Page 1

SeasonMaker® ThinLine Fan-coil Units

Type TSH & TSC Horizontal Design

TSS, TPF, TSF & TSB Vertical Design

Catalog

C: 720-12

C

L

I

S

E

T

Ratings Certified by the

Air Conditioning & Refrigeration Institute

D

®

®

Page 2

Page 3

Contents

Computer fan-coil selection ......................................... 2

Design features

TSH & TSC ceiling units ........................................ 5 - 6

TSS, TPF, TSF & TSB floor units ........................... 7 - 8

Optional features and accessories .............................. 9 - 10

Control Systems ........................................................... 11

Unit selection ................................................................ 13

Capacity data ............................................................... 14 - 21

TSH & TSC ceiling units ........................................ 14 - 18

TSS, TPF, TSF & TSB ............................................ 18 - 21

Dimensional data .......................................................... 22 - 26

TSH & TSC ceiling units ........................................ 22 - 23

TSS, TPF, TSF & TSB floor units ........................... 24 - 27

Shipping weights .......................................................... 28

Engineering guide specifications ................................. 29 - 30

Computer fan-coil selection program

To provide optimal fan coil unit selection, McQuay International

provides McQuayTools™ and SelectTools™ for Fan Coil for

computer fan coil selection capability . These computer programs

aid in the selection of the most economical unit size and coil

option to meet the specification. The program capabilities include

hot and chilled water, hot and chilled water with glycol, electric

heat, supplemental steam heat, and unit external static pressure.

To operate the McQuayTools and SelectTools software the user

needs a computer using Windows® 2000 or higher. McQuay will

provide the software to run McQuayTools and SelectTools for

Fan Coil.

Contact your nearest McQuay representative for a copy of

SelectTools or for a fan coil selection that meets the most

exacting specifications.

Nomenclature

Fan-coil

ThinLine

Type of Unit

SF = Floor Cabinet Unit, Flat Top

SB = Floor Basic Unit

SH = Ceiling Hideaway Unit

SC = Ceiling Cabinet Unit

SS = Slope Top

PF = Tamper-Proof

“McQuay” and “SeasonMaker” are registered trademarks of McQuay International, Auburn, New York

“Bulletin illustrations cover the appearance of McQuay International products at the time of publication

and we reserve the right to make changes in design and construction at anytime without notice.”

F T SF - 1 S02

Unit Size

Nominal cfm in 100’s

(02 = 200, etc.)

Design Series

©2006 McQuay International. All rights reserved throughout the world.

Catalog 720 / Page 3

Page 4

Total fan-coil flexibility

TSH hideaway unit

TSH hideaway unit

The TSH hideaway unit is designed for fully concealed installation in areas where a ceiling enclosure is furnished by others.

Unit features include:

•6 unit sizes from 300 to 1200 cfm.

• Heavy-gauge galvanized steel base casing.

• Standard or high capacity cooling coil.

• Quiet, 3-speed permanent split capacitor motor(s).

• High performance, forward curved centrifugal fan wheels.

• Rigid, self-locking fan deck with split design, die-formed

fan housings for exceptional serviceability.

• Single power location for field wiring connections in unit electrical raceway.

• ARI certified performance.

• ETL and CETL safety agency approval listing.

TSC ceiling unit

The TSC ceiling unit is designed for exposed or recessed ceiling applications. An optional trim flange ceiling frame allows

installation with the TSC hinged bottom panel flush with the

ceiling. The unit includes all of the features listed above for the

TSH unit plus the following:

TSC ceiling unit; exposed cabinet

TSB basic unit; (Top discharge shown)

•6 unit sizes from 300 to 1200 cfm.

• Heavy 18 gauge steel decorative cabinet with stamped discharge grille.

• Attractive Antique Ivory electrostatically applied, baked-on

finish.

• Hinged bottom panel for total accessibility to the unit, controls and filter.

• Stamped return air grille in bottom access panel or back

return duct opening.

• Optional telescoping trim flange ceiling frame to accommodate any ceiling type.

• Cabinet design permits complete removal of the basic unit

for installation in steps coinciding with the various trades.

TSB basic unit

The TSB basic unit is designed for fully concealed or fully recessed applications. The unit can be installed in a custom enclosure or behind a McQuay wall plate. Decorative wall plates

include stamped return air grilles and access door. They are

available with or without stamped discharge grille. Wall plates

are finished with an attractive Antique Ivory electrostatically

applied, baked-on finish. TSB basic unit features include:

•7 unit sizes form 200 to 1200 cfm.

• Heavy-gauge galvanized steel basic cabinet.

• Standard or low flow cooling coil.

• Quiet, 3-speed permanent split capacitor motor.

• High performance forward curved centrifugal fan wheels.

• Split design fan housings or single-piece fan housings with

separate inlets for exceptional serviceability.

• Single power location for field wiring connections in unit electrical box.

• ARI certified performance.

• ETL and CETL safety agency approval listing.

Page 4 / Catalog 720

Page 5

Total fan-coil flexibility

TPF, TSF flat top floor unit

TSF floor unit

The TSF floor unit is designed for use in different installations

as a floor console most frequently installed below a window

for draft free performance or as a wall hung console. The TSF

unit is provided with a flat top discharge. The standard discharge grille is made of a heavy gauge steel. The unit includes

all of the features listed for the TSB unit incorporated in an

attractive cabinet painted with electrostatically applied, bakedon, Antique Ivory finish.

TPF floor unit-Tamper Proof

The TPF floor unit is designed for use as a floor console unit,

as the floor console units above. The TPF unit is standard with

a 16 gauge front panel, tamper-proof screws and locking access doors.

TSS floor unit

The TSS floor unit is designed for use as a floor console unit,

as the TSF unit and is provided with a slope top discharge

grille made of heavy gauge steel. The standard slope top discharge grille directs the air into the room and not into the curtains.

TSS, slope top floor unit

McQuay SeasonMaker® ThinLine fan-coil units

ARI certification, ETL & CETL listing

McQuay ThinLine fan-coil units are tested and rated in accordance with Air Conditioning and Refrigeration Institute (ARI)

Standard 440 and certified in accordance with the ARI certification program. ARI certification assures you full rated performance and offers confidence in unit selection.

ThinLine fan-coil units are listed by ETL and CETL as complying with nationally recognized safety standards for fan-coil

air conditioning units.

Ratings Certified by the

Air Conditioning &

Refrigeration Institute

C

L

I

D

S

E

T

®

Catalog 720 / Page 5

Page 6

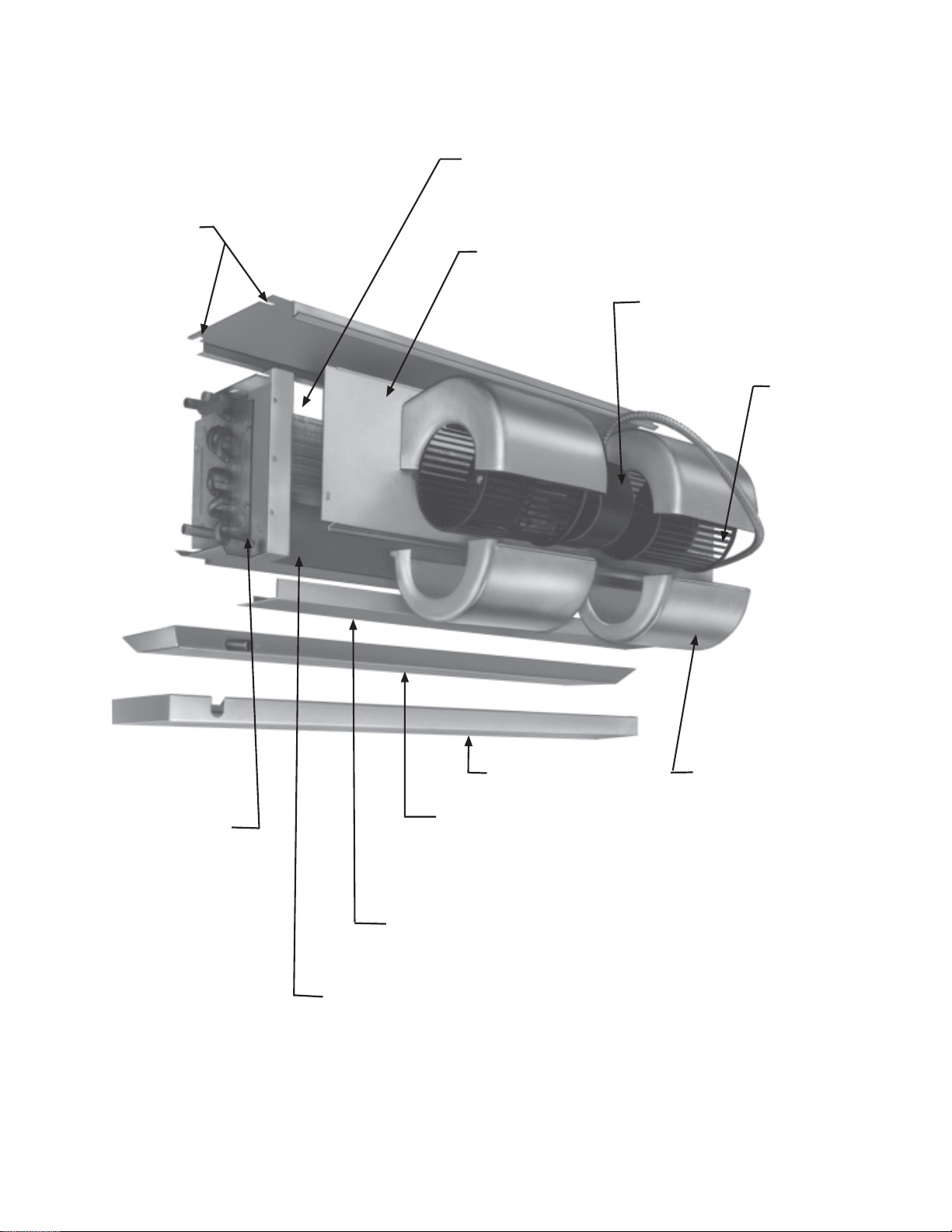

Design features — TSH & TSC ceiling units

Staggered tube coil

with manual air vent

Full size

mounting

slots

for quick

installation

Heavy-gauge galvanized

steel construction for

corrosion resistance

Efficient 3-speed

PSC motor

Fan wheel

Field wiring connection

location (both ends)

Page 6 / Catalog 720

Outer drain pan

Primary drain pan

Electrical raceway

access cover

Electrical raceway

A Complete Line of Ceiling

Fan-coils For Optional Design Flexibility

Split design fan

housing

for quiet air

delivery and

exceptional

service access

Page 7

Quality, efficiency & reliability built into every unit

Coils

Standard and optional high capacity cooling coils are available

with manual air vents for all unit sizes. Optional water heating

and steam coils are available for 4-pipe systems. Field installed

automatic air vents are optional for water cooling coils.

