Page 1

Installation, Operation and Maintenance Manual

Variable Frequency Drives

Air-Cooled, LiquiFlo™ and LiquiFlo 2.0™

For Centrifugal Chillers

With MicroTech 200™ or MicroTech II™ Control

IOMM VFD-2

Group: Chiller

Part Number: 331375701

Effective: Sept. 2005

Supercedes: IOMM VFD

Page 2

Table of Contents

Introduction...........................................3

Environmental Conditions................................5

Harmonic Distortion.........................................5

General Description..............................6

Air-Cooled/LiquiFlo (LF ), Standard Features.6

LiquiFlo 2.0 (LF 2.0), Standard Features.........7

Codes/Standards...............................................7

Quality Assurance ............................................7

A-C/LiquiFlo, Nomenclature ...........................7

LiquiFlo 2.0, Nomenclature.............................7

Definition of Terms...............................9

Installation........................................... 11

Cooling Requirements for VFDs....................13

Separate Cooling Module (LF VFD 090, 120 and

all LF 2.0)....................................................15

Wiring, General..............................................21

Power Wiring.................................................21

Terminal Sizes................................................23

Optional Line Reactor Installation, Air-Cooled/LF

Only.............................................................25

VFD/Chiller Interconnection Wiring Diagram30

VFD Dimensions .................................32

Air-Cooled .....................................................32

LiquiFlo...........Error! Bookmark not defined.

LiquiFlo 2.0.....Error! Bookmark not defined.

MicroTech™ 200 VFD Control..........41

VFD Chiller Control States............................41

Control Sequence, MicroTech 200.................42

WDC/WCC, Dual Compressor VFD Operation43

MicroTech 200 Controller VFD Menu Screens43

MicroTech II™ VFD Control.............50

General Description: ......................................50

Sequence of Operation...................................50

Interface Panel Screens, MT II.......................52

Operation, Small A/C SP600 & LF 2.057

Using the Interface.........................................57

Using the LEDs..............................................59

About Alarms.................................................61

About Faults...................................................64

Troubleshooting.............................................73

Operation, Large A/C, PF700H.........77

Using the Interface.........................................77

Using the LEDs..............................................80

Faults and Alarms...........................................80

Troubleshooting.............................................87

Operation, LF .....................................90

Using the Interface.........................................90

Using the LEDs..............................................93

Troubleshooting.............................................95

Indices: Figures & Tables.................103

"Information and illustrations cover the McQuay International products at the time of publication and we reserve the right to make changes

“McQuay" is a registered trademark of McQuay International LiquiFlo and Reliance are trademarks of Rockwell Automation.

Manufactured in an ISO Certified facility

©2005 McQuay International

in design and construction at anytime without notice".

2 IOMM VFD-2

Page 3

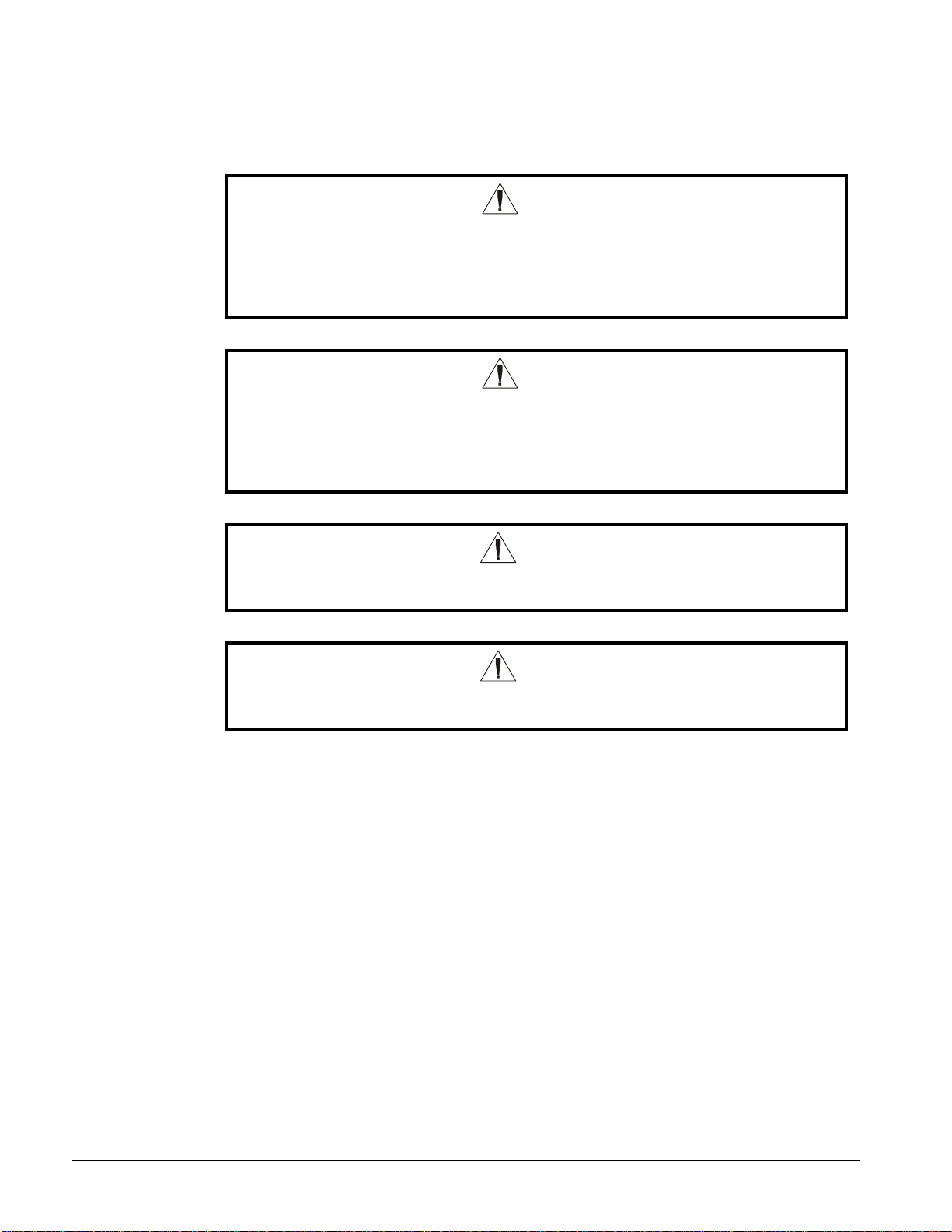

DANGER

Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, adjust, operate, or service

this equipment. Read and understand this ma nual and other applicable manuals

in their entirety before proceeding. Failure to observe this precaution could result

in severe bodily injury or loss of life.

DANGER

DC bus capacitors re tain hazardous voltages after power has been disconnected.

After disconnecting input power to the unit, wait five (5) minutes for the DC bus

capacitors to discharge, and then check the voltage with a voltmeter to ensure the

DC capacitors are discharged before touching any internal components. Failure

to observe this precaution could result in severe bodily injury or loss of life.

CAUTION

The user is responsible for conforming to all applicable local, national and

international codes. Failure to observe this precaution could result in damage to,

or destruction of the equipment.

The drive contains printed circuit boards that are static-sensitive. Anyone who

touches the drive components should wear an anti-static wristband. Erratic

machine operation and damage to, or destruction of, equipment can result if this

Failure to observe this precaution can result in bodily injury.

Introduction

This manual covers Air-Cooled, LiquiFlo (LF ) and LiquiFlo 2.0 (LF 2.0) VFDs on

centrifugal chillers with MicroTech 200™ or the newer MicroTech II™ controllers. Many

issues are the same for both and are treated in common. Where differences occur,

information will be designated as being for a specific VFD or controller model.

The above three types of VFDs have four family designations as show in Table 1 and Table

2. Each of these VFD families has a separate section in this manual. There is considerable

overlap in programming methods and general operation of the drives, but they are in

separate sections to avoid confusion. The beginning page number for each control section

in the manual is noted in the tables.

WARNING

procedure is not followed.

IOMM VFD-2 3

Page 4

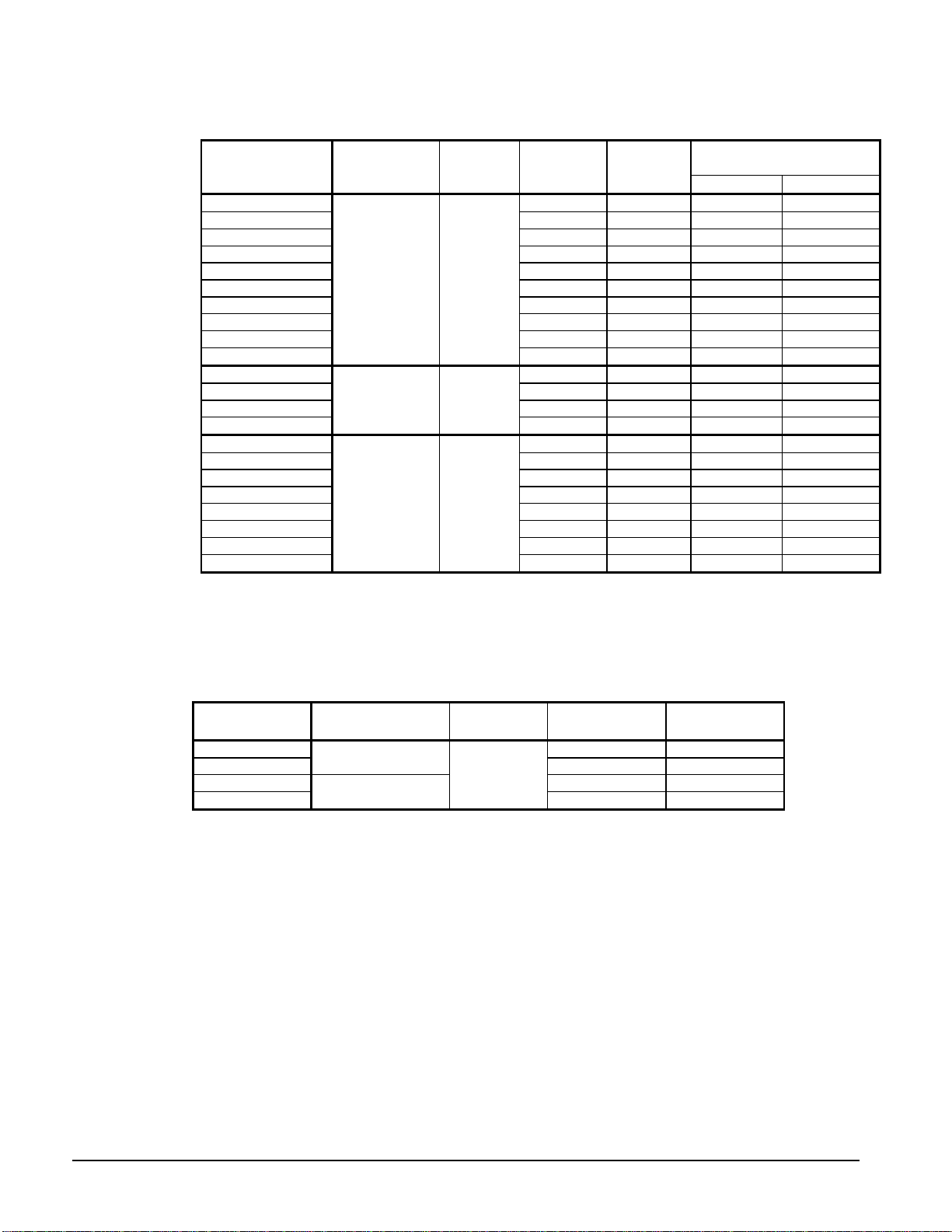

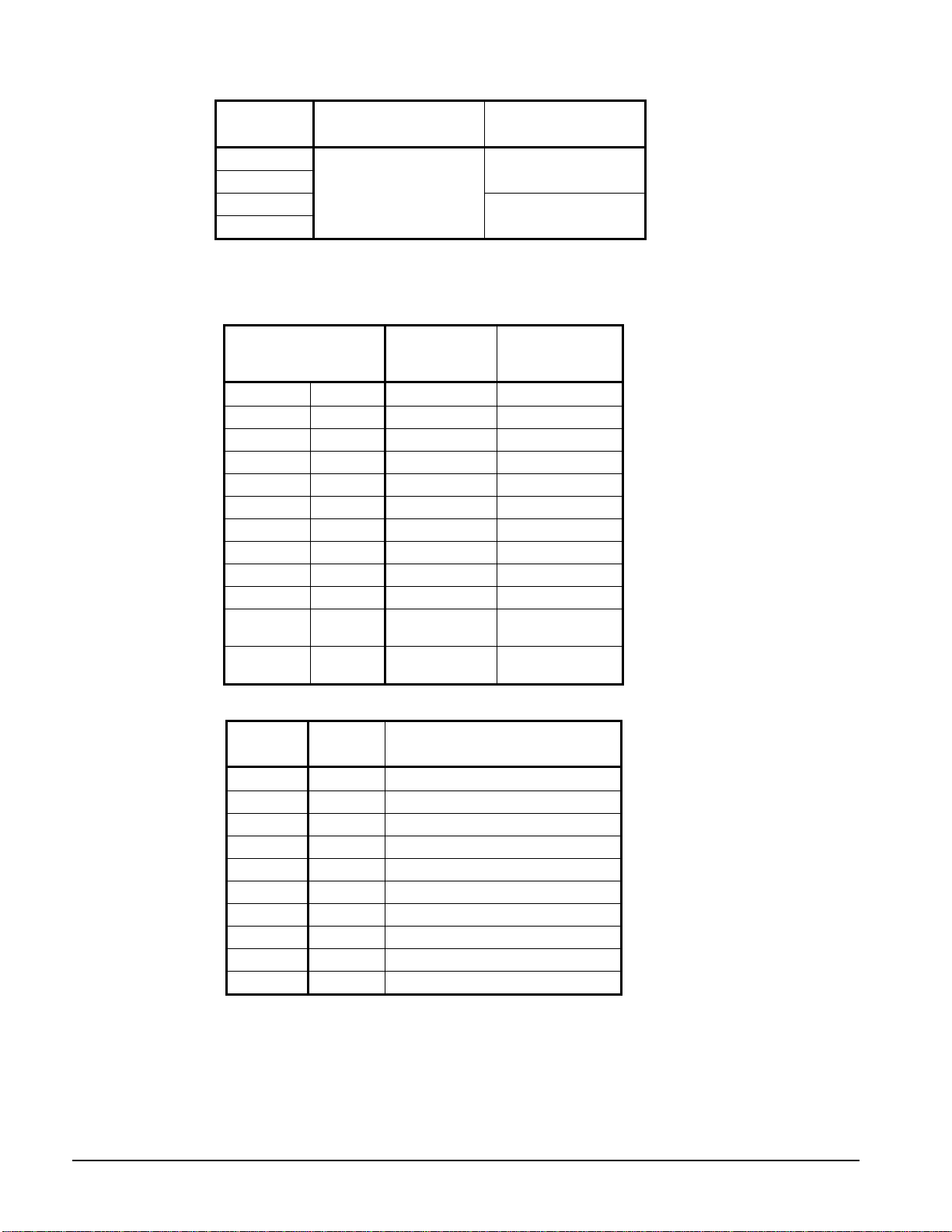

Table 1, Model Sizes, Air-Cooled/LiquiFlo

L=Shipped loose, M=Mounted, A=Air-cooled, W=Water-cooled

VFD Model

VFD 009LA 87 Air RC 100

VFD 009MA 87 Air RC 100

VFD 012LA 114 Air R1 130

VFD 012MA 114 Air R1 130

VFD 015LA 142 Air R2 160

VFD 015MA 142 Air R2 160

VFD 017LA 164 Air R3 200

VFD 017MA 164 Air R3 200

VFD 023LA 225 Air R4 250

VFD 023MA

VFD 024LA 237 Air RY STD.

