Page 1

Installation & Maintenance Manual

Vertical Stack Water Source Heat Pumps

Model VHC Vertical Stack Chassis

Model VHF Vertical Stack Cabinet

Unit Sizes 009 – 036 / R-410A Refrigerant

IM 986-2

Group: WSHP

Part Number: 669646403

Date: May 2012

©2012 McQuay International • 800.432.1342 • www.daikinmcquay.com

Page 2

Page 2 of 48 / IM 986-2

Page 3

Table of Contents

Model Nomenclature ............................ 4-5

Vertical Stack Model VHF (Cabinet)...............4

Vertical Stack Model VHC (Chassis)...............5

Receiving, Storage & Handling ................... 6-7

Disassembling Upper & Lower Cabinet Sections..... 7-8

Dimensional Data .............................. 9-10

Unit Size 009-018 ..............................9

Unit Size 021-036 .............................10

Pre-Installation Considerations ....................11

Cabinet Configurations...........................12

Typical Framing & Discharge Arrangements.........13

Critical Dimensions ..............................14

Framing Locations to Unit Openings..............14

Vertical Riser Stub-Outs Locations to

Unit Knockouts...............................14

Return Air Grille/Panel Dimensions...............15

Installation Procedure.........................16-26

Risers & Cabinet........................... 16-17

Cleaning & Flushing Water System............ 17-19

Power Wiring From Building to Unit...........19-20

Connect Condensate Drain Hose to Drain Stubout ...20

Water Connections ......................... 20-21

Installing Unit Chassis .........................22

Making Cabinet to Chassis Wiring Connections . . . . . 22

Installing & Wiring the Remote Control Node ......23

Installing the Return Air Grille/Panel..............24

Installing the Discharge Air Diffuser ..............25

Twin Units Installation .........................26

Controls..................................... 27-34

MicroTech III Unit Controller ................... 27

Remote Reset Feature ..........................27

MicroTech III Controller Terminal Locations

& Descriptions ............................ 28-29

I/O Expansion Module .........................30

MicroTech III Controller with Lon Module.........31

MicroTech III Controller with BACnet Module .. 32-33

MicroTech III Controller with Lon Module on

Board Diagram ...............................34

Typical Wiring Diagrams ...................... 35-38

MicroTech III Unit Controller, 2-Speed Fan (Toggle or

Thermostat), PSC Motor 208-230/60Hz/1-Phase,

Unit Sizes 009-018............................35

MicroTech III Unit Controller, 2-Speed Fan (Toggle or

Thermostat), PSC Motor 265-277/60Hz/1-Phase,

Unit Sizes 009-036............................36

MicroTech III Unit Controller, 2-Speed Fan (Toggle or

Thermostat), X13 Motor 208-230/60Hz/1-Phase,

Unit Sizes 021-036............................37

MicroTech III Unit Controller, 2-Speed Fan (Toggle or

Thermostat), X13 Motor 265-277/60Hz/1-Phase,

Unit Sizes 021-036............................38

Start-up........................................39

Additional Accessories (General) ................ 39-43

Thermostats & Temperature Sensors ........... 39-43

Troubleshooting .............................. 44-47

The in and outs of R-410A ......................44

Refrigeration Circuit...........................45

The Water Source Heat Pump Unit ...............46

General Use & Information .....................47

IM 986-2 / Page 3 of 48

Page 4

Model Nomenclature

Vertical Stack Water Source Heat Pump – Cabinet (VHF)

W VHF 1 009 B E DP LRY F 12 S 088

Product

Category

W - WSHP

Product Code

VHF - Cabinet

Design Series

1

2

Unit Size - Tons

009 - 3/4 Ton

012 - 1 Ton

015 - 1-1/4 Ton

018 - 1-1/2 Ton

021 - 1-3/4 Ton

024 - 2 Ton

030 - 2-1/2 Ton

036 - 3 Ton

Controls

B - MicroTech III

C - MicroTech III With LonWorks

D - MicroTech III With BACnet

Voltage

A - 115/60/1 ph

E - 208-230/60/1 ph

J - 265-277/60/1 ph

Secondary Drain Pan

GL - Standard Galvanized Steel

SS - Stainless Steel

Cabinet Type

080 - 80" Cabinet Height

088 - 88" Cabinet Height

092 - 92" Cabinet Height

096 - 96" Cabinet Height

Filter Option

S - Standard 1" Throwaway

P - 2" Pleated (Merv 7)

Y - None

Blower Motor

12 - 2-Speed PSC Motor

32 - ECM 2-speed 2.3 Motor

33 - ECM 2-speed X13 Motor

Power Connection

F - Fused Disconnect

N - Non-Fused Disconnect

H - HACR Breaker

Supply Air Conguration

LYY - Single Supply Outlet, Left Side

RYY - Single Supply Outlet, Right Side

FYY - Single Supply Outlet, Front Side

BYY - Single Back Side Supply Outlet

TYY - Single Top Supply Outlet

LFY - Double Supply, Left Side and Front Side

LRY - Double Supply, Left Side and Right Side

LBY - Double Supply, Left Side and Back Side

RFY - Double Supply, Right Side and Front Side

RBY - Double Supply, Right Side and Back Side

BFY - Double Supply, Back Side and Front Side

LTY - Double Supply, Left Side and Top

RTY - Double Supply, Right Side and Top

BTY - Double Supply, Back Side and Top

FTY - Double Supply, Front Side and Top

LFT - Triple Supply, Left Side, Front Side and Top

LRT - Triple Supply, Left Side, Right Side and Top

FRT - Triple Supply, Front Side, Right Side and Top

FBT - Triple Supply, Front Side, Back Side and Top

BRT - Triple Supply, Back Side, Right Side and Top

BLT - Triple Supply, Back Side, Left Side and Top

YYY - Closed Supply Plenum for eld modication

Page 4 of 48 / IM 986-2

Note: For illustration purposes only. Not all options avail-

able with all models.

Please consult McQuay Sales Representative for

specic availability.

Page 5

Model Nomenclature

Vertical Stack Water Source Heat Pump – Chassis (VHC)

W VHC 1 012 B E A C AMY C

Product

Category

W - WSHP

Product Code

VHC - Chassis

Design Series

1

2

Unit Size - Tons

009 - 3/4 Ton

012 - 1 Ton

015 - 1-1/ 4 Ton

018 - 1-1/2 Ton

021 - 1-3/4 Ton

024 - 2 Ton

030 - 2-1/2 Ton

036 - 3 Ton

Controls

B - MicroTech III

C - MicroTech III With L

D - MicroTech III With BACnet

onWorks

Voltage

A - 115/60/1 ph

E - 208-230/60/1 ph

J - 265-277/60/1 ph

Coax Coil Construction

C - Copper Inner - Steel Outer

S - CuproNickel Inner - Steel Outer

X - Special

Chassis Construction

AYY - Standard Fiberglass Insulation

EYY - IAQ - Cellular Insulation

AMY - Standard w/Compressor Blanket

EMY - IAQ w/Compressor Blanket

AYC - Standard w/E-Coated Air Coil

EYC - IAQ - Cellular w/E-Coated Air Coil

AMC - Standard w/Comp Blanket and Coated Air Coil

EMC - IAQ w/Comp Blanket and Coated Air Coil

Motorized 2-Way Isolation Valve

C - 2-Way Motorized 1/2" Iso-Valve, General Close-Off Pressure N.C.

(Normally Closed)

V - 2-Way Motorized 1/2" Iso-Valve, General Close-Off Pressure N.O.

(Normally Open)

H - 2-Way Motorized 1/2" Iso-Valve, High Close-Off Pressure N.C.

(Normally Closed)

D - 2-Way Motorized 3/4" Iso-Valve, General Close-Off Pressure N.C.

(Normally Closed)

K - 2-Way Motorized 3/4" Iso-Valve, General Close-Off Pressure N.O.

(Normally Open)

J - 2-Way Motorized 3/4" Iso-Valve, High Close-Off Pressure N.C.

(Normally Closed)

Y - None

X - Special

Refrigerant

A - R-410A

X - Special

Note: For illustration purposes only. Not all options

available with all models.

Please consult McQuay Sales Representative

for specic availability.

IM 986-2 / Page 5 of 48

Page 6

Receiving and Storage

Upon receipt of the equipment, check the carton and

pallets for visible damage. Make a notation on the

shipper’s delivery ticket before signing. If there is any

evidence of rough handling, immediately open the

cartons to check for concealed damage. If any damage

is found, notify the carrier within 48 hours to establish

your claim and request their inspection and a report.

The Warranty Claims Department should then be

contacted.

IMPORTANT

This product was carefully packed and thoroughly

inspected before leaving the factory. Responsibility for its

safe delivery was assumed by the carrier upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must therefore be made upon the carrier as follows:

VISIBLE LOSS OR DAMAGE

Any external evidence of loss or damage must be noted

on the freight bill or carrier’s receipt, and signed by the

carrier’s agent. Failure to adequately describe such

external evidence of loss or damage may result in the

carrier’s refusal to honor a damage claim. The form

required to le such a claim will be supplied by the carrier.

CONCEALED LOSS OR DAMAGE

Concealed loss or damage means loss or damage which

does not become apparent until the product has been

unpacked. The contents may be damaged in transit due

to rough handling even though the carton may not show

external damages. When the damage is discovered upon

unpacking, make a written request for inspection by the

carrier’s agent within fteen (15) days of the delivery date

and le a claim with the carrier.

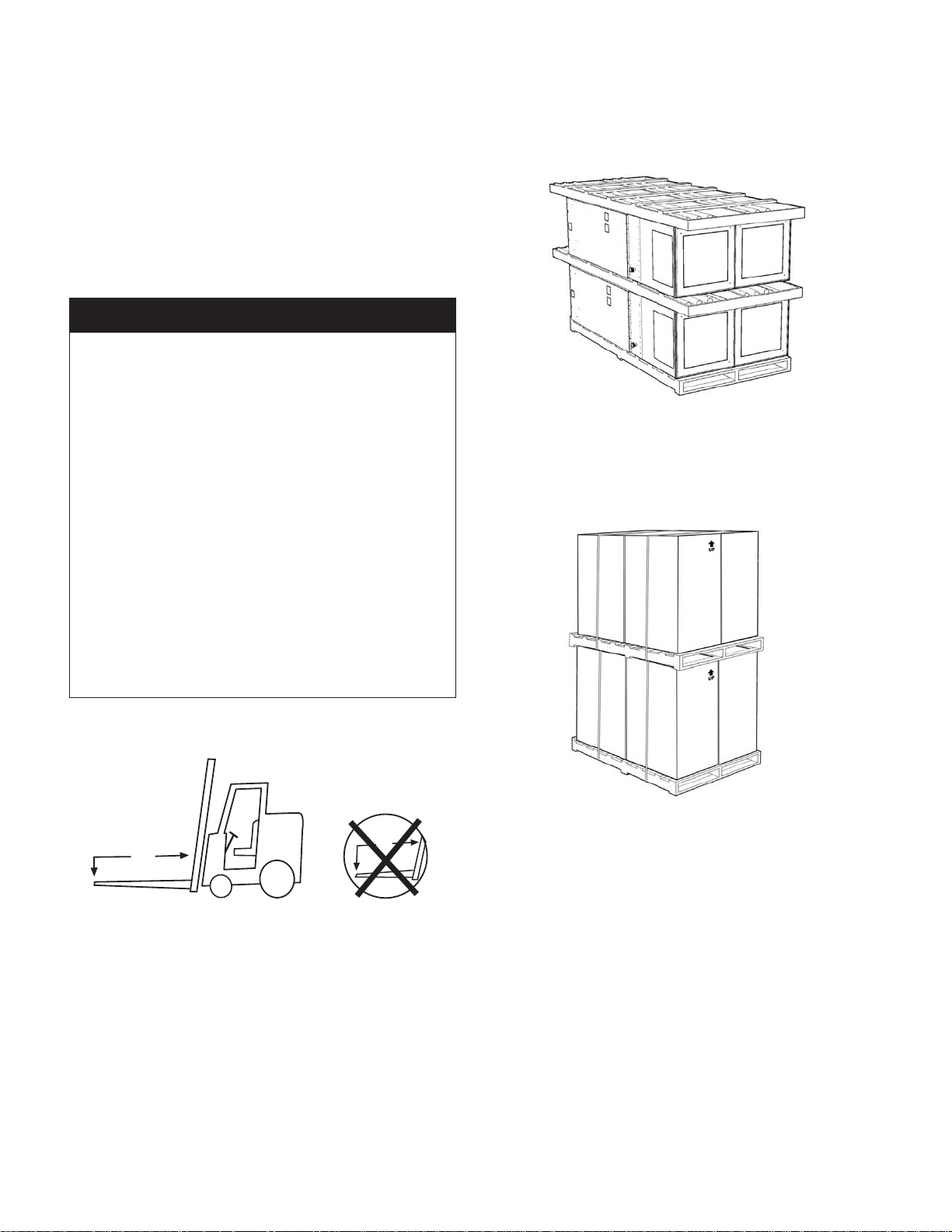

Cabinet Skid (4-units per skid)

Never stack cabinets higher than as illustrated in Figure

1 at any time during transportation or storage or damage

may occur.

