Page 1

McQuay® Horizontal Concealed Fan Coil Unit

®

Model THC (Vintage B)

Sizes 200 Through 1200 CFM

Catalog

C: 700-3

Page 2

Table of Contents

Nomenclature..........................................................page 2

Introduction .............................................................page 3

Design Features...................................................page 3-4

Fan coil Construction Illustration ..........................page 3

Performance Data

Cooling Capacity (2-Pipe) .....................................page 5

Heating Capacity (2-Pipe) .....................................page 5

General Unit Data (2-Pipe) ...................................page 5

.............................................pages 5-6

All standard units

All custom units

Cooling Capacity (4-Pipe) .....................................page 6

1-Row Heating Capacity (4-Pipe) .........................page 6

General Unit Data (4-Pipe) ...................................page 6

Dimensional Data

Air Volume Capacity Data.........................................page 8

Motor Data

Wiring Diagrams

Engineering Guide Specications

Ratings certied by the Air Conditioning

& Refrigeration Institute (ARI)

................................................................page 8

...................................................page 7

.....................................................page 9

Nomenclature

F THC 2 H02 A A 70 A 69 AX 20 A A

................. page 10-11

Fan Coil

Description /Type of Product

THC = Horizontal THC Concealed

Design Series

1 = A Design

2 = B Design

Unit Size

Nominal Cfm

H02 = 200 H04 = 400 H08 = 800

H03 = 300 H06 = 600 H10 = 1000

H12 = 1200

Power Supply/Motor Voltage

A = 115V-60-1

E = 208/230V-60-1

J = 277-265V-60-1

Main Coil (Heating/Cooling)

A = 3-Row Coil

Secondary Coil (Heating)

70 = 1-Row Heating

SKU Type

A = Stock

C = Build to Order

Power Connection

A = Junction Box

Return Air

17 = Rear Ducted with Plenum, Filter & Duct

Collar

20 = No Plenum, Open Return

Discharge

AX = Front Discharge with Built in Duct Collar

Controls

00 = JBox with Terminal Strip & Wired Motor

Leads

69 = LV-3SP JBox, DDC Ready Interface and

Toggle Disconnect Switch

70 = Overow Switch, LV-3SP,

DDC Ready Interface and Toggle

Disconnect Switch

Hand Orientation

A = Same Hand - Left

B = Same Hand – Right

Page 2 of 12 / Catalog 700

Page 3

Introduction

McQuay fan coils have been widely applied in hotels,

apartments, dormitories and military barracks, as-

sisted living facilities and ofces. They have earned

a reputation for quality - providing years of efcient,

reliable, quiet heating and cooling and easy, low-cost

installation and maintenance. The Model THC horizontal concealed fan coil unit is a slim, lightweight unit

that is ideal for installation in ceilings where height is

limited. Units are available in seven sizes from 200 to

1,200 cfm.

Design Features

Slim Prole

The highly compact, super lightweight design of the

Model THC fan coil unit makes it ideal for inside

ceiling installations where height is limited.

High Efciency Coil

Unique coil design promotes the mixture of warm and

cold air, resulting in high thermal efciency and lower

operating costs

.

Quiet and Efcient Centrifugal Fan-Motor

Assembly

With a dynamically balanced centrifugal fan wheel and

a high efciency motor assembly, the THC offers you:

1. Minimized vibration.

2. Low noise operation.

3. Low operating cost.

4. 4 speed tap motor for better speed control.

Indoor Air Quality Design

1. Coils

• All THC water coils feature aluminum blue ns

mechanically bonded to seamless copper tubes.

The blue ns are covered with an epoxy poly-

mer that causes condensation to drip off more

quickly, preventing mold build-up and increas-

ing the coil and n life expectancy.

• Hand operated brass air vent, conveniently lo-

cated over the drain pan, requires no tools for

venting, and is supplied with a clear plastic hose

to prevent spills.

