Page 1

Installation and Maintenance Manual IM 987

RoofPak™ Applied Rooftop Systems

Air Handler

RAH 047C - 077C, 12,000 to 50,000 cfm

RDS 800C - 802C, 4000 to 20,000 cfm

with MicroTech® III Unit Controller

Group: Applied Air Systems

Part Number: IM 987

Date: May 2009

© 2009 McQuay International

Page 2

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Gas Burner Nameplate . . . . . . . . . . . . . . . . . . 3

Hazard Identification Information . . . . . . . . . . 3

Typical Component Locations. . . . . . . . . . . . . 4

Control Locations . . . . . . . . . . . . . . . . . . . . . . 4

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . 5

Controls, Settings, and Functions . . . . . . . . . 12

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . 14

Unit Clearances. . . . . . . . . . . . . . . . . . . . . . . 14

Ventilation Clearance . . . . . . . . . . . . . . . . . . 15

Overhead Clearance . . . . . . . . . . . . . . . . . . . 15

IBC Seismic Compliant Units . . . . . . . . . . . . 20

Roof Curb Arrangement . . . . . . . . . . . . . . . . 20

Post and Rail Arrangement . . . . . . . . . . . . . . 22

Post and Rail Mounting . . . . . . . . . . . . . . . . . 24

Rigging and Handling . . . . . . . . . . . . . . . . . . 24

Split Units . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Unit Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Steam Coil Piping (All Units) . . . . . . . . . . . . . 33

Steam Piping Recommendations . . . . . . . . . 33

Steam Trap Recommendations . . . . . . . . . . 34

Vestibule Assembly Instructions . . . . . . . . . . 38

Damper Assemblies . . . . . . . . . . . . . . . . . . . 40

Cabinet Weather Protection . . . . . . . . . . . . . 44

Installing Ductwork . . . . . . . . . . . . . . . . . . . . 45

Installing Duct Static Pressure Sensor Taps. 46

Installing Building Static Pressure

Sensor Taps . . . . . . . . . . . . . . . . . . . . . . . . . 47

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . 48

Field Power Wiring . . . . . . . . . . . . . . . . . . . . 48

Field Control Wiring. . . . . . . . . . . . . . . . . . . . 51

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . 52

Preparing Unit for Operation . . . . . . . . . . . . . 52

Spring Isolated Fans . . . . . . . . . . . . . . . . . . . 52

Relief Damper Tie-Down. . . . . . . . . . . . . . . . 53

Adjusting Scroll Dampers . . . . . . . . . . . . . . . 53

Adjusting Supply Fan Thrust Restraints . . . . 53

Adjusting Seismic Restraints. . . . . . . . . . . . . 54

Sequences of Operation . . . . . . . . . . . . . . . . . . . . 55

Power-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . 55

Economizer Operation . . . . . . . . . . . . . . . . . 56

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

MicroTech III Controller Operation . . . . . . . . . . . 57

Using the Keypad/Display . . . . . . . . . . . . . . . 57

Passwords. . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Navigation Mode . . . . . . . . . . . . . . . . . . . . . . 58

Edit Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

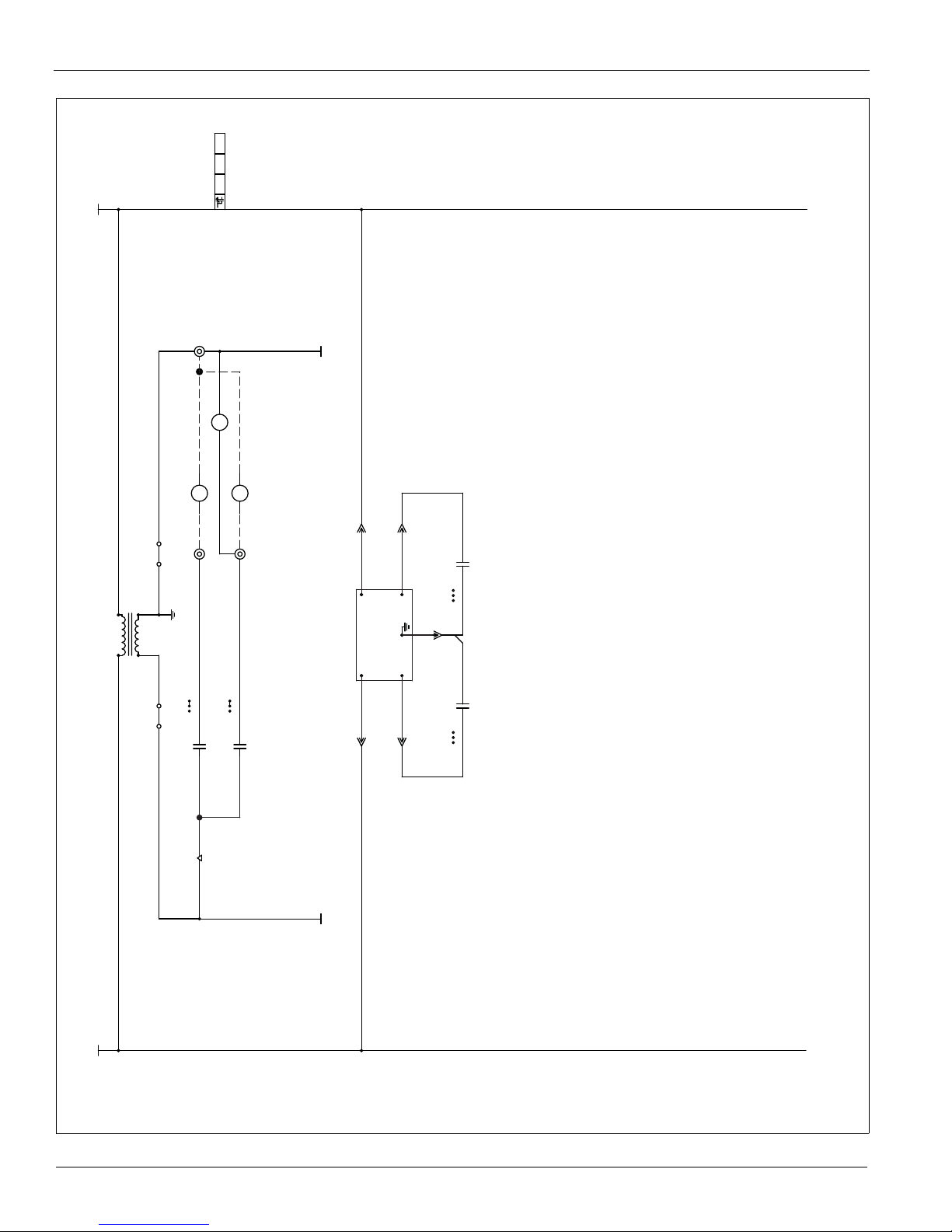

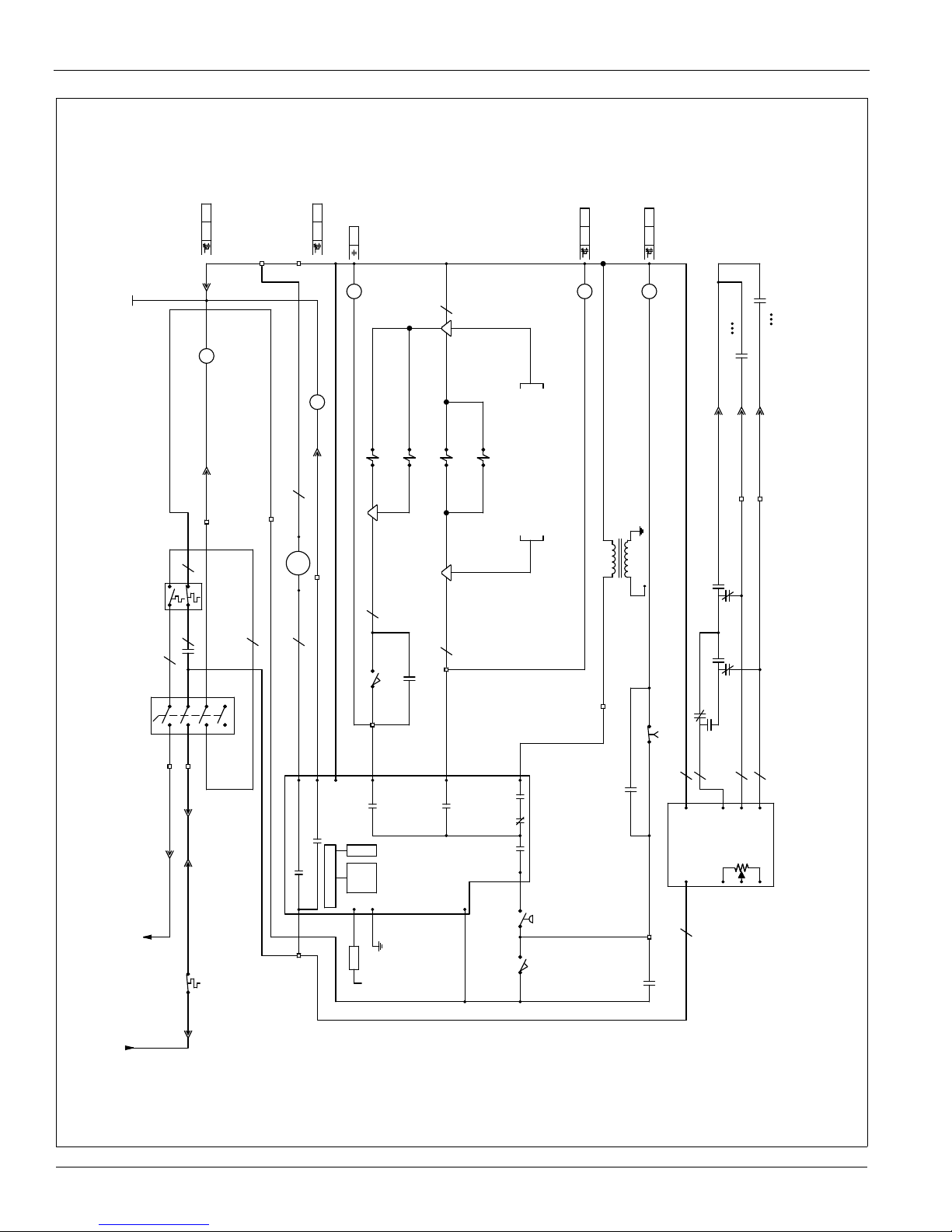

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Unit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Control Actuators . . . . . . . . . . . . . . . . . . . . . 84

Enthalpy Control . . . . . . . . . . . . . . . . . . . . . . 84

External Time Clock . . . . . . . . . . . . . . . . . . . 85

Smoke and Fire Protection . . . . . . . . . . . . . . 85

Smoke Detectors . . . . . . . . . . . . . . . . . . . . . 85

Emergency Shutdown . . . . . . . . . . . . . . . . . 86

Freeze Protection . . . . . . . . . . . . . . . . . . . . . 86

Field Output Signals . . . . . . . . . . . . . . . . . . . 87

Entering Fan Temperature Sensor . . . . . . . . 87

Duct High Pressure Limit . . . . . . . . . . . . . . . 88

Variable Frequency Drive Operation . . . . . . 88

Convenience Receptacle/Section Lights . . . 88

DesignFlow™ Outdoor Air Damper Option . 88

Propeller Exhaust Fan Option . . . . . . . . . . . 91

Exhaust Fan On/Off Control . . . . . . . . . . . . . 93

Ultraviolet Lights Option . . . . . . . . . . . . . . . . 94

Ultraviolet Light Operation . . . . . . . . . . . . . . 95

Check, Test, and Start Procedures . . . . . . . . . . . 96

Servicing Control Panel Components. . . . . . 96

Before Start-up . . . . . . . . . . . . . . . . . . . . . . . 96

Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Fan Start-up . . . . . . . . . . . . . . . . . . . . . . . . . 97

Economizer Start-up. . . . . . . . . . . . . . . . . . . 97

Heating System Startup . . . . . . . . . . . . . . . . 98

Air Balancing . . . . . . . . . . . . . . . . . . . . . . . . 98

Sheave Alignment . . . . . . . . . . . . . . . . . . . . 99

Drive Belt Adjustment . . . . . . . . . . . . . . . . . . 99

Mounting and Adjusting Motor Sheaves. . . 100

Final Control Settings. . . . . . . . . . . . . . . . . . . . . 103

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Servicing Control Panel Components. . . . . 106

Planned Maintenance. . . . . . . . . . . . . . . . . 106

Unit Storage . . . . . . . . . . . . . . . . . . . . . . . . 106

Gas Furnace. . . . . . . . . . . . . . . . . . . . . . . . 107

Bearing Lubrication. . . . . . . . . . . . . . . . . . . 107

Setscrews . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Supply Fan Wheel-to-Funnel Alignment. . . 110

Winterizing Water Coils . . . . . . . . . . . . . . . 111

Control Panel Components . . . . . . . . . . . . 111

Replacement Parts List . . . . . . . . . . . . . . . . . . . 115

Replacement Parts . . . . . . . . . . . . . . . . . . . 115

Service and Warranty Procedure . . . . . . . . . . . 116

In-Warranty Return Material Procedure . . . 116

Limited Product Warranty (North America) . . . 117

Exceptions . . . . . . . . . . . . . . . . . . . . . . . . . 117

Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 117

Sole Remedy . . . . . . . . . . . . . . . . . . . . . . . 117

Rooftop Equipment Warranty Regist. Form. . . 118

Page 3

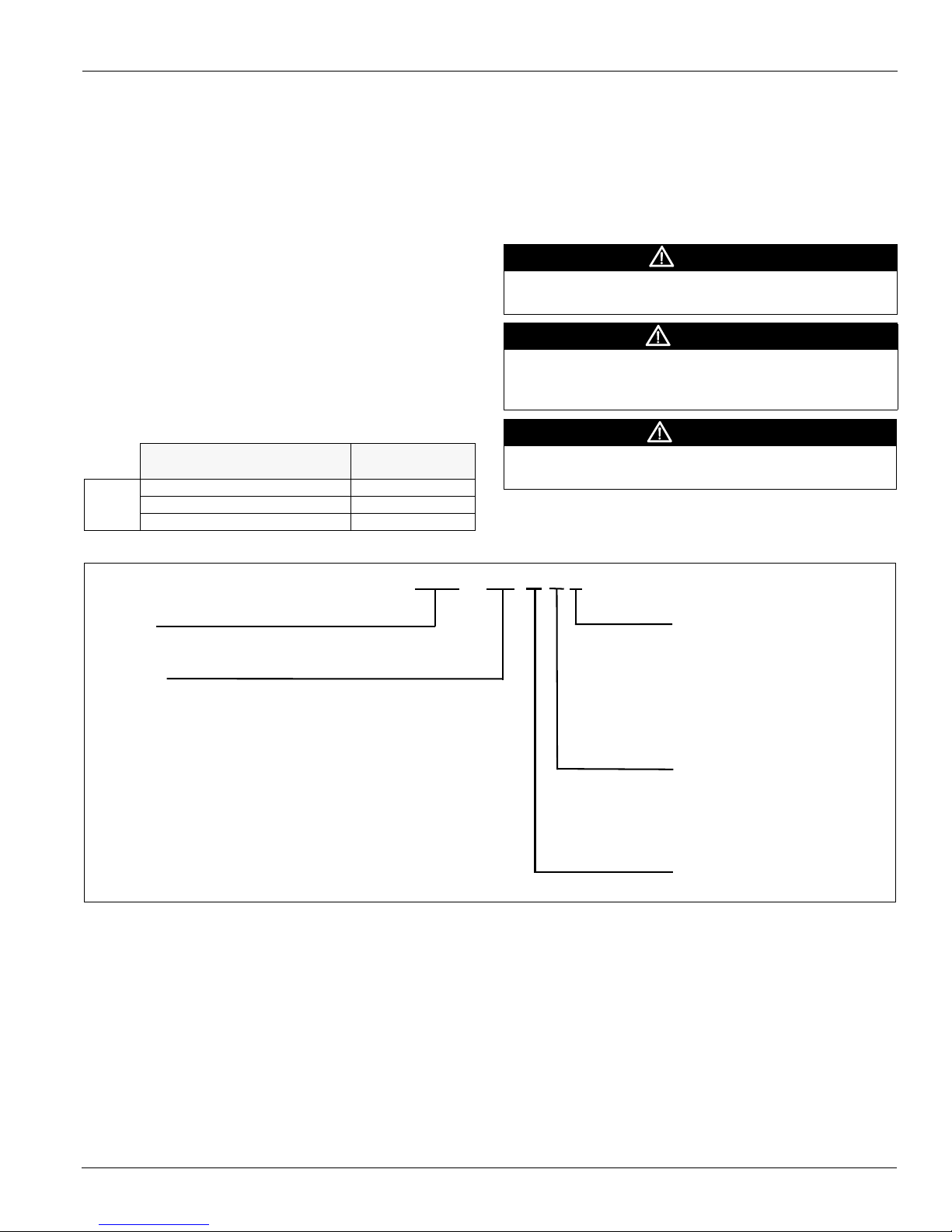

Introduction

RAH – 047 C S E

RoofPak

Unit Size

RDS 800 = 4000 – 16,000 CFM

RDS 802 = 8000 – 20,000 CFM

RAH 047 = 12,000 – 30,000 CFM

RAH 077 = 23,000 – 50,000 CFM

Heat medium

A = Natural gas

E = Electric

F = Fuel oil

S = Steam

W = Hot water

Y = None

Design vintage

Cooling coil size

S = Standard (low airflow)

L = Large (high airflow)

Y = None or contractor coil

This manual provides general information about the “C”

vintage McQuay RoofPak applied rooftop unit, models RDS

and RAH. In addition to an overall description of the unit, it

includes mechanical and electrical installation procedures,

commissioning procedures, sequence of operation information,

and maintenance instructions. For further information on the

optional forced draft gas-fired furnace, refer to Bulletin No.

IM 684 or IM 685.

Introduction

Gas Burner Nameplate

On units that include gas heat, the nameplate is located on the

lower right corner of the main control box door. It includes the

burner model number, minimum/maximum input, maximum

temperature rise, and minimum cfm.

Hazard Identification Information

The MicroTech III applied rooftop unit controller is available.

For a detailed description of the MicroTech III components,

input/output configurations, field wiring and information on

using and programming the MicroTech III unit controller, refer

to OM 920.

For a description of operation and information on using the

keypad to view data and set parameters, refer to the

appropriate program-specific operation manual (see Table 1).

Table 1: Program Specific Rooftop Unit Literature

Rooftop unit control configuration

McQuay 208 - 460 V OM 844-1

VFDs

Figure 1: Nomenclature

McQuay 575 V OM 895

Non-McQuay See vendor manuals

Operation manual

number

DANGER

Dangers indicate a hazardous situation which will result in

death or serious injury if not avoided.

WARNING

Warnings indicate potentially hazardous situations, which can

result in property damage, severe personal injury, or death if

not avoided.

CAUTION

Cautions indicate potentially hazardous situations, which can

result in personal injury or equipment damage if not avoided.

