Page 1

DesignFlow™Precision

Ventilation Air Control System

How can I continuously provide the minimum ventilation

air requirements outlined in ASHRAE Standard 62.1-2004

and still keep my building project within budget?

Variable air volume (VAV) systems offer many

performance and cost benefits. However, providing

minimum ventilation air volumes prescribed by ASHRAE

Standard 62.1-2004 can be a challenge. Up until now, the

available options have been expensive and generally not

effective, especially at maintaining minimum ventilation

airflow under part-load conditions.

Now there is a solution: the patented DesignFlow precision

ventilation air control system from McQuay. DesignFlow

provides the ultimate in accurate ventilation control for

rooftop VAV systems to help comply with the minimum

ventilation requirements of ASHRAE Standard 62.1-2004.

Its cataloged performance has been verified in tests

witnessed by an independent laboratory: Intertek Testing

Services, Inc.

McQuay’s patented DesignFlow control system is

available today, factory-installed in RoofPak™ applied

rooftop systems and rooftop air handlers. Whether your

requirements are for a 45,000 CFM packaged DX system, or

an 8,000 CFM roof-mounted air handler, DesignFlow is the

efficient, effective solution to your ventilation control needs.

DesignFlow Features

• Repeatable, minimum ventilation airflow control

accuracy of ±5% from 10% to 30% of design air, as

verified by independent, third-party performance testing.

• Unique, patented, precision mass flow sensor

assemblies directly measure the total mass volume of

air flowing through the ventilation air intakes.

• Fully engineered, factory-installed/calibrated

components are integrated with McQuay’s advanced

MicroTech II

®

control system.

• MicroTech II logic automatically responds to mass

flow sensor signals and adjusts the ventilation air

damper position.

DesignFlow Benefits

• Minimum-ventilation air requirements are maintained

for good indoor air quality (IAQ) and compliance with

ASHRAE standard 62.1-2004.

• Improved system energy performance because only the

minimum amount of ventilation air has to be treated.

• Requires no additional design engineering beyond

specifying appropriate performance characteristics.

• Requires no additional field-installed devices.

System Solutions From McQuay

Engineered for flexibility and performance.

TM

DesignFlow Mass Flow Sensor

Page 2

DesignFlow Precision Ventilation Air Control For VAV Systems

© 2005 McQuay International • (800) 432-1342 • www.mcquay.com

A/SP 31-157 (0605)

Independently Tested & Verified Accuracy

The importance of providing adequate ventilation air for

good IAQ has been extensively researched and documented. VAV systems face the added challenge of consistently

maintaining minimum ventilation air requirements as

system airflow modulates throughout the unit’s operating

range. This challenge has culminated into an almost

universal recognition that direct ventilation air measurement

is needed for consistent ventilation control in VAV systems.

Intertek Testing Services (ITS) has verified that the

DesignFlow system consistently measures and controls

minimum ventilation air intake volume with an accuracy

of ±5% from 10% to 30% of design air. This is

substantially better than the

±1

0% goal in the industry.

DesignFlow also measures ventilation air during

economizer operation, but tolerances may increase during

this non-critical operating condition. ITS is a respected

independent testing laboratory, known for its internationally

accepted ETL product safety certification program.

Superior Design Features

The superior accuracy of the DesignFlow system is due to

its superior design features:

• Mass air flow is sensed, not velocity or pressure. No air

temperature or air pressure conversions are required.

• Mass air flow is sensed across the entire cross-

sectional area of the ventilation air intake. Competitive designs sense airflow at various points, then

calculate an average airflow number.

• The system is calibrated to account for changing

airflow patterns caused by damper blade rotation.

• Airflow measurement is not compromised by turbulence.

Competitive systems use hot wire anemometers that require

straight, non-turbulent airflow entering and leaving the

sensors. Or, they use fixed orifices, which generate measurable air pressure drops at full airflow but are not accurate

for measuring minimum airflow in turbulent conditions.

Energy Efficient Operation

The reliability and accuracy of the DesignFlow system

means ventilation air intake volumes can be set at just the

right value for the most energy-efficient control. By

supplying “just enough” ventilation air, the energy dollars

needed to treat the ventilation air supply are minimized.

Reduced Design And Installation Costs

The DesignFlow system is fully engineered and factoryinstalled to provide optimum system operating

performance while minimizing installation costs. No

additional components or design engineering are needed.

For the contractor, only customary commissioning is

required, with no added installation expense.

