Page 1

Installation and Maintenance Data

Group: WSHP

Part Number: 667691801

Date: March 2010

IM 1072

Water to Water Source Heat Pumps 3 to 35 Tons with R-410A

WRA - Heating and Cooling Models

WHA - Heating Only Models

WCA - Cooling Only Models

©2010 McQuay International

Page 2

Table of Contents

Nomenclature ..........................................................................2

Safety Information ..................................................................3

Electrical Data .........................................................................4

Installation ........................................................................... 4-7

Pre Installation and Code Requirements ..........................4

Applications ................................................................. 5-6

Start Up ...................................................................................7

Maintenance Procedures ..................................................7

Dimensional Data .............................................................. 8-10

WRA, WCA, WHA, Size 036-072, 60Hz .......................8

WRA, WCA, WHA, Size 120-180, 60Hz .......................9

WRA, WCA, WHA, Size 240-420, 60Hz .....................10

Physical Data .......................................................................1 1

Cooling Mode Operating Pressure (PSIG)

WRA and WCA Models ................................................11

Heating Mode Operating Pressures

WRA and WHA Models ................................................ 11

Antifreeze Correction Factors ........................................11

Wiring Diagrams ............................................................. 12-14

208-230/60 Hz - 1 Phase, Sizes 036, 048, 060 & 072 ...1 2

3-Phase, Unit Sizes 036, 048, 060 & 072 ......................1 3

3-Phase, Unit Sizes 120, 150, 180, 240, 300,

360 & 420 ......................................................................14

Circuit Diagrams ............................................................. 15-17

WHA Circuit Diagram ...................................................1 5

WRA Circuit Diagram ...................................................1 6

WCA Circuit Diagram ...................................................1 7

Check, Test & Start Form .....................................................18

General Service Guide ..........................................................19

Replacement Parts List .........................................................20

McQuay WSHP Product Model Nomenclature

W WRA 1 036 E F T F YY FS A C Y A PVM

Product Category

W = WSHP

Product Identier

WRA = Heating and Cooling Models

WHA = Heating Only Models

WCA = Cooling Only Models

Design Series

1 = 1st Design

2 = 2nd Design

3 = 3rd Design

4 = 4th Design

Nominal Capacity

036 = 36,000 Btuh Nominal Cooling

048 = 48,000 Btuh Nominal Cooling

060 = 60,000 Btuh Nominal Cooling

072 = 72,000 Btuh Nominal Cooling

120 = 120,000 Btuh Nominal Cooling

150 = 150,000 Btuh Nominal Cooling

180 = 180,000 Btuh Nominal Cooling

240 = 240,000 Btuh Nominal Cooling

300 = 300,000 Btuh Nominal Cooling

360 = 360,000 Btuh Nominal Cooling

420 = 420,000 Btuh Nominal Cooling

Controls

E = Electromechanical

T = Temperature

Control System

Voltage

E = 208-230/60/1

F = 208-230/60/3

K = 460/60/3

L = 575/60/3

Source Water to Refrigerant

Heat Exchanger Construction

C = Copper Inner Tube Steel Outer Tube

S = Cupro-Nickel Inner Tube Steel Outer Tube

Y = None

Construction Type

A = Standard

Refrigerant

A = R-410A

Desuperheater

Y = None

D = Waste Heat Recovery

Water Heater

Cabinet Electrical

YYY = None

PVM = Phase Monitor

Monitors Voltage

and Phase Loss

Water Piping Location

F = Front

T = Top

L = Left Hand Side

R = Right Hand Side

Status Lights

YY = None

SL = Three Lights-Compressor-1,

Compressor-2, Compressor fault

The information in this manual supersedes and replaces previous manuals with regard to McQuay products. Illustrations cover the general appearance of McQuay prod-

ucts at the time of publication and McQuay reserves the right to make changes in design and construction at anytime without notice.

Page 2 of 20 / IM 1072 Water to Water Source Heat Pumps

Control Box Location

F = Front

L = Left Side Control Box

R = Right Side Control Box

NOTE: For illustration purposes only. Not all options available with all models.

PleaseconsultyourlocalMcQuayRepresentativeforspecicavailability.

Freezestat

YY = None

FS = Adjustable for Geothermal and

Boiler/Tower Application

Page 3

Safety Information

Safe Operation Rules

Installation and maintenance are to be performed only by

qualied personnel who are familiar with and in compliance with

state, local and national codes and regulations, and experienced

with this type of equipment.

Please take a few minutes to read the instructions before

you install the heat pump. This will help you obtain the full

value from this unit. It will also help you avoid needless costs

that result from incorrect installation and are not covered in

the warranty.

Follow these instructions carefully. Failure to do so could

cause a malfunction of the heat pump, resulting in injury, death

and/or property damage.

Tubing and compressor contain high pressure refrigerant

and they must not be exposed to high temperature or be punctured.

To prevent electrical shock, disconnect electric power to

system at main fuse or circuit breaker box until installation

is complete.

Sharp edges and coil surfaces are injury hazards. Avoid

contact with them.