VFD 024MA 237 Air RY STD.

VFD 028LA 273 Air RY STD.

VFD 028MA

VFD 047LW 414 Water RD 500

VFD 047MW 414 Water RD 500

VFD 060LW 500 Water R7 600

VFD 060MW 500 Water R7 600

VFD 072LW 643 Water R8 750

VFD 072MW 643 Water R8 750

VFD 090LW 890 Water RM 900

VFD120LW

VFD Family

Designation

SP 600 Page 57

PF700H Page 77

LF Page 90

Page

Location

Max.

Amps

225 Air R4 250

273 Air RY STD.

1157 Water R9 1200

Cooling

Optional Line Reactor

(Note 1)

Size Amp Rating

NOTES

1. Line reactors are optional on all sizes except Models VFD 024 and 028, where they are included as

standard.

2. Electrical characteristics: 380/460 VAC ±10%, 3 phase, 50/60 Hertz, ±5 Hz.

3. Optional line reactors are 3% impedance.

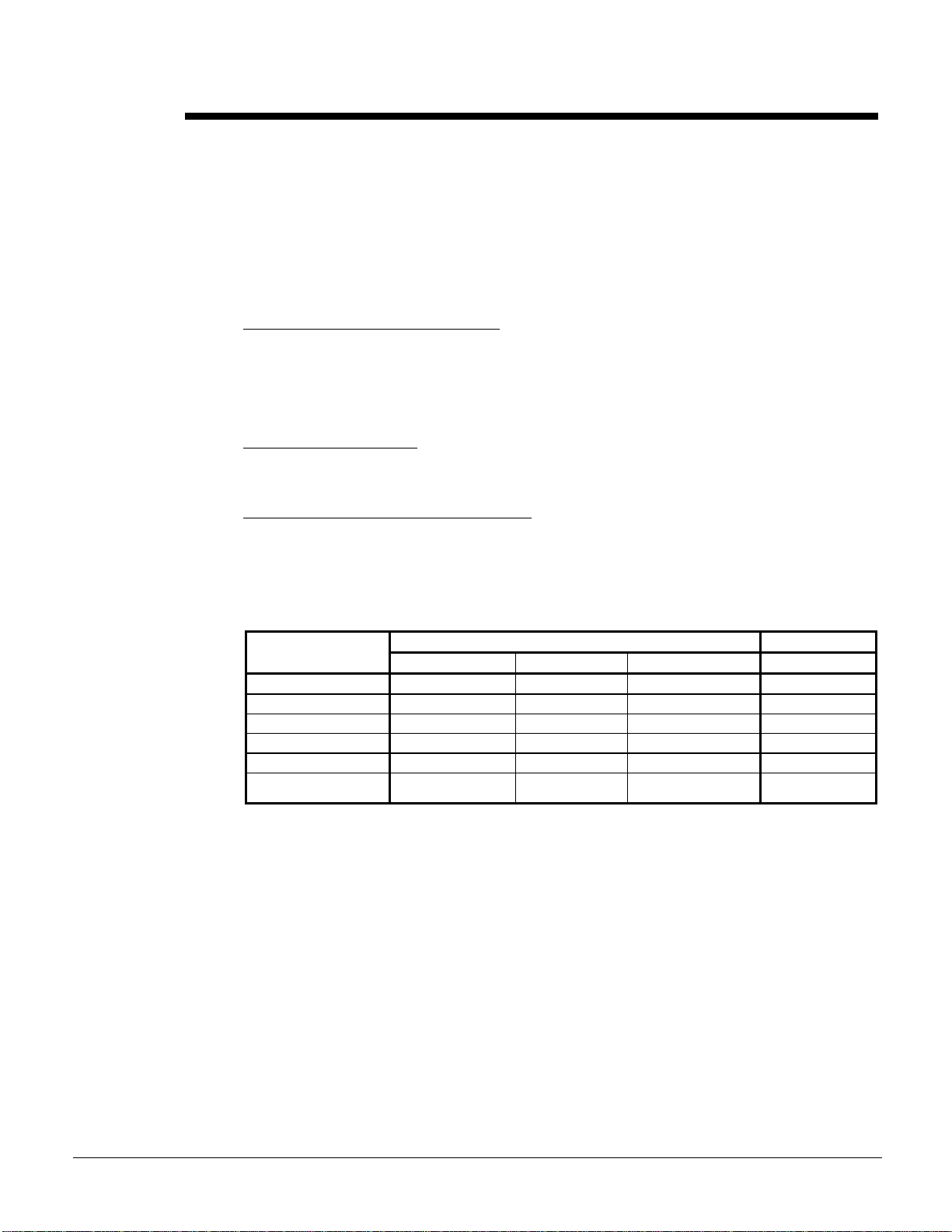

Table 2, Model Sizes, LiquiFlo 2.0

VFD Model

VF 2037 368 Water

VF 2055

VF 2080 809 Water

VF 2110

VFD Family

Designation

LF 2.0, Frame 3

LF 2.0, Frame 4

Page

Location

Page 57

Max. Amps Cooling

553 Water

1105 Water

WSC and WDC single and dual compressor, and WCC dual compressor chillers can be

equipped with Variable Frequency Drives (VFD). A VFD starts the compressor motor and then

modulates the compressor speed in response to load, evaporator pressure, and condenser

pressure, as sensed by the chiller microprocessor. Despite the small power penalty attributed to

the VFD internal losses, a chiller can achieve outstanding overall efficiency by using a VFD.

VFDs are effective when there is a reduced load, combined with a low compressor lift (lower

condenser water temperatures), dominating the operating hours.

The traditional method of controlling centrifugal compressor capacity is by inlet guide vanes.

Slowing down the compressor, thereby reducing the impeller tip speed, can also reduce

capacity. However, sufficient impeller tip speed must always be maintained to meet the

chiller’s discharge pressure requirements. The speed control method is more efficient than

guide vanes by themselves.

In actual practice, a combination of the two techniques is used. The microprocessor slows the

compressor (to a programmed minimum percent of full load speed) as much as possible,

4 IOMM VFD-2

Page 5

considering the need for sufficient tip speed, to make the required compressor lift. Then the

guide vanes take over for further capacity reduction. This methodology provides the optimum

efficiency under any operating condition.

Inlet guide vanes control compressor capacity based on a signal from the microprocessor, which

is sensing changes in the leaving chilled water temperature. The guide vanes vary capacity by

changing the angle and flow of the suction gas entering the impeller. The impeller takes a

smaller “bite” of the gas. Reduced gas flow results in less capacity. Compressors start

unloaded (guide vanes closed) in order to reduce the starting effort. A vane-closed switch (VC)

signals the microprocessor that the compressor vanes are closed.

VFDs can be found on centrifugal chillers with the older MicroTech 200 controller (sometimes

referred to as MicroTech I or just plain MicroTech) or the newer MicroTech II™ controller.

The two MicroTech controller versions are easily differentiated as shown below. The

MicroTech II panel shown below is the initial version known as Panel 1. Panel 2, shown on

page 50, replaced it in mid-2005.

MicroTech 200 Control Panel

MicroTech II Operator Interface Panel 1

Operation and adjustment of the VFD involves settings on both the VFD itself and also to the

chiller controller, either MicroTech 200 controller or MicroTech II controller. This manual

consists of a section relating to VFD operation common to both chiller controllers and also

separate sections for the settings specific to either of the chiller MicroTech controllers.

NOTE: VFDs are programmed differently in the factory for 50 and 60 hertz applications. It is

prudent to verify this by checking the settings sticker in the unit and the actual unit settings

using the Reliance manual shipped with the VFD unit as a reference.

Environmental Conditions

Operating Temperature (inside NEMA 1 enclosure) 32° to 131°F (0°C to 55°C)

Ambient T em perature (outside NEMA 1 enclosure) 32° to 104°F (0°C to 40°C)

Storage Temperature (Ambient) 32° to 131°F (0°C to 55°C)

Humidity 5% to 95% (non-condensing)

AC line distribution system capacity shall not exceed 85,000 amps symmetrical available fault

current.

Harmonic Distortion

Harmonic distortion, the effect that any variable frequency drive has on the electrical system

supplying it power, is a consideration on most applications and is discussed in detail in Catalog

Starter, which can be obtained from the local McQuay sales office or on www.mcquay.com.

IOMM VFD-2 5

Page 6

General Description

The VFD will not generate damaging voltage pulses at the motor terminals when applied

within 500 feet of each other. The VFD drive complies with NEMA MG1 section

30.40.4.2, which specifies these limits at a maximum peak voltage of 600 volts and a

minimum rise time of 0.1 microseconds.

All VFDs require cooling. Models VFD 019 and VFD 028, rated at 273 amps or less, are

air-cooled. All others are water-cooled.

Factory-mounted, water-cooled VFDs have VFD cooling water combined in the factory

with the compressor oil cooling system.

Freestanding water-cooled VFDs require field-installed chilled water supply and return

piping for the VFD. Models VFD 090 and 120 and all LF 2.0 models have an intermediate

cooling module, field installed, between the cooling source and the VFD.

Water-cooled VFD’s have a liquid-cooled heatsink assembly enabling liquid cooling of the

drive though a single inlet and outlet connection point.

There is a temperature-regulating valve located in the drive. It must be set to maintain 95°F

(35°C) leaving coolant temperature. This is necessary to prevent condensation from

forming in the heatsink. Minimum entering coolent temperature is 40°F (4.4°C).

Air-Cooled/LiquiFlo (LF ), Standard Features

• Electronic overload circuit designed to protect an AC motor, operated by the VFD

output, from extended overload operation on an inverse time basis. This electronic

overload is UL and NEC recognized as adequate motor protection. No additional

hardware, such as motor overload relays, or motor thermostats are required.

• An LED display that digitally indicates:

Frequency output Input kW DC bus voltage

Voltage output Elapsed time Motor RPM

Current output Time stamped fault indication

• The VFD is capable of maintaining operation through power dips up to 10 seconds

without a controller trip, depending upon load and operating conditions. In this

extended ride-through, the drive uses the energy generated by the load inertia of the

motor as a power source for electronic circuits.

• An isolated 0-20mA, 4-20mA, or 0-4, 0-8, 0-10 V analog speed input follower.

• An isolated 0-10V or 4-20mA output signal proportional to speed or load.

• Standard I/O expansion interface card with the following features:

• Four isolated 24VDC programmable digital inputs

• One frequency input (0 to 200Hz) for digital control of speed or trim reference

• Four programmable isolated digital outputs (24 VDC rated)

• One Form A output relay rated at 250 VAC or 24VDC

• Two NO/NC programmable output relays rated at 250 VAC or 24 VDC

• The VFD includes the following standard protective circuit features:

• Output phase-to-phase short circuit condition

• Total ground fault under any operating condition

• High input line voltage

• Low input line voltage

• Loss of input or output phase

• External fault (This protective circuit will permit wiring to a remote normally

closed equipment protection contact to shut down the drive.)

6 IOMM VFD-2

Page 7

LiquiFlo 2.0 (LF 2.0), Standard Features

• NEMA 1 enclosure with hinged door.

• Package includes a circuit breaker with shunt trip with AIC rating of 65,000 amps.

• Full motor voltage is applied regardless of the input voltage.

• Efficiency at rated load and 60 hertz is 97%.

• Drive thermal overload is 110% for 60 seconds in volts per hertz mode and 150% for

five seconds in sensorless vector mode.

• Achieves IEEE519 using actively controlled IGBT front-end maximum of 5% THD.

• 0.99 power factor at full load and provides power factor correction at lighter loads.

• IGBT switching: 2kHz carrier frequency.

• The entire drive package is UL/CUL listed.

• Optional multi language LCD keypad.

• Power line dip ride through capability for up to 10 seconds.

• Adjustable auto restart (number of restarts and time delay between attempts are

selectable.) Display indicates when controller is attempting to restart.

• Control power transformer for chiller unit controls

Codes/Standards

• VFDs are UL 508 listed

• VFDs are designed to comply with the applicable requirements of the latest standards

of ANSI, NEMA, National Electric Code (NEC), NEPU-70, IEEE 519-1992, FCC Part

15 Subpart J, CE 96.

Quality A ssurance

• Every VFD is functionally tested under motor load. During this test the VFD is

monitored for correct phase current, phase voltages, and motor speed. Correct current

limit operation is verified by simulating a motor overload.

• Scrolling through all parameters verifies proper factory presets. The computer port also

verifies that the proper factory settings are loaded into the drive.

• Every VFD’s heatsink is tested to verify proper embedding of the tubing for flow of

coolant liquid. Thermal tests are performed on the VFD to verify that the cooling

occurs within the correct temperature range.

A-C/LiquiFlo, Nomenclature

VFD XXX M A

Variable Frequency Drive

2037 through 2110 (LF 2)

Model Number

009 through 120

Cooling Method

A=Air-cooled

W=Water-cooled

Mounting

M=Factory-mounted

L= Shipped Loose for

Field Mounting

LiquiFlo 2.0, Nomenclature

Since all LF 2.0 models are field-mounted and water-cooled, there are no characters after

the Model Number, typically VFD 2037.