Figure 1: Unit Cabinet Skid as Shipped and Stored

Chassis Skid (4 per skid, stored two skids high)

Never stack chassis´ higher than as illustrated in Figure

2 at any time during transportation or storage or damage

may occur.

Figure 2: Chassis Skids Stacked 2 High Maximum

For storing, each carton is marked with “up” arrows.

4'

6'

Storage and Operating Environment

Temporary storage at the job site must be indoor,

completely sheltered from rain, snow, etc. High or low

temperatures naturally associated with weather patterns

will not harm the units. Excessively high temperatures,

140°F (60°C) and higher, may deteriorate certain plastic

materials and cause permanent damage.

Storage Temperature:

-40ºF (-40ºC) to 140ºF (60ºC)

Operating Temperature:

32ºF (0ºC) to 140ºF (60ºC)

Humidity:

10%RH to 90%RH Non-condensing

PCB Material and Flammability Rating:

IPC/ANSI FR or CEM material as required to meet UL

94V-0 ammability rating.

Page 6 of 48 / IM 986-2

Page 7

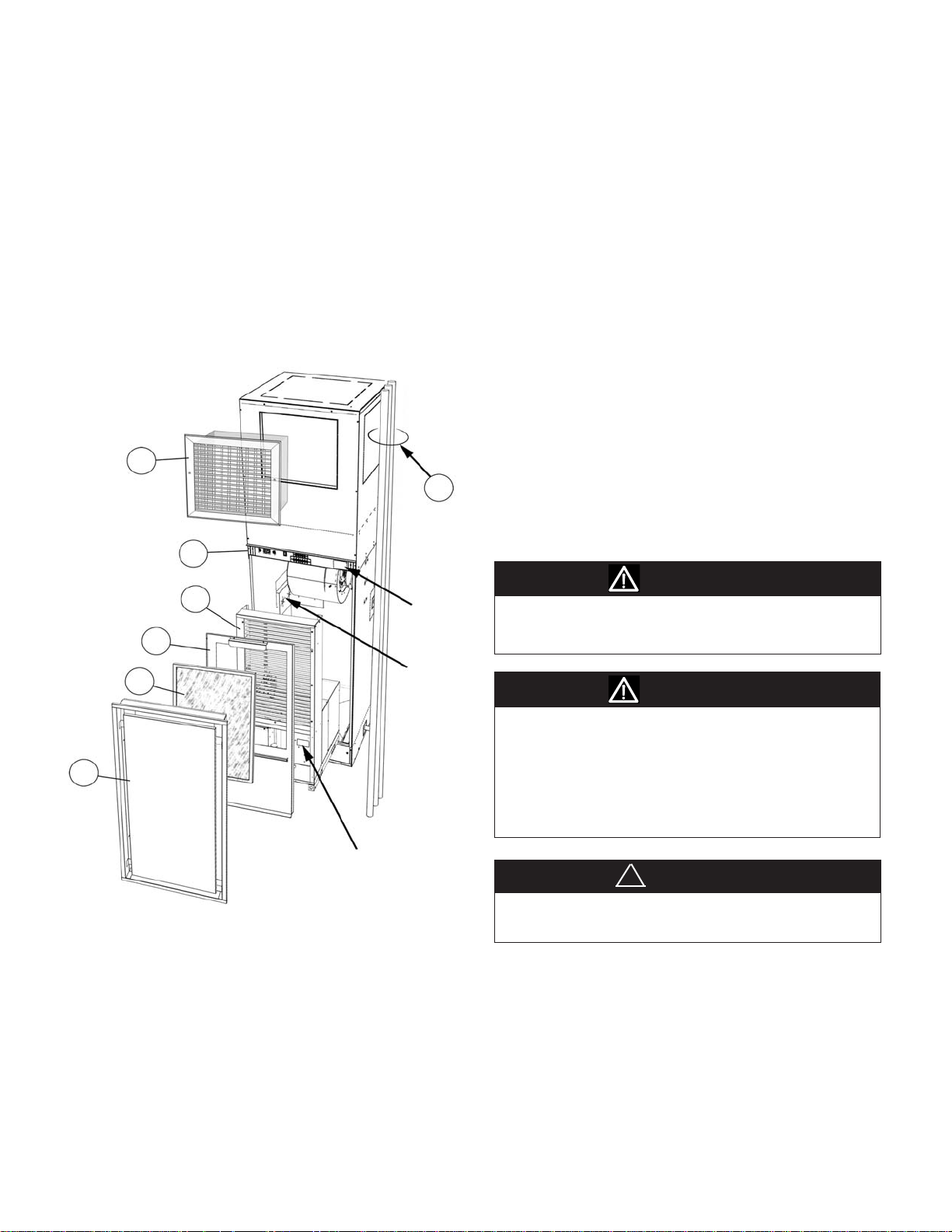

Handling

Carefully check items against the bills of lading to

verify all crates and cartons have been received.

Cabinets and Chassis normally ship four to a pallet.

Carefully inspect all units for shipping damage. Report

damage immediately to the carrier and le a claim.

Check the unit data plate to be sure the unit electrical

agrees with the power supply available (Figures 3).

Figure 3: Unit Components & Descriptions - Received as

Assembled Cabinet with Chassis Shipped Separate

4

1a

1

2

1b

1b

3

Unit

Data Plate

Stub-out

Seals

DO NOT handle units by the riser piping. Riser clamps

hold the riser in position; they are not designed to

support the cabinet weight. The clamps are removed

after the unit is installed.

Unit cabinets are factory assembled and wired and

have individual thermostat control capability. They are

installed by stacking one unit on top of the other. While

installing, prevent dirt and other foreign matter from

entering the risers and plugging lines or valves. See

"Cleaning & Flushing Water System" on page 16.

General Information

McQuay Vertical Stack units are designed for use in

multiple oor apartments, ofce buildings, hotels,

nursing homes and other similar applications. They

require a minimum amount of oor space and are

designed for multiple discharge arrangement.

Installation and maintenance must follow accepted

industry practices as described in the ASHRAE

Handbook, the National Electric Code, and other

applicable standards. Install this equipment in

accordance with regulations of authorities having

jurisdiction and with all applicable codes.

WARNING

Installation and maintenance are to be performed by

qualied personnel who are familiar with local codes and

regulations, and experienced with this type of equipment.

WARNING

The installer must determine and follow all applicable

codes and regulations. This equipment presents hazards

of electricity, rotating parts, sharp edges, heat and weight.

Failure to read and follow these instructions can result in

property damage, severe personal injury or death. This

equipment must be installed by experienced, trained

personnel only.

Chassis

Data Plate

Component Descriptions (Assembled

Cabinet)

1. Cabinet assembly complete (without chassis)

1a. Pipe riser sets (inlet, outlet and condensate)

1b. Inner front panel and lter bracket

2. Cooling and heating chassis (shipped separate)

3. Return air grille/panel (accessory)

4. Double-deection diffuser (accessory)

!

CAUTION

Sharp metal edges are a hazard, use care when servicing

to avoid contact with them.

IM 986-2 / Page 7 of 48

Page 8

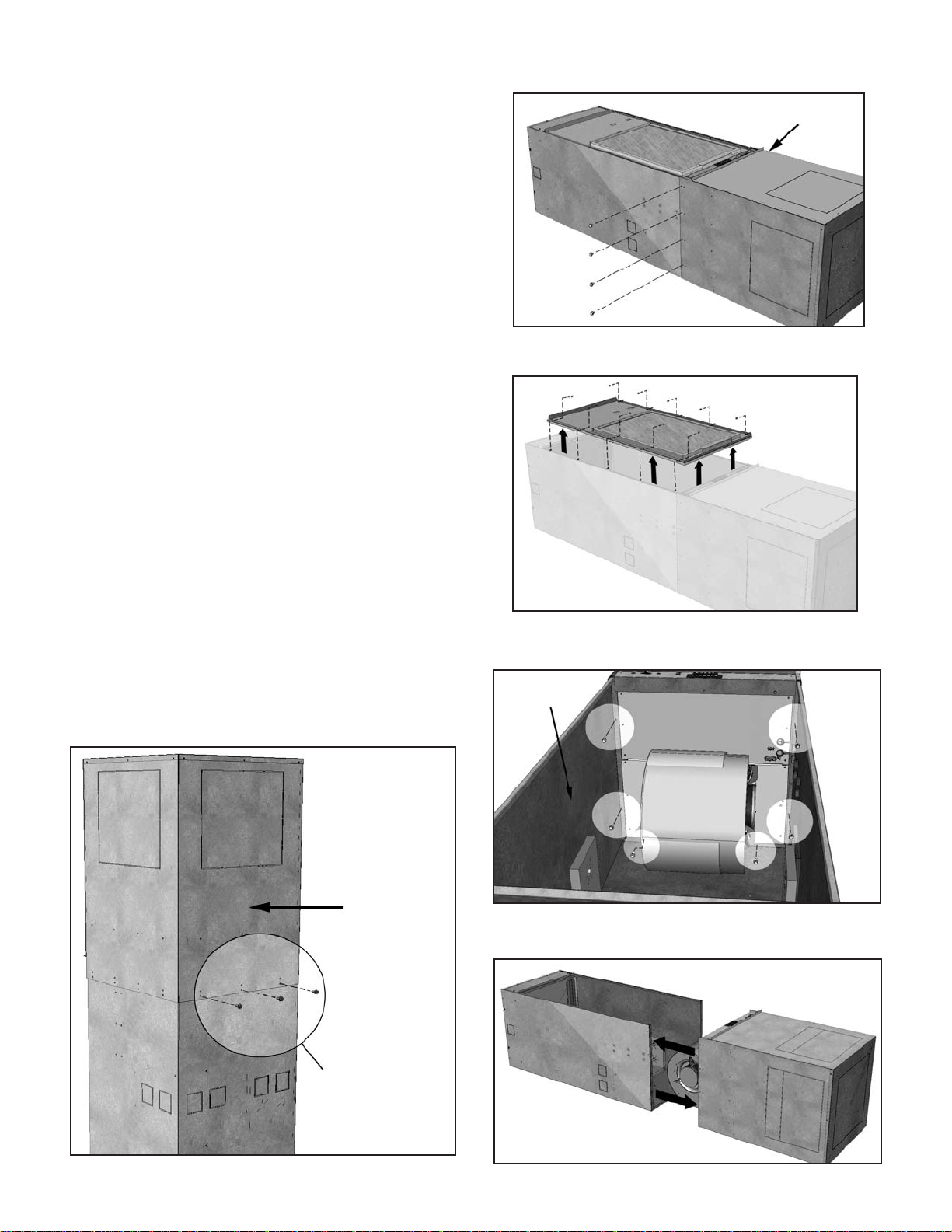

Disassembling Upper and Lower

Cabinet Sections

The Vertical Stack unit cabinet ships completely

assembled. If required, it may be disassembled into two

(2) sections (upper-fan/discharge cabinet) and (lower

chassis/return air cabinet) to make it easier to handle. To

disassemble, do the following.

1. Remove risers (if received attached).

2. Remove the three (bottom row) screws on the back

of the unit as shown in Figure 4.

Note: Retain all screws for later use to reassemble

unit in reverse order as described in steps 1-7.

Number of screws will vary depending on unit size.

3. Carefully lay the unit down on its back and remove

the remaining eight (8) screws on the left and right

side of the cabinet (Figure 5).

5. Remove the ten (10) screws and lift off the front

panel/lter rack to gain access to the cabinet interior

(Figure 6).

Figure 5: Remove remaining eight (8) screws on the left and

right sides of the cabinet

Four (4) screws located

on left side of cabinet

Figure 6: Remove the ten (10) screws from the front panel/

lter rack.

6. Locate and remove the six (6) screws located inside

the cabinet joining the upper and lower cabinet

sections (Figure 7).

Note: Pull the insulaton away from the walls of the

cabinet interior to get access to the screws.

7. Separate the lower return air cabinet section from

the upper blower/discharge cabinet section

(Figure 8).

Figure 4: Remove three (3) screws (bottom row) on the back

of the unit.

Back of Unit

Figure 7: Remove the six (6) screws located on the interior

of the unit.

