Page 1

Installation and Maintenance Manual IM 787

Field Installed SpeedTrol™ for

RoofPak™ Singlezone Rooftop Units

RPS/RDT/RCS 036C-135C

Group: Aftermarket Products

Part Number: 300040599

Date: December 2003

© 2003 McQuay International

Page 2

Table of Contents

Typical Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 1 Typical Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Condenser Fan Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2 Condenser Fan Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Field Installation of SpeedTrol Option to “C” Vintage Rooftop Units: RPS/RDT/RCS (Sizes 036-135) . . . . . . . . . . . . . . . 5

Figure 3 Typical Schematic for RPS/RDT Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4 Typical Schematic for RCS Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 5 Remove Panel V04 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6 SpeedTrol Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7 Typical Condenser Box Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 8 Typical Condenser Box Power Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

WARNING

Moisture in control panel can cause severe personal injury and damage equipment.

When servicing this equipment during rainy weather, protect electrical components in main control panel from

rain.

™ ® The following are trademarks or registered trademarks of McQuay International: FanTrol, MicroTech, MicroTech II,

RoofPak and SpeedTrol.

2 IM 787

Page 3

Typical Component Locations

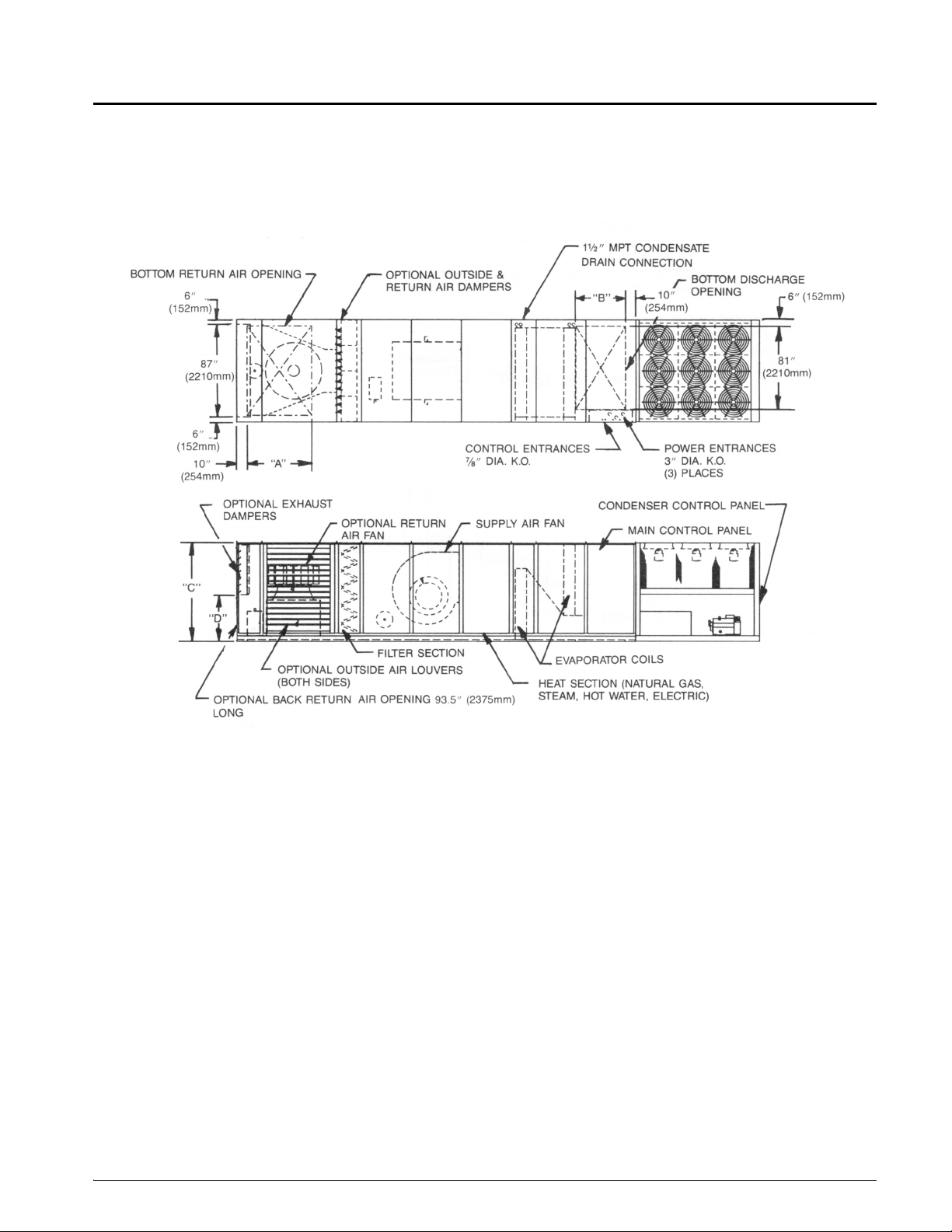

Figure 1 shows a typical RPS unit with the location of the

major components and also lists some major dimensions.

These figures are for reference only.

Figure 1: Typical Component Locations

IM 787 3

Page 4

Condenser Fan Arrangement

Figure 2 shows the condenser fan numbering conventions and locations for each unit size with SpeedTrol application.

Figure 2: Condenser Fan Arrangement

Unit Size Refrig.Circuit Arrangement

12

11

036C

040C

May be a

Singular or

Dual Circuit Unit

22

21

100" (2540 mm)

12

1

2

100" (2540 mm)

11

22

21

83”

COND. AHU

045C

1

11 12

050C

060C

2

1

2

21 22

11 12

23

21 22

83”

13

Low Ambient (SpeedTrol)

Fan No.

11

21

11

21

11

21

11

21

070C

075C

080C

090C

105C

115C

125C

135C

1

2

1

2

1

2

1

2

1

2

11

21

11

24

21

11

24

21

11

25

21

11

251526

21

12

22

12

22

12

25

22

12

22 23

12

22 23

119”

13

23

119”

13

14

23

119”

13

14

23

139”

13 14

139”

13 14

16

11

21

11