Coils are constructed of seamless copper tubes with headers and aluminum fins. Full depth collars, drawn in the fin stock,

provide accurate control of fin spacing and completely cover

the copper tubes to lengthen coil life. Tubes are mechanically

expanded into the fins for a permanent primary to secondary

surface bond, assuring maximum heat transfer efficiency.

The vertical position of the coil assures rapid condensate

drainage to provide even airflow and full rated capacity at all

conditions.

Motors

Tap wound, three-speed, permanent split capacitor motors are

standard for TSH and TSC units. Motors have sleeve bearings

with oilers, inherent thermal overload protection and automatic

reset. Motors are resiliently mounted to assure quiet, vibrationfree operation and are easily removed.

Fan Wheels

All fan wheels are forward curved, double width, double inlet,

centrifugal type and are statically and dynamically balanced

for smooth, quiet operation.

Fan Housings

Split design fan housings allow quick service of fans and

motors.

Fan Deck

Heavy-gauge continuous galvanized steel rigidly supports

motors, fan assembly, and fan housings as a single unit. The

fan deck is self-locking to the basic chassis and is easily removed for service.

Casing and Cabinet

All units are constructed of heavy gauge steel for long life and

durability. TSC units and optional trim flange ceiling frames are

finished with an electrostatically applied, baked-on Antique Ivory

paint.

Single Power Location

All electrical components of the TSH and TSC units are factory

wired to an electric raceway accessible from the bottom of the

unit. All field wiring connections can be made at the electrical

raceway. Electric heaters, depending on amperage, may require more than one field circuit, all of which can be brought to

the raceway.

Speed Controller

A three-speed switch with off position is available for all sizes.

The speed switch must be field mounted in a 2 x 4 x 2

electrical box by others.

1

⁄2" deep

Controls Systems

A wide variety of two- and four-pipe control systems are available with wall mounted thermostats or combination thermostat/speed switches (see page 10).

Drain Pans

The galvanized steel drain pan with copper connection is insulated on the external surface with fire rated closed cell foam.

The drain pan extends under the entire coil and coil connections. An optional galvanized steel secondary drain pan provides complete condensate drainage from valve package

components.

Filter

TSC units have as standard a 1" throwaway filter. The filter is

easily removable through the bottom access panel. For TSH

units a filter is supplied only with the optional return

air plenum.

TSC Ceiling Unit

TSH Hideaway Unit

TSC Ceiling Unit with

Optional Trim Flange

Catalog 720 / Page 7

Page 8

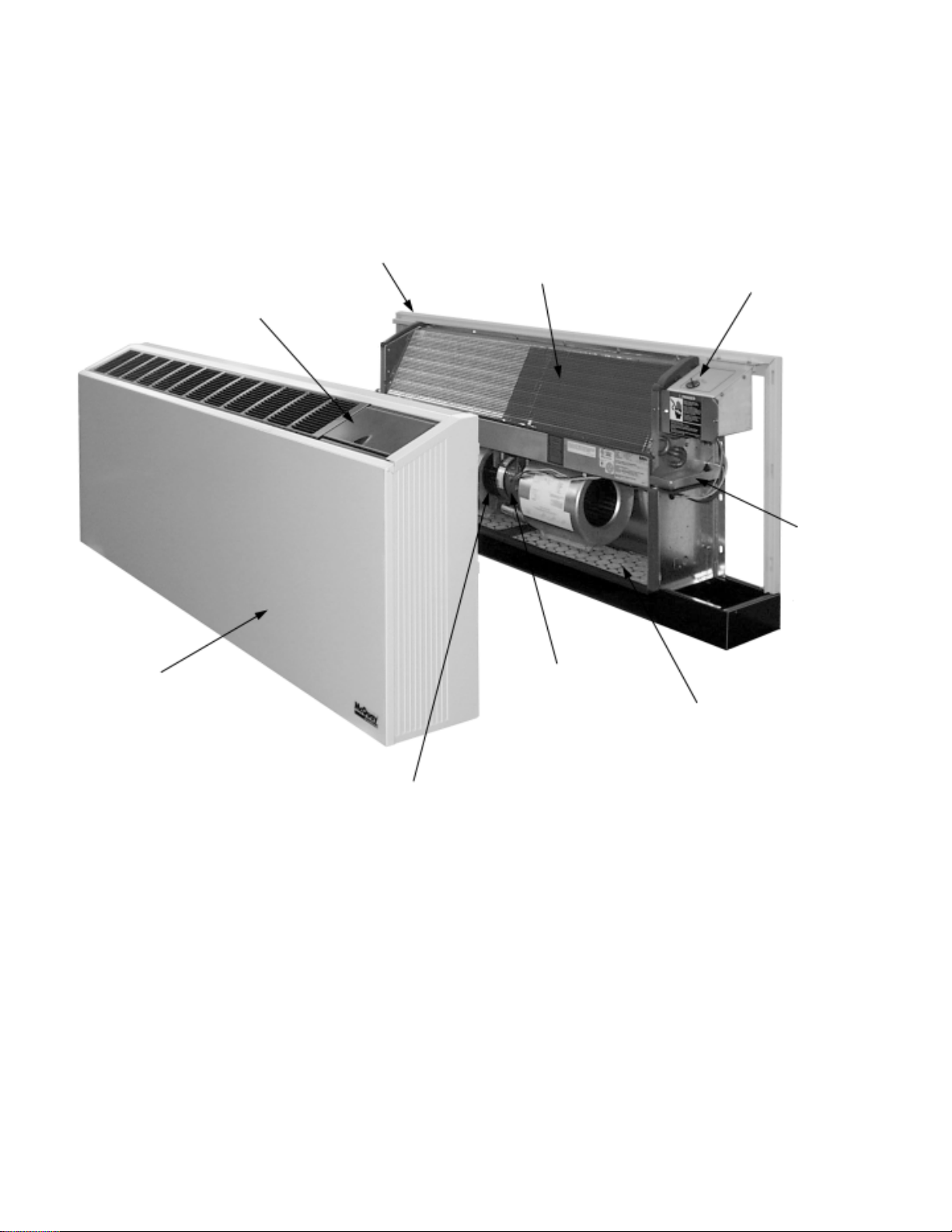

Design features — TSS, TPF, TSF & TSB floor units

Heavy-gauge galvanized

steel construction for

corrosion resistance

Staggered tube coil

Control panel

access door

Temperature control pad

and speed switch

Wrap-around front panel

designed for easy removal

and easy access to all

components

Primary

drain pan

3-speed permanent

split capacitor motor

Filter is easily

removed

through

return air

opening.

Forward curved

fan(s)

High Performance Coils and Motors

Page 8 / Catalog 720

For Exceptional Energy Economy

Page 9

Quiet, dependable, trouble-free performance

Coils

Standard and optional low flow cooling coils are available with

manual air vents for all unit sizes. Optional water heating and

steam coils are available for 4-pipe systems. Field installed automatic air vents are optional for water cooling coils.

Coils are constructed of seamless copper tubes and headers with aluminum fins. Full depth collars, drawn in the fin stock,

provide accurate control of fin spacing and completely cover

the copper tubes to lengthen coil life. Tubes are mechanically

expanded into the fins for a permanent primary to secondary

surface bond, assuring maximum heat transfer efficiency.

The position of the coil assures rapid condensate drainage

to provide even airflow and full rated capacity at all conditions.

Motors

Tap wound, three-speed, permanent split capacitor motors are

standard for TSS, TPF, TSF and TSB units. Motors have sleeve

or ball bearings with oilers, inherent thermal overload protection with an automatic reset. Motors are resiliently mounted to

assure quiet, vibration-free operation and are easily removed.

Fan Wheels

All fan wheels are forward curved, double width, double inlet,

centrifugal type and are statically and dynamically balanced

for smooth, quiet operation.

Fan Housings

Split design fan housings or single-piece fan housings with

separate inlets offer exceptional serviceability.

Fan Deck

Heavy-gauge continuous galvanized steel rigidly supports

motors, fan assembly and fan housings as a single unit.

Casing and Cabinet

All units are constructed of heavy-gauge steel for long life and

durability. TSS sizes S02 through S06 are provided with

Hi-impact plastic sides. TSS sizes S08 through S12 are

provided with metal sides. TSS, TPF, TSF units and TSB wall

plates are finished with an electrostatically applied, baked-on

Antique Ivory paint. TPF units have 16 gauge front panel and

locking access door.

Discharge Grille

TSS, TPF and TSF units are furnished with a stamped metal

discharge grille. Matching access door offers a distinctive appearance that complements any room decor.

Single Power Location

All electrical components of the TSS, TPF, TSF and TSB units

are factory wired to a single electrical box on the unit. All field

wiring connections can be made at the electrical box. Electric

heaters, depending on amperage, may require more than one

field circuit, all of which can be brought to the electrical box.

Speed Controller

A three-speed switch with off position is provided for all unit

sizes. The speed switch is available unit mounted or for field

installation in a wall mounted 2 x 4 x 2

box by others.

1

⁄2 inch deep electrical

Controls Systems

A wide variety of two- and four-pipe control systems are available with unit mounted or remote thermostats. Unit mounted

controls are provided with an access door, 3-speed fan with

off switch, and optional temperature control knob.

Drain Pans

The galvanized steel primary drain pan is provided with copper

connections, and is insulated on the external surface with fire

rated closed cell foam. The primary drain pan extends under

the entire coil and coil connections. An injection molded secondary drain pan provides complete condensate drainage from

valve package components. The secondary drain pan rotates

o

180

to accommodate field piping.

Filter

TPF, TSF and TSB units have as standard a 1⁄2" throwaway filter. The filter is easily removable through the return air toe space

of TPF, TSF units and wall plate return air grille for TSB units.

