Page 1

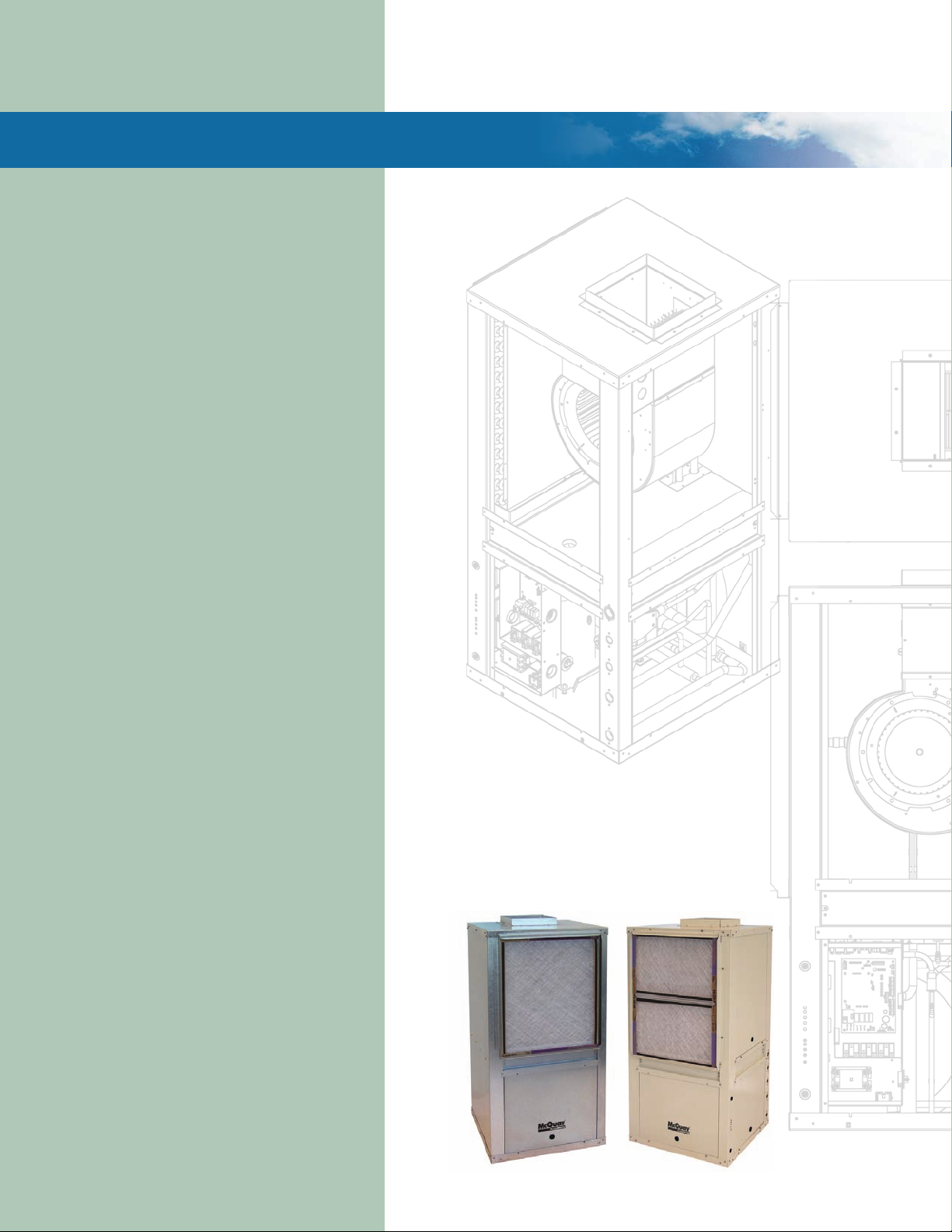

Flexible, High Efficiency Cooling and Heating Solutions.

™

Enfinity

Vertical Water Source

Heat Pumps

Standard Range – Model VFC

Geothermal Range – Model VFW

Engineered for flexibility and performance

™

Page 2

™

Water Source Heat Pumps

With Enfinity Water Source Heat

Pumps You Benefit From:

■

High efficiency, low operating costs.

■

R-410A refrigerant with no ozone

depletion potential or phase-out date.

■

Easy, low cost design and

installation.

■

Open Choices™ controls feature

allows easy, low cost integration

with a Building Automation System

(BAS) of your choice.

■

Boiler/tower or geothermal

application flexibility.

■

Integral electric heat coil for

supplemental electric heat.

More than 30 years ago, McQuay designed the rst complete

line of water source heat pumps for high efciency, individually-

zoned comfort control in ofces, schools, assisted living

facilities, manufacturing facilities and other commercial

buildings. Our reputation for outstanding reliability and quiet

operation has been reinforced in thousands of successful

installations.

