Page 1

BULLETIN NO. IM 150-4

INSTALLATION AND

MAINTENANCE DATA

FORM NO. 308972Y REV. A

MODELS RHP & RHQ

FEBRUARY, 1981

AIR COOLED CONDENSING UNIT

3/4,

1,

1

1/2,

2,,

3,

5,

7

1/22

and

10

HP

Page 2

Page 3

INSPECTION

When the equipment is received,

all items should be carefully checked

against the bill of lading to be sure all crates and cartons have

been received.

when received.

carrier immediately and a claim should be filed.

All units should be carefully inspected for damage

If any damage is found,

it should be reported to the

The unit nameplate

should be checked to make sure that the voltage agrees with the power

supply available.

RIGGING

Remove nuts from bolts that hold unit to skid.

from skid.

protect the cabinet.

steel pipe,

points.

Rig unit as shown in Figure 1.

On 007 through 020 units, use two lengths of

inserted through holes in the unit base, as lifting

See Table 1 for unit weights.

This will free unit

Use a spreader bar to

FIGURE 1

UNIT RIGGING

Page 3

Page 4

INSTALLATION

General

Commercial equipment of this type is intended for installation by

qualified refrigeration mechanics.

As a condition of the warranty,

the check tests and startup procedure must be performed by qualified

personnel and must be properly reported on the form provided with

each unit.

Arrangements for service should be made prior to in-

stallation as it is not included in the warranty or the selling

price.

Unit Location

Units are designed for outdoor application and may be mounted on a

roof or concrete slab (ground level installation).

Roof mounted

units should be installed level on steel channels or an I-beam frame

to support the unit above the roof.

lators is recommended.

the weight of the unit.

The roof must be strong enough to support

See Table 1 for unit weights.

Use of vibration pads or iso-

Concrete

slabs used for unit mounting should be installed level and be prop-

erly supported to prevent settling.

A one piece concrete slab with

footings extended below the frost line is recommended.

The condenser coil side of the unit should be located no closer than

four feet from any wall or other obstruction to provide sufficient

clearance for air entrance.

be provided on the discharge side of the unit.

work to the coil inlet or fan outlet.

At least four feet of clearance should

Do not attach duct-

Care should be taken to avoid

air recirculation conditions that can be caused by sight screening,

walls, etc.

Also keep unit fan discharge away from any building air

intakes.

TABLE 1

l 1

l/8

on

050B-H

PHYSICAL DATA

CONNECTIONS

SHIPPING

Page

4

Page 5

Sound and Vibration

Units should be installed away from occupied spaces and above or outside of utility areas,

transmission of sound and vibration to occupied spaces.

corridors and auxiliary spaces to reduce the

The refrig-

erant piping should be flexible enough to prevent the transmission

of noise and vibration from the unit into the building.

If the re-

frigerant lines are to be suspended from the structure of the building, isolation hangers should be used to prevent the transmission of

vibration.

Where piping passes through a wall, it is advisable to

pack fiberglass and sealing compound around the lines to minimize

vibration and retain flexibility in the lines.

FIELD WIRING

Make the

on the unit,

codes and ordinances.

ation must not exceed

supply

All wiring must be done in accordance with applicable

power connection to the fused safety switch supplied

Size conductors using Table

+lO%

of the nameplate value.

on three-phase units must not exceed 2%.

TABLE 2

TOTAL

23Ol

1P

10.9

10.6

1 1.2

23.4

20.0

26.6

UNIT

A

MPS

5.1

5.9

5.9

6.7

6.5

7.8

7.8

7.8

1 I

,

I

-

_ _

I

23.3

208-

:

!30/3P(

-___

17.2

15.9

14.9

23.4

23.2

21 .6

35.1

34.1

35.3

57.1

58.0

_

46.0

L

RHP/RHQ

r

:ONDENSINC

UNIT SIZE

007&M

OlOB-L

0100-M

015B-L

015B-M

OZOB-L

OZOB-M

02OB-H

030B-L

030B-M

030B-H

050B-L

050B-M

05OB-H

075B-L

075B-M

075B-H

1 OOB-L

1008&l

1 OOB-H

NOTE:

1. Based on condenser fan motor FLA at 208 volts.

2. Based on 125% of compressor RATED LOAD AMPS plus 100%

of FLA for all other motors. Select conductors based on NEC

310-16 or

3. Use only time delay dual element fuses.

4. Based on maximum allowable unit cooler motor amps as shown

in table 9.

T

I

2081

1P

7.8 7.7

9.0 7.4

8.9 7.6

9.1 6.5

9.0 6.8

12.4

13.1

_

-

_ 22.9

-

_ 29.1

-

_ 35.2

_ _

- -

_ _

_ _

_ _

-

310-18.

ELECTRICAL RATINGS

MINIMUM CIRCUIT AMPS MINIMUM CIRCUIT AMPS

FOR UNITS WITHOUT

5.7

6.7

6.7

7.9

7.7

9.3

9.3

9.3

.J

.9

(2) ADE

4601

3P

+

_

_ 16.6

_ 16.4

_ 16.8

_ 16.7

_ 27.6

-

_

_ _

-

_

_ _

22.6

22.6

19.4

35.1

35.6

27.9

_

] - 1 -

13.5

28.2

T CIRCUIT

208- I

230/38(l)

20.4

18.8

17.5

28.2

27.9

25.9

41

40.4

41

69.2

70.3

55.3

FOR UNITS WITH

ROST

2081

YTZ-

IP

16.3

27.8

_

_

_

-

-

-

-

-

-

CIRCUI

2.

