Page 1

Installation and Maintenance Manual IM-805

Group: Light Commercial

Part Number: IM-805

Date: August 2005

Supersedes: March 2005

RG Single Package Gas-Electric

Heating and Cooling Unit

2 to 5 ton

© 2004 McQuay International

IM-805 Page 1

Page 2

Table of Contents

MODEL NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Codes and Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Important Message to the Installer . . . . . . . . . . . . . . . . . . . .4

Important Message to the Owner . . . . . . . . . . . . . . . . . . . . .4

Recognize Safety Symbols, Words, and Labels . . . . . . . . . .4

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

GENERAL WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

UNIT LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

All Installations: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Ground Level Installations Only: . . . . . . . . . . . . . . . . . . . . . .6

Rooftop Installations Only:. . . . . . . . . . . . . . . . . . . . . . . . . . 6

Roof Curb Installations Only:. . . . . . . . . . . . . . . . . . . . . . . . .6

GENERAL INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . 7

RIGGING DETAILS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

GAS PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PROPANE GAS INSTALLATION. . . . . . . . . . . . . . . . . . . . 9

Tanks and Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ELECTRICAL WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Thermostat Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Unit Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Heat Anticipator Setting . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CIRCULATING AIR AND FILTERS . . . . . . . . . . . . . . . . . . 11

Airflow Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Horizontal Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Down Discharge Applications . . . . . . . . . . . . . . . . . . . . . . . 11

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

VENTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Flue Hood Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

CONDENSATE DRAIN . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Condensate Drain Connection . . . . . . . . . . . . . . . . . . . . . .12

NORMAL SEQUENCES OF OPERATION . . . . . . . . . . . . 12

Heating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Fan Only. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

STARTUP, ADJUSTMENTS, AND CHECKS . . . . . . . . . . .13

Heating Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Cooling Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ignition Control Error Codes . . . . . . . . . . . . . . . . . . . . . . . .16

Abnormal Operation - Heating . . . . . . . . . . . . . . . . . . . . . . .16

Abnormal Operation - Cooling . . . . . . . . . . . . . . . . . . . . . . 17

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Filter Replacement or Cleaning . . . . . . . . . . . . . . . . . . . . . 17

Cabinet Finish Maintenance. . . . . . . . . . . . . . . . . . . . . . . . 17

Clean Outside Coil (Qualified Servicer Only) . . . . . . . . . . .17

Condenser, Evaporator, and Induced Draft Motors. . . . . . 17

Flame Sensor (Qualified Servicer Only). . . . . . . . . . . . . . . 17

Flue Passages (Qualified Servicer Only) . . . . . . . . . . . . . .18

Cleaning Flue Passages (Qualified Servicer Only) . . . . . . .18

Main Burner Flame (Qualified Servicer Only) . . . . . . . . . . .18

Cleaning Burners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

ACCESSORIES AND FUNCTIONAL PARTS. . . . . . . . . . 19

Sheet Metal Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Functional Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

This Forced Air Central Unit Design Complies With Requirements Embodied in

The American National Standard / National Standard of Canada Shown Below.

ANSI Z21.47•CSA-2.3 Central Furnaces

"McQuay" is a registered trademark of McQuay International.

© 2004 McQuay International

"Illustrations and information cover the McQuay International products at the time of publication and we reserve the right to make changes in

design and construction at any time without notice."

Manufactured by Goodman Manufacturing Co., L. P., Houston, TX 77008

Page 2 IM-805

Page 3

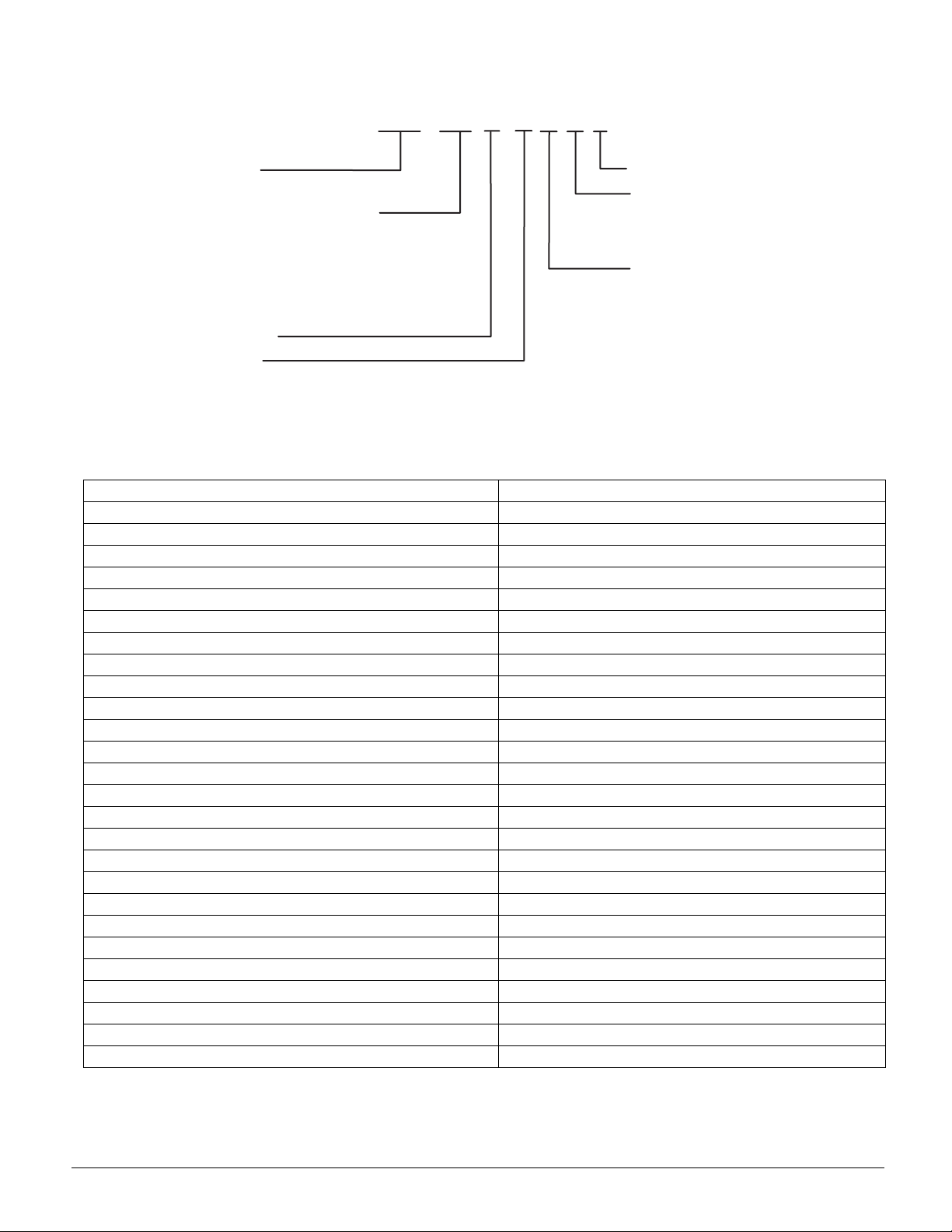

MODEL NOMENCLATURE

M

R

N

2

3

3

4

4

6

*

RG

odel

G = Rooftop Gas

ominal Capacity (tons)

4 = 2

0 = 3

6 = 3

2 = 3-1/2

8 = 4

0 = 5

Vintage

SEER

A = 10

B = 12

* 10 SEER Size 036, 042, 048 and 060 only.

Table 1: Unit Nameplate Model Number Ide nt if i er

024

A

ARY

A

Future Use

Voltage/Phase

P = 208-230/3/60

R = 208-230/1/60

Heating Input

(BTUH)

A = 45,000

B = 70,000

C = 90,000

D = 115,000

E = 140,000

Unit Nameplate McQuay Model Number

GPG10240451A RG024AAARY

GPG10240701A RG024AABRY

GPG10300701A RG030AABRY

GPG10360701A RG036AABRY

GPG10360901A RG036AACRY

GPG10420701A RG042AABRY

GPG10420901A RG042AACRY

GPG10480901A RG048AACRY

GPG10481151A RG048AADRY

GPG10600901A RG060AACRY

GPG10601401A RG060AAERY

GPG10360903A RG036AACPY

GPG10480903A RG042AACPY

GPG10600903A RG048AACPY

GPG10601403A RG060AAEPY

GPG12240451A RG024ABARY

GPG12240701A RG024ABBRY

GPG12300701A RG030ABBRY

GPG12360701A RG036ABBRY

GPG12360901A RG036ABCRY

GPG12420701A RG042ABBRY

GPG12420901A RG042ABCRY

GPG12480901A RG048ABCRY

GPG12481151A RG048ABDRY

GPG12600901A RG060ABCRY

GPG12601151A RG060ABDRY

IM-805 Page 3

Page 4

INTRODUCTION

General Description

These installation instructions cover the outdoor installation of

single package gas-electric heating and cooling units. See the

product catalog applicable to your model for information

regarding specifications applicable to your model and accessories.

