Page 1

SINGLE AND DUAL COMPRESSOR CENTRIFUGAL

TEMPLlFlER@

HEAT PUMPS

13600 Industrial Park Blvd., P 0. Box 1551 Minneapolis, Minnesota 55440

Page 2

Page 3

INTRODUCTION

GENERAL

The McQuay Model TEH and TFH Centrifugal Templifier

units are complete, self contained, automatically

trolled liquid heating units. Each unit is completely

assembled and factory tested prior to shipment.

Installation of the Templifier units is the responsibility

of the installing contractor and/or the owner’s

sentatives, and normally consists of properly setting

con-

repre-

UNIT IDENTIFICATION

Each unit is assigned a unique series of identifying

numbers which are stamped on the unit nameplate. As

soon as the unit is received, these identifications should

be checked with the shipping papers and project information. If any discrepancies exist, contact your McQuay

representative immediately.

Some McQuay Templifiers are equipped with a second

condenser as required by project conditions.

In addition to the unit nameplate shown in Figure 1,

each component has a nameplate affixed with certain

data for the installer, including electrical data for the

compressors and oil pumps.

sentatives, and normally consists of properly setting

the unit in place and connecting the necessary wiring

and piping services to the machine.

All McQuay Templifiers must be started only by a

McQuay Service Representative. The installer should

make no attempt to start the machine before the

complete system checkout has been made by McQuay

and the unit has been initially started.