Ennity water source heat pumps incorporate the best of our

past and the best of what’s new. Using feedback from building

owners, consulting engineers, contractors and service engineers,

we designed Ennity products to give you maximum exibility

to design, install, operate and maintain the ideal water source

heat pump system for your building project. And we incorporated non-ozone depleting R-410A refrigerant, which–along

with high Energy Efciency Ratios (EER’s)–helps preserve our

environment and precious energy resources.

■

Desuperheater (optional) reduces

energy required to produce domestic

hot water and may eliminate

requirement for separate water

heating equipment.

■

Hot Gas Reheat (optional) helps

improve comfort in the conditioned

space. During dehumidification mode,

the return air is cooled and dried over

the evaporator coil and then reheated

through the hot gas reheat coil to

maintain space temperature setpoint.

ommon Applications:

C

●

Indoor swimming facilities, locker

rooms.

●

Units pulling outside air for

ventilation requirements.

●

Computer rooms.

●

Auditoriums / Gymnasiums.

■

Quiet, reliable operation.

■

Easy, low cost maintenance

and service.

To learn how you can take advantage of the benets of

McQuay Ennity water source heat pumps on your next new

building or replacement project, contact your local McQuay

Representative or visit www.mcquay.com.

5 Cabinet Sizes – G-60 Galvanized or Pre-painted (Optional)

1/2 to 6 ton – Size *007 through 070

Model VFC (Standard Range: 55ºF to 110ºF)

Model VFW (Extended Range/Geothermal: 30ºF to 110ºF)

* Unit size 007 not available at time of publication. Please contact your local

McQuayrepresentativeforspecicavailability.

■

Painted cabinet – ideal for

residential applications.

2

Page 3

Save Energy & Reduce Design, Installation, Operating Costs

Owner, Engineer and Contractor Benefits

The Building Owner

■

High efciency units reduce energy consumption/operating costs

and can contribute to earning points toward LEED® certication.

■

Open Choices control feature gives you the exibility to select

standalone thermostat operation or easy, low cost integration with

the BAS of your choice using an add-on communication module.

■

R-410A refrigerant has no ozone depletion potential or phase-

out date, helping to minimize environmental impact and protect

against refrigerant availability issues over the economic life of

your equipment investment.

■

Large fan wheel, quiet compressor selections and low vibration

design promote quiet operation.

■

Double-sloped polymer drain pan and optional closed cell insula-

tion promote superior indoor air quality.

■

Durable construction promotes long life, reliable operation.

The Engineer

■

Boiler/tower or geothermal unit selections provide flexibility in

designing the system that best meets the performance and budget

requirements of your project.

■

Multiple configurations reduce design time and cost by allowing

you to avoid obstructions and use minimum ductwork.

■

Multiple features and options (ECM motor, desuperheater, hot gas

reheat, integral electric heat, painted cabinet) give you the flexibility to select units that closely match application requirements.