Voltage vari-

Phase unbalance

MAXIMUM

2301

I

45

35

50

FUSE

4

SI2

;

_

_

T

I

2)

(41

T(

T

,

4601

ZOO81

1P lP

3P

_

15 15

_

15 15

-

15 15

_

15 15

-

15 15

25 20

25 20

_ 20

-

_ 45

-

_

-

-

_ 50

_

_ 60

_ _

37.6

_

37.6

32.9

-

50.1

_ _

50.6

- -

,

42.9

15 _

15

15

15

15

15

15 _

15

30

25

25

45

45 _

40 _

60 35

60 35

60 30

100 50

100 60

90 45

I

-

-

-

_

-

-

-

-

-

-

Page 5

Page 6

The unit is designed to operate with a pumpdown cycle, therefore a

solenoid valve must be installed in the liquid line (see Figure 2).

Make sure that the system is wired so that the pumpdown cycle is initiated if power to the unit cooler fan motors is disconnected.

Diagrams 1and 2 show typical control wiring for air and electric

defrost applications respectively.

SEAsommm

Diagram 15 shows field wiring of the Seasonmiser system.

must have a pump down solenoid valve in the liquid line.

FIELD

WIRING (RHQ

ONLY)

All units

The primary

of the Class II transformer is connected in parallel with the pump

down solenoid valve.

in series with the sensor and heat motor assembly.

pressure control is required,

The transformer secondary (24 VAC) is connected

If a differential

it is connected in parallel with the

subcooling sensor.

DIAGRAM I

DIAGRAM 2

PIPING

Install piping according to standard accepted refrigeration practice.

See Figure 2 for typical refrigerant piping. The following recom-

mendations should be adhered to.

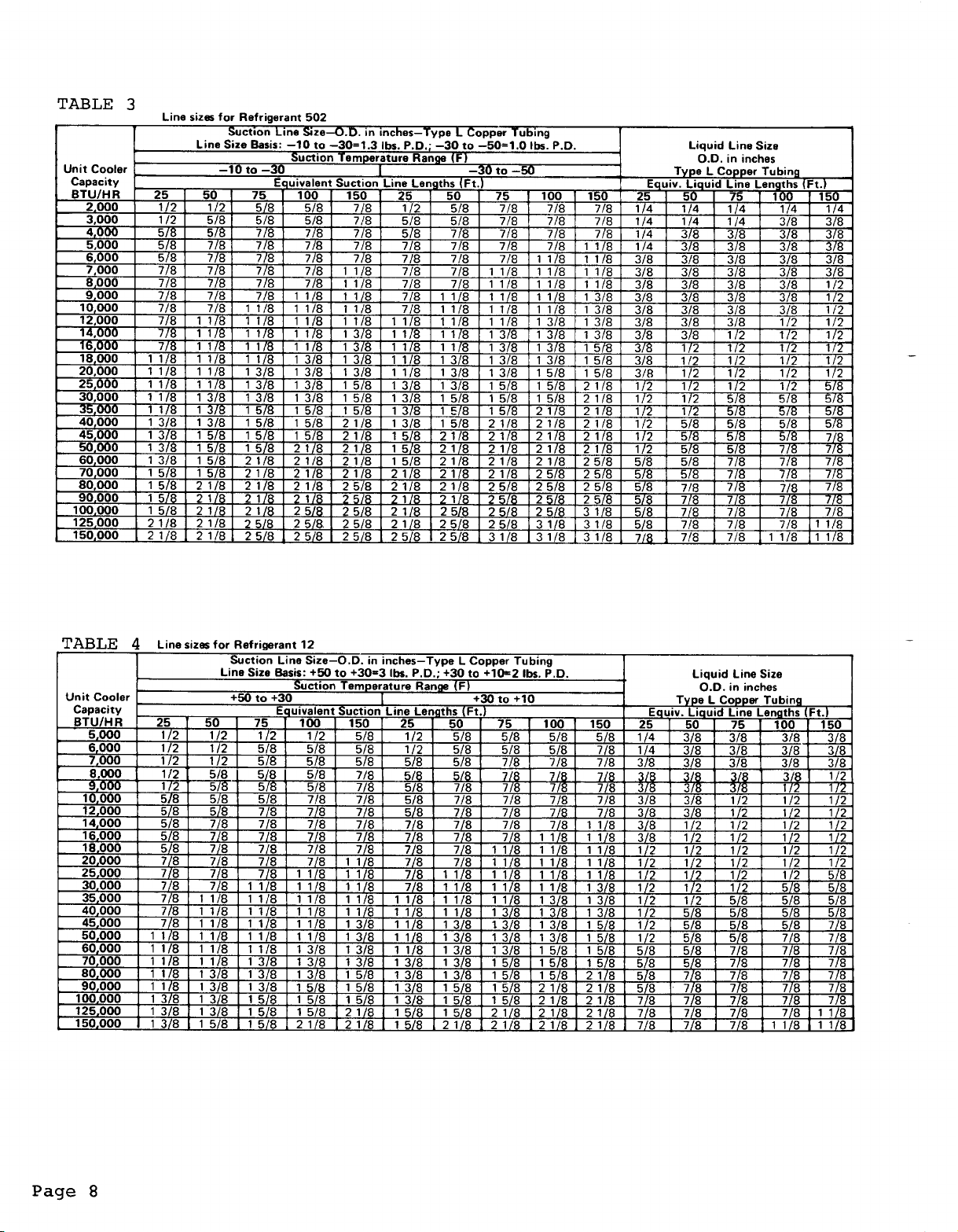

See Tables 3,4 and 5 for recommended liquid and suction line

1.

sizing.