MODEL

STYLE

SERIAL

S.O. NO.

~~~~

~_

FACTORY CHARGED

~

LBS. REFRIGERANT

LEAK TEST PRESSURE 100 PSIG.

MOTOR

- COMPRESSOR

AND OVERLOAD PROTECTION FIELD

SUPPLIED. SEE SPEC.

UNIT NAMEPLATE

CONTROLLER

PE-D4

FIGURE 1

_

SAFETY CONSIDERATIONS

McQuay equipment is designed to provide safe and

reliable service when properly installed and operated

within the design specifications. The installer and

operator should observe good safety precautions to

prevent damage to the equipment or injury ‘to personnel. Particular attention should be given to the

following:

.

Do not climb on the unit or step on electrical or

refrigerant lines.

.

Never exceed specified test pressures. Verify allowable test pressures by checking the instruction

literature and/or the equipment nameplates.

.

Do not use oxygen to purge or to pressurize the

unit.

.

Do not obstruct or valve off any safety or relief

devices.

Never open valves or connections under pressure in

a way that can cause loss of refrigerant or oil or

create a personnel hazard.

Nameplate and warning/instruction tags should not

be removed.

Fluorocarbon refrigerants must be handled with

caution and release to the atmosphere should be

minimized.

Use only the correct refrigerant

nameplate.

Only qualified electricians should make electrical

installations.

Make certain that rigging equipment is adequate for

the unit weights.

-

consult the unit

Page 4

RECEIVING AND HANDLING

INSTALLATION

The unit should be inspected immediately after receipt

for possible shipping damage.

All

McQuay

Centrifugal Templifier Heat Pumps are

shipped F.O.B. factory and all claims for handling and

shipping damage are the responsibility of the

consignee.

Leave the shipping skid in place until the unit is in its

final position. This will aid in handling the equipment.

Extreme care should be used when rigging the equipment to prevent damage to the control center, or

refrigerant piping.

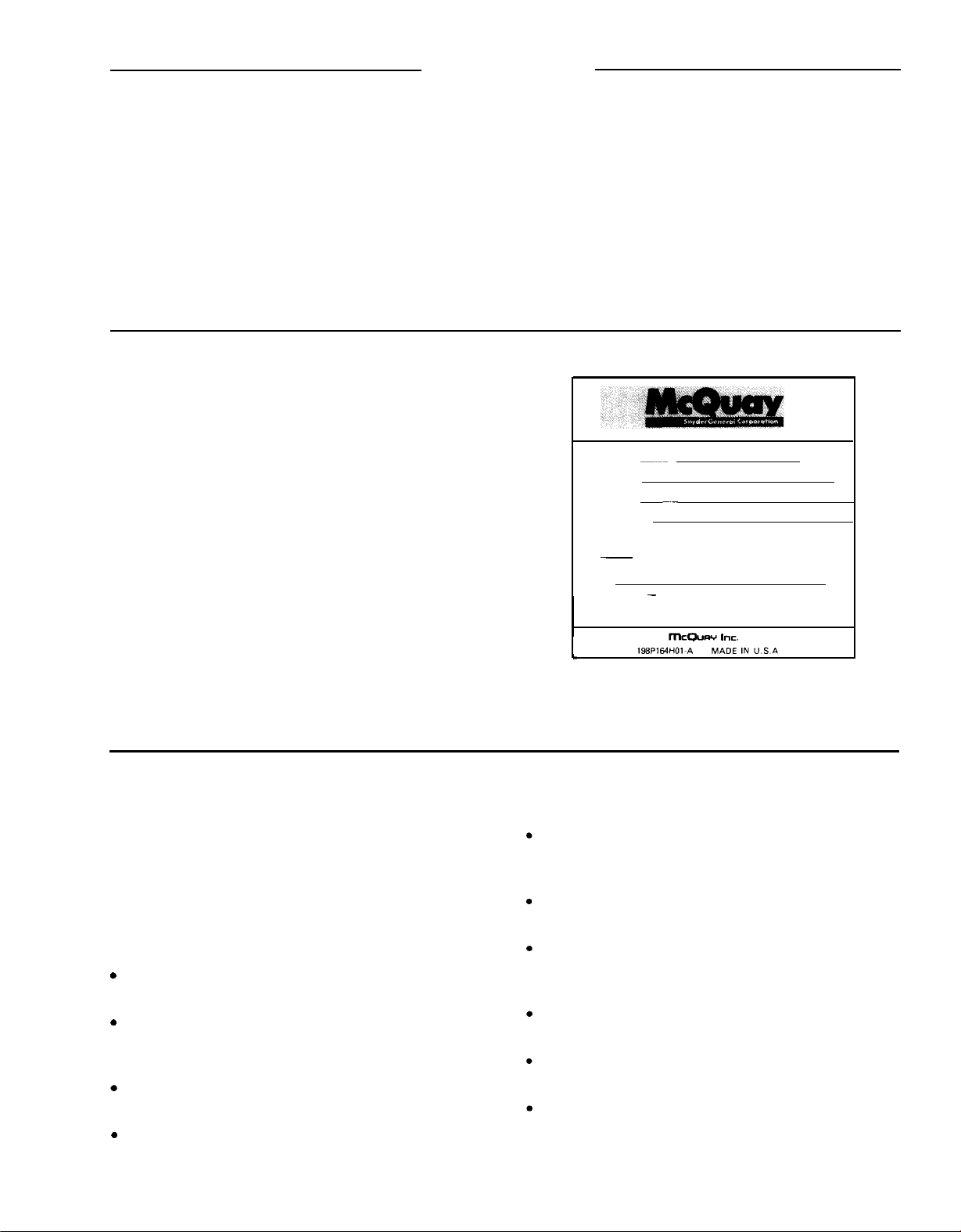

On units with top mounted compressors, the unit can

be lifted by fastening the rigging hooks to the 4

corners of the evaporator where the rigging eyes are

located. (See Figure 2.) Spreader bars should be used

between the rigging lines to prevent damage to the

control center and other components.

On units with side mounted compressors, the unit can

be lifted by the three corner fitting eyes and the

extended eye at the compressor end. The center of

gravity is located approximately where the discharge

line enters the upper condenser shell. Adjust cable or

chain lenghs accordingly. The compressor support is

not designed to support the full weight of the unit.

Therefore, unit must be lifted so that it is level or

canted to assure that the compressor supports leave

the ground first and touch down last. Spreader

bars are a must. (See Figure 3).

For equipment weights for rigging and installation

requirements, refer to the certified equipment data.

1.

2.

3.Condenser Water

4.Condenser Water

FIGURE 3

SIDE MOUNTED COMPRESSOR UNITS

Lifting Eyes

Shipping Skid 6.Source Water - Out

-

In 7.

-

Out 8.

Source Water - In

5.

Control Center

Condenser Relief Valves

TOP MOUNTED COMPRESSOR

FIGURE 7.

UNITS

Page 5

LOCATING AND MOUNTING

INSTALLATION

The unit should be mounted on a level concrete or

steel base and should be located so as to provide

service clearance at one end of the unit for possible

removal of evaporator tubes and/or condenser tubes.

Clearances required are 16 feet for units with 14 foot

long shells, 14 feet for units with 12 foot shells, and

feet for units with 8 foot long shells. Evaporator and

condenser tubes are rolled into the tube sheets to

permit replacement if necessary. Clearance at all other

points, including the top, is 3 feet.

Make certain that the floor or structural support is

adequate to support the full operating weight of the

complete unit.

WATER PUMPS

The use of 3600 rpm or two pole pump motors is not

recommended. It is not uncommon to find these

pumps operate with objectionable noise and vibration.

It is also possible to build up a frequency beat due to

the slight difference in the operating rpm of the pump

motor and the McQuay centrifugal motor. McQuay

encourages the use of

motors whenever possible.

1750

rpm or four pole pump

10

Rubber Shearflex or “lsomode”, pads are supplied

