Page 1

Page 2

Page 3

APPLICATION

The operation and maintenance procedures presented in this

manual apply to the models

TEH050-126.

Reference to the

installation manuals for these units should be made for details

pertaining to receiving and handling, installation, piping and

wiring, and preparation for initial start up.

All McQuay Centrifugal Templifiers are factory tested prior

to shipment and must be initially started by a factory trained

McQuay Service technician. Failure to follow this start-up procedure may affect the equipment warranty.

The standard warranty on this equipment covers parts

which prove defective in material or workmanship. Specific

OPERATION

OPERATOR RESPONSIBILITIES

It is important that the operator become familiar with the

equipment and the system before attempting to operate the

Templifier.

In addition to reading this manual the operator should study

all the control diagrams furnished with the unit so that he

understands the starting, operating and shut-down sequences

as well as the safety shut-down modes.

When the McQuay Service technician performs the initial

start-up of the Templifier he will be available to answer any

questions and to instruct in proper operating procedures.

It is recommended that the operator maintain an operating

log for each individual unit. In addition, a seoarate

maintenance log should be kept of the periodic maintenance

details of this warranty can be found in the warranty state-

ment furnished with the equipment.

In the application of Templifiers, each unit is designed for

specific heat recovery conditions to achieve the highest possible performance. In order to maintain the design performance

levels, the equipment must be operated and maintained according to the procedures in this manual. The operating and

maintenance procedures in this manual will apply equally to

both TEH and THH models unless specifically noted. For

simplicity only the TEH designation will be used.

and servicing activities.

This McQuay centrifugal Templifier represents a substan-

tial investment and deserves the attention and care normally given to keep this equipment in good working order. If the

operator should encounter abnormal or unusual operating

conditions, it is recommended that a McQuay Service technician be consulted.

McQuay conducts training for centrifugal operators at its

factory Training Center several times a year. These sessions

are structured to provide basic classroom instruction and include hands-on operating and troubleshooting exercises. For

further information, contact vour

McQuav reoresentative.

MODEL CODE

T EH

~~~;;y~

T

NOMENCLATURE

Each centrifugal Templifier is assigned a set of identifying

numbers which are used to describe the unit features and

to identify each individual unit. These four-number groups

are stamped on each unit nameplate. A typical nameplate

is shown in Figure 1.

The first number is the unit model number, this identifies

the unit. The second is the unit style number, followed by

a serial number and a shop order number (S.O.). The unit

nameplate is also stamped with the type and operating charge

of refrigerant.

All inquiries pertaining to operating and servicing of this

unit should include all identification numbers.

Each of the individual components also have nameplates

to provide certain necessary information to the installer and

the operator.

The compressor nameplate identifies the compressor

model, style and serial numbers and includes the electrical

characteristics of the compressor motor. The CEO50 com-

pressor nameplate also shows the oil pump electrical

characteristics.

The condenser and evaporator vessels have nameplates

stamped with the maximum working pressure of the vessel.

It should be noted that the vessel relief valve maximum settings coincide with the maximum refrigerant side vessel working pressure.

063K AR

FIGURE

1. Unit Nameplate.

MODEL

STYLE

SERIAL

S.O. NO.

~~~~~~~

~

~_.__

FACTORY CHARGED

~_

LSS. REFRIGERANT-

LEAK TEST PRESSURE 100 PSIG.

MOTOR - COMPRESSOR CONTROLLER

AND OVERLOAD PROTECTION FIELD

SUPPLIED. SEE SPEC.

PE-D4

NOMENCLATURE CHANGE: The model nomenclature TPE and TPH has been changed to TEH and THH respectively. TPE

and TPH are synonymous with TEH and THH respectively.

IM 315

I

Page 3

Page 4

OPERATING

The operation of a Templiifer is similar in some ways to that

conventional chiller, Heat is picked up by the evaporator and

transfered to the condenser via the conventional refrigeration cycle. Source fluid temperatures entering the evaporator

are usually higher than chilled water systems, consequently, the water leaving the condenser is at higher temperature

and thereby more useful for heating purposes.

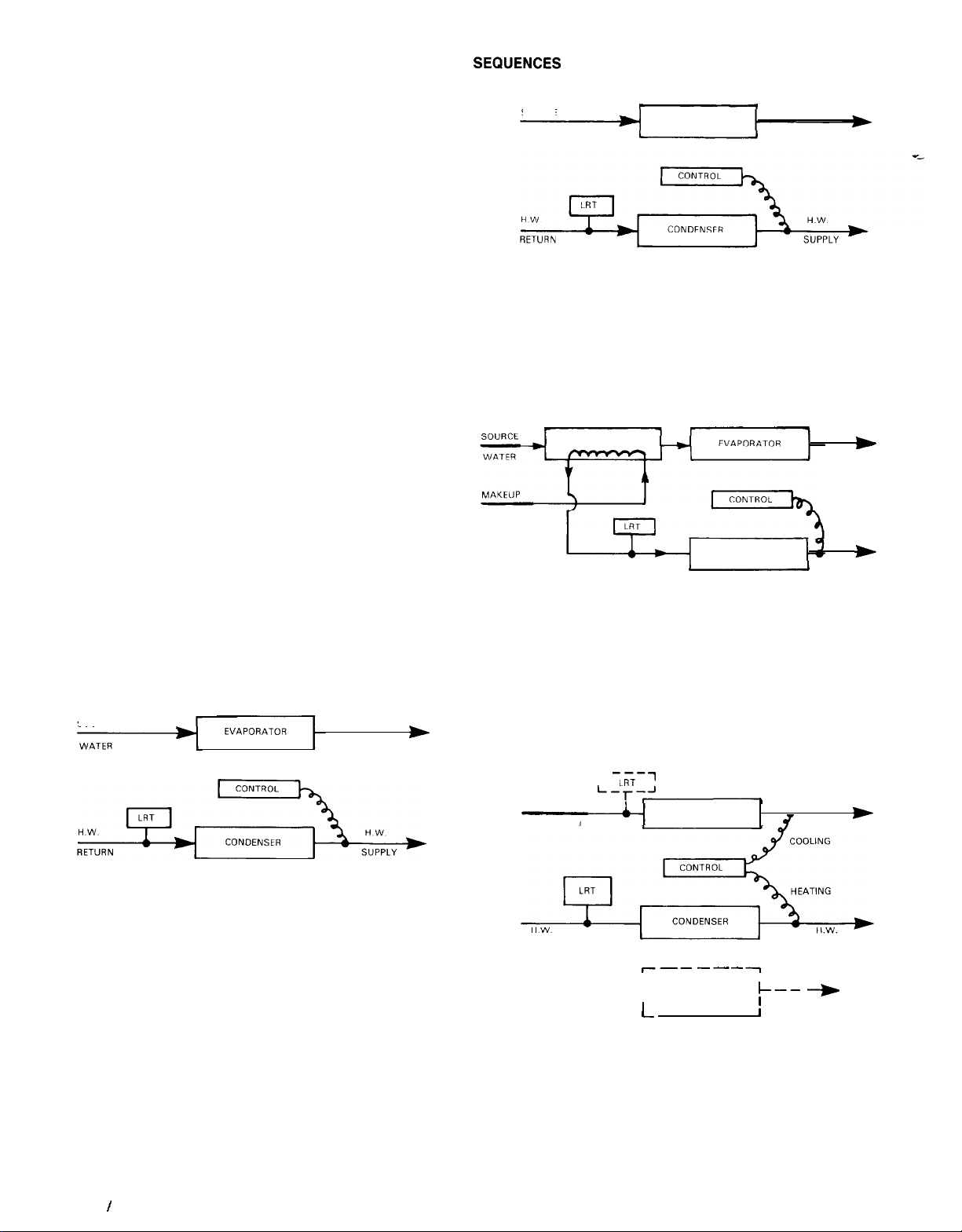

Although there are no two Templifier control schemes ex-

actly alike, there are four basic control arrangements, and

most applications are adapted from one of them. They are:

1. Process or Service Water Heating

2. Environmental Heating

3. Boiler Feedwater Heating

4. Combination Heating/Cooling

When in automatic control mode, the compressor is nor-

mally cycled on and off in responce to a Load Recycling Thermostat (LRT); during operation the compressor capacity is

controlled by as control module located in the control center.

The sensing point for these controls varies with the application. Schematics of the four arrangements are shown in

Figures 2

-

5.

