McQuay TGZ 050A, TGZ 080A, TGZ 120A, TGZ 150A, TGZ 060A Operation And Maintenance Manual

...Page 1

Operation and Maintenance Manual

TGZ Scroll Compressor Templifiers

OMM TGZ-1

Group: Chiller

Part Number: 331975601

Effective: February 2011

Supercedes: June 2009

TGZ 040A to TGZ 190A, Packaged Water Heater

600 to 3100 MBH

R134a

Software: WGZDU0102E

Corrections

2/22/11 Changed/added setpoints pgs 62, 63,+

Page 2

Table of Contents

Introduction ........................................... 3

General Description .......................................... 3

Nomenclature.................................................... 3

Water Pressure Drop............................. 3

TGZ Scroll........................................................ 4

TGZ Electrical Data.............................. 7

Field Wiring Diagram ......................... 16

Start-Up and Shutdown ...................... 18

Pre Start-up ..................................................... 18

Start-up ........................................................... 18

Weekend or Temporary Shutdown.................. 19

Start-up after Temporary Shutdown................ 19

Extended Shutdown ........................................ 19

Start-up after Extended Shutdown .................. 19

Sequence of Operation ........................ 20

MicroTech II Controller...................... 23

TGZ Controller Software Version................... 23

General Description ........................................ 23

Inputs and Outputs ............................. 25

Large PCO2/PCO3 Controller ........................ 25

Expansion I/O Controller................................ 27

Setpoints ......................................................... 27

Events & Alarms.................................. 30

Protection (Shutdown) Alarms........................ 30

Alarms and Events .............................. 30

Unit Stop Alarms............................................. 30

Limit Events.................................................... 34

Controller Operation ........................... 37

EXV Control ................................................... 52

Using the Controller.............................53

Menu Screens.................................................. 55

Menu Descriptions .......................................... 55

BAS Interface ................................................. 72

Optional Controls................................. 74

Part Winding Start........................................... 74

Phase/Voltage Monitor (Optional) .................. 74

Hot Gas Bypass (Optional) ............................. 74

System Maintenance ............................ 76

General............................................................ 76

Electrical Terminals ........................................ 77

Operating Limits ............................................. 77

Compressor Oil ............................................... 77

Oil Equalization .............................................. 78

Sightglass and Moisture Indicator................... 78

Crankcase Heaters........................................... 78

System Service......................................79

Filter-Driers..................................................... 79

Liquid Line Solenoid Valve ............................ 79

Troubleshooting Chart ........................80

©2007 McQuay International. Illustrations and data cover the McQuay International product at the time of publication and we reserve

the right to make changes in design and construction at anytime without notice. ™® The following are trademarks or registered

trademarks of their respective companies: BACnet from ASHRAE; LONM

managed, granted and used by LONM

Corporation; Modbus from Schneider Electric; MicroTech II and Open Choices from McQuay International

Manufactured in an ISO Certified facility

ARK

ARK

International under a license granted by Echelon Corporation; Compliant Scroll from Copeland

, LonTalk, LONW

ORKS

, and the LONM

ARK

logo are

2 TGZ 040A through TGZ 190A OMM TGZ-1

Page 3

Introduction

General Description

McQuay Type TGZ water heaters are scroll compressor refrigeration units that recover heat from warm

fluid streams in the evaporator and deliver hot water, at a useful temperature, from the condenser to a

heating load. They are designed for indoor installations only and are completely assembled, wired,

charged and tested. Each unit consists of four or six (depending on unit size) scroll compressors,

brazed-plate evaporators on models 040 to 120 and shell-and-tube evaporators on models 150 to 190,

shell-and-tube condenser/heater, and complete refrigerant piping.

There are two refrigerant circuits, each with manual liquid line shutoff valves, charging valves, filterdriers, liquid line solenoid valves, sightglass/moisture indicators, and expansion valves (thermal on

TGZ 040-120, electronic on TGZ 150-190.

The electrical control center includes a MicroTech II control system and other components necessary

for dependable automatic operation.

NOTE: Additional information not included in this manual, such as unit dimensions and weights,

physical data, and performance data can be found in Catalog Templifier-1.

Nomenclature

T G Z 100 A

Templifier

Vintage

Global

Scroll Compressor

Nominal Evaporator

Capacity in Tons

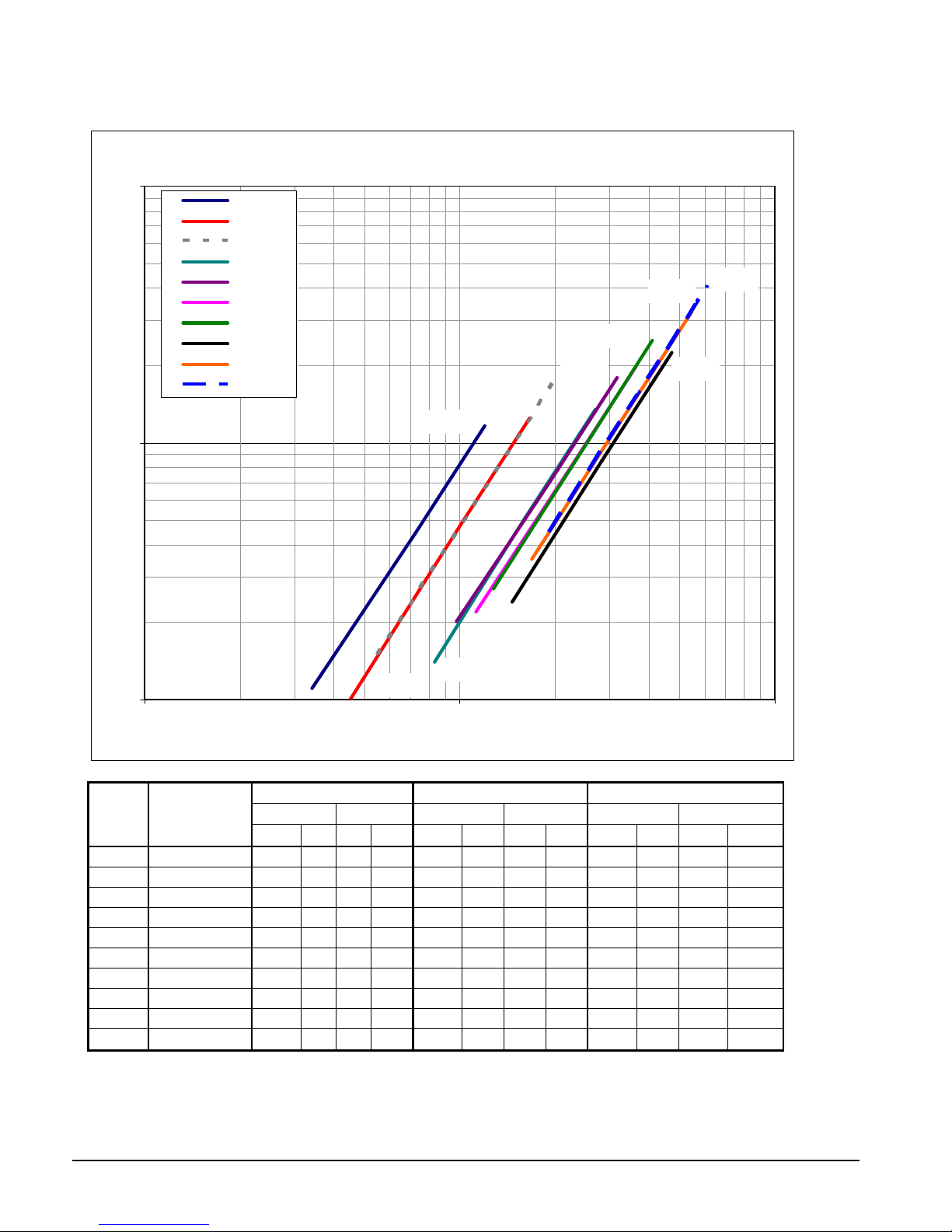

Water Pressure Drop

The vessel flow rates must fall between the minimum and maximum values shown on the appropriate

evaporator and condenser curves on pages 4 through 6. Flow rates below the minimum values shown will

result in laminar flow that will reduce efficiency, cause erratic operation of the expansion valve and could

cause low temperature cutoffs. On the other hand, flow rates exceeding the maximum values shown can cause

erosion on the evaporator water connections and tubes.

Measure the water pressure drop through the vessels at field installed pressure taps. It is important not to

include valves or strainers in these readings.

The condenser flow rate will determine whether 2-pass or 4-pass condensers are used, according to the

following table:

CONDENSER DELTA-T PASSES FLOW

10- to 20 Degrees F 2-Pass High Flow Rate

20 to 40 Degrees F 4-Pass Low Flow Rate

The entering water should be piped to the bottom connection of the condenser and out the top.

OMM TGZ-1 TGZ 040A through TGZ 190A 3

Page 4

TGZ Scroll

Figure 1, Evaporator Pressure Drop

TGZ Evaporator Water Pressure Drop

100

10

Dp (ft)

TGZ040

TGZ050

TGZ060

TGZ080

TGZ100

TGZ110

TGZ120

TGZ150

TGZ170

TGZ190

TGZ040

TGZ060

TGZ110

TGZ100

TGZ120

TGZ170

TGZ150

TGZ190

TGZ050

TGZ080

1

10 100 1000

Flow Rate (gpm)

TGZ UNIT

MODEL

040A

050A

060A

080A

100A

110A

120A

150A

170A

190A EV34191212/7 192 4.5 12.1 13.4 369 15.5 23.3 46.3 615 40.9 38.8 122.3

Note: Nominal Flow Rate is gpm for 10ºF Delta-T at unit operating conditions of evaporator at 75/65ºF water temp and condenser at

110/30º F water temp.

EVAPORATOR

MODEL

AC250-70DQ 34 1.1 2.1 3.2 72 4.4 4.5 13.2 120 11.6 7.6 34.7

AC250-94DQ 45 1.0 2.8 3.1 100 4.7 6.3 14.0 167 12.5 10.5 37.2

AC250-94DQ 55 1.5 3.5 4.5 121 6.7 7.6 20.0 202 17.7 12.7 53.0

AC350-162DQ 83 1.4 5.2 4.3 162 5.1 10.2 15.2 270 13.5 17.0 40.2

AC350-162DQ 98 2.0 6.2 5.8 189 6.8 11.9 20.3 315 17.9 19.9 53.6

AC350-182DQ 113 2.2 7.1 6.4 218 7.5 13.8 22.4 363 19.8 22.9 59.1

AC350-182DQ 128 2.7 8.1 8.2 246 9.5 15.5 28.4 410 25.1 25.9 74.9

EV34191111/9 147 2.4 9.3 7.3 283 8.5 17.9 25.4 472 22.5 29.8 67.1

EV34191212/7 169 3.5 10.7 10.5 326 12.2 20.6 36.5 543 32.2 34.3 96.1

MINIMUM FLOW RATE NOMINAL FLOW RATE MAXIMUM FLOW RATE

INCH-POUND S.I. INCH-POUND

GPM FT. L/S KPA GPM FT. LPS KPA GPM FT. LPS KPA

S.I. INCH-POUND

S.I.

4 TGZ 040A through TGZ 190A OMM TGZ-1

Page 5

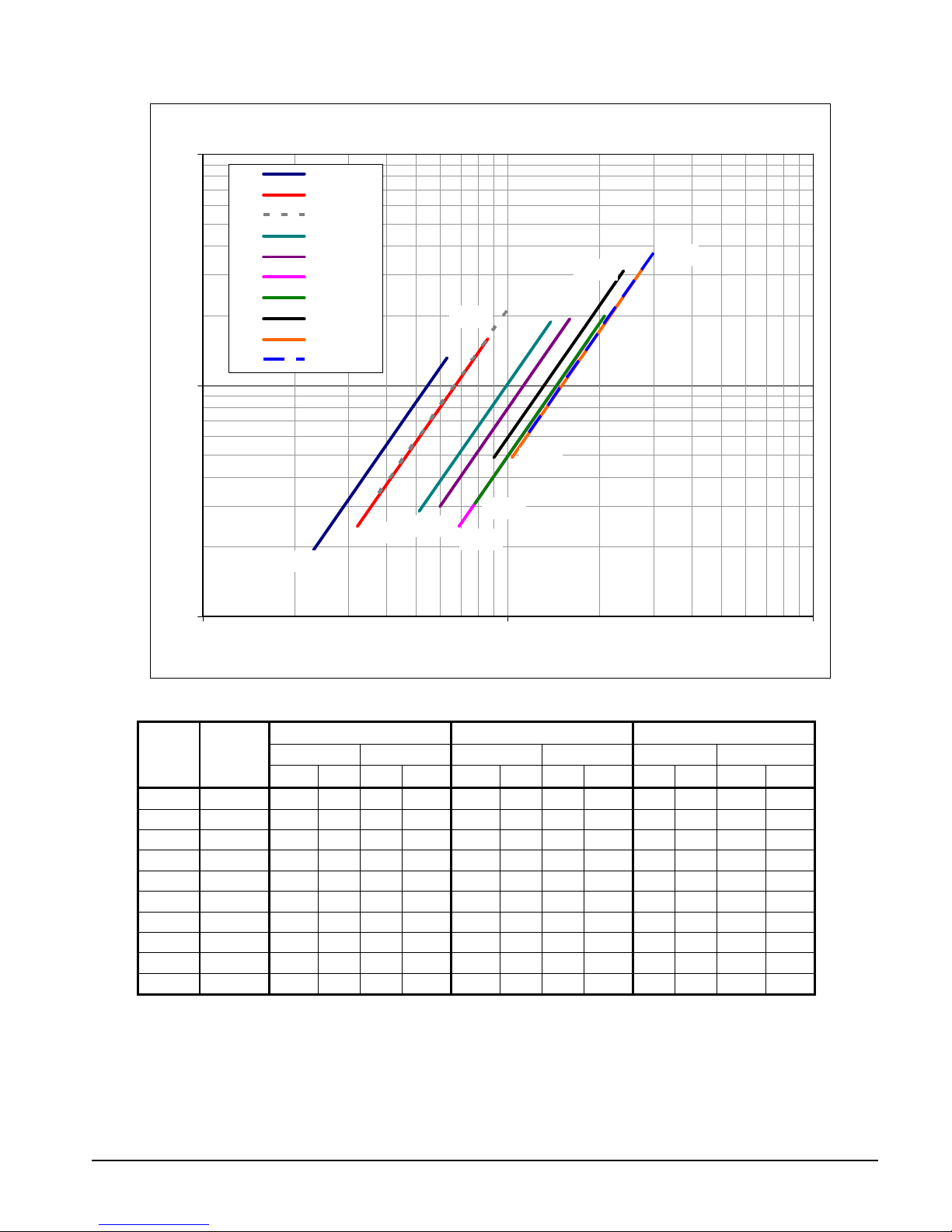

Figure 2, Standard Four-pass Condenser Pressure Drop

TGZ 4-Pass Condenser Water Pressure Drop

100

TGZ040

TGZ050

TGZ060

TGZ080

TGZ100

TGZ110

TGZ120

TGZ150

TGZ170

TGZ190

TGZ060

TGZ100

10

Dp (ft)

TGZ170

TGZ120

TGZ080

TGZ050

TGZ040

TGZ110

TGZ150

TGZ190

1

TGZ UNIT

MODEL

TGZ040

TGZ050

TGZ060

TGZ080

TGZ100

TGZ110

TGZ120

TGZ150

TGZ170

TGZ190

10 100 1000

Flow Rate (gpm)

COND.