with unit, for use under each corner of the base

members. These pads are packed in the control box

for shipment.

It is not normally necessary to bolt the unit to the

mounting slab or framework; but should this be

desirable,

the unit supports at the four corners and under the

compressor base on the side mounted compressor

units. The unit must be level.

The condenser is connected with the coolest water

entering at the bottom.

The piping should be supported to reduce the weight

and strain on the fittings and connections. Piping

should also be adequately insulated. A cleanable 20

mesh water strainer should be installed at both inlets.

Sufficient shut-off valves should be installed to permit

draining the water from the evaporator or condenser

without draining the complete system.

1-1/8

inch mounting holes are provided in

EVAPORATOR AND CONDENSER

WATER PIPING

All Templifier evaporators and condensers come

equipped with groove-type mechanical clamp or flange

connections. The installing contractor must provide

matching mechanical connections of the sizes given in

the system dimension and capacity tables. NOTE: IF

WELDING IS TO BE PERFORMED ON THE

MECHANICAL OR FLANGE CONNECTIONS, THE

SOLID STATE TEMPERATURE SENSOR AND

THERMOSTAT BULBS MUST BE REMOVED FROM

THE WELLS TO PREVENT DAMAGE TO THOSE

COMPONENTS.

Small water pressure test valves or pipe plugs are

provided at both the inlets and outlets of the vessel

heads. The test valves permit the water flow pressure

drops to be checked. The pressure drops and flow

rates for the evaporator and condenser are specified on

each installation.

Figures 2 and 3 show the inlets and outlets of the

evaporators and condensers. The evaporator is connected with the warmest water entering at the top.

NOTE: NEITHER THE EVAPORATOR NOR THE CON-

DENSER IS SELF-DRAINING: BOTH MUST BE

BLOWN OUT. THE PIPING SHOULD ALSO INCLUDE

THERMOMETERS AT THE INLET AND OUTLET

CONNECTIONS AND AIR VENTS AT THE HIGH

POINTS.

In cases where the water pump noise may be objectionable, rubber isolation sections are recommended at

both the inlet and outlet of the pump. In most cases,

it will not be necessary to provide vibration eliminator

sections in the condenser inlet and outlet water lines;

but where noise and vibration are critical (for example,

where a pipe chase goes through walls), they may be

required. A bypass around the evaporator and/or

condenser must be provided where uninterrupted

source and/or process water flow is required.

Where a cooling tower is used to supply source water,

a flow balancing valve is required when the evaporator

does not have full flow.

OIL COOLER PIPING

Templifier oil coolers normally utilize water for removing heat from the lubricating oil. The water source

must never exceed

gOoF.

In some applications,

refrig-

5

Page 6

INSTALLATION

erant cooled oil coolers are provided and are completely piped up in the factory. Refrigerant cooling is

usually limited to the

TP050

models.

Water Cooled Oil Coolers

When water is to be the coolant, the oil cooler is

factory mounted with the oil piping installed. Water

piping for the oil coolers must be installed in the field

according to good piping practice and should include:

stop valves to isolate the cooler for servicing, cleanable

strainer

(40

mesh maximum), balancing valve to adjust

water flow, solenoid operated water shut-off valve

wired in accordance with Field Connection Control

Diagram, and a drain valve or plug. Water supply for

the oil cooler may be obtained from:

A. Source Water Circuit. See Figure 4.

B. Independent source, such as city water.

C. Cooling tower makeup if the flow is adequate and

continuous and the temperature never exceeds

90°F. See Figure 5.

TABLE 1

1

Maximum Oil Cooler Water Requirements

Model

TEH063

TEH079

TEH100

TEH126 16.0

*Pressure drop through two oil coolers with water sides piped in

series

-

TEH 126 only.

When the oil cooler is piped into the source water

supply, its water piping should be connected across

the source water pump so that the full pressure

differential of the pump is maintained across the cooler

system at all times the pump is running. This is the

recommended arrangement, and most systems will

accommodate it. For those installations where it could

be desirable to pipe the oil cooler system across the

