Page 1

Installation and Maintenance Manual IM-809

SAH Air Handler

7-1/2 and 10 Tons

Group: Unitary

Part Number: IM-809

Date: August 2005

Supersedes: July 2005

© 2004 McQuay International

IM-809 Page 1

Page 2

Table of Contents

MODEL NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL WARNINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PRODUCT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 6

ORIENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ELECTRICAL SUPPLY WIRE AND MOP . . . . . . . . . . . . . . 8

CONVERSION TO 460V ELECTRICAL POWER SUPPLY 9

ELECTRICAL CONNECTIONS . . . . . . . . . . . . . . . . . . . . . .10

HEAT KIT INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . 11

REFRIGERANT LINES . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

EVAPORATOR COIL TXV . . . . . . . . . . . . . . . . . . . . . . . . . 12

AIRFLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

BELT TENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

"McQuay" is a registered trademark of McQuay International.

© 2004 McQuay International

"Illustrations and information cover the McQuay International products at the time of publication and we reserve the right to make changes in

Page 2 IM-809

design and construction at any time without notice."

Page 3

MODEL NOMENCLATURE

M

S

g

*

odel

AH= Split Air Handler Unit

Nominal Capacity (tons)

090 = 7-1/2

120 = 10

SAH090 and 120 units are field-convertible to 460/3/60 voltage.

Table 1: Unit Nameplate Model Number Identifier

Unit Nameplate McQuay Model Number

AR090 SAH090APTY

AR120 SAH120APTY

SAH 090

A

PTY

Future Use

Refrigerant Meterin

T = TXV

Voltage/Phase

P = 208-460/3/60*

Vintage

IM-809 Page 3

Page 4

INTRODUCTION

General Description

These installation instructions cover the indoor installation of

AR series electric split system cooling and heat pump air handlers. See the product catalog for information regarding specifications applicable to your model and accessories.

Receiving Inspection

McQuay products are carefully inspected prior to shipment

and the carrier has assumed responsibility for loss or damage

upon acceptance of the shipment.

Upon receiving your shipment, check all items carefully

against the Bill of Lading. Inspect the unit and/or accessories

for shipping damage as soon as they are received. Immediately file claims for loss or damage, either shipping or concealed, with the shipping company.

Check the unit nameplate to verify the model number and electrical characteristics are correct. In the event an incorrect unit

is shipped, it must be returned to the supplier and must NOT

be installed. The manufacturer disclaims all responsibility for

the installation of incorrectly shipped units.

The SAH evaporator coil contains a high-pressure inert gas

holding charge. Before installing the unit, depress the liquid

line Schrader fitting(s) to verify the integrity of the evaporator

coil. Note that SAH120 units have two (2) liquid line Schrader

valves, both of which should be depressed.

Codes and Regulations

This product is designed and manufactured to permit installation in accordance with National Codes. System design

should, where applicable, follow information presented in

accepted industry guides such as the ASHRAE Handbooks. It

is the installer' s responsibility to install the product in accordance with National Codes and/or prevailing local codes and

regulations. The manufacturer disclaims all responsibility for

equipment installed in violation of any code or regulations.

IMPORTANT

The United States Environmental Protection Agency

(EPA) regulations cover introduction and disposal of

refrigerants in this unit. Failure to follow those

regulations can harm the environment and lead to

substantial fines. Because regulations can change, a

certified technician should perform any work done on

this unit. If you have any questions, please contact the

local office of the EPA.

Important Message to the Owner

Read these instructions carefully and keep them near the product for future reference. Although these instructions are

addressed primarily to the installer, useful maintenance information is included. Have the installer acquaint you with the

operation of the product and periodic maintenance requirements.

Recognize Safety Symbols, Words, and Labels

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards. It is the

owner's and installer's responsibility to read and comply with

all safety information and instructions accompanying these

symbols. Failure to heed safety information increases the risk

of property damage and/or product damage, serious personal

injury or death. Improper installation, operation or mainte-

nance can void the warranty.

DANGER

Immediate hazards which WILL result in property

damage, product damage, severe personal injury and/

or death.

WARNING

Hazards or unsafe practice CAN result in property

damage, product damage, sever personal injury and/or

death.

CAUTION

Hazards or unsafe practices which CAN result in

property damage, product damage, and/or personal

injury.

Replacement Parts

Replacement parts can be obtained by contacting McQuay at

1

-800-37-PARTS. When contacting McQuay for service or

replacement parts, refer to the model number and serial number of the unit as stamped on the nameplate attached to the

unit.

