Page 1

Page 2

TABLE OF CONTENTS

INTRODUCTION

General Description . . . . . . . . . . . . . . . . . . . . . . . . . ...3

Nomenclature . . . . . . . . . . . . . . . . ., . ., . . . . . . . . . ...3

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...3

INSTALLATION

Handling . ., ., . . . . . . . . . . . . . . ., . . . . . . . . . . . . . ...3

Moving The Unit, ., . .,,..,... . . . . . . . . . . . . . . . ...4

Location .,.....,........,.. ., . ., ., ., . . . . . . . ...4

Clearance Requirements ...,. . . . . . . . . . . . . . . . . ...4

Placing the Unit . ., ..,.,.... , . . . . . . . . . . . . . . . ...4

Vibration isolators,.,...,.,.. . . . . . . . . . . . . . . ...5.6

WATER PIPING

General . . . . . . . . . . . . . . . . . . . . . . ., . . . . . . . . . . . ...6

Evaporator Piping . ., ..,.,.... . .,.,......,....,.6

Evaporator Temperature Limits . ., . . . . . . . . . . . . . ...6

Flow Rate Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...7

Evaporator Pressure Drop Corrections . . . . . . . . . . ...7

Evaporator Pressure Drop Curve.... . ., . . . . . . . . ...7

CONDENSER WATER PIPING . . . . . . . . . . . . . . . . . . ...8

Condenser Temperature Limits . . . . . . . . . . . . . . . . ...8

Condenser Temperature Rise . . . . . . . . . . . . . . . . . ...8

Condenser Flow Rate Limits... . . . . . . . . . . . . . . . ...8

Condenser Water Arrangements . . . . . . . . . . . . . . . ...9

Condenser Pressure Drop Correction ., .,........,.9

Condenser Pressure Drop Curves . ., . . . . . . . . ...9. 10

TYPICAL PIPING DIAGRAMS., . . . . . . . . . . . . . . . . ...11

Water Quality . . . . . . . . . . . . . . . , . ., ., . ., . . . . . ...12

Condenser Water Thermostat .,, . . . . . . . . . . . . . ...12

Flow Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...12

Relief Valve Piping . . . . . . . . . . . . . . . . . . . . . . . . . ...13

DIMENSIONAL DATA . . . . . . . . . . . . . . . . . . . . .14.15.16

STARTUP&SHUTDOWN

Pre Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...45

Startup . . . . . . . . . . . . . . . . . . . . . . . . .,.,.....,.,.,45

Temporary Shutdown .,,.,... . . . . . . . . . . . . . . . ...45

Extended Shutdown .,,.,.... , . . . . . . . . . . . . . . ...46

Startup After Extended Shutdown ,, ., . . . . . . . . . ...46

SYSTEM MAINTENANCE

General ..,.,..,..,....,.,.. . . . . . . . . . . . . . . ...47

Control Center Service, .,..... . . . . . . . . . . . . . . ...47

Electrical Terminals.,....,.. ., ., . . . . . . . . . . . ...47

Compressor Oil Level, .,....,. . ., ., . . . . . . . . . ...47

Refrigerant Sightglass .,.,.... ., . . . . . . . . . . . . ...48

Lead-Lag . . . . . . . . . . . . . . . . . . . . . ., ., . . . . . . . . ...48

Crankcase Heaters .,, ..,..... . ., . ., ., . ., ..,...48

SYSTEM SERVICE

Filter-driers ., . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...49

Liquid Line Solenoid Valve.... , . . . . . . . . . . . . . . ...49

Thermostatic Expansion Valve, ...,.,.,. . .,.....,49

Evaporator, . . . . . . . . . . . . . . . . . .,,...,.,,..,.,.,50

Watercooled Condenser,..,.. ., ., ., . . . . . . . . ...50

IN-WARRANTY RETURN MATERIAL PROCEDURE

Compressor . ., .,, . . . . . . . . . . . . . . . . . . . . . . . . . ...50

Components Other Than Compressor . . . . . . . . . . ...51

APPENDIX

STANDARD CONTROLS:

Thermostat, . . . . . . . . . . . . . . . . . ., ..,.,.......,51

Oil Pressure Safety Control ., . ., . ., ., . ., ..,.,.51

Compressor Lockout ., . . . . . . . . . ., . . . . . . . . . ...52

High Pressure Control. .,...... . . . . . . . . . . . . ...52

Low Pressure Control .,.....,. . . . . . . . . . . . . ...52

Freezestat . . . . . . . . . . . . . . . . . . , ., . ., . . . . . . ...52

Compressor Motor Protector . . . . . . . . . . . . . . . ...53

PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . ...17.18

Compresor Locations . . . . . . . . . , . . . . . . . . . . . . . ...19

Contactor Designation . . . . . . . . . . . . . . . . . . . . . . ...19

Major Components . . . . . . . . . . . . . . . . . . . . . . . . . ...19

WIRING

Field Wiring, Power...,..,.. . . . . . . . . . . . . . . . ...20

Field Wiring, Control, . . . . . . . . . . . . . . . . . . . . . . . . ..2o

Interlock Wiring . . . . . . . . . . . . . . , . . . . . . . . . . ...20.21

Sequence of Operation . . . . . . . . ., . . . . . . . . ...22.23

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...24

Control Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...25

Electrical Legend . . . . . . . . . . . . . . . . . . . . . . . . . . ...26

Power Schematics . . . . . . . . . . . ,. ... . . . . . ..27—33

Control & Safety Schematics . . . . . . . . . . . . . . ...34.35

Thermostat Schematics . . . . . . . . . . . . . . . . . ..36—41

Electrical Schematic Drawing Decision Tables.42—44

Page2/lM377

OPTIONAL CONTROLS:

Part Winding Start, . . . . . . . . . . , . ., . ., ., ..,....53

Phase/VoltageMonitor., . . . . . . . . . . . . . . . . . . ...53

Alarm Bell . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . ...53

Low Source Water, . . . . . . . . . . , . . . . . . . . . . . . ...54

Hot Gas Bypass . . . . . . . . . . . . . . . . . . . . . . . . . ...54

CONTROLS, SETTINGS, & FUNCTIONS. ., . . . . . . ...55

TROUBLESHOOTING CHART,. . . . . . . . . . . . . . . . ...56

PRESSURE TEMPERATURE TABLE . . . . . . . . . . . ...57

—

Page 3

INTRODUCTION

GENERAL

McQuay Type THR Templifier heat pump water heaters are

designed for indoor installations. Each unit is completely

assembled and factory wired before evacuation, charging and

testing. Each unit consists of multiple accessible hermetic

compressors, replaceable tube dual circuit shell-and-tube

evaporator, water cooled condenser, and complete refrigerant

piping.

Liquid line components that are included are manual liquid

line shutoff valves, charging valves, filter-driers, liquid line

solenoid valves, sightglass/moisture indicators, and diaphragm element thermal expansion valves. Other features

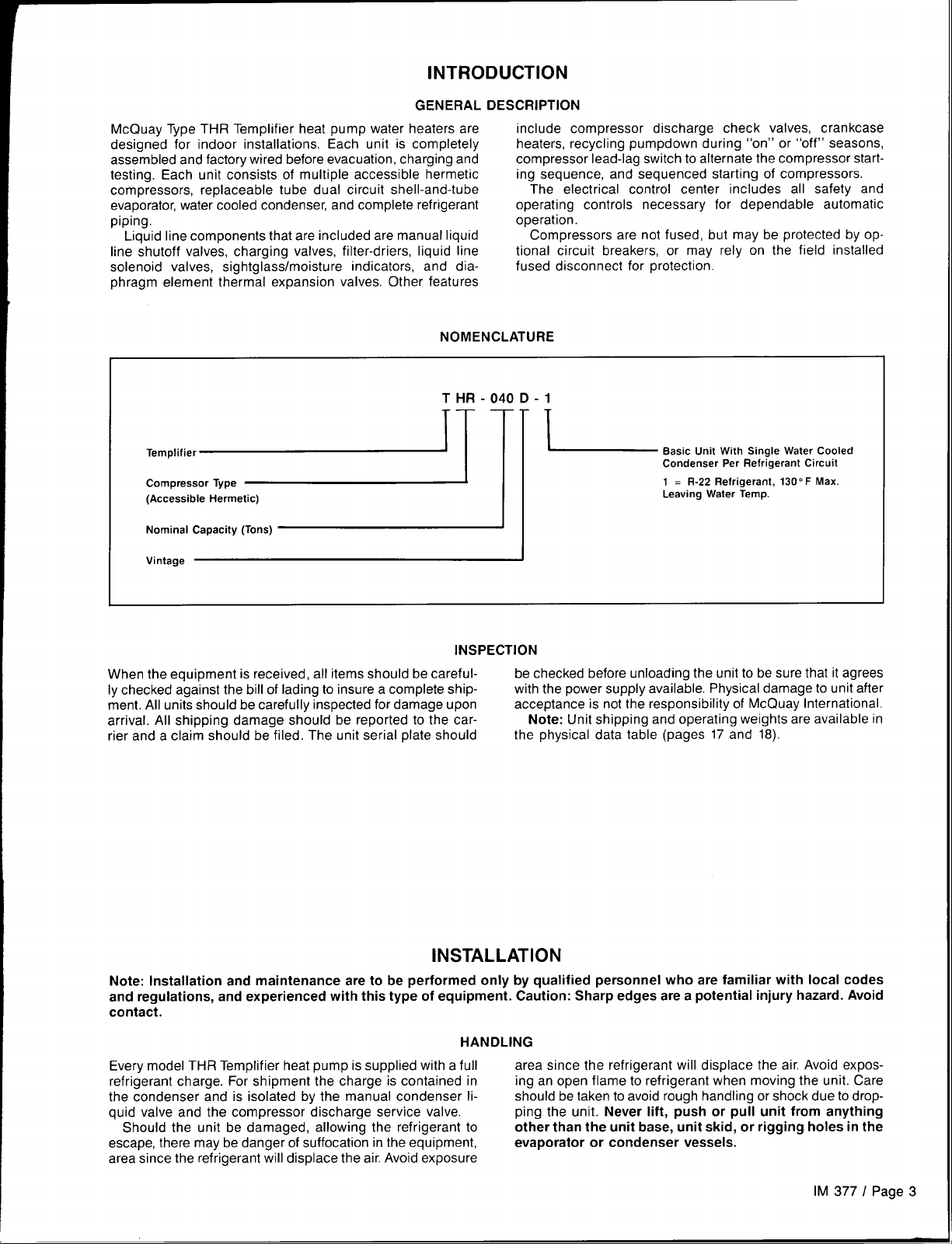

NOMENCLATURE

THR-040 D-1

D;::+J

(Accessible Hermetic)

Nominal Capacity (Tons)

DESCRIPTION

include compressor discharge check valves, crankcase

heaters, recycling pumpdown during “on” or “off” seasons,

compressor lead-lag switch to alternate the compressor starting sequence, and sequenced starting of compressors.

The electrical control center includes all safety and

operating controls necessary for dependable automatic

operation.

Compressors are not fused, but may be protected by op-

tional circuit breakers, or may rely on the field installed

fused disconnect for protection.

Basic Unit With Single Water Cooled

Condenser Per Refrigerant Circuit

L

‘1

1 = R-22 Refrigerant, 130” F Max.

Leaving Water Temp.

INSPECTION

When the equipment is received, all items should be careful- be checked before unloading the unit to be sure that it agrees

Iy checked against the bill of lading to insure a complete shipment. All units should be carefully inspected for damage upon

arrival. All shipping damage should be reported to the carrier and a claim should be filed. The unit serial plate should

with the power supply available. Physical damage to unit after

acceptance is not the responsibility of McQuay International.

Note: Unit shipping and operating weights are available in

the physical data table (pages 17 and 18).

INSTALLATION

Note: Installation and maintenance are to be performed only by qualified personnel who are familiar with local codes

and regulations, and experienced with this type of equipment. Caution: Sharp edges are a potential injury hazard. Avoid

contact.

HANDLING

Every model THR Templifier heat pump is supplied with a full area since the refrigerant will displace the air. Avoid exposrefrigerant charge. For shipment the charge is contained in ing an open flame to refrigerant when moving the unit. Care

the condenser and is isolated by the manual condenser li- should be taken to avoid rough handling or shock due to dropquid valve and the compressor discharge service valve. ping the unit.

Should the unit be damaged, allowing the refrigerant to other than the unit base, unit skid, or rigging holes in the

escape, there may be danger of suffocation in the equipment,

area since the refrigerant will displace the air. Avoid exposure

evaporator or condenser vessels.

Never lift, push or pull unit from anything

IM 377 I Page 3

Page 4

MOVING THE UNIT

The McQuay Templifier heat pump is mounted on heavy

wooden skids to protect the unit from accidental damage and

to permit easy handling and moving.

It is recommended that all moving and handling be performed with the skids under the unit when possible and that

the skids not be removed until the unit is in the final location.

When moving the unit, dollies or simple rollers can be

used under the skids.

Never put the weight of the unit against the control box.

In moving, always apply pressure to the base on skids only and not to the piping or shells, A long bar helps move the

unit easily. Avoid dropping the unit at the end of the roll.

If the unit must be hoisted, it is necessary to lift the unit

by attaching cables or chains at the lifting holes in the

evaporator tube sheets. Spreader bars must be used to protect the control cabinet and other areas of the chiller (see

Figure 1).

Do not attach slings to piping or equipment. Move unit in

the upright horizontal position at all times. Set unit down gently

when lowering from the trucks or rollers.

Note: On unit sizes 120 through 170D, ordered with the op-

tional acoustical enclosure, there will be extension brackets

attached to the evaporator tube sheets. These brackets will

be used for hoisting the unit and should be removed when

unit is in place.

Figure 1.

I

Unit is designed for indoor application and must be located

in an area where the surrounding ambient temperatures are

40F or above,

Because of the electrical control devices, the units should

not be exposed to the weather. A plastic cover over the control box is supplied as temporary ’protection during transfer.