evaporator, this may be done providing the water

pressure drop through the evaporator is greater or

equal to the oil cooler pressure drop.

Under no circumstances should the oil cooler be piped

in parallel with a single pass evaporator. This will result

in inadequate cooling water to the oil cooler due to the

low evaporator pressure drop.

When supplied with city water, the oil cooler water

piping should discharge into an open drain to prevent

draining the cooler by siphoning. This water may also

And Pressure Drops

Maximum

Water Requirement

@

85 F Entering

GPM

8.0

8.0

12.25 5.2

Water

Pressure Drop Thru

Oil Coolers Only

PSI

1.8

1.8

10.4’

be used for cooling tower makeup by discharging it

into the tower sump from a point above the highest

possible water level.

On

R12

units, the water flow through the oil cooler

must be adjusted with the balancing valve so that the

temperature of oil supplied to the compressor bearings

(entering the compressor) is not less than 90°F nor

more than 120°F. On systems using source water for a

cooling medium, the leaving oil temperature should be

on the low side of the acceptable temperature range

when operating with the coldest water.

For

R114

units oil temperatures are normally higher.

For settings consult special instructions furnished with

the unit.

I

I

FIGURE 5

OIL COOLER PIPING

On some units, oil cooler water solenoid valves are

factory furnished. On those units where the solenoid

valve is required and not furnished, the installing

contractor must supply the solenoid.

Refrigerant Cooled Oil Coolers

On those Templifier units furnished with refrigerant oil

cooling, the shut-off and flow control are built into the

refrigerant piping.

Subcooled liquid from the condenser is fed to the oil

cooler through an oil temperature control valve whose

control bulb is located on the oil line leaving the oil

cooler. The gas

the evaporator. Refrigerant flow is controlled to

tain an oil temperature of approximately

R12 Templifiers. Oil Coolers in

at higher temperatures.

-

liquid mixture returns to the inlet of

R114

Templiers operate

main-

90-lOOoF

in

6

Page 7

INSTALLATION

1.

CEO63 Compressors

2.Lube Boxes

3.Suction Shutoff Valve

4.Condenser Relief Valves

5. Expansion Valves

6. Oil Pumps

7.Oil Level Sight Glass

8.Hot Gas Bypass

9.

Oil Coolers

10.

Discharge Check Valve

11. Motor Cooling Liquid Line

12. Motor Cooling Liquid Filter-Drier

TFH063

VENT PIPING

As a safety precaution, each system is equipped with

pressure relief valves located on the condenser and on

the evaporator for the purpose of relieving excessive

refrigerant pressure to the atmosphere. Many local

codes require that relief valves be vented to the

outside, and this is desirable installation practice for all

installations. NOTE: Remove plastic thread protectors

from the inside of the valves prior to making pipe

connections. Whenever vent piping is installed, the

lines should be run in accordance with local code

requirements; or where local codes do not apply, ANSI

B9-1

-Sec. 12 code recommendations should be

followed.

Current condenser design incorporates two relief

valves

the two valves. (See Figure 7). When piping the vent

line to a dual valve set, it may be sized for one relief

valve and piped to both valves. If one relief valve of the

two valve set fails, the shut-off valve may be used to

isolate the faulty relief valve, easing replacement. On

(1

set) with a

3-way

shut-off valve separating

FIGURE 6

(Rear View)

13.

CondenserInlet

14.

CondenserOutlet

15.

EvaporatorInlet

16.

Evaporator

17. Motor Terminal Cover

18. Liquid Line Shutoff Valve

Outlet

Condenser Relief Valve Set

1. #l Relief

2.

3.

4.

larger capacity condenser designs, two sets of dual

relief valves are used. These vents must be sized for

the total of two valves.

Valve

#2

Relief

Valve

Relief Valve

3-Way

Access Valve

3-Way

Shutoff

FIGURE 7

Page 8

THERMAL INSULATION

INSTALLATION

Factory installed thermal insulation is furnished on all

parts of the Templifier unit as needed to prevent

sweating, to retain thermal efficiency, and to protect

operating personnel from hot surfaces.

ELECTRICAL

Wiring, fuse and wire size must be in accordance with

information provided in the Electrical Data. Standard