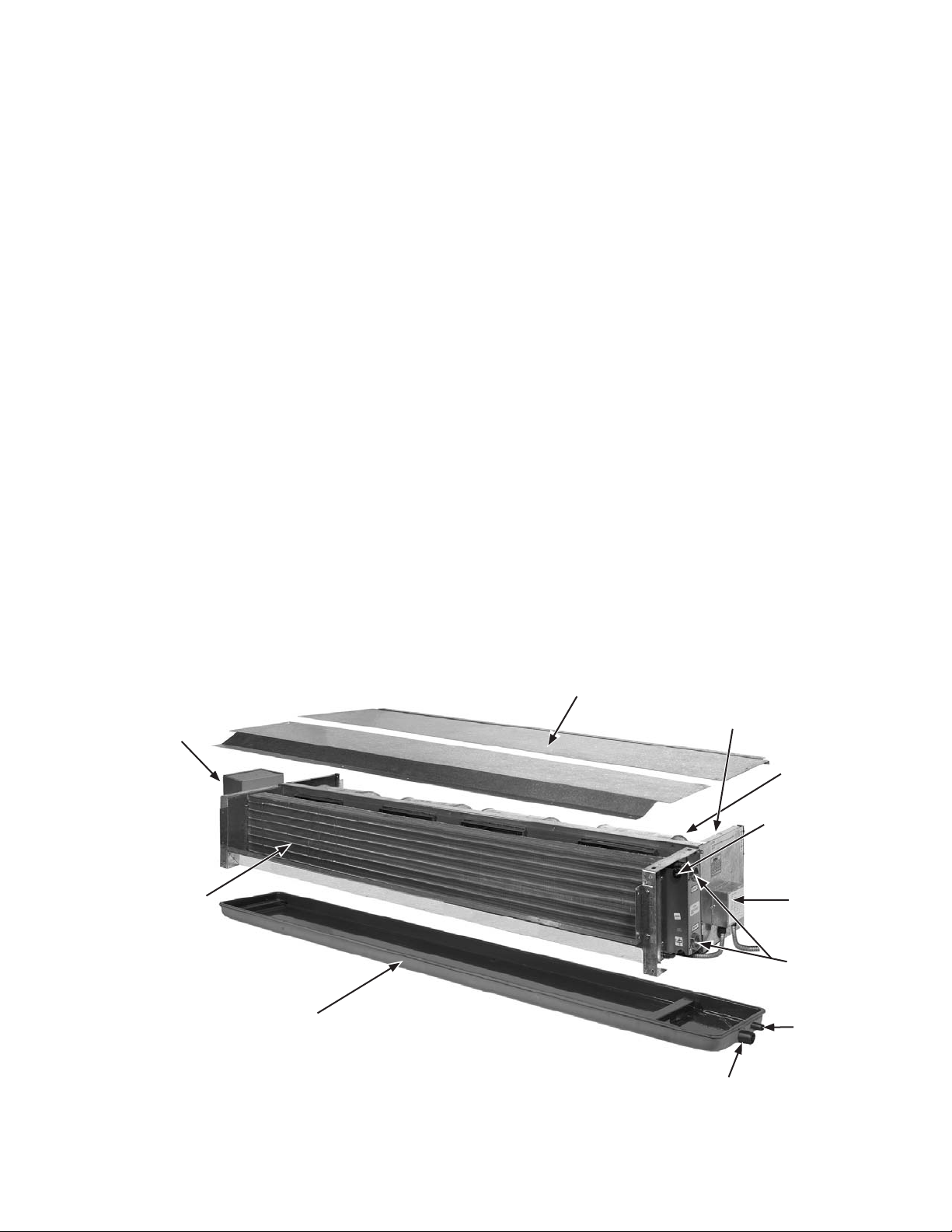

Fan coil Construction Illustration

LV-3SP Jbox - Interface Control

Junction Box (Optional)

High Efciency Coil

Extended Positive Slope,

Indoor Air Quality Drain Pan

Top Panels built to keep

insulation out of airstream

Units with Plenum, removable Filter from

either side of the unit or bottom

Quiet

Centrifugal

Fan Assembly

Service-friendly

Manual Air Vent

Terminal Box (Basic)

Threaded Piping

Connections

Auxiliary Overow

Drain Connection

3/8" I.D.

Main Condensate Drain Connection

1/2" O.D. Smooth

Page 3 of 12 / Catalog 700

Page 4

2. Drain Pan

• Galvanized or stainless steel.

• Extends past the coil to collect condensation

from valve and piping packages.

• Stamped with no welded corners.

• Positively sloped to provide proper drainage and

minimize microbial growth.

