Page 1

Installation Instructions 698

Solid-State Speed Controller

Steam/Hot Water Unit Heaters

Application

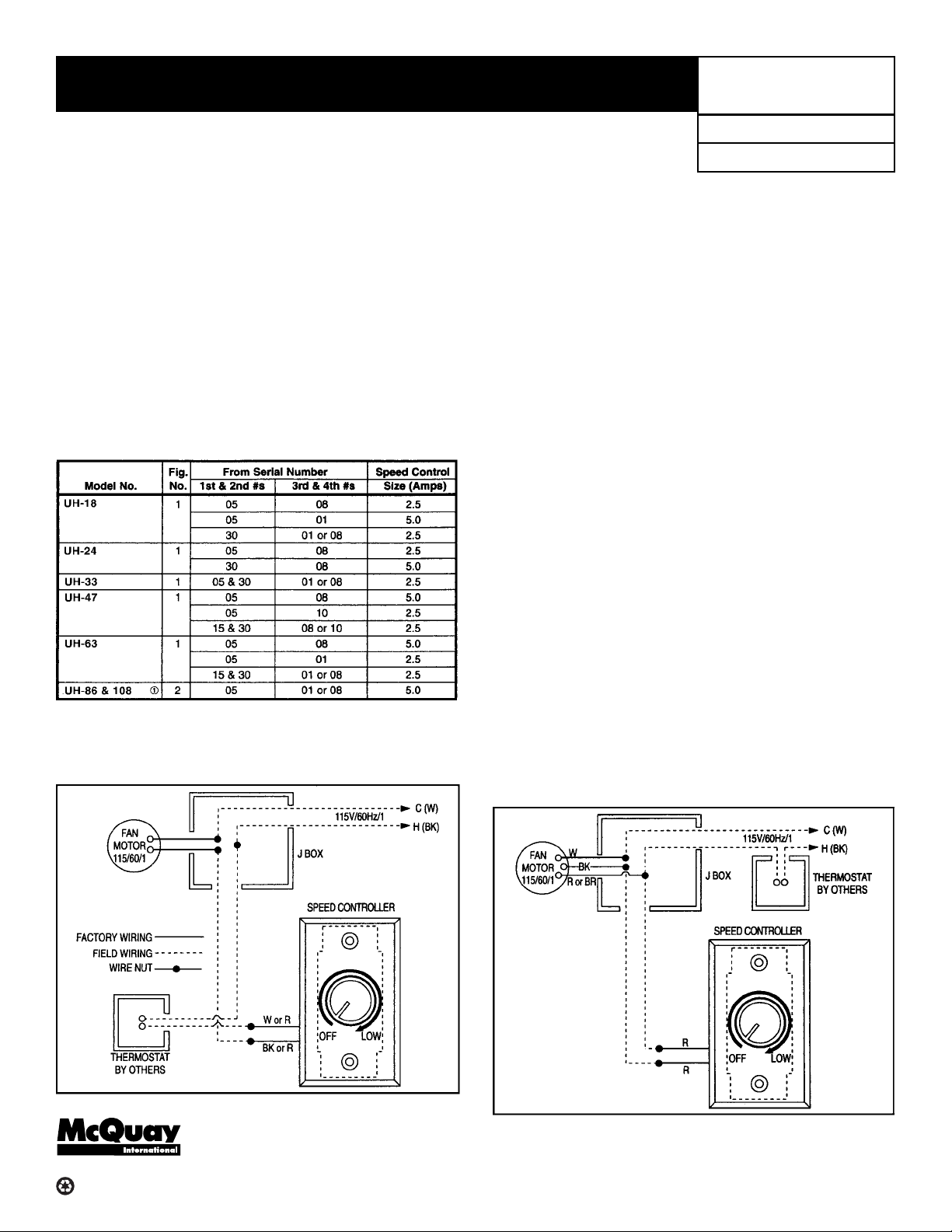

For remote control of air delivery, solid-state speed controllers

are available for McQuay steam/hot water unit heaters. Models

UH-18 through 108 with 115/60/1 motors (Power Code A).

A solid-state module in the controller controls motor input

voltage to maintain steady-state speed regulation at any setting

between “High” and “Low”. Controllers are packed separately

and must be connected according to wiring diagram, Figure 1

or 2.

NOTE: These controllers are not interchangeable with different

motor sizes or motor manufacturers. Before installation, check

unit heater model number, motor manufacturer and speed

controller size (listed in Amps on back of controller), to verify

compatibility. See chart below. If not matched correctly and

failure occurs, warranty will be nullified.

➀ Speed control cannot be used to turn unit on/off for 3-lead motors.

A thermostat or disconnect switch must be used.

Figure 1

Wiring Diagram

Group: Fan Coil

Date: February 2001

Installation

1. Controllers are furnished assembled and must be connected

between the fan motor and the thermostat; see Figure 1 or 2.

2. Install thermostat at desired location, (see instructions

packed with thermostat).

3. Install speed controller in a suitable location that will not

invite tampering.

Wiring Connections

1. Disconnect line voltage supply from service at the main

electrical panel. Bring power supply leads into junction box.

2. Remove speed controller cover and make wiring connections

as per the appropriate wiring diagram. CAUTION: Failure to

wire this device according to the appropriate diagram may

result in failure of the equipment or injury to the installer or user.

Operation Check

Set thermostat to lowest possible position. Turn controller to

minimum speed. Turn on power to the system. Adjust thermostat above room temperature. Motor will then start on lowest

speed. Adjust the controller to select the desired fan speed.

If motor does not start on lowest setting, the minimum control

speed may be adjusted. This can be accomplished on the 5

amp model by removing the cover plate to the controller and

turning the screw labeled MIN SPEED ADJ with a small screw

driver. Turn as indicated to increase or decrease minimum set

point. For the 2.5 amp model, the same procedure can be

followed with exception of the screw being located on the left

side of controller. If the motor still does not start, check power

supply and wiring. On new motors, bearings may be slightly

tight until motor is “broken-in”. Do not adjust speed controller

below minimum speed level until motor has experienced some

running time. Periodically repeat above procedure if lower

speeds are desired.

Figure 2

Wiring Diagram

®

4900 Technology Park Blvd., Auburn, NY 13021-9030 USA (315) 253-2771

Printed on recycled paper containing at least 10% post-consumer recycled material.

ALL WIRING MUST COMPLY WITH NATIONAL ELECTRIC CODE AND

ALL LOCAL CODES. ALL COMPONENTS MUST AGREE WITH THEIR

RESPECTIVE POWER SOURCE.

©2001 AAF-McQuay Incorporated

Loading...

Loading...