Return air cabinet

section interior

Figure 8: Separate the lower cabinet section from the upper

cabinet

Page 8 of 48 / IM 986-2

Three screws (bottom row)

Page 9

Dimensional Data

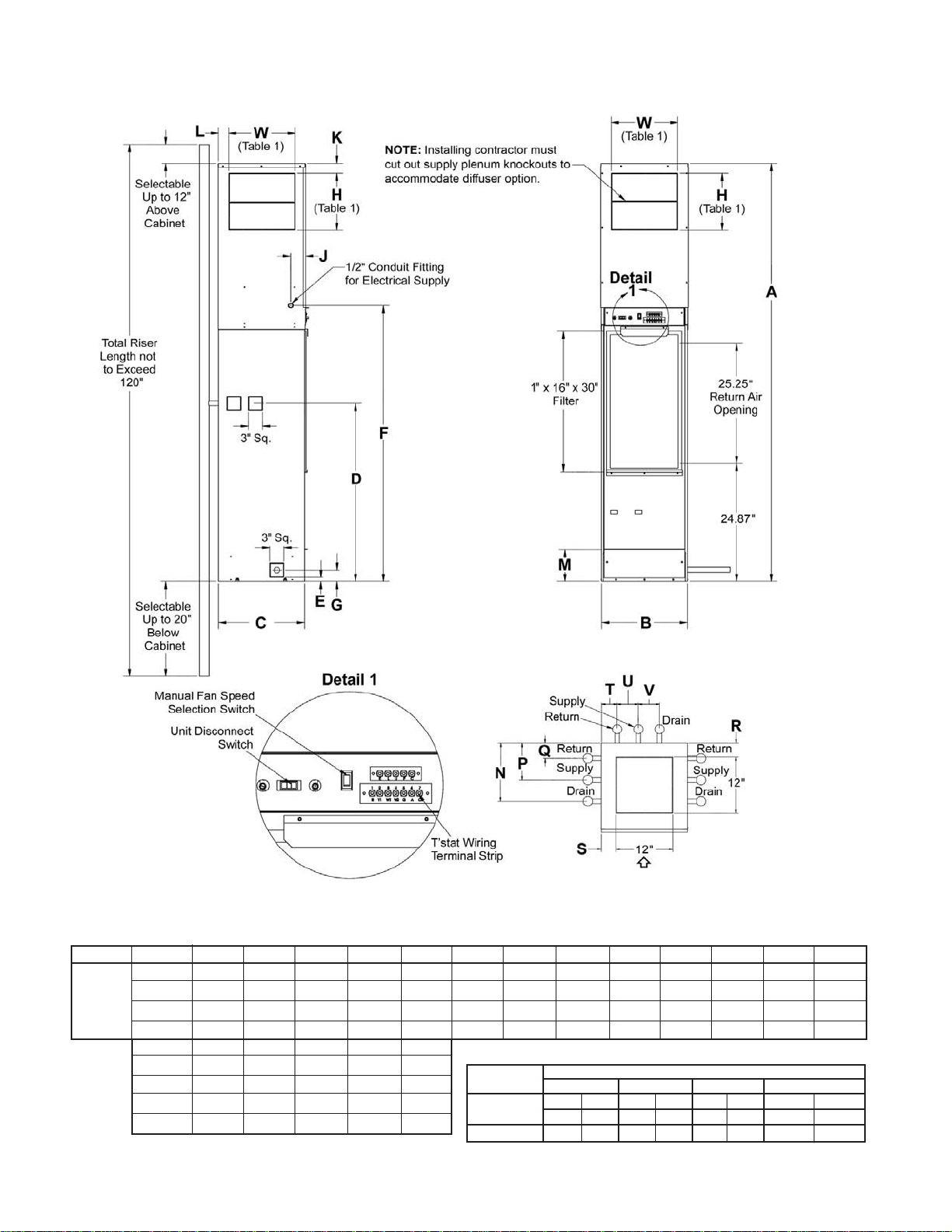

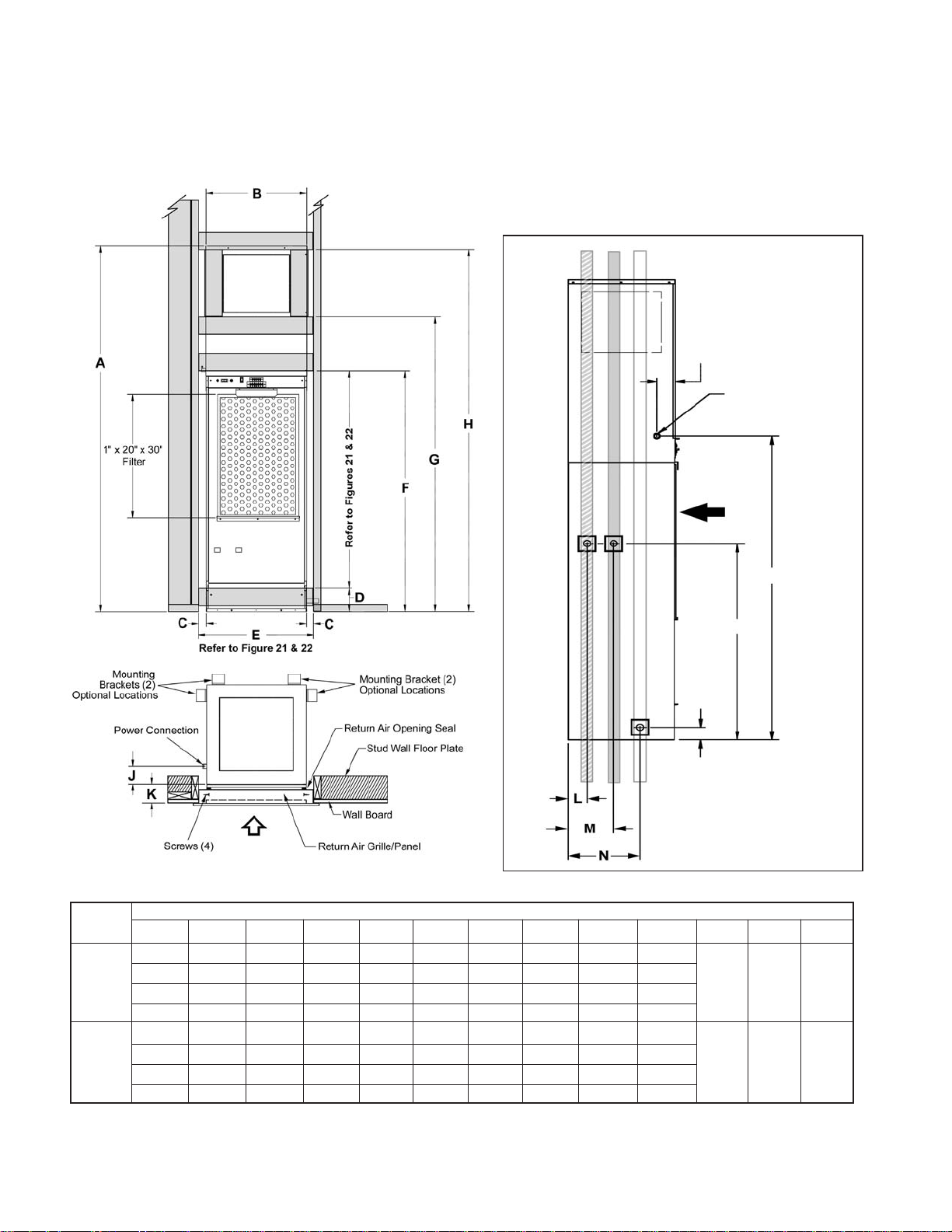

Figure 9: Model VHC/VHF – 18" × 18" Cabinet – Size 009-018

Left Side View

Front View

Top View

Dimensions

80" 18.07" 18.11" 37.50" .88" 58.09" 2.38" 3.125" 2" 2" 6.72" 12.4" 7.9" 3.3"

Unit Size

009–018

18" × 18"

Cabinet

A B C D E F G J K L M N P Q

88" 18.07" 18.11" 37.50" .88" 58.09" 2.38" 3.125" 2" 2" 6.72" 12.4" 7.9" 3.3"

92" 18.07" 18.11" 37.50" .88" 58.09" 2.38" 3.125" 2" 2" 6.72" 12.4" 7.9" 3.3"

96" 18.07" 18.11" 37.50" .88" 58.09"

A R S T U V

80" 3" 3" 3.3" 4.5" 4.5"

88" 3" 3" 3.3" 4.5" 4.5"

92" 3" 3" 3.3" 4.5" 4.5"

96" 3" 3" 3.3" 4.5" 4.5"

2.38" 3.125"

Table 1.

Discharge Openings

Unit Size

W H W H W H W H

009 – 012

015 – 018

2" 2" 6.72" 12.4" 7.9" 3.3"

Single Double Triple Single-Top Opening

14" 16" 14" 8" NR NR 12" 12"

14" 16" 14" 8" 14" 8" 12" 12"

NR = Not Recommended

IM 986-2 / Page 9 of 48

Page 10

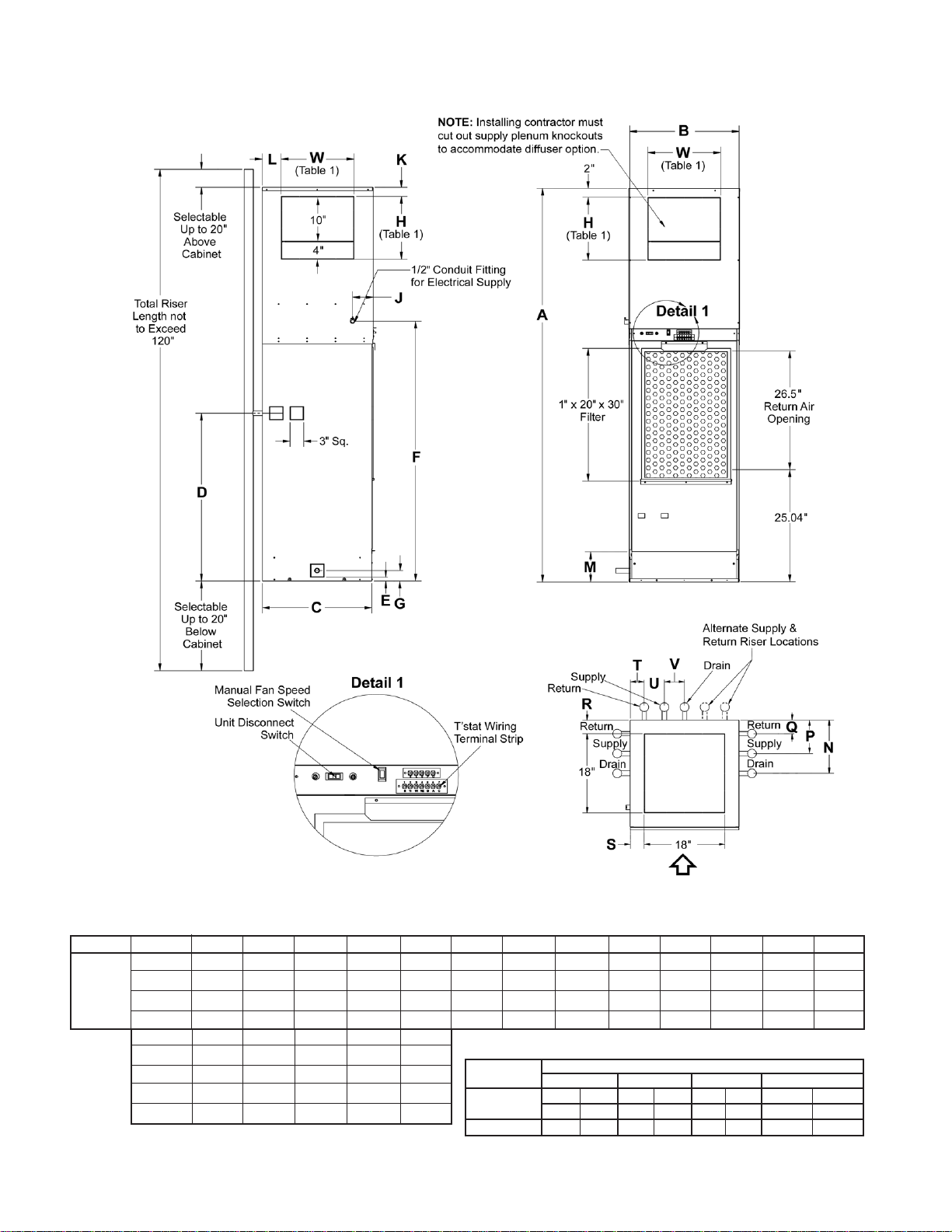

Dimensional Data

Figure 10: Model VHC/VHF – 24" × 24" Cabinet – Size 021-036

Front View

Left Side View

Top View

Dimensions

Unit Size

80" 24" 24.04" 37.50" .88" 58.08" 2.38" 4.54" 2" 3" 6.72" 12.13" 7.63" 3.13"

A B C D E F G J K L M N P Q

021–036

88" 24" 24.04" 37.50" .88" 58.08" 2.38" 4.54" 2" 3" 6.72" 12.13" 7.63" 3.13"

24" × 24"

92" 24" 24.04" 37.50" .88" 58.08" 2.38" 4.54" 2" 3" 6.72" 12.13 7.63" 3.13"

Cabinet

96"

A R S T U V

80" 3.09" 3.10" 3.12" 4.50" 4.50"

88" 3.09" 3.10" 3.12" 4.50" 4.50"

92" 3.09" 3.10" 3.12" 4.50" 4.50"

96" 3.09" 3.10" 3.12" 4.50" 4.50"

24" 24.04"

37.50" .88" 58.08"

2.38" 4.54"

2" 3" 6.72" 12.13" 7.63" 3.13"

Table 1.