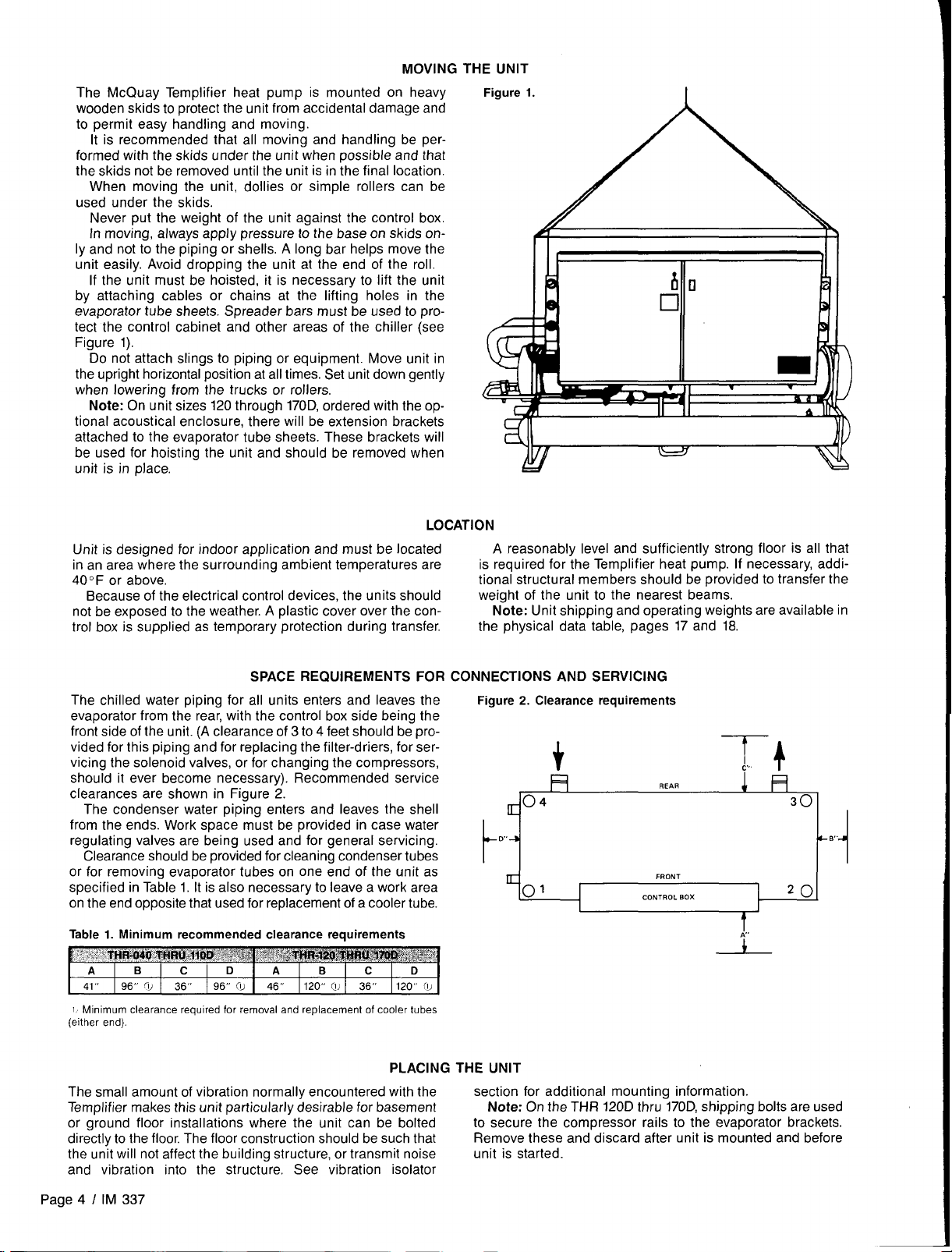

SPACE REQUIREMENTS FOR CONNECTIONS AND SERVICING

The chilled water piping for all units enters and leaves the

evaporator from the rear, with the control box side being the

front side of the unit. (A clearance of 3 to 4 feet should be provided for this piping and for replacing the filter-driers, for servicing the solenoid valves, or for changing the compressors,

should it ever become necessary). Recommended service

clearances are shown in Figure 2.

The condenser water piping enters and leaves the shell

from the ends. Work space must be provided in case water

regulating valves are being used and for general servicing.

Clearance should be provided for cleaning condenser tubes

or for removing evaporator tubes on one end of the unit as

specified in Table 1. It is also necessary to leave a work area

on the end opposite that used for replacement of a cooler tube.

Table 1. Minimum recommended clearance requirements

B

A

961<

41“

I Minimum clearance required for removal and replacement of cooler tubes

(either end).

flJ 36,,

c

I 96” 0! 46 “

D

A B

120” @ 36 “ 120“ (u

LOCATION

A reasonably level and sufficiently strong floor is all that

is required for the Templifier heat pump. If necessary, additional structural members should be provided to transfer the

weight of the unit to the nearest beams.

Note: Unit shippinq and operating weights are available in

the physical data’ table, pages 17 and I8

Figure 2. Clearance requirements

01

FRONT

cONTROL BOX

20

1

f

The small amount of vibration normally encountered with the

Templifier makes this unit particularly desirable for basement

or ground floor installations where the unit can be bolted

directly to the floor. The floor construction should be such that

the unit will not affect the building structure, or transmit noise

and vibration into the structure, See vibration isolator

Page 4 I IM 337

PLACING

THE UNIT

section for additional mountina information.

Note: On the THR 120D thru 170D, shipping bolts are used

to secure the compressor rails to the evaporator brackets.

Remove these and discard after unit is mounted and before

unit is started.

Page 5

VIBRATION ISOLATORS

Rubber-in-shear or spring isolators can be furnished and field

placed under each corner of the package, It is recommended that a rubber-in-shear pad be used as the minimum

isolation on all upper level installations or areas in which vibra-

tion transmission is a consideration.

Transfer the unit as indicated under “Moving the Unit.” In

all cases, set the unit in place and level with a spirit level.

When spring type isolators are required, install springs running under the main unit supports. Adjust spring type mountings so that upper housing clears lower housing by at least

1/4” and not more than 1/2”.A rubber anti-skid pad should be

used under isolators if hold-down bolts are not used.

Vibration eliminators in all water piping connected to the

Templifier are recommended to avoid straining the piping and

transmitting vibration and noise.

Table 2.

-----

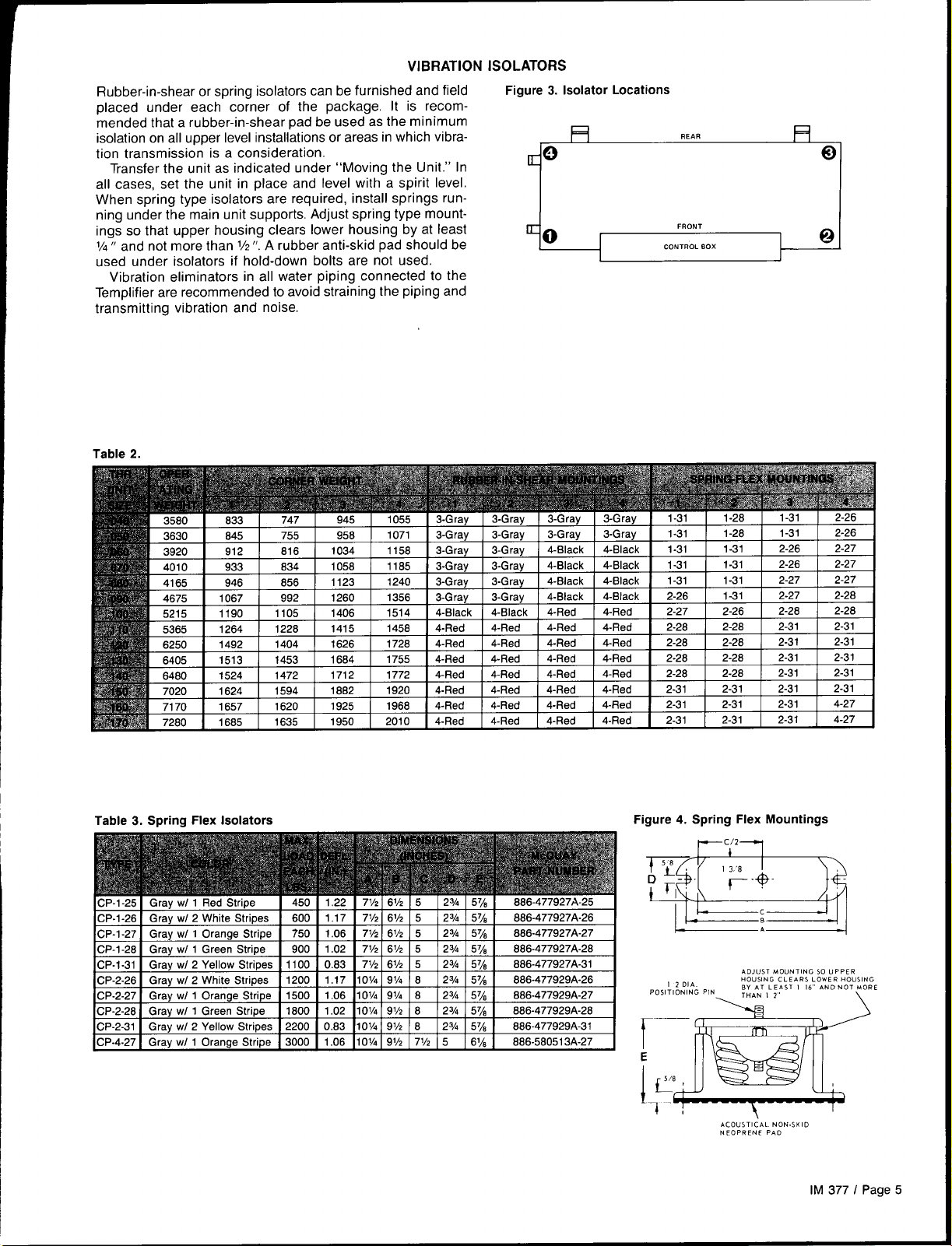

Figure 3. Isolator Locations

REAR

= o Q

K 0

FRONT

CONTROL BOX

!5

Q

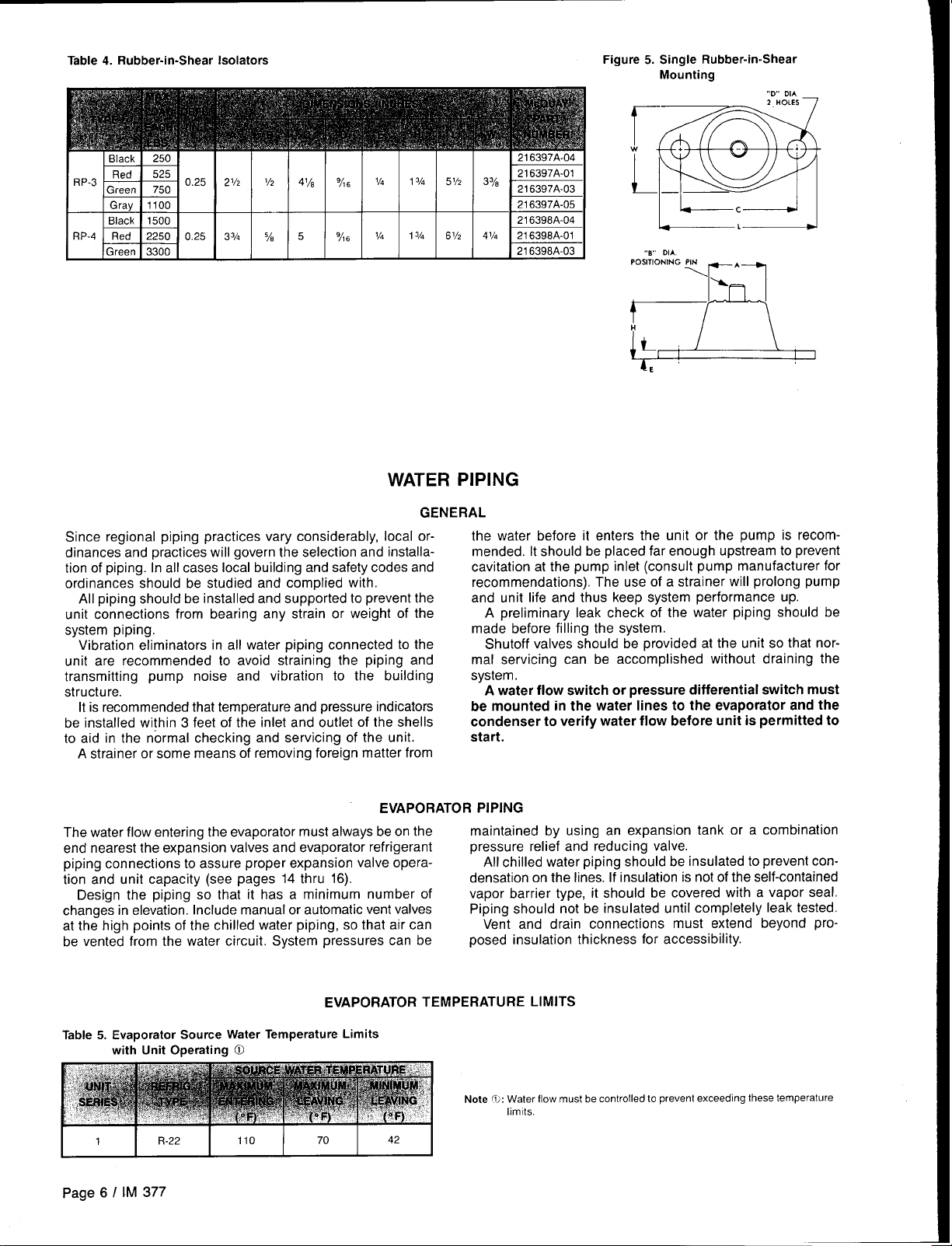

Table 3. Spring Flex Isolators

CP-1-25 Gray WI 1 Red Stripe

CP-1-26 Gray WI 2 White Stripes

CP-1-27 Gray WI 1 Orange Stripe

CP-1-28 Gray WI 1 Green Stripe

CP-1-31 Gray WI 2 Yellow Stripes 1100 0.63 7%

CP-2-26 Gray WI 2 White Stripes

CP-2-27 Gray WI 1 Orange Stripe 1500 1.06 1

CP-2-28 Gray WI 1 Green Stripe

CP-2-31 I Gray w/ 2 Yellow Stripes I 2200 I 0.83 IIOV. I 9Vz I 6

CP-4-27 I Gray w/ 1 orange Stripe I 3000 I 1.06 II ol/4 [ 9’/2 I 7’/2 I 5 ] 6% ] 886-58051 3A-27

450 1.22 71/z

600 1.17 ?kJ

750 1.06 71/2

900 1.02 i’~/2

1200 1,17 I ol/4

1800 1.02 1ol/4

6V2 5

6VZ 5

6VZ 5

6VZ 5

6V2 5

9Vi 6

ov4

9v4 8

91/2 8

23h 5y8 886-477927A-25

23h 57/s 886-477927A-26

23h 5778 886-477927A-27

23,4 57/8 886-477927A-28

23h 578 886-477927A-31

23h 5y~

23h 5778 866-477929A-27

23h 5778 886-477929A-28

] 23A I 578 I 866-477929A-31

888-477929A-26

Figure 4. Spring Flex Mountings

wc/2y

ADJUST MOUNTING S0 UPPER

HOUSING CLEARS LOWER HOUSING

BY AT LEAST I 16’ AND NOT MORE

THAN I 2

\

w

\

ACOUSTICAL NON. SKID

NEOPRENE PAD

1

I 2 DIA

POSITIONING PIN

r–

E

ivJ_

1

4!