TSB basic unit

(Top discharge shown)

TSS slope top metal

Floor Unit

TPF, TSF flat top

Floor Unit

Catalog 720 / Page 9

Page 10

Optional features and accessories

Optional Coils

In addition to the standard cooling coil, an optional low flow

water coil is available for TSS, TPF, TSF and TSB floor units for

use in a two-pipe system. A standard capacity coil or a high

capacity coil is available for TSH and TSC ceiling units for use

in two-pipe systems. A separate one-row heating coil can be

factory installed with any of the above coils for four-pipe

systems. A steam coil is also available for installation with the

TSH Heating Coil

standard cooling coil. (Manual air vents supplied with water

heating coils must be field mounted.)

Motors

Tap wound, three-speed 115/60/1 or 265/60/1 permanent split

capacitor motors are available on all unit types and sizes. All

motors have sleeve bearings with oilers and inherent thermal

overload protection with automatic reset. Motors are resiliently

mounted to assure quiet, vibration-free operation and are easily

removed for service.

TSH Electric Heater

Valve Body

1

Electric Heat

Electric heat is offered in a wide variety of sizes and voltages.

Each is equipped with an automatic thermal overload switch.

Electric

1

Valve Actuator

Electric heaters can be used for supplementary between-season heating when chilled water is being supplied to the system, or for year-round electric heat.

Return Plenum (TSH Units Only)

A galvanized steel plenum section is available to enclose the

motor and fans. It facilitates making the return air connection

to the unit without interfering with the piping for the unit sup-

6

7

8

5

Supply

4

3

ply, return or drain connections. It is equipped with a 1" throwaway filter holding frame with side or bottom filter access. A

3

/4" duct collar offers easy field duct connections. The plenum

is available factory mounted or as a field mounted kit. The filter

frame and bottom panel can be interchanged for back or bottom return air.

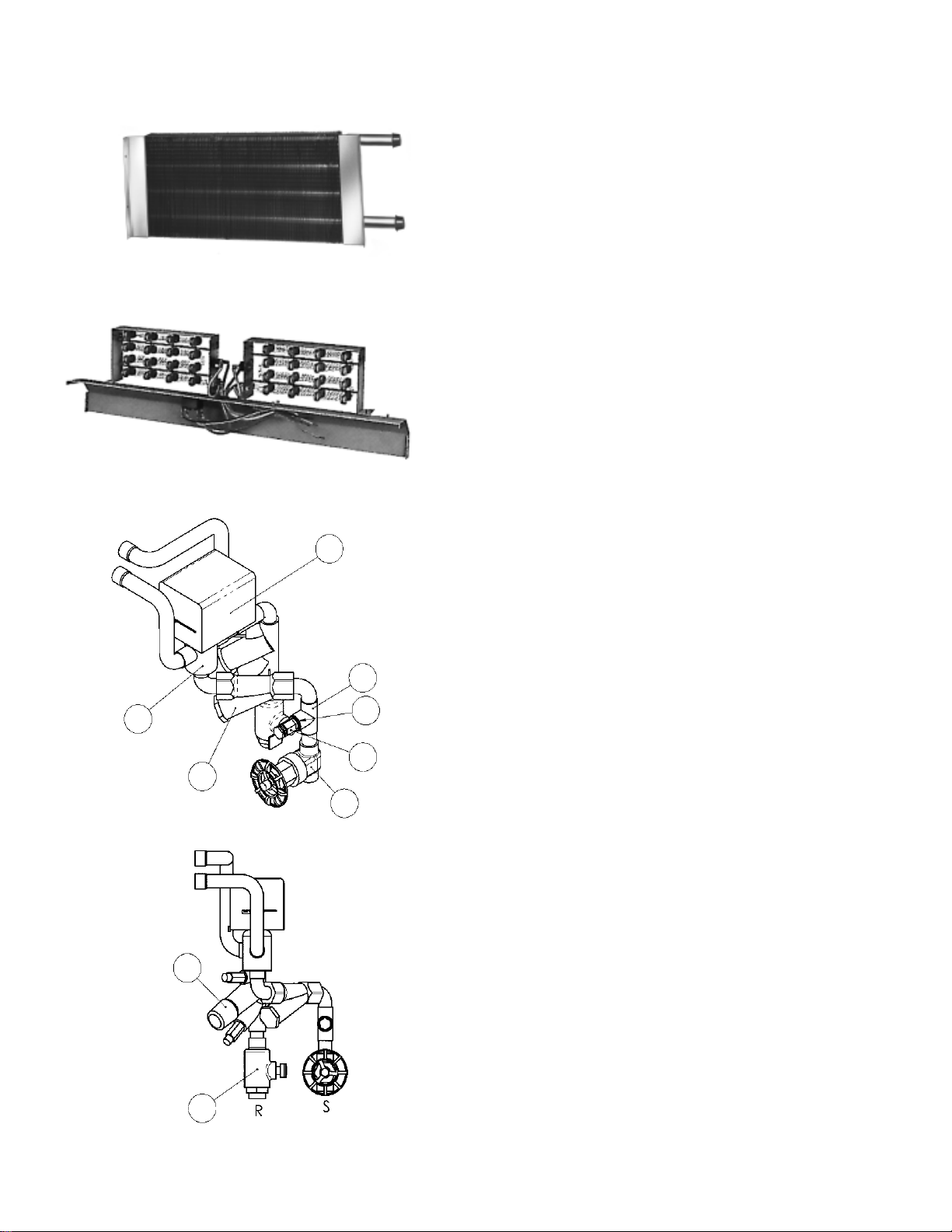

Valve Packages

Two-way and three-way electric valves are available with hand

valves for factory or field mounting opposite hand on all units.

When valve packages are supplied, a secondary drain pan is

also supplied to assure positive drainage of condensate from

valves and piping manifolds (unit types TSS, TPF, TSF and TSB

have a secondary drain pan as standard). Basic package includes electric valve with hand valves . Basic package

with P/T plugs includes above with pressure/temperature taps

. Deluxe package includes all the above plus a strainer

and a flow control device . See Table 1 on page 11 for a

brief description of control systems.

Deluxe Valve Packages

Page 10 / Catalog 720

2

Page 11

Wall Plates (TSB units only)

Decorative wall plates have rounded corners and an Antique

Ivory finish for an attractive appearance.

TSB Wall Plate

Ceiling Flange (TSC Units Only)

Optional field installed ceiling flange accommodates acoustic

type ceiling panels in drop ceiling applications and has an Antique Ivory finish.

Fresh Air Damper

A fresh air intake that will provide up to 25% dilution air with

insect air screen and damper blade, can be ordered either

factory installed or as a field installed kit. The kit consists of

an intake with damper blade and insect screen. The damper

may be manually controlled through the return air opening

or with an optional field installed damper motor. If freezing

air temperatures are expected, the damper must be closed

or outside air must be tempered before entering the unit.

TSS/TPF, TSF/TSB Manual Fresh Air Damper

Rear Cabinet Extension

For applications requiring additional cabinet depth, TSS, TPF

and TSF have available a 4" extension kit. Kit is available

for applications where additional depth is necessary for piping or electrical routing. This kit

duct or outside air plenum.

is not designed to be an air

TSC Unit Shown with Ceiling Flange

Fresh Air Wall Intake Box

Fabricated of aluminum with weep holes and a double set of

louvers in series to prevent moisture draw-through.

TSS/TPF, TSF/TSB Wall Box

Leveling Legs (TSF, TPF, TSS Units Only)

Field installed kits are available with 0 to 1" adjustment for positive leveling of floor-mounted units.

Vertical ThinLine 4" Cabinet Rear Extension

TSS, TPF and TSF Leveling Legs

Catalog 720 / Page 11

Page 12

Thermostats

Wall-mounted thermostats for all application requirements are

available as either thermostats only or combination thermostat

and three-speed switch. Unit mounted thermostats are available for TSF, TPF, TSS and TSB units.

Wall mounted three-speed fan switch and thermostats

Control Systems

Table 1. Electric valve package kits

System Fan Control ➀

Two-Pipe Manual Motorized 2-way or on supply line.

Valve Cycle. (Constant Fan) 3-way. Normally closed. Manual. Unit

(Water Cooling Factory or mounted on control plate

or Heating) Field installed or wall mounted on

Two-Pipe

Valve Cycle. None

With Manual Motorized 2-way or

Electric Heat. (Constant Fan) 3-way. Normally closed.

(Water Cooling Factory or Manual. Unit

and Electric Field installed. mounted on control plate Unit or wall mounted

Heating) ➂ or wall mounted on heating/cooling, SPDT.

Four-Pipe Motorized 2-way or Unit or wall mounted,

Valve Cycle Manual 3-way. Normally closed. None DPDT. Neutral dead-

(Water Cooling (Constant Fan) Factory or band for sequenced

and Heating) Field installed. heating/cooling.

Two-Pipe

Valve Cycle

With Intermediate Factory or

Heat Field installed.

Manual

(Constant Fan)

Control Valve Changeover Control

Type ➁ and Location

Automatic.

Field installed

subbase of thermostat.

subbase of thermostat.

Motorized 2-way or

3-way. Normally closed.

Two automatic Changeovers

(ACO's) required on supply line

to provide ACO and lock out

electric heater when hot water

is available.

Thermostat Type

Unit or wall mounted

heating/cooling, SPDT.

Unit or wall mounted.

DPDT. Neutral dead-

band for sequenced

heating/cooling.

Unit or wall mounted,

DPDT. Neutral dead-

band for sequenced

heating/cooling.

NOTES: ➀ A three-speed fan switch is supplied on all vertical units.

➁ Valve packages are factory mounted or field installed.

➂ Available for supplementary between-season electric heating when chilled water is in the system or for year-round full electric heat.

Page 12 / Catalog 720

Page 13

Unit selection

Selection of unit type

General

The achievement of an efficient fan-coil system is dependent upon accurate system design and proper equipment

selection. Variations, limitations and control of fan-coil systems, design conditions and design load calculations are

not described in detail in this catalog. More detailed information may be found in the ASHRAE Guide. This catalog

contains ARI certified ratings and application ratings for

ThinLine SeasonMaker fan-coil units from which the design

engineer can make initial unit selections to meet the requirements of the system.

The mechanical system designer must select the unit

types best suited to the overall system before the actual

unit sizes can be determined. The factors that generally influence this decision are intended building usage, building

layout, architectural and aesthetic values, economics, geographical location, and type of maintenance service available. The general results may be a mixture of various unit

types within a given system. McQuay International manufactures a fan-coil unit to meet your every need including

ThinLine, HiLine and Large Capacity models.

Basic design data

Prior to selecting the individual unit sizes, the design engineer must fix or determine the following factors:

1. Inside and outside wet and dry bulb design temperatures.

2. Method of introducing the ventilation air.

3. Wet and dry bulb temperatures of the air mixture enter-

ing the unit coil.

