Page 1

Installation Manual

Group: Chiller

Part Number: 331975501

Effective: October 2008

Supersedes: New

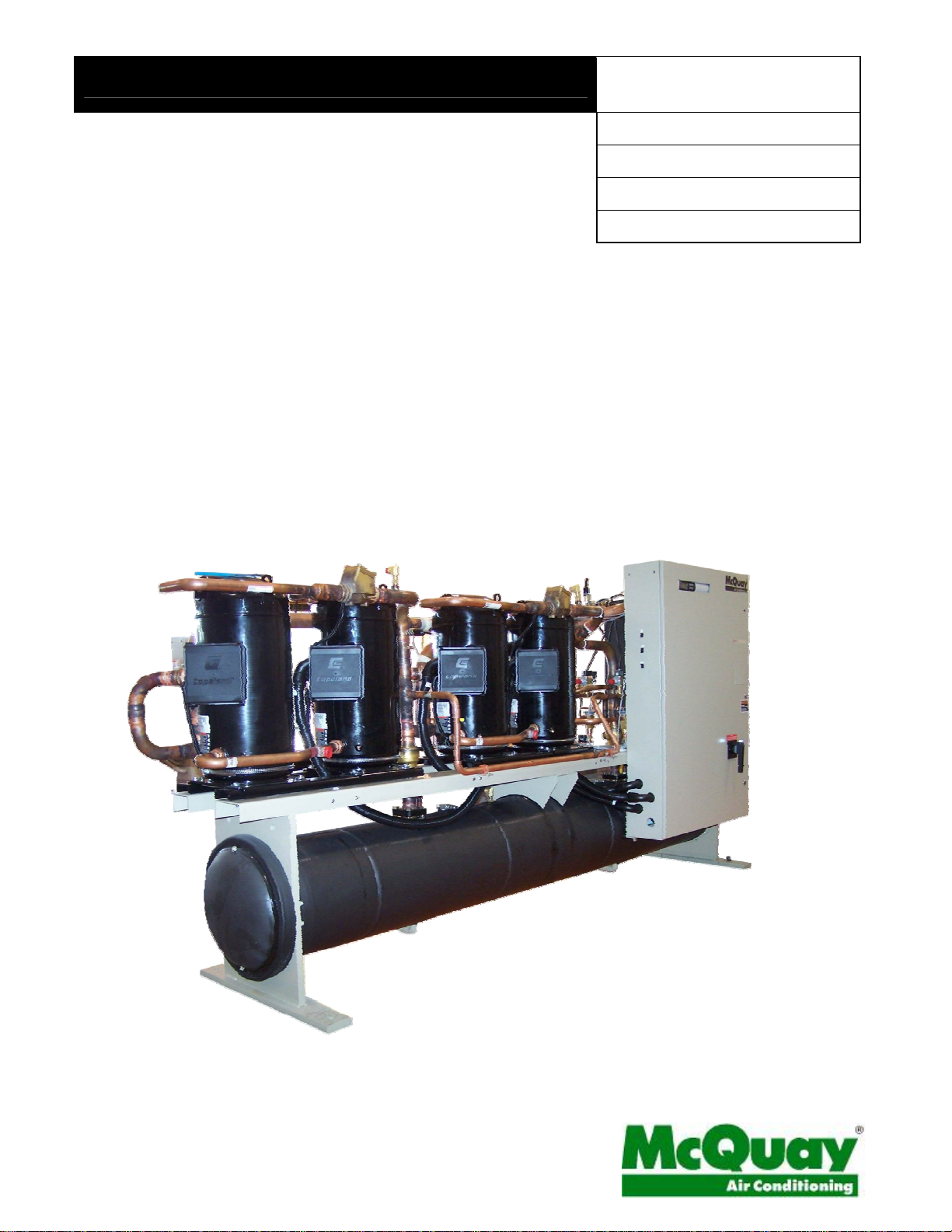

Templifier® Heat Recovery Water Heaters

TGZ 040A to TGZ 190A, Packaged Water Heater

600 to 3100 MBH

R134a

50/60 Hz

IM TGZ

Page 2

TABLE OF CONTENTS

Introduction .........................................2

General Description...............................

Nomenclature.........................................

2

2

Inspection ..............................................2

Installation............................................

Handling ................................................

3

3

Moving the Unit ....................................3

Location.................................................4

Vibration Isolators.................................5

Water Piping........................................7

General ..................................................7

Source Water Piping..............................8

Source/Hot Water Thermostat...............

Flow Switch...........................................

8

9

Glycol Solutions..................................10

Condenser Water Piping......................10

Heating and Cooling Units..................11

Water Pressure Drop............................11

TGZ Scroll...........................................12

Dimensional Data...........................16

Weights............................................24

Physical Data..................................25

TGZ Scroll.......................................25

Unit Components ...........................29

Wiring.............................................31

Electrical Data................................33

Start-Up and Shutdown.................41

Pre Start-up ......................................41

Start-up.............................................41

Extended Shutdown.........................42

Start-up after Extended Shutdown...42

General............................................42

Electrical Terminals.........................43

Operating Limits..............................43

Compressor Oil................................44

Sightglass and Moisture Indicator ...44

Troubleshooting Chart..................45

HAZARD IDENTIFICATION INFORMATION

!

DANGER

Dangers indicate a hazardous situation which will result in death or serious injury if not avoided.

!

WARNING

Warnings indicate potentially hazardous situations, which can result in property damage,

severe personal injury, or death if not avoided.

!

CAUTION

Cautions indicate potentially hazardous situations that can result in personal injury or equipment

damage if not avoided.

Manufactured in an ISO Certified facility

©2008 McQuay International. Illustrations and data cover the McQuay International product at the time of publication and we reserve the right to make

changes in design and construction at anytime without notice. ™® The following are trademarks or registered trademarks of their respective companies:

BACnet from ASHRAE;

license granted by Echelon Corporation; Modbus from Schneider Electric; MicroTech II and Open Choices from McQuay International

LONMARK, LonTalk, LONWORKS, and the LONMARK logo are managed, granted and used by LONMARK International under a

1 TGZ 040A through TGZ 190A IM TGZ

Page 3

Introduction

General Description

McQuay TGZ water heaters are scroll compressor refrigeration units that recover heat from warm fluid streams in

the evaporator and deliver hot water, at a useful temperature, from the condenser to a heating load. They are

designed for indoor installations only and are completely assembled, wired, charged and tested. Each unit consists

of four or six (depending on unit size) scroll compressors, brazed-plate evaporators on models 040 through 120

and shell-and-tube evaporators on models 150 to 190, shell-and-tube condenser/heater, and complete refrigerant

piping.

There are two refrigerant circuits, each with manual liquid line shutoff valves, charging valves, filter-driers, liquid

line solenoid valves, sightglass/moisture indicators, and thermal expansion valves.

®

The electrical control center includes a MicroTech II

dependable automatic operation.

Nomenclature

T G Z 100 A

Templifier

Global

control system and other components necessary for

Vintage

Scroll Compressor

Nominal

Evaporator Tons

Inspection

When the equipment is received, all items should be carefully checked against the bill of lading to provide a

complete shipment. All units must be carefully inspected for damage upon arrival. All shipping damage must be

reported to the carrier and a claim must be filed with the carrier. The unit serial plate should be checked before

unloading the unit to be sure that it agrees with the power supply available. Physical damage to unit after

acceptance is not the responsibility of McQuay.

Note: Unit shipping and operating weights are given in the Physical Data Tables beginning on page

24.

IM TGZ TGZ 040A through TGZ 190A 2

Page 4

Installation

TGZ040-190A / WGZ030-200C

Note: Installation and maintenance are to be performed only by qualified personnel who are

familiar with local codes and regulations, and experienced with this type of equipment.

!

WARNING

Avoid contact with sharp edges. Personal injury can result.

Handling

Every model TGZ water heater is shipped with a full refrigerant charge that is isolated in the condenser by the

manual condenser liquid valve and the compressor discharge service valve.

If the unit has been damaged, allowing the refrigerant to escape, there can be danger of suffocation in the

equipment area since the refrigerant will displace the air. Be sure to review Environmental Protection Agency

(EPA) requirements if damage has occurred. Avoid exposing an open flame to the refrigerant.

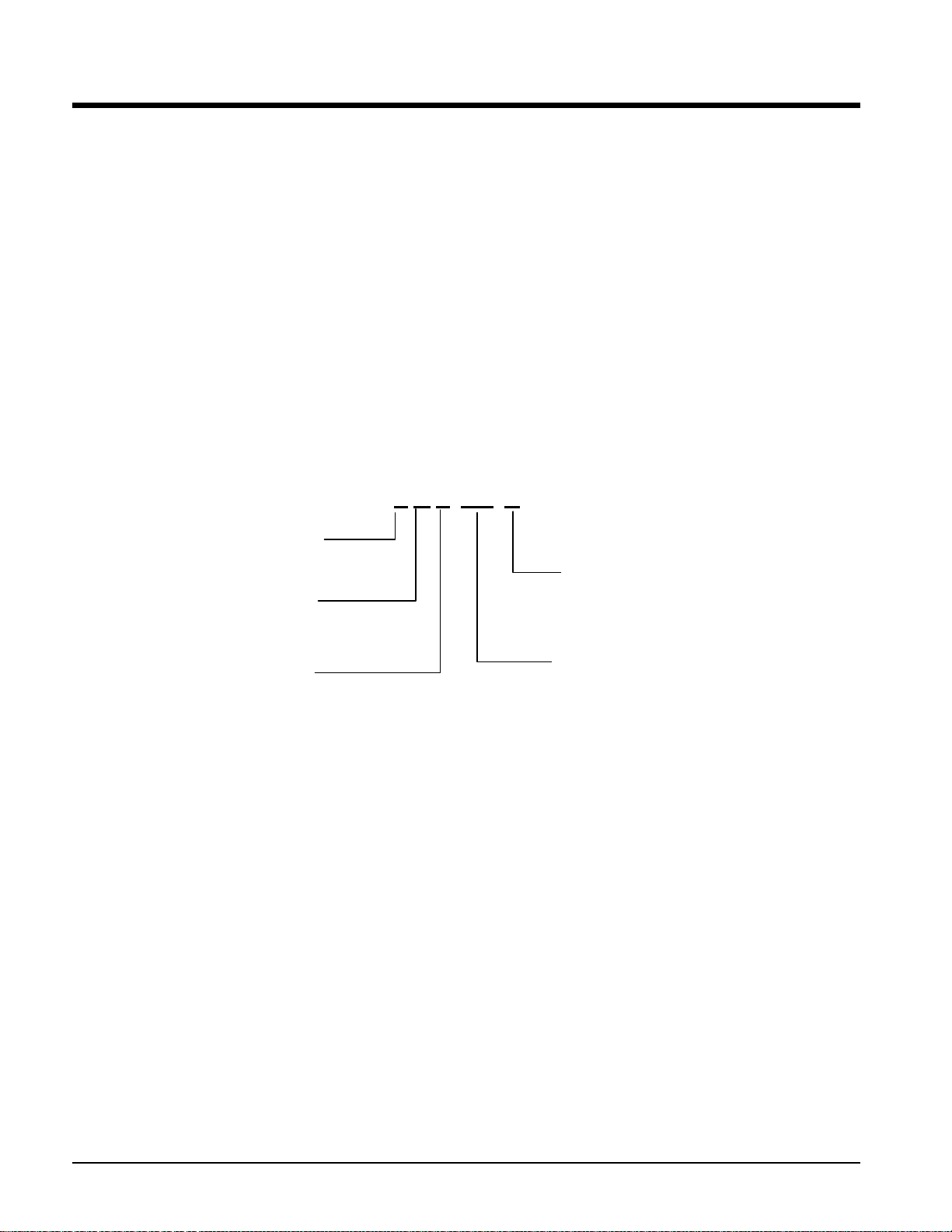

Moving the Unit

Moving the Unit The skid option is strongly recommended for ease of handling and to help prevent damage

if a crane is not available for rigging at site.

Figure 1, Lifting the Unit

RIGGING INSTRUCTIONS

SPREADER BARS MUST

BE USED FOR STABILITY

DURING LIFTING OF

ALL SIZE UNITS

WGZ150-200C

UNIT SHOWN

3 TGZ 040A through TGZ 190A IM TGZ

331926901 REV. 0A

Page 5

It is recommended that all moving and handling be performed with skids under the unit when possible and that the

skids not be removed until the unit is in the final location. When moving the unit, dollies or simple rollers can be

used under the skids. Never put the weight of the unit against the control box.

In moving, always apply pressure to the base on the skids only and not to the piping or shells. A long bar will help

move the unit easily. Avoid dropping the unit at the end of the roll.

If the unit must be hoisted, it is necessary to lift the unit by attaching cables or chains at the lifting holes located on

the disposable lifting bars. Spreader bars must be used to protect the control cabinet and other areas of the unit (see

Figure 1)

Do not attach slings to piping or equipment. Move unit in the upright horizontal position at all times. Set unit down

gently when lowering from the trucks or rollers.

Location

The unit is designed for indoor application and must be located in an area where the ambient temperature is above

40°F (4°C) minimum.

Because of the electronic control devices, the units should not be exposed to the weather. A plastic cover over the

control box is supplied as temporary protection during shipment. A reasonably level and sufficiently strong floor is

required for the unit. If necessary, additional structural members should be provided to transfer the weight of the unit

to the nearest beams.

Note: Unit shipping and operating weights are available in the Weights section beginning on page

24.

Space Requirements for Connections and Servicing

Allow a minimum of 4-foot clearance in front of the control panel. The source water and hot water piping enters and

leaves the unit from the right side when looking at the control panel. Left-hand condenser connections are an option.

A clearance of at least 3 feet (1219 mm), or more if codes require, should be provided beyond this piping and on all

other sides and ends of the unit for general servicing or for changing the compressors, if it ever becomes necessary.

Clearance should also be provided for cleaning or removal of condenser tubes, and evaporator tubes on models 150

to 190, on one end of the unit. The clearance for cleaning depends on the type of apparatus used, but can be as much

as the length of the largest condenser (12 feet, 3660 mm). Tube replacement requires the tube length plus one to two

feet of workspace. This space can often be provided through a doorway or other opening.

Placing the Unit

The small amount of vibration normally encountered with the water chiller makes this unit particularly desirable for

basement or ground floor installations where the unit can be mounted directly to the floor. The floor construction

should be such that the unit will not affect the building structure, or transmit noise and vibration into the structure.

