Page 1

Installation & Maintenance Manual IM 745-2

Ceiling Concealed Fan-Coil Unit

Models: THC02, THC03, THC04, THC06, THC08, THC10, THC12

Group: Fan-coil

Part Number: 106572801

Date: June 2003

©2003 McQuay International

®

Page 2

Table of Contents

Installation ............................................................. 3

Receiving ............................................................... 3

Air duct connection ............................................... 4

Drain pipe connection............................................ 4

Pipe connection ..................................................... 4

Wiring .................................................................... 4

Maintenance........................................................... 4

General................................................................... 4

Monthly intervals................................................... 4

Dimensional Data .................................................. 5

CAUTION

!

Sharp edges and coil surfaces are injury hazards. Avoid

contact with them.

Suggested Drain Trapping ..................................... 6

Wiring Diagrams ................................................ 6-7

Motor ............................................................... 6

Control ............................................................. 7

Limited Warranty

Consult your local McQuay Representative for

warranty details. Refer to Form 933-43285Y. To find

your local McQuay Representative, go to

www.mcquay.com.

WARNING

!

Moving machinery and electrical power hazards may cause

severe personal injury or death. Disconnect and lock off

power before servicing equipment.

NOTICE

Installation and maintenance are to be performed only by qualified personnel who are familiar with and in compliance with

state, local and national codes and regulations, and experienced with this type of equipment.

IM 745 / Page 2 of 8 ©2003 McQuay International

Page 3

Installation

Discharge Air

Return Air

Ceiling

Ceiling Access Panel

with Air Return

Terminal

Block

A

Fan Coil

Unit

Flat

Washer

Hanging

Rod

Expansion

Screw

Nut

Detail A

Vibration

Isolator

(by others)

Receiving

All units leaving the McQuay plant are inspected for quality

prior to shipment.

Carefully inspect all shipments immediately upon delivery. Note

visible damage on the carrier’s freight bill and request that the

carrier send a representative to inspect the damage. This may

be completed by telephone or in person, but should always be

confirmed in writing.

The shipment should be unpacked in the presence of the agent

so that the extent of the damage or loss can be determined. The

carrier’s agent will make an inspection report and a copy will

be given to the consignee for forwarding to the carrier with a

formal claim.