During all phases of operation, the critical functions of the

Templifier are under constant surveillance by the safety controls Abnormal conditions will cause the chiller to be shut

down and usually will require some corrective action to prevent recurrence. A set of panel lights on the control panel

will indicate the cause of shutdown. For the protection of the

equipment, the operator should determine the exact cause

of shutdown and correct the situation prior to operating the

unit again.

PROCESS/SERVICE WATER HEATING

This system is applied to process heat recovery and service

water installations when the requirement is to maintain a constant hot water temperature. The sensor for capacity regulation is located in the condenser leaving water, and the com-

pressor on/off control (LRT) responds to condenser entering

temperature. (See Figure 2).

FIGURE 2.

SOURCE

>

FIGURE 3.

SOURCE

WATER

EVAPORATOR

BOILER FEEDWATER HEATING

This system utilizes a waste heat source to preheat makeup

water for heating

or process

boilers. Capacity control is usually set at maximum design temperature and the Templifier will

normally operate at or near full load to take full advantage

of the available waste heat. The load recycling thermostat

functions more like a safety control since the makeup water

should not rise to cutout temperature. (See Figure 4).

FIGURE 4.

HEAT EXCHANGER

WATER

CONDENSER

w

TO BOILER

*

PREHEATER

COMBINATION HEATING/COOLING

The combination system operates as a chiller for comfort cooling during summer periods and as a heating unit in winter

heating periods. During heating mode, a waste heat source

is channeled through the evaporator. Compressor on/off control is from thermostats (LRT) in the evaporator inlet for cooling and in the condenser inlet for heating. This system is

sometimes fitted with a separate cooling tower condenser for

summer heat rejection. (See Figure 5

FIGURE 5.

r

1~i-i

SOURCE OR

CHW RETURN

EVAPORATOR

).

*

ENVIRONMENT HEATING

For space heating applications, the compressor capacities

may be controlled to maintain a constant return water

temperature. This system effectively varies (or resets) the

temperature of the heating water with system load changes.

Compressor starting is controlled from condenser entering

water temperature, whereas compressor shutdown is signaled from condenser leaving temperature. (See Figure 3).

For the proper operation of the centrifugal Templifier, a

thorough understanding of the control is essential.

The controls are housed for the most part in the Control

Center and in the Lube Box, both of which are mounted on

the Templifier assembly.

Page 4

I IM 315

RETURN

CONTROL SYSTEMS

A complete summary of the control components presented

in Table 1 identifies each control, its location and setting,

along with a brief description of its purpose in the control

scheme. Most of these controls are standard on all units while

a few may be special purpose or optional devices. Using this

-4

------7

OPTIONAL

TOWER

/_

CONDENSER

SUPPLY

I

I--1

--)

Page 5

chart in conjunction with the control diagram shipped with

the unit will aid in understanding the various control modes.

For the purpose of describing the controls, they have been

divided into two categories Operating Controls and

Protective Controls and in each group, certain of the

important controls will be reviewed in some detail. There are

a dozen or so relays in the control center which respond to

another controlling device to open or close circuits. These

relays can be identified by the operator from the control

diagram.

OPERATING CONTROLS

The operating control group consists of devices which serve

specific functions in starting, operating and shutting down

the centrifugal compressor during normal operating conditions. For this description it is assumed that the system conditions monitored by the safety and protective controls are

normal and that those controls are positioned for running.

The ON-OFF switch on the control panel provides a means

of manual control to energize or de-energize the operating

circuit. When this switch is turned on, its self-contained light

will energize and the control circuit is ready for automatic

operation of the compressor.

The Load Recycling Thermostat (LRT) sensing water

temperature will cycle the compressor on the line when the

water temperature reaches the ON control point, and will shut

the compressor down when the water temperature drops to the OFF setpoint. The setting procedure is detailed in the adjustment section of this manual.

To assure that the compressor will not be started too frequently, the Time Delay Relay (TDR) will prohibit a restart

within 20 minutes of the last shutdown. This timing is for the

protection of the compressor motor and is not adjustable. It

is classified as an operating control because it functions as

a part of the starting sequence.

On R12 units, once the TDR contacts close, the oil pump

is started and the Prelube Timer (PLT) is energized to assure

oil pumping and bearing lubrication for a fixed time prior to

compressor start. On

after the vane closed switch (VC) closes. At the same time,

the oil heaters which have been energized during the

compressor-off period are now shut off.

Simultaneous with starting the oil pump, the Oil Cooler

Solenoid (OCS) in R12 units is energized, permitting coolant

to flow through the oil cooler to remove the heat generated

by the compressor bearings once the compressor starts.

When RI 14 is used the OCS is energized simultaneously with

oil pump starting providing the vane closed switch (VC) is

closed.

For R12 units at the end of the prelube period the control

circuit is completed up to the Vane Closed switch (VC) which

monitors the position of the compressor capacity control

vanes. This switch permits compressor starting only when

the vanes are in the fully closed position. On

prelube period starts as soon as the vane closed switch

closes.

To complete the control circuit for compressor starting, the

pump interlocks and water flow interlocks for the condenser

water and source water must be closed.

Once the compressor is started, the Control Module functions to load and unload the compressor in response to

changes in the water temperature. The Control Module will

be discussed in greater detail in a later section.

As the system toad reduces and the Control Module

unloads the compressor, the compressor will continue to run

until the LRT shuts off the machine when the water

temperature reaches the OFF set point.

The control panel has two lights which indicate the status

of control. The COMP. RUN light shows that the compressor

is running under normal control and the LOAD RECYCLE

light indicates the compressor has been taken off line by a

normal operating control and is waiting for a restart signal.

R114

units the PLT timing starts only

R114

units the

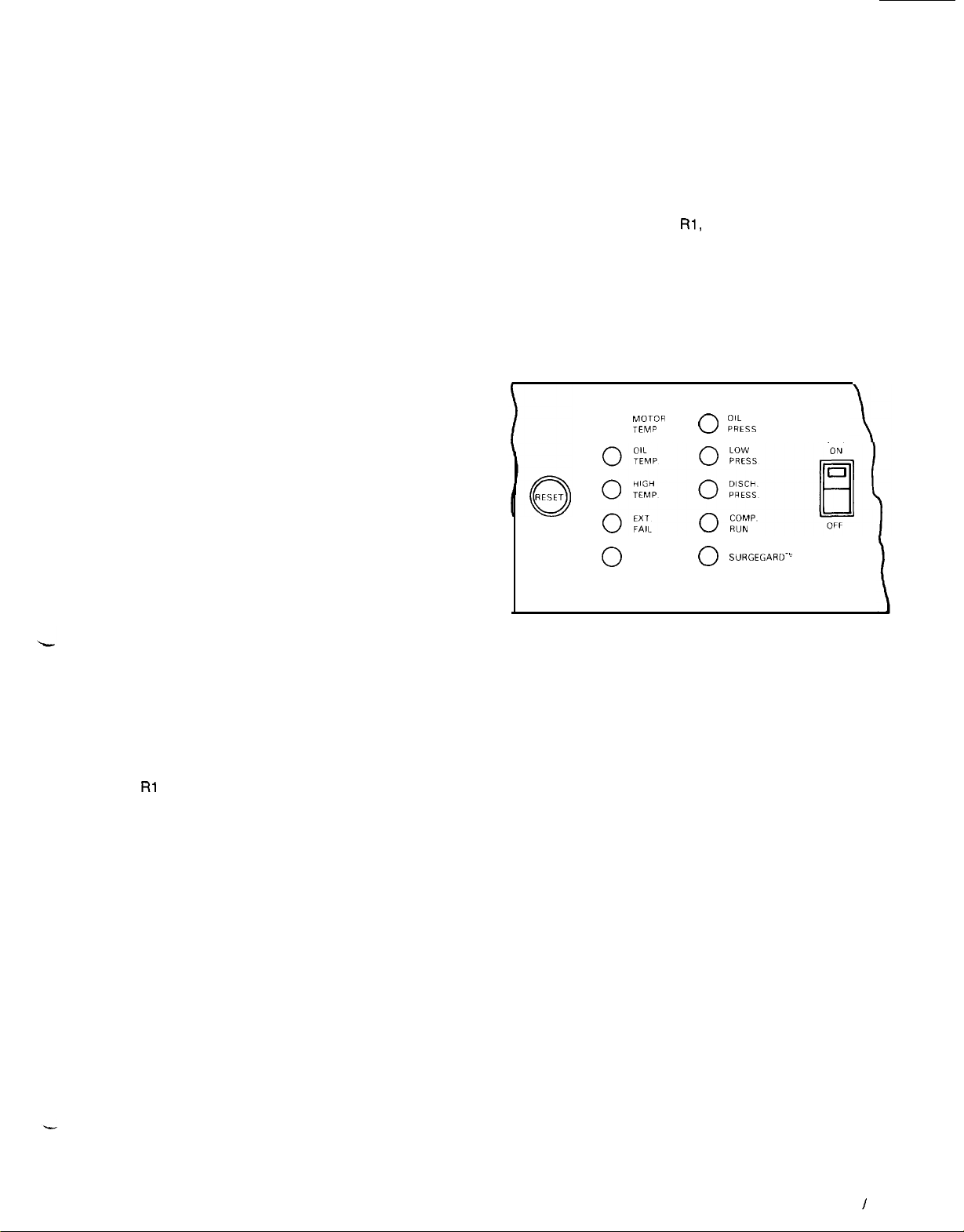

PROTECTIVE CONTROLS

Each McQuay centrifugal Templifier is equipped with a complement of safety controls to prevent the compressor from

starting under adverse conditions or to take the machine offline when abnormal or unsafe conditions develop during

operation.