How It Works

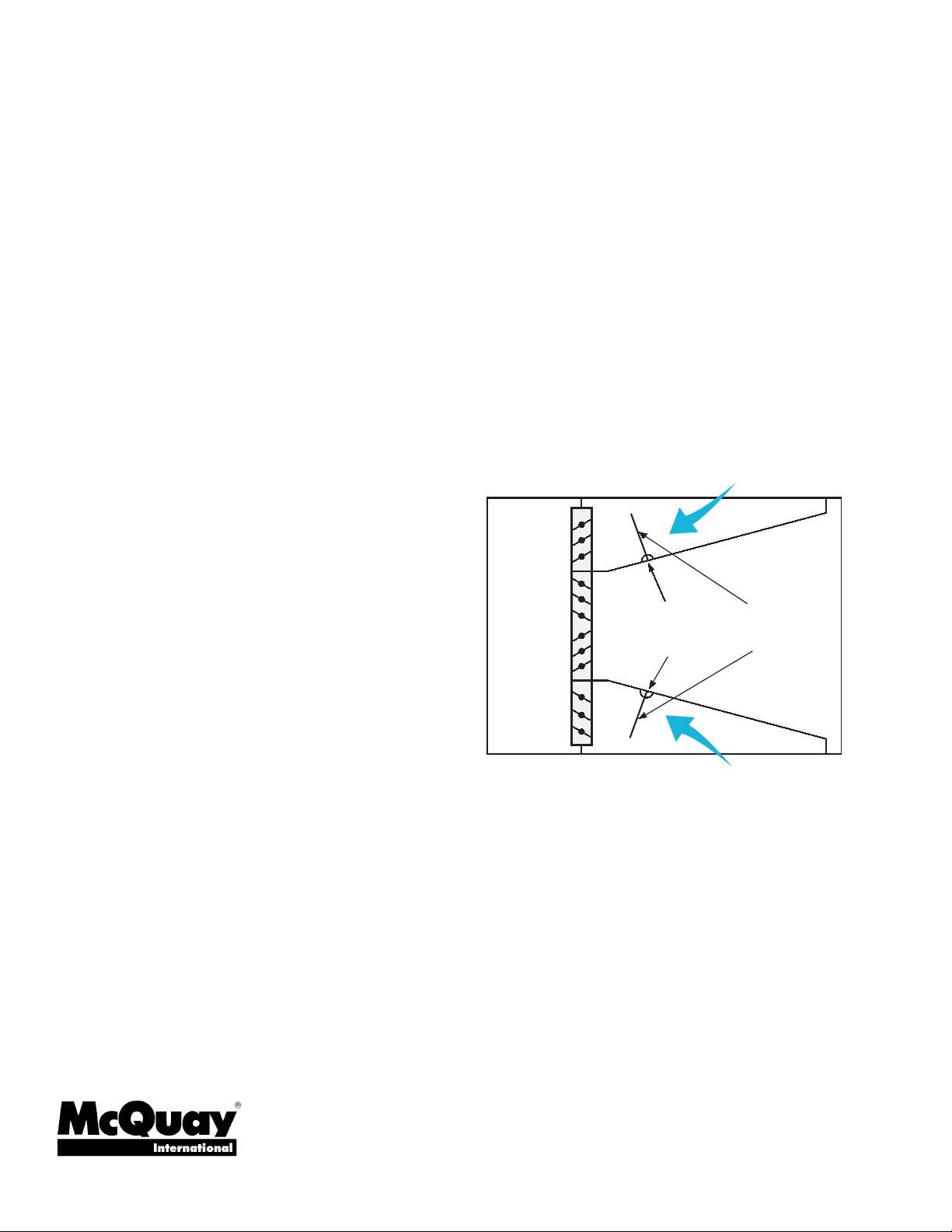

The DesignFlow system uses two hinged, spring-loaded,

rectangular vanes to measure air flow. These are installed in

the two ventilation air intakes on McQuay rooftop systems.

The lower hinge is a specially designed, low-friction, watchpin pivot. The upper hinge is a precisely calibrated assembly

that includes a rotary potentiometer. Electrical resistance

varies proportionately with the rotation of the vanes.

The vanes are connected to a set of cams such that the

force on the spring is many times the force of the air

velocity pressure on the vane. This allows measurable

spring deflection (about 0.5") and reliable control at

low airflow.

The system’s MicroTech II controller monitors

potentiometer resistance, compares it to an adjustable

set point, and modulates the OA dampers to maintain

minimum OA volume.

Contact your local McQuay Sales Representative or visit

www.mcquay.com for more information on how your

building environment can benefit from innovative

McQuay rooftop systems.

OA

OA

Damper

RA

Damper

Design

Flow

Hinges

Design

Flow

Vanes

OA

Damper

OA

Loading...

Loading...