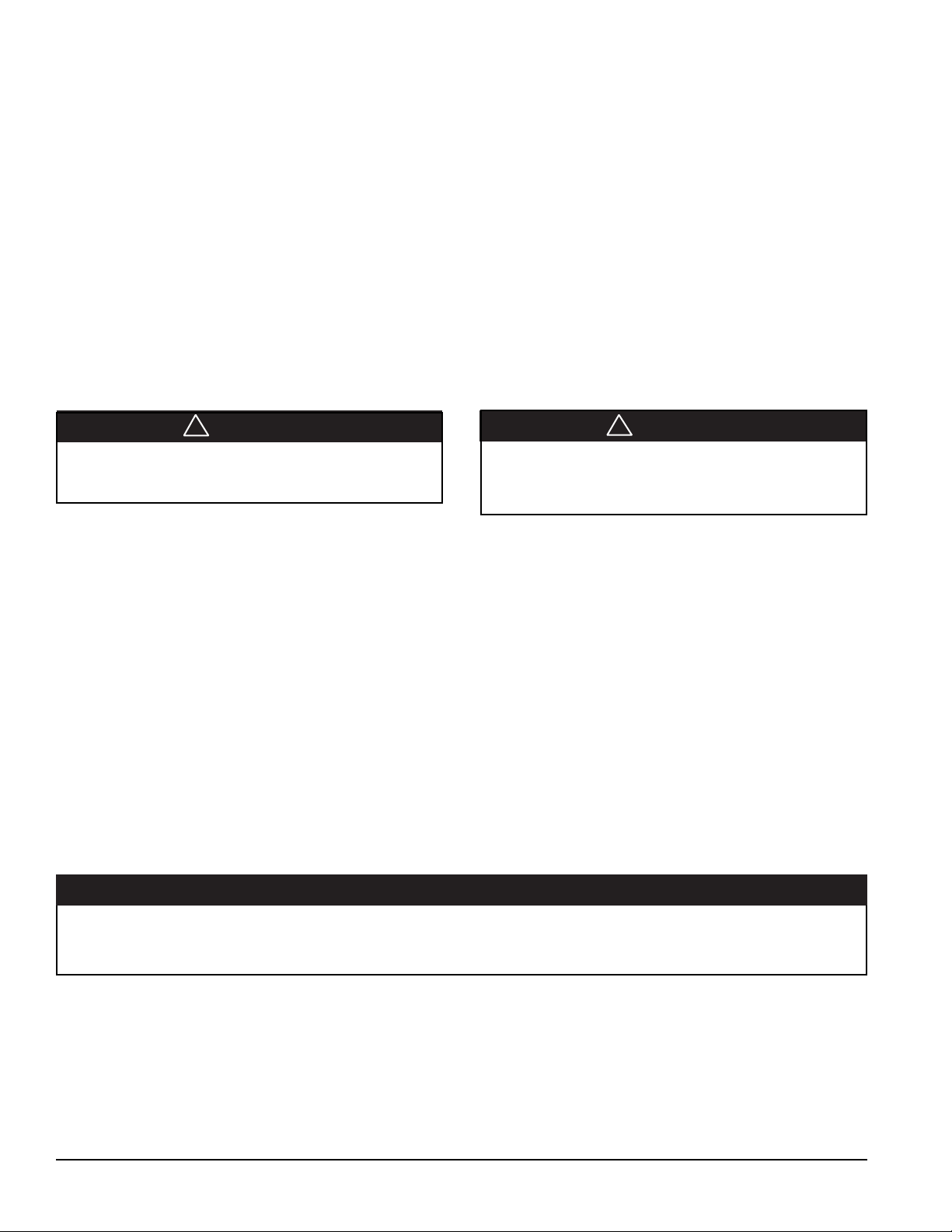

Unit Installation

The unit is designed to be concealed in the ceiling. Installation

and maintenance should be performed by qualified personnel

who are familiar with local codes and regulations, and experienced with this type of equipment.

There are holes on the top of the unit for hanging the unit above

the ceiling. Please refer to Figure 1. , Figure 2., and Figure 3.

NOTE: Vibration isolaters provided by others.

NOTICE

Make sure the top of the unit is level after installation. The

drain pan is designed with a little gradient to facilitate

drainage. Do Not Level Drain Pan!

NOTICE

Before installation and running the unit, please check the

following:

1. There must be enough space for the unit installation

and maintenance. Please refer to the unit outline and

dimensions in Figure 1 for the minimum distance

between the unit and obstacles.

2. Mount with the lowest moving parts at least 8 feet above

the floor or grade level.

3. Ensure enough space for piping connection and

electrical wiring.

4. Leave a means for disconnection from the electrical

supply according to NEC or local codes.

5. Check whether the hanging rods can support the weight

of the unit.

6. The unit must be installed horizontally for proper

operation and condensate draining.

7. The external static pressure must be within the

allowable static pressure range.

8. The installing contractor must supply service valves and

insulation for water piping in accordance with local codes

and regulations.

Figure 1.

Figure 2.

Obstacle

B

Ceiling

Obstacle

A=8 in.

B= 16 in.

C=16 in.

A

C

9. To prevent strain on the wire connections, use either

conduit or approved strain relief device.

10. Confirm that the power has been switched OFF before

installing or servicing the unit.