Important Message to the Installer

This equipment is to be installed by an experienced installation

company and fully trained personnel. Carefully read all

instructions and take into account any special considerations

prior to installing the unit. Give this manual to the owner and

explain its provisions.

Page 4 IM-809

Page 5

GENERAL WARNINGS

WARNING

Verify that all power is disconnected prior to installing

of this equipment. There may be more than one

disconnect servicing this equipment.

WARNING

Before servicing or installing this equipment, the

electrical power to this unit must be in the "OFF"

position. More than one disconnect may exist. Failure

to disconnect power can cause electrical shock, serious

personal injury or death.

WARNING

The unit must have an uninterrupted, unbroken

electrical ground. Failure to properly ground can cause

severe personal injury or death.

WARNING

Installation and service by trained, qualified technicians

only. High pressure and electricity can cause severe

personal injury or death. Observe ALL warnings

contained in this manual and the labels/tags attached to

the equipment.

WARNING

This product is factory shipped for use with a 208-230/

3/60 electrical power supply. However, the air handler

can be reconfigured to operate with a 460/3/60 power

supply provided the conversion noted in the

"Conversion to 460 Electrical Supply" section of this

manual is performed. Failure to observe this warning

can result in personal injury, equipment damage and

fire.

WARNING

This air handler is designed for Upflow or Horizontal Left applications. DO NOT INSTALL IN THE

DOWNFLOW OR HORIZONTAL-RIGHT

ORIENTATION.

WARNING

When installing or servicing, wear protective gloves,

gear and eyeware. Also observe special safety

requirements (hard hats etc.).

CAUTION

To protect the unit when welding close to the painted

surfaces, use a quenching cloth to help prevent

scorching or marring the equipment finish.

IM-809 Page 5

Page 6

PRODUCT DESCRIPTION

When matched with a ACU090 and ACU120 condenser, this

system complies with the minimum efficiency equirements

found in ASHRAE 90.1-1999. See the Product Catalog for

details on these condensers. For other McQuay condenser(s)

that can be matched with this air handler to obtain ASHRAE

90.1-1999 compliance, consult with your local representitive.

Units are intended for use with a room thermostat. This thermostat is not supplied with this equipment. Thermostats that

use 24 VAC control circuitry must be used.

SAH090 SAH120

Net Weight (Lbs.) 375 400

Shipping Weight (Lbs.) 405 430

Refrigerant R22 R22

Blower Wheel (Dia x Width) 11 x 10 11 x 10

Blower Wheel Quantity 2 2

Motor Type Belt Drive

Motor Qty 1 1

Motor (HP) 1 ½ 2 1 ½ 2

Motor (RPM) 1750 1750

Motor Sheave Type Adjustable Variable Pitch

Motor Sheave Diameter (in) 1.9" - 2.9" 2.8" - 3.8"

Blower Wheel Pulley Type Fixed Diameter

Blower Wheel Pulley Dia (in) 5.9 6.5

Evaporator Coil Material Copper Tubes / Al Fins

Face Area (Ft2) 8.9 10.0

Number of Rows 4 4

Suction Line Quantity 1 2

Suction Line Connection (in) * 1 1/8 1 1/8

Liquid Line Quantity 1 2

Liquid Line Connection (in)* 5/8 3/8

Metering Device Thermal Expansion Valve (TXV)

TXV Type Adjustable

TXV Quantity 1 2

* Note: Consult with the condenser specifications for suction and liquid line

sizing.

ELECTRIC HEAT

WARNING

To avoid fire and equipment damage, refer to the "Heat

Kit Installation" section of this manual for the proper

installation procedure.

WARNING

To avoid fire, equipment damage and electric shock, the

electrical characteristics of the air handler, the electric

heat kit, and the building power supply must agree.

This air handler does not have factory-installed electric heat.

Electric heat is available as an accessory. If installing this

option the ONLY heat kits that can be used is the AHKD series

as indicated in Table 2.

Table 2: AHKD Electric Heaters

AHKD Model Number Nominal W

AHKD15-3 15 208-230/3/60 1

AHKD15-4 15 460/3/60 1

AHKD20-3 20 208-230/3/60 2

AHKD20-4 20 460/3/60 2

AHKD30-3 30 208-230/3/60 2

AHKD30-4 30 460/3/60 2

E l e c tr i c a l

Characteristics

Stages

For all supply voltages, use the correction factors in Tables 3

and 4 multiplied by W and (or) temperature rise for corrected

results.