NEMA motor starters require modification to meet

McQuay specifications. Refer to Electrical Data supplied with the unit for details.

IMPORTANT: The voltage of these units should be

within the limitation of plus or minus

voltage unbalance between phases must not exceed

3%. Since a 3% % voltage unbalance will cause an

approximate 25% increase in motor temperature, it is

most important that the unbalance between phases be

at a minimum.

NOTE: Do not make final power connections to the

starter until wiring has been checked and approved by

an authorized McQuay Service Representative. Under

no circumstances should the compressor be brought

up to speed unless proper phase sequence and rotation

have been established. Serious damage may result if

the compressor starts in the wrong direction. Jog the

machine to check rotation using the sight glasses on

the rear motor cover to observe direction.

Power Wiring

Power wiring to the compressor must be in proper

phase sequence. Motor rotation is set up for clockwise

rotation facing motor end cover with phase sequence

of l-2-3. Care should be taken that proper phase

sequence is carried through the starter to the compressor. With the phase sequence of l-2-3 and

connected to T1 and T6, L2 connected to T2 and T4,

and L3 connected to T3 and T5, rotation is proper. See

diagram in terminal box cover.

T**063/079/100/126

10%,

and the

Care should be taken not to tear, damage or remove

any of this factory insulation.

All field piping connections to the Templifier should be

insulated by the installer if required by good practice

and personnel safety.

CAUTION: Wiring connection to compressor terminal

studs must be made with copper lugs and copper wire.

Power Wiring

All

T**048/050

factory wired and mounted star delta starter equipped

with ambient compensated quick trip overloads, factory set at 1

be in accordance with information located in the elec-

trical data supplied with the unit

cal Data pertaining to your unit.

The power wiring to the compressor starter must be in

proper phase sequence. See second paragraph under

T**063/079/100/126

All units are factory equipped with open transition

starters. Closed transition starters are supplied on a

special order basis. Transition should be set to 15

seconds.

15% F.L.A. Wiring, fuse and wire size must

T**048/050

units are normally supplied with a

or the

McQuay Electri-

Power Wiring.

Control Wiring

The control circuit on the McQuay

and 126 Templifiers is designed for 1 15 volts. Power

should be supplied from a separate circuit and fused at

10 amps. (See Table 2). The control circuit on the

TP048/050

power is provided to the control panel by a .75 or 1

KVA 1 15 volt transformer supplied and mounted in the

starter package.

L1

unit is also designed for 115 volts, but

TABLE 2 MAXIMUM CONDUCTOR LENGTH*

T**063/079/100

Phase sequence can be determined by using GE No.

546703265 phase sequence meter or equal. Before

connecting the starter load leads to the compressor

terminals and while checking the field connection

wiring, the transition timer in the starter should be

adjusted to make the transition in 15 seconds. This

should be reset when the compressor is put on the

line. The timer should be adjusted to actuate (discon-

nect Star winding connection and connect Delta)

when the motor has come up to speed and before any

speed reduction occurs.

-I

l Maximum length is distance conductor will traverse between

control power source and the unit control panel. Wire size based

on voltage drop not to exceed 3 percent.

Panel terminal connectors will accommodate wire size up to 10

AWG, larger conductors will require an intermediate junction box.

The disconnect switch should be tagged to prevent

current interruption. SWITCH IS TO REMAIN ON AT

ALL TIMES IN ORDER TO KEEP OIL HEATERS

8

Page 9

INSTALLATION

b

8

1.

CEO63 Compressor

2.Evaporator

3.Condenser

4.Relief Valves

5.

Control Panel

6.

Lube Box

Oil Pump

7.

Oil Level Sight Glass

8.

Discharge Line

9.

Hot Gas Bypass

10.

Expansion Valve

11.

OPERATIVE AND PREVENT REFRIGERANT FROM

ACCUMULATING IN OIL.

The control center off-on switch should be turned to

the “Off” position any time compressor operation is

not desired.

If the control voltage is supplied by a transformer, the

transformer should be rated at 2 KVA, with an inrush