IM 745 / Page 3 of 8 ©2003 McQuay International

Page 4

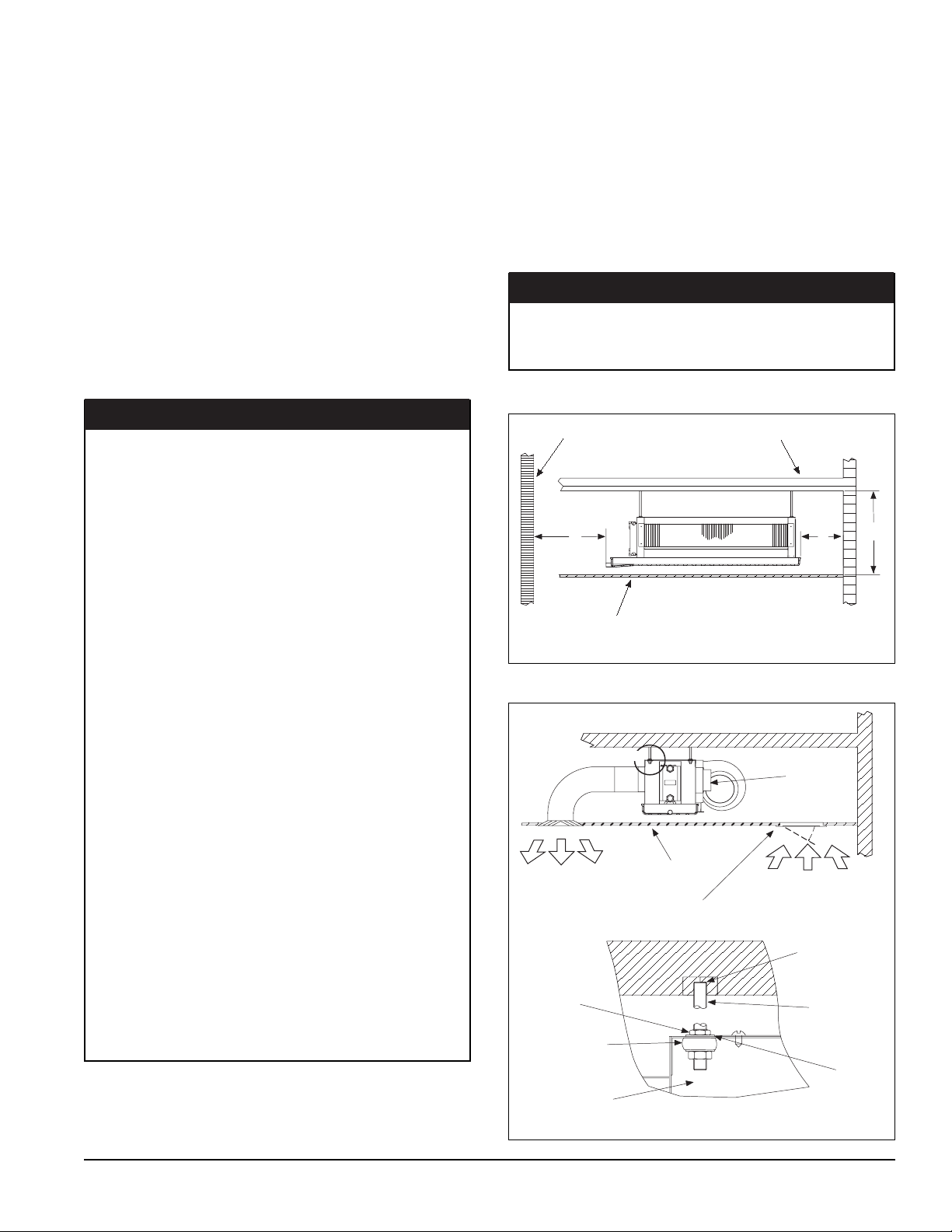

Figure 3.

Pipe Connection

Chilled Water Pipe Connection

Connect chilled water pipes to the unit. The water inlet is on the

A

bottom and water outlet is on top.

Return Air

Plenum

Ceiling

Discharge Air

Nut

Vibration

Isolator

(by others)

Fan Coil

Unit

Return Air

Detail A

Return Air Grille

with Filter

Expansion

Screw

Hanging

Rod

Flat

Washer

Air Duct Connection

Air ducts should be made of galvanized steel and

connected to the flange of the unit with a canvas connector.

Refer to the unit dimensions. Insert the duct into the flange and

fix with screws.

Duct connections must be installed in accordance with national

and local codes.

Wiring

Wiring connection must be completed according to the wiring

diagram on the unit.

The unit must be GROUNDED.

Installation of all field wiring must comply with NEC and

local codes.

WARNING

!

A means for disconnect from electrical supply shall be

provided according to NEC or local codes. Confirm that the

power has been switched OFF before installing or servicing

the unit.

Maintenance

General

A good general maintenance plan will avoid performance loss

and unexpected shut-down of the equipment.

A dirty filter reduces air flow as well as unit performance. Changing or cleaning the filter is very important. Check the filter

monthly and replace or clean as required.