McQuay IM 987 3

Page 4

Introduction

Economizer

Filter

DX

Heat

section

Supply fan

discharge

plenum

section

C19, 20

RAT

LT11 (optional)

S11, REC11

SD2

RAE

ACT3

PC5

OAE

VM1

LT10 (optional)

DAT

OAT

SV1, 2

(optional)

section

section

return air

(optional)

(optional)

(optional)

(optional)

C9

FS1

(optional)

SV5, 6 (optional)

S10, REC10 (optional)

SD1 (optional)

ACT6

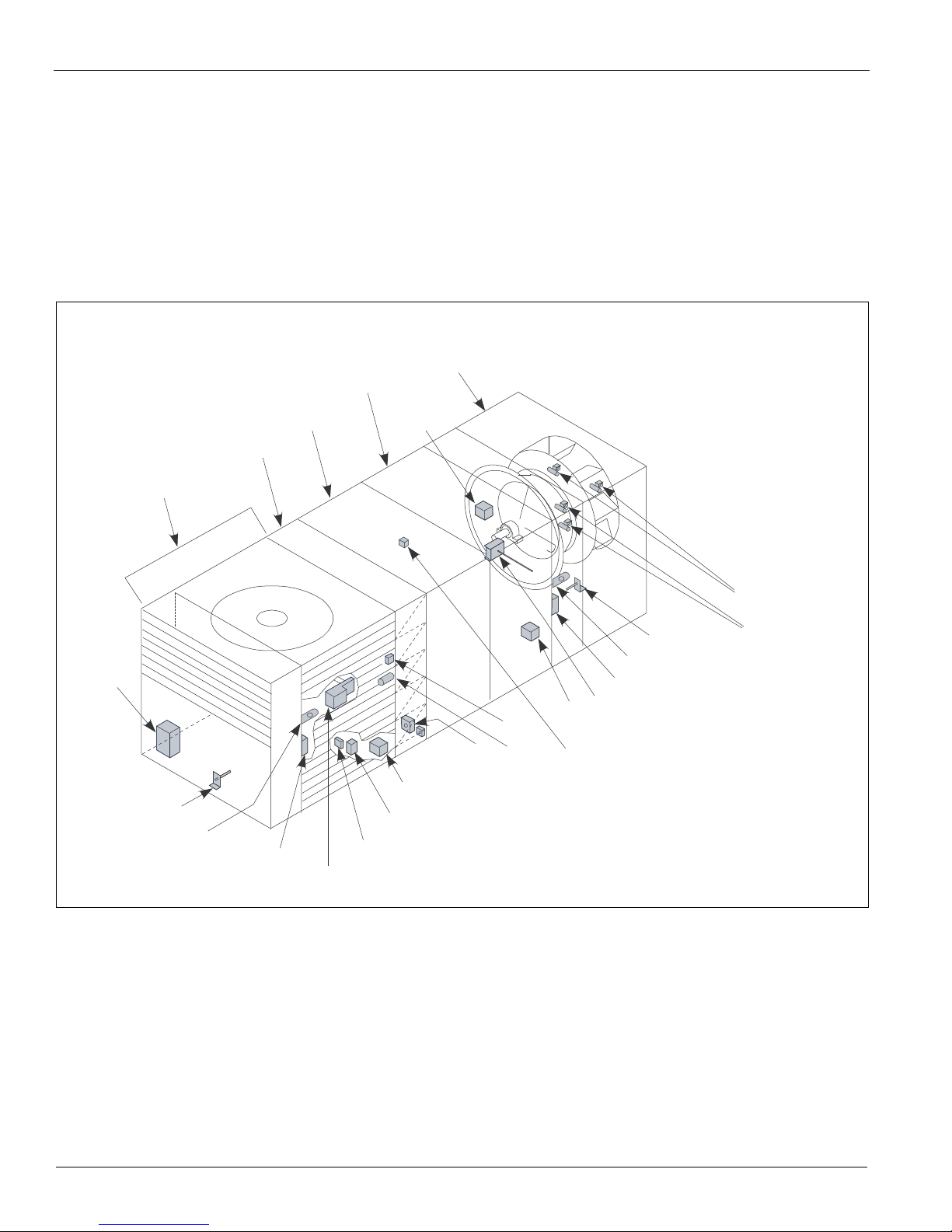

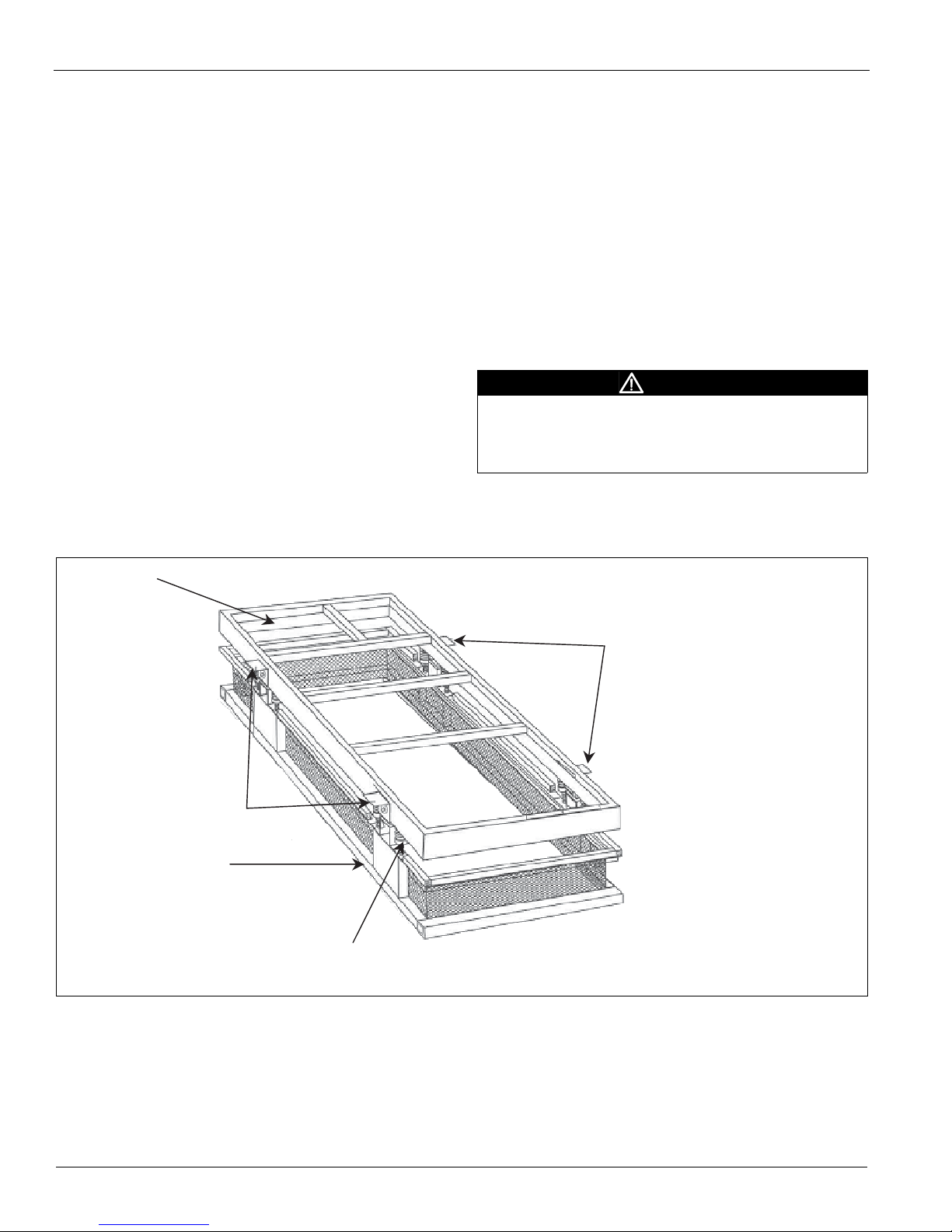

Typical Component Locations

Figure 2 shows a typical unit with locations of major

components. These figures are for general information only.

See the project’s certified submittals for actual specific

dimensions and locations.

Control Locations

All controls are optional. If controls are ordered, Figure 2

shows the locations of the various control components

Figure 2: Control Locations

mounted throughout the units. See Figure 3, page 5 for the

locations of control components mounted in control panels.

Additional information is included in Table 2, page 12 and the

wiring diagram legend, which is included in "Wiring

Diagrams"‚ page 59. Figure 2 shows the blow-through heat

and the blow-through coil sections.

4 McQuay IM 987

Page 5

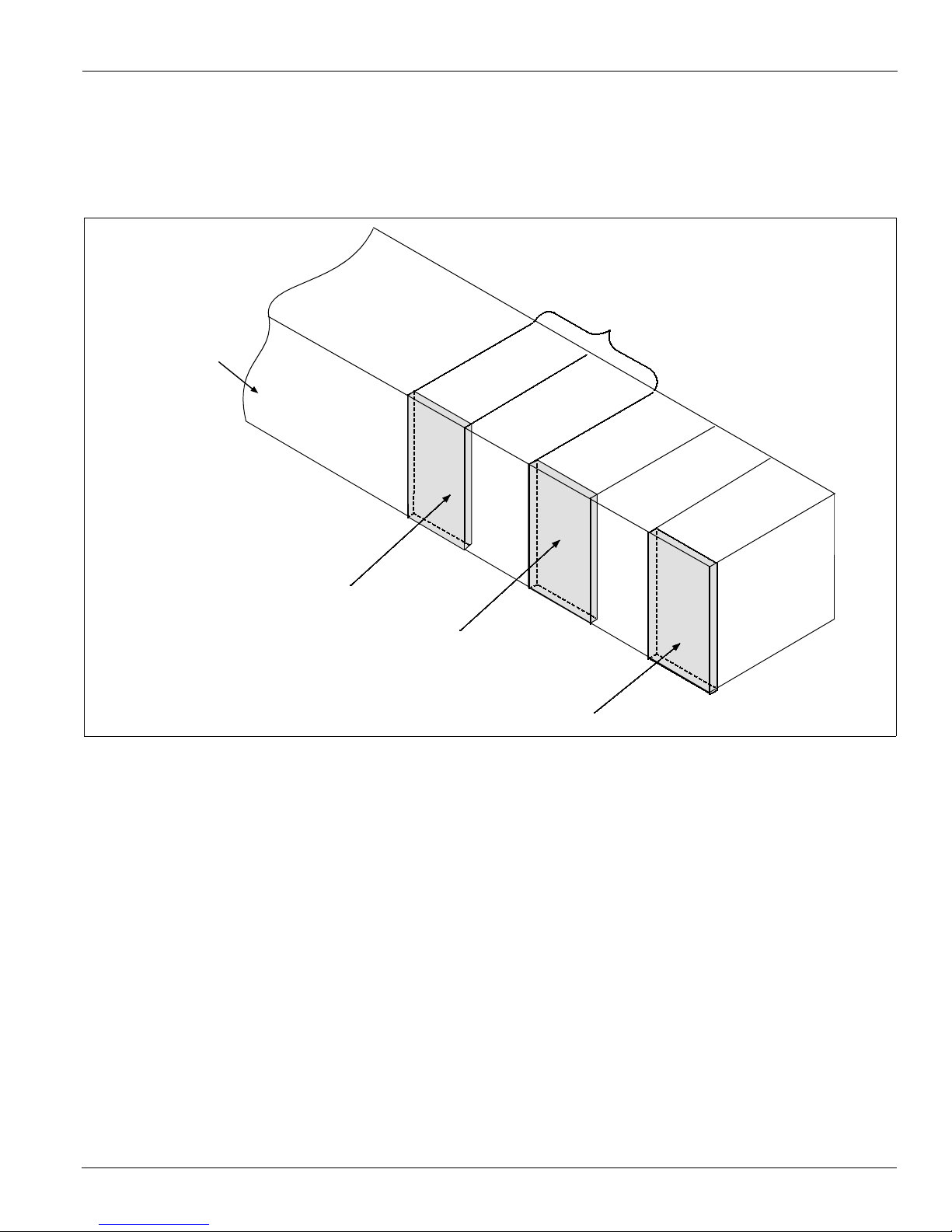

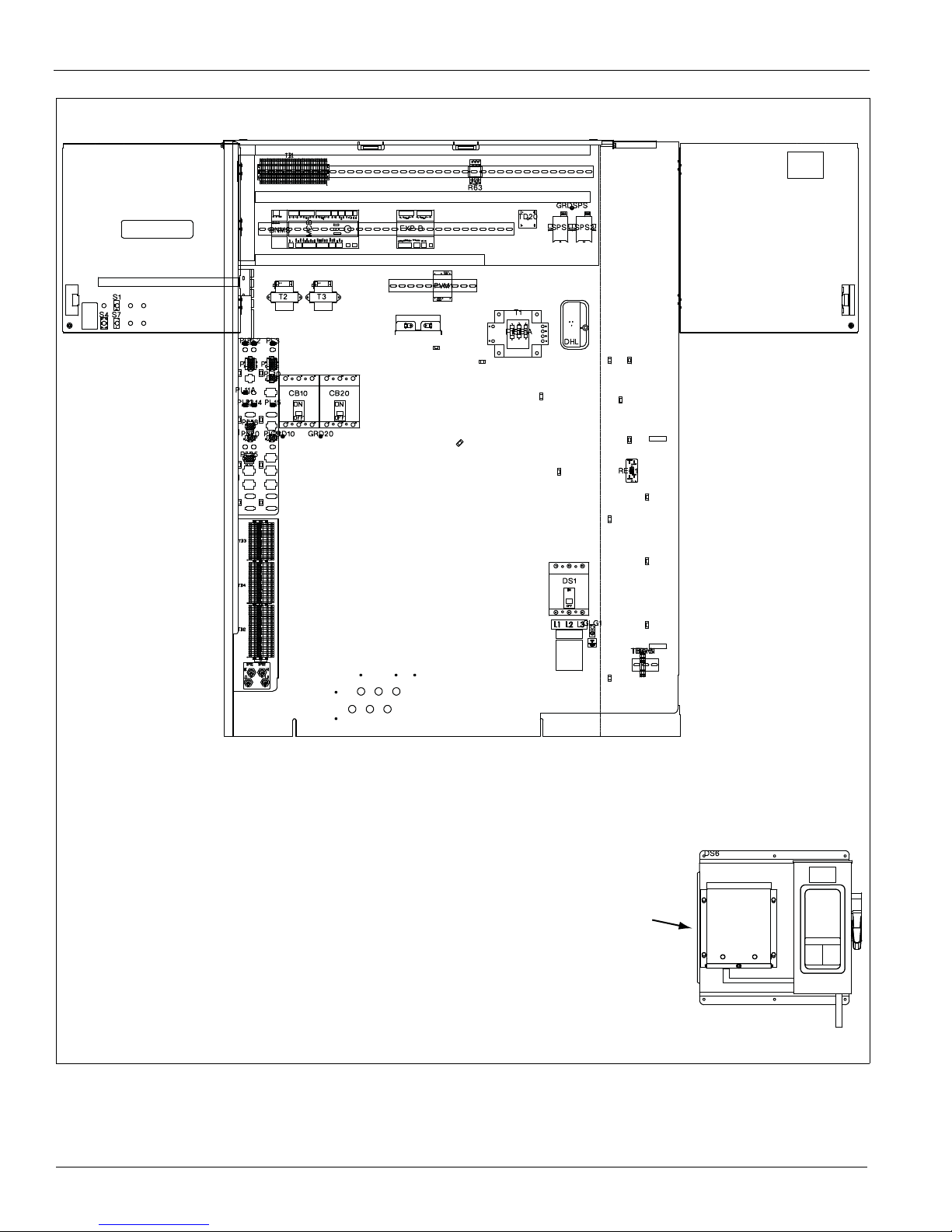

Control Panel

Main control panel

Electric heat

control panel

(optional)

Supply fan

section

VFDs, line reactors, and

manual bypass

(optional)

Prop exhaust VFDs

(not shown)

(optional)

The unit control panels and their locations are shown in the

following figures. These figures show a typical unit

configuration. Specific unit configurations may differ slightly

from these figures depending on the particular unit options.

Figure 3: Control Panel Locations

Introduction

McQuay IM 987 5

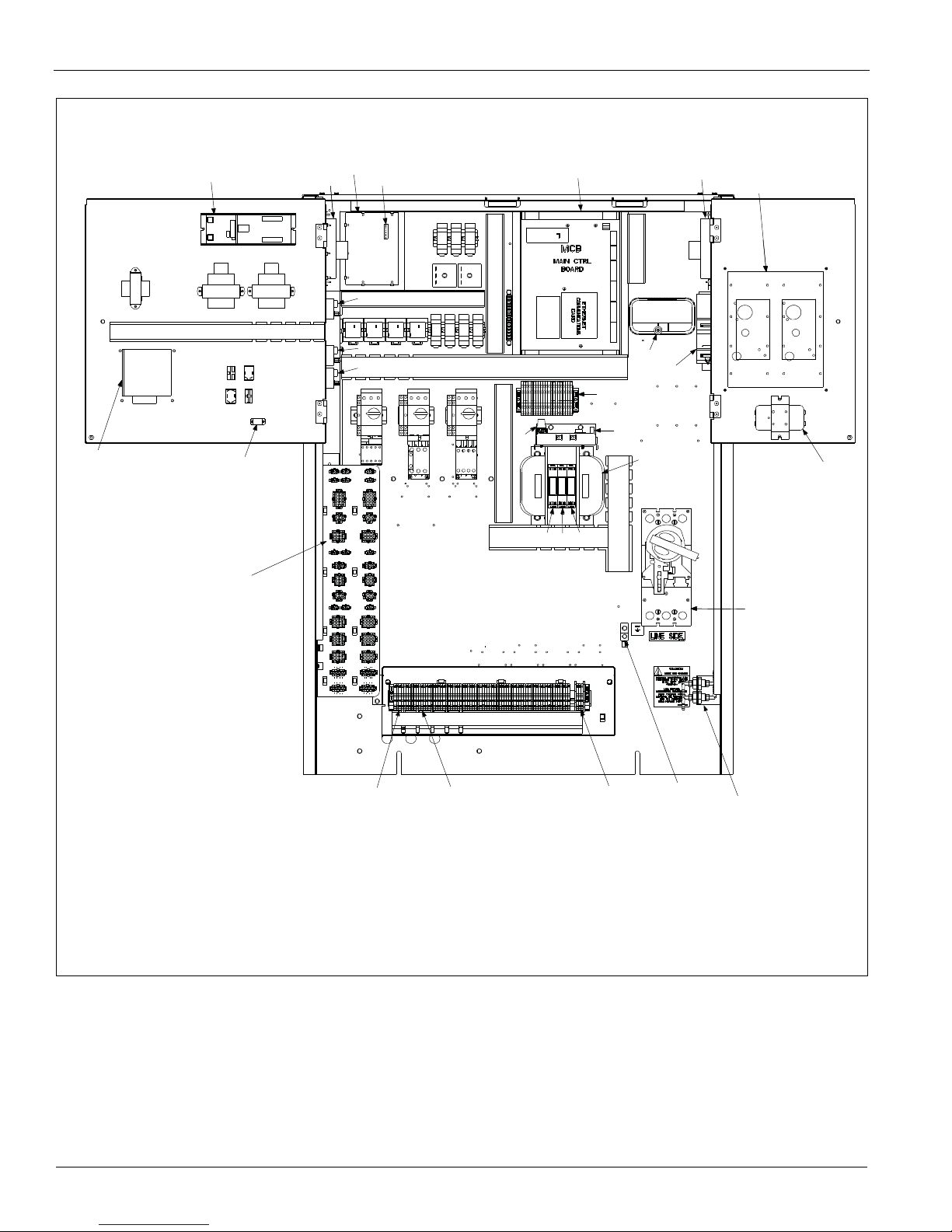

Page 6

Introduction

R24 R25 R28

R20 R26 R27 R28

R30

R45

R60

R69

R58

GCB1

Resistor

keypad

Remote

MCB

EHB1

ERB1

VFD remote

display

REC1

TB1

DHL

SPS1

SPS2

MMP60 MMP10 MMP20

R46

R48

HS1 S1

S7S4

Keypad display

Serial conn

M60

M10

F3

M20

supply

Power

F1A

F1B

F1C

T1

DS1

GND LUG DS1

TB7

blocks

remaining

TB2,

blocks

first seven

TB3,

detail, page 14.