Table 3: W Correction Factors (-3 models).

Supply Voltage 240 230 220 210 208

Correction Factor 1.0 0.92 0.84 0.77 0.75

Table 4: W Correction Factors (-4 models)

Supply Voltage 480 460 440 415 380

Correction Factor 1.0 0.92 0.84 0.75 0.63

The heating mode temperature rise is dependent upon the system airflow, the supply voltage, and the heat kit size (W)

selected. Use Tables 5 and 6 to determine the temperature rise

o

(

F):

Table 5: SAH090 Temperature Rise Table (Degrees F)

Air

Handler

SAH090 15 2800 14 19 19

Heat Kit W CFM

2900 14 18 18

3000 13 18 18

3100 13 17 17

3200 12 17 17

20 2800 19 25 25

2900 18 24 24

3000 18 24 24

3100 17 23 23

3200 17 22 22

30 2800 28 38 38

2900 27 37 37

3000 27 35 35

3100 26 34 34

3200 25 33 33

Table 6: SAH120 Temperature Rise Table (Degrees F)

Air

Handler

SAH120 15 3800 10 14 14

Heat Kit W CFM

3900 10 14 14

4000 10 13 13

4100 10 13 13

4200 9 13 13

20 3800 14 19 19

3900 14 18 18

4000 13 18 18

4100 13 17 17

4200 13 17 17

30 3800 21 28 28

3900 20 27 27

4000 20 27 27

4100 19 26 26

4200 19 25 25

Supply Voltage

208 240 480

Supply Voltage

208 240 480

Page 6 IM-809

Page 7

Note: Tables 5 and 6 are calculated with both stages of

electric heat engaged (2-stage heat systems). For

systems using staged electric heat, divide the temperature rise from the tables by 2 for 1st stage operation.

ORIENTATION

Units can be mounted in the following orientations:

• Upflow

• Horizontal - Left Hand

DO NOT INSTALL THIS AIR HANDLER IN THE HORIZONTAL-RIGHT OR DOWNFLOW ORIENTATION.

LOCATION

DANGER

This unit can distribute carbon monoxide (CO), an

oderless, colorless toxic gas that can cause severe

personal injury or death. The area must be properly

vented and joints must be tight so CO cannot enter duct

work or enclosed space.

WARNING

Units are not weather tight and are designed for indoor

installations only. DO NOT INSTALL OUTDOORS.

DUCTWORK

Units are designed for a complete supply and return ductwork

system. DO NOT OPERATE THIS PRODUCT WITHOUT

BOTH DUCTWORK SYSTEMS ATTACHED.

For proper system performance, size the ductwork systems to

accommodate 375-425 CFM per ton of cooling with a static

pressure not to exceed 0.5" W.C. Inadequate ductwork that

restricts airflow can result in improper cooling performance

and compressor failure. Construct ductwork in a manner that

limits restrictions and maintains suitable air velocity. Seal

ductwork to the unit in a manner that will prevent leakage.

Supply Ductwork Flanges. The supply ductwork flanges

are shipped loose and must be field installed.

further details. Dimensions are approximately 40" x 13-1/8"

Figure 1. Supply Ductwork Flanges

See Figure 1 for

Units are suitable for installation in multiple locations including:

• Overhead (Attic/Mezzanine, etc)

• Closet/Mechanical Room

When installing this air handler, give careful consideration to

minimizing the length of refrigerant tubing. Do not install the

air handler in a location either above or below the condenser

that violates the instructions provided with the condenser.

Allow a minimum of 36" in front of the unit for service clearance. Allow sufficient clearance to remove heater elements for

service or replacement when heat kits are utilized in the application.

When installing in an area directly over a finished ceiling

(such as an attic) an emergency drain pan is required directly

under the unit. See local and state codes for additional requirements.

When installing this unit in an area that may become wet, elevate the unit with a sturdy, non-porous material.

In installations that may lead to physical damage (warehouse,

industrial sites, etc.), install a protective barrier to prevent

equipment damage.

Return Ductwork. DO NOT TERMINATE THE RETURN

DUCTWORK IN AN AREA WHICH CAN INTRODUCE

TOXIC FUMES/ODORS INTO THE DUCTWORK. Introduce the return ductwork

into the air handler bottom. The cabi-

net dimensions are 48" x 24".