IOMM VFD-2 7

Page 8

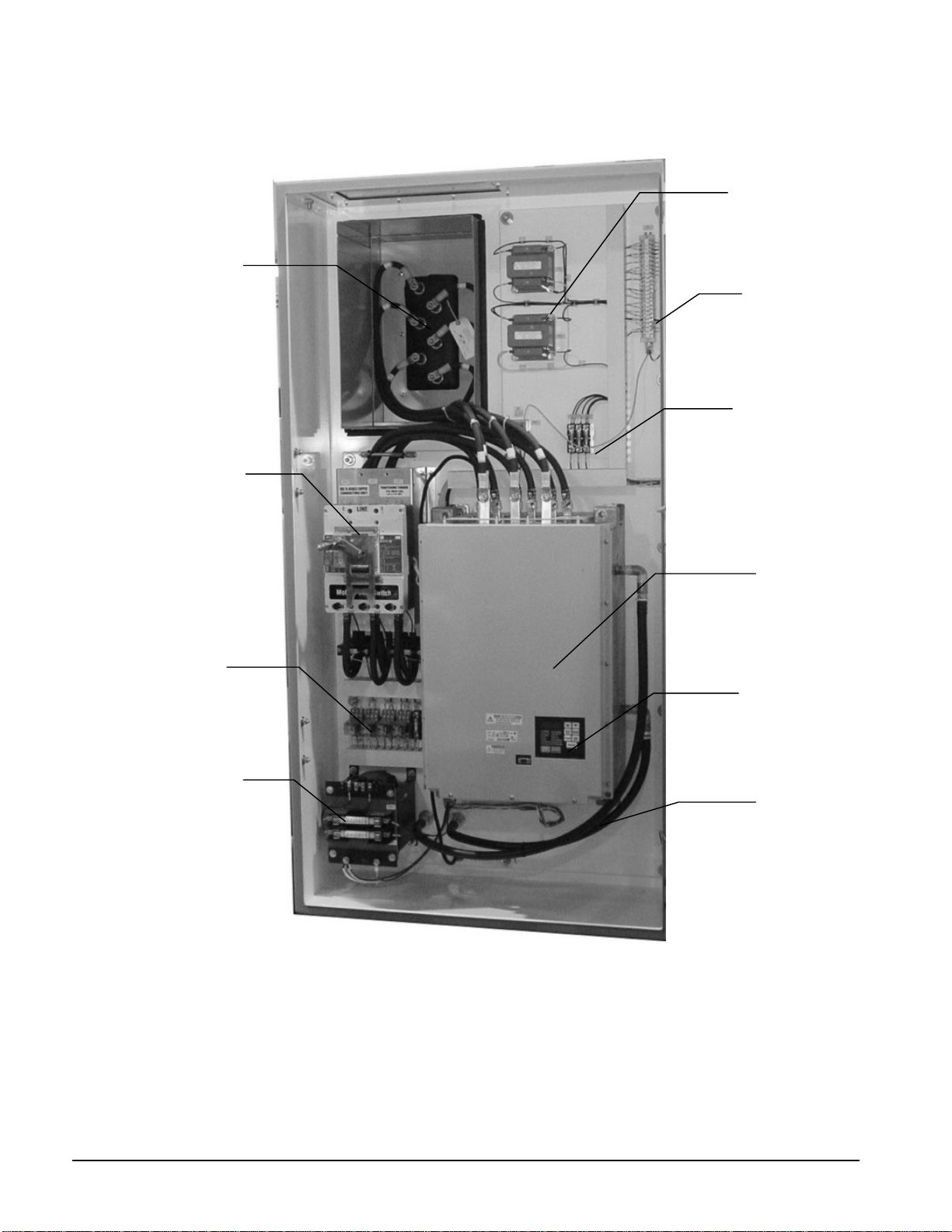

Figure 1, LiquiFlo, Internal Component s, Factory Mounted, Water-Cooled Model

Optional Meter

Transformers (2)

Motor Terminals

Fuses

Disconnect Switch

Terminal Board

Motor Control

Relays (MCR)

Control

Transformer

w/ Fuses

Drive Unit

Keyboard/Display

Cooling Water

Lines

8 IOMM VFD-2

Page 9

Definition of Terms

Acc2

Active LEWT Setpoint

Analog in loss

Anig Cal Chksum

Autotune

AutoT MagRot

AutoT Rs Stat

CAN Bus Fit

Command Speed

DB

Dec2

Decel Inhibit

Demand Limit

Dig in Conflict

Drive OL

Esc/Prog

Flux Amps

Full Load

FVC

HIM

IGBT

IntDBResOvrHeat

Lift Temperature

Lift Temperature Control

Speed

Low evap pressure inhibit

setpoint

Manual Load Setpoint

Maximum Pulldown Rate

MCB

MCR

Minimum Amp Setpoint

Minimum Rate Setpoint

Minimum Speed

Mod

Net

Network Setpoint

NP Hz

OIM

PCB

Continued next page.

Acceleration time 2

The current Leaving Evaporator Water Temperature Setpoint

Analog input loss

Analog input calculation check sum, math function

Set point adjustments made automatically, not used by McQuay

Autotune rotate, not used by McQuay

Autotune static, not used by McQuay

Controlled area network bus fit

The speed command issued by the MicroTech controller to the VFD

Dynamic breaking (not used on McQuay units)

Deceleration 2, not used by McQuay

Deceleration inhibited

The maximum amp draw as established by the Demand Limit setpoint

Digital input conflict, contradictory instructions

Drive overload

Exit a menu, cancel a change to a parameter, or toggle between program and

process (user) display screens.

Amount of current out of phase with the fundamental voltage component

The vane open switch closes and the speed output = 100%. Or

Load pulses exceed the full load setpoint timer (default 300 cumulative

seconds) and the speed output = 100%. Or

% RLA is above or equal to Max Amp Limit or Demand Limit. Or

The evaporator pressure is below the low evap. pressure inhibit setpoint.

Flux vector control

Human interface module

Insulated Gate Bi-polar Transistors

Dynamic breaking resistor temp. exceeded setpoint(not used on McQuay

units)

Saturated condenser refrigerant temperature minus saturated evaporator

temperature.

The minimum speed to maintain lift and avoid surge. The controller

continuously calculates the minimum operating speed in all modes, based on

the lift temperature.

The low evaporator pressure that inhibits any further compressor loading

MicroTech controller manual operation of the guide vanes for testing

Maximum pulldown rate of chilled water in degrees per minute

Main control board

Motor control relay

MicroTech controller minimum unloading setpoint

Pulldown rate for MicroTech 200 controller

The minimum speed allowed, usually set at 70%

Module

Network

Chilled water setpoint from an external source

Operator interface module

Printed circuit board

IOMM VFD-2 9

Page 10

Precharge

PWM

Rapid Shutdown

RLA

RMI

Softloading

Speed

Stage Delta

SVC

Parameters

Throughout this manual, you will see references to parameter names and numbers that

identify them for the drive. This manual uses the same format that will be shown on the

keypad/display to refer to parameters:

P.nnn H.nnn R.nnn

Where: nnn is a number

P designates general parameters

H designates Volts/Hertz parameters

R designates optional RMI parameters

Precharge capacitors

Pulse-width-modulated

If there is a fault, the MicroTech switches the state to VFD OFF. This includes

changing the Unit Control Panel switch to OFF.

Rated Load Amps, the maximum motor amps

Remote meter interface, located in the VFD panel

Extended ramp-up in capacity, set in the MicroTech controller

Speed signal to the compressor motor from the variable frequency drive (VFD)

based on analog output (0 – 10 VDC) from the MicroTech controller.

Multi compressor (or dual compressor unit) on/off cycling temperature delta-T

Sensorless vector control

CAUTION

The original parameters values set by the McQuay startup technician must never be

changed by anyone not specifically trained and experienced with these VFDs. Damage

to the chiller or drive could occur.

10 IOMM VFD-2

Page 11

Installation

Mounting Arrangement s

Depending on size and type, VFDs may be factory-mounted with power and control wiring

factory-installed or free-standing, requiring field mounting remote from the unit and fieldwiring of power and control wiring. Because of dimension restrictions for shipping, some

“factory-mounted” VFDs for some large chillers are shipped separate from the unit.

Mounting supports are on the unit and preassembled cable kits are provided. Mounting and

wiring on site are the customer’s responsibility and can be subcontracted to McQuay

Factory Service if desired.

Factory-Mounted (extra cost option):

The VFD is mounted on the chiller unit with the back

of the VFD against the motor terminal box and wired directly to the motor. This

arrangement is only available on WSC/WDC 063, 079, or 087 units and with LF.

On models WSC/WDC 048/050, the VFD (LF only) is factory-mounted on the front of the

chiller unit and connected to the motor with conduit and cable.

Free-standing (standard):

Floor-mounted, separate from the chiller unit, and field wired to

the compressor motor. This is available on all VFDs and is the only VFD arrangement

available for WDC/WCC 100 and 126 dual compressor units.

Brackets and cable (extra cost option):

VFDs (LF only) for WSC 100 to 126 single

compressor units may be shipped separately from the chiller unit and furnished with

mounting brackets and interconnecting cables for field mounting and connection by others.

This option must be clearly specified when chillers are ordered since brackets are welded

onto the evaporator during its construction.

Table 3, VFD Mounting Arrangements

Chiller

Size

WSC/WDC 050 X X X

WSC/WDC 063 X X X

WSC/WDC 079 X X X

WSC/WDC 087 X X X

WSC 100 - 126 X X X

WDC 100 – 126,

WCC 100 - 126

Factory- Mounted Free-Standing Brackets & Cables Free-Standing

X X

Air-Cooled/LiquiFlo LiquiFlo 2.0

Receiving

Since factory-mounted VFDs are mounted and wired at the factory, this section will only

apply to free-standing units.

The unit should be inspected immediately after receipt for possible damage.

All McQuay centrifugal VFDs are shipped FOB factory and all claims for handling and

shipping damage are the responsibility of the consignee.

Rigging

Extreme care must be used when rigging the equipment to prevent damage. See the

certified dimension drawings included in the job submittal for the center of gravity of the

unit. Consult the local McQuay sales office for assistance if the drawings are not available.

IOMM VFD-2 11

Page 12

Air-Cooled, The unit can be lifted by fastening the rigging hooks to the two lifting eyes

located on the top of the unit.

LiquiFlo; The unit can be lifted by fastening the rigging hooks to the four lifting eyes

located on the top of the unit.

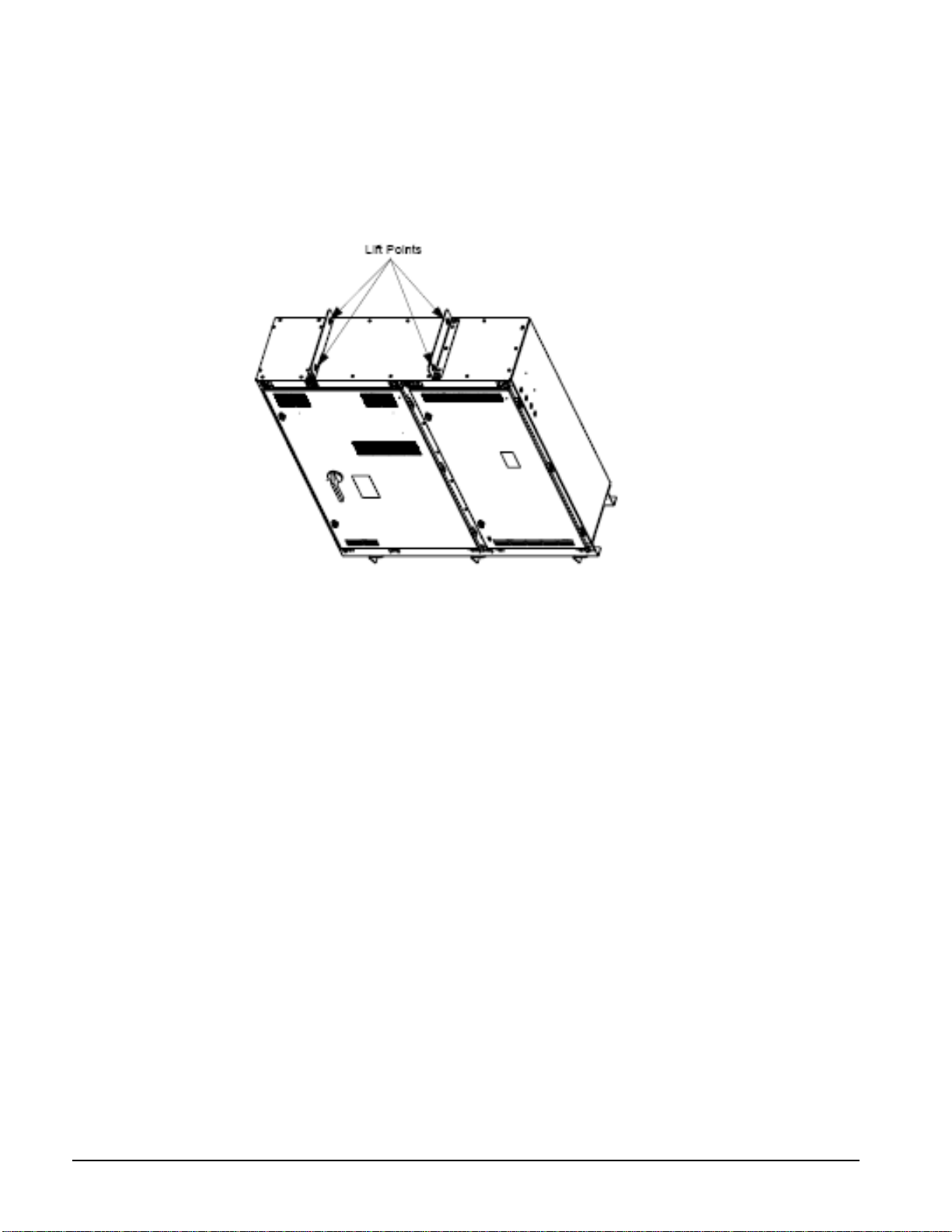

LiquiFlo 2.0:

Figure 2, LF 2.0, Lifting Point s

Use the following procedure to lift and mount the LiquiFlo 2.0 drive:

Step 1. Using an overhead or portable hoist (minimum 2 ton rated capacity), attach a

free-fall chain to the chain secured to the drive. Take up any vertical slack in the chain.

Step 2. Using the hoist, lift the drive from the horizontal shipping pallet.

Step 3. Position the drive.

Step 4. Machine or floor-mount the drive enclosure using 1/2-inch bolts, grade 5 or

better, with compression washers.

Location and Mounting

Location

Consider the following guidelines: •

• Verify that NEMA 1 enclosure drives can be kept clean and dry.

• The area chosen should allow the space required for proper air flow. A minimum of 6-

inch clearance is required wherever vents are located.

• Be sure that the NEMA 1 enclosure is installed away from oil, coolants, or other

airborne contaminants.

• Do not install the drive above 1000 meters (3300 feet) without derating output power.

For every 91.4 meters (300 feet) above 1000 meters (3300 feet), derate the output

current 1%.

• Verify that the drive location meets the environmental conditions specified on page 5.

• Floor-mounted units should be attached to the floor with the C-channel rails provided.

12 IOMM VFD-2

Page 13

Clearance

The VFDs must be mounted on a level concrete or steel base and must be located to provide

adequate service. Local codes or the National Electric Code (NEC) can require more

clearance in and around electrical components and must be checked.

Mounting

Make sure that the floor or structural support is adequate to support the weight of the unit

shown on the dimension drawing.

Standard NEMA 1 and NEMA 12 VFDs must be installed indoors in an area that is not

exposed to direct water spray. Do not install in areas where the ambient temperature falls

below 32°F (0°C) or exceeds 104°F (40°C) enclosed, or 122°F (50°C) open unless this was

noted at the time of order placement and special precautions were taken to protect against

these abnormal temperatures.

Heatsink temperatures can run as high as 158°F (70°C) during normal operation. Do not

mount the starter in contact with any material that cannot accept this heat. The VFD must

be mounted with the heat sink fins oriented vertically in an area that will not experience

excessive shock or vibration.

Grounding the Drive

Use the following steps to ground the drive:

Step 1. Open the door of the enclosure.

Step 2. Run a suitable equipment grounding conductor unbroken from the drive

enclosure ground lug to earth ground. See figure 2.2. Tighten these grounding

connections to the proper torque.

Step 3. Close the door of the enclosure.