See separate

SPS1,2 fittings

for static

pressure tubing

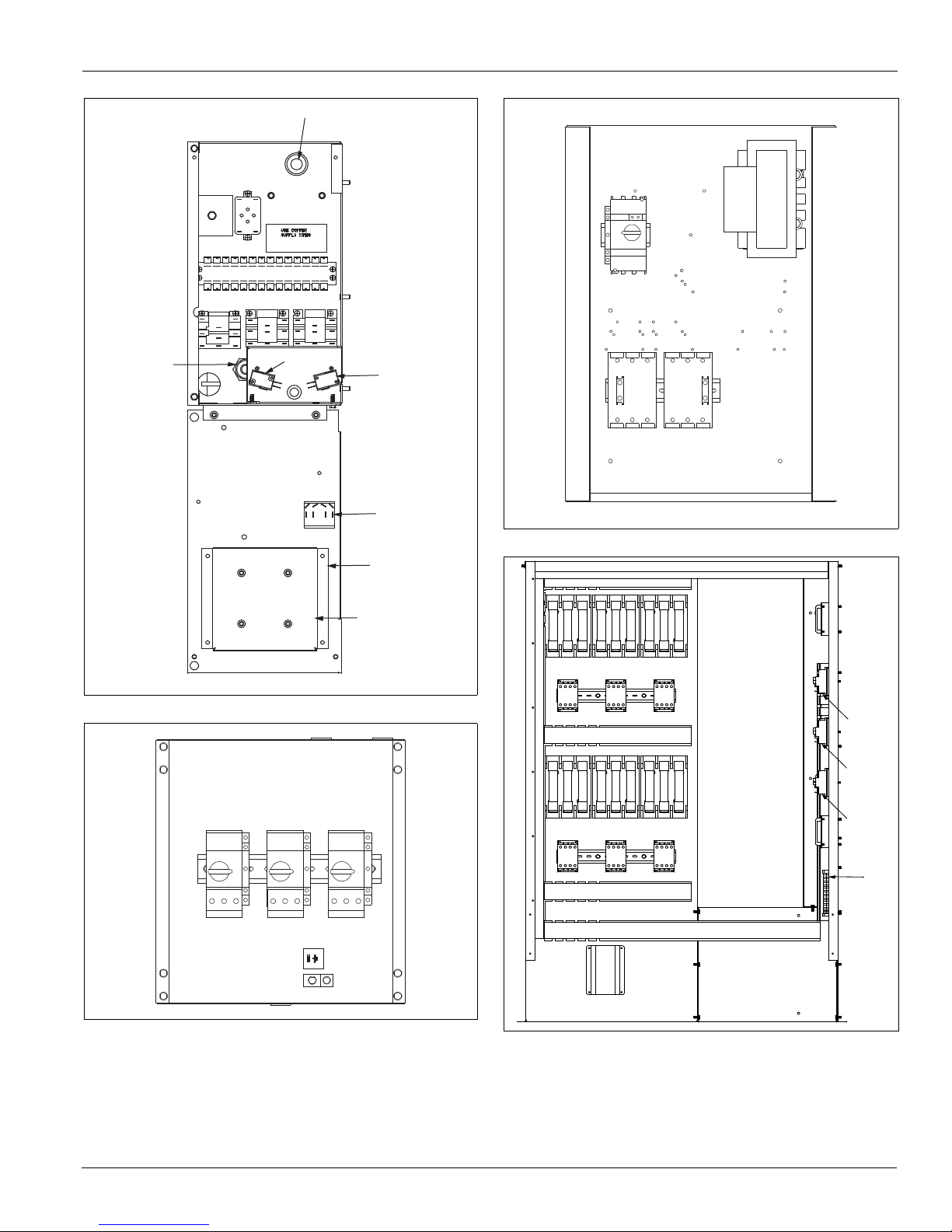

Figure 4: Typical Main Control Panel, Sizes 800C to 802C, 460 Volt

6 McQuay IM 987

Page 7

Figure 5: Typical Main Control Panel, Size 047C, 460 Volt

VFD remote

display

GFR1

TB7

SPS1,2

fittings for

static pressure

tubing

TB2

F1A

F1B

F1C

Harness

Plugs

Introduction

McQuay IM 987 7

Page 8

Introduction

Unit powered outlet and

associated disconnect in

seperate panel

Figure 6: Typical Main Control Panel, Size 077C, 460 Volt

8 McQuay IM 987

Page 9

Introduction

e

A

M41 M42 M41

M33 M32 M31

FB33 FB32 FB31

FB43 FB42 FB41

PB3

SR2

SR3

SR1

TB11

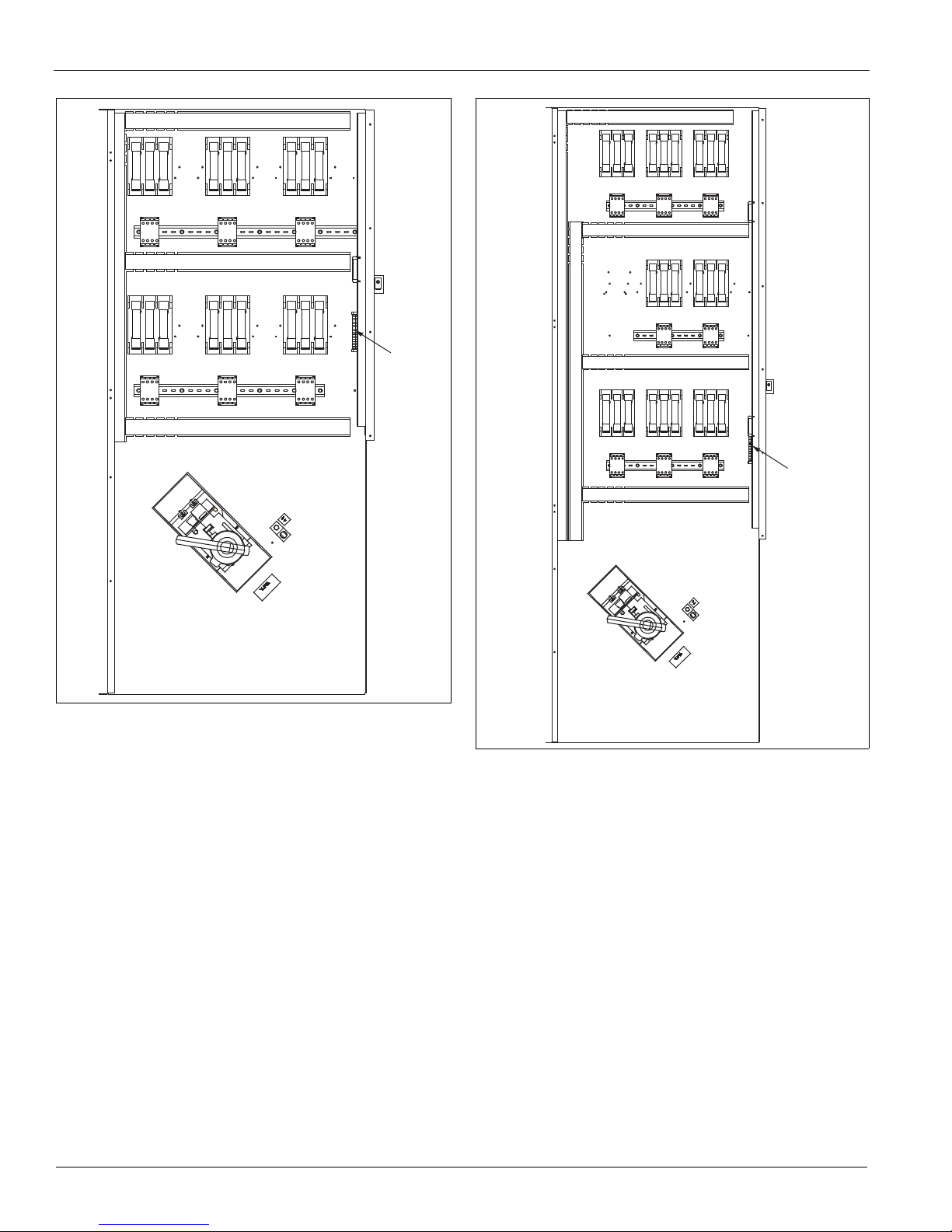

Figure 7: TypicaL Gas Heat Panel, 1000 MBH

IT

R22

TD10

R20

S

R23 R21

LS2

Figure 9: VFD Bypass Panel, 40 Hp, 460 Volt

LR10, 20

MMP30, 40

M30, 40

LS1

S3

Figure 10: Electric Heat Panel, Sizes 800C, 802C

FSG

FSG Tim

Figure 8: TypiCal Propeller Exhaust Panel, 3 Fans, 460 Volt

McQuay IM 987 9

Page 10

Introduction

GLG3

DS3

M41M43

FB41FB42FB43

H53

TB11

M31M32M33

FB31FB32FB33

M42

Figure 11: Electric Heat Panel, Size 047C Figure 12: Electric Heat Panel, Size 077C

FB31FB32FB33

M31M32M33

FB34FB44

M34M44

FB41FB42FB43

M41M42M43

GLG3

DS3

H53

TB11

10 McQuay IM 987

Page 11

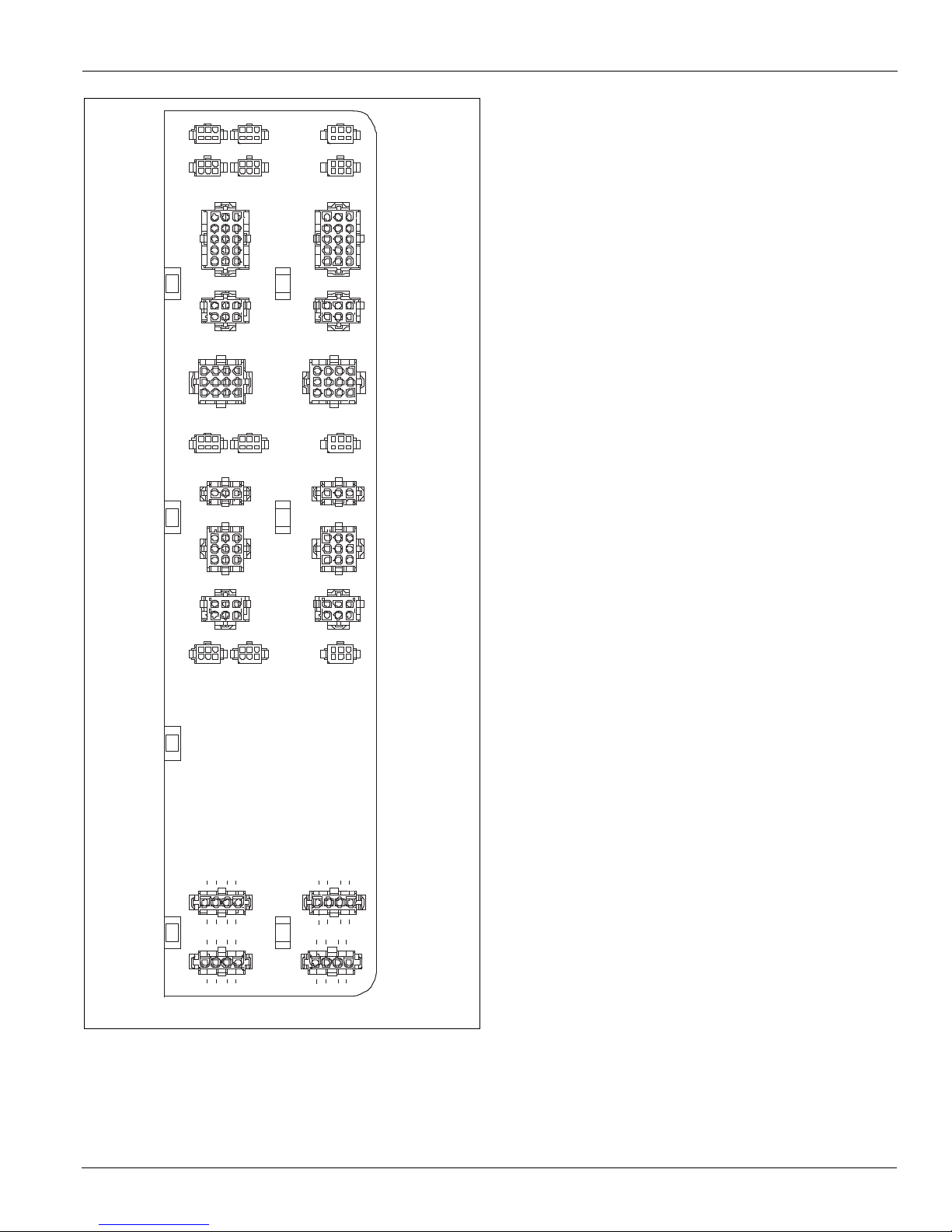

Figure 13: Harness Plug Connector Detail

LT OP1 LT OP2

LT11LT1 0

DFRH DFLH OPEN4

SD1 SD2

GSHT1 GSHT2

HL22 OPEN3

OAE PC7PC5

ACT3 OPEN2

SV12 SV56

AFD10 AFD20

FP1 OPEN1EPTS

RATS OATSDATS

Introduction

McQuay IM 987 11

Page 12

Introduction

Controls, Settings, and Functions

Table 2 below lists all of the unit control devices and

associated information.

Table 2: Controls, Settings, and Functions

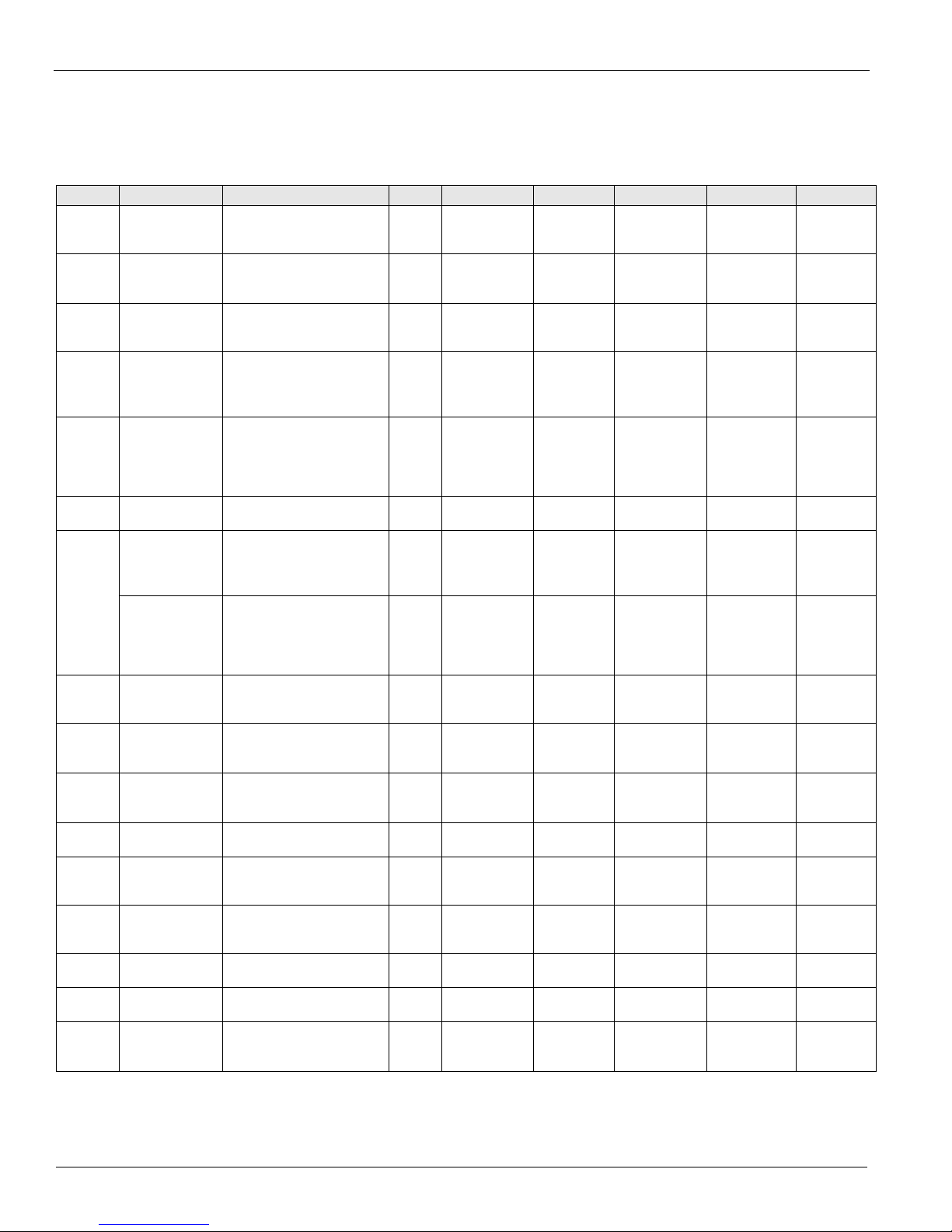

Symbol Description Function Reset Location Setting Range Differential Part no.

DAT

DHL

EFT

FP1, 2

FS1

MCB

OAE

OAT

PC5

PC6

PC7

RAE

RAT

SD1

SD2

SPS1

Discharge air

temperature

sensor

Duct high limit

switch

Entering fan air

temperature

sensor

Evaporator frost

protection

Freezestat

Main control

board

Enthalpy control

(electromechanical)

Enthalpy control

(electronic)

Outside air

temperature

sensor

Dirty filter switch Senses filter pressure drop

Dirty filter switch Senses filter pressure drop

Airflow proving

switch

Return air

enthalpy sensor

Return air

temperature

sensor

Smoke detector,

supply air

Smoke detector,

return air

Static pressure

sensor duct #1

Senses discharge air

temperature

Prevents excessive VAV

duct pressures; shuts off fan

Senses entering fan air

temperature

Senses low refrigerant

temperature

Shuts off fans, opens heating

valve, and closes outdoor

damper if low air

temperature at coil is

detected

Processes input information

Returns outside air dampers

to minimum position when

enthalpy is too high

Returns outside air dampers

to minimum position when

outside air enthalpy is higher

than return air empalthy (use

RAE)

Senses outside air

temperature

Senses supply fan pressure

to prove airflow

Used to compare return air

enthalpy to outside air

enthalpy (used with OAE)

Senses return air

temperature

Initiates unit shutdown if

smoke is detected

Initiates unit shutdown if

smoke is detected

Converts static pressure

signals to voltage signals

N/A

Auto

N/A

N/A

Auto

N/A

Auto

Auto

N/A N/A N/A 060004705

Auto

Auto

Auto

N/A

N/A

Manual

Manual

N/A

Discharge air

section

Main control

panel

Inlet of supply

fan

Return bends

of evaporative

coil

Heating

section

Main control

box

Economizer

section

Economizer

section

First filter

section

Final filter

section

Supply fan

section

Economizer

section

Return air

section

Discharge air

section

Return air

section

Main control

box

N/A N/A 060004705

3.5" w.c

(871.8 Pa)

N/A N/A 060004705

Opens at

30°F

Closes at

45°F

38°F (3°C)

or as

required

N/A N/A N/A 060006101

“B” or as

required

Fully CW

past “D”

(when used

with RAE)

As required

As required

.10" wc (25

Pa)

N/A N/A N/A 049262202

N/A N/A 060004705

N/A N/A N/A 04925001

N/A N/A N/A 04925001

N/A

0.05–5.0" wc

(12.5–1245.4

Pa)

N/A N/A 072501901

35°F–45°F

(2°C–7°C)

A–D

A–D N/A 049262201

.05-5" wc

(12.5–1245.4

Pa)

.05-5" wc

(12.5–1245.4

Pa)

.03-1.40" wc

(7.5–348 Pa)

0–5" wc

(0–1245.4 Pa)

1–6 V (dc) out

.05" wc

(12.5 Pa),

fixed

12°F (7°C),

fixed

Temperature:

3.5°F (2°C)

Humidity:

5% fixed

.05" wc

(12.5 Pa)

.05" wc

(12.5 Pa)

.03" wc

(7.5 Pa), fixed

N/A 049545007

065493801

072502001

030706702

065493801

065493801

060015801

12 McQuay IM 987

Page 13

Introduction

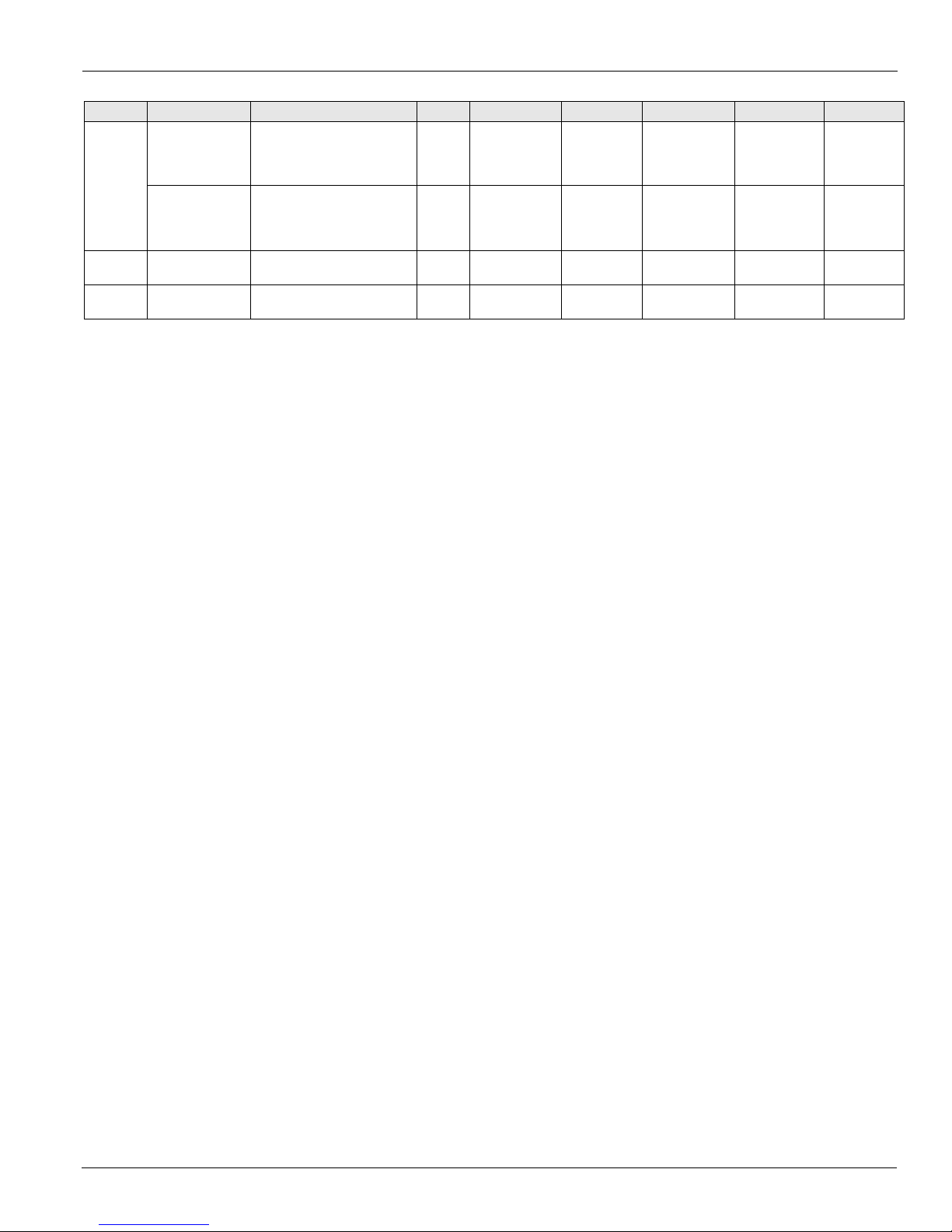

Table 2: Controls, Settings, and Functions (continued)

Symbol Description Function Reset Location Setting Range Differential Part no.