\

I

IM 377 I Page 5

Page 6

Table 4. Rubber-in-Shear Isolators

Figure 5. Single Rubber-in-Shear

Mounting

-D DIA

,-0- DIA.

‘Os’’’O”’”’ w--A--

a

WATER PIPING

Since regional piping practices vary considerably, local ordinances and practices will govern the selection and installation of piping. In all cases local building and safety codes and

ordinances should be studied and complied with.

All piping should be installed and supported to prevent the

unit connections from bearing any strain or weight of the

system piping.

Vibration eliminators in all water piping connected to the

unit are recommended to avoid straining the piping and

transmitting pump noise and vibration to the building

structure.

It is recommended that temperature and pressure indicators

be installed within 3 feet of the inlet and outlet of the shells

to aid in the normal checking and servicing of the unit.

A strainer or some means of removing foreign matter from

EVAPORATOR PIPING

The water flow entering the evaporator must always be on the

end nearest the expansion valves and evaporator refrigerant

piping connections to assure proper expansion valve opera-

tion and unit capacity (see pages 14 thru 16).

Design the piping so that it has a minimum number of

changes in elevation. Include manual or automatic vent valves

at the high points of the chilled water piping, so that air can

be vented from the water circuit, System pressures can be

GENERAL

the water before it enters the unit or the pump is recom-

mended. It should be placed far enough upstream to prevent

cavitation at the pump inlet (consult pump manufacturer for

recommendations). The use of a strainer will prolong pump

and unit life and thus keep system performance up.

A preliminary leak check of the water piping should be

made before filling the system.

Shutoff valves should be provided at the unit so that normal servicing can be accomplished without draining the

system.

A water flow switch or pressure differential switch must

be mounted in the water lines to the evaporator and the

condenser to verify water flow before unit is permitted to

start.

maintained by using an expansion tank or a combination

pressure relief and reducing valve.

All chilled water piping should be insulated to prevent con-

densation on the lines. If insulation is not of the self-contained

vapor barrier type, it should be covered with a vapor seal.

Piping should not be insulated until completely leak tested.

Vent and drain connections must extend beyond pro-

posed insulation thickness

for accessibility.

Page 6 I IM 377

EVAPORATOR TEMPERATURE LIMITS

Page 7

EVAPORATOR FLOW RATE LIMITS–GPM*

Table 6.

THR

UNIT

SIZE

040D

0500

0600

0700

080D

0900

1000

1100

1200

t30D

1400

1500

1600

1700

‘ Water flows are basedon 10 FPS for max. flow and3 FPS formin, flow.

CHILLER WATER FLOW *

MAX.

230

244

316

312

352

352

370

460

403

463

463

439

579

579

MIN.

31

34

45

47

44

44

54

68

50

67

67

41

93

93

EVAPORATOR

MODEL

NUMBER

E-1008-2

E-1OO8-1

E-1208-3

E-1208-2

E-1208-1

E-1208-1

E-1408-2

E-1408-1

E-141 O-2

E-141 O-1

E-141 O-1

E-161 O-3

E-161 O-1

E-161 O-1

EVAPORATOR PRESSURE DROP CORRECTION

EVAPORATOR PRESSURE DROP CURVE

NOTE: Maximum allowable evaporator water pressure is 175 psig

WATER FLOW –GPM

lM3771Page7

Page 8

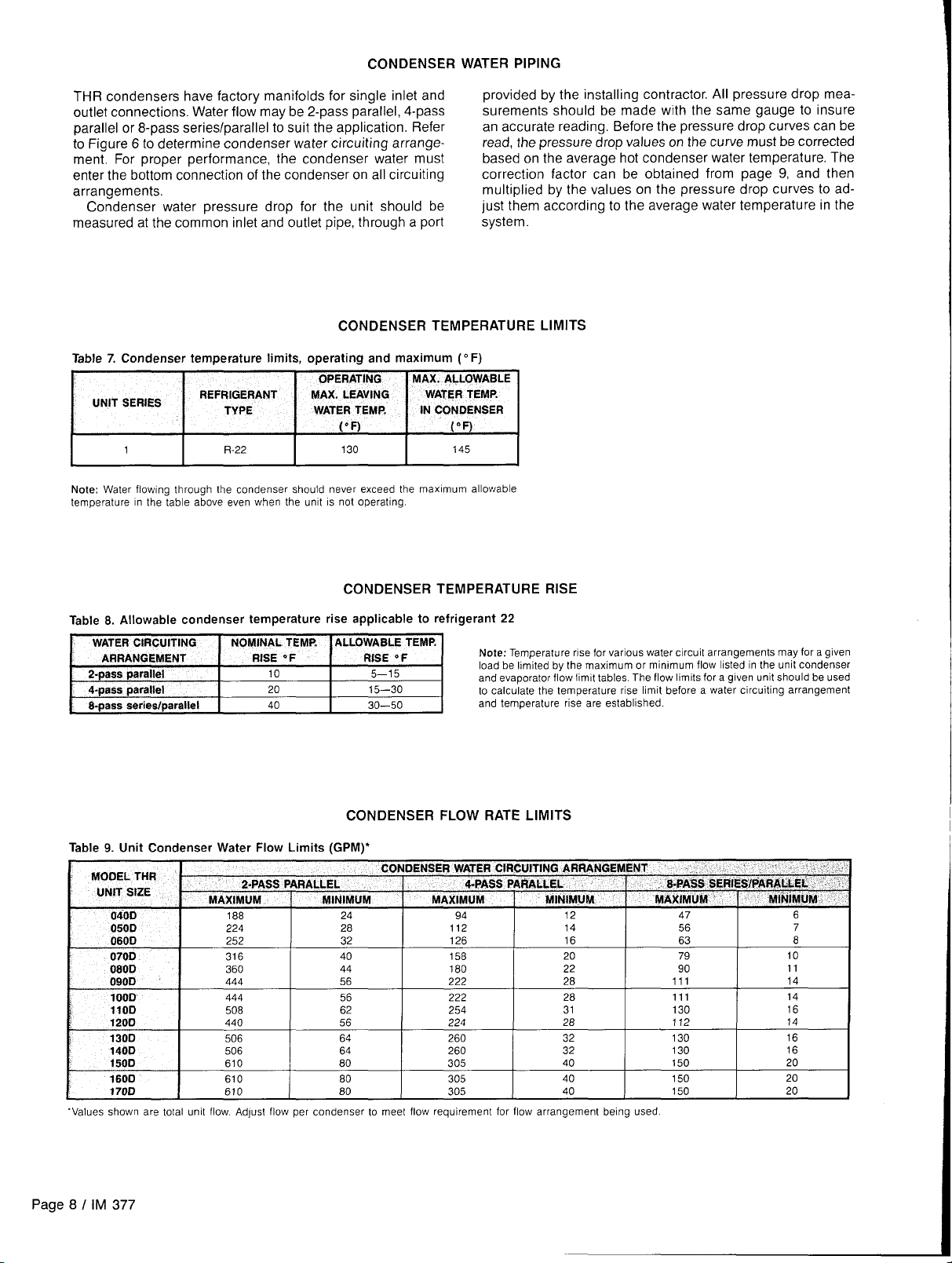

CONDENSER WATER PIPING

THR condensers have factory manifolds for single inlet and

outlet connections. Water flow may be 2-pass parallel, 4-pass

parallel or 8-pass series/parallel to suit the application, Refer

to Figure 6 to determine condenser water circuiting arrangement. For proper performance, the condenser water must

enter the bottom connection of the condenser on all circuiting

arrangements.

Condenser water pressure drop for the unit should be

measured at the common inlet and outlet pipe, through a port

provided by the installing contractor. All pressure drop measurements should be made with the same gauge to insure

an accurate reading, Before the pressure drop curves can be

read, the pressure drop values on the curve must be corrected

based on the average hot condenser water temperature. The

correction factor can be obtained from page 9, and then

multiplied by the values on the pressure drop curves to adjust them according to the average water temperature in the

system.

CONDENSER TEMPERATURE LIMITS

Table 7. Condenser temperature limits, operating and maximum ( 0F)

!,

UNIT SERIES

REFRIGERANT

TW%

OPERATING MAX. ALLOWABLE

MAX. LEAVING

WATERTEMP.

WATERTEMP, IN CONDENSER

(“F) (“F)

I

Note: Water flowlng through the condenser should never exceed the maximum allowable

temperature in the table above even when the urmt IS not operating.

1

R-22

I

I

130

I

145

I

CONDENSER TEMPERATURE RISE

Table 8. Allowable condenser temperature rise applicable to refrige

!rant 22

Note: Temperature rise for various water circuit arrangements may for a given

load be limited by the maximum or minimum flow hsted in the unit condenser

and evaporator flow Iimlt tables. The flow Iimlts for a given unit should be used

to calculate the temperature rise limit before a water circuiting arrangement

and temperature rise are established.

CONDENSER FLOW RATE LIMITS

Table 9. Unit Condenser Water Flow Limits (GPM)*

060D

070D

080D

090D

100D

I1OD 508

1200 440 56

130D 506 64 260 32

\

140D 506 64 260 32

150D 610 80

1600 610

170D 610

‘Values shown are total unit flow AdJust flow per condenser to meet flow requirement for flow arrangement being used

252 32 126 16 63 8

316

360

444 56

444

40

44

56

62

80

80

158

180 22 90

222

222

254

224

305

305

305

20 79 10

28 111 14

28 111 14

31 130

28 112 14

40 150

40 150 20

40 150

130 16

130 16

11

16

20

20

Page 8 I IM 377

Page 9

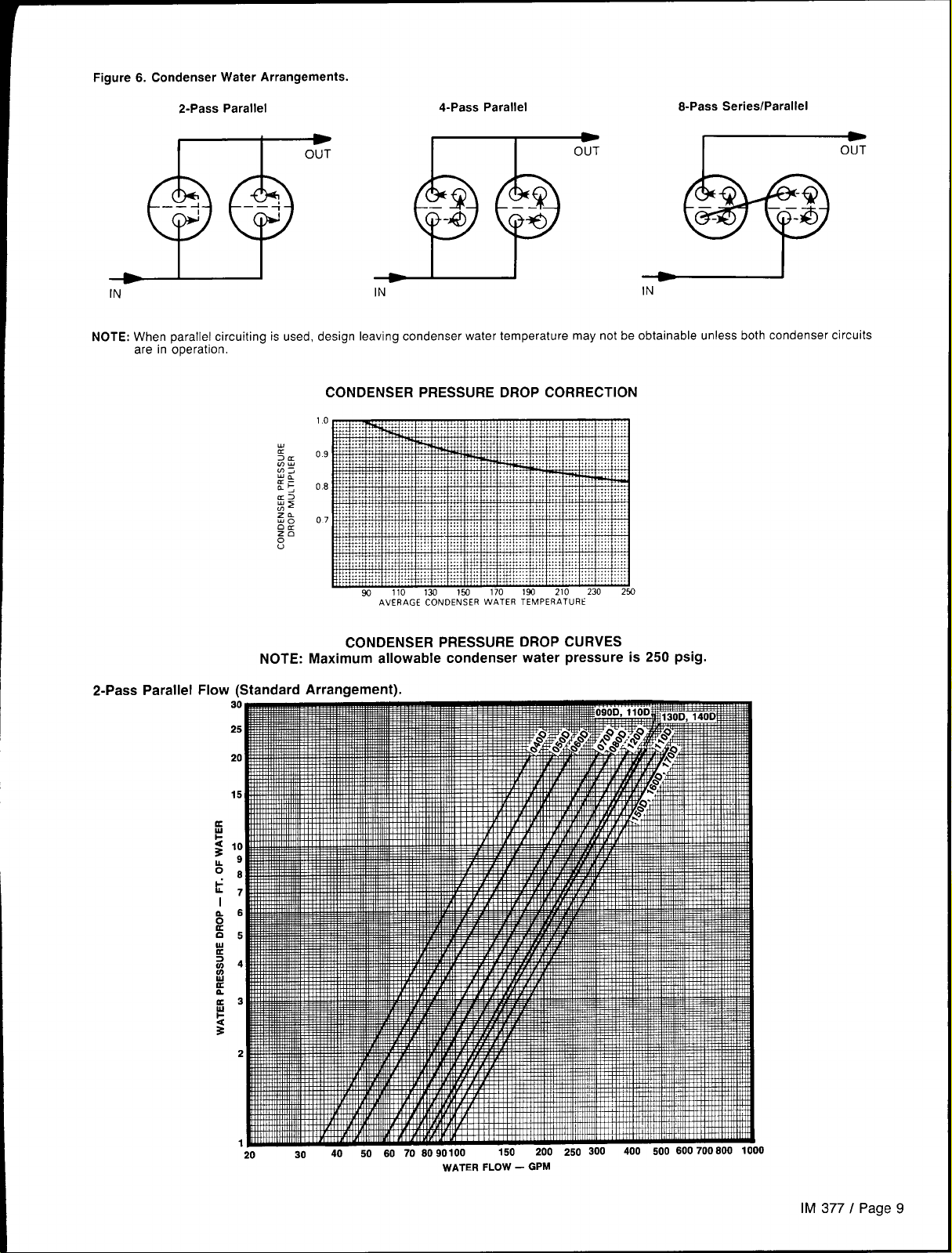

Figure 6. Condenser Water Arrangements.

2-Pass Parallel

m

OUT

IN

NOTE: When parallel circuiting is used, design leaving condenser water temperature may not be obtainable unless both condenser circuits

are in operation.

IN

4-Pass Parallel

w

OUT

8-Pass Series/Parallel

-

OUT

IN

CONDENSER PRESSURE DROP CORRECTION

10

#

09

2E

W;

:: O*

J

~$

m

z% o,

gg

0

u

w

CONDENSER PRESSURE DROP CURVES

NOTE: Maximum allowable condenser water pressure is 250 psig.