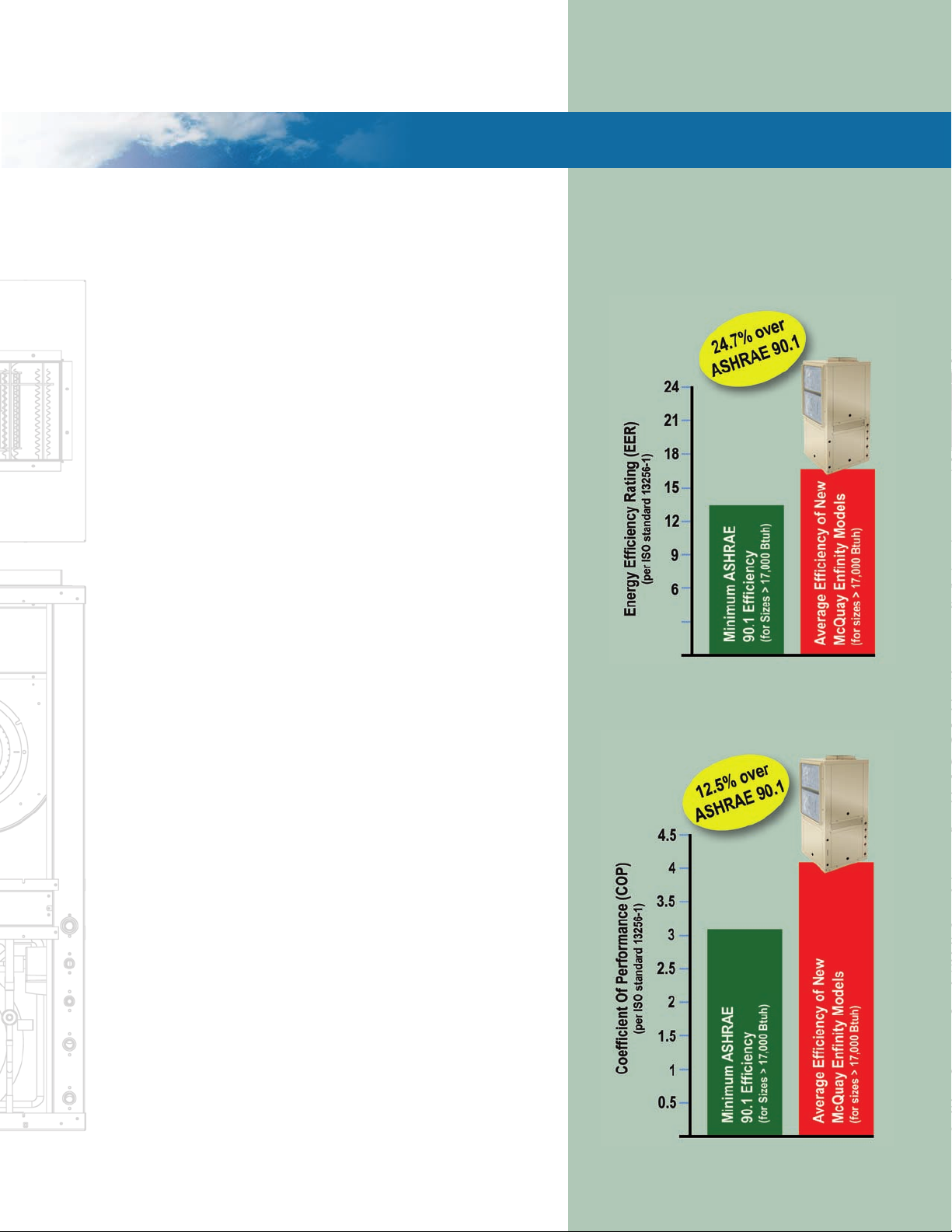

Exceeds ASHRAE 90.1

Efficiency Requirements

Ground Loop – Cooling

Ground Loop – Heating

Installing Contractor / Service Personnel

■

Small footprint design makes it easier to meet space requirements

of new construction and replacement applications.

■

Flush FTP water fittings save time in making water connections

using one wrench.

■

Factory-installed filter rack saves time and expense to field-install

a filter rack.

■

External LED status lights allow quick troubleshooting – no need

to open up the unit.

■

Easy access to the unit compressor (2-sides), fan section (1-side),

motor (1-side) and unit controls (front access).

■

A removable orifice ring allows the blower and motor to be re-

moved without removing the blower housing or disconnecting the

unit from the ductwork.