IM TGZ TGZ 040A through TGZ 190A 4

Page 6

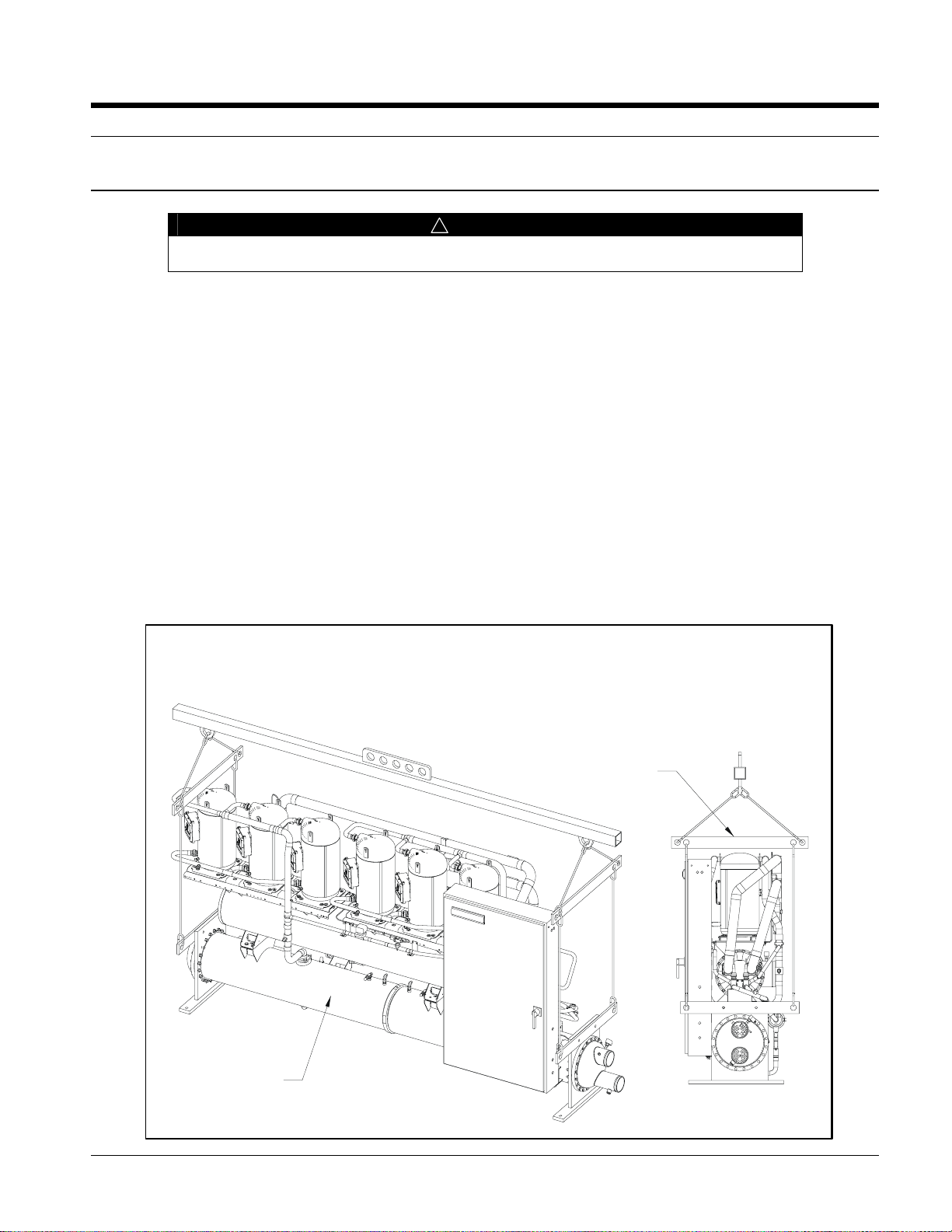

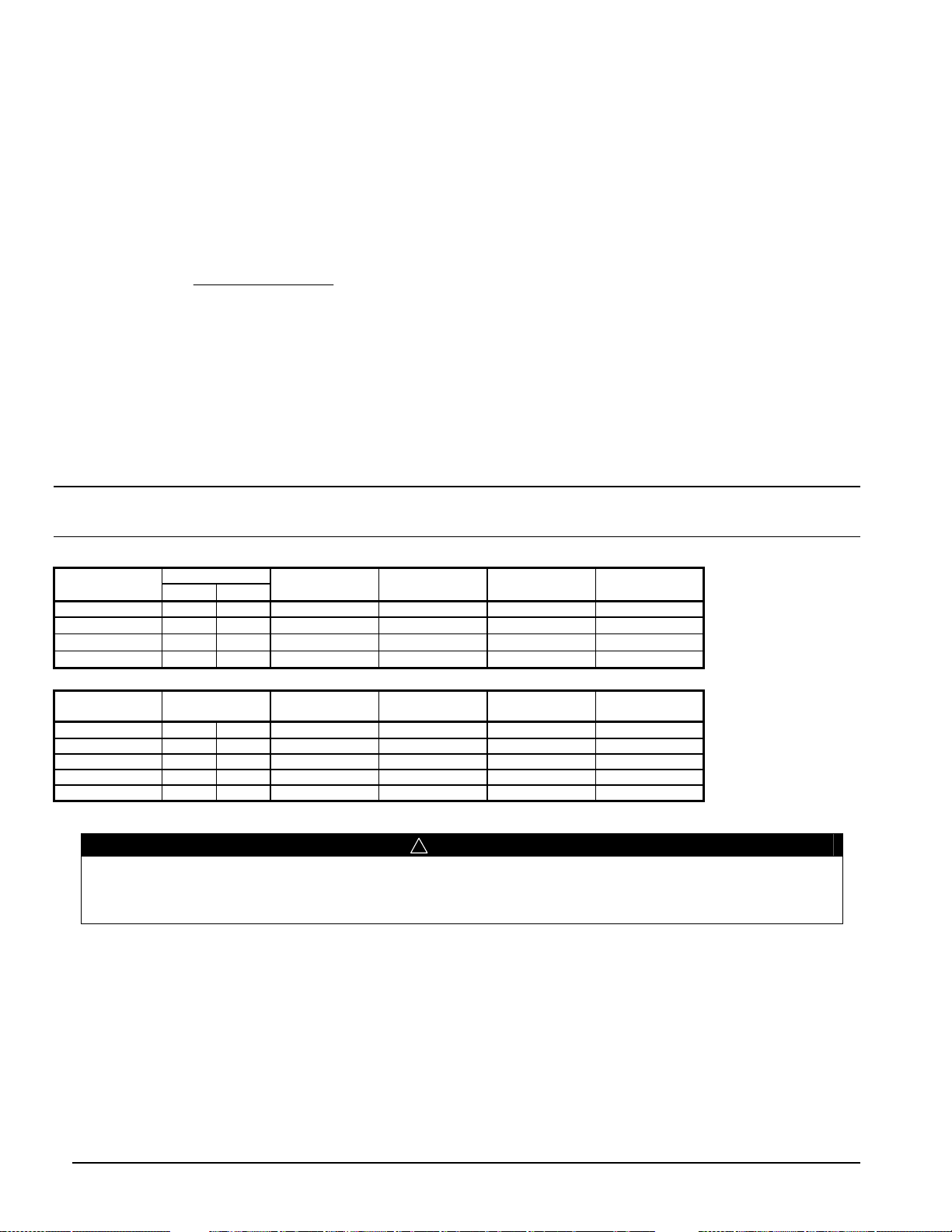

Vibration Isolators

It is recommended that isolators be used on all upper level installations or in areas where vibration transmission

is a consideration.

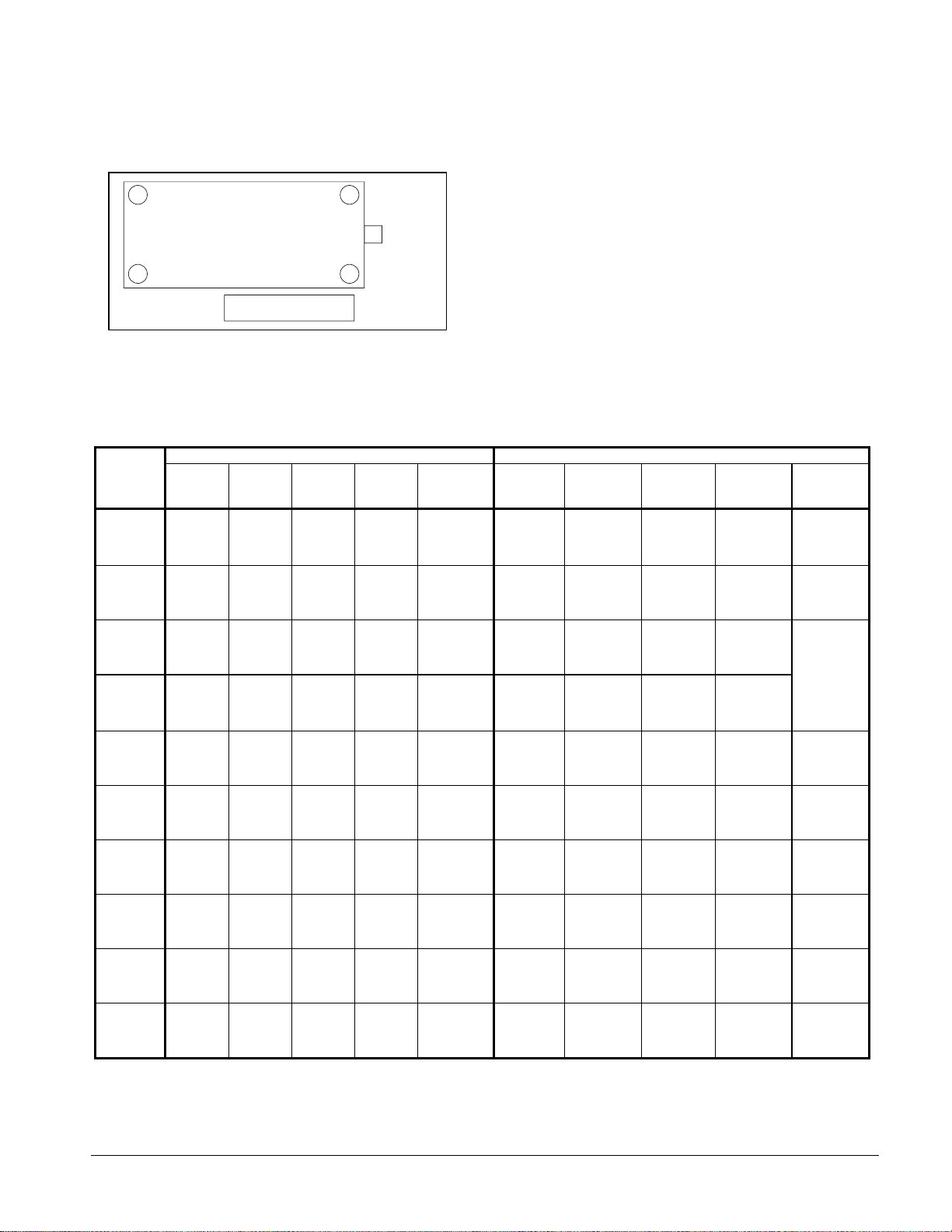

Figure 2, Isolator Locations

4

LB

RB

3

Water

Connections

Transfer the unit as indicated under “Moving the Unit.” In

all cases, set the unit in place and level with a spirit level.

When spring-type isolators are required, install springs

running under the main unit supports.

1

LF

FRF

2

The unit should be set initially on shims or blocks at the

listed spring free height. When all piping, wiring, flushing,

Control Panel

charging, etc., is completed, the springs are adjusted upward

to loosen the blocks or shims that are then removed.

A rubber anti-skid pad should be used under isolators if hold-down bolts are not used.

Installation of spring isolators requires flexible piping connections and at least three feet of flexible electrical

conduit to avoid straining the piping and transmitting vibration and noise

.

Table 1, Vibration Mounting Location and Kit Number

TGZ

MODEL

040A

050A

060A

080A

M1

(LEFT-

FRONT)

RP-3

Gray-WR

RP-3

Gray-WR

RP-3

Gray-WR

RP-4

Brown-WR

R-I-S MOUNTING LOCATION SPRING-FLEX MOUNTING LOCATION

M2

(RIGHTFRONT)

RP-3

Gray-WR

RP-3

Gray-WR

RP-3

Gray-WR

RP-4

Brown-WR

M3

(RIGHT-

REAR)

RP-3

Gray-WR

RP-3

Gray-WR

RP-3

Gray-WR

RP-4

Brown-WR

M4

(LEFTREAR)

RP-3

Gray-WR

RP-3

Gray-WR

RP-3

Gray-WR

RP-4

Brown-WR

KIT PART

NUMBER

332325701

332325701

332325701

332325702

M1

(LEFT-

FRONT)

CP1E-

ID-900

Dk. Green

CP1E-

ID-900

Dk. Green

CP1E-

ID-900

Dk. Green

CP2E-

ID-1350

Dk. Purple

M2

(RIGHTFRONT)

CP1EID-900

Dk. Green

CP1EID-900

Dk. Green

CP1EID-900

Dk. Green

CP2E-

ID-1350

Dk. Purple

M3

(RIGHT-

REAR)

CP1E-

ID-900

Dk. Green

CP1E-

ID-900

Dk. Green

CP1E-

ID-900

Dk. Green

CP2E-

ID-1350

Dk. Purple

M4

(LEFTREAR)

CP1E-

ID-900

Dk. Green

CP1E-

ID-900

Dk. Green

CP1E-

ID-900

Dk. Green

CP2E-

ID-1350

Dk. Purple

KIT PART

NUMBER

332320701

332320701

332320701

332320702

100A

110A

120A

150A

170A

190A

RP-4

Brown-WR

RP-4

Red-WR

RP-4

Red-WR

RP-4

Lime-WR

RP-4

Lime-WR

RP-4

Lime-WR

RP-4

Brown-WR

RP-4

Red-WR

RP-4

Red-WR

RP-4

Lime-WR

RP-4

Lime-WR

RP-4

Lime-WR

RP-4

Brown-WR

RP-4

Red-WR

RP-4

Red-WR

RP-4

Lime-WR

RP-4

Lime-WR

RP-4

Lime-WR

RP-4

Brown-WR

RP-4

Red-WR

RP-4

Red-WR

RP-4

Lime-WR

RP-4

Lime-WR

RP-4

Lime-WR

332325702

332325703

332325703

332325704

332325704

332325704

CP2E-

ID-1800

Dk. Green

CP2E-

ID-1800

Dk. Green

CP2E-

ID-1800

Dk. Green

CP2E-

ID-2400

Gray

CP2E-

ID-2400

Gray

CP2E-

ID-2400

Gray

CP2E-

ID-1800

Dk. Green

CP2E-

ID-1800

Dk. Green

CP2E-

ID-1800

Dk. Green

CP2E-

ID-2400

Gray

CP2E-

ID-2400

Gray

CP2E-

ID-2400

Gray

CP2E-

ID-1800

Dk. Green

CP2E-

ID-1800

Dk. Green

CP2E-

ID-1800

Dk. Green

CP2E-

ID-2400

Gray

CP2E-

ID-2400

Gray

CP2E-

ID-2400

Gray

CP2E-

ID-1800

Dk. Green

CP2E-

ID-1800

Dk. Green

CP2E-

ID-1800

Dk. Green

CP2E-

ID-2400

Gray

CP2E-

ID-2400

Gray

CP2E-

ID-2400

Gray

332320703

332320703

332703703

332320704

332320704

332320704

NOTE: For Spring-flex mountings, CP2E have two springs per isolator housing, CP1E have one spring per housing.