MODEL

C1010-62 23 1.93 1.45 5.77 47 7.5 3.0 22.4 63 13.1 4.0 39.1

C1010-62 32 2.44 2.02 7.29 64 9.1 4.0 27.2 86 16.0 5.4 47.7

C1010-76 38 3.40 2.40 10.16 77 13.0 4.9 38.9 103 22.6 6.5 67.5

C1410-112 51 2.84 3.22 8.49 103 10.8 6.5 32.3 138 18.8 8.7 56.3

C1410-128 60 3.00 3.79 8.97 120 11.2 7.6 33.5 160 19.3 10.1 57.8

C1610-164 69 2.44 4.35 7.29 138 9.1 8.7 27.2 184 15.7 11.6 47.0

C1610-164 78 3.08 4.92 9.21 156 11.5 9.8 34.4 208 19.9 13.1 59.4

C1612-164 90 4.85 5.68 14.50 180 18.1 11.4 54.1 240 31.3 15.1 93.4

C1612-184 103 4.89 6.50 14.60 207 18.4 13.1 55.0 276 31.8 17.4 95.0

C1612-184 117 6.24 7.38 18.66 234 23.3 14.8 69.6 312 40.2 19.7 120.3

MINIMUM FLOW RATE NOMINAL FLOW RATE MAXIMUM FLOW RATE

INCH-POUND

GPM FT L/S KPA GPM FT L/S KPA GPM FT L/S KPA

S.I. INCH-POUND

S.I. INCH-POUND

S.I.

OMM TGZ-1 TGZ 040A through TGZ 190A 5

Page 6

100

10

Dp (ft)

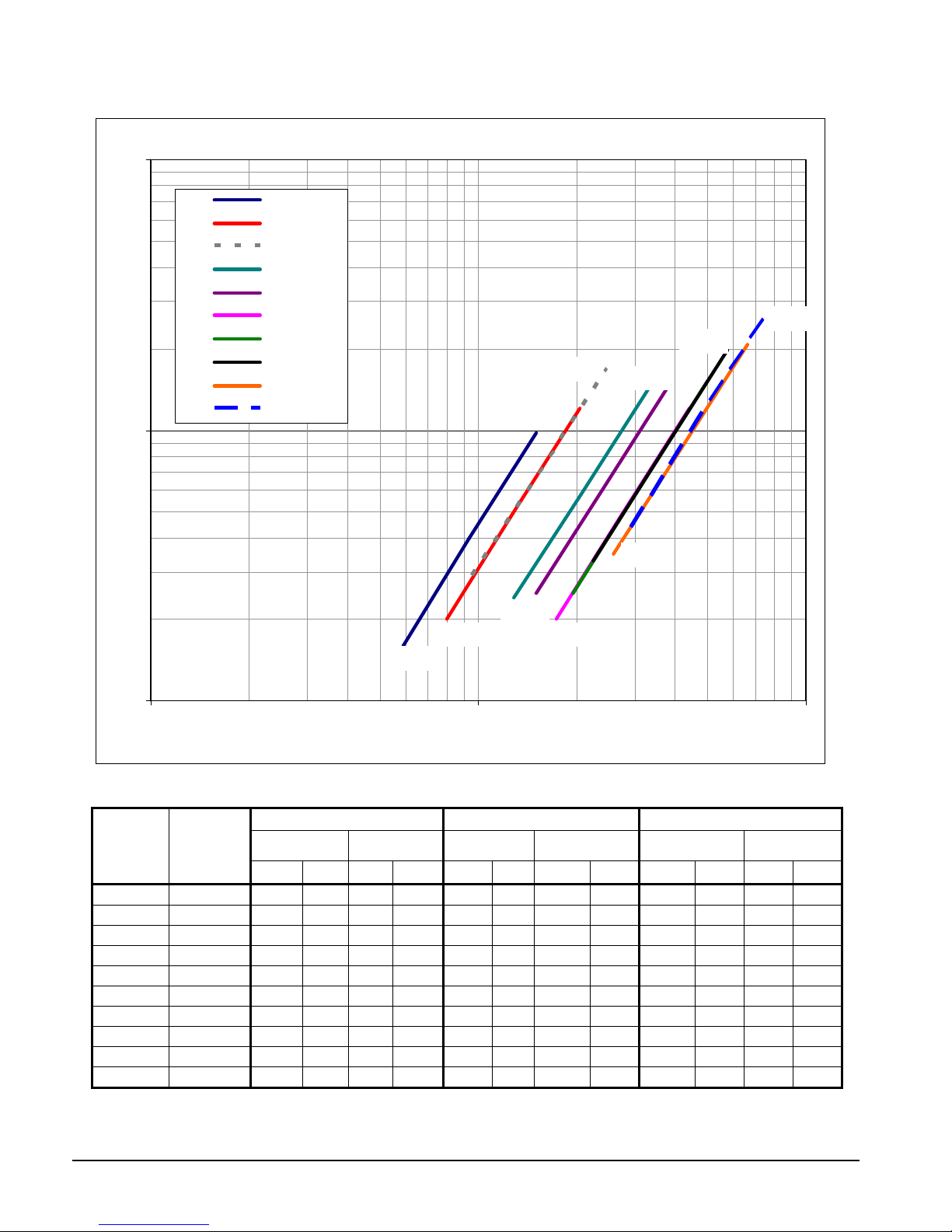

Figure 3, Optional Two-pass Condenser

TGZ 2-Pass Condenser Water Pressure Drop

TGZ040

TGZ050

TGZ060

TGZ080

TGZ100

TGZ110

TGZ120

TGZ150

TGZ170

TGZ190

TGZ060

TGZ190

TGZ150

TGZ100

TGZ170

TGZ080

TGZ050

TGZ040

TGZ120

TGZ110

1

10 100 1000

Flow Rate (gpm)

MINIMUM FLOW RATE NOMINAL FLOW RATE MAXIMUM FLOW RATE

TGZ UNIT

MODEL

TGZ040

TGZ050

TGZ060

TGZ080

TGZ100

TGZ110

TGZ120

TGZ150

TGZ170

TGZ190

COND.

MODEL.

C1010-62 59 1.6 3.7 4.9 94 4.0 5.9 12.0 150 9.8 9.5 29.3

C1010-62 80 2.0 5.0 6.0 128 4.9 8.1 14.6 205 12.0 12.9 35.8

C1010-76 96 2.9 6.1 8.5 154 7.0 9.7 20.9 246 17.0 15.5 51.0

C1410-112 129 2.4 8.1 7.1 206 5.8 13.0 17.3 330 14.2 20.8 42.3

C1410-128 150 2.5 9.5 7.3 240 6.0 15.1 17.9 384 14.7 24.2 43.8

C1610-164 173 2.0 10.9 6.0 276 4.9 17.4 14.6 442 12.0 27.9 35.8

C1610-164 195 2.5 12.3 7.6 312 6.2 19.7 18.5 499 15.1 31.5 45.3

C1612-164 225 3.3 14.2 9.9 360 8.1 22.7 24.2 576 19.8 36.3 59.1

C1612-184 259 3.5 16.3 10.4 414 8.5 26.1 25.4 662 20.8 41.8 62.1

C1612-184 293 4.4 18.5 13.2 468 10.8 29.5 32.3 749 26.4 47.2 78.8

INCH-POUND S.I.

GPM FT L/S KPA GPM FT L/S KPA GPM FT LPS KPA

INCH-

POUND

S.I. INCH-POUND S.I.

