Page 1

Operation & Maintenance Data

Group: WSHP

Part Number: 910127707

Date: June 2012

OM 1149

MicroTech® III SmartSource Unit Controller with I/O Expansion Module for

Single and Two Stage Water Source Heat Pump Units, Models GS/GT

I/O Expansion Module

MicroTech III SmartSource Unit Controller

©2012 McQuay International

Page 2

Contents

Introduction ..........................................................................3

Control Boards Terminals and Connectors Descriptions 4

MicroTech III Unit Controller .............................................4

I/O Expansion Module .....................................................5

BACnet Communication Module.......................................5

LonWorks Communication Module .................................5

Replacing a MicroTech III Circuit Board: ........................... 7

Initial Power-Up ...................................................................7

General Use and Information .............................................8

Operating Modes ..............................................................8

Control Inputs (HP, LP, SLTS, COF, U, E, O) .................. 10

Control Outputs {A and IV/PR (H8)}................................10

Unoccupied Operation – Stand Alone Thermostat Control 11

Thermostat Inputs (G, Y1, Y2, W1, and W2) .................. 11

Additional Fault Modes ..................................................... 11

High / Low Pressure Faults (HP/LP) ...............................12

Fan Operation During Most Modes, Faults and

Shutdowns .........................................................................14

Faults and Modes ...........................................................14

Troubleshooting the Water Source Heat Pump Unit ......16

Microtech® III Unit Controller Interface to External

Equipment ..........................................................................17

Appendix A .........................................................................17

Operation and Maintenance of I/O Expansion Module ...17

Introduction .....................................................................17

Initial Power up ..................................................................17

Operation ............................................................................18

Thermostat Inputs ...........................................................18

Electric Heat Controls .......................................................18

Supplemental Electric Heat Control ................................18

Boilerless Heat Control ...................................................18

Compressor Heating Source Selection ...........................19

Fan Speed Control .............................................................19

I/O Expansion Module Faults and Fan Operating Modes

Tables .................................................................................20

Unit Options: ......................................................................21

Waterside Economizer ....................................................21

SmartSource Dehumidication ........................................21

Hot Gas Reheat Smart Dehumidication ........................21

Simplied Dehumidication.............................................22

Humidistat Controlled Dehumidication ..........................22

Dehumidication Only: ....................................................24

MicroTech III Unit Controller with LonWorks®

Communication Module ..................................................25

MicroTech III Controller with an Optional BACnet®

Communication Module ..................................................26

Appendix C – Typical Wiring Diagrams ......................27-35

115V, 1Ph – Model WGS, MicroTech III SmartSource Unit

Controller with BACnet Communication Module

(Hot Gas Reheat) (See page 28 for Service & Disconnect

Wiring) ............................................................................27

265V, 1Ph – Model WGS-WGT, MicroTech III SmartSource

Unit Controller with BACnet Communication Module (Hot

Gas Reheat) (See page 30 for Service & Disconnect

Wiring) ............................................................................29

208-230V, 1Ph – Model WGS-WGT, MicroTech III

SmartSource Unit Controller with BACnet Communication

Module (Waterside Economizer, Desuperheater, 115V Loop

Pumps & 20kW Electric Heat) (See page 32 for Service &

Disconnect Wiring)..........................................................31

208-230V, 3Ph – Model WGS-WGT, MicroTech III

SmartSource Unit Controller with BACnet Communication

Module (Waterside Economizer, 230V Loop Pumps &

5kW Electric Heat) (See page 34 for Service & Disconnect

Wiring) ............................................................................33

460V, 3Ph – Model WGS-WGT, MicroTech III SmartSource

Unit Controller with BACnet Communication Module

(Waterside Economizer, 230V Loop Pumps & 20kW

Electric Heat) (See page 36 for Service & Disconnect

Wiring) ............................................................................35

Controller Comparison ....................................................37

Page 3

Introduction

This installation and operation manual covers the MicroTech® III unit controller for Daikin McQuay G-Series Water

Source Heat Pumps. For information on LonWorks® or

BACnet® communication modules and other ancillary components, see:

■ IM 927 - MicroTech III Water Source Heat Pump

LonWorks Communication Module.

■ IM 928 - MicroTech III Water Source Heat Pump Unit

Controller BACnet MS/TP Communication Module.

■ IM 933 - LonWorks Plug-In Software for use

with MicroTech III Unit Controller - LonWorks

Communication Module.

■ IM 952 - Multiple Unit Control Panel (MUCP) for use

with MicroTech III Unit Controller and Mark IV Unit

Controller.

■ IM 955 - MicroTech III Water Source Heat Pump Wall-

Mounted Room Temperature Sensors.

■ IM 956 - Temperature Sensors for Units with MicroTech

III Unit Controller and LonWorks Communication

Module.