• Equipped with main condensate and auxiliary drain connections to provide overow

protection.

• Easily removable.

• Coated with a thick layer of powder paint and

baked for easy cleaning and to help protect

against microbial growth and corrosion.

• Insulated with form-tted, closed cell insulation

to prevent condensation build-up on the exterior

of the drain pan.

3. Return Air Plenum

• Units are available with or without a return air

plenum. Units with a plenum are supplied with a

high quality lter, lter guide and 3/4" return air

duct collar. Easy lter removal encourages fre-

quent changing, especially when the unit is used

with a McQuay T170 thermostat, which has a

lter reminder.

• Aluminum foil faced insulation is used in the

return air plenum to prevent glass bers from

entering the air stream, to reduce unit sweating,

and to attenuate fan noise.

• Top and side panels surrounding the coil are

also insulated with aluminum foil face to prevent the possibility of condensation forming on

the outside of the cabinet.

Electrical Connection - Control Interface

All remote thermostats and controls generally require

low voltage control wiring from the thermostat/control

device to the unit control box. That is why McQuay pro-

vides a full range of control options. See Thermostats

and Controls below.

Thermostats and Controls

Wall-mounted thermostats are available for all applications, ranging from a simple thermostat and/or 3-speed

switch to a digital, ADA display thermostat with auto-

stage control.

Note: For details on thermostats and wiring refer to ED18513.

Factory installed options include:

• Basic: A single point power connection junction box

that consists of a terminal strip for line-voltage con-

trol connection to an Off, Hi, Med, Lo switch, plus a

thermostat or a control.

• DDC ready interface via an LV-3SP control box: For

low-voltage applications, it includes three 24 volt

relays, a line voltage/24volt transformer, two sets of

terminal strips and a toggle disconnect. This interface control can be used with a simple 24 volt ther-

mostat or with building automation systems. This

interface is also available as a eld installed option.

Interface Control Junction Box

Flexible Coil and Piping Connections

Units are easily converted to opposite-hand orientation

without requiring additional parts or a conversion kit.

Heating and cooling pipe connections are located on the

same end. Four pipe coils are factory installed in the reheat position, but are easily eld-converted to the preheat position. Coils can be factory installed in the pre-

heat position as a special request.

Threaded or Sweat Connections

Coils feature a brass header with 3/4" FPT connections

to facilitate quick installation of McQuay threaded or

quick-connect, factory built valve packages. A galva-

nized steel cover plate protects the header and provides

additional structural support to facilitate connection of

any type of valve package and matched load pumps. If

sweat copper tube connections are desired, sets of two

(2) 3/4" MPT x 1/2" copper male adapters are provided

in the basic units.

Page 4 of 12 / Catalog 700

Note: For wiring diagram details for Vintage B THC units and the

LV-3SP Jbox refer to Certied Drawing FC-THC-H02-H012

Valve Packages

Two-way and three-way electric valves are available in

low- and line-voltage congurations for eld installation

on 2-pipe and 4-pipe systems. Basic, enhanced and de-

luxe valve/piping packages are also available with and

without quick-connect, threaded connections.

Valve/piping packages are available with and without

bleed lines. Packages without bleed lines will require

thermostats capable of sampling the entering water temperature to sense automatic changeover on two-pipe

changeover units. (Refer to valve/piping package Engi-

neering Data documentation).

Page 5

Performance Data

–

THC Horizontal Concealed (2-Pipe System)

ARI Approved Standard Coil Water Cooling Capacity Ratings

UNIT

SIZE TOTAL SENSIBLE

H02 8500 6100 1.94 5.10

H03 11,100 8400 2.51 3.26

H04 14,500 10,800 3.26 5.80

H06 21,200 16,100 4.70 12.82

H08 22,700 18,000 5.14 3.68

H10 25,300 20,000 5.70 4.76

H12 34,200 27,000 7.75 8.29

BTUH

FTHC HORIZONTAL CONCEALED UNIT

1

COOLING CAPACITY

BTUH

WATER WATER

GPM FT. W.C.

FLOW

P.D.