Discharge Openings

Unit Size

W H W H W H W H

021 – 024

030 – 036

Single Double Triple Single-Top Opening

NR NR 18" 10" 18" 10" 18" 18"

NR NR 18" 14" 18" 10" 18" 18"

NR = Not Recommended

Page 10 of 48 / IM 986-2

Page 11

Pre-Installation Considerations

1. To prevent damage to equipment, do not operate

supplementary heating and cooling during the

construction period.

2. Inspect the carton for any specic tagging numbers

indicated by the factory per a request from the

installing contractor. At this time the voltage, phase

and capacity should be checked against the plans.

3. Check the unit size against the plans to verify that

the unit is being installed in the correct location.

4. Before installation, check the available dimensions

of the area where the unit is to be installed versus

the dimensions of the unit.

5. Note the location and routing of water piping,

condensate drain piping, and electrical wiring.

The locations of these items are clearly marked on

submittal drawings.

6. The installing contractor will nd it benecial

to confer with piping, sheet metal, and electrical

foremen before installing any unit.

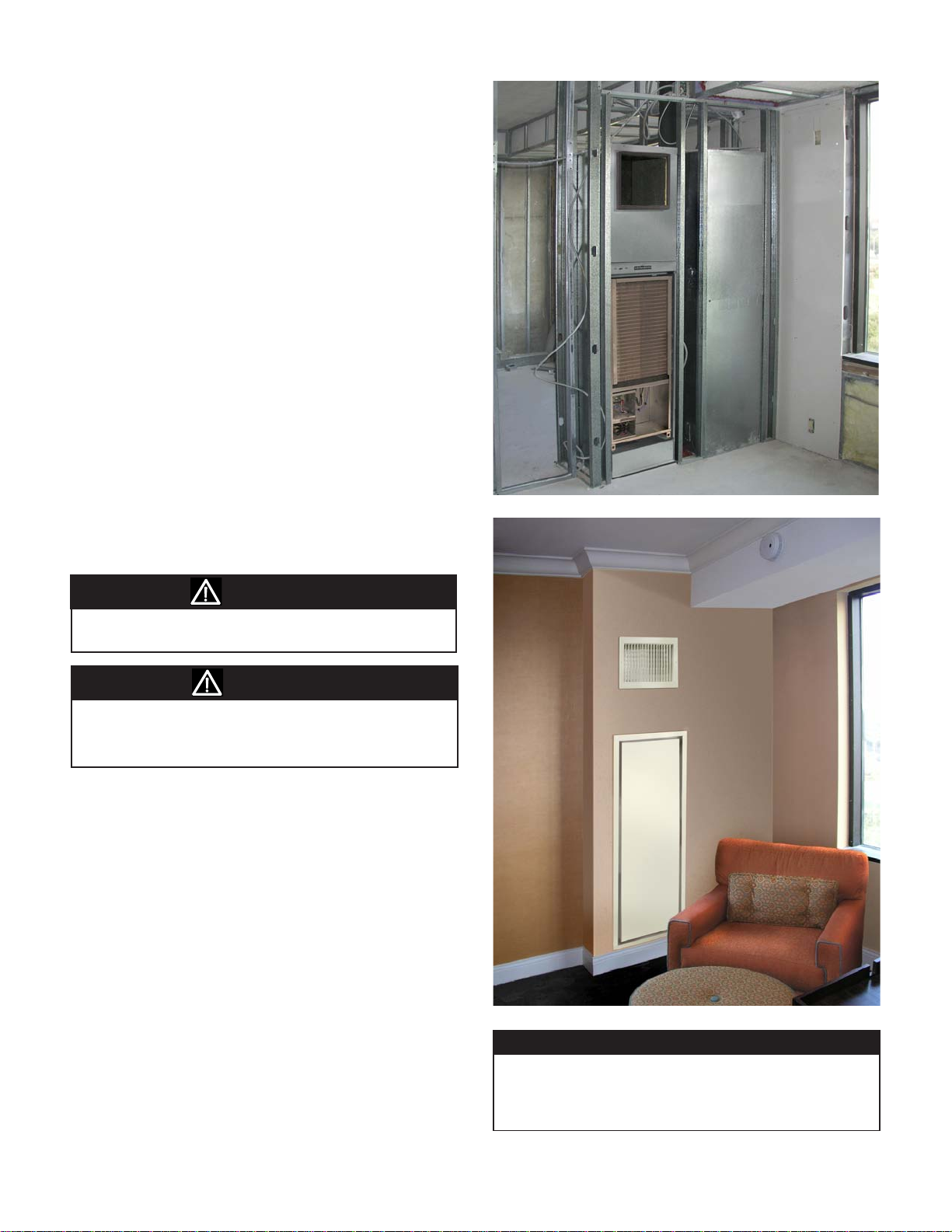

Figure 11: Typical Side by Side Unit Installation

Note: Check the unit data plate for correct voltage

with the plans before installing the equipment.

WARNING

Make sure all electrical ground connections are made in

accordance with local code.

WARNING

The contractor shall cover the units to protect the machines

during nishing of the building. This is critical while spraying

reproong material on bar joists, sandblasting, spray painting

and plastering.

For Optimum Unit Performance and to

Help Minimize Noise and Vibration

● Adhere to the "Critical Dimensions" for locations of

framing and distances to the cabinet.

● Install a 1/4" thick vibration isolation pad under the

entire footprint of the unit cabinet base.

● Be sure there are no kinks and that the stainless

steel braided hoses do not come in contact with and

vibrate on chassis and cause noise.

● Ensure there is no metal-to-metal contact between

return air grille and cabinet and the discharge

diffuser and the cabinet, use provided gaskets.

● Air balancing in ducted applications is critical for

proper airow at each diffuser.

NOTICE

Top air discharge units will require turning vanes and/or a

volume damper for proper air flow and balancing, to minimize turbulence. These components must be field-installed

and furnished in accordance with SMACNA guidelines.

IM 986-2 / Page 11 of 48

Page 12

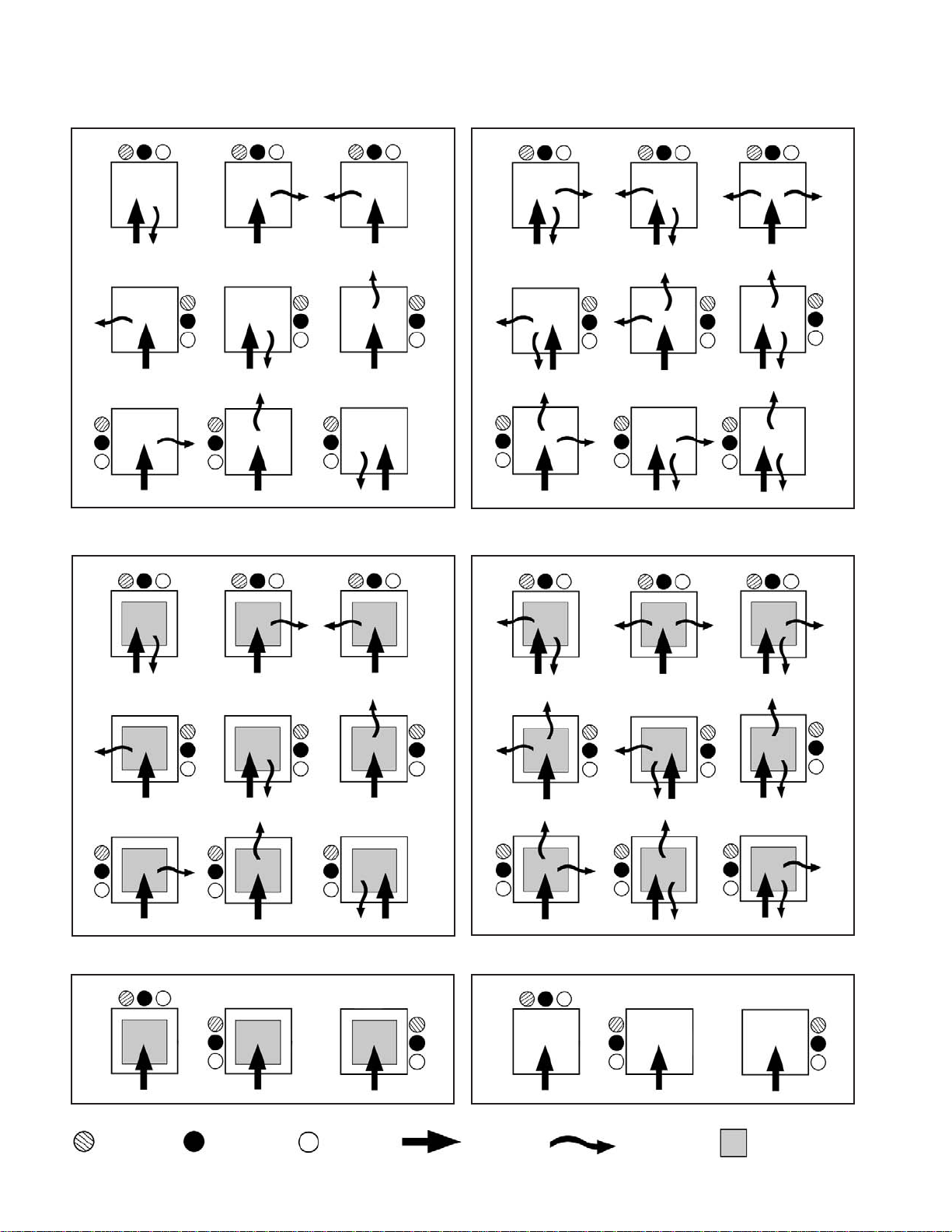

Cabinet Configurations

Figure 12: Single Side Discharge

Figure 13: Double Side Discharge

Figure 14: Side & T op Discharge (See Notice on page 11) Figure 15: Double Side & Top Discharge (See Notice on page 11)

Figure 16: Top Discharge (See Notice on page 11) Figure 17: Closed Plenum – Field Modication Required

= Return Riser = Supply Riser = Drain = Return Air = Discharge Air = Top Discharge

Page 12 of 48 / IM 986-2

Page 13

Figure 18: Typical Framing & Discharge Arrangements

Double Side Discharge

= Return Air

= Discharge Air

Typical Ducted

Application

NOTICE

Top air discharge units will require turning vanes and/or a

volume damper for proper air flow and balancing, to minimize turbulence. These components must be field-installed

and furnished in accordance with SMACNA guidelines.

Note: All ducted applications require a unit that utilizes an ECM-X13 or ECM 2.3 motor (sizes 021-036).

X13 motors are factory set for 2-speeds, 2 and 4 tap. For ducted unit applications only position 1 and 2-speed

motor taps should be used.

Additionally, static pressure must not exceed 0.40 inch static. See table below.

ECM-X13 Motor CFM - Sizes 021 - 036 External Static Pressure (Ducted Applications)

External Static Pressure, WC"

Unit Size Speed

Speed 1

Speed 1

021

024

Speed 2

030

Speed 2

036

Speed 2

Speed 1

Speed 2

Speed 1

0 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40

830

770

830

770

1200

1080

1200

1080

820

760

820

760

1180

1060

1180

1060

800

740

800

740

1160

1030

1160

1030

780

720

780

720

1140

1010

1140

1010

770

700

770

700

1120

990

1120

990

760

690

760

690

1100

970

1100

970

730

660

730

660

1080

950

1080

950

850

780

850

780

1230

1100

1230

1100

710

640

710

640

1060

930

1060

930

IM 986-2 / Page 13 of 48

Page 14

Critical Dimensions

Critical Dimensions

Location of studs is critical for proper installation and

t up and can help to reduce unit noise due to vibration

when properly installed.