2-Pass Parallel Flow (Standard Arrangement).

k

t

n

o

K

n

u

a

:

m

u

K

n.

a

w

1-

S

110 130 lwl

AVERAGECONDENSERWATERTEMPERATURE

170 193 210

230 253

WATER FLOW – GPM

IM 3771 Page 9

Page 10

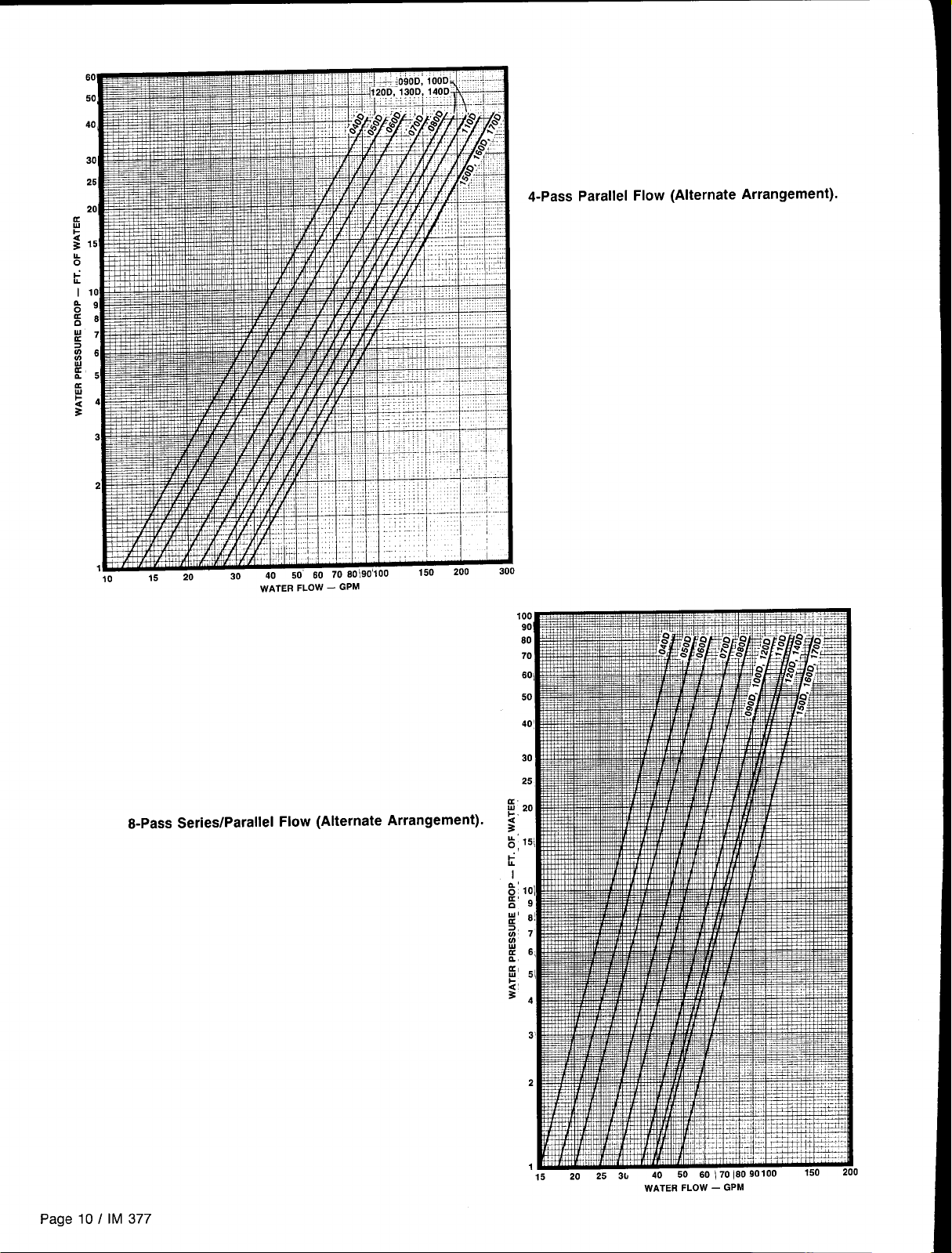

4-Pass Parallel Flow (Alternate Arrangement).

.

8-Pass Series/Parallel Flow (Alternate Arrangement).

WATERFLOW– GPM

Page 10 / IM 377

WATERFLOW— GPM

Page 11

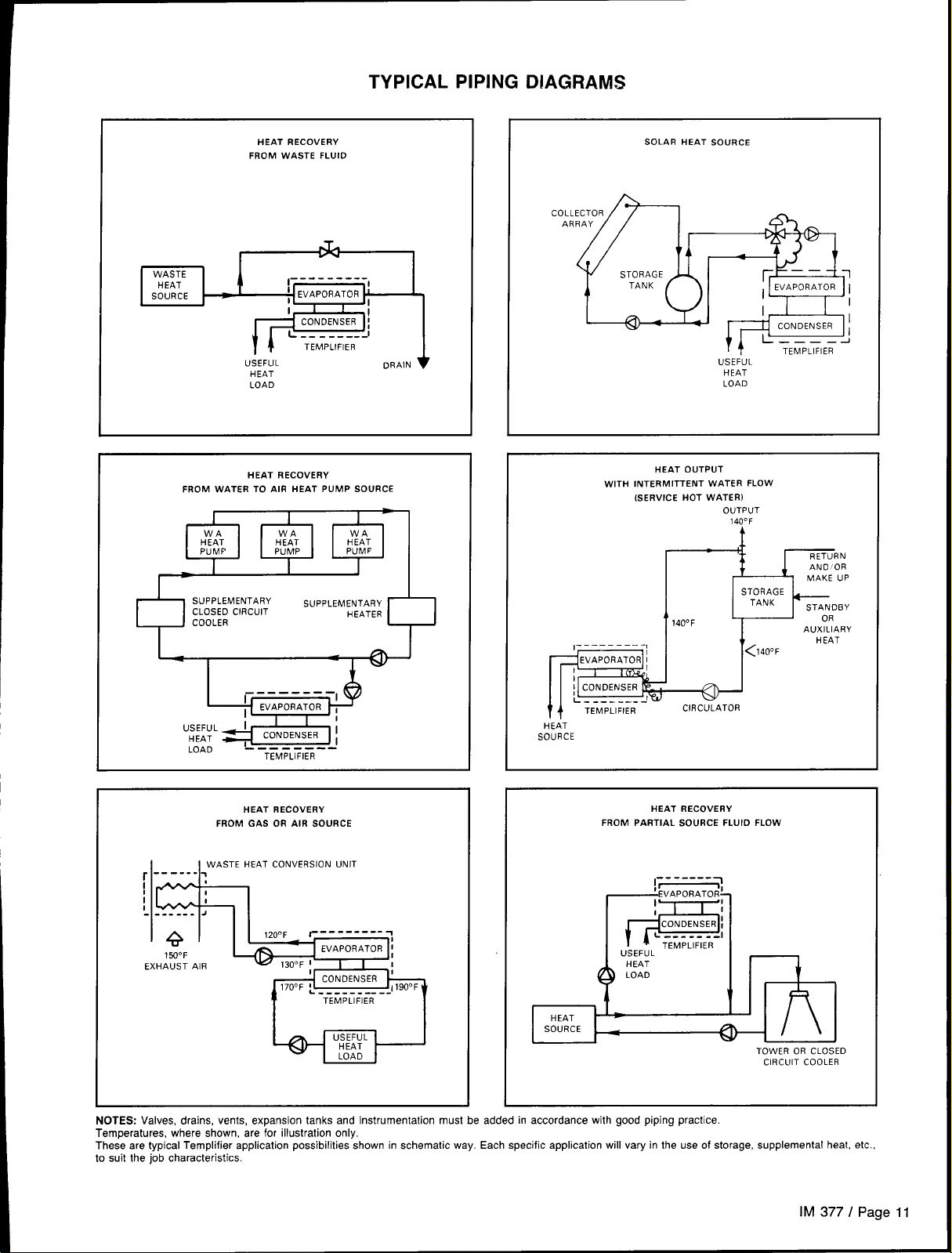

TYPICAL PIPING DIAGRAMS

HEAT RECOVERY

FROM WASTE FLUlO

I

WASTE

HEAT

SOURCE

up ORAIN1

HEAT

LOAD

FROM WATER TO AIR HEAT PUMP SOURCE

SUPPLEMENTARY

CLOSEOCIRCUIT

COOLER

HEAT RECOVERY

P

1=

--------

I

USEFUL

HEAT

LOAO

J

------ -.

TEMPLIFIER

L

-

SUPPLEMENTARY

HEATER

SOLAR HEAT SOURCE

COLLECTOR

ARRAY

I

TANK

i i

I_/

USEFUI

HEAT

LOAD

WITH INTERMITTENT WATER FLOW

HEAT OUTPUT

(SERVICEHOT WATERI

OUTPUT

140° F

TEMPLIFIER

t

STORAGE

TANK

<140”C

t- STANOBY

I

OR

AUXILIARY

I I

A

140°F

P

I

I 1(T

I

L--------J

f

b

HEAT

SOURCE

TEMPLIFIER

CIRCULATOR

L

,r HEAT

HEAT RECOVERY

FROM GAS OR AIR SOURCE

------ _

r

I

i

1

- ----.- .I

EXHAUSTAIR

NOTES: Valves, drains, vents, expansion tanks and instrumentation must be added in accordance with good piping practice.

Temperatures, where shown, are for illustration only.

These are typical Templifier application possibilities shown in schematic way. Each specific application will vary in the use of storage, supplemental heat, etc.,

to suit the job characteristics

WASTE HEATCONVERSIONUNIT

#

I

4

150°F

170”F *

L------ ----

-------. ~

TEMPLIFIER

FROM PARTIAL SOURCE FLUIO FLOW

HEAT RECOVERY

-------

!~~

—EVAPORATOR-

I

I

CONDENSER!

L

--..-.-

1+=

TEMPLIFIER

USEFUL

1

TOWEROR CLOSEO

CIRCUITCOOLER

IM 377 I Page 11

Page 12

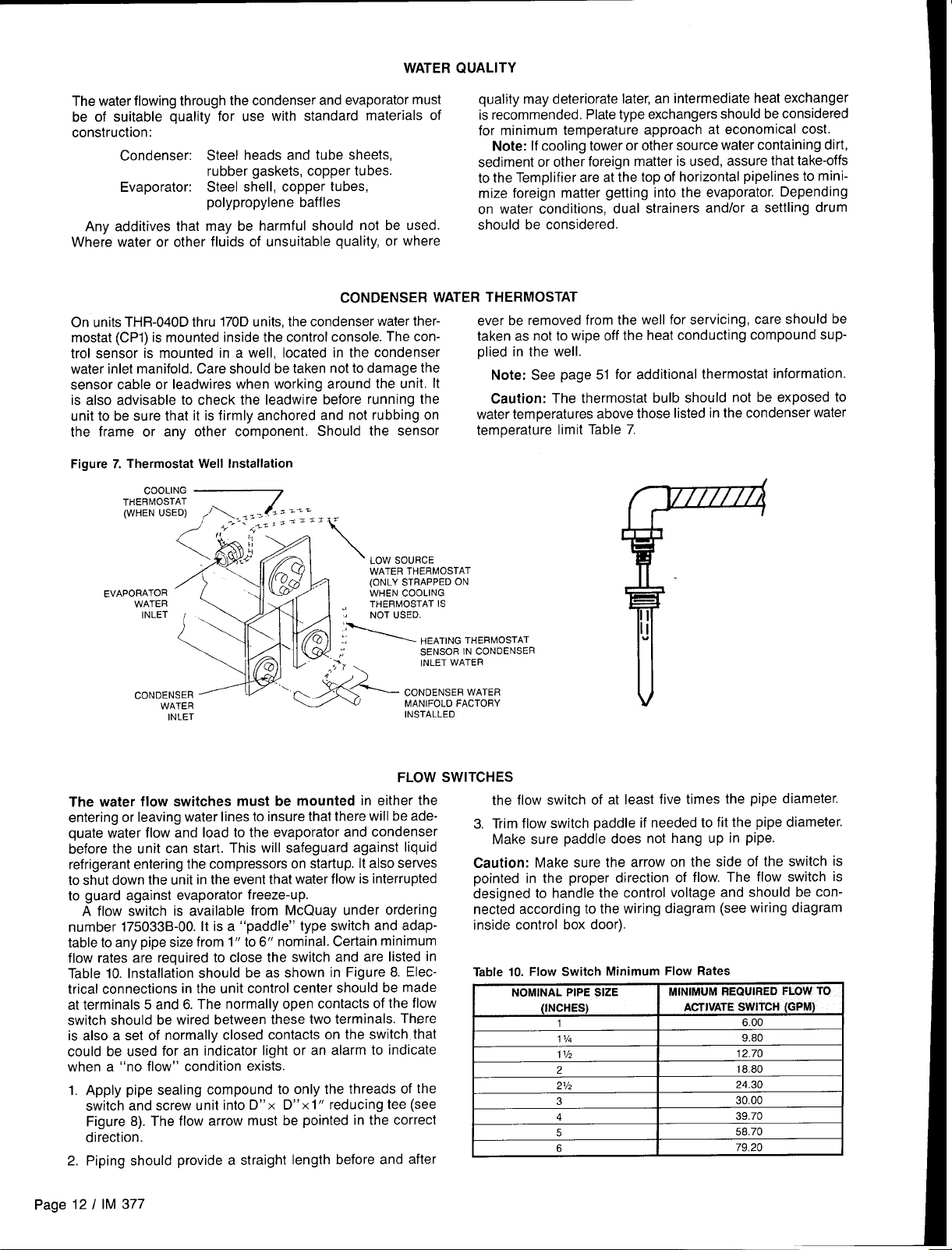

WATER QUALITY

The water flowing through the condenser and evaporator must

be of suitable quality for use with standard materials of

construction:

Condenser: Steel heads and tube sheets,

rubber gaskets, copper tubes.

Evaporator: Steel shell, copper tubes,

polypropylene baffles

Any additives that may be harmful should not be used.

quality may deteriorate later, an intermediate heat exchanger

is recommended, Plate type exchangers should be considered

for minimum temperature approach at economical cost.

Note: If cooling”tower or other source water containing dirt,

sediment or other foreign matter is used, assure that take-offs

to the Templifier are at the top of horizontal pipelines to minimize foreign matter getting into the evaporator. Depending

on water conditions, dual strainers and/or a settling drum

should be considered.

Where water or other fluids of unsuitable quality, or where

CONDENSER WATER THERMOSTAT

On units THR-040D thru 170D units, the condenser water thermostat (CP1) is mounted inside the control console. The con-

ever be removed from the well for servicing, care should be

taken as not to wipe off the heat conducting compound suptrol sensor is mounted in a well, located in the condenser plied in the well.

water inlet manifold. Care should be taken not to damage the

sensor cable or leadwires when working around the unit. It

is also advisable to check the leadwire before running the

unit to be sure that it is firmly anchored and not rubbing on

the frame or any other component, Should the sensor

Figure 7. Thermostat Well Installation

Note: See page 51 for additional thermostat information.

Caution: The thermostat bulb should not be exposed to

water temperatures above those listed in the condenser water

temperature limit Table 7.

EVA

INLET

The water flow switches must be mounted in either the

entering or leaving water lines to insure that there will

INSTALLED

FLOW SWITCHES

be adequate water flow and load to the evaporator and condenser

before the unit can start. This will safeguard against liquid

refrigerant entering the compressors on startup. It also serves

to shut down the unit in the event that water flow is interrupted

to guard against evaporator freeze-up.

A flow switch is available from McQuay under ordering

number 175033 B-00. It is a “paddle” type switch and adaptable to any pipe size from 1“ to 6“ nominal. Certain minimum

flow rates are required to close the switch and are listed in

Table 10. Installation should be as shown in Figure 8. Electrical connections in the unit control center should be made

at terminals 5 and 6. The normally open contacts of the flow

switch should be wired between these two terminals. There

is also a set of normally closed contacts on the switch that

could be used for an indicator light or an alarm to indicate

when a “no flow” condition exists.