5 TGZ 040A through TGZ 190A IM TGZ

Page 7

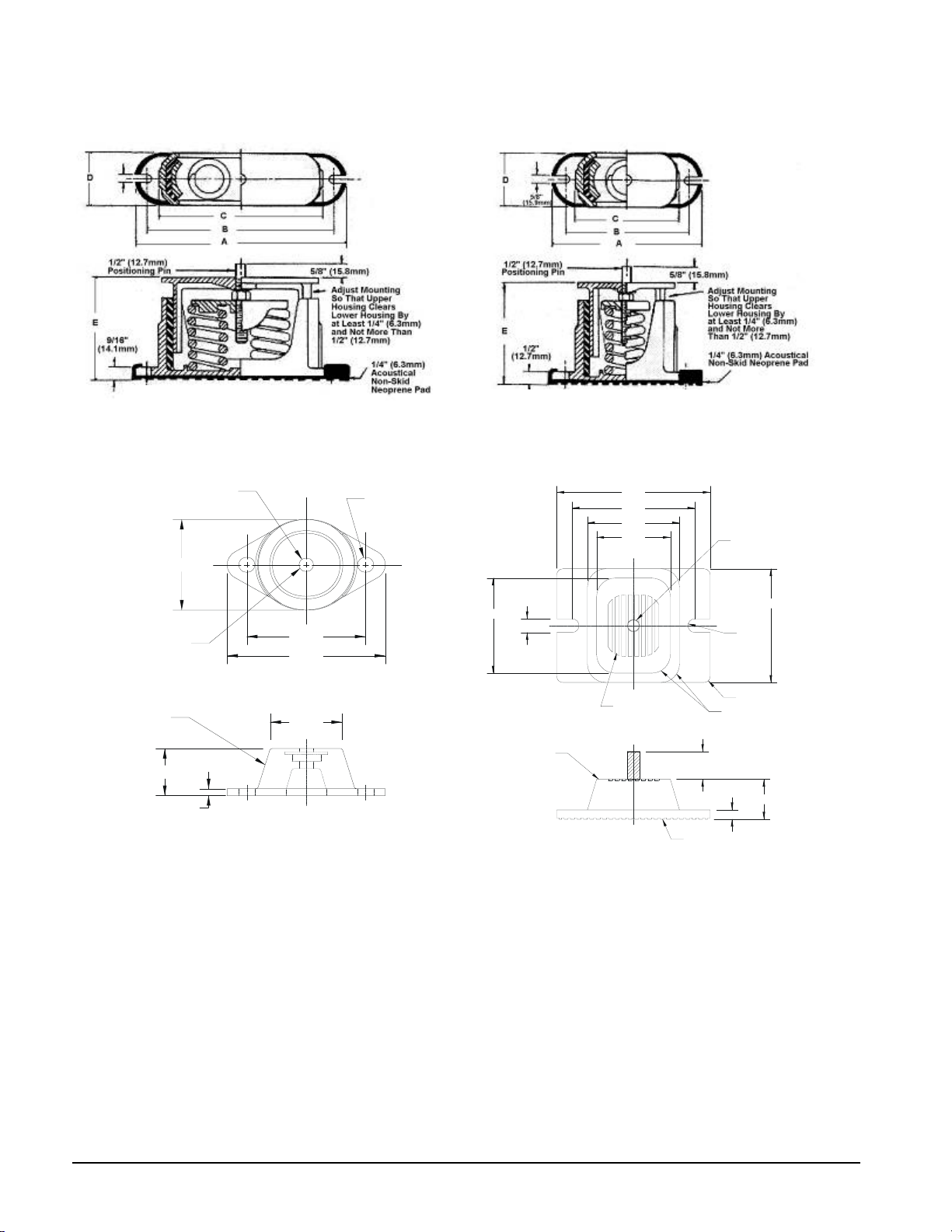

Figure 3, Isolator Dimensions

6

D

S

E

A

Spring Flex Mounting. CP-2 Spring Flex Mounting, CP-1

Rubber-in-Shear Mounting, RP-3

1/2-13 TAP

ø3.38

ø.5

2 HOL

Rubber-in-Shear, RP-4

6.25

5.00

3.75

3.00

R4

ø .500-13NC-2B

LOCA TING PIN TO

BE INSTALLED HERE

MOUNTING MOLDED IN

DURULENE. WEATHER

RESISTANT (WR)

1.75 (R)

.25

4.13

5.50

DRAWING NUMBER 3319880

ALL DIMENSION

2.50

ARE IN DECIMAL INCH

3.87

.56 TYP.

DURULENE

MATERIAL

NOTES:

MOUNT MATERIAL TO BE DURULENE RUBBER.1.

MOLDED STEEL AND ELASTOMER MOUNT FOR2.

OUTDOOR SERVICE CONDITIONS.

3. RP-4 MOUNT VERSION WITH STUD IN PLACE.

VM&C

RECESSED

GRIP RIBS

VM&C

R4

1.13 ± .25

APPROX.

RAISED GRIP RIBS

DRAWING NUMBER 3314814

LL DIMENSIONS ARE IN DECIMAL INCHES

R.28

TYP.

R.250 TYP.

R.750 TYP.

.38

4.63

1.63

IM TGZ TGZ 040A through TGZ 190A 6

Page 8

Water Piping

General

Due to the variety of piping practices, it is advisable to follow the recommendations of local authorities. They can

supply the installer with the proper building and safety codes required for a safe and proper installation.

Note: Since the Templifier evaporator and/or condenser may have to be valved off for cleaning or repair, it may

be essential that a bypass be piped around them so that source and hot water flow is not interrupted.

The piping should be designed with a minimum number of bends and changes in elevation to keep system cost

down and performance up. It should contain:

1. All piping should be installed and supported to prevent the unit connections from bearing any strain or

weight of the system piping.

2. Vibration eliminators to reduce vibration and noise transmission to the building.

3. Shutoff valves to isolate the unit from the piping system during unit servicing.

4. Manual or automatic air vent valves at the high points of the system. Drains should be placed at the

lowest points in the system.

5. Some means of maintaining adequate system water pressure (e.g., expansion tank or regulating valve).

6. Temperature and pressure indicators located within 3 feet (0.9 meters) of the inlet and outlet of the

vessels to aid in unit servicing.

7. A strainer or some means of removing foreign matter from the water before it enters the pump is

recommended. It should be placed far enough upstream to prevent cavitation at the pump inlet (consult

pump manufacturer for recommendations). The use of a strainer will prolong pump life and thus keep

system performance up.

8. A cleanable strainer must

condenser, 40-mesh on models TGZ 040 to 120 evaporators and 20-mesh on all other vessels. This will

aid in preventing foreign material from entering and decreasing the performance of the evaporator and

condenser.

9. Any water piping to the unit must be protected to prevent freezing. Consult the ASHRAE handbook for

standard industry practice.

10. If the unit is used in an existing piping system, the system should be thoroughly flushed prior to unit

installation. When job conditions permit, regular water analysis and chemical water treatment on the

evaporator and condenser is recommended commencing at equipment start-up.

11. The total quantity of water in the evaporator and condenser systems should be sufficient to prevent

frequent “on-off” cycling. For closed loop applications where the cooling load changes relatively

slowly, a minimum system volume of two to three minutes times the flow

recommended. For example, if the design chiller flow rate is 120 gpm, we recommend a system

volume of 240 to 360 gallons.

12. In the event glycol is added to the water system, as an afterthought for freeze protection, recognize that

the refrigerant suction pressure will be lower, cooling and heating performance lower, and water side

pressure drop will be greater. If the percentage of glycol is large, or if propylene is employed instead of

ethylene glycol, the added pressure drop and loss of performance could be substantial. Reset the

freezestat and low leaving water alarm temperatures. The freezestat is factory set to default at 36°F

(2.2°C). Reset the freezestat setting to approximately 4° to 5°F (2.3° to 2.8°C) below the leaving

chilled water setpoint temperature. See the section titled “Glycol Solutions” on page

information concerning glycol.

13. A preliminary leak check of the water piping should be made before filling the system.

A flow switch must be installed in the horizontal piping of the evaporator and condenser outlet

also be placed in the water lines just prior to the inlets of the evaporator and

rate (GPM) is

10 for additional

!

CAUTION

piping to prove water flow..

7 TGZ 040A through TGZ 190A IM TGZ

Page 9

Source Water Piping

r

The system water piping must be flushed thoroughly prior to making connections to the unit evaporator. Lay out

the water piping so the source water circulating pump discharges into the evaporator inlet.

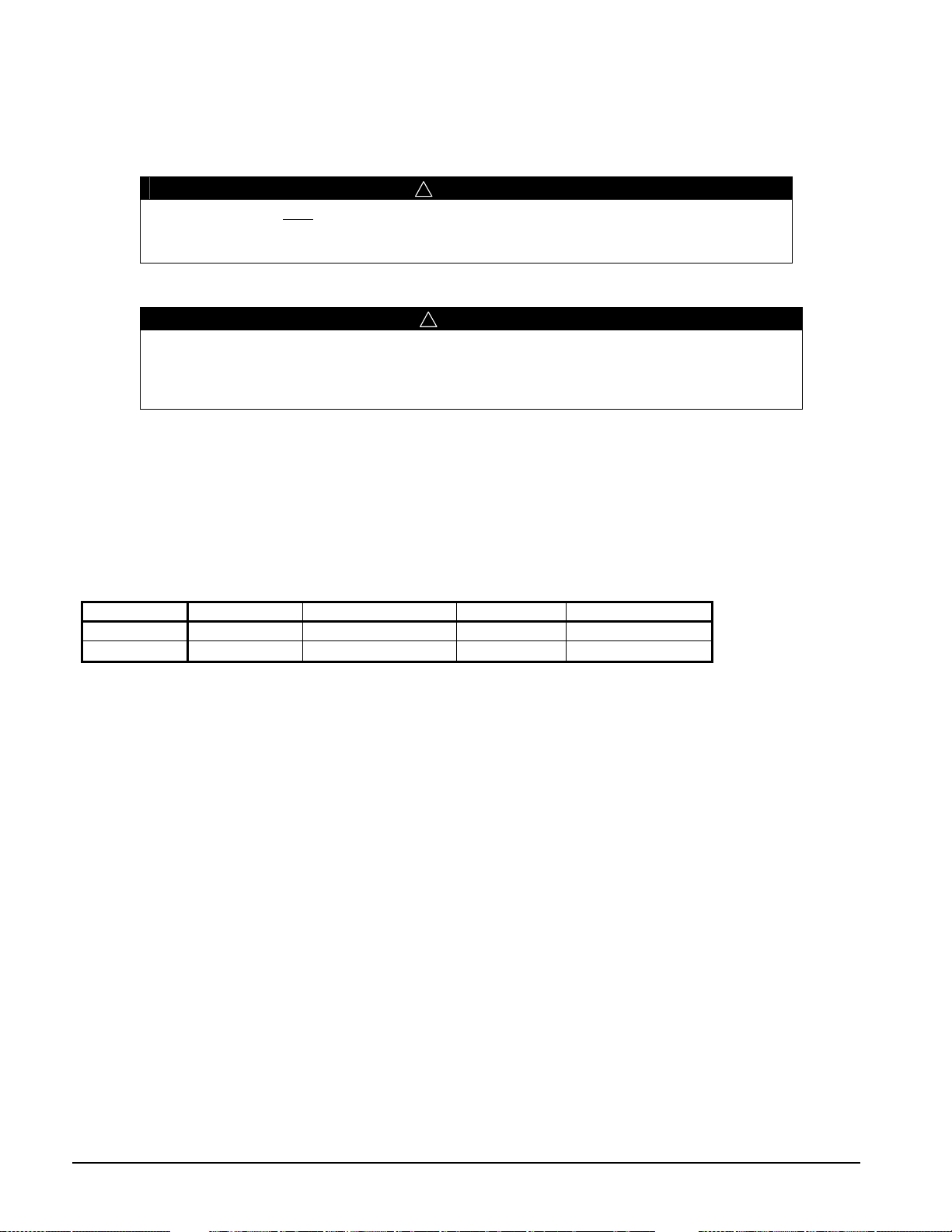

!

CAUTION

A cleanable strainer must be placed in the water lines just prior to the inlets of the evaporator and

condenser, 40-mesh on models 040 to 120 evaporators and 20-mesh on all other vessels. Failure

to do so will cause damage to the equipment.

!

CAUTION

Templifier Models TGZ 040 through TGZ 120 must have clean source water from a closed and

treated loop going to the brazed-plate evaporator. For open water loop applications, an intermediate

heat exchanger between the source water and evaporator is required. Failure to provide a clean,

closed water loop can cause equipment failure and possible revocation of the unit warranty.

Templifier evaporator water can come from various sources and care must be exercised to avoid sources that can

cause corrosion, fouling, or accumulation of debris in the heat exchanger. Borderline cases will require a careful

and rigorously performed maintenance schedule.

Extensive, detailed information on the suitability of source water for brazed-plate exchangers can be found in an

Alfa Laval, June 2001 publication titled A Technical Reference for Plate Heat Exchangers in Refrigeration & Air-

conditioning Applications

Table 2, Evaporator Characteristics

TGZ UNIT SIZE EVAPORATOR MATERIALS STRAINER CLEANING

040A – 120A Brazed Plate Stainless Steel, Coppe

150A – 190A Shell-and-Tube Carbon Steel, Copper 20-Mesh Chemical

40-Mesh Chemical

Inlet and outlet connections are clearly marked on the unit and also appear on the dimension drawings, beginning

on page

16.

Drain connections should be provided at all low points in the system to permit complete drainage. Air vents

should be located at the high points in the system to purge out air. A vent connection, located on top of the

evaporator vessel, permits the purging of air out of the evaporator. Air purged from the water system prior to unit

start-up provides adequate flow through the vessel and prevents safety cutouts on the freeze protection. System

pressures can be maintained by using an expansion tank as a combination pressure relief and reducing valve.

Pressure gauges should be installed in the inlet and outlet water lines to the evaporator. Pressure drop through the

evaporator should be measured to calculate proper gpm (L/s) as specified in the Physical Data section tables,

beginning on page

25. Vibration eliminators are recommended in both the supply and return water lines.

Source water piping may have to be insulated (depending on its temperature) to reduce heat loss and prevent

condensation if cold water is used. If cooling tower water is used, insulation is not necessary. Complete unit and

system leak tests should be performed prior to insulating the water piping. Insulation with a vapor barrier is

recommended. If the vessel is insulated, the vent and drain connections must extend beyond the proposed

insulation thickness for accessibility. If the unit operates year-round, or if the system is not drained for the winter,

the chilled water piping exposed to outdoor ambient should be protected against freezing by wrapping the lines

with a heater cable.

Source/Hot Water Thermostat

The source water temperature sensor is factory installed in the leaving water connection on the evaporator. The

controlling hot water sensor is in the leaving condenser connection. A sensor is also located in the entering

IM TGZ TGZ 040A through TGZ 190A 8

Page 10

water connection in order to measure the condenser Delta-T. Care should be taken not to damage the sensor

V

cable or leadwires when working around the unit. It is also advisable to check the leadwire before running the

unit to be sure that it is firmly anchored and not rubbing on the frame or any other component.

If the sensor is ever removed from the well for servicing, care must be taken as not to wipe off the heat

conducting compound supplied in the well. The units can be switched from heating to cooling. In the cooling

mode they are controlled by a thermostat in the leaving evaporator connection, in the heating mode by the

condenser thermostat.

Flow Switch

A water flow switch must be mounted in the evaporator and condenser leaving water lines to prove adequate

water flow to the vessels before the unit can start. This will safeguard against slugging the compressors on

start-up. It also serves to shut down the unit in the event that water flow is interrupted to guard against

evaporator freeze-up.

A flow switch is available from McQuay under ordering number 01750330. It is a “paddle” type switch and

adaptable to any pipe size from 1” (25mm) to 6” (152mm) nominal. Certain minimum flow rates are required

to close the switch and are listed in

Diagram on page

32 for terminal locations. The normally open contacts of the flow switch should be wired

between these two terminals. There is also a set of normally closed contacts on the switch that could be used

for an indicator light or an alarm to indicate when a “no flow” condition exists.