Figure 19: Framing Locations to Unit Openings

Note: If the unit cabinet was shipped without

risers attached it will be necessary to remove the

appropriate riser knockouts prior to positioning the

cabinet and connecting to the riser stub outs.

Figure 20: Vertical Riser Stub-Outs Locations to Unit

Knockouts

Unit Size 021-036 = 4.54"

Unit Size 009-018 = 3.125"

1/2" Conduit Fitting

for Electrical Supply

Unit Front

Return Air

Table 1: Reference Locations for Framing

Framing Locations

Unit

Size

A

80" 18" 2.07" 6" 22.25" 58.75" 61" 79" 3.125" 3.125"

18" × 18"

92" 18" 2.07" 6" 22.25" 58.75" 73" 91" 3.125" 3.125"

96" 18" 2.07" 6" 22.25" 58.75" 77" 95" 3.125" 3.125"

80" 24" 2.125" 6" 28.25" 59.5" 63" 79" 4.54" 3.125"

24" × 24"

92" 24" 2.125" 6" 28.25" 59.5" 75" 91" 4.54" 3.125"

96" 24" 2.125" 6" 28.25" 59.5" 79" 95" 4.54" 3.125"

1

Dimension includes approximately 1/4" for vibration isolation pad

2

Dimension “E” ± 0.125

3

Dimension “G” will vary based on diffuser size. Refer to Table 2, Discharge Knockout Openings on page 16.

4

Dimension “H” will vary based on cabinet height selected.

88" 18" 2.07" 6" 22.25" 58.75" 69" 87" 3.125" 3.125"

88" 24" 2.125" 6" 28.25" 59.5" 71" 87" 4.54" 3.125"

B

C

1

D

2

E

1

F

Dimensions do not include 1/4" vibration isolation pad

1, 3

G

1, 4

H

J K L M N

58.08"

37.50"

2.38"

3.3" 7.9" 12.4"

3.13" 7.63" 12.13"

Page 14 of 48 / IM 986-2

Page 15

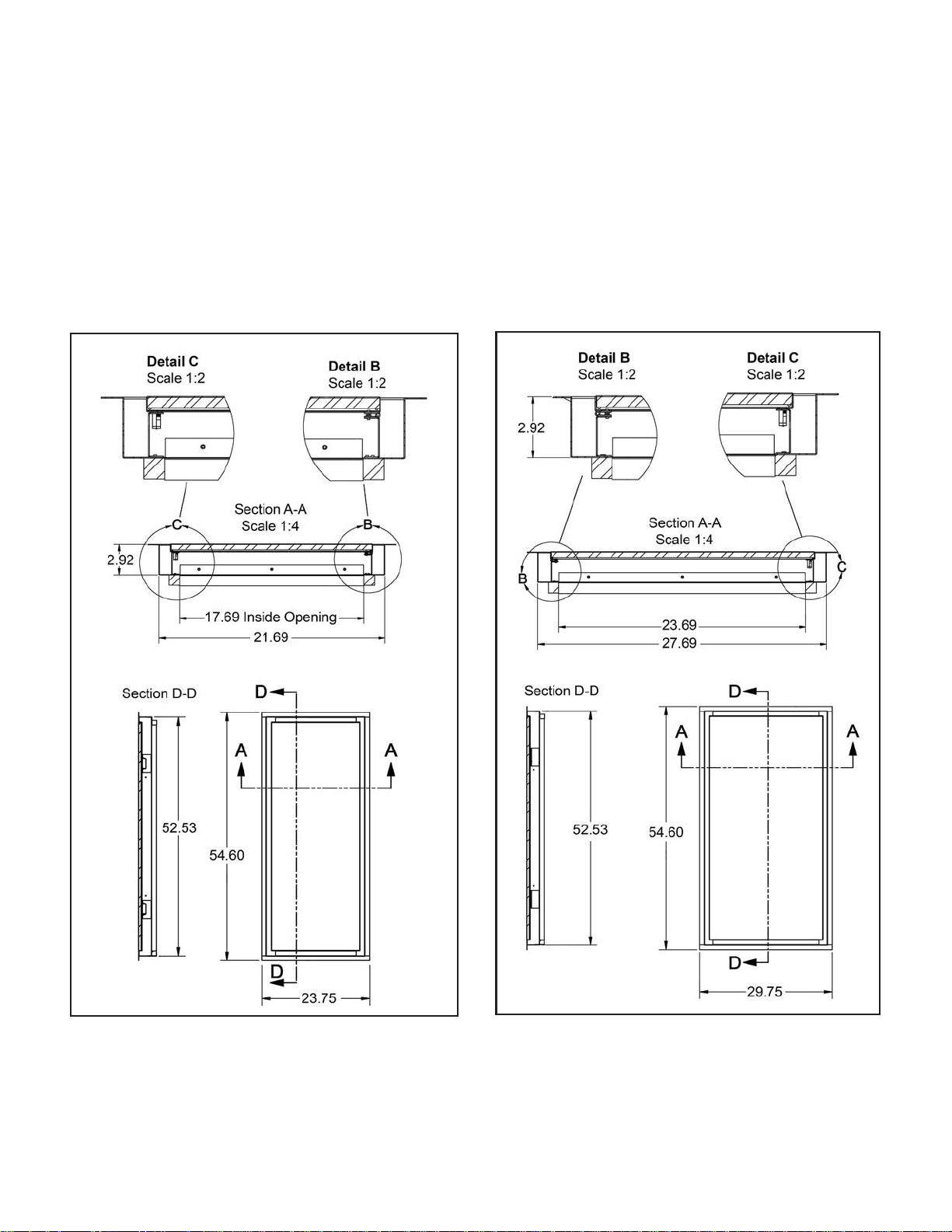

Critical Dimensions

Return Air Grille/Panel Dimensions

Location of studs in relation to the unit and the return

air grille panel are critical for proper installation and

t up. When installed, the return air grille gasket must

compress and seal completely against the outer edge of

the cabinet and around the inner front panel and lter

bracket. See page 24, “Installing The Return Air/Grill

Panel” and page 14, gure 19 “Framing Locations to

Unit Openings”.

Figure 21: Unit Sizes 009 - 018 (18" x 18" Cabinet)

Figure 22: Unit Sizes 021 - 036 (24" x 24" Cabinet)

IM 986-2 / Page 15 of 48

Page 16

Installation Procedure

CAUTION

!

Installation and maintenance is to be performed only by qualied

personnel who are familiar with, and in compliance with state, local

and national codes and regulations, and experienced with this

type of equipment. Sharp edges and coil surfaces are potential

injury hazards. Avoid contact with them.

Note: Refer to "Critical Dimensions", page 14 to

determine the correct recess depth from the front of

the unit to the drywall face. When the installation is

complete, the return air grille/panel frame must meet

to seal with the cabinet discharge opening and the

discharge air diffuser duct must meet and seal with

the discharge opening.

Risers and Cabinet

1. Position the cabinet and risers within the building

pipe chase and align with the unit on the oor above

and/or below (Figure 23).

Figure 23: Position the Cabinet and Risers

Riser Couplings

Connect to Risers

on Unit Above

Inlet, Outlet and

Condensate

Risers

2. Using the riser extensions, make preliminary riser

connections between the units above and or below

to assure proper riser alignment (supply, return and

condensate). See gure 20 on page 14.

3. After all components are aligned properly, anchor

the unit cabinet to the oor using the McQuay

provided mounting brackets (Figure 24).

4. Locate the two (2) mounting brackets in the parts

bag and position them near the back corners of

the unit, or one on a side and one on the back,

whichever location or combination is most suitable,

as illustrated in gure 24. Cut away an area of the

1/4" isolation pad at the mounting bracket locations.

Contractor is responsible for the appropriate

fasteners to secure the brackets to the oor, as local

codes dictate.

Figure 24: Position the Cabinet for Securing to the Floor

with Mounting Brackets (2)

Stud Wall Floor Plate

and Finish Wall

Location

Risers Through

Floor Opening

1/4" Isolation Pad

Riser Extensions

Align and Connect

to Couplings and

Unit Above

IMPORTANT

A eld-supplied ¼” thick isolation pad should be installed now

(Figure 23).

IMPORTANT

The cabinet must be centered between the wall studs and plumb

vertically for the grille/panel frame and diffuser to properly align

and seal to the cabinet. Use of a 4' level is recommended.

1/4" Vibration

Isolation Pad

Unit Cabinet 3

Finished Wall

Unit Front

1

/

8

" from Finished Wall

Back of

Unit

Provided Mounting

Brackets (2)

Fasteners (by others)

Stud Wall Floor Plate

Page 16 of 48 / IM 986-2

Page 17

Note: Be sure that each riser stub-out (supply &

return) are centered within the riser knockout in

the cabinet (Figure 25). If there is a void between

the stub-out and the stub-out seal on the cabinet

interior, this indicates that the stub-out is not properly

centered within the knockout.

Figure 25: Center the Riser Stub-Outs in the Knockouts and

within Seals on the Cabinet Interior

Knockouts

on Cabinet

Exterior

Riser Knockouts

WARNING

Before furring-in units, hydrostatically test the risers and

unit connection joints in accordance with local building

codes, to make sure they are leak-proof.

Note: Perform "Cleaning and Flushing Water

System" Procedure Below.

CAUTION

When furring-in units make sure that no screws or nails

penetrate the unit cabinet.

8. Layout the stud wall oor plates and frame-in

unit referencing “T ypical Framing & Dischar ge

Arrangements” on page 13 and “Critical Dimensions”

on page 14 and table 1.

Note: Before cutting and hanging drywall, remove

the appropriate discharge air opening knockout. See

T able 2). Protect unit from construction debris with a

protective cover.

Cabinet

Interior

Stub-Out Connections with

Valves Centered within

Knockouts and Seals

Stub-Outs

Seals

CAUTION

The unit is not designed to support the weight of the risers.

Anchor them securely to the building structure.

5. Anchor risers to the building structure to prevent

vertical riser movement greater than, plus or minus

one inch to allow for riser expansion or contraction.

Table 2: Discharge Knockout Openings

Unit Size

W H W H W H W H

009–012

015–018

021–024 NR NR 18" 14" 18" 10" 18" 18"

030–036 NR NR

NR = Not Recommended

Single Double Triple Single-Top Opening

14" 16" 14" 8" NR NR 12" 12"

14" 16" 14" 8"

Discharge Openings

14" 8"

18" 14" 18" 10" 18" 18

12" 12"

Cleaning and Flushing Water

System

CAUTION

Prior to first operation of any unit, the water circulating

system must be cleaned and flushed of all construction dirt

and debris or damage will occur.

1. Prior to rst operation of any unit, the water

circulating system must be cleaned and ushed of all

construction dirt and debris.

If the units are equipped with water shutoff valves,

either electric or pressure operated, the supply and

return runouts must be connected together at each

unit location. This will prevent the introduction of

dirt into the unit (Figure 26).

6. Solder all supply and return riser connections to

units above and/or below.

7. Remove riser ties used to secure the risers to the

cabinet during shipping.

IM 986-2 / Page 17 of 48

Page 18

Figure 26: Connections for ushing system piping

Adapter, MPT x Straight Pipe Thread

included with flexible hoses

Note: Use for making connections to the

supply & return valves for the "Cleaning

and Flushing Water System" procedure.

2. Fill the system at the city water makeup connection

with all air vents open. After lling, close all air vents.

The contractor should start main circulator with

the pressure reducing valve open. Check vents in

sequence to bleed off any trapped air, ensuring

circulation through all components of the system.

Power to the heat rejector unit should be off, and the

supplementary heat control set at 80°F (27°C).

While circulating water, the contractor should check

and repair any leaks in the unit and surrounding

piping. Drains at the lowest point(s) in the system

should be opened for initial ush and blow-down,

making sure city water ll valves are set to make up

water at the same rate. Check the pressure gauge at

pump suction and manually adjust the makeup to

hold the same positive steady pressure both before

and after opening the drain valves. Flush should

continue for at least two hours or longer until the

drain water is clean and clear.

Once the system has been lled with clean water and

antifreeze (if used), precautions should be taken to

protect the system from dirty water conditions.

NOTICE

It is not McQuay International’s policy to make recommendations on water treatment. However, the general contractor or owner should contact a local water treatment company regarding water treatment. A fouled closed loop water

system will lead to premature component failure.

Note: Contact a local water treatment company to

conrm water clarity prior to unit operation.

Dirty water will result in system wide degradation

of performance and solids may clog system-wide

valves, strainers, ow regulators, etc. Additionally,

the heat exchanger may become clogged which

reduces compressor service life or causes premature

failure.