Return Air Filters. This unit is factory equipped with disposable return air filters. To provide optimum performance frequent filter replacement is advised. See Table 7 for the

factory-installed filter sizes:

Table 7: Factory-Installed Filter Sizes

Model Filter Size (in.) Qty.

SAH090 16 x 20 x 2 4

SAH120

16 x 20 x 2

20 x 20 x 2

2

2

IM-809 Page 7

Page 8

ELECTRICAL SUPPLY WIRE

AND MOP

WARNING

Before servicing or installing this equipment, the

electrical power to this unit must be in the "OFF" position.

More than one disconnect may exist. Failure to observe

this warning may result in an electrical shock that can

cause personnel injury or death.

WARNING

The unit must have an uninterrupted, unbroken electrical

ground. Failure to properly ground can cause severe personal injury or death.

Voltage Balance. The supply voltage shall be unbalance

(phase to phase) within 2%. To calculate the percentage of

voltage unbalance, use the following formula:

Percentage

Voltage = 100 x

Unbalanace

Max Voltage Deviation From Average

Average Voltage

Example

L1 - L2 = 220 V

L2 - L3 = 216 V

L1 - L3 = 213 V

Avg. Voltage = (220+216+213) / 3

= 649 / 3

= 216

Max. Deviation from Avg. = 220 - 216 = 4

The unit must have an uninterrupted, unbroken electrical ground.

The electrical ground circuit may consist of an appropriately

sized electrical wire connecting the ground lug in the unit control box wire to the building electrical service panel. Other

methods of grounding are permitted if performed in accordance with the National Electric Code (NEC)/American

National Standards Institute (ANSI)/National Fire Protection

Association (NFPA) 70 and local/state codes. In Canada, electrical grounding is to be in accordance with the Canadian Electric Code CSA C22.1. Failure to observe this warning can

result in electrical shock that can cause serious personal injury

or death.

WARNING

To avoid the risk of fire or equipment damage, use only

copper conductors.

WARNING

This product is capable of using either 208-230/3/60 or

460/3/60 supply voltage. Units are factory shipped for use

with 208-230/3/60 voltage. Installations using 460/3/60

require modification to the motor and transformer

electrical circuits. Refer to the "Conversion to 460V

Power Supply" section of this manual. Do not operate this

appliance using a 460V power supply unless this

modification has been made. Failure to observe this

warning may result in personal injury, equipment damage

and fire.

Inspection of the Building Electrical Service. This unit

is designed for 3-phase operation. DO NOT OPERATE ON A

SINGLE PHASE POWER SUPPLY. Measure the power supply to the unit. The supply voltage must be in agreement with

the unit nameplate power requirements and within the range

shown in Table 8.

Table 8: Minimum and Maximum Supply Voltage

Nominal

208-230 187 253

460 414 506

Minimum Supply

Vol tag e

Maximum Supply

Vol tag e

% Voltage Unbalance = 100 x (4 / 216)

= 400 / 216

= 1.8%

Determine Wire Size. The selection of the appropriate supply wire size is important for proper operation of the equipment. The following are important considerations:

• The wire size is adequately sized to carry the Minimum Circuit

Ampacity (MCA). Refer to the NEC (USA) or CSA (Canada) for

wire sizing. The unit MCA for the airhandler and the optional

electric heat kit can be found on the equipment nameplate and

Table 9.

Table 9: Minimum Circuit Ampacity

Air Handler Voltage Heat Kit MCA

SAH090 208-230 NONE 6.5

AHKD15-3 48.6

AHKD20-3 63.0

AHKD30-3 91.9

460 NONE 3.3

AHKD15-4 24.3

AHKD20-4 31.5

AHKD30-4 46.0

SAH120 208-230 NONE 7.5

AHKD15-3 49.4

AHKD20-3 63.8

AHKD30-3 92.7

460 NONE 3.8

AHKD15-4 24.7

AHKD20-4 31.9

AHKD30-4 46.4

Page 8 IM-809

Page 9

• The wire size is appropriately sized to allow for no more than a

2% voltage drop from the building breaker/fuse panel to the unit.