rating of 12 KVA minimum at 80% power factor and

95% secondary voltage. For control wire sizing, refer

to the N.E.C. article 215 and 310. In the absence of

complete information to permit calculations, the voltage drop should be physically measured.

Control Interlocks

Water flow interlock terminals are provided on the

control center terminal strip. See field connection

diagram in the Electrical Data or in cover of control

center for proper connections.

The purpose of the water flow interlocks is to prevent

compressor operation until both the source water and

condenser water pumps are running and flow is

proven.

12.

Liquid Line Shut-Off Valve

13.

Oil Cooler

14.

Motor Liquid Cooling Line

15.

Motor Terminal Cover

16.

Discharge Check Valve

FIGURE 8

TEH063

Operation of the source water pump may be to cycle

the pump with the compressor or it may be operated

continuously. The hot water (condenser) pump normally will be run continuously. The holding coil of

the cooling tower pump motor starter must be rated at

115 volts 60 Hz with a maximum 25 volt-ampere rating.

All interlock contacts must be rated for no less than 10

inductive amps. The alarm circuit provided in the

control center utilizes 115 volts. The alarm used should

not draw more than

10

volt-amperes.

TESTING CONTROL CIRCUIT

The installing contractor should complete all field

connections to the Templifier control panel after which

he should check out all remote interlocks for proper

operation. Do not disturb the internal wiring of the

control center or change the factory settings of

operating and safety controls.

At the time of startup the

will completely check out the power and control

circuits. Final power connections to the compressor

should be made only after the

inspection.

McQuay

Service Technician

McQuay

pre-startup

9

Page 10

@--

@-----

INSTALLATION

10

Q

CE126 Compressor

1.

Motor Terminal Cover

2.

Lube Box

3.

Oil Coolers

4.

Expansion Valves

5.

Liquid Line Shut-Off Valve

6.

7.Evaporator

8.Condenser

9.Control Center

Discharge Check

10.

Oil Pump

11.

REPAIR OF SYSTEM (If Necessary)

Pressure Testing

No pressure testing is necessary unless some damage

has been incurred during shipment. Damage may be

determined upon a visual inspection of the exterior

piping assuring no breakage occurred or fittings

loosened. Panel gauges should show a positive pressure (except R-114 units in cold locations). If no pres-

sure is evident on the gauges, a leak may have oc-

curred discharging the entire refrigerant charge. In this

case, the unit should be leak tested to determine the

location of the leak. R-114 units must be above an

ambient of

Leak Testing

50°F

to show a positive pressure.

FIGURE 9

TEH 126

Oil Level Sight Glass

12.

13.

Oil Sump

Oil Cooler Water Lines

14.

Valve

Motor Liquid Cooling Line

15.

Condenser Relief Valves (Hidden)

16.

test pressure given above. When the test pressure is

reached, disconnect the gas cylinder.

If any leaks are found in welded or brazed joints or if it

is necessary to replace a gasket, relieve the test

pressure in the system before proceeding. For copper

joints, braze alloy is recommended.

After making any necessary repair, the system should

be evacuated as described in the section following.

Evacuation

After it has been determined that there are no

refrigerant leaks, the system should be evacuated

using a vacuum pump with a capacity of approximately

3 cu.

ft./min.

and that will reduce the vacuum to at

least 1 millimeter (1000 microns).

In the case of loss of the entire refrigerant charge, the

unit should be checked for leaks prior to charging the

complete system. This can be done by charging

enough refrigerant into the system to build the

pressure up to approximately

1-

psig and adding

sufficient dry nitrogen to bring the pressure up to a

maximum of 125 psig and then leak test with a Halide

or electronic leak detector. WATER FLOW THROUGH

THE VESSELS SHOULD BE MAINTAINED ANY TIME

REFRIGERANT IS ADDED OR REMOVED FROM THE

SYSTEM. CAUTION: DO NOT USE OXYGEN TO

BUILD UP PRESSURE AS A SERIOUS EXPLOSION

CAN RESULT. A pressure regulating valve should

always be used on the nitrogen drum being used to

build up the system pressure. Also, do not exceed the

A mercury manometer, electronic or other type of