Receiving Inspection

McQuay products are carefully inspected prior to shipment

and the carrier has assumed responsibility for loss or damage

upon acceptance of the shipment.

Upon receiving your shipment, check all items carefully

against the Bill of Lading. Inspect the unit and/or accessories

for shipping damage as soon as they are received. Immediately file claims for loss or damage, either shipping or concealed, with the shipping company.

Check the unit nameplate to verify the model number an d electrical characteristics are correct. In the event an incorrect unit

is shipped, it must be returned to the supplier and must NOT

be installed. The manufacturer disclaims all responsibility for

the installation of incorrectly shipped units.

Codes and Regulations

This product is designed and manufactured to permit installation in accordance with National Codes. System design

should, where applicable, follow information presented in

accepted industry guides such as the ASHRAE Handbooks. It

is the installer' s responsibility to inst all the pro duct in ac cordance with National Codes and/or prevailing local codes and

regulations. The manufacturer disclaims all responsibility for

equipment installed in violation of any code or regulations.

Important Message to the Installer

This equipment is to be installed by an experienced installation

company and fully trained personnel. Carefully read all

instructions and take into account any special considerations

prior to installing the unit. Give this manual to the owner and

explain its provisions.

Important Message to the Owner

Read these instructions carefully and keep them near the product for future reference. Although these instructions are

addressed primarily to the installer, useful maintenance information is included. Have the installer acquaint you with the

operation of the product and periodic maintenance requirements.

Recognize Safety Symbols, Words, and Labels

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards. It is the

owner's and installer's responsibility to read and comply with

all safety information and instructions accompanying these

symbols. Failure to heed safety information increases the risk

of property damage and/or product damage, serious personal

injury or death. Improper installation, operation and maintenance can void the warranty.

DANGER

Immediate hazards which WILL result in property

damage, product damage, severe personal injury and/

or death.

WARNING

Hazards or unsafe practice CAN result in property

damage, product damage, sever personal injury and/or

death.

CAUTION

Hazards or unsafe practices which CAN result in

property damage, product damage, and/or personal

injury.

Replacement Parts

Replacement parts can be obtained by contacting McQuay at

1

-800-37-PARTS. When contacting McQuay for service or

replacement parts, refer to the model number and serial number of the unit as stamped on the nameplate attached to the

unit.

Page 4 IM-805

Page 5

GENERAL WARNINGS

DANGER

CARBON MONOXIDE (CO) POISONING HAZARD

CO can cause brain damage and death. It is odorless

and colorless. Do not install this unit in any enclosure

or location where fumes many enter an enclosure.

DANGER

To avoid property damage, personal injury or death, do

not store or use gasoline or other flammable vapors or

liquids in the vicinity of this unit or in any area sharing

ventilation.

WARNING

IF YOU SMELL GAS

• Immediately evacuate the area.

• Do not try to light any appliances.

• Do not touch any electrical switches.

• Do not use any phones in your building.

• Immediately call your gas supplier from a phone

located in a neighboring building.

• Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

Failure to follow these instructions can result in fire,

explosion, severe personal injury or death.

WARNING

If overheating occurs or the gas supply fails to shut off,

turn off the manual gas shutoff valve outside the

furnace before turning off the electricity supply to avoid

property damage, severe personal injury or death.

WARNING

To avoid property damage, personal injury or death, do

not use this unit if any part has been under water.

Immediately call a qualified service technician to

inspect the furnace an replace any affected part.

WARNING

This product contains or produces substances which

may cause serious illness or death, and which are

known to the State of California to cause cancer, birth

defects or other reproductive harm.

WARNING

To avoid property damage, personal injury or death,

follow the planned maintenance instructions provided in

the "Maintenance" section of this document..

CAUTION

Freezing can burst pipes. Routinely inspect and

monitor unit and premise. If vacant, drain all water

pipes and close water source. Drain hydronic coils and

use alternative heat source.

CAUTION

Do not use this unit as a "construction heater" during

finishing phases of construction on a new structure.

Extremely low return air temperatures and corrosive or

dirty atmosphere can damage unit.

CAUTION

Sheet metal parts, screws, clips and similar items have

sharp edges. Use caution and wear protective clothing

when installing or servicing this equipment.

CAUTION

Keep these instructions in a safe and accessible space

for future reference or in case of an emergency.

UNIT LOCATION

WARNING

To prevent possible equipment damage, property

damage, personal injury or death, all illustrations

included in this manual must be observed when

installing the unit.

IMPORTANT NOTE: Remove wood shipping rails prior to

installation of the unit.

All Installations:

• For proper flame pattern within the heat exchanger and

proper condensate drainage, the unit must be mounted

level.

• The flue outlet hood must be at least 12 inches from any

opening through which flue gases could enter a buil ding,

and at least three feet above any forced air inlet located

within ten feet. The economizer/manual fresh air intake/

motorized fresh air intake and combustion air inlet

mounted on the unit are not affected by this restricti on.

• To avoid possible corrosion of the heat exchanger, do not

locate the unit in an area where the outdoor air (i.e. combustion air for the unit) will be frequently contaminated by

compounds containing chlorine or fluorine. Common

sources of such compounds include swimming pool chemicals and chlorine bleaches, paint stripper, adhesives, paints,

varnishes, sealers, waxes (which are not yet dried) and solvents used during construction and remodeling. Various

commercial and industrial processes may also be sources of

chlorine/fluorine compounds.

IM-805 Page 5

Page 6

• To avoid possible illness or death, do NOT locate outside

air intake device (economizer, manual fresh air intake,

motorized fresh air intake) too close to an exhaust outlet,

gas vent termination or plumbing vent outlet. For specific

distances required, consult local codes.

• Allow minimum clearances from the enclosure for fire protection, proper operation, and service access (see Appendix

Figure 25). These clearances must be permanently maintained.

• The combustion air inlet and flue outlet hoods on the unit

must never be obstructed. If used, do not allow the economizer/manual fresh air damper/ motorized fresh air damper

to become blocked by snow or debris. In some climates or

locations, it may be necessary to elevate the unit to avoid

these problems.

• When the unit is heating, the temperature of the return air

entering the unit must be between 50° F and 100° F.

Ground Level Installations Only:

• When the unit is installed on the ground adjacent to the

building , use a level concrete (or equal) base. Prepare a

base that is 3” larger than the package unit footprint and a

minimum of 3” thick.

• Locate the base where no runoff of water from higher

ground can collect in the unit.

Figure 1. Outside Slab Installation

Figure 2. Rooftop Installation

Roof Curb Installations Only:

• Sufficient structural support must be determined prior to

locating and mounting the curb and package unit.

• Ductwork must be constructed using industry guidelines.

The duct work must be placed into the roof curb before

mounting the package unit.

• Curb insulation, cant strips, flashing and general roofing

material are furnished by the contractor.

Figure 3. Roof Curb Installation

Rooftop Installations Only:

• To avoid possible property damage or personal injury, the

roof must have sufficient structural strength to carry the

weight of the unit(s) and snow or water loads as required

by local codes. Consult a structural engineer to determine

the weight capabilities of the roof.

• The unit may be installed directly on wood floors or on

Class A, Class B, or Class C roof covering material.

• To avoid possible personal injury, provide a flat surface for

service personnel.

Page 6 IM-805

Page 7

GENERAL INFORMATION

WARNING

To prevent property damage, personal injury or death,

due to fire, explosions, smoke, soot, condensation,

electric shock or carbon monoxide, this unit must be

properly installed, repaired, operated, and maintained.

This unit is approved for outdoor installation ONLY. For

proper operation the unit must be installed, operated, and

maintained in accordance with these installation and operating

instructions, all local building codes and ordinances, or in their

absence, with the latest edition of the National Fuel Gas Code

NFPA54/ANSI Z223.1 and National Standard of Canada

CAN/CSA B149 Installation Codes.