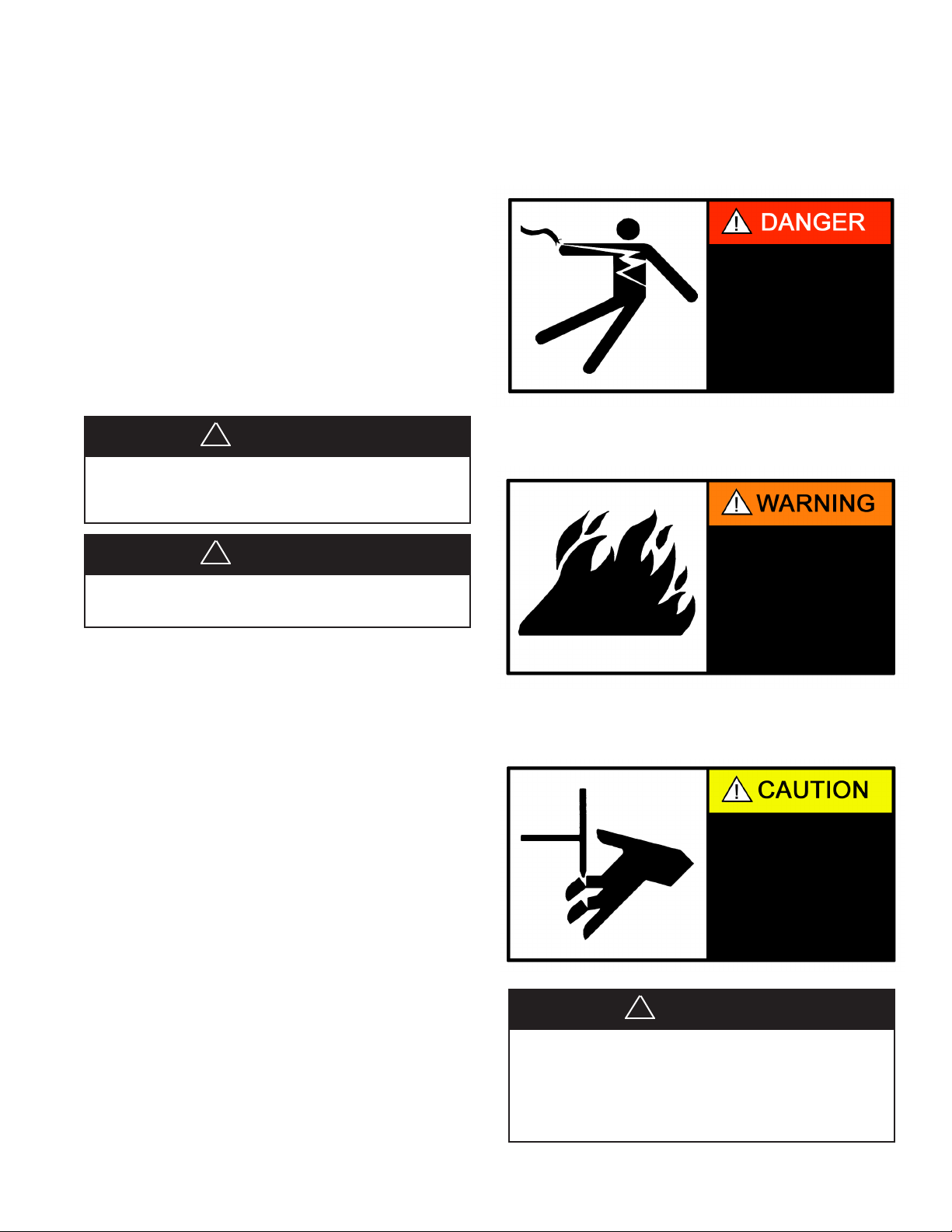

Safety and Signal Words

!

WARNING

!

CAUTION

Danger Label

White lettering on a black background except the word

DANGER which is white with a red background.

Electric Shock Hazard.

Turn Off All Power

Before Servicing.

Warning Label

White lettering on a black background except the word

WARNING which is white with an orange background.

Fire Hazard.

Use copper wire only.

Failure to observe

could result in property

damage, bodily injury

or death

The signal words DANGER, WARNING and CAUTION

are used to identify levels of hazard seriousness. The signal word

DANGER is only used on product labels to signify an immedi-

ate hazard. The signal words WARNING and CAUTION will

be used on product labels and throughout this manual and other

manuals that may apply to the product.

DANGER

Immediate hazards which WILL result in severe personal

injury or death.

WARNING

Hazards or unsafe practices which COULD result in severe

personal injury or death.

CAUTION

Hazards or unsafe practices which COULD result in minor

personal injury or product or property damage.

Caution Label

White lettering on a black background except the word

CAUTION which is white with a yellow background.

Cuts and Abrasion

Hazard.

Wear gloves and handle

with care.

Failure to observe could

result in bodily injury.

This unit contains HFC-(R-410A), a azeotropic mixture of

R-32(Diuoromethane)andR-125(Pentauoroethane).Do

Not Vent HFC-(R-410A) to the atmoshpere. The U.S. Clean

Air Act requires the recovery of any residual refrigerant. Do

not use R-22 service equipment or components on R-410A

systems.

!