In addition, there are a number of relay type devices which

operate to assure that the starting, operating and stopping

functions are carried out in proper sequence for the protection of the equipment. These relays can be identified on the

unit control diagram as

The control panel is equipped with several indicator lights

to provide the operator with a quick status condition when

the compressor is shut down. With the reference to Figure

6 it will be noted that there are eight safety signal lights to

describe some condition which has caused the compressor

to be shut down. In a fault condition only one light can be

energized at one time.

FIGURE 6. Control Panel Lights

MOTOR

TEMP

0

LOAD

0

RECYCLE

Most of these indicator lights are operated when some abnormal condition exists with the Templifier unit. Conditions

such as low suction pressure, high discharge pressure, low

oil pressure or temperature, high motor winding temperature

and surge condition may cause some damage to the equipment if allowed to continue uncorrected.

The troubleshooting guide on page 19 gives the operator

a comprehensive list of fault conditions and the probable

causes. This guide should be consulted whenever the com-

pressor is shutdown by a protective control.

Each unit is equipped with an “External Failure” light on

the control panel. When energized, this signal indicates the

compressor cannot run due to a control problem external to

the control panel. Faults in the condenser water/source water

circuits or in the compressor starter could trigger such an external failure signal. This feature helps the operator locate

control system problems. Causes and corrective actions are

further described in the troubleshooting guide.

The two most severe failures which can occur in a hermetic

centrifugal compressor are surge conditions and motor

failure. McQuay has developed highly reliable protective

systems to guard against both of these failures. An understan-

ding of each will be helpful to the operator in analyzing the

unit performance. Both Guardistor and Surgegard are safe-

ty protective systems developed by McQuay.

Guardistor Motor Protection-Positive protection against

motor overheating is provided by the Guardistor system. The

heart of the Guardistor protective circuit are the thermistors

embedded in the motor windings to sense motor winding

temperature. When the motor temperatures are normal, the

thermistors have low resistance which remains nearly cons-

tant up to a predetermined critical temperature. At this

temperature, a sharp increase in resistance causes the

Rl,

R2,. etc.

0

KS,

0 SURGEGARD-”

UNIT

Guar-

IM

315 I Page 5

Page 6

distor relay to drop out and cause the control circuit to stop

the compressor. Such failure causes a lockout mode requiring manual reset.

Surgegard-McQuay

uses Surgegard to sense the occurrence of surge condition and to stop the compressor before

the machine is damaged. The Surgegard relay will also prevent the compressor from restarting until the cause of the

malfunction has been corrected. Possible causes for surge,

or rotating stall condition, may be dirty condenser tubes or

cooling tower or pump malfunction, which acts to elevate the

system’s head. The Surgegard relay is the safety control

which shuts shuts off the compressor under abnormal conditions in the

TEH063,

079, 087, 100 and 126 Templifiers.

In the TEH050 the high temperature thermostat provides this

safety function. These controls are factory set and require

no field adjustment.

SAFETY CONTROL RESET

Certain safety controls in the Templifier control panel will lock

out automatically when operating conditions exceed trip set-

tings. As an example, if the refrigerant discharge pressure

leaving the compressor exceeds the trip setting of the high

pressure cutout switch, the compressor will be taken off-line

and cannot be restarted until the pressure has returned to

normal and the high pressure cutout has been manually reset.

In the control center several other safety functions also lock

out under abnormal operating conditions. These controls include the low pressure cutout, high discharge temperature

thermostat, high oil temperature switch, low oil pressure, high

suction temperature switch

(TEH/THHO63-126)

and external system failure.

(TEHITHH050 only), Surgegard

Each of these fault signals can be identified by the control

panel lights and all can be reset with the single RESET but-

ton on the front of the control panel when the fault has been

corrected.

In the event of electrical system power interruption, the

Templifier units

will lock

out and will not restart automatical-

ly. The EXT. FAIL light will go on when power is restored and

the RESET button must be manually reset to restore

automatic operation.

CONTROL COMPONENT SUMMARY

CONTROL

Alarm Relay

Chiller Pump,

Waterflow Interlocks Supplied

Cold Oil Temperature

Switch Section Temp.

Condenser Pump,

Waterflow Interlocks Supplied

Flow Switch

Time Delay

Guardistor Relay

Hot Gas Override

Solenoid

Hot Gas Solenoid

Hot Gas Thermostat

High Oil Temperature

Switch Temo. lR12) Section Temo. ina

High Pressure Switch

High Suction Temp.

Switch

High Discharge

Temp. Switch

Interval On Timer

Low Casting Temp.

Thermostat

Liquid Injection

Solenoid

Load Meter

Low Oil Temp.

Thermostat

Low Pressure

Switch

Pumpdown

Switch

Law Pressure

Override Switch

Control

SYMBOL SETTING

R9

CHWI None

COT

CWI

FSTD None

GR None

HGO None None

HGS None None

HGT

HOT

HP See Manual Switch

HST

HT

IOT

LCT

LIS

LM

LOT

LP

LPC

LPO

None

105°F Auto/Man

None

Field Set

140°F

Function Section Press.

150°F Auto/Man

225°F

Field Set

110°F

None None

None None Panel

130°F Auto

See

Function

2-5 psig Auto Side of

above LP

2 psig Auto

above LP

RESET

(Note 1)

Auto/Man

Auto/Man

Auto/Man

Auto

Auto/Man

None

Manual Switch

Manual Switch High

Ngne

Auto Temp.

Manual Switch

LOCATION

Relay

Section

Field Ext.

Switch

Field Ext.

Relay

Section

Relay

Section

Hot Gas

Piping

Hot Gas

Piping

Condenser

Frame

Temp.

Section

Section Temp.

Lead/Lag

Box

Section Temp.

Refrig.

Pipinq

Temp.

Section

Section

Panel one-time pumpdown

Switch None

Section

Surgegard Stops compressor when suction temperature exceeds setting prevents

SIGNAL

LIGHT

None

Fail

Oil

Fail

Ext.

Fail

Motor

Temp.

None

None

None

Oil

Disch.

None

Oil

None

None

Oil

Temp.

LOW

Press.

None

-

STANDARD APPLICATIONS

Actuates circuit for remote alarm.

Prevents chiller operation

flow is established.

Stops compressor if oil temperature entering compressor drops below

setting.

Prevents chiller operation until condenser water pump is energized

and flow is established.

Delays water flow bypass for three seconds to prevent false shutdown

Stops compressor motor when winding temperature exceeds limit.

Opens hot gas bypass at starting of 2nd compressor oil pump to

reduce starting head. Dual compressor units only.

Opens hot gas bypass from discharge to evaporator, providing false

evaporator load. Helps prevent surge conditions.

Energizes hot gas solenoid on drop in water temperature entering

evaporator (senses entering condenser water in Templifier).

Stops compressor if oil temperature entering compressor exceeds

Stops compressor when discharge pressure exceeds setting. Set

lo--12

ceed 90% condenser nameolate maximum warkina oressure).

camoressor surae

Stops compressor when discharge gas temperature exceeds setting.

Actuates circuit for

time delay.

Assures minimum compressor casting temperature at startup.

(CE126 compressor only).

Opens liquid injection valve after compressor starts-standard on

CE126.

Displays percent of full load amps when compressor runs

Prevents compressor start with cold oil. Set as high as conditions

allow. Protects compressor bearings from refrigerant diluted oil.