The heating and cooling capacities of the unit should be

greater than or equal to the design heating and cooling loads of

the area to be conditioned. The loads should be calculated by

an approved method or in accordance with ASHRAE Guide or

Manual J - Load Calculations published by the Air Conditioning Contractors of America.

Obtain from:

American National Standards Institute

1430 Broadway

New York, NY 10018

RIGGING DETAILS

WARNING

To avoid equipment and property damage, the unit

should remain in an upright position during all rigging

and moving operations.

To facilitate lifting and moving when a crane is used, place the

unit in an adequate cable sling..

IMPORTANT NOTE: If using bottom discharge with roof

curb, ductwork should be attached to the curb prior to installing the unit. Ductwork dimensions are shown in roof curb

installation instructions.

Refer to the Roof Curb Installation Instructions for proper curb

installation. Curbing must be installed in compliance with the

National Roofing Contractors Association Manual.

Lower the unit carefully onto the roof mounting curb. While

rigging the unit, the center of gravity will cause the condenser

end to be lower than the supply air end.

Figure 4. Rigging

GAS PIPING

IMPORTANT NOTE: This unit is factory set to operate on

natural gas at the altitudes shown on the nameplate.

WARNING

To avoid property damage, personal injury or death

when either using propane gas alone or at higher

altitudes, obtain and install the proper conversion kit(s).

Failure to do so can result in unsatisfactory operation

and/or equipment damage. High altitude kits are for

U.S. installations only and are not approved for use in

Canada.

The nameplate is stamped with the model number, type of gas

and gas input rating. Verify that the unit is eq uipped t o oper at e

on the type of gas available. Conversion to LP gas is permitted

with the use of factory-authorized conversion kit LPT-00A.

Table 2: Inlet Gas Pressure

Natural Min. 5.0" W.C., Max. 10.0" W.C.

Propane Min. 11.0" W.C., Max. 13.0" W.C.

Inlet gas pressure must not exceed the maximum value shown

in table above.

For dependable ignition, the minimum supply pressure should

not vary from the value shown in Table 2. In addition, gas

input to the burners must not exceed the rated input shown on

the nameplate. Overfiring of the unit could result in premature

heat exchanger failure.

High Altitude Derate (U.S. Installations Only)

IMPORTANT NOTE: The gas/electric units naturally derate

with altitude. Do not attempt to increase the firing rate by

changing orifices or increasing the manifold pressure. This can

cause poor combustion and equipment failure. At all altitudes,

the manifold pressure must be within 0.3 inches W.C. of the

value listed on the nameplate for the fuel used. At all altitudes

and with either fuel, the air temperature rise must be within the

range listed on the nameplate.

Refer to the Installation Manual provided with the LP kit for

conversion from natural gas to propane gas, and for altitude

adjustments.

Piping

IMPORTANT NOTE: To avoid unsatisfactory operation or

equipment damage due to under-firing of equipment, do not

undersize the natural/propane gas piping from the meter/tank

to the unit. When sizing a trunk line, as shown in Table 3,

include all appliances on that line that co uld be oper ated simu ltaneously.

The nameplate is stamped with the model number, type of gas

and gas input rating. Verify that the unit is equipped to operate

on the type of gas available. The gas line installation must

comply with local codes, or in the absence of local codes, with

the latest edition of the National Fuel Gas Code NFPA 54/

ANSI Z223.1.

IM-805 Page 7

Page 8

Natural Gas Connection

Table 3: Natural Gas Capacity of Pipe in Cubic Feet of Gas

Per Hour (CFH

Length of

Pipe in Feet

10 132 278 520 1050 1600

20 92 190 350 730 1100

30 73 152 285 590 980

40 63 130 245 500 760

50 56 115 215 440 670

60 50 105 195 400 610

70 46 96 180 370 560

80 43 90 170 350 530

90 40 84 160 320 490

100 38 79 150 305 460

Pressure =.50 PSIG or less and Pressure Drop of 0.3" W.C. (Based on 0.60

Specific Gravity Gas)

)

Nominal Black Pipe Size (inches)

1/23/4 11 1/41 1/2

BTUH Furnace Input

CFH =

Heating Value of Gas (BTU/Cubic Foot)

Refer to the Proper Piping Practice drawing for the general

layout at the unit. The following rules apply:

Figure 5. Proper Piping Practice

GROUND JOINT UNION

(INSTALLED AHEAD OF GAS VALVE)

GROMMET

NOTE:

The unit gas supply entrance is factory sealed with

plugs. Keep plugs in place until gas supply is ready

to be installed. Once ready, replace the plugs with the

supplied grommets and install gas supply line.

Gas Piping Checks

DRIP LEG

MANUAL

SHUT-OFF

VALV E

1. Use black iron pipe and fittings for the supply piping. The

use of a flex connector and/or copper piping is permitted as

long as it is in agreement with local codes.

2. Use pipe joint compound on male threads only. Pipe joint

compound must be resistant to the action of the fuel used.

3. Use ground joint unions.

4. Install a drip leg to trap dirt and moisture before it can enter

the gas valve. The drip leg must be a minimum of three

inches long.

5. Use two pipe wrenches when making connection to the gas

valve to keep it from turning.

6. Install a manual shut-off valve in a convenient location

between the meter and the unit (within six feet of unit).

7. Tighten all joints securely.

8. The unit must be connected to the building piping by one of

the following methods:

• Rigid metallic pipe and fittings

• Semirigid

metallic tubing and metallic fittings (Aluminum

alloy tubing must not be used in exterior locations)

• Listed gas appliance connectors, used in accordance with

the terms of their listing, that are completely in the same

room as the equipment

• In the prior two methods above, the connector or tubing

must be protected from physical and thermal damage.

Aluminum alloy tubing and connectors must be coated to

protect against external corrosion when contacting

masonry, plaster or insulation, or when they are subject to

repeated wettings by liquids.

CAUTION

To avoid property damage or personal injury due to fire,

the following instructions must be followed regarding

gas connections and pressure testing:

• The unit and its gas connections must be leak tested

before operation. Because of the danger of explosion

or fire, never use a match or open flame to test for

leaks. Never exceed specified pressures for testing.

Higher pressure may damage the gas v al ve and cause

overfiring, which may result in premature heat

exchange failure.

• This unit and its shut-off valve must be disconnected

from the gas supply during any pressure testing of that

system at test pressures in excess of 1/2 PSIG (3.48

kPa).

• This unit must be isolated from the gas supply system

by closing its manual shut-off valve during any

pressure testing of the gas supply piping system at

test pressures equal to or less than 1/2 PSIG (3.48

kPa).

WARNING

To a v oid property damage or personal injury during air

bleeding, be sure there is no open flame, sparks, arcing

switches on equipment, cigarette or other sources of

ignition in the vicinity or in areas sharing ventilation.

There will be air in the gas supply line after testing for leaks on

a new installation. Before bleeding the line, verify that there is

no flame, arcing switch on equipment, cigarette, or other

source of ignition in the area or areas sharing ventilation.

Bleed air from the line by loosening the ground joint union

until pure gas is expelled. Tighten the union and wait for at

least five minutes until all gas has been evacuated from the

area. The unit is placed in operation by closing the main electrical disconnect switch for the unit.

Page 8 IM-805

Page 9

PROPANE GAS INSTALLATION

WARNING

To avoid property damage, personal injury or death due

to fire or explosion caused by a propane gas leak, install

a gas detecting warning device. Since rust can reduce

the level of odorant in propane gas, a gas detecting

warning device is the only reliable way to detect a

propane gas leak. Contact a local propane gas supplier

about installing a gas detecting warning device.

IMPORTANT NOTE: Propane gas conversion kits must be

installed to convert units to propane gas. See the product catalog for the appropriate kit part number.

All propane gas equipment must conform to the standards of

the National Board of Fire Underwriters (See NBFU Manual

58).

For satisfactory operation, propane gas supply pressure must

be within 9.7 - 10.3 inches W.C. at the manifold with all gas

appliances in operation. Maintaining proper gas pressure

depends on three main factors:

1. Vaporization rate, which depends on (a) temperature of the

liquid, and (b) wetted surface area of the container or containers.

2. Proper pressure regulation.

3. Pressure drop in lines between regulators, and between second stage regulator and the appliance. Pipe size required

will depend on length of pipe run and total load of all appliances.