SPS2

S1

S7

Static pressure

sensor duct #2

Static pressure

sensor: building

(space) pressure

System switch

ON-OFF-AUTO

switch

Converts static pressure

signals to voltage signals

and sends them to

MicroTech III controller

Converts static pressure

signals to voltage signals.

Shuts off entire control circuit

(except crankcase heaters)

Used to manually switch unit

N/A

N/A

N/A

N/A

Main control

box

Main control

box

Main control

box

Main control

box

N/A

N/A

N/A N/A N/A 001355000

N/A N/A N/A

0–5" wc

(0–1245.4 Pa)

1–6 V (dc) out

-025–0.25" wc

(-62.3–62.3

Pa)

1–5 V (dc) out

N/A 049545007

N/A 049545006

McQuay IM 987 13

Page 14

Mechanical Installation

Mechanical Installation

Note: The installation of this equipment shall be in accordance

with the regulations of authorities having jurisdiction and

all applicable codes. It is the responsibility of the installer

to determine and follow the applicable codes.

CAUTION

Sharp edges on sheet metal and fasteners can cause personal

injury.

This equipment must be installed, operated, and serviced only

by an experienced installation company and fully trained

personnel.

Receiving Inspection

When the equipment is received, all items should be carefully

checked against the bill of lading to be sure all crates and

cartons have been received. If the unit has become dirty

during shipment (winter road chemicals are of particular

concern), clean it when received.

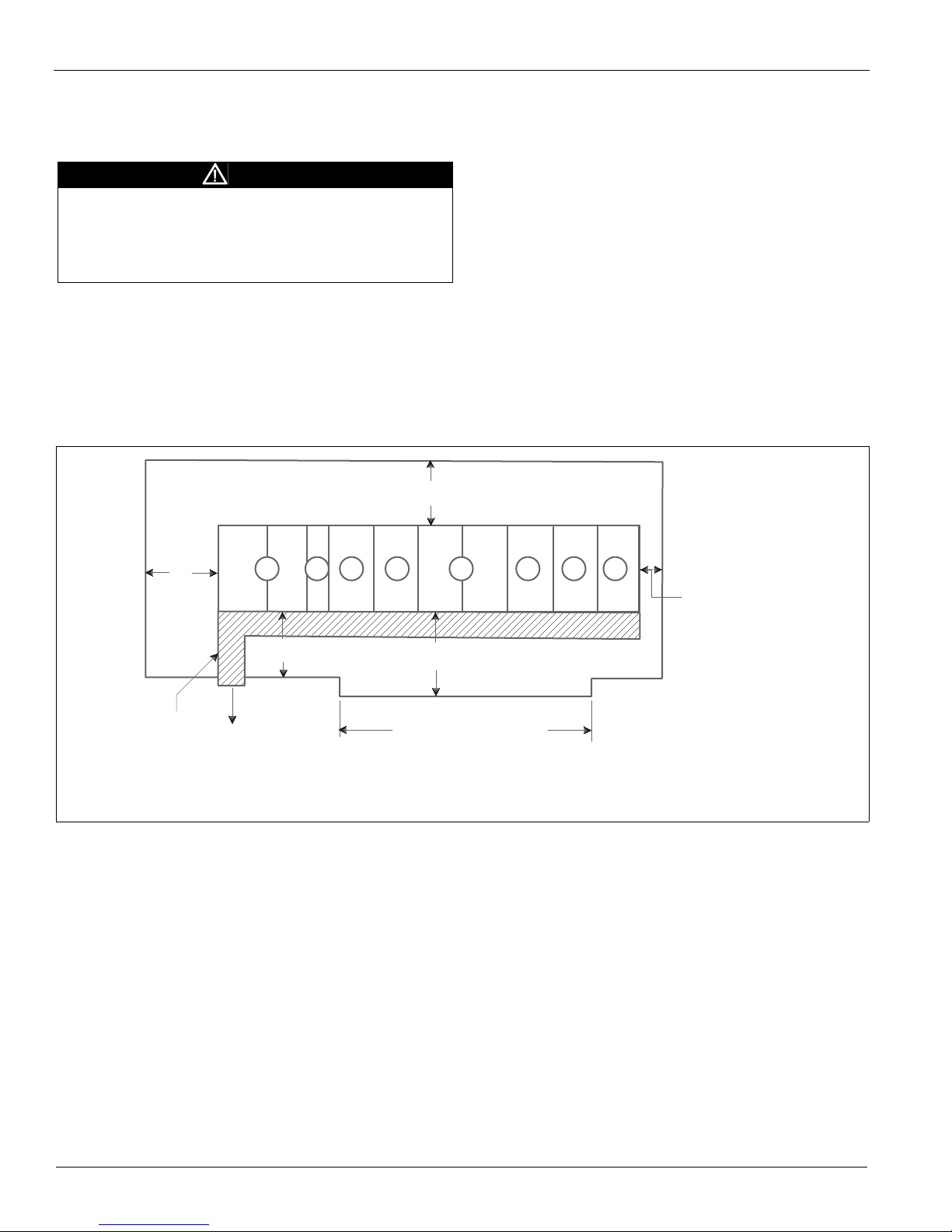

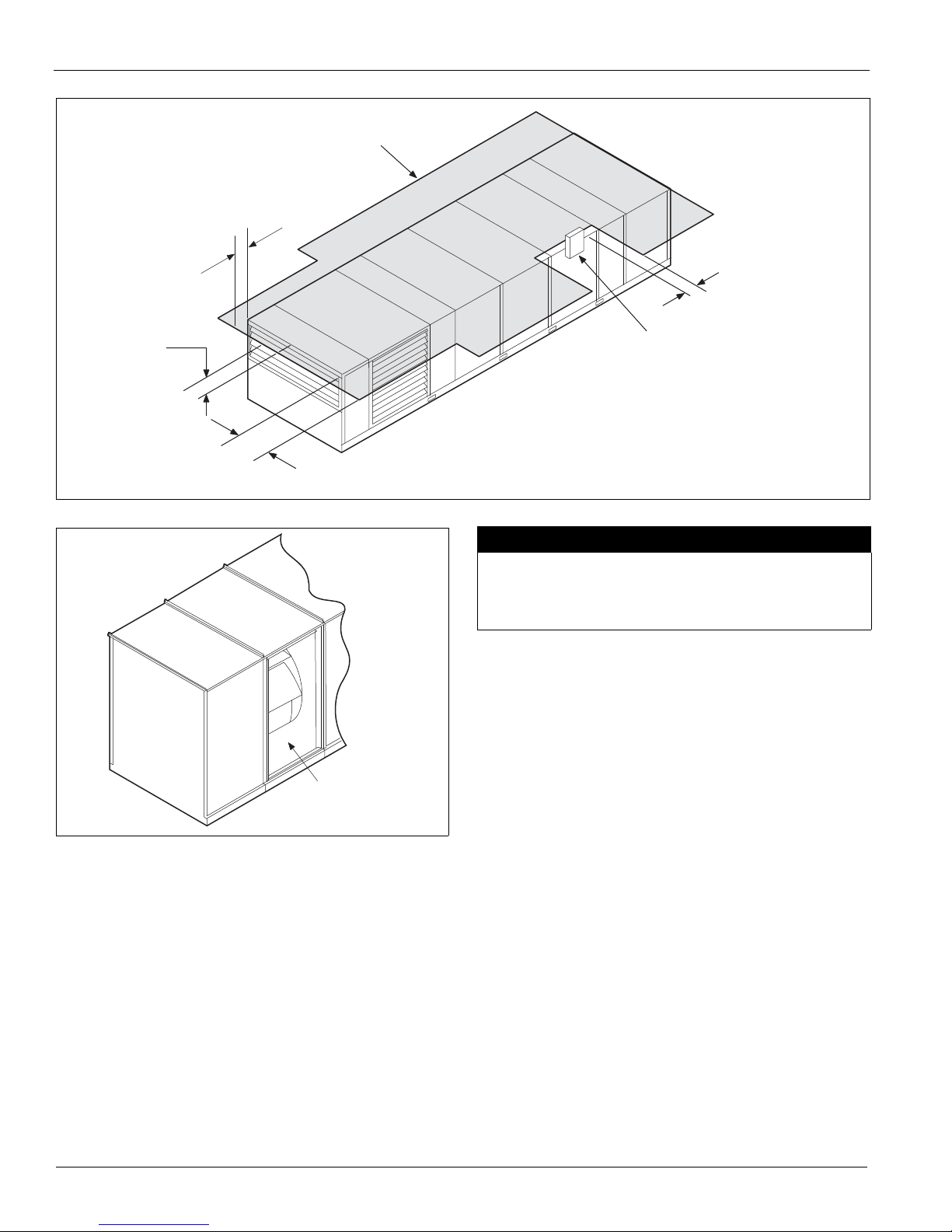

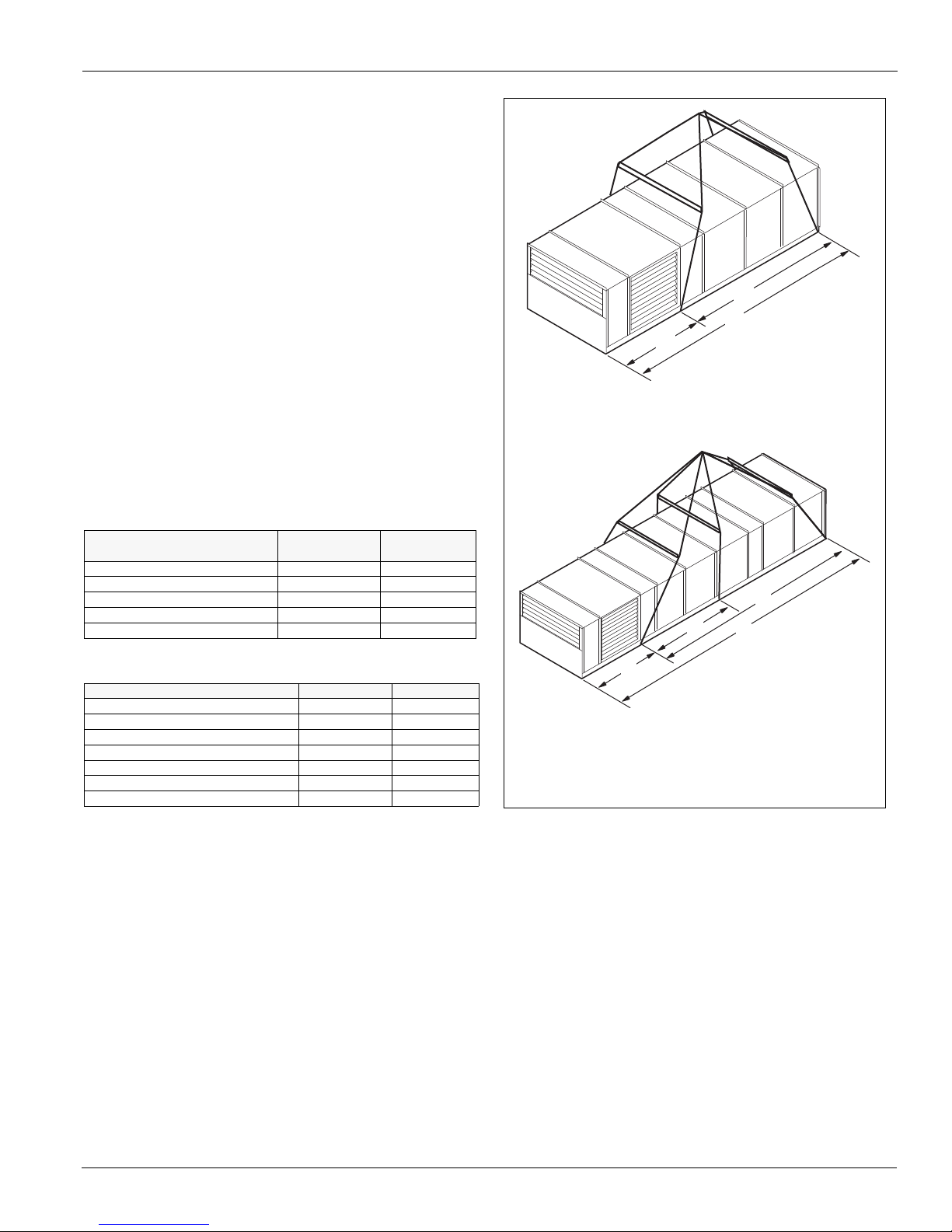

Figure 14: Service Clearances, Unit with Housed DWDI Supply Fan

72"

(1829 mm)

All units should be inspected carefully for damage when

received. Report all shipping damage to the carrier and file a

claim. In most cases, equipment ships F.O.B. factory and

claims for freight damage should be filed by the consignee.

Before unloading the unit, check the unit nameplate to make

sure the voltage complies with the power supply available.

Unit Clearances

Service Clearance

Allow an approximate service clearance as indicated in

Figure 14. Also, McQuay recommends providing a roof

walkway to the rooftop unit as well as along two sides of the

unit that provide access to most controls and serviceable

components.

72"

(1829 mm)

Roof

Walkway

Note:

Sections with heating and/or cooling coils or DWDI

supply fan must have noted service clearance on the

control box side.

To Roof

Access

Location

A

(1524 mm)

B C

60"

D

Varies With Unit Arrangement

Refer to Certified Drawing & Note

E

X

Dimension "X"

RDS 800-802 = 90" (2286mm)

RAH 47-77 = 96" (2438mm)

D

C

F

24"

(635 mm)

Legend:

A = Return Air Section

B = Filter Section

C = Cooling Section

D = Cooling/Supply Fan Section

E = Heat Section

F = Discharge Plenum Section

14 McQuay IM 987

Page 15

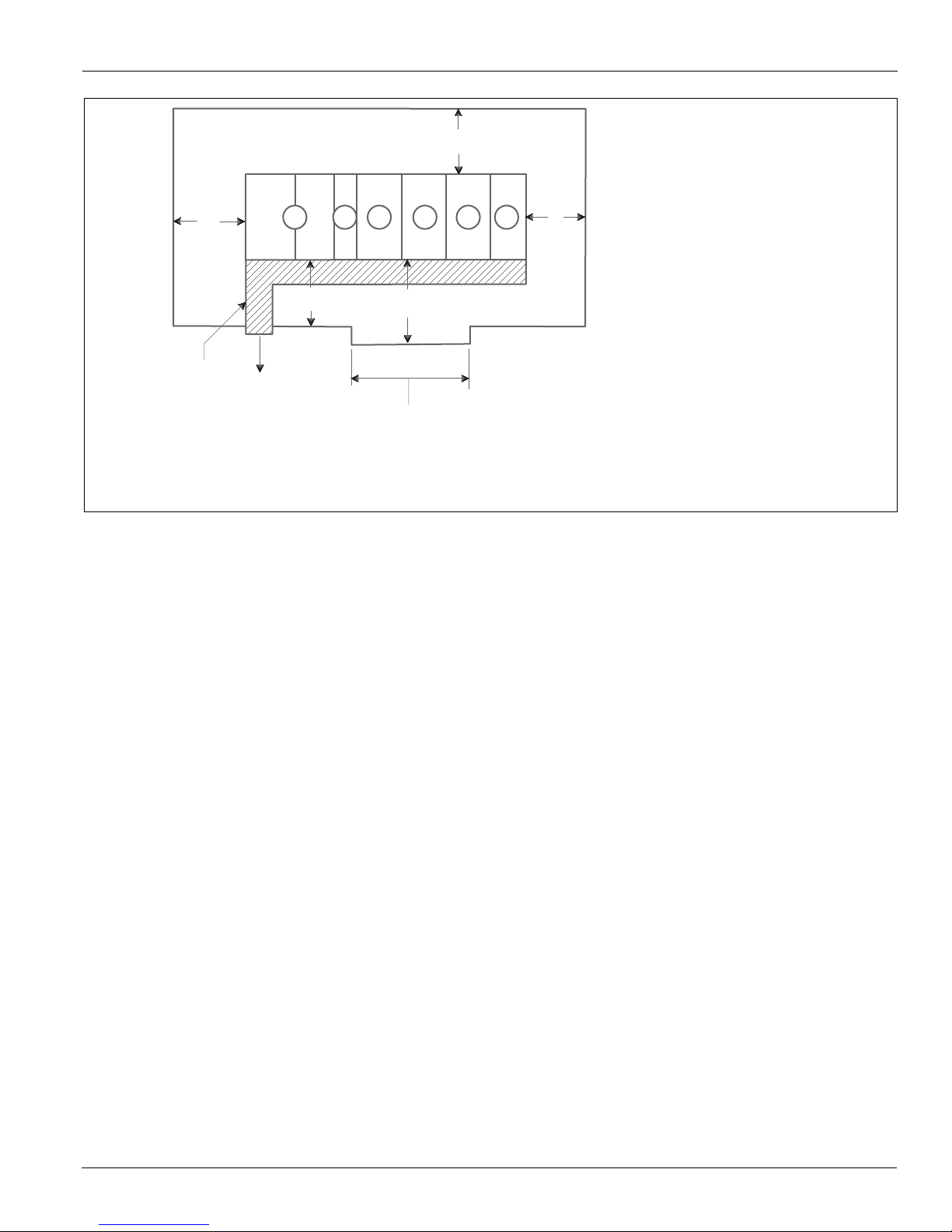

Figure 15: Service Clearances, Unit with SWSI Plenum Supply Fan

Roof

walkway

To roof

access

location

Varies with unit arrangement.