1. Apply pipe sealing compound to only the threads of the

switch and screw unit into D“x D“x1” reducing tee (see

Figure 8). The flow arrow must be pointed in the correct

direction.

2. Piping should provide a straight length before and after

R

the flow switch of at least five times the pipe diameter.

3. Trim flow switch paddle if needed to fit the pipe diameter.

Make sure paddle does not hang up in pipe.

Caution: Make sure the arrow on the side of the switch is

pointed in the proper direction of flow.

The flow switch is

designed to handle the control voltage and should be connected according to the wiring diagram (see wiring diagram

inside control box door).

Table 10. Flow Switch Minimum Flow Rates

NOMINAL PIPE SIZE MINIMUM REQUIRED FLOW TO

(INCHES) ACTIVATESWITCH (GPM)

1 6.00

11A

I 1/2

2 18.80

21/2

3

A

5

6

I

9.80

12.70

24.30

30.00

39.7C

-. .

58.70

79,20

Page 12 I IM 377

Page 13

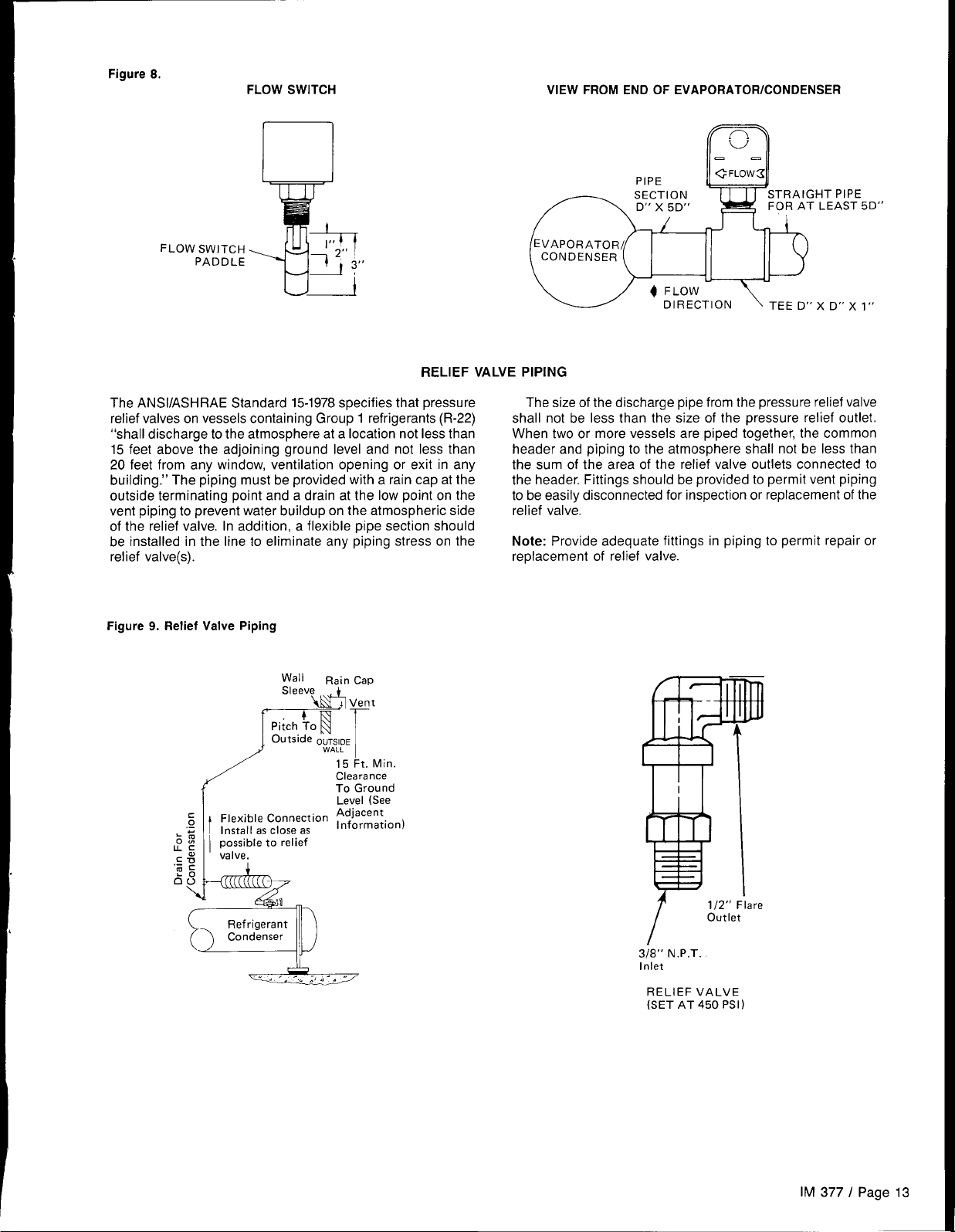

Figure 8.

FLOW SWITCH

PADDLE

FLOW SWITCH

*

1“2,,

VIEW FROM END OF EVAPORATOR/CONDENSER

--

m

PIPE

-EF;?’ )

~ FLOW3

w

STRAIGHT PIPE

FOR AT LEAST 5D”

Y

The ANSI/ASHRAE Standard 15-1978 specifies that pressure

relief valves on vessels containing Group 1 refrigerants (R-22)

“shall discharge to the atmosphere at a location not less than

15 feet above the adjoining ground level and not less than

20 feet from any window, ventilation opening or exit in any

building.” The piping must be provided with a rain cap at the

outside terminating point and a drain at the low point on the

vent piping to prevent water buildup on the atmospheric side

of the relief valve. In addition, a flexible pipe section should

be installed in the line to eliminate any piping stress on the

relief valve(s).

Figure 9. Relief Valve Piping

rl

f“’”

I

‘EI %%’:,w%’on

I ;~;~ble to relief

~:

c:

‘;

c

66

3“

Wall

Rain Cap

“eeve&Vent

Pitch !O

Outside OUTSIDE

[r

WALL

15 Ft. Min.

Clearance

To Ground

Level (See

Adjacent

Information)

RELIEF VALVE PIPING

The size of the discharge pipe from the pressure relief valve

shall not be less than the size of the pressure relief outlet.

When two or more vessels are piped together, the common

header and piping to the atmosphere shall not be less than

the sum of the area of the relief valve outlets connected to

the header. Fittings should be provided to permit vent piping

to be easily disconnected for inspection or replacement of the

relief valve.

Note: Provide adequate fittings in piping to permit repair or

replacement of relief valve.

Refrigerant

Condenser

[1

/

3/8” N.P.T

Inlet

RELIEF VALVE

(SET AT 450 PSI)

Outlet

IM 377 / Page 13

Page 14

Figure 10. THR-040D thru 11 OD, 2-pass parallel.

‘i- I ‘-w:’”’

29 ~

DIMENSIONAL DATA

— L—

I %4 MOUI{TIIIG HOLES -1 k7vz

7,,8 DIA

b IEVLP03LTOR

w,i TER !PILET)

~ fl:~CTATOR

f

. . .

—90 7/8

– POWER

I 1

k“

A [EVAPORATOR

4

--F

wIRING

CONNECTION

I?; OUIRED

FOR TUBE

REMO$IAL

EITHER

END

!

u

I

I

WATER OUTLET)

de

h

Table 11. THR-040D thru 11 OD, 2-pass parallel.

THR

MODEL

N&

O@

0500

060D

070D

0s00

OSOD

100D

11OD

Ficrure 11. THR-120D thru 170D, 2-pass parallel.

Recommended

t-36”–

lFOr ‘“W’””’

“D” Evaporator _

Water Corm

MAX. OVERALL

DIMENSIONS

L

125% 34

125%

125?4 34

125% 34

125% 34

127

127

127

— 34” ~46°

\

w

34

34 65?4

34

34

EVAP. WATER CONN.

A

H

621/4 23h

621/4

633~

633A

633A

661/4

661/4

IClearance” ‘

—

23A

31/2

31/2

31/2

31/2

51/2

51/2

H

(VIcTAULtC)

c

23%

23~8

24V8

24T/o

24VB

261/2

271~

271~

1] Door SwIna

e

r

‘f

P“ Victaul,c

Top Outlet

Bottom Inlet

---E

CONDENSER WATER

CONNECTIONS (VICTAULlc) ~

D

4

4

E “F

65/8

65A

65/8

5

65/8

5

6%

5

71/2

5

71/2

6

71/2

6

Q&31fl,.--j

\

11~*

11~8

lly~

llye

lly*

131A

131/s

13%

x-Ae

J

Q

11~/2

17%

111/2

171h

I I 1/2

171~

111/2

171/E

I I 1/2

171/E

161/4

12y8

161/4

12y8

161/4

123/8

~ Ind(cator L,ghts

/

. . . . . . . . .

~ u:

P

283/3 561/k

3

28% 58%

3

28% 59% 43

3

26~8 59% 43

3

28% 59% 43

3

293A 61 1/>

4

29% 62%

4

29% 62%

4

1517A ~’’””l

D

Power Wlrlng

ConnectIons

CENTER, OFWWWTY

‘

“x

4278 23

42~8 23

431/2

4378 28

433~

y ‘ “z

251/3

251A

25%

27V8 13

28

i

\

13

13

123A

123~

123A

I 25h

125/8

Requ,red For

ube Removal

E,ther End

I

I

t

L..

27A -

Tabie 12. THR-120D thru 170D, 2-pass parallel.

34 77

34

34

34 77

77

77

160D

160D

170D

Page 14 I IM 377

1517*

1517~

151y~

151T/~

EVAP. WATER CONN.

3131A

51/2

51/2

51/2

51/2

3131/4

3131/4

301/4

6

6

6

6

Evaporator

‘AL

Water Inlet

1

I

CONDENSER WATER

131/Is

77A 6

131/16

7~16

13~h6

7~16

131/Is

7YIS

109A6

109/16

10%6

10%6

@

167/,s 4

167/,6 4

167/,6 4

167/,,3 4

~ A fi::~:;e,

163/4

l-/-

CENTER OF

@liWITY .’

,

P x y z

293~

293A

293~

293A

561/3

56%

561/2

561/4

32V8

32%

331/4

337/2

131/2

131/2

13ye

13y8

Page 15

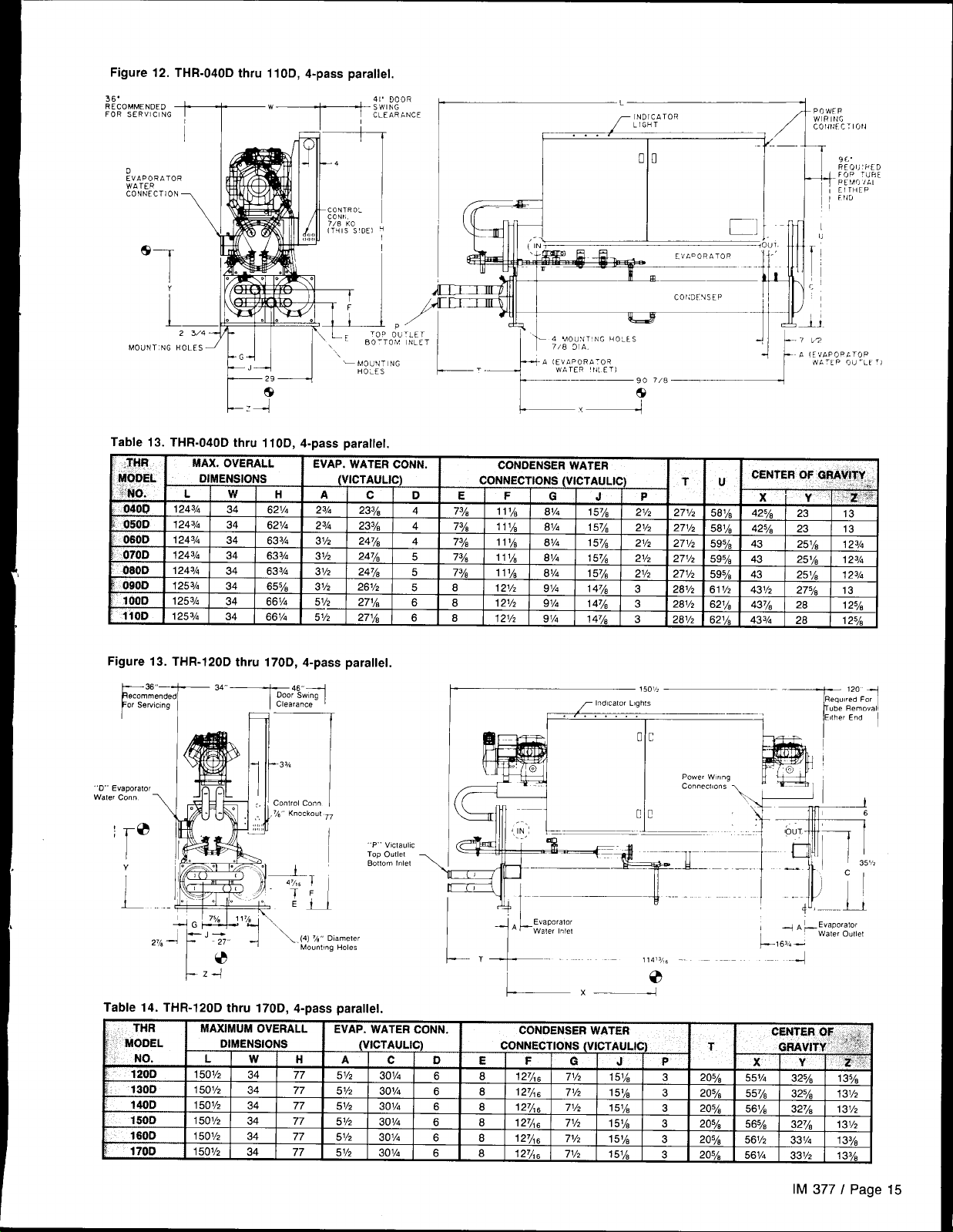

Figure 12. THR-040D thru 110D, 4-paas parallel.

36RECOMMENDED

FOR SERVICING

D

EVAPORATOR

WATER

CONNECTION

1

\

SI 1111/ II (iTls”s’DE1

I

&3’1

L–

1.

-1

2 3/4 -

MAX. OVERALL

DIMENSIONS

L

124% I 34

124% I 34

124% ] 34

124%4

124% 34

125% 34

125% 34

125% 34

MO UN T:NG HOLES

Table 13. THR-040D thru 110D, 4-pass parallel.

,THR

k

. . .

T- l\L

29+

r

?49

w

34

H

621A

621/4

I

633A 31/2

&j3~

633A

65%

661/4

661/4 51/2

F

II

E

BOTTOM

‘.