Tanks and Piping

Complete information regarding tank sizing for vaporization,

recommended regulator settings and pipe sizing is available

from most regulator manufacturers and propane gas suppl iers.

See Figure 6 for typical propane gas piping.

Since propane gas will quickly dissolve white lead or most

standard commercial compounds special pipe dope must be

used. Shellac-based compounds that are resistant to the actions

of liquefied petroleum gases, such as Gasolac®, Stalactic®,

Clyde’ s® o r Joh n Cr ane ®, ar e sa tisf ac tory.

Figure 6. Typical Propane Gas Piping

Table 4: Propane Gas Pipe Sizing

Sizing Between First and Second Stage Regulator

Maximum Propane Capacities listed are based on 1 PSIG Pressure Drop at 10

PSIG Setting. Capacities in 1,000 BTU/HR

Pipe or

Tubing

Lenght,

Feet

30 309 700 1303 2205 3394 1843 3854

40 265 599 1115 1887 2904 1577 3298

50 235 531 988 1672 2574 1398 2923

60 213 481 896 1515 2332 1267 2649

70 196 446 824 1394 2146 1165 2437

80 182 412 767 1297 1996 1084 2267

90 171 386 719 1217 1873 1017 2127

100 161 365 679 1149 1769 961 2009

150 130 293 546 923 1421 772 1613

200 111 251 467 790 1216 660 1381

250 90 222 414 700 1078 585 1224

300 89 201 378 634 976 530 1109

350 82 185 345 584 898 488 1020

400 78 172 321 543 836 454 949

To convert to Capacities at 15 PSIG Settings -- Multiply by 1.130

To convert to Capacities at 5 PSIG Settings -- Multiply by 0.879

Sizing Between Single or Second Stage Regulator and Appliance*

Maximum Propane Capacities Listed are Based on 1/2" W.C. Pressure Drop at

11" W.C. Setting. Capacities in 1,000 BTU/HR

Pipe or

Tubing

Lenght,

*DATA IN ACCORDANCE WITH NFPA PAMPHLET NO. 54

3/8" 1/2" 5/8" 3/4" 7/8" 1/2" 3/4" 1" 1 1/4" 1 1/2"

Feet

10 49 110 206 348 539 291 608 1146 2353 3525

20 34 76 141 239 368 200 418 788 1617 2423

30 27 61 114 192 296 161 336 632 1299 1946

40 23 52 97 164 253 137 284 541 1111 1665

50 20 46 86 146 224 122 255 480 985 1476

60 19 42 78 132 203 110 231 436 892 1337

80 16 36 67 113 174 94 198 372 764 1144

100 14 32 59 100 154 84 175 330 677 1014

125 12 28 52 89 137 74 155 292 600 899

150 11 26 48 80 124 67 141 265 544 815

200 10 22 41 69 106 58 120 227 465 697

250 9 19 36 61 94 51 107 201 412 618

300 8 18 33 55 85 46 97 182 374 560

350 7 16 30 51 78 43 89 167 344 515

400 7 15 28 47 73 40 83 156 320 479

Tubing Size, O.D. Type L

3/8" 1/2" 5/8" 3/4" 7/8" 1/2" 3/4"

Tubing Size, O.D. Type L Nominal Pipe Size, Schedule 40

Nominal Pipe

Size, Schedule

40

First Stage

Regulator

5 to 15 PSIG

(20 PSIG Max.)

200 PSIG

Maximum

Second Stage

Regulator

Continuous

11” W.C.

WARNING

To prevent property damage or serious personal injury

due to fire or explosion caused by a propane gas leak,

install a gas detecting warning device.

• Propane gas is heavier than air and any leaking gas

can settle in any low areas or confined spaces.

• Propane gas odorant may fade, making the gas

undetectable, except with a warning device.

IM-805 Page 9

Page 10

ELECTRICAL WIRING

Thermostat Location

Mount the thermostat approximately five feet above the floor,

in an area that has an inside, vibration-free wall and good air

circulation.

Air movement must not be obstructed by furniture, door, draperies, etc. The thermostat must not be mounted where it will be

affected by drafts, hot or cold water pipes or air ducts in walls,

radiant heat from a fireplace, lamps, the sun, a television, etc.

Consult the Instruction Sheet packaged with thermostat for

mounting instructions.

WARNING

To a void property damage or personal injury due to fire,

use only copper conductors.

CAUTION

To prevent improper operation due to wiring errors,

label all wires prior to disconnection when servicing

controls. Verify proper operation after servicing.

All units have one stage of heating and one stage of mechanical cooling. Units with economizers may use thermostats with

one or two stages of cooling.

WARNING

To avoid injury, electrical shock or death, disconnect

electrical power before servicing or changing any

electrical wiring.

The units are designed for operation on 60 hertz current and at

voltages shown on the nameplate. All internal wiring in the

unit is complete. It is necessary to bring in the power supply to

the contactor as shown on the unit wiring diagram supplied

with the unit. 24-volt wiring must be connected between the

unit control panel and the room thermostat. Do not run control

wiring next to or in the same conduit as higher voltage wiring.

Figure 7. Low Voltage Wiring

0

0

A

4

8

3

-

-

1

0

6

8

1

8

B

0

9

9

-

1

WYR

C

LOW VOLTAGE

CONNECTOR

G

8

K4

K3

L

0

E

0

D

4

-

O

8

M

6

0

1

M

E

T

S

Y

S

N

O

I

T

I

N

.

X

G

I

A

C

M

I

T

A

A

m

M

0

0

O

4

T

z

U

H

A

0

0

6

/

2

.

0

1

5

2

Z

C

I

A

S

V

N

4

2

A

E

G

A

R

T

S

O

S

O

S

W

E

T

R

P

R

M

O

F

O

C

K

A

E

R

B

T2

R

Y

W

G

L

O

O

C

T

2

A

L

E

H

2

L

D

E

2

S

L

U

N

U

2

L

1

L

1

L

I

D

K2

S

F

K1

9

6

2

1

3

2

3

9

6

2

1

6

9

1

3

1

1

C22

1

1

1

1

0

0

1

0

1

1

F1

FUSE 3 AMP MAX

2

2

8

5

2

5

8

7

4

1

1

7

4

1

1

7

4

P

N

O

C

E

120

135

P3

150

P

U

-

D

E

E

P

P2

S

T1

For unit protection, use a fuse or HACR circuit breaker that is

in excess of the circuit ampacity, but less than or equal to the

maximum overcurrent protection device. DO NOT EXCEED

THE MAXIMUM OVERCURRENT DEVICE SIZE

SHOWN ON UNIT NAMEPLATE.

All line voltage connections must be made through weatherproof fittings. All exterior power supply and ground wiring

must be in approved weatherproof conduit. Low voltage wiring from the unit control panel to the thermo stat r equires coded

cable. See below for ground level and rooftop wiring .

Figure 8. Typical Electrical Wiring

Note:Junction box location

shown is optional and is

for illustration purposes only.

JUNCTION BOX

Electrical Power Directly To Junction Box

Refer to the unit wiring diagram for electrical connections.

When installed, the unit must be electrically grounded in

accordance with local codes, or in the absence of local codes,

with the National Electrical Code, ANSI/NFPA No. 70, and/or

the CSA C22.1 Electrical Code. Verify that low voltage con-

nections are waterproof.

WARNING

To avoid the risk of electrical shock, wiring to the unit

must be polarized and grounded.

Electrical Power Routed Through Bottom of Unit

Page 10 IM-805

Page 11

Unit Voltage

The unit transformer is factory connected for 230V operation.

If the unit is to operate on 208V, reconnect the transformer primary lead and induced draft blower motor leads as shown on

the unit wiring diagram.

Heat Anticipator Setting

The heat anticipator is to be set by measuring the load (amperage) at the “R” circuit. Follow the instructions provided by the

thermostat for more details.

Figure 9. Typical Thermostat and Unit 24V Wiring Hookup

G

Y

R

W

R

From

Unit

W

Y

G

CIRCULATING AIR AND FILTERS

Airflow Conversion

Units can easily be converted from horizontal to down-discharge airflow delivery. In down-discharge or high static

installations, the installer should measure the total external

static and review the blower performance charts before performing the installation. In some installations it will be necessary to change the blower speed to prov id e prop er ai r flow.

Horizontal Air Flow

Remove the supply and return duct covers which are attached

to the unit as shown in Figure 10.