Stops compressor when suction pressure drops below setting. Set

5 psig below shop order suction pressure.

Stops compressor when suction pressure setting is reached-part of

Overrides control module, unloads compressor when suction pressure

approaches setting of LP cutout-prevents nuisance trip.

FUNCTION

unttl

chilled water pump is energized and

R114

Templifiers only.

(reset auto/man with

psig above design saturated condensing pressure (not to ex-

(Optional for

R114

Temolifiers).

(CEO50 comoressor onlv).

specific

time and returns to normal position after

CEO63

079, 087, 100) (Not used on R114 units).

control feature-SEH units only.

set

Page 6 I IM 315

Page 7

Continued. CONTROL COMPONENT SUMMARY - STANDARD APPLICATIONS

CONTROL

SYMBOL SETTING

RESET

(Note 1)

LOCATION

SIGNAL

LIGHT

FUNCTION

Load Recycle

Thermostat

Liquid Line Solenoid

Valve

Oil Pump Contactor

Motor Control

Relay

Motor Cooling

Solenoid

Valve

Oil Cooler

Solenoid

Oil Pressure

Diff. Switch

011 Pump

Overload

Oil Pump Safety

Timer

Oil Pump Time

Delay Switch

Pushbutton Switch

Prelube

Timer

Protective Signal

Interlock

Phase Voltage Relay

Range Shift

Resistor

Capacity Control

Solenoid

Capacity Control

Solenoid

Starts Counter

Surgegard Relay

System Monitor

Timer

Sump Oil

Thermostat

Sequence Relay

Source Water

Thermostat

Anti-Recycle Time

Delay Relay

Transition Resistor

Protector

Pilot Expanasion

Valve Solenoid

Vane Closed

Switch

Vane Delay

Contacts

Voltage Relay

NOTE

#l.

Auto-This control automatically resets itself.

Auto/Man-This control automatically resets itself but electrical lockout

NOTE X2. This table contains all standard and most optional control components used in McQuay centrifugals. All listed controls are not necessarily used on

all units. Controls for specific units can be identified by

Field Set

LRT

LS

IM

MCR

MCS None None

ocs

OD

OL

OPT

OTDPB60 sec.

PLT

PS

PVR

RSR

SA None

SB

SC

SGR

SM

SOT

SR None None Field

SWT

TDR

TRP

TXS

vc 40 psig

VD

VR Non-

None None Field

None None Relay

None None

None None

50 psig Auto/Man

opens

Non-

Adjust.

60 sec.

None

60 sec.

None

None

None

None None Lube

None

Non-

Adjust.

60 sec.

140°F

Field Set

20 Min.

None

None

Differential

None None

Adiust.

None Temp.

Auto/Man

Auto/Man

None

None

None

None

Auto/Man

None Control None

None Lube

None

Auto/Man

Auto/Man

Auto Control

Auto

None

Auto/Man

None

None

None Lube

Section

Supplied

Section

Starter

Refrig.

Piping

Chiller

Pioina

Lube

Lube

Relay

SectIon Press.

Relay

Section

Switch

Section

Relay

Section

Starter

Starter

Module

Panel

Relay

Section

Relay Ext.

Section

SuppIled

Temp.

Section

Relay

Section

Starter

Piping

Lube

Starter

Manual-This control requires manual reset which is done mechanically with RESET button.

Load

Recycle

None

None

Comp.

Run

None

None

Box

Box

Box

Box

Box maintain set temperature.

Box

Box

referrmg

Press.

Press. circuit

None

None

None

Ext.

Fall

Ext.

Fail

Module Part of

Red

Module

Green

None

Surgegard Works with thermistor to sense impeller cavity temperature. Protects

Fail

None

None

Load

Recycle

None

Ext.

None

Press.

None

None

to control diagram and/or the unit control center.

Starts/stops compressor in response to load changes-stops

compressor 3°F below control point. (See TFH manual for

setting.)

Opens on call for cooling or heating. Closes when system thermostat

or controller is satisfied.

Starts oil pump when energized.

Energizes compressor motor starter when unit control circuit is

energized.

Opens to feed

operation.

Opens valve to permit coolant flow during oil pump operation

Oil

Stops compressor when difference between oil and suction pressure

drops to setting. Closes at 60 psig to permit compressor start.

Oil

Stops oil pump and compressor if oil pump motor overloads electric

Stops pump by interrupting safety circuit if vane closed switch fails lo

Oil

close

Keeps pump

Pushbutton switches reset the safety

on the control panel is pushed.

Provides a pre-lubrication period for bearings prior to compressor

start.

De-energizes system monitor

delta contactor

Protects compressor against damage from single phase, phase

sal or undervoltaqe.

Provides temperature range shift for control module on Templifier

units.

on control piston and closes vanes-UNLOAD.

Part of

on control piston and opens vanes-LOAD.

Counts number of compressor starts.

compressor from a surge (CEO63 thru 126).

If compressor fails to start in 60 seconds after system monitor is

energized, system monitor terminates start effort.

On units with refrigerant cooled oil cooler, controls oil sump heater lo

Relay controlled by system thermostat (or other control) to start unit

on call for cooling.

Stops compressor when water temperature entering evaporator is too

low for practical heat recovery.

Prevents compressor from restarting for 20 minutes after previous

shutdown.

Abort compressor starting sequence if starter fails to make transition

from star lo delta within 1 second.

Fail

Opens when 2nd compressor starts, closes when 2nd compressor

stops (TFH063 only).

Oil

Prevents compressor starting unless capacity control vanes are closed

(fullv

unloaded).

Auxiliary contacts in compressor starter prevent compressor loading

and liquid solenoid valves from opening (SEH units only) until compressor motor connected across the line.

Disconnects oil pump motor capacitor affer start (CEO50 only)

circutt

requires that RESET button be pushed to reset the circuit.

ltquid

refrigerant for motor cooling during compressor

withln

60 seconds after oil pump starts.

runnmg

for 60 seconds after compressor is stopped.

4-way solenoid

4-way

valve. When energized, applies full oil pressure

solenoid valve. When energized, applies full oil pressure

ctrcult

when the RESET button

timer

when compressor starter closes

LRTZ

rever-

IM

315 I Page 7

Page 8

CONTROL CENTER

The control panel and compressor lube box contain most of

the operating and protective controls. The control center is

completely prewired and most adjustable controls have been

set during the factory test procedure.

Inspection of the control panel will reveal that it is divided

into three functional sections as shown in Figure 8.

TEMPERATURE SECTION

The temperature section contains the control module and

several thermostats with adjustments accessible with the

panel door open.

RELAY SECTION

The relay section is located behind the large left front door

with the McQuay logo. This section contains the operating

and safety relays and wiring terminal strip. Most relays are

plug-in type and can easily be removed for servicing.

Templifiers using R114 have an auxillary relay section

mounted on top of the standard panel.

SWITCH SECTION

Mounted in the lower section front panel are pressure gauges,

indicator lights, RESET button and the unit ON/OFF switch.

Behind this front panel is the switch section containing several

safety/operating switches and the reset pushbutton switches.

CONTROL MODULE

The McQuay solid-state capacity control module provides

temperature control and current limit control and is equip-

ped with several auxiliary features which provide the operator

with considerable flexibility in system control.

Two switches provide the operator with the options of

automatic or manual load/unload control. The switch positions are:

AUTO This position provides for automatic operation

of the control module to load or unload the

compressor to control water temperature leaving at the sensor location.

MAN Disconnects the automatic temperature con-

trol functions to permit manual control.

LOAD. With switch in MAN, the SB loading solenoid

can be manually energized.

UNLOAD With switch in MAN, the SA unloading

solenoid can be manually energized.

Indicator lights on the module will function as follows:

Red will light during unloading control action, green will light

during loading and amber will light when the load action is

overridden by the current limit control. Red and green can-

not light simultaneously nor can amber and green. Red and

amber indicate current limit has been exceeded by 5% of full

load and will signal “unload” until current is reduced to the

setpoint. Current limit will override manual load control.

A pulse rate adjustment is provided on the control module

to provide a means of matching load or unload speed to suit

the system size. Pulse rate can be set over the range of 2

to 25 pulses per minute and is effective only when the water

temperature is within

4°F

of setpoint. In a large volume water

system a lower pulse rate (i.e., 8 pulses/minute) will provide

adequate control response. Conversely a higher pulse rate

in a small volume system will allow the control to react quickly

to temperature changes.