6. Set the loop water controller heat add setpoint

to 70°F (21°C) and the heat rejection setpoint to

85°F (29°C). Supply power to all motors and start

the circulating pumps. After full ow has been

established through all components including the

heat rejector (regardless of season) and the vented

air and loop temperatures have been stabilized, each

of the units will be ready for check, test and start-up,

air balancing, and water balancing.

Table 3: Air Limits

Cooling Heating Cooling Heating

Min. Ambient Air 50°F/10°C 50°F/10°C 40°F/5°C 40°F/5°C

Normal Ambient Air 80°F/27°C 70°F/21°C 80°F/27°C 70°F/21°C

Max. Ambient Air 100°F/38°C 85°F/29°C 100°F/38°C 85˚F/29°C

Min. Entering. Air 50°F/10°C 50°F/10°C 50°F/10°C 40°F/5°C

Normal Entering Air, 80°F/67°F 70°F 80°F/67°F 70°F

db/wb 27/19°C 21°C 27/19°C 21°C

Max. Entering Air 100/83°F 80°F 100/83°F 80°C

db/wb 38/28°C 27°C 38/28°C 27°C

Standard Range Geothermal Range

Units Units

3. Shut off supplemental heater and circulator pump

and open all drains and vents to completely drain

down the system. Short circuited supply and return

runouts should now be connected to the unit supply

and return connections. Do not use sealers at the

swivel are connections of hoses.

4. Flush system with water for 2 hours or longer until

water is clean.

5. Rell the system with clean water. Test the water

using litmus paper for acidity, and treat as required

to leave the water slightly alkaline (pH 7.5 to 8.5).

The specied percentage of antifreeze may also be

added at this time. Use commercial grade antifreeze

designed for HVAC systems only. Do not use

automotive grade antifreeze (See Table 5 on page 19

for Antifreeze Correction Factors).

Page 18 of 48 / IM 986-2

Table 4: Water Limits

Standard Range Geothermal Range

Units Units

Cooling Heating Cooling Heating

Min. Entering. Water 55°F/13°C 55°F/13°C 30°F/-1°C 20°F/-6°C

Normal Entering. Water 85°F/29˚C 70˚F/21°C 77°F/25˚C 40˚F/5°C

Max. Entering. Water 110°F/43°C 90°F/32°C 110°F/43°C 90°F/32°C

At ARI flow rate.

Maximum and minimum values may not be combined. If one value

is at maximum or minimum, the other two conditions may not exceed the

normal condition for standard units. Extended range units may combine any

two maximum or minimum conditions, but not more than two, with all other

conditions being normal conditions.

CAUTION

Units must be checked for water leaks upon initial water

system start-up. Water leaks may be a result of mishandling or damage during shipping. Failure by the installing

contractor to check for leaks upon start-up of the water

system could result in property damage.

Page 19

Table 5: Antifreeze Correction Factors

Ethylene Glycol

Cooling Capacity 0.9950 0.9920 0.9870 0.9830 0.9790

Heating Capacity 0.9910 0.9820 0.9770 0.9690 0.9610

Pressure Drop 1.0700 1.1300 1.1800 1.2600 1.2800

10% 20% 30% 40% 50%

Propylene Glycol

Cooling Capacity 0.9900 0.9800 0.9700 0.9600 0.9500

Heating Capacity 0.9870 0.9750 0.9620 0.9420 0.9300

Pressure Drop 1.0700 1.1500 1.2500 1.3700 1.4200

10% 20% 30% 40% 50%

Methanol

10% 20% 30% 40% 50%

Cooling Capacity 0.9980 0.9720 – – –

Heating Capacity 0.9950 0.9700 – – –

Pressure Drop 1.0230 1.0570 – – –

Ethanol

10% 20% 30% 40% 50%

Cooling Capacity 0.9910 0.9510 – – –

Heating Capacity 0.9950 0.9600 – – –

Pressure Drop 1.0350 0.9600 – – –

Power Wiring From Building to Unit

DANGER

!

To avoid electrical shock, personal injury or death:

1. Installer must be qualied, experienced technician.

2. Disconnect power supply before installation to prevent

electrical shock and damage to equipment.

1. Locate the electrical power supply wiring from the

building and feed wiring through the 1/2" conduit

tting (strain relief) on the unit as shown in Figure

27 & 28, following local electrical codes and

regulations.

Figure 27: Supply Electric Wiring from Building to Unit

1/2" Knockout for

Supply Wiring

Figure 28: Wire to Unit Switch

2. If a remote wall-mounted thermostat is being used,

install a 24-volt thermostat wiring cable with at

least 6 wires from the unit low voltage terminal strip

(Figure 29) to the thermostat location.

Flexible Metal Conduit &

Strain Relief

3. If a wireless remote thermostat was ordered to

control the unit, it is recommended that the Remote

Control Node (RCN) be installed now.

IM 986-2 / Page 19 of 48

Page 20

Figure 29: Low V oltage Terminal Strip for Thermostat Wiring

2-Speed

Fan Switch

Thermostat Low

Voltage Terminal Strip

Note: See specic thermostat installation manual

for wiring and operation of thermostat. Install wall

mounted thermostat while completing dry wall

installation.

Connect Condensate Drain Hose to Drain

Stub Out

1. Remove the two (2) screws located along the back

edge of the drain pan, holding it in place

(Figure 30).

Water Connections

All piping connections should be made using good

plumbing practices and in accordance with any and all

local codes that may apply.

Unit Piping Connection

Unit sizes 009 through 018 coil connections are

gooseneck style, made of copper tubing with 1/2" FPT.

Unit sizes 021 through 036 have 3/4" FPT connections

(Figure 31).

Shutoff/Balancing Valve

Each heat pump requires a shutoff valve on both the

supply and return risers for easy serviceability and

removal of the chassis when necessary.

We suggest using a factory installed 2-way motorized

isolation valve on the return line of the chassis and a

Auto Flow Regulator (AFR) installed on the supply line

which allows proper water ow in a given size unit.

Each valve package has 1/2" FPT or 3/4" FPT threaded

connections (Figure 32).

Figure 31: Typical Motorized Valve Piping

2. Adjust the direction of the condensate drain hose

and slip it over the drain stub out. Using the

provided clamp, secure the hose by tightening the

clamp.

3. Reinstall the secondary drain pan with the two (2)

screws removed in step 1.

Figure 30: Connect Drain Hose to Drain Stub Out

Two (2) Screws Holding

Pan in Place

Drain

Stub Out

Hose Clamp

FPT Return

Connection

2-Way

Motorized

Valve

FPT Supply

Auto Flow

Regulator

Connection

Adding A Motorized Valve & Auto Flow

Regulator

The Vertical stack water source heat pump chassis can

be congured with a 2-way motorized valve. The 2-way

motorized valve is mounted on the return line of each

unit and the Auto Flow Regulator (AFR) is mounted to

the supply line. Valve assemblies terminate with either

a 1/2" (unit sizes 009-018) or 3/4" (unit sizes 021-036)

NPT threaded connection and will accommodate factory

supplied hoses.

Page 20 of 48 / IM 986-2

Page 21

Make Flexible Hose Connections to the

Supply and Return Valves From Riser

Stub-Outs

1. Using the specied supply and return hoses make

supply and return hose connections to the riser stubouts (Figure 32).

Note: The MPT straight pipe adapters can be

removed from the swivel end of the exible hoses

now and threaded onto the chassis FPT supply

and return pipe connections (Figure 33). This will

make hose connections to the chassis easier when

the chassis is partially installed.

Note: To complete the exible hose connections

to the chassis, only partially install the chassis

into the cabinet as shown on page 22, gure 35

“Installing Unit Chassis”.

Important When Handling Chassis

Note: If using a hand truck to move chassis, tip

the chassis forward or back only, pivoting on the

ends of the chassis rails. Tipping and pivoting

the chassis side to side on the long edge of the

rails will damage the rails and the rubber vibration

isolators.

!

CAUTION

2. Attach the (MPT) xed hose ends to the female

connections on the valves. Using two crescent

wrenches, one to hold the valve pipe connection and

the second on the hose end, tighten the connections.

Figure 32: Make supply and return hose connections to the

valves from the riser stub-outs

Flexible Hose

2-Position

Hand Valve

Slots in the chassis rails that may be used as hand holds

have sharp metal edges. To avoid personal injury, heavy

protective gloves should be used while moving and lifting

the unit chassis.

Figure 34: Tip Chassis Front to Back Only, Pivoting on the

Ends of the Rails

Do not tilt chassis side to

side on long edge of rails

or damage will occur

Tilt chassis front to back on

end of rails when handling

and moving

Figure 33: Flexible Return and Supply Hoses (Field-installed)

Assembled Length

Fixed End, MPT

Female Swivel

Adapter, MPT x Straight Pipe Thread

Note: Connects to the chassis FPT supply & return

connections.

IM 986-2 / Page 21 of 48

Page 22

Installing Unit Chassis

1. Thread the MPT adapters removed from the swivel

ends of the exible hoses onto the chassis FPT

supply and return pipe connections. Using two

crescent wrenches, one to hold the chassis pipe

connection and the second on the adapter tting,

tighten the connections.

2. Install the chassis by sliding it into the cabinet

opening until the chassis support rails sit on the

cabinet rails. Slide the chassis into the cabinet

until there is approximately a 10" space between

the chassis coil and the cabinet. This will allow

adequate clearance to connect the exible hoses to

the chassis coil. For safety, place a 6" high block

under the chassis rails to support the chassis as

shown in Figure 35.

Figure 35: Slide chassis partially into the unit cabinet

Approximately

10" gap to

make hose

connections

Figure 36: Slide Chassis into Cabinet Leaving a 10" Gap

for Clearance to Make Flexible Hose Connections

Supply

Connection

Return Connection

Making Cabinet to Chassis Wiring

Connections

6" high blocks to

support chassis

2. Thread the female swivel ends of the hoses on to

the water supply and return connections. Using two

crescent wrenches, one to hold the straight MPT

adapter and the second on the exible hose swivel,

tighten the connections. (Figure 36).

1. Locate the wires and plugs in the upper fan section

of the unit that connect to the unit chassis.

2. Plug in the wires from the top cabinet section into

the proper molex connectors on the chassis (Figure 37).

Figure 37: Plug unit component wiring from the top cabinet

section into the proper connectors on the chassis (Unit Size

021-036 Chassis Shown)

Main Power Connector

Note: On unit sizes

009-018 the Main

Power Receptacle and

Thermostat Connector

locations are switched

Fan Control

Connector

Thermostat Wiring

Connector

2. Push the chassis into the cabinet until it makes

contact with the stops on the rails at the rear of the

cabinet.

Page 22 of 48 / IM 986-2

Note: Be sure there are no kinks and that the

stainless steel braided hoses do not come in contact

with and vibrate on chassis and cause noise. Also be

sure not to pinch wires between cabinet and chassis

when inserting chassis.

Page 23

Installing the (Optional) Remote Control

Node (RCN) For Use With The Optional

Wireless Thermostat

DANGER

!

Disconnect all electrical power before servicing unit.

Electrical shock will cause severe injury or death.

Figure 39: Connect Wires to the RCN Terminals and snap

the plastic standoffs onto Board

Plastic Standoffs (4)

Remote Control

Node (RCN)

1. Remove the panel with the low voltage terminal

strip by removing two (2) screws at the front of the

cover and three (3) located on the underside. (Figure

38). The wires connected to the manual fan speed

switch may be removed for easier access.

Note: There are two methods for installing the RCN

to the unit. The RCN mounts on the back of the bezel

(blank control pad) and this assembly snaps into

the knockout on the face of the unit. This method

is not recommended since future replacement is

more difcult. The preferred method for a new unit

installation is illustrated below (Figures 38 – 40).

Figure 38: Remove the Cover Plate with the Low Voltage

Terminal Strip

Terminals

on Back of

Low Voltage

Terminal Strip

RCN Terminals

3. Snap the plastic standoffs into the RCN as illustrated

in Figure 39.

4. Reach inside the area behind the removed terminal

strip cover and up behind the knockout. Align the

standoffs on the board with the provided standoff

holes on the knockout plate and snap the standoffs

into the holes (Figure 40).

Figure 40: Secure the RCN to the Unit with the Standoffs

2. Connect the provided wiring to the RCN terminals

as shown in Figure 39.

Plastic

Standoffs

(4)

RCN

RCN to Low Voltage

Terminal Connectors

5. Connect the RCN wires with connectors to the low

voltage terminals and reinstall the terminal strip

cover.