micron gauge should be connected at the farthest

point from the vacuum pump. For readings below 1

millimeter, the electronic or other micron gauge should

be used.

The triple evacuation method is recommended and is

particularly helpful if the vacuum pump is unable to

obtain the desired 1 millimeter of vacuum. The system

is first evacuated to approximately 29 inches of

mercury. Enough refrigerant vapor is then added to the

system to bring the pressure up to zero pounds.

Then the system is once again evacuated to approxi-

mately 29 inches of mercury. This is repeated 3 times.

The first pull down will remove about 90% of the

10

Page 11

INSTALLATION

non-condensables, the second about 90% of that

remaining from the first pull down and after the third

only 1

/10

of 1% of the non-condensables will remain.

Charging the System

All Templifier Heat Pumps are leak tested at the

factory and shipped with the operating charge of

refrigerant as indicated on the unit nameplate. In the

event the refrigerant charge was lost due to shipping

damage, the system should be charged as follows after

first repairing the leaks and evacuating the system.

Connect the refrigerant drum to the gauge port on

the liquid shut-off valve and purge the charging line

between the refrigerant cylinder and the valve. Then

open the valve to the mid position.

Turn on both the supply water pump and source

water pump and allow water to circulate through the

condenser and the evaporator.

If the system is under a vacuum, stand the refrigerant drum with the connection up and open the drum

and break the vacuum with refrigerant gas.

With a system gas pressure higher than the equiva-

lent of a freezing temperature, invert the charging

cylinder and elevate the drum above the condenser.

With the drum in this position, valves open, water

pumps operating, liquid refrigerant will flow into the

condenser. Approximately 75% of the total requirement estimated for the unit can be charged in this

manner.

After 75% of the required charge has entered the

condenser,

reconnect the refrigerant drum and

charging line to the service valve on the evaporator.

Again purge the connecting line, stand the drum

with the connection up and place the service valve in

the open position.

The normal ambient pressure of

R114

refrigerant is

so low that a refrigerant pump may be desirable and

helpful in charging with that refrigerant.

Important

At this point, the charging procedure should be inter-

rupted and pre-start checks made before attempting

to complete refrigerant charge. The compressor must

not be started at this time.

Operation and Maintenance manuals pertaining to the

individual units are available from your local McQuay

Service Representative.

PRE-START SYSTEM CHECKLIST

SOURCE (EVAPORATOR) WATER

Cooling tower flushed, filled and vented

Water system filled, vented (if used)

Pumps installed, (rotation checked) strainers cleaned

Controls (3-way valves, by-pass valves, etc.) operable

Water system operated and flow balanced to meet unit design requirements

HOT (CONDENSER) WATER

Piping complete

Water system filled, vented (if

Pumps installed, (rotation checked) strainers cleaned

Controls (3-way valves, face and by-pass dampers, by-pass valves, etc.) operable

Water system operated and flow balanced to meet unit requirements

used)

ELECTRICAL

-

service completed, but not connected to control panel

*Power leads connected to starter; load leads run to compressor ready for connection when

Service Engineer is on hand for start-up

(Do not connect to starter or compressor terminals)

All interlock wiring complete between control panel and complies with specifications

Starter complies with specifications

“Oil cooler solenoid wired to control panel as shown on wiring diagram

Pump starter and interlock wired

Cooling tower fans and controls wired

Wiring complies with National Electrical Code and local codes

*Condenser pump starting relay

MISCELLANEOUS

Oil cooler water piping complete. (Units with water cooled oil coolers

Relief valve piping complete

Thermometer wells, thermometers, gauges, control wells, controls, etc. installed

A minimum system load of 25% of machine capacity is available for testing and

adjusting controls

(if

used)

(HWR)

installed and wired.

only)

No

Not

Applicable

11

Loading...

Loading...