WARNING

Water to Water Source Heat Pumps IM 1072 / Page 3 of 20

Page 4

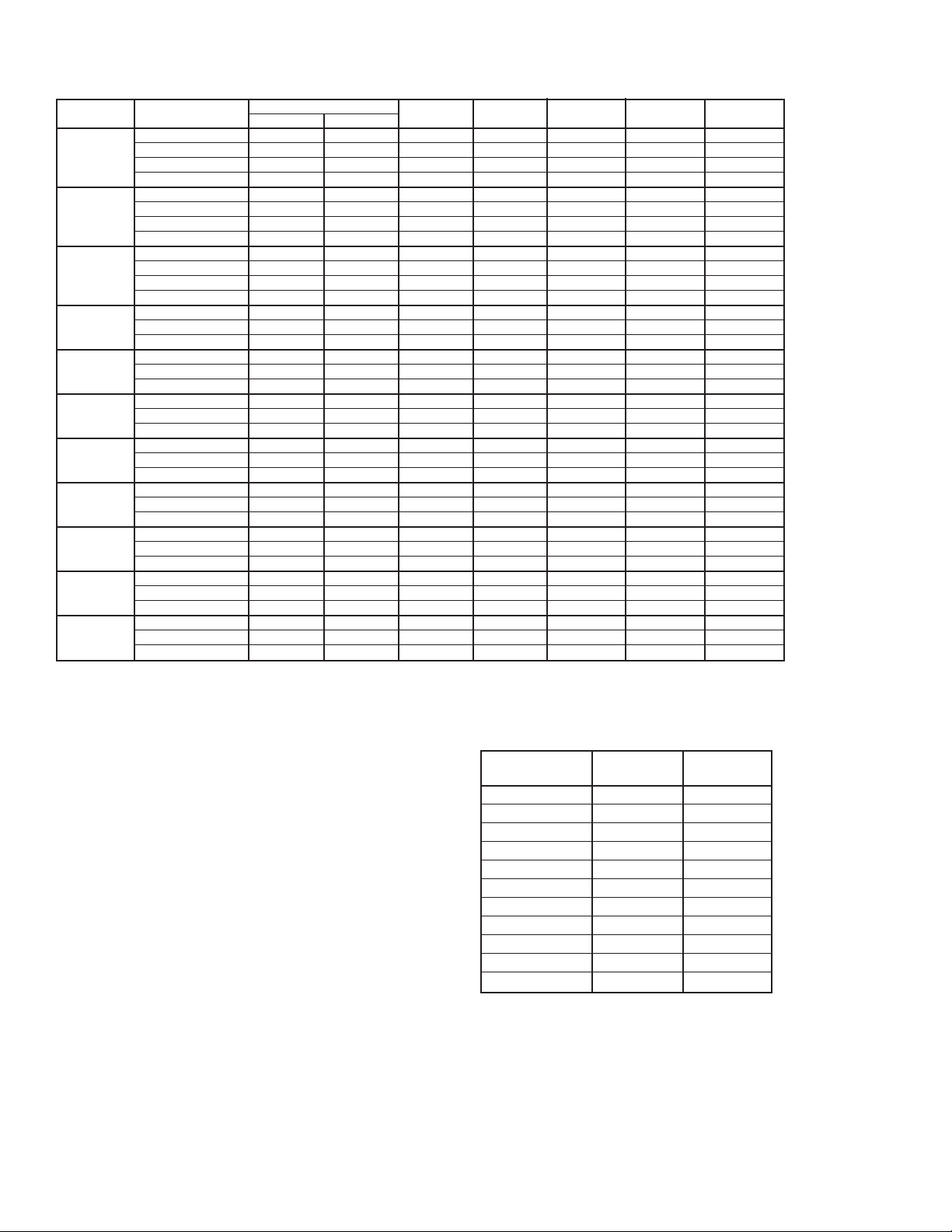

Electrical Data – WRA, WHA, WCA 036 – 420

Unit Size

Compressor Total Min./Max. Min. Circuit Max. Circuit Max. Fuse

036

048

060

072

120

150

180

240

300

360

420

Voltage-Hz-Phase

208-230/60/1

208-230/60/3

460/60/3

575/60/3

208-230/60/1

208-230/60/3

460/60/3

575/60/3

208-230/60/1

208-230/60/3

460/60/3

575/60/3

208-230/60/3

460/60/3

575/60/3

208-230/60/3

460/60/3

575/60/3

208-230/60/3

460/60/3

575/60/3

208-230/60/3

460/60/3

575/60/3

208-230/60/3

460/60/3

575/60/3

208-230/60/3

460/60/3

575/60/3

208-230/60/3

460/50/3

575/60/3

208-230/60/3

460/60/3

575/60/3

RLA (each) LRA (each)