Down Discharge Applications

Cut the insulation around bottom openings and remove panels

from the bottom of the unit, saving the screws holding the panels in place.

Ductwork

Duct systems and register sizes must be properly designed for

the CFM and external static pressure rating of the unit. Ductwork should be designed in accordance with the recommended

methods of Air Conditioning Contractors of America Manual

D (Residential) or Manual Q (Commercial). All ductwork

exposed to outdoor conditions must include a weatherproof

barrier and adequate insulation.

A duct system should be installed in accordance with Standards of the National Board of Fire Underwriters for the Installation of Air Conditioning, Warm Air Heating and Ventilating

Systems. Pamphlets No. 90A and 90B.

The supply duct from the unit through a wall may be installed

without clearance. However, minimum unit clearances as

shown in the Appendix must be maintained. Provide the supply duct with an access panel large enough to inspect the air

chamber downstream of the heat exchanger. Tightly attach a

cover to prevent air leaks.

For duct flange dimensions on the unit refer to the Uni t

Dimension illustration in the Appendix.

For down-discharge applications, attach the ductwork to the

roof curb prior to installing the unit. Ductwork dimensions are

shown in the roof curb installation manual.

If desired, supply and return duct connections to the unit may

be made with flexible connections to reduce unit operating

sound transmission.

Figure 10. Duct Cover Installation

Remove these covers

for horizontal duct

applications

Remove these panels

for downflow duct

applications

IM-805 Page 11

Page 12

Filters

CAUTION

To prevent property damage due to fire and loss of

equipment efficiency or equipment damage due to dust

and lint build up on internal parts, never operate unit

without an air filter installed in the return air system.

Even though a return air filter is not supplied with this unit,

there must be a means of filtering all return air. The 12 SEER

size 048 and 060 models are provided with internal filter racks

for down-discharge applications. All units may be externally

filtered.

CONDENSATE DRAIN

Condensate Drain Connection

A 3/4” NPT drain connection is supplied for condensate piping. An external trap must be installed for proper conden sate

drainage.

Figure 12. Drain Connection

DRAIN

CONNECTION

UNIT 2" MINIMUM

Refer to the unit filter size chart in the Appendix for filter size

information.

Filters installed external to the unit should be sized in accordance with their manufacturer’s recommendations. A throwaway filter must be sized for a maximum face velocity of 300

feet per minute.

Filter Installation

Important: When installing a filter, the air flow arrows on the

filter must point toward the circulator blower.

VENTING

NOTE: Venting is self-contained. Do not modif y or blo ck.

Flue Hood Installation

Install the flue hood and bug screen prior to operation of the

unit.

T o inst all th e flue hood cover and bug screen:

1. Remove the flue hood and bug screen from inside the heat

exchanger compartment.

2. Slide the bug screen over the flanges of the flue hood and

attach the flue hood and screen to the unit with the sheet

metal screws provided.

Figure 11. Flue Hood and Bug Screen Installation

FLEXIBLE

TUBING-HOSE

OR PIPE

A POSITIVE LIQUID

SEAL IS REQUIRED

3" MINIMUM

NORMAL SEQUENCES OF

OPERATION

Heating

This unit is equipped with an ignition control that automati-

cally lights the main burner. DO NOT attempt to light the

main burners by any other method.

1. Thermostat calls for heat. The induced draft blower energizes for a 15-second pre-purge.

2. The spark igniter and gas valve energizes for 7 seconds.

NOTE: The igniter produces a very intense electrical spark

that ignites the gas.

3. The 30-second HEAT FAN ON delay time begins.

4. The unit delivers heat to the conditioned space until the

thermostat is satisfied.

5. The gas valve deenergizes. The induced draft blower continues operation for a 29-second post-purge.

6. Ignition control begins timing the HEAT FAN OFF delay.

There is an adjustable HEAT FAN OFF delay of approximately 120/135/150 seconds (factory set at 150). After the

HEAT FAN OFF delay time has elapsed, the blower will

deenergize. This allows any additional heat in the heat

exchanger to be transferred to the conditioned space.

Cooling

1. Thermostat calls for cooling. The compressor and outdoor

FLUE HOOD

BUG SCREEN

fan are energized.

2. Approximately seven seconds later , the indo or fan st ar ts.

3. The unit will deliver cooling to the conditioned space until

the thermostat is satisfied.

4. The compressor and outdoor fan will be deenergized when

the thermostat opens.

5. The indoor fan continues to run for approximately 60 seconds after the thermostat is satisfied. This allows additional cooling from the indoor coil to be transferred to the

conditioned space. Then, the indoor fan stops.

Page 12 IM-805

Page 13

NOTE: A 180-second anti-short cycle is integral to the contr ol

and prevents recycling of the compressor.

Fan Only

1. Thermostat calls for FA N ONLY by ener gizing “G”.

2. Approximately seven seconds later, the indoor fan starts.

Secondary Limit Control

The secondary limit control is located on the top of the blower

scroll assembly. This control opens when elevated temperatures are sensed. Elevated temperatures at the control ar e normally caused by blower failure. The reason for the control

opening should be determined and repaired prior to resetting.

3. The indoor fan continues to run for approximately 60 seconds after “G” is deenergized.

STARTUP, ADJUSTMENTS, AND

CHECKS

Heating Startup

This unit is equipped with an electronic ignition dev ice to

automatically light the main burners. It also has a power vent

blower to exhaust combustion products.

On new installations, or if a major component has been

replaced, the operation of the unit must be checked.

Check unit operation as outline d in th e fo llow in g inst ru ction s.

If any sparking, odors, or unusual sounds are encountered, shut

off electrical power and recheck for wiring errors or obstructions in or near the blower motors. Duct covers must be

removed before operating unit.

Heat Anticipator Setting

Set the heat anticipator on the room thermostat to 0.4 amps to

obtain the proper number of heating cycles per hour and to

prevent the room temperature from overshooting the room

thermostat setting.

Rollout Protection Control

The rollout protection device opens to cut power to the gas

valve if the flames from the burners are not properly drawn

into the heat exchanger. The rollout protection device is

located on the burner bracket. The reason for elevated temperatures at the control should be determined and repaired prior to

resetting this manual reset control.

WARNING

To avoid property damage, personal injury or death due

to fire or explosion, a qualified service technician must

investigate the reason that the rollout pr otect i on dev ice

opened prior to manually resetting the rollout protection

device.

Figure 13. Rollout Protection on Burner Bracket

If the power to the unit is interrupted during the heating cycle,

it may cause the secondary limit to trip. Once the blower compartment temperature drops below the limit reset temperature,

the limit will automatically reset.

Figure 14. Secondary Limit Control

Secondary

Control Limit

Back of Unit

Pre-Operation Checks

1. Close the manual gas valve external to the unit.

2. Turn of f the electri cal power su pply t o the u ni t.

3. Set the room thermostat to its lowest possible setting.

4. Remove the heat exchanger door on the side of the unit by

removing screws.

5. This unit is equipped with an ignition device which automatically lights the main burner. DO NOT try to light

burner by any other method.

6. Move the gas control valve switch to the OFF position. Do

not force.

7. Wait five minutes to clear out any gas.

8. Smell for gas, including near the ground. This is important

Rollout Protection

because some types of gas are heavier than air. If you have

waited five minutes and you do smell gas, immediately follow the warnings regarding gas leaks included under the

"General W arnings" section of this manual (page 4). If after

five minutes no gas smell is noted, move or rotate the gas

control valve switch to the ON position.

9. Replace the heat exchanger door on the side of the unit.

10.Open the manual gas valve external to the unit.

11.T ur n on th e electrical p ow er su pply t o the u ni t.

12.Set the thermostat to desired settin g.

IM-805 Page 13

Page 14

Figure 15. Gas Valve On/Off Selector Switch

Gas Valve

On/Off

Selector

Switch

INLET

*

OFF

ON

*

**

*

*

*

Figure 16. Measuring Inlet Gas Pressure-Alternate Method

Gas Line

Gas Shutoff Valve

OUTLET

White-Rodgers Model 36F22

INLET

Gas Valve

On/Off

Selector

Switch

White-Rodgers Model 36G22

OUTLET

Gas Supply And Manifold Check

Gas supply pressure and manifold pressure with the burners

operating must be as specified on the rating plate.

Gas Inlet Pressure Check

Gas inlet pressure must be checked and adjusted in accordance

with the type of fuel being consumed.