3

Page 4

Flexible Design with Added Features

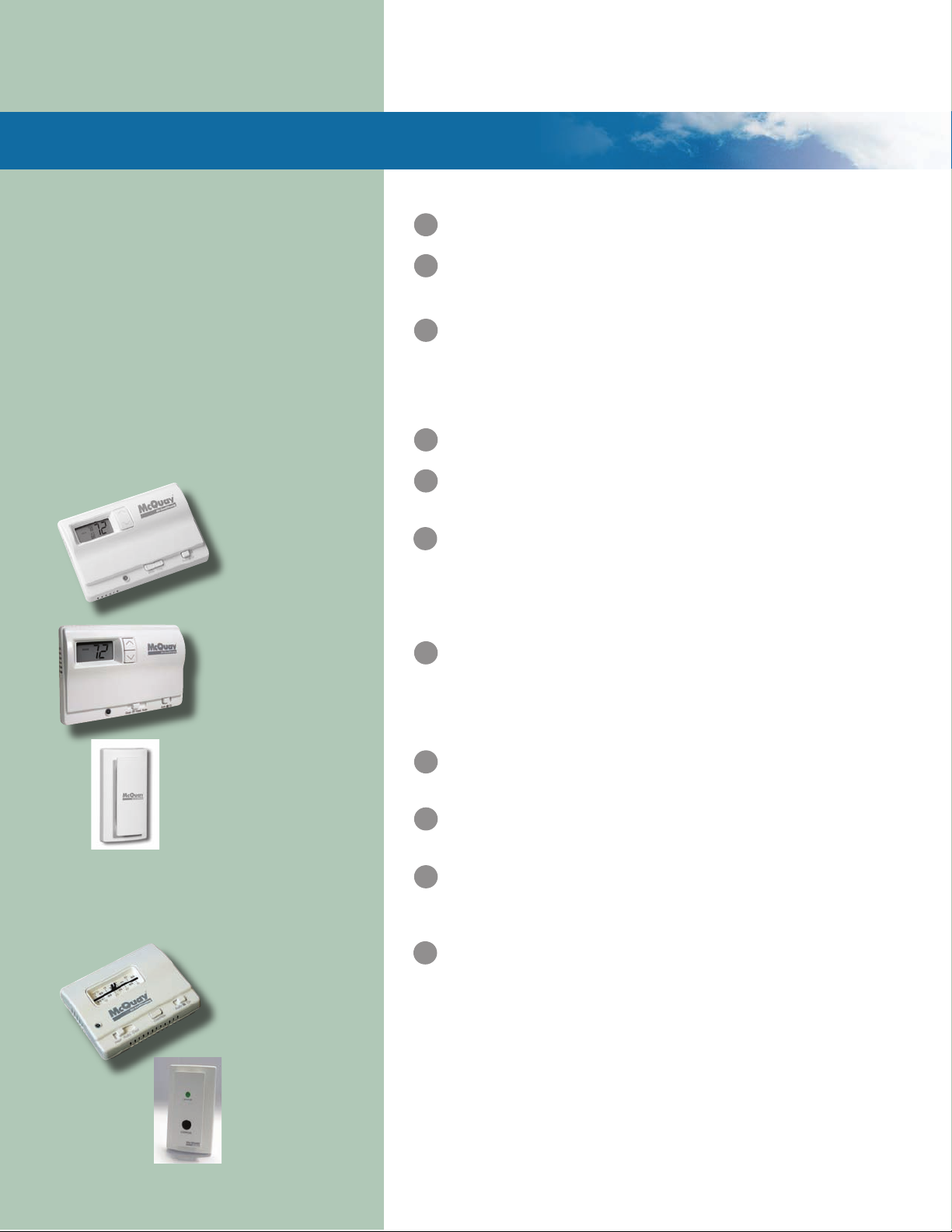

Wall Thermostats and Wall Sensors

Easy-to-operate comfort command

centers provide a complete range of

deluxe features. Choose between a 7-day

programmable or a non-programmable

thermostat for temperature control to match

your application, provide convenience

and help save energy and money. Three

wall temperature sensors are available;

sensor with tenant override, with set point

adjustment (55° to 95°F) and wall sensor

with setpoint adjustment (-3° to +3°F).

Two-Stage Heat/TwoStage Cool, 7-Day

Programmable Electronic

Thermostat

Auto or Manual Changeover

Two-Stage Heat/Two-Stage

Cool, Nigh Setback Override

Non-Programmable

Electronic Thermostat

Remote Sensor

667720401

(Used with wall mounted thermostat)

Room Temperature Sensors

• Set Point Adjustment (55° to 95°F)

• Set Point Adjustment (-3° to +3°F)

Sensor 668900801

•

Set Point Adjustment

• LED

• Override feature

Sensor 669088101

•

Status LED

• Override Button

Electric Heat (Optional) – Integral electric heat coil provides

1

supplemental or emergency heat when conditions require.

Electronically Commutated Motor (ECM-Optional) – ECM motor provides

2

quiet, efcient operation while maintaining constant CFM over its static

operating range. Factory programmed for 3-speeds.

3

MicroT

LED

4

Compact Cabinet – The standard unit is constructed of unpainted G-60

5

Desuperheater (Optional) – Saves energy by producing domestic hot

6

Filter & Filter Rack – Units come standard with a 1" (25.4 mm) thick

7

Removable

8

9

Piping Connections – Water connections are FPT water ttings, ush

10

Coaxial Heat Exchanger – Designed for maximum heat transfer at normal

Hot Gas Reheat Coil – Optional coil provides superior humidity control

11

2-W

ech® III Unit Controller – Designed for exibility, the main control

board is used in standalone applications. An optional I/O expansion

module can be used to control electric heat and multiple fan speeds. A

separate LonWorks® or BACnet® communication module can be easily

snapped onto the board to accommodate the building automation system

of your choice.

Annunciator – External LED status lights display fault conditions to

provide easy troubleshooting and diagnosis.

galvanized steel, with the smallest possible footprint. Optional painted

cabinet is ideal for aesthetic requirements of residential applications.

water using a small heat exchanger and water pump located in the

compressor compartment. Superheated refrigerant gas from the

compressor, which would otherwise be wasted, is used to heat water.

This reduces the amount of additional energy required to heat water and

it may eliminate the requirement for separate water heating equipment.

throwaway lter mounted in a 4-sided combination lter rack and return

air duct collar. This eliminates the added labor and cost to eld-mount

brackets. Filters can be easily removed from any side. A 2" lter rack is

available as a factory-installed selectable option to accept higher

efciency lters

Access Panels – Two front panels provide easy access to the

blower motor and unit controls. Two rear panels provide easy access to

the fan housing and compressor section.

with the outside of the cabinet for easy one-wrench connection to units.

A large condensate connection provides proper condensate removal.

and low water ow rates with minimum pressure drop. The inside tube

is deeply uted to enhance heat transfer and minimize fouling. A cupronickel heat exchanger is available as a selectable option.

for occupant comfort. Uses expelled heat from the refrigeration cycle

and redirects it through an isolated circuit in the evaporator section. For

every 10°F of temperature rise across the hot gas reheat coil there is

approximately a 20% drop in the discharge air relative humidity (%Rh).