2.

Use only refrigeration grade copper tubing.

3.

Soft solder joints are not acceptable.

Pass dry nitrogen through lines while brazing.

4.

Do not leave dehydrated piping or components open to the atmos-

5.

phere any longer than is absolutely necessary.

Use a P-trap at the base of suction risers greater than 3

6.

to 4ft.in

height to improve oil return.

Page 6

Page 7

7.

8.

9

_ .

10.

Slope suction line

l/2"

per 10 ft.

in direction of flow to improve

oil return.

Support piping with hangers to prevent transmission of vibration

to the building.

If not furnished with condensing unit, install a filter-drier

and a sight glass in the liquid line.

A solenoid valve must be installed in the liquid line because

the condensing unit is designed to operate with a pump down cycle.

FIGURE

1

2

3

4 Thermostatic Expansion Valve

5 Liquid Line

6 Suction Line, Pitched Toward Compressor

7

NOTE: FILTER-DRIER AND SIGHT GLASS MAY BE

2

LEGEND

Filter-Drier

Solenoid Valve

Sight-Glass/Moisture indicator

Drain Line, Heat Trace for Low Temperature

FURNISHED WITH CONDENSING UNIT.

TYPICAL REFRIGERANT PIPING

SEASONMISER PIPING

(RHQ

ONLY)

To maximize the energy-saving potential of the Seasonmiser system,

keep tubing runs as short as possible and insulate the liquid line

all the way to the cold zone.

desired to prevent sweating.

prevent suction gas at the compressor from rising above

The suction line may be insulated if

In any case,

care must be taken to

65OF

under

any condition.

Locate the subcooling sensor (and differential pressure switch where

required) at the point where the liquid line enters the refrigerated

space.

The location should be outside of the refrigerated space.

The subcooling sensor should be within 12" of the entry point.

Pump down solenoid valves and heat exchangers (where used) should be

downstream of the subcooling sensor.

with the evaporator shortens sensor life.

Making the sensor pump down

Heat exchangers upstream

of the sensor can allow the formation of flash gas upstream of the

heat exchanger.

The subcooling sensor is assembled with low melting point solder.

It should be installed using flare connections provided.

Brazing

or soldering will damage the sensor.

The differential pressure control should have the pressure tap

labelled liquid connected to the liquid line and the tap labelled

suction connected to the suction line.

Page 7

Page 8

Page 9

Page 10

TABLE 6 CONDENSING UNIT CHARGE(LBS.)

AMBIENT TEMPERATURE F

RHPIRHQ

0070-M

OlOB-L

01OB-M

015B-L

015B-M

02OB-L

02OB-M

020B-H

03OB-L

030B-M

03OB-H

05OB-L

05oB-M

OBOB-H

075B-L

075B-M

075B-H

lOOB-L

lOOB-M

IOOB-H

10 0

1

4.7

4.5

4.7

5.6

5.9

5.6

5.9 6.0 6.1

5.4

10.4

10.9

9.9

18.2 I 18.7

34.6 35.5 36.1 37.0

36.5 37.4

33.2 33.9 34.6

4.8 4.9 5.0

I

4.6

4.8

1

5.7 7

610

1

5.7

5.5 5.6

I 10.5

11.1 11.3

10.1

-10

1

4.7

419

2::

1

Tmp5.8

1

10.7

10.3

I

19.0 I 19.5 1

38.0 38.9

-20

lower

.I

I

1

4.8

5.0

5.9

6.2

5.9

6.2

5.7

11 .o

11.6

10.6

35.5

%I

TABLE 7

LGTH.

OF

LIQ. LINE O.D. OF LIQUID LINE

(FT.)

in

20 0.34

30 0.51

40

50

60

70 1.19

a0

90

100

l/4

0.17 0.47

0.68

0.85 2.35

1

.02

1.36 3.76 6.96 11.20

1.53 4.23 7.88 12.60

1.70 4.70 8.70 14.00

CHARGING AND INITIAL STARTUP

1.

Make sure all electrical

2.

The compressor oil level

ter of the sight glass.

3.

Make sure the compressor

They should be tightened

under the hold down nuts

Check all system controls and adjust if necessary.

4.

in pressure of the low pressure switch for the lowest ambient in

which the condensing unit will be operated, using Table 8.

the cut-out pressure low enough to avoid short cycling.

Make sure compressor suction and discharge valves are back-seated.

5.

Attach charging line to charging port on liquid line valve and

6.

front-seat the valve.

Turn on electrical power to the condensing unit and the unit

7.

cooler(s).

8.

Open the valve on the refrigerant cylinder and begin charging

liquid refrigerant into the system.

when the low pressure switch closes.

total system charge, as calculated,

9.

When the correct charge has been added back-seat the liquid line

valve.

Page 10

LIQUID LINE CHARGE

3/a

0.94

1.41

1

2.82

3.29

I

1

.88

connections are tight.

should be at or slightly above the

Use only Suniso 3G or 3GS compressor oil.

hold down bolts are properly tightened.

to the point where the rubber spacers

just begin to deform.

WEIGHT OF REFRIGERANT (LB.)

l/2

0.87 1.40

1.74

2.61 4.20

3.48 5.60

4.35 7.00

5.22 8.40

6.09 9.80

I

518

2.80

I

The compressor will start

Continue charging until the

has been added to the system.