1. Apply pipe sealing compound to only the threads of the switch and screw unit into D” x D” x 1 (25mm)

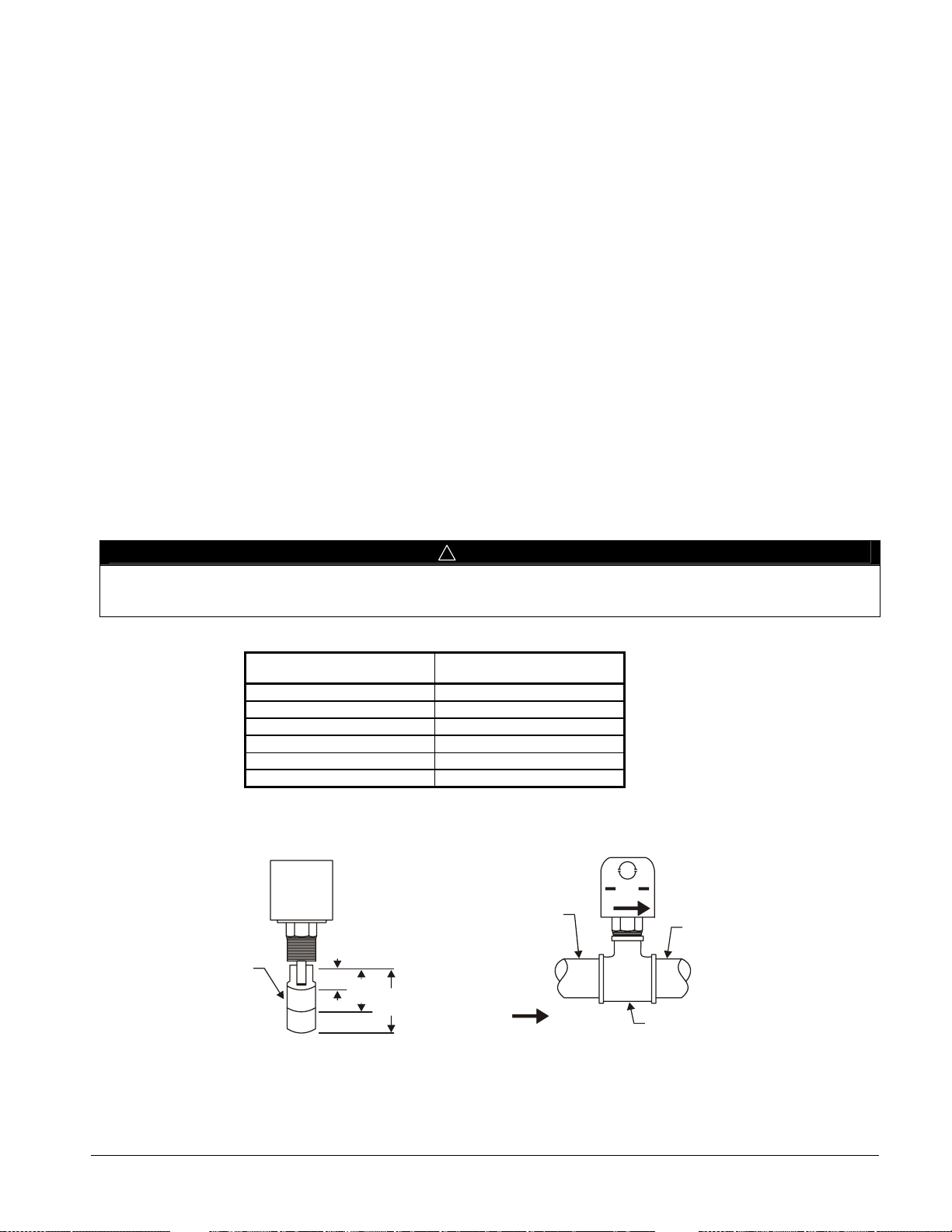

reducing tee (see

Figure 4). The flow arrow must be pointed in the correct direction.

2. Provide a straight length of pipe before and after the flow switch of at least five times the pipe diameter.

3. Trim flow switch paddle if needed to fit the pipe diameter. Make sure paddle does not hang up in pipe.

Table 3. Installation should be as shown on page 9. See the Field Wiring

!

CAUTION

Make sure the arrow on the side of the switch is pointed in the direction of flow. Install per manufacturer’s

instructions. Incorrect installation will cause improper operation and possible evaporator damage.

Table 3, Flow Switch Minimum Flow Rates

Nominal Pipe Size

Inches (mm)

2 (50.8) 18.8 (1.2)

2 1/2 (63.5) 24.3 (1.5)

3 (76.2) 30.0 (1.9)

4 (101.6) 39.7 (2.5)

5 (127.0) 58.7 (3.7)

6 (152.4) 79.2 (5.0)

Minimum Required Flow to

Activate Switch – GPM (l/s)

Figure 4, Flow Switch

iew From End of CoolerFlow Switch

Flow Switch

Paddle

1

(25)

(51)

Pipe Section

D” x 5D”

2

3

(76)

From

Evaporator

Flow

Direction

Flow

Straight Pipe

for at Least 5D”

Tee

D” x D” x 1”

9 TGZ 040A through TGZ 190A IM TGZ

Page 11

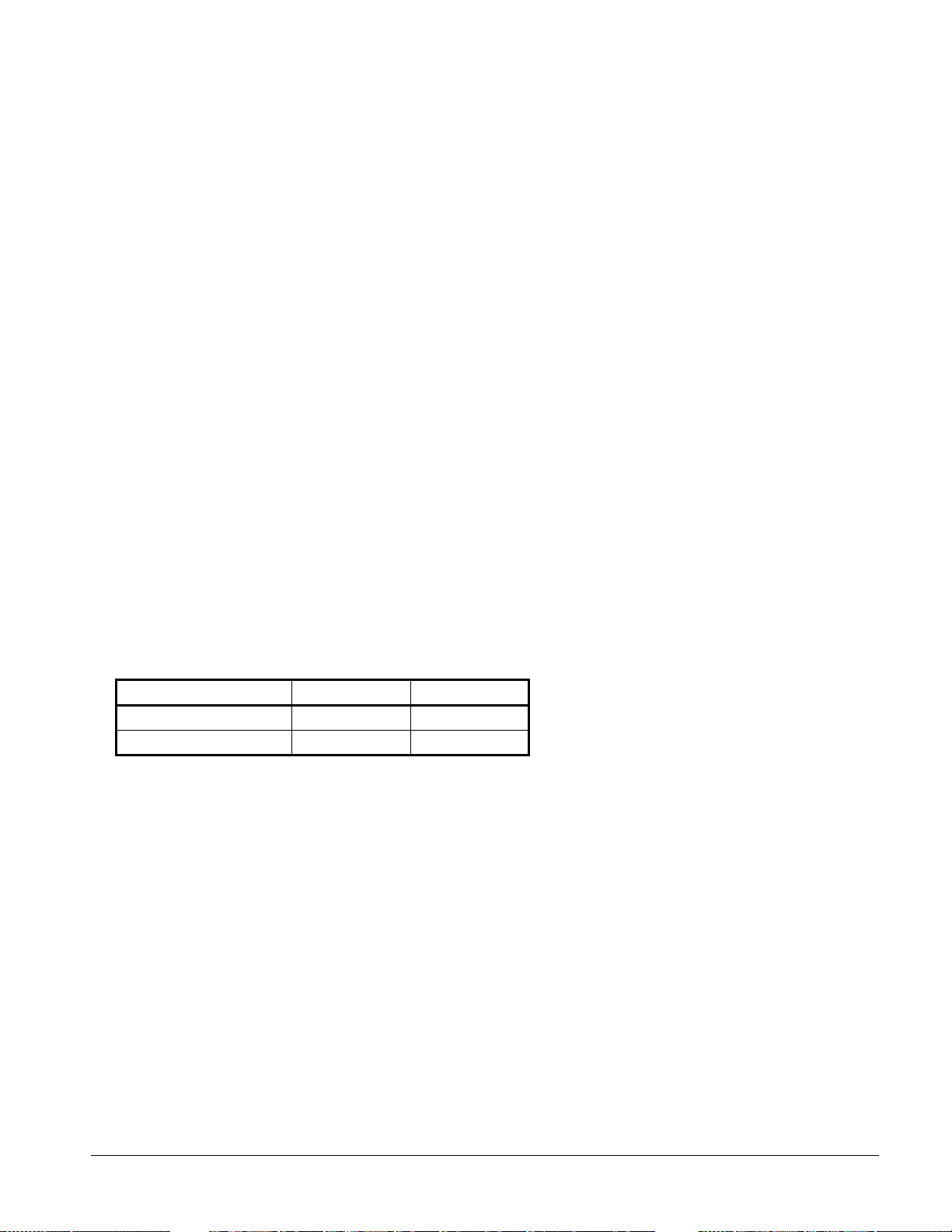

Glycol Solutions

T

The use of glycol in Templifier systems is rare but if used, the system glycol capacity, glycol solution flow rate in

gpm (lps), pressure drop through the cooler, and system pressure drop can be calculated using the following

formulas and table.

1. Capacity — Capacity is reduced from that with plain water. To find the reduced value multiply the unit’s

water system capacity by the capacity correction factor C, as shown in

capacity in the glycol system.

2. GPM —To determine evaporator gpm (or ΔT) knowing ΔT (or gpm) and capacity:

GPMGlycol

24

=

CapacityGlycolx

Δ

FromTablesGx

3. Pressure Drop — To determine glycol pressure drop through the cooler, enter the proper water pressure drop

curve, beginning on page

11, at the water flow. Multiply the water pressure drop found there by P to obtain

corrected glycol pressure drop.

4. To determine glycol system kW, multiply the water system kW by factor K.

Test coolant with a clean, accurate glycol solution hydrometer (similar to that found in service stations) to

determine the freezing point. Obtain percent glycol from the freezing point table below.

McQuay encourages a minimum glycol concentration of 25% be provided on all glycol applications. Glycol

concentrations below 25% have too little inhibitor content for long-term corrosion protection of ferrous metals.

Note: The effect of glycol in the condenser is negligible and there is no capacity derate. There is a

significant increase in pressure drop.

Table 4 and Table 5, to find the unit’s

Table 4, Ethylene Glycol

Glycol

20 18 -8 0.982 0.992 1.040 1.129

30 7 -14 0.972 0.986 1.074 1.181

40 -7 -22 0.961 0.976 1.121 1.263

50 -28 -33 0.946 0.966 1.178 1.308

Freezing Point Percent

°F °C

C (Capacity) K (Power) G (Flow)

P (Pressure

Drop)

Table 5, Propylene Glycol

Percent

Glycol

20 19 -7 0.975 0.985 1.028 1.147

30 9 -13 0.962 0.978 1.050 1.248

40 -5 -21 0.946 0.971 1.078 1.366

50 -27 -33 0.929 0.965 1.116 1.481

Freezing Point C (Capacity) K (Power) G (Flow)

°F °C

P (Pressure

Drop)

!

CAUTION

Do not use automotive grade antifreeze. Industrial grade glycols must be used. Automotive antifreeze contains

inhibitors which all cause plating on the copper within the unit evaporator. The type and handling of glycol used

must be consistent with local codes.

Condenser Water Piping

Arrange the condenser water so the water enters the bottom connection of the condenser. The condenser water

will discharge the condenser from the top connection. Failing to arrange the condenser water as stated above will

negatively affect the capacity and efficiency. Note that the condensers are shipped as either two-pass (10 to 20degree Delta-T) or four-pass (20 to 40-degree Delta-T). For 2-pass, the connections are on the vertical centerline

of the condenser. For 4-pass, they are off to one side.

Pressure gauges should be installed in the inlet and outlet water lines to the condenser. Pressure drop through the

condenser should be measured to determine gpm (L/s) from pressure drop curves on page

eliminators are recommended in both the supply and return water lines.

11. Vibration

IM TGZ TGZ 040A through TGZ 190A 10

Page 12

Templifier hot water systems usually have a supplementary heater located after (downstream) of the

Templifier condenser to either boost the hot water temperature or to function as a standby heater.

Care should be exercised to avoid overly warm water coming back to the Templifier from the system and

causing a relief valve discharge. This is true whether the unit is running or off. Maximum temperature is 165°F

Some jurisdictions require double heat exchange walls between refrigerant and potable water. Potable water

run directly through a condenser has only one heat exchange wall (the condenser tube) and these jurisdictions

may require an intermediate heat exchanger.

Heating and Cooling Units

Templifiers can be arranged and controlled to act as either a water chiller or a water heater. These

systems vary considerably in the specifics of the piping arrangement. Care must be exercised when

changeover occurs to avoid mixing water streams that could possibly contaminate a water system. For

example a unit can have chilled water in the evaporator and tower water in the condenser when in the

cooling mode. Changeover to heating could put tower water through the evaporator and hot water

(possibly potable water) through the condenser. This could introduce tower water into the chilled

water system and into the hot water system and should be avoided.

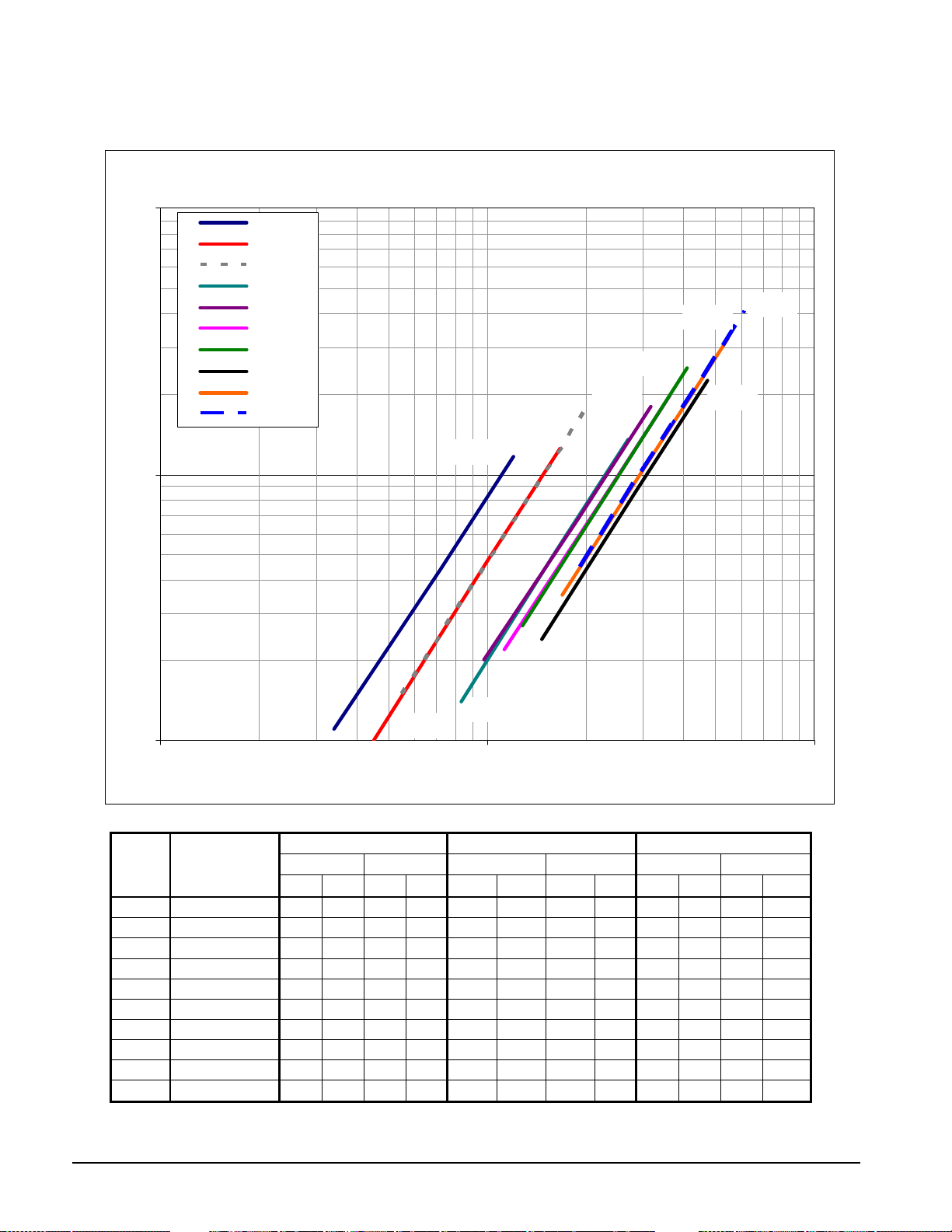

Water Pressure Drop

The vessel flow rates must fall between the minimum and maximum values shown on the appropriate

evaporator and condenser curves on pages

laminar flow that will reduce efficiency, cause erratic operation of the expansion valve and could cause low

temperature cutoffs. On the other hand, flow rates exceeding the maximum values shown can cause erosion on

the evaporator water connections and tubes.

Measure the water pressure drop through the vessels at field installed pressure taps. It is important not to

include valves or strainers in these readings.

The condenser flow rate will determine whether 2-pass or 4-pass condensers are used, according to the

following table:

12 to 14. Flow rates below the minimum values shown will result in

CONDENSER DELTA-T PASSES FLOW

10- to 20 Degrees F 2-Pass High Flow Rate

20 to 40 Degrees F 4-Pass Low Flow Rate

The entering water should be piped to the bottom connection of the condenser and out the top.