The controller is also equipped with a Ramp-up function

which can be adjusted to control the loading of a compressor

at start-up. The Start Point setting determines the point at

which controlled loading begins; the Ramp Time setting

establishes the time of controlled loading.

The adjustment knob marked

ly be positioned at

1000/o

“O/o

Current” would normal-

to permit the compressor to fully

load. If the operator desires to limit the motor amperes or compressor capacity for any reason, this control can be set to

limit the motor current to any point between 30% and 100%.

The “Temperature” knob permits setting the condenser

water control point to the desired temperature. However, it

should not be raised above the design point without factory

approval.

Setting and calibration procedures for all functions of the

control module are detailed in the adjustments section of this

manual.

FIGURE 7. Control Panel.

Load

Light

(Green)

Unload Light (Red)

Current Limit

Light

(Amber)

Manual/Auto

Switch

Load; Unload

Switch

Current Limit

Setting

Water

Temperature

Setting

Pulse

Rate

Adjustmen

Current

Limit

Calibration

Ramp

Start

Point

Ramp

Setting

T

‘ime

Page 8

I

IM 315

Page 9

Page 10

CAPACITY CONTROL SYSTEM

The compressor capacity is controlled by the movement of

the inlet vanes, opening or closing to permit the correct quantity of refrigerant to enter the wheel or impeller. The vane

movement occurs in response to oil flow from the SA or SB

solenoid valve which, in turn, respond to a control module

signal. This oil flow activates a piston to rotate the vanes.

VANE OPERATION

The hydraulic system for the vane control operation consists

of a 4-way normally open solenoid valve. Oil under pressure

is directed by the 4-way valve to either or both sides of the

piston depending on whether the control signal is to load,

unload or hold.

FIGURE 9. Vane Control Solenoid, Operation.

FLOATING PISTON

COMPRESSOR

UNLOADER

CYLINDER

LINKED TO INLET VANES

-

OPENS VANES

-

/

CLOSES VANES

-

To open the vanes (or load the compressor) solenoid

“SA”

is de-energized allowing oil flow from port SA to one side of

the piston and solenoid “SB” is energized, allowing oil from

the other side of the piston to drain through port SB.

To close the vanes (unload compressor) valve SB is deenergized and valve SA is energized to move the piston and

vanes to unload position.

When both solenoid valves SA and SB are de-energized,

full oil pressure is directed to both sides of the piston through

ports SA and SB, thus the vanes are held in that position.

Refer to Figure 9 for solenoid action. Note that both solenoids

cannot be energized simultaneously.

LEGEND-

UNDER PRESSURE

SUMP PRESSURE

TO

Oil

-

PUMP

“SB”

“SA”

SUMP

SECTION

DE ENERGIZED

SECTION

DE ENERGIZED

j

CLOSING

DRAIN FROM PISTON

1

--

SECTION

SECTION SA”

_

DE ENERGIZED

SECTION

DC ENERGIZED

DISCHARGE

VALVE

“SB

“SB

DISCHARGE

VALVE

Page 10 I IM 315

DRAINFROM

PlSTON

DISCHARGE

VALVE

Page 11

METERING VALVES

The speed at which the capacity control vanes are opened

or closed can be adjusted to suit system operating requirements. Adjustable needle valves in the oil drain lines

are used to control the rate of bleed-off and consequently the

“vane speed”. These needle valves are part of the

4-way

solenoid valve assembly located in the compressor lube box

(see Figure 10).

The valves are normally factory set so the vanes will move

from fully closed to fully open in approximately 3 minutes and

from fully open to fully closed in 1 minute (except CE126).

The speed should be slow enough to prevent over-controlling

and hunting. For adjustment procedure, refer to the Ad-

justments section of this manual.

OIL SYSTEM

FIGURE 10. Lube Box.

The oil system for the Templifier units provides lubrication

and heat removal for the compressor bearings and internal

parts. In addition, the system provides oil under pressure to

hydraulically operate the piston for positioning the inlet guide

vanes for capacity control.

Proper operation of the hydraulic system and bearing

lubrication system can be assured only if McQuay recommended oil is used. For proper oil selection, consult Figure

11.

Each unit is factory charged with the proper oil. Under

normal operation, no additional oil should be needed.

The oil pump for the CEO50 compressor is completely selfcontained within the compressor housing. The assembly includes the pump, pump motor, oil heater and oil separator.

The oil is pumped through the oil discharge line to the oil filter

in the compressor casting and then to the oil cooler.

The other compressor sizes-CE063, 079, 087, 100 and

126-utilize

a separate oil pump contained in its own oil reservoir. This assembly includes pump, motor, heater and oil

separator. Oil is pumped through the discharge line, through

the external oil cooler and then to the oil filter inside the compressor housing. Standard

TEH/THH

063-126 units utilize

a water-cooled oil cooler although an optional refrigerantcooled oil cooler is available.

The oil coolers serve to maintain the proper oil temperature

under normal operating conditions. In Templifiers using

Refrigerant 12, the coolant flow control valve should main-

tain

9O”F-120°F

oil temperature leaving the oil cooler for

optimum operation of the oil system. Those units with

Refrigerant 114 operate at higher oil temperatures and are

equipped with special controls.

Bearings are supplied with oil through internally drilled

passages within the compressor assembly. The oil drains

from the bearings into the gear housing and is gravity returned

to the oil sump.

The oil heaters in the gear case and in the oil pump reser-

voir must remain energized whenever the compressor is off.

IN THE EVENT OF POWER LOSS TO THE HEATERS

ALLOWING THE OIL TO COOL, THE HEATERS SHOULD

BE ENERGIZED FOR 24 HOURS PRIOR TO STARTING

THE COMPRESSOR.

A low oil temperature thermostat (LOT) in the control center

prevents the oil pump from starting with cold sump oil. This

thermostat should be set as high as ambient conditions will

allow. This is an automatic reset device and, when tripped,

will cause the OIL TEMP light to glow. In refrigerant 114 units

the high oil temperature thermostat (HOT) and the cold oil

temperature thermostat (COT), monitor the temperature of

the oil flowing to the compressor during the running mode.

They are electrically interlocked and must be reset manually with the reset button on the control panel if the oil

temperature exceeds the settings.

The compresssor is equipped with lubrication protection

for coast down in the event of a power failure. This is accomplished by the use of a spring loaded piston in models

CEO50 thru 100. When the oil pump is started, the piston is

forced back by oil pressure, compressing the spring and filling the piston cavity with oil. When the pump stops, the spring

pressure on the piston forces the oil out to the bearings.

In model CE126 the compressor coast down lubrication is

supplied from a gravity feed lube reservoir.

FIGURE

11. Oil for Centrifugal Compressors.

HOT GAS BYPASS

All Templifiers are equipped with a hot gas bypass system

4

used to feed discharge gas directly into the evaporator when

the system load falls below a prescheduled minimum

com-

pressor capacity.

Light load conditions are signaled by a thermostat (HGT)

sensing return water temperature entering the evaporator.

This thermostat energizes the hot gas solenoid (HGS). This

introduction of hot gas provides a stable refrigerant flow and

keeps the machine from short cycling under light load

conditions.

IM 315

/

Page 11

Page 12

OPERATING THE TEMPLIFIER

The initial startup of the McQuay centrifugal Templifiers after

all installation is complete must be performed by a factory

trained McQuay Service technician.

The following procedures apply to normal daily operation

of the equipment. In cases of continuous operation, the

operator should make operational checks on the equipment

at least once each day.

PRELIMINARY CHECKS BEFORE STARTING

Prior to attempting to start the Templifier, the operator should

make a series of routine checks of the equipment to assure

that all components are ready for operation.

1.

Assure that power has been on to the oil heaters since

shutdown. An EXT FAIL light on will signal if power has

been interrupted and has been restored.

2.

Check oil sump by hand touch to see that oil heaters have

been energized during the shutdown. Check position of

all valves to assure valves are open for operation.

Verify that all condenser and chilled water valves are in

3.

proper starting mode.

All safety indicator lights on the control panel should be

4.

out for proper starting mode. If any light is on, consult the

Troubleshooting Guide.

Visually check the oil level in the sightglass. In the

5.

TEH/THH050 units, this sightglass is in the front end of

the compressor; all larger units have this sightglass as part

of the oil pump.

STARTING THE TEMPLIFIER

Start the evaporator and condenser water pumps and

verify that proper flow has been established.

Position the ON-OFF switch on the control panel to the

ON position. A self-contained light will glow.