OM 1149 / Page 3 of 40

Page 4

Control Boards Terminals and Connectors Descriptions

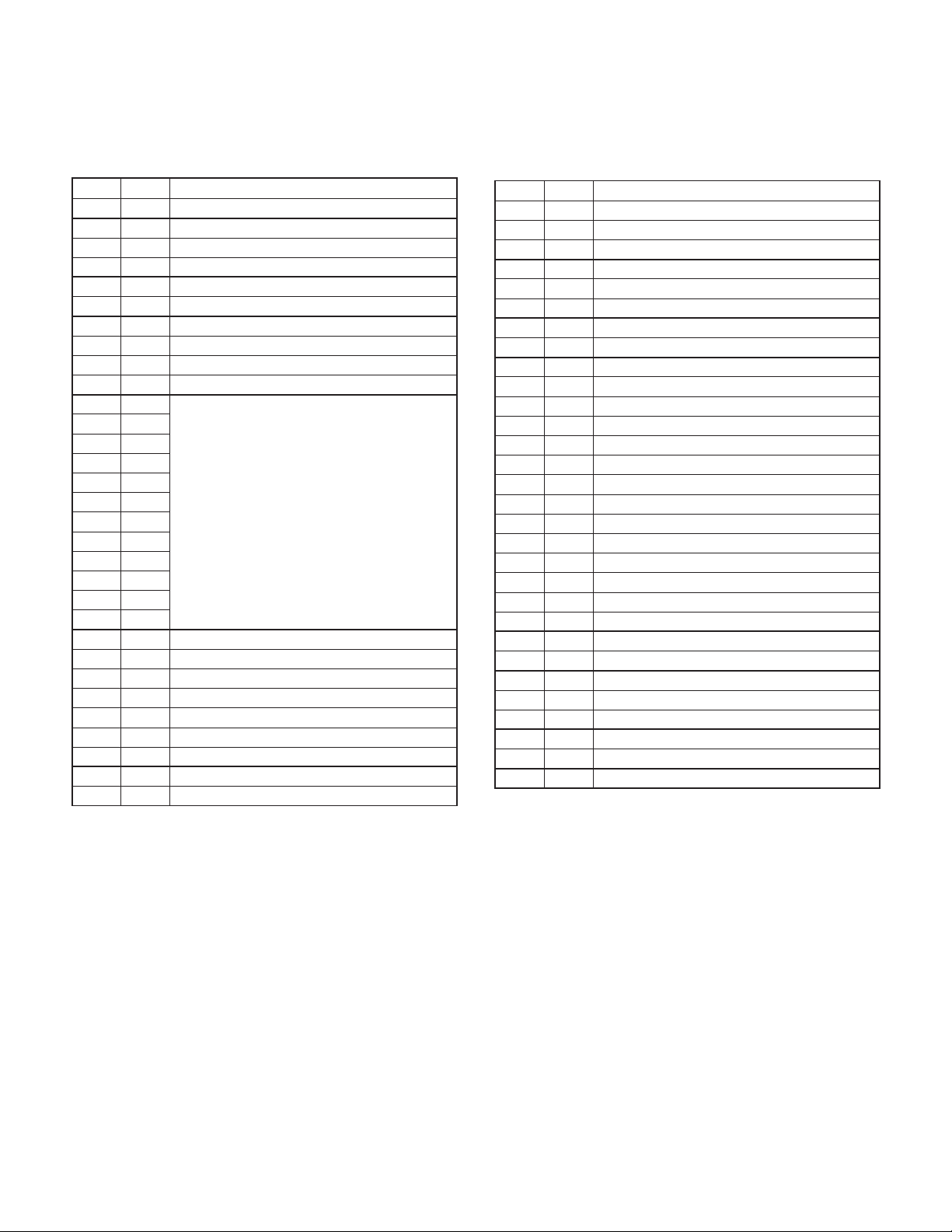

MicroTech III Unit Controller

Table 1: MicroTech III Unit Controller Terminals &

Descriptions

H1 – 1 24 24 VAC Power Input

H1 – 2 C 24 VAC common

H2 – 1 SL1 Fan Main Required Output – Switched L1

H2 – 2 Blank Terminal

H2 – 3 N Fan Main Required Output – Neutral

H3 – 1 HP1-1 Comp High Pressure Switch (HP1) Input Terminal 1

H3 – 2 HP1-2 Comp High Pressure Switch (HP1) Input Terminal 2

H4 – 1 1 Discharge Air Temp Sensor – Common

H4 – 2 Discharge Air Temp Sensor – Signal

H4 – 3 Leaving Water Temp Sensor – Common

H4 – 4 Leaving Water Temp Sensor – Signal

H5 – 1 1

H5 – 2

H5 – 3

H5 – 4

H5 – 5

H5 – 6

H5 – 7

H5 – 8

H5 – 9

H5 – 10

H5 – 11

H5 – 12

H6 – 1 1 Condensate Overow Signal Input

H6 – 2 Compressor Suction Temp Sensor (LT1) – Common

H6 – 3 Compressor Suction Temp Sensor (LT1) – Signal

H6 – 4 Compressor Low Pressure Switch (LP1) – Source Voltage

H6 – 5 Compressor Low Pressure Switch (LP1) – Signal

H6 – 6 Reversing Valve – Common

H6 – 7 Reversing Valve – Output

H7 – 1 1 No Connection

H7 – 2 No Connection

Connections to I/O Expansion Board

H7 – 3 Red LED Output

H7 – 4 Green LED Output

H7 – 5 Yellow LED Output

H7 – 6 Red-Green-Yellow LED Common

H8 – 1 1 Isolation Valve/Pump Request Relay N/O

H8 – 2 Isolation Valve/Pump Request Relay N/C

H8 – 3 24 VAC Common

H9 – 1 1 Room Temp Sensor & Tenant Override – Signal

H9 – 2 Room Temp Sensor & Tenant Override – Common

TB1 – 1 1 Room Sensor – Status LED Output

TB1 – 2 2 Room Sensor – Fan Mode & Unit Mode Switches

TB1 – 3 3 Room Sensor – Setpoint Adjust Potentiometer

TB1 – 4 4 Room Sensor – Room Temp Sensor & Tenant Override

TB1 – 5 5 Room Sensor – DC Signal Common

TB2 – 1 R 24 VAC

TB2 – 2 A Thermostat – Alarm Output

TB2 – 3 W2 Thermostat – Heat Stage #2 (W2) Input

TB2 – 4 W1 Thermostat – Heat Stage #1 (W1) Input

TB2 – 5 Y2 Thermostat – Cool Stage #2 (Y2) Input

TB2 – 6 Y1 Thermostat – Cool Stage #1 (Y1) Input

TB2 – 7 G Thermostat – Fan Input

TB2 – 8 O Thermostat – Heat Stage #3 (W3) Input

TB2 – 9 C 24 VAC Common

TB3 – 1 E Emergency Shutdown Input

TB3 – 2 U Unoccupied Input

L1 – 1 L1 - 1 Line Voltage Terminal 1

L1 – 2 L1 - 2 Line Voltage Terminal 2

L1 – 3 L1 - 3 Line Voltage Terminal 3

N1 N1 Neutral Terminal 1

N2 N2 Neutral Terminal 2

N3 N3 Neutral Terminal 3

Page 4 of 40 / OM 1149

Page 5

I/O Expansion Module

Table 2: I/O Expansion Module Connectors/Terminals

H1 – 1 1

H1 – 2

H1 – 3

H1 – 4

H1 – 5

H1 – 6

H1 – 7

H1 – 8

H1 – 9

H1 – 10

H1 – 11

H1 – 12

H2 – 1 1 Auxiliary Heat Stage #2 Output – N/O

H2 – 2 No Connection

H2 – 3 24 VAC Common

H3 – 1 1 Ext. 24 VAC In

H3 – 2 Ext. 24 VAC Common In

H3 – 3 HGR / Waterside Economizer Output – N/O

H3 – 4 Ext. 24 VAC Common

H3 – 5 ECM Fan Motor Variable Speed Signal Output

H3 – 6 ECM Fan Motor Variable Speed Signal – Common

H4 – 1 1 Entering Water Temp Sensor – Signal

H4 – 2 Entering Water Temp Sensor – Common

H5 – 1 1 No Connection

H5 – 2 No Connection

H5 – 3 Red LED Output

H5 – 4 Green LED Output

H5 – 5 Yellow LED Output

H5 – 6 Red-Green-Yellow LED Common

H6 – 1 HP2-1 Comp High Capacity High Press Sw (HP2) Input Terminal 1

H6 – 2 HP2-2 Comp High Capacity High Press Sw (HP2) Input Terminal 2

H7 – 1 Fan Speed Table Row Select – Signal

H7 – 2 Fan Speed Table Row Select – Common

H7 – 3 Thermostat – Heat Stage #4 (W4) Input – Signal

H7 – 4 Auxiliary 24 VAC Out

H8 – 1 1 Compressor – High Capacity Output – N/O

H8 – 2 24 VAC Common

H8 – 3 No Connection

H8 – 4 Auxiliary Heat Stage #1 Output – N/O

H8 – 5 24 VAC Common

TB1 – 1 1 Humidistat Signal Input

TB1 – 2 2 Thermostat - Heat Stage #4 (W4) Input – Signal

Connections to Main Board

BACnet Communication Module

Table 3: BACnet Communication Module Connectors/

Terminals

P4 – 1 P4 GND

P4 – 2 + 5 VDC

P4 – 3 SPI SELECT (SPI Select To Communications Board)

P4 – 4 SPI CLK (Master Clock)

P4 – 5 SPI RCV (MOSI)

P4 – 6 SPI XMIT (MISO)

P4 – 7 SRDY OUT (SPI Ready To Baseboard)

P4 – 8 No Connection

P3 – 1 P3 Network Signal +

P3 – 2 Network Signal –

P3 – 3 REF

P3 – 4 Shield

LonWorks Communication Module

Table 4: LON Communication Module Connectors/

Terminals

CN_SPI – 1 CN_SPI GND

CN_SPI – 2 + 5 VDC

CN_SPI – 3

CN_SPI – 4 SPI_CLK_0 (Master Clock)

CN_SPI – 5 SPI_RX_0 (MOSI)

CN_SPI – 6 SPI_TX_0 (MISO)

CN_SPI – 7 SREADY_0 (SPI Ready To Baseboard)

CN_SPI – 8 No Connection

TB1 – 1 TB1 Network Signal A

TB1 – 2 Network Signal B

TB1 – 3 REF

SPI_SELECT1_0 (SPI Select To CommunicationsBoard)

OM 1149 / Page 5 of 40

Page 6

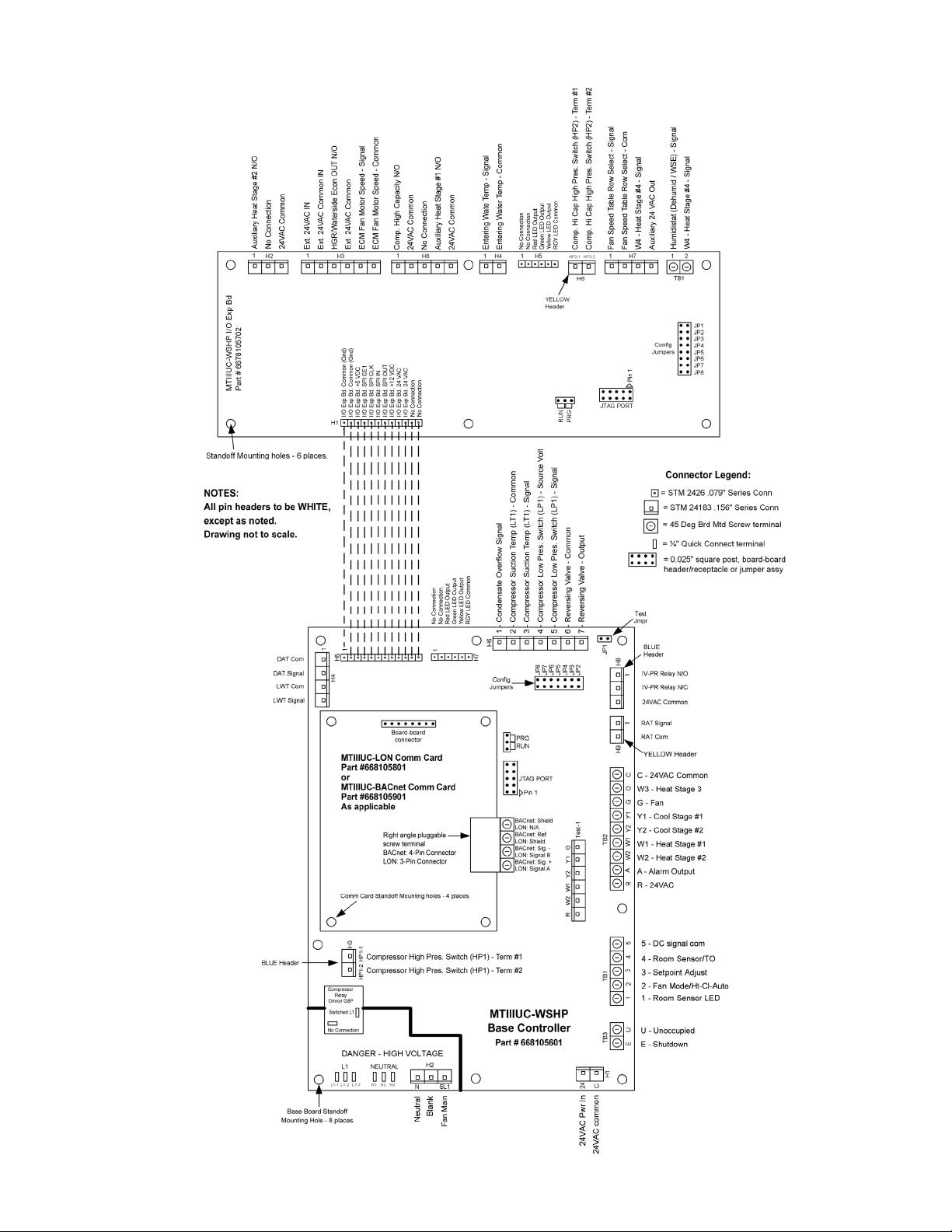

Figure 1: MicroTech III Unit Controller & I/O Expansion Module Connectors Descriptions

Page 6 of 40 / OM 1149

Page 7

CAUTION

Initial Power-Up

The MicroTech III circuit board incorporates static sensitive de-

vices. A static charge from touching the device can damage the

electronic components. To help prevent damage during service,

use static discharge wrist straps.Static discharge wrist straps

are grounded to the heat pump chassis through a 1 Mohm resistor.

Pre start check list:

A random start delay time between 180 and 240 seconds is

generated at power up.

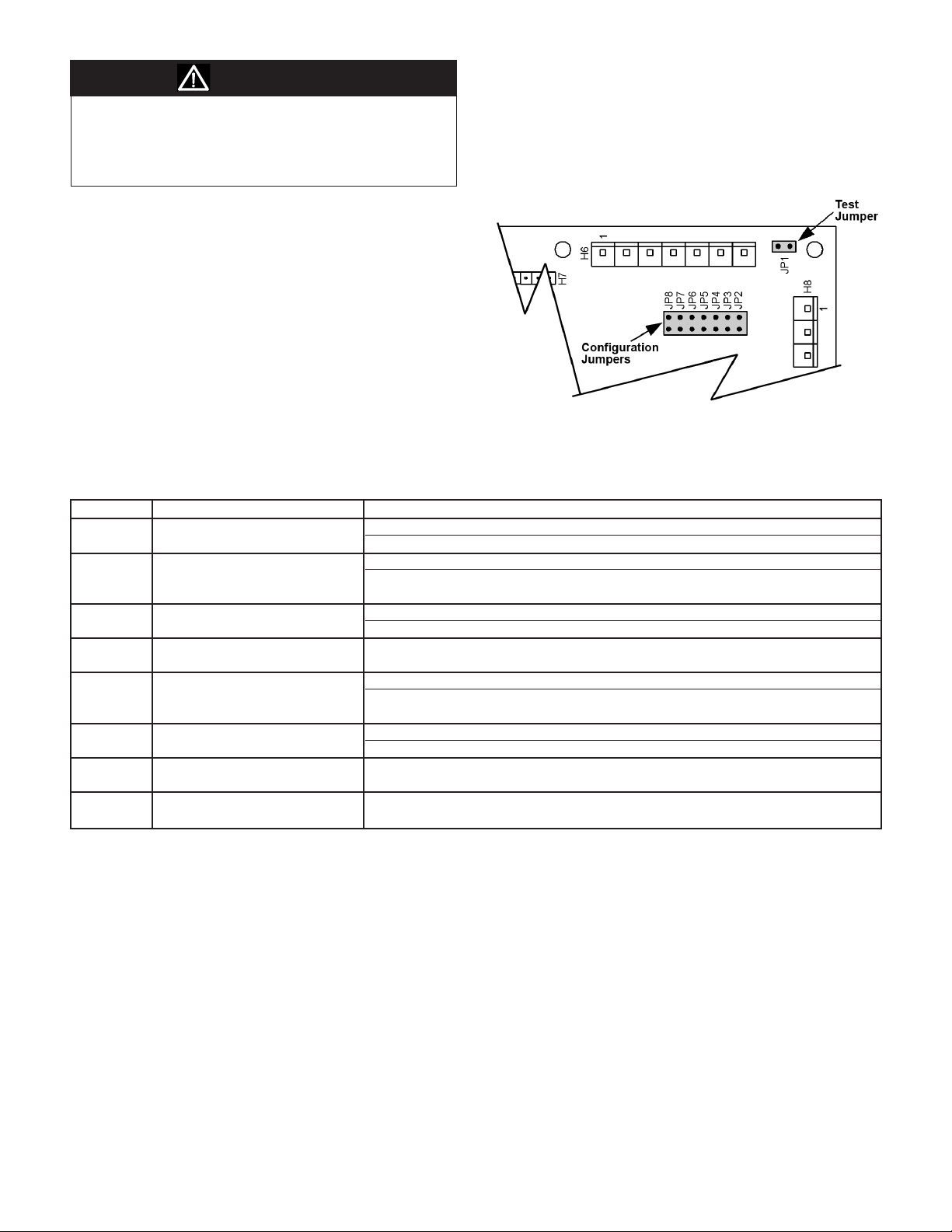

Figure 2: Location of Configuration Jumpers on the Base

Board Controller

Replacing a MicroTech III Circuit Board:

1. Connect wrist strap to unit.

2. Remove faulty board and place on static protected surface.

3. Remove replacement board from static protected bag.

Do not touch circuit board; hold by edges.