With Power And Gas Off:

1. Connect a water manometer or adequate gauge to the inlet

pressure tap of the gas valve to measure inlet gas pressure.

Inlet gas pressure can also be measured by removing the

cap from the dripleg and installing a predrilled cap with a

hose fitting (Figure 16).

With Power And Gas On:

2. Put unit into the heating cycle and turn on all other gas consuming appliances

Table 5: Maximum Inlet Gas Pressure

Natural Min. 5.0" W.C., Max. 10.0" W.C.

Propane Min. 11.0" W.C., Max. 13.0" W.C.

NOTE: Inlet Gas Pressure Must Not Exceed the Maximum

Value Shown in Table 5.

If operating pressures differ from Table 5, make the necessary

pressure regulator adjustments, check the piping size, and/or

consult with the local utility.

Gas Line

To Furnace

Open To

Atmosphere

Drip Leg Cap

With Fitting

Manometer Hose

Manometer

Manifold Pressure Check

The gas valve has a tapped opening to facilitate measurement

of the manifold pressure. A “U” Tube manometer having a

scale range from 0 to 12 inches of water should be used for this

measurement. The manifold pressure must be measured with

the burners operating.

To adjust the pressure regulator, remove the adjustment screw

or cover on the gas valve. Turn out (counterclockwise) to

decrease pressure. Turn in (clockwise) to increase pressure.

Only small variations in gas flow should be made by means of

the pressure regulator adjustment. In no case should the final

manifold pressure vary more than plus or minus 0.3 inches

water column from the specified nominal pressure. Any major

changes in flow should be made by changing the size of the

burner orifices. The measured input rate to the furnace must

not exceed the rating specified on the unit rating plate.

For natural gas, the manifold pressure must be between 3.2 and

3.8 inches water column (3.5 nominal).

For propane gas, the manifold pressure must be between 9.7

and 10.3 inches water column (10.0 nominal).

Gas Input (Natural Gas Only) Check

To measure the gas input use a gas meter and proceed as follows:

1. Turn off gas supp ly to all othe r appl iances except the un it.

2. With the unit operating, time the smallest dial on the meter

for one complete revolution. If this is a 2 cubic foot dial,

divide the seconds by 2; if it is a 1 cubic foot dial, use the

seconds as is. This gives the seconds per cubic foot of gas

being delivered to the unit.

Page 14 IM-805

Page 15

3. INPUT=GAS HTG VALUE x 3600 / SEC. PER CUBIC

FOOT

Example: Natural gas with a heating value of 1000 BTU per

cubic foot and 34 seconds per cubic foot as determined by Step 2, then:

Input = 1000 x 3600 / 34 = 106,000 BTU per hour.

NOTE: BTU content of the gas should be obtained from the

gas supplier. This measured input must not be greater

than the value shown on the unit nameplate.

4. Relight all other appliances turned off in Step 1. Be sure all

pilot burners are operating.

Main Burner Flame Check

Flames should be stable, soft and blue (dust may cause orange

tips but they must not be yellow) and extending directly outward from the burner without curling, floating or li fting o ff.

Temperature Rise Check

Check the temperature rise through the unit by placing thermometers in supply and return air registers as close to the unit

as possible. Thermometers must not be able to sample temperature directly from the unit heat exchangers, or false readings

could be obtained.

1. All registers must be open; all duct dampers must be in

their final (fully or partially open) position and the unit

operated for 15 minutes before taking read ings .

2. The temperature rise must be within the range specified on

the nameplate.

NOTE: Air temperature rise is the temperature difference

between supply and return air.

With a properly designed system, the proper amount of temperature rise will normally be obtained when the unit is operated at rated input with the recommended blower speed.

If the correct amount of temperature rise is not obtained, it

may be necessary to change the blower speed. A higher

blower speed will lower the temperature rise. A slower blower

speed will increase the temperature rise.

NOTE: Blower speed MUST be set to give the correct air tem-

perature rise through the unit as marked on the rating

plate.

External Static Pressure Check

The total external static pressure must be checked on this unit

to determine if the airflow is proper.

Blower Speed Adjustments

WARNING

To avoid personal injury or death due to electric shock,

remove electrical power from the unit before changing

speed taps on the blower motor.

Refer to the wiring diagram in the Appendix to verify speed

tap settings.

Blower speeds are to be changed at the ignition control board.

Both heat speed and cool speed terminals are supplied on the

board along with two unused motor lead terminals.

Limit Check

Check limit control operation after 15 minutes of operation by

blocking the return air grille(s).

1. After several minutes, the main burners must go OFF. The

blower will continue to run.

2. Remove air restrictions and the main burners will relight

after a cool down period of a few minutes.

Adjust the thermostat setting below room t emper at ure.

1. The main burners must go OFF.

2. The circulating air blower will continue to run for 120, 135

or 150 seconds, depending on the setting.

Figure 17. Control Board (Top)

1068-83-400A

LED

R36

D11

COOL

UNUSED HEAT

L1

L1

D1

FS

9

6

6

9

5

8

L2

L2L2

L2

3

2

23

1

R25

D5

D7

NOTE:

D12

R42

C13

R29

R22

R31

R11

R4

Z1

C27

R35

R34

C20

D14

D10

D9

R38

D3

K4

K3

R3

R8

K2

R10

K1

12

12

11

11

10

If necessary, adjust fan OFF delay settings to obtain a

satisfactory comfort level.

WARNING

This unit must not be used as a "construction heater"

during the finishing phases of construction on a new

structure. This type of use may result in premature

failure of the unit due to extremely low return air

termperatures and exposure to corrosive or very dirty

at mospheres.

Unit Shutdown

1. Set the thermostat to lowest setting.

2. Turn of f the electri cal power su pply t o the u ni t.

3. Remove the heat exchanger door on the side of the unit by

removing screws.

4. Move or rotate (Figure 15) the gas control valve switch to

the OFF position. Do not force.

IM-805 Page 15

Page 16

5. Close the manual gas shutoff valve external to the unit.

6. Replace the heat exchanger door on the unit.

7. If cooling and/or air circulation will be desired, turn ON

the electrical power.

Cooling Startup

NOTE: Check all manual reset limit controls in the heating cir-

cuit if the cooling mode does not operate.

Compressor Protection Devices

The compressor includes components which are designed to

protect the compressor against abnormal operat ing co nditi ons.

WARNING

To prevent personal injury or death, always disconnect

electrical power before inspecting or servicing the unit.

All compressor protection devices reset automatically,

energizing the contactor and outdoor fan.

Cooling Refrigerant Charging

Check unit charge before putting the cooling section into full

operation. The unit is factory charged with R-22 for nominal

air flow and static pressure conditions. The unit has a piston

flowrator expansion device. To verify that the unit is properly

charged for the intended application, check the unit refrigerant

superheat at the compressor. The refrigerant superheat is a

function of outdoor ambient temperature and return air temperature of the conditioned space. It is the installing contractor’s

responsibility to verify that the proper refrigerant superheat at

the compressor is adjusted for each application. For example, a

10 degree refrigerant superheat level is adequate for a 95

degree outdoor ambient temperature and a 78 - 80 degree

indoor return air temperature. As the outdoor ambient temperature rises, the superheat decreases. As the outdoor ambient

temperature lowers, the superheat increases. Proper superheat

adjustment optimizes cooling performance.

Cooling Operation

NOTE: Mechanical cooling cannot be reliably provided at

ambient temperatures below 50° F.

1. Turn on the electrical power supply to the unit.

2. Place the room thermostat selector switch in the COOL

position (or AUTO if available, and if automatic

changeover from cooling to heating is desired).

3. Set the room thermostat to the desired temperature.

TROUBLESHOOTING

WARNING

Troubleshooting can present hazards of electricity,

rotating parts, sharp edges and weight. troubleshooting

must be done by trained, experienced technicians only.

Improper troubleshooting can result in equipment

damage, severe personal injury or death.

The following presents probable causes of questionable unit

operation.

Ignition Control Error Codes

Remove the control box access panel and note the number of

diagnostic LED flashes. Refer to the "Diagnostic Indicator

Chart" in the Appendix for an interpretation of the signal and

to this section for an explanation.