Assuming that the condenser water temperature is below

the setting of the Load Recycling Thermostat (LRT), and

the source water temperature is above the setting of the

source water thermostat (SWT) and the unit has been off

more than 20 minutes, the pump will start.

After the prelube operation of the oil pump and all interlocks verify condenser water flow, the compressor will

be started and the COMP RUN light on the control panel

will glow.

The control module will take over load/unload functions

in response to condenser water temperature. Normally,

the compressor will load to full load according to the set-

tings of the control module ramp-up control.

OPERATING CHECKS

1. While operating under automatic control, the operator

should observe the discharge, suction, and oil pressure

and verify that these pressures are normal. For R12 units,

discharge pressure can range from 100 psig to 225 psig

and suction pressure from 35 psig to 90 psig, depending

on load conditions and system operating characteristics.

Normal operating presures with

R114

systems are

FIGURE

12.

TEH-063

1.

CEO63 Compressor

2. Evaporator

3. Condenser

4. Relief Valves

5. Control Panel

6. Lube Box

Page 12 I IM 315

7.

Oil Pump

8. Oil Level Sight Glass

9.

Discharge Line

10.

Hot Gas Bypass

11.

Expansion Valve

12. Liquid

Lme

Shut-Off Valve

LEGEND

13.

Oil Cooler

14. Motor Liquid

15.

Motor Terminal Cover

16.

Discharge Check Valve

Coolmg

Line

Page 13

discharge 85 psig to 210 psig and suction 15 psig to 50

psig. (Refer to refrigeration charts, Figure 15). Oil pressure

must be 50 psig above suction pressure to keep the com-

pressor on line. Normal oil pressures are: CEO50

to 175 psig;

-

100 psig. All pressures are oil gauge reading minus suc-

CE063,079,087,100 -

120 psig; and

-

CEI

150

26

tion gauge reading.

2. Observe the loading and unloading of the compressor by

the red and green lights on the control module. If short

cycling, refer to the Troubleshooting Guide (see page 19).

3. Each time the compressor is shut down on control of the

Load Recycle Thermostat, the LOAD RECYCLE light will

glow, if all other conditions are normal.

4. Once the controlled water temperature has stabilized and

the compressor is intermittently loading or unloading at

less than full load, compare the water temperature with

the module setpoint. If different, consult the

Troubleshooting chart (see page 19).

5. Occasionally check the panel lights. The compressor

should not run if any of the eight safety lights are

energized.

SHUTDOWN

Stopping the unit at night or for weekends can be easily accomplished by switching the ON-OFF switch on the control

panel to the OFF position. The switch light will go out and

the compressor will stop.

The oil pump will continue operating for 60 seconds after

the compressor starter is de-energized to assure lubrication

to compressor bearings during spin-down.

Once the switch is turned off, the compressor cannot be

restarted unless the switch is repositioned.

If the operator has the need to secure the Templifier and

prohibit starting by unauthorized personnel, removal of relay

R7 from its plug-in base in the control panel will open the

protective circuit and immobilize the unit. In this condition,

none of the control panel lights are energized and the oil

heater circuit is still operative. Relay R7 is identified in Figure

8. When relay R7 is replaced, the EXT. FAIL light will come

on and the RESET button must be pushed to restore the safety circuits to the operating mode.

FIGURE

13. THH-063 HEAT

RECOVERY DUAL CONDENSER

TEMPLIFIER

1.

CEO63 Compressor

2. Oil Pump

3.

Oil Cooler

4. Hot Gas Bypass

5. Discharge Check Valve

6.

Evaporator

LEGEND

7. Heat Rejection Condenser

8. Heat Recovery Condenser

9. Condenser Relief Valves

10. Evaporator Relief Valve

11.

Motor Terminal Cover

12 Oil Filter

13. Lube Box

14. Control Panel

15. Motor Cooling

16. Expansion Valve

17. Compressor Suction

Lrquid

Line

Lme

IM 315 I Page 13

Page 14

FIGURE 14. TEH 126

7.

1.

CE126 Compressor

2.

Motor Terminal Cover

3.

Lube

Box

4. Oil Coolers

5. Expansion Valves

6. Liquid Line Shut-Off Valve

Evaporator

Condenser

8.

9.

Control Center

10.

Discharge Check Valve

11.

Oil Pump

12. Oil Level Sight Glass

MAINTENANCE

ROUTINE MAINTENANCE

LUBRICATION (See CAUTION)

After the system is once placed into operation, no other additional oil is required except in the event that repair work

becomes necessary to the oil pump or unless a large amount

of oil is lost from the system due to a leak.

If oil must be added with the system under pressure, use

a hand pump with its discharge line connected to the service valve at the bottom of the oil pump.

pressor with its internal oil pump is equipped with an oil service valve on the compressor).

Units using R114 should have a complete oil change at

least once a year along with the filter change.

CHANGING OIL FILTERS (See CAUTION)

CEO50 Compressors-If the unit is equipped with a suction

line service valve, close this valve and close the valve on the

motor cooling liquid line to isolate the compressor. Vent the

refrigerant pressure from the compressor. Remove the filter

cover and the old filter and install the new filter, open end

first. Replace the cover using a new gasket. Reopen the suction and liquid line valves.

If the unit is not equipped with a suction line service valve,

the unit will have to be pumped down in order to remove the

pressure in the compressor before removing the cover and

changing the filter. Refer to later section for

procedure.

(The

CEO50 com-

pumpdown

LEGEND

13.Oil

Sump

Cooler

WaterLines

14.Oil

15. Motor Liquid Cooling Line

16. Condenser Relief Valves (Hidden)

CEO63 and Larger Compressors-The oil filter in each of

these machines can be changed by simply isolating the filter

cavities. Close the oil discharge line service valve at the oil

pump (at the filter on CE126). Remove the filter cover; some

foaming may occur but the check valve should limit leakage

from other compressor cavaties. Remove the filter, replace

with new element and replace filter cover using new gasket.

Reopen valve in pump discharge line.

When the machine is operated again, the oil level should

be checked to determine if oil needs to be added to main-

tain proper operating level.

CAUTION

Improper servicing of the lubrication system, including

the addition of excessive or incorrect oil, substitute

quality oil filter, or mishandling of the equipment under

pressure is hazardous. Only authorized and trained service personnel should attempt this service. For qualified

assistance, contact your local McQuay Service

technician.

Page 14

I

IM 315

Page 15

REFRIGERANT CYCLE

Maintenance of the refrigerant cycle consists of maintaining

a log of the operating conditions, and assuring the unit has

the proper oil and refrigerant charge.

At every inspection, the oil, suction and discharge

pressures should be noted and recorded, as well as condenser and evaporator water temperatures. Assuming water

flow is correct, this confirms correct refrigerant charge. Correct suction pressure will be indicated by reference to past

suction readings on the same unit.

The suction line temperature at the compressor should be

taken at least once a year. Subtracting from this, the saturated

temperature equivalent of the suction pressure will give the

superheat. Extreme changes in superheat over a period of

time will indicate losses of refrigerant or possible deterioration of the expansion valves. Proper R12 superheat setting

is

2” to 6°F at full load. Corresponding

R114

superheat is

8” to 10°F.

ELECTRICAL SYSTEM

Maintenance of the electrical system involves the general re-

quirement of keeping contacts clean and connections tight

and checking on specific items as follows:

1. The compressor current draw should be checked and compared to nameplate RLA value. Normally the actual cur-

rent will be lower since the nameplate rating represents

full load operation. Also check all pump and fan motor

amperages and compare with nameplate ratings.

2. Inspection should verify that the oil heaters are operative.

The heaters are insert cartridge type and can be

checked by ammeter reading. They should be energized

whenever power is available to the control circuit and

com-

pressor is inoperative. When the compressor starts the

heaters are de-energized.

At least once a year, all safety controls except compressor

overloads should be made to operate and their operating

points checked. Any control may shift its operating point

as it ages, and this must be detected so the controls can

be readjusted or replaced. Pump interlocks and flow switches should be checked to assure they interrupt the control circuit when tripped.

Contactor in the motor starter should be inspected and

cleaned annually. Tighten all terminal connections.

The compressor motor resistance to ground should be

checked and logged annually. This log will track insulation deterioration. A reading of 5 megohms or less indicates possible insulation failure and should be further

checked.

The centrifugal compressor must rotate in the direction

indicated by the arrow on the casting near the rotation

sightglass. If the operator has any reason to suspect that

the power system connections may have been altered, the

compressor should be jogged to check rotation. For

assistance, call McQuay Service.