4. Total and sensible heat gains and losses of the area to be

served.

5. Properties of the heating and cooling medium.

6. Available electric power service.

7. Any special design requirements of the building or sys-

tem.

culating the peak load requirements due to unusually high

occupancy or severe climatic conditions and with fan operating at high speed. Ordinary day to day cooling and heating requirements are then achieved at low and medium

speeds.

Ventilation requirements should be considered along with

heating and cooling capacity to determine the proper unit

size. Outside fresh air must be tempered before entering the

unit if freezing conditions are expected.

Cooling coil requirements

Having checked the minimum unit size to meet the ventilation requirement, the unit size is generally selected on the

basis of matching the sensible cooling capacity of the unit

with the calculated requirements when operating at high

speed.

Coil Types

Standard and low flow coil types are available for all TSF

and TSB floor unit sizes. Standard and high capacity coil

types are available for all TSH and TSC ceiling unit sizes to

permit unit selections for optimum performance.

• Standard coils are designed to meet both the cooling and

heating requirements in a typical system.

• Low flow coils are designed to meet both the normal cool-

ing and heating requirements while operating with reduced

gpm and correspondingly higher water temperature rises.

Their use is enhanced by the lower first cost of both riser

piping and pump, plus lower overall fan-coil unit and water

pump operating cost.

• High capacity coils are designed to meet cooling and

heating loads that exceed typical system requirements

for ceiling units.

Selection of unit size

The capacity ratings presented in this catalog are provided

for initial unit selection only. Unit size selection should be

determined by using the SelectTools for Fan-coil computer

selection program. Water cooling and heating capacities, unit

air flow, static pressure, electric heat, and glycol solutions

are all incorporated into the program to provide the best

possible selection. Consult your McQuay representative for

a selection tailored to your application.

Unit sizes for the ideal system should be selected by cal-

Heating requirements

Heating requirements for two-pipe systems are generally met

by employing the same water flow rate as cooling and adjusting the entering hot water temperature to obtain a matching unit heat output at low fan speed. Four-pipe systems are

generally designed by specifying the flow rate through the

separate heating coil to meet the required heat load with the

fan operating at low speed.

Electric heaters are available for primary year-round heating or intermediate between-seasons heat loads for twopipe systems when chilled water is in the system.

Catalog 720 / Page 13

Page 14

TSH & TSC Series horizontal units

ARI approved standard ratings - ceiling units

Table 2. Standard coil water cooling capacity ratings ➀

TSH Hideaway Units TSC Ceiling Units

Unit

Size Total Sensible

S03 8,100 6,800 1.7 3.7 5,800 4,600 1.2 2.0

S04 11,900 10,100 2.5 8.0 10,900 9,100 2.2 6.5

S06 19,100 15,200 4.0 3.0 17,100 13,000 3.4 2.4

S08 22,100 17,600 4.6 3.9 19,900 15,200 3.9 2.8

S10 29,000 23,500 6.2 11.5 26,500 20,300 5.3 8.8

S12 38,300 29,700 7.8 21.6 34,500 25,300 6.9 17.2

NOTES:

➀ Rated in accordance with ARI Standard 440. Cooling capacities based on 80

temperature rise and high fan speed with standard 115/60/1 motor. See tables 10 and 11 for air volume capacities.

➁ For cooling coil capacity ratings at conditions other than those listed refer to the SelectTools for Fan-coil computer selection program or consult

your McQuay representative.

Cooling Capacity ➁

(BTUH) (BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Table 3. High capacity coil water cooling capacity ratings ➀

TSH Hideaway Units TSC Ceiling Units

Unit

Size Total Sensible

S03 10,200 7,700 2.1 6.3 7,300 5,400 1.5 3.6

S04 15,100 11,000 3.2 4.5 14,000 10,100 2.8 3.6

S06 24,200 17,500 5.0 8.0 21,800 15,400 4.4 5.7

S08 28,000 20,000 5.8 10.4 24,700 17,400 5.1 8.3

S10 37,800 26,700 7.7 14.7 35,700 24,700 7.2 12.3

S12 43,200 30,200 8.6 21.6 39,400 26,800 7.8 17.6

NOTES:

➀ Rated in accordance with ARI Standard 440. Cooling capacities based on 80oF DB/67oF WB entering air, 45oF entering water, 10oF water

temperature rise and high fan speed with standard 115/60/1 motor. See tables 10 and 11 for air volume capacities.

➁ For cooling coil capacity ratings at conditions other than those listed refer to the SelectTools for Fan-coil computer selection program or consult

your McQuay representative.

Cooling Capacity ➁

(BTUH) (BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Cooling Capacity ➁

TOTAL SENSIBLE

BTUH BTUH

o

F DB/67oF WB entering air, 45oF entering water, 10oF water

Cooling Capacity ➁

Total Ssnsible

(BTUH) (BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Water heating coil ratings - ceiling units

Table 4. Standard coil water heating capacity ratings ➀

TSH Hideaway Units TSC Ceiling Units

Unit

Size Sensible

S03 16,600 1.7 3.7 13,200 1.2 2.0

S04 22,500 2.5 8.0 19,900 2.2 6.5

S06 36,800 4.0 3.0 31,500 3.4 2.4

S08 42,800 4.5 3.8 37,500 3.9 2.8

S10 58,700 6.2 11.5 50,200 5.3 8.8

S12 72,100 7.8 21.6 59,500 6.9 17.2

➀ Water heating coils at 70oF DB entering air, 140oF entering water and high fan speed with standard 115/60/1 motor. See tables 10 and 11 for air

volume capacities.

➁ For heating coil capacity ratings at conditions other than those listed refer to the SelectTools for Fan-coil computer selection program or consult

your McQuay representative.

Heating Capacity ➁

(BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Page 14 / Catalog 720

Heating Capacity ➁

Sensible

(BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Page 15

TSH & TSC Series horizontal units

Table 5. High capacity coil water heating capacity ratings ➀

TSH Hideaway Units TSC Ceiling Units

Unit

Size Ssnsible

S03 18,600 2.1 6.3 14,800 1.5 3.6

S04 28,100 3.2 4.5 24,400 2.8 3.6

S06 41,600 5.0 8.0 35,600 4.4 5.7

S08 49,400 5.8 10.4 43,800 5.1 8.3

S10 68,800 7.7 14.7 58,800 7.2 12.3

S12 75,700 8.6 21.6 61,600 7.8 17.6

➀ Water heating coils at 70oF DB entering air, 140oF entering water and high fan speed with standard 115/60/1 motor. See tables 10 and 11 for air

volume capacities.

➁ For heating coil capacity ratings at conditions other than those listed refer to the SelectTools for Fan-coil computer selection program or consult

your McQuay representative.

Heating Capacity ➁

(BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Table 6. Standard coil water heating capacity ratings ➀

TSH Hideaway Units TSC Ceiling Units

Unit

Size Sensible

S03 27,272 1.86 5.88 23,177 1.58 4.18

S04 36,189 2.47 10.61 32,095 2.19 8.3

S06 60,155 4.1 2.15 51,283 3.5 1.73

S08 70,391 4.8 2.91 61,519 4.2 2.13

S10 95,483 6.51 8.78 82,518 5.63 6.61

S12 115,984 7.91 16.28 94,829 6.47 11.25

➀ Water heating coils at 70oF DB entering air, 180oF entering water, 30oF water temperature drop, and high fan speed with standard 115/60/1 motor.

See tables 10 and 11 for air volume capacities.

➁ For heating coil capacity ratings at conditions other than those listed refer to the SelectTools for Fan-coil computer selection program or consult

your McQuay representative.

Heating Capacity ➁

(BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Heating Capacity ➁

Sensible

(BTUH)

Heating Capacity ➁

Sensible

(BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Table 7. High capcity coil water heating capacity ratings ➀

TSH Hideaway Units TSC Ceiling Units

Unit

Size Sensible

S03 29,660 2.02 5.02 24,627 1.68 4.67

S04 44,400 3.03 3.24 38,600 2.63 2.57

S06 64,852 4.42 4.63 55,299 3.77 3.26

S08 77,477 5.28 6.27 68,605 4.68 5.13

S10 108,772 7.42 10.1 91,712 6.26 7.05

S12 120,325 8.21 12.33 95,417 6.51 7.91

➀ Water heating coils at 70oF DB entering air, 180oF entering water, 30oF water temperature drop, and high fan speed with standard 115/60/1 motor.

See tables 10 and 11 for air volume capacities.

➁ For heating coil capacity ratings at conditions other than those listed refer to the SelectTools for Fan-coil computer selection program or consult

your McQuay representative.

Heating Capacity ➁

(BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Heating Capacity ➁

Sensible

(BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Catalog 720 / Page 15

Page 16

TSH & TSC Series horizontal units

Table 8. Separate 1-row heating coil capacity ratings ➀

TSH Hideaway Units TSC Ceiling Units

Unit

Size Sensible

S03 12,300 0.8 1.9 12,300 0.8 1.9

S04 16,800 1.1 3.8 16,500 1.0 3.1

S06 22,200 1.5 1.7 18,000 1.2 0.8

S08 23,100 1.6 1.8 21,800 1.5 1.4

S10 36,100 2.4 3.9 31,800 2.1 2.9

S12 46,900 3.2 8.0 46,100 3.1 7.6

➀ Water heating coils at 70oF DB entering air, 180oF entering water, 30oF water temperature drop and high fan speed with standard 115/60/1 motor.

See tables 10 and 11 for air volume capacities.

➁ For heating coil capacity ratings at conditions other than those listed refer to the SelectTools for Fan-coil computer selection program or consult

your McQuay representative.

Heating Capacity ➁

(BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Steam coil ratings – ceiling units

Table 9. Separate 1-row steam coil capacity ratings ➀

TSH Hideaway Units TSC Ceiling Units

Unit

Size

S03 20,300 84.6 62 21.0 20,300 84.6 62 21.0

S04 28,300 117.9 65 29.3 27,900 116.3 64 28.8

S06 36,100 150.4 54 37.4 31,000 129.2 51 32.1

S08 50,000 208.3 57 51.8 48,100 200.4 58 49.8

S10 65,100 271.3 53 67.4 61,300 255.4 57 63.4

S12 71,400 297.5 51 73.9 70,400 293.3 55 72.9

➀ Steam coil capacity ratings based on 60oF DB entering air temperature, 2 psig steam pressure and high fan speed with standard 115/60/1

➁ For steam coil capacity ratings at conditions other than those listed, use the steam heating coil conversions found on page 20.