Safety Precautions

Electrical codes require that all equipment (VFD, motor, operator station, etc.) be properly

grounded. An incoming disconnect must be locked open before wiring or servicing the

starter, motor, or other related equipment. The equipment must only be serviced by

qualified personnel fully trained and familiar with the equipment.

The opening of the branch circuit protective device may be an indication that a fault current

has been interrupted. To reduce the risk of electrical shock, current carrying parts and other

components of the starter should be inspected and replaced if damaged.

Equipment is at line voltage when AC power is connected. Pressing the Stop push-button

does not remove AC mains potential. All phases must be disconnected before it is safe to

work on machinery or touch motor terminals and control equipment parts.

Cooling Requirements for VFDs

Air-cooled VFDs: all air-cooled have self-contained cooling systems and require no field

work.

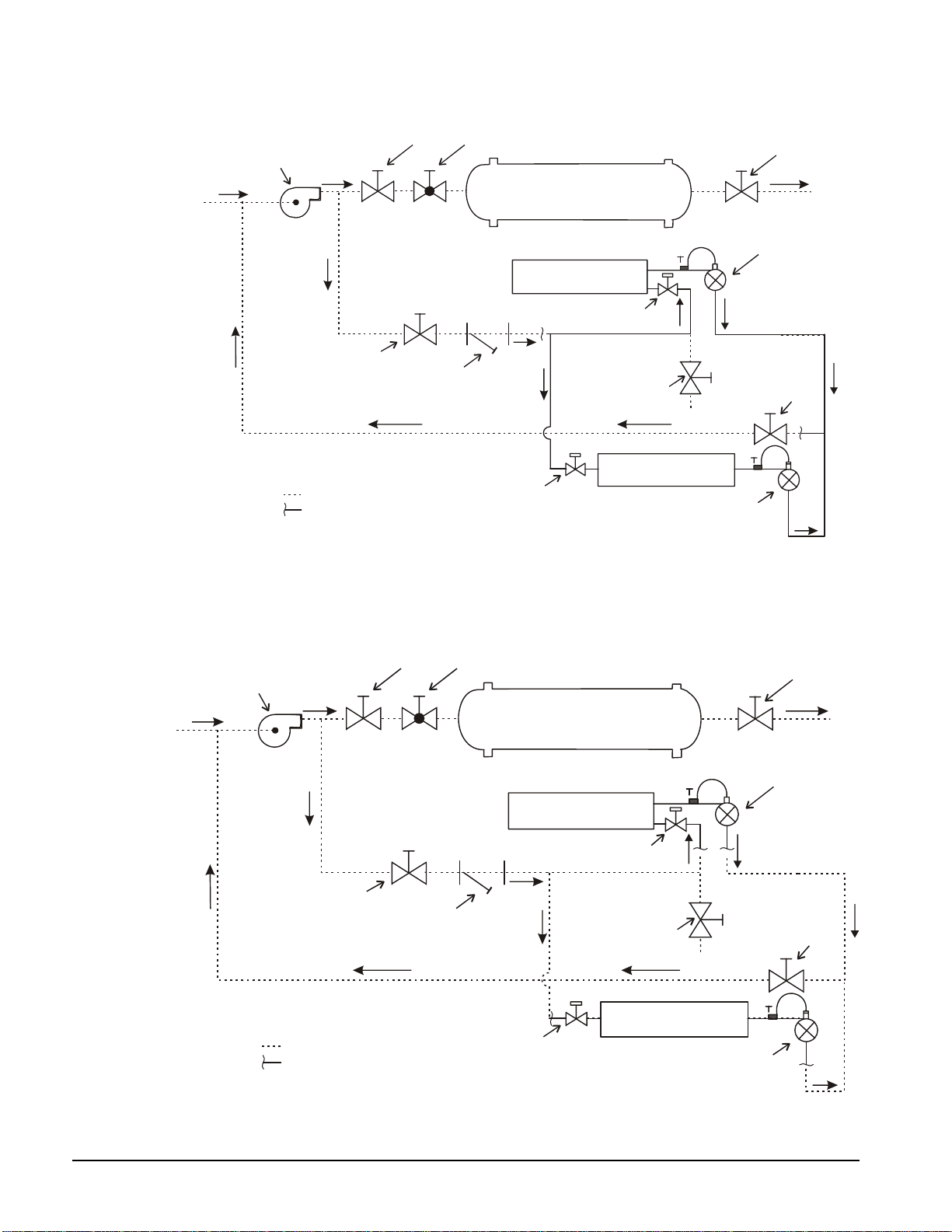

Water-cooleed, factory-mounted VFDs: VFD cooling water piping is factory-connected

to the chiller’s oil cooling system. See Figure 3. Cooling water piping is to the normal

chiller oil-cooling system connections.

Freestanding VFDs: VFD cooling water piping must be field connected on freestanding

units. See Figure 4. Cooling water is connected directly to models 047LA through 072LW.

Models 090LW and 120LW, and all LF 2.0 units, are always freestanding and have a

separate cooling module that must be field piped to the cooling water supply and also

interconnected to the VFD. See page 15 for detailed installation instructions.

IOMM VFD-2 13

Page 14

Figure 3, VFD 047 through 072, Cooling Water Piping for Factory-M ount ed VFD

*

CHILLED

WATER

PUMP

STOP

VALVE

*

STOP

VALVE

Field Supplied Piping Components

*

Field Piping

Connection Point

*

BALANCING

VALV E

*

STRAINER

MAX. 40 MESH

CHILLER

VFD HEAT

EXCHANGER

SOLENOID

VALV E

(Factory Mounted)

SOLENOID

VALV E

(Factory Mounted)

*

DRAIN VALVE

OR PLUG

COMPRESSOR

OIL COOLER CIRCUIT

WATER

REGULATING

VALV E

(Factory Mounted)

*

STOP

VALVE

WATER

REGULATING

VALV E

(Factory Mounted)

*

STOP

VALV E

Figure 4, VFD 047 – 120 and all LF 2.0, Cooling Water Piping f or Free- Standing VFD

*

CHILLED

WATER

PUMP

STOP

VALV E

*

STOP

VALVE

Field Supplied Piping Components

*

Field Piping

Connection Point

*

BALANCING

VALV E

*

STRAINER

MAX. 40 MESH

CHILLER

COMPRESSOR

OIL COOLER CIRCUIT

SOLENOID

VALV E

(Factory Mounted)

SOLENOID

VALV E

(Factory Mounted)

*

DRAIN VALVE

OR PLUG

VFD HEAT

EXCHANGER

WATER

REGULATING

VALV E

(Factory Mounted)

*

STOP

VALV E

WATER

REGULATING

VALV E

(Factory Mounted)

*

STOP

VALVE

14 IOMM VFD-2

Page 15

NOTE: In some cases, the “VFD HEAT EXCHANGER” may be a separate-mounted cooling module that is, in turn, connected

to the VFD.

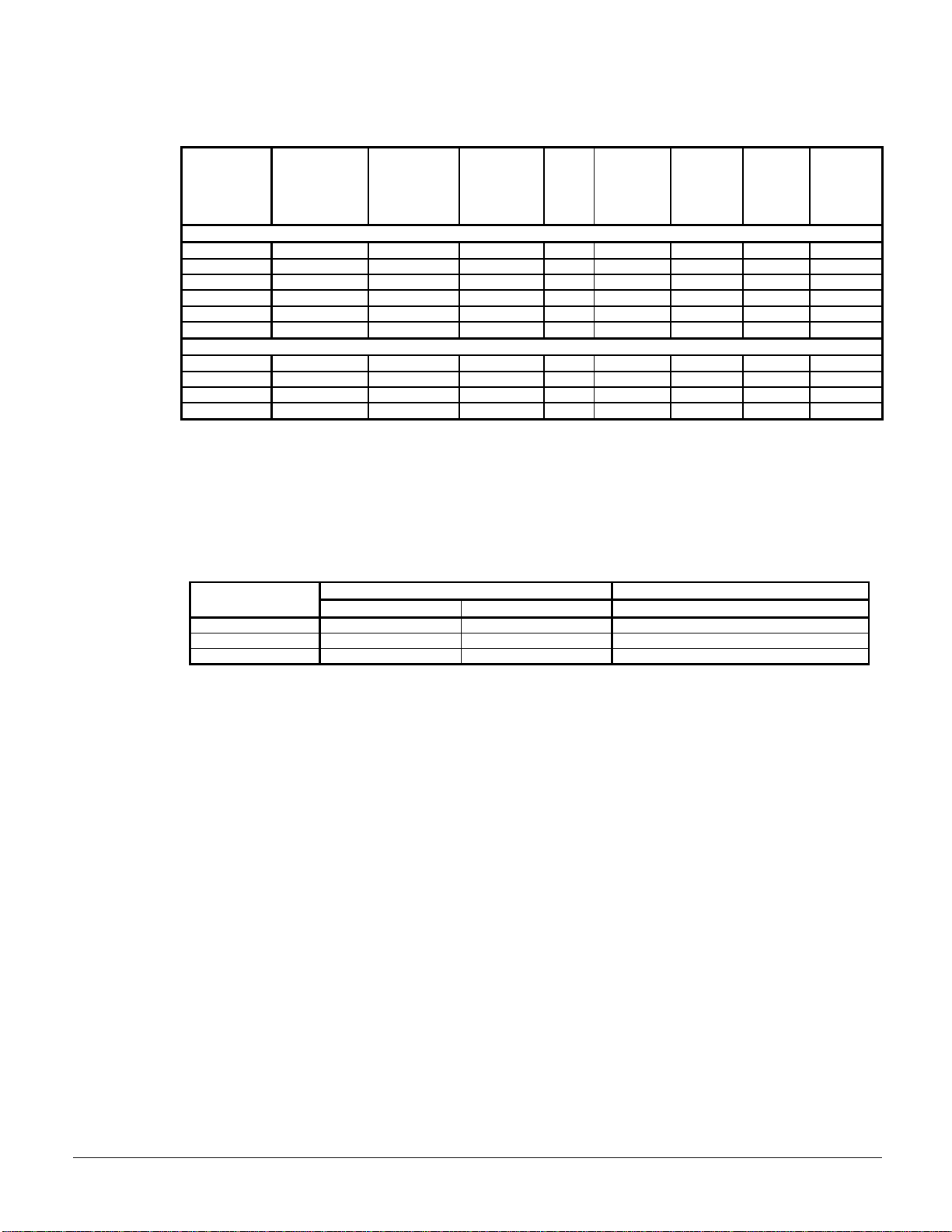

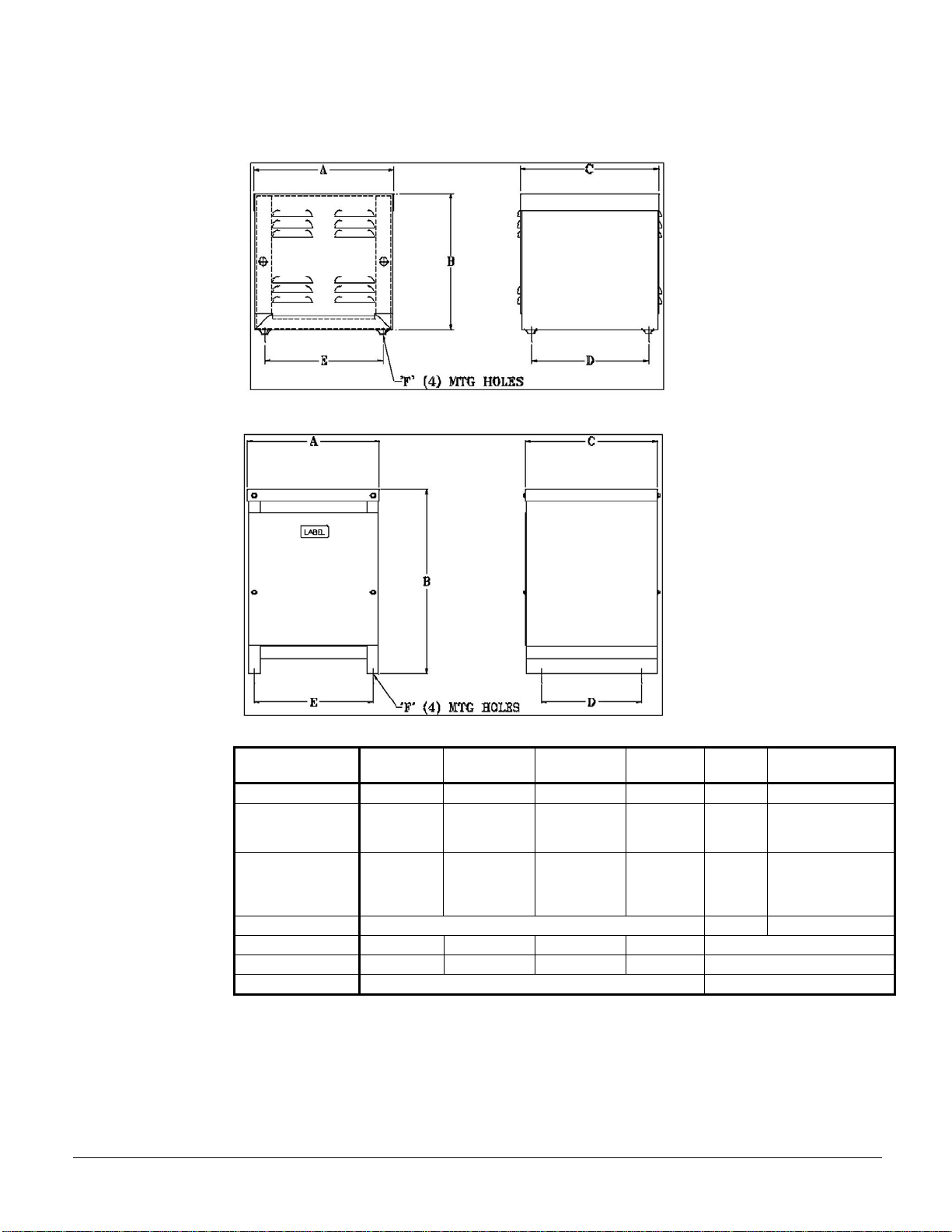

Table 4, Cooling Requirements

Combined

McQuay

Drive Model

Number

VFD 009-028 N/A N/A Air N.A. 104 40 NA N/A

VFD 047 1.0 7/8 in. Water (1) 2.0 90 40 10 (2) 300

VFD 060 1.0 7/8 in. Water (1) 2.0 90 40 30 (2) 300

VFD 072 1.0 7/8 in. Water (1) 2.5 90 40 30 (2) 300

VFD 090 1 1/4 1.0 in. Water (1) (3) 7.0 90 40 30 (2) 300

VFD 120 1 1/4 1.0 in. Water (1) (3) 7.0 90 40 30 (2) 300

VF 2037 N/A 3/4 NPT Water (1) (3) 7.0 90 40 N.A. 180

VF 2055 N/A 3/4 NPT Water (1) (3) 7.0 90 40 N.A. 180

VF 2080 N/A 3/4 NPT Water (1) (3) 15.0 90 40 N.A. 180

VF 2110 N/A 3/4 NPT Water (1) (3) 15.0 90 40 N.A. 180

Notes:

1. Cooling water must be from the closed, chilled water circuit with corrosion inhibitors for steel and copper, and must be

piped across the chilled water pump.