718

2.90 4.95

5.80 9.90

8.70 14.85 22.65

11.60 19.80 30.20

14.50 24.75 37.75

17.40

20.30 34.65 52.85

23.20 39.60 60.40

26.10 44.55 67.95

29.00 49.50 75.50

I

Ill8

29.70

1

1 318

I

7.55

15.10

45.30

cen-

Set the

cut-

A

Set

Page 11

10.

Record the system charge on the unit nameplate.

TABLE 8

\

(F)

50

40

30

20

10

0

-10

-20

45 35 25 15

3";

25 25

19 19

12 12

30 22

30 22

8

2

1

LOW

PRESSllRF

:;

22

19 15

12 17

15

CCINTR~II CII I-r_Inl ci=-r-rlnlc IDCICI

5

::

10

10

ill

65

50

40

OPERATIONAL CHECKOUT

1.

Check supply voltage.

It must be within

?lO%

of the voltage lis-

ted on the unit nameplate.

2.

Check the compressor amp draw. It must not exceed the value listed on the unit nameplate.

On 3-phase compressors phase unbal-

ance must not exceed 2%.

3.

Make sure discharge and suction pressures are within normal design

limits.

units furnished with Seasonmiser control.

Note:

Discharge pressure may be lower than normal on

See information on

Seasonmiser system operation.

4.

Make sure that the crankcase heater is functioning.

5.

After several hours of operation,

check the compressor oil level.

It should be maintained approximately at the center of the sight

glass on the compressor.

SEQUENCE OF OPERATION

Wiring for all units is shown in Diagrams 3 through

8.On

208 volt or230

volt units line voltage power is fed to the compressor crankcase heater

and the unit control circuit. On 460 volt units a transformer

Tl

is

furnished to reduce the line voltage to 230 volt power for the crankcase heater and control circuit.

When the fused safety switch is closed,power is supplied to the con-

densing unit. Compressor operation is typically controlled by a

field mounted liquid line solenoid valve. On a call for cooling, the

solenoid valve opens.

low pressure switch in Dual Pressure Control

tacts.

Switch

MPl),

When all operating safety controls are closed (High Pressure

PCl,

Oil Failure Control

the compressor and condenser fan(s) start.

When the demand for cooling is satisfied,

valve closes,

initiating the pumpdown cycle. The condensing unit con-

An increase in refrigerant pressure closes the

PCl,

energizing its con-

OPl,

and Compressor Motor Protector

the liquid line solenoid

tinues to run until the low pressure switch in the Dual Pressure Control PC1 opens.

Opening the low pressure switch in PC1 deenergizes

its contacts and shuts down the unit.

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Defrost Circuit Applications

DEFROST CIRCUIT

When an RHP or

matched with an electric defrost unit cooler

REM-007B through

1OOB

unit with a defrost circuit is

(s)

make sure that the

condensing unit voltage and the unit cooler voltage are the same.

Also,

use Table 9 to determine whether or not

the

total unit cooler

motor load and defrost heater load fall within the limits of the de-

frost circuit components. Example No.

1 shows a typical system

match in which the limits of the defrost circuit components are not

exceeded.

Table 2 lists the minimum circuit amps for the

supply

conductors on a

condensing unit furnished with a defrost circuit. The minimum circuit amps shown in Table 2 are based on either the unit cooler motor

load or the defrost heater load being the maximum allowable value.

Field wiring between the condensing unit and the unit cooler fan

motors on 208 or 230 volt units must have a minimum ampacity equal

to 125% of the largest unit cooler fan motor FLA plus 100% of the

remaining fan motor

conductors to the fan motors must be at least

FLA's.

On 460 volt units the ampacity of the

l/3

of the ampacity

of the supply conductors to the condensing unit (see Table 2).

The ampacity of the supply circuit conductors from the defrost con-

tactor to the defrost heaters must be equal to or greater than the

condensing unit safety switch fuse amp rating.

It may be possible

to reduce the size of the supply circuit conductors by installing

branch circuit fusing outside of the condensing unit control panel,

Select the branch circuit fusing for the total defrost heater load.

The ampacity of the supply circuit conductors must be at least equal

to the fuse size.

TABLE 9

RHPI

RHG

CONDENSING

UNIT

SIZE

0076-M

OlOB-L

0106-M

015B-L

015B-M

OZOB-L

02OB.M

OZOB-H

03OB-L

030B-M

030B.H

05OB-L

050B.M

050B-H

075B-L

075B-M

075B-H

lOOB-L

1 OOB-M

1 OOB-H

MAX. MAX. MAX.

UNIT

COOLER COOLER

FAN MTR. OEF. HTR. FAN MTR. DEF. HTR. FAN MTR. DEF. HTR. FAN MTR. DEF. HTR.

AMPS AMPS

7.2

6.0 15 7.4

6.0 15 7.4

5.9

5.9

12.6

1 1

.9

_ _

_ _

_ _

_ _

-

_ _

_ _

_ _ _

_ _

_

_ _

_ _ _

MAXIMUM UNIT COOLER MOTOR AND HEATER LOADS

ELECTRICAL POWER SUPPLY

208/60/l

UNIT

15

15

15 8.2

25 9.1

25 9.1

_

_ _

230/60/l

UNIT

COOLER COOLER COOLER

AMPS

7.3

6.2 15 8.3

8.8

13.5

13.5

13.5

13.5

13.5

13.5

_

_

_

MAX. MAX. MAX.