➂ Equivalent Direct Radiation.

Heating Cap. Air Temp.

Sensible EDR ➂

(BTUH)

motor. See tables 10 and 11 for air volume capacities.

Rise

o

F

Condensate

LB/HR.

Heating Capacity ➁

Sensible

(BTUH)

Heat. Cap. ➁ Air Temp.

Sensible EDR ➂

(BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Rise

o

F

Condensate

LB/HR.

Air volume capacity data – ceiling units – Standard Coil

Table 10. Air volume versus external static pressure – Standard motors, high speed operation (cfm)

External Static Pressure (inches of water)

Unit TSH Unit Wc" TSH With Plenum TSC Unit Wc"

Size .00 .05 .10 .15 .20 .25 .30 .00 .05 .10 .15 .20 .25 .30 .00 .05 .10 .15 .20 .25 .30

S03 390 360 340 290 200 170 - 340 290 200 170 110 - - 350 300 250 210 160 - -

S04 520 510 500 480 460 450 430 500 480 460 450 430 410 390 480 460 450 430 420 400 390

S06 700 680 670 650 610 570 510 670 650 610 570 510 460 400 640 610 570 540 500 470 430

S08 880 860 830 800 760 710 670 830 800 760 710 670 620 580 790 750 710 680 640 610 570

S10 1300 1270 1220 1180 1120 1060 960 1220 1180 1120 1060 960 900 800 1160 1110 1060 1000 950 900 850

S12 1480 1440 1390 1340 1280 1210 1140 1390 1340 1280 1210 1140 1060 980 1190 1140 1090 1040 990 940 890

Note: Based on 115/60/1 electric service, standard unit options, and dry coils.

Page 16 / Catalog 720

Page 17

TSH & TSC Series horizontal units

Air volume capacity data – ceiling units – Hi Capacity Coil

Table 11. Air volume versus external static pressure – Standard motors, high speed operation (cfm)

External Static Pressure (inches of water)

UNIT TSH Unit Wc" TSH With Plenum TSC Unit Wc"

SIZE .00 .05 .10 .15 .20 .25 .30 .00 .05 .10 .15 .20 .25 .30 .00 .05 .10 .15 .20 .25 .30

S03 370 340 310 270 170 150 - 310 270 170 150 130 100 - 320 280 240 190 150 110 -

S04 510 500 480 460 450 430 410 480 460 450 430 410 390 360 460 450 430 420 400 380 370

S06 710 690 670 640 590 550 500 670 640 590 550 500 460 400 650 610 570 540 500 460 420

S08 870 850 820 800 770 740 690 820 800 770 740 690 640 590 740 710 660 630 590 530 490

S10 1290 1240 1200 1150 1080 1020 950 1200 1150 1080 1020 930 880 820 1130 1070 1000 880 810 750 690

S12 1400 1320 1260 1200 1120 1050 950 1260 1200 1120 1050 950 900 850 1160 1100 1050 990 930 870 810

Note: Based on 115/60/1 electric service, standard unit options, and dry coils.

Motor Data – ceiling units

Table 12. Motor data – TSH & TSC units

Unit Size

Motor S03 S04 S06 S08 S10 S12

Speed Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM

High 0.70 75 1080 1.4 185 1200 1.6 190 1070 2.30 250 1280 4.30 450 1350 3.80 395 1160

Medium 0.40 47 820 1.00 110 880 1.00 104 810 1.60 160 1030 2.30 209 1060 3.00 347 1020

Low 0.30 34 600 0.60 58 530 0.70 67 520 0.90 90 920 1.50 137 600 1.90 195 650

High 0.34 80 1080 0.50 135 1200 0.70 170 1070 1.00 220 1280 1.30 290 1360 1.40 305 1160

Medium 0.30 66 800 1.40 88 880 0.43 74 815 0.63 131 925 1.00 220 1050 1.30 260 1000

Low 0.29 60 600 0.25 45 530 0.32 50 520 0.36 73 630 0.90 180 600 0.70 145 650

115/60/1

265/60/1

Electric heat data – ceiling units

Table 13. Electric resistance heater capacities – TSH & TSC units

Single Stage Heaters – Electrical Service

Unit 120/60/1 208/60/1 240/60/1 265/60/1

Size Watts BTUH Amps Watts BTUH Amps Watts BTUH Amps Watts BTUH Amps

S03 2000 6826 16.6 2000 6826 9.6 2000 6826 8.3 2000 6826 7.2

S04 2000 6826 16.6 2000 6826 9.6 2000 6826 8.3 2000 6826 7.2

S06 ---4000 13652 19.2 4000 13652 16.7 4000 13652 14.4

S08 ---4000 13652 19.2 4000 13652 16.7 4000 13652 14.4

S10

S12

1000 3413 8.3 1000 3413 4.8 1000 3413 4.2 1000 3413 3.6

---3000 10239 14.4 3000 10239 12.5 3000 10239 10.8

1000 3413 8.3 1000 3413 4.8 1000 3413 4.2 1000 3413 3.6

---3000 10239 14.4 3000 10239 12.5 3000 10239 10.8

2000 6826 16.6 2000 6826 9.6 2000 6826 8.3 2000 6826 7.2

---6000 20478 28.8 6000 20478 25.0 6000 20478 21.7

2000 6826 16.6 2000 6826 9.6 2000 6826 8.3 2000 6826 7.2

---6000 20478 28.8 6000 20478 25.0 6000 20478 21.7

---4000 13652 19.2 4000 13652 16.7 4000 13642 14.4

---6000 20478 28.8 6000 20478 25.0 6000 20478 21.7

---4000 13652 19.2 4000 13652 16.7 4000 13652 14.4

---6000 20478 28.8 6000 20478 25.0 6000 20478 21.7

Catalog 720 / Page 17

Page 18

TSF & TSB Series floor units

ARI approved standard ratings - floor units

Table 14.

TSS, TPF, TSF & TSB units ➀

Standard coil water cooling capacity ratings

Table 15.

Low flow coil water cooling capacity ratings

TSS, TPF, TSF & TSB units ➀

Unit

Size Total Sensible

S02 5,600 4,400 1.2 1.4

S03 8,000 6,100 1.7 1.1

S04 10,900 8,800 2.3 1.6

S06 15,600 11,700 3.1 6.4

S08 20,100 15,900 4.1 6.5

S10 28,300 21,600 6.0 6.6

S12 30,100 24,600 6.4 11.3

NOTES:

➀ Rated in accordance with ARI Standard 440. Cooling capacities based on 80

➁ For cooling coil capacity ratings at conditions other than those listed refer to the SelectTools for Fan-coil computer selection program or consult

Cooling Capacity ➁

(BTUH) (BTUH)

temperature rise and high fan speed with standard 115/60/1 motor. See table 21 & 22 for air volume capacities.

your McQuay representative.

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Unit

Size Total Sensible

S02 6,800 5,200 1.4 2.7

S03 9,200 6,600 1.9 1.3

S04 13,500 10,200 2.7 3.1

S06 17,900 13,700 3.7 7.9

S08 29,800 19,800 6.1 12.9

S10 33,400 25,000 6.9 10.6

S12 35,600 25,900 7.7 13.2

o

F DB/67oF WB entering air, 45oF entering water, 10oF water

Cooling Capacity ➁

(BTUH) (BTUH)

Water Water

Flow P.D.

(GPM) (FT. W.C.)

Water heating coil ratings - floor units

Table 16.

TSS, TPF, TSF & TSB units ➀

Unit Capacity ➁ Water Water

Size (Sensible Flow P.D.

S02 10,600 1.2 1.4

S03 15,400 1.7 1.1

S04 21,900 2.3 1.6

S06 27,300 3.1 6.4

S08 35,300 4.1 6.5

S10 50,700 6.0 6.6

S12 55,700 6.4 11.3

NOTES:

➀ Water heating coils at 70o F DB entering air, 140o F entering water and high fan speed with standard 115/60/1motor. See table 21 & 22 for air

volume capacities.

➁ For heating coil capacity ratings at conditions other than those listed refer to the SelectTools for Fan-coil computer selection program or consult

your McQuay representative.

Standard coil water heating capacity ratings

Heating

BTUH) (GPM) (FT. W.C.)

Table 17.

Low flow coil water heating capacity ratings

TSS, TPF, TSF & TSB units ➀

Unit Capacity➁ Water Water

Size (Sensible Flow P.D.

S02 11,600 1.4 2.7

S03 17,100 1.9 1.3

S04 24,700 2.7 3.1

S06 31,000 3.7 7.9

S08 45,500 6.1 12.9

S10 55,100 6.9 10.6

S12 60,800 7.7 13.2

Heating

BTUH) (GPM) (FT. W.C.)

Page 18 / Catalog 720

Page 19

TSF & TSB Series floor units

Table 18. Water heating capacity ratings

TSS, TPF, TSF & TSB units ➀

Standard Coil Water Heating Capacity Ratings High Capacity Coil Water Heating Capacity Ratings

Unit Heating Heating

Size Capacity➁ Water Flow Water P.D. Capacity➁ Water Flow Water P.D.

(Sensible BTUH) (GPM) (FT.W.C.) (Sensible BTUH) (GPM) (FT.W.C.)

S02 17,005 1.16 1.25 18,189 1.24 2.07

S03 24,798 1.69 1.03 27,183 1.85 1.19

S04 35,720 2.44 1.7 39,421 2.69 2.93

S06 43,671 2.98 5.68 48,789 3.33 6.24

S08 55,233 3.77 5.3 69,596 4.75 7.82

S10 79,854 5.45 5.28 84,637 5.77 7.34

S12 88,384 6.03 9.69 94,191 6.43 9.12

NOTES:

➀ Water heating coils at 70o F DB entering air, 180o F entering water, 30o F water temperature drop, and high fan speed

with standard 115/60/1 motor. See table 21 & 22 for air volume capacities.

➁ For heating coil capacity ratings at conditions other than those listed refer to the SelectTools for Fan-coil computer

selection program or consult your McQuay representative.

Table 19. Separate 1-row coil water heating capacity

ratings TSS, TPF, TSF & TSB units ➀

Unit Capacity➁ Water Water

Size (Sensible Flow P.D.