4. Holding board in grounded hand, install board in unit.

5. Insert faulty board in empty static bag for return.

Table 5: Configuration Jumper Settings

Jumper Description Options

JP1 Mode

Shorted for service/test operation mode

JP2 Fan operation only applies to Open for continuous fan operation

room sensor control without a Shorted for cycling fan operation

fan mode On/Auto switch

JP3 Freeze protection

Shorted for antifreeze protection

JP4 Freeze fault protection Open for none

Shorted to enable freeze fault protection based on Leaving Water Temperature (LWT)

JP5 Set point adjustment range only Open for adjustment range of -5.0° to +5.0° F

applies to network controls with a Shorted for 55° to 95° F adjustment range

room temperature sensor

JP6 Room control type

Shorted for room temperature sensor control, MicroTech III only

JP7 Compressor heating source Open to enable compressor heating

Shorted to disable compressor heating

JP8 I/O expansion module Open when I/O expansion module is not needed

Shorted when I/O expansion module is required

Open for normal operation mode

Open for water freeze protection

Open for thermostatic room control

OM 1149 / Page 7 of 40

Page 8

General Use and Information

The Microtech III SmartSource unit controller is a water

source heat pump control platform used to control the heat

pump in all modes of operation, including variable speed

fans, two stage compressors, loop pumps, economizers,

reversing valves, and all components used to control conditioned space temperature and humidity. By adding communi-

cations cards, (LonWorks or BACnet) network integration is

possible. The controller can be used with thermostat control

or wall sensor control.

All MicroTech III unit controller inputs must be operated by

dry contacts powered by the control board’s power terminals.

No solid state devices (Triacs) may be used to operate MicroTech III unit controller inputs. No outside power sources may

be used to operate MicroTech III. All units must be properly

grounded per local code requirements. See the Installation

and Maintenance bulletin specic to your Water Source Heat

Pump.

Occupied Operation

The board will be in occupied mode if the unoccupied termi-

nal (U) is not shorted to ground.

Yellow Green Red

Off On Off

Operating Modes

■ Start-up – The unit will not operate until all the inputs

and safety controls are checked for normal conditions.

■ Cooling mode – On an initial call for cooling, the fan

will energize at its “fan only” setting, the pump request

will engergize, the 45 second ow timer will start after

the ow, compressor minimum off, and random startup

timers are expired, the compressor and fan will start at the

stage 1 cooling settings. If room setpoint conditions are

not satised, the fan will operate at the stage 2 cooling

settings. When the room setpoint conditions are satised,

the compressor will shut off and the fan will operate

according to its “fan only” setting when enabled for

continuous fan operation. If fan cycling is enabled, the fan

will turn off once room setpoint conditions are satised.

■ Dehumidication modes – There are four

dehumidication modes of operation;

1. Smart Dehumidication with Hot Gas Reheat

2. Simplied Dehumidication

3. Humidistat Controlled Dehumidication

4. Dehumidication Only

See "SmartSource Dehumidication" on page 21 for details.

▪ Smart Dehumidication – Uses hot gas reheat,

a humidistat, a 2-stage thermostat and air ow

management for precise humidity control. When the

cooling and heating temperature setpoint is satised

and there is a call for dehumidication, maximum

dehumidication is initiated by energizing the

fan at its “fan only” setting, energizing the pump

Board LED Status – Occupied

request, engergizing the 30 second proof-of-ow

timer, energizing the hot gas reheat solenoid valve,

energizing the compressor at maximum cooling, and

energizing the fan at the dehumidication setting.

When the room humidity conditions are satised,

the compressor will shut off and the fan will operate

according to its “fan only” setting when enabled for

continuous fan operation. If fan cycling is enabled, the

fan will turn off, once room humidity conditions are

satised.

▪ Simplied Dehumidication – Uses a 3-stage

thermostat and air ow management to optimize unit

capacity and fan speed for maximum latent capacity

while decreasing room humidity levels. On a call for

cooling, the fan will energize at its “fan only” setting,

the pump request will energize, the 30 second ow

timer will start, after the ow, compressor minimum

off, and random startup timers are expired, the

compressor will start at stage 1 cooling and the fan

will energize at its dehumidication setting. If the

room setpoint temperature is still not satised, the fan

will be energized at the stage 1 cooling settings. If

the room setpoint temperature is still not satised, the

compressor and fan will operate at the stage 2 cooling

settings. When the room temperature conditions are

satised, the compressor will shut off and the fan

will operate according to its “fan only” setting when

enabled for continuous fan operation. If fan cycling

is enabled, the fan will turn off, once room setpoint

conditions are satised.

▪ Humidistat Controlled Dehumidication – Uses

a humidistat and 2-stage thermostat to control room

humidity levels. On a call for dehumidication, the

fan will energize at its “fan only” setting, the pump

request will energize, the 30 second ow timer will

start, after the ow, compressor minimum off, and

random startup timers are expired, the compressor

will start at stage 1 cooling and the fan will energize

at its dehumidication setting. If the room setpoint

temperature is not satised, the fan will be energized

at the stage 1 cooling settings. If the room setpoint

temperature is still not satised, the compressor and

fan will operate at the stage 2 cooling settings. When

the room temperature and humidity conditions are

satised, the compressor will shut off and the fan

will operate according to its “fan only” setting when

enabled for continuous fan operation. If fan cycling

is enabled, the fan will turn off once room setpoint

conditions are satised.

▪ Dehumidication Only – Uses a humidistat in the

cooling only mode. On a call for dehumidication, the

fan will energize at its “fan only” setting, the pump

request will energize, the 30 second ow timer will

start, after the ow, compressor minimum off, and

random startup timers are expired, the compressor

will start at stage 1 cooling and the fan will energize

Page 8 of 40 / OM 1149

Page 9

at its dehumidication setting. Room temperature

conditions are not monitored or maintained. The unit

only responds to a call for dehumidication. When the

room humidity conditions are satised, the compressor

will shut off and the fan will operate according to its

“fan only” setting when enabled for continuous fan

operation. If fan cycling is enabled, the fan will turn

off once room setpoint conditions are satised.

■ Heating mode – On an initial call for heating, the fan will

energize at its "fan only" setting, the pump request

will energize, the 30 second ow timer will start,

after the ow, compressor minimum off, and random

startup timers are expired, the compressor and fan will

start at stage 1 heating settings; the reversing valve

shall energize 5 seconds after the compressor turns

on. If room setpoint conditions are not satised, the

fan will operate at stage 2 heating settings. When the

room setpoint conditions are satised, the compressor

will shut off and the fan will operate according to its

“fan only” setting when enabled for continuous fan

operation. If fan cycling is enabled, the fan will turn

off, once room setpoint conditions are satised.

■ Boilerless Electric Heat mode – When the entering water

temperature is below setpoint, the compressor will not

be allowed to operate. On an initial call for heating,

stage 1 electric heat will be energized and the fan will

start at its electric heat setting. For units equipped with

2 stages of electric heat, if room setpoint conditions

are not satised, the second stage of electric heat

will be energized and the fan will continue to operate

at its electric heat setting. When the room setpoint

conditions are satised, electric heat will be de-

energized and the fan will continue to operate at its

“fan only” setting when enabled, for continuous fan

operation. If fan cycling is enabled, the fan will turn

off after 30 seconds once room setpoint conditions are

satised.

■ Supplemental Electric Heat mode – On an initial call

for heating, the fan will energize at its “fan only”

setting, the pump request will energize, the 30 second

ow timer will start. After the ow, compressor

minimum off, and random startup timers are expired,

the compressor and fan will start at stage 1 heating

settings; the reversing valve shall energize 5 seconds

after the compressor turns on. If room setpoint

conditions are not satised, the fan will operate at

stage 2 heating settings. If room setpoint conditions

are still not satised, the compressor will continue

to operate and stage 1 electric heat will be energized

and the fan will operate at its electric heat setting. For

units equipped with 2 stages of electric heat, if room

setpoint conditions are still not satised, the second

stage of electric heat will be energized and the fan will

continue to operate at its electric heat setting. When

the room setpoint conditions are satised, electric

heat will be de-energized allowing the compressor

to remain on if necessary to maintain room setpoint

conditions. The fan will operate according to its

“fan only” setting when enabled, for continuous fan

operation. If fan cycling is enabled, the fan will turn

off once room setpoint conditions are satised.

■ Primary Electric Heat mode – On an initial call for

heating, stage 1 electric heat will be energized and

the fan will start at its electric heat setting. For units

equipped with 2 stages of electric heat, if room

setpoint conditions are not satised, the second stage

of electric heat will be energized and the fan will

continue to operate at its electric heat setting. When

the room setpoint conditions are satised, electric

heat will be de-energized and the fan will continue

to operate at its “fan only” setting when enabled, for

continuous fan operation. If fan cycling is enabled, the

fan will turn off after 30 seconds once room setpoint

conditions are satised.

■ Emergency Electric Heat mode – A 24v control signal

from the thermostat will initiate a call for stage 1 or stage

2 electric heat. The compressor will not operate and the

fan will start at its electric heat setting.

■ Occupied Mode – The MicroTech III SmartSource unit

controller will manage occupied and unoccupied modes

of operation. The occupancy mode can be established by

a BACnet or LonWorks communication signal, from a

room sensor equipped with “Occupied/Unoccupied” mode

functions, or a thermostat equipped with an “Occupied/

Unoccupied” mode switch. When in the occupied

mode, the unit will be controlled to its occupied setpoint

conditions. The occupancy state will be displayed on

sensors equipped with “Occupied/Unoccupied” mode

functions and annunciation capabilities.

■ Unoccupied Mode – When operating in the unoccupied

mode, the unit will be controlled to its unoccupied setpoint

conditions and the fan will cycle according to a call for

cooling, dehumidication or heating. A simple “grounded”

signal between terminals U and C on the MicroTech

III SmartSource unit controller will place the unit into

the unoccupied mode for night setback operation. The

occupancy state will be displayed on sensors equipped

with “Occupied/Unoccupied” mode functions and

annunciation capabilities.

■ Override Mode – A momentary (4 to 9 seconds) press of

the “Override” button on the thermostat or room sensor

during the unoccupied mode will cause the unit to operate

in the occupied mode for two hours, for after-hours

heating, cooling or dehumidication. “OVERRIDE” will

be displayed on sensors equipped with override button and

annunciation capabilities.

OM 1149 / Page 9 of 40

Page 10

■ “Energy Save” Bypass Mode – BACnet or LonWorks

units can receive a signal from the Building Automation

System (BAS) to initiate the energy savings mode. This

mode is typically initiated by the BAS with smart grid

technologies to save energy. The savings is driven by

reducing peak electrical demand for the building. Once

initiated, the MicroTech III SmartSource unit controller

will reset its effective setpoint to minimize the stage

of compressor operation. “E-SAVE” will be displayed

on sensors equipped with bypass mode annunciation

capabilities.

■ Motorized Water Valve or Pump Start – When there

is a call for cooling, dehumidication or heating, the

MicroTech III SmartSource unit controller will energize

its IV/PR (H8) terminal to open the motorized water

valve or start the loop pump 30 seconds prior to starting

the compressor. The IV/ PR (H8) terminal may be “daisy

chained” between 200 units.

Control Inputs (HP, LP, SLTS, COF, U, E, O)

The control inputs are High Pressure (HP), Low Pressure

(LP), Suction Line Temperature Sensor (SLTS), Condensate

Overow (COF), Unoccupied (U), and Remote Shutdown

(E). The control inputs are in normal states during occupied

mode. The state of each control in occupied mode during

normal operation is as follows:

■ High Pressure (HP): Normally closed switch that opens

on a high refrigerant pressure condition. Control will

generate a high pressure fault and disables the compressor

output when the switch is open.