21

11

21

11

15

24

21

11

21

24

4 IM 787

Page 5

Field Installation of SpeedTrol Option to “C” Vintage

Rooftop Units: RPS/RDT/RCS (Sizes 036-135)

McQuay's SpeedTrol system of head pressure control operates in conjunction with FanTrol™ by modulating the motor

speed of the last condenser fan of each refrigeration circuit

in response to condenser pressure. By varying the speed of

the last condenser fan of each refrigeration circuit, the

SpeedTrol option allows mechanical cooling operation in

ambient temperatures down to 0°F (-18°C). SpeedTrol controllers SC11 and SC21 sense refrigerant head pressure and

vary the fan speed accordingly. When the pressure rises,

SpeedTrol increases the fan speed; when the pressure falls,

SpeedTrol decreases the fan speed. The SpeedTrol controller's throttling range is 140 to 200 psig (965-1379 kPa) fixed.

The SpeedTrol fan motor is a single phase, 208/240 volt,

thermally protected motor specially designed for variable

speed application. Units with 460-volt power have a transformer mounted inside the condenser fan compartment to

step the voltage down to 230 volts for the SpeedTrol motor.

A portion of a typical SpeedTrol power circuit schematic is

shown in Figure 3 on page 6 and Figure 4 on page 7.

1. Before proceeding, confirm all electrical power has

been terminated to the entire unit.

2. Using Figure 2 on page 4, (Condenser fan arrangements) identify the correct fan arrangement according to

the unit size being worked on and locate condenser fans

11 and 21.

3. Make note of the fan blade position in relation to the fan

deck panel so the fan blade is installed in the exact same

position during reassembly on the motor shaft to assure

maximum efficiency.

4. Remove condenser motor assemblies 11 and 21. Do not

discard the motor mount or mounting hardware, and

make sure not to damage the existing motor wire harness. These items will be needed during reassembly.

Note: The three phase motors and fan blades that were

removed will no longer be needed.

WARNING

Electric shock hazard. Before proceeding, lock and tag out all power sources to unit.

IM 787 5

Page 6

5. Install the new single phase motor, motor slinger (6-3/4"

diameter plastic disc), and fan blade into fan positions

11 and 21 using the existing motor mount and hardware

Figure 3: Typical Schematic for RPS/RDT Units

mentioned in step 4. Position fan blade in the same

location that was noted in step 3.

6. Reconnect motor wire harness to motor as shown on

schematics in Figures 3 or 4.