S02 11,400 0.8 1.8

S03 15,100 1.0 3.4

S04 20,500 1.4 6.1

S06 28,400 1.9 12.6

S08 38,900 2.6 7.2

S10 48,500 3.3 1.9

S12 55,300 3.8 2.5

NOTES:

➀ Water heating coils at 70o F DB entering air, 180o F entering water, 30o F water temperature drop and high fan speed with standard 115/60/1

motor. See table 21 & 22 for air volume capacities.

➁ For heating coil capacity ratings at conditions other than those listed refer to the SelectTools for Fan-coil computer selection program or consult

your McQuay representative.

Heating

BTUH) (GPM) (FT. W.C.)

Catalog 720 / Page 19

Page 20

TSF & TSB Series floor units

Steam coil ratings - floor units

Table 20. Standard steam coil heating capacity

ratings TSS, TPF, TSF & TSB units ➀

Unit

Size

S02 13.2 55.2 54 13.7

S03 16.9 70.8 56 17.5

S04 23.8 99.5 56 17.5

S06 32.7 136.8 56 33.8

S08 54.1 226.0 62 55.9

S10 65.1 274.6 65 67.9

S12 74.8 312.9 59 77.4

Heating Air

Capacity➁

(Sensible Rise

BTUH) (oF)

EDR ➂

Temp.

Condensate

(LB/HR)

Air volume capacity data – floor units

Standard Coil

Table 21. Air volume versus external static pressure

TSS, TPF, TSF & TSB units (cfm)

Unit TSF Standard Unit Wc"

Size .00 .05 .10 .15 .20

S02 240 200 160 120 80

S03 280 240 200 150 100

S04 430 370 320 250 180

S06 560 490 410 330 260

S08 770 710 650 590 520

S10 1080 1020 970 920 870

S12 1250 1210 1170 1130 1100

NOTES:

➀ Steam coil capacity ratings based on 60

psig steam pressure and high fan speed with standard 115/60/1 motor.

➁ For steam coil capacity ratings at conditions other than those listed, use the

steam heating coil conversion factors found on page 21.

➂ Equivalent Direct Radiation.

o

F DB entering air temperature, 2

Air volume capacity data – floor units

High Capacity Coil

Table 22. Air volume versus external static pressure

TSS, TPF, TSF & TSB units (cfm)

Unit TSF HiCap Unit Wc"

Size .00 .05 .10 .15 .20

S02 230 180 150 110 60

S03 290 240 200 120 70

S04 480 410 360 300 220

S06 670 640 580 530 480

S08 700 640 580 520 450

S10 1070 1020 980 930 880

S12 1220 1190 1150 1110 1080

NOTES:

➀ Air volumes based on 115/60/1 electric service, standard unit options and dry coils.

➁ The SelectTools for Fan-coil computer selection program will not allow cooling coil face velocities below 90 ft./min. Some of the airflows found on

the chart are included for heating only or ventilating applications.

Motor data – floor units – Standard Coil

Table 23. Motor data – TSS, TPF, TSF & TSB units

Unit Size

Motor

Speed

High 0.60 82 1050 0.60 75 1100 0.90 105 1000 2.00 212 1050 1.90 190 850 3.10 328 1000 8.00 356 1270

Medium 0.40 41 845 0.42 48 950 0.60 70 830 1.70 83 800 1.50 169 790 1.65 180 840 3.40 235 940

Low 0.30 35 600 0.36 36 700 0.55 63 600 1.65 75 600 1.40 155 570 1.60 162 650 2.30 175 650

High 0.40 57 1050 0.40 78 1100 0.48 86 1000 0.50 120 1050 0.80 180 850 1.40 731 1000 3.00 330 1270

Medium 0.30 54 845 0.31 60 990 0.44 85 905 0.43 86 1005 0.60 160 800 0.65 175 800 2.25 235 1000

Low 0.20 53 600 0.29 58 890 0.42 82 725 0.39 80 845 0.55 150 700 0.60 150 650 1.63 165 800

S02 S03 S04 S06 S08 S10 S12

Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM

115/60/1 PSC Motor

265/60/1 PSC Motor

Page 20 / Catalog 720

Page 21

TSF & TSB Series floor units

Electric heat data – floor units

Table 24. Electric resistance heater capacities – TSS, TPF, TSF & TSB units

Unit

Size

S02

S03 1000 3413 8.3 1000 3413 4.8 750 2560 3.1 1000 3413 3.6

S04 2000 6826 16.6 2000 6826 4.8 1500 5120 6.3 2000 6826 7.2

S06 2000 6826 16.6 2000 6826 9.6 1500 5120 6.3 2000 6828 7.2

S08 ---4000 13652 19.2 3000 10239 12.5 4000 13652 14.4

S10

S12

*240V Heaters are derated 265V heaters.

Watts BTUH Amps Watts BTUH Amps Watts BTUH Amps Watts BTUH Amps

750 2560 6.3 750 2560 3.6 560 1911 2.3 750 2560 2.7

1000 3413 8.3 1000 3413 4.8 750 2560 3.1 1000 3413 3.6

1500 5120 12.5 1500 5120 7.2 1125 3840 4.7 1500 5120 5.4

750 2560 6.3 750 2560 3.6 560 1911 2.3 750 2560 2.7

1500 5120 12.5 1500 5120 7.2 1125 3840 4.7 1500 5120 5.4

2000 6826 16.6 2000 6826 9.6 1500 5120 6.3 2000 6826 7.2

1000 3413 8.3 1000 3413 4.8 750 2560 3.1 1000 3413 3.6

1500 5120 12.5 1500 5120 7.2 1125 3840 4.7 1500 5120 5.4

3000 10239 25.0 3000 10239 14.4 2250 7679 9.4 3000 10239 10.8

1000 3413 8.3 1000 3413 4.8 750 2560 3.1 1000 3413 3.6

1500 5120 12.5 1500 5120 7.2 1125 3840 4.7 1500 5120 5.4

3000 10239 25.0 3000 10239 14.4 2250 7679 9.4 3000 10239 10.8

120/60/1 208/60/1 240/60/1* 265/60/1

---3000 10239 14.4 2250 7679 9.4 3000 10239 10.8

---6000 20478 28.8 4500 15360 18.8 6000 20478 21.7

---3000 10239 14.4 2250 7679 9.4 3000 10239 10.8

---4000 13652 19.2 3000 10239 12.5 4000 13652 14.4

---6000 20478 28.8 4500 15360 18.8 6000 20478 21.7

---3000 10239 14.4 2250 7679 9.4 3000 10239 10.8

---4000 13652 19.2 3000 10239 12.5 4000 13652 14.4

---6000 20478 28.8 4500 15360 18.8 6000 20478 21.7

Single Stage Heaters – Electrical Service

Steam heating coil conversion factors

Table 25. For ratings at other than base conditions, multiple coil capacity by proper conversion factor

Steam

Pressure

0 212.0 970.3 1.34 1.27 1.21 1.15 1.08 1.02 0.96 0.90 0.83 0.77

2 218.5 966.0 1.38 1.31 1.25 1.19 1.13 1.06 1.00 0.94 0.87 .081

5 227.1 960.6 1.43 1.37 1.31 1.24 1.18 1.12 1.06 0.99 0.93 0.87

10 239.4 952.6 1.51 1.45 1.38 1.32 1.26 1.20 1.13 1.07 1.01 0.94

15 249.7 945.6 1.57 1.51 1.45 1.38 1.32 1.26 1.20 1.13 1.07 1.01

20 258.8 939.6 1.63 1.57 1.51 1.44 1.38 1.32 1.25 1.19 1.13 1.06

25 266.8 934.0 1.68 1.62 1.56 1.50 1.43 1.37 1.31 1.24 1.17 1.12

To determine the capacity at conditions other than 2 PSIG steam and 60oF entering air, multiply the rated capacity by the proper conversion factor.

Steam

Temp.

(SAT.)

Latent

Heat

0102030405060708090

Entering Air Temperature (oF)

Catalog 720 / Page 21

Page 22

Dimensional data – Type TSH Series

hideaway ceiling unit

TSH Unit Return Plenum

Size Filter Size

S03 207⁄8 X 97⁄8 X 1

S04 267⁄8 X 97⁄8 X 1

S06 35

S08 35

S10 437⁄8 X 97⁄8 X 1

S12 597⁄8 X 97⁄8 X 1

7

7

8 X

8 X

97⁄8 X 1

97⁄8 X 1

TSH Unit

Size Cooling Heating

S03 Thru S12

Coil Connection Size

5

⁄8 O.D. SW

LEFT HAND UNIT SHOWN

Hand of unit determined by cooling

connection when facing front of unit.

5

⁄8 O.D. SW

TOP VIEW

OPTIONAL PLENUM SIDE VIEW

(SIDE VIEW)

FRONT VIEW DRAIN CONN. DETAIL

(FRONT VIEW)

TSH Unit

Size A B C D E F G H J K L

S03 201⁄4 19 27 51⁄2 21⁄2 47⁄8 17⁄8 21 22 4 1

S04 26

S06 351⁄4 34 42 51⁄2 21⁄2 47⁄8 17⁄8 36 37 4 1

S08 351⁄4 34 42 51⁄2 21⁄2 47⁄8 17⁄8 36 37 4 1

S10 431⁄4 42 50 5

S12 591⁄4 58 68 61⁄2 31⁄2 57⁄8 27⁄8 60 61 5 2

1

⁄4 25 33 51⁄2 21⁄2 47⁄8 17⁄8 27 28 4 1

1⁄

2

ALL DIMENSIONS APPROXIMATE. CERTIFIED DRAWINGS AVAILABLE ON REQUEST.

Dimensions (inches)

21⁄2 47⁄8 17⁄8 44 45 4 1

Page 22 / Catalog 720

Page 23

Dimensional data – Type TSC Series

cabinet ceiling unit

Front View

Remote 3-Speed

fan switch with off

position

P/N 107112101

Back View

*Coil and drain connections

may not be in line with cabinet

knockouts.

Top View

Note: Caution must be exercised when

units are used with outside air as standard units are insulated on the leaving

air side only. Outside fresh air must be

tempered before entering the unit if freezing conditions are expected.

End View

Detail A

LEFT HAND UNIT SHOWN

Hand of unit determined by cooling coil

connection when facing front of unit.

