Page 1

System Solutions From McQuay

McQuay Evaporative Condenser

Rooftop System

How can I benefit from the substantial energy savings of

evaporative condensing in a cost-effective, factory-packaged

rooftop system?

McQuay RoofPak™ applied rooftop systems can be specified

with an evaporative condenser, allowing you to benefit from

substantial energy savings at the reduced design and

installation costs of a factory-packaged system. Evaporative

condensers can save as much as 40% on energy versus aircooled alternatives, and they often draw less energy than any

alternative HVAC system.

Features

• Seven sizes from 75 to 150 tons.

• Blow through (Model RPE) or draw through (Model

RDE) cooling.

• Modular flexibility with multiple filter, fan, coil, heating

and specialty equipment options to match strict

application requirements.

• Factory assembled and tested units minimize field labor

for installation and commissioning.

• Walk-in service vestibule with raised floor grate and drain

pan contains water connections and most electrical, water

treatment and refrigerant service components.

Benefits

Reduced Energy Consumption

• Up to 40% savings in condensing unit energy

consumption versus air-cooled alternatives.

• Reduced peak electrical demand at design conditions

allows unit electrical service to be downsized for lower

installation costs and electrical demand charges.

• Airfoil fan selections require up to 20% less energy than

competitive forward curve fans.

• Patented UltraSeal™ low leak dampers minimize losses

(0.5% at 1.5” external static pressure).

• Factory-installed variable frequency drives further reduce

energy consumption.

Designed For Long Life and Easy Maintenance

• Stainless steel spray enclosure and sump, copper tube

bundles and polypropylene spray tree provide superior

corrosion resistance.

• All refrigerant service can be performed inside the walk-in

service vestibule – away from compressor noise and

outdoor conditions.

• Sufficient space is available inside the service vestibule to

house water treatment equipment required to prevent

scale build-up and microbial growth.

• Easy removal and replacement of spray nozzles, condenser

tube bundles and sump reduce service costs and down

time.

McQuay RoofPak™ Evaporative Condenser Rooftop System

Model RPE (shown) – 75 to 150 tons (blow through cooling)

Model RDE – 75 to 150 tons (draw through cooling)