1

Standard Coil Water Heating Capacity Ratings

UNIT

SIZE SENSIBLE

H02 14,900 1.94 5.10

H03 20,300 2.51 3.26

H04 26,800 3.26 5.80

H06 37,600 4.70 12.82

H08 42,400 5.14 3.68

H10 48,300 5.70 4.76

H12 68,800 7.75 8.29

Water heating coils at 70

FTHC HORIZONTAL CONCEALED UNIT

2

WATER

FLOW

HEATING CAPACITY

BTUH

o

F DB entering air, 140oF entering water, 30

2

GPM FT. W.C.

WATER

P.D.

o

F water temperature drop and high fan speed with standard 115/60/1 motor.

For heating coil capacity ratings at conditions other than those listed refer to the RepTools Computer Selection Program or consult your McQuay

representative.

General Unit Data

Unit Size

H02 H03 H04 H06 H08 H10 H12

Fan

Type Centrifugal Fan (forward-curved galvanized steel fan wheel)

Number of Fans 1 1 2 2 3 3 4

Coil

Number of Rows 3/1 Split

Type Water - (3-Row Chilled Water) (1-Row Hot Water)

Motor(s)

Type PSC

Number of Motors 1 1 1 1 2 2 2

Power Supply 115/60/1, 208-230/50/60/1, 277/60/1

Watts - High Speed

50Hz 62 91 109 171 242 249 321

60Hz 75 109 131 205 291 299 385

Coil Connection 3/4" FPT

Drain Pipe Connections Main Drain - 3/4" O.D. Smooth / Auxiliary Drain - 3/8" I.D. Smooth

Unit with Return Air Plenum and Filter

Length in. 23.25 23.25 23.25 23.25 23.25 23.25 23.25

Width in. 32.05 38.74 43.86 51.73 61.57 65.51 75.75

Height in. 9.88 9.88 9.88 9.88 9.88 9.88 9.88

Ship Weight lb. 63.00 73.00 88.00 102.00 134.00 143.00 153.00

Conditions:

1 Cooling Capacity: Entering air temp.80oF (DB), 67

2 Heating Capacity: Entering air temp.70

Air Flow: Under dry coil conditions, fan speed high.

Weight: Includes return air plenum and packing.

o

F (DB); Entering water temp.140oF, The same amount of water ow with cooling.

o

F (WB); Entering water temp.45

o

F, Leaving water temp. 55oF.

Page 5 of 12 / Catalog 700

Page 6

Performance Data

–

THC Horizontal Concealed (4-Pipe System)

ARI Approved Standard Coil Water Cooling Capacity Ratings

UNIT

SIZE TOTAL SENSIBLE

H02 8500 6100 1.94 5.10

H03 11,100 8400 2.51 3.26

H04 14,500 10,800 3.26 5.80

H06 21,200 16,100 4.70 12.82

H08 22,700 18,000 5.14 3.68

H10 25,300 20,000 5.70 4.76

H12 34,200 27,000 7.75 8.29

BTUH

FTHC HORIZONTAL CONCEALED UNIT

1

COOLING CAPACITY

BTUH

WATER WATER

GPM FT. W.C.

FLOW

P.D.

1

Standard Coil Water 1-Row Heating Capacity Ratings

UNIT

SIZE SENSIBLE

H02 11,500 0.64 1.47

H03 16,300 0.91 2.89

H04 20,400 1.12 5.32

H06 29,600 1.65 10.72

H08 36,100 2.00 3.24

H10 40,300 2.24 4.07

H12 49,800 2.76 6.45

1-ROW HEATING CAPACITY

Water heating coils at 70

FTHC HORIZONTAL CONCEALED UNIT

BTUH

o

F DB entering air, 180oF entering water, 40

2

WATER

FLOW

GPM FT. W.C.

2

WATER

P.D.

o

F water temperature drop and high fan speed with standard 115/60/1 motor.

For heating coil capacity ratings at conditions other than those listed refer to the RepTools Computer Selection Program or consult your McQuay

representative.