• Refer to the latest edition of the National Electric Code or in Canada the Canadian Electric Code when determining the correct wire

size. Table 10 shows the current carrying capabilities for copper

o

conductors rated at 75

C with a 2% voltage drop

Table 10: Maximum Allowable Length in Feet to Limit Voltage

Drop to 2%*

Wire Size

(AWG)

14 75 50 37 NR NR NR NR NR

12 118795947NRNRNRNR

10 188 125 95 75 63 54 NR NR

8 301 201 150 120 100 86 75 68

6 471 314 235 188 157 134 118 110

Based on NEC 1996*

10 15 20 25 30 35 40 45

Min. Circuit Ampacity (MCA)

Maximum Overcurrent Protection (MOP)

Every installation must include an NEC (USA) or CEC (Canada) approved overcurrent protection device. Also check with

local or state codes for any special regional requirements.

This protection can be in the form of fusing or HACR style circuit breakers. Table 11 can be used as a guide for selecting the

MAXIMUM overcurrent device. This information is also

stated on the equipment nameplate. Note: Fuses or circuit

breakers are to be sized larger than the equipment MCA but

not to exceed the MOP listed below.

Table 11: Maximum Overcurrent Protection

Air Handler Heat Kit MOP

SAH090 NONE 15

AHKD15-3 60

AHKD20-3 70

AHKD30-3 100

NONE 15

AHKD15-4 30

AHKD20-4 35

AHKD30-4 50

SAH120 NONE 15

AHKD15-3 60

AHKD20-3 70

AHKD30-3 100

NONE 15

AHKD15-4 30

AHKD20-4 35

AHKD30-4 50

CONVERSION TO 460V ELECTRICAL

POWER SUPPLY

Transformer. The transformer is multi-rated with a 208V,

240V, or 480V primary input.. To change from the factory setting of 230V to 460V applications, remove the Orange colored

wire attached to the 240 terminal on the primary side of the

transformer. Install this wire on the transformer terminal

marked 480. Similarly, move the Orange wire from 240 to 208

for 208V applications.