CLEANING AND PRESERVING

A common cause of service calls and equipment malfunction is dirt. This can be prevented with normal maintenance.

Insulation should be inspected regularly and repaired as

necessary.

Remove and clean strainers in the evaporator water

system, water cooled oil cooler line and condenser water

system at every inspection.

SEASONAL SERVICING

Prior to shutdown periods and before starting again, the

following service procedures should be completed.

untreated water may result in corrosion, erosion, sliming,

scaling or algae formation. It is recommended the service

of a reliable water treatment firm be obtained to determine

ANNUAL SHUTDOWN

1.

Templifiers are normally used nearly year round. If the

Templifier system may be subject to freezing temperature

during a shutdown, care should be taken to remove all

water from the vessels and piping to prevent damage to

the equipment.

2.

Take measures to prevent the shutoff valve in the water

supply line from being accidentally turned on.

3.

If a cooling tower is used and if the water pump will be

exposed to freezing temperatures, be sure to remove the

pump drain plug and leave it out so that any water which

may accumulate will drain away.

4.

Open compressor disconnect switch, and remove

Fusetrons. If transformer is used for control voltage, the

disconnect must remain on to provide power to oil heater.

Set compressor switch to OFF position. To insure against

the possibility of an accidental start, remove relay R7 in

each control panel.

Check for corrosion and clean and paint rusted surfaces.

5.

Clean and flush water tower for all units operating with

6.

a water tower. Make sure tower “blowdown” or bleedoff

is operating. Set up and use a good maintenance program

,

to prevent “liming up” of both tower and evaporator (or

condenser if unit is used for cooling). It should be recognized that atmospheric air contains many contaminants which

increase the need for proper water treatment. The use of

what treatment is required. McQuay assumes no responsibility for the results of untreated or improperly treated

water.

7. Remove condenser and evaporator heads at least once

a year and clean tubes.

ANNUAL STARTUP

A dangerous condition can exist if power is applied to a faulty compressor motor starter which has been burned out. This

condition can exist without the knowledge of the person start-

ing the equipment.

This is a good time to check the motor winding resistance

to ground. Annual checking and recording of this resistance

will provide a record of any deterioration of the winding insulation. All new units have well over 100 megohms

resistance between any motor terminal and ground.

Whenever great discrepancies in readings occur or uniform

readings of less than 5 megohms are obtained, the motor

cover should be removed for inspection of the winding prior

to starting the unit. Uniform readings of less than 5 megohms

indicate motor failure is imminent and motor should be replaced or repaired. Repair before failure occurs can save a

great deal of time and labor expended in the cleanup of a

system after motor burnout.

1. The control circuit should be energized at all times, except when the unit is being serviced. If the control circuit

has been off and the oil is cool, energize the oil heaters

IM 315

I

Page 15

Page 16

and allow 24 hours for heater to remove refrigerant from

the oil before starting.

2. Check and tiahten all electrical connections.

3. Install Fusetrons in the main disconnect switch (if

removed).

I

REPAIR OF SYSTEM

4. Reconnect water lines and turn on supply water. Flush out

evaporator and check for leaks. Purge any air in the

system.

5. Refer to the procedures of “Preliminary Checks Before

Starting” before energizing the compressor circuit.

PUMPING DOWN

If it becomes necessary to pump the system down, extreme

care should be used to avoid damage to the water circuits

due to freezing. Always make sure that full water flow is maintained through the evaporator while pumping down. To pump

system down, close all liquid line valves. With all liquid line

valves closed and water flowing through evaporator, start the

compressor. In order to pump system down as far as possi-

ble, it will be necessary to bypass the low pressure override

switch and jumper the low pressure cutout. Set temperature

module to manual load position. Vanes must be open while

pumping down to avoid a surge or other damaging condition.

Operate machine until the suction pressure stabilizes at

approximately 20 to 25 psig

(R12),

2 to 5 psig

(R114).

Stop the machine. Allow pressure to build up. Repeat this

procedure 3 times.

After the system has been pumped down, the gas pressure

remaining will have to be purged before the machine can be

serviced.

PRESSURE TESTING

No pressure testing is necessary unless some damage was

incurred. After repairs are made, pressure test the system

at a pressure that does not exceed the standby pressure in

the condenser. (A test pressure higher than condenser

pressure would open the discharge check valve and allow

flow of test pressure into condenser). In cases where the entire refrigerant charge is lost, refer to the following paragraphs. The evacuation procedure can be followed in both

cases.

LEAK TESTING

In case of the loss of the entire refrigerant charge, the unit

should be checked for leaks prior to charging the complete

system. This can be done by charging only enough refrigerant

into the system to build the pressure up to approximately 10

psig and adding sufficient dry nitrogen to bring the pressure

up to a maximum of 125 psig and then leak test with Halide

or electronic leak detector. CAUTION: DO NOT USE OXYGEN TO BUILD UP PRESSURE AS A SERIOUS EXPLOSION CAN RESULT. A pressure regulating valve should

always be used on the drum being used to build the system

pressure. Also, do not exceed the test pressure given above.

When the test pressure is reached disconnect the gas

cylinder.

If any leaks are found in welded or brazed joints or if it is

necessary to replace a gasket, relieve the test pressure in

the system before proceeding. For copper joints, braze alloy

is recommended.

After making any necessary repair, the system should be

evacuated as described below.

EVACUATION

After it has been determined that there are no refrigerant

leaks, the system should be evacuated using a vacuum pump

with a capacity of approximately 3 cu. ft/min. and that will

reduce the vacuum to at least 1 millimeter (1000 microns).

A mercury manometer, electronic or other type of micron

gauge should be connected at the farthest point from the

vacuum pump. For readings below 1 millimeter, the electronic

or other micron gauge should be used.

The triple evacuation method is recommended and is particularly helpful if the vacuum pump is unable to obtain the

desired 1 millimeter of vacuum. The system is first evacuated

to approximately 29 inches of mercury. Enough refrigerant

vapor is then added to the system to bring the pressure up

to zero gauge pressure. Then the system is once again

evacuated to approximately 29 inches of mercury. This is

repeated 3 times. The first pull down will remove about 90%

of the noncondensables, the second pull down will remove

about 90% of that remaining from the first pull down and after

the third, only

l/IO

of 1% non-condensables will remain.

REFRIGERANT CHARGING

The McQuay Templifiers normally use R-12, or R-114

refrigerants; however, it is recommended that the operator

check the unit nameplate to assure the correct refrigerant

selection prior to charging or adding refrigerant.

An initial operating charge is made at the factory prior to

shipment. In the event the operator needs to add refrigerant

after the unit is installed, certain precautions should be taken

to protect equipment components. Refrigerant charging lines

must be kept dry, clean and free of non-condensable gases.

Care should be taken in selecting the best charging point in

the unit so as to protect the equipment from damage.

If the entire charge is lost or removed from the unit, recharg-

ing can be accomplished quickly and safely by introducing

the liquid refrigerant directly into the bottom of the evaporator

with the expansion valve manually opened. Both condenser

water and evaporator water must be flowing through the

respective vessels to prevent localized freezing. Consult the

Templifier nameplate for the proper refrigerant charge.

The normal ambient pressure of R114 is so low that a

refrigerant pump may be helpful in charging the system.

With a near-normal charge in the system, final charging

can best be accomplished with the unit running with the com-

pressor al full load. In this operating mode the unit should

be charged until suction superheat is between

(R12), 8”

to 10°F

(R114)

adjusting the thermal expansion

valve as necessary. Continue charging until the liquid

2”

to

6°F

subcooling is as listed on the startup sheet (or design

specification).

PRESSURE RELIEF VALVE REPLACEMENT

Current condenser designs use two relief valves (1 set)

separated by a three-way shutoff valve. In the event one of

the relief valves is leaking on the two valve set, the following

procedures should be followed:

If the valve closest to the valve stem is leaking, back seat

the three-way valve all the way, closing the port to the leak-

ing pressure relief valve. Remove and replace the faulty relief

valve. The three-way shutoff valve should remain either fully

back seated or fully forward for normal operation. If the relief

valve furthest from the valve stem is leaking, front seat the

three-way valve and replace the relief valve and replace the

relief valve as stated above.