Refer to Certified Drawing and

note below.

96"

(2438 mm)

60"

(1524 mm)

72"

(1829 mm)

72"

(1829 mm)

A

B C

D

Legend:

A = Return air section

B = Filter section

C = Cooling section

D = Cooling/supply fan section

E = Heat section

F = Discharge plenum section

Dimension "X"

RDS 800–802 = 90" (2286mm)

RAH 47–77 = 96" (2438mm)

Note:

Sections with heating and/or cooling coils or DWDI

supply fan must have noted service clearance on the

control box side.

X

E F

Mechanical Installation

Ventilation Clearance

Below are minimum ventilation clearance recommendations.

The system designer must consider each application and

provide adequate ventilation. If this is not done, the unit will

not perform properly.

Unit(s) surrounded by a screen or a fence:

The bottom of the screen or fence should be at least 1 ft.

1

(305 mm) above the roof surface.

2 The distance between the unit and a screen or fence

should be as described in Figure 15.

3 The distance between any two units within a screen or

fence should be at least 120" (3048 mm).

Unit(s) surrounded by solid walls:

1

If there are walls on one or two adjacent sides of the unit,

the walls may be any height. If there are walls on more

than two adjacent sides of the unit, the walls should not

be higher than the unit.

2 The distance between the unit and the wall should be at

least 96" (2438 mm) on all sides of the unit.

3 The distance between any two units within the walls

should be at least 120" (3048 mm).

Do not locate outside air intakes near exhaust vents or other

sources of contaminated air.

If the unit is installed where windy conditions are common,

install wind screens around the unit, maintaining the

clearances specified (see Figure 16). This is particularly

important to prevent blowing snow from entering the outside

air intake and to maintain adequate head pressure control when

mechanical cooling is required at low outdoor air

temperatures.

Overhead Clearance

1 Unit(s) surrounded by screens or solid walls must have

no overhead obstructions over any part of the unit.

2 The following restrictions must be observed for overhead

obstructions above the air handler section (see

Figure 16):

a There must be no overhead obstructions above the

furnace flue, or within 9" (229 mm) of the flue box.

b Overhead obstructions must be no less than 96"

(2438 mm) above the top of the unit.

c There must be no overhead obstructions in the areas

above the outside air and exhaust dampers that are

farther than 24" (610 mm) from the side of the unit.

McQuay IM 987 15

Page 16

Mechanical Installation

24" (610 mm)

Maximum

2" (51 mm)

Minumum

Top of Unit

to Overhead

Obstruction

24" (610 mm)

Maximum

Overhead

Canopy

9" (229 mm)

Minumum to Flue Box

Typical All Sides

Flue Box

Figure 16: Overhead Clearance

Figure 17: Side Discharge

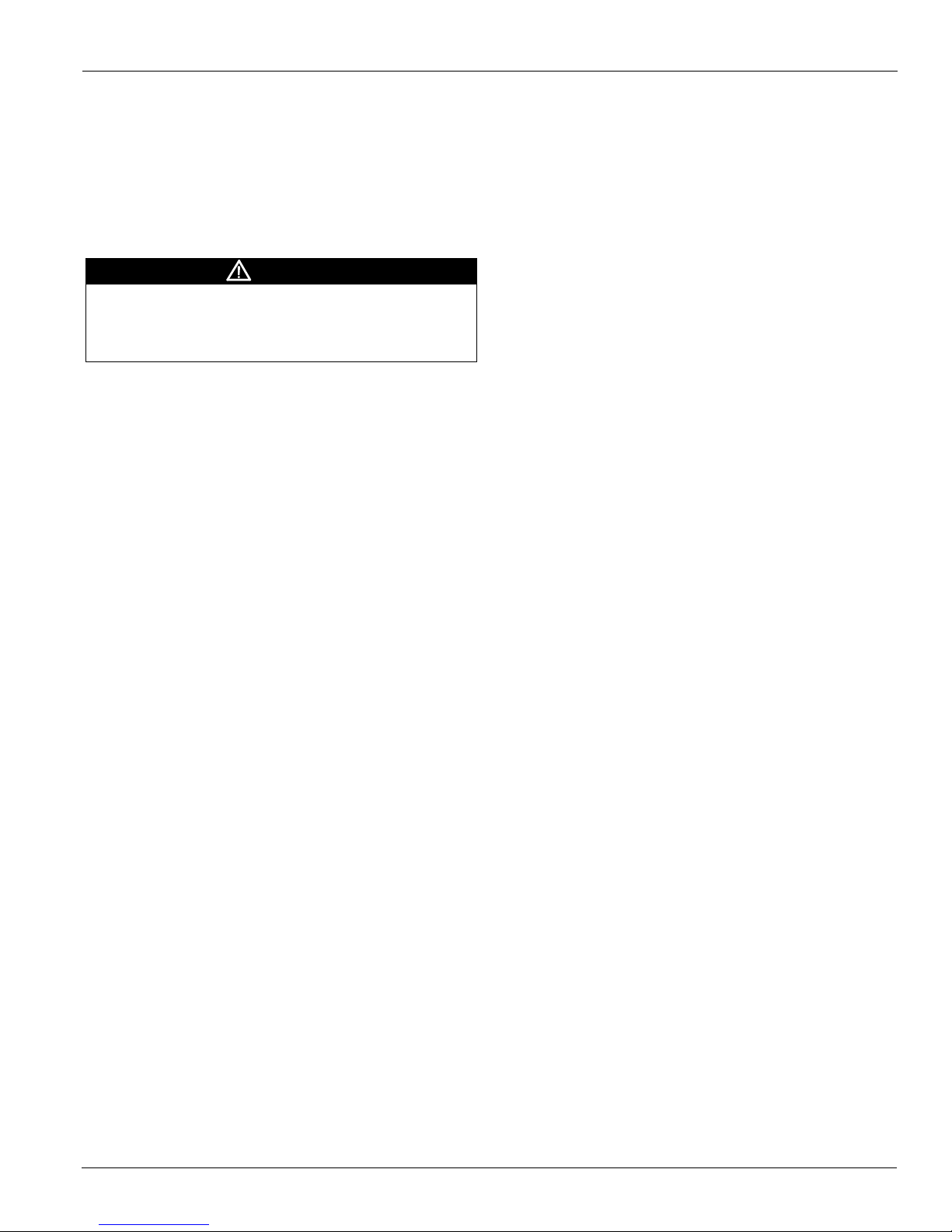

NOTICE

On units with side discharge, access to plenum-mounted

components becomes difficult once ductwork is installed.

Installer must provide access in the ductwork for plenum

mounted controls

Side Discharge Opening

(Access in Ductwork

Must be Removed)

16 McQuay IM 987

Page 17

Mechanical Installation

Roof Curb Assembly and Installation

Locate the roof curb and unit on a portion of the roof that can

support the weight of the unit. The unit must be supported to

prevent bending or twisting of the machine.

If building construction allows sound and vibration into the

occupied space, locate the unit over a non-critical area. It is

the responsibility of the system designer to make adequate

provisions for noise and vibration in the occupied space.

WARNING

Mold can cause personal injury. Some materials such as

gypsum wall board can promote mold growth when damp.

Such materials must be protected from moisture that can enter

units during maintenance or normal operation.

Install the curb and unit level to allow the condensate drain to

flow properly and allow service access doors to open and close

without binding.

Integral supply and return air duct flanges are provided with

the RAH roof curb, allowing connection of duct work to the

curb before the unit is set. The gasketed top surface of the duct

flanges seals against the unit when it is set on the curb. These

flanges must not support the total weight of the duct work.

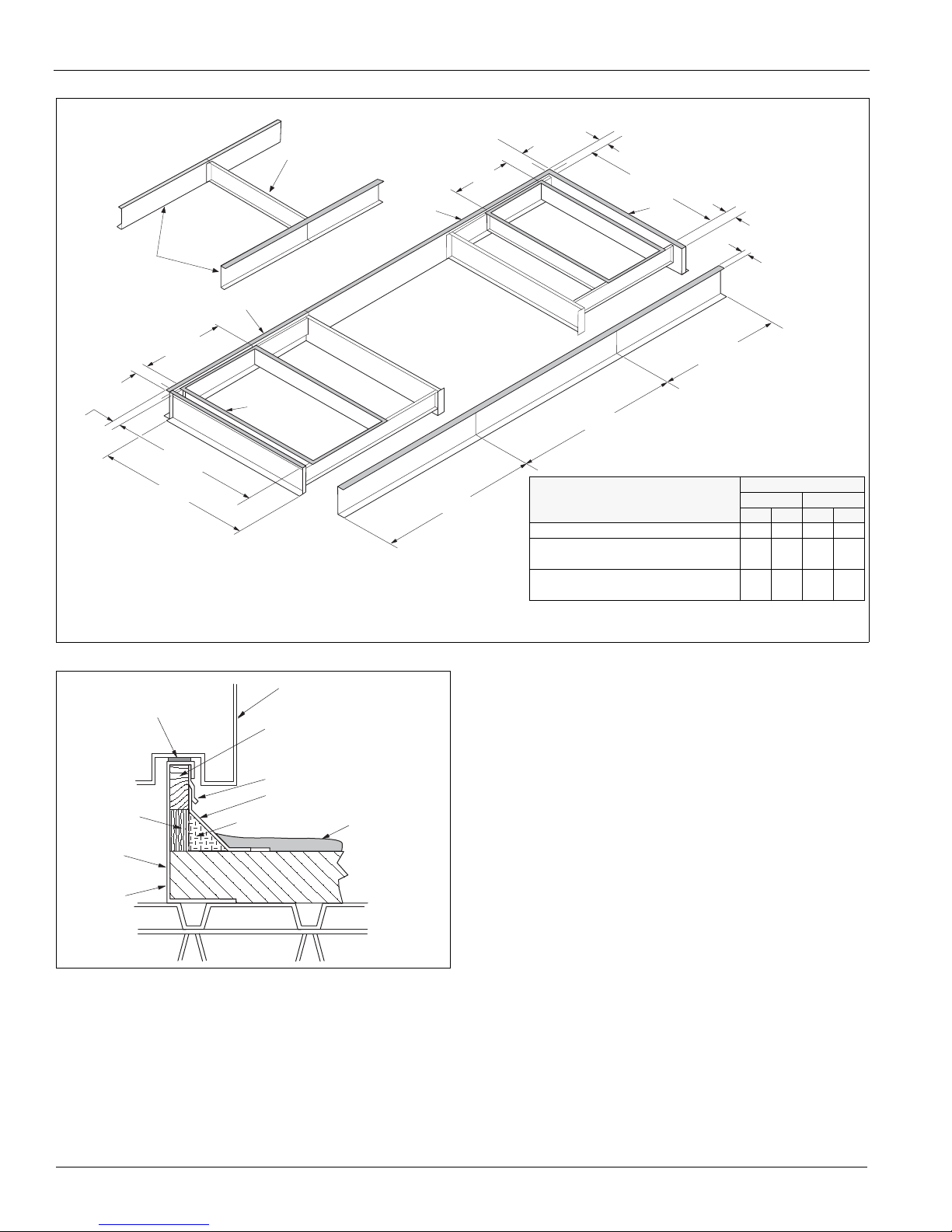

Assembly of a typical RAH roof curb is shown in Figure 18,

page 18. Parts A through H are common to all units having

bottom return openings. Depending on the unit length, Parts L

and M may be included with the roof curb kit to create the

correct overall curb length.

Assembly instructions

1 Set curbing parts A through H per dimensions shown

over roof opening or on a level surface (see Figure 18,

page 18). Note location of return and supply air

openings.

2 If applicable, set other curbing parts (D, L, M, etc.) in

place making sure that the orientation complies with the

assembly instructions (see Detail A). Check alignment of

all mating bolt holes.

3 Bolt curbing parts together using fasteners provided.

Tighten all bolts finger tight.

4 Square entire curbing assembly and securely tighten all

bolts.

5 Position curb assembly over roof openings. Curb must be

level from side to side and over its length. Check that top

surface of the curb is flat with no bowing or sagging.

6 Weld curbing in place. Caulk all seams watertight.

Remove backing from 0.25" (6 mm) thick × 1.50"

(38 mm) wide gasketing and apply to surfaces shown by

cross-hatching.

7 Flash curbing into roof as shown in detail view B

(Figure 19).

8 Parts E and F are not required on units with no return

shaft within the curb perimeter.

9 Parts G and H are not required on units with no supply

shaft within the curb perimeter.

10 Be sure that electrical connections are coordinated (see

Figure 26).

McQuay IM 987 17

Page 18

Mechanical Installation

D

Return

Air

F

B

F

E

"X"

Inside

87.00"

(2210 mm)

Inside

90.00"

(2286 mm)

94.75"

(2407 mm)

A

B

E

8.75"

(222mm)

D

See Detail "A"

70.75"

(1797 mm)

C

G

G

C

H

H

A

"Y"

Inside

81.00"

(2057 mm)

Inside

8.75"

(222 mm)

3.50"

(90 mm)

7.50"

(191 mm)

2.00"

(51 mm)

Supply

Air

3.50"

(90mm)

Equal Length

Side Supports

L

Using remaining side supports

in this area, align lengths on

opposite sides of assembly

and install a cross support

"D" at each side.

D

M

L

M

Detail A

RAH unit

Dimensions

X Y

in mm in mm

047C

38 965 28 711

077C with flat cooling coil and /or 44"

SWSI plenum supply fan

62

157

5

38 965

077C with staggered or no cooling coil,

and/or 49" SWSI plenum supply fan

62

157

5

46 1168

Main unit

curb

Unit base

Curb gasketing

2 × 4 nailer strip

Galvanized

curb

Cant strip

(not furnished)

Roffing material

(not furnished)

Rigid insulation

(not furnished)Counterflashing

(not furnished)

Flashing (not furnished)

Figure 18: RAH Roof Curb Assembly Instructions

Figure 19: Roofing Detail “B”

18 McQuay IM 987

Page 19

Figure 20: RDS Roof Curb Assembly Instructions

D

Return

Air

F

B

F

E

"X"

Inside

"Y"

Inside

85.00"

(2159 mm)

62.80"

(1594 mm)

A

B

E

"YY"

"XX"

D

See Detail "A"

38.80"

(984 mm)

C

G

G

C

H

H

A

20.00"

(508 mm)

Inside

76.00" (1930 mm)

Inside

6.80"

(173 mm)

1.50"

(38 mm)

7.50"

(191 mm)

2.00"

(5.1 mm)