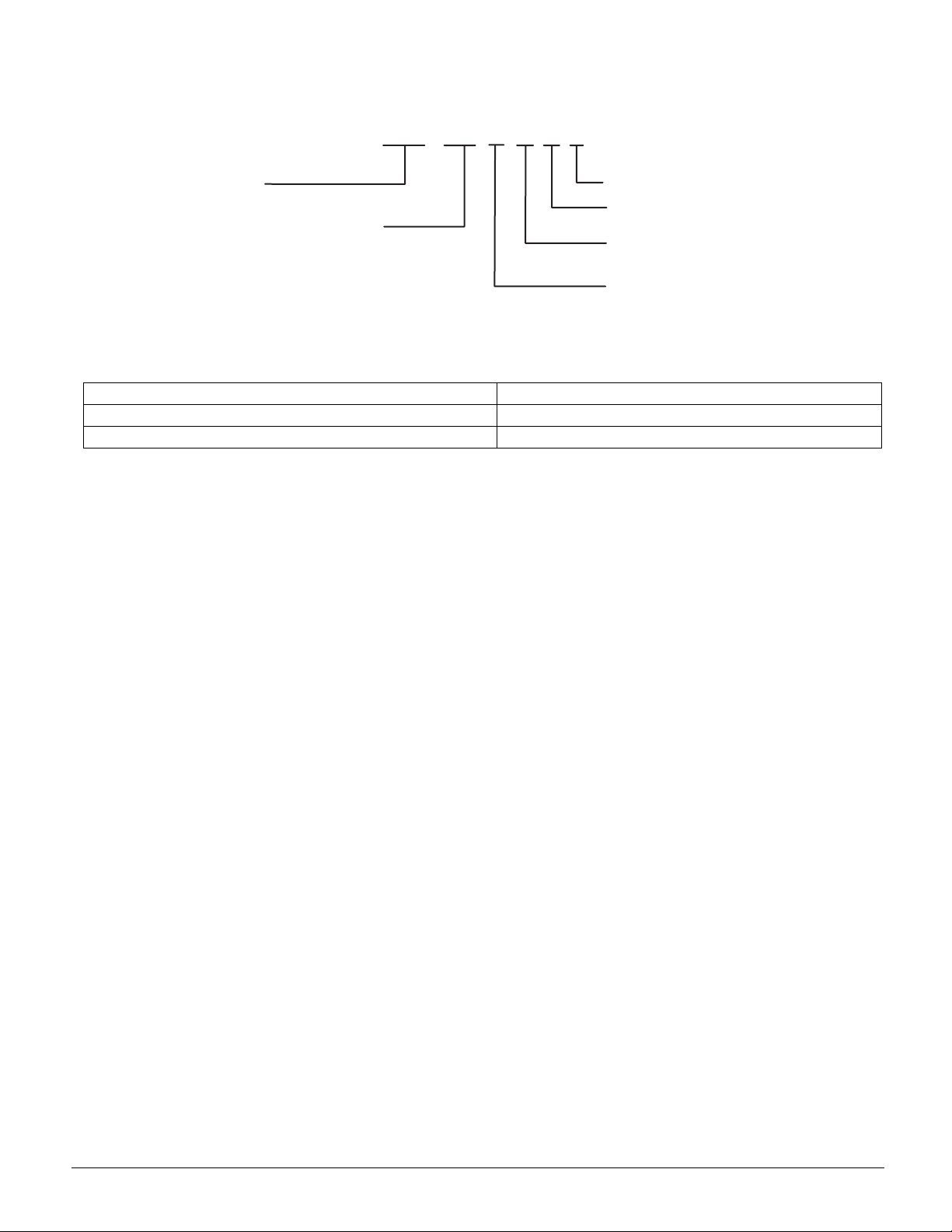

Figure 2. Transformer Conversion

Motor Conversion. This conversion requires access to the

motor electrical junction box that is located on the motor endplate on the side opposite from the shaft. Use the following

diagrams when performing this procedure.

Figure 3. Motor Conversion

SAH090

SAH120

WARNING

This product is capable of using either 208- 230/3/60 or

460/3/60 supply voltage. this air handler is factory

shipped for use with 208-230/3/60 voltage. Installations

using 460/3/60 requiring modification to the motor and

transformer electrical circuits. Do not operate this

appliance using a 460V power supply unless this

modification has been made. Failure to observe this

warning may result in personal injury, equipment damage

and fire.

Note: Perform this conversion in an area that will permit

easy accessibility.

IM-809 Page 9

Page 10

ELECTRICAL CONNECTIONS

Supply Voltage. A single point supply voltage termination is

provided in the air handler control box (non-heat kit models)

or heat kit control box (heat kit models). This termination is

common to both the air handler, and heat kit. The wire is to be

sized in accordance with the "Electrical Wire and MOP" section of this manual.

Supply Voltage - Non-Heat Kit Models. Route supply

wire through conduit from the service disconnect box to the

unit. The air handler is equipped with a knockout suitable for

¾" conduit. Figure 4 illustrates the supply voltage hook-up.

Figure 4. Supply Voltage Hook-up (Non Heat Kit Models)

Low Voltage. The 24V control voltage connects the air handler to the room thermostat and condenser. For systems using

staged electric heat, the thermostat is to have W1 and W2

functions. Use copper conductors and a minimum of 18AWG

for low voltage wiring. A provision on the cabinet side to

accept the low voltage wiring is provided. See Figure 6 for

typical low voltage connections

Figure 6. Low Voltage Connections

No Heat - Single Stage Cooling where R… Red,

G… Green, BL…. Blue Note white wire and brown

wire are not used and are to be taped.

Supply Voltage - Heat Kit Models. When a heat kit is

used, the system uses a single point wiring hook-up. Route the

supply wire through conduit from the service disconnect box

to the heat kit. The heat kit is equipped with a knockout suitable for ½" or ¾" conduit dependent on the kW. Install the supply voltage on the terminal block located in the heat kit control

box.

The heat kit is factory-equipped with the supply and low voltage wires for the air handler. The low voltage connection from

the heat kit is provided through a multi-pin plug that connects

to a mating plug in the air handler. The high voltage connections are to be made at the air handler contactor. These wires

are to be routed through the pipe nipples supplied with the heat

kit as shown in Figure 5:

Figure 5. Supply Voltage Hook-up (Heat Kit Models)

Single Stage Heat - Single Stage Cooling where R…

Red, W… White, G… Green, BL…. Blue Note brown

wire is not used and is to be taped.

Two Stage Heat – Single Stage Cooling - where

R… Red, W… White, BR… Brown, G… Green,

BL…. Blue

Page 10 IM-809

Page 11

HEAT KIT INSTALLATION

Inspect for Shipping Damage. The heat kit is an optional

accessory that is shipped separately from the air handler.

Inspect the heat kit for damage and report any damage to the

carrier. Do not install this accessory if it is determined that the

integrity has been compromised by freight damage.

Check the Nameplate. From the heat kit nameplate check

the following:

• The model number agrees with the approved models (see

the "Electric Heat" section of this manual).

• The correct size (kW)

• Electric characteristics, voltage and phase agree with the

building electrical supply.