Page 2

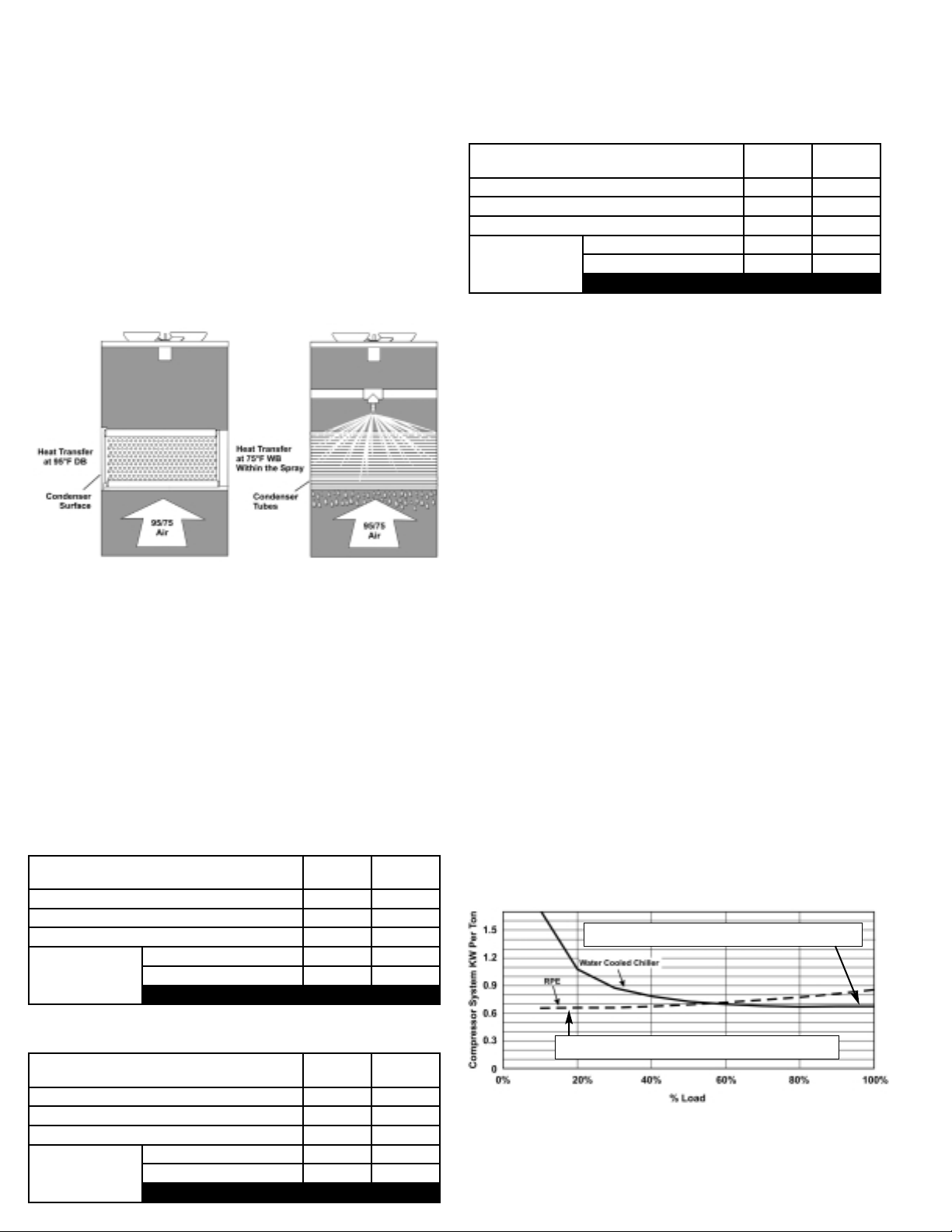

Evaporative Condensing Reduces Energy Consumption

Air-cooled condensers reject heat to the ambient dry bulb

(typically 95°F design) as air passes over the condenser

surface. Evaporative condensers use a water spray that coats

the condenser tubes (Figure 1). As air passes over the tubes,

the spray evaporates and cools the tubes down toward the

ambient wet bulb (typically 75°F). The lower condensing

temperature reduces compressor work and energy

consumption, resulting in lower electrical demand and

consumption. In addition, the electrical service to the unit

can be sized for lower amps to reduce installed costs.

Air-Cooled Condenser Evaporative-Cooled Condenser

Figure 1 – Evaporative condensers use the cooling effects of

evaporation to reduce compressor work and electrical demand

and consumption.

Typical Savings Versus Air-Cooled Rooftop

Systems*

To illustrate the savings generated by evaporative condensing,

consider a two-story shopping mall using several 125-ton

VAV rooftop units and occupied 365 days a year. Tables 1 to

3 show the McQuay RPE condensing unit savings if the mall

is located in Los Angeles, New York and Las Vegas.

Table 1 – McQuay RPE versus a typical air-cooled rooftop unit

for a Los Angeles area mall.

Conditions Air-Cooled

Design Ambient Dry Bulb/Wet Bulb 95°F/72°F 95°F/72°F

Electrical Consumption Rate (per kW Hour) $0.15 $0.15

Electrical Demand Rate (per kW) $24 $24

Efficiency (kW/ton) 1.15 0.85

Condensing Unit

Electrical Cost $30,200 $22,100

Percent Savings 27%

McQuay

RPE

Table 3 – McQuay RPE versus a typical air-cooled rooftop for a

Las Vegas area mall.

Conditions Air-Cooled

Design Ambient Dry Bulb/Wet Bulb 110°F/72°F 110°F/72°F

Electrical Consumption Rate (per kW Hour) $0.07 $0.07

Electrical Demand Rate (per kW) $8 $8

Efficiency (kW/ton) 1.40 0.85

Condensing Unit

Electrical Cost $19,042 $11,351

Percent Savings 40%

McQuay

RPE

Tables 1 to 3 show evaporative condensing savings of $5,500

to $8,100 (or 27% to 40%) of your annual condensing unit

energy costs versus air-cooled systems.* The superior design

of McQuay RoofPak applied rooftop air handling section can

significantly increase these savings with features that include:

• More efficient airfoil fan selections versus commonly- used

forward curved fans.

• Blow through cooling coil selection and Optimal Air

Temperature systems reduce design cfm and fan energy

costs.

McQuay RPE Energy Costs Are Competitive

With Any HVAC System – Even Water-Cooled

Chillers

Using the 0.85 kW/ton condensing unit efficiency, Figure 2

shows a comparison of a McQuay RPE evaporative condenser

rooftop system with a 0.55 kW/ton water-cooled chiller

system.* In this case, we assumed that the chiller system

would have constant flow pumps and that it unloads to 0.46

kW/ton.

The energy performance of the two systems is very

comparable (Figure 2). The RPE offers a significant part load

advantage and the chiller offers a small full load advantage.

Given that most air-conditioning systems operate at 60%

load or less over the great majority of a typical year, the

McQuay RPE may be the best equipment choice for energy

savings and installed costs.

Chiller Offers Minor Full Load Advantage

Table 2 – McQuay RPE versus a typical air-cooled rooftop for a

New York area mall.