6 IM 787

Page 7

Figure 4: Typical Schematic for RCS Units

IM 787 7

Page 8

7. Remove panel V04 . Locate and add a rectangular cutout per dimensions shown on tabulated chart per unit

Figure 5: Remove Panel V04

size. Set panel V04 aside for the time being and keep

panel mounting screws for later.

CABINET

SIZE

PANEL SIZE

(REF. ONLY)

A x B

CUTOUT SIZE

C x D

RPS 125 SHOWN

FAN QTY. WILL VARY PER UNIT SIZE

SEE FIGURE 2 FOR APPROPRIATE

FAN LAYOUT

E

F

A

D

E

C

B

F

V04

CONDENSER END PANEL

CONDENSER BOX

CONTROL DOOR

V04

CONDENSER BOX

POWER DOOR

V14 SPEEDTROL COVER

#10 DRILL SCREW

8 IM 787

Page 9

8. With the condenser end panel V04 removed, the condenser bulkhead will be accessible to mount (2) SpeedTrol panels. See Figure 6 to aid in positioning SpeedTrol

panel for circuit 1 and circuit 2.

9. Locate the wire harness for condenser motors 11 and 21

in the condenser power box and disconnect the wire harnesses from their respective contactors M11 and M21.

Reroute both motor wire harnesses to the SpeedTrol

panels for circuit 1 and 2 as shown in Figure 6. Condenser motor 11 to be assigned circuit 1 and motor 21 to

be assigned circuit 2. Trim the motor harness wires to

the appropriate length and crimp the 1/4 quick connects

in place. Wire SpeedTrol panels as shown in Figures 3

or 4.

Figure 6: SpeedTrol Panels

NOTE:

1. ATTACH SPEEDTROL CAPILLARIES TO SCHRAEDER FITTINGS

ON DISCHARGE TUBING AS SHOWN BELOW.

2. UNITS WITH VOLTAGES 380/460/415/575V HAVE A TRANSFORMER

T11, 208/230 DO NOT.

SEE NOTE #1

SEE NOTE #1

FROM

MTR. #11

FROM

MTR. #21

SEE NOTE #2

TO CONDENSER

CONTROL BOX

SPEEDTROL PANEL #1

(CIRCUIT #1)

TO CONDENSER

CONTROL BOX

SPEEDTROL PANEL #2

(CIRCUIT #2)

IM 787 9

Page 10

10. Mounting condenser control and power electrical components:

• Figure 7 (Condenser Box Control Panel) shows locations of the time delay relays TD11 & TD12 and relays

R11 & R12. These components are required for units

with MicroTech™ controls and units with no controls.

RCS rooftop units require an additional transformer

(T10), mount this transformer in upper left of control

panel as shown. Refer to original condenser box control

schematic for wiring instructions.

Figure 7: Typical Condenser Box Control Panel

• Figure 8 (Condenser Box Power Panel) on page 11

shows the mounting location of fuse block FB11. Refer

to Figure 3 or 4 for rewiring of existing fuse blocks, as

well as fuse block FB11.

• If the rooftop unit being worked on has MicroTech II™

controls, the software configuration string position 5

must be set to value 1 or (YES) as shown in Table 1 on

page 11. Changing this requires an AAHU MicroTech

II service tools.

CIRCUIT 1

RELAY

CIRCUIT 1

TIME DELAY

CIRCUIT 2

TIME DELAY

CIRCUIT 2

RELAY

10 IM 787

Page 11

Figure 8: Typical Condenser Box Power Panel

NOTE:

QUANTITIES OF FUSE BLOCKS AND

CONTACTORS WILL VARY PER UNIT SIZE.

NOTE DIRECTION OF

L1 - L3 ON THIS DRAWING.

FOR ALL COMPONENTS.

.

MOUNTING LOCATION

OF FUSEBLOCK FB11

Table 1: Software Configuration String

Configuration

String Position

Description

5 Low Ambient

Values

(Default in bold)

0 FanTrol

1 SpeedTrol

11. Replace condenser end panel V04 using existing mounting screws and place SpeedTrol cover V14 over the

opening created in V04 in step 7.

12. Add SpeedTrol Access label on SpeedTrol cover V14.

13. Please place this Instruction Manual in the Condenser

Control Box.

14. Return electrical power to unit.

IM 787 11

Page 12

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.mcquay.com.

www.mcquay.com • 800-432-1342

Loading...

Loading...