2. The pressure drop is given for the maximum coolant temperature (maximum flow). The water-regulating valve will

reduce the flow when the coolant temperature is below the maximum in the table. The pressure drop includes the drop

across the solenoid valve, heat exchanger and water regulating valve.

3. Models VFD 090and 120 and all LF 2.0 models have a separate self-contained cooling loop with a recirculating water

pump and heat exchanger, but have the same cooling source water piping as all water-cooled VFDs.

Comp. Oil and

VFD Cooling

Copper Tube

Size

VFD Cooling

Only, Copper

Tube Size

Type K or L

Coolant

Method

Air-Cooled/LF

LF 2.0

Flow

(gpm)

Max.

Entering

Coolant

Temp. (° F)

Min.

Entering

Coolant

Temp(° F)

Pressure

Drop

(feet)

Max.

Pressure

(Water

Side) psi

Table 5, Chiller Cooling Water Connection Sizes

Chiller Unit

WDC/WCC 100/126 1 1/2 in. FPT ¾ in. MPT 1 1/2 in. FPT

WSC/WDC 050 Not Required Air-Cooled Not Required

All Others 1 in. FPT 3/4 in MPT 1 in. FPT

Free-Standing VFD, LF and LF 2.0 Factory-Mounted VFD, LF Only

To Oil Cooler To VFD Combined

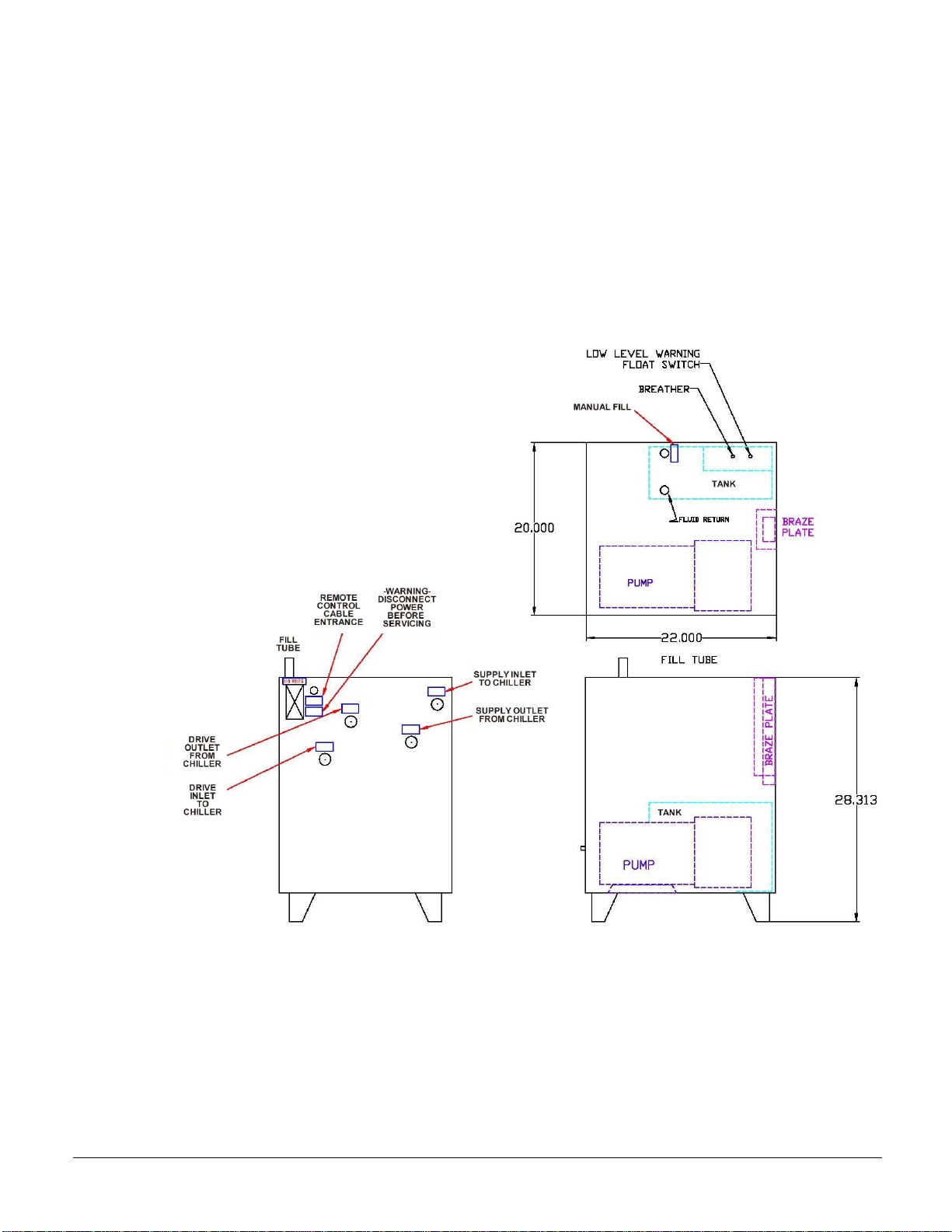

Separate Cooling Module (LF VFD 090, 120 and all LF 2.0)

The cooling module for the LF models VDF 090 and 120 has a self-contained coolant

temperature control system and no associated programming of the VDF is required. All cooling

modules used with LF 2.0 VFD models are controlled by the VFD and require VFD programming

as shown on page 19. This is done by McQuay at startup.

Closed loop cooling system operation

• A pump circulates a glycol/ water mixture (coolant) through the VFD heat sink, a coolant

reservoir and a small plate heat exchanger. Heat is removed from the VFD heat sink and

rejected to the plate heat exchanger.

• The pump and control valve are controlled by the VFD control system on LF 2.0 VFD models

and self-contained on LF models.

• The plate heat exchanger is cooled by water from the chilled water system

Installation steps:

• Place cooling loop module in desired location.

• Attach coolant and chilled water piping. Seven to nine gpm of coolant will be circulated. A

40 mesh strainer is required at the drive inlet. Include service isolation valves in the coolant

and chilled water inlet and outlet piping.

IOMM VFD-2 15

Page 16

• Wire according to the supplied wiring diagrams.

16 IOMM VFD-2

Page 17

The following is required from the customer's chilled water supply for the McQuay VFD cooling

loop to perform properly.

Water Quality:

Water must be compatible with components supplied in the cooling loop; brass, copper, stainless

steel and neoprene rubber seals. Supply water circulates through a copper brazed stainless steel,

plate type heat exchanger by way of a stainless steel and brass ball valve and associated stainless

steel, brass and copper piping.

Water Source:

Clean and non-corrosive chilled water must be used as the coolant.

Figure 5, Cooling Module Dimensions

Weights

Shipping weight: 300 lbs (136 kg)

Dry weight: 250 lbs (114 kg)

Operating weight: 270 lbs. (123 kg)

IOMM VFD-2 17

Page 18

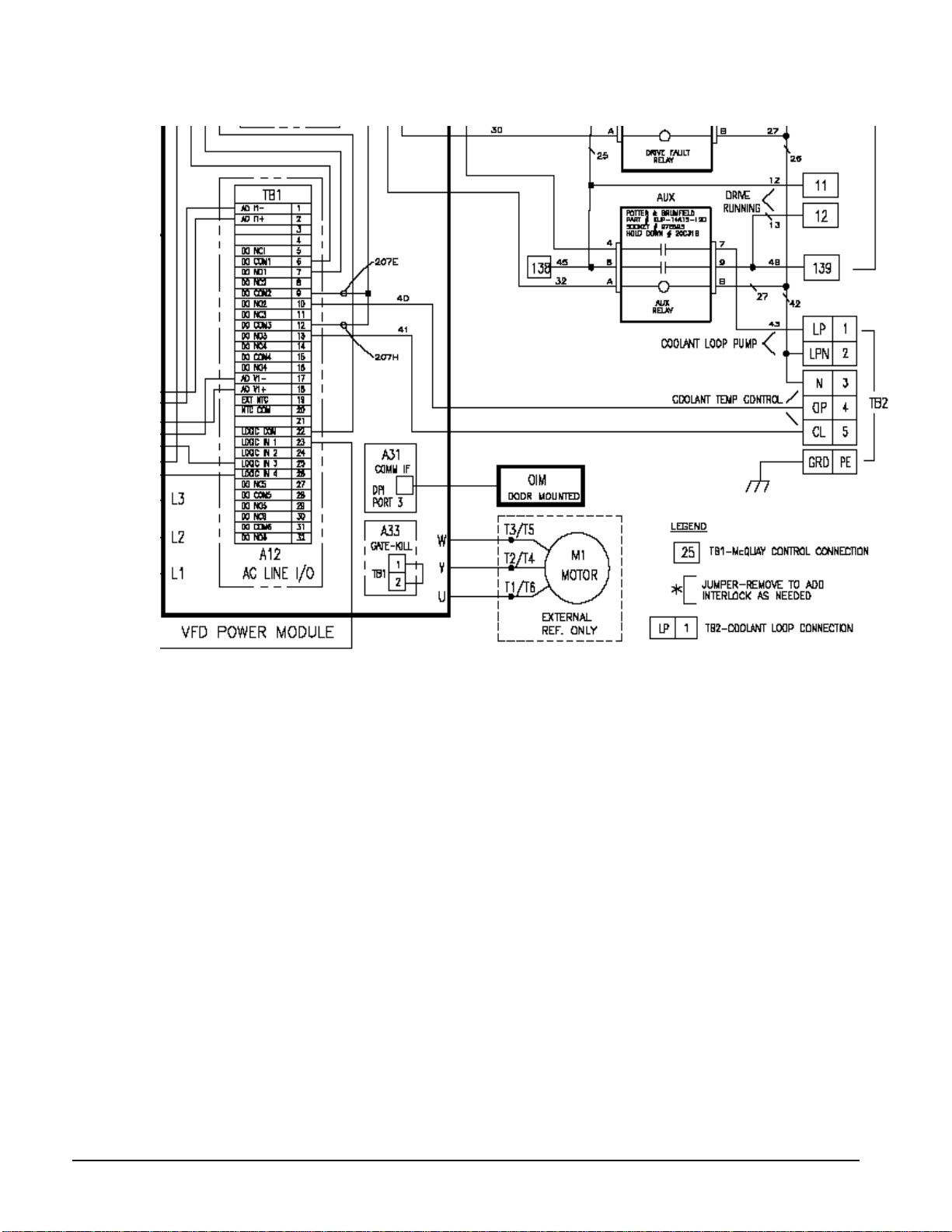

Figure 6, LF 2.0 Remote Cooling Module Int erconnect i ng Wiring

TB2 is the terminal board located in the remote module.

TB1 is a terminal board located in the VFD.

Field Wiring:

• TB1-10 (DO NO2) to TB2-4 (OP, Open)

• TB1-13 (DO NO3) to TB2-5 (CL, Close)

• Wire 42 (Aux Relay) to TB2-3 (Neutral)

• Wire 42 (Aux Relay) to TB2-2 (LPN, Loop Pump Neutral)

• Aux Relay Terminal 7 to TB2-1 (LP, Loop Pump)

• GRD (PE) to Ground

18 IOMM VFD-2

Page 19

Maximum Static Pressure:

300 psi nominal limited by ball valve and piping pressure ratings.

Requirements for proper operation of the drive/ cooling module

cooling loop.

Cooling Loop Liquid:

25% inhibited (corrosion protected) propylene glycol (DOWFROST or equivalent)

concentration by volume with distilled water. Non-inhibited or silicate containing glycols

may cause equipment damage.

Coolant Volume:

Approx. 1 gallon is required with side-by-side connection of cooling module to the drive

cabinet. More coolant volume will be required if coolant loop is located up to 20 feet away

from drive.

Coolant Maintenance:

The coolant liquid should be checked and refreshed as needed on a yearly basis. The pH

should be maintained between 8.0 and 10.0. A 50% solution of sodium hydroxide or

potassium hydroxide can be used to raise pH if falls below 8.0. Any time the coolant falls

below a pH of 7.0 the loop should be flushed and coolant replaced. Any time the coolant

appears other than water white it should be replaced.

Remote Mounted Cooling Loop:

The maximum distance the cooling loop can be installed away from the drive cabinet

connections is 20 feet. Careful planning of remote mounting is required to minimize

coolant flow restrictions introduced by piping connections.

Cooling Module Parameters Set in LF 2.0 VFD models

LF 2.0 drives control the operation of the cooling module. The parameters are set by

McQuay at chiller commissioning.

How to Monitor Cooling Loop Operation

FX-05 Screen Navigation (see Figure 7)

After power-up the process temperature will be displayed.

Alarms

When an alarm is present the alarm LED will blink fast and the error code will flash. The

following is a list of the error code.

• E0: OK

• E1: Low Level Fault

• E2: Fluid Over-Temperature Fault

• E3: Fluid Under-Temperature Fault

• E4: Fluid Low Flow Fault

To acknowledge the alarms hold the φ key for 3 seconds. The alarm error code will be

displayed and the reset led will light while the button is depressed. After the φ key is

released the process temperature will be displayed.

To view the alarm summary hold both the ↵ ↓ keys for 3 seconds. To exit the alarm

summary screen press the φ key or the screen will automatically time out after 10 seconds.

IOMM VFD-2 19

Page 20

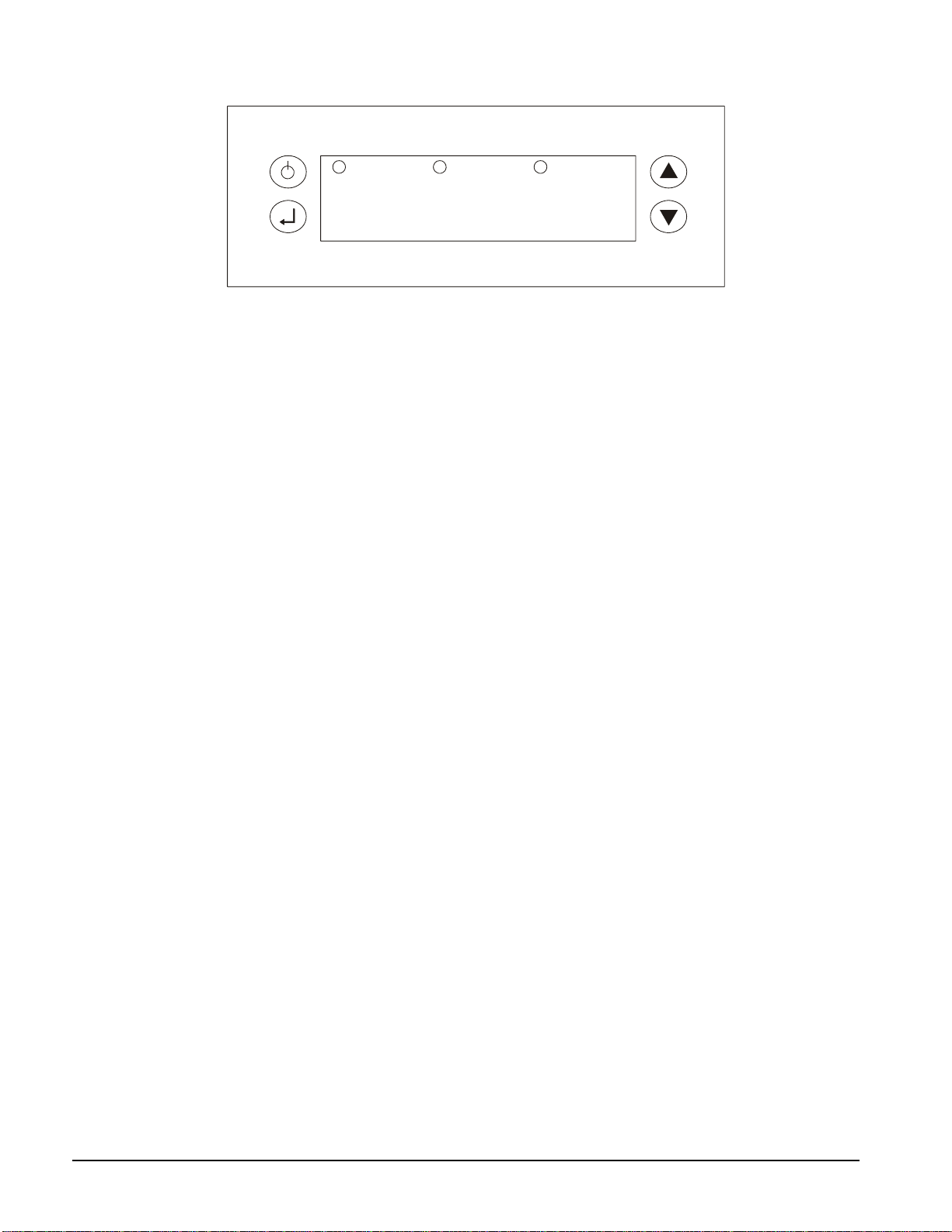

Figure 7, FX05 Display Panel

ALARM RESET PUMP ON

Fx05

Operation

The FX controller controls to a fixed loop water setpoint.