...-

EVAP. WATER CONN.

(WCTAULIC)

A

23A

23~

31/2

31/2

31/2

51/2

c D

23Y8 4

23%

24~B

24~a

24Y8

261/2

271~

271~

TO. Ou

P

‘LET

INLET

4 7%

4

5 72/~

5

5 8

6

6 8

I

irD=r

1

E F

73/4

I

73/3

778 11~~

8

. . .

nn

=lnrz

IIL‘i%

r

CONDENSER WATER

CONNECTIONS (VICTAULIC)

111/s

111A

111/s

111A

I 21/2 gl~

121/2

121/2 914

ka

— 4 UOUNT’NG HOLLS J~

7/8 31A

1-1

r---

—Y<e

G

81/4

61A

61/4

al~

81/4

91/4

/

—90 7/8

J

1578

157/,

157/8

157/8

157/8

1478 3

14y8 3

14T/~ 3

I

EVLDORb TOP 4-’

CO I:DF!SEP

I I

P

21/2

271/2

21/2

271/2

21/2

271/2

21/2 271/2

21/2

271/,

281/2

281/2

281/2

-/

T-l n r

LJ[. ”-

<oUT.

,1

--ill

--/

t-

CENTER OF

y

2514

251k

251~

27Ye 13

26

581~

42S~ 23

581~

425~ 23

59y* 43

595A 43

59y* 43

61 1/2 431/2

621A

437/, 28

433A

621A

x

-P OWFI?

WIRING

c01it4Fc Tlotl

1)

c’

b7

GRAV!W.

!3

,..’;J;:F

13

13

lz3~

123A

123~

123/8

125h

1

,’::

Figure 13. THR-120Dthru 170 D,4-passparalleI.

— 46,,

Door SW,ng

i

Clearance

D,, Evaporamr

walercm”

:@

T

Y

I

,

Control Con.

% Knockout ,7

I

I

I

L

lanleter

Holes

l-z+

Table 14. THR-120D thru 170D, 4-pass parallel,

THR

>

MODEL

NO.

1201J 15u12

1300

!

140D

D

wor

160D

170D

MAXIMUM OVERALL

I

DIMENSIONS

L w H A c o

# .. -.,.

150Yz I

!

1501/2]~

1

1501/z I 34

I

i501/z I

I

1501/2 34

34

!

I

34

I

34

34

EVAP. WATER CONN.

1

I

51/2

77

I

51/2 3131,4

77

51/2

77

51/2

77

51/2 301~

77

I

5 1/,

77

----- ,.w

P Vlcla”l,c

ToDOu!lel Bottom Inlet

(VICTAULIC)

30 1/4

I

3r31A

3(31/4

q(l

1/”

I

150%

Ind,cator L,ghls

. . . . . .

I

\

I +1 4“-—.-~

I- T+... __

1

‘AL

Evaporator

Wz!er Inlet

11413/,, –-

0

CONDENSER WATER

CONNECTIONS (WCTAULIC

F F n .1

1 I !

127A6

8

I

8 12fi6

127A6

8

8 127/4~

8 127/, ~

8I127/,6

71/2

151/& I

71/2

151/s

71/2

151~

71/2

151A

77/2

151/s

71/2

151/s

I

I

I I

$ 1

I I

h!:.m

3

203/,

3

205A

3 203/~

3

203/8

!

3

2os~

1

557/*

561A 32VB

56~B

561/2

I

561/4 331/2

1

I

I R

1

I

m

6

I

6

6

6

6

!

I

–~ 120 -

Req., red For

“be Remov:

.p.aporatm

~

--4

325h

32V8

331~

Erlher End

waler

I

1

131/2

131/2

133h

133/4

I I

(

k16,4-–

CENTER OF ..+ “]

35,%

outlet

31/2

I

I

I

IM 377 I Page 15

Page 16

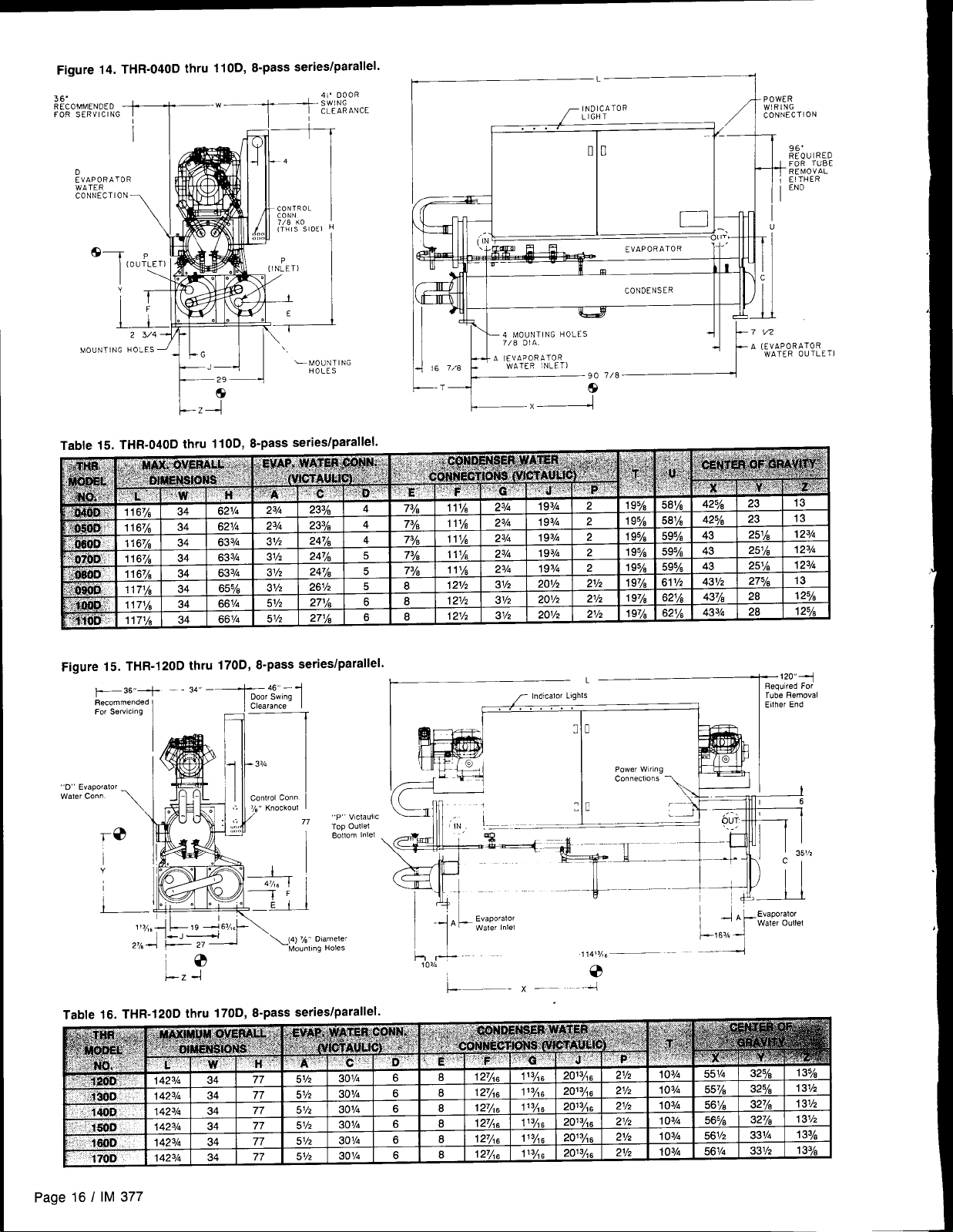

Figure 14. THR-040Dthru 11OD, 8-pass series/parallel.

L7/yiiR$’:LEs,o,/

‘“”NT’NGH”LESJ++] ‘-,,,,:

Lz4e

Table 15. THR-040Dthru 11OD, 8-pass series/parallel.

.-rrn

7 !/2

4

A (EVAPORATOR

J~

—T

e

WATER OUTLETI

Fiaure15. THR-120Dthru 170 D,8-pass series/parallel.

_

l==

1

Q~,-

Door Sw,ng

Clearance

- 3%

~

Control Con.

~%,,Knockout

/

1

p,, V,claullc

77

Too Outlet

BotlomInlet

*36+ _. 3--

Recommended

For Sermng

,,D ~

Waler

I

Lz -/

L

T Ind!calor L,ahts

I V’”””””:, I

3 D

Power W,r(ng

Connections ~

Evaporator

‘AL

Waler Inlet

‘1

~o,A+ --

L——- x –– ---J

114>%-

0

L6:~fi~r~fi”

120--+

Mequired For

Tube Flemoval

E(lher End

Page 16 / IM 377

Page 17

PHYSICAL DATA

Table 17. THR-040D thru 11 OD

~ UNIT SIZE

Nominal Horsepower

Number

Speed RPM (60 Hz/50

No. of Cylindera

Oil Charge (Oz.)

Discharge Line Size (In.)

Number 2 2 2

Diameter (In,)

Tube Length (In.) 96 I 96

Design W.P, (PSIG):

Refrigerant Side

Water Side

I Rc,l,.nfl=, ore

Purge Valve Flare

Liquid Subcooler

No. Water Passes

Pump-Out Capacity 0

I

Connections:

Water inlet&Outlet (Victaulic)l 2V2

P

No. Water Passes

Pump-Out Capacity @

I

Connections:

Water Inlet & Outlet (Victaulic)

Water Passes@

No.

Pump-Out Capacity 0 130

Hz) _

I

20 ] 25

1],

040D

0500

25 I 25 30 35 35 35

1 1

1750/1 450 1750/1 450 1750/ 1450

4

I 4

136 136 136 I 1:

I

11A 11/2

8Y8 85/8 8%

4 4 4 6 6

36

11A 1ye 1yo

11A

85/8 878

96 I 96 96 [ 96 96 I 96

450 450

I

I

250

1/,

Y4 & ~/2

I

I

250

1/..

1/4 & J/2

Integral Integral Integral Integral Integral

2 I 2 I 2 12 I 2 / 2 I 2 I 2 I 2 I 2 I 2 I 2 I 2 12 I 2 I .2

I

130 130

I

I

41414 41414/4 4 14 I 4 14 14 I 4 I 4 14 I 4

I

130

I

2V2

4 4

130

130 125

21/2 21/2 21/2 21/2 21/2

130 130

21/2 27/2

130

21/2

4 4 14 14 14 I 4 I 4 14 I 4 I 4 14 I 4

130 130

130

060D

070D

080D

G60D

I

1OOD

I

cOMPRESSORS

40 40 50 50 50

1 1 1

152 160

1750/ 1450

160 160

1% 1ye

1 1 1 1

1

1750 II 450

6 6 6 8 8 8

242

1ye

1750/ 1450 1750/

242

260

260 260

1% 1yeI1ye 1ye 1yeI1ye

1

CONDENSERS

2 2

85~ 6Y8 85/, 85/3 85A

96 ] 96 96 ] 96 96 I 96

450 450 450 450 450 450

250 250 250

1/,

I

I

J14 & V2

I v?

~/4 & ~/2

I

I v, I v? I

Y4 & J/2

I

2.PASS ARRANGEMENT

125 116 116

21/2 21/2

109 199 199

109

21/21 3 I 3 I 3 I 3

21/2

4-PASSARRANGEMENT

125 125 116 116 109

21/2 21/2 21/2

21/2

109 199

21/2 21/2 I 3 I 3

2 2 2

103A 103/4

103A

250

I

250 I 250

I

Y4 & ~/2

Integral

!

7/4 & 3/2

Integral

188

199 166

313/3 3

8-PASSARRANGEMENT

125 125 116 116 109 109

199 199 166 188 166 188

1100

I

60 60 I 60

1 1 1

1750/1 450

1450

8 618

260 260

lf33~

v, I v? I

166 168

186

103A 103~

96 ! 96

J/a & 7/2

1

Integral

3 3

188 188

4

260

15h

I

186

4

I

Water inlet&Outlet (Victaulic) I 2 21212121212 121212

EVAPORATOR

Refrigerant Circuits

No.

Diameter (In.)

Tube Length (In.)

Water Volume (Gallons)

Refrigerant Side D.W.P. (PSIG)

Water Side D.W.P. (PSIG)

Water Connections:

Inlet & Outlet (NPT EXT.)

Drain & Vent (NPT INT.)

2 2 2

103,4

lo3~

lz3~

96 96 96

20.6 17.9 26.0

225

225

225

175 175 175

4

%

4

=/8

5 5 5

%

DlMENSIONS– 2-PASS

Length (In,)

Width (In,)

Height (In.)

3/i

125

125%

34 34 34

&J1/4 &.1/4 ss3~

125?4

DlMENSiONS– 4-PASS

Length (In,)

Width (In,)

Height (In.)

124%

34

szl/4

124?4

34

Gzl/4

124%

34

Gs3~

DIMENSIONS– 6-PASS

Length (In.)

Wdth (In,)

Height (In,)

1167/s 116VS

34 34 34

621/4 621/4

1167/s 1167/s

Gs3~

WEIGHTS—2-& 4-PASS

Operating Weight (Lbs.)

Shipping Weight (Lbs.)

Operating Charge Lbs. R-22

&

Operating Weight (Lbs.)

I

Shipping Weight (Lbs.)

Operating Charge Lbs. R-22

NOTES:

@ 60Vo Full refrigerant at90° F.

@ 8-Pass Series/Parallel Arrangement.