6 TGZ 040A through TGZ 190A OMM TGZ-1

Page 7

TGZ Electrical Data

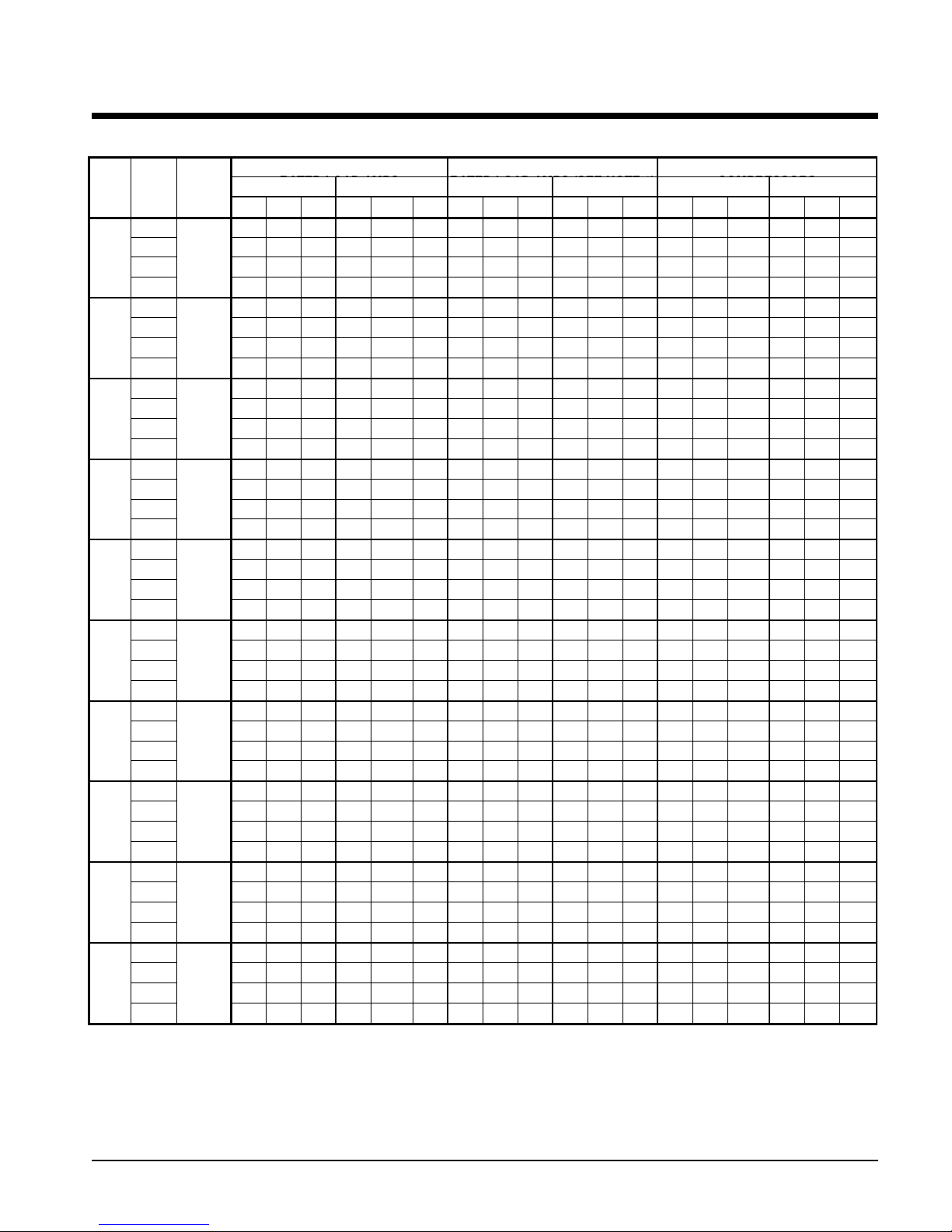

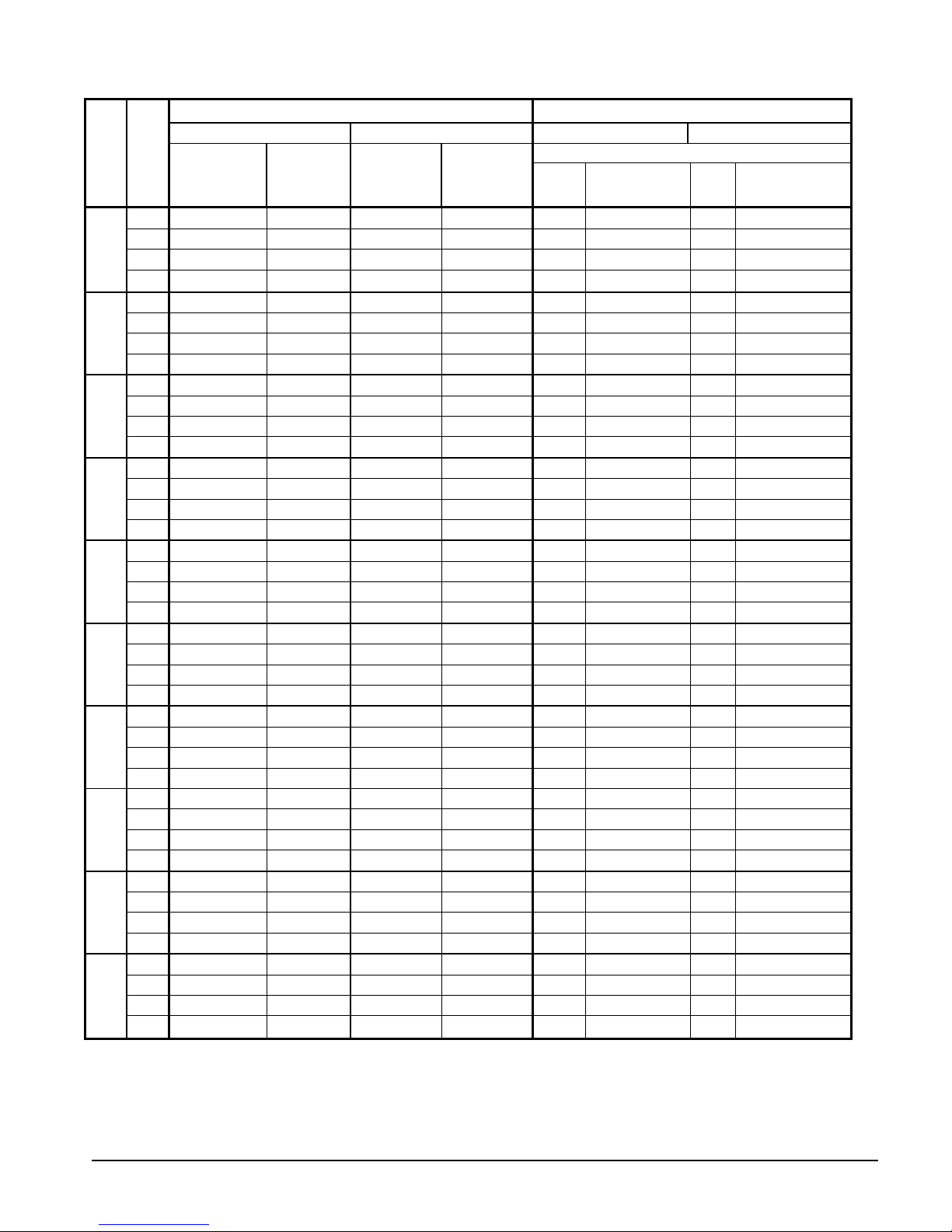

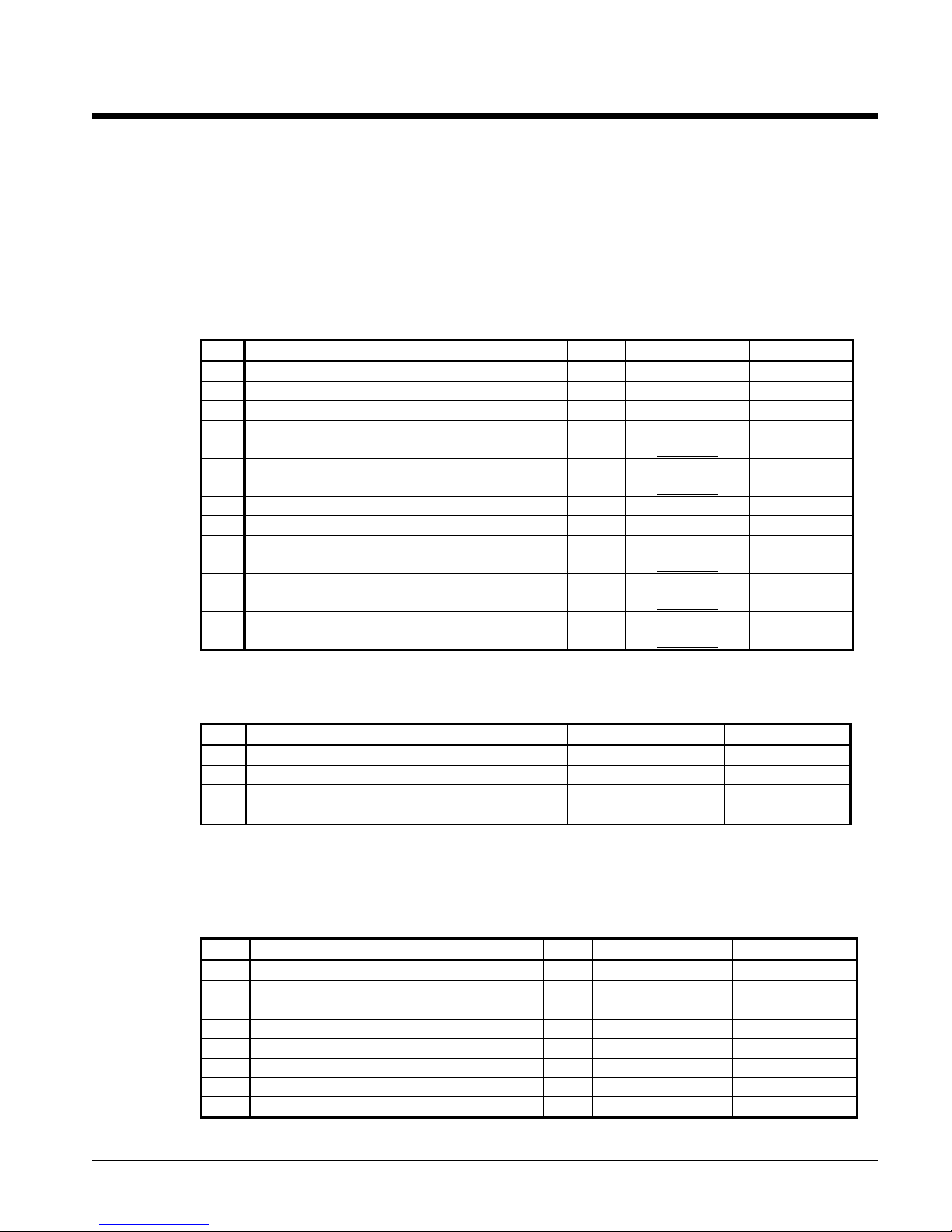

Table 1, Compressor Amp Draw

TGZ

UNIT

VOLTS

SIZE

040

050

060

080

100

110

120

150

170

190

NOTES:

1. External overloads only available on Templifier units with 140°F maximum condenser leaving water temperature.

2. Unit wire sizing amps are equal to 125% of the largest compressor-motor RLA plus 100% of RLA of all other loads in the circuit including control

transformer.

3. Single point power supply requires a single fused disconnect to supply electrical power to the unit.

4. Compressor RLA values are for wire sizing purposes only and do not reflect normal operating current draw.

FREQ.

(HERTZ)

208 35.3 35.3 - 35.3 35.3 - 30.8 30.8 - 30.8 30.8 - 239 239 - 239 239 -

230 35.3 35.3 - 35.3 35.3 - 28.0 28.0 - 28.0 28.0 - 239 239 - 239 239 -

460 17.9 17.9 - 17.9 17.9 - 14.0 14.0 - 14.0 14.0 - 125 125 - 125 125 -

575

208 48.1 48.1 - 48.1 48.1 - 42.0 42.0 - 42.0 42.0 - 300 300 - 300 300 -

230 48.1 48.1 - 48.1 48.1 - 38.4 38.4 - 38.4 38.4 - 300 300 - 300 300 -

460 21.8 21.8 - 21.8 21.8 - 19.2 19.2 - 19.2 19.2 - 150 150 - 150 150 -

575

208 54.0 54.0 - 54.0 54.0 - 54.0 54.0 - 54.0 54.0 - 340 340 - 340 340 -

230 52.6 52.6 - 52.6 52.6 - 48.8 48.8 - 48.8 48.8 - 340 340 - 340 340 -

460 25.6 25.6 - 25.6 25.6 - 24.4 24.4 - 24.4 24.4 - 173 173 - 173 173 -

575

208 73.1 73.1 - 73.1 73.1 - 58.0 58.0 - 58.0 58.0 - 505 505 - 505 505 -

230 73.1 73.1 - 73.1 73.1 - 52.8 52.8 - 52.8 52.8 - 505 505 - 505 505 -

460 30.1 30.1 - 30.1 30.1 - 26.4 26.4 - 26.4 26.4 - 225 225 - 225 225 -

575

208 73.1 73.1 - 73.1 73.1 - 69.2 69.2 - 69.2 69.2 - 500 500 - 500 500 -

230 73.1 73.1 - 73.1 73.1 - 62.4 62.4 - 62.4 62.4 - 500 500 - 500 500 -

460 35.3 35.3 - 35.3 35.3 - 31.2 31.2 - 31.2 31.2 - 250 250 - 250 250 -

575

208 73.1 73.1 - 93.6 93.6 - 69.2 69.2 - 88.8 88.8 - 500 500 - 599 599 -

230 73.1 73.1 - 93.6 93.6 - 62.4 62.4 - 80.0 80.0 - 500 500 - 599 599 -

460 35.3 35.3 - 45.5 45.5 - 31.2 31.2 - 40.0 40.0 - 250 250 - 310 310 -

575

208 93.6 93.6 - 93.6 93.6 - 88.8 88.8 - 88.8 88.8 - 599 599 - 599 599 -

230 93.6 93.6 - 93.6 93.6 - 80.0 80.0 - 80.0 80.0 - 599 599 - 599 599 -

460 45.5 45.5 - 45.5 45.5 - 40.0 40.0 - 40.0 40.0 - 310 310 - 310 310 -

575

208 73.1 73.1 73.1 73.1 73.1 73.1 69.2 69.2 69.2 69.2 69.2 69.2 500 500 500 500 500 500

230 73.1 73.1 73.1 73.1 73.1 73.1 62.4 62.4 62.4 62.4 62.4 62.4 500 500 500 500 500 500

460 35.3 35.3 35.3 35.3 35.3 35.3 31.2 31.2 31.2 31.2 31.2 31.2 250 250 250 250 250 250

575

208 73.1 73.1 73.1 93.6 93.6 93.6 69.2 69.2 69.2 88.8 88.8 88.8 500 500 500 599 599 599

230 73.1 73.1 73.1 93.6 93.6 93.6 62.4 62.4 62.4 80.0 80.0 80.0 500 500 500 599 599 599

460 35.3 35.3 35.3 45.5 45.5 45.5 31.2 31.2 31.2 40.0 40.0 40.0 250 250 250 310 310 310

575

208 93.6 93.6 93.6 93.6 93.6 93.6 88.8 88.8 88.8 88.8 88.8 88.8 599 599 599 599 599 599

230 93.6 93.6 93.6 93.6 93.6 93.6 80.0 80.0 80.0 80.0 80.0 80.0 599 599 599 599 599 599

460 45.5 45.5 45.5 45.5 45.5 45.5 40.0 40.0 40.0 40.0 40.0 40.0 310 310 310 310 310 310

575

STANDARD UNIT W/O EXT. OL'S

CIRCUIT 1 CIRCUIT 2 CIRCUIT 1 CIRCUIT 2 CIRCUIT 1 CIRCUIT 2

No.1 No.3 No.5 No.2 No.4 No.6 No.1 No.3 No.5 No.2 No.4 No.6 No.1 No.3 No.5 No.2 No.4 No.6

60

11.5 11.5 - 11.5 11.5 - 11.2 11.2 - 11.2 11.2 - 80 80 - 80 80 -

60

19.9 19.9 - 19.9 19.9 - 15.2 15.2 - 15.2 15.2 - 109 109 - 109 109 -

60

21.2 21.2 - 21.2 21.2 - 19.6 19.6 - 19.6 19.6 - 132 132 - 132 132 -

60

24.4 24.4 - 24.4 24.4 - 21.2 21.2 - 21.2 21.2 - 180 180 - 180 180 -

60

28.2 28.2 - 28.2 28.2 - 25.2 25.2 - 25.2 25.2 - 198 198 - 198 198 -

60

28.2 28.2 - 36.5 36.5 - 25.2 25.2 - 32.0 32.0 - 198 198 - 239 239 -

60

36.5 36.5 - 36.5 36.5 - 32.0 32.0 - 32.0 32.0 - 239 239 - 239 239 -

60

28.2 28.2 28.2 28.2 28.2 28.2 25.2 25.2 25.2 25.2 25.2 25.2 198 198 198 198 198 198

60

28.2 28.2 28.2 36.5 36.5 36.5 25.2 25.2 25.2 32.0 32.0 32.0 198 198 198 239 239 239

60

36.5 36.5 36.5 36.5 36.5 36.5 32.0 32.0 32.0 32.0 32.0 32.0 239 239 239 239 239 239

OPTIONAL UNIT WITH EXT. OL'S

LOCKED ROTOR AMPS

OMM TGZ-1 TGZ 040A through TGZ 190A 7

Page 8

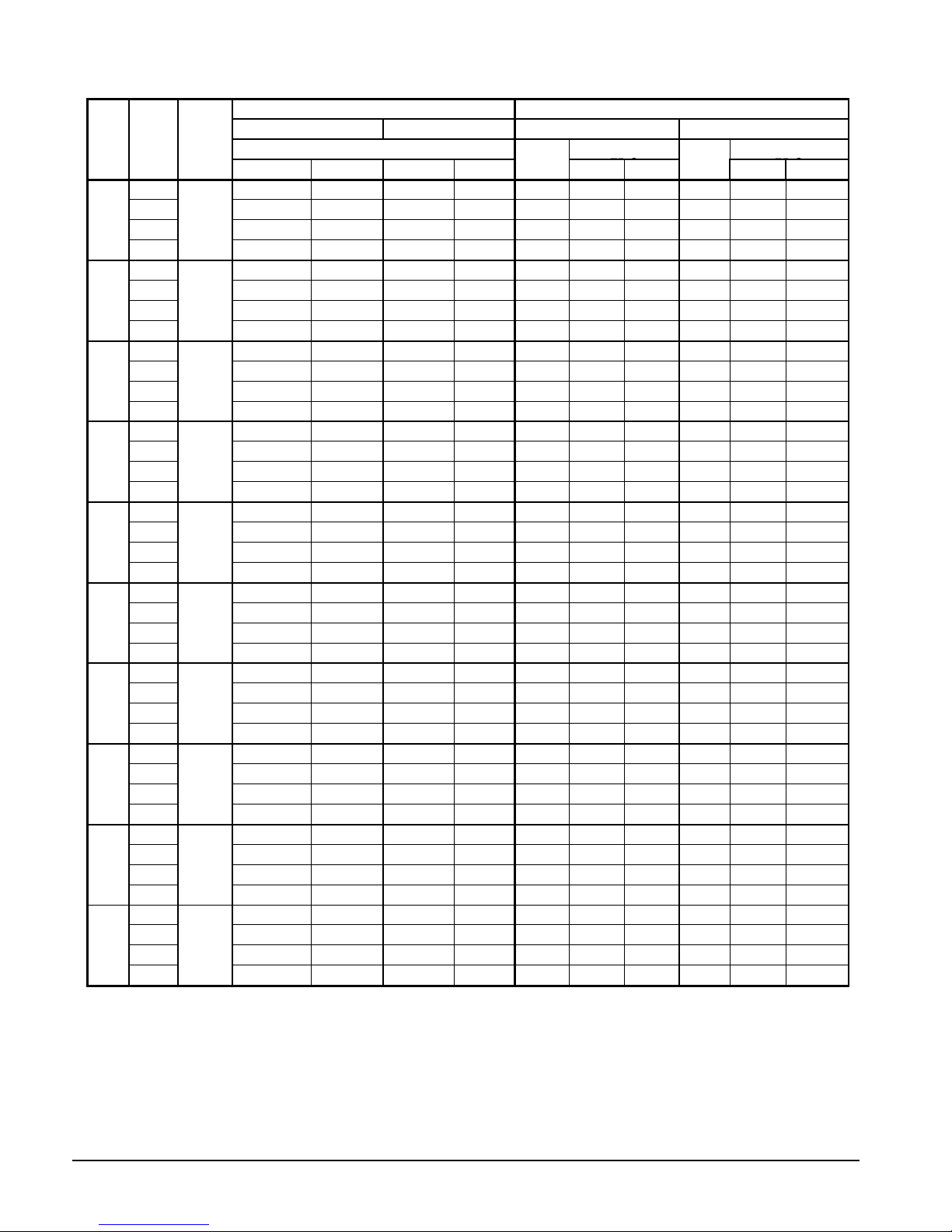

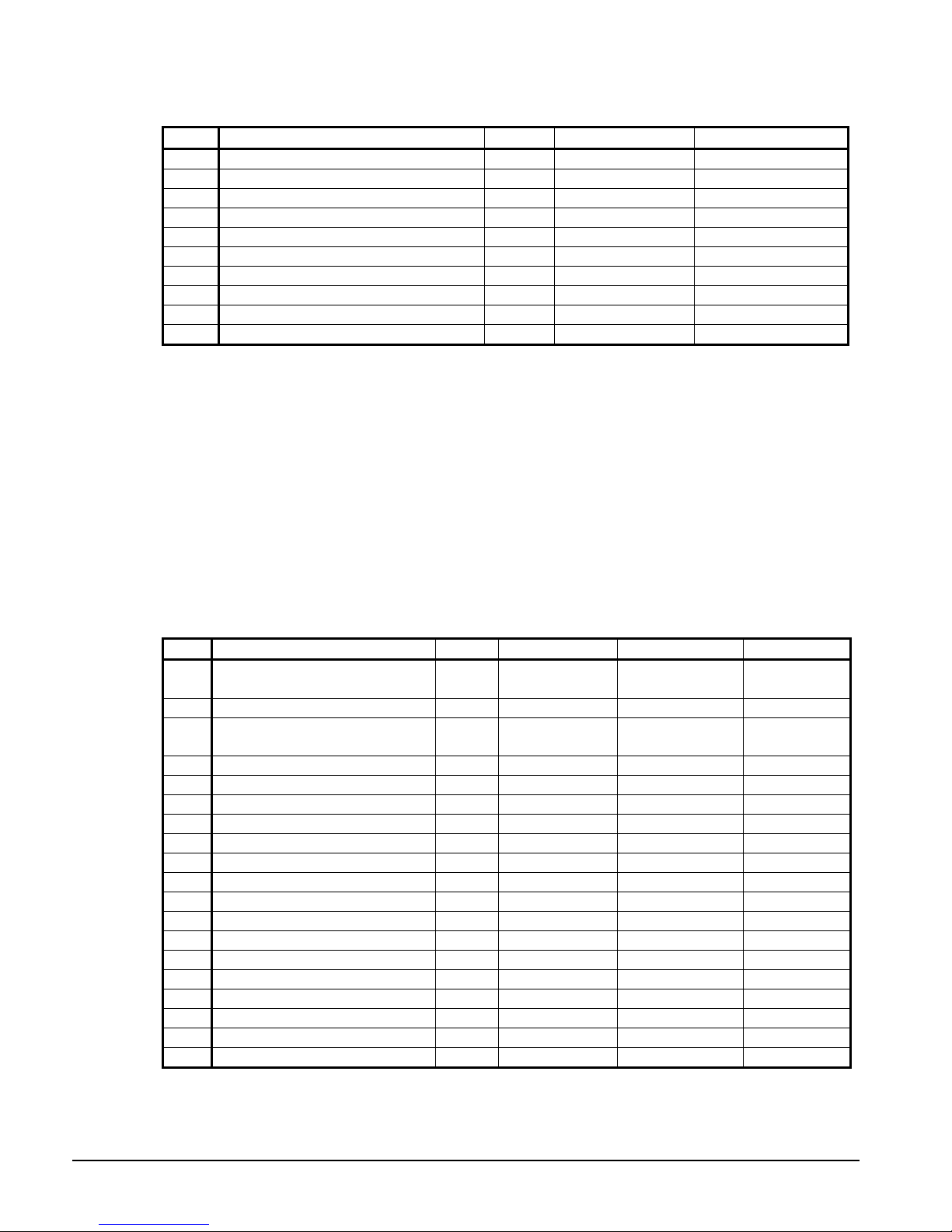

Table 2, Wire Sizing Amps, Standard Multi-Point Power Supply

CIRCUIT

CIRCUIT

CIRCUIT

TGZ

UNIT

VOLTS

SIZE

040

050

060

080

100

110

120

150

170

190

NOTES:

1. Unit wire sizing amps are equal to 125% of the largest compressor-motor RLA plus 100% of the other compressor RLA's.

2. Multiple point power supply requires a separate fused disconnect for each circuit to supply electrical power to the unit.

