

Freeze Protect

Leaving Evaporator

Water Temperature

Sensor Fault

Cond EWT/Outside

Air Temperature

Sensor Fault

pLAN Failure

Digital Input = No Flow for time > Flow Proof

SP, OR Cond Pump State = START AND

Cond Flow Digital Input = No Flow for time >

Cond Recirc Time SP

Evap LWT goes below evap freeze protect

setpoint

Sensor shorted or open Rapid Stop Manual

Sensor shorted or open Rapid Stop Manual

No other controllers found on pLAN for 60

seconds

Rapid Stop See Note

Rapid Stop Manual

Rapid Stop Manual

NOTE: Each day (beginning at 12:00 am), two automatic resets (based on the flow switch closing)

are allowed before a manual reset requirement occurs. When an auto-clear occurs, the unit will go to

the Start state and be waiting for flow. When flow is detected, the unit goes through the normal

starting sequence and the flow loss alarm will clear. Flow loss is only triggered when a compressor is

running.

Condenser flow loss is auto-reset, regardless of the number of occurrences. When a flow loss is

detected, the unit goes back to the “Start” state, waiting for flow

Table 17, Circuit Stop Alarms, Shutdown

Alarm Description Occurs When: Action Taken Reset

Low Evaporator

Pressure

High Lift Pressure Cond Sat Temp > Max Sat Cond Value Rapid Stop Manual

Mechanical High

Pressure

Below Minimum Lift

Pressure

High Discharge

Temperature

Low Oil Level

High Oil Pressure

Difference

Starter Fault

Current Overload

Trip

Current Imbalance

Low Motor Current

High Motor

Temperature

Phase Loss

Phase Reversal

Overvoltage

Undervoltage

Continued next page.

Evaporator Press < 5 psi OR [Freezestat

trip AND Compressor State = Run]

Digital Input 6 = Open Rapid Stop Manual

Cond Press < Min Sat Cond Value for time

> Min Lift Delay SP

Temp > High Discharge Temperature SP Rapid Stop Manual

DI9 = Open for Time greater than Low Oil

Level Delay AND the Low Oil Level Event

has occurred in the past hour

Digital Input 5 = Open for time greater than

High Press Diff Delay SP

Starter Status bit 4 set (fault) and Starter

Fault Code =

12,13,40,47,50,51,52,61,71,94,95,96,97,9

8,99

Starter Status bit 4 set (fault) and Starter

Fault Code = 2, 30, or 31

Starter Status bit 4 set (fault) and Starter

Fault Code = 37

Starter Status bit 4 set (fault) and Starter

Fault Code = 39

Starter Status bit 4 set (fault) and Starter

Fault Code = 60

Starter Status bit 4 set (fault) and Starter

Fault Code = 15 or 27

Starter Status bit 4 set (fault) and Starter

Fault Code = 10

Starter Status bit 4 set (fault) and Starter

Fault Code = 24, 25, or 26

Starter Status bit 4 set (fault) and Starter

Fault Code = 21, 22, 23, or 28

Rapid Stop Manual

Pumpdown Manual

Rapid Stop Manual

Rapid Stop Manual

Rapid Stop Manual

Rapid Stop Manual

Rapid Stop Manual

Rapid Stop Manual

Rapid Stop Manual

Rapid Stop Manual

Rapid Stop Manual

Rapid Stop Manual

Rapid Stop Manual

OM WGS-1 WGS 130A to 190A 33

Alarm Description Occurs When: Action Taken Reset

Ground Fault

Protection

No Starter Transition

Evaporator Pressure

Sensor Fault

Condenser Pressure

Sensor Fault

Liquid Line Pressure

Sensor Fault

Suction Temperature

Sensor Fault

Discharge

Temperature Sensor

Fault

Liquid Line

Temperature Sensor

Fault

Slide Position

Sensor Fault

Starter Status bit 4 set (fault) and Starter

Fault Code = 38

Starter Status bit 4 set (fault) and Starter

Fault Code = 1 or 48

Sensor shorted or open Rapid Stop Manual

Sensor shorted or open Rapid Stop Manual

Sensor shorted or open Pumpdown Manual

Sensor shorted or open Pumpdown Manual

Sensor shorted or open Pumpdown Manual

Sensor shorted or open Pumpdown Manual

Sensor shorted or open Pumpdown Manual

Rapid Stop Manual

Rapid Stop Manual

Events (Limit)

The following events do not cause a rapid shutdown, but limit chiller operation in some way

as described in the Action Taken column. These events do not trigger a remote alarm signal

or the red Alarm LED on the controller. They appear only in the Event Log menu. They

reset automatically when conditions return to a normal range.