General Unit Data

Unit Size

H02 H03 H04 H06 H08 H10 H12

Fan

Type Centrifugal Fan (forward-curved galvanized steel fan wheel)

Number of Fans 1 1 2 2 3 3 4

Coil

Number of Rows 3/1 Split

Type Water - (3-Row Chilled Water) (1-Row Hot Water)

Motor(s)

Type PSC

Number of Motors 1 1 1 1 2 2 2

Power Supply 115/60/1, 208-230/50/60/1, 277/60/1

Watts - High Speed

50Hz 62 91 109 171 242 249 321

60Hz 75 109 131 205 291 299 385

Coil Connection 3/4" FPT

Drain Pipe Connections Main Drain - 3/4" O.D. Smooth / Auxiliary Drain - 3/8" I.D. Smooth

Unit with Return Air Plenum and Filter

Length in. 23.25 23.25 23.25 23.25 23.25 23.25 23.25

Width in. 32.05 38.74 43.86 51.73 61.57 65.51 75.75

Height in. 9.88 9.88 9.88 9.88 9.88 9.88 9.88

Ship Weight lb. 63.00 73.00 88.00 102.00 134.00 143.00 153.00

Conditions:

1 Cooling Capacity: Entering air temp.80oF (DB), 67

2 Heating Capacity: Entering air temp.70

Air Flow: Under dry coil conditions, fan speed high.

Weight: Includes return air plenum and packing.

Page 6 of 12 / Catalog 700

o

F (DB); Entering water temp.180

o

F (WB); Entering water temp.45

o

F.

o

F, Leaving water temp. 55oF.

Page 7

Terminal Block

(Basic Unit Only)

4.53"

1.25"

9.53"

Chilled Water

Connections 3/4" FPT

9.88"

1.25"

5.82"

9.25"

23.25"

1.25"

4.72"

9.53"

Plenum Back with Filter

Filter Rail

Water Return

Connection

3/4" FPT

Air Vent

Filter

E

D

4 - Mounting Holes

3/8" x 5/8"

TOP VIEW

8.125"

2- R/A Plenum

Mounting Holes

3/8" x 5/8"

F

2"

Auxiliary Overflow

Drain 3/8" I.D.

Auxiliary Overflow

Drain 3/8" I.D.

Basic terminal box

located at the same

side as the coil

connection

Unit with plenums,

filter removable

from either side or

bottom of unit

Terminal box located

at the same side as

coil connection

Main

Condensate

Drain 3/4" O.D.

1/2"

1.25"

23.25"

9.25"

9.88"

1.73"

2.75"

3.46"

2.32"

7.36"

6.38"

A

9.75"

B

1.5"

C

1.02"

5.75"

9.75"

1.40"

12.75"

8.75"

2"

6.54"

7.73"

.88"

FRONT VIEW

Main

Condensate

Drain 3/4" O.D.

Terminal Block

Water Supply

Connection

3/4" FPT

Hot Water

Connection

3/4" FPT

Main Drain

Connection

3/4" O.D.

8.82"

(Unit w/o Plenum)

18.35"

(Unit w/o Plenum)

(Optional) LV-3SP Jbox

7.73"H x 6.54"W x 3.38"D

(always located on the end

opposite the coil connection)

8.94"

(Unit w/o Plenum)

Dimensional Data –

Unit Size

H02 32.05" 17.64" 19.17" 19.96" 18.46" 21.13"

H03 38.74" 24.33" 25.87" 26.65" 25.15" 27.82"

H04 43.86" 29.45" 30.98" 31.77" 30.20" 32.94"

H06 51.73" 37.32" 38.86" 39.65" 38.07" 40.82"

H08 61.57" 47.17" 48.70" 49.49" 47.91" 50.66"

H10 65.51" 51.10" 52.64" 53.43" 51.85" 54.60" 253/

H12 75.75" 61.34" 62.87" 63.66" 62.09" 64.83" 307/

A

THC Horizontal Concealed, with Plenum Box

B

C

D

E

F

Filters

Size Qty

181/

" x 8" x 1"

8

247/

" x 8" x 1"

8

297/

" x 8" x 1"

8

187/

" x 8" x 1"

8

233/

" x 8" x 1"

4

" x 8" x 1"

4

" x 8" x 1" 2

8

1

1

1

2

2

2

Note: For wiring diagram details for Vintage B THC units and the LV-3SP Jbox

refer to Certied Drawing FC-THC-H02-H012

6.54"

4.66"

Detail

(Optional) LV-3SP Jbox Interface Control Junction Box

.877"