UNIT

(2)

AMPS

15 9.9

15 9.1

15 9.1 15

15 8.3 15

20 7.2 15

20 7.2 15

20 7.2 15

30

30

30

_

_

_

_

_

_

_

-

_

208-230/W/3

UNIT UNIT

AMPS AMPS

9.6

9.1 25

10.1

13.5

13.5 40

13.5 40

13.5

13.5 60 15.0 35

13.5

13.5 60

13.5 60

13.5 60 15.0 40 60 40

46Ol6013

MAX.

COOLER COOLER COOLER (AMPS

15

15

15

30

25

40

60

60 13.5 30

UNIT

AMPS

_

_

_

_

_

_

_ _

_ _

_

_

15.0 35

150

150

_

_

_

_

_

_

_

_

_

DEFROST

CONTACTOF

RATING0 I

(208- 460

30

30

30

30

30

30

30

30

30

30

30

40

40

40

60 40

60 40

60 40

MAX.

UNIT

AMPS 230

_

40 - 60 40

40 60 40

RES.)

-

-

-

-

~

-

-

~

-

-

-

-

NOTES:

1. 2 pole on single phase units, 3 pole on three phase units, N.A. on

single phase

0508

units.

2.Defrost contactor N.A. on single phase 0508 units.

Page 18

Page 19

Example No. 1

A

208-230/60/3

unit cooler.

RHQ-030B-L condensing unit matched with (1) EEP-012B

(DSl)

RHQ unit safety switch

Maximum allowable unit cooler fan motor load:

9)

Maximum allowable defrost heater load:

Voltage of EEP unit:

Total EEP fan motor load:

Total EEP defrost heater load

208-230 V (See

fuse rating:

Catalog 72)

1.9 amps (See

(rated at

30 amps (See Table

30 amps (See Table 9)

Catalog 72)

24OV):

18.1 amps

(See Catalog 72)

Check of unit cooler fan motor circuit:

A.

Condensing unit voltage and unit cooler fan motor voltage

1.

are the same.

Total unit cooler fan motor load does not exceed the listed

2.

maximum of 12.8 amps.

Therefore,

the

limits of the defrost circuit,

The supply circuit conductors to the motors must have a min-

imum ampacity equal to:

the unit cooler fan motor load does not exceed

1.25 x 1.9 = 2.4 amps.

9.6 amps (See

2)

Table

Check of unit cooler defrost heater circuit:

B.

1.

Condensing unit voltage and unit cooler defrost heater voltage agree.

2.

Total unit cooler defrost heater load does not exceed the

listed maximum of 30 amps,

Therefore,

ceed the limits of the defrost circuit.

The supply circuit conductors to the defrost heaters must have a

minimum ampacity of 30 amps unless branch circuit fusing is used.

If branch circuit fusing is used it must be sized for the total defrost heater load or 18.1 amps.

size should be used or 20 amp fuses.

must have minimum ampacity of 20 amps.

In some applications,

ceed the maximum defrost circuit limits listed in Table 9.

limits are exceeded,

selecting and wiring additional circuit components.

Applications Exceedinq the Limits of the Defrost Circuit

A.

Unit Cooler Fan Motor Load

If the total unit cooler fan motor load exceeds the limits of the

defrost circuit listed in Table 9,

motors can not be supplied through the condensing unit defrost

circuit.

A separate power supply must be field installed out-

the unit cooler defrost heater load does not ex-

The next larger standard fuse

The supply circuit conductors

one or both of the unit cooler loads may ex-

If the

see the following section for instructions on

power to the unit cooler fan

Page 19

Page 20

side of the condensing unit control panel for the motor load.

It must include a contactor rated for the total motor FLA and a

fused safety switch, Select fuses for a maximum of 175% of the

FLA of the largest unit cooler fan motor plus 100% of the FLA of

the remaining motors.

B.

Unit Cooler Defrost Heater Load

If the total unit cooler defrost heater load exceeds the limits

of the defrost circuit listed in Table 9, power to the unit cooler defrost heaters can not be supplied through the condensing

unit defrost circuit.

A separate power supply must be field

installed outside of the condensing unit control panel for the

defrost heater load.

It must include a contactor and a fused

safety switch rated for the total heater load,

The following example shows a system match in which the limits

of the defrost circuit in the condensing unit are exceeded.

Example No. 2

A 208-230/60/3

RHP-lOOB-L

condensing unit matched with (2) EEP-036B

unit coolers.

RHP unit safety switch

(DSl)

fuse rating: 100 amps (See Table

Maximum allowable unit cooler fan motor load:

9)

Maximum allowable defrost heater load:

Voltage of EEP unit:

Total EEP fan motor load:

Total EEP defrost heater load:

A.

Check of unit cooler fan motor circuit:

1.

Condensing unit voltage and unit cooler fan motor are the

208-230V (See Catolog 72)

17.6 amps (See Catolog 72)

68 amps (See Catolog

60 amps (See Table

same.

2.

Total unit cooler fan motor load does exceed the listed

maximum of

13-5

amps.

Since the total fan motor load exceeds the limits of the

defrost circuit a separate circuit must be provided for

the unit cooler fan motors.

Maximum fuse size is equal to:

(1.75 X 4.4 + (3 X 4.4) = 20.9 amps. Therefore use 20 amp

fuses.

2)

13.5 amps (See Table

9)

72)

Page 20

Page 21

B.

Check of unit cooler defrost heater circuit:

1.

Condensing unit voltage and unit cooler defrost heater voltage agree.

2.

Total unit cooler defrost heater load does exceed the limits

of the defrost circuit.