IM 986-2 / Page 23 of 48

Page 24

Installing The Return Air Grille/Panel

1. Install the return air grille/panel assembly (Figure

41). Center, level and plumb the frame inside the

framed opening. Push the assembly into the opening

until the gaskets compress against the cabinet, and

the frame face is tight to the nished wall.

Note: Shims should be used to make up the space

between the studs and the panel frame at the

locations of the fasteners on the panel frame (4).

Adhere them to the panel frame to keep them in

place (Figure 41).

Figure 41: Installing the Panel Door Frame

Note: Be sure the bottom ange of the door frame

slides beneath the cabinet ange, as shown in Figure

41. This seal must compress between the bottom

panel ange and the bottom cabinet ange when

the installation of the panel door frame is complete.

2. Check that the panel door frame is centered within

the opening and seals completely to the cabinet

return air opening. Also conrm that the room

side ange of the frame is level, plumb and rmly

against the drywall. Secure the hinged panel door

frame with the 4 screws provided.

Seal Gasket on the

Back of the Panel

Door Frame along

top and two sides

Shims to Make Up

Space Between Framed

Opening and Panel

Door Frame

Door Panel Bottom

Flange to Slide

Beneath Cabinet

Flange

Seal Gasket on Underside of

Cabinet Flange. Door Panel

Flange Slides Underneath and

Compresses to Cabinet

Page 24 of 48 / IM 986-2

Page 25

Installing The Discharge Air Diffuser

1. Adhere eld-provided 1/2" foam seal to the face of

the cabinet around the perimeter of the discharge air

opening (Figure 42).

3. Push the diffuser frame in until it compresses

against the foam seal and the room side frame is

ush against the drywall. Be sure the diffuser frame

is level and plumb and secure it with the two (2)

screws provided.

2. Insert the diffuser into the wall opening and align

the frame with the foam seal.

Note: To avoid bending the adjustable discharge

louvers do not press on them

Figure 42: Installing the Discharge Air Diffuser

Foam seal applied to

the cabinet face, around

perimeter of discharge

air opening

Note: When installed correctly the diffuser frame

should seal to the cabinet discharge air opening and

no discharge air will be lost between the unit and the

wall cavity.

Foam seal (field-furnished & installed)

Diffuser flange

compresses into the

foam seal

Double-deflection

Diffuser

IM 986-2 / Page 25 of 48

Page 26

Twin Units Installation

Twin opposite hand units share a common riser system;

i.e., supply, return, and drain riser. This is commonly

called a “master/secondary” arrangement. The master

unit is shipped with the risers attached. These special

risers have stub-outs for both the master unit and the

secondary unit which must be eld connected and the

following procedures must be followed for all twin unit

installations.

1. Secondary units ship without risers and share

common risers with the master unit. Knockout holes

on the cabinet are provided for the 6" stub outs to

make piping connections to the coil supply and

return and the condensate drain.

Figure 43: Twin Unit Arrangement (Side by Side)

2. Master units are offered in two-pipe systems

with either right-hand or left-hand connections.

Secondary units are offered to accommodate

internal connections to any of these riser systems or

locations.

3. The riser location (right or left) is determined by

facing the return air grille panel. The risers are

located on either the right or left of the unit. This

denes the riser location. See Unit Congurations

on page 12.

4. The riser block-off plates are located in the base of

the secondary unit. Block-offs must be installed on

the secondary unit before putting it into position.

Master Unit

Secondary Unit

in Adjoining

Room

6" Stubs on

Master Unit

Risers for

Secondary Unit

Stud Wall

Separating

Rooms

Common

Risers

Page 26 of 48 / IM 986-2

Page 27

MicroTech® III Unit Controller

The MicroTech III Unit Controller includes built-in

features such as random start, compressor time delay,

shutdown, condensate overow protection, defrost

cycle, brownout, and LED/fault outputs. Table 6 shows

the LED and fault output sequences.

The unit has been designed for operation with either

a unit mounted thermostat or a microelectronic wall

thermostat, selected by the manufacturer. Do not operate

the unit with any other type of wall thermostat.

Each unit has a printed circuit board control system. The

low voltage output from the low voltage terminal strip

is AC voltage to the wall thermostat. R is A/C voltage

output to the wall stat.

The 24 volt low voltage terminal strip is set up so R-G

energizes the fan only. R-Y1 energizes the compressor

for cooling operation, R-W1 energizes the compressor

and reversing valve for heating operation. The reversing

valve is energized in the heating mode. The circuit

board has a fan interlock circuit to energize the fan

whenever the compressor is on if the thermostat logic

fails to do so.

The output to the wall stat is AC current. Terminal (R)

on the wall stat can be connected to terminal (R) on the

PC board for AC voltage.

R = AC current

R to G = fan only

R to Y1 = cooling

R to W1 = heat

The MicroTech III unit controller has a lockout circuit

to stop compressor operation if any one of its safety

devices is triggered (high pressure switch and low

temperature sensor). If the low temperature sensor is

triggered, the unit will go into the cooling mode for 60

seconds to defrost any slush in the water-to-refrigerant

heat exchanger. After 60 seconds the compressor is

locked out. If the condensate sensor detects a lled drain

pan, the compressor operation will be suspended only

in the cooling mode. The unit is reset by opening and

closing the disconnect switch on the main power supply

to the unit in the event the unit compressor operation

has been suspended due to low temperature sensor or

high pressure switch. The unit does not have to be reset

on a condensate overow detection.

The MicroTech III unit controller fault output sends a

signal to an LED on a wall thermostat. Table 6 shows

for which functions the fault output is “on” (sending a

signal to the LED).

Table 6: MicroTech III unit controller LED & fault outputs

Mode / Fault

Occupied, Bypass,

Standby, or Tenant Off On Off Energized

Override

Unoccupied On On Off Energized

Condensate Overow On Off Off De-engergized

High Pressure 1 Fault Off Off Flash De-energized

Low Pressure 1 Fault Off Off On De-energized

Low Temperature 1 Fault Flash Off Off De-energized

Brownout

Emergency Shutdown Off Flash Off De-energized

Room/Return Air or Low

Temp Sensor 1 Failure

Service Test Mode

Corrupted

Received

1

1

Enabled

Serial EEPROM

Network “Ofine”

Compressor relay/compressor terminal is labeled COMP, switched line of the

same electric input as any of the L1 terminals.

Yellow Green Red

Flash Flash On De-engergized

Status LED’s Thermostat Alarm Light

Off Flash Off De-energized

On On Off De-energized

On On On De-energized

Off Off Off De-enegized

Output-Terminal “A”

Remote Reset Feature

The Remote Reset feature provides the means to

remotely reset automatic lockouts generated by highpressure and/or low-temperature (in heating) faults.

When the MicroTech III unit controller is in automatic

lockout due to one of these faults, and the cause of

the fault condition has been alleviated, energizing

the O-terminal for 10 seconds or more will force the

MicroTech III unit controller to clear the lockout. A

unit power cycle can also be used to clear an automatic

lockout if the conditions causing the fault have been

alleviated.

The Intelligent reset feature helps to minimize nuisance

trips of automatic reset lockouts caused by highpressure and/or low-temperature (in heating) faults. This

feature clears faults the rst two times they occur within

a 24-hour period and triggers an automatic lockout on

the 3rd fault. The retry count is reset to zero every 24

hours.

The MicroTech III unit controller has built-in night

setback operation. A “grounded’ signal to the “U”

terminal on TB3 of the unit control puts the unit into

the unoccupied mode for night setback operation.

Fan operation terminates and unit control will only

respond to signal at the W2 terminal. Daytime heating

and cooling operation is locked out. +24VAC to W2

energizes the compressor and reversing valve for

heating operation. Night setback operation can be

overridden for two hours by energizing the O on the

TB2 terminal of the unit control for 3 seconds. Day

thermostat setpoints then control the heating and

cooling operation. The MicroTech III unit controller

also accommodates shutdown operation on receipt of a

“grounded” signal to the “E” input, respectively, on TB3

input terminal of the unit control.

IM 986-2 / Page 27 of 48

Page 28

MicroTech® III Unit Controller Terminal Locations and Descriptions

H1 - 1 24 24 VAC Power Input

H1 - 2 C 24 VAC Common

H2 - 1 SL1 Fan Output - Switched L1

H2 - 2 Blank Terminal

H2 - 3 N Fan Neutral

H3 - 1 HP1-1 High Pressure Switch 1 Input Terminal 1

H3 -2 HP1-2 High Pressure Switch 1 Input Terminal 2

H4 - 1 Discharge Air Temp Common

H4 - 2 Discharge Air Temp Signal

H4 - 3 Leaving Water Temp Common

H4 - 4 Leaving Water Temp Signal

H5 - 1 1 I/O Exp Module Common (Gnd)

H5 - 2 I/O Exp Module Common (Gnd)

H5 - 3 I/O Exp Module +5 VDC

H5 - 4 I/O Exp Module SPI CE1

H5 - 5 I/O Exp Module SPI CLK

H5 - 6 I/O Exp Module SPI OUT

H5 - 7 I/O Exp Module SPI IN

H5 - 8 I/O Exp Module +12 VDC

H5 - 9 I/O Exp Module 24 VAC

H5 - 10 I/O Exp Module 24 VAC

H5 - 11 Spare

H5 - 12 Spare

H6 - 1 1 Condensate Overow Signal Input

H6 - 2 Low Temp 1 Sensor Common

H6 - 3 Low Temp 1 Sensor Signal

H6 - 4 Low Pressure Switch 1 Source Voltage

H6 - 5 Low Pressure Switch 1 Signal

H6 - 6 Reversing Valve 1 Common

H6 - 7 Reversing Valve 1 Output

H7 - 1 1 Dummy Terminal

H7 - 2 Dummy Terminal

H7 - 3 Red LED Output

H7 - 4 Green LED Output

H7 - 5 Yellow LED Output

H7 - 6 Red-Green-Yellow LED Common

H8 - 1 1 Isolation Valve/Pump Request Relay N/O

H8 - 2 Isolation Valve/Pump Request Relay N/C

H8 - 3 24 VAC Common

H9 - 1 1 Return Air Temperature Signal

H9 - 2 Return Air Temperature Common

TB1 - 1 1 Room Sensor LED Output

TB1 - 2 2 Fan Mode / Heat-Cool-Auto Input

TB1 - 3 3 Setpoint Adjust Input

TB1 - 4 4 Room Temperature Sensor / Tenant Override

TB1 - 5 5 DC Signal Common

Test-1 R 24 VAC

Test-2 W2 Heat Stage 2 Input

Test-3 W1 Heat Stage 1 Input

Test-4 Y2 Cool Stage 2 Input

Test-5 Y1 Cool Stage 1 Input

Test-6 G Fan

TB2 - 1 R 24 VAC

TB2 - 2 A Alarm Output

TB2 - 3 W2 Heat Stage 2 Input

TB2 - 4 W1 Heat Stage 1 Input

TB2 - 5 Y2 Cool Stage 2 Input

TB2 - 6 Y1 Cool Stage 1 Input

TB2 - 7 G Fan Input

TB2 - 8 O Tenant Override Input

TB2 - 9 C 24 VAC Common

TB3 - 1 E Mark IV Emergency Shutdown Input

TB3 - 2 U Mark IV Unoccupied/Occupied Input

L1 - 1 L1 - 1 Line Voltage Terminal 1

L1 - 2 L1 - 2 Line Voltage Terminal 2

L1 - 3 L1 - 3 Line Voltage Terminal 3

N1 N1 Neutral Terminal 1

N2 N2 Neutral Terminal 2

N3 N3 Neutral Terminal 3

Table 7: Conguration Jumper Settings

Jumper Description Options

JP1 Mode

Shorted for service/test operation mode

JP2 Fan operation only applies to Open for continuous fan operation

network controls Shorted for cycling fan operation

JP3 Freeze protection

Shorted for antifreeze protection

JP4 Future spare Future spare

JP5 Set point adjustment range only Open for adjustment range of -3.0° to +3.0° F

applies to network controls with a Shorted for 50° to 90° F adjustment range

room temperature sensor

JP6 Room control type

Shorted for room temperature sensor control, MicroTech III only

JP7 Future spare Future spare

JP8 Future spare Future spare

Page 28 of 48 / IM 986-2

Open for normal operation mode

Open for water freeze protection

Open for thermostatic room control

Page 29

Note: A random start delay time between 180 and

240 seconds is generated at power up.

Figure 44: MicroT ech III Unit Controller Terminal Locations

Location of Conguration Jumpers on the MicroTech III

Unit Controller

IM 986-2 / Page 29 of 48

Page 30

I/O Expansion Module

Table 8: I/O Expansion Module LED & Fault Outputs

Mode / Fault

Terminal “A”

Yellow Green Red

Status LED's

Thermostat Alarm

Light Output

For installation and operation information on MicroTech

III unit controller and other ancillary components, see:

• IM 927 - MicroTech III Unit Controller for Water

Source Heat Pumps (LonWorks).