Drain Pipe Connection - Per Local Codes

The drain pipe can be PVC or steel. Connect the drain pipe to

the unit. Pipe insulation is recommended to avoid condensation. The suggested slope of the drain pipe is at least 1/8" per

foot, but local code will prevail. Refer to Figure 4 for typical

piping installation.

NOTE: See suggested condensate (trap) drawing on page 6.

Figure 4.

Air Flow

Return Ball Valve

Control Valve

Actuator

Supply Gate Valve

Coils should be cleaned of dust, dirt and lint with compressed

air or water. They can be vacuumed or brushed with a soft brush.

CAUTION

!

Water coils exposed to freezing temperatures should be

drained or anti-freeze should be added to the water circuit

to avoid freezing.

Monthly intervals

1. Inspect and clean the condensate drain pan to help avoid

clogging of drainage by dirt, dust, etc. Inspect drainage

piping for proper condensate flow.

2. Check and clean the coil. Clean the coil with a low pressure

water jet or low pressure air.

3. Clean and tighten all the wiring connections.

IM 745 / Page 4 of 8 ©2003 McQuay International

Page 5

Dimensional Data – THC Horizontal Concealed, with Extended Drain Pan and Plenum Filter Box

Unit Size A B C D E F

Number

of Fans Size Qty

H02 32.05" 17.64" 19.17" 19.96" 18.46" 21.13" 1 181/8" x 8" x 1" 1

H03 38.74" 24.33" 25.87" 26.65" 25.15" 27.82" 1 247/8" x 8" x 1" 1

H04 43.86" 29.45" 30.98" 31.77" 30.20" 32.94" 2 297/8" x 8" x 1" 1

H06 51.73" 37.32" 38.86" 39.65" 38.07" 40.82" 2 187/8" x 8" x 1" 2

H08 61.57" 47.17" 48.70" 49.49" 47.91" 50.66" 3 233/4" x 8" x 1" 2

H10 65.51" 51.10" 52.64" 53.43" 51.85" 54.60" 3 253/4" x 8" x 1" 2

H12 75.75" 61.34" 62.87" 63.66" 62.09" 64.83" 4 30

All dimensions ± 0.10"

F

Filters

7

/8" x 8" x 1" 2

8.75"

2.32"

7.36"

1.5"

D

E

2"

A

TOP VIEW

B

C

FILTER

- R/A PLENUM

MOUNTING HOLES 3/8" x 5/8"

4 - MOUNTING

HOLES 3/8" x 5/8"

CONDENSATE

DRAIN

6.38"

9.75"

AIR

VENT

3/4" MPT

Plenum Back with Filter

1.02"

5.75"

9.75"

FRONT VIEW

1.40"

CONDENSATE

DRAIN 3/4" MPT

FILTER

RAIL

CHILLED WATER

CONNECTION 3/4" FPT

WATER RETURN

CONNECTION 3/4" FPT

1.25"

1.25"

4.53"

9.25"

23.25"

1.73"

12.75"

TERMINAL BLOCK

1.25"

1.25"

9.25"

5.82"

23.25"

TERMINAL BLOCK

2.75"

9.88"

3.46"

HOT WATER

CONNECTION

3/4" FPT

9.53"

WATER SUPPLY

CONNECTION 3/4" FPT

4-Pipe System

9.88"

4.72"

8.125"

9.53"

2-Pipe System

IM 745 / Page 5 of 8 ©2003 McQuay International

Page 6

Suggested Condensate Trapping

The condensate trap provides the water seal (water level in the

condensate trap) to prevent the flow of air from the condensate

drain line into the coil section during normal operation.

Suggested Condensate Trap

CONDENSATE

PAN

Improper trapping can lead to several problems. If the trap is

too tall, back pressure will prevent drainage, causing condensate backup. If the trap is too short the seal will be destroyed or

nonexistent, producing the same effect as a non-trapped

C

system.

The trap should be constructed of 7/8" clear plastic piping. The

condensate piping from the drain trap must be sloped to facilitate proper drainage. The clear plastic trap should be clamped

and removable for cleaning. It may be necessary to manually

fill the trap at system start-up, or to run the unit for sufficient

time to build a condensate seal. The condensate trap and condensate piping drainage should be free of any foreign debris.

Condensate Drain Trap Dimensions

ABC

1

/2" 3/4" 31/8"

1

Foreign debris can prevent proper operation resulting in condensate buildup.