Since the total defrost heater load exceeds the limits of

the defrost circuit a separate circuit must be provided for

the unit cooler defrost heaters.

A contactor rated at least

68 amps or two contactors each rated at least 34 amps must

be provided.

Also,

a fused safety switch must be provided.

Size fuses for the total heater load. Therefore, use 70

amp fuses.

Or if two switches are installed use 35 amp

fuses.

Field Wiring of Defrost Circuit

Diagrams 9 through 14 show typical defrost circuit wiring between a

condensing unit and single or multiple unit coolers.

wiring to the room thermostat and liquid line solenoid valve.

wiring is shown dashed.

Diagrams 9 through 12 show wiring for cases

Also shown is

Field

where the total unit cooler fan motor or defrost heater loads are

within the amperage limits of the defrost circuit components provided

in the condensing unit.

Diagrams 13 and 14 show cases where the am-

perage limits of the defrost circuit components are exceeded.

Defrost circuit wiring is the same whether a single-phase or a three-

phase condensing unit is furnished except that a three-pole defrost

contactor is provided on three-phase units.

three-phase condensing unit,

most unit cooler defrost heaters may be

wired for either single-phase or three-phase operation.

When matched with a

See the Installation and Maintenance Bulletin shipped with the unit coolers for

specific information on defrost heater wiring.

Disconnect switches must be installed within sight of the unit

cooler if required by local codes.

If a disconnect switch is installed

for the unit cooler fan motors it must also disconnect the liquid line

solenoid valve so that when the unit cooler fans are disconnected the

condensing unit pumps down.

It is recommended that when a disconnect

is installed for the fan motor and solenoid valve circuits that one

also be installed for the defrost heaters.

This will allow total

shut-down of the unit cooler and will prevent the possibility of the

defrost heaters being energized when the fan motor and solenoid valve

circuits are disconnected.

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Defrost Circuit Operation

Diagrams 3 through 8 show the defrost circuit wiring provided in each

condensing unit.

Diagrams 9 through 14 show field wiring between the

condensing unit and the unit cooler(s) for typical applications.

During normal refrigeration operation defrost timer

closed from terminal 1 to terminal 4.

This energizes the unit cooler

(TD)

contacts are

fan motors through the contacts of defrost termination thermostat

(TCl)

(the unit cooler fan motor contactor is energized on 460V units).

The fan motors operate continously during the refrigeration cycle.

The liquid line solenoid valve

4 on timer

(TD)through

the room thermostat(TC2).

(SV)

is also energized from terminal

Compressor operation

is controlled by the solenoid valve (SV).

When a defrost cycle is initiated by timer

(TD)its contacts open from

terminal 1 to terminal 4 and close from terminal 1 to terminal 3.

Opening the circuit to terminal 4 de-energizes the unit cooler fan

motors and the liquid line solenoid valve (SV)

The compressor will

continue to run in a pumpdown cycle until the low pressure switch

in the dual pressure

control (PC)opens.

When the compressor shuts

off the auxiliary contacts on the compressor contactor(Ml)close.

This closes the circuit to the defrost contactor(M2),which energizes

the defrost heaters in the unit cooler.

The heaters remain energized

until the defrost is terminated by thermostat(TC1).

NOTE:

The auxiliary contacts on compressor contactor(Ml)serve

as an interlock so that the defrost heaters can never be

energized when the compressor is running. If, for exam-

ple,

during a defrost cycle the refrigerant pressure

builds up to the point where the low pressure switch

closes,

when the compressor starts,

the compressor will run in a pumpdown cycle.

the auxiliary contacts will

But

open the circuit to the defrost contactor de-energizing

the defrost heaters.

The defrost contactor will be

re-

energized when the pumpdown cycle is completed.

The defrost cycle is terminated when the termination thermostat(TC1)

switches,

energizes the solenoid in

3 and closing the circuit to terminal 4.

terminal 3 de-energizes the defrost heaters.

closing its contacts from terminal R to terminal Y.

timer(TD),

opening the circuit to terminal

Opening the circuit to

Closing the circuit to

This

terminal 4 energizes the liquid line solenoid valve(SV]circuit and

the unit cooler fan motor circuit.

The fan motors will not start

until the temperature has cooled down to the point where the con-tacts

of the thermostat

[TCl)switch,

so they are closed from R to B.

SEASONTROL HEAD PRESSURE CONTROL SYSTEM

Figure 3 illustrates the piping of the Seasontrol valve.

and R22 systems,

R12 systems it controls at approximately 115 psig.

the valve controls at approximately 200 psig. On

At condensing

On R502

pressures above the valve setting flow enters port C and leaves port

R.

When the condensing pressure falls below the valve setting, the

valve modulates to permit discharge gas to enter port B.

Metering

discharge gas into the flow leaving the condenser produces a higher

pressure at condenser outlet,

of liquid to rise in the condenser.

reduces the flow and causes the level

Flooding the condenser with

liquid reduces the available condensing surface, holding the condensing pressure at the valve setting.

Page

27

Page 28

FIGURE 3

CONDENSER

COIL

\

CONTROL VALVE

t

COMPRESSOR

SEASONMISER HEAD PRESSURE CONTROL SYSTEM

Installation

Figure 4 and Diagram 15 show typical piping and wiring for a Season-

miser system.

Operational Checkout

7

1.

Before connecting power to the heat motor, check its continuity.

Resistance through the heat motor should measure between 50 and

100 ohms.

2.

Also, before connecting the two power leads to the heat motor,

check the voltage drop across the leads.