11 TGZ 040A through TGZ 190A IM TGZ

Page 13

TGZ Scroll

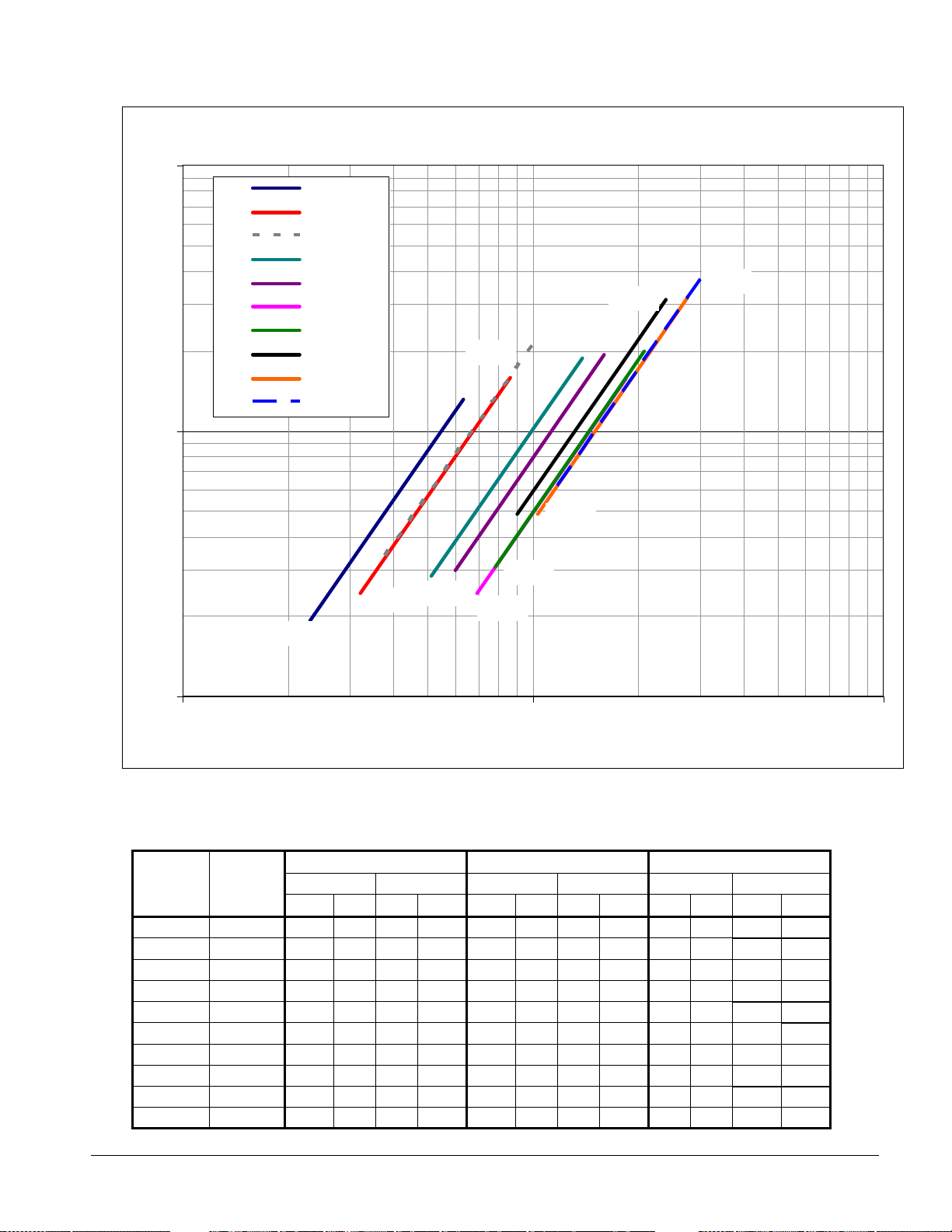

Figure 5, Evaporator Pressure Drop

TGZ Evaporator Wat er Pressur e Dr op

100

10

Dp (ft)

TGZ040

TGZ050

TGZ060

TGZ080

TGZ100

TGZ110

TGZ120

TGZ150

TGZ170

TGZ190

TGZ040

TGZ060

TGZ110

TGZ100

TGZ170

TGZ190

TGZ120

TGZ150

TGZ080

TGZ050

1

10 100 1000

Flow Rate (gpm)

TGZ UNIT

MODEL

040A

050A

060A

080A

100A

110A

120A

150A

170A

190A

Note: Nominal Flow Rate is gpm for 10 F Delta-T at unit operating conditions of evaporator at 75/65 F water temp and condenser at 110/30 F water temp.

EVAPORATOR

MODEL

AC250-70DQ 34 1.1 2.1 3.2 72 4.4 4.5 13.2 120 11.6 7.6 34.7

AC250-94DQ 45 1.0 2.8 3.1 100 4.7 6.3 14.0 167 12.5 10.5 37.2

AC250-94DQ 55 1.5 3.5 4.5 121 6.7 7.6 20.0 202 17.7 12.7 53.0

AC350-162DQ 83 1.4 5.2 4.3 162 5.1 10.2 15.2 270 13.5 17.0 40.2

AC350-162DQ 98 2.0 6.2 5.8 189 6.8 11.9 20.3 315 17.9 19.9 53.6

AC350-182DQ 113 2.2 7.1 6.4 218 7.5 13.8 22.4 363 19.8 22.9 59.1

AC350-182DQ 128 2.7 8.1 8.2 246 9.5 15.5 28.4 410 25.1 25.9 74.9

EV34191111/9 147 2.4 9.3 7.3 283 8.5 17.9 25.4 472 22.5 29.8 67.1

EV34191212/7 169 3.5 10.7 10.5 326 12.2 20.6 36.5 543 32.2 34.3 96.1

EV34191212/7 192 4.5 12.1 13.4 369 15.5 23.3 46.3 615 40.9 38.8 122.3

MINIMUM FLOW RATE NOMINAL FLOW RATE MAXIMUM FLOW RATE

INCH-POUND S.I. INCH-POUND S.I. INCH-POUND S.I.

gpm ft. L/S kpa gpm ft. lps kpa gpm ft. lps kpa

IM TGZ TGZ 040A through TGZ 190A 12

Page 14

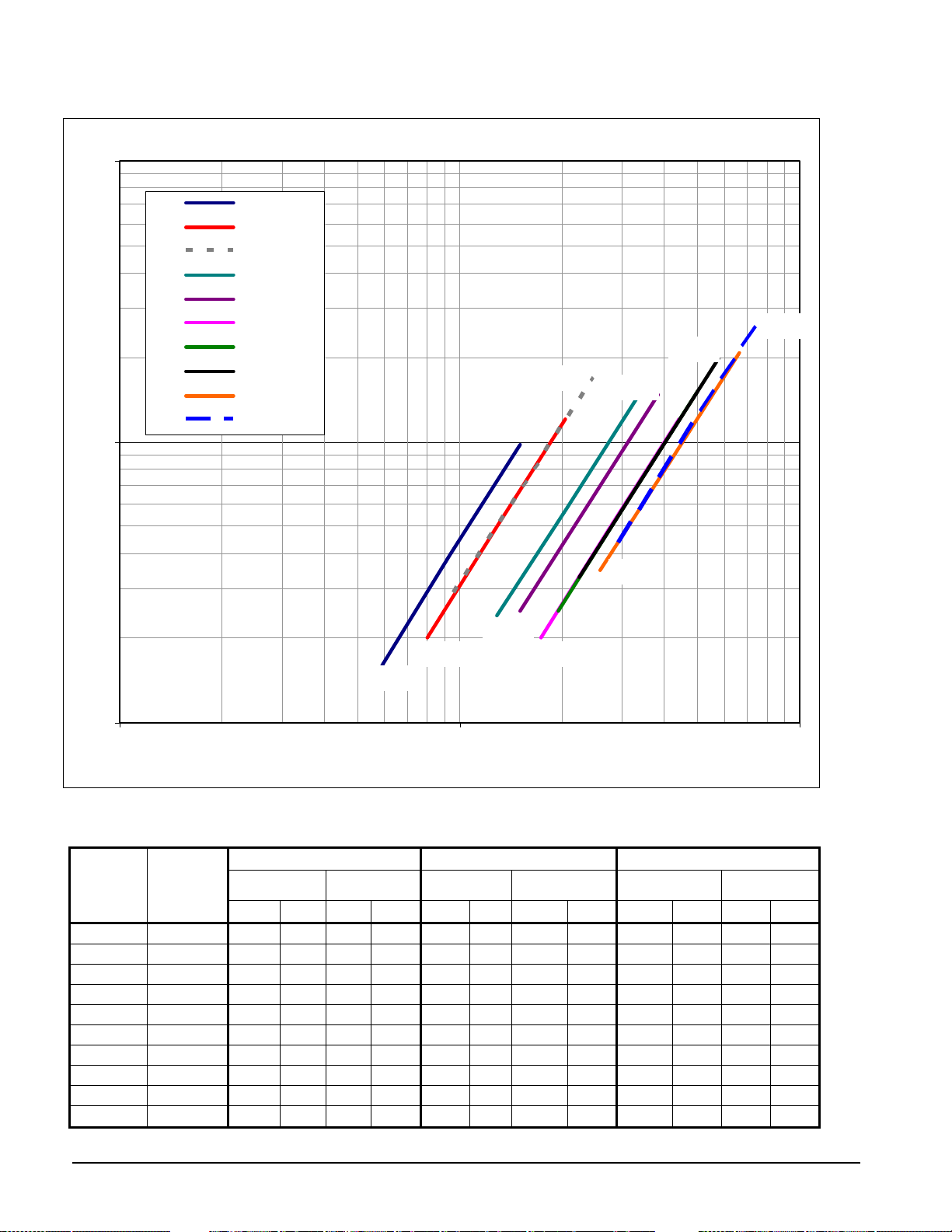

Figure 6, Standard Four-pass Condenser Pressure Drop

TGZ 4-Pa ss Conde nse r Wa t er Pressur e Dr op

100

TGZ040

TGZ050

TGZ060

TGZ080

TGZ100

TGZ110

TGZ120

TGZ150

TGZ060

TGZ170

TGZ190

10

Dp (ft)

TGZ170

TGZ150

TGZ100

TGZ190

TGZ120

TGZ050

TGZ040

TGZ080

TGZ110

1

10 100 1000

Flow Rate (gpm)

UNIT

MODEL

TGZ040

TGZ050

TGZ060

TGZ080

TGZ100

TGZ110

TGZ120

TGZ150

TGZ170

TGZ190

COND.

MODEL

C1010-62 23 1.93 1.45 5.77 47 7.5 3.0 22.4 63 13.1 4.0 39.1

C1010-62 32 2.44 2.02 7.29 64 9.1 4.0 27.2 86 16.0 5.4 47.7

C1010-76 38 3.40 2.40 10.16 77 13.0 4.9 38.9 103 22.6 6.5 67.5

C1410-112 51 2.84 3.22 8.49 103 10.8 6.5 32.3 138 18.8 8.7 56.3

C1410-128 60 3.00 3.79 8.97 120 11.2 7.6 33.5 160 19.3 10.1 57.8

C1610-164 69 2.44 4.35 7.29 138 9.1 8.7 27.2 184 15.7 11.6 47.0

C1610-164 78 3.08 4.92 9.21 156 11.5 9.8 34.4 208 19.9 13.1 59.4

C1612-164 90 4.85 5.68 14.50 180 18.1 11.4 54.1 240 31.3 15.1 93.4

C1612-184 103 4.89 6.50 14.60 207 18.4 13.1 55.0 276 31.8 17.4 95.0

C1612-184 117 6.24 7.38 18.66 234 23.3 14.8 69.6 312 40.2 19.7 120.3

MINIMUM FLOW RATE NOMINAL FLOW RATE MAXIMUM FLOW RATE

INCH-POUND S.I. INCH-POUND S.I. INCH-POUND S.I.

gpm ft L/S kpa gpm ft L/S kpa gpm ft L/S kpa

13 TGZ 040A through TGZ 190A IM TGZ

Page 15

Figure 7, Optional Two-pass Condenser

TGZ 2- Pass Condenser Water Pressur e Drop

100

TGZ040

TGZ050

TGZ060

TGZ080

TGZ100

TGZ110

TGZ120

TGZ150

TGZ170

TGZ190

10

Dp (ft)

TGZ060

TGZ190

TGZ150

TGZ100

TGZ170

TGZ080

TGZ050

TGZ040

TGZ120

TGZ110

1

10 100 1000

Flow Rate (gpm)

MINIMUM FLOW RATE NOMINAL FLOW RATE MAXIMUM FLOW RATE

TGZ UNIT

MODEL

TGZ040

TGZ050

TGZ060

TGZ080

TGZ100

TGZ110

TGZ120

TGZ150

TGZ170

TGZ190

COND.

MODEL.

C1010-62 59 1.6 3.7 4.9 94 4.0 5.9 12.0 150 9.8 9.5 29.3

C1010-62 80 2.0 5.0 6.0 128 4.9 8.1 14.6 205 12.0 12.9 35.8

C1010-76 96 2.9 6.1 8.5 154 7.0 9.7 20.9 246 17.0 15.5 51.0

C1410-112 129 2.4 8.1 7.1 206 5.8 13.0 17.3 330 14.2 20.8 42.3

C1410-128 150 2.5 9.5 7.3 240 6.0 15.1 17.9 384 14.7 24.2 43.8

C1610-164 173 2.0 10.9 6.0 276 4.9 17.4 14.6 442 12.0 27.9 35.8

C1610-164 195 2.5 12.3 7.6 312 6.2 19.7 18.5 499 15.1 31.5 45.3

C1612-164 225 3.3 14.2 9.9 360 8.1 22.7 24.2 576 19.8 36.3 59.1

C1612-184 259 3.5 16.3 10.4 414 8.5 26.1 25.4 662 20.8 41.8 62.1

C1612-184 293 4.4 18.5 13.2 468 10.8 29.5 32.3 749 26.4 47.2 78.8

INCH-POUND S.I.

gpm ft L/S kpa gpm ft L/S kpa gpm ft lps kpa

INCH-

POUND

S.I. INCH-POUND S.I.

IM TGZ TGZ 040A through TGZ 190A 14

Page 16

Relief Valve Piping

The current ANSI/ASHRAE Standard 15 specifies that pressure relief valves on vessels containing Group 1

refrigerant (R-134a) “shall discharge to the atmosphere at a location not less than 15 feet (4.6 meters) above the

adjoining ground level and not less than 20 feet (6.1 meters) from any window, ventilation opening or exit in any

building.” The piping must be provided with a rain cap at the outside terminating point and a drain at the low point

on the vent piping to prevent water buildup on the atmospheric side of the relief valve. In addition, a flexible pipe

section should be installed in the line to eliminate any piping stress on the relief valve(s).

The size of the discharge pipe from the pressure relief valve shall not be less than the size of the pressure relief

outlet. When two or more vessels are piped together, the common header and piping to the atmosphere shall not be

less than the sum of the area of the relief valve outlets connected to the header. Fittings should be provided to permit

vent piping to be easily disconnected for inspection or replacement of the relief valve.

NOTE: Provide adequate fittings in piping to permit repair or replacement of relief valve.

Figure 8, Relief Valve Piping

15 TGZ 040A through TGZ 190A IM TGZ

Page 17

Dimensional Data

Figure 9, Dimensions, TGZ 040A - 060A, Standard 4-pass Condenser

4 PASS CONDENSER

L4 / M4

CONTROL BOX

"A"

L3 / M3

WATER

CONNECTIONS

VENT

DRAIN

3.8

REF.