20 IOMM VFD-2

Page 21

Wiring, General

Unit-Mounted: Unit mounted VFDs have factory-wired control wiring plus power wiring

from the VFD to the compressor motor terminals. The VFDs only require a power supply.

Cable entrance is shown on the dimension drawings beginning on page 32 for LF and page

Error! Bookmark not defined. for LF 2.0 models. An exception is on models LF models

090 and 120 and all LF 2.0 models that require some interconnection control wiring from

the VFD to the remote cooling module as described in the section beginning on page 15.

Freestanding: Freestanding units require both field control and power wiring from the

VFD to the chiller and. some interconnection control wiring on models 090 and 120.

Wiring Diagram: The control and power wiring diagram is located on page 25.

Power Wiring

Wiring, fuse and wire size must be in accordance with local codes and the National Electric

Code (NEC).

CAUTION

Voltage unbalance not to exceed 2% with a resultant current unbalance of 6 to

10 times the voltage unbalance per NEMA MG-1, 1998 Standard. This is an

important requirement to avoid excessive motor or drive heating.

WARNING

Qualified and licensed electricians must perform wiring. Shock hazard exists.

Power wiring to compressors must be in proper phase sequence. Motor rotation is set up

for clockwise rotation facing the lead end with phase sequence of 1-2-3. Care must be

taken that the proper phase sequence is carried through the VFD to the compressor. With

the phase sequence of 1-2-3 and L1 connected to T1 and T6, L2 connected to T2 and T4,

and L3 connected to T3 and T5, rotation is proper. See diagram in terminal box cover.

The McQuay start-up technician will check the phase sequence.

CAUTION

Connections to terminals must be made with copper lugs and copper wire.

Care must be taken when attaching leads to compressor terminals.

Note: Do not make final connections to motor terminals until wiring has been

checked and approved by a McQuay technician.

Under no circumstances should a compressor be brought up to speed unless proper

sequence and rotation have been established. Serious damage can result if the compressor

starts in the wrong direction. Such damage is not covered by product warranty.

Compressor Motor Terminal Insulation

It is the installing contractor's responsibility to insulate the compressor motor terminals (as

described below) when the unit is installed in a high humidity location that could cause

condensate to form on the motor terminals. The terminals are cooled to 45°F to 50°F as a

result of the motor cooling. The required material can be ordered and shipped in as a kit

(775123601).

IOMM VFD-2 21

Page 22

This is to be done after the McQuay start-up technician has checked for proper phase

sequence and motor rotation.

Following this verification by the McQuay technician, the contractor should apply the

following items.

Materials required:

1. Loctite® brand safety solvent (12 oz. package available as McQuay part number

350A263H72)

2. 3M™ Co. Scotchfil brand electrical insulation putty (available in a 60-inch roll as

McQuay part number 350A263H81)

3. 3M Co. Scotchkote™ brand electrical coating (available in a 15 oz. can with brush as

McQuay Part Number 350A263H16)

4. Vinyl plastic electrical tape

The above items are available at most electrical supply outlets.

Application procedure:

1. Disconnect and lock out the power source to the compressor motor.

2. Using the safety solvent, clean the motor terminals, motor barrel adjacent to the

terminals, lead lugs, and electrical cables within the terminal 4OX to remove all dirt,

grime, moisture and oil.

3. Wrap the terminal with Scotchfil putty, filling in all irregularities. The final result

should be smooth and cylindrical.

4. Doing one terminal at a time, brush the Scotchkote coating on the motor barrel to a

distance of up to '/2" around the terminal and on the wrapped terminal, the rubber

insulation next to the terminal, and the lug and cable for approximately 10". Wrap

additional Scotchfil insulation over the Scotchkote coating.

5. Tape the entire wrapped length with electrical tape to form a protective jacket.

6. Finally, brush on one more coat of Scotchkote coating to provide an extra moisture

barrier.

22 IOMM VFD-2

Page 23

General Wiring Practice

1. Never connect input AC power to the motor output terminals T1/U, T2/V or

T3/W.

2. Power wiring to the motor must have the maximum possible separation from all

other wiring. Do not run control wiring in the same conduit; this separation

reduces the possibility of coupling electrical noise between circuits. Minimum

spacing between metallic conduits containing different wiring groups should be

three inches (76 mm).

3. Minimum spacing between different wiring groups should be six inches (152

mm).

4. Wire runs outside of an enclosure should be run in metallic conduit or have

shielding/armor with equivalent attenuation.

5. Different wire groups should cross at 90 degrees whenever power and control

wiring cross.

6. Different wire groups should be run in separate conduits.

7. Adhere to local electrical codes.

8. The National Electrical Code and Canadian Electrical Code requires that an

approved circuit disconnecting device be installed in series with the incoming

AC supply in a location readily accessible to personnel installing or servicing

this equipment. If a disconnect switch is not supplied with the starter, one must

be installed.

9. Supply lines and motor lines may enter the enclosure from the top, bottom or

sides. Wire connections can be determined to best suit specific installations.

Wire runs should be properly braced to handle both starting and fault currents.

Size power cable per local electrical codes. Long lengths of cable to the motor

of over 150 feet must be de-rated.

Terminal Sizes

Compressor Motor Terminals

Power wiring connections at the motor are “spark plug” type terminals with threaded

copper bar, sized per the following table.

Table 6, Chiller Compressor Motor Terminal Sizes

Type/Size Comp. Size Terminal Size

Low Voltage to 275 A, to 575 V CE 050 0.375-16 UNC2A, 0.94 in. long

Low Voltage to 750 A, to 575V CE 063-126 0.635-11 UNC-2A, 1.88 in. long

VFD Terminals

For field wiring freestanding VFDs, the outgoing terminals and incoming power

block terminals are determined by the VFD size listed in Table 8. For factorymounted VFDs, the outgoing terminals are factory-connected to the compressor

motor.

When wiring to a VFD with a disconnect switch or circuit breaker, the incoming lug

size is determined by the device size as shown in Table 9.

IOMM VFD-2 23

Page 24

Table 7, LiquiFlo 2.0, Terminal Size Range

VFD Size

VF2037

VF2055

VF2080

VF2110

Incoming Terminals Outgoing

Terminals

Incoming connecti on is

to the standard circuit

breaker. See

Table 9.

(3) 1.5 inch wide tab

w/ 0.472 inch hole

(3) 2.25 inch wide tab

w/ 0.56 inch hole

Table 8, Air-Cooled/LiquiFlo, Outgoing, Incoming Power Block,

Terminal Size Range

Incoming

VFD Size

Power Block

Terminals

VFD 009 SP600 #14 – 1/00 #14 – 1/00

VFD 012 SP600 #4 – 3/0 #4 – 3/0

VFD 015 SP600 #14 - 250 #14 - 250

VFD 017 SP600 #14 - 250 #14 - 250

VFD 023 SP600 #14 - 250 #14 - 250

VFD 024 PF700H 4/0 - 350 4/0 - 350

VFD 028 PF700H 4/0 - 350 4/0 - 350

VFD 047 LF (2) #4 - 500 (2) #6 - 300

VFD 060 LF (2) #4 - 500 (2) #4 - 350

VFD 072 LF (2) #4 - 500 (2) #4 - 350

VFD 090 LF (2) #4 - 500

VFD 120 LF (2) #4 - 500

Outgoing

Terminals

2 in. x 1/4 in. bus

(1) 9/16 in. hole

2 in. x 1/4 in. bus

(1) 9/16 in. hole

Table 9, Incoming Terminal Size Range, Disconnects & Circuit Breakers

Max

RLA

Size

74 100 (1) #6- 300

93 125 (1) #6- 300

148 200 (1) #6- 300

163 220 (1) 4/0 - 500

185 250 (2) 3/0 - 500

296 400 (2) 3/0 - 500

444 600 (3) 1/0 - 500

593 800 (4) 250 – 500

889 1200 (5) 300 – 600

1185 1600 (5) 300 - 600

NOTE: (X) is the number of terminals per phase.

Incoming Terminal, Disconnect

Switch or Circuit Breaker

24 IOMM VFD-2

Page 25

Optional Line Reactor Installation, Air-Cooled/LF Only

Mounting Options

Optional line reactors can be mounted in the VFD enclosure on free-standing units and must

be field-mounted and wired when the VFD is factory-mounted. When the reactor is installed

in the VFD enclosure, a much larger enclosure is required and it is too large to mount on the

chiller.

VFD Line Harmonics

VFDs have many benefits, but care must be taken when applying VFDs due to the effect of

line harmonics on the building electric system. VFDs cause distortion of the AC line because

they are nonlinear loads, that is, they don't draw sinusoidal current from the line. They draw

their current from only the peaks of the AC line, thereby flattening the top of the voltage

waveform. Some other nonlinear loads are electronic ballasts and uninterruptible power

supplies.

Reflected harmonic levels are dependent on the source impedance and the KVA of the of the

power system to which the drive is connected. Generally, if the connected power source has

a capacity greater than twice the drive’s rated amps (see Table 1 or Table 2 for rated amps),

the installation will conform to IEEE Standard 519 with no additional attenuation.

Presumably, the application on which this drive is applied has been checked for harmonic

levels. If not, contact the local McQuay office.

The IEEE 519-1991 Standard

The Institute of Electrical and Electronics Engineers (IEEE) has developed a standard that

defines acceptable limits of system current and voltage distortion. A simple form is available

from McQuay that allows McQuay to determine compliance with IEEE 519-1991. Line

harmonics and their associated distortion may be critical to AC drive users for three reasons:

1. Current harmonics can cause additional heating to transformers, conductors, and

switchgear.

2. Voltage harmonics upset the smooth voltage sinusoidal waveform.

3. High-frequency components of voltage distortion can interfere with signals transmitted

on the AC line for some control systems.

The harmonics of concern are the 5

by three, and high magnitude harmonics are usually not a problem.

Current Harmonics

An increase in reactive impedance in front of the VFD helps reduce the harmonic currents.

Reactive impedance can be added in the following ways:

1. Mounting the drive far from the source transformer.

2. Adding line reactors.

3. Using an isolation transformer.

Voltage Harmonics

Voltage distortion is caused by the flow of harmonic currents through a source impedance. A

reduction in source impedance to the point of common coupling (PCC) will result in a

reduction in voltage harmonics. This may be done in the following ways:

1. Keep the point of common coupling (PCC) as far from the drives (close to the power

source) as possible.

2. Increase the size (decrease the impedance) of the source transformer.

th

, 7th, 11th, and 13th. Even harmonics, harmonics divisible

IOMM VFD-2 25

Page 26

3. Increase the capacity of the busway or cables from the source to the PCC.

4. Make sure that added reactance is "downstream" (closer to the VFD than the source) from

the PCC.

DANGER

High voltage is used in the operation of line/load reactors. Use Extreme caution to

avoid contact with high voltage when operating, installing or repairing equipment

containing line/load reactors.

INJURY OR DEATH MAY RESULT IF SAFETY PRECAUTIONS ARE NOT

OBSERVED

DANGER

Even if the upstream disconnect/protection device is open, a drive or inverter

down stream of the line/load reactor may feed back high voltage to the reactor.

The inverter or drive safety instructions must be followed.

INJURY OR DEATH MAY RESULT IF THE SAFETY PRECAUTIONS ARE NOT

OBSERVED

CAUTION

An upstream disconnect/protection device must be used as required by the

National Electrical Code

CAUTION

The frame of line/load reactors must be grounded at least at one of the reactor’s

mounting holes.

This section is intended for use by personnel experienced in the operation and maintenance

of electronic drives, inverters and similar types of power electronic equipment. Because of

the high voltages required by the equipment connected to line reactors and the potential

dangers presented by rotating machinery, it is essential that all personnel involved in the

operation and maintenance of line/load reactors know and practice the necessary safety

precautions for this type of equipment. Personnel should read and understand the

instructions contained in this section before installing, operating or servicing line/load

reactors and the drive to which the reactor is connected

AGENCY A PPROVALS:

UL-508, File E180243 Component Recognized (1 amp – 2400 amps)

UL-508, File E180243 UL Listed Nema 1 units (1 amp – 2400 amps)

CSA C22.2, File LR29753-13 CSA Certified (1 amp – 1200 amps)

Class H, 200 C, File E66214, Type 180-36, UL Recognized Insulation System

CE

26 IOMM VFD-2

Page 27

Ambient Temperature

Maximum ambient temperature is 45°C (113°F).

Figure 8, Line Reactor Dimensions, Models VFD 009 - 017

Figure 9, Line Reactor Dimensions, Models VFD 047 - 072

Table 10, Line Reactor Data

VFD Model

009MA 13.2 (335) 13.2 (335) 13.2 (335) 86 (39) 6-0 6-4=45, 2-0=500

012MA–017MA 13.2 (335) 13.2 (335) 13.2 (335) 98 (44) 2-0000

023MA 17.0 (432) 17.0 (432) 24.0 (610) 151 (69) 00-500

024-028 See Note 3

047MW-060MW 17.0 (432) 17.0 (432) 24.0 (610) 225 (102) See Note 2

072MW 24 (610) 24 (610) 30 (762) 393 (178) See Note 2

090LW-120LW See Note 3 See Note 4

Width “A”

in. (mm)

NOTES:

1. Models 012MA through 023MA have box lugs, one wire per lug.

2. Models 047MW through 072MW have copper tabs with (1) 0.656 hole.

3. Models 024LA/MA through 028LA/MA have reactor as standard and it is mounted in VFD.

Wiring required to incoming reactor terminals.