Metal Sheet

1

2 Terminal Block - Line Voltage

3 Terminal Block - Line Voltage

4 Relays, 24v coil - Line Voltage Contact

5 Terminal Block - Low Voltage

6 Terminal Block, 24v - Line Voltage

7 Transformer, 24v - Line Voltage

8 Divider

3.13"

3.75"

7.73"

4-Pipe System - Right Hand Unit*

*Factory supplied left hand units also available

2-Pipe System - Right Hand Unit*

Page 7 of 12 / Catalog 700

Page 8

Air Volume Capacity Data

Air volume versus external static pressure

Fan Motor Speed

Unit Size

.00 .05 .10 .15 .20 .25 .30 .00 .05 .10 .15 .20 .25 .30 .00 .05 .10 .15 .20 .25 .30

H02

RPM 1070 1130 1170 1200 1230 1262 1291 869 899 966 1012 1051 1104 1142 704 773 826 887 965 1032 1091

H03

RPM 1143 1172 1202 1226 1255 1282 1313 838 890 945 992 1043 1097 1144 714 756 833 886 953 1023 1081

H04

RPM 1122 1165 1201 1221 1258 1285 1314 788 851 903 964 1043 1093 1156 678 737 811 891 957 1028 1091

H06

RPM 1295 1311 1333 1361 1382 1399 1416 990 1017 1060 1102 1151 1182 1230 894 937 994 1049 1086 1141 1181

H08

RPM 1172 1192 1221 1259 1286 1320 1341 931 1003 1027 1072 1124 1167 1219 892 935 956 1014 1070 1121 1174

H10

RPM 1251 1279 1303 1331 1344 1386 1412 984 1037 1068 1115 1169 1245 1255 902 969 1001 1062 1123 1161 1204

H12

RPM 1344 1367 1389 1408 2845 2886 1462 1039 1062 1106 1149 1192 1235 1277 958 1003 1043 1095 1141 1178 1224

Note: Based on 115V operation, and dry coils.

Air Flow cfm

Air Flow cfm

Air Flow cfm

Air Flow cfm

Air Flow cfm

Air Flow cfm

Air Flow cfm

External Static Pressure (inches of water) External Static Pressure (inches of water) External Static Pressure (inches of water)

311 293 276 258 240 223 203 231 211 195 178 164 152 134 181 157 139 125 111 94 87

423 391 368 344 319 297 270 296 277 262 244 229 213 197 234 202 179 161 144 122 113

507 472 444 416 386 359 326 349 327 310 288 268 247 227 278 241 214 192 171 145 134

798 770 742 714 688 654 627 581 555 530 508 483 456 432 518 497 471 444 425 406 376

949 915 874 828 775 730 690 740 701 652 615 572 528 490 662 620 580 535 490 442 400

1032 981 932 881 836 712 716 775 723 688 631 582 533 493 697 643 602 538 496 463 410

1428 1380 1334 1287 1229 1173 1114 1067 1022 976 927 875 833 781 960 912 877 826 788 806 705

High Medium Low

Motor Data

Unit Size

Fan

Motor

Speed

High 0.7 75 1043 1.0 109 1143 1.2 131 1122 1.8 205 1295 2.6 291 1172 2.7 299 1251 3.5 385 1344

Medium 0.6 61 869 0.7 73 838 0.9 93 788 1.4 155 990 2.0 229 931 2.0 225 984 2.7 305 1039

Low 0.5 53 704 0.6 63 714 0.8 83 678 1.3 145 894 1.9 211 892 1.9 211 902 2.5 279 958

Note: Based on 115V operation, dry coil, and 0.0 ESP

H02 H03 H04 H06 H08 H10 H12

Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM

115/60/1

.

Page 8 of 12 / Catalog 700

Page 9

Wiring Diagrams

L

G/Y: GREEN/YELLOW

FIELD WIRING

LF: FAN SPEED LOW

M: FAN MOTOR

MAIN SWITCH

NOTE:

POWER

SOURCE

WHITE

G/Y

BLACK

MF: FAN SPEED MEDIUM

HF: FAN SPEED HIGH

SHF: FAN SPEED SUPER HIGH

G

G/Y

BLUE

N

L

H

FAN SPEED

SWITCH

M

WIRING (115V/1P/60Hz)(208-230V/1P/60Hz)