3. External compressor overload option is only available for units with 140° F maximum leaving condenser water temperature.

4. Wire sizes shown above are for standard ambient temperature and short runs of wire.

FREQ.

(HERTZ)

208 79 79 69 69 3 #4 #4 3 #4 #4

230 79 79 63 63 3 #4 #4 3 #6 #6

460 40 40 32 32 3 #8 #8 3 #10 #10

575

208 108 108 95 95 3 #2 #2 3 #3 #3

230 108 108 86 86 3 #2 #2 3 #3 #3

460 49 49 43 43 3 #8 #8 3 #8 #8

575

208 122 122 122 122 3 #1 #1 3 #1 #1

230 118 118 110 110 3 #1 #1 3 #2 #2

460 58 58 55 55 3 #6 #6 3 #6 #6

575

208 165 165 131 131 3 2/0 2/0 3 1/0 1/0

230 165 165 119 119 3 2/0 2/0 3 #1 #1

460 68 68 59 59 3 #4 #4 3 #6 #6

575

208 165 165 156 156 3 2/0 2/0 3 2/0 2/0

230 165 165 140 140 3 2/0 2/0 3 1/0 1/0

460 79 79 70 70 3 #4 #4 3 #4 #4

575

208 165 211 156 200 3 2/0 4/0 3 2/0 3/0

230 165 211 140 180 3 2/0 4/0 3 1/0 3/0

460 79 102 70 90 3 #4 #2 3 #4 #3

575

208 211 211 200 200 3 4/0 4/0 3 3/0 3/0

230 211 211 180 180 3 4/0 4/0 3 3/0 3/0

460 102 102 90 90 3 #2 #2 3 #3 #3

575

208 238 238 225 225 3 250 250 3 4/0 4/0

230 238 238 203 203 3 250 250 3 4/0 4/0

460 115 115 101 101 3 #2 #2 3 #2 #2

575

208 238 304 225 289 3 250 350 3 4/0 350

230 238 304 203 260 3 250 350 3 4/0 300

460 115 148 101 130 3 #2 1/0 3 #2 #1

575

208 304 304 289 289 3 350 350 3 350 350

230 304 304 260 260 3 350 350 3 300 300

460 148 148 130 130 3 1/0 1/0 3 #1 #1

575

60

60

60

60

60

60

60

60

60

60

MINIMUM CIRCUIT AMPACITY (MCA) POWER SUPPLY

WITHOUT EXTTERNAL

MULTIPLE POINT POWER SUPPLY

CIRCUIT

26 26 25 25 3 #10 #10 3 #10 #10

45 45 34 34 3 #8 #8 3 #10 #10

48 48 44 44 3 #8 #8 3 #8 #8

55 55 48 48 3 #6 #6 3 #8 #8

64 64 57 57 3 #6 #6 3 #6 #6

64 82 57 72 3 #6 #4 3 #6 #4

82 82 72 72 3 #4 #4 3 #4 #4

92 92 82 82 3 #3 #3 3 #4 #4

92 119 82 104 3 #3 #1 3 #4 #2

119 119 104 104 3 #1 #1 3 #2 #2

CIRCUIT

WITH EXTERNAL

CIRCUIT

CIRCUIT

WITHOUT EXTERNAL

FIELD

WIRE

WIRE GAUGE

WITH EXTERNAL

FIELD

WIRE

WIRE GAUGE

CIRCUIT

8 TGZ 040A through TGZ 190A OMM TGZ-1

Page 9

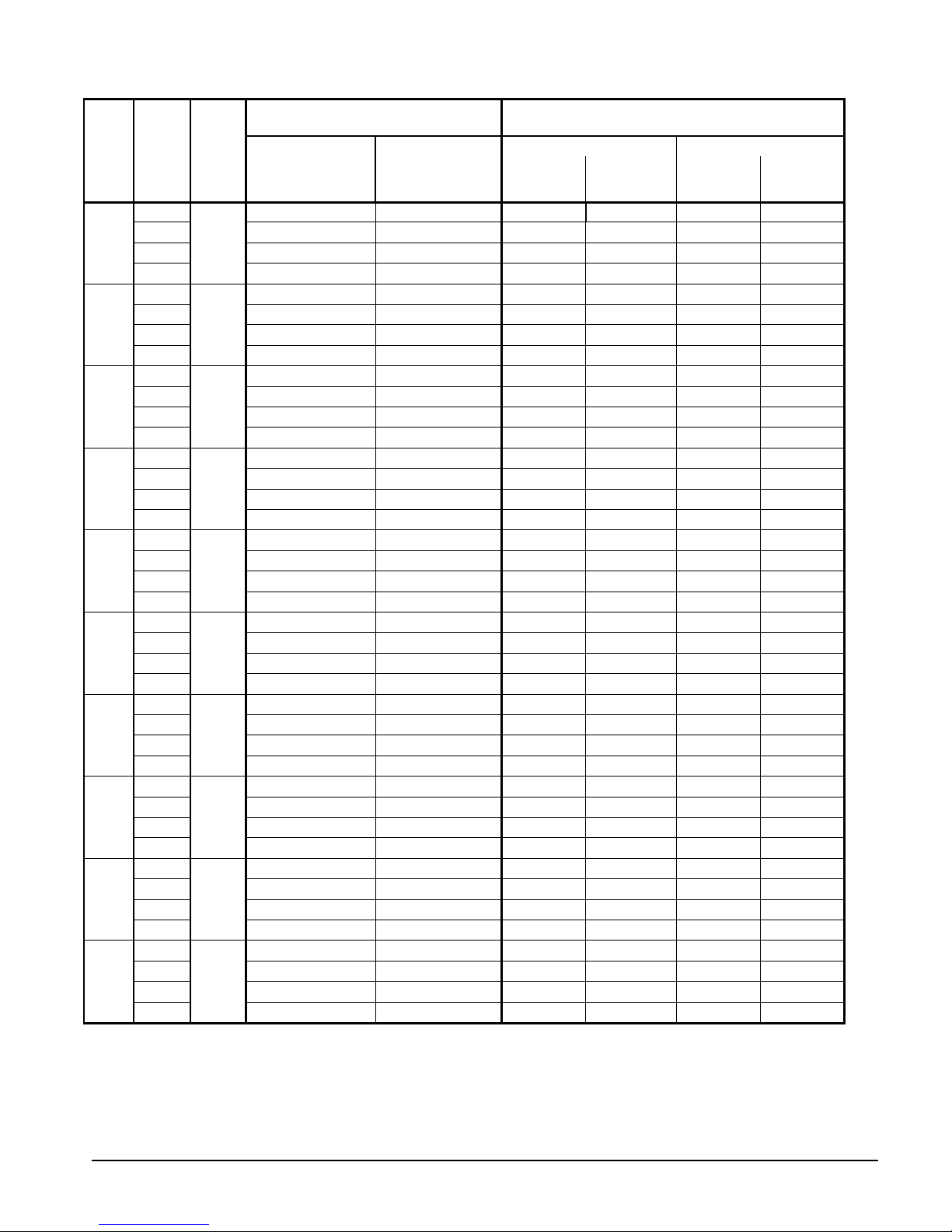

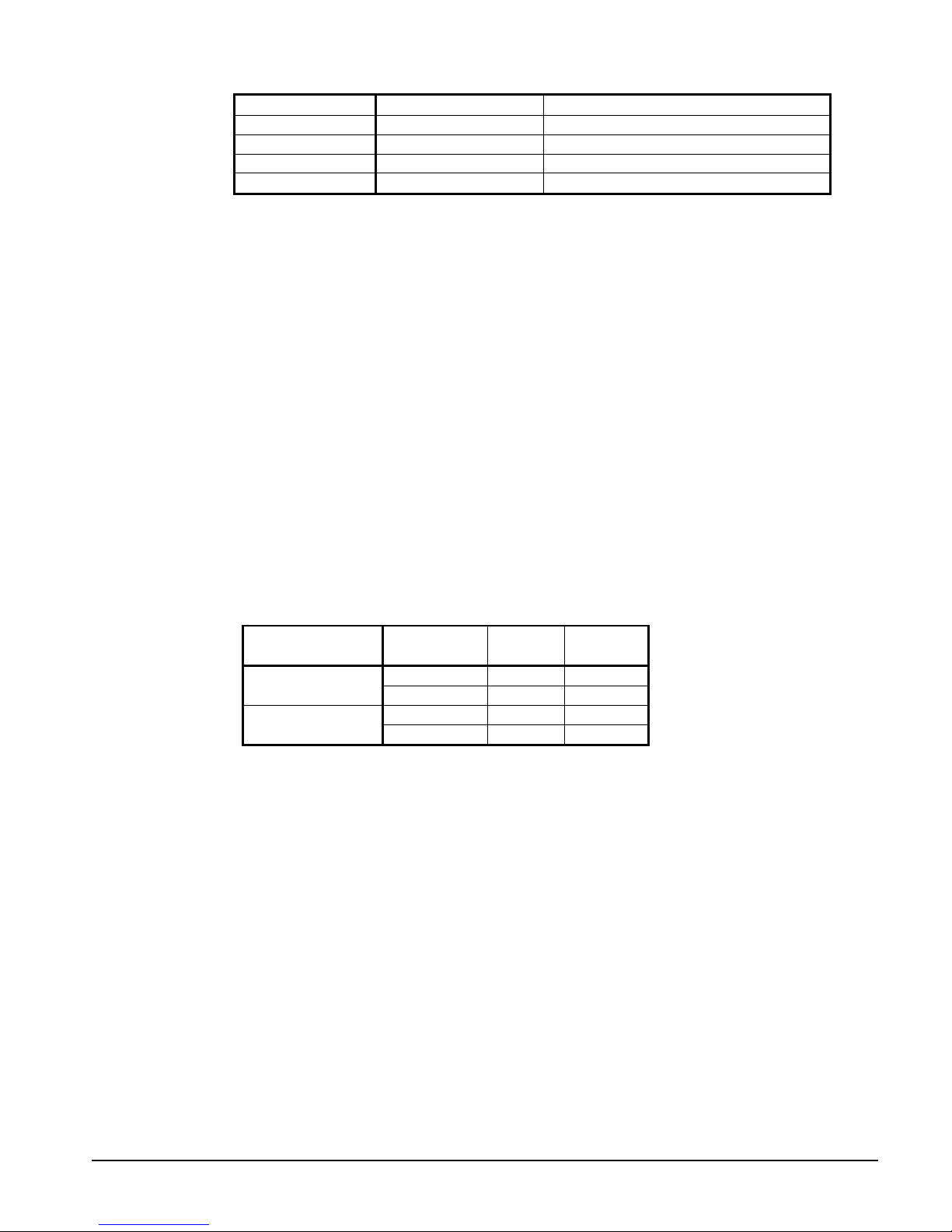

Table 3, Wire Sizing Amps, Optional Single Point Power Supply

WIRE GAUGE

208 150 131 3 1/0 3 1/0

TGZ

UNIT

SIZE

NOTES:.

1. Unit wire sizing amps are equal to 125% of the largest compressor-motor RLA plus 100% of the other compressor RLA's.

2. Single point power supply requires a single fused disconnect to supply electrical power to the unit.

3. External compressor overload option is only available for units with 140° F maximum leaving condenser water temperature.

4. Wire Sizes shown above are for standard ambient temperature and short runs of wire.

040

050

060

080

100

110

120

150

170

190

VOLTS

230 150 119 3 1/0 3 #1

460 76 60 3 #4 3 #6

575

208 204 179 3 4/0 3 3/0

230 204 163 3 4/0 3 2/0

460 93 82 3 #3 3 #4

575

208 230 230 3 4/0 3 4/0

230 224 207 3 4/0 3 4/0

460 109 104 3 #2 3 #2

575

208 311 247 3 400 3 250

230 311 224 3 400 3 4/0

460 128 112 3 #1 3 #2

575

208 311 294 3 400 3 350

230 311 265 3 400 3 300

460 150 133 3 1/0 3 1/0

575

208 357 338 6 (2) 3/0 6 (2) 2/0

230 357 305 6 (2) 3/0 3 350

460 173 152 3 2/0 3 2/0

575

208 398 377 6 (2) 3/0 6 (2) 3/0

230 398 340 6 (2) 3/0 6 (2) 2/0

460 193 170 3 3/0 3 2/0

575

208 457 433 6 (2) 4/0 6 (2) 4/0

230 457 390 6 (2) 4/0 6 (2) 3/0

460 221 195 3 4/0 3 3/0

575

208 524 496 6 (2) 300 6 (2) 250

230 524 447 6 (2) 300 6 (2) 4/0

460 254 224 3 250 3 4/0

575

208 585 555 6 (2) 350 6 (2) 300

230 585 500 6 (2) 350 6 (2) 250

460 284 250 3 300 3 250

575

FREQ.