■ Low Pressure (LP): Normally closed switch that opens on

a low refrigerant pressure condition. Control will generate

a low pressure fault when the switch is open. Suction Line

Temperature Sensor (SLTS): temperature sensor on the

suction line.

■ Condensate Overow (COF): senses condensate level

in condensate pan. Control will generate a fault when

condensate level is too high.

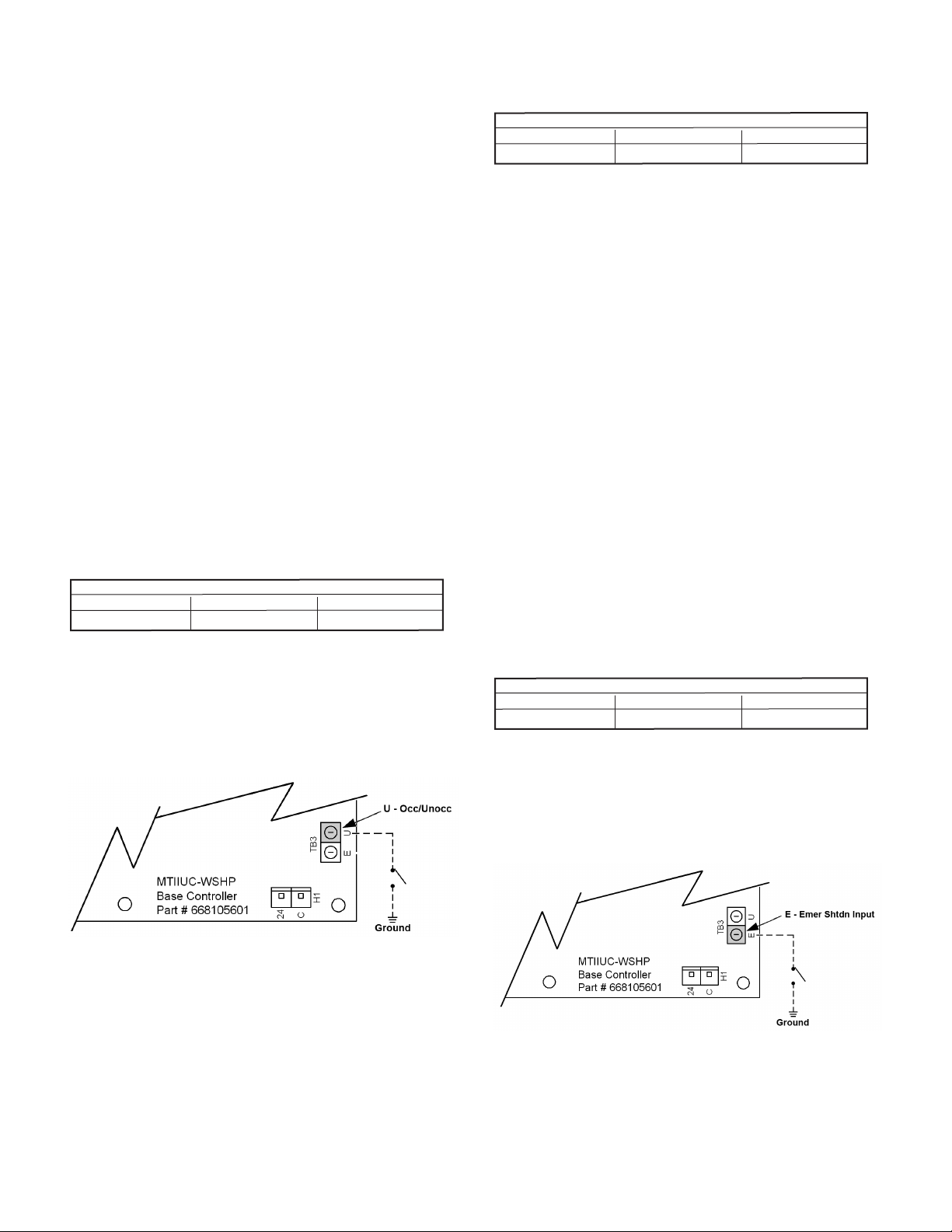

■ Unoccupied (U): Grounding this terminal puts the control

into unoccupied mode.

■ Remote Shutdown (E): Grounding this terminal forces the

control to shutdown the unit.

Control Outputs {A and IV/PR (H8)}

The control outputs are Alarm Fault (A) and Isolation Valve

/ Pump Request {IV/PR (H8)}. The operation of the control

outputs during occupied mode is as follows:

■ The thermostat alarm output will be energized when there

are fault conditions presently active. Without any fault

conditions active, the alarm output shall be de-energized.

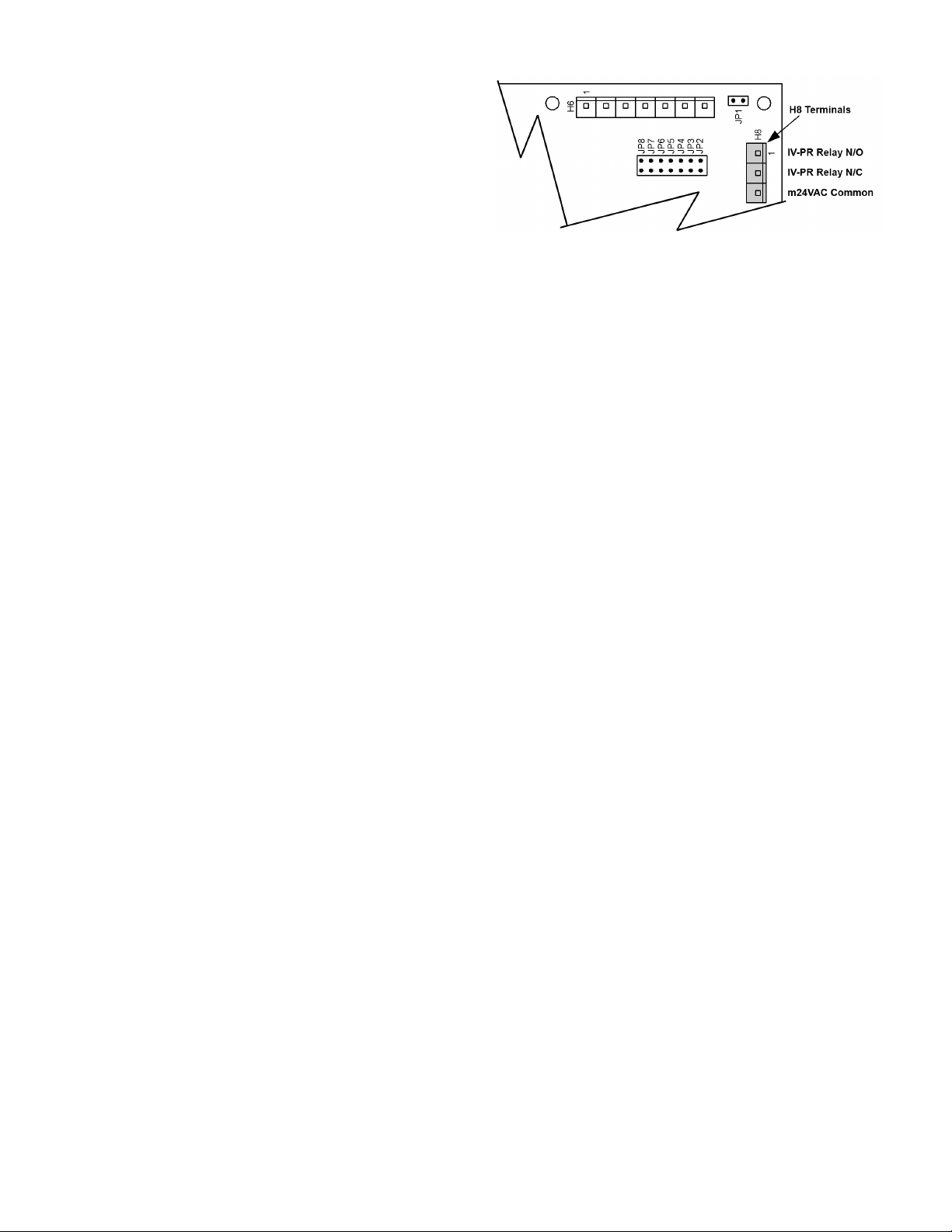

■ Isolation Valve / Pump Request {IV/PR (H8)}: is

selectable to be energized when the compressor is

off (normally closed), or when the compressor is

on (normally open), by moving the wire lead to the

appropriate terminal.

Figure 3: H8 Terminals on MicroTech III Board

■ Reversing Valve: 24V signal that is energized upon a call

for heat mode.

■ Compressor Relay: Line or low voltage output used to

control compressor. (On/Off)

Fan Operation

The G terminal controls continuous fan operation. The fan

runs continuously when the G terminal is energized. When the

G terminal is de-energized, the fan cycles with the compressor.

Cooling Mode

The Y1 terminal controls the Cooling Mode of operation.

When the Y1 terminal is energized (24VAC), the following

occurs:

1. The fan energizes.

2. The IV/PR (H8) control output de-energizes or energizes

depending on the H8 terminal wiring (refer to Table 1 on

page 4 & Figure 1 on page 6).

3. The compressor energizes after 30 seconds.

4. The reversing valve de-energizes 5 seconds after the

compressor turns on.

When the Y1 terminal is de-energized, the following occurs:

1. The compressor de-energizes.

2. The IV/PR (H8) control output energizes or de-energizes

depending on the H8 terminal wiring (refer to Table 1 on

page 4 & Figure 1 on page 6).

3. The fan de-energizes, unless the G terminal is energized

(24VAC).

Note: To prevent compressor cycling and all compressors

from starting up together after loss of power, the

required minimum on/off time default is 180 seconds.

This may cause the compressor time delay to be

longer than indicated above.

Page 10 of 40 / OM 1149

Page 11

Heating Mode

The W1 terminal controls the occupied Heating Mode of

operation. When the W1 terminal is energized, the following

occurs:

1. The fan energizes.

2. The IV/PR (H8) control output de-energizes or energizes

depending on the H8 terminal wiring (refer to Table 1 on

page 4 & Figure 1 on page 6).

3. The compressor energizes after 30 seconds.

4. The reversing valve energizes 5 seconds after the

compressor turns on.

When the W1 terminal is de-energized, the following occurs:

1. The compressor de-energizes.

2. The IV/PR (H8) control output energizes or de-energizes

depending on H8 terminal wiring (refer to Table 1 on page

4 & Figure 1 on page 6).

3. The fan de-energizes, unless the G terminal is energized.

Note: To prevent compressor cycling, the required minimum

on/off time default is 180 seconds. This may cause

the compressor time delay to be longer than indicated

above.

Unoccupied Operation – Stand Alone Thermostat Control

The board will be in unoccupied mode if the unoccupied

terminal (U) is grounded.

Yellow Green Red

On On Off

Board LED Status – Unoccupied

Thermostat Inputs (G, Y1, Y2, W1, and W2)

The only thermostat inputs used during unoccupied operation

are Y2 and W2, which when energized will activate Cooling

Mode or Heating Mode respectively. Inputs G, Y1 and W1

have no effect during unoccupied mode.

Figure 4: Terminal "U" - Grounded for Unoccupied

Additional Fault Modes

Brownout

Yellow Green Red

Off Flash Off

Brownout condition is provided to protect the water source

heat pump’s motor electrical damage due to low voltage

conditions.

The MicroTech III unit controller is designed to monitor the

24VAC power supply to the board. If the line voltage supplied to the water source heat pump drops, the 24VAC supply

to the control board will also drop. When the line voltage

supplied to the unit drops below approximately 80% of the

unit nameplate rated value, the controller goes into brownout

condition. The controller remains in brownout condition until

line voltage returns to approximately 90% of the unit nameplate value.