ORANGE

M

G/Y

YELLOW

RED

SHF

HF

MF

BROWN

LF

BLACK

BLACK

SOURCE

POWER

NOTE:

SHF: FAN SPEED SUPER HIGH

HF: FAN SPEED HIGH

MF: FAN SPEED MEDIUM

G/Y: GREEN/YELLOW

LF: FAN SPEED LOW

M: FAN MOTOR

FIELD WIRING

MAIN SWITCH

G/Y

BLACK

WHITE

BLUE

N

L

WIRING (220V/1P/50Hz)

FAN SPEED

SWITCH

H

RED

SHF

YELLOW

HF

M

L

BROWN

MF

ORANGE

LF

G/Y

BLACK

M

BLACK

H

YELLOW

SHF: FAN SPEED SUPER HIGH

BLACK

YELLOW

LF: FAN SPEED LOW

M1,M2: FAN MOTOR

FIELD WIRING

NOTE:

HF: FAN SPEED HIGH

MF: FAN SPEED MEDIUM

G/Y

RED

G/Y

BLUE

RED

L

SOURCE

POWER

N

FAN SPEED

SWITCH

SHF

HF

ORANGE

BROWN

M2

BLACK

G/Y

BLACK

ORANGE

BROWN

L

M

MF

LF

WIRING (115V/1P/60Hz)(208-230/1P/60Hz)

M1

BLACK

MAIN SWITCH

G

G/Y

WHITE

BLACK

G/Y: GREEN/YELLOW

BLACK

G/Y: GREEN/YELLOW

FIELD WIRING

M1,M2: FAN MOTOR

LF: FAN SPEED LOW

NOTE:

POWER

SOURCE

MAIN SWITCH

BLACK

WHITE

MF: FAN SPEED MEDIUM

HF: FAN SPEED HIGH

SHF: FAN SPEED SUPER HIGH

M2

G/Y

RED

BLUE

N

YELLOW

BROWN

G/Y

BLACK

SWITCH

FAN SPEED

H

M

WIRING (220V/1P/50Hz)

L

LF

G/Y

L

RED

SHF

ORANGE

MF

YELLOW

HF

BROWN

M1

BLACK

ORANGE

BLACK

For Models: THCH02, THCH03, THCH04, and THCH06 (Basic Unit Only)

Wiring (115V/1P/60Hz)(208-230V/1P/60Hz)(265/277V/1P/60Hz) Wiring (220V/1P/50Hz)

For Models: THCH08, THCH10, THCH12 (Basic Unit Only)

Page 9 of 12 / Catalog 700

Page 10

McQuay THC Horizontal Concealed Fan Coil

Engineering Guide Specications

Furnish and install where shown on the plans and specications, McQuay THC Horizontal Concealed Fan-Coil Units.

Types, sizes and performance are as tabulated in the schedule. Unit performance is substantiated by computer gener-

ated output data. Each unit is ARI certied and consists of and complies with the following:

Construction

General – Basic unit consist of a chassis, hydronic coil(s), drain pan, junction box, motor, centrifugal fan assembly.

Top and side panels surrounding the coil are insulated with aluminum foil face to prevent condensation. The casing,

fabricated of heavy gauge galvanized steel with four-sided one inch duct collar for an easy connections to discharge

duct work. Units are available with or without return air plenum. Units with return air plenum have a lter frame

with 3/4" return air duct collar. Plenum is fully insulated with foil faced, thermal and acoustical insulation to prevent

glass bers in the air stream, unit sweating, and to attenuate fan noise. Mounting holes are to be provided on all four

corners to allow the units to be suspended from the ceiling with threaded rods. Selectable either as 2 or 4-pipe systems

with coil pipe connections located on the same side. Units are tested in accordance with ARI 440. The units comply

with NFPA 90A and are ETL listed in the U.S. and Canada. Top panel and drain pan is easily removed to allow coil

access.

Coils – All THC water coils feature aluminum blue ns mechanically bonded to seamless copper tubes. The blue

ns are covered with an epoxy polymer that causes condensation to drip off more quickly, preventing mold build-up

and increasing the coil and n life expectancy. All water coils are 12 ns per inch. Factory burst tested at 425 psig

(2930kPa) and leak tested at 225 psig (1552 kPa). Maximum main coil working pressure is 300 psig (2,069 kPa).