(HERTZ)

60

60

60

60

60

60

60

60

60

60

MINIMUM CIRCUIT AMPACITY (MCA) POWER SUPPLY

SINGLE POINT

POWER SUPPLY )

WITHOUT EXT OL'S

49 48 3 #8 3 #8

85 65 3 #4 3 #6

90 83 3 #3 3 #4

104 90 3 #2 3 #3

120 107 3 #1 3 #2

139 122 3 1/0 3 #1

155 136 3 2/0 3 1/0

176 158 3 3/0 3 2/0

203 180 3 4/0 3 3/0

228 200 3 4/0 3 3/0

SINGLE POINT

POWER SUPPLY

WITH EXT OL'S

WITHOUT EXTERNAL OL'S WITH EXTERNAL OL’S

FIELD WIRE

QUANTITY

WIRE GAUGE

75°°°°C

FIELD WIRE

QUANTITY

75°°°°C

OMM TGZ-1 TGZ 040A through TGZ 190A 9

Page 10

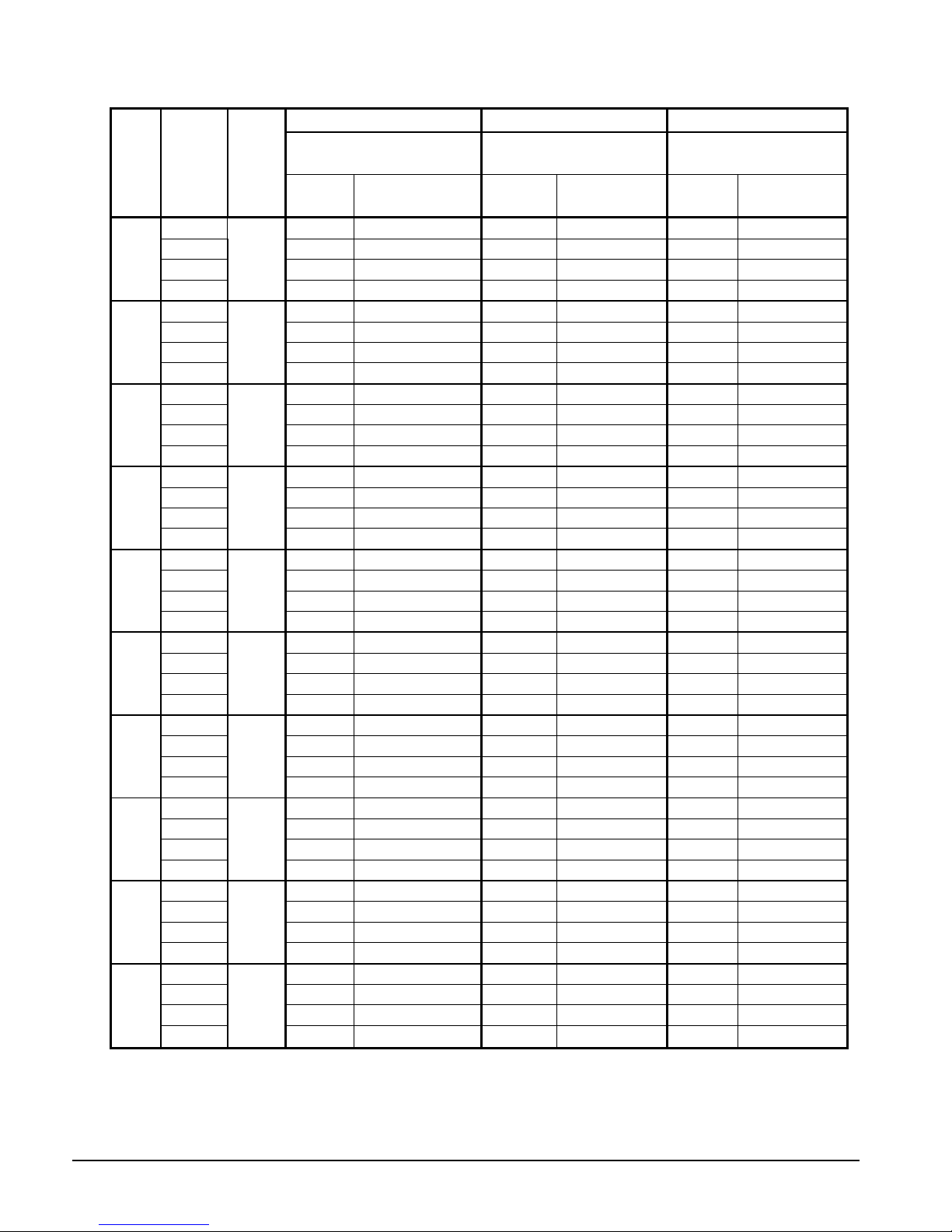

Table 4, Maximum Fuse Sizing

TGZ

VOLTAGE

UNIT

SIZE

040

050

060

080

100

110

120

150

170

190

NOTE:

1. "Maximum Fuse Sizes" are selected at approximately 225% of the largest compressor RLA plus 100% of other compressor RLA values.

PHASE

208 175 150 110 110 100 100

230 175 125 110 110 90 90

460 90 70 50 50 45 45

575

208 250 200 150 150 125 125

230 250 200 150 150 110 110

460 110 100 70 70 60 60

575

208 250 250 175 175 175 175

230 250 250 150 150 150 150

460 125 125 80 80 70 70

575

208 350 300 225 225 175 175

230 350 250 225 225 150 150

460 150 125 90 90 80 80

575

208 350 350 225 225 200 200

230 350 300 225 225 200 200

460 175 150 110 110 100 100

575

208 450 400 225 300 200 250

230 450 350 225 300 200 250

460 200 175 110 125 100 125

575

208 450 450 300 300 250 250

230 450 400 300 300 250 250

460 225 200 125 125 125 125

575

208 500 500 300 300 250 250

230 500 450 300 300 250 250

460 250 225 150 150 125 125

575

208 600 500 300 350 250 350

230 600 500 300 350 250 300

460 250 250 150 175 125 150

575

208 600 600 350 350 350 350

230 600 500 350 350 300 300

460 300 250 175 175 150 150

575

FREQ.

(HERTZ)

60

60

60

60

60

60

60

60

60

60

SINGLE POINT POWER SUPPLY MULTIPLE POINT POWER SUPPLY

WITHOUT

EXTERNAL OL'S

TOTAL UNIT

60 50 35 35 35 35

100 70 60 60 45 45

110 100 60 60 60 60

125 110 70 70 60 60

125 125 90 90 80 80

175 150 90 110 80 100

175 150 110 110 100 100

200 175 110 110 100 100

225 200 110 150 100 125

350 225 150 150 125 125

WITH

EXTERNAL OL'S

TOTAL UNIT

WITHOUT EXTERNAL OL'S WITH EXTERNAL OL'S

CIRC.#1 CIRC.#2 CIRC.#1 CIRC.#2

10 TGZ 040A through TGZ 190A OMM TGZ-1

Page 11

Table 5, Connection Sizes, Single Point Power Supply, Without External Overloads

Power Block Terminal Factory Installed Disconnect Factory Installed HSCCR

TGZ

Unit

Size

040

050

060

080

100

110

120

150

170

190

Volts

208 380 #4 - 500 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

230 380 #4 - 500 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

460 175 #14 - 2/0 100 #10 - 1/0 150 #6 - 350 kcmil

575

208 380 #4 - 500 kcmil 250 #6 - 350 kcmil 350 (2) 3/0 - 500 kcmil

230 380 #4 - 500 kcmil 250 #6 - 350 kcmil 350 (2) 3/0 - 500 kcmil

460 175 #14 - 2/0 125 #3 - 3/0 175 #6 - 350 kcmil

575

208 380 #4 - 500 kcmil 250 #6 - 350 kcmil 400 (2) 3/0 - 500 kcmil

230 380 #4 - 500 kcmil 250 #6 - 350 kcmil 400 (2) 3/0 - 500 kcmil

460 175 #14 - 2/0 125 #3 - 3/0 200 #6 - 350 kcmil

575

208 380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

230 380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

460 175 #14 - 2/0 250 #6 - 350 kcmil 225 #6 - 350 kcmil

575

208 380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 600 (2) 3/0 - 500 kcmil

230 380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 600 (2) 3/0 - 500 kcmil

460 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

575

208 380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 600 (2) 3/0 - 500 kcmil

230 380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 600 (2) 3/0 - 500 kcmil

460 380 #4 - 500 kcmil 250 #6 - 350 kcmil 300 (2) 3/0 - 500 kcmil

575

208 760 (2) #2 - 500 kcmil 600 (2) 3/0 - 500 kcmil 700 (2) 3/0 - 500 kcmil

230 760 (2) #2 - 500 kcmil 600 (2) 3/0 - 500 kcmil 700 (2) 3/0 - 500 kcmil

460 380 #4 - 500 kcmil 250 #6 - 350 kcmil 400 (2) 3/0 - 500 kcmil

575

208 760 (2) #2 - 500 kcmil 600 (2) 3/0 - 500 kcmil 800 (3) 1/0 - 500 kcmil

230 760 (2) #2 - 500 kcmil 600 (2) 3/0 - 500 kcmil 800 (3) 1/0 - 500 kcmil

460 380 #4 - 500 kcmil 250 #6 - 350 kcmil 400 (2) 3/0 - 500 kcmil

575

208 760 (2) #2 - 500 kcmil 600 (2) 3/0 - 500 kcmil 1000 (3) 1/0 - 500 kcmil

230 760 (2) #2 - 500 kcmil 600 (2) 3/0 - 500 kcmil 1000 (3) 1/0 - 500 kcmil

460 380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 450 (2) 3/0 - 500 kcmil

575

208 760 (2) #2 - 500 kcmil 800 (3) 1/0 - 500 kcmil 1000 (3) 1/0 - 500 kcmil

230 760 (2) #2 - 500 kcmil 800 (3) 1/0 - 500 kcmil 1000 (3) 1/0 - 500 kcmil

460 380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 500 (2) 3/0 - 500 kcmil

575

Freq.

(Hertz)

60

60

60

60

60

60

60

60

60

60

NOTES:.

1. "Size" is the maximum amperage rating for the terminals or the main electrical device...

2. "Connection" is the range of wire sizes that the terminals on the electrical device will accept.

Power Block or

Bus Bar Lugs

Size (1)

175 #14 - 2/0 100 #10 - 1/0 90 #10 - 1/0

175 #14 - 2/0 100 #10 - 1/0 150 #6 - 350 kcmil

175 #14 - 2/0 100 #10 - 1/0 150 #6 - 350 kcmil

175 #14 - 2/0 125 #3 - 3/0 175 #6 - 350 kcmil

175 #14 - 2/0 250 #6 - 350 kcmil 200 #6 - 350 kcmil

175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

175 #14 - 2/0 250 #6 - 350 kcmil 300 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 250 #6 - 350 kcmil 300 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 250 #6 - 350 kcmil 350 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

Connection (2)

Wire Range - CU

Disconnect Switch

Molded Case

Switch

Size (1)

Connection (2)

Wire Range - CU

Disconnect Switch

(Circuit Breaker )

Circ. Brkr Connection (2)

Size (1) Wire Range - CU

OMM TGZ-1 TGZ 040A through TGZ 190A 11

Page 12

Table 6, Connection Sizes, Single Point Power Supply with External Overloads

Power Block Terminal Factory Installed Disconnect Factory Installed HSCCR

TGZ

Unit

Size

040

050

060

080

100

110

120

150

170

190

Volts

208 335 #6 - 400 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

230 335 #6 - 400 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

460 175 #14 - 2/0 100 #3 - 3/0 150 #4 - 350 kcmil

575

208 335 #6 - 400 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

230 335 #6 - 400 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

460 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

575

208 335 #6 - 400 kcmil 250 #6 - 350 kcmil 400 (2) 3/0 - 500 kcmil

230 335 #6 - 400 kcmil 250 #6 - 350 kcmil 400 (2) 3/0 - 500 kcmil

460 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

575

208 760 (2) #2 - 500 kcmil 400 (2) 3/0 - 500 kcmil

230 760 (2) #2 - 500 kcmil 400 (2) 3/0 - 500 kcmil

460 335 #6 - 400 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

575

208 760 (2) #2 - 500 kcmil 400 (2) 3/0 - 500 kcmil

230 760 (2) #2 - 500 kcmil 400 (2) 3/0 - 500 kcmil

460 335 #6 - 400 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

575

208 760 (2) #2 - 500 kcmil 400 (2) 3/0 - 500 kcmil

230 760 (2) #2 - 500 kcmil 400 (2) 3/0 - 500 kcmil

460 335 #6 - 400 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

575

208 760 (2) #2 - 500 kcmil 600 (2) 3/0 - 500 kcmil

230 760 (2) #2 - 500 kcmil 600 (2) 3/0 - 500 kcmil

460 335 #6 - 400 kcmil 250 #6 - 350 kcmil 400 (2) 3/0 - 500 kcmil

575

208 760 (2) #2 - 500 kcmil 600 (2) 3/0 - 500 kcmil

230 760 (2) #2 - 500 kcmil 600 (2) 3/0 - 500 kcmil

460 335 #6 - 400 kcmil 250 #6 - 350 kcmil 400 (2) 3/0 - 500 kcmil

575

208 760 (2) #2 - 500 kcmil 800 (3) 1/0 - 500 kcmil

230 760 (2) #2 - 500 kcmil 800 (3) 1/0 - 500 kcmil

460 335 #6 - 400 kcmil 400 (2) 3/0 - 500 kcmil

575

208 760 (2) #2 - 500 kcmil 800 (3) 1/0 - 500 kcmil

230 760 (2) #2 - 500 kcmil 800 (3) 1/0 - 500 kcmil

460 335 #6 - 400 kcmil 400 (2) 3/0 - 500 kcmil

575

Freq.

(Hertz)

60

60

60

60

60

60

60

60

60

60

Power Block or

Bus Bar Lugs

Size (1)

175 #14 - 2/0 100 #3 - 3/0 150 #4 - 350 kcmil

175 #14 - 2/0 100 #3 - 3/0 100 #3 - 3/0

175 #14 - 2/0 100 #3 - 3/0 125 #3 - 3/0

335 #6 - 400 kcmil 125 #3 - 3/0 125 #3 - 3/0

335 #6 - 400 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

335 #6 - 400 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

335 #6 - 400 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

335 #6 - 400 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

335 #6 - 400 kcmil 250 #6 - 350 kcmil 400 (2) 3/0 - 500 kcmil

335 #6 - 400 kcmil 400 (2) 3/0 - 500 kcmil

Connection (2)

Wire Range - CU

Disconnect Switch

Molded Case

Switch

Size (1)

Connection (2)

Wire Range - CU

Disconnect Switch

(Circuit Breaker )

Circ. Brkr

Size (1)

400 (2) 3/0 - 500 kcmil

400 (2) 3/0 - 500 kcmil

600 (2) 3/0 - 500 kcmil

600 (2) 3/0 - 500 kcmil

600 (2) 3/0 - 500 kcmil

600 (2) 3/0 - 500 kcmil

600 (2) 3/0 - 500 kcmil

600 (2) 3/0 - 500 kcmil

800 (3) 1/0 - 500 kcmil

800 (3) 1/0 - 500 kcmil

800 (3) 1/0 - 500 kcmil

800 (3) 1/0 - 500 kcmil

400 (2) 3/0 - 500 kcmil

800 (3) 1/0 - 500 kcmil

800 (3) 1/0 - 500 kcmil

400 (2) 3/0 - 500 kcmil

400 (2) 3/0 - 500 kcmil

NOTES:

1. "Size" is the maximum amperage rating for the terminals or the main electrical device.

2. "Connection" is the range of wire sizes that the terminals on the electrical device will accept.