16.7

10.4

5.8

3.8

23.1

16.1

7.1

5.6

30.2

20.6

9.7

7.7

22.5

10.6

7.7

20.1

9.7

7.7

22.5

10.6

7.7

25

12.2

9

30.2

16.7

12.2

48.1

18.6

14.8

51.3

22.5

19.9

55.8

27

23.8

79

73

38

36.5

134

91

46

37

158

155

75

54

149

75

54

155

75

54

149

75

54

164

100

78

225

114

80

245

125

100

300

150

109

340

173

132

Amps Volts Ampacity Breaker Size

16.7

10.4

5.8

3.8

23.1

16.1

7.1

5.6

30.2

20.6

9.7

7.7

22.5

10.6

7.7

40.2

19.4

15.4

45

21.2

15.4

50

24.4

18

60.4

33.4

24.4

96.2

37.2

29.6

102.6

45

39.8

111.6

54

47.6

197/253

187/253

414/506

517/632

197/253

187/253

414/506

517/632

197/253

187/253

414/506

517/632

187/253

414/506

517/632

187/253

414/506

517/632

187/253

414/506

517/632

187/253

414/506

517/632

187/253

414/506

517/632

187/253

414/506

517/632

187/253

414/506

517/632

187/253

414/506

517/632

20.9

13

7.3

4.8

28.9

20.1

8.9

7

37.8

25.8

12.1

9.6

28.1

13.3

9.6

46.4

21.8

17.3

50.6

23.9

17.3

56.3

27.5

20.3

68

37.6

27.5

108.2

41.9

33.3

115.4

50.6

44.8

125.6

60.8

53.6

35

20

15

15

50

35

15

15

60

45

20

15

50

20

15

60

30

25

70

30

25

80

35

25

90

50

35

150

60

45

150

70

60

175

80

70

35

20

15

15

50

35

15

15

60

45

20

15

50

20

15

60

30

25

70

30

25

80

35

25

90

50

35

150

60

45

150

70

60

175

80

70

Capacity Data

Installation

Pre-Installation and Code Requirements

After removing the unit from the carton, immediately remove

the panels and inspect for any damage that might have occurred

during shipment. Report concealed damage immediately to the

transportation company and request inspection.

The electric power source must be the same voltage and

phase as shown on the serial plate. Line and low voltage wiring must be done in accordance with local codes or the national

electric code.

Make a survey of the nal location for the unit before setting

it in place. The unit should be centrally located with respect to

the distribution system. Install the unit within a heated area.

Exposure to inclement weather conditions may cause freeze

damage that is not covered by the warranty.

Heating Cooling

Model

36 48,200 34,300

48 58,200 42,100

60 67,200 46,600

72 85,500 62,200

120 129,000 94,500

150 170,400 122,140

180 237,000 157,000

240 290,900 202,400

300 339,720 221,800

360 416,900 284,700

420 493,200 358,600

Note:

At standard rating conditions of:

Heating - 100°F entering load water, 70°F entering source water.

Cooling - 55°F entering load water, 85°F entering source water.

Page 4 of 20 / IM 1072 Water to Water Source Heat Pumps

Btuh Btuh

Page 5

Installation

Mounting the Unit

The unit should be mounted level on a vibration absorbing

pad slightly larger than the base to provide isolation between

the unit and the oor. It is not necessary to anchor the unit to

the oor.

The electrical connections are accessible from the front. The

compressor can be accessed from either side. A minimum of 24"

clearance in front and sides of the unit should be provided to al-

low sufcient room to make water and electrical connections. If

the unit is located in a conned space such as a closet, provisions

must be made for unit servicing. Unit sizes 036 thru 072 may be

stacked vertically (2 high) in tight mechanical rooms.

Piping the Unit

Both source and load connections must be at least as large

as the unit connection on the unit. The unit may be furnished

with either copper or optional cupronickel coil on either source

or load coaxial heat exchanger. Cupronickel should always be

used when chlorinated water or ground water which is high in

mineral content is the load or source load uid. Never use exible hoses that are smaller (inside diameter) than that of the water

connection on the unit. Make sure hoses and pipes are suitable

for system water pressure and sized for proper ow rate.

The supply and the discharge pipes should be insulated to

prevent condensation damage caused by low water temperature

in the pipes.

If water hammer should occur during start-up or shut down,

slow closing diaphragm type solenoid valves should be used.

Placing the solenoid valve on the outlet side of the system helps

relieve this situation. Due to high pressure drop or poor throttling characteristics, globe and gate valves should not be used,

all ow valves should be ball type.

Domestic Hot Water Heat Recovery

The unit may have an optional factory installed waste heat

recovery feature. The heat recovery device is factory piped to

the refrigerant circuit of the unit. The plumbing to the water

tank and the power to the recovery pump are to be completed

in the eld as required.

Care should be exercised in plumbing water lines to and from

the water heater. Note: It is important that both water lines be

insulated. For run less than 50 feet one way, use 1/2" O.D. water

lines on models sizes 036 thru 072. A run over 50 feet should

be avoided. On models 120 thru 420 specic system data must

be matched to industry standard pipe sizing charts.

To make a connection to Hot Water Heat Recovery:

1. Turn off power or gas valves to the water heater.

2. Turn off water supply to the water heater.

3. Open hot water faucet and drain tank.

4. Connect tubing to “Heat Recovery Water Out” on the unit

and extend this line to the hot water heater. Attach to hot

water heater with ttings.

!

CAUTION

5. Connect tubing to “Heat Recovery Water In” on the unit

and extend this line to the water heater. Attach to cold water

supply. Place pump in this line.

6. Set water heater thermostat as follows:

Electric, Double element - Upper 12 5° F, Lowe r

minimum

Gas, Oil or Single element - 125°F

7. Wire according to single phase diagram (page 12) and three

phase diagram (pages 13 and 14).

8. The piping and wiring are now complete. Turn on water

supply to water heater. With an open hot water faucet, allow tank to ll. Bleed air from water lines. Check for water

leaks. Do not restore power to water heater until after you

have veried that the heat recovery unit is working and you

have hot water circulating back to the water heater. Restore

power to the water heater.

9. On start up of the unit, make the following operation

checks:

■ Pump runs only when the compressor is on. Pump is

turned on by thermostat on compressor discharge

line.

■ All air is purged from water lines.

■ Verify water circulation to and from water heater.

Applications

Cooling Tower/ Boiler Application Closed Loop

Cooling Tower and Boiler Loop System temperature is

usually maintained between 55°F and 90°F. In the cooling

mode, heat is rejected from the unit into the source water loop.