Conditions Air-Cooled

Design Ambient Dry Bulb/Wet Bulb 95°F/75°F 95°F/75°F

Electrical Consumption Rate (per kW Hour) $0.11 $0.11

Electrical Demand Rate (per kW) $18 $18

Efficiency (kW/ton) 1.15 0.88

Condensing Unit

Electrical Cost $17,860 $12,375

Percent Savings 31%

McQuay

RPE

RPE Offers Significant Part-Load Advantage

Figure 2 – McQuay RPE unit versus a 0.55 kW/ton watercooled chiller system.

Page 3

Designed For Long Life And Easy Maintenance

Corrosion Resistant

Stainless Steel Fan Decks

With Severe Duty Motors

and Corrosion-Resistant

Fans

Stainless Steel Sump Copper Tube

PVC Spray

Tubes

Bundles

Easy Maintenance and Service

Replaceable Nozzles

With 150

o

Spray Arc

Replaceable, Slide Out

Tube Bundles

Polymer Tube

Sheets

Stainless Steel

Spray Enclosure

Walk-In Service Compartment

Perform Most Refrigerant Service In Comfort, Away From

Compressor Noise

Access To Most

Electrical Components

Marine Lights

Exhaust Fan

Access Doors

On Both Sides

Replaceable Sump

Walk-In Service Compartment

Easy Compressor Access

Charging, Suction,

Discharge and Liquid

Schrader Connections

Solenoid, Sight

Glass and

Filter Drier

Raised Floor

Grate and

Drain Pan

Hot Gas Bypass Valves

Space For Water

Treatment

Equipment

* All energy analysis and comparison charts provided in this document are estimates and have been generated using McQuay Energy

Analyzer™ software. Actual customer results may vary. For access to Energy Analyzer software, contact your local McQuay

Representative. To locate your local McQuay Representative, visit www.mcquay.com or call (800) 432-1342.

Page 4

McQuay RoofPak™ Applied Rooftop Systems

Total Indoor Environment Control, Only From

McQuay

The evaporative condenser system is among the many

innovative solutions for rooftop systems from McQuay that

help you deliver a superior indoor environment at lower

installed, operating and maintenance costs. Other

innovations include:

• MicroTech II™ controls with our Protocol Selectability™

feature for easy, low cost integration with the building

automation system of your choice.

• Patented DesignFlow™ precision outdoor air control

system for precise measurement and control of outdoor air

in support of ASHRAE Standard 62.1-1999.

• Patented SuperMod™ 20:1 turndown gas burner for

precise temperature control in conventional or high

minimum outdoor air applications.

• Fully integrated energy recovery wheel that recovers both

heat and moisture from exhaust air for maximum energy

and humidification savings, and to comply with ASHRAE

Standard 90.1 efficiency guidelines.

• A liquid refrigerant subcooling reheat system for improved

dehumidification control.

• Available with alternative non-HCFC refrigerant.

Contact your local McQuay sales representative for more

information on how your building environment can benefit

from innovative McQuay rooftop systems, or visit

www.mcquay.com.

Air-Cooled Packaged Rooftop Systems

Model RPS (shown) – 15 to 135 tons (blow through cooling)

Model RDT – 45 to 135 tons (draw through cooling)

Packaged Air Handlers

Model RAH – 12,000 to 50,000 CFM

Model RDS – 5,000 to 20,000 CFM

Packaged Energy Recovery Systems

Model RPR (shown) – 15 to 60 ton packaged rooftop systems

Model RAR – 5,000 to 15,000 CFM rooftop air handler

McQuay International delivers engineered, flexible solutions for commercial, industrial and institutional HVAC requirements with reliable

products, knowledgeable applications expertise and responsive support. McQuay products and services are provided through a worldwide network

of dedicated sales and service offices. In addition to Applied Rooftop Systems and air handlers, McQuay is your source for value-added HVAC

systems including Centrifugal, Screw and Scroll Compressor Water Chillers (10-2,500 tons), Evaporative Cooled Chillers (60-240 tons), Packaged

Chiller Plants, Skyline™ Outdoor Air Handlers (900-25,000 cfm), Destiny™ Indoor Air Handlers (600-15,000 cfm), Vision™ Customized Indoor Air

Handlers (900-50,000 cfm), Vertical Self-Contained Floor-By-Floor Units (15-125 tons), Coils, Fan Coils, Unit Ventilators, Water Source Heat Pumps,

Packaged Terminal Air Conditioners and Ductless Split Systems. For more information or the name of your local McQuay representative, call

1-800-432-1342 or visit www.mcquay.com.

©2004 McQuay International (800) 432-1342 www.mcquay.com ASP 31-791 (6/04)

Loading...

Loading...