98

L1 / M1

MICROTECH II USER INTERFACE

CIRCUIT 1CIRCUIT 2

RELIEF VALVES

121.1

3075

138.0

3506

32.9

837

30.2

768

" Y "

" X "

L2 / M2

13.1

333

3.9

100

OUTLET

CONDENSER

INLET

4 PASS CONDENSER

3"/(76) NOM. WATER

CONNECTIONS

CONTROL

CONNECTION

.88 KNOCKOUTS

ON OPPOSITE SIDE

POWER

CONNECTIONS

REMOVABLE

DISC. HANDLE

" Y "

.88 KNOCKOUTS

63.2

1605

23.5

597

2.0

51

20.0

508

12.2

309

INLET

OUTLET

29.0

737

32.0

813

40.0

1016

10.9

277

" Z "

15.7

398

.875 DIA MOUNTING HOLES (4)

EVAPORATOR

REMOVE BRKT.

FOR SHIPPING

ONLY

8.6

218

52.4

1331

27.7

703

13.4

340

ALL DIMENSIONS ARE IN DECIMAL INCHES

DRAWING NUMBER

SCALE

NONE

3324297

IM TGZ TGZ 040A through TGZ 190A 16

Page 18

Figure 10, Dimensions, TGZ 040A – 060A, Optional 2-Pass Condenser

A

OPTIONAL 2 PASS CONDENSER

Table 6, 2-Pass and 4-pass Dimensions

CONDENSER WATER

CONNECTION IN(MM)

VICTAULIC

(4 PASS)

TGZ

MODEL

NUMBER

TGZ 040

TGZ 050

TGZ 060

CHILLER WATER

CONNECTION IN(MM)

VICTAULIC

SIZE A SIZE SIZE X Y Z

3 (76) 13.1 (333) 3 (76) 4 (102) 58.3 23.5 14.4

3 (76) 10.5 (267) 3 (76) 4 (102) 57.4 24.0 14.4

3 (76) 10.5 (267) 3 (76) 4 (102) 57.5 23.9 14.4

NOTE: Lifting and corner weights are in the “Weights” section on page 16.

4.1

103

13.7

349

CONDENSER WATER

CONNECTION IN(MM)

VICTAULIC

(2 PASS)

4" / (102) NOMINAL

WATER CONNECTIONS

LL DIMENSIONS ARE IN DECIMAL INCHES

DRAWING NUMBER

SCALE

NONE

CENTER OF GRAVITY

3324297

5.9

150

8.0

204

13.3

338

17 TGZ 040A through TGZ 190A IM TGZ

Page 19

Figure 11, Dimensions, TGZ 080A – 100A, Standard 4-Pass Condenser

D

S

4 PASS CONDENSER

CONTROL BOX

L1 / M1 L2 / M2

MICROTECH II USER INTERFACE

CIRCUIT 2 CIRCUIT 1

L3 / M3L4 / M4

CONDENSER

INLET/OUTLET

EVAP WATER

CONNECTION

"A"

VENT

RAIN

3.9

100

OUTLET

CONDENSER

INLET

RELIEF VALVES

" X "

"T"

CONTROL

CONNECTION

.88 KNOCKOUTS

ON OPPOSITE SIDE

REMOVABLE

DISC. HANDLE

POWER

CONNECTIONS

" Y "

23.5

597

2.0

51

"H"

20.0

508

14.5

369

121.1

3075

"L"

40.2

1021

"W"

32.5

825

INLET

OUTLET

10.6

269

EVAPORATOR

REMOVE BRKT.

FOR SHIPPING

ONLY

32.8

834

16.0

407

57.6

1462

14.4

367

4 PASS CONDENSER

4"/(102) NOM. WATER

CONNECTIONS

.88 KNOCKOUTS

16.0

406

" Z "

.875 DIA MOUNTING HOLES (4)

29.0

737

32.0

813

40.0

1016

10.0

255

ALL DIMENSIONS ARE IN DECIMAL INCHES

DRAWING NUMBER

SCALE

NONE

3324298

IM TGZ TGZ 040A through TGZ 190A 18

Page 20

Figure 12, Dimensions, TGZ 080A - 100A, Optional 2-Pass Condenser

A

OPTIONAL 2 PASS CONDENSER

TGZ

MODEL

TGZ 080

TGZ 100

NOTE: Lifting and corner weights are in the “Weights” section on page 16.

Table 7, 2-Pass and 4-Pass Dimensions

CHILLER WATER

CONNECTION

IN(MM) VICTAULIC

SIZE A SIZE (NOM) SIZE (NOM)

3

(76)

3

(76)

1.7

(43)

1.7

(43)

CONDENSER WATER

CONNECTION IN(MM)

VICTAULIC (4 PASS)

4

(102)

4

(102)

CONDENSER WATER

CONNECTION IN(MM)

VICTAULIC (2 PASS)

4

(102)

4

(102)

18.2

463

T

13.6

(345)

14.4

(366)

4"/ (102) NOMINAL

WATER CONNECTIONS

4.0

102

LL DIMENSIONS ARE IN DECIMAL INCHES

DRAWING NUMBER

NONE

SCALE

CENTER OF GRAVITY

X Y Z

63.2 30.1 15.1

65.6 31.3 15.4

3324298

7.9

200

10.0

253

13.0

330

19 TGZ 040A through TGZ 190A IM TGZ

Page 21

Figure 13, Dimensions, TGZ 110 – 120, Standard 4-Pass Condenser

4 PASS CONDENSER

CONTROL BOX

L1 / M1 L2 / M2

MICROTECH II USER INTERFACE

CIRCUIT 2 CIRCUIT 1

L3 / M3L4 / M4

CONNECTIONS

"A"

CONDENSER

INLET/OUTLET

EVAP WATER

VENT

DRAIN

4.0

102

OUTLET

CONDENSER

INLET

RELIEF VALVES

3324298

14.2

361

" X "

"T"

CONTROL

CONNECTION

.88 KNOCKOUTS

ON OPPOSITE SIDE

REMOVABLE

DISC. HANDLE

POWER

CONNECTIONS

.88 KNOCKOUTS

" Y "

23.5

597

2.0

51

"H"

20.0

508

16.0

407

121.1

3075

148.6

3774

41.2

1046

"W"

34.5

876

INLET

OUTLET

29.0

32.0

10.3

261

737

813

40.0

1016

" Z "

15.7

400

.875 DIA MOUNTING HOLES (4)

9.9

251

EVAPORATOR

REMOVE BRKT.

FOR SHIPPING

ONLY

18.0

456

59.1

1500

34.3

872

ALL DIMENSIONS ARE IN DE CIMAL INCHES

SCALE

NONE

DRAWING NUMBER

4 PASS CONDENSER

4"/(102) NOM. WATER

CONNECTION

IM TGZ TGZ 040A through TGZ 190A 20

Page 22

Figure 14, Dimensions, Optional 2-Pass Condenser

OPTIONAL 2 PASS CONDENSER

TGZ

MODEL

TGZ 110

TGZ 120

5" / (127) NOMINAL

WATER CONNECTIONS

4.0

102

18.2

462

ALL DIMENSIONS ARE IN DECIMAL INCHES

SCALE

NONE

DRAWING NUMBER

13.3

3324298

NOTE: Lifting and corner weights are in the “Weights” section on page 16.

Table 8, 2-Pass and 4-pass Dimensions

CHILLER

WATER

CONNECTION

IN (MM)

VICTAULIC

SIZE A SIZE SIZE

3

(76)

3

(76)

0.5

(13)

0.5

(13)

CONDENSER

WATER

CONNECTION IN

(MM) VICTAULIC

(4 PASS)

4

(102)

4

(102)

CONDENSER

WATER

CONNECTION

IN(MM) VICTAULIC

(2 PASS)

5

(127)

5

(127)

T

13.3

(338)

13.3

(338)

CENTER OF

GRAVITY

X Y Z

64.3 30.6 15.0

64.0 30.1 15.0

8.7

221

9.6

243

337

21 TGZ 040A through TGZ 190A IM TGZ

Page 23

Figure 15, Dimensions, TGZ 150A – 190A, Standard 4-Pass Condenser

23

2

.5

596

EVAPORATOR

OUTLET

77.

1961

EVAPORATOR

INLET

1.3

34

4 PASS CONDENSER

L3 / M3L4 / M4

CONDENSER

INLET / OUTLET

VENT

DRAIN

L1 / M1

10.9

276

CIRCUIT 2

VENT

DRAIN

" Y "

CIRCUIT 1

145.1

3685

170.2

4322

36.5

927

T.B.D .

33.8

41.2

1046

859

RELIEF VALVES

" X "

CONTROL BOX

L2 / M2

MICROTECH II USER INTERFACE

4.0

102

CONDENSER

14.2

361

OUTLET

INLET

4 PASS CONDENSER

4" / (102) NOM. WATER

CONNECTIONS

CONTROL

CONNECTION

.88 KNOCKOUTS

ON OPPOSITE SIDE

REMOVABLE

DISC HANDLE

POWER

CONNECTIONS

77.7

1973

.88 KNOCKOUT

2.0

51

17.0

432

15.5

394

23.5

597

5.0

127

" Z "

.875 DIA MOUNTING HOLES (4)

29.0

737

32.0

813

40.0

1016

10.3

261

REMOVE BRKT.

FOR SHIPPING

ONLY

36.9

938

EVAP

INLET/

OUTLET

18.0

456

9.9

251

ALL DIMENSIONS ARE IN DECIMAL INCHES

DRAWING NUMBER

SCALE

NONE

3324299

IM TGZ TGZ 040A through TGZ 190A 22

Page 24

Figure 16, Dimensions, TGZ 150A - 190A, Optional 2-Pass Condenser

OPTIONAL 2 PASS CONDENSER

TGZ

MODEL

TGZ 150

TGZ 170

TGZ 190

5" / (127) NOMINAL

WATER CONNECTIONS

4.0

102

18.2

462

ALL DIMENSIONS ARE IN DECIMAL INCHES

DRAWING NUMBER

SCALE

NONE

NOTE: Lifting and corner weights are in the “Weights” section on page

Table 9, 2-Pass and 4-pass Dimensions

CHILLER WATER

CONNECTION IN(MM)

VICTAULIC

SIZE SIZE SIZE X Y Z

8 (203) 4 (102) 5 (127) 78.5 36.0 15.1

8 (203) 4 (102) 5 (127) 78.4 37.3 15.1

8 (203) 4 (102) 5 (127) 78.5 38.9 15.0

CONDENSER WATER

CONNECTION IN(MM)

VICTAULIC (4 PASS)

CONDENSER WATER

CONNECTION IN(MM)

VICTAULIC (2 PASS)

CENTER OF

GRAVITY

3324299

16.

8.7

221

9.6

243

13.3

337

23 TGZ 040A through TGZ 190A IM TGZ

Page 25

Weights

NOTE: Refer to the unit dimension drawing for lifting and mounting point’s physical location.

Table 10, TGZ Lifting, Mounting, and Total Weights (Inch-Lbs Units)

MODEL

TGZ040A

TGZ050A

TGZ060A

TGZ080A

TGZ100A

TGZ110A

TGZ120A

TGZ150A

TGZ170A

TGZ190A

LIFTING WEIGHT FOR EACH

L1 L2 L3 L4 M1 M2 M3 M4

592 638 625 580 633 682 668 620 2434 2604

590 653 641 580 633 701 688 622 2464 2644

597 660 650 588 646 714 703 636 2496 2699

1034 947 1021 1115 1111 1017 1097 1198 4116 4422

1126 952 1072 1268 1211 1023 1152 1363 4418 4749

1271 1123 1207 1366 1375 1215 1305 1478 4967 5373

1257 1122 1195 1339 1361 1214 1294 1450 4913 5319

1823 1546 1675 1975 2046 1735 1880 2216 7019 7877

1846 1570 1694 1991 2077 1767 1906 2241 7101 7991

1848 1566 1682 1986 2081 1763 1894 2235 7082 7972

POINT (LBS)

TGZ Lifting, Mounting, and Total Weights (SI Units)

MODEL

TGZ040A

TGZ050A

TGZ060A

TGZ080A

TGZ100A

TGZ110A

TGZ120A

TGZ150A

TGZ170A

TGZ190A

LIFTING WEIGHT FOR EACH

L1 L2 L3 L4 M1 M2 M3 M4

269 289 283 263 287 309 303 281 1104 1181

268 296 291 263 287 318 312 282 1118 1199

271 299 295 267 293 324 319 288 1132 1224

469 430 463 506 504 461 498 543 1867 2006

511 432 486 575 549 464 523 618 2004 2154

577 509 547 620 624 551 592 670 2253 2437

570 509 542 607 617 551 587 658 2229 2413

827 701 760 896 928 787 853 1005 3184 3573

837 712 768 903 942 802 865 1017 3221 3625

838 710 763 901 944 800 859 1014 3212 3616

POINT (KG)

MOUNTING LOADS FOR EACH

POINT (LBS)

MOUNTING LOADS FOR EACH

POINT (KG)

SHIPPING

SHIPPING

WEIGHT

(LBS)

WEIGHT

(KG)

OPERATING

WEIGHT

(LBS)

OPERATING

WEIGHT

(KG)

Figure 17, Lifting and Mounting Points Location

4

LB

1

LF

Control Panel

RB

FRF

3

Water

Connections

2

IM TGZ TGZ 040A through TGZ 190A 24

Page 26

Physical Data

TGZ Scroll

Table 11, TGZ040A - 060A

TGZ Unit Model TGZ 040A TGZ 050A TGZ 060A

No. Of Circuits 2 2 2

COMPRESSORS

Nominal Horsepower 10 10 13 13 15 15

Number per Circuit 2 2 2 2 2 2

Unloading Steps, % 25 / 50 / 75 100 25 / 50 / 75 100 25 / 50 / 75 100

Oil Charge, per compr. oz (l) 110 (3.3) 110 (3.3) 110 (3.3)

CONDENSER

Number 1 1 1

No. Refrigerant Circuits 2 2 2

Diameter, in. (mm) 10.75 (273) 10.75 (273) 10.75 (273)

Tube Length, in (mm) 122 (3099) 122 (3099) 122 (3099)

Design W.P.,psig (kPa):

Refrigerant Side 500 (3447) 500 (3447) 500 (3447)

Water Side 232 (1599) 232 (1599) 232 (1599)

Relief Valve Setting, psig (kPa) 500 (3447) 500 (3447) 500 (3447)

No. Of Water Passes - Standard 4 4 4

No. Of Water Passes - Optional 2 2 2

Water Volume, gallons (l) 13.6 (51.5) 13.6 (51.5) 16.3 (61.8)

Pump-Down Capacity lb., (kg) 121.7(55.2) 121.7(55.2) 121.7(55.2) 121.7(55.2) 107.3(48.7) 107.3(48.7)

Connections:

Water In & Out, in., (mm) (4 Pass) 3 (76) 3 (76) 3 (76)

Water In & Out, in., (mm) (2 Pass) 4 (102) 4 (102) 4 (102)

Relief Valve, Flare in., (mm) 5/8 (15.9) 5/8 (15.9) 5/8 (15.9)

Purge Valve, Flare in., (mm) 5/8 (15.9) 5/8 (15.9) 5/8 (15.9)

Vent & Drain, in (mm) FPT 1/2 (12.7) 1/2 (12.7) 1/2 (12.7)

Liquid Subcooling Integral Integral Integral

EVAPORATOR, BRAZED-PLATE

Number 1 1 1

No. Refrigerant Circuits 2 2 2

Water Volume, gallons (l) 3.7 (14.0) 5.0 (18.9) 5.0 (18.9)

Refrigerant Side D.W.P., psig, (kPa) 450 (3102) 450 (3102) 450 (3102)

Relief Valve Setting, psig (kPa) 450 (3102) 450 (3102) 450 (3102)

Water Side D.W.P., psig, (kPa) 450 (3102) 450 (3102) 450 (3102)

Water Connections:

In & Out, in. (mm) victaulic 3 (76) 3 (76) 3 (76)

Drain & Vent Field Supplied Field Supplied Field Supplied

UNIT DIMENSIONS

Length, in. (mm) 139 (3530) 139 (3530) 139 (3530)