To reject excess heat from the water loop, the use of a closed

circuit evaporative cooler or an open type cooling tower with

a secondary heat exchanger between the tower and the water

loop is recommended. When utilizing open cooling towers

chemical water treatment is mandatory so that the water is free

from corrosive minerals. It is imperative that all air be removed

from the source closed loop side of the heat exchanger to protect

against fouling.

In the heating mode, heat is absorbed from the source water

loop. A boiler can be utilized to maintain the loop at the desired

temperature. In milder climates a “ooded tower” concept is

often used. This concept involves adding makeup water to the

cooling tower sump to maintain the desired loop temperature.

When making water connections to unit sizes 036 thru 072,

a Teon taped thread sealant is recommended to minimize fouling of the pipes. Sweat connections are used for unit sizes 120

thru 420. The water lines should be routed so as not to interfere

with access to the unit. The use of short lengths on high pressure

hose with a swivel type tting may simplify the connections and

prevent vibration transmission to the building.

Before nal connection to the unit, the supply and return

hose kits must be connected together and the system ushed

to remove dirt, piping chips and foreign material. Ball valves

should be installed in the supply and return lines for unit isola-

tion and unit water ow rate balancing. The return valve can

be adjusted to obtain the proper ow rate whenever the unit

heats or cools.

Improperwaterowinthesystemduetopiping,valvingor

improper pump operating will void the warranty.

Water to Water Source Heat Pumps IM 1072 / Page 5 of 20

Water piping exposed to outside may freeze.

!

CAUTION

Page 6

Pressure/temperature ports recommended both supply and

return lines adjacent to the unit for system ow balancing. Flow

can be accurately set by measuring the refrigerant-to-water heat

exchangers water side pressure drop.

Well Water Application Open Loop

Water pressure must be maintained in the heat exchanger by

placing water control valves at the outlet of the unit. A bladder

type expansion tank may be used to maintain pressure on the

system. Pressure/temperature ports should be used to set ow

rates by checking pressure drop across the heat exchanger. Avoid

using low voltage (24 volt) solenoids, using them may overload

the unit transformer or interfere with the lockout impedance

circuit. Line voltage solenoids across the load side of compressor contactor are recommended. Normally residential systems

require about 2-gpm of ow rate per ton of cooling capacity is

needed in open loop systems.

Discharge water from a heat pump is not contaminated in

any manner and can be disposed of in various ways depending

on local building codes.

Disposal methods may be by recharge well, storm sewer,

drain eld, adjacent stream or pond. Most local codes forbid the

use of sanitary sewer for disposal. Consult the local building and

zoning department to determine compliance in your area.

Earth Coupled Application Closed Loop

Earth coupled closed loop systems should follow the same

International Ground Source Heat Pump Association guidelines

used for closed loop heat pump applications. Once piping is

completed between the loop pump kit and the earth loop, nal

purging and charging of the loop is required. A ush/purge

assembly capable of obtaining a velocity of 2 fps throughout

the entire system is required. Usually a pump of at least 1.5 hp

will be adequate to purge air and dirt particles from the loop

itself for most residential systems. Commercial systems must

be sized carefully using pump manufacturer pump curves and

system specic data. Flush the system adequately to remove as

much air as possible then pressurize the loop to a static pressure

of 20 to 30 psi. This is normally adequate for proper system

operation. Check for proper ow through the unit by checking

pressure drop across the heat exchanger and compare it to the

cooling and heating operating pressure tables on page 11. In

order to achieve proper cooling capacity in a earth coupled close

loop application, a rate of 3 gpm per ton is required. Antifreeze

solutions are required when low evaporating conditions are

anticipated. Always use pressure/temperature ports to provide

proper uid ow rates.

Typical Load Side Applications

There are many load side applications for which the uid to

uid liquid chiller heat pumps can be used. The most popular

used would include: Hydronic baseboard heating, hydronic inslab oor heating, forced air fan coil heating or cooling, ice and

snow removal, heating potable water, heating swimming pools

and spas, and process uid heating and cooling. When specify-

ing load side heat transfer surface it is important to consider the

heat pump output capacities and uid ow rates. Insufcient

load side heat transfer surface may cause unstable heat pump

operating. Pressure/temperature ports should always be used

to determine load side ow rates. Avoid contact of dissimilar

metals in the load side piping system.

The units can provide heating or cooling for pools and spas

without the use of a secondary heat exchanger. This application

would however require a cupronickel load side heat exchanger.

Automatic chemical feeders must never be installed upstream of

the heat pump. An external bypass should be installed to avoid

over owing the heat exchanger which could cause erosion.

Proper pool PH levels and chemical balances must be maintained

to avoid possible heat exchanger damage.

Page 6 of 20 / IM 1072 Water to Water Source Heat Pumps

Page 7

Start Up

Check the following before powering the unit.

• Avoid starting any electrical equipment for the rst time

alone, always have another person a safe distance from

the unit that can turn off the main power in the event of an

accident.

• High voltage supply matches the nameplate rating.

• Field wire size, breakers and fuses are the correct size.

• Low voltage control circuit is correct.

• Water piping is complete and correct.

• Closed loop system is ushed and purged.

• Isolation valves are open.

• Loop pumps are correctly wired.

• Access panels are in place and secured.

• Thermostat is in “off” position.

Maintenance Procedures

Proper maintenance is important to provide the most efcient

operation and longest life for your equipment. The following

points are to serve as a general guide. Always consult with your

maintenance contractor with regard to the specic requirements

of your own installation.