Supply

Air

Mechanical Installation

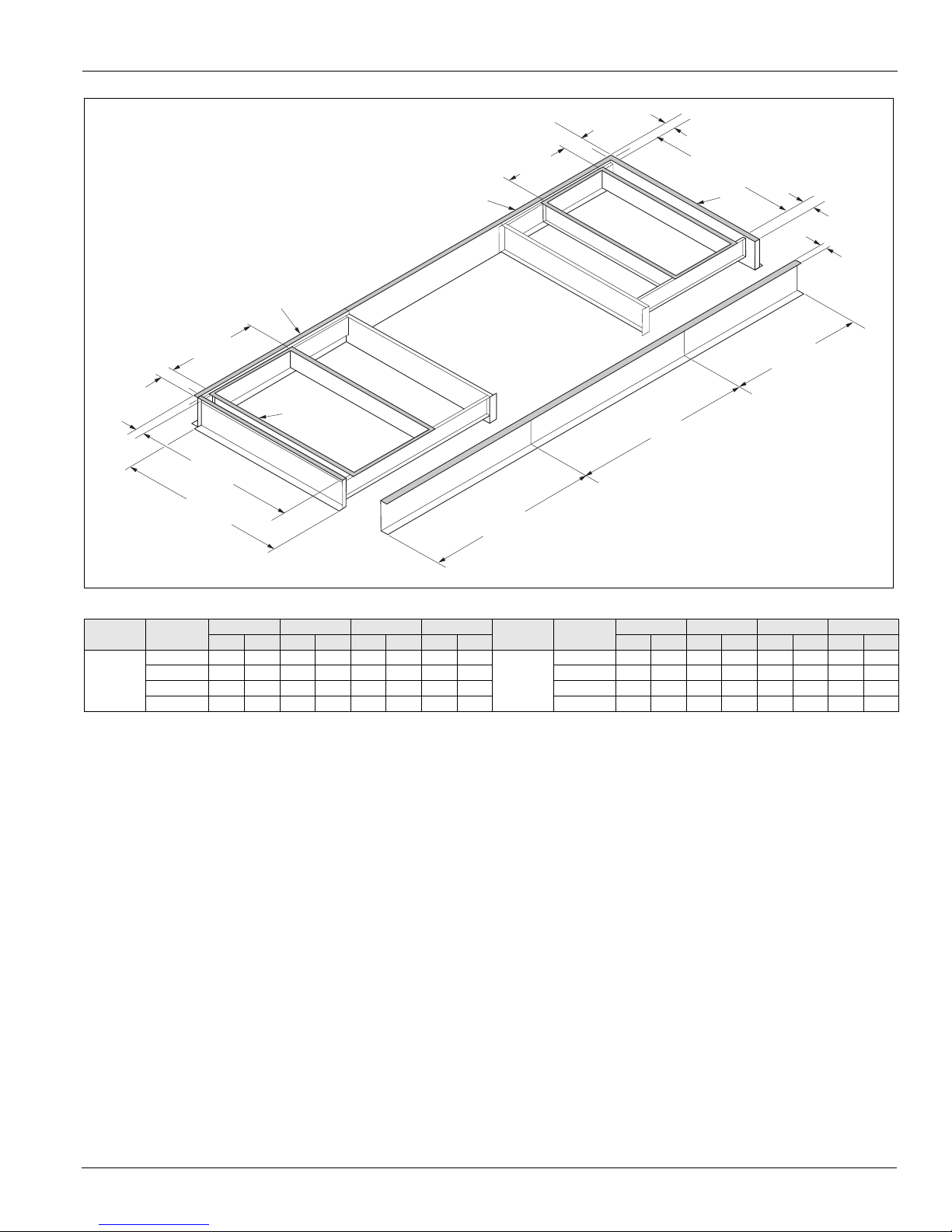

Table 3: Rds Roof Curb Assembly Instructions

Unit size Fan

None 24.0 610 82.0 2083 6.8 173 1.5 38

800–802C

(2) 15” FC 24.0 610 82.0 2083 6.8 173 1.5 38 (2) 15" FC 24.0 610 82.0 2083 6.8 173 1.5 38

30" AF 30.0 762 76.0 1930 6.8 173 4.5 114 30" AF 30.0 762 76.0 1930 6.8 173 4.5 114

40" AF 36.0 914 78.0 1981 14.8 376 3.5 89 40" AF 36.0 914 78.0 1981 14.8 376 3.5 89

X Y XX YY

in mm in mm in mm in mm in mm in mm in mm in mm

Unit size

800–802C

Return

X Y XX YY

fan

None 24.0 610 82.0 2083 6.8 173 1.5 38

McQuay IM 987 19

Page 20

Mechanical Installation

Seismic hold down brackets

Seismic hold down brackets

Structural steel frame

Spring

isolator

Duct opening

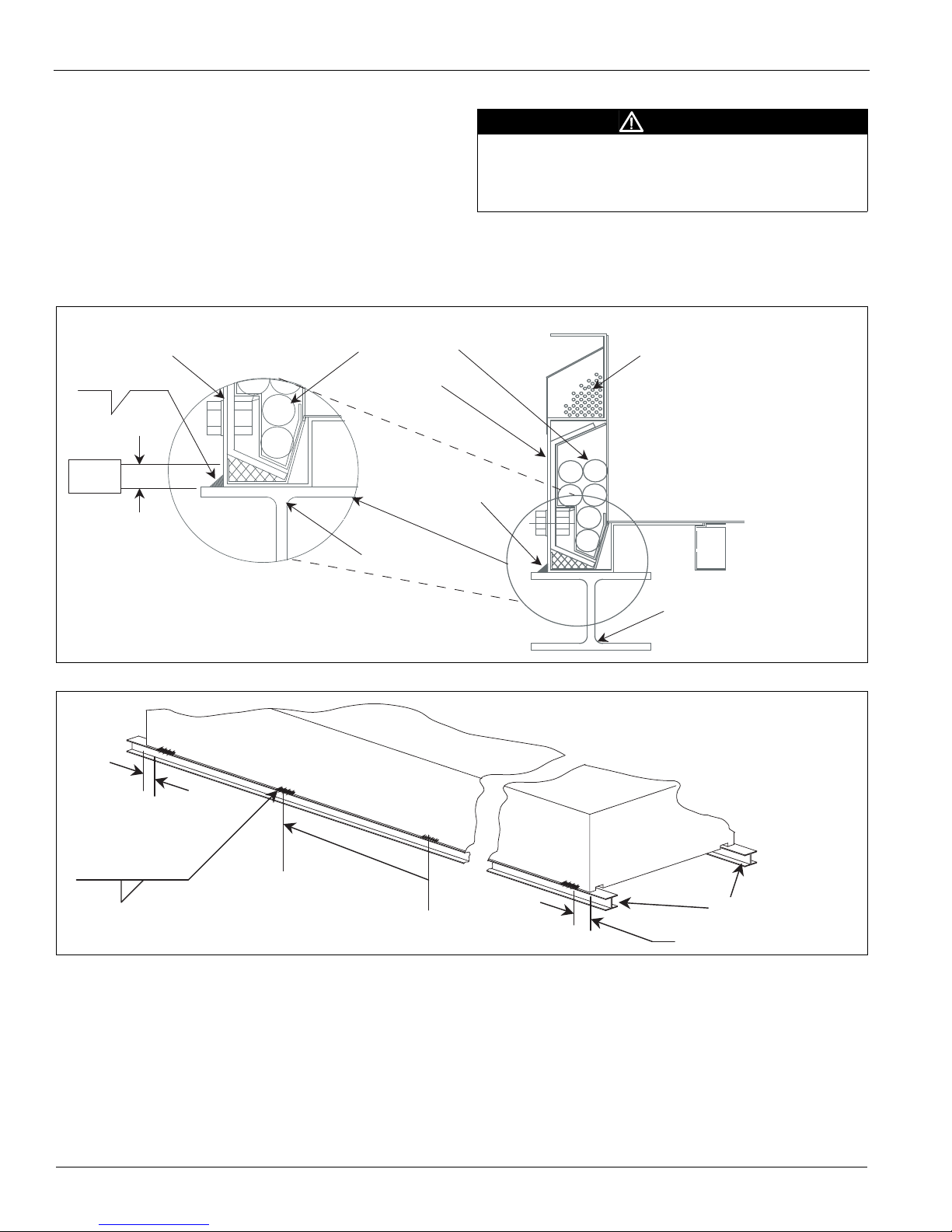

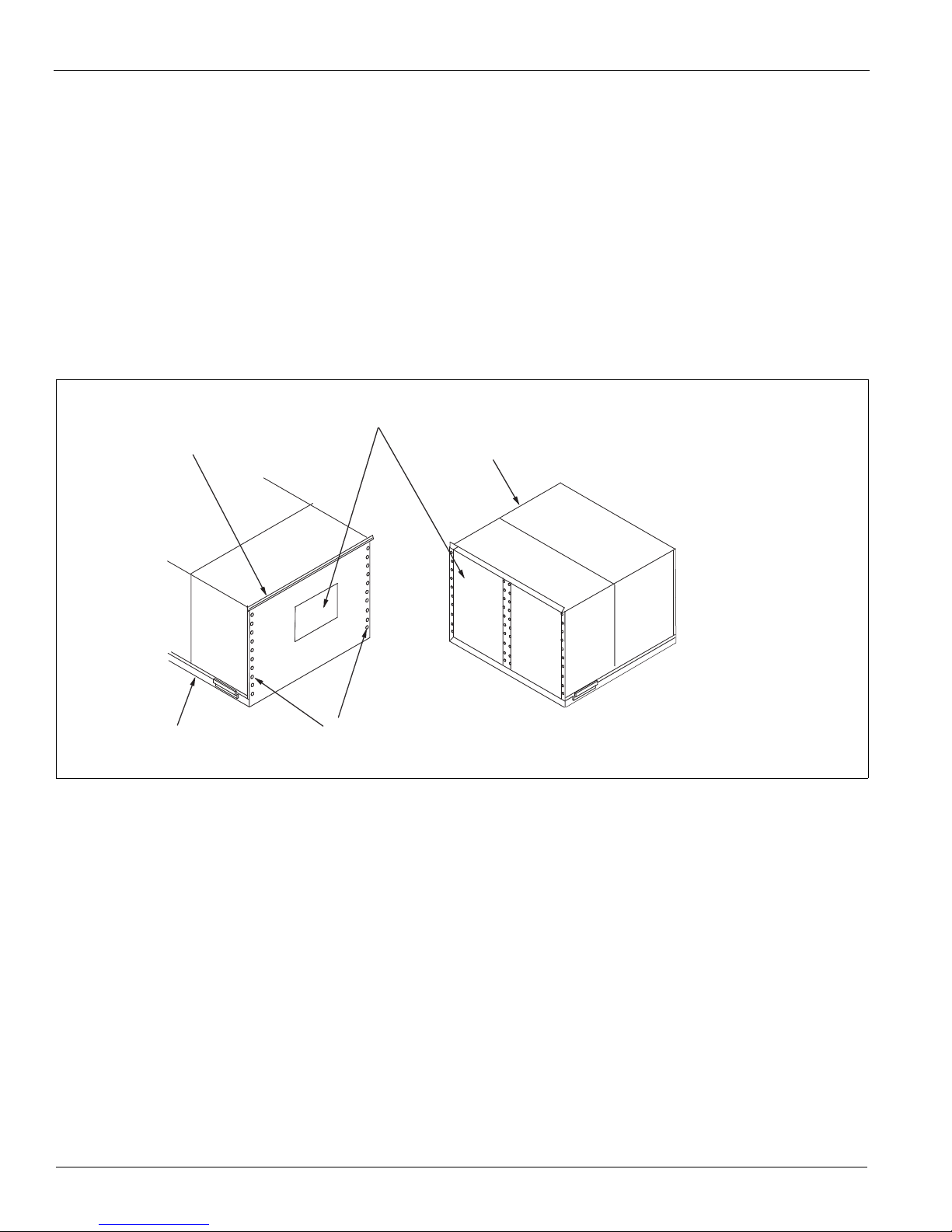

IBC Seismic Compliant Units

It is important to follow these installation instructions for all

IBC Seismic compliant McQuay Rooftop units.

IBC Seismic compliant McQuay Rooftop units can be

mounted to either a roof curb or a post and rail setup. If using a

roof curb, it must be specifically designed for seismic restraint

and be IBC seismic compliant (spring isolated or non-isolated

type seismic roof curbs are available). Typical construction of

a seismic rated roof curb is from structural steel framing and

contains seismic hold down brackets for attachment of the

rooftop unit (see Figure 21). Post and rail arrangements rated

for seismic applications are also available (spring isolated or

non-isolated).

IMPORTANT: An acceptable IBC seismic installation

provides a direct positive attachment to both the building

structure and the roof mounted equipment.

Refer to the roof curb manufacturer’s submittal drawings for

actual roof curb assembly, attachment details and rigging

instructions for both roof curb and post and rail arrangements.

Roof Curb Arrangement

1 Set the rooftop unit on the roof curb (McQuay Rooftop

units are designed to overhang from the roof curb).

2 Adjust the seismic hold down brackets so they come into

contact with the unit base per Figure 22 and Figure 23,

page 21.

a The seismic hold down brackets should be adjustable

and accommodate the overhang of the rooftop unit.

b If the hold down bracket cannot reach the unit base,

use a shim spacer. See Figure 23, page 21.

3 Weld each seismic hold down bracket (and shim spacer,

if required) to the unit base as shown in the acceptable

weld zone detail in Figure 22, page 21.

CAUTION

When welding unit to the curb, do not damage wiring (control

panel side). Weld ONLY in the specified zone in the acceptable

weld zone (see Figure 22, page 21). Welding must comply with

weld fillet size, etc. as indicated in Figure 22, page 21.

Note: High temperature insulation is installed at the factory to

allow for field welding along the lower front edge region

of the unit base.

Figure 21: Typical Seismic Roof Curb (Spring Isolated)

20 McQuay IM 987

Page 21

Figure 22: Welding Of Hold Down Brackets—Unit Base, Cross-Sectional View

Unit base

Seismic hold down bracket

Unit power wiring

(by factory)

Unit control wiring

(by factory)

High temp

Insulation

Roof curb

Acceptable weld zone

Field attachment

weld

Weld

zone

.25

.50"

Unit base

Seismic hold

down bracket

Unit power wiring

(by factory)

Unit control wiring

(by factory)

Roof curb

Shim

spacer

It may be necessary for

the contractor to field

fabricate spacers or new

seismic hold-downs for

rooftop units having larger

overhang dimensions.

Figure 23: Shim Spacers On Hold Down Brackets

Mechanical Installation

McQuay IM 987 21

Page 22

Mechanical Installation

2–48

Rail

.25

Unit power wiring

(by factory)

Unit control wiring

(by factory)

High temp

insulation

Rail

Acceptable weld zone

Field attachment

weld

Weld

zone

.50"

Unit base

Unit base

6–12"

2–48

Rooftop unit

.25

Weld every 48"

6–12"

Rails

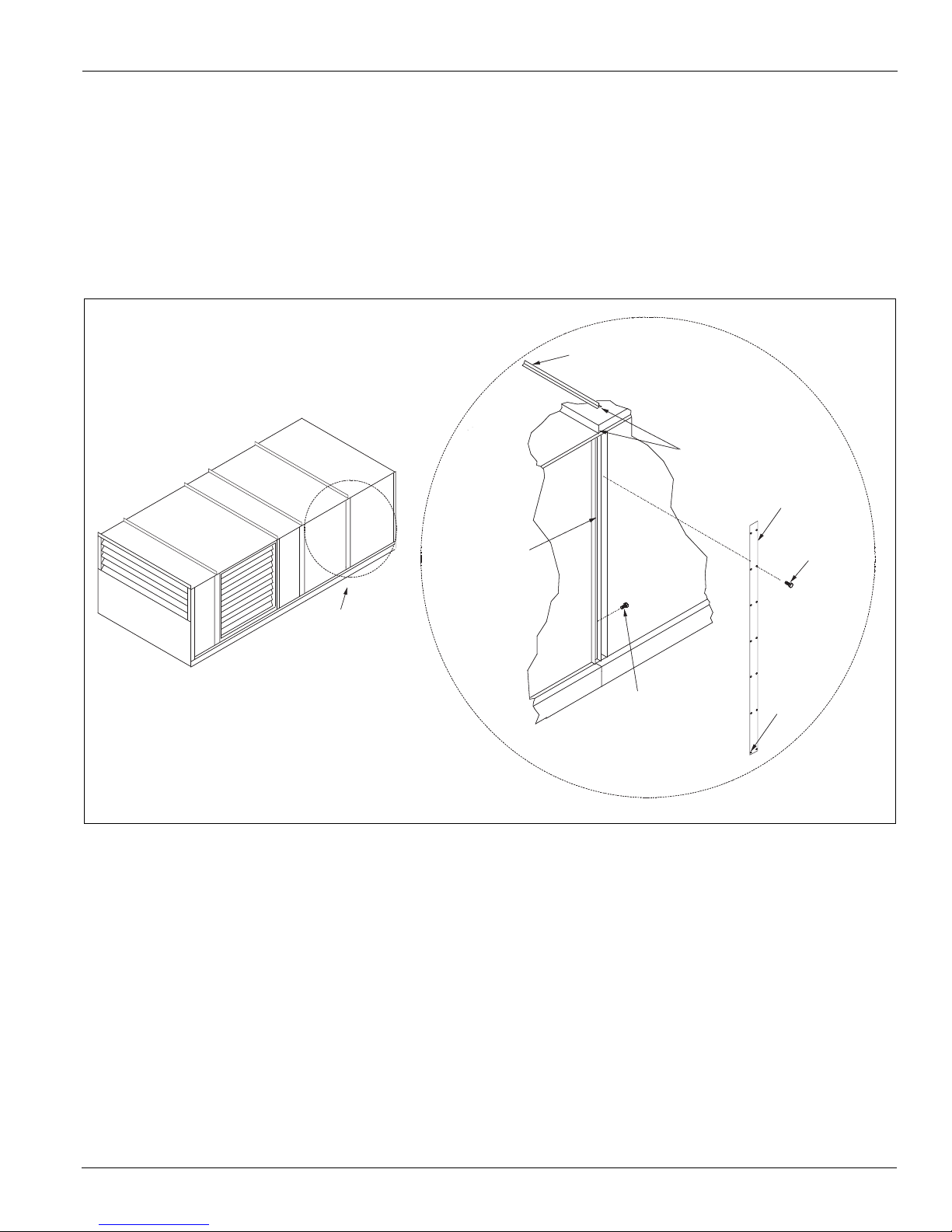

Post and Rail Arrangement

1 Set the rooftop unit on the rails. The rails should run

lengthwise and support the entire unit base.

2 Weld both sides of the unit directly to each rail as shown

in Figure 24 and Figure 25.

The total number of welds

required is dependent on the length of the unit.

a Make the fillet welds 2 inches long, spaced 48 inches

apart on centers.

b Place the end welds 6 to 12 inches from the unit edge.

Figure 24: Welding of Unit To Rail—Unit Base, Cross-Sectional View

When welding unit to the curb, do not damage wiring (control

panel side). Weld ONLY in the specified zone in the acceptable

weld zone (see Figure 24). Welding must comply with weld

fillet size, etc. as indicated in Figure 24.

Note: High temperature insulation is installed at the factory to

CAUTION

allow for field welding along the lower front edge region

of the unit base.

Figure 25: Weld Locations for Rail Arrangement

22 McQuay IM 987

Page 23

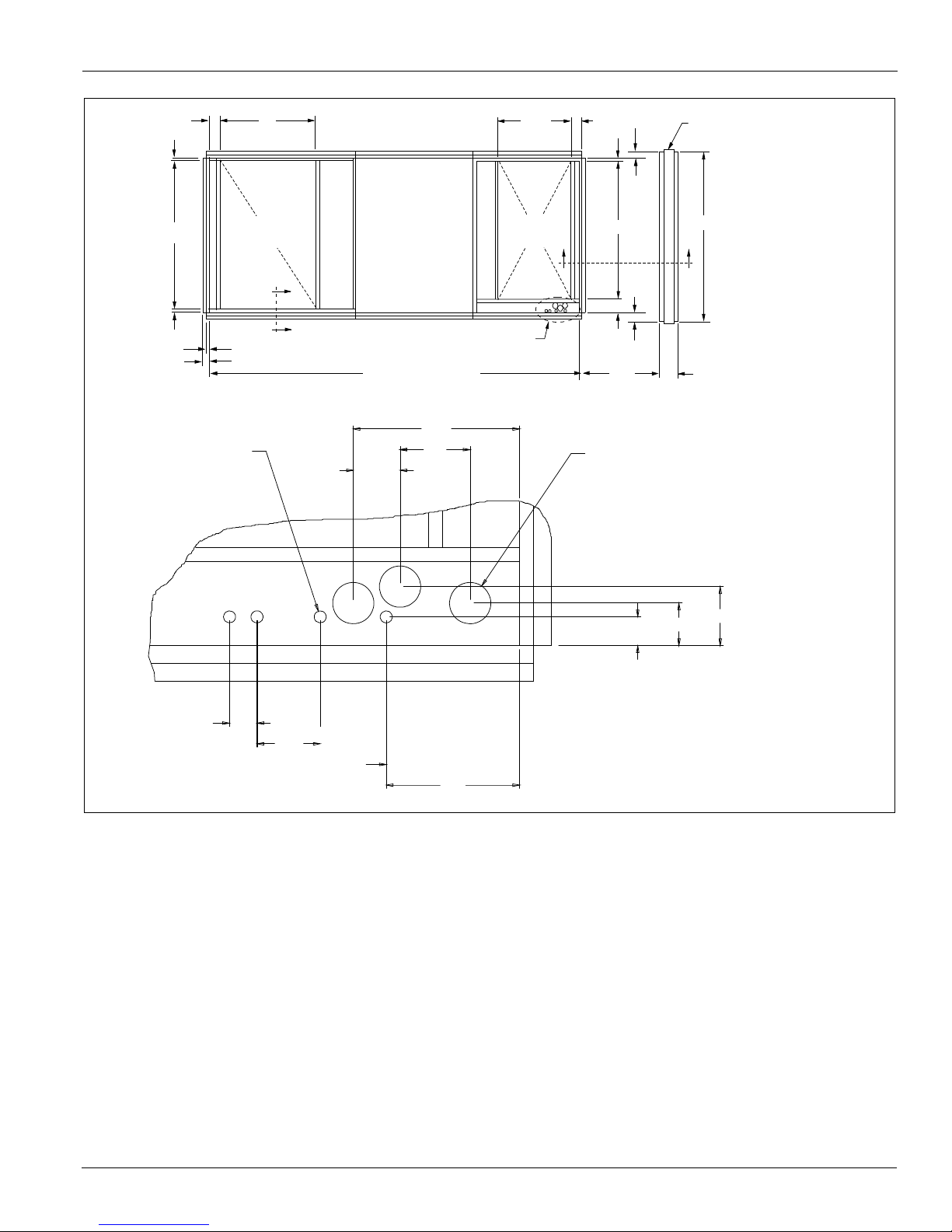

Mechanical Installation

Unit length minus 6.4

12.1

See Detail A

Detail A

3.4

5.1

0.9 Dia.

K.O.

3.0 Dia.

K.O.

4.6

4.8

2.0

2.1

4.3

3.1

9.7

E

8.0

97.0

76.0

6.0

7.5

20.0

1.5

6.0

6.8

RA

OPNG

B

2Typ

A

A

D

C

D

4Typ

A

B

B

SA

OPNG

RPS only

Figure 26: Typical Power Wire Entrance, Curb View (RDS 800C–802C Shown (For Exact Values, Refer to Submittal)

McQuay IM 987 23

Page 24

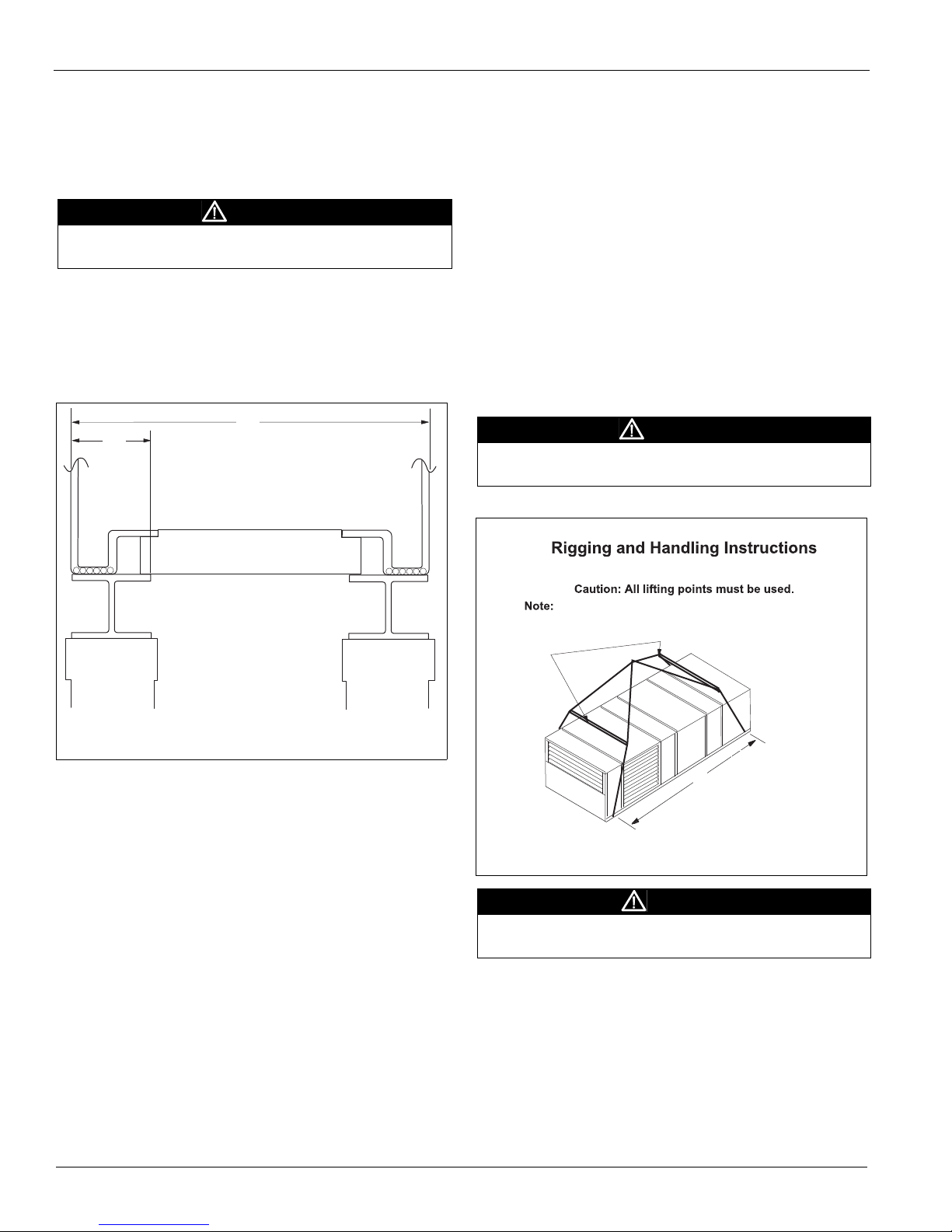

Mechanical Installation

99"

5" *

Max.