Connection (2)

Wire Range - CU

12 TGZ 040A through TGZ 190A OMM TGZ-1

Page 13

Table 7, Connection Sizes, Multi-Point Power Connection, without External Overloads

Power Terminal Block Factory Installed Disconnect

TGZ

Unit

Volts

Size

040

050

060

080

100

110

120

150

170

190

Power Block or

Bus Bar Lugs

208 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

230 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

460 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

230 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

460 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

230 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

460 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

230 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

230 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 380 #4 - 500 kcmil

230 380 #4 - 500 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 125 #3 - 3/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 380 #4 - 500 kcmil

230 380 #4 - 500 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 380 #4 - 500 kcmil

230 380 #4 - 500 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

575 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

208 380 #4 - 500 kcmil

230 380 #4 - 500 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

575 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 250 #6 - 350 kcmil

208 380 #4 - 500 kcmil

230 380 #4 - 500 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

575 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

Circuit #1 Circuit #2 Circ.#1 Circ.#2

Molded Case

Switch

Size (1)

Size (1)

Connection

Wire Range

(2)

Power Block/

Bus Bar Lugs

Size (1)

380 #4 - 500 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

380 #4 - 500 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

380 #4 - 500 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

380 #4 - 500 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

Connection (2)

Wire Range

Switch

Size (1)

Connection (2)

Wire Range

Connection (2)

Wire Range U

OMM TGZ-1 TGZ 040A through TGZ 190A 13

Page 14

Table 8, Connection Sizes, Multi-Point Power Connection, with External Overloads

Power Block or

Power Terminal Block Factory Installed Disconnect

TGZ

Unit

Volts

Size

040

050

060

080

100

110

120

150

170

190

Power Block or

Bus Bar Lugs

208 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

230 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

460 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

230 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

460 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

230 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

460 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

230 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

230 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 380 #4 - 500 kcmil

230 380 #4 - 500 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 125 #3 - 3/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 380 #4 - 500 kcmil

230 380 #4 - 500 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

575 175 #14 - 2/0 175 #14 - 2/0 100 #10 - 1/0 100 #10 - 1/0

208 380 #4 - 500 kcmil

230 380 #4 - 500 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

575 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 125 #3 - 3/0

208 380 #4 - 500 kcmil

230 380 #4 - 500 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

575 175 #14 - 2/0 175 #14 - 2/0 125 #3 - 3/0 250 #6 - 350 kcmil

208 380 #4 - 500 kcmil

230 380 #4 - 500 kcmil

460 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

575 175 #14 - 2/0 175 #14 - 2/0 250 #6 - 350 kcmil 250 #6 - 350 kcmil

Circuit #1 Circuit #2 Circ.#1 Circ.#2

Molded Case

Switch

Size

Size

Connection)

Wire Range

Bus Bar Lugs

Size

380 #4 - 500 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

380 #4 - 500 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

380 #4 - 500 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

380 #4 - 500 kcmil 250 #6 - 350 kcmil 250 #6 - 350 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

380 #4 - 500 kcmil 400 (2) 3/0 - 500 kcmil 400 (2) 3/0 - 500 kcmil

Connection

Wire Range

Switch

Size

Connection

Wire Range

Connection

Wire Range -

14 TGZ 040A through TGZ 190A OMM TGZ-1

Page 15

Field Wiring, Power

The TGZ units are supplied standard with compressor contactors and power terminal block, designed for multipoint power supply to the unit, no compressor circuit breakers. Available options are:

• Single-point connection to power block with compressor circuit breakers

• Single-point connection to disconnect switch with compressor circuit breakers

• High short circuit current rating with single-point disconnect switch

• Multi-point connection to disconnect switch, no compressor circuit breakers

A factory installed control circuit transformer is standard. Optionally, a field-installed control power source

can be wired to the unit.

Wiring and conduit selections must comply with the National Electrical Code and/or local requirements.

An open fuse indicates a short, ground, or overload. Before replacing a fuse or restarting a compressor,

the trouble must be found and corrected. Tables in the Electrical Data section (page 4) give specific

information on recommended wire sizes.

Unit power inlet wiring must enter the control box through the right side. A 7/8-inch pilot knockout is provided.

Refer to the unit dimension drawings for the location of power and control connections.

!

CAUTION

To avoid equipment damage, use only copper conductors in main terminal block.

Control Power

A factory mounted control transformer is provided to supply the correct control circuit voltage.

OMM TGZ-1 TGZ 040A through TGZ 190A 15

Page 16

Field Wiring Diagram

DWG. 330538901 REV.0D (MOD)

WITH MICROTECH CONTROLLER

DISCONNECT

UNIT MAIN

120 VAC

TB1

TB1-20

(BY OTHERS)

2

1

N

120 VAC

GND

10

15

TB2

51

52

42

60

40

53

43

55

49

50

ALARM BELL

ALARM BELL OPTION

BELL

COM

MANUAL

AUTO

MANUAL

IF REMOTE STOP

CONTROL IS USED,

FROM TERM. 40 TO 53.

897

4-20MA FOR

4-20MA FOR

DEMAND LIMIT

GND

33

44

NOR. OPEN PUMP AUX. CONTACTS (OPTIONAL)

41

54

NOR. OPEN PUMP AUX. CONTACTS (OPTIONAL)

N

N

120 VAC

120 VAC

120 VAC

120 VAC

CDW PUMP RELAY (BY OTHERS)

TB1-12

J15-NO8

TB1-12

J16-NO9

J16-NO10

TB3-91

TB3-92

79

80

N

0-10 VDC

77

78

N

0-10 VDC

COOLING TOWER BYPASS

COOLING TOWER BYPASS

TB3

Figure 4, Field Wiring Diagram

(BY OTHERS)

3 PHASE

POWER

SUPPLY

TERMINAL BLOCK

FUSED CONTROL

CIRCUIT TRANSFORMER

OPTION

GND LUG

TO COMPRESSOR(S)

AND FAN MOTORS

FIELD

SUPPLIED

OPTION

120VAC

CONTROL POWER

NOTE: ALL FIELD WIRING TO BE

INSTALLED AS NEC CLASS 1

WIRING SYSTEM WITH CONDUCTOR

RATED 600 VOLTS

FACTORY SUPPLIED ALARM

FIELD WIRED

ALARM BELL RELAY

TIME

CLOCK

AUTO

ON

ON

REMOTE STOP

SWITCH

(BY OTHERS)

ICE MODE SWITCH

(BY OTHERS)

ALARM

BELL

OPTION

DISCONNECT

N

FUSE

(BY OTHERS)

CHW PUMP RELAY (BY OTHERS)

120 VAC 1.0 AMP MAX

120 VAC 1.0 AMP MAX

TOWER FAN #1 COIL (BY OTHERS)

120 VAC 1.0 AMP MAX

TOWER FAN #2 COIL (BY OTHERS)

120 VAC 1.0 AMP MAX

OFF

OFF

10A

CONTROLLER

TB3-90

CONTROL

CIRCUIT

FUSE

11

14

REMOVE LEAD 897

1 2

RELAY

NO

CHW FLOW SWITCH

---MANDATORY–(BY OTHERS)

CDW FLOW SWITCH

---MANDATORY–(BY OTHERS)

LEAVING WAT ER RESET

(BY OTHERS)

(BY OTHERS)

16 TGZ 040A through TGZ 190A OMM TGZ-1

+

-

+

-

(BY OTHERS)

(BY OTHERS)

FIELD WIRING FOR TGZ

KDL 09-04-08

Page 17

Figure 5, Control Center Layout

Fuses, Primary

Microtech II

Controller

(2) Circuit

Mechanical

Hi-Pressure Switch

Relays

Switches

On Side

(3) 120V/24V

Transformers

LineV/120V

Control

Transformer

Control

Transformer

7/8-in. KO for

control wiring

(4) Compressor

Contactors

Location for

Optional External

Overloads

Control

Transformer

Fuse, Secondary

Optional Disconnect

Switch

KO for Power

Wiring

Grounding Lug

OMM TGZ-1 TGZ 040A through TGZ 190A 17

Page 18

Start-Up and Shutdown

Pre Start-up

1. With main disconnect open, check all electrical connections in control panel and starter to be sure

they are tight and provide good electrical contact. Although connections are tightened at the factory,

they can have loosened enough in shipment to cause a malfunction.

2. Check and inspect all water piping. Make sure flow direction is correct and piping is made to

correct connection on evaporator and condenser.

3. Open all water flow valves to the condenser and evaporator.

4. Flush the cooling tower (if one is in the system) and system piping to be sure the system is clean.

Start source water pump and manually start hot water pump. Check all piping for leaks. Vent the air

from the evaporator and condenser water circuit as well as from the entire water system. The cooler

circuits should contain clean, non-corrosive water.

5. Check to see that the water temperature thermostat sensor is installed in the correct water line.

6. Making sure control stop switch S1 is open (off) and pumpdown switches PS1 and PS2 are on

“manual pumpdown”, move the main power and control disconnect switches to “on.” This will

energize crankcase heaters. Wait a minimum of 12 hours before starting up unit.

7. Check compressor oil level. The oil level should be at least one-third of the oil sightglass.

8. Check pressure drop across evaporator and condenser, and see that water flow is correct per the

design flow rates and data on pages 4 through 6.

9. Check the actual line voltage to the unit to make sure it is the same as called for on the compressor

nameplate within + 10% and that phase voltage unbalance does not exceed 2%. Verify that adequate

power supply and capacity is available to handle load.

10. Make sure all wiring and fuses are of the proper size. Also make sure all interlock wiring is

completed per McQuay diagrams.

11. Verify that all mechanical and electrical inspections by code authorities have been completed.

12. Make sure all auxiliary load and control equipment is operative and that an adequate cooling load is

available for initial start-up.

Start-up

1. Open the compressor suction and discharge shutoff valves until backseated. Replace valve caps.

2. Open the manual liquid line shutoff valve.

3. Check to see that the unit circuit breakers are in the “off” position.

4. Check to see that the pumpdown switches PS1 and PS2 are in the “manual pumpdown” position and

the control system switch S1 is in the “off” position.

5. Place the main power and control circuit disconnects to the “on” position.

6. Verify crankcase heaters have operated for at least 12 hours prior to start-up. Crankcase should be

warm.

7. Adjust the setpoint on the MicroTech controller to the desired hot water temperature.

8. Start the auxiliary equipment for the installation by turning on the time clock, ambient thermostat

and/or remote on/off switch and chilled water pump.

9. Check resets of all equipment protection controls.

10. Switch the unit circuit breakers to on.

11. Place pumpdown switch(es) PS1 and PS2 to “auto” for restart and normal operation.

12. Start the system by pushing the system switch S1 to on.

13. After running the unit for a short time, check the oil level in each compressor crankcase and check

for flashing in the refrigerant sightglass.

14. After system performance has stabilized, it is necessary that the “Compressorized Equipment

Warranty Form” (Form No. 206036A) be completed to obtain full warranty benefits. Be sure to list

the pressure drop across both vessels. This form is shipped with the unit and after completion

should be returned to the McQuay Service Department through your sales representative.

18 TGZ 040A through TGZ 190A OMM TGZ-1

Page 19

Weekend or Temporary Shutdown

Move pumpdown switch(es) PS1 and PS2 to the “manual pumpdown” position.

Note: With the unit in this condition, it is capable of limited pumpdown. To defeat this mode of

operation, simply move control system switch S1 to the “off” position.

!

CAUTION

The compressors must complete pump down before the water flow to the unit is interrupted to

avoid freeze-up damage in the evaporator.

Start-up after Temporary Shutdown

1. Start the source water and hot water flow through the unit.

2. With the control system switch S1 in the “on” position, move the pumpdown switch(es) PS1

and PS2 to the “auto pumpdown” position.

3. Observe the unit operation for a short time, noting unusual sounds or cycling of compressors.

Extended Shutdown

1. Close the manual liquid line shutoff valves.

2. After the compressors have pumped down, stop or bypass the source water and hot water flow.

3. Turn off all power to the unit.

4. Move the control service switch S1 to the “off” position.

5. Close the suction and discharge shutoff valves on the compressor(s) and the liquid outlet

valves at the condenser(s) or receiver(s).

6. Tag all opened disconnect switches to warn against start-up before opening the compressor

suction and discharge valves.

7. Drain all water from the unit evaporator and chilled water piping if the unit is to be shut down

during the winter and exposed to below freezing temperatures. Do not leave the vessels or

piping open to the atmosphere over the shutdown period.

Start-up after Extended Shutdown

1. Inspect all equipment to see that it is in satisfactory operating condition.

2. Backseat the compressor suction and discharge valves. Always replace valve seal caps.

3. Open the manual liquid line shutoff valves.

4. Check circuit breakers. They must be in the “off” position.

5. Check to see that the pumpdown switches PS1 and PS2 are in the “manual shutdown” position

and the control system switch S1 is in the “off” position.

6. Throw the main power and control circuit disconnects to the “on” position.

7. Allow the crankcase heaters to operate for at least 12 hours prior to start-up.

8. Start the source water flow and purge the water piping as well as the evaporator in the unit.

9. Start the auxiliary equipment for the installation by turning on the time clock, ambient

thermostat and/or remote on/off switch.

10. Adjust the setpoint on the MicroTech controller to the desired hot water temperature.

11. Check resets of all equipment protection controls.

12. Switch the unit circuit breakers to “on.”

13. Start the system by pushing the system switch S1 to “on.”

!

CAUTION

Most relays and terminals in the control center are powered when S1 is closed and the

control circuit disconnect is on. Do not close S1 until ready for start-up or serious

equipment damage can occur.

14. Place pumpdown switch(es) PS1 and PS2 to the “auto pumpdown” position for restart and

normal operation.

15. After running the unit for a short time, check the oil level in each compressor crankcase

and for flashing in the refrigerant sightglass (see Maintenance section).

OMM TGZ-1 TGZ 040A through TGZ 190A 19

Page 20

Sequence of Operation

The following sequence of operation is typical for TGZ Templifier models when in the

heating mode. The sequence can vary slightly depending upon options.

Start-up/Compressor Staging (when compressors start and stop)

Stage Up Temperature (displayed on ‘VIEW UNIT TEMP (3)’ screen) is the Condenser

Leaving Water Temperature by which the next compressor to start will stage up (start) after at

least one compressor on the unit has started and is running.

Start Up Temperature (displayed on ‘VIEW UNIT TEMP (3)’ screen) is the Condenser

Leaving Water Temperature by which the first compressor starts. The start up temperature

equals the Stage Up Temperature minus the Start Delta Temperature set point. A higher Start

Delta Temperature set point value will keep the unit off longer and reduce unit cycling at low

loads. However, this high Start Delta Temperature set point will cause a larger excursion from

the Active Heat Leaving Water Temperature set point before the unit starts. Stated another

way, the Start Delta Temperature set point is the number of degrees below the Active Heat

Leaving Water Temperature set point, minus ½ the Control Band, that determines when the

first compressor starts. The Start Delta is in effect for only the first start after all compressors

have been off. Additional compressor starts and stops are determined by the Condenser

Leaving Water Temperature (LWT) with respect to the Control Band only. The Control Band

is automatically set based upon the number of stages (compressors) for the unit. A four (4)

compressor unit will have a Control Band that is 30% of the CondDeltaT set point. A six (6)

compressor unit will have a Control Band that is 20% of the CondDeltaT set point.

The following sequence would occur for the settings shown below for a four compressor unit:

CondDelta T set point = 10.0°F

StartDelta set point = 5.0°F

StopDelta set point = 2.0°F

Heat LWT set point = 140.0°F

The calculated Control Band will be 30% of 10ºF (Cond Delta T) which is 3ºF.

For a cold start-up (no compressors running), the first compressor will start at any temperature

below 133.5°F. Each subsequent compressor will start after the Stage Up Timer has timed out and if

the temperature is below the Control Band, 138.5°F in this case.