Width, in. (mm) 33 (838) 33 (838) 33 (838)

Height, in. (mm) 63.2 (1605) 63.2 (1605) 63.2 (1605)

UNIT WEIGHTS

Operating WT., lb., (kg) 2604 (1181) 2644 (1199) 2699 (1224)

Shipping WT., lb. (kg) 2434 (1104) 2464 (1117) 2496 (1132)

R-134a Ref. Charge, lb. (kg) 45 (20.4) 45 (20.4) 45 (20.4) 45 (20.4) 50 (22.7) 50 (22.7)

25 TGZ 040A through TGZ 190A IM TGZ

Page 27

Table 12, TGZ 080A – 100A

TGZ Unit Model TGZ 080A TGZ 100A

No. Of Circuits 2 2

COMPRESSORS

Nominal Horsepower 20 20 25 25

Number per Circuit 2 2 2 2

Staging Steps, % 25 / 50 / 75 100 25 / 50 / 75 100

Oil Charge, per compressor. oz (l) 158 (4.7) 200 (5.9)

CONDENSER

Number 1 1

No. Refrigerant Circuits 2 2

Diameter, in. (mm) 14 (356) 14 (356)

Tube Length, in (mm) 122 (3099) 122 (3099)

Design W.P.,psig (kPa):

Refrigerant Side 500 (3447) 500 (3447)

Water Side 232 (1599) 232 (1599)

Relief Valve Setting, psig (kPa) 500 (3447) 500 (3447)

No. Of Water Passes - Standard 4 4

No. Of Water Passes - Optional 2 2

Water Volume, gallons (1) 27.5 (104) 27.5 (104)

Pump-Down Capacity lb., (kg) 186(84.2) 186(84.2) 186(84.2) 186(84.2)

Connections:

Water In & Out, in., (mm) (4 Pass) 4 (102) 4 (102)

Water In & Out, in., (mm) (2 Pass) 4 (102) 4 (102)

Relief Valve, Flare in., (mm) 5/8 (15.9) 5/8 (15.9)

Purge Valve, Flare in., (mm) 5/8 (15.9) 5/8 (15.9)

Vent & Drain, in (mm) FPT 1/2 (12.7) 1/2 (12.7)

Liquid Subcooling Intergral Intergral

EVAPORATOR, BRAZED PLATE

Number 1 1

No. Refrigerant Circuits 2 2

Water Volume, gallons (l) 8.7 (32.9) 8.7 (32.9)

Refrigerant Side D.W.P., psig, (kPa) 450 (3102) 450 (3102)

Relief Valve Setting, psig (kPa) 450 (3102) 450 (3102)

Water Side D.W.P., psig, (kPa) 450 (3102) 450 (3102)

Water Connections:

In & Out, in. (mm) victaulic 3 (76) 3 (76)

Drain & Vent Field Supplied Field Supplied

UNIT DIMENSIONS

Length, in. (mm) 153 (3886) 153 (3886)

Width, in. (mm) 32.5 (826) 32.5 (826)

Height, in. (mm) 65.5 (1664) 65.5 (1664)

UNIT WEIGHTS

Operating WT., lb., (kg) 4422 (2005) 4749 (2154)

Shipping WT., lb. (kg) 4116 (1867) 4418 (2004)

R-134a Ref. Charge, lb. (kg) 85 (38.6) 85 (38.6) 90 (40.8) 90 (40.8)

IM TGZ TGZ 040A through TGZ 190A 26

Page 28

Table 13, TGZ 110A – 120A

TGZ Unit Model TGZ 110A TGZ 120A

No. Of Circuits 2 2

COMPRESSORS

Nominal Horsepower 25 30 30 30

Number per Circuit 2 2 2 2

Staging, 4 Stages, Circuit #1 in Lead 23/50/73/100 25 / 50 / 75 100

Staging, 4 Stages, Circuit #2 in Lead 27/50/77/100 25 / 50 / 75 100

Oil Charge, per compressor. oz (l) 200 (5.9) 213 (6.3) 213 (6.3)

CONDENSER

Number 1 1

No. Refrigerant Circuits 2 2

Diameter, in. (mm) 16.0 (406.4) 16.0 (406.4)

Tube Length, in (mm) 120 (3048) 120 (3048)

Design W.P.,psig (kPa):

Refrigerant Side 500 (3447) 500 (3447)

Water Side 232 (1599) 232 (1599)

Relief Valve Setting, psig (kPa) 500 (3447) 500 (3447)

No. Of Water Passes - Standard 4 4

No. Of Water Passes - Optional 2 2

Water Volume, gallons (l) 35.4 (134) 35.4 (134)

Pump-Down Refrig Capacity 252(114) 252(114) 252(114) 252(114)

lb., (kg) (3)

Connections:

Water In & Out, in., (mm) (4 Pass) 4 (102) 4 (102)

Water In & Out, in., (mm) (2 Pass) 5 (127) 5 (127)

Relief Valve, Flare in., (mm) 5/8 (15.9) 5/8 (15.9)

Purge Valve, Flare in., (mm) 5/8 (15.9) 5/8 (15.9)

Vent & Drain, in (mm) FPT 1/2 (12.7) 1/2 (12.7)

Liquid Subcooling Integral Integral

EVAPORATOR, BRAZED-PLATE

Number 1 1

No. Refrigerant Circuits 2 2

Water Volume, gallons (l) 9.7 (36.7) 9.7 (36.7)

Refrigerant Side D.W.P., psig, (kPa) 450 (3102) 450 (3102)

Relief Valve Setting, psig (kPa) 450 (3102) 450 (3102)

Water Side D.W.P., psig, (kPa) 450 (3102) 450 (3102)

Water Connections:

In & Out, in. (mm) victaulic 3 (76) 3 (76)

Drain & Vent Field Supplied Field Supplied

UNIT DIMENSIONS

Length, in. (mm) 153 (3886) 153 (3886)

Width, in. (mm) 34.5 (876) 34.5 (876)

Height, in. (mm) 67 (1702) 67 (1702)

UNIT WEIGHTS

Operating WT., lb., (kg) 5373 (2437) 5319 (2412)

Shipping WT., lb. (kg) 4967 (2253) 4913 (2228)

R-134a Ref. Charge, lb. (kg) 110 (49.9) 110 (49.9) 110 (49.9) 110 (49.9)

27 TGZ 040A through TGZ 190A IM TGZ

Page 29

Table 14, TGZ 150A – 190A

TGZ Unit Model TGZ 150A TGZ 170A TGZ 190A

No. Of Circuits 2 2 2

COMPRESSORS

Nominal Horsepower 25 25 25 30 30 30

Number per Circuit 3 3 3 3 3 3

Staging, 6 Stages, Circuit #1 in Lead 17 / 3350 / 67 / 83 / 100 15 / 3348 / 67 / 81 / 100 17 / 3350 / 67 / 83 / 100

Staging, 6 Stages, Circuit #2in Lead 17 / 3350 / 67 / 83 / 100 19 / 3352 / 67 / 85 / 100 17 / 3350 / 67 / 83 / 100

Oil Charge, per compressor. oz (l) 200 (5.9) 200 (5.9) 213 (6.3) 213 (6.3)

CONDENSER

Number 1 1 1

No. Refrigerant Circuits 2 2 2

Diameter, in. (mm) 16 (406.4) 16 (406.4) 16 (406.4)

Tube Length, in (mm) 144 (3658) 144 (3658) 144 (3658)

Design W.P.,psig (kPa):

Refrigerant Side 500 (3447) 500 (3447) 500 (3447)

Water Side 232 (1599) 232 (1599) 232 (1599)

Relief Valve Setting, psig (kPa) 500 (3447) 500 (3447) 500 (3447)

No. Of Water Passes - Standard 4 4 4

No. Of Water Passes - Optional 2 2 2

Water Volume, gallons (l) 42.5 (160.9) 47.1 (178.4) 47.1 (178.4)

Pump-Down Refrig Capacity 302(137) 302(137) 277(126) 277(126) 277(126) 277(126)

lb., (kg) (3)

Connections:

Water In & Out, in., (mm) (4 Pass) 4 (102) 4 (102) 4 (102)

Water In & Out, in., (mm) (2 Pass) 5 (127) 5 (127) 5 (127)

Relief Valve, Flare in., (mm) 5/8 (15.9) 5/8 (15.9) 5/8 (15.9)

Purge Valve, Flare in., (mm) 5/8 (15.9) 5/8 (15.9) 5/8 (15.9)

Vent & Drain, in (mm) FPT 1/2 (12.7) 1/2 (12.7) 1/2 (12.7)

Liquid Subcooling Integral Integral Integral

EVAPORATOR, SHELL-and-TUBE

Number 1 1 1

No. Refrigerant Circuits 2 2 2

Water Volume, gallons (1) 57.6 (218) 56.9 (215.4) 56.9 (215.4)

Refrigerant Side D.W.P., psig, (kPa) 450 (3102) 450 (3102) 450 (3102)

Water Side D.W.P., psig, (kPa) 150 (1034) 150 (1034) 150 (1034)

Relief Valve Setting, psig (kPa) 450 (3102) 450 (3102) 450 (3102)

Water Connections:

In & Out, in. (mm) victaulic 8 (203) 8 (203) 8 (203)

Drain & Vent 1/2 (12.7) 1/2 (12.7) 1/2 (12.7)

UNIT DIMENSIONS

Length, in. (mm) 174 (4420) 174 (4420) 174 (4420)

Width, in. (mm) 34 (864) 34 (864) 34 (864)

Height, in. (mm) 78 (1981) 78 (1981) 78 (1981)

UNIT WEIGHTS

Operating WT., lb., (kg) 7877 (3572) 7991 (3624) 7972 (3616)

Shipping WT., lb. (kg) 7019 (3183) 7101 (3220) 7082 (3212)

R-134a Refrigerant Charge, lb. (kg) 140 (63.5) 140 (63.5) 150 (68) 150 (68) 150 (68) 150 (68)

IM TGZ TGZ 040A through TGZ 190A 28

Page 30

Unit Components

r

Figure 18, Compressor Locations

423

Evaporator and

1

Evaporator

Condenser

Connections

Circuit 2 Circuit 1

NOTE: Models TGZ 150 to 190 add a #5 compressor to circuit #1 and a #6 compressor to circuit #2 and

substitute an underslung shell-and-tube evaporator for the brazed-plate evaporator.

Figure 19, Electric Panel Components

(On Panel Side)

S1, System Switch

PS1, Pumpdown Switch

PS2, Pumpdown Switch

Control Panel

MT II Controlle

Expansion Board

Heat/Cool

Switch

T3, T4, 110V/24V

Transformers (Note)

Trans. Secondary Fuse

Trans. Primary Fuses

SR1, SR2, Solenoid Relays

Optional Compressor

Circuit Breakers

Contactors

Optional Compressor

Overloads

HPR1, HPR2, High

Pressure Relays

Optional Disconnect

Switch

Grounding Lug

Note: Models TGZ 150 – 190 have additional T5 for electronic expansion valves.

29 TGZ 040A through TGZ 190A IM TGZ

Page 31

Figure 20, Piping Schematic, Models TGZ 040 – 120

W

R

RELIEF

VALVE

CHARGING

VALVE

DISCHARGE

TRANSDUCER

(S03, S04)

SCHRADER

SCROLL

COMPRESSOR

(TANDEM)

VALVE

HIGH

PRESSURE

SWITCH

OIL

SIGHT GLASS

CHARGING

VALVE

R332541601 Rev.00

Package Templifier

(Sheet 1)

LEAVING

WATER TEMP.

SENSOR

(S10)

CONDENSER

ASSEMBLY

DISCHARGE

TUBING

DISCHARGE

SHUT-OFF

VALVE

CHECK

VALVE

RELIEF

VALVE

RELIEF

VALVE

HOT GAS

BYPASS

TUBING

(OPTIONAL)

SUCTION

TRANSDUCER

(S01, S02)

SCHRADER

VALVE

SUCTION

TUBING

SUCTION

TEMP. SENSOR

(S12, S13)

ENTERING

WATER TEMP.

SENSOR

(S08)

SUCTION

CIR. 1

WATER

IN

WATER OUT

WATER IN

ENTERING

WATE R TEMP.

SENSOR

(S09)

SYSTEM #1 SYSTEM #2

LIQUID

SHUT-OFF

VALVE

ACCESS

FITTING

LIQUID

TUBING

LIQUID TEMP.

(S14, S15)

Figure 21, Models TGZ 150 - 190

R332541601 rev.00

Package Templifier

DISCHARGE

TUBING

SOLENOID

VALVE

SCHRADER

VALVE

LEAVING WATER

TEMP. SENSOR

(S10)

(SV1, SV2)

FLOW

SIGHT

GLASS

FILTER

DRIER

SCHRADER

VALVE

DISCHARGE

SHUT-OFF

VALVE

SENSOR

DISCHARGE

CHECK VALVE

SUCTION

TUBING

ELECTRONIC

EXPANSION

VALVE

FILTER

DRIER

FLOW

CHARGING

VALVE

RELIEF

VALVE

SCHRADER

VALVE S

TEMP. SENSOR

HGBP

VALVE

(SV5, SV6)

RELIEF

VALVE

SCHRADER

VALVE

TRANSDUCER

SUCTION

(S12, S13)

DISCHARGE

TRANSDUCER

(S03, S04)

SUCTION

(S01, S02)

SUCTION

LIQUID

HOT GAS

BYPASS TUBING

(OPTIONAL)

SOLENOID

VALVE

(SV1, SV2)

RELIEF

VALVE

SIGHT

GLASS

SCHRADER

VALVE

CHARGING

VALVE

WATER

IN

ENTERING WATER

TEMP. SENSOR

(S08)

HGBP

VALVE

(SV5, SV6)

SCHRADER

VALVE

LIQUID

CIR. 1

THERMAL

EXPANSION

VALVE

PRESSURE

TUBE AND SHELL

EVAPORATOR

HIGH

SWITCH

LEAVING WATER

TEMP. SENSOR

OIL

SIGHT GLASS

(OPPOSITE SIDE)

(S00)

PLATE TYPE

EVAPORATOR

SCROLL

COMPRESSOR

(TRIO)

WATER

OUT

LEAVING WATER

TEMP. SENSOR

(S00)

WATER

OUT

WATER

OUT

ATE

IN

ENTERING WATER

TEMP. SENSOR

(S09)

LIQUID TEMP.

SENSOR

(S14, S15)

SYSTEM #1 SYSTEM #2

CONDENSER

ASSEMBLY

LIQUID

TUBING

LIQUID

SHUT-OFF

VALVE

ACCESS

FITTING

IM TGZ TGZ 040A through TGZ 190A 30

Page 32

Wiring

Field Wiring

The TGZ units are supplied as standard with compressor contactors and power terminal block, designed for multipoint power supply to the unit, no compressor circuit breakers. Available options are:

• Single-point connection to power block with comp ressor circuit breakers

• Single-point connection to disconnect switch with comp ressor circuit breakers

• High short circuit current rating with single-point disconnect switch

• Multi-point connection to disconnect switch, no comp ressor circuit breakers

A factory-installed control circuit transformer is standard. Optionally, a field-installed control power source can

be wired to the unit.

Wiring and conduit selections must comply with the National Electrical Code and/or local requirements.

An open fuse indicates a short, ground, or overload. Before replacing a fuse or restarting a compressor, the trouble

must be found and corrected. Tables in the Electrical Data section (page

recommended wire sizes.

Unit power inlet wiring must enter the control box through the right side. A 7/8-inch pilot knockout is provided.

(Refer to the unit dimension drawings beginning on page

16 for the location of power (and control) connections.)

!

To avoid equipment damage, use only copper conductors in main terminal block.