A wall-mounted humidistat must be used in conjunction with the unit to

measure and adjust the humidity setpoint in the space.

ay Motorized Isolation Valve (Optional - Not Shown) –

Control valve can be factory-installed or eld-installed to handle

variable speed pumping requirements. Both standard and high cut-off

pressure valves are available as a selectable option.

4

Page 5

Features and Benefits

2" Filter Rack for High Efficiency

Filters & Easy Tooless Removal (Optional)

I/O Expansion Module

LonWorks & BACnet

MicroTech III

Unit Controller

Desuperheater – Heat Exchanger and

Water Pump Piping Circuit (Optional)

Communication Modules

Hot Gas Reheat Coil & Piping Circuit (Optional)

5

Page 6

®

MicroTech

Page Headline Here Page Headline Here

III Unit Controller – A Complete Control Solution

MicroTech III Unit Controller

The MicroTech III unit controller is a standalone microprocessor-based control board conveniently

located in the unit control box for accessibility. The board is designed to provide standalone control

of a Water Source Heat Pump using a wall thermostat or a wall-mounted temperature sensor.

Each unit controller is factory programmed, wired, and tested for complete control of single zone,

standalone operation of your McQuay Water Source Heat Pump.

Each unit controller orchestrates the following unit operations:

Enable heating and cooling to maintain setpoint Monitor discharge air temperature

based on a room sensor Monitor leaving water temperature

Enable fan and compressor operation Relay status of all vital unit functions

Monitor all equipment protection controls Support optional control outputs

MicroTech III

Unit Controller

I/O Expansion Module

For added functionality, an optional I/O expansion module interconnects to the

MicroTech III unit controller.

Adding an I/O Expansion Module (with an interconnect cable) allows for:

Monitoring of entering water temperature for boilerless electric heat control

Outputs for optional electric heat

I/O Expansion Module

®

LonWorks

The MicroTech III unit controller can accept a plug-in LonWorks communication module to provide

network communications and added functionality to easily integrate with an existing BAS.

The communication module can be factory- or eld-installed and is tested with all logic required to

monitor and control the unit.

The LonWorks communication module is LonMark 3.4 certied for BAS integration to provide

centralized scheduling and management of multiple heat pumps.

An amber, on-board status LED indicates the status of the MicroTech III LonWorks module.

Communication Module

BACnet® Communication Module

The MicroTech III unit controller can accept a plug-in BACnet

communication module to provide network communications and added

functionality to easily integrate with an existing BAS.

The communication module can be factory- or eld-installed and is

tested with all logic required to monitor and control the unit.

It is designed to be linked with a centralized building automation

system (BAS) through a BACnet communications network for

centralized scheduling and management of multiple heat pumps.

BACnet

Communication Module

LonWorks

Communication Module

External LED status lights - allow

6

quick troubleshooting

Page 7

Network Communication - with

L

onWorks or BACnet

communication module

Typical VFC Closet Installation

1 Discharge air

2 Acoustic thermal duct lining - 10 feet

3 Line voltage disconnect

4 Low voltage control wiring to unit control box

5 Flexible duct collar

6 Louvered closet door

7 Condensate drain

8 Flexiblereturnhosewithowcontroller/ballvalve

9 Flexible supply hose with Y-strainer/ball valve

10 Access to unit control box

11 LED annunciator lights indicate unit operation status and

faults

12 Fullvibrationisolationpadbetweenunitandoor

13 Minimum distance between return air duct collar and wall for

non-ducted return applications

• Size 007-012 – 4 inches

• Size 015-024 – 5 inches

• Size 030-036 – 6 inches

• Size 042-048 – 8 inches

7

Page 8

Dimensional Data

Page Headline Here Page Headline Here

Left Hand and Right Hand Return

Left and Right Hand Return determined by facing the water connection side of the unit – Unit size 015 thru 024 dimensional drawing shown.

Top View – Left Hand Top View – Right Hand

Overall Unit Dimensions

UNIT SIZE Dimensions

*

007 – 012

015 – 024

030 – 036

042 – 048

060 – 070

Note: Dimensions are approximate.

22¼"D x 20"W x 37"H

24¼"D x 23"W x 46½"H

24¼"D x 23"W x 50½"H

32½"D x 25"W x 46½"H

32½"D x 25"W x 58½"H

Left Hand Return

Low Voltage

7/8" (22mm)

Hole

Line Voltage

7/8" (22mm) Hole

Filter (Side) View Right Hand Return

Condensate

Drain Connection

Desuperheater

Water Return

Desuperheater

Water Supply

Water Return

Low

Voltage

7/8"

(22mm)

Hole

Line

Voltage

7/8"

(22mm)