3655 3705

I

3655

I

40 I 50 I 50 I 50 150 160 I 60 I 60

3635 3665

I

3635 3695 3895

I

3735

40 I 50 I 50 ] 50 I 50 I 60 I 60 I 60

3995 4065 4240

3935

WEIGHTS-8-PASS

3955

21/2 21/2 21/2 21/2 21/2I21/2

2 2

1 z3~

lZ3~

2 2

1 z3~

96 96 96 96

25,6 24.3 24.3 30.5

225

225

175 175

225 225

175

5 6 6

3/8 % =/8 %

125% 125%

34 34

6? 3/4

633A

12434 124%

34

&,3~

34 34 34

Gs3~

1167/8

127 127

34

655A

125% 125%

65%

117% 1171~

34 34 34 34

Gs3~ ss3~

655/3

4675

4025 4185

4690

65 I 65 I 70 I 70 [ 60 I 60 I 60 I 60

4045

4200

3965 4045

4715

4630

5255

5115

65 I 65 70 I 70 60 I 80

14

175

34

~~l/d

sG1/4

GG1/4

5315

5175

2

14

96

27.6

225

175

%

127

34

fjfjlfi

125?4

34

&jl/4

117%

34

GG1/4

5465

5325

5405

5265

60 I 80

Page 18

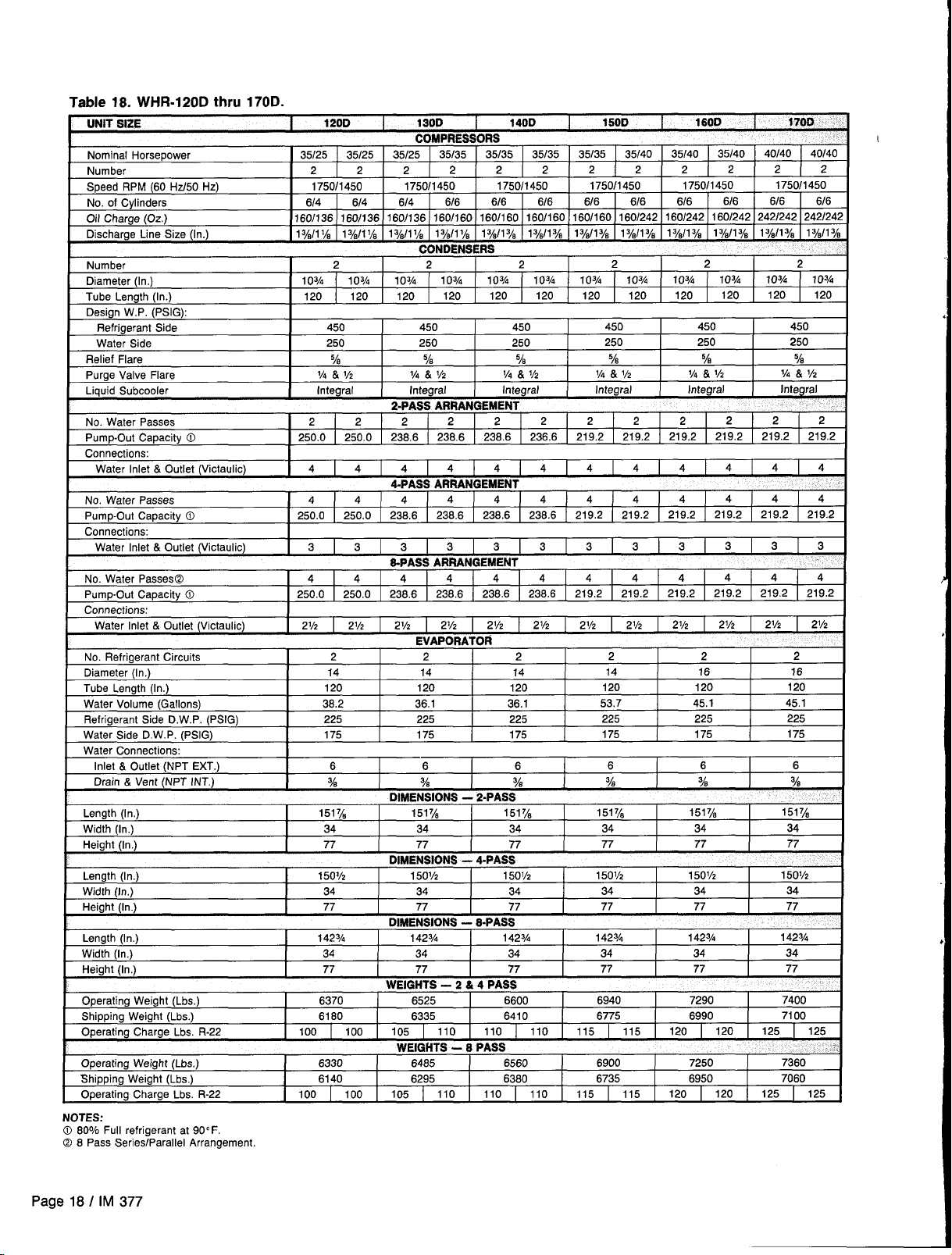

Table 18. WHR-120D thru 170D.

UNIT SIZE

120D

1

130D 140D

COMPRESSORS

Nominal Horsepower

Number

Speed RPM (60 Hz/50 Hz)

No. of Cylinders

Oil Charge (Oz.)

Discharge Line Size (In.)

Number

Diameter (In,)

Tube Length (In.)

Design W.P, (PSIG):

Refrigerant Side

Water Side

Relief Flare

Purge Valve Flare

Liquid Subcooler Integral

No. Water Passes

PumpOut Capacity 0

Connections:

Water Inlet & Outlet (Victaulic)

No. Water Passes

Pump-Out Capacity @ I 250.0

I

Connections:

Water Inlet & Outlet (Victaulic)

160/1 36 160/136 160/1 36 160/1 60 160/1 60

I

I

I

35/25 35/25 35/25

2 2 2 2

1750/ 1450

6/4 6/4 614

1%111A 1y*ll 1/3 12/8/11A

2 2

103~ liJ3~ lrJ3~ 1133~

120 120 120

450 450 450

250 250 250

% 5/8

V4 & V2

2 2 2

250.0 250.0

4 4 4

4 4 4

3 3 3

2-PASS ARRAN QEMENT

238.6 238.6 238.6 236.6

4-PASS ARRANGEMENT

250,0 238,6

35135 35135 35/35 35/35 35/40

2 2

1750/1 450

6/6

1yJl 1A

CONDENSERS

120 120

V4 & V2 V4 & V2

Integral

2 2

4 4 4

4 4 4 4 4

238,6 236,6 236.

3 3 3 3 3 3

1750/ 1450 1750/ 1450

6/6 6/6 6/6 6/6 6/6

160/1 60 160/160 160/242

1%/1 ye

13/Jl Ya

2

1034 103~ f 03~ I03/4

1133~

I

120 120 120

5/8

Integral Integral Integral

2 2 2 2

6 219.2 219.2

S-PASS ARRANGEMENT

No. Water Passes@

PumpOut Capacity @ 250.0 250.0

Connections:

Water Inlet & Outlet (Victaulic)

No. Refrigerant Circuits

Diameter (In,)

Tube Length (In.)

Water Volume (Gallons) 38.2 36.1 36.1

Refrigerant Side D.W.P. (PSIG)

Water Side D.W.P. (PSIG)

Water Connections:

Inlet & Outlet (NPT EXT.) 6 6 6

Drain & Vent (NPT INT.)

Length (In.)

Width (In,)

Height (In.) 77 77

t nla*EM@lnNe

Length (In.)

Width (In,)

Mainht (In 1 77 77 77 77 77 77

,,“, =,!. ,, !!.,

4 4 4

I

21/2

2 2 2

14 14 14

120 120 120

225 225 225

175 175 175

% %

1517/~ 1517/8

I

34 34 34

I

150% t501/2 150Vz

34 34 34

,,

1

238.6 236.6 238.6 238.6 219.2

21/2 21/2

DIMENSIONS - 2-PASS

“,!wE,.e,”$.” — .rr””!

1

4 4 4

21/2 21/2

EVAPORATOR

,,

1

21/2

3/8

151y~ 1517/8

77

I

A-CI&~s

,,

DIMENSIONS - 8-PASS

Length (In.)

Width (In,)

Height (In,)

142s%

I

34 34 34

77 77 77

I

14234

142% 142%

WEIGHTS -2 & 4 PASS

Operating Weight (Lbs.)

Shipping Weight (Lbs.) 6160 6335

Operating Charge Lbs. R-22

6370 6525

100 100 105

110 110 110

6600 6940 7290

6410 6775 6990

WEIGHTS -6 PASS

Operating Weight (Lbs.) 6330 6485

Shipping Weight (Lbs.) 6140 6295

Operating Charge Lbs. R-22 100 100

NOTES:

0 60°/0 Full refrigerant at 90” F.

@ 8 Pass Series/Parallel Arrangement.

105 110 110 110 115 115

6560 6900 7250

6380 6735 6950

150D 160D

35/40 35/40

2 2 2

1750/ 1450

160/242 160/242 242/242 242/242

1%11%

1%11%

I %1~%

2 2

120 120

450 450 450

250 250 250

=% %

X4 & Y2

219.2 219.2

4 4 4

4 4 4

219,2

Y4 & V2

219.2 219.2 219.2 219.2

4

219.2

219,2 219.2 219.2 219.2

21/2 21/2 .21/2

2 2

14

120 120

53.7

225 225

175 175

6

%

34 34

77 77

15ol/z

34 34

. .

1

34 34

77 77

115

115 120 120

16 16

45.1

6 6

Y8 %’s

I

1517/8

1507/2

. .

1

142?4

120 120 125 125

2 2 2

6/6 6/6 6/6

1%11ye 13/”11Vi 12/!!11ye

103~ 103/4

2 2 2

4 4 4

4 4 4

219.2 219.2

3 3 3

4 4 4

21/2 21/2 21/2

170D .

40/40 40/40

1750/1 450

120 120

7/4& V2

Integral

120

45.1

225

175

1517/~

34

77

150%’

34

.,

1

142%

34

77

7400

7100

125 125

7360

7060

2

103~

I

%

,.

219.2

2

.,

Page 18 I IM 377

Page 19

Figure 16. Compressor Locations

UNITS 040D thru 11OD

t

n

1

1

,

cOMP.

G

.J–

I

\

\

\

SUCTION

PIPING

Table 19. Contactor Designation

1

1

CONTROL BOX

COOLER

‘–

COMP,

2

I

k

n

I

UNITS 120D thru 170D

t

I

\

I

SUCTION

PIPING

n

I I

CONTROL aOX

!

n

I

1

I

Two contractors are used per compressor on all 208 volts units. Two

NOTE:

contractors are also used on THR-090—I 10 all voltages, and on all 460 & 575

part winding start units.

IM 377 I Page 19

Page 20

WIRING

FIELD WIRING, POWER

The THR TEMPLIFIERS are built standard with compressor

contractors and power terminal block, designed for single

power supply to unit. Optional power connections include a

non-fused disconnect switch mounted in the control box or

multi-point power connection.

A factory installed control circuit transformer is available

as an option with single power supply or disconnect switch;

it is not available with multi-point option.

Optional circuit breakers are available for backup compressor short circuit protection on 040D thru 110D units and

are standard on all four (4) compressor units 120D thru 170D.

Wiring and conduit selections must comply with the National Electrical Code and/or local requirements.

FIELD WIRING, CONTROL

Control circuits on all units are designed for 115 volt operation. A separate source of 20 amp, 115 volt AC power may

be brought to terminals 1 and 14 (terminal 14 on the ground

side) to power the control circuit. On 208 volt power, leads

from any line and neutral of the 208 volt system may be

brought to terminals 1 and 14 to provide 120 volts to the control circuit.

An optional factory mounted transformer is available to pro-

vide the correct control circuit voltage. All models include the

An open fuse indicates a short, ground, or overload. Before

replacing a fuse or restarting a compressor or fan motor, the

trouble must be found and corrected. Tables in the Electrical

Data section give specific information on recommended wire

sizes.

Unit power inlet wiring must enter the side of the control

box (right side) through an inlet hole provided for field terminating conduit. (Refer to control panel layout drawings for

general location of power inlet and components.)

WARNING: Use only copper conductors in main terminal

block. If the power input conductors are aluminum, use a compression splice to change to copper before terminating in

block.

necessary factory wiring to power the transformer.

On models THR-040D thru 170D the transformer power

leads are connected to the power block PBI or disconnect

switch DS1.

Six 1/2° conduit knockout openings are provided for field

wired options and are located on the left side of the control

panel when facing the unit control panel doors.

NOTE: See page 51 for additional information on the con-

trol thermostat.

INTERLOCK WIRING

The control arrangement shown on the wiring diagram will

permit continuous or cycling operation of the source water

pump. Provision has been made to permit source water pump

cycling by the addition of a field supplied relay “MA” and

wiring it between terminals 11 and 16. if relay “MA” is not

added the pump must be wired for continuous operation.

When continuous source water circulation is used, the flow

switch contacts should be tied into the control circuit as shown

on the interlock schematic (see Figure 17).

The condenser water pump must be arranged for con-

tinuous water circulation, otherwise leaving condenser water

– PUMP STARTERS

temperatures will not be properly controlled.

Condenser water flow switches must be wired into the control circuit as shown on the interlock schematic and depending on the application it may be necessary to install a time

delay relay with timed open contacts connected into the control circuit in parallel with the flow switch to prevent nuisance

tripping.

Whenever the application will permit, continuous water circulation in both the source water and condenser water circuits is preferred and the use of flow switches in both circuits is recommended.

Page 20 I IM 377

Page 21

Figure 17. Typical Interlock Schematic

NOTE: FOR SINGLE STARTER APPLICATION, JUMPER TERMINAL 11 AND 12 AND WIRE STARTER BETWEEN 11 AND 16.

PHASE

3

POWER SUPPLY

UNIT DISCONNECT

SWITCH(BY OTHERS)

rt

Ml

—7

I

L

M2

I

COMP.

#1

COMP.

#3

@!&d

-2

M3 CB1

—

I

l——

I

I

1

2

S1 CONTROL

~

(b

()

()

RELAY

1~-

R9

IQ--U–––––-J

RIO

4 CONTACTS 11

41

r——x

——

--M~i=~

41

Al

I

1

I

120V

UNIT OPERATING

CONTROLS(CKT. 1)

I OPTIONAL CONTROL

I CKT. TRANSFORMER

COMP

#2

COMP.

.U4

15

NB

LEGEND

@

—— .

——— —

I)

71

5

TIMECLOCK

CONTACTS

6

EVAPORATOR

FLOW SWITCH

7

8

NOTE: For single starter application, jumper terminal 11 and 12 and wire starter between 11 and 16.

FIELD CONNECTION TERMINAL

FACTORY WIRING

FIELD WIRING

OPTIONAL FACTORY WIRING

Ml—MB COMPRESSOR CONTRACTORS

CB1—CB4

PB1

MA, MB

UNITOPERATING

CONTROLS(CKT.2)

TEMPLIFIERUNIT

CAPACITYCONTROLS

1

COMPRESSOR CIRCUIT BREAKERS

UNIT POWER TERMINAL BLOCK

CONDENSER PUMP STARTERS (MAX. 20VA EA.)

NB

NB

IM 377 I Page 21

Page 22

SEQUENCE OF OPERATION – THR-040D thru 110D

The following sequence of operation is typical for THR

TEMPLIFIER HEAT PUMP, models THR-040D thru

THR-110D. The sequence varies somewhat depending upon

options.

HEAT ONLY OPERATION

Compressor Heaters

and the control stop switch S1 open, 115V power is applied

through the control circuit fuse F1 to the compressor

crankcase heaters HTR1 and HTR2.

Startup —

power is applied to the compressor motor protectors MPI and

MP2 and the primary of the 24V control circuit transformer.

The 24V transformer provides power to the central processor

thermostat CPI and to the optional alarm bell.

When the remote time clock or manual shutdown switch

turns on the water pump, the flow switch closes and 115V

power is applied to the relay contacts on the central processor

CP1. The unit will automatically operate in response to the central processor CP1 provided the manual

pumpdown switches PSI and PS2 are closed (in the auto

position), the compressor lockout time delays TD1 and TD2

have closed, energizing the safety relays R5 and R6, and the

freezestats FS1 and FS2, high pressure controls HPI and

HP2, and compressor motor protectors MPI and MP2 do not

sense failure conditions.