Wiring Diagrams

For Models: THCH02, THCH03, THCH04, and THCH06

Wiring (115V/1P/60Hz)(208-230V/1P/60Hz)(265/277V/1P/60Hz) Wiring (220V/1P/50Hz)

7/8" I.D.

A

B

FAN SPEED

SWITCH

BLACK

POWER

WHITE

G/Y

SOURCE

NOTE:

MAIN SWITCH

M~: FAN MOTOR

G/Y: GREEN/YELLOW

LF: FAN SPEED LOW

L

M

H

FIELD WIRING

LF

MF

HF

SHF

N

G

ORANGE

BROWN

YELLOW

RED

L

BLUE

G/Y

For Models: THCH08, THCH10, THCH12

FAN SPEED

SWITCH

BLACK

POWER

WHITE

G/Y

SOURCE

NOTE:

M1,M2: FAN MOTOR

G/Y: GREEN/YELLOW

LF: FAN SPEED LOW

L

M

H

MAIN SWITCH

FIELD WIRING

LF

MF

HF

SHF

L

N

G

ORANGE

BROWN

YELLOW

RED

BLUE

G/Y

BLACK

M~

BLACK

G/Y

MF: FAN SPEED MEDIUM

HF: FAN SPEED HIGH

SHF: FAN SPEED SUPER HIGH

BLACK

M1

BLACK

G/Y

ORANGE

BROWN

YELLOW

RED

MF: FAN SPEED MEDIUM

HF: FAN SPEED HIGH

SHF: FAN SPEED SUPER HIGH

BLACK

M2

BLACK

G/Y

FAN SPEED

POWER

SOURCE

NOTE:

M~: FAN MOTOR

G/Y: GREEN/YELLOW

LF: FAN SPEED LOW

FAN SPEED

SWITCH

POWER

SOURCE

NOTE:

M1,M2: FAN MOTOR

G/Y: GREEN/YELLOW

LF: FAN SPEED LOW

SWITCH

L

M

H

BLACK

WHITE

MAIN SWITCH

FIELD WIRING

L

M

H

BLACK

WHITE

MAIN SWITCH

FIELD WIRING

LF

MF

HF

SHF

SHF

L

N

LF

MF

HF

L

N

ORANGE

BROWN

YELLOW

RED

BLUE

ORANGE

BROWN

YELLOW

RED

BLUE

G/Y

MF: FAN SPEED MEDIUM

HF: FAN SPEED HIGH

SHF: FAN SPEED SUPER HIGH

ORANGE

BROWN

YELLOW

G/Y

RED

MF: FAN SPEED MEDIUM

HF: FAN SPEED HIGH

SHF: FAN SPEED SUPER HIGH

BLACK

M~

BLACK

G/Y

BLACK

M1

BLACK

G/Y

BLACK

M2

BLACK

G/Y

IM 745 / Page 6 of 8 ©2003 McQuay International

Page 7

Control Wiring Schematic - Heating/Cooling 2-Pipe With Automatic Changeover

Legend

16

Wire No.

ORG

CLG

BLU

BLU

C/O

BLK

BLK

V

WHT

TCI

RED

HTG

RED

Control Wiring Schematic - Heating/Cooling 4-Pipe With Sequencing Thermostat

Legend

ORG

WHT

CLG

HTG

TCI

V

C/O

TCI

CLG

BLU

HTG

RED

BLK

BLK

CLG

V

HTG

V

WHT

WHT

WHT

CLG

HTG

TCI

V

C/O

Wire No.

16

Wire Color

WHT

Wire Connector

Wire Connector

Field Connector

Cooling

Heating

Thermostat

Val ve

Change over Switch

(Manual or Auto)

Wire Color

Wire Connector

Wire Connector

Field Connector

Cooling

Heating

Thermostat

Valve

Change over Switch

(Manual or Auto)

IM 745 / Page 7 of 8 ©2003 McQuay International

Page 8

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.mcquay.com.

®

4900 Technology Park Boulevard • Auburn, New York 13021-9030 • 800-432-1342 • www.mcquay.com IM 745-2 / (Rev 6-03) Pg 8 of 8

©2003 McQuay International

Loading...

Loading...