Hole

Water Supply

Desuperheater

Water Return

Desuperheater

Water Supply

Water Return

Water Supply

Dimensions

Unit Size A B C D E F (Left Hand) F (Right Hand) G H J K M

*007 – 012

015 – 024

(616mm) (584mm) (238mm) (264mm) (189mm) (265mm) (135mm) (483mm) (67mm) (1181mm) (578mm)

030 – 036

(616mm) (584mm) (238mm) (264mm) (189mm) (265mm) (135mm) (483mm) (67mm) (1283mm) (680mm)

042 – 048

(826mm) (635mm) (337mm) (349mm) (245mm) (245mm) (143mm) (737mm) (45mm) (1181mm) (578mm)

060 – 070

(826mm) (635mm) (337mm) (349mm) (245mm) (245mm) (143mm) (737mm) (45mm) (1486mm) (883mm)

Notes:

Dimensionsareapproximate.“M”dimensionincludesductange.

* Not available at time of publication. Please consult your McQuay Representative for specific availability.

22¼" 20" 9½" 5"

(508mm) (241mm) (127mm) (162mm) (118mm) (265mm) (483mm) (41mm) (940mm) (476mm) 2

(565mm)

24¼" 23" 9⅜" 10⅜" 77/16" 107/16" 55/16" 19" 2⅝" 46½" 22¾"

24¼" 23" 9⅜" 10⅜"

32½" 25" 13¼" 13¾"

32½" 25" 13¼" 13¾"

6⅜" 4⅝" 107/16" 19" 1⅝" 37" 18¾"

77/16" 107/16" 55/16" 19" 2⅝" 50½" 26¾"

9⅝" 9⅝" 5⅝" 29" 1¾" 46½" 22¾"

9⅝" 9⅝" 5⅝" 29" 1¾" 58½" 34¾"

8

1

11

11

1

2

11

1

2

11

1

2

11

1

11

2

Condensate

Drain

Connection

/16" (43mm)

/16" (68mm)

11

/16" (43mm)

11

/16" (68mm)

/16" (43mm)

11

/16" (68mm)

/16" (43mm)

11

/16" (68mm)

/16" (43mm)

/16" (68mm)

Page 9

ISO Performance Data

Water Loop

Water Loop Performance Data Rated in Accordance with ISO Standard 13256-1 Boiler/Tower

Standard Unit ECM at High Static

Size

*007

009

012

015

019

024

030

036

042

048

060

070

* Not available at time of publication. Please consult your McQuay Representative for specific availability.

n/a – ECM option not available in unit sizes 007, 009, 012.

Unit

CFM

*

300

400

500

600

800

1000

1300

1400

1600

2000

2160

Airow Waterow

Voltage

Cooling Heating Cooling Heating

L/S GPM L/S Btuh Watts EER COP Btuh Watts COP Btuh Watts EER COP Btuh Watts COP

115-1-60

*

142

189

236

283

378

472

614

661

755

944

1019

*

2.3

3.0

3.6

4.68

5.81

7.25

9.50

11.00

12.00

15.50

19.00

*

0.15

0.19

0.23

0.30

0.37

0.46

0.60

0.69

0.76

0.98

1.20

208/230-1-60

265-1-60

230-1-50

115-1-60

208/230-1-60

265-1-60

230-1-50

115-1-60

208/230-1-60

265-1-60

230-1-50

208/230-1-60

265-1-60

230-1-50

208/230-1-60

265-1-60

230-1-50

208/230-1-60

265-1-60

230-1-50

208/230-1-60

265-1-60

208/230-3-60

230-1-50

208/230-1-60

208/230-3-60

460-3-60

380-3-50

208/230-1-60

208/230-3-60

460-3-60

575-3-60

380-3-50

208/230-1-60

208/230-3-60

265-1-60

460-3-60

575-3-60

230-1-50

380-3-50

208/230-1-60

208/230-3-60

265-1-60

460-3-60

575-3-60

230-1-50

380-3-50

208/230-3-60

460-3-60

575-3-60

380-3-50

*

9060

12000

14700

19200

23800

30000

39500

43900

48100

63200

75400

*

2650

3510

4300

5620

6980

8800

11500

12800

14100

18500

22100

*

*

*

14.0

14.4

16.0

15.2

15.1

17.0

14.8

15.0

14.7

15.1

13.5

4.1

4.2

4.7

4.5

4.4

5.0

4.3

4.4

4.3

4.4

4.0

10600

14000

16100

18300

26700

33400

45000

52500

56800

68300

87300

*

*

4.7

3110

4.8

4110

5.1

4720

4.4

5370

4.9

7820

5.2

9780

4.6

13200

4.8

15400

4.8

16600

4.7

20000

4.4

25500

n/a

n/a

n/a

*

19500

24100

29900

39900

44200

48700

63600

76200

n/a

n/a

n/a

*

5710

7050

8750

11700

12900

14200

18600

22300

n/a

n/a

n/a

16.6

16.3

17.0

15.0

16.2

16.0

15.7

14.0

n/a

n/a

n/a

n/a

n/a

n/a

*

*

4.9

4.8

5.0

4.4

4.7

4.7

4.6

4.1

*

18000

26300

33400

44500

52300

56400

67700

86300

n/a

n/a

n/a

*

5270

7700

9780

13000

15300

16500

19800

25300

n/a

n/a

n/a

*

4.6

5.2

5.4

4.6

5.1

5.1

5.0

4.5

9

Page 10

ISO Performance Data

Page Headline Here Page Headline Here

Ground Loop

Ground Loop Performance Data Rated in Accordance with ISO Standard 13256-1 Ground Coupled