When in brownout condition, thermostat and control inputs

have no affect upon unit operation. Remote shutdown and

brownout conditions have the same level of priority. See "Pri-

ority Level of Faults and Modes" on page 14.

When the unit is in brownout condition the following occurs:

1. The compressor de-energizes.

2. The fan de-energizes.

3. Fault terminal (A) energizes (fault). A to R will be used to

indicate an alarm signal.

When the line voltage supplied to the unit returns to accept-

able levels (~90% of nameplate) the controller returns to the

current mode.

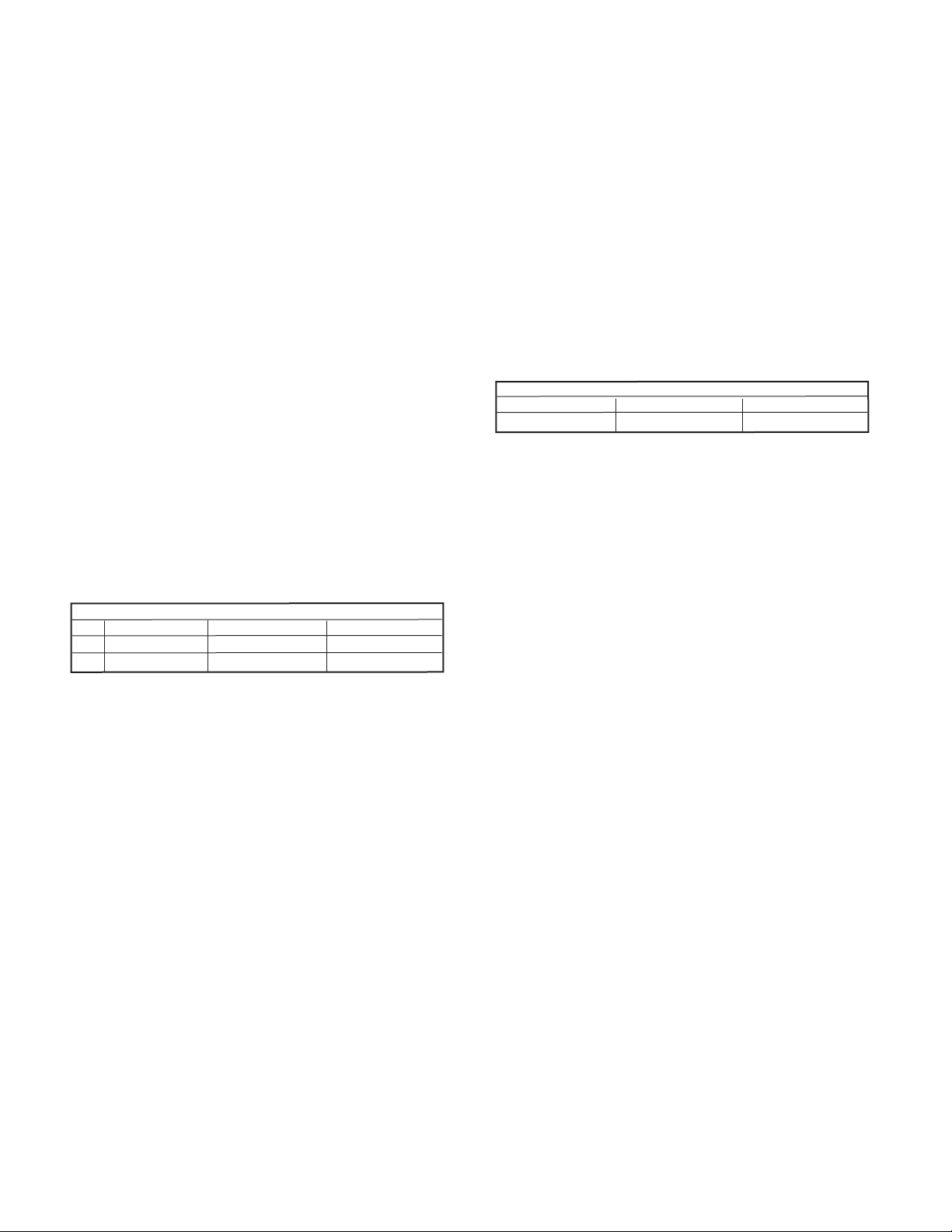

Remote Shutdown

Yellow Green Red

Off Flash Off

When the E terminal is grounded, the MicroTech III unit

controller enters remote shutdown mode. Remote shutdown

is provided so that when properly connected to a building

automation system, remote switch, etc., the E terminal can be

used to shut down the water source heat pump.

Figure 5: Terminal "E" - Grounded for Remote Shutdown

Board LED Status – Brownout

Board LED Status – Remote Shutdown

OM 1149 / Page 11 of 40

Page 12

When in remote shutdown (E terminal grounded), thermostat

and control inputs have no affect upon unit operation. No faults

or modes have higher priority than remote shutdown. Remote

shutdown and brownout condition have the same level of

priority. See "Priority Level of Faults and Modes" on page 14.

When the unit is in remote shutdown mode, the following

occurs:

1. The compressor de-energizes (if enabled).

2. The fan de-energizes (if enabled).

3. Fault terminal (A) will remain de-energizes because

emergency shutdown is a "mode". A to C will be used to

indicate normal operation.

When the E terminal is no longer grounded the unit will automatically return to normal operation.

Note: The remote shutdown input (E) will suspend unit

operation. Disconnect power when servicing the unit/

controller.

High / Low Pressure Faults (HP/LP)

Normally closed high and low refrigerant pressure switches

help protect the water source heat pump from excessively

high or low refrigerant pressures. The MicroTech III unit controller monitors these switches individually. If the compressor

is running and the HP circuit is open, the controller enters

a pressure fault mode. If the LP circuit is open after a time

delay (default of 30 seconds, adjustable if a communication

module is present) the controller enters a low pressure fault

mode.

Yellow Green Red

HP Off Off Flash

LP Off Off Solid

See "Priority Level of Faults and Modes" on page 14..

When the unit is in high or low pressure fault modes the following occurs:

1. The compressor de-energizes.

2. The IV/PR(H8) output will change state. (On to Off / Off

to On).

3. The fan de-energizes.

4. The fault terminal (A) energizes (fault). A to R will be

used to indicate an alarm signal.

High Pressure Reset

After the HP circuit is closed, the unit does not return to

normal operation until the alarm is manually reset. The unit is

locked out in this manner until the unit can be serviced.

The alarm is reset by a short interruption of unit power, by

holding down the tenant override button for more than 10

seconds, or via the Building Automation System (BAS).

Low Pressure Reset

The low pressure switch fault is subject to intelligent reset.

If the pressure recovers, it resets two times within a 24-hour

time period. If further faults are detected within the 24 hours,

the controller must be manually reset as described in the High

Pressure Reset section above.

Board LED Status – High/Low Pressure Faults

Low Suction Temperature Fault Heating

1. The control will attempt to recover from a low suction

temperature condition by defrosting water heat exchanger

(coaxial coil).

2. See the Defrost Process below for details.

Low Suction Temperature Fault Cooling

1. When the suction line temperature falls below 28° F

disable the compressor output only.

2. The fan will continue to run drawing warmer air over the

air heat exchanger.

3. When the suction line temperature increases by Low Temp

Protect Diff (the default is 8° F) degrees.

4. The compressor is available for cooling if the Compressor

Minimum Off timer has expired.

5. Mark the occurrence of the fault.

Yellow Green Red

Flash Off Off

Board LED Status – Low Suction Line Temperature Fault

Defrost Sequence of Operation:

1. Immediately turn off the compressor if operating in the

cooling or dehumidication modes.

2. The fan will remain on at the existing fan speed if the unit

is cooling, dehumidifying or congured for electric heat

3. The reversing valve output is de-activated, placing the

reversing valve in the cooling mode and moving warm

refrigerant to the coax coil.

4. Fan speed is not changed, however “Heat Stage #1” speed

is used if the fan is presently off.

5. If the compressor was on at the beginning of the defrost

process, then start the 60 second xed defrost timer.

6. Wait for the defrost timer to expire.

7. If the alarm condition has cleared:

· Return to normal operation.

8. If the alarm condition remains active:

• Compressor High Capacity is turned off

• Compressor is immediately turned off, ignoring the

Compressor Minimum ON timer

• Compressor is disabled for heating and cooling

• Electric heating can be used if it is available

• Fan and pump remain available for operation

Heating Mode

When the suction line temperature falls below 28°F on standard equipment (6.5°F on Geothermal) the low temperature

fault generates the following:

■ The reversing valve de-energizes. The compressor and fan

continue to operate in cooling mode for 60 seconds, which

results in a defrost mode. This defrosts any ice that may

have accumulated in the water-to-refrigerant coil, because

of a lack of condenser water ow in heat mode.

■ In heat mode the low temperature fault is subject to

Intelligent Reset.

Page 12 of 40 / OM 1149

Page 13

■ The fault terminal (A) energizes while the unit is in defrost

mode. It will stay energized until the temperature recovers

to 36°F for standard equipment (14.5°F for geothermal). A

to R will be used to indicate an alarm signal. The previous

operation of heating or cooling determines how the low

suction temp alarm must be reset.

■ The fan and pump remain available for operation.

Cooling Mode

When the suction line temperature falls below 28°F standard

equipment (28°F geothermal) in cool mode the:

■ Compressor de-energizes.

■ The fan and pump remain available for operation.

■ Alarm output energizes.

■ When the suction line temperature recovers to 36°F

standard equipment (14.5°F on geothermal) the low

temperature fault continues and the compressor will be

locked out.

Fan Only Mode

When the suction line temperature falls below 28°F standard

equipment (28°F geothermal) in cool mode the:

■ The fan and pump remain available for operation.

■ Alarm output energizes.

The previous operation of heating or cooling determines how

the low suction temp alarm must be reset.

Condensate Overow

Yellow Green Red

On Off Off

Board LED Status – Condensate Overow

The MicroTech III unit controller's condensate sensor is

designed to detect excessively high condensate water levels in

the drain pan. When high condensate water levels are detect-

ed during cooling or dehumidication modes, the controller

enters into condensate fault mode. The fan operates normally

during the condensate overow fault mode.

Some faults and modes have higher priority than condensate

overow mode. See "Priority Level of Faults and Modes" on

page 14.

When the unit senses a condensate overow fault while in

cooling mode the following occurs:

1. The compressor de-energizes.

2. The fault terminal (A) energizes (fault). A to R will be

used to indicate an alarm signal.

When condensate levels return to normal, the controller will

automatically return to normal operation.

Remote Reset of Automatic Lockouts

The Remote Reset feature provides the means to remotely

reset some lockouts generated by high-pressure and/or lowtemperature faults. When the MicroTech III unit controller

is locked out due to one of these faults, and the cause of the

fault condition has been cleared, energizing the O-terminal

for 11 seconds or more forces the MicroTech III unit controller to clear the lockout. Cycling unit power also clears a lockout if the conditions causing the fault have been alleviated.

Intelligent Reset (See Table 6)

The Intelligent Reset feature helps to minimize nuisance trips

of automatic lockouts caused by low pressure or low-tem-

perature faults. This feature clears faults the rst two times

they occur within a 24-hour period and triggers an automatic

lockout on the 3rd fault. The retry count is reset to zero every

24 hours.

Table 6: Fault Recovery and Reset

Button Reset

IO Expansion Communication Fail Yes No No

Invalid Jumper Conguration No No No

Low Voltage Brownout Yes No Yes

All Sensor Failures No No Yes

Compressor High Pressure No Yes Yes

Compressor Low Pressure Yes

Compressor Low Suction Temp or Freeze Fault Detect

(In Heating Mode)

Compressor Low Suction Temp or Freeze Fault Detect

(In Cooling or Dehumidication Modes)

Condensate Overow Yes No Yes

Low Entering Water Temp. Yes No No

EEPROM Corrupted No No No

Waterside Economizer Low Temp. Cutout Yes No No

Note: 1 Indicates auto recover is subject to intelligent alarm reset. Alarm auto recovers on rst two occurrences, locked out on third

within 24 hour period. See “Intelligent Alarm Resetting” section on the previous page for further details.