Make sure that the

liquid line solenoid valve is energized so that the primary of

the Seasonmiser circuit transformer is receiving power.

3.

Pump down the system by closing the liquid line shutoff valve.

Pumping down the system will assure that the sub-cooling controller switch is closed.

A voltage drop of 24 volts should be

measured across the two power leads.

4.

When the ambient temperature is below about

700

F operation of

the Seasonmiser system can be checked by slowly throttling the

liquid line shutoff valve to create flashing in the liquid line.

If the system is functioning properly,

will rise when there is flash gas in the liquid line.

the condensing pressure

It should

fall when the valve is reopened.

Seasonmiser Operation

The pressure at which the Seasonmiser valve begins to control is var-

iable.

R12 and R22 systems a differential pressure controller.

The valve is controlled by a sub-cooling controller and on

The

sub-

cooling controller monitors the amount of sub-cooling at the TEV and

the differential pressure controller monitors the pressure differen-

tial across the TEV.

pressure differential remain above

not begin to control regardless of

flow will be through the condenser

As

lonq

as the amount of sub-cooling and the

preset minimums, the valve will

the ambient temperature.

and the condensing pressure will

Full

fall as the ambient falls.

_

Page 28

Page 29

however,

If,

either the amount of sub-cooling or the differential

pressure fall below the preset minimums, the heat motor will be ener-

gized.

This will raise the control point of the valve and the valve

will begin to modulate to permit discharge gas to enter port B. Metering discharge gas into the flow leaving the condenser produces a

higher pressure at the condenser outlet, reduces the flow and causes

the level of liquid to rise in the condenser.

Flocding the conden-

ser with liquid reduces the available condensing surface and raises

the condensing pressure. Pressure will continue to rise until both

the amount of sub-cooling and the differential pressure are above

preset minimums.

ential pressure controller are satisfied, the heat motor will be

When both the sub-cooling controller and the differ-

de-

energized and the condensing pressure will begin to fall until either

sensor calls for an increase.

The condensing pressure thus cycles

up and down through a narrow range during low outdoor ambient operation.

The temperature limiting thermostat in the heat motor assembly prevents excessive temperatures from damaging the valve or motor and

limits the receiver pressure increase in the event that one of the

switches fails to open.

The thermostat will automatically reset and

the system can cycle on the temperature limiting thermostat without

damage.

FIGURE 4

1

2

3

4

5

6

7

8

9

10

11

12

LEGEND

Liquid Line

Sight Glass/Moisture Indicator

Filter-Drier

Solenoid Valve

Thermal Expansion Valve

Drain Line, Heat Trace for Low Temp

Liquid Line

Suction Line

SEASONMISER Valve

Heat Motor

Subcooling Controller

Differential Pressure Controller (Med. & High Temp

Units Only)

Shutoff

Valve

Page

29

Page 30

DIAGRAM

15

sv

T2

PC1

PC2

HM

TC3

H2

NOTE:

t-------

LEGEND

Liquid Line Solenoid Valve

I I

Transformer

Class

Subcooling Controller

Differential Pressure Controller

Heat Motor

Heat Motor Limit Switch

Heat Motor Heater

- - -

Field Wiring

HM

I

MAINTENANCE

Periodic Service

The following should be checked annually:

1.

Make sure that the liquid line sight glass is clear.

2.

Make sure the compressor oil level is near the center of the oil

sight glass on the compressor.

3.

Check the condenser coil face for obstruction.

flush with cold water,

4.

Make sure that the crankcase heater is functioning.

5.

Oil the fan motor bearings with SAE-20 weight oil.

Make a general inspection of the entire system for any unusual

6.

brush off or clean with a vacuum cleaner.

noise or vibration.

Page 30

If necessary,

Page 31

Condenser Fan and Motor Access

On the 007Bthrough

the condenser fan or motor is easily accomplished by

tire top section of the unit as shown in Figure 5.

six screws as shown,

020B

units access for service or replacement of

removing the en-

By removing the

the top can be lifted off from the unit.

Then,

when the two screws at the top of the fan deck are removed, the fan

deck can be tilted toward the compressor to provide enough space to

remove the fan.

Once the fan is removed from the motor shaft and the

motor mount bolt holding the motor in place is loosened, the motor

can be removed.

The 030B through

1OOB

units have enough access space around the fan

guards so that servicing the fan or motor is most easily done by removing the bolts that hold the fan guard to the fan deck.

FIGURE 5

FAN AND MOTOR ACCESS

Page 31

Page 32

Adding Refrigerant to an Undercharged System

To add refrigerant to a system that has been leaking, use the fol-

lowing procedure after repairing the leak.

A.

If there is flash gas in the sight glass at the condenser:

Add refrigerant until the sight glass remains clear.

1.

2.

Use Table 1 to determine the required condensing unit charge

for the current ambient and also for the minimum design am-

bient.

3.

Add additional charge equivalent to the difference between

the two charging requirements determined in step 2.

B.

If there is no flash gas in the sight glass:

If the system has leaked but not to the point where the sight

glass is flashing,

should be added is to remove refrigerant from the system until

the sight glass begins to flash.

above.

the only way to determine how much refrigerant

Then proceed with steps l-3

SERVICE AND WARRANTY PROCEDURE

Motor

Copeland Refrigeration Corporation has stocking wholesalers who maintain a stock of replacement

serve refrigeration contractors and servicemen as required.

When a

compressor can be taken to any authorized Copeland Wholesaler for an

over-the-counter exchange,

Credit is issued on the returned motor-compressor upon receipt and

factory inspection of the inoperative motor-compressor.