CAUTION

33) give specific information on

31 TGZ 040A through TGZ 190A IM TGZ

Page 33

Figure 22, Field Wiring Diagram

IM TGZ TGZ 040A through TGZ 190A 32

Page 34

Electrical Data

Table 15, Compressor Amp Draw

STANDARD UNIT W/O EXT. OL'S

TGZ

VOLTS

UNIT

SIZE

No.1 No.3 No.5 No.2 No.4 No.6 No.1 No.3 No.5 No.2 No.4 No.6 No.1 No.3 No.5 No.2 No.4 No.6

208 35.3 35.3 - 35.3 35.3 - 30.8 30.8 - 30.8 30.8 - 239 239 - 239 239 -

040

050

060

080

100

110

120

150

170

190

NOTES:

1. External overloads only available on Templifier Units with 140°F maximum condenser leaving water temperature.

2. Unit wire sizing amps are equal to 125% of the largest compressor-motor RLA plus 100% of RLA of all other loads in the circuit including

3. Single point power supply requires a single fused disconnect to supply electrical power to the unit.

4. Compressor RLA values are for wire sizing purposes only and do not reflect normal operating current draw.

230 35.3 35.3 - 35.3 35.3 - 28.0 28.0 - 28.0 28.0 - 239 239 - 239 239 460 17.9 17.9 - 17.9 17.9 - 14.0 14.0 - 14.0 14.0 - 125 125 - 125 125 575 11.5 11.5 - 11.5 11.5 - 11.2 11.2 - 11.2 11.2 - 80 80 - 80 80 208 48.1 48.1 - 48.1 48.1 - 42.0 42.0 - 42.0 42.0 - 300 300 - 300 300 230 48.1 48.1 - 48.1 48.1 - 38.4 38.4 - 38.4 38.4 - 300 300 - 300 300 460 21.8 21.8 - 21.8 21.8 - 19.2 19.2 - 19.2 19.2 - 150 150 - 150 150 575 19.9 19.9 - 19.9 19.9 - 15.2 15.2 - 15.2 15.2 - 109 109 - 109 109 208 54.0 54.0 - 54.0 54.0 - 54.0 54.0 - 54.0 54.0 - 340 340 - 340 340 230 52.6 52.6 - 52.6 52.6 - 48.8 48.8 - 48.8 48.8 - 340 340 - 340 340 460 25.6 25.6 - 25.6 25.6 - 24.4 24.4 - 24.4 24.4 - 173 173 - 173 173 575 21.2 21.2 - 21.2 21.2 - 19.6 19.6 - 19.6 19.6 - 132 132 - 132 132 208 73.1 73.1 - 73.1 73.1 - 58.0 58.0 - 58.0 58.0 - 505 505 - 505 505 230 73.1 73.1 - 73.1 73.1 - 52.8 52.8 - 52.8 52.8 - 505 505 - 505 505 460 30.1 30.1 - 30.1 30.1 - 26.4 26.4 - 26.4 26.4 - 225 225 - 225 225 575 24.4 24.4 - 24.4 24.4 - 21.2 21.2 - 21.2 21.2 - 180 180 - 180 180 208 73.1 73.1 - 73.1 73.1 - 69.2 69.2 - 69.2 69.2 - 500 500 - 500 500 230 73.1 73.1 - 73.1 73.1 - 62.4 62.4 - 62.4 62.4 - 500 500 - 500 500 460 35.3 35.3 - 35.3 35.3 - 31.2 31.2 - 31.2 31.2 - 250 250 - 250 250 575 28.2 28.2 - 28.2 28.2 - 25.2 25.2 - 25.2 25.2 - 198 198 - 198 198 208 73.1 73.1 - 93.6 93.6 - 69.2 69.2 - 88.8 88.8 - 500 500 - 599 599 230 73.1 73.1 - 93.6 93.6 - 62.4 62.4 - 80.0 80.0 - 500 500 - 599 599 460 35.3 35.3 - 45.5 45.5 - 31.2 31.2 - 40.0 40.0 - 250 250 - 310 310 575 28.2 28.2 - 36.5 36.5 - 25.2 25.2 - 32.0 32.0 - 198 198 - 239 239 208 93.6 93.6 - 93.6 93.6 - 88.8 88.8 - 88.8 88.8 - 599 599 - 599 599 230 93.6 93.6 - 93.6 93.6 - 80.0 80.0 - 80.0 80.0 - 599 599 - 599 599 460 45.5 45.5 - 45.5 45.5 - 40.0 40.0 - 40.0 40.0 - 310 310 - 310 310 575 36.5 36.5 - 36.5 36.5 - 32.0 32.0 - 32.0 32.0 - 239 239 - 239 239 208 73.1 73.1 73.1 73.1 73.1 73.1 69.2 69.2 69.2 69.2 69.2 69.2 500 500 500 500 500 500

230 73.1 73.1 73.1 73.1 73.1 73.1 62.4 62.4 62.4 62.4 62.4 62.4 500 500 500 500 500 500

460 35.3 35.3 35.3 35.3 35.3 35.3 31.2 31.2 31.2 31.2 31.2 31.2 250 250 250 250 250 250

575 28.2 28.2 28.2 28.2 28.2 28.2 25.2 25.2 25.2 25.2 25.2 25.2 198 198 198 198 198 198

208 73.1 73.1 73.1 93.6 93.6 93.6 69.2 69.2 69.2 88.8 88.8 88.8 500 500 500 599 599 599

230 73.1 73.1 73.1 93.6 93.6 93.6 62.4 62.4 62.4 80.0 80.0 80.0 500 500 500 599 599 599

460 35.3 35.3 35.3 45.5 45.5 45.5 31.2 31.2 31.2 40.0 40.0 40.0 250 250 250 310 310 310

575 28.2 28.2 28.2 36.5 36.5 36.5 25.2 25.2 25.2 32.0 32.0 32.0 198 198 198 239 239 239

208 93.6 93.6 93.6 93.6 93.6 93.6 88.8 88.8 88.8 88.8 88.8 88.8 599 599 599 599 599 599

230 93.6 93.6 93.6 93.6 93.6 93.6 80.0 80.0 80.0 80.0 80.0 80.0 599 599 599 599 599 599

460 45.5 45.5 45.5 45.5 45.5 45.5 40.0 40.0 40.0 40.0 40.0 40.0 310 310 310 310 310 310

575 36.5 36.5 36.5 36.5 36.5 36.5 32.0 32.0 32.0 32.0 32.0 32.0 239 239 239 239 239 239

control transformer.

RATED LOAD AMPS

PER COMPRESSOR

CIRCUIT #1 CIRCUIT #2 CIRCUIT #1 CIRCUIT #2 CIRCUIT #1 CIRCUIT #2

OPTIONAL UNIT WITH EXT. OL'S

RATED LOAD AMPS (SEE NOTE 1)

PER COMPRESSOR

LOCKED ROTOR AMPS

COMPRESSORS

ACROSS-THE-LINE STARTING

33 TGZ 040A through TGZ 190A IM TGZ

Page 35

Table 16, Wire Sizing Amps, Standard Multi-Point Power Supply

MINIMUM CIRCUIT AMPACITY (MCA) POWER SUPPLY

WITHOUT EXTERNAL

TGZ

UNIT

VOLTS

SIZE

040

050

060

080

100

110

120

150

170

190

NOTES:

1. Unit wire sizing amps are equal to 125% of the largest compressor-motor RLA plus 100% of the other compressor RLAs.

2. Multiple point power supply requires a separate fused disconnect for each circuit to supply electrical power to the unit.

3. External compressor overload option is only available for units with 140° F maximum leaving condenser water temperature.

4. Wire sizes shown above are for standard ambient temperature and short runs of wire.

FREQ.

(HERTZ)

208 79 79 69 69 3 #4 #4 3 #4 #4

230 79 79 63 63 3 #4 #4 3 #6 #6

460 40 40 32 32 3 #8 #8 3 #10 #10

575

208 108 108 95 95 3 #2 #2 3 #3 #3

230 108 108 86 86 3 #2 #2 3 #3 #3

460 49 49 43 43 3 #8 #8 3 #8 #8

575

208 122 122 122 122 3 #1 #1 3 #1 #1

230 118 118 110 110 3 #1 #1 3 #2 #2

460 58 58 55 55 3 #6 #6 3 #6 #6

575

208 165 165 131 131 3 2/0 2/0 3 1/0 1/0

230 165 165 119 119 3 2/0 2/0 3 #1 #1

460 68 68 59 59 3 #4 #4 3 #6 #6

575

208 165 165 156 156 3 2/0 2/0 3 2/0 2/0

230 165 165 140 140 3 2/0 2/0 3 1/0 1/0

460 79 79 70 70 3 #4 #4 3 #4 #4

575

208 165 211 156 200 3 2/0 4/0 3 2/0 3/0

230 165 211 140 180 3 2/0 4/0 3 1/0 3/0

460 79 102 70 90 3 #4 #2 3 #4 #3

575

208 211 211 200 200 3 4/0 4/0 3 3/0 3/0

230 211 211 180 180 3 4/0 4/0 3 3/0 3/0

460 102 102 90 90 3 #2 #2 3 #3 #3

575

208 238 238 225 225 3 250 250 3 4/0 4/0

230 238 238 203 203 3 250 250 3 4/0 4/0

460 115 115 101 101 3 #2 #2 3 #2 #2

575

208 238 304 225 289 3 250 350 3 4/0 350

230 238 304 203 260 3 250 350 3 4/0 300

460 115 148 101 130 3 #2 1/0 3 #2 #1

575

208 304 304 289 289 3 350 350 3 350 350

230 304 304 260 260 3 350 350 3 300 300

460 148 148 130 130 3 1/0 1/0 3 #1 #1

575

60

60

60

60

60

60

60

60

60

60

OVERLOADS

MULTIPLE POINT POWER SUPPLY

CIRCUIT

#1

26 26 25 25 3 #10 #10 3 #10 #10

45 45 34 34 3 #8 #8 3 #10 #10

48 48 44 44 3 #8 #8 3 #8 #8

55 55 48 48 3 #6 #6 3 #8 #8

64 64 57 57 3 #6 #6 3 #6 #6

64 82 57 72 3 #6 #4 3 #6 #4

82 82 72 72 3 #4 #4 3 #4 #4

92 92 82 82 3 #3 #3 3 #4 #4

92 119 82 104 3 #3 #1 3 #4 #2

119 119 104 104 3 #1 #1 3 #2 #2

CIRCUIT

#2

WITH EXTERNAL

OVERLOADS

CIRCUIT

#1

CIRCUIT

#2

WITHOUT EXTERNAL

OVERLOADS

FIELD

WIRE

QTY.

WIRE GAUGE

75°C

CIRCUIT

CIRCUIT

#1

#2

WITH EXTERNAL

OVERLOADS

FIELD

WIRE

QTY.

WIRE GAUGE

CIRCUIT

#1

75°C

CIRCUIT

#2

IM TGZ TGZ 040A through TGZ 190A 34

Page 36

Table 17, Wire Sizing Amps, Optional Single Point Power Supply

TGZ

UNIT

VOLTS

SIZE

208 150 131 3 1/0 3 1/0

040

050

060

080

100

110

120

150

170

190

NOTES:.

1. Unit wire sizing amps are equal to 125% of the largest compressor-motor RLA plus 100% of the other compressor RLAs.

2. Single point power supply requires a single fused disconnect to supply electrical power to the unit.

3. External compressor overload option is only available for units with 140° F maximum leaving condenser water temperature.

4. Wire sizes shown above are for standard ambient temperature and short runs of wire.

230 150 119 3 1/0 3 #1

460 76 60 3 #4 3 #6

575

208 204 179 3 4/0 3 3/0

230 204 163 3 4/0 3 2/0

460 93 82 3 #3 3 #4

575

208 230 230 3 4/0 3 4/0

230 224 207 3 4/0 3 4/0

460 109 104 3 #2 3 #2

575

208 311 247 3 400 3 250

230 311 224 3 400 3 4/0

460 128 112 3 #1 3 #2

575

208 311 294 3 400 3 350

230 311 265 3 400 3 300

460 150 133 3 1/0 3 1/0

575

208 357 338 6 (2) 3/0 6 (2) 2/0

230 357 305 6 (2) 3/0 3 350

460 173 152 3 2/0 3 2/0

575

208 398 377 6 (2) 3/0 6 (2) 3/0

230 398 340 6 (2) 3/0 6 (2) 2/0

460 193 170 3 3/0 3 2/0

575

208 457 433 6 (2) 4/0 6 (2) 4/0

230 457 390 6 (2) 4/0 6 (2) 3/0

460 221 195 3 4/0 3 3/0

575

208 524 496 6 (2) 300 6 (2) 250

230 524 447 6 (2) 300 6 (2) 4/0

460 254 224 3 250 3 4/0

575

208 585 555 6 (2) 350 6 (2) 300

230 585 500 6 (2) 350 6 (2) 250

460 284 250 3 300 3 250

575

FREQ.

(HERTZ)

60

60

60

60

60

60

60

60

60

60

MINIMUM CIRCUIT AMPACITY (MCA) POWER SUPPLY

SINGLE POINT

POWER SUPPLY )

WITHOUT EXT OL'S

49 48 3 #8 3 #8

85 65 3 #4 3 #6

90 83 3 #3 3 #4

104 90 3 #2 3 #3

120 107 3 #1 3 #2

139 122 3 1/0 3 #1

155 136 3 2/0 3 1/0

176 158 3 3/0 3 2/0

203 180 3 4/0 3 3/0

228 200 3 4/0 3 3/0

SINGLE POINT

POWER SUPPLY

WITH EXT OL'S

WITHOUT EXTERNAL OL'S WITH EXTERNAL OL’S

FIELD WIRE

QUANTITY

WIRE GAUGE

75°C

FIELD WIRE

QUANTITY

WIRE GAUGE

75°C

35 TGZ 040A through TGZ 190A IM TGZ

Page 37

Table 18, Maximum Fuse Sizing

TGZ

VOLTAGE

UNIT

SIZE

NOTE: "Maximum Fuse Sizes" are selected at approximately 225% of the largest compressor RLA plus 100% of other compressor RLA values.

040

050

060

080

100

110

120

150

170

190

PHASE

208 175 150 110 110 100 100

230 175 125 110 110 90 90

460 90 70 50 50 45 45

575

208 250 200 150 150 125 125

230 250 200 150 150 110 110

460 110 100 70 70 60 60

575

208 250 250 175 175 175 175

230 250 250 150 150 150 150

460 125 125 80 80 70 70

575

208 350 300 225 225 175 175

230 350 250 225 225 150 150

460 150 125 90 90 80 80

575

208 350 350 225 225 200 200

230 350 300 225 225 200 200

460 175 150 110 110 100 100

575

208 450 400 225 300 200 250

230 450 350 225 300 200 250

460 200 175 110 125 100 125

575

208 450 450 300 300 250 250

230 450 400 300 300 250 250

460 225 200 125 125 125 125

575

208 500 500 300 300 250 250

230 500 450 300 300 250 250

460 250 225 150 150 125 125

575

208 600 500 300 350 250 350

230 600 500 300 350 250 300

460 250 250 150 175 125 150

575

208 600 600 350 350 350 350

230 600 500 350 350 300 300

460 300 250 175 175 150 150

575

FREQ.

(HERTZ)

60

60

60

60

60

60

60

60

60

60

SINGLE POINT POWER SUPPLY MULTIPLE POINT POWER SUPPLY

WITHOUT

EXTERNAL. OL'S

TOTAL UNIT

60 50 35 35 35 35

100 70 60 60 45 45

110 100 60 60 60 60

125 110 70 70 60 60

125 125 90 90 80 80

175 150 90 110 80 100

175 150 110 110 100 100

200 175 110 110 100 100

225 200 110 150 100 125

350 225 150 150 125 125

WITH

EXTERNAL. OL'S

TOTAL UNIT

WITHOUT EXTERNAL. OL'S WITH EXTERNAL OL'S

CIRC.#1 CIRC.#2 CIRC.#1 CIRC.#2

IM TGZ TGZ 040A through TGZ 190A 36

Page 38