(side view)

Bottom View

TSC

Unit Size A B D E F G H J K L

S03 43 37 611⁄

S04 43 37 611⁄

S06 52 46 63⁄

S08 52 46 63⁄

S10 78 72 611⁄

S12 78 72 611⁄

16

16

8

8

16

16

Dimensions (inches)

2911⁄

2911⁄

391⁄

391⁄

6411⁄

6411⁄

16

16

4

4

16

16

385⁄

385⁄

475⁄

475⁄

735⁄

735⁄

8

8

8

8

8

8

87⁄

87⁄

83⁄

83⁄

113⁄

113⁄

8

8

8

8

8

8

2411⁄

2411⁄

16

16

2

91⁄

2

91⁄

34 9 34 541⁄

34 9 34 541⁄

58 10 58 801⁄

58 10 58 801⁄

24 451⁄

24 451⁄

TSC

4

4

4

4

4

4

Filter Size

8

267⁄

97⁄

X

8

267⁄

97⁄

X

8

357⁄

97⁄

X

8

357⁄

97⁄

X

8

597⁄

97⁄

X

8

597⁄

97⁄

X

Catalog 720 / Page 23

8

1

X

8

1

X

8

1

X

8

1

X

8

1

X

8

1

X

Page 24

Dimensional data

Type TSF Series flat top cabinet floor unit

LEFT HAND UNIT SHOWN

Hand of unit determined by cooling coil

connection when facing front of unit.

Control Box

NOTE: Outside fresh air must be

tempered before entering the unit

if freezing conditions are expected.

*Dimensions may vary for units with

nonstandard valve packages.

TSF Unit Return Air

Size Filter Size (IN.)

S02 73⁄4 X 183⁄4 X 1⁄2

S03 73⁄4 X 243⁄4 X 1⁄2

S04 73⁄4 X 333⁄4 X 1⁄2

S06 73⁄4 X 433⁄4 X 1⁄2

S08 10 X 433⁄4 X 1⁄2

S10 10 X 553⁄4 X 1⁄2

S12 10 X 553⁄4 X 1⁄2

TSH Unit

Size Cooling Heating

S02 Thru S12

Unit

Size A B C D F G H J K M N P R S T U

TSF-S02 37 25 91⁄4 27⁄8 217⁄8 193⁄4 157⁄8 107⁄8 57⁄8 411⁄16 81⁄16 31⁄2 10 21⁄2 79⁄16 415⁄16

TSF-S03 43 25 91⁄4 27⁄8 277⁄8 193⁄4 157⁄8 107⁄8 57⁄8 411⁄16 81⁄16 31⁄2 10 21⁄2 79⁄16 415⁄16

TSF-S04 51 25 91⁄4 27⁄8 367⁄8 193⁄4 157⁄8 107⁄8 57⁄8 411⁄16 81⁄16 31⁄2 16 21⁄2 71⁄16 411⁄16

TSF-S06 61 25 91⁄4 27⁄8 467⁄8 193⁄4 157⁄8 107⁄8 57⁄8 411⁄16 81⁄16 31⁄2 16 21⁄2 71⁄16 411⁄16

TSF-S08 61 28 121⁄4 57⁄8 467⁄8 213⁄8 17 12 6 77⁄16 1013⁄16 31⁄2 16 3 71⁄16 411⁄16

TSF-S10 75 28 121⁄4 57⁄8 587⁄8 213⁄8 17 12 6 77⁄16 1013⁄16 31⁄2 16 3 81⁄16 57⁄16

TSF-S12 75 28 121⁄4 57⁄8 587⁄8 213⁄8 17 12 6 77⁄16 1013⁄16 31⁄2 16 3 81⁄16 57⁄16

Page 24 / Catalog 720

ALL DIMENSIONS APPROXIMATE. CERTIFIED DRAWINGS AVAILABLE ON REQUEST.

Unit Dimensions (inches)

Coil Connection Size

5

⁄8 O.D. SW

5

⁄8 O.D. SW

Page 25

Dimensional data

Type TSS Series slope top cabinet floor unit

SLOPE TOP

WITH METAL

DISCHARGE GRILLE

TSS sizes S04 thru S06 have

hi-impact plastic sides.

S08-S12 have metal sides.

Control Box

NOTE: Outside fresh air must be

tempered before entering the unit

if freezing conditions are expected.

*Dimensions may vary for units with

nonstandard valve packages.

TSS Unit Return Air

Size Filter Size (IN.)

S02 73⁄4 X 183⁄4 X 1⁄2

S03 73⁄4 X 243⁄4 X 1⁄2

S04 73⁄4 X 333⁄4 X 1⁄2

S06 73⁄4 X 433⁄4 X 1⁄2

S08 10 X 433⁄4 X 1⁄2

S10 10 X 553⁄4 X 1⁄2

S12 10 X 553⁄4 X 1⁄2

TSS Unit

Size Cooling Heating

S02 Thru S12

Unit

Size A B C D F G H J K M N P R S T U

TSS-S02 37 25 91⁄4 251⁄2 217⁄8 193⁄4 157⁄8 107⁄8 57⁄8 411⁄16 81⁄16 31⁄2 10 21⁄2 79⁄16 415⁄16

TSS-S03 43 25 91⁄4 251⁄2 277⁄8 193⁄4 157⁄8 107⁄8 57⁄8 411⁄16 81⁄16 31⁄2 10 21⁄2 79⁄16 415⁄16

TSS-S04 51 25 91⁄4 251⁄2 367⁄8 193⁄4 157⁄8 107⁄8 57⁄8 411⁄16 81⁄16 31⁄2 16 21⁄2 71⁄16 411⁄16

TSS-S06 61 25 91⁄4 251⁄2 467⁄8 193⁄4 157⁄8 107⁄8 57⁄8 411⁄16 81⁄16 31⁄2 16 21⁄2 71⁄16 411⁄16

TSS-S08 61 28 121⁄4 281⁄2 467⁄8 213⁄8 17 12 6 77⁄16 1013⁄16 31⁄2 16 3 71⁄16 411⁄16

TSS-S10 75 28 121⁄4 281⁄2 587⁄8 213⁄8 17 12 6 77⁄16 1013⁄16 31⁄2 16 3 81⁄16 57⁄16

TSS-S12 75 28 121⁄4 281⁄2 587⁄8 213⁄8 17 12 6 77⁄16 1013⁄16 31⁄2 16 3 81⁄16 57⁄16

ALL DIMENSIONS APPROXIMATE. CERTIFIED DRAWINGS AVAILABLE ON REQUEST.

Unit Dimensions (inches)

Coil Connection Size

5

⁄8 O.D. SW

5

⁄8 O.D. SW

Catalog 720 / Page 25

Page 26

Dimensional data Type TSB

Top View

Series basic floor unit

LEFT HAND UNIT SHOWN

Hand of unit determined by cooling coil

connection when facing front of unit.

D

Optional Front Panel Wall Plate

NOTE: Optional top duct discharge

unit shown. Front discharge units

are also available. Outside fresh air

must be tempered before entering

the unit if freezing conditions are

expected.

B

Control Box

G

C

D

15⁄16"

13

⁄16"

Q

Return Air Opening

5

⁄8"

H

J

K

Front Panel for

Top Discharge is

Optional Front Panel - Wall Plate

Optional Top Duct Discharge - E x D

A

E

T

Front View

3

5

⁄8" (S02 – S06)

3

5

⁄4" (S08 – S12)

1

2

1

⁄2" Filter - Removable Thru Return Air Opening

F

⁄8"

9

⁄16" x 2" Mounting Slots

(3 Each Side)

Back View

5

⁄8"

Optional Unit Mounted

Control Box

Standard Electrical

Junction Box

7*

Optional Back Fresh Air Intake

with Damper and Insect Screen (See Detail)

RV

U

*Dimensions may vary for units with

nonstandard valve packages.

TSB Unit Return Air

Size Filter Size (IN.)

S02 73⁄4 X 183⁄4 X 1⁄2

S03 73⁄4 X 243⁄4 X 1⁄2

S04 73⁄4 X 333⁄4 X 1⁄2

S06 73⁄4 X 433⁄4 X 1⁄2

S08 10 X 433⁄4 X 1⁄2

S10, S12 10 X 553⁄4 X 1⁄2

S10*, S12* (2) 10 X 271⁄4 X 1⁄2

*Filter dimensions on sizes S10 and S12 change when ordered with

a wall plate.

TSB Unit

Size Cooling Heating

S02 Thru S12

Unit

Size A B C D E F G H J K M N P Q R S T U V

TSB-S02 20

TSB-S03 265⁄8 257⁄16 93⁄4 41⁄8 25 217⁄8 193⁄4 157⁄8 1015⁄16 515⁄16 411⁄16 931⁄2 17⁄16 10 21⁄2 73⁄4 81⁄16 41⁄16 363⁄4

TSB-S04 355⁄8 257⁄16 93⁄4 41⁄8 34 367⁄8 193⁄4 157⁄8 1015⁄16 515⁄16 411⁄16 931⁄2 17⁄16 16 21⁄2 71⁄4 79⁄16 313⁄16 453⁄4

TSB-S06 455⁄8 257⁄16 93⁄4 41⁄8 44 467⁄8 193⁄4 157⁄8 1015⁄16 515⁄16 411⁄16 931⁄2 17⁄16 16 21⁄2 71⁄4 79⁄16 313⁄16 553⁄4

TSB-S08 455⁄8 283⁄16 121⁄2 51⁄2 44 467⁄8 213⁄8 17 12 6 77⁄16 113⁄4 31⁄2 116371⁄4 79⁄16 313⁄16 553⁄4

TSB-S10 575⁄8 283⁄16 121⁄2 51⁄2 56 587⁄8 213⁄8 17 12 6 77⁄16 113⁄4 31⁄2 116381⁄4 813⁄16 413⁄16 673⁄4

TSB-S12 575⁄8 283⁄16 121⁄2 51⁄2 56 587⁄8 213⁄8 17 12 6 77⁄16 113⁄4 31⁄2 116381⁄4 813⁄16 413⁄16 673⁄4

5

⁄8 257⁄16 93⁄4 41⁄8 19 217⁄8 193⁄4 157⁄8 1015⁄16 515⁄16 411⁄16 931⁄2 17⁄16 10 21⁄2 73⁄4 81⁄16 41⁄16 303⁄4

ALL DIMENSIONS APPROXIMATE. CERTIFIED DRAWINGS AVAILABLE ON REQUEST.