Abnormal Operation - Heating

Internal Control Failure

If the integrated ignition control in this unit encounters an

internal fault, it will go into a “hard” lockout and turn off the

diagnostic LED. If the diagnostic LED indicates an internal

fault, check the power supply to unit for proper voltage. Ch eck

all fuses, circuit breakers and wiring. Disconnect the electric

power for five seconds. If the LED remains off after restoring

power, replace the control board.

External Lockout

An external lockout occurs if the integrated ignition control

determines that a measurable combustion cannot be established within three (3) consecutive ignition attempts. If flame

is not established within the seven (7) second trial for ignition,

the gas valve is deenergized, a 15 second inter-purge cycle is

completed, and ignition is reattempted. The contr ol wil l repeat

this routine three times if a measurable combustion is not

established. The control will then shut off the induced draft

blower and go into a lockout state.

If flame is established but lost, the control will energize the circulator blower at the heat speed and then begin a new ignition

sequence. If flame is established and lost on subsequent

attempts, the control will recycle for four (4) consecutive ignition attempts (five attempts total) before locking out.

The diagnostic fault code is 1 flash for a lockout due to failed

ignition attempts or flame dropouts. The integrated control

will automatically reset after one hour, or it can be reset by

removing the thermostat signal or disconnecting the electrical

power supply for over five seconds. If the diagnostic LED

indicates an external lockout, perform the following checks:

• Check the supply and manifold pr essures

• Check the gas orifices for debris

• Check the gas valve for proper op eratio n

• Check the secondary limit

A dirty filter, excessive duct static, insufficient air flow, a

faulty limit, or a failed circulator blower can cause this limit to

open. Check the filters, the total external duct static, the circulator blower motor, the blower motor speed tap (see wiring

diagram) and the limit. An interruption in electrical power

during a heating cycle may also cause the auxiliary limit to

open. The secondary limit is located on top of the circulator

blower assembly. The automatic reset auxiliary limit is located

on the circulator blower scroll.

• Check the rollout limit

If the burner flames are not properly drawn into th e heat

exchanger, the flame rollout protection device will open. Possible causes are restricted or blocked flue passages, a blocked

or cracked heat exchanger, a failed induced draft blower or

insufficient combustion air. The rollout protection device is a

manual reset limit located on the burner bracket. The cause of

the flame rollout must be determined and corrected before

resetting the limit.

Page 16 IM-805

Page 17

• Check the flame sensor

A drop in flame signal can be caused by nearly invisible coating on the sensor. Remove the sensor and carefully clean with

steel wool.

• Check the wiring

Check wiring for opens/shorts and miswiring

IMPORTANT NOTE: If you have to frequently reset your

gas/electric package unit, it means that a problem exists that

should be corrected. Contact a qualified servicer for further

information.

Pressure Switch Stuck Open

A pressure switch that is stuck open can be caused by a faulty

pressure switch, faulty wiring, a disconnected or damaged

hose, a blocked or restricted flue, or a faulty induced draft

blower.

If the control senses an open pressure switch during the prepurge cycle, only the induced draft blower will be energized.

If the pressure switch opens after ignition has begun, the gas

valve is deenergized, the circulator blower heat off cycle

begins, and the induced draft blower remains on. The diagnostic fault code is two flashes.

Pressure Switch Stuck Closed

A pressure switch that willl not open can be caused by a faulty

pressure switch or faulty wiring. If the control encounters a

pressure switch that willl not open, the induced draft blower

remains off. The diagnostic LED code for this fault is thr ee (3)

flashes.

Open Thermal Protection Device

If the primary limit switch opens, the gas valve is immediately

deenergized, the induced draft and air circulating blowers are

energized. The induced draft and air circulator blowers

remain energized until the limit switch recloses. The diagnostic fault code for an open limit is four (4) flashes.

A primary limit will open due to excessive supply air temperatures. This can be caused by a dirty filter, excessive duct

static, insufficient air flow, or a faulty limit. Check filters, total

external duct static, blower motor, blower motor speed tap (see

wiring diagram), and limit. This limit will automatically reset

once the temperature falls below a preset level.

Flame Detected with Gas Valve Closed

If flame is detected with the gas valve deenergized, the combustion and air circulator blowers are energized. The diagnostic fault code is five (5) flashes for this condition. The control

can be reset by removing the power supply to the unit or it will

automatically reset after one hour. Improper wiring is the

probable cause for this fault.

Abnormal Operation - Cooling

Short Cycle Compressor D el ay

The automatic ignition control has a built-in feature that helps

prevent damage to the compressor in short cycling situations.

In the event of intermittent power losses or intermittent thermostat operation, the ignition control will delay output to the

compressor contactor for three minutes from the time power is

restored (compressor is off a total of three minutes). The diagnostic LED will flash six (6) times to indicate the compressor

contactor output is being delayed.

NOTE: Some electronic thermostats also have a built-in com-

pressor short cycle timer that may be longer than the

three minute delay. If you are using an electronic

thermostat and the compressor has not started after

three minutes, wait an additional five minutes to

allow the thermostat to complete its short cycle delay

time.

MAINTENANCE

WARNING

To avoid personal injury or death due to electric shock,

disconnect electrical power before performing any

maintenance.

Have the gas heating section of the unit checked at least once

a year before the heating season begins to verify that the combustion air inlet and flue outlet hoods are not blocked by debri s

that prevents adequate combustion air and/or proper vent system operation.

Filter Replacement or Cleaning

A return air filter is not supplied with this unit; however, there

must be a means of filtering all of the return air. The filter(s)

may be located in the return air duct(s) or return air filter

grille(s). Consult with your installer for the actual location of

the return air filter(s) for your unit.

Dirty filters are the most common cause of inadequate heating

or cooling performance. Filter inspection should be made at

least every two months; more often if required by local conditions and usage.

Dirty throwaway filters should be discarded and replaced with

a new, clean filter. Dirty permanent filters should be washed

with water, thoroughly dried and sprayed with a filter adhesive

before being reinstalled. Filter adhesives may be found at

many hardware stores. Permanent filters should last several

years, but they should be replaced if they become torn or

uncleanable.

Cabinet Finish Maintenance

Use a fine grade automotive wax on the cabinet finish to maintain the finish’s original high luster. This is especially important in installations with extended periods of direct sunlight.

Clean Outside Coil (Qualified Servicer Only)

The coil with the outside air flowing over it should be

inspected annually and cleaned as often as required to keep the

finned areas free of lint, hair and debris.

Condenser, Evaporator, and Induced Draft Motors

Bearings on the air circulating blower motor, condenser motor

and the combustion fan motor are permanently lubricated. No

additional oiling is required.

Flame Sensor (Qualified Servicer Only)

A drop in the flame current can be caused by a nearly invisible

coating on the flame sensor. This coating, created by the fuel

or combustion air supply, can be removed by carefully cleaning the flame sensor with steel wool (Figure 18).

NOTE: After cleaning, the microamp signal should be stable

and in the range of 4 - 6 microamps DC.

IM-805 Page 17

Page 18

Figure 18. Flame Sensor

Flame

Sensor

Flue Passages (Qualified Servicer Only)

At the start of each heating season, inspect and clean the unit

flue passage if it has become dirty.

Cleaning Flue Passages (Qualified Servicer Only)

1. Shut off the electric power and gas supply to the unit .

2. Remove the burner assembly by disconnecting the gas line

and removing the manifold bracket from the partition

panel.

3. Remove the flue from the induced draft blower and the collector box cover from the partition panel.

4. The primary heat exchanger tubes can be cleaned using a

round wire brush attached to a length of high grade stainless steel cable, such as drain cleanout cable. Attach a variable speed reversible drill to the other end of the spring

cable. Slowly rotate the cable with the drill and insert it into

one of the primary heat exchanger tubes. While reversing

the drill, work the cable in and out several times to obtain

sufficient cleaning. Use a large cable for the large tube, and

then repeat the operation with a small cable for the smaller

tube. Repeat for each tube.

5. When all heat exchanger tubes have been cleaned, replace

the parts in the reverse order in which they were removed.

6. To reduce the chances of repeated fouling of the heat

exchanger, perform the steps listed in “Startup, Adjustments, and Checks”.

Main Burner Flame (Qualified Servicer Only)

Flames should be stable, soft and blue. Dust may cause orange

tips, but the flame must not be y ellow. The flames must extend

directly outward from the burner without curling, floating or

lifting off.

Figure 19. Burner Flame

WARNING

To avoid personal injury or death due to electric shock,

do not remove any internal compartment covers or

attempt any adjustment. Contact a qualified servicer at

once if an abnormal flame develops.