Maximum entering water temperature is 200°F (93°C). Cooling coil (2-Pipe) or combination cooling and heating

coils (4-Pipe) are available. Heating coils are factory installed in the reheat position with same hand coil connection.

Heating coils are capable to be eld converted to preheat position. Coils are provided with a brass header, 3/4" FPT

coil connections, and a hand operated brass manual air vent, conveniently located over the drain pan, and supplied

with a clear plastic hose to prevent spills. The 3/4" FPT connections facilitate the eld installation of McQuay thread-

ed, quick-connect factory built valve package. Coil brass headers are protected with a galvanized steel cover plate and

held in position with holding screws thus providing additional structural support to thread piping-valve package and

matched load pumps.

On Basic units optional sets of two (2) 3/4" MPT x 1/2" copper male adapters are provided if sweat copper tube con-

nections are desirable.

Note: Units provided with factory installed LV-3SP interface board (with or without plenum) are provided with sets of

two (2) 3/4" MPT x 1/2" piping elbow adapter to be used with McQuay threaded, quick-connect valve packages.

Fan Assembly – Aluminum fan wheels are dynamically balanced, forward curved, double-width, inside double-inlet

scroll centrifugal type housings constructed of galvanized steel for corrosion resistance. The rest of the assembly is

made with a heavier gauge galvanized steel which provides additional strength and rigidity resulting in smoother,

quieter operation.

Sound – Units shall have published sound power level data tested in accordance with ARI 350.

(For more information contact your local Mcquay Sales Representative).

Motors – 4 speed, permanently lubricated sleeve bearing, permanent split capacitor motors, (115/60/1) (208-230/60/1)

(265/60/1) with UL listed automatic reset integral thermal overload protection. Maximum ambient operating tempera-

ture of 104°F. Run tested in assembled units.

Motors are resiliently mounted to assure quiet, vibration free operation.

Page 10 of 12 / Catalog 700

Page 11

Drain Pan – Stamped with no welded corners. The galvanized steel drain pans are cleaned, phosphatized before

they are coated with a thick layer of powder paint. Insulated with form-fitted closed cell insulation the drain pan is

positively sloped and easily removable for cleaning. Extended out 6½" beyond the coil connections for valve/piping

packages. Vintage B drain pans include a auxiliary drain connection. Optional stainless steel drain pan is also avail-

able with the same features as above, excluding the backed powder paint.

Insulation – Hideaway return air plenum is fully insulated with foil faced, thermal and acoustical insulation to pre-

vent glass bers entering the air stream, unit sweating, and to attenuate fan noise.

Filters – Standard lter is 1" nominal throwaway type. Design vintage B lters are removable from the sides or

bottom

.

Electrical – THC fan-coils are made available with the following factory installed options:

- Basic: Unit is furnished with single point power connection junction box that includes a terminal strip for line

voltage control connection.

- DDC ready interface: LV-3SP control box includes (3) - 24 volt relays, line voltage/24volt transformer, 4 sets of

terminal strips and toggle disconnect (See Notes below).

Piping Packages - All THC units are available with factory-built piping package options for eld installation. Basic,

enhanced and deluxe piping package options are available with a variety of control valve options:

• 2 or 3-way

• 1/2" control valve

• 2-position or modulating.

Basic piping package consists of a quick-connect union, shutoff ball valve with memory stop and control valve on the

supply and quick-connect union, shutoff ball valve with memory stop on the return.

Enhanced piping package consists of a quick-connect union, shutoff ball valve, control valve on the supply; quickconnect union, shutoff ball valve and manual circuit setter balancing valve on the return.

Deluxe piping package has one quick-connect union, shutoff ball valve, control valve and a strainer on the supply;

quick-connect union, shutoff ball valve, manual circuit setter balancing valve on the return.

Valve packages for sweat connection are also available.

Units with the LV-3SP junction box are provided with a set of two (2) 3/4" MPT x 1/2" piping elbow

Notes:

adapters to be used with McQuay quick-connect, threaded valve packages.

Page 11 of 12 / Catalog 700

Page 12

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.mcquay.com.

©2007 McQuay International • www.mcquay.com • 1.800.432.1342 Catalog 700-3 / Page 12 of 12 (11-07)

Loading...

Loading...