Paint Finish

The electrodeposition paint nish may be polished if desired. Spray paint is available in case of accidental scratching

or chipping.

The following should be checked only by a competent

contractor.

Contactor Points

Check contactor points twice a year to see that they are not

burned or pitted as a result of low voltage, lightning strikes, or

other electrical difculties.

Electric Shock Hazard.

Turn Off All Power

Before Servicing.

Check, Test and Start (See Form on page 18)

1. Set thermostat to highest position.

2. Set thermostat switch to “cool”. Compressor should not

operate. The source water pump should energize.

3. Slowly lower the thermostat setting until the compressor is

energized. Regulate the water ow utilizing the P/T plugs

and compare to the performance tables on page 11.

4. Check the cooling refrigerant pressures against valves with

the tables .

5. Turn thermostat switch to the “off” position. The unit will

stop running and the reversing valve should de-energize.

6. Leave unit “off” for approximately ve minutes to allow

pressure to equalize.

7. Adjust thermostat to lowest setting.

8. Set thermostat switch to “heat” position.

9. Slowly adjust thermostat to higher temperature until com-

pressor energizes.

10. Compare the heating refrigerant pressure with valves with

the tables .

11. Check for vibrations, noise, water leaks, etc.

12. Adjust thermostat to correct mode and set to maintain

desired temperature.

13. Instruct the equipment owner/operator of correct thermostat

and system operation.

14. Be certain to complete and forward the warranty papers to

McQuay.

Water System

The water circulating pump should be checked and cleaned,

so that it is operating normally. Clogged coils lead to high head

pressures and inefcient operation. If coil is limed, a cleaning

treatment may be necessary. Water coils should be checked

yearly for liming or clogging.

Improper Unit Functioning

If unit is not performing properly, several readings of temperature, pressure and electrical characteristics need to be taken.

The normal required troubleshooting information is listed on the

Check, Test and Start Form on page 18.

Note: DO NOT place refrigeration gauges on system for

Check, Test and Start procedure. (To be used for major

service only.)

To Installer: Fill out Check, Test and Start Form on page 18

and leave copy with the customer.

Water to Water Source Heat Pumps IM 1072 / Page 7 of 20

Page 8

Dimensional Data – WRA, WCA, WHA – Size 036-072

Dimensions - Size 036

Dimensions (inches) Pipe Sizes (FPT) Connection Sizes

A B C D E F G H J K L M N P Control Electric

Electric Source Hot Water

28⅛ 28⅛ 19 1¾ 6⅜ 3⅞ 2 11⅞ 17⅛ 4 1½ 14⅞ 10⅝ 8⅝ 1/2"KO 3/4"KO 1/2"KO 3/4"FPT 1/2"FPT

Auxiliary Load Domestic

Dimensions - Size 048-060

Dimensions (inches) Pipe Sizes (FPT) Connection Sizes

A B C D E F G H J K L M N P Control Electric

Electric Source Hot Water

28⅛ 28⅛ 21 2¼ 7½ 3⅞ 2 13¾ 19 4 1½ 14⅞ 10⅝ 8⅝ 1/2"KO 3/4"KO 1/2"KO 1"FPT 1/2"FPT

Auxiliary Load Domestic

Dimensions - Size 072

Dimensions (inches) Pipe Sizes (FPT) Connection Sizes

A B C D E F G H J K L M N P Control Electric

Electric Source Hot Water

28⅛ 28⅛ 21 211/16 10⅝ 95/16 2 11½ 19 4 1½ 14⅞ 10⅝ 8⅝ 1/2"KO 3/4"KO 1/2"KO 1"FPT 1/2"FPT

Page 8 of 20 / IM 1072 Water to Water Source Heat Pumps

Auxiliary Load Domestic

Page 9

Dimensional Data – WRA, WCA, WHA – Size 120-180

Dimensions - Size 120-150

Dimensions (inches) Water Connections Size

A B C D E F G H K L M N P Q R S

26¼ 19½ 12¼ 4½ 8⅜ 22¼ 4⅜ 18¾ 41 22⅛ 34 1 113/16 37 29¾ 42 1½"

Load Source FPT

Dimensions - Size 180

Dimensions (inches) Water Connections Size

A B C D E F G H K L M N P Q R S

26¼ 19½ 12¼ 4½ 8⅜ 22¼ 4⅜ 18¾ 41 22⅛ 34 1 113/16 37 29¾ 42 2"

Water to Water Source Heat Pumps IM 1072 / Page 9 of 20

Load Source FPT

Page 10

Dimensional Data – WRA, WCA, WHA – Size 240-420

Dimensions - Size 240-420

Dimensions (inches) Water Connections Size

A B C D E F K L M N P Q R S

31 20⅞ 16½ 4⅞ 22½ 27½ 63⅛ 22⅛ 34 1 113/16 52⅛ 44⅛ 50 2"

Page 10 of 20 / IM 1072 Water to Water Source Heat Pumps

Load Source FPT

Page 11

Physical Data – WRA, WCA, WHA 036 – 420

Unit Size

Nominal

036

048

060

072

120

150

180

240

300

360

420

Cooling Mode Operating Pressures (PSIG)

WRA and WCA Models

Leaving

Load °F

45 90–109 210–250 95–110 270–310 98–115 355–395

50 97–114 215–255 100–115 280–315 105–123 365–410

55 106–123 220–265 110–125 285–320 118–135 385–420

Heating Mode Operating Pressures (PSIG)