4. Models 090LW through 120LW have (2) 0.656 holes, and are always shipped loose with reactors

factory-mounted in VFD. Wiring required to incoming terminals.

Depth “C”

in. (mm)

Height “B”

in. (mm)

Weight

lbs (kg)

Wire

Range

Torque

In. lb.

2-1=150, 1/0-

2/0=180, 3/0-

4/0=250

00=180, 000-

0000=250

250-350=325,

500=375

IOMM VFD-2 27

Page 28

Mounting

NEMA 1 enclosures designed for floor mounting must be mounted with the enclosure base

horizontal for proper ventilation. Wall mounting a floor mounted enclosure with the base

against the wall will cause the reactor to over heat resulting in equipment damage.

Allow a minimum side, front, and back clearances of 12 inches (305 mm) and vertical

clearances of 18 inches (457 mm) for proper heat dissipation and access. Do not locate the

enclosure next to resistors or any other component with operating surface temperatures above

260°F (125°C).

Allow a minimum side, front, and back clearances of 12 inches (305 mm) and vertical

clearances of 18 inches (457 mm) for proper heat dissipation and access. Do not locate the

enclosure next to resistors or any other component with operating surface temperatures above

260°F (125°C).

Select a well ventilated, dust-free area away from direct sunlight, rain or moisture, where the

ambient temperature does not exceed 45°C (113°F).

Do not install in or near a corrosive environment.

Avoid locations where the reactor will be subjected to excessive vibrations.

Where desirable, enclosures may be mounted on vibration isolating pads to reduce audible

noise. Standard vibration control pads made from neoprene or natural rubber and selected for

the weight of the enclosed reactor are effective.

Reactor Power Wiring

WARNING

Input and output power wiring to the reactor must be performed

by authorized personnel in accordance with the NEC

and all local electrical codes and regulations.

Verify that the power source to which the reactor is to be connected is in agreement with the

nameplate data on the reactor. A fused disconnect switch or circuit breaker should be

installed between the reactor and its source of power in accordance with the requirements of

the NEC and all local electrical codes and regulations. Refer to the drive, inverter, or other

electrical equipment user manual for selection of the correct fuse rating and class.

The reactor is suitable for use on a circuit capable of delivering not more than 65,000 rms

symmetrical amperes at 480 volts when protected by Bussman type JJS, KTK, KTK-R, PP or

T class fuses.

Reactors are designed for use with copper conductors with a minimum temperature rating of

75°C. Table 10 lists the wire range for the power input and output connections by VFD

model.

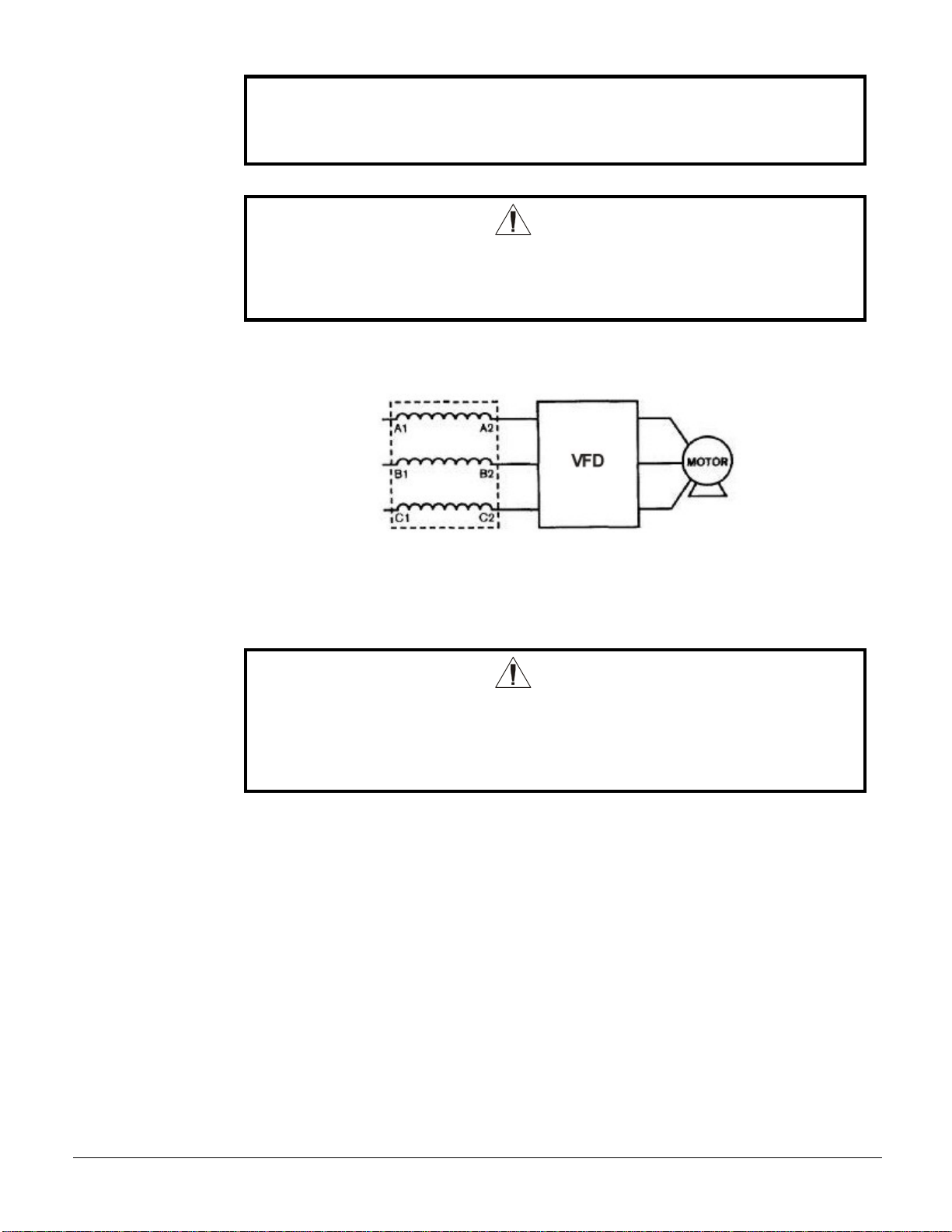

Refer to

Figure 10 for a typical electrical diagram of a reactor in its proper location, upstream of a

VFD.

Where desirable, a flexible conduit connection to the reactor enclosure should be made to

reduce audible noise.

28 IOMM VFD-2

Page 29

Failure to connect reactors supplied as a component part of a drive system or

other power electronic system according to the system interconnection diagram

supplied by the System Engineer will result in equipment damage, injury, or

death.

WARNING

If a line reactor or a line reactor and a load reactor are used with a drive equipped

with a bypass circuit, the reactors must be removed from the motor circuit in the

bypass mode. Damage to the motor and other equipment will result if this

warning is not observed.

Figure 10, Line Reactor Wiring

Grounding

A stud is provided in the reactor enclosure for grounding the enclosure. The enclosure must

be grounded.

WARNING

The frame of line/load reactors must be grounded at the designated grounding

terminal or one of the reactor mounting holes if no designated grounding terminal

is provided. The enclosure of reactors supplied in enclosures must be grounded.

INJURY OR DEATH MAY RESULT IF SAFETY PRECAUTIONS ARE NOT

OBSERVED.

IOMM VFD-2 29

Page 30

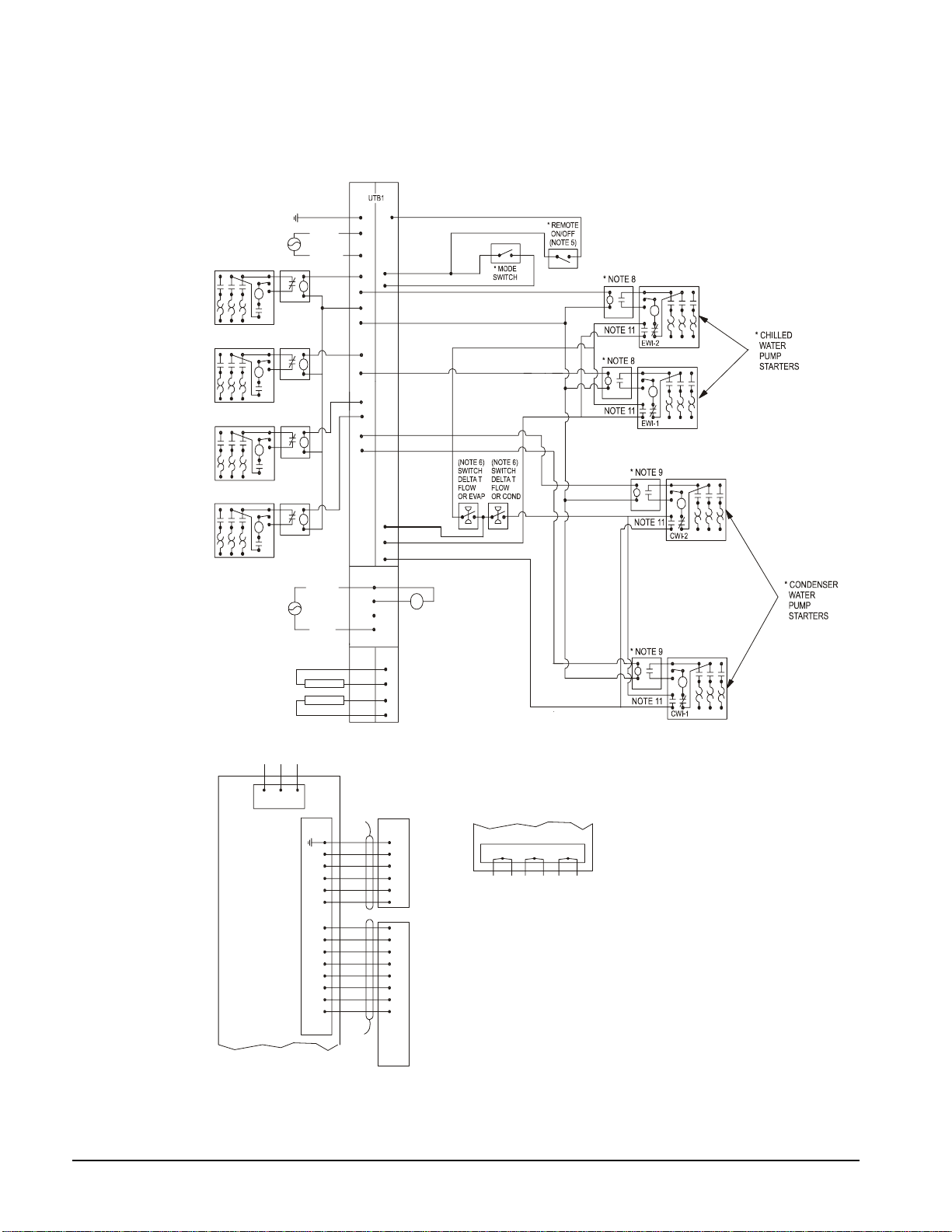

VFD/Chiller Interconnection Wiring Diagram

A

A

A

A

Figure 11, Control and Power Wiring Diagram

MICROTECH CONTROL

BOX TERMINALS

(115V) (24V)

PE

54

85

86

70

80

55

74

86

86

EP2

H

O

C

* COOLING

TOWER

FOURTH

STAGE

STARTER

* NOTE 10

H

O

A

GND

POWER

* NOTE 7

NEUTRAL

C4

* COOLING

TOWER

THIRD

STAGE

STARTER

* COOLING

TOWER

SECONDH

STAGE

STARTER

* COOLING

TOWER

FIRST

STAGE

STARTER

* NOTE 10

H

O

A

* NOTE 10

H

O

A

* NOTE 10

H

O

A

COOLING TOWER

BYPASS VALVE

COOLING TOWER VFD

L1 L2 L3

COMPRESSOR

MOTOR

STARTER

(NOTE 1)

-LOAD-

C3

C2

C1

COMMON

23(5A)

24(5)

11(6 )

1-10 VDC

1-10 VDC

CP1

CP2

79

73

78

77

76

75

POWER

COMPRESSOR CONTROL

NOTE 2

GND

25

1

2

3

4

11

12

22

NOTE 2

81

82(NO)

83(NC)

84

MICROTECH

BOX TERMINALS

115 VAC

See notes on following page.

T3-S

EF

CF

52

71

71

53

CTB1

LESS

THAN

30V

OR

24VAC

H

O

C

EP1

H

O

C

CP2

ALARM RELAY

A

(NOTE 4)

H

O

C

CP1

STARTER LOAD SIDE TERMINBALS

PE

L1

L2

23

24

25

1

2

3

4

11

11

12

22

VFD

UV W

T4 T3 T5T1 T6 T2

COMPRESSOR TERMINALS

- COMPRESSOR CONTROL

SCHEMATIC 330342201

- LEGEND: 330343001

* FIELD SUPPLIED ITEM

330387901-0A

30 IOMM VFD-2

Page 31

NOTES for Wiring Diagram

1. Compressor motor VFDs are either factory-mounted and wired, or shipped separate for

field-mounting and wiring. VFDs must be provided by McQuay. All line and load side power

conductors must be copper.

2. If VFDs are freestanding, then field control wiring between the starter and the control panel

is required. Minimum wire size for 115 Vac is 12 GA for a maximum length of 50 feet. If

greater than 50 feet, refer to McQuay for recommended wire size minimum. Wire size for

24 Vac is 18 GA. All wiring to be installed as NEC Class 1 wiring system and must be made

with copper wire and copper lugs only. All 24 Vac wiring must be run in separate conduit

from 115 Vac wiring.

3. Main power wiring between VFD and motor terminals is factory-installed when chillers are

supplied with unit-mounted VFDs.

4. Six conductors are used between the VFD and the motor as shown in the wiring diagram.

Wiring of free-standing VFDs must be in accordance with the NEC and connection to the

compressor motor terminals must be made with copper wire and copper lugs only.

5. LF models VFD 090 and 120 and all LF 2.0 models require field wiring between the VFD

and the field mounted cooling module per instruction beginning on page 15.

IOMM VFD-2 31

Page 32

VFD Dimensions

6.0

8.0

m

Air-Cooled

Figure 12, VFD 009LA/023LA, Air-Cooled, Free-Standing

(203.2)

Power Wiring

(152.4)

Entry Panel

2.0

(50.8)

14.0

(355.6)

Removable

Lifting Eyes

Note: Remove before drilling

to prevent metal particles fro

falling into drive components.

VM

AM

72.0

(1828.8)

36.0 (914.4)

19.1 (485.1)

Unit Weights

Model VFD 009 VFD 012 VFD 015 VFD 017 VFD 023

Operating Weight, lb (kg) 725 (329) 725 (329) 796 (361) 796 (361) 796 (361)

Shipping Weight, lb. (kg) 795 (361) 795 (361) 866 (393) 866 (393) 866 (393)

32 IOMM VFD-2

Page 33

Figure 13, VFD 024LA/028LA, Air-Cooled, Free-Standing

Unit Weights

Model VFD 024LA VFD 028LA

Operating Weight, lb. (kg) 1206 (548) 1206 (548)

Shipping Weight, lb (kg) 1326 (602) 1326 (602)

IOMM VFD-2 33

Page 34

Figure 14, VFD 009MA/028MA (Air-Cooled), Unit Mount ed

NOTE: Incoming cable entrance is top-left. Outgoing wiring is factory-installed.