20 TGZ 040A through TGZ 190A OMM TGZ-1

Page 21

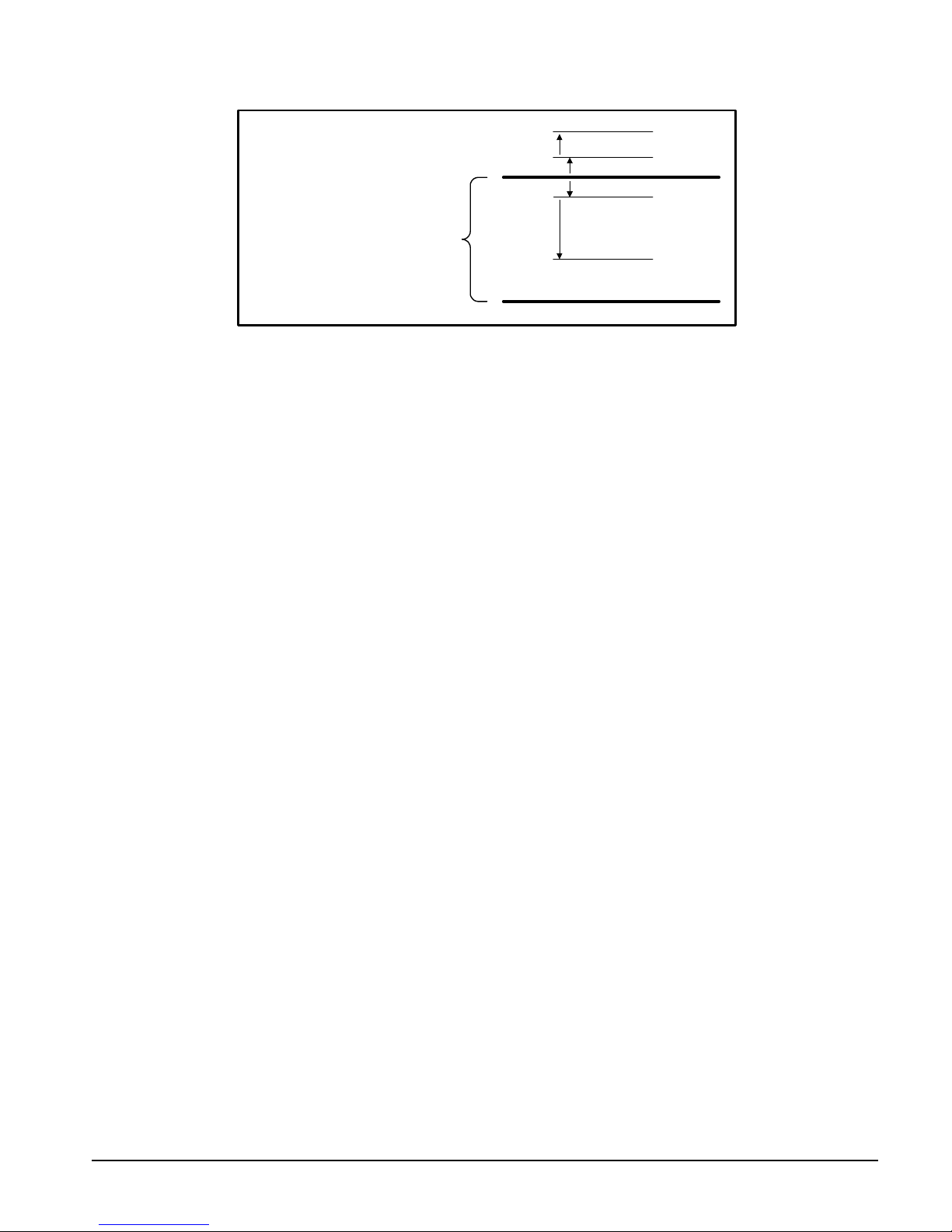

Figure 1, Staging/Starting Temperatures

Leaving Water Temperature

Set Point

Condenser Delta Temperature

Set Point

140º F

10º F

Stop Delta T

½ Control Band

½ Control Band

Start Delta T

143.5º F

141.5º F

138.5º F

133.5º F

Entering Water Temperature

130º F

If the Condenser Leaving Water Temperature stays below 138.5°F, all three (or five)

remaining compressors will eventually stage on after the Stage Up Timer times out between

each stage. At some point, the Condenser Leaving Water Temperature will be rising and begin

to approach the point when compressors should begin staging off, which is the Active Heat

Leaving Water Temperature set point plus ½ of the Control Band, 141.5°F in this case.

If the Condenser Leaving Water Temperature remains above the Active Heat Leaving Water

Temperature set point plus ½ Control Band and the Stage Down Timer times out, additional

compressors will stage off. The last compressor will stage off when the Condenser Leaving

Water Temperature raises above the Active Leaving Water Temperature set point plus ½ the

Control Band plus the Stop Delta T. The Stop Delta T is in effect for only the last compressor

running.

If the condenser leaving water temperature falls below 141.5°F, all running compressors will

remain on. No compressor staging occurs within the Control Band. The next-on compressor

will start when the condenser leaving water temperature drops below 138.5°F and the Stage

Up Timer times out. In the example shown in Figure 7, the Shutdown Temp (last compressor

off) would be 143.5°F.

Manual Compressor Disable Logic

Logic is available that allows the operator to manually enable and disable compressors. When a

compressor is disabled, it is considered unavailable to start in the staging logic. This allows a

damaged compressor to be taken offline while the remaining compressor can still provide some

cooling

• The Compressor Disable set points are found on Compressor Set Points screens three and

four.

• A running compressor cannot be disabled until it has been shutdown.

• If all of the compressors on a circuit are disabled, then the circuit will be disabled.

• If both circuits have all of their compressors disabled, the Unit State will remain Off

OMM TGZ-1 TGZ 040A through TGZ 190A 21

Page 22

Automatic Pumpdown

TGZ units are equipped with single pumpdown control. When the last compressor running

on either circuit is ready to shut off, the liquid line solenoid valve (LLSV) is closed first

and the compressor continues to run until the pumpdown pressure is reached, at which time

the compressor shuts off. The shut off pressure is set at 15 psi below the Low Evaporator

pressure Unload setpoint.

When the first compressor on a circuit starts, the LLSV opens simultaneously.

Manual Pumpdown

When the Pumpdown Switch is in the pumpdown position, all compressors except #1 and

#2 will shut off. Then the Liquid Line and Hot Gas Bypass Valves will close. The

operating compressor will pump out the refrigerant. When the Suction Pressure is at 40

psig, the compressors will stop.

Evaporator and Condenser Water Pumps

Most TGZ Templifier unit applications are not arranged to controll the pumps from the

TGZ MicroTech II control system. But if desired, the chiller MicroTech II controller can be

programmed to start and stop the system evaporator and condenser water pumps. They may

also be controlled by the BAS or manually . Programming directions and the sequence of

operation can be found beginning on page 42.

22 TGZ 040A through TGZ 190A OMM TGZ-1

Page 23

MicroTech II Controller

TGZ Controller Software Version

This manual is based on software version WGZDU0102E. The “02E” is the version

descriptor. The version installed in a unit can be viewed by pressing the MENU and

ENTER keys simultaneously, then pressing MENU to return to the regular menu screen.

General Description

The MicroTech II controller’s design will not only permit the chiller to run more efficiently

but will also simplify troubleshooting if a system failure occurs. Every MicroTech II

controller is programmed and tested prior to shipment to assist in a trouble-free start-up.

Operator Friendly

The MicroTech II controller menu structure is separated into three distinct categories,

which provide the operator or service technician with a full description of

1) Current unit status

2) Control parameters (setpoints)

3) Alarms.

Security protection prevents unauthorized changing of the setpoints and control parameters

The MicroTech II controller continuously performs self-diagnostic checks, monitoring all

system temperatures, pressures and protection devices, and will automatically shutdown a

compressor, a refrigerant circuit or the entire unit should a fault occur. The cause of the

shutdown and date stamp is retained in memory and can be easily displayed in plain

English for operator review, which is an extremely useful feature for troubleshooting. In

addition to displaying alarm diagnostics, the MicroTech II chiller controller also provides

the operator with a warning of pre-alarm conditions.

Staging

The four scroll (or six) compressors are staged on and off as a function of leaving hot water

temperature in the Heating Mode or leaving evaporator water temperature in the Cooling

Mode, number of starts and number of run-hours. See Sequence of Operation on page 20.

Equipment Protection

The unit is protected by alarms that shut it down and require manual reset, and also by limit

alarms that limit unit operation in response to some out-of-limit condition. Shut down

alarms activate an alarm signal that can be wired to a remote device.

Unit Enable Selection

Enables unit operation from local keypad or digital input.

Unit Mode Selection

Selects standard cooling, ice, glycol, or test operation mode.

OMM TGZ-1 TGZ 040A through TGZ 190A 23

Page 24

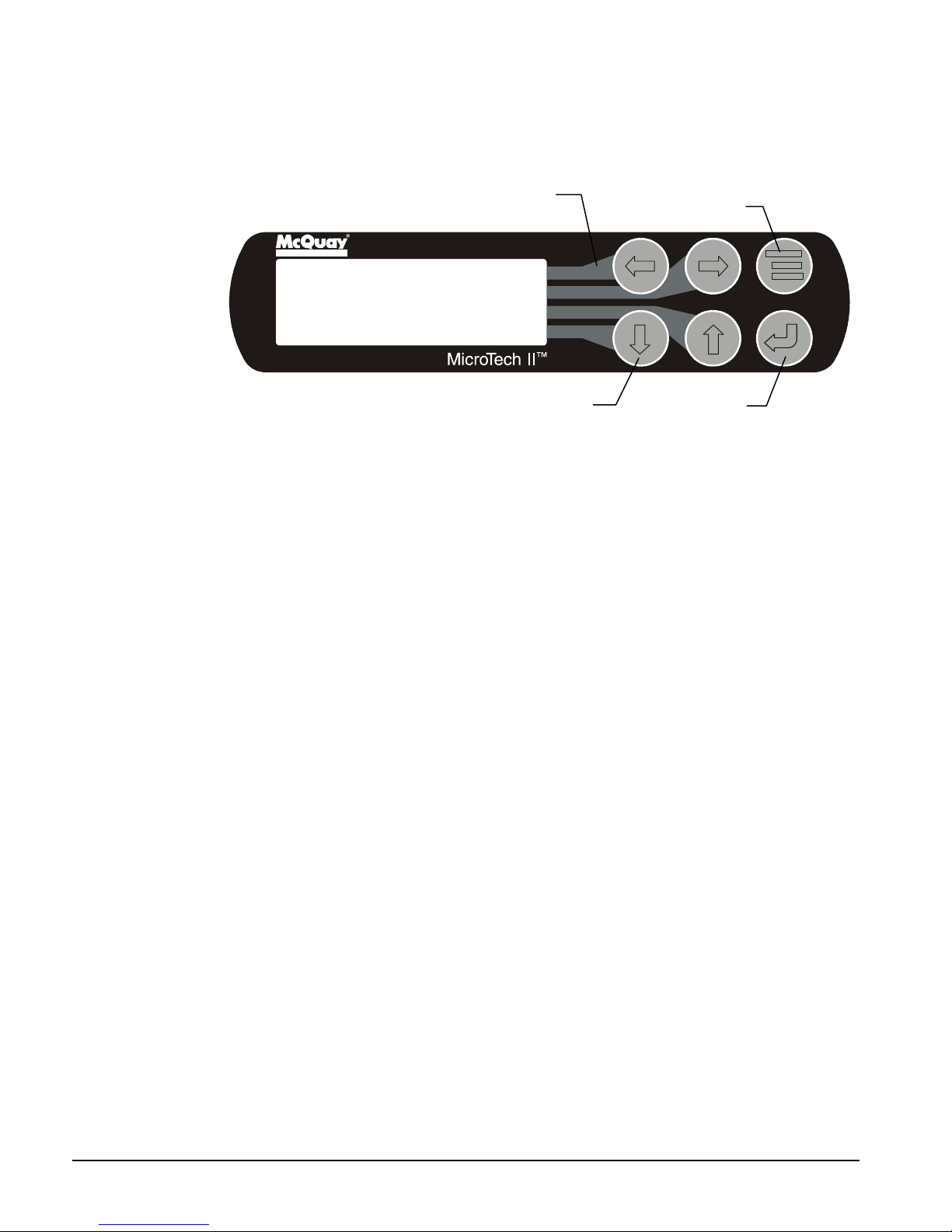

Keypad/Display

ALARM

Key to Screen Pathway

Arrow Keys

A 4-line by 20-character/line liquid crystal display and 6-key keypad is mounted on the unit

controller. Its layout is shown below.

Figure 6, Keypad and Display in MENU Mode

Air Conditioning

Menu Key

<

VIEW

<

<

SET

"Enter" Key

The four arrow keys (UP, DOWN, LEFT, RIGHT) have three modes of use.

1. Scroll between data screens as indicated by the arrows (default mode).

2. Select a specific data screen in a hierarchical fashion using dynamic labels on the right

side of the display (this mode is entered by pressing the MENU key).

3. Change field values in edit mode according to the following table:

LEFT Default

RIGHT Cancel

UP Increment

DOWN Decrement

These four edit functions are indicated by one-character abbreviation on the right side of

the display (this mode is entered by pressing the ENTER key).

24 TGZ 040A through TGZ 190A OMM TGZ-1

Page 25

Inputs and Outputs

The main controller used in the TGZ is either a Carel PCO2 or a PCO3. An expansion module is

also be required for additional outputs on some unit configurations. The software is designed for

use with R-410a water chillers as well as TGZ Templifier units. The selection of the type of

refrigerant (R-134a) is made at the factory and sets certain inputs and outputs.

Large PCO2/PCO3 Controller

Table 9, Analog Inputs

The following parameters are analog inputs to this controller.

Type: C1 = Refrigerant Circuit #1, C2 = Refrigerant Circuit #2, UT = Unit

# Description Type Signal Source Range

*1 Evaporator Refrigerant Pressure #1 C1 0.1 to 0.9 VDC

*2 Evaporator Refrigerant Pressure #2 C2 0.1 to 0.9 VDC

*3 Condenser Refrigerant Pressure #1 C1 0.1 to 0.9 VDC

4 Leaving Evaporator Water Temperature UT

5 Condenser Entering Water Temperature UT

*6 Condenser Refrigerant Pressure #2 C2 0.1 to 0.9 VDC

7 Reset of Leaving Water Temperature UT 4-20 mA Current 0-(10 to 80°F)

*8 Condenser Leaving Water Temperature UT

9 Compressor Suction Temperature #1 C1

10 Compressor Suction Temperature #2 C2

NTC Thermister

(10k@25°C)

NTC Thermister

(10k@25°C)

NTC Thermister

(10k@25°C)

NTC Thermister

(10k@25°C)

NTC Thermister

(10k@25°C)

0 to 132 psi

0 to 132 psi

3.6 to 410 psi

-58 to 212°F

-58 to 212°F

3.6 to 410 psi

-58 to 212°F

-58 to 212°F

-58 to 212°F

Table 10, Analog Outputs

The following parameters are analog outputs from this controller.

# Description Output Signal Range

1 Cooling Tower Bypass Valve Position 0 to 10 VDC 0 to 100% Open

2 Cooling Tower VFD Speed 0 to 10 VDC 0 to 100%

3 Circuit #1 Electronic Expansion Valve 0 to 10 VDC 0 to 100%

4 Circuit #2 Electronic Expansion Valve 0 to 10 VDC 0 to 100%

Table 11, Digital Inputs

The following parameters are digital inputs to this controller.

C1 = Refrigerant Circuit #1, C2 = Refrigerant Circuit #2, UT = Unit, & *n = Refrigerant

Dependent

# Description Type Signal Signal

1 Unit OFF Switch UT 0 VAC (Stop) 24 VAC (Auto)

2 Pump Down Switch #1 C1 0 VAC (Stop) 24 VAC (Start)

3 Evaporator Water Flow Switch UT 0 VAC (No Flow) 24 VAC (Flow)

*4 Open

5 Open

6 Pump Down Switch #2 C2 0 VAC (Stop) 24 VAC (Start)

*7 Open

*8 Condenser Water Flow Switch UT 0 VAC (No Flow) 24 VAC (Flow)

Continued on next page.