Note: Maximum recommended width for structural member is 5" (127

mm) to allow for adequate space for duct connections and

electrical entry.

Unit has either four or six lifting points (four-point shown below).

Rigging cables must be at least as long as distance “A.”

Spreader bars

required

Lift only as indicated

Caution: Lifting points may not

be symmetrical to center of

gravity of unit. Balast or unequal

cable lengths may be required.

A

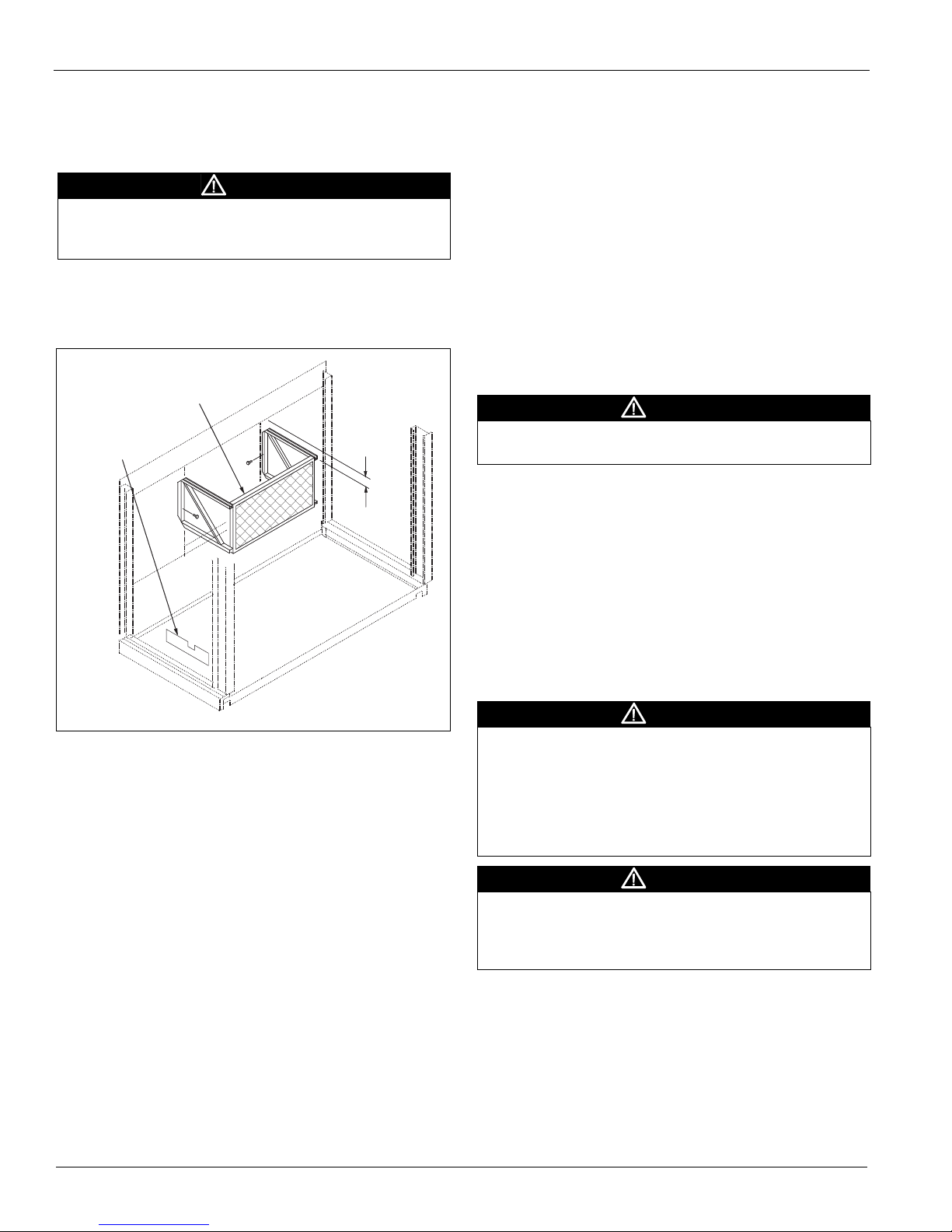

Post and Rail Mounting

When mounting by post and rail, run the structural support the

full length of the unit. Locate the structural member at the base

of the unit as shown in Figure 27, assuring the I-beam is well

supported by the structural member.

CAUTION

The unit must be level side to side and over the entire length.

Equipment damage can result if the unit is not level.

If resilient material is placed between the unit and the rail,

insert a heavy steel plate between the unit and the resilient

material to distribute the load. Seal cabinet penetrations

(electrical, piping, etc.) properly to protect against moisture

and weather.

Figure 27: Post and Rail Mounting

1 Support the unit well along the length of the base rail.

2 Level the unit (no twists or uneven ground surface).

3 Provide proper drainage around the unit to prevent

flooding of the equipment.

4 Provide adequate protection from vandalism, mechanical

contact, etc.

5 Securely close the doors.

6 If there are isolation dampers, make sure they are

properly installed and fully closed to prevent the entry of

animals and debris through the supply and return air

openings.

7 Cover the supply and return air openings on units

without isolation dampers.

Figure 28 shows an example of the rigging instruction label

shipped with each unit.

WARNING

Use all lifting points. Improper lifting can cause severe personal

injury and property damage.

Figure 28: Rigging and Handling Instruction Label

Rigging and Handling

Lifting brackets with 2" (51 mm) diameter holes are provided

on the sides of the unit.

Use spreader bars, 96" to 100" (2438 to 2540 mm) wide, to

prevent damage to the unit cabinet. Avoid twisting or uneven

lifting of the unit. The cable length from the bracket to the

hook should always be longer than the distance between the

outer lifting points.

If the unit is stored at the construction site for an intermediate

period, follow these additional precautions:

24 McQuay IM 987

CAUTION

Lifting points may not be symmetrical to the center of gravity of

the unit. Ballast or unequal cable lengths may be required.

Page 25

Mechanical Installation

X

6 Lifting Points

B

A

Z

RDS 800: B Min. = 62" (1515 mm)

RDS 802: B Min. = 84" (2134 mm)

RAH 47: B Min. = 96" (2438 mm)

RAH 77: B Min. = 120" (3048 mm)

Lifting Points

To determine the required lifting cable lengths and whether

four-point or six-point lifting is required, use Tables 4 and 5

and Figure 29.

Referring to Figure 29, note that dimension A is the distance

between the outer lifting points. The four outer rigging cables

must be equal to or longer than dimension A. Dimension B

shows the minimum distance between the outer and the inner

lifting points for six-point lifting. Use this to roughly

determine the required length of the middle cables for sixpoint lifting. Determine dimension A by subtracting

dimensions X and Y from dimension Z (e.g., A = Z – X – Y).

• Where:

• Z = Total unit length in inches

(refer to certified drawings for this dimension).

• X = Outdoor/return air section length (refer to Figure 29 and

Table 5 for this dimension).

• If A 288" (7315 mm), 4-point lifting is sufficient.

• If A > 288" (7315 mm), 6-point lifting is required.

Table 4: RAH X Dimension (See Figure 29) Economizer

Section

Type of economizer

section

100% OA 0 0

Plenum 48” (1219 mm) 72” (1829 mm)

0–30% OA 48” (1219 mm) 72” (1829 mm)

0–100% economizer 72” (1829 mm) 96” (2438 mm)

0–100% economizer with return fan 72” (1829 mm) 96” (2438 mm)

047C 077C

Figure 29: Unit Type RAH Lifting Points

4 Lifting Points

A

Z

X

Table 5: RDS X Dimension (See Figure 29) Outdoor/return

Air Section

0–100% economizer with 15" return fan 62" (1575 mm) —

0–100% economizer with 30" return fan 52" (1321 mm) 52" (1321 mm)

0–100% economizer with 40" return fan — 80" (2032 mm)

Outdoor/return air section 800C 802C

100% OA 0 0

Plenum 40” (1016 mm) 52" (1321 mm)

0–30% OA 40” (1016 mm) 52" (1321 mm)

0–100% economizer 40” (1016 mm) 52" (1321 mm)

McQuay IM 987 25

Page 26

Mechanical Installation

Remove top cap and

save for reassembly.

Remove plywood and retaining

angles from unit and discard.

Discharge end of unit

Fan end of unit

Remove screws on fan panel,

leaving retainer clips in place.

Save screws for reassembly.

Split Units

Although units typically ship from the factory as complete

units, they can be factory split at the supply fan bulkhead and

connected later on the roof. This configuration is ordered if the

shipping length or a weight limitation prevents ordering a

packaged unit.

A single nameplate is attached to the air handler section and

power is supplied to both sections through the optional main

control box as in a packaged unit.

RAH Factory Split at Fan

Field reassembly of an RAH unit that shipped split at the fan

takes place in three phases: (1) setting the sections,

Figure 30: Set Sections

(2) mechanically recoupling the cabinet, and (3) reconnecting

power and control wiring.

Phase I. Set sections

1 Remove top cap and save for Phase II, Step 1.

2 Remove screws on fan panel, leaving retainer clips in

place to secure bulkhead. Save screws for Phase II,

Step 5.

3 Remove plywood and retaining angles from unit and

discard.

4 Carefully lower both sections of unit (fan end and

discharge end) into place, making sure the roof curb

engages the recesses in the unit base.

26 McQuay IM 987

Page 27

Phase II. Reassemble cabinet (Figure 31)

Reinstall top cap

saved in step 1

Caulk ends

of splice cap

See detail

Splice cover,

provided

#10 screws,

provided

Nut clip-on,

provided

Caulk

vertical

seam

Install screws

(.25 to 20 × .75)

saved from step 1

1 Reinstall top cap removed in Phase I, Step 1.

2 Caulk (watertight) ends of splice cap.

3 Caulk (watertight) vertical seam.

4 Install #10 screws (provided).

5 Install screws (.25–20 ×.75) removed in Phase I, Step 2.

6 Install splice cover (provided).

Figure 31: Reassemble Cabinet

Mechanical Installation

McQuay IM 987 27

Page 28

Mechanical Installation

If applicable, install as shown

with provided fasteners.

After routing wires,

install inner raceway

cover (see step 6).

3.72 ref.

(94 mm)

Phase III. Reconnect power and control wiring

Once the sections are physically reconnected, the ends of the

power harness are fed back through the unit base into the

junction box, per the unit’s electrical schematics.

CAUTION

Connect the power block correctly and maintain proper

phasing. Improper installation can cause severe equipment

damage.

1 Make electrical connections and reinstall inner raceway

cover as shown in Figure 32.

Figure 32: Electrical Connections and Raceway Cover

Installation

6 Reinstall the external raceway covers after routing of the

control wires is complete.

Field Refrigerant Piping and Charging of DX Coils

Units that ship from the factory with DX coils installed do not

include refrigerant piping or refrigerant controls. The coil

assembly is ready for field connections at the distributors and

at the suction headers. Piping kits that provide the necessary

liquid and hot gas piping and control components are available

for field installation. Field-installed refrigerant piping may exit

the unit cabinet at one of the following locations:

• Through the floor of the unit.

• Through the discharge and bulkhead of the unit.

• Through a cabinet door near the DX coil that is not required

for service areas.

CAUTION

For any of the above cabinet penetrations, tightly seal the hole

to prevent water or air leakage.

In preparing for field piping, remove the plastic plugs on the

distributors and unsweat the copper caps at the suction header

connections.

2

3 Run the control harnesses by removing the external

4 Remove the excess harness length from the external

5 Make all electrical connections per the unit’s electrical

When power wire reconnection is complete, reinstall the

inner raceway cover in the blank or heat section.

Figure 32 shows a typical installation of the raceway

cover.

raceway covers on either side of the unit split.

raceway on the downstream side of the split; then route

along the raceway, through the bushed hole in the fan

section and into the junction box where control wiring

terminal blocks are provided for reconnection.

schematics.

Follow piping design, sizing, and installation information

presented in ASHRAE handbooks in the design and

installation of interconnecting piping. The DX coil and

condensing unit are intended to be set at the same elevation, as

close as possible to each other to minimize refrigerant pressure

drop. Design piping to prevent liquid refrigerant carryover to

the compressor and to provide a continuous return of

compressor oil from the system.

CAUTION

The pounds of refrigerant in the system may exceed the

capacity of the condenser, depending on the amount of

refrigerant in the liquid lines between the DX coil and the

condensing unit.

Refer to condenser manufacturer for information about

refrigerant capacity. Suitable means of containing the

refrigerant is required.

CAUTION

To prevent liquid return and damage to the compressor on

systems with optional hot gas bypass, it is important to locate

the bypass solenoid valve at the condensing unit and not at the

DX coil.

28 McQuay IM 987

Page 29

Mechanical Installation

Piping Recommendations

1 Use type K or L clean copper tubing. Thoroughly clean

or braze all joints with high temperature solder. Base

piping sizes on temperature/pressure limitations as

recommended in the following paragraphs. Under no

circumstances should pipe size be based strictly upon

coil or condensing unit piping connection size.

2 Do not exceed suction line piping pressure drop

equivalent to 2°F (1°C), 3 psi (20.7 kPa) per 100 feet

(30.5 m) of equivalent pipe length. After the suction line

size is determined, check the vertical suction risers to

verify that oil will be carried up the riser and back to the

compressor. Pitch the suction line(s) in the direction of

refrigerant flow and make sure they are adequately

supported. Lines should be free draining and fully

insulated between the evaporator and the compressor.

Install a trap on the vertical riser to the compressor.

3 To determine the minimum tonnage required to carry oil

up suction risers of various sizes, check the vertical

suction risers using Table 6. Insulate suction lines inside

the unit cabinet to prevent condensation.

Table 6: Minimum Tonnage (R-22) to Carry Oil Up Suction

Riser at 40°F Saturated Suction

Line size O.D. Minimum tonnage

1 1/8" 1.5

1 3/8" 2.5

1 5/8" 3.8

2 1/8" 7.6

2 5/8" 13.10

3 1/8" 20.4

3 5/8" 29.7

4 1/8" 41.3

4 Size the liquid line for a pressure drop not to exceed

the pressure equivalent of 2°F (1°C), 6 psi (41.4 kPa)

saturated temperature.

Leak Testing

In the case of loss of the nitrogen holding charge, the unit

should be checked for leaks prior to charging the complete

system. If the full charge was lost, leak testing can be done by

charging the refrigerant into the unit to build the pressure to

approximately 10 psig and adding sufficient dry nitrogen to

bring the pressure to a maximum of 125 psig. The unit should

then be leak tested with halide or electronic leak detector.

After making any necessary repair, the system should be

evacuated as described in the following paragraphs.

WARNING

Do not use oxygen or air to build up pressure. Explosion hazard

can cause severe personal injury or death.

Evacuation

After determining the unit is tight and there are no refrigerant

leaks, evacuate the system. Use a vacuum pump with a

pumping capacity of approximately 3 cu.ft./min. and the

ability to reduce the vacuum in the unit to at least 1 mm (1000

microns).

1 Connect a mercury manometer or an electronic or other

type of micron gauge to the unit at a point remote from

the vacuum pump. For readings below 1 millimeter, use

an electronic or other micron gauge.

2 Use the triple evacuation method, which is particularly

helpful if the vacuum pump is unable to obtain the

desired 1 mm of vacuum. The system is first evacuated

to approximately 29" (740 mm) of mercury. Then add

enough refrigerant vapor to the system to bring the

pressure up to 0 pounds (0 microns).

3 Evacuate the system again to 29" (740 mm) of vacuum.

Repeat his procedure three times. This method is most

effective by holding system pressure at 0 pounds

(0 microns) for a minimum of 1 hour between

evacuations. The first pulldown removes about 90% of

the noncondensables; the second removes about 90% of

that remaining from the first pulldown. After the third

pulldown, only 1/10 of 1% of noncondensables remains.

Table 7, page 30 shows the relationship between pressure,

microns, atmospheres, and the boiling point of water.

CAUTION

Before replacing refrigerant sensors or protective devices, see

"Refrigerant Charge"‚ page 31 for an important warning to

prevent an abrupt loss of the entire charge.

McQuay IM 987 29

Page 30

Mechanical Installation

Table 7: Pressure-Vacuum Equivalents

Absolute pressure above zero Vacuum below 1 atmosphere

Microns PSIA Mercury (mm) Mercury (in)

0 0 760.00 29.921 — —

50 0.001 759.95 29,920 1/15,200 –50

100 0.002 759.90 29.920 1/7,600 –40

150 0.003 759.85 29.920 1/5,100 –33

200 0.004 759.80 29.910 1/3,800 –28

300 0.006 759.70 29.910 1/2,500 –21

500 0.009 759.50 29.900 1/1,520 –12

1,000 0.019 759.00 29.880 1/760 1

2000 0.039 758.00 29.840 1/380 15

4,000 0.078 756.00 29.760 1/189 29

6000 0.117 754.00 29.690 1/127 39

8,000 0.156 752.00 29.600 1/95 46

10,000 0.193 750.00 29.530 1/76 52

15,000 0.290 745.00 29.330 1/50 63

20,000 0.387 740.00 29.130 1/38 72

30,000 0.580 730.00 28.740 1/25 84

50,000 0.967 710.00 27.950 1/15 101

100,000 1.930 660.00 25.980 2/15 125

200,000 3.870 560.00 22.050 1/4 152

500,000 9.670 260.00 10.240 2/3 192

760,000 14.697 0 0 1 atmosphere 212

Approximate fraction

of 1 atmosphere

H2O boiling point at each

pressure (

o

F)

Charging the System

Units are leak tested at the factory and shipped with a nitrogen

holding charge. If the holding charge has been lost due to

shipping damage, charge the system with enough refrigerant to

raise the unit pressure to 30 psig after first repairing the leaks

and evacuating the system.

1 After all refrigerant piping is complete and the system is

evacuated, it can be charged as described in the

paragraphs following. Connect the refrigerant drum to

the gauge port on the liquid shutoff valve and purge the

charging line between the refrigerant cylinder and the

valve. Then open the valve to the mid position.

2 If the system is under a vacuum, stand the refrigerant

drum with the connection up, open the drum, and break

the vacuum with refrigerant gas.

3 With a system gas pressure higher than the equivalent of

a freezing temperature, invert the charging cylinder and

elevate the drum above the condenser. With the drum in

this position and the valves open, liquid refrigerant flows

into the condenser. Approximately 75% of the total

requirement estimated for the unit can be charged in this

manner.