Standard Unit ECM at High Static

*007

012

* Not available at time of publication. Please consult your McQuay Representative for specific availability.

n/a – ECM option not available in unit sizes 007, 009, 012.

Unit

Size

009

015

019

024

030

036

042

048

060

070

CFM

*

300

400

500

600

800

1000

1300

1400

1600

2000

2160

Airow Waterow

Cooling Heating Cooling Heating

Voltage

L/S GPM L/S Btuh Watts EER COP Btuh Watts COP Btuh Watts EER COP Btuh Watts COP

115-1-60

*

0.15

0.19

0.23

0.30

0.37

0.46

0.60

0.69

0.76

0.98

1.20

208/230-1-60

265-1-60

230-1-50

115-1-60

208/230-1-60

265-1-60

230-1-50

115-1-60

208/230-1-60

265-1-60

230-1-50

208/230-1-60

265-1-60

230-1-50

208/230-1-60

265-1-60

230-1-50

208/230-1-60

265-1-60

230-1-50

208/230-1-60

265-1-60

208/230-3-60

230-1-50

208/230-1-60

208/230-3-60

460-3-60

380-3-50

208/230-1-60

208/230-3-60

460-3-60

575-3-60

380-3-50

208/230-1-60

208/230-3-60

265-1-60

460-3-60

575-3-60

230-1-50

380-3-50

208/230-1-60

208/230-3-60

265-1-60

460-3-60

575-3-60

230-1-50

380-3-50

208/230-3-60

460-3-60

575-3-60

380-3-50

*

9720

12700

15700

19400

24800

30700

40300

45400

51600

65100

76500

*

2850

3720

4600

5690

7260

9000

11800

13300

15100

19100

22400

*

*

16.7

16.9

19.6

17.3

17.7

19.1

17.3

17.0

15.8

16.3

13.7

4.9

5.0

5.7

5.1

5.2

5.6

5.1

5.0

4.6

4.8

4.0

*

7020

9300

10000

13700

17800

22300

30300

35100

40300

47000

58900

2050

2720

2920

4010

5210

6530

8900

10300

11800

13700

17200

*

*

3.3

3.5

3.5

3.5

3.6

3.9

3.4

3.6

3.4

3.5

3.1

n/a

n/a

n/a

*

19700

25100

30600

40500

46100

50200

66000

78400

n/a

n/a

n/a

*

5770

7350

8960

11800

13500

14700

19300

22900

n/a

n/a

n/a

19.0

19.2

19.3

16.6

18.9

18.2

18.0

16.2

n/a

n/a

n/a

*

*

5.6

5.6

5.7

4.9

5.5

5.3

5.3

4.7

n/a

n/a

n/a

*

13400

17500

22300

30000

34400

37600

46000

56800

n/a

n/a

n/a

*

3920

5120

6530

8790

10100

11000

13500

16600

142

189

236

283

378

472

614

661

755

944

1019

*

*

2.3

3.0

3.6

4.68

5.81

7.25

9.50

11.00

12.00

15.50

19.00

n/a

n/a

n/a

*

3.7

3.8

4.0

3.3

3.8

3.8

3.8

3.6

10

Page 11

ISO Performance Data

Ground Water

Ground Water Performance Data Rated in Accordance with ISO Standard 13256-1

Standard Unit ECM at High Static

Size

*007

009

012

015

019

024

030

036

042

048

060

070

* Not available at time of publication. Please consult your McQuay Representative for specific availability.

n/a – ECM option not available in unit sizes 007, 009, 012.