The I/O Expansion Module is a eld-installed or factory

installed option. It is an extension of the MicroTech III

unit controller and provides extra functionality.

The I/O Expansion Module has 2 main purposes:

• The I/O Expansion Module has outputs to control

electric heat on a standard Water Source Heat Pump.

• The I/O Expansion Module has an independent LED

annunciator to identify operational fault conditions

on second stage equipment.

Figure 45: I/O Expansion Module Conguration Jumper

Terminals

Jumper Terminals

Features

Second Circuit

• High pressure switch

• Low pressure switch

• Low suction line temperature sensor

• Compressor output

• Reversing valve

Standard Heat Pumps / Single Circuit Units

• Monitors entering water temperature for

boilerless electric heat control

• Outputs for medium and high speed fan controls.

Invalid Conguration

Jumper Setting

Base Board

Communication Fail

High Pressure #2 Fault Off Off Flash De-energized

Low Pressure #2 Fault Off Off On De-energized

Low Suction Temp #2 Fault Flash Off Off De-energized

Sensor Failures Low Suction

Low Suction Temp #2, Flash Flash On De-energized

1

EWT (w/ Boilerless EH only)

2

Service Test Mode Enabled Flash Flash Flash De-energized

Unoccupied Mode On On Off Energized

Occupied, Bypass,

Standby, or Tenant

Override Modes

Normal Operation Off On Off De-energized

Flash Flash Off De-energized

Off Flash Flash N/A

Off On Off Energized

Note: Mode / Faults are listed in order of priority.

1

Boilerless electric heat only

2

Alarm/fault LED indications take precedence over service test mode LED

indication. The controller shall use service test mode if the service test mode

jumper is installed, even if the LED’s indicate an alarm/fault.

Table 9: I/O Expansion Module Jumper Designations

Jumper Description Options

JP1 Number of

JP2

Water Reheat Shorted to enable reheat

JP3 and JP4 open for no

supplemental heat

JP3 Supplemental JP3 open, JP4 shorted for

& JP4 Heat Type boilerless electric heat

JP3 and JP4 shorted is an

invalid setting

JP5 and JP6 open for single-speed fan

JP5

& JP6 Selection JP5 shorted and JP6 open for

two-speed fan

JP 5 and JP6 shorted is an

invalid setting

JP7

Speed Type Shorted for two-speed compressor

JP8 Future Spare

Compressors Shorted for dual compressor

Hot Gas/

Fan Speed three-speed fan

JP5 open, JP6 shorted for

Compressor Open for single-speed compressor

Open for single compressor

Open to disable reheat

Adding an I/O Expansion Module (with an interconnect

cable) to the main controller allows two-stage operation

of the Water Source Heat Pump.

Page 30 of 48 / IM 986-2

Page 31

MicroTech III Controller With

LonWorks® Communication Module

For installation and operation information on

onWorks Communication Module and other ancillary

L

control components, see:

• IM 927 - MicroTech III Unit Controller for Water

Source Heat Pumps (LonWorks).

• IM 933 - LonMaker Integration Plug-in Tool: For

use with the MicroTech III Unit Controller.

• IM 955 - MicroTech III Wall Sensor For use with

MicroTech III Unit Controller with LonWorks

Figure 46: LonWorks Communication Module

The LonWorks communication module will plug into

the MicroTech III unit controller at the CN_LON1

Header (see gure 48, page 34).

Each McQuay water source heat pump can be equipped

with a L

controller is microprocessor-based and is designed

to communicate over a L

network. The unit controller is factory programmed

and tested with all the logic required to monitor and

control the unit. The wall thermostat sets the unit mode

of operation. The unit controller monitors water and air

temperatures, and can communicate fault conditions to a

L

The MicroTech III unit controller include unit-mounted

return air, discharge air and leaving water temperature

sensors. Options include setpoint adjustment and tenant

override and the capability of substituting the return air

sensor with a wall-mounted temperature sensor.

Each unit controller orchestrates the following unit

operations:

Enable heating and cooling to maintain setpoint

Enable fan and compressor operation.

Monitor all equipment protection controls.

onWorks communication module. The

onWorks communications

onWork communications network.

based on a room sensor.

Monitor leaving water temperature.

Relay status of all vital unit functions.

Support optional control outputs.

A set of three status LED's aid in diagnostics by

indicating the water source heat pump operating mode

and alarm conditions. If there are no current alarm

conditions, the Green LED will indicate the normal unit

operating mode as shown in the table below. If there are

one or more alarm conditions present, various LED's

will ash to indicate an alarm condition.

MicroTech III heat pumps with a MicroTech III unit

controller are LonMark certied and designed to be

linked with a centralized building automation system

through a L

onWorks communications network for

centralized scheduling and management of multiple

heat pumps. Wall-mounted room sensors are available

to control the heating and cooling operation of each

MicroTech III Water Source Heat Pump Unit Controller.

Available room sensors include: room sensor with

LED status and tenant override button, room sensor

with LED status, timed-override button, room sensor

with LED status, timed-override button, and setpoint

adjustment, and room sensor with LED status, timedoverride button, setpoint adjustment.

The MicroTech III water source heat pump unit

controller provides control of McQuay water source

heat pumps. The controller enables the mode of

operation, monitors the water and air temperatures, and

indicates fault conditions. Each unit controller is factory

programmed, wired, and tested for effective operation

of your McQuay water source heat pump.

The MicroTech III water source heat pump controller

onWorks technology. One of the following two

uses L

versions of the application software is loaded into the

controller at the factory.

LonMark® 3.4 certied application code is the current

standard application code for MicroTech III units.

Use LonMark application code in new applications

including:

Units that operate stand alone.

Monitor discharge air temperature.

IM 986-2 / Page 31 of 48

Page 32

MicroTech III Controller With BACnet

Communication Module for Native

BACnet Communications

McQuay water source heat pumps are available with

a factory mounted and tested McQuay BACnet communication module The module is factory programmed

and tested with all the logic required to control the unit,

and is designed to communicate over a BACnet MS/TP

communications network to a building automation system (BAS). The module operates the compressor, fan,

and reversing valve as required to maintain the space

temperature within the current setpoints. Data regarding

equipment status, water and air temperatures, and fault

conditions can be monitored by any BAS. Setpoints and

other system preferences may be changed remotely using a front end workstation or service tool software.

Each BACnet-compliant controller has the following

operating features:

Start-up – The unit will not operate until all the

inputs and safety controls are checked for normal

conditions.

Fan operation – Fan operation can be customized in

software to run continuously during occupied mode,

or to cycle ON or OFF appropriately on a call for

heating and cooling.

Cooling mode – On a call for cooling, the compres-

sor and fan start immediately. Compressor runtime is calculated as a percent of full cycle time

(17 minutes) using proportional-integral control to

maximize efciency.

The module makes operational data and commands

available on a communications network using BACnet

objects and properties. Each heat pump controller connects to the communication network using a BACnet

MS/TP communication network, which is a simple

twisted-pair communications connection that operates at

up to 76.8 Kbps. DIP switches on the controller enable

the MS/TP MAC address to be set in the range 0-127. A

status LED on the unit indicates communication activity

on the MS/TP communication network.

Figure 47: MicroTech III BACnet W ater Source Heat Pump

Snap-in Communication Module

Each BACnet-compliant unit includes discharge air

and leaving water temperature sensors, as well as all

equipment protection sensors, signals, and switches.

Wall-mounted room sensors are available to control

heating and cooling operation. Sensors are available

for status override; wall-mounted sensors with tenant

setpoint adjustment lever and timed-override button;

wall-mounted sensors with LED status, timed-override

button, tenant setpoint adjustment buttons, password-

protected eld service access to operational data, and

optional humidity sensor; and wall-mounted sensors

with LCD and programmable operation.

Heating mode – On a call for heating, the com-

pressor and fan start immediately, and compressor

run-time is calculated as a percent of full cycle time

(17 minutes) using proportional-integral control to

maximize efciency.

Short Cycle Protection and Random Start – A start

delay of 180 seconds plus the compressor’s MAC

address in seconds prevents short-cycling and

simultaneous start-up. A minimum 2-minute on time

and 5-minute off time for the compressor further

ensures short-cycle protection.

Occupied Mode – A simple software control signal

from the building automation system or a wallmounted unit puts the unit into occupied mode.

The unit controls compressor and fan operation to

maintain occupied setpoints. High and low limits

for occupied setpoints are software congurable.

Unoccupied Mode – A simple software control

signal from the building automation system or a

wall-mounted unit puts the unit into unoccupied

mode for night setback operation. The unit controls

compressor and fan operation to maintain unoccupied heating and cooling setpoints, which are also

software congurable.

Page 32 of 48 / IM 986-2

Page 33

After-hours Override Mode – A simple software

control signal from the building automation system

or a wall-mounted unit can initiate after-hours heating or cooling in half-hour increments. Maximum

override time is software congurable up to 9.5

hours. This feature can also be disabled in software.

Reversing valve delay – On a call for cooling,

the compressor and fan will start 0 to 30 seconds

later. If the reversing valve output is energized, the

reversing valve output will de-energize 5 seconds

after the compressor energizes. When the load is

satised, the compressor and fan shut off. On a

call for heating, the compressor and fan start. If the

reversing valve output is de-energized, the reversing valve output will be energized 5 seconds after

the compressor starts. When the load is satised, the

compressor and fan shut off. The reversing valve

remains energized.

Load Shed – Load shedding can be orchestrated by

the building automation system using the occupied/

unoccupied command in software.

Brownout Protection – An on-board sensor mea-

sures input voltage and suspends compressor and

fan operation if the supply voltage drops below 82%

of the normal line voltage for a minimum of 10 seconds, creating an alarm available in software. The

alarm automatically resets when the supply voltage

returns to above 90% of normal.

Condensate Overow Protection – A liquid sensor

at the top of the drain pan senses a high water level.

Upon sensing water, cooling operation is suspended,

while heating operation is allowed. The controller

creates an alarm available in software. The alarm

automatically resets when the water level returns to

normal.

Attained T emperature and Water Temperature

Alarms –Attained temperature, water temperature

alarms with software-adjustable setpoints are available in software. The controller samples supply air

and records attained temperatures for heating and

cooling. If after two hours of operation, the attained

temperature does not meet the software-congurable setpoint for heating or cooling as appropriate,

a software alarm occurs. The alarm automatically

resets when the attained temperature is within setpoints. The controller also monitors leaving water

temperature. If the leaving water temperature is

outside software-congurable setpoints, compressor operation is suspended and high or low water

temperature alarms occur. The alarm automatically

resets when the water temperature returns to within

6 deg. F of the setpoint.

Unit Self-test Mode – While the unit is in occu-

pied mode, a self-test can be initiated via software.

Upon initiation of the test, compressor operation is

suspended for a minimum of ve minutes, cooling

attained temperatures are cleared, and attained temperature alarms are cleared. The unit then switches

to full heat for four minutes and then records the

attained supply air temperature. Compressor opera-

tion is then suspended for ve minutes. The unit

then switches to full cooling for four minutes and

the attained supply air temperature is recorded.

Attained temperature alarms are set if the attained

temperatures failed to reach alarm setpoints during

heating or cooling.

Safety Control – The unit monitors refrigerant pres-

sure and generates separate high-pressure and lowpressure alarms available in software. While either

alarm is active, compressor operation is suspended.

In a refrigerant low-temperature condition, an alarm

occurs and the unit operates in cooling mode for 60

seconds to defrost the heat exchanger, after which

compressor operation is suspended. These alarms

can be reset in software or by cycling power to the

controller.

IM 986-2 / Page 33 of 48

Page 34

Figure 48: LonWorks Communication Module Placement on MicroTech III Unit Controller

Page 34 of 48 / IM 986-2

Page 35

Typical Wiring Diagram

Figure 49: MicroTech III Unit Controller, 2-Speed Fan (Toggle or Thermostat), PSC Motor 208-230/60Hz/1-Phase,

Unit Sizes 009-018

Drawing No. 669349301

Legend

Description

Item

C1

C2

CM

COS Condensate Overow Sensor

DSC

FMP

FMR Fan Motor Connect Receptacle

FCP

FCR

FSR Fan Speed Relay

FSS

FS1 Fuse 1

FS2 Fuse 2

HP

ISO

LED1

LP

MIII MicroTech III Main Board

MPP

MPR

OVL Compressor Overload Protector

PDPG Primary Drain Pan Ground

RV

SOS

SLTS

TS1 Fan Speed Terminal Strip

TS2 Thermostat Terminal Strip

TSP