34 IOMM VFD-2

Page 35

LiquiFlo

Figure 15, VFD 047LW, Water-Cooled, Free- Standing

NOTES: Power entry for unit-mounted VFD is on top, left hand.

Unit Weights

Model VFD 047LW

Operating Weight, lb. (kg) 982 (446)

Shipping Weight, lb (kg) 1070 (486)

IOMM VFD-2 35

Page 36

Figure 16, VFD 060LW/072LW, Water-Cooled, Free-Standing

12.0

6.0

T

(

)

3.0 (76.2)

12.0

(304.8)

(152.4)

(304.8)

POWER WIRING

ACCESS PANEL

12.0

(304.8)

POWER WIRING

ACCESS PANEL

15.0

(381)

3.0 (76.2)

12.0

(304.8)

Note: Remove before drilling

to prevent metal particles from

falling into drive components.

60.0

(1524)

9.0

(228.6)

72.0

(1828.8)

19.1

(485.1)

OUTLET VALVE

3/4 (19.1) NPT

3.5

(88.9)

7.5

190.5

INLET VALVE

3/4 (19.1) NP

18.6

(473.2)

NOTES: Power entry for unit-mounted VFD is on top, left hand.

Unit Weights

Model VFD 060 VFD 072

Weight lb. (kg) 1272 (577) 1272 (577)

36 IOMM VFD-2

Page 37

A

A

A

A

Figure 17, VFD 090LW/120LW, Water-Cooled, Free-Standing Only

3.38

(85.8)

TYP

16.0

(406.4)

72.0

(1828.8)

10.5

(266.7)

11. 9

(302.3)

24.3

(617.2)

LINE LEAD ACCESS

COVER PLATE

11. 9

(302.3)

78.2

(1986.3)

Note: Remove before drilling

to prevent metal particles from

falling into drive components.

MOTOR LEAD ACCESS

COVER PLATE

POWER

ON

W

DRIVE

F

ULT

PUMPMOTOR

RUNNING

B

POWE

ON

W

DRIVE

F

ULT

PUMP

MOTOR

RUNNING

B

(614.7)

R

24.2

FAN

AIR

FLOW

NOTE: T he shipped loose, field installed, closed loop cooling module is shown installed adjacent to

the VFD. It can also be install separated from it. See page 15 for installation instructions.

Unit Weights

Model VFD 090 VFD 120

Weight lb. (kg) 1800 (817) 1800 (817)

IOMM VFD-2 37

Page 38

Figure 18, VFD 047MW-072MW, Water-Cooled, Unit Mounted

A

A

(

8.00

4.00

4.00

POWER WIRING

16.00

ENTRY PANEL

38.00

15.26

38.0

APPROX.)

ON

OFF

72.00

VM

SS1

AM

SS2

38 IOMM VFD-2

Page 39

LiquiFlo 2.0

Figure 19, VF 2037-2055;Free Standing

NOTE: Closed loop cooling module is also required.

Unit Shipping Weights

Model VF 2037 VF 2055

Weight lb. (kg) 1600 (726) 1600 (726)

IOMM VFD-2 39

Page 40

Figure 20, VF 2080-2110, Free Standing

NOTE: Closed loop cooling module is also required.

Unit Shipping Weights

Model VF 2080 VF 2110

Weight lb. (kg) 2000 (908) 2000 (908)

40 IOMM VFD-2

Page 41

MicroTech™ 200 VFD Control

Figure 21, MicroTech 200 Control Panel

frequency drive to the MicroTech to indicate the speed of the motor. The actual percent

motor speed is within 1% of the analog output signal from the MicroTech controller.

Digital Input, DI 10, is wired to a switch on the compressor that indicates when the vanes

are 100% open (VO switch). If the switch is open, the status of the vanes is Not Open. If

the switch is closed, the status of the vanes is Open.

The MicroTech 200™ unit

controller has control wiring to

the variable frequency drive

instead of to a motor starter.

The MicroTech controller

provides the speed setpoint

signal to a hardwired input on

the VFD. The output on the

MicroTech AOX (auxiliary

output) board is configured

(using jumpers) to provide a 010 VDC signal to a hard wired

analog input on the VFD.

There is no feedback signal

required from the variable

VFD Chiller Control States

There are seven VFD chiller control states viewable as shown below. They are based on

the unit status. See Table 12 on page 45 for relationships.

MicroTech: Menu 1, Screen 2, States

MicroTech 200

VFD Off

VFD Start

VFD Running: Adjust Speed & Open Vanes

VFD Running: Hold Minimum Speed & Adjust Vanes

VFD Routine Shutdo wn

VFD Locked Speed

VFD Override Capacity Control

VFD Off: The VFD is turned off, the speed output is 0%, and the vanes are closed.

VFD Start: The VFD is turned on, the speed output is minimum speed, and the vanes are

modulated to maintain the leaving evaporator setpoint. (VFD running, hold minimum

speed, and adjust vanes mode.)

VFD Running Adjust Speed & Open Vanes: The VFD remains on, the speed output is

modulated to maintain the leaving evaporator setpoint, and the vanes are pulsed to the open

position. This mode drives the vanes open and uses the speed to control capacity based on

the evaporator leaving water setpoint.

IOMM VFD-2 41

Page 42

VFD Running Hold Minimum Speed & Adjust Vanes: The VFD remains on, the speed

output is held at Minimum Speed, and the vanes are modulated to maintain the evaporator

leaving water setpoint. This mode occurs when the load (tons) can be satisfied with the

vanes not fully open while at minimum speed. Decreasing speed can no longer reduce

capacity, so the vanes maintain temperature control. When the load increases, the vanes

will pulse open until the vane open switch shows that the vanes are full open. At this point,

the MicroTech controller changes the mode to VFD Running: Adjust Speed and Open

Va nes.

VFD Routine Shutdown: The VFD remains on, the speed output remains the same,

dependent on the prior state, and the vanes are driven closed.

VFD Locked Speed: The MicroTech has a VFD LOCKED Speed Setpoint that can be

selected either “ON” or “OFF” from the MicroTech controller keypad. When the VFD

Locked Speed mode is set to ON, the VFD speed will be locked at the locked speed setpoint

(keypad adjustable). The purpose of this mode is to allow proper setup (calibration, testing,

etc.) of the chiller at a constant speed with constant conditions.

NOTE: Do not set the drive minimum speed above the factory setpoint to limit

reduced speed. A control incompatibility will result between the MicroTech

controller and the drive.

Override Capacity Control: Any capacity override (see Capacity Overrides on page 48)

that forces the VFD out of normal speed control. To return to normal speed control, the

capacity override condition is corrected.

First level capacity overrides hold speed and vane position while waiting for the condition

to correct.

If the override condition becomes critical (second level capacity override), speed and vane

position will be modulated in an attempt to correct the critical condition.

Control Sequence, MicroTech 200

VFD Off: The VFD is turned off, the speed output is 0%, and the vanes are closed. If the

chiller is turned on and if there is a load, the chiller will go through its start sequence; and

when the unit status reaches Motor Control Relay (MCR) Started, the VFD status

(MicroTech II controller Menu 1 Screen 2) will switch to “VFD Start”.

VFD Start: The VFD is turned on, the speed output is minimum speed, and the vanes are

modulated to maintain the chilled water setpoint (Active Setpoint on keypad/display). At

the same time, the minimum speed will continually be re-calculated based on the lift

temperature.

In the start mode, capacity control is “Hold Minimum Speed & Adjust Vanes” to satisfy the

Active Setpoint (leaving chilled water temperature). When the vanes have been pulsed to

the full open position, the Vane Open (V.O) switch closes, the VFD mode changes to “VFD

Running” adjust speed, open vanes”.

VFD Running Adjust Speed & Open Vanes: The VFD remains on, the speed

output is modulated to maintain the Active Setpoint, and the vanes are driven to the open

position. As the load decreases; if the Speed equals the lift temperature control speed, and

the Leaving Evaporator Water Temperature (LEWT) is less than the active setpoint minus

one-half the control band, the mode switches to “VFD Running: Hold Minimum Speed &

Adjust Vanes”. Otherwise, the controller stays in this mode.

If any capacity override exists, the VFD mode changes to the ”Override Capacity Control”

mode (see Capacity Overrides on page 48).

42 IOMM VFD-2

Page 43

VFD Running Hold Minimum Speed & Adjust Vanes: The VFD remains on,

the command speed is held at Minimum Speed, and the vanes are modulated to maintain the

Active Setpoint. As the load increases; if the vane open switch closes, and the LEWT is

greater than the active setpoint plus ½ the control band, the mode switches to “VFD

Running Adjust Speed & Open Vanes”. Otherwise, the controller stays in this mode with

the speed at Minimum Speed and the vanes being controlled to satisfy the Active Setpoint.

If any capacity override exists, the VFD mode changes to the “Override Capacity Control”

mode.

VFD Routine Shutdown: The VFD remains on, the speed output remains constant,

and the vanes are driven closed. This state is used during a routine shutdown of the chiller.

If there is a rapid shutdown cause by a fault alarm, the state switches to “VFD Off”.

Rapid Shutdown: If there is a fault alarm, the mode immediately switches to VFD

OFF. ”Rapid Shutdown” also occurs by changing the front panel “Stop/Auto” switch on the

MicroTech to “Stop”.

WDC/WCC, Dual Compressor VFD Operation

The MicroTech 200 controller has the capability to control a dual compressor VFD chiller

or two stand-alone VFD chillers with interconnecting network communications, including

all lead/lag load balance functions.

The lead compressor starts and runs the same as a single VFD compressor, controlling

speed and vane position based on Leaving Evaporator Water Temperature (LEWT). When

the capacity of the lead compressor reaches an equivalent user defined speed, LEWT offset,

and pull down rate, it indicates to the master control panel that it is time to enable the lag

(second) compressor to satisfy additional cooling requirements.

When the master control panel sees the enable lag indication, it checks the LEWT and if it

is greater than the active setpoint plus the lag Start UP (S/U) Delta T, it will start the lag

delay timer (keypad adjustable). At this time, the MicroTech control will record the

evaporator chilled water Delta T for reference to determine lag compressor shutdown.

NOTE: Operation assumes constant chilled water flow for dual compressor, VFD

units.

The MicroTech is constantly looking at the recorded startup evaporator Delta T, the user

adjustable offset from the delta T, and the active setpoint. As the load decreases, and the

evaporator Delta T drops below the recorded Startup Delta T minus the user adjustable

offset, and the LEWT is below the active setpoint minus the control band plus user defined

offset, the user adjustable lag compressor shutdown timer (same time as the lag start timer)

is activated. When the timer times out, and the above conditions still exist, the lag

compressor will be shut down.

MicroTech 200 Controller VFD Menu Screens

The MicroTech controller screens are modified from standard when VFD software is

loaded into the microprocessor in the factory. VFDs require special software as described

in this section. The screens are grouped by “menus” that are further broken down to screen

numbers. Fields noted with an (*) are only active when a VFD is used. Arrows indicate

that addition related screens are located above or below.

IOMM VFD-2 43

Page 44

Menu 1, Screen 2– Unit Status

This entire screen only appears when a VFD is used.

1.Unit Status hh:mm mon-dd-yy

VFD:Off (etc)

Cmnd VFD Speed= XXX%Vanes=Not Open(Open)

Lift Ctl Speed= XXX%

Menu 2, Screen 2 – Water Temps and Flows

2. Water Temps/Flow hh:mm mon-dd-yy

(*) PulldwnRate= X.X° /M Evap Flow= XXXgpm

Ent Ht Rcvy=N/A °F Cond Flow= XXXgpm

Lvg Ht Rcvy=N/A °F

Menu 3, Screen 2 – Refrigerant Temps/Press

3.Refrig Temps/Press hh:mm mon-dd-yy

Lift Press= XX.Xpsi

Lift Temp= XX.XºF

(*) Calc Lift Speed= XXX%

Menu 9, Screen 1 – Network Status

9. Network Status hh:mm mon-dd-yy

Master Command=Auto Compress Req. One

Slave Command=Stop Status=Lead&Lag Off

Lead Unit=Slave (*) LagShtdwnDT = XX°F

Menu 11, Screen 1 – Control Mode

11.Control Mode hh:mm mon-dd-yy

Mode= Manual Off (etc)

(*) MinVFDSpeedSpt =XXX% (*) Max Speed Spt =XXX%

Menu 11, Screen 2 – Control Mode Setpoints

This entire screen only appears when a VFD is used.

11.Control Mode hh:mm mon-dd-yy

Sample Time =XXSec Max Spd Step = XX%

Mod Limit = X.XºF Lock VFD Speed Off (On)

Deadband = X.XºF Lock Speed @ XXX%

Menu 13, Screen 1 – Motor Amp Setpoints

13. Motor Amp Spts hh:mm mon-dd-yy

Amp Reset=No Reset Active Spt =XXX%

Reset Signal=XX.Xma (*) Min Amp Spt =XXX%

Network Spt =XXXA (*) Max Amp Spt =XXX%

44 IOMM VFD-2

Page 45

Menu 13, Screen 2 – Motor Amp Setpoints

13. Motor Amp Spts hh:mm mon-dd-yy

Soft Load =Off (*) Dual Speed Spt = XXX%

Begin Amp Lim= XX% (*)LagPDRateSpt = X.X°/M

Ramp Time= XXMin

Menu 23, Screen 1 – Dual / Netw ork Set poi nts

23. Dual / Net Spts hh:mm mon-dd-yy

Slave Address=01.01 Start-up=Unload

LL Mode=Auto (*)LagStrtup DT=X.X°F

LL SwOver=N/A 00:00 (*) LagShtdnOffst= X.X°

Menu 26, Screen 3 – Unit Setup

26. Unit Setup hh:mm Mon-dd-yy

Full Load Amp = XX Hi Mtr Cur = Enable

(*) Vane Open Switch Yes No Str Tran = Enable

Low Mtr Cur = Enable Starter Flt = Enable

Table 11, MicroTech 200, VFD Setpoints

Item Default Setpoints Ranges MicroTech Keypad Menu

Sample Time 10 Sec. (1 to 63 Sec.) Menu 11 Screen 2

Deadband 0.5% (00.2 to 91%) Menu 11 Screen 2

Mod Limit 2.5ºF (1.0 to 10ºF) Menu 11 Screen 2

Maximum Speed Steps 2% (1 to 5%) Menu 11 Screen 2

Motor Current

Motor Current Threshold 5% (1 to 20%) Menu 22 Screen 3

Minimum Amp Setpoint 10% (5 to 100%) Menu 13 Screen 1

Maximum Amp Setpoint 100% (0 to 100%) Menu 13 Screen 1

Locked VFD Speed On for Start-up /set up (On / Off) Menu 11 Screen 2

Locked VFD Speed Off for VFD operation (On / Off) Menu 11 Screen 2

Locked Speed 100% for Start-up Set up NA Menu 11 Screen 2