Fault Description

Yes1 Yes Yes

Auto Recovery

1

No Yes Yes

Tenant Override

Yes Yes

Network Reset

OM 1149 / Page 13 of 40

Page 14

Tenant Override

Note: It is recommended that the "All MicroTech III unit

controller inputs must be operated by dry contacts

powered by the control board’s power terminals. No

solid state devices (Triacs) may be used to operate

MicroTech III unit controller inputs. No outside power

sources may be used to operate MicroTech III. All

units must be properly grounded per local code

requirements. See the Installation and Maintenance

bulletin specic to your Water Source Heat

Pump." and "Unoccupied Operation – Stand Alone

Thermostat Control" sections be reviewed prior to this

section.

The MicroTech III unit controller enters tenant override mode

when the Tenant Override (TO) terminal is grounded for 4-10

seconds during a period when the Water Source Heat Pump is

in unoccupied mode.

Tenant override allows a tenant, returning to the controlled

space after the unit has been placed in unoccupied mode, to

activate the tenant override input and place the unit into occupied mode.

Any remote button or switch with momentary dry contacts

can be used for this purpose. During the 2-hour tenant override period all the thermostat inputs will be used, (see "Oc-

cupied Operation" on page 8) for unit operation. If the U

terminal is still grounded after the 2-hour time limit, the unit

will return to unoccupied mode. Refer to "Unoccupied Opera-

tion – Stand Alone Thermostat Control" on page 11.

Fan Operation During Most Modes, Faults and Shutdowns

The MicroTech III unit controller allows fan operation during

most modes, faults and shutdowns to facilitate maximum

space comfort and control. However, the fan does not operate

during brownout or emergency shutdown condition. During

most modes, faults, or shutdowns the fan will operate

normally:

may be damaged.

Table 7: Room Sensor Status LED

LED On

Time (Sec)

0.5 0.5

0.0 Continually Tenant Override is Active

0.5 5.5 Unoccupied Mode

5.5 0.5 Standby Mode

Continually 0.0 Occupied or Bypass Modes

LED Off

Time (Sec)

Operating Mode

Alarm Condition or Network “Wink”

Operation Active

Faults and Modes

Table 8: Priority Level of Faults and Modes

Priority Level Mode or Fault

1 I/O Expansion Communication Fail

2 Invalid Conguration

3 Low Voltage Brownout

4 Emergency Shutdown Mode

5 Compressor High Pressure

6 Compressor Low Pressure

7 Compressor Suction Temp Sensor Fail

8 Compressor Low Suction Temp

9 Freeze Fault

10 Room Temp Sensor Fail

11 Entering Water Temp Sensor Fail

12 Leaving Water Temp Sensor Fail

13 Condensate Overow

14 Low Entering Water Temp

15 Serial EEPROM Corrupted

16 Waterside Economizer Low Temp Cutout

17 Service Test Mode

Operation with the High Speed Jumper

■ The MicroTech III unit controller includes a high-speed

jumper terminal labeled JP1 to speed system check out

and trouble-shooting. See Figure 2 on page 7 for JP1

location.

Note: This jumper is intended for factory unit testing and

should only be used by trained service technicians as

several timing functions are reduced to speed system

check out.

■ Disconnect power to the unit when installing or removing

the high-speed jumper.

■ The high speed jumper should only be used for a short

period of time for testing of the unit’s operation by a

trained service technician. The jumper must be removed

for normal unit operation.

■ If the jumper is left on after system check out, the unit

Page 14 of 40 / OM 1149

Page 15

Table 9: MicroTech III Unit Controller Status LED's

Description Type Yellow Green Red

IO Expansion Communication Fail Fault ON Flash Flash

Invalid Jumper Conguration Fault Flash Flash OFF

Low Voltage Brownout Fault OFF Flash OFF

Emergency Shutdown Mode OFF Flash OFF

Compressor High Pressure Fault OFF OFF Flash

Compressor Low Pressure Fault OFF OFF ON

Compressor Suction Temp Sensor Fail Fault Flash Flash ON

Compressor Low Suction Temp Fault Flash OFF OFF

Freeze Fault Detect Fault Flash OFF Flash

Room Temp Sensor Fail (Room Sensor Control Only) Fault Flash Flash ON

Leaving Water Temp Sensor Fail Fault Flash Flash ON

Condensate Overow Fault ON OFF OFF

Serial EEPROM Corrupted Fault ON ON ON

Waterside Economizer Low Temp Cutout

(WSE Control & Call for Cooling)

Service Test Mode Enabled Mode Flash Flash Flash

Unoccupied Mode Mode ON ON OFF

Occupied, Bypass, Standby, or Tenant Override Modes Mode OFF ON OFF

Mode Flash ON Flash

OM 1149 / Page 15 of 40

Page 16

Troubleshooting the Water Source Heat Pump Unit

Figure 6: Troubleshooting Guide - Unit Operation

Low voltage, check

power supply voltage

Check wiring - loose or

broken and check for faulty

connection

Check relays and contacts,

also capacitor and wiring

Check high pressure switch,

low pressure switch and low

temperature switch to see if

unit is cycling on the safety

Check to see if the reversing

valve is not hung up and is

operating correctly

Check condensate overflow

switch in cool mode of

operation

Check thermostat for

proper location

Fuse may be blown,

circuit breaker is open

Neither fan, nor compressor

runs and all LED lights

are off

Compressor runs

in short cycle

Wire may be loose or broken.

Replace or tighten wires

Fan operates,

Unit

compressor does not

Unit control, check thermostat

for correct wiring or faulty

thermostat

Check capacitor

Check wiring - loose or broken

and check for bad connection

High or Low pressure lockout

A. Cool mode, check water flow

B. Heating mode, check air flow

C. Check reversing valve for

proper valve position

Check compressor overload -

make sure it is closed

Check compressor to ground, or

for internal short to ground

Compressor winding may be

open. Check continuity with

ohm meter

Compressor attempts to

start but does not

Check compressor wiring

for defective wiring or loose

connection

Check for defective

compressor internal windings

with ohm meter

Check for faulty compressor

capacitor

Check for lock rotor amp

draw

Insufficient cooling or

heating

Check thermostat for

improper location

Check for proper air flow filter could be dirty

Check blower assembly for

dirt or faulty fan motor

capacity

Check for low refrigerant

charge

Check amp draw on blower

assembly

Check for proper water flow

and delta T (°F)

Page 16 of 40 / OM 1149

Page 17

Microtech® III Unit Controller Interface to External Equipment

■ The MicroTech III unit controller’s thermostat input

terminals may be directly interfaced with any standard

or night setback thermostat that uses mechanical dry

contacts. Power cannot be supplied from the water

source heat pump for electronic thermostats that require a

separate power supply for their internal operation except

those provided by Daikin McQuay. Only thermostats

offered by Daikin McQuay are proven to operate properly

with the MicroTech III unit controller. Daikin McQuay

makes no guarantees about any other thermostat or control

device interfaced by the end user with the MicroTech III

unit controller.

■ Care must be used to isolate all external power sources

from the MicroTech III unit controller to prevent ground

loops and other unpredictable electrical problems. Only

dry mechanical contacts should be used to operate

or interface with the MicroTech III unit controller’s

thermostat and or control inputs. Use mechanical relays

to isolate two power systems when external equipment

with its own power supply is used to interface with or

control the MicroTech III unit controller’s thermostat and

or control inputs. For example, if you have a Building

Automation System (BAS), controller, etc., and you

wish to use a digital output from the building automation

system or controller that is internally powered, then you

must use an additional mechanical relay (not supplied

by Daikin McQuay) to isolate the MicroTech III unit

controller.

■ Due to the nature of triacs and other solid state devices,

triacs cannot be directly used to operate the MicroTech

III’s unit controller’s thermostat or control inputs. To

interface triacs or other solid state switching devices to the

MicroTech III unit controller inputs, separate them from

the board using mechanical relays. To do this, use the

triac or solid state device to drive a mechanical relay (not

supplied by Daikin McQuay), then use the mechanical

relay’s dry contacts to drive the desired MicroTech III unit

controller input.

■ The MicroTech III unit controller’s valve or pump request

terminal {IV/PR (H8)} is an output signal to external

devices to allow water ow as required by the heat pump.

The IV/PR (H8) terminal follows compressor operation

inversely if connected to the normally open terminal and

simultaneously when connected to the normally closed

terminal. The IV/PR (H8) terminal can be used as a signal

to an external pump or valve to enable ow to the unit.

The compressor start is delayed for 30 seconds after the

IV/PR (H8) output is energized.

Table 10: IV/PR(H8) Terminal and Compressor Operation

IV/PR(H8) Compressor On Compressor Off

Normally Open 24 VAC 0 VAC

Normally Closed 0 VAC 24 VAC

Appendix A

Operation and Maintenance of I/O Expansion Module

Introduction

The I/O Communication Module is an expansion of the main

board and provides extra functionality to the MicroTech III

control system.

■ The MicroTech III unit controller in combination with the

I/O Expansion Module will be the standard control system

for SmartSource Water Source Heat Pumps.

Adding an I/O Expansion Module (with an interconnect

cable) to the main controller allows:

■ Compressor High Capacity On/Off Control

■ Variable Speed Fan Control

■ Water Side Economizer Control

■ Active Hot Gas/Reheat (HGR), or Low Capacity

Dehumidication Options

■ Boilerless & Supplemental Auxiliary Heating Options

■ The fourth thermostat Heating Stage (W4) Input

The I/O Expansion Module has an independent LED annun-

ciator to identify operational fault conditions.