On all out--of-warranty motor-compressor failures, Copeland offers the

same field facilities for service and/or replacement as described

above.

determined by the repair charge established for that particular unit.

In Warranty Return Material Procedure

(Other than compressors) material may not be returned except by permission of authorized factory service personnel of McQuay Group at

Minneapolis, Minnesota. A "Return Goods"

cluded with the returned material. Enter the information as called

for on the tag,

prompt issuance of credits.

The return of the part does not constitute an order for replacement.

Therefore,a purchase order must be entered through your nearest

McQuay Group representative or

include part name, part number,

unit involved.

-

Comoressor

motor-compressors

motor-compressor fails in warranty,the inoperative motor-

or an advance replacement can be obtained.

The credit issued on the returned motor-compressor will be

tag will be sent to be in-

in order to expedite handling at our factories and

McQuay

model number and serial number of the

Distributor.

and service parts to

The order should

If it is determined that the failure of the part is due to faulty

material or workmanship, and is in warranty, credit will be issued

on the customer's account.

All parts shall be returned to the pre-designated McQuay Group fac-

tory,

Page 32

transportation charges prepaid.

Page 33

Replacement Parts

your

Replacement service parts can be ordered through

representative or McQuay Distributor.

scription of service part,

part number (if known), plus complete

serial and model number of unit involved.

Always provide complete de-

Replacement parts for the

nearest McQuay

motor-compressor assembly can be procured direct from your nearest

franchised Copeland Refrigeration Corporation Wholesaler.

TROUBLE SHOOTING CHART

PROBLEM

Compressor will not run

Compressor noisy or vibrating

High Discharge Pressure

Low Discharge Pressure

High Suction Pressure

Low Suction Pressure

Little or no oil pressure

Compressor loses oil

Compressor thermal

protector switch open

POSSIBLE CAUSES

1.

Main switch open.

2. Fuse blown.

3. Thermal overloads tripped.

4. Defective contactor or coil.

5. System shut down by safety devices.

6. No cooling required.

7. Liquid line solenoid will not open.

8. Motor electrical trouble.

9. Loose wiring.

1. Flooding of refrigerant into crankcase.

2. Improper piping support on suction

or liquid line.

3. Worn compressor.

1.

Non-condensibles in system.

2. System overcharges with refrigerant.

3. Discharge shut-off valve partially closed.

4. Fan not running.

5. Insufficient refrigerant in system

(RHO onlv).

1.

Faulty condenser temperature regulation.

2. Suction shut-off valve partially closed.

3. Insufficient refrigerant in system.

4. Low suction pressure.

1.

Excessive load.

2. Expansion valve overfeeding.

1. Lack of refrigerant.

2. Evaporator dirty.

3. Clogged liquid line filter drier.

4. Clogged suction line or compressor

suction gas strainers.

5. Expansion valve malfunctioning.

6. Condensing temperature too low.

7. Failure of heat motor electrical

circuit

(RHO

only).

8. Failure of bellows in subcooling

controller

1. Clogged suction oil strainer.

2. Excessive liquid in crankcase.

3. Low oil pressure safety switch defective.

4. Worn oil pump.

5. Oil pump reversing gear stuck in wrong

position.

6. Worn bearings.

7. Low oil level.

8. Loose fitting on oil lines.

9. Pump housing

1. Lack of refrigerant.

2. Excessive compression

1. Operating beyond design conditions.

2. Discharge valve partially shut.

3. Blown valve plate gasket.

(RHQ

onlv).

qasket

leaks.

rinq

.-

blow-by.

POSSIBLE CORRECTIVE STEPS

1.

Close switch.

2. Check electrical circuits and motor winding for shorts or grounds. Investigate for

possible overloading. Replace fuse after

fault is corrected.

3. Overloads are auto. reset. Check unit

closely when unit comes back on line.

4. Repair or replace.

5. Determine type and cause of shutdown

and correct it before resetting safety switch

6. None. Wait until unit calls for cooling.

7. Repair or replace coil.

8. Check motor for opens, short circuit, or

burn out.

9. Check all wire junctions. Tighten all

terminal screws.

1. Check setting of expansion valve.

2. Relocate, add or remove hangers.

3. Replace.

1. Purge the noncondensibles.

2. Remove excess.

3. Open valve.

4. Check electrical circuit.

5. Check for leaks, repair and add charge.

1. Check condenser control operation.

2. Open valve.

3. Check for leaks. Repair and add charge.

4. See Corrective steps for low suction

pressure below.

1.

Reduce load or add additional equipment.

2. Check remote bulb. Regulate superheat.

1.

Check for leaks. Repair and add charge.

2. Clean chemically.

3. Replace cartridge(s).

4. Clean strainers.

5. Check and reset for proper superheat.

6. Check means for regulating condensing

temperature.

7. Replace defective component. NOTE:

If heat motor is defective,entire assembly

must be replaced.

8. Replace control.

l.Clean.

2. Check crankcase heater. Reset expansion

valve for higher superheat. Check liquid

line solenoid valve operation.

3. Replace.

4. Replace.

5. Reverse direction of compressor rotation.

6. Replace compressor.

7. Add oil.

8. Check and tighten system.

9. Replace gasket.

1. Check for leaks and repair. Add refrigerant.

2. Replace compressor.

1.

Add facilities so that conditions are

within allowable limits.

2. Open valve.

3. Replace gasket.

Page

33

Loading...

Loading...