WRA and WHA Models

100 66–90 375–410 90–114 398–435 120–143 420–455 145–170 445–490

120 66–90 503–542 92–115 515–556 123–145 530–570 153–175 555–600

Entering

Load °F

80 63–87 275–318 85–110 295–332 115–138 325–365 138–162 365–400

BTUH

Cooling

36,000

48,000

60,000

72,000

120,000

150,000

180,000

240,000

300,000

360,000

420,000

Cabinet Cabinet Cabinet

Width

28.125

28.125

28.125

35.125

34.00

34.00

34.00

34.00

34.00

34.00

34.00

Depth

28.125

28.125

28.125

28.125

42.00

42.00

42.00

50.00

50.00

50.00

50.00

Height

19.00

21.00

21.00

21.00

41.00

41.00

41.00

63.13

63.125

63.125

63.125

Operating Shipping

Weight lbs. Weight lbs.

250

297

302

320

570

735

900

1040

1130

1420

1620

259

300

305

370

610

770

950

1140

1230

1540

1750

Entering Source Temperature °F

50 70 90

Suction Discharge Suction Discharge Suction Discharge

Entering Source Temperature °F

30 50 70 90

Suction Discharge Suction Discharge Suction Discharge

Refrigeration

Charge

2.80

3.50

4.40

5.00

2.75

4.25

8.00

10.00

16.00

17.50

20.00

Water Connection

FPT

.75

1.00

1.00

1.00

1.50

1.50

1.50

2.00

2.00

2.00

2.00

Antifreeze Correction Factors (Load Side)

Ethylene Glycol

Cooling Capacity 0.9950 0.9920 0.9870 0.9830 0.9790

Heating Capacity 0.9910 0.9820 0.9770 0.9690 0.9610

Pressure Drop 1.0700 1.1300 1.1800 1.2600 1.2800

Propylene Glycol

10% 20% 30% 40% 50%

Cooling Capacity 0.9900 0.9800 0.9700 0.9600 0.9500

Heating Capacity 0.9870 0.9750 0.9620 0.9420 0.9300

Pressure Drop 1.0700 1.1500 1.2500 1.3700 1.4200

Note:

Manufacturer recommends maximum glycol mixture not to exceed 25%

Methanol

10% 20% 30% 40% 50%

Cooling Capacity 0.9980 0.9720 – – –

Heating Capacity 0.9950 0.9700 – – –

Pressure Drop 1.0230 1.0570 – – –

Ethanol

10% 20% 30% 40% 50%

Cooling Capacity 0.9910 0.9510 – – –

Heating Capacity 0.9950 0.9600 – – –

Pressure Drop 1.0350 0.9600 – – –

10% 20% 30% 40% 50%

Water to Water Source Heat Pumps IM 1072 / Page 11 of 20

Page 12

Wiring Diagram – 208-230/60/1 Phase, unit Sizes 036, 048, 060

and 072

Page 12 of 20 / IM 1072 Water to Water Source Heat Pumps

Page 13

Wiring Diagram – 3 Phase, Unit Sizes 036, 048, 060 and 072

Water to Water Source Heat Pumps IM 1072 / Page 13 of 20

Page 14

Wiring Diagram – 3 Phase, Unit Sizes 120, 150, 180, 240, 300, 360

and 420

Page 14 of 20 / IM 1072 Water to Water Source Heat Pumps

Page 15

WHA Circuit Diagram

WHA

Load Coil = Heater-Condenser

Source Coil = Evaporator

Water to Water Source Heat Pumps IM 1072 / Page 15 of 20

Page 16

WRA Circuit Diagram

WRA

Reverse Cycle

No Domestic Hot Water

WRA

Reverse Cycle

With Domestic Hot Water H.R. Coil

Page 16 of 20 / IM 1072 Water to Water Source Heat Pumps

Page 17

WCA Circuit Diagram

WCA

Load Coil = Chiller-Evaporator

Source Coil = Condenser

No Domestic Hot Water

WCA

Load Coil = Chiller-Evaporator

Source Coil = Condenser

With Domestic Hot Water H.R. Coil

Water to Water Source Heat Pumps IM 1072 / Page 17 of 20

Page 18

Check, Test and Start Form

General Information

Customer Name ____________________________________ Dealer Name ______________________________________

Address ___________________________________________ Address __________________________________________

__________________________________________________ _________________________________________________

__________________________________________________ _________________________________________________

Phone # ___________________________________________ Phone # __________________________________________

Product Information

Unit Model # ____________________________________________________________

Unit Serial # _____________________________________________________________

Source Coil Application Ground Source Open Well Other _________________

Load Coil Application Fan Coil Unit Radiant Htg/Clg Coils Baseboard Radiation

Other _____________________________________________

Voltage _____________ Amperage ________________ Phase ________________ Transformer Volts _______________

Unit Function

HEATING (WRA & WHA) ENTERING LEAVING DIFF (TD)

Load Liquid Temperature, °F

From fan coil unit, radiant coils,

baseboard radiation, etc. _________________ _________________ ________________

Source Liquid Temperature, °F

From well, geothermal closed loop,

plate heat exchanger, etc. _________________ _________________ ________________

COOLING (WRA & WCA)

Load Liquid Temperature, °F

To fan coil unit, radiant coils,

baseboard radiation, etc. _________________ _________________ ________________

Source Liquid Temperature, °F

From well, geothermal closed loop,

plate heat exchanger, etc. _________________ _________________ ________________

Load Fluid Pressure FT. HD or PSIG

[Note 1 PSIG = 2.31 FT. HD] _________________ ________________ _________________

Source Fluid Pressure _________________ ________________ _________________

Load GPM ____________________ Source GPM __________________

Source Fluid Water Anti-freeze

HA or HR = 500 x TD x GPM For Anti-Freeze solution = 485 x TD x GPM

Calculation __________ x __________ x __________ = ________________

(Load) 500 or 485 TD GPM HA or HR

Check product performance tables on page 11 to determine if calculation is within 10% of table value.