Unit Dimensions (inches)

Coil Connection Size

5

⁄8 O.D. SW

5

⁄8 O.D. SW

Overall Width

with Drain Pan

Page 27

Wall plate

Wall Plate With Front Discharge

WALL PLATE ARRANGEMENTS

Wall Mounted (Four Side Overlap)

TSB Unit

TSB

Unit Size A C Wall Opening

S02 40 28 253⁄4 X 37

S03 46 28 253⁄4 X 43

S04 55 28 253⁄4 X 52

S06 65 28 253⁄4 X 62

S08 65 31 283⁄4 X 62

S10 Thru

S12

Wall Plate Dimensions Recommended

77 31 28

3

⁄4 X 74

Fresh air wall intake box

For use with Types TSF & TSB units

STYLE

2 BRICK X 2 BRICK 163⁄4 43⁄4 33⁄4

4 BRICK X 2 BRICK 331⁄2 43⁄4 33⁄4

DIMENSIONS (INCHES)

ABC

NOTE:

1. All dimensions in inches.

2. Wall plates for TSB unit sizes S10 and S12 are provided in two sections

split vertically down the center.

ALL DIMENSIONS APPROXIMATE.

CERTIFIED DRAWINGS AVAILABLE ON REQUEST.

Page 28

Secondary drain pan

For use with Type TSF floor Unit and Type TSB Basic Unit

7/8" O.D copper sweat connection

7/8" O.D molded plastic connection suitable for 1/2"

NOTE: Drain pan can be rotated 90 or 180 degrees.

* On sizes S04, and S08 the drain pan is 1/2" smaller. The 8" dimensions become 71⁄2" and the 2" dimensions become 13⁄4".

ALL DIMENSIONS APPROXIMATE. CERTIFIED DRAWINGS AVAILABLE ON REQUEST.

nominal PVC socket elbow or coupling

Shipping weights

Table 28. Approximate shipping weights (lbs.) – TSH and TSC ceiling units

Unit Type

TSH LESS PLENUM 34 40 52 56 78 104

TSH RETURN AIR PLENUM 23 27 31 31 38 52

TSC 102 105 128 130 184 211

NOTE: Approximate shipping weights do not include valve packages, hot water coils, electric heaters or other

options.

S03 S04 S06 S08 S10 S12

Unit Size

Table 29. Approximate shipping weights (lbs.) – TSF and TSB floor units

Unit Type

TSS, TPF, TSF 77 87 105 123 160 182 220

TSB 58 62 80 101 131 151 187

NOTE: Approximate shipping weights do not include valve packages, hot water coils, electric heaters or other options.

S02 S03 S04 S06 S08 S10 S12

Unit Size

Page 29

Engineering guide specifications — ceiling units

Furnish and install where shown on the plans and specifications, McQuay (horizontal hideaway type) (ceiling exposed type)

(ceiling recessed type) ThinLine SeasonMaker fan-coil units. Types, sizes and performance shall be tabulated in the schedule.

Unit performance shall be substantiated by computer generated output data. Each unit shall be ARI certified and consist of

and comply with the following:

Casing and Cabinets

Ceiling hideaway type (TSH) — Basic unit shall consist of a base casing and optional return air plenum fabricated of heavy

gauge galvanized steel with four-sided

shall have a filter frame with one-inch return air duct collar that can be interchanged for back or bottom return air. Plenum shall

be fully insulated to prevent unit sweating and attenuate fan noise.

Ceiling (exposed) (recessed) cabinet type (TSC) — Unit shall consist of basic unit casing enclosed in an attractive heavygauge steel cabinet finished with an electrostatically applied, baked-on Antique Ivory paint. Cabinet shall have a stamped

horizontal discharge grille with return air through the (bottom grille) (rear duct opening) of the unit. Cabinet shall include a

bottom hinged access panel as standard.

Electrical Raceway — Unit shall have an electrical raceway providing a single location for all field wiring connections. All

factory mounted electrical components shall have wire leads terminating in the unit raceway.

Coils — Coils shall have aluminum fins with copper tubes mechanically expanded for a permanent bond. Coils are tested at

320 psig. Water coils shall have a manual air vent. Unit performance shall be as tabulated in the schedule.

Fan assembly — Fans shall be DWDI forward curved, centrifugal type. Fan housing shall be of two-piece construction with a

split fan housing that is easily removed, thus allowing complete service access to the fans and motors.

Motors — Units shall have (115/60/1) (265/60/1) three-speed, sleeve bearing, permanent split capacitor motors with oilers,

inherent thermal overload protection with automatic reset and resilient mounts.

3/4" duct collar for ease of connecting discharge ductwork. Optional return air plenum

Drain pan — Drain pan shall be constructed of 20-gauge galvanized steel, insulated with

Insulation — Ceiling model TSC shall be insulated with 1/2" multi-density glass fiber on the cabinet bottom panel and discharge

transition between coil and discharge opening. Hideaway TSH return air plenum shall be insulated with

fiber.

Filters — Filters shall be throwaway type.

1/4" multi-density closed cell insulation.

1/2" multi-density glass

Optional accessories

Electric heat — Units shall be provided with (120/60/1)(265/60/1) electric heat. Heaters shall be fully protected by a high-limit

thermal cut-out with automatic reset. All electric heat controls are to be unit mounted, wired and enclosed by the unit

manufacturer at the factory. All ceiling models shall have heating elements located on the entering air side of the cooling coil.

Valve packages — Valve packages shall consist of 2-or 3-way motorized valve with gate hand valve on supply and ball hand

valve on return piping, (P/T plugs), (strainer and flow control device). Two-way motorized valve packages shall have bypass

capillary tubes to provide minimal flow to enable automatic changeover aquastats, where required, to sense system water

temperature.

Secondary drain pan — Units with valve packages shall be provided with galvanized steel secondary drain pan to channel

valve package condensate into primary pan.

Speed Control — Units shall have a three-speed switch with integral on/off switch suitable for wall mounting which shall

provide high/medium/low fan speed control.

Page 30

Engineering guide specifications — floor units

Furnish and install where shown on the plans and specifications, McQuay (floor type) (basic type) ThinLine SeasonMaker

fan-coil units. Types, sizes and performance shall be tabulated in the schedule. Unit performance shall be substantiated by

computer generated output data. Each unit shall be ARI certified and consist of and comply with the following:

Casing and cabinets

Flat top floor type (TSF) — Cabinet shall be a vertical console type enclosure fabricated of heavy gauge steel and finished

with a electrostatically applied, baked-on Antique Ivory paint. Cabinet shall include a stamped metal discharge grille in the top

panel and full width electrical and piping end compartments. Units provided with mounted controls shall have a single access

door.

Tamper-proof floor type (TPF) — Cabinet shall be a vertical console type enclosure fabricated of heavy gauge steel and

finished with a electrostatically applied, baked-on Antique Ivory paint. Cabinet shall include a stamped metal discharge grille

in the top panel and full width electrical and piping end compartments. Units provided with mounted controls shall have a

single access door. Unit provides a 16 gauge front panel, tamper-proof screws and locking access doors.

Slope top floor type (TSS) (metal) — Cabinet shall be a vertical console type enclosure fabricated of heavy-gauge steel and

finished with an electrostatically applied, baked on Antique Ivory paint. Side panels of S02 thru S06 will be hi-impact plastic.

The discharge grille shall be made of stamped metal. Units provided with unit mounted controls shall have a single access door.

Basic type (TSB) — Basic unit shall consist of base casing fabricated of heavy-gauge galvanized steel with (top duct) (front

discharge) opening for installation in custom enclosure furnished by contractor.

Basic type with wall plates (TSB) — Basic unit shall consist of base casing fabricated of heavy-gauge galvanized steel with

(top duct) (front) discharge. Wall plates shall be fabricated of 18-gauge steel, finished with an electrostatically applied, bakedon Antique Ivory paint. Wall plates shall include stamped discharge grille, access doors and return air grille.

Electrical box — Unit shall have an electrical box providing a single location for all field wiring connections. All factory

mounted electrical components shall have wire leads terminating in the unit electrical box.

Coils — Coils shall have aluminum fins with copper tubes mechanically expanded for a permanent bond. Coils are tested at

320 psig. Water coils shall have a manual air vent. Coil performance shall be as tabulated in the schedule.

Fan assembly — Fans shall be DWDI forward curved, centrifugal type. Fan housing shall be fabricated of heavy-gauge

galvanized steel and of two-piece construction with a split fan housing that is easily removed, thus allowing complete service

access to the fans and motors.

Motors — Units shall have (115/60/1) (265/60/1) three-speed, sleeve bearing, permanent split capacitor motors with oilers,

inherent thermal overload protection with automatic reset and resilient mounts.

Speed control — TSB/TSF with metal grille: Units shall have a (unit)(wall) mounted three-speed switch with integral on/off

switch which shall provide high/medium/low fan speed control.

Drain pan — Primary drain pan shall be constructed of 20-guage galvanized steel and insulated with closed cell insulation.

Secondary drain pan shall be constructed of injection molded polystyrene and meet UL code 94V-2 for smoke and flame

spread. Secondary drain pan shall be equipped with a drain connection suitable to receive a

Insulation — Cabinet insulation shall be 1/2" multi-density glass fiber.

Filters — Filters shall be throwaway type.

1/2" PVC socket elbow or coupling.

Optional accessories

Electric heat — Units shall be provided with (120/60/1) (265/60/1) electric heat. Heaters shall be fully protected by a high-limit

thermal cut-out with automatic reset. All electric heat controls are to be unit mounted, wired and enclosed by the unit

manufacturer at the factory. Floor and basic models through 600 cfm shall have fully sheathed elements located on the

leaving air side of the cooling coil. Units 800 cfm and greater shall have open type heater elements located on the entering air

side of the cooling coil.

Valve packages — Valve packages shall consist of 2- or 3-way motorized valve with gate hand valve on supply and ball hand

valve on return piping, (P/T plugs), (strainer and flow control device). Two-way motorized valve packages shall have bypass

capillary tubes to provide minimal flow to enable automatic changeover aquastats, where required, to sense system water

temperature.

Fresh air kit — A manual fresh air intake damper shall be provided by the unit manufacturer for (factory) (field) installation. An

electric, damper motor shall be provided by the unit manufacturer for field installation.

Aluminum wall box — An aluminum wall box with two sets of louvers shall be provided by the unit manufacturer for field

installation into the outside wall of the building.

Page 31

Page 32

Warranty

All McQuay equipment is sold pursuant to its standard terms and conditions of sale, including Limited

Product Warranty. Consult your local McQuay Representative for warranty details. Refer to Form

933-43285Y. To find your local McQuay Representative, go to www.mcquay.com.

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.mcquay.com.

Products Manufactured in an ISO Certified Facility.

®

©2005 McQuay International (800) 432-1342 www.mcquay.com Catalog 720 (10/06)

Loading...

Loading...