Initial Power up

Figure 7: I/O Expansion Board Configuration Jumper

Terminals

OM 1149 / Page 17 of 40

Page 18

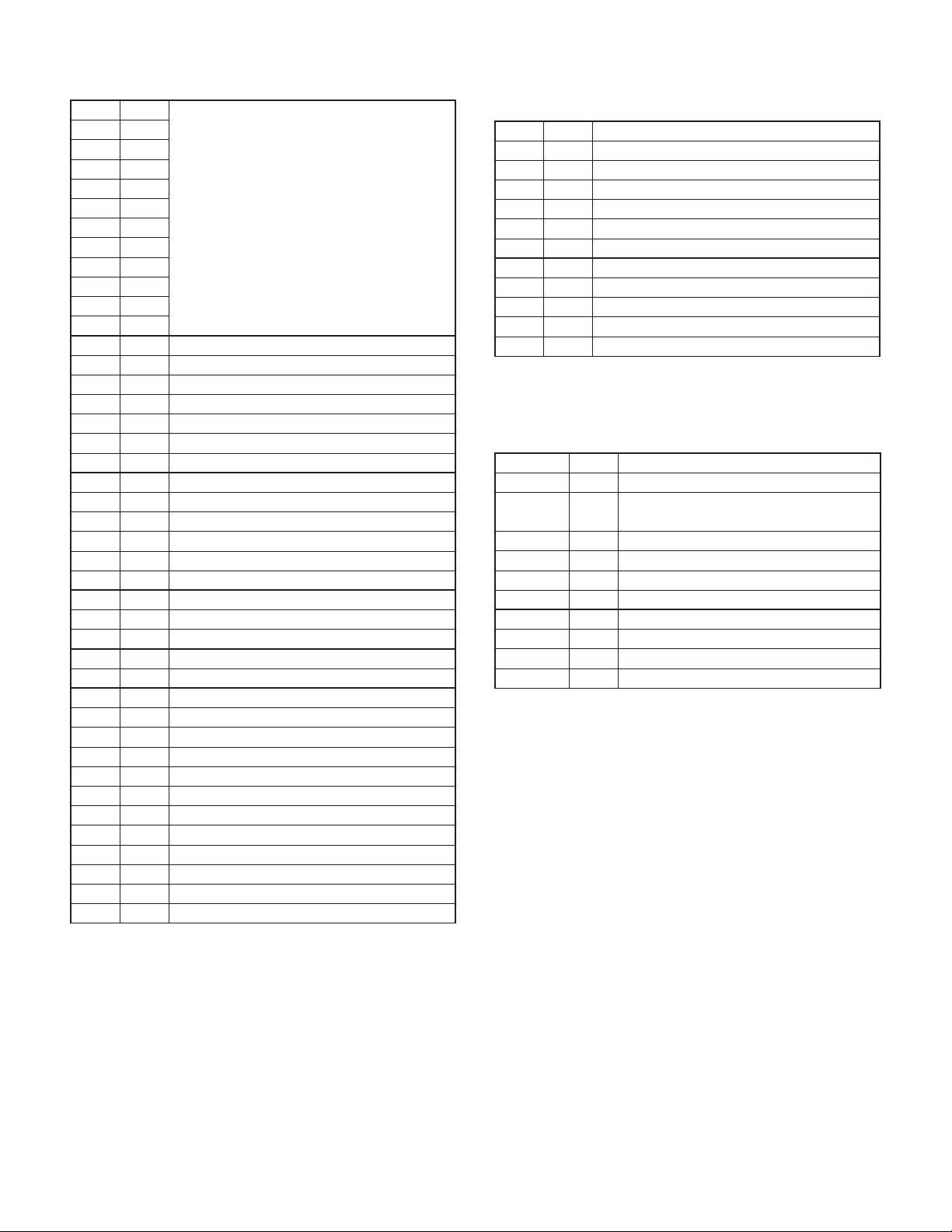

Table 11: I/O Expansion Module Jumper Settings

I/O Expansion Description Jumper(s) Setting Model

Not Used JP1 JP1 = Open

Not Used JP2 JP2 = Open

JP3 = Open

JP4 = Open

Secondary Heating Options JP3 & JP4

Dehumidication Options / Waterside Economizer JP5 & JP6

Not Used JP7 JP7 = Open

Compressor Capacity Option JP8

JP3 = Shorted

JP4 = Open

JP3 = Open

JP4 = Shorted

JP5 = Open

JP6 = Open

JP5 = Shorted

JP6 = Open

JP5 = Open

JP6 = Shorted

JP8 = Open

JP8 = Shorted

Operation

Thermostat Inputs

None

Supplemental Electric Heat

Boilerless Electric Heat

None

Hot Gas/Water Reheat (HGR)

Waterside Economizer

Single-Stage Capacity

Dual-Stage Capacity

Waterside Economizer/ Dehumidication

• The Waterside Economizer/Dehumidication input (TB1-

1), when energized from the thermostat, enables Waterside

Economizer or Dehumidicaiton operation depending on

jumper conguration.

W4

• The W4 (TB1-2) terminal enables the second stage of

electric heat.

Electric Heat Controls

Supplemental Electric Heat Control

The supplemental electric heating option provides addi-

tional stages of heating that can be used in conjunction with

compressor heating, or exclusively if the compressor is not

available for heating.

General Rules:

• Supplemental electric heater and the compressor may

operate simultaneously.

• Minimum Compressor ON and OFF timers do not apply

to electric heat control.

Operation:

Fan Main Output: will turn ON and the Fan PWM signal

will be at “Auxiliary Heat” duty cycle when:

• Any auxiliary heat output is energized.

• For 30 xed seconds after all auxiliary heat outputs have

been de-activated.

Electric Heat Outputs: are allowed to energize when either

condition exists:

• Inter-Stage ON timer must be expired.

• Compressor is not available for heating.

When Compressor is Available:

• Auxiliary Heat Stage #1 output energizes upon activation

of Heating – Stage #3.

• Auxiliary Heat Stage #2 output energizes upon activation

of Heating – Stage #4.

When Compressor is Unavailable:

• Auxiliary Heat Stage #1 output energizes upon activation

of “Heating – Stage #1.

• Auxiliary Heat Stage #2 output energizes upon activation

of Heating – Stage #4.

Boilerless Heat Control

• Turns on the heater when the entering water temperature

is less than setpoint (default is 55°F), the temperature set

point is adjustable through the network.

• For geothermal applications the heater turns on when the

entering water temperature is less than setpoint (default

28°F).

Note: In both cases the compressor is shut down.

Page 18 of 40 / OM 1149

Page 19

Compressor Heating Source Selection

Compressor heating source selection provides a method to

disable the compressor operation when in the heating mode.

Baseboard JP7 conguration jumper operation:

• Open: Enables compressor operation in the heating mode.

• Shorted: Disables compressor operation in the heating

mode.

When compressor operation is disabled in the heating mode

and electric heat is available:

• Auxiliary Heat Stage #1: output energizes upon

activation of the “Heating – Stage #1”.

• Auxiliary Heat Stage #2: output energizes upon

activation of the “Heating – Stage #4”.

When compressor operation is disabled in the heating mode

and electric heat is unavailable:

• The unit will not provide any form of heating.

Fan Speed Control

Fan Speed Selection via four position switch

A 4-position rotary switch located in the control box allows

CFM settings to be eld adjustable. Each position on the

rotary switch represents settings 1-4 (Figure 8).

Figure 8: 4-Position Rotary Fan Speed Switch

• Fan Speed control (located in the unit control box) will

optimize unit fan speed based on thermostat/room sensor

inputs.

• The installer shall have ability to further optimize fan

speeds for specic application requirements by means of

a 4 position rotary switch. (See Unit specic Installation

Manual).

Table 12: Rotary Fan Speed Settings (2-Ton, 2-Stage Unit)

CFM Setting

Setting 4 650 900 650 900 450 600 900

Setting 3 525 800 525 800 400 533 800

Setting 2 470 670 470 670 335 447 800

Setting 1 400 525 400 525 263 350 800

Part Load

Stage 1 Heat

Full Load

Stage 2 Heat

Part Load

Stage 1 Cool

Full Load

Stage 2 Cool

Fan Only Dehumidication

Electric

Heat

OM 1149 / Page 19 of 40

Page 20

I/O Expansion Module Faults and Fan Operating Modes Tables

Table 13: I/O Expansion Module LED & Fault Outputs

Description Type Yellow Green Red

Baseboard Communication Fail Fault Flash OFF Flash

Entering Water Temp Sensor Fail

(Boilerless Electric Heat or Waterside Economizer Only)

Low Entering Water Temperature

(No Display On Boilerless Electric Heat)

Fan is OFF Mode OFF ON OFF

Fan Running at Low Speed (0 to 33%) Duty Cycle Mode OFF Flash OFF

Fan Running at Medium Speed (34 to 66%) Duty Cycle Mode ON Flash OFF

Fan Running at High Speed (67 to 100%) Duty Cycle Mode Flash Flash OFF

Note: Mode / Faults are listed in order of priority.

Fault ON OFF Flash

Fault OFF ON Flash

Table 14: I/O Expansion Module Connectors and Descriptions

H1 – 1 1

H1 – 2

H1 – 3

H1 – 4

H1 – 5

H1 – 6

H1 – 7

H1 – 8

H1 – 9

H1 – 10

H1 – 11

H1 – 12

H2 – 1 1 Auxiliary Heat Stage #2 Output – N/O

H2 – 2 No Connection

H2 – 3 24 VAC Common

H3 – 1 1 Ext. 24 VAC In

H3 – 2 Ext. 24 VAC Common In

H3 – 3 HGR / Waterside Economizer Output – N/O

H3 – 4 Ext. 24 VAC Common

H3 – 5 ECM Fan Motor Variable Speed Signal Output

H3 – 6 ECM Fan Motor Variable Speed Signal – Common

Connections to Main Board

H4 – 1 1 Entering Water Temp Sensor – Signal

H4 – 2 Entering Water Temp Sensor – Common

H5 – 1 1 No Connection

H5 – 2 No Connection

H5 – 3 Red LED Output

H5 – 4 Green LED Output

H5 – 5 Yellow LED Output

H5 – 6 Red-Green-Yellow LED Common

H6 – 1 HP2-1 Comp High Capacity High Press Sw (HP2) Input Terminal 1

H6 – 2 HP2-2 Comp High Capacity High Press Sw (HP2) Input Terminal 2

H7 – 1 Fan Speed Table Row Select – Signal

H7 – 2 Fan Speed Table Row Select – Common

H7 – 3 Thermostat – Heat Stage #4 (W4) Input – Signal

H7 – 4 Auxiliary 24 VAC Out

H8 – 1 1 Compressor – High Capacity Output – N/O

H8 – 2 24 VAC Common

H8 – 3 No Connection

H8 – 4 Auxiliary Heat Stage #1 Output – N/O

H8 – 5 24 VAC Common

TB1 – 1 1 Humidistat Signal Input

TB1 – 2 2 Thermostat - Heat Stage #4 (W4) Input – Signal

Page 20 of 40 / OM 1149

Page 21

Unit Options:

Waterside Economizer

Waterside Economizer Control

• The Microtech III controls the waterside economizer.

Upon a call for economizer operation via TB1-1, the

output to the 3-way diverting valve and the fan motor are

energized, allowing water ow through the economizer

coil and fan operation.

SmartSource Dehumidication

■ Hot Gas Reheat Smart Dehumidication

■ Simplied Dehumidication

■ Humidistat Controlled Dehumidication

■ Dehumidication Only

4. Wiring:

■ Thermostat (Part No. 910121746 or 910121748)/Sensor

(Part No. 667720401) Combination:

Figure 9: Model GT thermostat and sensor combination

hot gas reheat smart dehumidification wiring diagram

Model GT

Unit Thermostat

R R 24VAC

C C Common

G G Fan

Y1 Y1 Cool Stage 1

Y2 Y2 Cool Stage 2

Humidistat

TB-1 R 24VAC

DH Dehumid

Hot Gas Reheat Smart Dehumidication

1. Application:

By utilizing the factory installed hot gas reheat and smart air

ow management; dehumidiation can be achieved in applications where precise humidity control is required.

2. Items Required:

■ Unit with Hot Gas Reheat option

■ Humidistat and a Thermostat OR Digitally Adjustable

Wall Sensor

3. Unit Control Settings:

Figure 10: Model GS thermostat and sensor combination

hot gas reheat smart dehumidification wiring diagram

Model GS

Unit Thermostat

R R 24VAC

C C Common

G G Fan

Y1 Y1 Cool Stage 1

Humidistat

TB-1 R 24VAC

DH Dehumid

■ I/O Expansion Module Jumper Settings:

• JP5=Shorted

• JP6=Open

Figure 11: SmartSource MicroTech III board to digital room temperature sensor wiring

SmartSource Board

Terminal Block Label TB2-1 TB1-1 TB1-2 TB1-3 TB1-4 TB1-5 TB3-1 TB3-2 TB1-1

Unit Status Output

24VAC

Description

Fan & Unit Mode

MicroTech III Board

■ Digitally adjustable room temperature sensor (Part No.