General Guidelines. The following guidelines must be followed when installing heat kits:

• When installed in a garage, the elements must be at least

18 above the floor.

• If this appliance is installed in an enclosed area such as a

garage or utility room with any carbon monoxide (CO)

producing appliance (i.e. automobile, furnace, water-heater

etc.), verify that the area is properly ventilated.

• A means of strain relief and conductor protection must be

provided at the supply wire entrance.

• This appliance must be installed following the ANSI/

NFPA70 (National Electrical Code) and other applicable

codes. If in doubt, contact the local authority having jurisdiction.

• Use copper conductors only

• Some localities require the installer be licensed. Contact

the local authority if in doubt.

Failure to follow these instructions can cause fire, explosion, electrical shock, property damage, personal injury, or

death.

DANGER

This unit can distribute carbon monoxide (CO), an

oderless, colorless toxic gas that can cause severe

personal injury or death. The area must be properly

vented and joints must be tight so CO cannot enter duct

work or enclosed space.

Attaching the Heat Kit. The heat kit attaches directly to the

top panel (when viewed in the upflow position) of the air handler. Do not screw the heat kit into the duct flanges (Figure 7).

Figure 7. Attaching The Heat Kit

The wires from the heat kit are to be routed through the pipe

nipple into the air handler electrical compartment. See the

"Electrical Connection" section of this manual for wiring

details.

REFRIGERANT LINES

CAUTION

To protect the unit when welding close to the painted

surfaces, use a quenching cloth to prevent scorching or

marring the equipment finish.

Preparing the Tubing. All cut ends are to be round, burr

free and cleaned. Failure to follow this practice can result in

refrigerant leaks. The equipment suction line(s) are spun

closed and require pipe cutters to cut off the closed end. The

liquid lines have a Schrader valve soldered on the end. Unsweat the Schrader valve(s) and clean the end of these tubes.

Post Brazing. Quench all welded joints with water or a wet

rag.

IM-809 Page 11

Page 12

Piping Size. For the correct size tubing, follow the specification for the condenser/heat pump.

The SAH090 coil is circuited to accept a single suction and liquid line. The SAH120 evaporator coil has (2) suction lines and

(2) liquid lines. When using a single condenser, such as the

ACU120 with the SAH120, it is necessary to manifold the suction lines into a single connection. Similarly, the liquid lines of

the SAH120 are to be manifolded when matched with a single

condenser/heat pump. The manifolds must be sized to accept

the suction and liquid line diameters prescribed within the

condenser Installation Manual. See Figure 8 for additional

details.

Figure 8. Liquid and Suction Lines with a Single

Condensor/Heat Pump

SAH090

EVAPORATOR COIL TXV

Note: The Thermal Expansion Valve (TXV) Bulb is not

permanently connected to the suction line from the

factory. After the suction and liquid line tubing is

brazed in the field, the TXV bulb must be attached

to the suction line(s) inside the cabinet at the 10 or 2

o'clock position and insulated. This location will be

different for vertical or horizontal orientation.

Always locate the TXV bulb on the top of the suction tube at 10 or 2 o'clock.

For most installations, no adjustment to the TXV setting is

required. However, if the measured superheat is less than 80 or

greater than 200, an adjustment is required. The adjustment

stem is at the base of the valve (opposite the diaphragm) under

a flair nut.

To increase the superheat (when measured at the condenser

base valve), turn the stem clockwise (in). To decrease the

superheat, turn the stem out (counterclockwise). Use a ¼"

refrigeration wrench for this function.

Refer to the condensing unit / heat pump installation instructions for the charging method.

AIRFLOW

The blower uses a belt drive motor that has an adjustable

sheave. The factory setting for the SAH090 is 2 turns open.

The SAH120 is 3 turns open.

SAH120 SINGLE OUTDOOR UNIT

Multiple Condensers. The AR120 can accept (2) condensers/heat pumps. See Figure 9 when using two condensers.

Figure 9. Liquid and Suction Lines with Multiple

Condensers/Heat Pumps

SAH120 TWO OUTDOOR UNITS

To increase the airflow:

• Remove the blower belt

• Loosen the set screw as shown in Figure 10, rotate the other half

clockwise (screw in).

• Tighten the set screw

• Re-install the belt

Figure 10. Airflow Adjustment

To decrease the airflow perform the same steps, but rotate the

sheave counterclockwise (screw out).