OMM TGZ-1 TGZ 040A through TGZ 190A 25

Page 26

Table 11, Digital Inputs, Continued

# Description Type Signal Signal

9 Phase Voltage Fault #1 (See Note 1 Below) C1 0 VAC (Fault) 24 VAC (No Fault)

10 Phase Voltage Fault #2 (See Note 1 Below) C2 0 VAC (Fault) 24 VAC (No Fault)

11 Ground Fault Prot. #1 (See Note 2 Below) C1 0 VAC (Fault) 24 VAC (No Fault)

12 Ground Fault Prot. #2 (See Note 2 Below) C2 0 VAC (Fault) 24 VAC (No Fault)

13 Remote Start/Stop UT 0 VAC (Stop) 24 VAC (Start)

*14 Open

*15 Motor Protection #1 C1 0 VAC (Fault) 24 VAC (No Fault)

*16 Motor Protection #2 C2 0 VAC (Fault) 24 VAC (No Fault)

17 Ice Mode Switch UT 0 VAC (Normal) 24 VAC (Ice)

18 Heat Mode Switch UT 0 VAC (Normal) 24 VAC (Heat)

Notes:

1. See Safety Alarms Table for “Phase Voltage Protection”. Units with single point electrical

connection will have one PVM with Inputs 9 and 10 wired together. Units with multiple point

connection will have two PVM’s with Input 9 for Electrical Circuit #1 and Input 10 for

Electrical Circuit #2.

2. See Safety Alarms Table for “Ground Fault Protection”. Units with single point electrical

connection will have one GFP with Inputs 11 and 12 wired together. Units with multiple point

connection will have two GFP’s with Input 11 for Electrical Circuit #1 and Input 12 for

Electrical Circuit #2.

Table 12, Digital Outputs

The following parameters are digital outputs from this controller.

C1 = Refrigerant Circuit #1, C2 = Refrigerant Circuit #2, UT = Unit, & *n = Refrigerant Dependent

# Description Type Load Output OFF Output ON

1 Alarm

2 Evaporator Water Pump UT Pump Contactor Pump OFF Pump ON

Condenser Water Pump – Water

3

Cooled = Y

4 Motor Control Relay #1 = Compr#1 C1 Starter Compressor OFF Compressor ON

5 Motor Control Relay #3 = Compr#3 C1 Starter Compressor OFF Compressor ON

*6 Motor Control Relay #5 = Compr#5 C1 Starter Compressor OFF Compressor ON

7 Liquid Line #1 C1 Solenoid Cooling OFF Cooling ON

8 Tower Fan #1-Water Cooled=Y C2 /UT Fan Contactor Fan OFF Fan ON

9 Motor Control Relay #2 = Compr#2 C2 Starter Compressor OFF Compressor ON

10 Motor Control Relay #4 = Compr#4 C2 Starter Compressor OFF Compressor ON

*11 Motor Control Relay #6 = Compr#6 C2 Starter Compressor OFF Compressor ON

12 Liquid Line #2 C2 Solenoid Cooling OFF Cooling ON

13 Condenser Fan #3 C1 Fan Contactor Fan OFF Fan ON

14 Hot Gas Bypass #1 C1 Solenoid Cooling OFF Cooling ON

15 Hot Gas Bypass #2 C2 Solenoid Cooling OFF Cooling ON

*16 Condenser Fan #4 (R134a) C2 Fan Contactor Fan OFF Fan ON

*17 Condenser Fan #5&7 (R134a) C1 Fan Contactor Fan OFF Fan ON

18 Condenser Fan #8 C2 Fan Contactor Fan OFF Fan ON

18 Condenser Fan #6&8 C2 Fan Contactor Fan OFF Fan ON

C1,C2,

UT

C1 / UT

Alarm Indicator Alarm OFF Alarm ON

Fan Contactor/

Pump Contactor

Fan OFF Fan ON

26 TGZ 040A through TGZ 190A OMM TGZ-1

Page 27

Expansion I/O Controller

Table 13, Digital Outputs

The following parameters are digital outputs from this controller.

Types: C1 = Refrigerant Circuit #1, C2 = Refrigerant Circuit #2, & UT = Unit

# Description Type Output Off Output On

1 Evap Water Pump Output #2 UT Pump Off Pump On

2 Cond Water Pump Output #2 UT Pump Off Pump On

3 Condenser Fan #9 C1 Fan OFF Fan ON

4 Condenser Fan #10 C2 Fan OFF Fan ON

Table 14, Analog Inputs

The following parameters are digital outputs from this controller.

Types: C1 = Refrigerant Circuit #1, C2 = Refrigerant Circuit #2, & UT = Unit

# Description Type Output Off Output On

1 Entering Evaporator Water Temperature UT

2 Demand Limit UT 4-20 mA Current 0-100 % Load

3 Liquid Line Temperature #1 C1

4 Liquid Line Temperature #2 C2

NTC Thermister

(10k@25°C)

NTC Thermister

(10k@25°C)

NTC Thermister

(10k@25°C)

-58 to 212°F

-58 to 212°F

-58 to 212°F

Setpoints

The following parameters are remembered during power off, are factory set to the Default value,

and can be adjusted to any value in the Range column.

The PW (password) column indicates the password level that must be active in order to change the

setpoint. Passwords are as follows:

O = Operator [0100] M = Manager [2001]

Table 15, Setpoints

Description Default Range PW

Unit Enable Off Off, On O

*Unit Mode Cool

Control source Switches Keypad, Network, Switches O

*Available Modes

(R134a)

Evap LWT 44. 0 °F

Heat LWT 110.0°F 110.0 to 165.0°F

Evap LWT sensor offset 0.0 ± 5.0 degrees F O

Cond LWT sensor offset 0.0 ± 5.0 degrees F O

Evap EWT sensor offset 0.0 ± 5.0 degrees F O

Cond EWT sensor offset 0.0 ± 5.0 degrees F O

Evap Delta T 10.0 °F 6.0 to 16.0 °F O

Cond Delta T O

Startup Delta T 10.0 °F 1.0 to 15.0 °F O

Stop Delta T 0.5 °F 0 to 3.0 °F O

Max Pulldown Rate 1.0 °F 0.5 to 5.0 °F M

Max Rate (R134a) 1.0 ºF 0.5 to 5.0 ºF M

Evap Recirculate Timer 30 15 to 300 seconds M

Cool

Cool, Cool w/Glycol, Heat

Test

Cool, Cool w/Glycol, Heat, Test

Cool/Heat, Cool/Heatw/Glycol,

Heatw/Glycol

40.0 to 60.0 °F, No Glycol

20.0 to 60.0, With Glycol:°

Continued next page.

O

M

O

OMM TGZ-1 TGZ 040A through TGZ 190A 27

Page 28

Table 15, Setpoints, Continued

Description Default Range PW

Evap Pump #1 Only

Cond Delta T 10.0 ºF 5.0 to 40.0 ºF O

Cond Pump Recirculate Timer 30 15 to 90 seconds M

Cond Pump #1 Only

Demand Limit Off Off, On M

Hot Gas Delay Time 30 seconds 30 to 180 seconds M

BAS Protocol Modbus BACnet, LonWorks, Modbus M

Ident number 001 000-200 M

Baud rate 9600 1200,2400,4800,9600,19200 M

Units F/psi F/psi (only)

Language English English (only)

* Refrigerant Select None R134a,R22, R407C,R410A

Cooling Reset Type None

Cooling Maximum Reset 10 ºF 0 to 16 ºF O

Cooling Start Reset Delta T 10 ºF 0 to 16 ºF O

Heating Reset Type None None, 4-20mA, Return O

Heating Maximum Reset 10 ºF 0 to 40 ºF O

Heating Start Reset Delta T 10 ºF 0 to 40 ºF O

Compressor

# of Compressors 4 4, 6 M

Clear Cycle Tmr Off On/Off M

Stage Up Delay 240 seconds 120 to 480 seconds M

Stage Down Delay 30 20 to 60 sec M

Start-Start 15 min 10 to 60 min M

Stop-Start 5 min 3 to 20 min M

Expansion Valve Type, Thermal for TGZ

040-120, Electronic for TGZ 150-190

Circuit 1 EXV Control Auto Auto, Manual M

Circuit 1 EXV Position N/A 0-100% M

Circuit 2 EXV Control Auto Auto, Manual M

Circuit 2 EXV Position N/A 0-100% M

Alarms

Low Evap Pressure-Hold M

Low Evap Pressure-Unload M

High Cond Pressure – Unload M

High Cond Pressure – Stop

Evap. Freeze 38.0 °F

Cond. Freeze 34.0 °F 18 to 42 °F M

High Condenser Pressure Stop 185 psi 170 to 425 psi M

Evap Flow Proof 5 seconds 5 to 15 seconds M

Cond Flow Proof 5 seconds 5 to 15 seconds M

Recirc Timeout 3 minutes 1 to 10 minutes M

* Phase Voltage Protection N N,Y M

* Ground Fault Protection N N,Y M

Cooling Tower TGZ in Cooling Mode

Tower Control None None, Temperature M

Tower Stages 2 0 to 2 M

Thermal

See Table 16

and Table 17

#1 Only, #2 Only, Auto, #1 Prim, #2

Prim

#1 Only, #2 Only, Auto, #1 Prim, #2

Prim

None, 4-20mA,

[Return( Refrig = R134a only)]

Thermal, Electronic

See Table 16 and Table 17

w/water 37 to 42 °F

w/glycol: 12.5 to 42.0 °F

M

M

O

M

M

M

28 TGZ 040A through TGZ 190A OMM TGZ-1

Page 29

Continued next page.

Table 15, Setpoints, Continued

Description Default Range PW

Stage Up Time 2 min 1 to 60 min M

Stage Down Time 5 min 1 to 60 min M

Stage Differential 3.0 °F 1.0 to 10.0 °F M

Stage #1 On 70 °F 40 to 120 °F M

Stage #2 On 75 °F 40 to 120 °F M

Valve/VFD Control None

Valve Setpoint 65 °F 60 to 120 °F M

Valve Deadband 2.0 °F 1.0 to 10.0 °F M

Stage Fan Down @ 20% 0 to 100% M

Stage Fan Up @ 80% 0 to 100% M

Valve Control Range (Min) 10% 0 to 100% M

Valve Control Range(Max) 90% 0 to 100% M

Valve Type NC to tower NC, NO M

Minimum Start Position 0% 0 to 100% M

Minimum Position @ 60 °F 0 to 100 °F M

Maximum Start Position 100% 0 to 100% M

Maximum Position @ 90 °F 0 to 100 °F M

Error Gain 25 10 to 99 M

Slope Gain 25 10 to 99 M

*Set at McQuay factory.

None, Valve Set point, Valve Stage,

VFD Stage, Valve SP/VFD Stage

M

Table 16, Automatic Adjusted Limits

The following are set points that will be limited based on the option selected.

For Evaporator Leaving Water Temperature

Mode Refrigerant Type Range

Unit Mode = Cool R134a, R22, R407c, R410a

Unit Mode = Cool w/Glycol R134a, R22, R407c

For Condenser Leaving Water Temperature

Mode Refrigerant Type Range

Unit Mode=HEAT R134a 110 to 160ºF

Evaporator Freeze Temperature

Mode Refrigerant Type Range

Unit Mode = Cool

Unit Mode = Cool w/Glycol,

Ice w/Glycol

R134a,R22, R407c, R410a

R134a,R22, R407c

Low Evaporator Pressure Inhibit Loading and Unloading

Mode Refrigerant Type Range

Unit Mode = Cool R134a 26 to 54 psi

Unit Mode = Cool w/Glycol, Ice

w/Glycol

R134a 12 to 54 psi

40 to 60°F

20 to 60°F

36 to 42°F

18 to 42°F

OMM TGZ-1 TGZ 040A through TGZ 190A 29

Page 30

Table 17, Dynamic Defaults (Refrigerant Dependent)

Some set points will have a particular default value loaded when another setting is changed.

Defaults

Set Point

Low Evaporator Pressure Hold 29 psi

Low Evaporator Pressure Unload

High Condenser Pressure Unload 170 psi

High Condenser Pressure 185 psi

Events & Alarms

Protection (Shutdown) Alarms

Equipment protection alarms trigger a rapid compressor shutdown. The following section

identifies each equipment protection alarm, gives the trigger that causes the alarm to occur,

states the action taken because of the alarm and reset method. Most equipment protection

alarms require a manual reset. These alarms will energize a remote alarm if the unit is so

wired in the field.

Refrigerant Type

R134a

28 psi

Alarms and Events

Situations may arise that require some action from the chiller or that should be logged for

future reference. Conditions that cause a shutdown and require manual reset is known as a

stop alarm. Other conditions can trigger what is known as an event, which may or may not

require action in response. All stop alarms and events are logged.

Unit Stop Alarms

The alarm output and red button will be turned ON when any stop alarm occurs. They will

be turned off when all alarms have been cleared.

Evaporator Flow Loss

Alarm description (as shown on screen): Evaporator Flow Loss

Trigger:

1: Evaporator Pump State = Run AND Evaporator Flow Digital Input = No Flow for time

> Evap Flow Proof Set Point AND at least one compressor running.

2: Evaporator Pump State = Start for time greater than Recirc Timeout Set Point AND all

pumps have been tried AND Evaporator Flow Digital Input = No Flow.

Action Taken: Rapid stop all circuits.

Reset:

This alarm can be cleared at any time manually, via the keypad, or via the BAS clear alarm

signal.

If active via trigger condition 1:

30 TGZ 040A through TGZ 190A OMM TGZ-1

Page 31

When the alarm occurs due to this trigger, it can auto reset the first two times each day, with

the third occurrence being manual reset.

For the auto-reset occurrences, the alarm will reset automatically when the evaporator state

is Run again. This means the alarm stays active while the unit waits for flow, then it goes

through the recirculation process after flow is detected. Once the recirculation is complete,

the evaporator goes to the Run state which will clear the alarm. After three occurrences, the

count of occurrences is reset and the cycle starts over if the manual reset flow loss alarm is

cleared.

If active via trigger condition 2:

If the flow loss alarm has occurred due to this trigger, it is always a manual reset alarm.

Condenser Flow Loss

Alarm description (as shown on screen): Condenser Flow Loss

Trigger:

1: Condenser Pump State = Run AND Condenser Flow Digital Input = No Flow for time >

Cond Flow Proof Set Point AND at least one compressor running.

2: Condenser Pump State = Start for time greater than Recirc Timeout Set Point AND all

pumps have been tried AND Condenser Flow Digital Input = No Flow.

Action Taken: Rapid stop all circuits.

Reset:

This alarm can be cleared at anytime manually, via the keypad, or via the BAS clear alarm

signal.

If active via trigger condition 1:

When the alarm occurs due to this trigger, it can auto reset the first two times each day, with

the third occurrence being manual reset.

For the auto-reset occurrences, the alarm will reset automatically when the condenser pump

state is Run again. This means the alarm stays active while the unit waits for flow, then it

goes through the recirculation process after flow is detected. Once the recirculation is

complete, the condenser pump goes to the Run state which will clear the alarm. After three

occurrences, the count of occurrences is reset and the cycle starts over if the manual reset

flow loss alarm is cleared.

If active via trigger condition 2:

If the flow loss alarm has occurred due to this trigger, it is always a manual reset alarm.

Low Evaporator Pressure

Alarm description (as shown on screen): Evap Press Low Cir N

Trigger: [Circuit State = Run AND Freezestat trip AND Low OAT Start not active]

OR Evaporator Press < Absolute Low Pressure Limit AND Circuit State = Run

The absolute low pressure limit is 5 psi with R134a, R22, and R407C refrigerants and 20

psi with R410A refrigerant.