If the chiller fails to make the chilled water setpoint, the Event Log should be checked as a

forced limit on loading, or actual compressor unloading may be occurring.

NOTE: In some software versions the terms “inhibit” and “hold” are used interchangeably.

The following unit events are logged in the event log with a time stamp

Table 18, Unit Events (Limits)

Description Occurs When: Action Taken Reset

Entering Evaporator

Temperature Sensor

Fault

Condenser LWT Sensor

Fault

Sensor is open or shorted

Sensor is open or shorted None Automatic

Cannot use

return water

reset

Automatic

Table 19, Circuit Events (Limits)

Event Description Occurs When: Action Taken Reset

Low Evaporator

Pressure – Hold

Low Evaporator

Pressure – Unload

High Lift Pressure Hold

High Lift Pressure Unload

Subcooling Low

Continued on next page.

Pressure < Low Evap Pressure –

Hold SP

Pressure < Low Evap Pressure –

Unload SP

Pressure > High Sat Cond -

Hold Value

Pressure > High Sat Cond -

Unload Value

Subcool < Low Subcool SP for

longer than 5 minutes

Inhibit loading

Unload

Inhibit loading

Unload

None

Evap Press rises

above (SP + 3psi)

Evap Press rises

above (SP + 5psi)

Cond Press drops

below (Hold Value –

Cond Press drops

below (Unload Value

Subcool > setpoint

or Comp state = off

10

– 10

o

F)

o

F)

34 WGS 130A to 190A OM WGS

Event Description Occurs When: Action Taken Reset

Input Open for Time greater than

Oil Level Low

Failed Prepurge

Failed Pumpdown

Condenser Freeze

Protect

Power Loss While

Running

Low Oil Level Delay AND more

than one hour since last

occurrence

Circuit state = prepurge for more

than the Prepurge Time SP

Circuit state = pumpdown for

more than the Pumpdown Time

SP

Cond Sat Refr Temp <

Condenser Freeze SP AND

Cond Pump State = OFF

Note: Water Cooled = Y Only

Circuit controller is powered up

after losing power while

compressor was running

Rapid stop Comp state = off

Open EXV N/A

Stop N/A

Start

condenser

pump

Delay start of

compressor

Cond Sat Refr Temp

> (Condenser

Freeze SP + 2°F)

N/A

Clearing Alarms

Alarms may be cleared at the unit controller if any password level is active. If the user

attempts to clear an alarm while no password is active, then the controller will

automatically go to the ENTER PASSWORD screen. The user can then enter a password

normally, and scroll back to the active alarm column to clear the active alarm(s). The BAS

can clear evaporator flow loss, evaporator water freeze and pLAN failure regardless of

what other alarms are active.

Unit Controller Functions

Calculations

LWT Slope

LWT slope is calculated such that the slope represents the change in LWT over a time

frame of one minute.

Every 12 seconds, the current LWT is subtracted from the value 12 seconds back. This

value is added to a buffer containing values calculated at the last five intervals. The final

result is a slope value that is an average over the past 60 seconds.

Pulldown Rate

The slope value calculated above will be a negative value as the water temperature is

dropping. For use in some control functions, the negative slope is converted to a positive

value by multiplying by –1.

Unit Capacity

Unit capacity is estimated based on the slide target of each running circuit. The capacity of

a running circuit is estimated with this equation:

Circuit capacity = 0.8(slide target) + 20

A circuit that is off is assumed to be at 0% capacity. The unit capacity is then calculated by