Page 12 IM-809

Page 13

Table 12 can be used as guide for system airflow:

Table 12: System Airflow

SAH090

Static

Pressure

.1 4264 3930 3633 3273

.2 3996 3705 3325 2998

.3 3731 3379 3002 2517

.4 3445 3066 2613

.5 3113 2662

12345

SAH120

Static

Pressure

.1 5193 5037 4790 4097 4097

.2 5012 4873 4603 3842 3842

.3 4852 4675 4393 3589 3589

.4 4687 4484 4172 3295 3073

.5 4501 4268 3939 2922 2610

.6 4293 4041 3673 2642

.7 4073 3742 3347

.8 3807 3485 2962

.9 3540 3117

12345

Sheave Turns Open

Sheave Turns Open

BELT TENSION

The belt tension is to be checked at the time of installation and

after a "run in" period of about 24 hours. To perform the measurement, use a "Belt Tension Gauge" that is available from

most belt manufacturers. The force required to deflect the belt

1/8" (at the midpoint) should be between 3 ½ and 5 pounds.

MAINTENANCE

Routine maintenance is essential for the proper operation of

this air handler. A few preseason checks can help avoid costly

repairs and down time.

1. Check and change air filters as needed

2. Check, adjust or replace belts and check sheaves for proper

operation.

3. Clean the evaporator coil and check for duct leaks.

4.

Check for proper charge and (or) for refrigerant le

aks.

IM-809 Page 13

Page 14

WIRING DIAGRAM

THERMOSTAT

RBR

W1

W

C

GRW2

BL

G

SUPPLY VOLTAGE

L2 L1

1

4

G

L3

52

6

3

BL

CONTACTOR

SUPPLY VOLTAGE

L2

L3

L3

L2

L1

CONTACTOR

T3

EVAP.

MOTOR

T1

T2

B

B

B

O

FACTORY WIRED FOR 240V

SEE NOTE FOR MOTOR

CONNECTIONS

BL

COLOR CODE

B

BL

BR

G

O

R

W

BLACK

BLUE

BROWN

GREEN

ORANGE

RED

WHITE

L1

G

C

B

BL

PRIMARY

208V

240V

480V CDM

BL

SECONDARY

24V

TRANSFORMER

WIRING CODE

FACTORY WIRING

HIGH VOLTAGE

LOW VOLTAGE

FEILD WIRING

HIGH VOLTAGE

LOW VOLTAGE

G

W2

R

W1

RELAY

(SEQUENCER)

CDM

EVAP.

MOTOR

1

2

FACTORY WIRED

FOR 240V

SEE NOTE FOR

MOTOR

CONNECTIONS

R

R

PRIMARY

240V

480V

208V

TRANSFORMER

SECONDARY

24V

BLOWER

BL

RELAY

4

CONTACTOR

24V

BLOWER

R

RELAY

5

6

PLUG

W2

W1

G

C

R

NOTES:

1. ALL REPLACEMENT WIRES MUST BE

SAME GAUGE AND TYPE.

2. TO CHANGE VOLTAGE FROM 240V TO

208V, MOVE WIRE FROM 240V TAP TO

208V TAP AT TRANSFORMER PRIMARY.

3. TO CONVERT VOLTAGE FROM 240V TO

480V:

a. MOVE WIRE FROM 240V TAP TO

480V TAP AT TRANSFORMER PRIMARY.

b. IDENTIFY MODEL (AR120 OR AR090)

AND REWIRE MOTOR FROM LOW

VOLTAGE (240V) TO HIGH VOLTAGE

(480V) ACCORDING TO INSTRUCTIONS.

A.O. SMITH MOTOR

SAH120 MOTOR

HIGH VOLTAGE

(480V)

7

4

8

5

9

6

14

INSULATE

15

INSULATE

16

INSULATE

LOW VOLTAGE

(240V)

1

L1

2

L2

3

L3

14

4

15

5

16

6

1

7

8

9

L1

2

L2

3

L3

SAH090 MOTOR

HIGH VOLTAGE

(480V)

T4

T7

T5

T8

T6

T9

P4

INSULATE

P5

INSULATE

P6

INSULATE

LOW VOLTAGE

(240V)

T1

L1

T2

L2

T3

L3

T4

T5

T6

T7

P4

P5

P6

T1

T8

T9

L1

T2

L2

T3

L3

Page 14 IM-809

Page 15

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.mcquay.com.

www.mcquay.com • 800-432-1342

Loading...

Loading...