910121754)

Base Board

Emergency Shutdown

Input

Unoccupied Input

Setpoint Adjust

Room Temp Sensor &

Tenant Override

DC Signal Common

I/O Expan-

sion Module

Dehumidication Input

Terminal Label R 1 2 3 4 5 E U 1

Typical Wiring

Terminal Label R (24VAC) 1 (ST) 2 (FM) 3 (SP) 4 (UTS) 5 (GND) 6 (FC) E U DH

Unit Status Output

24VAC

Description

Sensor Digitally Adjustable Room Temperature Sensor (Part No. 910121754)

Fan & Unit Mode

Setpoint Adjust

Room Temp Sensor &

Tenant Override

DC Signal Common

Fan Speed Select - Fan

Coil Version Only

Emergency Shutdown

Unoccupied

OM 1149 / Page 21 of 40

Dehumidication

Page 22

5. Operation:

A call for heating or cooling has a higher priority than a call

for dehumidication. Dehumidication is allowed only if

the room temperature is satised. If the controller detects the

need for heating or cooling, or if the Humidistat is no longer

calling for dehumidication, dehumidication mode will be

suspended. Dehumidication mode will enable the 3-way hot

gas bypass valve, sending hot superheated refrigerant to the

hot gas reheat coil while running the compressor at full load

and the fan at dehumidication speed.

Note: See Fan Performance section in catalog for unit size

specic fan speeds.

Simplied Dehumidication

1. Application:

By utilizing a basic thermostat and conguring the Microtech

III unit controller for this mode of operation, the WSHP will

provide maximum latent capacity by optimizing blower fan

speeds resulting in decreased humidity levels in the conditioned space.

2. Items Required:

■ Model GT = 3 stage thermostat

■ Model GS = 2 stage thermostat

Note: This feature is not available if unit is controlled by wall

sensor

3. Unit Control Settings:

■ I/O Expansion Module Jumper Settings:

• JP5=Shorted

• JP6=Open

4. Wiring:

Figure 12: Model GT unit and thermostat simplified

dehumidification wiring diagram

Model GT

Unit Thermostat

R R 24VAC

C C Common

G G Fan

TB-1 Y1 Cool Stage 1

Y1 Y2 Cool Stage 2

Y2 Y3 Cool Stage 3

Figure 13: Model GS unit and thermostat simplified

dehumidification wiring diagram

Model GS

Unit Thermostat

R R 24VAC

C C Common

G G Fan

TB-1 Y1 Cool Stage 1

Y1 Y2 Cool Stage 2

5. Operation:

Unit will run at maximum compressor capacity with low

CFM to maximize latent capacity.

Example: A 2-stage model GT, unit size 026, wired for Simplied Dehumidifcation:

• Upon a call for Y1, TB1-1 on the unit control board

will be energized, allowing the compressor to operate

at full load and the fan to operate at 600 CFM.

• Upon a call for Y2, Y1 on the unit control board will

be energized, allowing the compressor to operate at

part load and the fan to operate at 700 CFM. (Factory

default fan speed setting #3)

• Upon a call for Y3, Y2 on the unit control board will

be energized, allowing the compressor to operate at

full load and the fan to operate at 800 CFM. (Factory

default fan speed setting #3)

Humidistat Controlled Dehumidication

1. Application:

Similar to the simplied dehumidication option, this option

also maximizes latent capacity by using a humidistat and

thermostat. This option allows the room thermostat to control

sensible cooling, while the independent humidistat controls

room humidity levels

2. Items Required:

■ Humidistat combined with a...

■ Model GT = 3 stage thermostat

■ Model GS = 2 stage thermostat

OR

■ I/O Expansion Module Jumper Setting:

• JP5=Shorted

• JP6=Open

Note: This feature is not available if unit is controlled by wall

sensor

3. Unit Control Settings:

■ I/O Expansion Module Jumper Settings:

• JP5=Shorted

• JP6=Open

4. Wiring:

■ Thermostat/Sensor combination:

■ Field supplied sensor

Figure 14: Model GT thermostat and humidistat

combination - humidistat controlled dehumidification

wiring diagram

Model GT

Unit Thermostat

R R 24VAC

C C Common

G G Fan

Y1 Y1 Cool Stage 1

Y2 Y2 Cool Stage 2

TB-1 R 24VAC

DH Dehumid

Humidistat

Page 22 of 40 / OM 1149

Page 23

Figure 15: Model GS thermostat and humidistat

combination - humidistat controlled dehumidification

wiring diagram

Model GS

Unit Thermostat

R R 24VAC

C C Common

G G Fan

Y1 Y1 Cool Stage 1

Humidistat

TB-1 R 24VAC

DH Dehumid

Figure 16: SmartSource MicroTech III board & I/O

expansion module to field supplied room temperature

sensor wiring

SmartSource Board

Terminal Block Label TB2-1 TB1-1 TB1-2 TB1-3 TB1-4 TB1-5 TB3-1 TB3-2 TB1-1 TB1-2

Unit Status Output

24VAC

Description

Fan & Unit Mode

MicroTech III Board

Base Board

Setpoint Adjust

Tenant Override

Room Temp Sensor &

DC Signal Common

Emergency Shutdown

Input

I/O Expansion Module

Unoccupied Input

Dehumidication Input

Voltage (24VAC)

Humidistat Source

Terminal Label R 1 2 3 4 5 E U 1

Typical Wiring

Terminal Label X X X X

Description

Sensor Field Supplied Room Temperature Sensor

5. Operation:

Unit will run at maximum compressor capacity with low

CFM to maximize latent capacity.

Example: A 2-stage model GT, unit size 026, wired for Humidistat Controlled Dehumidication:

• Upon a call for dehumidicaion, TB1-1 on the unit

control board will be energized by the humidistat,

10K Ohm ATP Curve Z or

Room Temp Sensor,

equivalent

DC Signal Common

• Upon a call for stage 2 cooling, Y2 on the unit control

board will be energized from Y2 on the themostat,

allowing the compressor to operate at full load and the

fan to operate at 800 CFM. (Factory default fan speed

setting #3)

Note: See Fan Performance section in catalog for unit size

specic fan speeds.

allowing the compressor to operate at full load and the

fan to operate at 600 CFM.

• Upon a call for stage 1 cooling, Y1 on the unit control

board will be energized from Y1 on the thermostat,

allowing the compressor to operate at part load and the

fan to operate at 700 CFM. (Factory default fan speed

setting #3)

Dehumidication Output

Dehumidication Source

Voltage

OM 1149 / Page 23 of 40

Page 24

Dehumidication Only:

1. Application:

In applications where only dehumidication is needed, the

humidistat can be wired to TB1-1 on the Microtech III unit

controller, allowing the WSHP unit to operate in dehumidi-

cation mode only. The unit will only respond to a call for

dehumidication.

2. Items Required:

■ Humidistat

3. Unit Control Settings:

■ I/O Expansion Module Jumper Settings:

• JP5=Shorted

• JP6=Open

4. Wiring:

Figure 17: Model GS & GT unit and humidistatdehumidification only wiring diagram

Model GS & GT

Unit Humidistat

R R 24VAC

C DH Dehumid

G

TB1-1

5. Operation:

Upon a call for dehumidication, the unit will run in cool

stage 1 compressor capacity and cool stage 1 fan speed.

Example: A 2-stage model GT, unit size 026, wired for

Dehumidication Only:

• Upon a call for dehumidication from the humidistat,

TB1-1 on the unit control board will be energized,

allowing the compressor to operate at full load and the

fan to operate at 600 CFM.

Note: See Fan Performance section in catalog for unit size

specic fan speeds.

Page 24 of 40 / OM 1149

Page 25

Appendix B

MicroTech III Unit Controller with LonWorks® Communication Module

For installation and operation information on LonWorks

Communication Module and other ancillary control components, see:

■ IM 927 - MicroTech III Water Source Heat Pump

LonWorks Communication Module.

■ IM 933 - LonMaker Integration Plug-in Tool: For use with

the MicroTech III Unit Controller.

■ IM 955 - MicroTech III Wall Sensor for use with

Microtech III Unit Controller

Each Daikin McQuay water source heat pump can be

equipped with a LonWorks communication module that

is LonMark 3.4 certied to meet the LonMark Space Comfort Control (SCC) prole for heat pumps. The controller is

microprocessor-based and is designed to communicate over

a LonWorks network. With the optional factory or eld-

installed communication module.

The unit controller is programmed and tested with all the

logic required to monitor and control the unit. An optional

wall sensor may be used with the communication module to

provide limited local control of the Water Source Heat Pump.

The unit controller monitors water and air temperatures and

passes information to the communication module. The module communicates with the BAS to provide network control

of the Water Source Heat Pump.

Figure 18: LonWorks Communication Module

MicroTech III Unit Controller with LonWorks Communica-

tion Module orchestrates the following unit operations:

Enable heating and cooling to maintain setpoint based on

a room sensor

Enable fan and compressor operation

Monitors all equipment protection controls

Monitors room and discharge air temperatures

Monitors leaving water temperature

Relays status of all vital unit functions

The MicroTech III unit controller with an optional

communication module includes:

■ Return Air Temperature sensor (RAT)(eld-installed)

■ Discharge Air Temperature sensor (DAT)(eld-installed)

■ Leaving Water Temperature sensor (LWT)

Note: Refer to IM 956-X for details to install (RAT) & (DAT)

sensors.

CAUTION

When an optional wall-mounted room temperature sensor is

connected to the unit controller, the Return Air Temperature

(RAT) sensor must not be installed. A wall-mounted room

temperature sensor and the return air temperature sensor

must not be connected simultaneously or the unit will not

operate properly.

The MicroTech III unit controller with communication

module includes a unit-mounted return air, discharge air and

leaving water temperature sensor. Wall mounted temperature

sensors include setpoint adjustment and tenant override. The

user has the capability of substituting the wall sensor with a

duct-mounted return air sensor.

The communication module provides access to setpoints for

operational control

Available wall sensors include:

Room sensor with LED status and tenant override button

Room sensor with LED status, tenant override button, and

±5°F setpoint adjustment

Room sensor with LED status, tenant override

button, 55° to 95°F setpoint adjustment

OM 1149 / Page 25 of 40

Page 26

MicroTech III Controller with an Optional BACnet® Communication Module

For installation and operation information on MicroTech III

unit controller and other ancillary components, see:

■ IM 928 - MicroTech III Water Source Heat Pump BACnet

Communication Module

■ IM 955 - MicroTech III Wall Sensor For use with

Microtech III Unit Controller

Daikin McQuay water source heat pumps are available with

an optional BACnet MS/TP communication module that is

designed to communicate over a BACnet MS/TP communica-

tions network to a building automation system (BAS). It can

be factory or eld-installed.

The unit controller is programmed and tested with all the

logic required to monitor and control the unit. An optional

wall sensor may be used with the communication module to

provide limited local control of the water source heat pump.

The unit controller monitors water and air temperatures and

passes information to the communication module. The module communicates with the BAS, to provide network control

of the water source heat pump.

The module makes operational data and commands available

on a communications network using BACnet objects and

properties:

■ The network cable is a shielded twisted-pair cable

■ Network communications run up to 76.8 Kbps

■ DIP switches on the controller enable the MS/TP MAC

address to be set in the range 0-127

■ Four green status LEDs on the communication module

indicate communication activity on the MS/TP

communication network and with the unit controller

Figure 19: MicroTech III BACnet MS/TP Snap-in

Communication Module

MicroTech III Unit Controller with BACnet MS/TP Communication Module orchestrates the following unit operations:

■ Enable heating and cooling to maintain setpoint based on

a room sensor

■ Enable fan and compressor operation

■ Monitors all equipment protection controls

■ Monitors room and discharge air temperatures

■ Monitors leaving water temperature

■ Relays status of all vital unit functions

The MicroTech III unit controller with an optional

communication module includes:

■ Return Air Temperature sensor (RAT)(eld-installed)

■ Discharge Air Temperature sensor (DAT)(eld-installed)

■ Leaving Water Temperature sensor (LWT)

Note: Refer to IM 956-X for details to install (RAT) & (DAT)

sensors.

CAUTION

When an optional wall-mounted room temperature sensor is

connected to the unit controller, the Return Air Temperature