‘age 16

I

IM 315

Page 17

EQUIPMENT WARRANTY

Each

TEHlTHH Templifier manufactured by

a standard limited warranty. This warranty covers repair or

replacement of component parts which prove defective in

.

material or workmanship within 12 months from initial

McQuay

carries

startup or 18 months from date shipped by the company,

whichever comes first.

For a complete description of this warranty refer to the

ranty form furnished with the equipment.

war-

FIGURE 15.

TEMPLIFIER REFRIGERANT CHARTS

ADJUSTMENTS

ADJUSTING AND CALIBRATING

CURRENT LIMIT CALIBRATION

The current limit feature of the control module functions to

limit the maximum compressor motor current and is set at

100% amperes with the compressor at full load. The following procedure will properly set this feature:

1. Remove the cover from Control Module. (See Figure 7).

2. Place the AUTO/MAN switch in MAN position. This switch

position effectively disconnects the temperature control

function and permits manual loading and unloading of the

compressor.

3. Adjust the Ramp Up Start Point to 100 (fully counterclockwise) and set Ramp time to MIN (fully clockwise).

4. Rotate Percent Current knob fully clockwise.

5. Using the LOAD/UNLOAD switch, manually load the com-

pressor until the motor current is at rated load amperes.

(Refer to RLA on compressor nameplate).

6. With full load current on the motor, adjust the blue CUR-

RENT CAL. potentiometer in a clockwise rotation until the

amber light on the module comes on. If the red unload

light comes on, back off the setting until only the amber

light is lit. A quick check can be made with a voltmeter

across terminals OP2 and COM of the module. This

voltage should be about 10 VDC.

7. Stop compressor, rotate metal indicator on percent current shaft to 100% on the scale. Install cover to module,

remove end cap from percent current knob, loosen

knob/shaft screw and align the knob indicator line with

100% on the module cover.

TEMPERATURE CALIBRATION

The control module has been factory calibrated and normal-

ly requires no field calibration. If field calibration becomes

necessary or a calibration check is desired, remove the cover

and proceed as follows:

Place AUTO/MAN switch in MAN position.

Operate Templifier loading and unloading manually until

the temperature of the condenser water is steady at the

desired control point using a reliable thermometer.

Switch the AUTO/MAN switch to AUTO position and quick-

ly position the TEMPERATURE knob to a position where

both the LOAD and UNLOAD lights are off. A voltmeter

between terminals 101 and COM on the upper terminal

strip of the module should read 7.5 volts

the adjustable temperature control pot is set at the actual

chilled water temperature.

Check the pointer on the shaft against the temperature

scale. It should read the same as the water temperature;

d.c.

In this mode

IM 315

I

Page

17

Page 18

if not, rotate the pointer to the proper setting without disturbing the shaft

Install cover on module and check knob

5.

positon.

positon;

the mark

should line up with the water temperature. If adjustment

is necessary, remove end cap from temperature knob,

loosen knob/shaft screw and make proper scale alignment.

RAMP-UP CALIBRATION

The ramp-up functions to control the loading of the compressor at startup and is initiated automatically each time the

compressor starts. Ramp-up ends when the selected time expires or when the chilled water temperature reaches the controller setpoint.

A maximum ramp-up time of 45 minutes is achieved by setting the START POINT at 0% LOAD and the RAMP TIME

at MAX. Both settings are made on the two dashpots so

marked on the right side of the module. (See Figure 7).

Any combination may be set to control the loading rate to

suit the system requirements. Obviously a START PT setting of 100% effectively voids the ramp function.

It should be remembered that the ramp-up feature controls

the compressor loading by temporarily resetting the current

limit. This override action can be observed during Ramp-Up

control by the alternate lighting of the amber current limit

signal and the green load signal.

Actual ramp-up time with the condenser water temperature

above the control point is determined by the formula:

Ramp-Up Time (min.) =

%

Current - % Start Point) x 45 x Ramp Time Setting

Example:

Ramp Time = 0.75 Start Point =

30%

% Current = 100%

Ramp Time = (1

.OO - 0.30)

x 45 x 0. ‘5 = 24 minutes

PULSE RATE CALIBRATION

The pulse rate (rate of corrective action) is applied to control

the loading rate. When the leaving chilled water temperature

differs from the control point by

+ 5”F,

the vanes must be

repositioned at the slowest rate that will maintain stable

control.

The pulse rate setting depends on the volume of chilled

water in the piping loop. The pulse rate is adjustable from

2 (DEC.) to 25 (INC.) pulse per minute. A system with a small

volume can be set at a fast rate and conversely slower for

large systems.

The pulse rate can be set by making an adjustment to the

blue PULSE RATE pot and counting the rate per minute that

the red or green lights come on when the condenser water

temperature is near the control point. Adjust the pot counterclockwise to increase pulse rate; clockwise to reduce rate.

CURRENT TRANSFORMER

The current transformer located in the motor starter is used

to generate an A.C. voltage signal which varies directly with

the compressor motor current.

This signal is calibrated at the factory or by the McQuay

Service technician performing the initial startup of the

Templifier. This signal normally is adjusted to approximate-

ly 5 volts a.c. corresponding to the Rated Load Ampere (RLA)

on the compressor nameplate.

The signal is continuously monitored by the control module

to prevent the motor current from exceeding the full load

amperes.

Calibration of this signal, although not complex, can be

hazardous with improper procedures. Therefore, if calibration is needed, it is recommended that the McQuay Service

technician be called to perform the work.

VANE SPEED ADJUSTMENT

The vane speed at which the capacity control vanes open

or close is controlled by the rate of oil bleed-off from the vane

actuating piston. This bleed-off rate is adjustable by positioning the needle valves on SA and SB solenoid valves located

in the lube box.

Screwdriver openings in the left side of the lube box permit access. The upper opening accesses the SB needle valve

for adjusting the vane OPENING speed for loading the compressor (Refer to Figure 10). Turn this screw clockwise to

decrease the vane opening speed and counterclockwise to

increase the opening speed.

The lower opening accesses the SA needle valve for adjusting the CLOSING speed for unloading the compressor.

The same adjustment applies clockwise to decrease

closing, counterclockwise to increase vane closing.

The vanes are factory set so that from fully closed to fully

open positioning of the vanes requires about 3 minutes and

about 1 minute from fully open to fully closed. (Exception:

CE126 settings are 9 minutes to open and 3 minutes to close).

LOAD RECYCLING THERMOSTAT SETTING

During the initial startup procedure the McQuay Service

technician will set the LRT to control the compressor on and

off line at the proper temperature.

Normally this control should stop the compressor when the

water temperature rises to within about

4°F

of the control

point.

Since the LRT scale is not highly accurate, a practical setting can be made with the machine running. Turn the dial

counterclockwise (to a lower temperature) until the compressor stops. At this point compare the actual water

temperature with the dial setting. If they agree, then reset

to the proper cutout setting

(4” below control point). If they

differ, note the difference and direction and make the setting accordingly.

LOW OIL TEMPERATURE THERMOSTAT

It is important to understand that this thermostat simply

prevents the compressor from starting with cold oil and has

no function after the compressor is started. It is shunted out

at the end of the prelube cycle.

Therefore, the setting needs to be as high as practical

without causing a nuisance. It is normally set about 40°F

above the normal high ambient temperature in the equipment

room. The operator making a setting of the LOT should,

however, consider the range of ambient temperature.

Checking the LOT calibration can be accomplished by adjusting the control with the compressor off. Adjust dial

clockwise (to higher temperature) until LOT switch clicks and

then compare the actual oil temperature with the dial reading.

If they differ, note the difference and make setting

accordingly.

Page 18

I

IM 315

Page 19

Page 20

Page 21

Page 22

Page 23

McQUAY SERVICE PROGRAMS

It

is important that an air conditioning system receive

quate maintenance if the full equipment life and full system

benefits are to be realized.

Maintenance should be an ongoing program from the

time the system is initially started. A full inspection should

be made after 3 to 4 weeks of normal operation on a new

installation and on a regular basis thereafter.

McQuay offers a variety of maintenance services

through its Nationwide Service Organization and can tailor

these services to suit the needs of the building owner.

ade-

Most popular among these services is the McQuay

prehensive Maintenance Plan wherein McQuay assumes

full responsibility for your air conditioning equipment.

cluded

are regular routine inspections andemergency

vice by factory trained technicians. All parts, labor,

materials, and refrigerant are included in a McQuay

prehensive Maintenance Contract.

For further information concerning the many services

available, contact your local McQuay Service representative.

Com-

In-

ser-

Com-

IM 315

I

Page 23

Loading...

Loading...