Unit

CFM

*

300

400

500

600

800

1000

1300

1400

1600

2000

2160

Airow Waterow

Cooling Heating Cooling Heating

Voltage

L/S GPM L/S Btuh Watts EER COP Btuh Watts COP Btuh Watts EER COP Btuh Watts COP

115-1-60

*

142

189

236

283

378

472

614

661

755

944

1019

*

2.3

3.0

3.6

4.68

5.81

7.25

9.50

11.00

12.00

15.50

19.00

*

0.15

0.19

0.23

0.30

0.37

0.46

0.60

0.69

0.76

0.98

1.20

208/230-1-60

265-1-60

230-1-50

115-1-60

208/230-1-60

265-1-60

230-1-50

115-1-60

208/230-1-60

265-1-60

230-1-50

208/230-1-60

265-1-60

230-1-50

208/230-1-60

265-1-60

230-1-50

208/230-1-60

265-1-60

230-1-50

208/230-1-60

265-1-60

208/230-3-60

230-1-50

208/230-1-60

208/230-3-60

460-3-60

380-3-50

208/230-1-60

208/230-3-60

460-3-60

575-3-60

380-3-50

208/230-1-60

208/230-3-60

265-1-60

460-3-60

575-3-60

230-1-50

380-3-50

208/230-1-60

208/230-3-60

265-1-60

460-3-60

575-3-60

230-1-50

380-3-50

208/230-3-60

460-3-60

575-3-60

380-3-50

*

10900

14100

17100

21400

26600

33000

42900

48800

56100

69000

79100

*

3200

4130

5010

6270

7790

9600

12500

14300

16400

20200

23100

*

8820

*

2580

3450

3830

4950

6360

8320

11000

12500

14300

17100

21300

*

4.0

4.2

4.3

4.1

4.2

4.6

4.1

4.2

4.0

4.1

3.6

*

*

23.8

23.8

28.1

23.5

23.3

25.1

22.3

22.1

20.3

20.5

16.6

7.0

7.0

8.2

6.9

6.8

7.4

6.5

6.5

5.9

6.0

4.9

11800

13100

16900

21700

28400

37700

42900

48900

58400

72700

n/a

n/a

n/a

*

21600

26900

32900

43000

49100

54300

69900

80600

n/a

n/a

n/a

*

6320

7880

9630

12600

14400

15900

20500

23600

n/a

n/a

*

26.1

25.8

25.5

21.3

24.8

23.8

22.9

19.6

n/a

n/a

n/a

7.7

7.6

7.5

6.2

7.3

7.0

6.7

5.7

n/a

n/a

n/a

*

16600

21300

28400

37400

43000

47100

57400

70500

n/a

n/a

n/a

n/a

n/a

n/a

n/a

*

*

4860

6240

8300

10900

12600

13800

16800

20600

*

4.4

4.5

4.8

4.0

4.5

4.5

4.4

4.1

11

Page 12

Water Source Heat Pump Geothermal Systems

Water source heat pump

systems are one of the

most efficient systems

available for heating and

cooling buildings. High

efficiency, self-contained

McQuay Enfinity units can

be placed in virtually any

location within a building.

Each unit responds only

to the heating or cooling

load of the individual zone

it serves. This provides

excellent comfort levels for

occupants, better control

of energy use for building

owners and lower seasonal

operating costs.

Boiler/Tower Loop

A “Boiler/Tower” application uses a simple

two pipe water circulating system that adds

heat, removes heat or transfers rejected

heat to other units throughout the building.

The water temperature for heating is usually

provided by a natural gas or electric boiler

located in a mechanical room. The condensing water temperature is provided by a cooling tower that dissipates waste heat. This

application can be the lowest cost of the

loop options available.

Open Loop “Well Water”

“Open Loop” well water systems use

ground water to remove or add heat to

the interior water loop. The key benefit

of an open loop system is the constant

water temperature, usually 50°F to 60°F,

which provides efficient operation at a

low first cost. Open Loop applications are

commonly used in coastal areas where

soil characteristics allow reinjection wells

to return the water back to the aquifer.

Reinjection wells must be approved by the

U.S. Environmental Protection Agency.

Non-Ozone Depleting

R-410A Refrigerant

A global leader in

system solutions for

air conditioning, heating,

ventilating and refrigeration.

(800) 432-1342

www.mcquay.com

Geothermal Closed Loop

Vertical loops (shown) are installed by

drilling vertical bore holes into the earth

and inserting a plastic polyethylene supply/

return pipe into the holes. Horizontal loops

are installed in trenches approximately 5

feet below the ground surface. Both

vertical and horizontal loops extract the

Earth’s natural heat and reject it back.

McQuay International delivers engineered, flexible solutions for commercial, industrial and institutional

HVAC requirements with reliable products, knowledgeable applications expertise and responsive support. McQuay products and services are provided through a worldwide network of dedicated sales

and service offices.

™ ® The following are trade names or registered trademarks of their respective companies:

LonTalk and LonMark from Echelon Corporation, BACnet from ASHRAE and Enfinity from McQuay

International.

Products Manufactured in an ISO Certified Facility.

Surface Water or Lake Loop

A “Surface Water” or “Lake” (shown) closed

loop system is a geothermal loop that is

directly installed in a lake or body of water

that is near the building. In many cases, the

body of water is constructed on the building

site to meet run-off or aesthetic requirements. The size and the depth of the lake

is critical, and commercial design services

should be used to certify that a given body

of water is sufficient for building loads.

© 2009 McQuay International

A/SP 31-249 (3/09)

Loading...

Loading...