4 After 75% of the required charge enters the condenser,

reconnect the refrigerant drum and charging line to the

suction side of the system. Again, purge the connecting

line, stand the drum with the connection side up, and

place the service valve in the open position.

Important: At this point, interrupt the charging procedure and

do prestart checks before attempting to complete the

refrigerant charge.

Note: Stamp the total operating charge per circuit on the unit

nameplate for future reference.

CAUTION

Adding refrigerant to the suction always risks liquid-related

damage to the compressor.

Take special care to add refrigerant slowly enough to the

suction to prevent damage. Adjust the charging tank hand

valve so liquid leaves the tank but vapor enters the compressor.

30 McQuay IM 987

Page 31

Mechanical Installation

S t a t i c P r e s s u r e " P "

( i n . w . o . )

D r a i n P a n

4 " ( 1 0 2 m m )

M i n i m u m

" A "

8 " ( 2 0 3 m m )

M i n . o r 2 x " P "

M i n i m i z e T h i s

D i m

e n s i o n

V i e w A

N o t e : D r a i n l i n e m u s t

n o t b e r u n h i g h e r

t h a n t h i s l e v e l

C o p p e r T u b e

( o n e e a c h e n d o f c o i l )

S e e V i e w " A "

Refrigerant Charge

Factory-installed DX coils are designed to use R-22. The total

charge per circuit is the sum of the following three values:

• Condenser section charge. Refer to manufacturer’s data.

• Evaporator coil charge.

• Charge for length of interconnecting piping installed by

field.

Note: Factory-installed DX coils are intended for one

refrigerant circuit on unit size 800C and two refrigerant

circuits containing identical weights of refrigerant on all

other sizes. The values shown in Ta bl e 8 and Table 9 are

for each circuit.

Note: The total operating charge per circuit should not exceed

the pumpdown capacity per circuit.

Table 8: Approximate DX Coil Refrigerant Charge Per

Circuit

Unit size

047C 3 x no. of DX rows 3.5 x no. of DX rows

077C 5 x no. of DX rows 6.5 x no. of DX rows

Table 9: Approximate Refrigerant Charge Per Circuit

Unit size Evaporator coil (lbs/ckt/coil row)

802 3.30

802C* 2.45

Note: * The RDS 802C unit has two refrigerant circuits.

DX Coil R-22 charge (lbs./circuit)

Flat coil Staggered coil

• Where the cooling coils have intermediate condensate pans

on the face of the evaporator coil, copper tubes near both

ends of the coil provide drainage to the main drain pan.

Check that the copper tubes are in place and open before the

unit is put into operation.

• On units with staggered cooling coils, the upper drain pan

drains into the lower coil drain pan through a copper tube

near the center of the drain pan. Check that this tube is open

before putting the unit into operation and as a part of routine

maintenance.

• Because drain pans in any air conditioning unit have some

moisture in them, algae, etc. will grow. Periodically clean to

prevent this buildup from plugging the drain and causing the

drain pan to overflow. Clean drain pans to prevent the spread

of disease. Cleaning should be performed by qualified

personnel

.

WARNING

Drain pans must be cleaned periodically.

Material in uncleaned drain pans can cause disease.

Cleaning should be performed by qualified personnel.

Figure 33: Condensate Drain Connection

Unit Piping

Condensate Drain Connection

• The unit is provided with a 1.5" male NPT condensate drain

connection. Refer to certified drawings for the exact

location. For proper drainage, level the unit and drain pan

side to side and install a P-trap

• Units may have positive or negative pressure sections. Use

traps in both cases with extra care given to negative pressure

sections. In Figure 57, dimension “A” should be a minimum

of 8" (203 mm). As a conservative measure to prevent the

cabinet static pressure from blowing or drawing the water

out of the trap and causing air leakage, dimension A should

be two times the maximum static pressure encountered in

the coil section in inches wc.

• Draining condensate directly onto the roof may be

acceptable; refer to local codes. Provide a small drip pad of

stone, mortar, wood, or metal to protect the roof against

possible damage.

• If condensate is piped into the building drainage system,

pitch the drain line away from the unit a minimum of 1/8"

per foot. The drain line must penetrate the roof external to

the unit. Refer to local codes for additional requirements.

Sealed drain lines require venting to provide proper

condensate flow.

Gas Piping

See the “Installation” section of the gas-fired furnace

installation manual, Bulletin No. IM 684 or 685.

McQuay IM 987 31

Page 32

Mechanical Installation

Supply

Bypass

2.12 " ODM

Copper Coil

Connections

Upper

Coil

Air Flow

Lower

Coil

Piping for Steam, Hot Water/ChIlled Water Coils

Factory-installed chilled water coils are installed in a coil

section that can be designed to accept a factory-installed

heating coil immediately upstream. The coil section can be

ordered in either the draw-through or blow-through position.

All chilled water piping can be done internal to the unit

without requiring a piping vestibule (except on sizes 800–802

when heating coils are included in the cooling coil section).

Steam and hot water coils can be factory installed in either a

heat section, or in the combination coil section. These sections

can be located either in the draw-through or blow-through

position. When a steam or hot water coil is installed in the heat

section, all piping can be done internal to the unit without

requiring a piping vestibule. Refer to Figure 35, page 33 and

Figure 37, page 34

When a steam or hot water coil is installed in the combination

coil section, the coil connections project to the inside surface

of the door panel. Holes can be cut in the door panels to

connect the piping to the coils, or an accessory piping

vestibule can be added to the unit to provide piping space.

Refer to the section on vestibule assembly instructions. The

piping can then be routed back within the unit as shown in

Figure 35, page 33.

When no factory piping or valve is included, the coil

connections are 1.625” ODM copper on 800 and 802C, and

2.125" ODM copper on 047 and 077C.

With the factory piping and valve package, the two coils are

piped in parallel and controlled through a single three-way

valve. Field piping connections are of the same NPT size as

the valve-male threads at the supply connection, female

threads at the return connection.

Figure 34: Hot Water Heat Section (Shown with Factory

Valve and Piping)

To avoid piping penetrations through the roof external to the

curb, holes can be cut through the floor of the unit at the

locations specified on the certified drawings.

CAUTION

Seal all holes in the unit floor to prevent water leakage into the

building.

Hot Water Piping

Hot water coils are provided without valves for field piping or

piped with three-way valves and actuator motors.With the

factory piping and valve package, the two coils are piped in

parallel and controlled through a single three-way valve. Field

piping connections are of the same NPT size as the valve-male

threads at the supply connection, female threads at the return

connection.

Hot water coils are not normally recommended for use with

entering air temperatures below 40°F (4°C). No control system

can guarantee a 100% safeguard against coil freeze-up. Glycol

solutions or brines are the only freeze-safe media for operation

of water coils at low entering air temperature conditions. Refer

to the “Maintenance” section of this manual for more on

winterizing coils. The hot water section consists of two

stacked soils, as shown in Figure 34.

The valve actuator spring returns to a stem up position upon

power failure. This allows full flow through the coil.

Refer to the certified drawings for the recommended piping

entrance locations. Seal all piping penetrations to prevent air

and water leakage.

Note: Factory-installed water valves and piping are bronze,

brass, and copper. Dissimilar metals within the plumbing

system can cause galvanic corrosion. To avoid

corrosion, provide proper di-electric fittings as well as

appropriate water treatment.

CAUTION

Coil freeze possible. Can damage equipment.

Follow instructions for mixing antifreeze solution used. Some

products have higher freezing points in their natural state than

when mixed with water. The freezing of coils is not the

responsibility of McQuay International. Refer to "Winterizing

Water Coils"‚ page 111.

32 McQuay IM 987

Page 33

Mechanical Installation

Return

Lower

Coil

2.12 " ODM

Copper Coil

Connections

Upper

Coil

Supply

Return

Steam Coil Piping (All Units)

The steam heat section consists of two stacked coils pitched at

1/8" (3 mm) per foot (305 mm) as shown in Figure 35 to

provide positive condensate removal. When no factory piping

or valve is included, the coil connections are 2.5" male NPT

iron pipe.

Note: The valve actuator spring returns to a stem up position

upon power failure. This allows full flow through the coil.

Figure 35: Steam Heat Section (Shown with Factory Valve

and Piping)

With the factory piping and valve package, the two coil

supplies are piped in parallel and controlled through a single

two-way valve. The field supply connection is of the same

female NPT size as the valve. Field return connections are

made at the 2.50" male NPT fittings on each of the two stacked

coils.

Note: Refer to the sections on steam coil piping and trap

recommendations for additional information.The valve

actuator spring returns to a stem up position upon power

failure. This allows full flow through the coil.

Figure 36: Two-Way Valve Package

Steam Piping Recommendations

1 Be certain that adequate piping flexibility is provided.

Stresses resulting from expansion of closely coupled

piping and coil arrangement can cause serious damage.

2 Do not reduce pipe size at the coil return connection.

Carry return connection size through the dirt pocket,

making the reduction at the branch leading to the trap.

3 Install vacuum breakers on all applications to prevent

retaining condensate in the coil. Generally, the vacuum

breaker is to be connected between the coil inlet and the

return main. However, if the system has a flooded return

main, the vacuum breaker to the atmosphere; the trap

design should allow venting of the large quantities of air.

4 Do not drain steam mains or takeoffs through coils.

Drain mains ahead of coils through a steam trap to the

return line.

5 Do not attempt to lift condensate when using modulating

or on-off control.

6 Pitch all supply and return steam piping down a

minimum of 1" (25 mm) per 10 feet (3 m) of direction of

flow.

McQuay IM 987 33

Page 34

Mechanical Installation

S t e m

S e t s c r e w s

S t e m C l i p

Steam Trap Recommendations

1 Size traps in accordance with manufacturers’

recommendations. Be certain that the required pressure

differential will always be available. Do not undersize.

2 Float and thermostatic or bucket traps are recommended

for low pressure steam. Use bucket traps on systems with

on-off control only.

3 Locate traps at least 12" (305 mm) below the coil return

connection.

4 Always install strainers as close as possible to the inlet

side of the trap.

5 A single tap may generally be used for coils piped in

parallel, but an individual trap for each coil is preferred.

Figure 37: Heating Coil Piping with Vestibule

Steam Coil Freeze Conditions

If the air entering the steam coil is below 35°F (2°C), note the

following recommendations:

1 Supply 5 psi (34.5 kPa) steam to coils at all times.

2 Modulating valves are not recommended. Control should

be by means of face and bypass dampers.

3 As additional protection against freeze-up, install the tap

sufficiently far below the coil to provide an adequate

hydrostatic head to ensure removal of condensate during

an interruption on the steam pressure. Estimate 3 ft. (914

mm) for each 1 psi (7 kPa) of trap differential required.

4 If the unit is to be operated in environments with

possible freezing temperatures, an optional freezestat is

recommended. See “Freeze Protection” on page 95 for

additional information.

Figure 38: Valve Assembly

Figure 39: Steam Valve Package

34 McQuay IM 987

Page 35

Mechanical Installation

Air Flow

Bypass

Supply

Return

Chilled Water Piping

Chilled water coils are provided without valves for field

piping, or piped with three-way valves with motor actuators.

Table 10 provides information on units with factory installed

piping and valve packages. The table also provides field sweat

connection information for units not furnished with factory

installed piping and valve packages.

With the factory piping and valve package, the coil assembly is

controlled through a single three-way valve. When two coils

are included in the assembly, they are piped in parallel. Field

connections are male NPT, sized as shown in Table 10. Refer

to Figure 40 for a typical cooling coil with factory valve and

piping.

Figure 40: Chilled Water Coil (with Factory Valve and

Piping)

McQuay IM 987 35

Page 36

Mechanical Installation

Table 10: Piping Connection Sizes/Valve Size Options for Chilled Water Piping

Cabinet

size

047C

077C

Application

code

Blow-thru or

draw-thru small

coil section

Blow-thru or

draw-thru large

coil section

Face and bypass

section with

small coil

Face and bypass

section with large

coil

Blow-thru or

draw-thru small

coil section

Blow-thru or

draw-thru large

coil section

Face and bypass

section with

small coil

Face and bypass

section with large

coil

Coil size

Hx 83"

(2108 mm)

long

33 + 33

(2 coils) (838

+

838 mm)

39 + 39

(2 coils) (991

+

991 mm)

48

(1219 mm)

39 + 39

(2 coils) (991

+

991 mm)

45 + 45

(2 coils)

(1143 +

1143 mm)

63 + 63

(2 coils)

(1600 +

1600 mm)

63

(1600 mm)

54 + 54

(2 coils)

(1372 +

1372 mm)

Face area sq.

ft. (sq. m)

38.0

(3.53 m²)

45.0

(4.18 m²)

27.7

(2.57 m²)

45.0

(4.18 m²)

51.9

(4.82 m²)

72.6

(6.74 m²)

36.3

(3.37 m²)

62.3

(5.74 m²)

Available rows

(available with 8,

10, 12 fins/in)

3DRDQ——AQAP

4 DRDQBQBQBP

5DRDQ——BQAP

6 DRDQBQBQAP

8 DRDQBQBQBP

3DRCQ——AQAP

4DRCQCQCQBP

5DRCQ——CQAP

6DRCQCQCQAP

8DRCQCQCQBP

3 FUET——ASAS

4 FUETCSCSCS

5FUET——CSAS

6FUETCSCSAS

8 FUETCSCSCS

3DRCQ——AQAP

4DRCQCQCQBP

5DRCQ——CQAP

6DRCQCQCQAP

8DRCQCQCQBP

3 CRCQ——APAP

4 CRCQCPBPBP

5 CRCQ——BPAP

6 CRCQCPBPAP

8 CRCQCPBPBP

3 BQBP——APAP

4 BQBPBPBPBP

5 BQBP——BPAP

6 BQBPBPBPAP

8 BQBPBPBPBP

3 ETCS——ASAS

4 ETCSCSCSCS

5ETCS——CSAS

6 ETCSCSCSAS

8 ETCSCSCSCS

3 CRCQ——APAP

4 CRCQBPBPBP

5 CRCQ——BPAP

6 CRCQBPBPAP

8 CRCQBPBPBP

5WH 5WL 5WS 5WM 5WD

Columns (see next page for explanation)

1 2 1 2 1 2 1 2 1 2

Available circuiting

36 McQuay IM 987

Page 37

Mechanical Installation

Table 10: Piping Connection Sizes/Valve Size Options for Chilled Water Piping

3 G T G T ——————

4 GTGTGT————

5 G T G T ——————

6 GTGTGT————

3 G T G T ——————

4 GTGTGT————

5 G T G T ——————

6 GTGTGT————

3 — L —M ——— N — N

4 — L —M—M—N—N

5 — L —M ——— N — N

6 — L —M—M—N—N

8 — L —M—M—N—N

10 — L —M——— N — N

3—L—M—K—N—N

4 — L —M ——— N — N

5—L—M—K—N—N

6—L—M—K—N—N

8—L—M—K—N—N

10 — L — M — K — N — N

800

or

802

Blow-thru or

draw-thru cooling

only coil section

Blow-thru or

draw-thru unit

coil section

Face and bypass

section with

small coil

Blow-thru or

draw-thru

contractor coil

section

48 + 78

(1220 +

1981 mm)

48 + 78

(1220 +

1981 mm)

30 + 79

(763 +

2006 mm)

36 + 79

(915 +

2006 mm)

26.0

(2.42 m²)

26.0

(2.42 m²)

16.5

(2.57 m²)

19.8

(4.18 m²)

Table 10 Available Circuiting Legend

Column 1:

These units are available with a factory installed package consisting of a three-way water valve and connecting piping.

A = This combination is not available with a factory-installed piping and valve package.

B = 300, 2.50, or 200 inch three-way valves can be specified

C = 300, 2.50, 2.00, or 150 inch three-way valves can be specified

D = 250, 200, or 150 inch three-way valves can be specified

E = 250, 200, 150, or 1.25 inch three-way valves can be specified

F = 200, 1.50, or 125 inch three-way vales can be specified

G = 1.25, 1.50, 2.00 or 2.50 inch three-way valves can be specified

Field supply and return female NPT connection sizes are the same as the valve size.

Column 2:

The following letters designate units that are not furnished with the factory installed piping/valve package. Required are field sweat

connections, at one or two coils, to male copper tubing for the supply and return water piping.

K = A single 2.00 inch NPT supply and return if fin height is 21–30 inches and 2.50 inches of fin height is 30–36 inches.

L = A single 1.50 inch NPT supply and return

M = A single 2.00 inch NPT supply and return if fin height is 21–30 inches

N = A single 2.50 inch NPT supply and return

P = Two 3.12 inch O.D. supply and two 3.12 O.D. return connections

Q = Two 2.62 inch O.D supply and two 2.62 O.D. return connections

R = Two 2.12 inch O.D. supply and two 2.12 O.D. return connections

S = One 3.12 inch O.D supply and one 3.12 O.D. return connections

T = One 2.62 inch O.D supply and one 2.62 O.D. return connections

U = One 2.12 inch O.D supply and one 2.12 O.D. return connections

McQuay IM 987 37

Page 38

Mechanical Installation

Door Latch Assembly

Door

Vestibule Assembly Instructions

An accessory vestibule is available to provide additional

piping space for coils installed in a four-foot section. A

vestibule is required to maintain door access on a combination

heating and cooling section. Assemble the vestibule to the unit

part by part as shown in Figure 41.

Note: The door, hinge, and latch assemblies from the unit are

used on the vestibule.

Step 1

Remove door from section where vestibule is to be located by

removing screws holding hinges to upright support (leave

hinges on door). Set door aside and save for Step 4.

• Remove door latch assembly from other side upright

support. Use offset Phillips screwdriver or a wrench to

remove screws holding latch assembly in place. Save door

latch assembly, screws and bushings for Step 4.

Figure 41: Step 1 Illustration

Step 2

Remove gasketing around door flange and save for use on

vestibule. See Step 4. Remove door and save for Step 4.

Figure 42: Step 2 Illustration

Gasketing

Door Prop

38 McQuay IM 987

Page 39

Mechanical Installation

Upright Angle

#10 Screw

Gasketing

Silicone

Sealant

Door Latch Assembly

(See Note)

Door

Prop

Door

Silicone

Sealant

Gasketing

Upright

Angle

Step 3

1 Assemble side panels A and B to uprights using #10 drill

screws supplied. Make certain side panels are flush

against uprights before securing into place.

2 Fasten bottom panel D to base channel using #10 drill

screws and to side panels A and B using #10 screws

supplied.

3 Set top panel C in place and fasten to side panels A and

B using #10 screws and to top panel using #10 screws

supplied.

Figure 43: Step 3 Illustration

#10 Screw

#10 Drill

Screw

Step 4

Reassemble access door to vestibule by screwing hinges

1

into side panel using screws saved from Step 1. (Access

door must be attached to the vestibule in the same

opening direction as it was on the unit.)

2 Remove and discard latch handle locking screws and

retaining washer. Fasten door latch assembly to side

panel using screws and bushings saved from Step 1.

(Latch must be fastened on the same side as when

located on the unit.)

3 Fasten upright angles to vestibule using #10 screws

supplied.

4 Seal between unit and vestibule with silicone sealant

along top and sides as shown.

Note: Any holes cut in the floor of the unit must be sealed to

prevent water leakage.

Figure 44: Step 4 Illustration

#10 Screw

McQuay IM 987 39

Page 40

Mechanical Installation

OA

Closed

OA

Open

90°

Stroke

.25" (6mm)

Outside

Air

Outside

Air

Optional Return Air Fan

Economizer

.500 (13mm) Dia. Shaft

x 1.30" (33mm) Long

OA

Closed

OA

Open

3.00

.25

.75

90°

Stroke

Shaft .500 Dia.

x 1.50 Long

RAH 047C - 077C

RDS 800C & 802C

Damper Assemblies

The optional damper assemblies described in this section

normally are ordered with factory-installed actuators and

linkages. The following sections describe operation and

linkage adjustment of the factory option.

Economizer Dampers

Outside air intake is provided on both sides of the unit, and the

return air path is at the center of the damper set. As the single

actuator modulates the outside air dampers open, the return air

dampers close. Exhaust air exits the unit through the gravity

relief dampers provided at the end of the economizer section.