At least once a year, prior to or during the heating season,

make a visual check of the burner flames.

NOTE: This will involve removing and reinstalling the heat

exchanger door on the unit, which is held by two

screws. Contact a qualified servicer if you are uncertain about performing this task.

If a strong wind is blowing, it may alter the airflow pattern

within the unit enough that an inspection of the burner flames

is not possible.

Cleaning Burners

1. Shut off the electric power and gas suppl y to the u nit.

2. Remove the screws securing the manifold to the burner

retention bracket. Remove the manifold and rotate each

burner counterclockwise to re mo ve.

Figure 20. Manifold Assembly

Burner

Burner

Bracket

Manifold

3. Remove the burners.

4. Use a bottle brush to clean burner insert and inside of the

burners.

5. Replace the burners and manifold and inspect the burner

assembly for proper seating of the burners in retention

slots.

6. Reconnect the electrical power and gas supply.

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper operation

and equipment or property damage.

Check the burner flames for:

1. Good adjustment

2. Stable, soft and blue

3. Not curling, floating, or lifting off.

Page 18 IM-805

To avoid equipment or property damage, always verify

proper operation after servicing.

CAUTION

Page 19

Turn the unit on at the thermostat. Wait a few minutes, since

any dislodged dust will alter the normal flame appearance.

Flames should be predominantly blue and directed into the

tubes. They should not be yellow. They should extend directly

outward from the burner ports without curling downward,

floating or lifting off the ports.

ACCESSORIES AND FUNCTIONAL

PARTS

Sheet Metal Accessories

Additional accessories can be purchased to fit specific application needs. Parts and instructions are available by contacting

McQuay at 1-800-37-PARTS.

Functional Parts

Functional Parts List

Auxliary Limit Switch Flame Roll-out Switch

Blower Housing Flame Sensor

Circulator Blower Motor Gas Orifice

Blower Wheel Gas Valve

Burner Heat Exchanger

Capacitor High Limit Switch

Compressor Igniter

Condenser Coil Ignition Control

Condenser Fan Blade Induced Draft Blower

Condenser Fan Motor Pressure Switch

Contactor Pressure Switch Hose

Gas Manifold Transformer

Evaporator Coil

General Information

1. Refer to the description in Functional Parts List when

ordering any of the listed functional parts. Be sure to provide the unit model and serial numbers with the order.

2. Although only functional parts are shown, all sheet metal

parts, doors, etc. may be ordered by description.

3. Parts are available by contacting McQuay at 1-800-37PARTS.

IM-805 Page 19

Page 20

APPENDIX

IGNITION CONTROL DIAGNOSTIC INDICATOR CHART

Light Signal Refer to Abnormal Heating or Cooling Operation Sections of this Manual

Off Internal Control Failure

1 Flash External Lockout

2 Flashes Pressure Switch Stuck Open

3 Flashes Pressure Switch Stuck Closed

4 Flashes Thermal Protection Device Open

5 Flashes Flame Detected with Gas Valve Closed

6 Flashes Short Cycle Compressor Delay (Cooling Only)

Figure 21. Heating Timing Chart

Circulator

Blower

Gas Valve

Igniter

Induced

Draft

Blower

Thermostat

On

Off

On

Off

On

Off

On

Off

On

Off

Seconds

Figure 22. Cooling Timing Chart

Circulator

Blower

Outdoor Fan

and

Compressor

0 15 22 52 0 29 120, 135,150

ON

OFF

ON

OFF

Thermostat

ON

OFF

Seconds 0 7 0 60

Page 20 IM-805

Page 21

Figure 23. Unit Dimensions

A

SUCTION/LIQUID PRESSURE PORTS

BEHIND COMPRESSOR ACCESS PANE

HEAT EXCHANGE ACCESS PANE

CONDENSATE DRAI N CONNECTION

47

SUPPLY GAS ENTRANCE

3/4" NPT FEMALE

4 3/4

16 1/8

19 1/8

7 5/16

7 7/8

POWER WIRE ENTRANCE

CONTROL WIRE ENTRANCE

18 7/16

FLUE EXHAUST

7 15/16

51

16

1 3/8

5 1/2

16

B

B

(INCHES)

A

B

B

SUPPLY

SMALL

SMALL MEDIUM LARGE

27 32 40

16 16 18

27

16

3

EVAPORATOR/CONTROL PANEL ACCESS PANEL

DIMENSIONS

DIMENSION

(INCHES)

A

2 3/4

RETURN

MEDIUM

16

32

40

16

COMBUSTION AIR INLETS

HOOD FLUE EXHAUST

BLOWER ACCESS PANEL

RETURN

11

22

22

11

SUPPLY

IM-805 Page 21

Page 22

Figure 24. Single Stage Wiring Diagram

T

Y

B

B

CH OPTIONAL

CONNECTED A T L1, L2

NOTE 4

CAP2

BR

BR

EM

1

2

4

3

ALT. 4-SPEED

MOTOR

ALS

PS

PU

RS

PU

W.R.

BL

GV

VM

S

COMP

NOTE 5

R

BL

B

PU

PL

R

CM

NOTE 6

PK

PU

BL

NOTE 3

C

PU

CAP2

BR

EM

234

1

4-SPEED

MOTOR

PU

Y

Y

G

3

6

2

5

1

4

(ALT.)

HONEYWELL

IGN

FS

B

PU

R

B

PU

B

BL

BL

T1

R

L1

CC

BL

B

BL

1

PU

G

PU

GR

BR

5

R

Y

BL

B

PU

R

LS

R

IIC

PU

Y

BL

Y

Y R W

MV

MV

PK

GV

Y2 Y1

Y

BL

CRYWG

G

R

T2

L2

23

208

TRANS

24V

B

BL

B

R

Y

Y

W

G

G

FUSE 3 AMP MAX.

C22

Y

240

Y

Y

R

R

BR

R

Y

B

B

FS

12

11

10 7 4 P1

F1

T1

O

Y

CH OPTIONAL

NOTE 2

BL

L2

L1

DI

63

9

785

2

P1

P3

P2

MOUNT

SCREW

REQUIRED

CAP 1

H

F

GRD

POWER SUPPLY

208-230/1/60

B

R

PU

PU

PU

PU

R

ECON

120

135

150

SPEED-UP

C

L1

L1

L1

1

FUSE

4

5

9

B

BL

R

CC

T1

C

COMP

L1

L1

L1 D1

FS FS

IIC

3

6

8

ECON

10

7

GW

SUPPLY VOLTAGE

208-230/1/60

R

S

CAP1

H

(HIGH)

C

(LOW)

H

TRANS

LS

ALS

PS

12

11

Y1 Y2

CH

NOTE 4

T2 CC

C

CM

F

NOTE 5

NOTE 3

VM

NOTE 2

IGN

RS

C

Y

CAP 2

EM

GV

CC

NOTE 6

L2

L2

L2

L2

L2

2

4

5

6

PL

1

23

R

NOTES:

1. REPLACEMENT WIRE MUST BE THE SAME SIZE AND TYPE OF

2. FOR 208 VOLT TRANSFORMER OPERATION MOVE BLACK WIRE

3. FOR 208 VENT MOTOR OPERATION CONNECT BLACK LEAD

4. CRANKCASE HEATER (OPTIONAL)

5. FOR DIFFERENT THAN FACTORY SPEED TAP. CHANGE COOLING

4 SPEED MOTOR

B - HIGH SPEED

R

BL - MEDIUM HIGH SPEED

Y - MEDIUM LOW SPEED

R - LOW SPEED

3 SPEED MOTOR

B - HIGH SPEED

BL - MEDIUM SPEED

R - LOW SPEED

6. ACCESSORY ECONOMIZER PLUG (ON SELECT MODELS) ADJACEN

COMPONENT LEGEND

ALS .......... AUXILLARY LIMIT SWITCH

CAP ......... CAPACITOR

COMP ...... COMPRESSOR

CM ........... CONDENSER MOTOR

CC ........... CONTACTOR

CH ........... CRANKCASE HEATER

EM ........... EVAPORATOR MOTOR

IIC ............ INTEGRATED IGNITION CONTROL

IGN .......... IGNITOR

PL ............ PLUG

PS ............ PRESSURE SWITCH

RS ........... ROLLOUT SWITCH

VM ........... VENT MOTOR

............ WIRE SPLICE