Page 18 of 20 / IM 1072 Water to Water Source Heat Pumps

Page 19

General Service Guide

All models employ an electromechanical control system for maximum reliability.

Symptom Possible Trouble Method of Finding

1. Noisy Operation. a. Chattering contactor noise. a. Check contactor points, check for adequate control

voltage from transformer, and check control circuit

for shorts or breaks, check thermostat.

2. Compressor will a. Lock Out Relay Open. a. Turn thermostat off, then on.

not start.

b. Loose electrical connections. b. Check all connections at contactor and compressor

terminal box for loose or burned connection on terminal.

c. Refrigerant charge lost, low pressure c. Check for R-410A pressure.

cutout open.

d. No control voltage to the compressor d. Check for 24 volts across contactor coil.

contactor. If no voltage, check for thermostat circuit trouble

or for compressor safety controls open.

e. Contactor pulled in, but compressor still e. Check compressor overload circuit, contactor points, etc.

won’t start.

3. Compressor starts but a. Run capacitor could be bad. a. Check capacitor.

hums and trips out

on overload. b. Voltage may be low. b. Check it.

c. Seized bearings on compressor. c. Replace compressor.

4. Compressor starts but a. Lowliquidow(heatingcycle). a. Checkliquidow.

cuts out on low

pressure control. b. Low refrigerant charge. b. Remove refrigerant, repair leak and recharge.

c. Restriction in liquid refrigerant line. c. Check pressures and look for frosting across

the restriction.

d. Lowairow(coolingcycle). d. Checkandcorrect.

e. Low pressure cutout may have incorrect e. Check low pressure cutout for correct pressure.

pressure function.

5. Compressor starts a. Condenser coils limed or restricted. a. Check it. (Open systems)

but cuts out on high

pressure control. b. Malfunctioning high pressure control. b. Check that the control is cutting out at the correct

pressure.

c. Reducedorlackofliquidow. c. Checkliquid.

d. Reducedevaporatorairow d. Checkairow.

(heating cycle).

6. Compressor runs on a. Reversing valve may be defective. a. See that it has shifted.

heating cycle,

but does not heat. b. Thermostat may be defective. b. Check wiring diagram.

Water to Water Source Heat Pumps IM 1072 / Page 19 of 20

Page 20

Replacement Parts List

# Description 036 048 060 072 120 150 180 240 300 360 420

1 Expansion Valve* 564-672 564-672 564-670 546-671 564-670 564-671 561-664 564-673 564-676 564-676 564-676

2 Contactor 841-040 841-040 841-040 841-040 841-039 841-039 841-072 841-072 841-072 841-155 841-162

3 Reversing Valve 564-677 564-508 564-609 564-508 564-508 564-608 564-608 564-574 564-574 564-589 564-589

4 Microprocessor 872-089 872-089 872-089 872-089 872-089 872-089 872-089 872-089 872-089 872-089 872-089

5

6 High Pressure

7

8

8

10

11

12

13

*Where same valve is used in two or more units superheat settings may differ. Consult factory for valve with correct setting.

(Compressor)

Board (comp ctrl)

Capacitor

(Compressor)

Switch (HP)

Low Pressure

Switch (LP1)

Fluid/Refrigerant

Coil S/W Copper

Fluid/Refrigerant

Coil S/W CU-NI

9 Transformer 846-056 846-056 846-056 846-056 846-129 846-129 846-129 846-129 846-129 846-129 846-129

Low pressure

switch (LP2)

230/3

Compressor

Reversing Valve

Coil

Refrigerant

Charge R-410A lb.

841-039 841-039 841-039 841-039 841-021

(1) (1) (1) (1) (2)

844-142 844-142 844-142 844-142 844-142 844-142 844-142 844-142 844-142 844-142 844-142

844-151 844-151 844-151 844-151 844-151 844-151 844-151 844-151 844-151 844-151 844-151

512-200 512-201 512-201 512-259 512-201 512-202 512-200 512-201 512-202 512-201 512-202

512-200 512-201 512-201 512-259 512-201 512-202 512-200 512-201 512-202 512-201 512-202

844-150 844-150 844-150 844-150 844-150 844-150 844-150 844-150 844-150 844-150 844-150

800-840 800-805 800-820 800-803 800-821 800-804 800-800 800-812 800-1014 800-814 800-914

874-209 874-209 874-209 874-209 874-209 874-209 874-209 874-209 874-209 874-209 874-209

(1) (1) (1) (1) (2)

2.8 3.5 4.4 5 5.5 8.5 16 20 32 35 40

841-021 841-039 841-039 841-039 841-072 841-065

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

(2)

4900 Technology Park Boulevard • Auburn, New York 13021-9030 • 1.800.432.1342 • USA IM 1072 / Page 20 of 20 (3-10)

©2010 McQuay International

Loading...

Loading...