On a call for heating, the central processor CP1 energizes

the liquid line solenoid SV1 for refrigerant circuit #1, opening the valve and allowing refrigerant to flow through the expansion valve and into the evaporator. As the evaporator

refrigerant pressure increases, the low pressure control LPI

closes. This energizes the compressor contractors M1 and

M5, starting the compressor. Also, R9 relay is energized. R9

relay is wired to terminals providing a means for interlocking

the pump starter, MA with the compressor operation. See

page 21 for pump control.

As additional stages of heating capacity are required, the

central processor CPI energizes the liquid line solenoid valve

SV2 of refrigerant circuit #2. After the compressor sequencing time delay TD11 has closed, the same starting sequence

is initiated in refrigerant circuit #2.

If additional heating is still required, the central processor

will de-energize the unloader solenoids of each compressor,

respectively.

HEATING/COOLING OPERATION

Heat/cool units are designed to supply hot water for heating

needs and to allow switching to cooling operation when it is

needed.

The sequence of operation for combination heating/cooling units is similar to heating only, the difference is in the

thermostat arrangement. On heat/cool models the heating

thermostat “CPI” is still used, but in conjunction with a

changeover switch and the addition of a separate cooling thermostat “CP2”. Changeover from heating to cooling operation or cooling to heating is accomplished by setting the

changeover switch for the desired mode to activate the

desired heat or cool thermostat. The thermostat relay con-

tacts then activate the control circuit whenever compressor

operation and/or loading or unloading is required to satisfy

the thermostat setting for the mode selected.

The heating thermostat controls the leaving hot water

temperature leaving the condenser through a sensor located

in the return water to the condenser.

Conversely the cooling thermostat controls the water

temperature leaving the evaporator through a sensor located

in the return water, to the evaporator temperature selection

With the control stop switch S1 closed, 115V

— With the control circuit power on

dials inside the thermostats, are used to set the desired leav-

ing water temperatures for either heating or cooling. Seethe

thermostat bulletin packed with the unit for additional

information.

Check the applicable 4 or 6 stage heat/cool wiring diagrams

starting on page 39 for specific wiring details.

Pumpdown Cycle System Shutdown — As the central pro-

cessor is satisfied, it will unload the compressors and then

de-energize the liquid line solenoid valves SV1 and SV2,

causing the valves to close, starting the pumpdown cycle.

When the compressor has pumped most of the refrigerant

out of the evaporator and into the condenser, the low pressure

controls LPI or LP2 will open, shutting down the compressors. During the off cycle, if a closed solenoid valve allows

refrigerant to leak into the evaporator, the increase in

pressure will cause the low pressure control LPI or LP2 to

close. This will energize the compressor contractors Ml and

M2 and start the compressor, which will quickly pump the

refrigerant out of the evaporator and into the condenser

(recycling pumpdown).

A compressor which repeats recycling pumpdown every

5 minutes indicates a malfunction due to the temperature control or a system cause. A buildup of heat in the compressor

without proper cooling of suction gas could cause a

mechanical failure in the compressor. McQuay recommends

corrective measures be taken if the compressor recycles

repeatedly within 15-minute intervals.

Safety Relay Operation —

be energized to permit normal operation. If the freezestats

FSI and FS2, high pressure controls HP1 and HP2, oil

pressure controls OP1 and 0P2 or compressor motor pro-

tectors MP1 and MP2 sense a fault condition and open, the

safety relay R5 or R6 will be de-energized. The relay contacts open and de-energize the compressor contactor and

the liquid line solenoid valve.

Compressor Anti-Short Cycle Time Delay — The unit is

equipped with 5-minute time delay relays TD1 and TD2 which

provide anti-short cycling protection. When low pressure control LP1 closes and energizes Ml compressor contactor, LP1

also energizes R9 which provides power to auxiliary relay MA

for control of a starter for a remote evaporator pump. A second contact on R9 shunts out TD1 opening up TDI. When

LPI opens, cutting power to R9, then compressor #1 cannot

be started until TD1 times out and energizes safety relay R5.

Operation of LP2, TD2, M2, R1O and R6 is similar for opera-

tion of the second compressor.

Note: The motor protector in the compressor terminal box

has a 2-minute time delay. When power is interrupted to terminals 3 and 4 of any motor protector, the MP contacts between MP terminals 1 and 2 open and will not close for two

minutes.

Indicator Lights —

with indicator lights to show the status of electrical control

operation.

1:

ON-STOP Switch — Has an inherent light which glows

when the control circuit is energized.

2.

Lights SV1 and SV2 — Glow when the safety relays are

energized indicating compressor circuit safety contacts are

closed, and compressor will operate in response to CP1

thermostat.

Lights RLI and RL2 — Glow when the compressor con-

3.

tractors are energized and cooling circuit is in operation.

4.

Heating Stage Indicator Lights — Red lights next to the

relays on the main central processor thermostat indicate

which heating stages are energized.

The safety relays R5 and R6 must

The THR unit control box is equipped

Page 22 I IM 337

Page 23

SEQUENCE OF OPERATION – THR-120D thru 170D

The following sequence of operation is typical for THR

TEMPLIFIER, models THR-120D thru THR-170D. The se-

quence varies somewhat depending upon options.

Compressor Heaters

— With the control circuit power on

and the control stop switch S1 open, 115V power is applied

through the control circuit fuse FI to the compressor

crankcase heaters HTRI, HTR2, HTR3, and HTR4.

Startup — With the control stop switch S1 closed, 115V

power is applied to the compressor motor protectors MP1,

MP2, MP3, and MP4 and the primary of the 24V control circuit transformer. The 24V transformer provides power to the

central processor thermostat CP1 and to the optional alarm

bell.

When the remote time clock or manual shutdown switch

turns on the water pump, the flow switch closes and 115V

power is applied to the relay contacts on the central processor

CP1. The unit will automatically operate in response to the

central processor CP1 provided the manual pumpdown switches PS1 and PS2 are closed (in the auto position), the compressor lockout time delays TD1 and TD2 have closed,

energizing the safety relays R5 and R6, and the freezestats

FSI and FS2, high pressure controls HPI and HP2, and compressor motor protectors MP1, MP2, MP3, and MP4 do not

sense failure conditions.

On a call for heating, the central processor CP1 energizes

the liquid line solenoid SVI for refrigerant circuit #1, opening the valve and allowing refrigerant to flow through the

expansion valve and into the evaporator refrigerant pressure

increases, the low pressure control LPI closes. This

energizes the compressor contractors Ml and M5, starting

the compressor. Also, R9 relay is energized. R9 relay is wired

to terminals providing a means for interlocking the pump

starter MA with the compressor operation.

As additional stages of capacity are required, the central

processor CP1 energizes the liquid line solenoid valve SV2

of refrigerant circuit #2. After the compressor sequencing time

delay TDI 1 has closed, the same starting sequence

is initiated in refrigerant circuit #2.

If additional heating is still required, the central processor

will activate additional cylinders on the lead compressor of

each system or activate compressors #3 and #4, depending

on the load requirements and the capacity control stops

available on the unit.

Pumpdown Cycle System Shutdown — As the central pro-

cessor is satisfied, it will cut off compressor #4 and #3, then

unload compressors #2 and #1, and finally de-energize the

liquid line solenoid valves SV1 and SV2, causing the valves

to close. When the compressor has pumped most of the

refrigerant out of the evaporator and into the con-

denser, the low pressure controls LP1 or LP2 will open, shutting down the compressors. In the event a closed solenoid

valve allows refrigerant to leak into the evaporator, the increase in pressure will cause the low pressure control LPI

or LP2 to close. This will energize the compressor contractorsMl and M2 and start the compressor, which will quickly

pump the refrigerant out of the evaporator and into the condenser (recycling pumpdown).

A compressor which repeats recycling pumpdown every

5 minutes indicates a malfunction due to the temperature control or a system cause. A buildup of heat in the compressor

without proper cooling of suction gas could cause a

mechanical failure in the compressor. McQuay recommends

corrective measures be taken if the compressor recycles

repeatedly within 15-minute intervals.

Safety Relay Operation —

The safety relays R5 and R6 must

be energized to permit normal operation. If the freezestats

FSI and FS2, high pressure controls HPI and HP2, oil

pressure controls OP1 and 0P2 or compressor motor protectors MP1 and MP2 sense a fault condition and open, the

safety relay R5 or R6 will be de-energized. The relay contacts open and de-energize the compressor contactor and

the liquid line solenoid valve. Safety relays

R7 and R8 pro-

vide a similar function for compressors #3 and #4.

Compressor Anti-Short Cycle Time Delay — The unit is

equipped with 5-minute time delay relays TD1, TD2, TD3 and

TD4 which provide anti-short cycling protection. When low

pressure control LPI closes and energizes Ml compressor

contactor, LPI also energizes R9 which provides power to

auxiliary relay MA for control of a starter for a remote pump.

A second contact on R9 shunts out TD1 opening up TD1.

When LP1 opens, cutting power to R9, then compressor #1

cannot be started until TDI times out and energizes safety

relay R5.

Operation of LP2, TD2, M2, RIO, R6 and Ml is similar for

operation of the second compressor.

Note: The motor protector in the compressor terminal box

has a 2-minute time delay. When power is interrupted to terminals 3 and 4 of any motor protector, the MP contacts between MP terminals 1 and 2 open and will not close for two

minutes.

Indicator Lights —

The THR unit control box is equipped

with indicator lights to show the status of electrical control

operation.

1:

ON-STOP Switch — Has an inherent light which glows

when the control circuit is energized.

2.

Lights SW, SV2, SV3, and SV4 — Glow when the safety

relays are energized indicating compressor circuit safety

contacts are closed, and compressor will operate in

response to CP1 thermostat.

3.

Lights RL1, RL2, RL3, and RL4 — Glow when the compressor contractors are energized and cooling circuit is in

operation.

4.

Heating Stage Indicator Lights — Red lights next to the

relays on the main central processor thermostat indicate

which heating stages are energized. Note: Located inside

control box.

377 / Page 23

IM

Page 24

Table 13. Compressor motor amp draw

--.,

,Uqw

4 . . .

‘.

---- ,: 230 162 202 1070

‘,

.:. .,.

11OD

J6VV

. .

“:14.90

.,.I?ww

:..,-,

..:.

.. z,-- 230 113.129 113.129 565.594

:9700: ,,

..-

230

460 Q

I

I 4600 I 53 I 61 I 235

575

I

208

208

I

208

230 202 202 1070

460 Q 101 101

I

1 460 Q I 61, 42 I 61, 421283,214

208

230 113, 113 113, 113 565,565

460 D 61, 61 61, 61 283.283

I

4600 I 61, 61 I 61, 651283,263

I

206

I

230 129, 129 129, 129 594, 594

460 ~ 65, 65 65, 65 297, 297

575 52, 52 52, 52 235, 235

77

42 42

I

I

I

I

113, 113 113, 113 565, 565

I

113, 153 113, 153 565, 660

I

45 45

153

I

162

I

202

I

153

202

202

428

214

172

428

428

214

172

565

565

283

230

565

565

283

230

660

594

297

235

1070

1070

535

405

1070

1070

535

405

1070

1070

535

405

-

orAfly9 ,

:&%$i;,:#)

~&&it:

T

186

84

61

250

-a--4-E

250

117

103

292

292

141

130

mm

340

340

156

138

400

w

340

170

135

654

654

330

262

654

654

330

262

654

654

330

262

340, 250

340, 250

156, 117

136 103

340, 250

340, 250

156, 117

138 103

340, 340

340, 340

156, 156

138 138

340, 340

340, 340

156, 156

138 138

-

340, 400

340, 340

156, 170

138, 135

400, 400

340, 340

170, 170

135, 135

mm

140, 340

156.156

ERiT

38, 135

100, 400

i40, 340 548

70, 170 I 276

35, 135 I

250

117 95

I

170

135

I

654

654 365

I

330

262 135

654

654

330 208

I

I

146

117 65

365

165

415

415

460

259

207

650 344

221 117

173

96

53

39

96

96

53

I

81

203

203

I

103

75

203

203

103

I

254

137

I

110

290

146

I

96

53

+

39

141

141

76

56

141

141

76

56

7

191

161

81

65

203

203

103

75

253

253

126

90

253

253

126

90

218

218

118

87

254

254

137

101

254

254

137

101

304

274

142

110

304

274

142

110

344

290

146

117

I

T5?i(

&i,?!!,:

circuit3

T

77

I

I

428

214

230

660

1070

I

1070

535

I

i65, 426

i65, 426

?83, 214

?30, 172

j65, 428

i65, 426

?83, 214

?30 172

;65, 565

;65, 565

I

!83, 283

!30, 230

;65, 660

i65, 660

!83, 297

!30, 235

i65, 660

i65, 594

!63, 297

!30, 235

;60, 660

’94, 594

’97, 297

’35, 235

NOTES:

@ ALLOWABLE VOLTAGE LIMITS:

Unit Nameplate 208V/60Hz/3Ph: 187V to 253V (except THR-080D: 180V to 220V).

Unit Nameplate 230V/60Hz13Ph: 187V to 253V (except THR-080D: 207V to 253V).

Unit Nameplate 460V/60Hz/3Ph: 414V to 506V.

Unit Nameplate 575V/60Hz/3Ph: 517V to 633V.

Unit Nameplate 380V/50Hz/3Ph: 342V to 418V.

Compressor RLA values are for wire sizing purposes only and do not reflect normal operating current draw

Compressor LRA for Dart windina starl are for the first windina,

Unit tire size amm a;e eaual to 725V0 of the Iaraest comoress~r-motor RLA DIUS100VO of RLA of all other loads in the circuit includina control transformer.

Wire size amps ;or separate 115V control circu~ power (s 10 amps.

Single point power supply requires a single fused disconnect to supply electrical power to the unit.

Multiple point power supply requires three independent power circuits with separate fused disconnects (two compressor circuits, one control circuit).

Data also applies to 380V/50Hz/3Ph units.

page 24 I IM 377

Page 25

CONTROL CENTER

All electrical controls are enclosed in a control center with

Iocking, hinged access door(s). A partition separates the adjustable safetv controls from the starting and operating con- justable controls are covered and can be adjusted without

trols. A “deadfront” panel covers all starting and operating

CONTROL CENTER LAYOUT, THR-040D thru 11OD

Figure 18. Left Side, 115V Control Section

controls so that no electrical contacts or terminals are exposed. The deadfront panel is hinged for servicing. The ad-

fear of contacting line voltage.

Figure 19. Right Side, High Voltage Control Section

u

——

-cmiP, ——— —————

TR HM

lx)

TB4(110–124,210-224)

r

B

n

CP2

!4604

IPS1 82

I

ElljallI

F1 PS2CTR HM

_ ~c)

TD

I

11

❑

1

D

~————.

mmlmlma